Page 1

MODEL

ME7840A

POWER AMPLIFIER TEST SYSTEM

OPERATION AND

MAINTENANCE MANUAL

490 JARVIS DRIVE - MORGAN HILL, CA 95037-2809

P/N: 10410-00225

REVISION: A

PRINTED: JUNE 2000

COPYRIGHT 2000 ANRITSU CO

Page 2

WARRANTY

The ANRITSU product(s) listed on the title page is (are) warranted against defects in materials and

workmanship for three years from the date of shipment.

ANRITSU’s obligation covers repairing or replacing products which prove to be defective during the

warranty period. Buyers shall prepay transportation charges for equipment returned to ANRITSU for

warranty repairs. Obligation is limited to the original purchaser. ANRITSU is not liable for consequential

damages.

LIMITATION OF WARRANTY

The foregoing warranty does not apply to ANRITSU connectors that have failed due to normal wear. Also,

the warranty does not apply to defects resulting from improper or inadequate maintenance by the Buyer,

unauthorized modification or misuse, or operation outside of the environmental specifications of the

product. No other warranty is expressed or implied, and the remedies provided herein are the Buyer’s sole

and exclusive remedies.

TRADEMARK ACKNOWLEDGEMENTS

V Connector and K Connector are registered trademarks of ANRITSU Company.

GPC-7 is a registered trademark of Amphenol Corporation.

Ink Jet and Think Jet are registered trademarks of Hewlett-Packard Co.

MS-DOS is a registered trademark of Microsoft Corporation.

NOTICE

ANRITSU Company has prepared this manual for use by ANRITSU Company personnel and customers

as a guide for the proper installation, operation and maintenance of ANRITSU Company equipment and

computer programs. The drawings, specifications, and information contained herein are the property of

ANRITSU Company, and any unauthorized use or disclosure of these drawings, specifications, and

information is prohibited; they shall not be reproduced, copied, or used in whole or in part as the basis for

manufacture or sale of the equipment or software programs without the prior written consent of ANRITSU

Company.

Page 3

Page 4

Page 5

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, ANRITSU Company uses

the following symbols to indicate safety-related information. For your own safety, please read the informa

tion carefully BEFORE operating the equipment.

Symbols used in manuals

-

DANGER

This indicates a very dangerous procedure that could result in serious

injury or death if not performed properly.

WARNING This indicates a hazardous procedure that could result in serious in

jury or death if not performed properly.

CAUTION This indicates a hazardous procedure or danger that could result in

light-to-severe injury, or loss related to equipment malfunction, if

proper precautions are not taken.

Safety Symbols Used on Equipment and in Manuals

(Some or all of the following five symbols may or may not be used on all ANRITSU equipment. In addition,

there may be other labels attached to products that are not shown in the diagrams in this manual.)

The following safety symbols are used inside or on the equipment near operation locations to provide infor

mation about safety items and operation precautions. Ensure that you clearly understand the meanings of

the symbols and take the necessary precautions BEFORE operating the equipment.

This indicates a prohibited operation. The prohibited operation is indi

cated symbolically in or near the barred circle.

-

-

-

This indicates a compulsory safety precaution. The required operation

is indicated symbolically in or near the circle.

This indicates warning or caution. The contents are indicated symboli

cally in or near the triangle.

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

ME7840A OMM Safety 1

-

Page 6

For Safety

WARNING

Always refer to the operation manual when working near locations at

which the alert mark, shown on the left, is attached. If the operation,

etc., is performed without heeding the advice in the operation manual,

there is a risk of personal injury. In addition, the equipment perfor

mance may be reduced.

Moreover, this alert mark is sometimes used with other marks and de

scriptions indicating other dangers.

WARNING

When supplying power to this equipment, connect the accessory 3-pin

power cord to a 3-pin grounded power outlet. If a grounded 3-pin outlet

is not available, use a conversion adapter and ground the green wire, or

connect the frame ground on the rear panel of the equipment to ground.

If power is supplied without grounding the equipment, there is a risk of

receiving a severe or fatal electric shock.

-

-

Repair

WARNING

This equipment can not be repaired by the operator. DO NOT attempt to

remove the equipment covers or to disassemble internal components.

Only qualified service technicians with a knowledge of electrical fire

and shock hazards should service this equipment. There are

high-voltage parts in this equipment presenting a risk of severe injury

or fatal electric shock to untrained personnel. In addition, there is a

risk of damage to precision components.

WARNING

Use two or more people to lift and move this equipment, or use an

equipment cart. There is a risk of back injury, if this equipment is lifted

by one person.

Safety 1 ME7840A OMM

Page 7

Table of Contents

Chapter 1 General Information

SCOPE OF THIS MANUAL...............................1-1

INTRODUCTION ....................................1-1

RELATED MANUALS .................................1-1

CONVENTIONS.....................................1-2

SERIAL NUMBER ...................................1-2

ONLINE MANUALS ..................................1-2

PATS SYSTEM OVERVIEW ..............................1-2

HARDWARE DESCRIPTION..............................1-2

SYSTEM DESCRIPTION ................................1-5

DRA Scorpion ....................................1-5

MS4782X Test Set .................................1-6

Connectors and Ports ................................1-7

K FACTOR........................................1-9

ADAPTIVE P STOP ...................................1-9

SOFTWARE DESCRIPTION ..............................1-9

TEST EXECUTIVE ...................................1-9

SOFTWARE STRUCTURE ..............................1-11

MS7840A OPTIONS ..................................1-12

OPTIONAL ACCESSORIES..............................1-12

PREVENTIVE MAINTENANCE ...........................1-13

USER SUPPLED TEST SET .............................1-13

PERFORMANCE SPECIFICATIONS.........................1-13

RECOMMENDED ITEMS...............................1-15

USER SUPPLIED ITEMS ...............................1-15

Chapter 2 Installation

INTRODUCTION ....................................2-1

EQUIPMENT COMPLEMENT .............................2-1

UNPACKING and INSPECTION............................2-1

INSTALLATION - HARDWARE ............................2-2

INSTALLATION - SOFTWARE.............................2-7

ME7840A OMM i

Page 8

Installation .....................................2-7

What else is on the CD?...............................2-7

Uninstalling the software..............................2-7

SERVICE CENTERS ..................................2-8

Chapter 3 Operations, General

INTRODUCTION ....................................3-1

PREPARING THE SYSTEM ..............................3-1

Unused Connections ................................3-2

USING PATS SOFTWARE ...............................3-4

Software

Organization.....................................3-4

COLLATERALFUNCTIONS ..............................3-5

File..........................................3-5

Help .........................................3-6

Tools .........................................3-7

Chapter 4 Operations, Calibration

INTRODUCTION ....................................4-1

OPERATION, GENERAL ................................4-1

PROGRAM FILES....................................4-1

TEST EQUIPMENT...................................4-2

GENERAL ........................................4-3

POWER LEVEL .....................................4-4

HOTS22.........................................4-8

S-PARAMETERS CAL .................................4-11

CAL FILE SETUP ...................................4-15

Chapter 5 Operations, Measurement

INTRODUCTION ....................................5-1

OPERATION, GENERAL ................................5-1

MEASUREMENT CALIBRATION ...........................5-1

GENERAL ........................................5-1

Calibration(s) Completed ..............................5-1

Calibration(s) Not Completed ...........................5-2

S-PARAMETER TESTS: S

S-PARAMETER TEST: K FACTOR...........................5-7

POWER SWEEP, TWO TONE.............................5-10

Single Frequency Power Sweep ..........................5-10

Multiple Frequency Power Sweep.........................5-14

21,S11,S22,S12

,ALL.....................5-4

ii ME 7840A OMM

Page 9

Gain and IMD Power Sweep ...........................5-18

POWER SWEEP, ONE TONE .............................5-22

Single Frequency Power Sweep ..........................5-22

IMD...........................................5-26

HARMONICS .....................................5-29

HOTS22........................................5-32

Chapter 6 Performance Verification Procedure

INTRODUCTION ....................................6-1

CONVENTIONS.....................................6-1

TEST

EQUIPMENT ......................................6-1

SOURCE OUTPUT ACCURACY ............................6-2

Setup: ........................................6-2

Test Procedure ...................................6-2

RETURN LOSS CONFIDENCE TEST.........................6-3

Setup.........................................6-3

Test Procedure: ...................................6-4

SYSTEM DYNAMIC RANGE .............................6-6

Test Procedure: ...................................6-6

RECEIVER DISPLAY LINEARITY ..........................6-8

Setup: ........................................6-8

Chapter 7 Preamplifier Operations

INTRODUCTION ....................................7-1

USE OF EXTERNAL PREAMPLIFIERS........................7-1

Alternative 1 ....................................7-1

Alternative 2 ....................................7-1

Appendix A Calibration Specification Files

INTRODUCTION ....................................A-1

FILE TYPES.......................................A-1

OPEN FILES ......................................A-1

TECHNICAL DETAILS.................................A-1

POWER LEVE.TXT ..................................A-11

CAL FILES SETUP.TXT................................A-11

HOT S

.TXT ......................................A-13

22

S-PARAMETERS. TXT ................................A-14

ME7840A OMM iii/iv

Page 10

Page 11

Figure 1-1. Model ME7840A Power Amplifier Test System (PATS)

Page 12

Chapter 1 General Information

1-1 SCOPE OF THIS

MANUAL

This manual provides operating and maintenance information for the

ME7840A Power Amplifier Test System (PATS, Figure 1-1). The follow

ing topics are discussed:

Equipment Description

q

Equipment Installation and Connection

q

Software Description

q

Software Installation

q

Calibration

q

System Operation

q

Test Procedures and Test Results Interpretation

q

System Performance Verification

q

The procedures described in this manual presume a working knowledge

of vector network analyzers and RF power amplifier testing procedures.

Refer to the other manuals supplied with the ME7840A (see below) for

more detailed explanations of the system equipment and procedures.

1-2 INTRODUCTION This chapter provides information to familiarize the user with the basic

ME7840A Power Amplifier Test System. Included is information about re

lated manuals, and the available models and options.

1-3 RELATED

MANUALS

The ME7840A manual set consists of the following manuals: The operat

ing and programming manuals are supplied with the equipment; the

maintenance manuals are optional items that may be purchased.

-

-

-

Manual Description ANRITSU Part Number

ME7840A Operating & Maintenance Manual

(OMM)

MS462XX Operating Manual (OM) 10410-00203

MS462XX Programming Manual (PM) 10410-00204

MS462XX Maintenance Manual (MM) 10410-00205 (Optional)

MS4782X Test Set Maintenance Manual (MM) 10410-00218 (Optional))

10410-00225

ME7840A OMM 1-1

Page 13

CONVENTIONS GENERAL INFORMATION

1-4 CONVENTIONS Throughout this manual, the ME7840A Power Amplifier System may be

referenced as PATS or ME7840A; the MS462XC may be referenced as

Scorpion or MS462XC; and the MS4782X Test Set may be referenced as

Test Set or MS4782X.

1-5 SERIAL NUMBER All ANRITSU instruments are assigned a unique six-digit serial number,

such as “940101.” This number is affixed to a decal on the rear panel of

each unit. In any correspondence with ANRITSU Customer Service,

please use this number.

1-6 ONLINE MANUALS This manual is available on CD ROM as an Adobe Acrobat™ (*.pdf) file.

The file can be viewed using Acrobat Reader™, a free program that is

also available on the CD ROM. This file is “linked” such that the viewer

can choose a topic to view from the displayed “bookmark” list and “jump”

to the manual page on which the topic resides. The text can also be

word-searched. CD ROM part numbers are available on ANRITSU’s

Internet home page (http://www.global.anritsu.com/ library/). You can also

contact ANRITSU Customer Service for price and availability.

1-7 PATS SYSTEM

OVERVIEW

1-8 HARDWARE

DESCRIPTION

The ANRITSU ME7870A Power Amplifier Test System (PATS) is intended for the measurement and real-time graphical display of the following parameters of a power amplifier in the frequency range of 10 MHz to

6 GHz:

q

S-Parameters including Hot S

q

K Factor

q

Gain Compression and Phase Distortion

q

Intermodulation Distortion

q

Harmonics

q

Drain Current and Power Added Efficiency (PAE)

PATS is designed to facilitate alignment, tuning and pass/fail testing of

the components, modules and subassemblies of a power amplifier as well

as the completed amplifier.

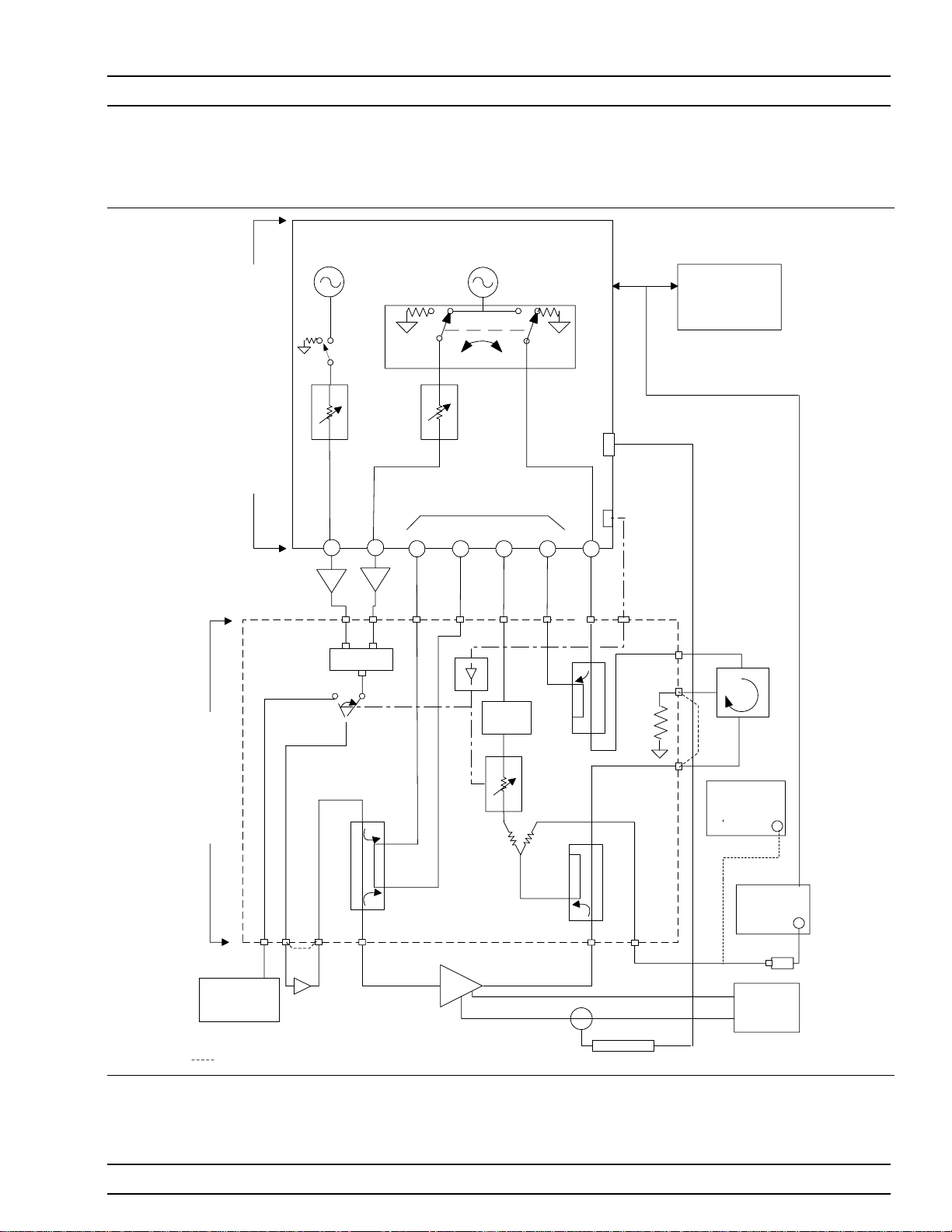

The ME7840A hardware (Figure 1-1) consists of a MS462XC, Direct Re

ceiver Access (DRA) Scorpion, a MS4782X Test Set, a customer supplied

Personal Computer (PC), and an optional current probe (refer to Chapter

2, Figure 2-4 ). The MS462XC is available in two frequency ranges: 10

MHz to 3 GHz or 10 MHz to 6 GHz.

The Test Set is available in two configurations, as described in Table 1-1

The MS4782D is standard, and the MS4782A is Option 2. A block dia

gram of the PATS is shown in Figure 1-2 and the Option 2 system in Fig

ure 1-3.

22

-

-

-

1-2 ME 7840A OMM

Page 14

GENERAL INFORMATION HARDWARE DESCRIPTION

SOURCE 2 SOURCE 1

MS4782D Test Set

ACCESS

SCORPION

DIRECT RECEIVER

OPTIONAL

EXTERNAL

PREAMPLIFIERS

ATTENUATORS

70dB, 10dB/step

RF3

N

N

COMBINER

-30dB

STEP

RF1

REVERSE

FORWAR

D

TRANSFER SWITCH

GPIB

ANALOG IN

SYSTEM

CONTROLLER

(PC)

GPIB

RECEIVERS

EXT I/O

a

b

1

1

N

KKKN

K

LIMITER

STEP

ATTENUATOR

70dB, 10dB/step

a

b

2

2

K

KKN

RF2

-30dB

CONTROL

LINES

NK

K

C3

K

C2

EXTERNAL

100 W

TERMINATION

K

C1

CIRCULATOR

OPTIONAL

SPECTRUM

ANALYZER

NK

OPTIONAL

MODULATION

SYNTHESIZER

OPTIONAL

EXTERNAL

PRE-AMP

-30dB

N

K

-30dB

N

N

AUT

POWER

METER

POWER

SUPPLY

CURRENT PROBE

Indicates coaxjumper in the as-shipped configuration

Figure 1-2. Overall Functional Block Diagram of the Basic Power Amplifier Test System (PATS) with MS4782D Test Set

ME7840A OMM 1-3

Page 15

HARDWARE DESCRIPTION GENERAL INFORMATION

SOURCE 2 SOURCE 1

ACCESS

SCORPION

DIRECT RECEIVER

OPTIONAL

EXTERNAL

PREAMPLIFIERS

ATTENUATORS

70dB, 10dB/step

RF3

N

N

COMBINER

STEP

RF1

REVERSE

FORWAR

D

TRANSFER SWITCH

GPIB

ANALOG IN

SYSTEM

CONTROLLER

(PC)

GPIB

RECEIVERS

EXT I/O

a

b

1

1

N

KKKN

K

a

b

2

K

KKN

RF2

2

CONTROL

LINES

NK

-30dB

LIMITER

ER

POW

OPTIONAL

SPECTRUM

ANALYZER

POWER

METER

POWER

SUPPLY

MS478A Test Set

NK

OPTIONAL

MODULATION

SYNTHESIZER

OPTIONAL

EXTERNAL

PRE-AMP

HIGH

STEP

ATTENUATOR

-30dB

-30dB

N

K

70dB, 10dB/step

-30dB

N

TERMINATION

N

AUT

CURRENT PROBE

Indicates coaxjumper in the as-shipped configuration

Figure 1-3. Overall Functional Block Diagram of the Option 2 Power Amplifier Test System (PATS) with MS4782A Test

Set

1-4 ME 7840A OMM

Page 16

GENERAL INFORMATION SYSTEM DESCRIPTION

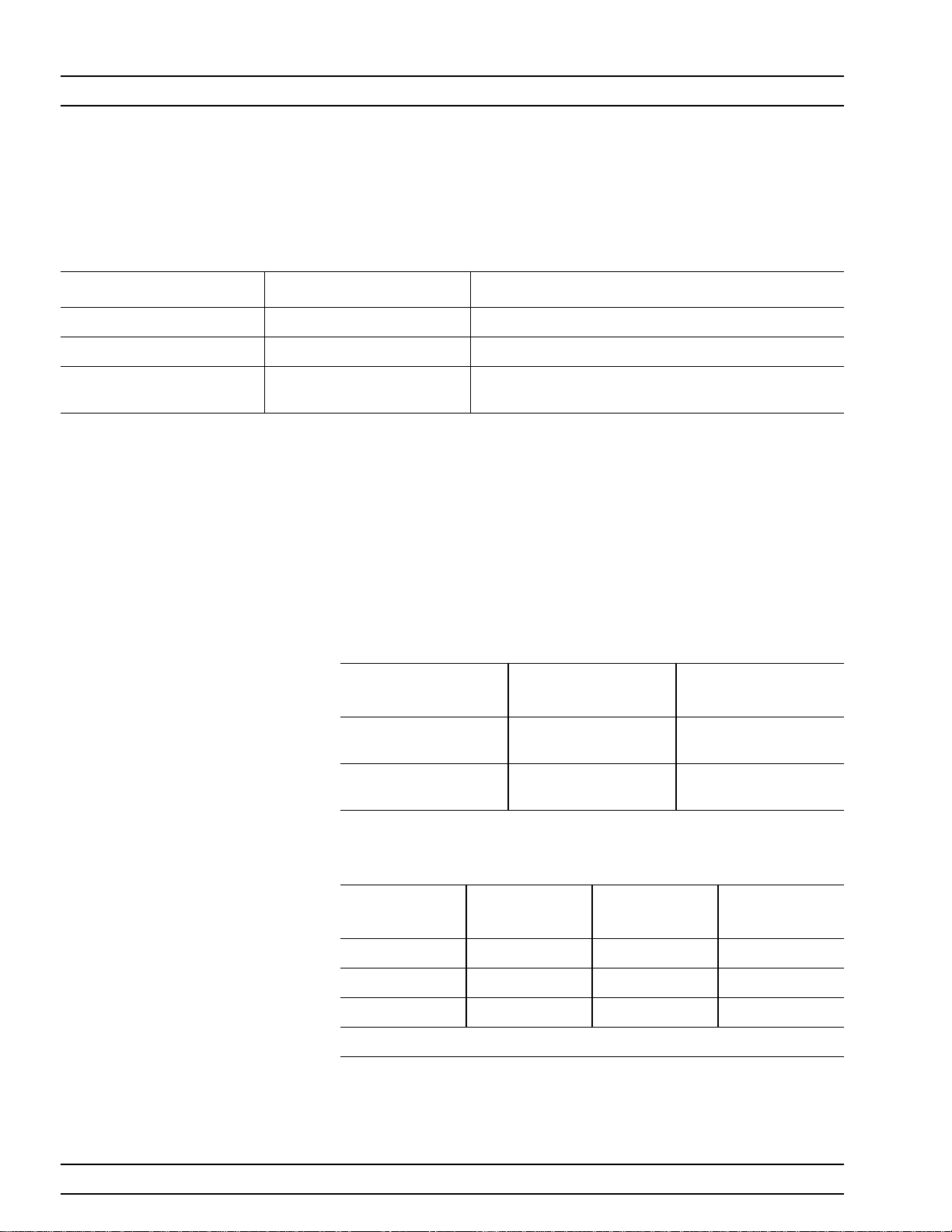

Table 1-1. Test Set Configurations

Model

MS4782A 800 to 1000 50 Yes Internal

MS4782D 800 to 2400

Notes:

1. This frequency range does not account for any restricting effects caused by use of external circulator.

2. This Max AUT power assumes a minimum isolation of 23 dB provided by external circulator(s). Two circulators may have to

be used to provide the required isolation.

Frequency Range

(MHz)

(Note 1)

1-9 SYSTEM

DESCRIPTION

Max AUT Power Output

(Watts)

100

(Note 2)

Reverse Measurements

(S

, Hot S22,S12Possible)

22

Yes External

(at AUT Output Path)

Circulator

Brief descriptions of the DRA Scorpion (MS462XC) and MS4782X Test

Set are given below.

DRA Scorpion The Scorpion Direct Receiver Access (DRA) version Vector Network Mea-

surement System (VNMS) (Figure 1-2) functions under control of the software residing in the PC through GPIB commands. The software supports

tuning and alignment operations by generating real time graphic displays

of the measured data on the PC screen.

Under software control, 3

rd,5th

and 7thorder IMD products can be measured and displayed. Also, the Upper and Lower Side Band (USB & LSB)

components of the IMD products are measured and displayed separately.

The DRA Scorpion includes the following capabilities:

q

Two internal, independent RF sources. Each source has a range of

–15 dBm to +10 dBm. A 0dB to 70dB step attenuator (10 dB / step)

is provided for each source resulting in a Power Output range of

–85 dBm to +10 dBm from each source.

NOTE

After test set losses, the maximum net power at the input of the amplifier

under test (AUT) is +5 dBm.

q

Complete built-in capability for IMD measurements. A combiner is

provided in the Test Set.

q

Internal Transfer Switch enabling S22and Hot S22measurements.

The reflectometer set-up is provided in the Test Set.

q

Direct access to each of the four receiver channels (two reference

channels and two test channels) for maximum flexibility in measur

ing forward and reverse S-parameters over a wide range of AUT

output power.The Test Set provides incident and reflected signal

separation.

-

ME7840A OMM 1-5

Page 17

SYSTEM DESCRIPTION GENERAL INFORMATION

MS4782X Test Set The Series MS4782X Test Set contains a Wilkinson type combiner that

combines the two RF signals from Ports 1 and 3 (RF1 & RF3) of the Scor

pion. External preamplifiers can optionally be provided at the combiner

input to boost the input RF power to the amplifier-under- test (AUT). The

combiner has power input rating of 30-Watts maximum when terminated

with a VSWR of 1.2:1. For an open or short at the combiner output, the

combiner input power rating is 0.5 Watts maximum.

The output of the combiner is fed to a source selection switch that enables

one of the following to be applied to the AUT:

The combined signal from the Scorpion sources.

q

A modulated signal from an optional external modulation synthe

q

sizer.

A provision for the insertion of an optional external pre-amplifier (after

the combiner and source selection switch) is also provided. Refer to Chap

ter 7, “Preamplifier Operations,” for details.

The test set includes a bi-directional coupler at the input of the AUT that

separates the incident signal from the reflected signal. The power rating

of this bi-directional coupler is 100 watts average. The –30 dB portion of

the incident and reflected signals are applied to the Scorpion reference

port a1 and test port b

, respectively, for S11measurement. The S11mea-

1

surement determined by the DRA Scorpion is simply the ratio of the reflected signal to the incident signal.

-

-

-

The amplified output of the AUT is fed to a high power coupler in the test

set. The power rating of this coupler is also 100-watts average. The –30

dB coupled arm of this coupler is routed to the test port b

of the Scorpion

2

througha6dBresistive divider and a 0-dB to 70-dB step attenuator

(10dB/step). A limiter is also provided in this path provide added protec

-

tion for the Scorpion reference channel .

The divider enables the connections of a power meter or Spectrum Ana

lyzer, when desired, to measure the AUT b

output.

2

-

The through arm of the 100-W coupler is routed to a high power

(100-Watt) termination through a circulator. In the MS4782A Test Set,

the circulator is internal and has a rating of 100 watts average. This

circulator has an isolation specification of 20-dB minimum. This means

that the AUT output power is attenuated by 20 dB (plus other losses) be

fore reaching the Scorpion port 2. Since the maximum (no-damage) power

level for this port is 27 dBm (0.5 watt), this establishes the maximum

AUT output power at 50 watts.

In the MS4782D Test Set, the circulator is external as shown in Figure

1-2. In selecting an external circulator, the following criteria should be

used.

q

Power rating: Should be no less than the power output of the ampli

fier-under-test (AUT). It should be noted that a 100 watt termina

tion is provided in the Test Set for the termination port of the exter

nal circulator.

-

-

-

1-6 ME 7840A OMM

Page 18

GENERAL INFORMATION SYSTEM DESCRIPTION

Bandwidth: Should be sufficiently wide to cover the frequency band

q

of the AUT.

Isolation: Should be no less than (Po-27 dB), where Pois the

q

power output in dBm of the AUT. Thus for Po = 47 dBm (50 watts),

a 20 dB isolation is required. For a P

dBm (100 watts), two circulators in series can be used.

Where S

or Hot S22measurements are not required, power amplifiers

22

with up to 100 watts average output power can be tested with the

MS4782D Test Set without any circulator by connecting the through arm

of the output coupler directly to the 100 watt termination (Port C1 con

nected to Port C2 on the rear. The unit is shipped from the factory with

this loop jumper.)

greater than 47 dBm up to 50

o

-

Connectors and

Ports

CAUTION

Connecting the external

circulator incorrectly or

placing a direct connection

between C1 and C3 on

MS4782D rear panel will

cause permanent damage

to MS462XC.

For S

measurements, the transfer switch located within the Scorpion

22

routes the source 1 output signal to the output port of the AUT via Port 2

(RF2) of the Scorpion. A separate 100-watt coupler in the test set applies

the –30 dB portion of this incident signal to the Scorpion reference port

a

. The –30 dB portion of the signal reflected from the AUT output port is

2

applied to the Scorpion test port b

by means of the AUT output coupler.

2

The PATS calibration is performed with the test set in place, at the connectors where AUT will be connected directly. Therefore, the test set components and cables are included in the calibration loop and their effects

are calibrated out, resulting in correct and accurate measurements of the

AUT.

The software supplied by ANRITSU supports operator control of the

source selection switch and step attenuator in the test set. This control is

achieved through the parallel TTL control lines available at the Scorpion

rear panel “External I/O” connector. The GPIB commands from the PC to

the Scorpion set the TTL control lines to the desired states.

On the front panel of the Model MS4622/3C DRA Scorpion three Type N

(female) connectors are provided for Ports 1, 2 and 3.

Port 1 provides RF source 1 when the transfer switch is in the forward

position, and is terminated in 50 ohms to ground when the transfer

switch is in the reverse position.

Port 2 provides RF source 1 when the transfer switch is in the reverse po

sition, and is terminated in 50 ohms to ground when the transfer switch

is in the forward position.

Port 3 is allocated to RF source 2. Under independent control, port 3 pro

vides RF source 2, or is terminated in 50 ohms to ground.

On the rear of the unit, four SMA connectors (Figure 1-4) are provided for

Reference ports a

and a2and Test Ports b1and b2. The front of the unit

1

as well as all other mechanical specifications is the same as the model

MS4623B.

-

-

On the MS4782D Test Set, three additional SMA connectors provide for

connecting an external circulator. If reverse measurements (S

and Hot

22

ME7840A OMM 1-7

Page 19

SYSTEM DESCRIPTION GENERAL INFORMATION

WARNING

NOOPERATOR SERVICE-

ABLEPARTS INSIDE.

REFERSERVICING TO

QUALIFIEDPERSONNEL.

IEEE 488.2

GPIB

Dedicated

GPIB

Serial Port

Ethernet

N274

Noise

+28V

Noise

In

Figure 1-4. MS462XC Rear Panel Showing Ports a1,a2,b1, and b

VGA

LPT LinePrinter

Ext

Ext

Analog

Trigger

Output

CAUTION

FORCONTINUED FIRE

PROTECTIONREPLACE

ONLYWITH SPECIFIED

TYPEAND RATED FUSE.

a

a

1

a

a

1

b1b

2

b

2

1

CAUTION

DONOT OPERATE

WITHPOWER CORD

UNGROUNDED

2

b

2

SCSI-2

REPLACE FUSEONLY WITH

ExtAnalogInExt

Ext I/O

47-440 Hz

85-264VAC

SAME TYPEAND RATING

Ext 10MHz

Source

In

2

Control

N274

In

a

1

WARNING

NO OPERATORSERVICE-

ABLE PARTSINSIDE.

REFER SERVICING TO

QUALIFIED PERSONNEL.

Output

Ext Preamp

a

CAUTION

DO NOT OPERATE

WITH POWER CORD

UNGROUNDED

Input

2

b

1

50 dBm

Max

b2To

AUT

TestPort 2

C1

C3

b

2

External

Circulator

C3

a2To

C2C1

27 dBm

VNMS

Port 2

50 dBm

Max

100W

Termination

(Internal)

Max

LINE INPUT

85-240 VAC

47-63 Hz

100 VAmax

FUSE 250 V 1.6A T

CAUTION

FOR CONTINUED FIRE

PROTECTION REPLACE

ONLYWITH SPECIFIED

TYPEAND RATED FUSE

C2

Figure 1-5. MS4782A Rear Panel Showing Circulator Connections C1, C2, and C3

1-8 ME 7840A OMM

Page 20

GENERAL INFORMATION K FACTOR

S22) are not desired, then a circulator is not required. Instead, a through

line should be connected between connectors C1 and C2 (Figure 1-5). The

MS4782A is shipped from the factory with this through line in place.

1-10 K FACTOR K factor is a parameter which is sometimes used to indicate the stability

of an amplifier. K factor is a function of all four S parameters and is de

fined by the formula

2

SS

--+1

K

Where

D =S

The necessary and sufficient condition for unconditional stability is that

K>1 and

K factor is available as the sixth choice in the S parameters menu (first

five choices are: S

setup as S-parameter measurements including a full 12-term calibration

applies to this measurement. The result is “dynamic” meaning that the

above formula is applied at each point for each sweep as the S parameters are reported to the PC over the GPIB.

11

=

11S22-S12S21

D<1

2

22

22

SS

11 21

.

11,S22,S21,S12

D

and ALL). The same conditions and

-

1-11 ADAPTIVE P STOP Adaptive P stop lets users enter a gain compression value at which the

value during a power sweep. For exam-

in

-

-

-

1-12 SOFTWARE

DESCRIPTION

program will adjust the final P

ple, if user sets 3 dB P-stop, the program commands the execution of one

sweep, find P

crement, and reset this as the upper bound of the power sweep.

The ME7840A software exhibits an open architecture that has been de

veloped using standard C++ and Visual Basic languages. The software is

compiled as an Active X exe module.

The software resides in the System Controller (PC), and communicates

with the Direct Receiver Access (DRA) Scorpionâ Vector Network Mea

surement System (VNMS) via the GPIB bus. Optionally, the ME7840A

software can also interface with additional GPIB capable test equipment,

such as a multimeter or a power meter.

value where 3 dB gain compression occurs, back up 1 in

in

1-13 TEST EXECUTIVE The Test Executive is an optional layer of test management software. The

ANRITSU measurement and display software does not require a separate

Test Executive, even though it can operate in conjunction with one such

as the National Instruments TestStand or customer’s proprietary Test

Executive. In the absence of a separate test executive, the ANRITSU soft

ware can be operated on a stand-alone basis or can be called directly by a

Microsoft Windows 95/98/2000 or NT program such as Word, Excel or Ac

cess that supports Visual Basic function calls.

-

-

ME7840A OMM 1-9

Page 21

TEST EXECUTIVE GENERAL INFORMATION

The functions of the Test Executive, if supplied by ANRITSU or by the

customer, would include:

Test Sequence development and management

q

Part number and serial number management

q

Interface with the Database

q

1-10 ME 7840A OMM

Page 22

GENERAL INFORMATION SOFTWARE STRUCTURE

1-14 SOFTWARE

STRUCTURE

The software structure is illustrated in Figure 1-6 (below).

Test Executive:

Automated Testing,

Test Plan Development

( optional item )

GUI/EXE

Measurement, Calibration & Tuning

Anritsu

Modules

VNA PowerTools

V4.00

DLL/GUI

DLL

MS Access

Local/Network Database

Scorpion VNMS

Figure 1-6. PATS Software Structure

GPIB

RF Power

Meter

(Optional)

MultiMeter

(Optional)

Te st St at i on

PC

Test Instruments

ME7840A OMM 1-11

Page 23

MS7840A OPTIONS GENERAL INFORMATION

1-15 MS7840A OPTIONS The following options are available:

Table 1-2. MS7840A Options

Model Option Number Description

ME7840/1 1 Replaces MS4623C with MS4622C (3 Ghz option)

ME7840/2 2 Replaces MS4782D Test Set with MS4782ATest Set

ME7840/3 3 Delete Test Set (Note: The ND43425 Accessory and Inter

1-16 OPTIONAL

ACCESSORIES

connect Kit will also be deleted with this option.)

The accessories described below are available from ANRITSU.

Model ML2430A Power Meter

q

Model MG3672A Digital Modulation Signal Generator/with

q

MG0314A W-CDMA Modulation Unit

Model MS2602A Spectrum Analyzer

q

Model MS8607A Digital Mobile Radio Transmitter Tester

q

q

AC/DC Current Probe (for AUT drain current and

power-added-efficiency (PAE) measurements) (See below).

Max Current

100 mV/A: 10A

10 mV/A: 100A

1 mV/mA: 1A

10 mV/A: 80A

Accuracy (at lesser cur-

rent range setting)

3% of reading ±50 mA 2000-1067

2% of reading ±5 mA 2000-1085

ANRITSU Part Number

-

q

Circulators to be used externally with the MS4782D Test Set (see

below).

Frequency Band Isolation Max AUT Power

800 to 1000 MHz 20 dB min 50 watts 1000-50

1.8 to 2.5 GHz 20 dB min 50 watts 1000-52

1.8 to 2.5 GHz 22 dB min 79 watts 1000-53

Note: All circulators have 3 SMA female connectors.

q

15SS50-0.35B Cable Assembly. Three of these cables can be used to

ANRITSU Part

Number

connect any one of the external circulators offered above to the

1-12 ME 7840A OMM

Page 24

GENERAL INFORMATION PREVENTIVE MAINTENANCE

MS4782D Test Set. The same cable is also used to connect the Test

Set to the MS462XC receivers on the rear panel.

1-17 PREVENTIVE

MAINTENANCE

1-18 USER SUPPLED

TEST SET

1-19 PERFORMANCE

SPECIFICATIONS

The ME7840A Power Amplifier Test System does not require any preven

tive maintenance.

The ANRITSU MS4782X is the recommended test set for PATS; however,

users supply their own test set. To ensure that such a test set will func

tion properly with the PATS, a set of specifications and caveats is pro

vided in Appendix B.

Specifications for the M7840A Power Amplifier Test System are provided

in Table 1-3.

-

-

-

ME7840A OMM 1-13

Page 25

PERFORMANCE SPECIFICATIONS GENERAL INFORMATION

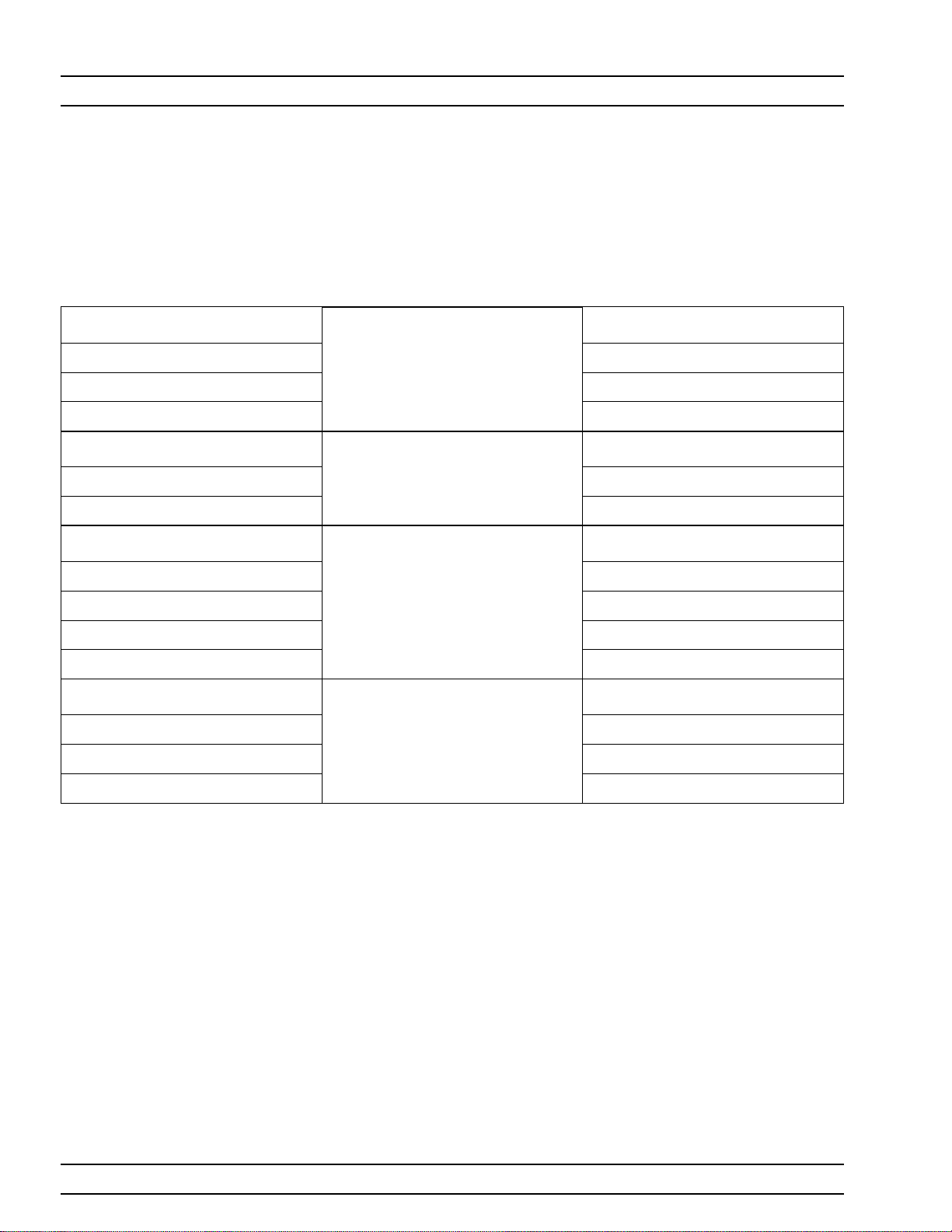

Table 1-3. Performance Specifications for ME7840A Power Amplifier Test System

Characteristic Value Notes

100 W maximum With MS4782D Test Set and with23 dB

Amplifier Under Test Power Output

50 W maximum With MS4782A TestSet

isolation between AUT power output and

MS4623C, Port 2

Bandwidth through Test Set

Amplifier Under Test Input Power range

available from PATS

IMD 3rd Order Dynamic Range 70 dB min With 10 Hz IF Bandwidth @300 kHz tone

Port Power Accuracy

Drift over 60 hours 0.15 dB maximum, peak to peak

Dynamic Range 80 dB minimum Overall system, including test set

Port Match (test ports 1 and 2)

Directivity 40 dB minimum Corrected value

Environmental

800 MHz to 2.4 GHz With MS4782D Test Set (Note 1)

800 MHz to 1.0 GHz With MS4782A TestSet

-85 to +5 dBm At AUT input

separation and -20 dBm tone levels

±0.1 dB maximum With flat power calibration

±1 dB maximum Without flat power calibration

40 dB minimum Corrected value

13 dB minimum Uncorrected value

Storage Temperature Range 40° Cto+75° C

Operating Temperature Range 0° Cto+50° C

Range Over Which Specifications Apply 23 ±3° C

Relative Humidity 5% to 95% at +40° C

Height 152.5 mm (6 in.)

Physical, MS4782X Test Set

Note 1: This frequency range does not take into account any restricting effects of the external circulator (if one is used for reverse

measurements)

Width 444 mm (17.4 in.)

Depth 500 mm (19.7)

Weight 10 kg (22 pounds) or less

1-14 ME 7840A OMM

Page 26

GENERAL INFORMATION RECOMMENDED ITEMS

1-20 RECOMMENDED

ITEMS

Table 1-4. Recommended Test Equipment

Item Critical Specification/Notes Manufacturer/Model

Power Meter GPIB capable ANRITSU Model ML243XA

Power Sensor 10 MHz to 6 GHz ANRITSU Model MA247XA

N connector Calibration Kit Type N Open, Short, Broadband Load ANRITSUModel 3653 or 3753LF

Offset Termination 6 dB ANRITSU Model SC5237

Offset Termination 20 dB ANRITSU Model SC5270

Power Divider ANRITSU Model 11N50B

Cable 50 Ohm, N-male to N-male ANRITSU Model 3670NN50-2

Adapter 50 Ohm, N-male to N-male ANRITSU Model 34NN50Ar

GPIB Cable None ANRITSU 2100-2

SMA/3.5 mm Connector Calibration Kit Required if amplifier-under-test (AUT)

Table 1-2 provides a list of test equipment and other items needed for cal

ibration and performance verification.

ANRITSU 3750LF

has SMA/3.5 mm connectors

-

1-21 USER SUPPLIED

ITEMS

Item Critical Specification

Personal Computer (PC) Pentium II or better, 200 MHz or faster, with WindowsÒ 95/98/2000 or NT operating

GPIB Cable None

The following items required for the operation of the ME7840A Power

Amplifier Test System must be supplied by the user.

system and National Instruments GPIB card installed.

ME7840A OMM 1-15/1-16

Page 27

Chapter 2 Installation

2-1 INTRODUCTION This chapter describes the installation, connection and set-up of the

equipment that comprises the ME7840A Power Amplifier Test Station.

2-2 EQUIPMENT

COMPLEMENT

2-3 UNPACKING and

INSPECTION

The ME7840A is made up of the following pieces of equipment:

Scorpionâ Vector Network Measurement System (VNMS), Direct

q

Receiver Access (DRA) version:

Model MS4622C (10 MHz to 3 GHz) or

Model MS4623C (10 MHz to 6 GHz)

Model MS4782X Power Amplifier Test Set

q

System measurement software

q

Current probe(s) (optional item)

q

One or more external circulators (optional item, for use with

q

MS4782D Test Set

q

Accessory Kit: Includes interconnect cables and 50W terminations

for Aux ports

The ME7840A equipment has been securely packaged. The packaging

material and container should be retained in case the equipment must be

re-shipped or placed into storage.

The MS4622C or MS4623C DRA Scorpionâ VNMS and the MS4782X

Test Set are each packed within heavy cardboard boxes.

Step 1. Carefully cut the sealing tape on the top box surface with a

packing knife.

Step 2. Open the box lids, and remove the upper layer of foam mate

rial.

-

Step 3. Lift the equipment from the boxes. Two persons should do

this, as the equipment is heavy and bulky.

ME7840A OMM 2-1

Page 28

INSTALLATION - HARDWARE INSTALLATION

A listing of the non-optional-accessories always supplied with PATS is

listed below. The cables and terminators are shown in Figures 2-3 and

2-2, on page 2-3.

Item Part No. Quantity

Broadband Termination 28N50LF 2

Control Cable 803-49 1

RF Cables, Type N connectors (front) 15NN50-0.25B 3

RF Cables, SMA connectors (rear) 15NN50-0.35B 4

2-4 INSTALLATION -

HARDWARE

System hardware is set-up is a straight-forward process. Follow the

steps below in sequence to ensure a trouble free installation.

Step 1. Place the MS462XC on top of the MS4782X Test Set. Figure

2-1 shows how the green colored feet on the case of each unit

stack on each other.

Foot

Foot

Figure 2-1. ME7840A Component Assembly

Step 2. Install the three front RF interconnect cables. Figure 2-3 (fol

lowing page) shows the installation of the RF interconnect ca

bles between the front panel of the MS462XC and the front

panel of the Test Set. Table 2-1 lists the applicable connectors

by designation or function.

2-2 ME 7840A OMM

-

-

Page 29

INSTALLATION INSTALLATION - HARDWARE

PORT 3

AUX

OUT

EXTERNAL

SOURCE

INSTALL 50 OHM TERMINATIONS

ON UNUSED PORTS

INSTALL 50 OHM TERMINATIONS

ON UNUSED PORTS

PORT 1

PORT 2

PORT 1PORT 2PORT 3

TEST PORT 2

TEST PORT 1

AUT

Figure 2-3. ME7840A Front RF Cable Connections (through-line shown between test port 1 and test port 2)

GPIB CONNECTOR

GPIB CABLE

EXTERNAL I/O CONNECTOR

DEDICATED

GPIB CONNECTOR

(Used during

power level calibration)

AC POWER CORD

CONTROL CABLE

RF CABLES (4ea)

CONTROL IN CONNECTOR

C3

C2

AC POWER CORD

EXT PREAMP

OUTPUT

C1

INPUT

CONTROL CABLE

CIRCULATOR

Figure 2-2. ME7840A Rear Cable Connections

ME7840A OMM 2-3

Page 30

INSTALLATION - HARDWARE INSTALLATION

Step 3. Install the four RF cables between the rear of the MS462XC

and the Test Set. Torque the cables to 8 inch-pounds (SMA

Connectors) or 12 inch-pounds (Type N connectors). Table 2-1

lists the applicable connectors by designation or function.

Table 2-1. RF Cable Connection

VNMS - FRONT

PORT 1 “TO PORT 1”

PORT 2 “TO PORT 2”

PORT 3 “TO PORT 3”

TEST SET - FRONT

TEST PORT 1 DUT INPUT

TEST PORT 2 DUT OUTPUT

VNMS - REAR

PORT a1 PORT a1

PORT a2 PORT a2

PORT b1 PORT b1

PORT b2 PORT b2

MS4782D TEST SET - REAR

C1 Circulator 1 or C2

C2 Circulator 2 or C1

(See Figure 1-2 for a block diagram)

Connects To:

Connects To:

Connects To:

Connects To

TEST SET - FRONT

DEVICE UNDER TEST

MS4782X -REAR

CIRCULATOR

C3 Circulator 3 or Open

Step 4. Install the control cable between the External I/O connector

on the rear panel of the MS462XC and the Control In connec

tor on the rear panel of the Test Set.

Step 5. Connect the GPIB cable from IEEE-488.2 connector on the

rear panel of the MS462XC to the PC/System Controller.

(Note: This cable is not supplied with the ME7840A PATS.)

Step 6. Connect an AC power cord to each of the three-prong connec

-

tors on the rear panel of the Test Set and the MS462XC.

Step 7. (Optional, for drain current PAE measurements) Connect the

current probe cable BNC connector to the Ext. Analog In con

nector on the rear of the MS462XC as shown in Figure 2-4

(page 2-5).

2-4 ME 7840A OMM

-

-

Page 31

INSTALLATION INSTALLATION - HARDWARE

Figure 2-4. Current Probe Connection

EXTERNAL ANALOG

IN CONNECTOR

CURRENT SENSOR

CABLE PASSAGE

CURRENT PROBE

HEAD

ME7840A OMM 2-5

Page 32

INSTALLATION - HARDWARE INSTALLATION

Figure 2-5. Software Installation Window

2-6 ME 7840A OMM

Page 33

INSTALLATION INSTALLATION - SOFTWARE

2-5 INSTALLATION -

SOFTWARE

Installation Run the appropriate Setup.exe files to install Power Tools then the

What else is on the

CD?

ME7840A software is delivered on a CD. The ANRITSU Power Tools li

brary Version 4.0 or higher, which is required to be installed on the target

system (the PC which is receiving the installation of ME7840A software).

Power Tools Version 4.0 is also included in the ME7840A Software CD.

ME7840A software (Figure 2-5). During installation, the system may in

dicate that some files being installed already exist. In general it is best to

accept copying newer versions of files and reject copying older versions. If

in doubt, cancel the installation, backup the files in question, and try

again. The Readme.txt file lists the files and versions copied to the target

system during installation of ME7840A Software.

The system may also copy some files during ME7840A installation

andthen ask you to reboot. If this happens, reboot your Windows PC and

run the ME7840A Setup.exe program again after rebooting.

The CD includes a Readme.txt file in the root directory and two folders.

The readme file contains specific instructions for installing the software

and a listing of the features in the version being installed. The folders are

as follows:

q Power Tools Version 4.0 Installation files

q

PATS Installation Files

-

-

Uninstalling the

software

To uninstall ME7840A software or Power Tools go to the Windows Control

Panel and click on “Add/Remove Programs.” Select the programs you

would like to remove and follow instructions.

ME7840A OMM 2-7

Page 34

SERVICE CENTERS INSTALLATION

2-6 SERVICE CENTERS ANRITSU Service Centers are listed in Table 2-2.

Table 2-2. ANRITSU Service Centers

UNITED STATES

ANRITSU COMPANY

685 Jarvis Drive

Morgan Hill, CA 95037-2809

Telephone: (408) 776-8300

1-800-ANRITSU

FAX: 408-776-1744

ANRITSU COMPANY

10 New Maple Ave., Unit 305

Pine Brook, NJ 07058

Telephone: (201) 227-8999, 1-800-ANRITSU

FAX: 201-575-0092

ANRITSU COMPANY

1155E. Collins Blvd

Richardson, TX 75081

Telephone: 1-800-ANRITSU

FAX: 972-671-1877

AUSTRALIA

ANRITSU PTY. LTD.

Unit 3, 170 Foster Road

Mt Waverley, VIC 3149

Australia

Telephone: 03-9558-8177

FAX: 03-9558-8255

BRAZIL

ANRITSU ELECTRONICA LTDA.

Praia de Botafogo, 440, Sala 2401

CEP22250-040, Rio de Janeiro, RJ, Brasil

Telephone: 021-527-6922

FAX: 021-53-71-456

CANADA

ANRITSU INSTRUMENTS LTD.

215 Stafford Road, Unit 102

Nepean, Ontario K2H 9C1

Telephone: (613) 828-4090

FAX: (613) 828-5400

CHINA

ANRITSU BEIJING SERVICE CENTER

Beijing Fortune Building

1515, 5 Dong San Huan Bei Lu

Chaoyang qu, Beijing 100004, China

Telephone: 011861065909231

FAX: 011861065909235

FRANCE

ANRITSU S.A

9 Avenue du Quebec

Zone de Courtaboeuf

91951 Les Ulis Cedex

Telephone: 016-09-21-550

FAX: 016-44-61-065

GERMANY

ANRITSU GmbH

Grafenberger Allee 54-56

D-40237 Dusseldorf, Germany

Telephone: 0211-968550

FAX: 0211-9685555

INDIA

MEERA AGENCIES (P) LTD.

A-23 Hauz Khas

New Delhi 110016

Telephone: 011-685-3959

FAX: 011-685-2275

ISRAEL

TECH-CENT, LTD.

4 Raul ValenbergSt

Tel-Aviv 69719

Telephone: (03) 64-78-563

FAX: (03) 64-78-334

ITALY

ANRITSU Sp.A

Roma Office

Via E. Vittorini, 129

00144 Roma EUR

Telephone: (06) 50-99-711

FAX: (06) 50-22-4252

KOREA

ANRITSU CORPORATIONLTD.

14F, Hyunjuk Bldg

832-41 Yeoksam-Dong

Kangnam-Ku

Seoul South Korea 150 010

Telephone: 02-553-6603

FAX: 02-553-6604, 02-553-6605

JAPAN

ANRITSU CUSTOMER SERVICE LTD.

1800 Onna Atsugi-shi

Kanagawa-Prf. 243 Japan

Telephone: 0462-96-6688

FAX: 0462-25-8379

SINGAPORE

ANRITSU (SINGAPORE) PTE LTD.

6 New Industrial Road #06-01/02

Hoe Huat Industrial Bldg

Singapore 536199

Telephone: 282-2400

FAX: 282-2533

SOUTH AFRICA

ETECSA

12 Surrey Square Office Park

330 Surrey Avenue

Ferndale, Randburt, 2194

South Africa

Telephone: 011-27-11-787-7200

FAX: 011-27-11-787-0446

SWEDEN

ANRITSU AB

Botivid Center

Fittja Backe 1-3

S145 84 Stockholmn

Telephone: (08) 534-707-00

FAX: (08) 534-707-30

TAIWAN

ANRITSU CO., LTD.

6F, No. 96, Section 3

Chien Kuo N. Road

Taipei, Taiwan, R.O.C.

Telephone: (02) 515-6050

FAX: (02) 509-5519

UNITED KINGDOM

ANRITSU LTD.

200 Capability Green

Luton, Bedfordshire

LU1 3LU, England

Telephone: 015-82-4332003

FAX: 015-82-731303

2-8 ME 7840A OMM

Page 35

Chapter 3 Operations, General

3-1 INTRODUCTION The basic operation of the Model ME7840A Power Amplifier Test Station

(without external preamplifiers) is described in this and the following two

chapters: Calibration Operations and Measurement Operations. “Calibra

tion Operations” describes the software measurement calibration func

tion and “Measurement Operations” describes the software measurement

function. This chapter describes the setup and general operation of the

software. (See Chapter 7 for operation with external preamplifiers.)

-

-

3-2 PREPARING THE

SYSTEM

CAUTION

The AUT RF power output

maximum level should be

no more than the level

shown in the tabulation at

right. Otherwise, damage

to equipment will occur.

Refer to Figure 3-1 to identify the equipment named in the recommended

power-up sequence for the ME7840A.

Step 1. Connect the output of the AUT to Test Port 2 of the MS4782X.

Step 2. Connect the input of the AUT to Test Port 1 of the MS4782X.

Step 3. Ensure that the power rating of the cables is suitable for the

test, and that the connections are tightened.

Step 4. Turn on the MS462XC then the MS4782X Test Set.

Step 5. Set the output of the MS462XC so that the AUT output power

does not exceed the maximum Test Port 2 input level. See be

low.

Test Set Model

MS4782A Not Applicable 50 watts

MS4782D None (port C1 directly

MS4782D 1000-50 or 1000-52 (20

External Circulator

Used

connected to port C2)

dB isolation)

Test Port 2 Max Power

100 watts

50 watts

-

MS4782D 1000-53 (22 dB isolation) 79 watts

MS4782D Two circulators providing

greater than 23 dB

isolation

100 watts

ME7840A OMM 3-1

Page 36

PREPARING THE SYSTEM OPERATIONS, GENERAL

Step 6. When ready for measurements, cautiously apply DC power to

the AUT.

Step 7. Check that the normally factory-installed RF coaxial “jumper”

cable is installed on the rear panel of the Test Set:

MS4782X: Between Ext Preamp Input and Output

n

connectors.

MS4782D: Between connectors C1 and C2, unless a

n

circulator is installed.

Step 8. If drain current and/or PAE measurements are desired, the

optional current probe (ANRITSU part number 2000-1067 or

-1085) can be used. Ensure the probe (Figure 3-1) has a fresh

battery, and set the zero offset using the MS4623C as follows:

a.

Using Domain softkey, set to Transmission & Reflec

tion; using the Display soft key, set for Single Channel;

using the Graph Type softkey, set for Real; using the

Scale softkey and Data Entry keys, set for 1 mU/Division.

Use the Avg key and associated softkeys to set Aver-

aging for 10 and IF Bandwidth for 300 Hz. Use the

Config key, DATA POINTS and associated softkeys to

set for 101 Max Data Points.

-

b.

Use the Measure softkey and select Ext. Analog In.

c. Turn on the current probe and set it for the desired

range.

d. Adjust the “Zero Adjustment” thumbwheel until the

reading is minimum (typically 0 ±100mU).

e. On the current probe:

Orient the probe such that the “Current Direction”

arrow points away from the power supply.

Place the jaws only over the DC wire (not both wires)..

Unused Connections The EXT. SOURCE and AUX. OUT connectors must be terminated with

50W terminations when not in use.

3-2 ME 7840A OMM

Page 37

OPERATIONS, GENERAL PREPARING THE SYSTEM

Customer Supplied

Power Meter

for flat test port

power calibration

8

9

7

4

5

6

1

3

2

+/-

0

CLR

ON/ OFF

Channel

Sensor

Trigger

GPIB

System

Cal/ Zero

GPIB

Customer Supplied

System Controller (PC)

with GPIB

MS462X3C

DRA Scorpion

Port 3

Port 1

Port 2

To: Ext. Analog

In connector

MS4782A or D

CALIBRATOR

A

B

Port 3

50 Ohm Terminations

Port 1

Test

Port 1

Port 2

Test

Port 2

Sensor

Test Set

*

Customer Supplied

Input

Output

Power Supply

for AUT

Amplifier Under Test (AUT)

Optional

Current Probe

Connect when directed by procedure for power calibrations

*

Figure 3-1. PATS Power On Sequence

ME7840A OMM 3-3

Page 38

USING PATS SOFTWARE OPERATIONS, GENERAL

3-3 USING PATS

SOFTWARE

PATS software requires a computer with GPIB capability running Win

dows 95 or better (98/NT/2000). The software is started by selecting the

“Start” button, then “Programs,” “Pats V1.1,” then “Pats” (Figure 3-2).

-

Select “Pats” to start the

software

Select “Readme” to read the

description and any

late-breaking information

Select “Start” then “Programs” then “Pats V1.1”

Figure 3-2. Starting the PATS Software

Software

Organization

.

The PATS software has two main and three collateral functions. The two

main functions, calibration and measurement, are described in Chapters

3 and 4, respectively. The collateral functions, accessed from the PATS

program’s top menu, are described in paragraph 3-6.

about the software.

3-4 ME 7840A OMM

Page 39

OPERATIONS, GENERAL COLLATERAL FUNCTIONS

3-4 COLLATERAL

FUNCTIONS

File The file menu (below) provides for saving files from the PC to the

The PATS software collateral functions are found on the top menu bar un

der “Files,” “Tools,” and “Help.” (below)

Top Menu Bar

Same as File, Save

Files from PC

Same as File, Recall

Files to PC

MS462XC, recalling files from the MS462XC to the PC, and for exiting

the system.

-

Click on File to display a drop-down list (above) that provides the three

options described below. PATS Save and Recall functions have the exact

same behaviors as the Save/Recall button on the Scorpion. However, in

stead of saving to the Scorpion hard disk or recalling from the hard disk,

the PATS software allows users to Save to the PC’s hard disk and Recall

from the PC’s hard disk.

ME7840A OMM 3-5

Page 40

COLLATERAL FUNCTIONS OPERATIONS, GENERAL

Save Cal Files to PC. Displays a dialog box (similar to that shown

q

for Recall Cal Files from PC, below) showing the cal files stored in

the default folder (Temp). This function is useful for saving the

front panel setup and calibration data to a file on the PC. The user

has the option of overwriting an existing file by selecting an exist

ing file from the file listing or creating a new file by typing in a file

name. The user must type in a “.cal” extension or the program will

report an error. The calibration procedure automatically saves cal

files to the PC. The file names of these files is specified in the cali

bration specification file (*.txt file).

Recall Cal Files from PC: Displays a dialog box similar to that

q

shown below with the listing of file name. This function transfers a

.cal file from the PC to the Scorpion over the GPIB bus (and names

the file a.cal on the Scorpion’s hard disk) and then recalls the front

panel setup and cal data from a.cal.

-

-

q

Exit: Exits the PATS software.

Help The “Help” function is not available in the current software. It will be

available in future software versions.

3-6 ME 7840A OMM

Page 41

OPERATIONS, GENERAL COLLATERAL FUNCTIONS

Tools The “Tools” menu (below) displays a drop-down list that provides three

collateral options described below. The “Run Calibration Files” option is

described in Chapter 4.

a. Check Communications to VNA: Runs a test to check

that the VNA communicates with the PC. Run this option first to ensure that the PATS setup is correct and

functioning properly. If so, a dialog box appears like that

shown below.

ME7840A OMM 3-7

Page 42

COLLATERAL FUNCTIONS OPERATIONS, GENERAL

b. Calibration File Options: Provides options for finding

and recalling calibration files (below). These files are

used to establish test setup for the measurements de

scribed in Chapter 5. If no file is selected in an area (S

Parameter, Power Sweep, IMD, etc., the associated mea

surement will assume the PATS default setting. Clicking

on “Find and Recall” button will display the list of files

as was shown for “File”, Step 1a, above. Clicking on a

filename will cause it to display in the associated win

dow in this screen.

-

-

-

c. Limits: Provides for setting limts for S-Parameter mea-

surements.

3-8 ME 7840A OMM

Page 43

Chapter 4 Operations, Calibration

4-1 INTRODUCTION Measurements always include a degree of uncertainty due to imperfec

tions in the measurement system. The measured value is always a combi

nation of the actual value plus the systematic measurement errors. Cali

bration, as it applies to network analysis, characterizes the systematic

measurement errors and subtracts them from the measured value to ob

tain the actual value. Each of the ME7840A measurements requires a cal

ibration to account for measurement uncertainties. This chapter de

scribes the measurement calibration operations of the Model ME7840A

Power Amplifier Test System software.

4-2 OPERATION,

GENERAL

Refer to Chapter 3 for general operation and setup of the ME7840A.

-

-

4-3 PROGRAM FILES The PATS software sets up the MS462XC DRA Scorpion according to in-

structions in the “Calibration Specification” files, which are accessed from

the “Tools,” “Run Calibration Procedure” function that is described later

in this chapter. These are user-editable text files that establish the conditions during calibration and measurement. How to edit these files is described in Appendix A.

The calibration data and Scorpion switch settings that result from follow

ing a “Run Calibration Procedure” specification file are saved as a *.cal

file. These *.cal files are accessed using the “Tools,” “Calibration File Op

tion” function that was described in paragraph 3-6, page 3-8. When one

of these files is recalled using the “Calibration File Option,” the Scorpion

is ready to acquire correct (calibrated) measurements.

-

-

-

-

-

-

Examples of instrument settings / conditions that reside in the Calibra

tion Specification files include:

q

Sweep start and stop frequencies

q

Number of data points

q

Source 1 and 2 power levels

q

Scorpion IF bandwidth

q

Averaging

q

Scorpion display settings

Some of these parameters can also be specified / modified by the User In

put window before each actual measurement so long as such modification

is consistent with the calibration to be applied.

-

-

ME7840A POM 4-1

Page 44

TEST EQUIPMENT OPERATIONS, CALIBRATION

Alternatively, Scorpion front panel settings may be set manually and ap

plied during the automated measurements under PATS software as fol

lows:

On the Measurement Window click the Pause button

q

On the Scorpion front panel press the “Clr / Local” button to take

q

manual control of the Scorpion.

Use Scorpion front panel controls to set the desired settings and/or

q

to perform a new calibration. (Note: Unless a new calibration is per

formed, the manual settings must be consistent with the calibration

to be applied).

Use the “Save Cal File to PC.” (Refer to Appendix A for detailed in

q

formation on how to use the “Calibration Specification Files.”

-

4-4 TEST EQUIPMENT A power meter, power sensor, and Type N calibration component kit is re

quired for power level and S-parameters calibrations. See Table 1-2, page

1-12.

-

-

-

-

4-2 ME 7840A POM

Page 45

OPERATIONS, CALIBRATION GENERAL

4-5 GENERAL Calibration operations are described in this and the following paragraphs

Step 1. Click on “Start,” “Programs,” “Pats V1.1,” then “Pats” (Figure

3-2, page 3-4) to start the software.

The PATS flash screen (below) briefly appears, then the main

screen.

The main screen (below) provides access to all software options.

Step 2. Click on “Tools” then “Check Communications to VNA” to en

-

ME7840A OMM 4-3

Page 46

POWER LEVEL OPERATIONS, CALIBRATION

sure that the equipment is properly connected to the bus. If

so, the following screen will be displayed:

Step 3. Click on “Run Calibration Procedure” to display a list of cali

bration specification files (below). (Refer to paragraph 4-3 for

a description of these files.) Running the files is described in

succeeding numbered paragraphs.

4-6 POWER LEVEL The A_Power Level.txt specification file provides prompts for a power

level calibration. Proceed as follows:

-

Step 1. Zero-set the power sensor for accurate measurement in fol

lowing steps.

Step 2. Select “Tools” then “Run Calibration Procedure.”

-

4-4 ME 7840A OMM

Page 47

OPERATIONS, CALIBRATION POWER LEVEL

Step 3. Double-click on “A_Power Level.txt.” . The program starts

with a linear power calibration (below).

Step 4. Before hitting the “Next” button, connect the power meter to

at the point where power enters the device-under-test (AUT),

which becomes the power reference plane as shown in the

prompt.

The use of cables and/or adapters does not effect the final

measurement result, if they are in place for the calibration pro

cess. The vector error corrections established during the cali

bration process eliminates cable and/or adapter effects as long

as the ports used are stable and exhibit good repeatability,

which is the case if good quality components are used.

Many calibration kits include adapters that are designed to

have equal phase length. These parts are called phase equal

adapters (PEA). ANRITSU designs in-series adapters (e.g.,

SMA Connector M-M, M-F, F-F) to be phase insertable when

technically possible.

-

ME7840A OMM 4-5

-

Page 48

POWER LEVEL OPERATIONS, CALIBRATION

NOTE

The linear power calibration takes up-to-5 minutes to

complete. It calibrates the output power at the refer

ence plane for both internal sources (power out of

Port 1 then Port 3) according to the target power

across the frequency range set in the calibration speci

fication file. When the test completes, the “Next” but

ton will become available.

Step 5. Press “Next” to calibrate flat power response (below).

-

-

-

NOTE

The flat power calibration also takes less than 1 min

ute to complete. It calibrates the output power at the

reference plane for both internal sources (power out

of Port 1 then Port 3) according to the target power

across the frequency range set in the calibration speci

fication file. When the test completes, the “Next” but

ton will become available.

-

-

-

4-6 ME 7840A OMM

Page 49

OPERATIONS, CALIBRATION POWER LEVEL

Step 6. Before pressing “Next” disconnect the power sensor and con

nect a throughline between Test Ports 1 and 2 on the

MS4782X Test Set, as shown below.

-

Step 7. Press “Next” to perform a receiver calibration. When this cali

bration finishes, the program returns to the main screen.

ME7840A OMM 4-7

-

Page 50

HOT S22 OPERATIONS, CALIBRATION

4-7 HOT S22 The “B_HotS22.txt” file provides prompts for setting up a Hot S

cation file. Hot S

port (Port 2) while stimulus is applied to its input port. The prompts

cause the Scorpion to be placed into a state where it is ready to make cali

brated measurements on the user’s AUT. At the completion of the pro

gram, the state information is saved to a *.cal file. To run this program,

proceed as follows.

Step 1. Select “Tools” then “Run Calibration Procedure.”

Step 2. Double-click on “C_Hot S22.txt” to begin the Hot S

setup. Follow the prompt and connect open, short, and load to

Port 2 as directed.

is a return loss measurement of an amplifier’s output

22

specifi

22

cal file

22

-

-

-

4-8 ME 7840A OMM

Page 51

OPERATIONS, CALIBRATION HOT S22

Step 3. Press “Next” for the next prompt (below). The 3653 or 3753LF

Calibration Kits contain a disk with calibration data. The

data has to be installed from the MS462C front panel. To do

so, place the floppy disk from the kit into the MS462XC disk

drive. Press the Cal key then COMPONENTS UTILITIES/IN

STALL KIT INFO FROM FLOPPY DISK. softkeys.

Step 4. Press “OK” for the next step (below). Connect the Open to

Port 2.

-

Step 5. Press “OK” for the next step (below). Connect the Short to

Port 2.

ME7840A OMM 4-9

Page 52

HOT S22 OPERATIONS, CALIBRATION

Step 6. Press “OK” for the next step (below). Connect the Load to Port

2.

Step 7. Press “OK” to complete the Hot S

calibration.

22

4-10 ME 7840A OMM

Page 53

OPERATIONS, CALIBRATION S-PARAMETERS CAL

4-8 S-PARAMETERS

CAL

The “C_S-Parameters Cal.txt” file to provides prompts for setting up

S-parameters specification file. The prompts cause the Scorpion to be

placed into a state where it is ready to make calibrated measurements on

the user’s AUT. At the completion of the program, the state information is

saved to a *.cal file. To run this program, proceed as follows.

Step 1. Select “Tools” then “Run Calibration Procedure.”

Step 2. Double-click on “D_S Parameters.txt” to begin the file

setup.Follow the prompt and connect open, short, and load to

Ports 1 and 2 as directed.

ME7840A OMM 4-11

Page 54

S-PARAMETERS CAL OPERATIONS, CALIBRATION

Step 3. Press “Next” for the next step (below). The 3653 or 3753LF

Calibration Kits contain a disk with calibration data. The

data has to be installed from the MS462C front panel. To do

so, place the floppy disk from the kit into the MS462XC disk

drive. Press the Cal key then COMPONENTS UTILITIES/IN

STALL KIT INFO FROM FLOPPY DISK softkeys.

Step 4. Press “OK” for the next step (below). Connect the Broadband

Load on Test Ports 1 and 2 on the ME7840A Test Set.

Step 5. Press “OK” for the next step (below). Connect the Open to

Test Port1 and the Short to Test Port 2.

-

4-12 ME 7840A OMM

Page 55

OPERATIONS, CALIBRATION S-PARAMETERS CAL

Step 6. Press “OK” for the next step (below). Connect the Short to

Test Port 1 and the Open to Test Port 2.

Step 7. Press “OK” for the next step (below). Connect the Throughline

between Test Ports 1 and 2.

ME7840A OMM 4-13

Page 56

S-PARAMETERS CAL OPERATIONS, CALIBRATION

Step 8. Press “OK” to complete the S Parameters calibration (below).

4-14 ME 7840A OMM

Page 57

OPERATIONS, CALIBRATION CAL FILE SETUP

4-9 CAL FILE SETUP The “D_Cal File Setup.txt” file provides prompts for setting up One-tone

power sweep, IMD, Two-Tone Power Sweep, and Harmonic specification

file. The prompts cause the Scorpion to be placed into a state where it is

ready to make calibrated measurements on the user’s AUT. At the com

pletion of the program, the state information is saved to a *.cal file. To

run this program, proceed as follows.

Step 1. Select “Tools” then “Run Calibration Procedure.”

Step 2. Double-click on “B_Cal Files Setup.txt.” to begin with the file

setup for a Transmission Frequency Response (S

One-Tone Power Sweep. Connect a throughline when di

rected in a following step.

cal) for

21

-

-

ME7840A OMM 4-15

Page 58

CAL FILE SETUP OPERATIONS, CALIBRATION

Step 3. Press “Next” for the next prompt (below). The 3653 or 3753LF

Calibration Kits contain a disk with calibration data. The

data has to be installed from the MS462C front panel. To do

so, place the floppy disk from the kit into the MS462XC disk

drive. Press the Cal key then COMPONENTS UTILITIES/IN

STALL KIT INFO FROM FLOPPY DISK. softkeys. Press OK

when ready to proceed.

Step 4. Connect the Throughline between Test Ports 1 and 2 on the

MS4782X Test Set.

-

4-16 ME 7840A OMM

Page 59

OPERATIONS, CALIBRATION CAL FILE SETUP

Step 5. Press “OK” to continue to the IMD cal file setup prompt (be

low). Follow the prompt and connect a throughline between

Test Ports 1 and 2 on the MS4782X Test Set.

-

ME7840A OMM 4-17

Page 60

CAL FILE SETUP OPERATIONS, CALIBRATION

Step 6. Press “Next” to begin the Power Sweep cal file setup (below).

4-18 ME 7840A OMM

Page 61

OPERATIONS, CALIBRATION CAL FILE SETUP

Step 7. Press “Next” to perform Harmonic Cal File Setup calibration

(below).

Step 8. Press “Next” to end the calibration and return to the main

screen.

ME7840A OMM 4-19/4-20

Page 62

Chapter 5 Operations, Measurement

5-1 INTRODUCTION This chapter describes the five measurements available with the

ME7840A software: S-Parameters, Power Sweep, IMD (intermodulation

distortion), Harmonics, and Hot S

22

.

5-2 OPERATION,

GENERAL

5-3 MEASUREMENT

CALIBRATION

Refer to Chapter 3 for general operation and setup of the ME7840A.

Measurements always include a degree of uncertainty due to imperfec

tions in the measurement system. The measured value is always a combination of the actual value plus the systematic measurement errors. Calibration, as it applies to network analysis, characterizes the systematic

measurement errors and subtracts them from the measured value to obtain the actual value. Each of the ME7840A measurements requires a calibration to account for measurement uncertainties. Refer to Chapter 4 for

measurement calibration procedures.

-

5-4 GENERAL Measurements can be approached from two directions: calibration(s) com-

pleted, calibration(s) not completed.

Calibration(s)

Completed

Proceed as follows:

Step 1. Click on “Tools,” and open “Check Communications to VNA.”

Step 2. Verify the communications are correct.

Step 3. Click on “Tools,” and open “Calibration File Options.”

Step 4. Click on “Find and Recall” and recall a *.cal file for each mod

ule. Filenames are listed below and shown in graphic below

last listing.

-

n

S Parameters: “S_Parameters_1.cal”

n

Power Sweep (2T): “PowSweep_1.cal”

n

Power Sweep (1T): “PSweep1T_1.cal”

n

C3, IMD: “Imd_1.cal”

n

C4, Harmonics: “Harmonics_1.cal”

ME7840A OMM 5-1

Page 63

GENERAL OPERATIONS, MEASUREMENT

C5, Hot S

n

Step 5. Select appropriate file “Open” (below).

¾ “Hots22_1.cal”

22

Calibration(s) Not

Completed

Sometimes users may wish to run a measurement using default settings,

that is, without spending the time required to calibrate. The procedure

below gives instructions.

Step 1. Click on “Tools,” and open “Check Communications to VNA.”

Step 2. Verify the communications are correct.

Step 3. Click on “Tools,” and open “Calibration File Options.”

Step 4. Clear the text for all modules then select “Return.”

Step 5. Press any measurement button on main menu and measure

ment will be run using “PATS software” default values: Cali

bration Off on MS462XC and MS462XC Default parameters

in place. The default values are shown below.

-

-

5-2 ME 7840A OMM

Page 64

OPERATIONS, MEASUREMENT GENERAL

D1, S-Parameters and Hot S

n

Points = 201

ü

Start Frequency = 800 MHz

ü

Stop Frequency = 2400 MHz

ü

Input Power=0dB

ü

D2, Power Sweep (2 tone power sweep)

n

Main Tone = 950 MHz

ü

Offset = 971 kHz

ü

Start Power = -15 dBm

ü

Stop Power=0dBm

ü

Data Points = 21

ü

D3, IMD

n

Main Tone = 900 MHz

ü

ü Offset Frequency = 977 kHz

ü Input Power=0dBm

ü IMD Order = 9

n D4, Harmonics

ü Start Frequency = 100 MHz

ü Stop Frequency = 3000 MHz

ü Main Tone = 800 MHz

ü Input Power=0dBm

22

ME7840A OMM 5-3

Page 65

S-PARAMETERS OPERATIONS, MEASUREMENT

5-5 S-PARAMETER TESTS:

S

21,S11,S22,S12

, ALL

This test measures the scattering parameters (S-parameters). The test

module comprises six tests: S11,S12,S21,S22, and ALL. (The K Factors

test is described in paragraph 5-6.) In each case, the measurement

screens are the similar. This procedure will present a test screen for the

“S

” measurement and will describe certain differences at the end of the

21

procedure.

Procedure.

Prepare the ME7840A as shown in Chapter 3.

Enter the appropriate test values in the displayed

User Input screen. The input fields are described

below: The inputs required for this test are de

-

scribed below.

S-Parameter: Drop down options. Set to S21for

n

this procedure. Other selections include S

S

, ALL, and K Factor (paragraph 5-6).

22

Data Points: Drop down options - number of data

n

11,S12

points in frequency sweep.

Frequency 1 (MHz): Lower frequency or start fre-

n

quency.

n

Frequency 2 (MHz): Upper frequency or stop fre-

quency.

n

Input Power (dBm):Input power level, in dBm.

n

IF Bandwidth (Hz):Intermediate frequency band-

width for test, in Hertz.

n

Test Set Setting: Byte value for setting test set

attenuation and source switch (below).

,

Internal Source Value External Source Value

0dB 8 0dB 0

10 dB 9 10 dB 1

20 dB 10 20 dB 2

30 dB 11 30 dB 3

40 dB 12 40 dB 4

50 dB 13 50 dB 5

60 dB 14 60 dB 6

70 dB 15 70 dB 7

5-4 ME 7840A OMM

Page 66

OPERATIONS, MEASUREMENT S-PARAMETERS

Select Start Test: Observe that the test screen

n

(Figure 5-1) appears.

Figure 5-1. S-Parameters Test Screen for S

21

Button Panel Options:

q

Print: Prints a copy of the screen graphic to a

printer.

q

Write Data: Two data files are written to the

C:\Program Files\Pats\Datafiles folder; the

file name will have a time stamp. One datafile

has a “.csv” file extension and the other has a

“.s2p” file extension. For example:

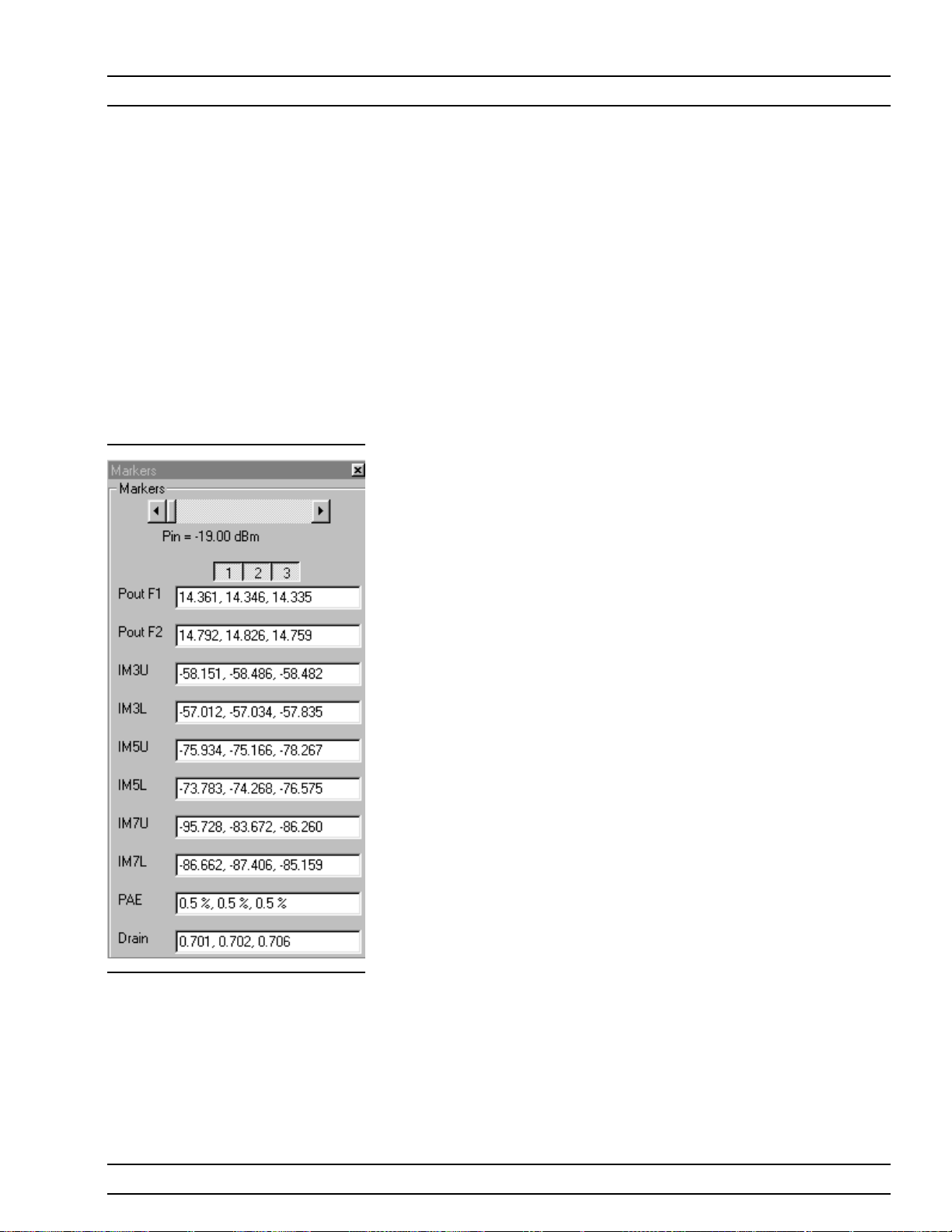

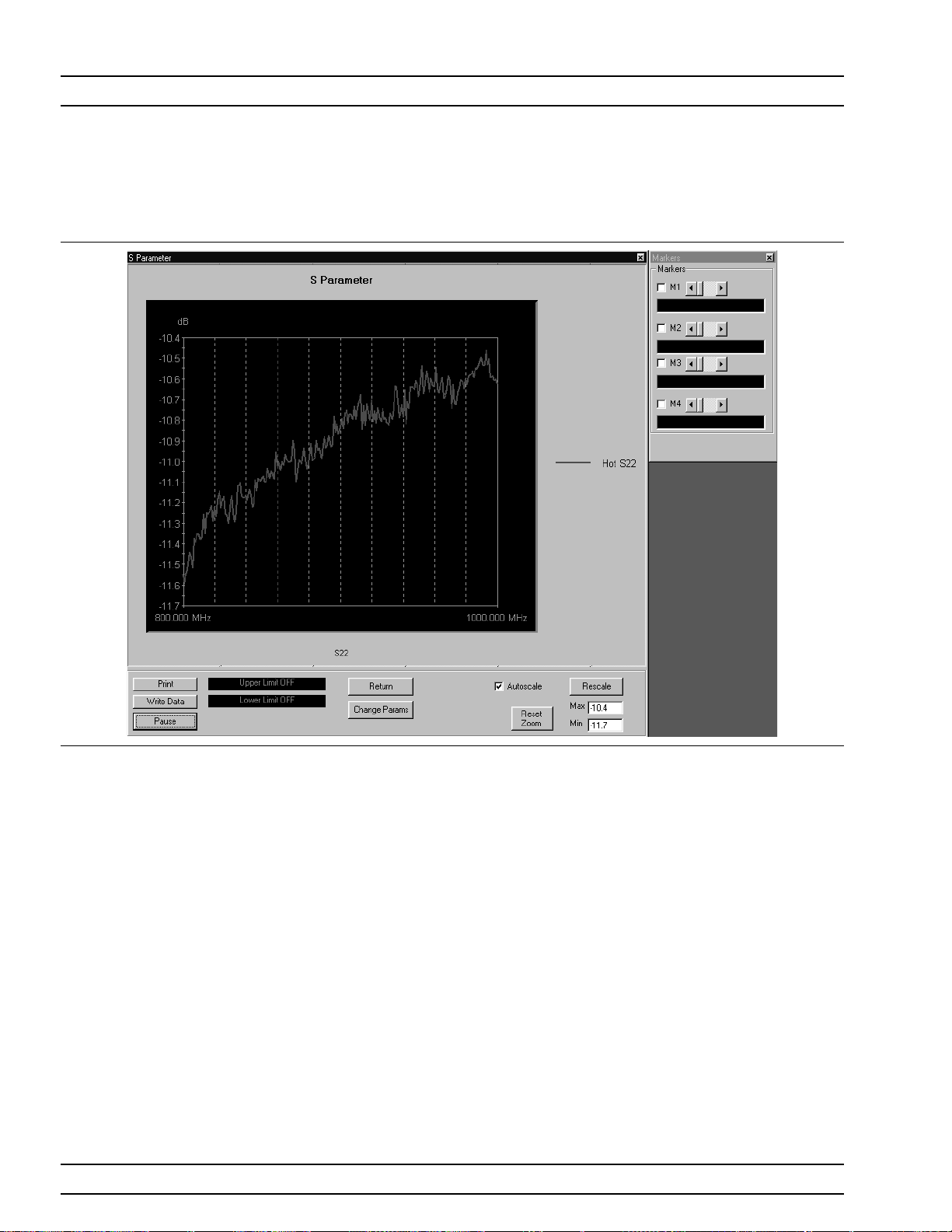

“S17-16-19-29.csv (and s2p)” was created on