Page 1

Agilent G3180B

Two-Way Splitter Kit

With Makeup Gas

Installation and Operation

Guide

Agilent Technologies

Page 2

Notices

©Agilent Technologies, Inc. 2006

No p art o f this manu al may be re produce d in

any form or by any means (including electronic storage and retrieval or translation

into a foreign language) without prior agreement and written consent from Agilent

Technologies, Inc. as governed by United

States and international copyright laws.

Manual Part Number

G3180-90120

Supercedes G3180-90110

Edition

First edition, April 2006

Printed in USA

Agilent Technologies, Inc.

2850 Centerville Road

Wilmington, DE 19808-1610 USA

Acknowledgement

Microsoft® is a U.S. registered trademark

of Microsoft Corporation.

Warranty

The material contained in this

document is provided “as is,” and

is subject to being changed, without notice, in future editions. Further, to the maximum extent

permitted by applicable law,

Agilent disclaims all warranties,

either express or implied, with

regard to this manual and any

information contained herein,

including but not limited to the

implied warranties of merchantability and fitness for a particular

purpose. Agilent shall not be

liable for errors or for incidental

or consequential damages in

connection with the furnishing,

use, or performance of this

document or of any information

contained herein. Should Agilent

and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the

separate agreement shall control.

Safety Notices

CAUTION

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or the like

that, if not correctly performed or

adhered to, could result in damage

to the product or loss of important

data. Do not proceed beyond a

CAUTION notice until the indicated

conditions are fully understood and

met.

WARNING

A WARNING notice denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like that, if not correctly performed or adhered to, could result

in personal injury or death. Do not

proceed beyond a WARNING

notice until the indicated conditions are fully understood and

met.

2 Installation and Operation Guide

Page 3

In this Guide. . .

This Installation and Operation Guide contains information for installing and

using an effluent splitter on an Agilent 6890 gas chromatograph (GC). The

G3180 splitter is intended for use with capillary columns and uses makeup gas

to maintain adequate flows throughout the system.

1 Introduction

This chapter describes how the splitter works, the GC and software

requirements of the system and the contents of the installation kit.

2 Hardware Installation

See this chapter for a detailed procedure for installing the splitter hardware

and connecting the makeup gas supply.

3 Splitter Configurations

The split ratio (how the column effluent divides between the two detectors) is

governed by two restrictors, which are lengths of deactivated fused silica

tubing. This chapter presents a set of precalculated “typical” configurations. If

desired, you can create a custom configuration to meet specific needs. The

chapter describes a set of software tools, included in the kit, to assist you in

designing such configurations. Finally, installation of the column and

restrictors is covered.

4Operation

This chapter contains a worked-out custom configuration, plus a few special

topics.

Installation and Operation Guide 3

Page 4

4 Installation and Operation Guide

Page 5

Contents

1 Introduction

Overview 8

How It Works 9

Details 10

Metal ferrules 10

Microfluidic plate 10

Constant pressure operation 10

Calculation of chromatographic parameters 11

GC Requirements 12

Other Requirements 12

Parts Supplied 13

Part Identification 14

Parts Not Supplied 15

Tools Required 15

2 Hardware Installation

Prepare the GC 18

Install the Column Clips 20

Install the Bracket and Splitter 21

Connect the Makeup Gas Supply 24

To supply the makeup gas froma PCM 24

To supply the makeup gas from an Auxiliary Pressure

controller 24

Installation and Operation Guide 5

Page 6

3 Splitter Configurations

Typical Configurations 26

Splitting to an MSD 28

Custom Configurations 29

Restrictor id and length 32

Maximum and minimum flows 33

Column outlet pressure 34

Inlet pressure 34

Restrictor and Column Installation 35

Install the column 35

Connect the splitter 35

Disconnect tubing from the splitter 37

4Operation

An Example 40

Column flow 40

Select restrictors 42

Calculate column flow 43

Calculate ECD restrictor flow 44

Calculate MSD restrictor flow 45

Changing Columns Without Venting the MSD 46

Backflushing the Column 47

6 Installation and Operation Guide

Page 7

Agilent G3180B Splitter Kit

Installation and Operation Guide

1

Introduction

Overview 8

How It Works 9

Details 10

Metal ferrules 10

Microfluidic plate 10

Constant pressure operation 10

Calculation of chromatographic parameters 11

GC Requirements 12

Other Requirements 12

Parts Supplied 13

Part Identification 14

Parts Not Supplied 15

Tools Required 15

This manual covers the installation and operation of the G3180B effluent

splitter with makeup gas kit on the Agilent 6890 series gas chromatograph

(GC).

Agilent Technologies

7

Page 8

1 Introduction

Overview

Splitter installation is done in three steps:

1 Hardware installation. This gets the hardware installed and the gas flows

connected.

2 Restrictor configuration. You can choose to use a typical, precalculated

configuration or create a custom one using software tools supplied on a CD.

3 Restrictor and column installation. Using the results of step 2, cut the

appropriate lengths of the appropriate diameter tubing for the restrictors.

Install the restrictors and the analytical column.

8 Installation and Operation Guide

Page 9

How It Works

Introduction 1

The splitter divides the effluent from a column between two different

detectors. The detectors can be operating at different pressures, that is, any

mix of the following can be used:

• Atmospheric pressure

FID (flame ionization detector)

TCD (thermal conductivity detector)

NPD (nitrogen phosphorus detector)

ECD (electron capture detector)

FPD (flame photometric detector)

• Below atmospheric pressure

MSD (mass selective detector)

• Above atmospheric pressure

AED (atomic emission detector)

The split ratio is determined by the length and diameter of tubing connecting

the splitter to the detectors. Tubing dimensions may be determined from

Table 2 on page 26 in this manual or from a spreadsheet calculator that is

included for calculating tubing dimensions for special situations.

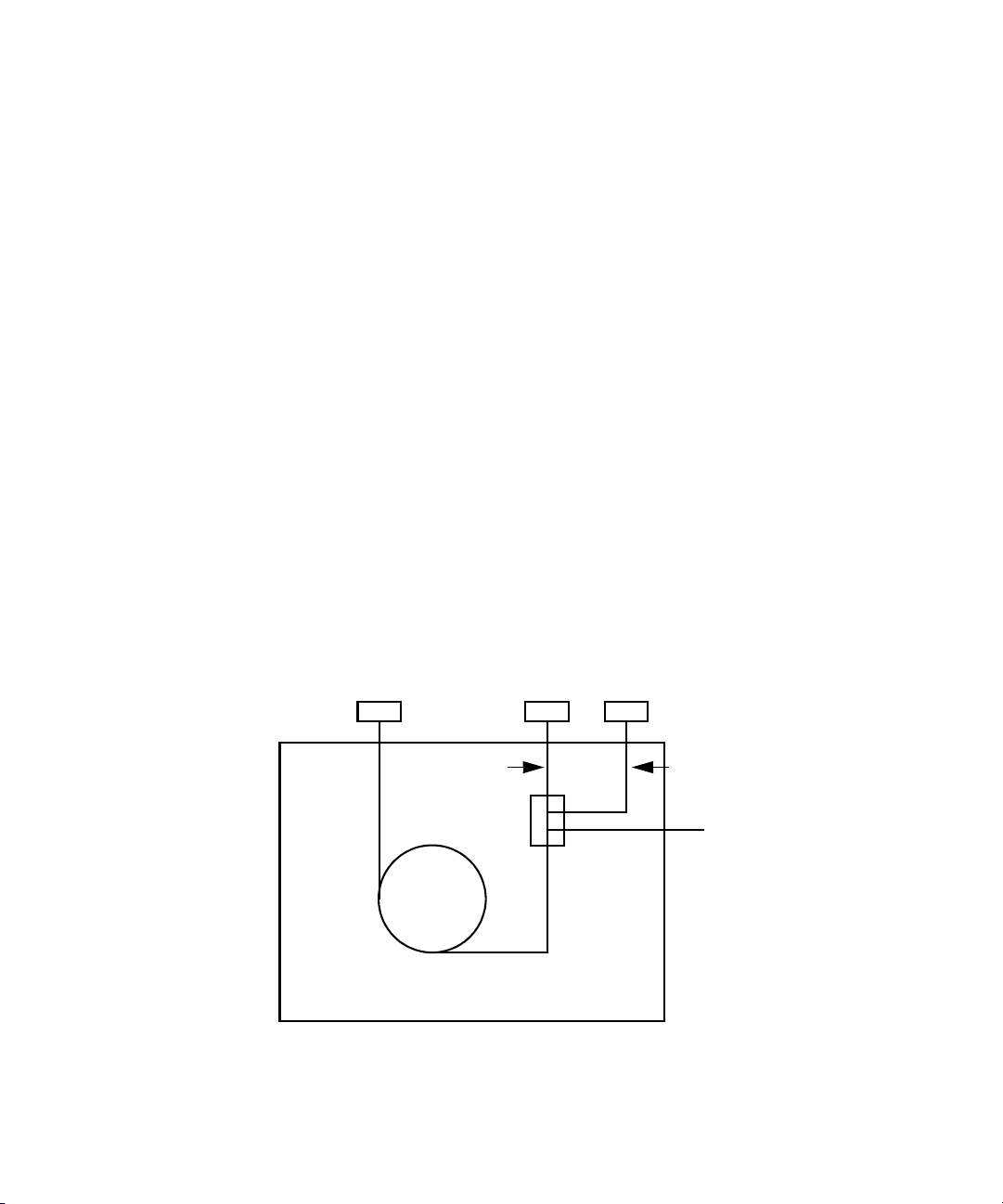

Figure 1 shows the plumbing configuration for the G3180B splitter.

Det 1 Det 2Inlet

Restrictor 1 Restrictor 2

Splitter

Column

GC oven

Constant pressure

makeup gas supply

Figure 1 Splitter plumbing

Installation and Operation Guide 9

Page 10

1 Introduction

Details

Metal ferrules

Microfluidic plate

The column flow mixes with the makeup flow in the splitter. This mixture then

flows through lengths of uncoated, deactivated, fused-silica tubing to each

detector. These tubes act as flow restrictors. While the flow through each

restrictor changes with oven temperature, the ratio of the two flows at any

temperature is the same.

The G3180B kit addresses several limitations of previous approaches to

splitting column effluent between two detectors:

The splitter uses metal column ferrules, which eliminate air leakage into the

sample stream. Unlike polyimide, metal ferrules do not loosen upon thermal

cycling of the oven. They also do not outgas contaminants or shed particles

(like graphite) that can result in chromatographic problems.

The splitting hardware is based on microfluidic plate technology. This allows

very low dead volume connections between the column end and the two

detector restrictor tubes. The thin metal plate has fast thermal response and is

mounted solidly on the oven wall for ease of use. The interior plate surfaces

are deactivated to prevent adsorption by active compounds.

Constant pressure operation

The splitter uses a source of makeup gas supplied by electronic pneumatics

control (EPC). This maintains the splitter at a known and constant pressure.

Constant pressure allows easier splitting to vacuum detectors like the MSD. It

simplifies choice of splitter parameters, allowing all aspects of the

chromatographic setup to be calculated. Constant pressure makeup allows the

column to be run in constant flow mode while still maintaining a constant

split ratio between two detectors of different operating pressures such as the

FPD and the MSD. Because the EPC pressure can be time programmed, useful

operations like backflushing unwanted heavy materials from the column and

changing columns in MSD systems without venting are possible.

10 Installation and Operation Guide

Page 11

Calculation of chromatographic parameters

Because the pressure at the split point is known and constant, the

chromatographic parameters can be calculated before setup. This is especially

useful with GC/MSD setups, where there are limitations on the flow rates of

carrier gas allowed into the MSD. If a method that was originally developed on

an MSD is converted to a splitter setup, a new inlet pressure can be calculated

to produce retention times very similar to the original method.

Introduction 1

Installation and Operation Guide 11

Page 12

1 Introduction

GC Requirements

The splitter mounts in an Agilent 6890 series GC.

The splitter requires an electronically controlled pressure source such as the

Three Channel Pressure controller (6890 option 205, 301, or 308) or a

Pneumatics Control Module (PCM).

Other Requirements

The calculator requires Microsof®t Excel 97 (or later), which is not supplied

with this kit.

12 Installation and Operation Guide

Page 13

Parts Supplied

Introduction 1

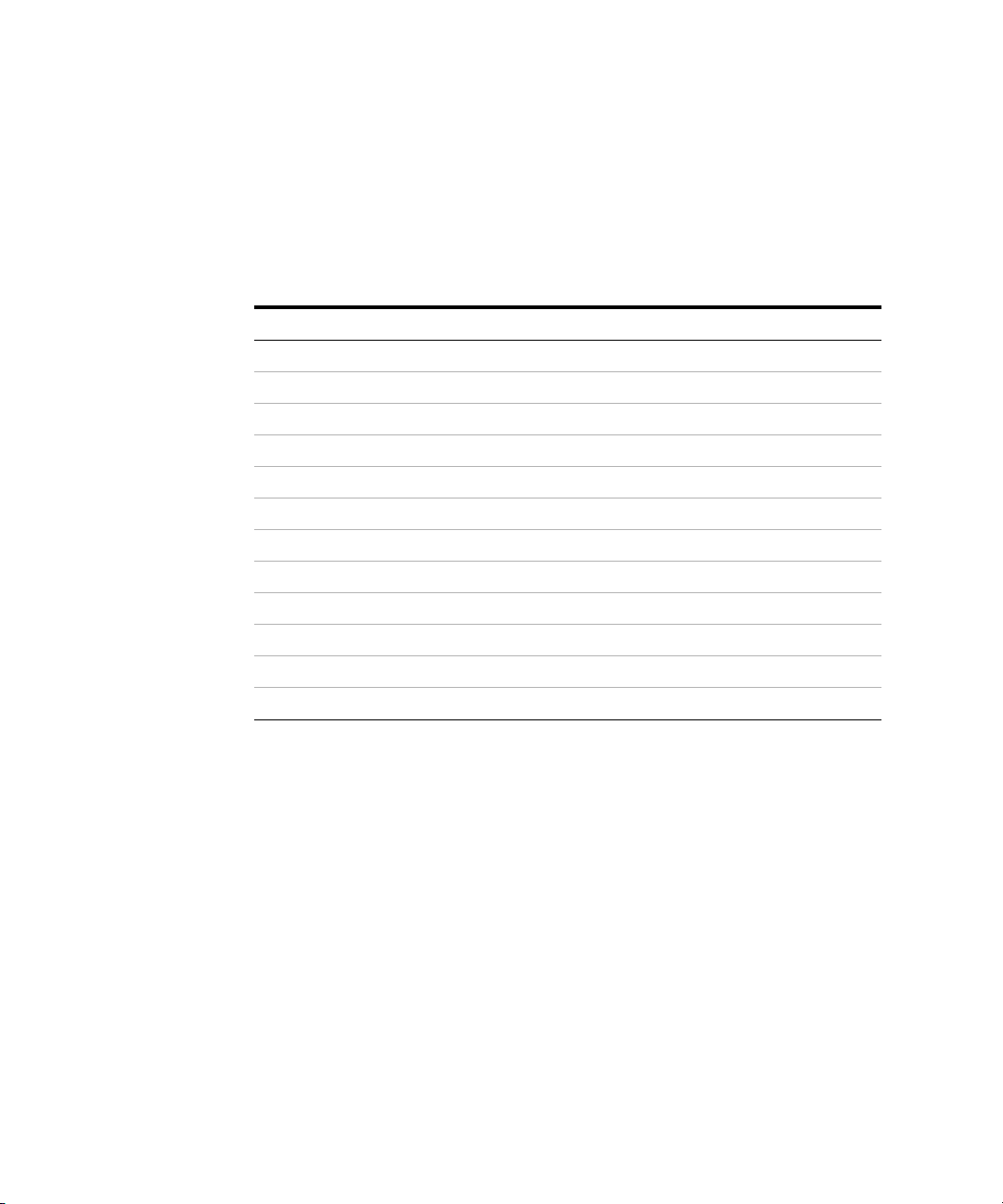

The G3180B kit contains the following parts (Table 1).

Tab l e 1 Parts supplied

Part number Description Quantity

0100-0124 Union, stainless steel, 1/16-inch tubing 2

0100-0241 Union, stainless steel, 1/8 to 1/16-inch reducing 1

G1580-00130 Valve box blanking plate 1

G1530-01340 Capillary column spring clips 4

0515-0374 Screw, M3 × 10 mm 7

G2855-60140 Oven bracket assembly 1

G2855-60560 T-screw oven bracket retainer 2

G2855-80022 Manual and calculator CD 1

G3180-90120 Manual, G3180B

0100-2354 Tubing, stainless steel, 1/16-inch od × 0.01-inch id, 1 m 1

G3180-61500 Compact splitter with makeup gas assembly 1

G2855-60150 Supplies and spares kit 1

Installation and Operation Guide 13

Page 14

1 Introduction

Part Identification

Most of the kit parts are easily recognized. The unique ones are identified in

Figure 2.

Capillary column

spring clips

Valve box

blanking plate

Oven bracket

assembly

This assembly is shipped in a

Compact splitter

with makeup gas

assembly

plastic bag to keep contaminants

out of the tubing and the fittings.

Do not open the bag until you are

ready to install the splitter.

Figure 2 Part identification

14 Installation and Operation Guide

Page 15

Parts Not Supplied

Brown-dot frit (19231-60610)

Tools Required

Side cutter, large

Open-end wrenches

Introduction 1

Installation and Operation Guide 15

Page 16

1 Introduction

16 Installation and Operation Guide

Page 17

Agilent G3180B Splitter Kit

Installation and Operation Guide

2

Hardware Installation

Prepare the GC 18

Install the Column Clips 20

Install the Bracket and Splitter 21

Connect the Makeup Gas Supply 24

This chapter describes the procedure for installing the splitter hardware and

connecting the makeup gas supply.

Agilent Technologies

17

Page 18

2 Hardware Installation

Prepare the GC

WARNING

Turn the power off and disconnect the power cord before proceeding.

1 Raise the GC top cover to expose the oven top.

2 Remove the valve box cutout using a side cutter (Figure 3).

Cut tabs

around edges

and remove

Figure 3 Remove the valve box cutout

18 Installation and Operation Guide

Page 19

Hardware Installation 2

3 This exposes a layer of soft insulation. Remove it to expose the hard oven

insulation. Remove the precut insulation piece at the location shown in

Figure 4.

Remove

this

cutout

Figure 4 Remove the insulation cutout

4 Replace the soft insulation. Install the valve box blanking plate, using one

screw at the front and one at the rear to secure it. See Figure 5.

Two screws

Figure 5 Install valve box blanking plate

Installation and Operation Guide 19

Page 20

2 Hardware Installation

Install the Column Clips

Install the four column clips on the oven shroud (Figure 6).

Clip

(1 of 4)

Oven

shroud

Figure 6 Oven clips

20 Installation and Operation Guide

Page 21

Install the Bracket and Splitter

The splitter is usually installed on the right side of the oven.

Hardware Installation 2

NOTE

The body of the splitter may be discolored as a result of the deactivation process. This is

not a defect.

1 Place the bracket against the side of the oven. The two notches should be up

and the standoffs should face the center of the oven.

2 Use two T-shaped thumbscrews to fasten the bracket to the T-slots in the

oven wall (Figure 7).

Thumbscrews

Bracket

Detail

Figure 7 Installing the bracket

Installation and Operation Guide 21

Page 22

2 Hardware Installation

CAUTION

CAUTION

Use extreme care to prevent any fragments of insulation or other material from

entering the makeup gas tubing or the fittings on the splitter assembly. Such materials

could block the internal passages in the splitter or the bore of the capillary restrictors.

In the following steps, bend the tubing over an object such as your thumb to avoid

kinks.

3 Open the plastic bag and remove the splitter assembly. Install a plastic cap

on the end of the makeup gas tubing. Place small pieces of tape over the

open end of the fittings.

4 Prebend the tubing according to Figure 8. This will make splitter

installation much easier.

Up through hole

in oven top and

blanking plate

195 mm

60 mm

Oven side wall

140 mm

Dimensions are approximate

All bends are 90°

45 mm

Splitter assembly

Figure 8 Prebending the splitter tubing

5 Push the end of the makeup gas tubing up through the top oven wall so that

the end of the tubing comes out in the hole of the valve box blanking plate.

22 Installation and Operation Guide

Page 23

Hardware Installation 2

6 Route the prebent tubing against the oven wall and top to keep it clean for

future maintenance. It should be behind the back detector location.

7 Screw the splitter assembly to the bracket (three screws). See Figure 9.

Makeup gas tubing

Mounting screws

Splitter assembly

Ferrule release hole

Mounting screw

Figure 9 Installing the splitter assembly

Installation and Operation Guide 23

Page 24

2 Hardware Installation

Connect the Makeup Gas Supply

Connect the makeup gas source to the PCM or Auxiliary Pressure controller.

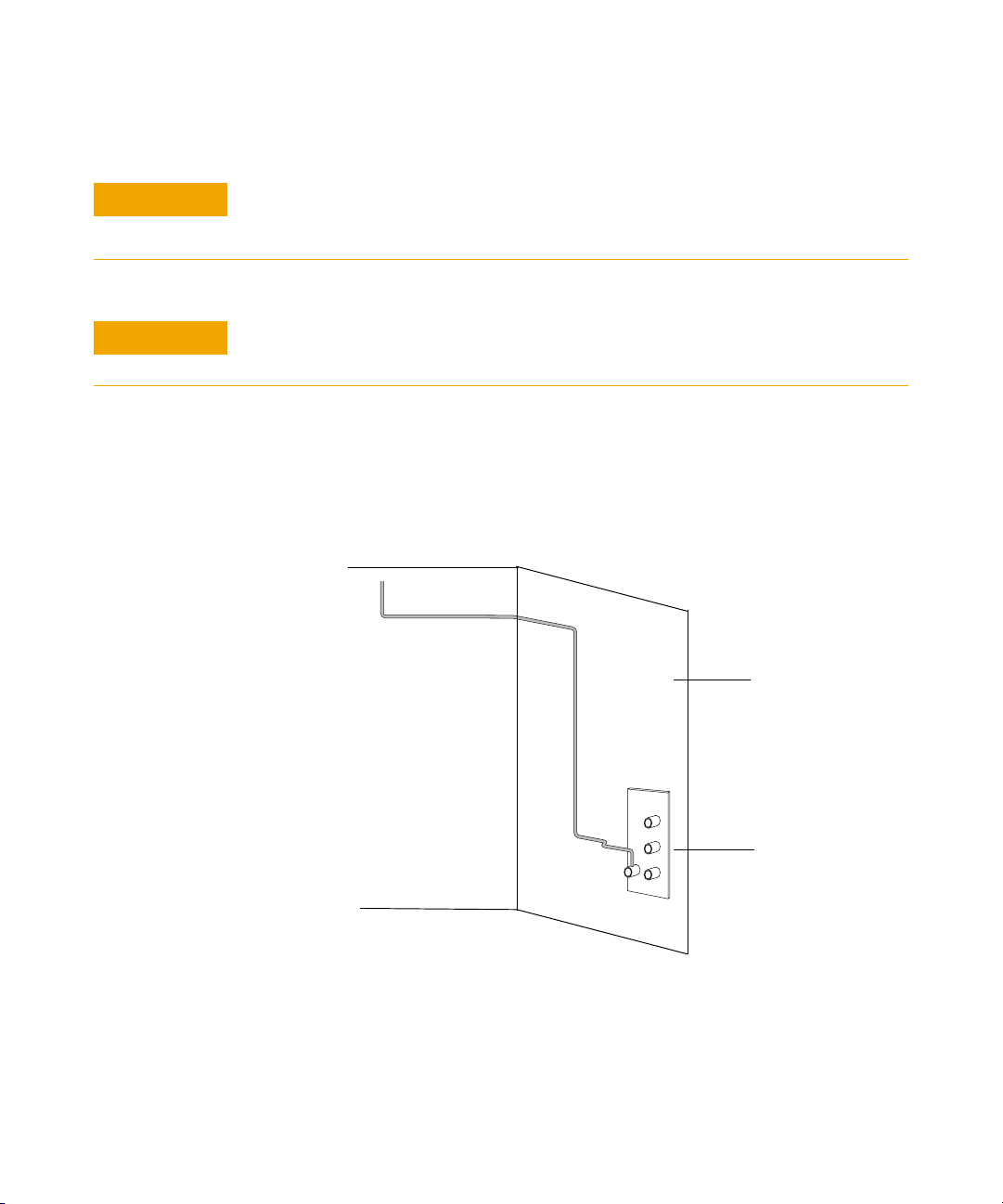

To supply the makeup gas froma PCM

1 Connect the tubing from the PCM to the 1 meter length of stainless steel

tubing from the kit with a union.

2 Connect the free end of the stainless steel tubing to the tubing from the

splitter assembly with a union. See Figure 10.

Stainless

steel

tubing

PCM

Union Union

Figure 10 Plumbing a PCM makeup supply

To splitter

To supply the makeup gas from an Auxiliary Pressure controller

1 Install the brown-dot frit (part no. 19231-60610) in the output channel. See

your GC manual for details.

2 Connect the tubing from the Auxiliary Pressure controller to the tubing

from the splitter assembly with the 1/8 to 1/16-inch stainless steel reducing

union.

This completes the hardware installation.

24 Installation and Operation Guide

Page 25

Agilent G3180B Splitter Kit

Installation and Operation Guide

3

Splitter Configurations

Typical Configurations 26

Splitting to an MSD 28

Custom Configurations 29

Restrictor id and length 32

Maximum and minimum flows 33

Column outlet pressure 34

Inlet pressure 34

Restrictor and Column Installation 35

Install the column 35

Connect the splitter 35

Disconnect tubing from the splitter 37

The combination of restrictor diameters and lengths determines how the

column effluent is divided (the split ratio) between the two detectors. There

are two approaches to setting up a splitter method.

• Use a typical configuration. A set of eight configurations is discussed

beginning on the next page. They apply to a variety of detector

combinations and split ratios. All of the flows have been calculated.

• Create a custom configuration. If the typical configurations do not meet

your needs, you can create one that does. The CD shipped with the splitter

kit provides tools for the necessary calculations.

We suggest examining the typical configurations first, since they cover a wide

variety of splitter applications and require no calculations.

Agilent Technologies

25

Page 26

3 Splitter Configurations

Typical Configurations

The important parameters when setting up a splitter are the lengths and

diameters of the restrictor tubes that go to the two detectors. The dimensions

of the restrictors are chosen to give the desired split ratio, flow to the detector,

and to minimize peak broadening.

The splitter restrictors are chosen based on:

• The range of column flows that will be used with the method

• The operating pressure of the two detectors

• The flow rate requirements of the two detectors

Table 2 lists typical splitting configurations. Table 3 shows the resulting gas

flows. All calculations assume helium as the carrier gas.

Tab l e 2 Restrictor configurations

Configuration Det 1 Det 2 Split ratio,

Det 2/Det 1

1 atm* atm 1 0.25 0.544 0.25 0.544

2 atm atm 5 0.18 0.418 0.25 0.311

3 atm MSD,D** 1 0.18 1.060 0.18 2.890

4 atm MSD, T*** 1 0.18 0.530 0.18 1.440

5 atm MSD, D 2 0.18 2.130 0.18 2.890

6 atm MSD, T 2 0.18 1.064 0.18 1.443

7 atm MSD, D 5 0.10 0.507 0.18 2.890

8 atm MSD, T 5 0.18 2.660 0.18 1.443

* atm Atmospheric pressure detectors such as FID, TCD, ECD, FPD and NPD

** MSD, D MSD with diffusion pump or standard turbo pump (2 mL/min flow capability)

*** MSD, T MSD with performance turbo pump (4 mL/min flow capability); makeup pressure supply is set to 3.8 psig

Diam R1,

mm id

Length R1, mDiam R2,

mm id

Length R2,

m

26 Installation and Operation Guide

Page 27

Tab l e 3 Splitter flows

Splitter Configurations 3

40 °C 200 °C 300 °C 400 °C

Configuration Flow R1,

mL/min

1 14.7 14.7 7.3 7.3 5.2 5.2 3.9 3.9

2 5.1 25.6 2.5 12.7 1.8 9.1 1.4 6.8

3 22110.70.70.540.54

4 44221.41.41.11.1

5 1 2 0.5 1 0.36 0.72 0.27 0.54

6 24120.711.40.531.06

7 0.4 2 0.2 1 0.14 0.7 0.1 0.5

8 0.8 4 0.4 2 0.28 1.4 0.21 1.1

Flow R2,

mL/min

Flow R1,

mL/min

Flow R2,

mL/min

Flow R1,

mL/min

Flow R2,

mL/min

Flow R1,

mL/min

Flow R2,

mL/min

To use the tables, select the configuration you wish to set up. For example,

Configuration 1 splits column effluent equally between two atmospheric

pressure detectors (FID, TCD, ECD, FPD, and NPD). To plumb this system,

0.544-m lengths of 0.25-mm id uncoated deactivated fused silica tubing are

connected as restrictors from the splitter to the two detectors.

The makeup supply (either Aux EPC or PCM module) is set to 3.8 psig. This

will add sufficient makeup flow to the column flow to maintain the splitter

(and thus the column outlet) at 3.8 psi. Column flow can be varied from 0 to a

maximum flow which is determined by the upper temperature of the GC oven

program.

If Configuration 1 is used with a method that programs to 200 °C using helium,

the flow through each restrictor at 200 °C will be 7.3 mL/min. The total flow

will be 14.6 mL/min. The maximum column flow should be equal to the total

flow minus about 1 mL/min to ensure that there is some f low for the makeup

supply to regulate with.

The column flow at 200 °C should be no more than 13.6 mL/min. This becomes

important when the column is run in constant flow mode. If constant flow

mode is used with Configuration 1 and the method programmed to 400 °C, the

column flow should not exceed 6.8 mL/min ([3.9 + 3.9] –1).

Installation and Operation Guide 27

Page 28

3 Splitter Configurations

For constant pressure methods, first find the maximum flow as above. Use the

GC, ChemStation, Flow Calculator Software or the Method Translation

Software to find the inlet pressure that gives the maximum flow at the upper

temperature of the method (make sure the column outlet pressure is set to

3.8 psig for the calculation).

For example, if a 30 m × 0.32-mm id column is used with Configuration 1, using

helium carrier and programming to 300 °C, the pressure that gives a flow of

9.4 mL/min ([5.2 + 5.2] – 1 = 9.4) is 56.3 psig. This is the maximum pressure at

which the inlet should be set. The inlet should not be set at or below 3.8 psig.

If you decide to use a typical configuration, note the restrictor dimensions

from Table 2 and proceed to “Restrictor and Column Installation" on page 35.

Splitting to an MSD

Note that the maximum column flows for an MSD are quite low. This limit is

imposed by the rating of the turbo or diffusion pump. Configurations with

split ratios greater than 1 can be used but peak broadening and/or tailing

should be expected. They are shown in the configuration tables more as a

caution than as a recommendation.

In practice, the column flow can be set to within 0.5 mL/min of the total flow

if necessary. For example, the 1:1 split to an MSD with a performance turbo

pump running a method programmed to 300 °C should have a column flow of

no more than 2.3 mL/min ([1.4 + 1.4] – 0.5) at 300 °C.

Split ratios to the MSD greater than 1 are very limited due to these flow

considerations and should be avoided if possible.

28 Installation and Operation Guide

Page 29

Custom Configurations

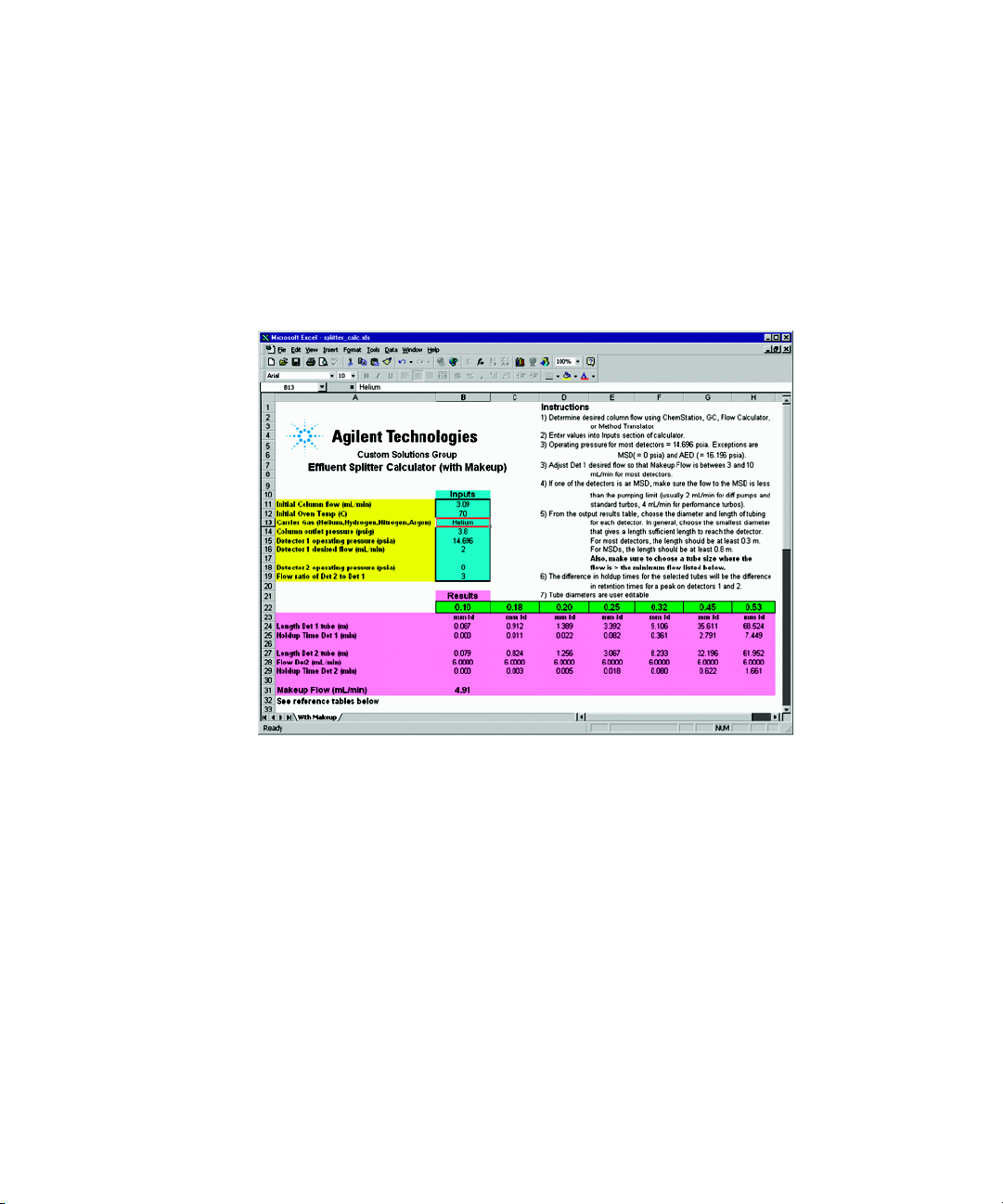

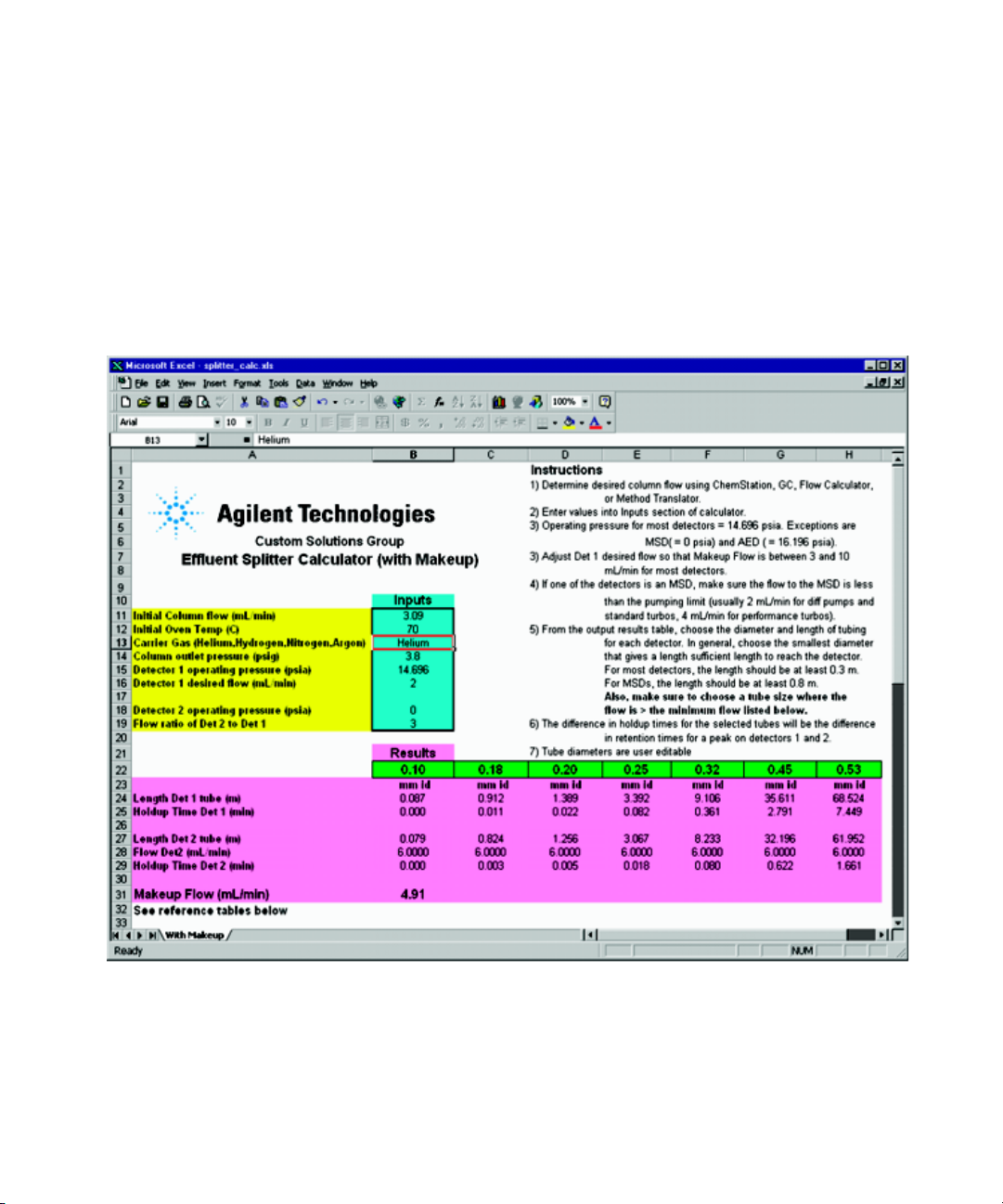

The CD supplied with this kit contains three software tools:

Effluent Splitter Calculator (with Makeup) Calculates dimensions (length and

inside diameter) of restrictors to obtain a desired split ratio (Figure 11).

Splitter Configurations 3

Figure 11 Effluent Splitter Calculator

Installation and Operation Guide 29

Page 30

3 Splitter Configurations

GC Method Translation Converts an analytical method from one set of

operating conditions to another (Figure 12).

Figure 12 GC Method Translation

30 Installation and Operation Guide

Page 31

Splitter Configurations 3

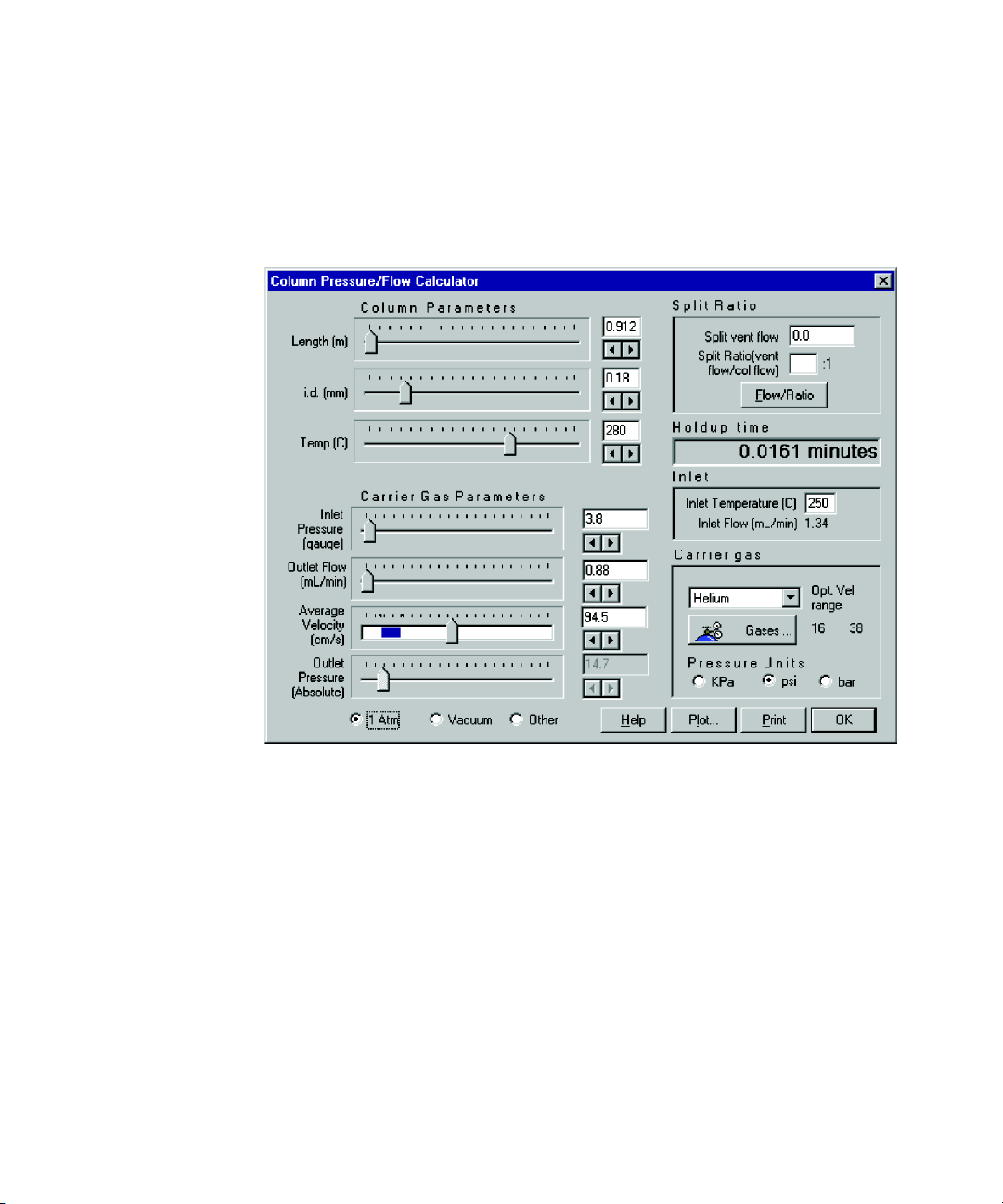

Column Pressure/Flow Calculator Calculates flows and pressures for a given

set of column (or restrictor) dimensions (Figure 13).

Figure 13 Column Flow/Pressure Calculator

These tools allow you to perform all the calculations needed to create a

custom splitter configuration. We recommend that you load the CD software

into your PC.

1 Insert the CD into the drive and click the Start icon in the bottom left of the

screen. Select Run and type X:\ Setup, where X is the letter assigned to the

CD drive.

2 Click Start, then select Programs and the program you wish to run.

Installation and Operation Guide 31

Page 32

3 Splitter Configurations

Restrictor id and length

1 Run the Effluent Splitter Calculator and enter the following information.

The calculator provides a list of possible restrictors.

• Column flow. Use the ChemStation, GC, Flow Calculator, or Method

• Initial oven temperature. This is the temperature setpoint for an

• Carrier gas type. Enter Helium, Hydrogen, Nitrogen, or Argon.

• Detectors 1 and 2 operating pressure (psia). The operating pressure

• Flow Ratio of Detector 2 to Detector 1. This is the desired split ratio

• Splitter (column outlet) pressure (psig). This is the desired pressure at

2 Choose the id tubing that gives a length closest to (and at least) 0.3 m for

most detectors and 0.8 m for MSDs. The green fields with tubing diameters

in mm can be edited if you have other sizes of deactivated tubing available.

Translation Software to determine the column flow in mL/min (with the

column outlet at 3.8 psig) at the initial oven temperature.

isothermal method or the initial temperature for a programmed method.

must be in absolute units. Most detectors (FID, TCD, ECD, NPD, and

FPD) operate at atmospheric pressure (14.696 psia). Exceptions are the

MSD (0 psia) and AED (16.196 psia).

between the two detectors. Usually this number is 1, meaning the

effluent divides equally between the detectors. This can be adjusted to

higher values, but should normally not exceed five.

which the splitter (and thus the end of the column) will operate. It can be

set between 2 and 4 psig, but is usually set to 3.8 psig. This number can

be varied to obtain an acceptable combination of restrictors that will

have sufficient flow velocity to give good peak shapes.

32 Installation and Operation Guide

Page 33

Maximum and minimum flows

The maximum suggested flow for MSDs depends on the vacuum pump used.

For diffusion pump and standard turbo systems, the flow should not exceed

2 mL/min. For performance turbo systems, the flow should not exceed

4 mL/min. These flow limits restrict the column flows and split ratios that can

be used with MSDs.

Make sure that the flow through each restrictor tube is at least equal to the

suggested minimum flow in Table 4. Restrictors that fail this test will still

work, but peak broadening and/or tailing may result.

Tab l e 4 Suggested minimum restrictor flows

Restrictor internal

diameter, mm Helium Hydrogen Nitrogen Argon

0.10 0.400 0.500 0.125 0.110

0.18 0.720 0.900 0.225 0.198

Splitter Configurations 3

Minimum carrier gas flow, mL/min

0.20 0.800 1.000 0.250 0.220

0.25 1.000 1.250 0.313 0.275

0.32 1.280 1.600 0.400 0.352

0.45 1.800 2.250 0.563 0.495

0.53 2.120 2.650 0.663 0.583

1 The makeup flow is listed in cell B 31 of the effluent splitter calculator. You

should have at least 0.5 mL/min for stable pressure regulation. Note that

this value will decrease as the oven temperature programs up.

2 Use the Column Pressure/Flow Calculator to determine the flow through each

restrictor at the maximum oven temperature of the method, add them and

subtract the calculated column flow at that temperature. This value should

be greater than 0.5 mL/min.

Installation and Operation Guide 33

Page 34

3 Splitter Configurations

Column outlet pressure

The 6890 GC needs to know the pressure at the end of the column to be able to

calculate column flows. Use either the GC keyboard or the ChemStation to set

the outlet pressure for the column to 3.8 psig. The ChemStation screen where

the column outlet pressure is set is shown in Figure 14.

Figure 14 Column outlet pressure screen

Inlet pressure

If this is a method used previously, you may want to reset the inlet pressure to

give similar retention times with the new column outlet pressure. Do this by

calculating the inlet pressure needed to keep the void (holdup) time the same

as the previous method. For constant inlet pressure methods, this will also

keep the elution order the same. The Method Translation Software tool or the

Flow Calculator tool can be used to do this calculation.

34 Installation and Operation Guide

Page 35

Restrictor and Column Installation

Splitter Configurations 3

NOTE

Install the column

Connect the splitter

CAUTION

Restrictors and the column exit are connected to the splitter assembly using internal nuts

and SilTite ferrules. See “Swaging SilTite Ferrules” on the CD for details.

1 Hang the analytical column on the column clips. The clips hold the outside

of the wire “basket” that supports the column. Adjust the clips if necessary.

2 Connect the column to the inlet fitting.

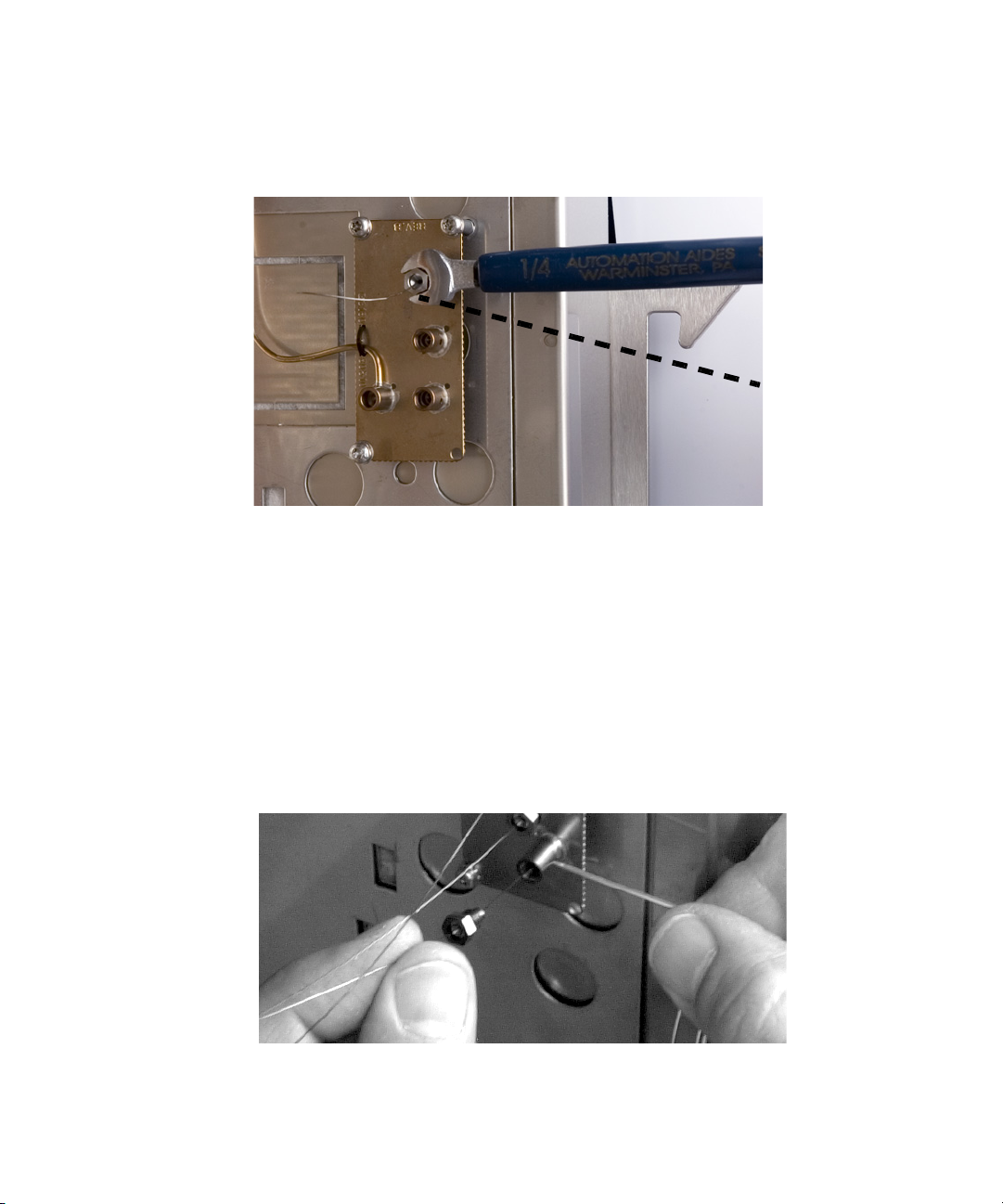

1 Connect the restrictors to the connectors on the splitter (Figure 15).

Finger-tighten until just snug, then tighten with a wrench an additional 15°

(Figure 16). Install the back restrictor first.

2 Connect the restrictors to the appropriate detectors.

3 Connect the column exit to the splitter. Tighten as you did the restrictors.

Arrange the tubing (restrictors and column) so that it does not touch the oven walls.

This could create a cold spot.

Installation and Operation Guide 35

Page 36

3 Splitter Configurations

To m a k e up

gas supply

Restrictor 2

to Detector 2

Restrictor 1

to Detector 1

Column exit

Figure 15 Restrictor and column connections

CAUTION

Do not overtighten the fittings. The dashed line in Figure 16 (about 15° clockwise from

finger-tight) is usually enough.

36 Installation and Operation Guide

Page 37

Figure 16 Tightening the connections

Disconnect tubing from the splitter

Loosen and remove the internal nut from the splitter fitting. Usually the

tubing and ferrule will fall out of the fitting.

Splitter Configurations 3

15°

Occasionally the ferrule will stick in the fitting. If this happens, use a pointed

object like a pen or a paper clip and insert it in the ferrule release hole in the

side of the fitting (Figure 17). Press firmly. The ferrule will click when it

breaks free.

Figure 17 Releasing a ferrule

Installation and Operation Guide 37

Page 38

3 Splitter Configurations

Protect the column and restrictors

Column and restrictor tubes with swaged metal ferrules can be disconnected

and reconnected several times. To protect the tubing end, use one of the

brass-sealing caps from the kit. Tighten to finger-tight plus 15 degrees.

Protect the splitter

Seal the ports of the splitter assembly with plugs when the splitter is not

connected. This keeps particulates and contamination out. To make a plug, cut

about 2 inches of the stainless steel wire and swage it as you would a column.

Use the metal ferrule that fits 0.25-mm id columns. After swaging, clip the

wire to within 0.5 mm of the ferrule end with a small high-quality wire cutter.

Leave the excess wire on the other end to serve as a handle when removing the

plug.

38 Installation and Operation Guide

Page 39

Agilent G3180B Splitter Kit

Installation and Operation Guide

4

Operation

An Example 40

Column flow 40

Select restrictors 42

Calculate column flow 43

Calculate ECD restrictor flow 44

Calculate MSD restrictor flow 45

Changing Columns Without Venting the MSD 46

Backflushing the Column 47

This chapter contains a worked-through custom configuration, plus some

special topics.

Agilent Technologies

39

Page 40

4 Operation

An Example

Column flow

Assume we have a method that uses an HP-5MS column (30 m × 250 µm

id × 0.25-µm film thickness) to measure pesticides with an MSD. The initial

oven temperature is 70 °C and is programmed to 280

constant pressure mode at 19.44 psig inlet pressure and the carrier gas is

helium. The initial column flow listed by the ChemStation is 2.1 mL/min.

We want to create a new splitter method with the column effluent split 1:3

between the ECD (detector 1) and an MSD (detector 2). We would also like to

preserve the retention times and relative elution order in the new method.

Since the column outlet pressure will be much higher in the new method, the

first step is to calculate the new inlet pressure and the resulting column flow.

The Method Translation software (Figure 18) is useful for this. Use the None

mode and check the button to make the hold-up times the same.

ο

C. The method is run in

40 Installation and Operation Guide

Page 41

Operation 4

Figure 18 Calculating column flow

The outlet pressure entered for the new splitter method must be in absolute

pressure units. Since the outlet of the column will be 3.8 psig, we need to

convert this to psia for the method translator. Absolute pressure = gauge

pressure + 14.696. Hence, 3.8 + 14.696 = 18.496 will be entered.

The calculated inlet pressure for the new splitter method is 30.93 psig and the

new column flow is 3.09 mL/min.

Installation and Operation Guide 41

Page 42

4 Operation

Select restrictors

Start up the spreadsheet "splitter_calc.xls" in Excel. We will choose to have

2 mL/min go to the ECD initially. With a split ratio of 3, this will send

6 mL/min to the MSD. This flow is acceptable with a performance turbo

system but will give somewhat degraded detection limits. Fill in the input

column as shown (Figure 19) with the ECD assumed to be Detector 1 and the

MSD as Detector 2.

Figure 19 The Effluent Splitter calculator

42 Installation and Operation Guide

Page 43

The calculator lists the lengths required for the different sizes of uncoated,

deactivated, fused-silica, restrictor tubing available. Choose the id tubing that

gives the shortest length of at least 0.3 m for most detectors and 0.8 m for

MSDs. In this case 0.18-mm id is the choice, requiring 0.912 m for the ECD

restrictor and 0.824 m for the MSD restrictor.

Table 4 on page 33 shows that in both cases the flow is higher than the

minimum 0.72 mL/min suggested for helium in 0.18-mm id tubing.

Calculate column flow

To find the makeup flow at 280 °C, first find the column f low at 280 °C. The

Flow Calculator software (Figure 20) requires that the output pressure be

entered in psia. Therefore 18.496 psia (3.8 psig) is entered.

Operation 4

Figure 20 Column flow calculation

The column flow drops to 1.38 mL/min at 280 °C.

Installation and Operation Guide 43

Page 44

4 Operation

Calculate ECD restrictor flow

The flow through the ECD restrictor at 280 °C is calculated to be 0.88 mL/min

(Figure 21).

Figure 21 ECD restrictor flow calculation

This flow is higher than the minimum 0.72 mL/min suggested for helium in

0.18-mm id tubing.

44 Installation and Operation Guide

Page 45

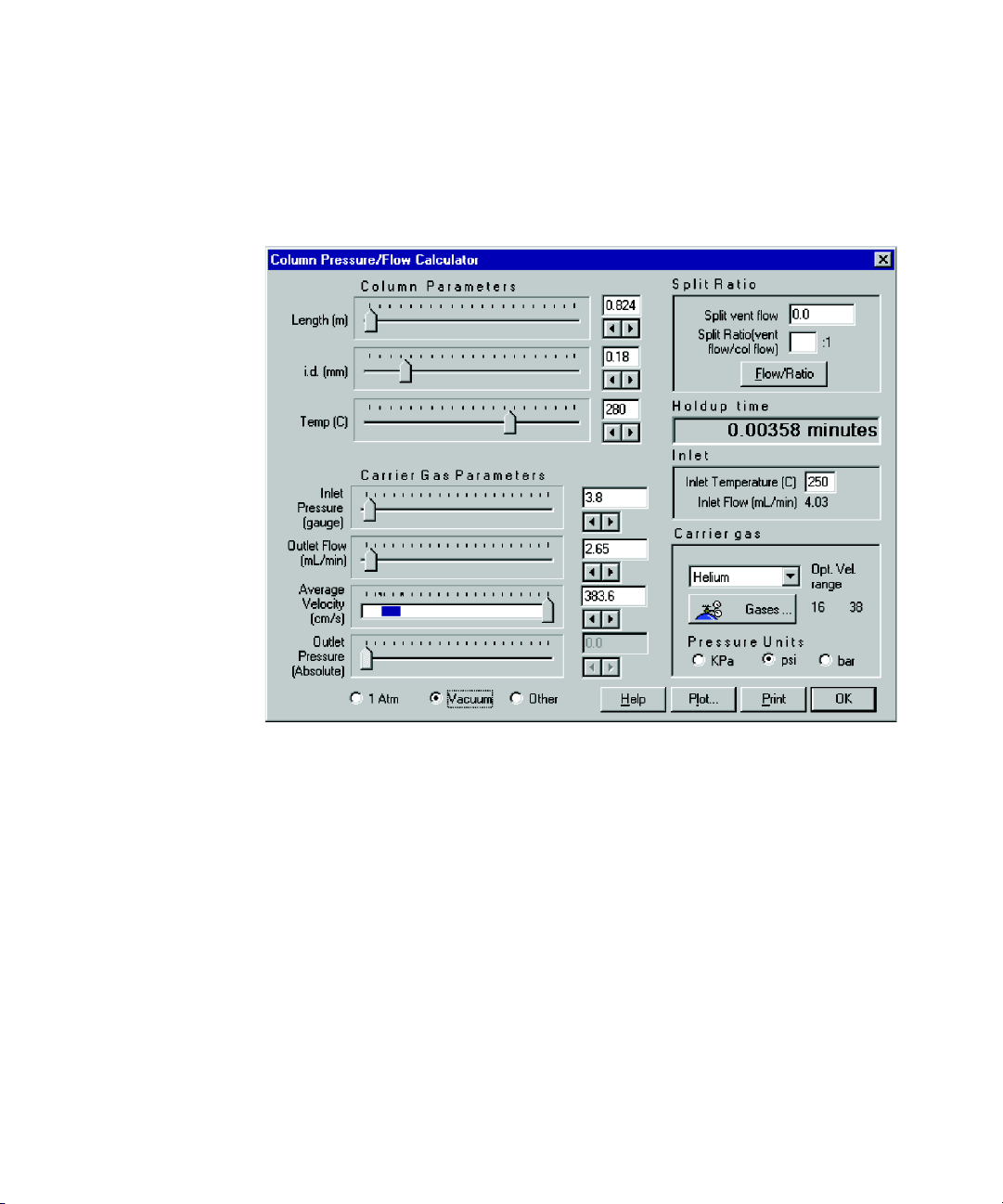

Calculate MSD restrictor flow

The flow through the MSD restrictor (Figure 22) at 280 °C is:

Operation 4

Figure 22 MSD restrictor flow calculation

The flow to the MSD at 280 °C is 2.65 mL/min. This flow is higher than the

minimum 0.72 mL/min suggested for helium in 0.18-mm id tubing. The

calculated makeup flow is then [0.88 + 2.65] – 1.38 = 2.15 mL/min. This should

work well.

The configuration can now be installed and used.

Installation and Operation Guide 45

Page 46

4 Operation

Changing Columns Without Venting the MSD

For systems that use an MSD attached to the splitter, one added advantage is

the GC column can be changed without venting the MSD. When the column is

disconnected from the splitter plate, the makeup gas purges air out of the

fitting, preventing air from reaching the MSD.

To change columns with the splitter, the recommended steps are:

1 Cool down the inlet to which the column to be removed is connected.

2 Disconnect the column from the splitter plate.

3 Immediately install a plug in the plate where the column was connected.

4 Change column in the inlet and turn on carrier gas to purge air from the

column.

5 Preswage metal ferrule on the outlet end of the column.

6 Remove plug from the connector.

7 Connect the new column to the splitter.

46 Installation and Operation Guide

Page 47

Backflushing the Column

One useful feature available with EPC control of the makeup is the ability to

backflush unwanted higher boiling analytes from the column. Use of this

feature requires that the split/splitless inlet be used. Backflushing reduces the

hold at the end of the run to clean out the column.

To backflush, the splitter makeup pressure is time-programmed to rise rapidly

after elution of the last peak of interest while the inlet pressure decreases

rapidly. These pressure changes reverse the flow through the column. Heavy

materials are then carried out the split vent of the inlet.

The inlet pressure is programmed to decrease to 0.5 psig. The makeup

pressure is programmed to rise to a maximum pressure determined by the

detectors and cleanout temperature used. Using the example from above, the

MSD will limit the flow, and thus pressure, that can be used for backflushing.

The flow allowed to go to the MSD (with a performance turbo) must be

8 mL/min or less. The backflushing conditions must be calculated to not

exceed this. We need to use the MSD restrictor tubing dimensions and the

backflushing temperature to find the backflushing pressure.

Operation 4

Installation and Operation Guide 47

Page 48

4 Operation

The restrictor to the MSD was 0.824 m of 0.18-mm id tubing. The backflushing

temperature used here is the hold temperature at the end of the run in the

original method (280 °C). The flow calculator (Figure 23) shows that the

makeup pressure can be programmed to 17.4 psig at 280 °C.

Figure 23 Column backflush flow calculation

The time required for complete backflushing of heavy materials is then

determined empirically. Blank runs after samples with different backflush

hold times are used to determine the minimum time to remove all heavy

material.

48 Installation and Operation Guide

Page 49

Index

A

Absolute pressure, 41

Aux EPC, 27

Auxiliary Pressure controller, 24

B

Backflushing, 47

C

Changing columns, 46

Column

connections, 35

flow, 10, 26, 27, 43

outlet pressure, 34

Column clips, 35

Column effluent, 27

Configuration, 9

custom, 25, 29

typical, 25, 26

Constant flow mode, 27

Constant pressure mode, 28

Constant pressure operation, 10

Custom configuration, 29

Example, 40

D

Detector

Above atmospheric pressure, 9

Atmospheric pressure, 9

Below atmospheric pressure, 9

flow rate, 26

operating pressure, 26

Diffusion pump, 26, 28

E

Effluent Splitter Calculator, 29, 32, 42

Electronic pneumatic control, 10

Excel, 12

F

Ferrule

release hole, 37

Flow

column, 10, 26, 27

detector, 26

makeup, 10

maximum and minimum, 33

Flow Calculator, 34

Fused silica tubing, 27

G

GC Method Translation, 30

GC requirements, 12

I

Inlet pressure, 28, 34, 47

M

Makeup flow, 33

Makeup pressure, 47

Makeup supply, 24, 27

Metal ferrules, 10

Method Translation, 34, 40

Microfluidic plate, 10

MSD, 10, 28, 33, 40, 45, 46

O

Outlet pressure, 41

P

Parameter calculation, 11

Parts supplied, 13

PCM, 12, 27

Peak broadening, 26, 28

Plugs, 38

Pneumatic Control Module, 12

Pressure controller, 12

psia, 41

psig, 41

R

Restrictor, 8, 27

dimensions, 26

flow, 44, 45

Retention times, 34

S

Software tools

Column Pressure/Flow Calculator, 31

Effluent Splitter Calculator, 29

GC Method Translation, 30

loading, 31

Split ratio, 9, 26, 28, 29

Splitter connections, 35

Spreadsheet calculator, 9

T

Tailing, 28

Turbo p u m p, 26, 28

Installation and Operation Guide 49

Page 50

Installation and Operation Guide 50

Page 51

Page 52

Agilent Technologies

© Agilent Technologies, Inc.

Printed in USA, April 2006

G3180-90120

Loading...

Loading...