Ametek CTC-140 A, CTC-320 A, CTC-320 B, CTC-650 A, CTC-650 B Specifications

...

t e m p e r a t u r e

» Temperature ranges

CTC-140 A |

-17 to 140°C / -1 to 284°F |

CTC-320 A |

33 to 320°C / 91 to 608°F |

CTC-320 B |

33 to 320°C / 91 to 608°F |

CTC-650 A |

33 to 650°C / 91 to 1202°F |

CTC-650 B |

33 to 650°C / 91 to 1202°F |

CTC-1200 A 300 to 1205°C / 572 to 2200°F

» Fast calibration is timesaving

The specially designed heating block profile heats up to 320°C / 608°F in just 4 minutes and to 650°C / 1202°F in only 10 minutes

» High flexibility

You are not limited by fixed holes. Inter-changeable insertion tubes are

used to match the diameter of your sensor- under-test

» Enhanced stability

MVI circuitry ensures stability despite mains supply variations in the process environment

» Timesaving features

Fast one-key-one-function access to the automatic switch test and auto stepping

» Documentation made easy

RS232 communication and JOFRACAL calibration software are included in the standard delivery

» Complete marine program

Part of a complete program of marine approved temperature, pressure and signal calibrators; including temperature sensors

ISO 9001 Manufacturer

Compact Temperature Calibrator

CTC-series

A fast, timesaving, and reliable true temperature calibrator designed for on-site use.

The CTC series is a fast dry-block that offers both interchangeable inserts, the MVI stability circuitry, and calibration software. Both speed and portability are superior to liquid baths. Dry-block calibrators do not require hazardous liquids and provide a wide temperature range.

Calibrate RTD’s, thermocouples, thermoswitches, thermistors, and other common temperature sensing devices.

The CTC series is designed for both on-site and maintenance shop use. The applications are generally critical process control but can vary based on calibration and testing requirements. The user interface is easy and intuitive. One-key-one-function gives you quick access to timesaving features such as the switch test or the auto-stepping function.

All models feature a large, backlit LCD display panel, which is easy- to-read even in well-lit areas. Units feature an informative display that provides icons and information regarding the status of the CTC and the calibration in-progress. The CTC series consists of six different models that differ in temperature ranges and immersion depths. All units offer similar features. A rugged, slim-line, aluminum outer casing with die-cast top and bottom protects the CTC series of dry-block calibrators.

For easy documentation and automatic calibration, all units are delivered with RS232 serial communication and JOFRACAL calibration software.

Specification Sheet

SS-CTC

Fast heating and cooling

The CTC-320 A and the CTC-650 A contain an innovative heating block profile. This design heats up the CTC-320 A to maximum temperature in just 4 minutes and the CTC650 A in only 10 minutes. The fast performance of the heating block is due to the special profile that minimizes mass and yet, still accepts an insertion tube with a 25 mm / 1 in. outer diameter. This design is a balanced compromise between temperature stability / homogeneity and rapid heating / cooling.

Deep immersion depth

The CTC-320 B and CTC-650 B models offer a deeper immersion depth of 200 mm / 7.9 in. If you have liquid-filled sensors or other sensors that require a deeper immersion depth, look for the B versions. While the units do not heat and cool as quickly as their shorter counterparts, they offer the capability to accommodate longer sensors.

Peltier effect (CTC-140 A)

The model CTC-140 A features Peltier elements. In 1834, Jean Peltier, a French physicist found that an ’’opposite thermocouple effect’’ could be observed when an electric current was connected to a thermocouple. Heat would be absorbed at one of the junctions and discharged at the other junction. This effect is called the ’’PELTIER EFFECT’’.

The practical Peltier element (electronic heating pump) consists of many elements of semiconductor material connected electrically in series and thermally in parallel. These thermoelectric elements and their electrical interconnections are mounted between two ceramic plates. The plates serve to mechanically hold the overall structure together and to electrically insulate the individual elements from one another.

Maximum temperature

From the setup menu, the user can select the maximum temperature limit for the calibrator. This function prevents damage to the sensor-under-test caused by the application of excessive temperatures. The feature also aids in reducing drift resulting from extended periods of exposures to high temperatures. This feature can be locked with an access code.

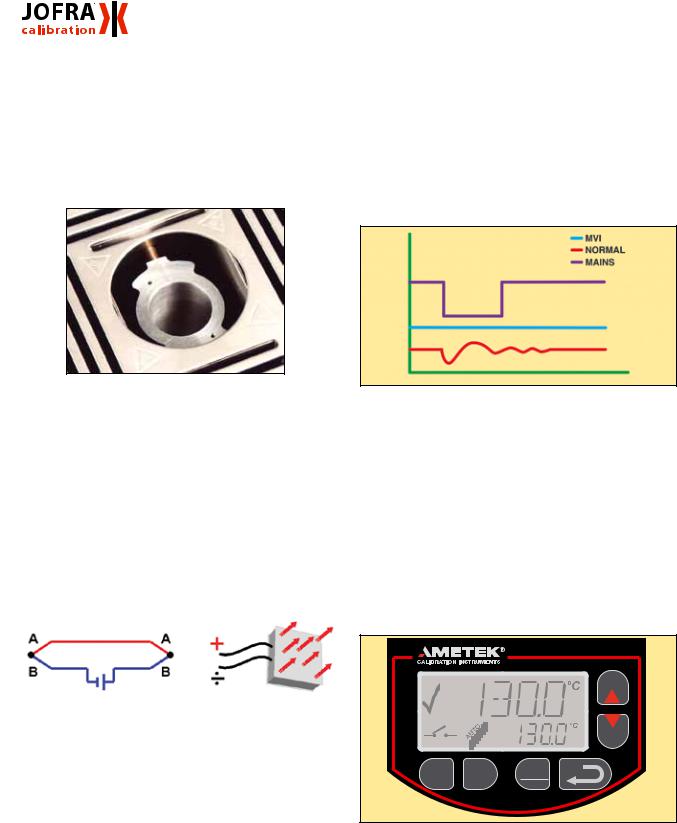

MVI - Improved temperature stability

MVI stands for ’’Mains power Variance Immunity’’.

Unstable mains power supplies are a major contributor to on-site calibration inaccuracies. Traditional temperature calibrators often become unstable in production environments where large electrical motors, heating elements, and other devices are periodically cycled on or off. The cycling of supply power can cause the temperature regulator to perform inconsistently leading to both inaccurate readings and unstable temperatures.

The CTC series employ the MVI, thus avoiding such stability problems. The MVI circuitry continuously monitors the supply voltage and ensures a constant energy flow to the heating elements.

Easy-to-use, intuitive operation

All instrument controls may be performed from the front panel. The heat source is positioned away from the panel. This design helps to protect the operator.

The main functions on the CTC series are designed with one-key-one-function logic. This means that there are no sub-menus or difficult to remember multiple keystrokes necessary to access primary functions. The easy-to-read, backlit display features dedicated icons, which help in identifying instrument conditions and operational steps.

SWITCH |

AUTO |

ESC |

TEST |

STEP |

MENU |

Set temperature

The ’’Up’’ and ’’Down’’ arrow keys allow the user to set the exact temperature desired with a resolution of 0.1°.

Instrument setups

The CTC series stores the complete instrument setup, including: engineering units, stability criteria, resolution, display contrast, slope (ramp) rate, auto-step settings, and maximum temperature.

2 |

www.jofra.com |

Compact Temperature Calibrator • CTC |

|

|

|

Stability indicator

A bold checkmark on the display indicates that the calibrator has reached the desired set temperature and is stable. The operator may change the stability criteria and establish a greater sense of security in the calibration results. A convenient countdown timer is activated five minutes before the unit reaches stability.

Automatic switch test

Operators can save a lot of time using the automatic thermoswitch test function to find values for the ’’Open’’ and ’’Close’’ temperatures. Additionally, this feature displays the hysteresis (deadband) between the two points. The feature ensures a very high repeatability when testing thermoswitches. Simply press the ’’SWITCH TEST’’ key to activate the function.

|

|

|

|

|

START |

Slope rate |

|

|

|

(Ramp) |

SWITCH |

AUTO |

ESC |

|

|

|

TEST |

STEP |

MENU |

Auto-stepping

This feature saves manpower. The operator may stay in the control room, or another remote location, monitoring the output from the sensor-under-test while the CTC

series calibrator is placed in the process and automatically changes the temperature using a programmed step value and rate. Up to 9 different temperature steps may be programmed, including the hold time for each step.

4

3

2

1 |

SWITCH |

AUTO |

ESC |

|

TEST |

STEP |

MENU |

START

Liquid filled sensors and switches

The tall B models with an immersion depth of 190 mm / 7.5 in are ideal for calibration of liquid filled sensors. The specially designed non-linear heating elements in the CTC-650 B and the increased block mass provide a very homogeneous temperature throughout the block. It is essential for the quality of the calibration/test that the full lenght of the sensing part of the sensor is exposed to the same temperature. Calibrate analog reading devices or switches with very high repeatability.

Re-calibration/adjustments

The CTC series has a very easy and straightforward procedure for re-calibration/adjustment. There is no need for a screwdriver or PC software. The only thing you need is a reliable reference thermometer.

Place the probe in the calibrator and follow the instructions on the display. Third-party labs and calibration facilities will be able to perform this function if a certificate from an independent source is necessary. Of course, AMETEK can provide you with a traceable calibration certificate from our labs when you require a higher level of confidence.

Calibration of up to 24 sensors with JOFRA ASM

Using the CTC series together with the ASM Advanced Signal Multi-scanner offers a great time-saving automatic solution to calibrate multiple temperature sensors at the same time.

The ASM series is an eight channel scanner controlled by JOFRACAL software on a PC. Up to 3 ASM units can be stacked to calibrate up to 24 sensors at the same time.

It can handle signals from 2-, 3- and 4 wire RTD’s, TC’s, transmitters, thermisters, temperature switches and voltage.

CTC • Compact Temperature Calibrator |

www.jofra.com |

3 |

|

|

|

Loading...

Loading...