Page 1

FuturePlus Systems Corporation

USB Analysis Probe

Users Manual-FS4100

For Agilent Logic Analyzers

Revision 2.7

FuturePlus Systems is a trademark of FuturePlus Systems Corporation

Copyright 1998 FuturePlus Systems Corporation

Page 2

HOW TO REACH US 4

PRODUCT WARRANTY 5

Limitation of warranty 5

Exclusive Remedies 6

Assistance 6

INTRODUCTION 7

How to Use This Manual 7

ANALYZING THE UNIVERSAL SERIAL BUS 9

Duplicating the Master Diskette 9

Accessories Supplied 9

Minimum Equipment Required 10

Revisions 10

Signal Naming Conventions 10

The USB Analysis Probe Switches and Diodes 10

The Slow Speed Only Switch and LED 10

USB Busy LED 10

Ready LED 10

VCC LED 10

Connecting to the USB Analysis Probe 11

Installing the USB Analysis Probe 11

Setting up the Analyzers installed in the 16500 mainframe. 12

Setting up the 167xx Analyzer 12

Setting up the 1680/90/900 Analyzer 13

1680/90/900 licensing 13

Loading 1680/90/900 configuration files 13

1680/90/900, 167xx Configuration files 15

Offline Analysis 15

The Format Menu 18

2

Page 3

The STAT variable 19

The ADDR and DATA variables 19

The PID variable 19

The CTLCMD variable 21

COMBINATION MODE 22

Bad EOP Detection 22

Low Speed/High Speed detection 23

STATE ANALYSIS 25

Installation Quick Reference 25

Acquiring Data 26

The State Display 26

Analysis Probe related error messages 27

USB CRC and Serial Bit Errors 27

Installation Quick Reference 29

Acquiring Data 30

POD 3 Description 30

End of Packet State Machine 31

Load Byte Count State Machine 32

USB Analysis Probe Test Points 33

POD 4 Description 34

The Waveform Display 34

GENERAL INFORMATION 35

Characteristics 35

Standards Supported 35

Power Requirements 35

Logic Analyzer Required 35

Number of Probes Used 35

Supported speeds 35

Signal loading 35

Operations 35

Environmental Temperature 36

Altitude 36

Humidity 36

Testing and Troubleshooting 36

Servicing 36

Signal Connections 36

3

Page 4

How to reach us

For Technical Support:

FuturePlus Systems Corporation

36 Olde English Road

Bedford NH 03110

TEL: 603-471-2734

FAX: 603-471-2738

On the web

For Sales and Marketing Support:

FuturePlus Systems Corporation

TEL: 719-278-3540

FAX: 719-278-9586

On the web

FuturePlus Systems has technical sales

representatives in several major countries. For an up

to date listing please see

http://www.futureplus.com/contact.html.

Agilent Technologies is also an authorized reseller of

many FuturePlus products. Contact any Agilent

Technologies sales office for details

http://www.futureplus.com

http://www.futureplus.com

.

.

4

Page 5

Product Warranty

This FuturePlus Systems product has a warranty

against defects in material and workmanship for a

period of 1 year from the date of shipment. During

the warranty period, FuturePlus Systems will, at its

option, either replace or repair products proven to be

defective. For warranty service or repair, this product

must be returned to the factory.

Limitation of warranty

For products returned to FuturePlus Systems for

warranty service, the Buyer shall prepay shipping

charges to FuturePlus Systems and FuturePlus

Systems shall pay shipping charges to return the

product to the Buyer. However, the Buyer shall pay

all shipping charges, duties, and taxes for products

returned to FuturePlus Systems from another country.

FuturePlus Systems warrants that its software and

hardware designated by FuturePlus Systems for use

with an instrument will execute its programming

instructions when properly installed on that

instrument. FuturePlus Systems does not warrant that

the operation of the hardware or software will be

uninterrupted or error-free.

The foregoing warranty shall not apply to defects

resulting from improper or inadequate maintenance

by the Buyer, Buyer-supplied software or interfacing,

unauthorized modification or misuse, operation

outside of the environmental specifications for the

5

Page 6

product, or improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR

IMPLIED. FUTUREPLUS SYSTEMS SPECIFICALLY

DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

Exclusive Remedies

Assistance

THE REMEDIES PROVIDED HEREIN ARE BUYER’S

SOLE AND EXCLUSIVE REMEDIES. FUTUREPLUS

SYSTEMS SHALL NOT BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED

ON CONTRACT, TORT, OR ANY OTHER LEGAL

THEORY.

Product maintenance agreements and other customer

assistance agreements are available for FuturePlus

Systems products. For assistance, contact the

factory.

6

Page 7

Introduction

The USB Analysis Probe module provides a complete

interface between any point on the USB and an

Agilent Logic Analyzer. The Analysis Probe interface

receives the USB serial bit stream and converts it to

an understandable parallel bus that is then acquired

by the logic analyzer.

The USB Analysis Probe is a passive bus monitor

which does not assert any signals on the USB . The

USB signals are received with a USB compliant

transceiver. The power for the Analysis Probe logic

and transceiver is taken from the logic analyzer. Thus

the Analysis Probe does not draw power from the

USB wire.

The USB Analysis Probe software configures all the

logic analyzer menus for compatibility with the USB

Analysis Probe. When the configuration file is loaded

and the analyzer is set to STATE mode, an inverse

assembler is also loaded which decodes USB packets

into easy to read mnemonics.

The USB Analysis Probe also provides access to the

actual USB wire for both digital and analog

measurements. D+, D-, GND, USB Power and the

transceiver outputs of VP, VM, and RCV are also

provided on the test points.

How to Use This Manual

7

This manual is organized to help you quickly find the

information you need.

• Analyzing the Universal Serial Bus chapter

introduces you to the USB Analysis Probe and lists

the minimum equipment required and accessories

supplied for USB analysis. Characteristics

common to state and timing analysis are also

detailed.

Page 8

• The State Analysis chapter explains how to

configure the USB Analysis Probe to perform state

analysis on your USB .

• The Timing Analysis chapter explains how to

configure the USB Analysis Probe to perform

timing analysis on your USB .

• The General Information chapter provides some

general information including the operating

characteristics for the USB Analysis Probe module

and the cable header pinout.

8

Page 9

Analyzing the Universal Serial Bus

This chapter introduces you to the USB Analysis

Probe and lists the minimum equipment required and

accessories supplied for Universal Serial Bus

analysis. This chapter also contains information that

is common to both state and timing analysis.

Before you use the USB Analysis Probe software,

Duplicating the Master Diskette

make a duplicate copy of the master diskette. Then

store the master diskette and use the back-up copy to

configure your logic analyzer. This will help prevent

the possibility of losing or destroying the original files

in the event the diskette wears out, is damaged, or a

file is accidentally deleted.

To make a duplicate copy, use the Duplicate diskette

Accessories Supplied

9

operation in the disk menu of your logic analyzer. For

more information, refer to the reference manual for

your logic analyzer.

The USB Analysis Probe product consists of the

following accessories:

• The USB Analysis Probe interface hardware

• The inverse assembly and configuration software

on a 3.5 inch diskette.

• This operating manual

Page 10

Minimum Equipment Required

The minimum equipment required for analysis of a

Universal Serial Bus consists of the following

equipment:

• A 166x, 167x , 1680/90, 1671x , 1674X, 1655x or

1675x logic analyzer

Revisions

Signal Naming Conventions

The USB Analysis Probe Switches and Diodes

The Slow Speed Only Switch and LED

• The USB Analysis Probe Product

• A USB target wire

This manual applies to Hardware revisions ACE or

later and software revision 3.0 or later.

This operating manual uses the same signal notation

as the UNIVERSAL SERIAL BUS SPECIFICATION REVISION 1.0.

The USB Analysis Probe contains one switch and four

LEDs

The slow speed switch should be in the ON position

(LED ON) when the USB Analysis Probe is on a slow

speed only wire or slow speed only segment of the

USB. When attached to a high speed segment or

mixed segment (slow speed and high speed traffic)

the switch should be in the OFF position (LED OFF).

USB Busy LED

Ready LED

VCC LED

10

The USB Busy LED is lit when the USB Analysis

Probe is actively receiving packets from the USB

wire. The LED may appear dim if the traffic load is

light.

The Ready LED indicates that the on board serial

ROM has successfully loaded the FPGA and that the

USB Analysis Probe is ready for USB analysis.

The VCC LED on the USB Analysis Probe indicates

that power is applied from the logic analyzer to the

USB Analysis Probe logic. For correct operation of

the USB Analysis Probe the VCC LED must be lit.

Page 11

Connecting to the USB Analysis Probe

The following explains how to connect the logic

analyzer to the USB Analysis Probe for either state or

timing analysis:

1. Remove the probe tip assemblies from the

logic analyzer cables.

2. Plug the logic analyzer cables into the USB

Analysis Probe cable headers as shown in the

appropriate following tables.

Installing the USB Analysis Probe

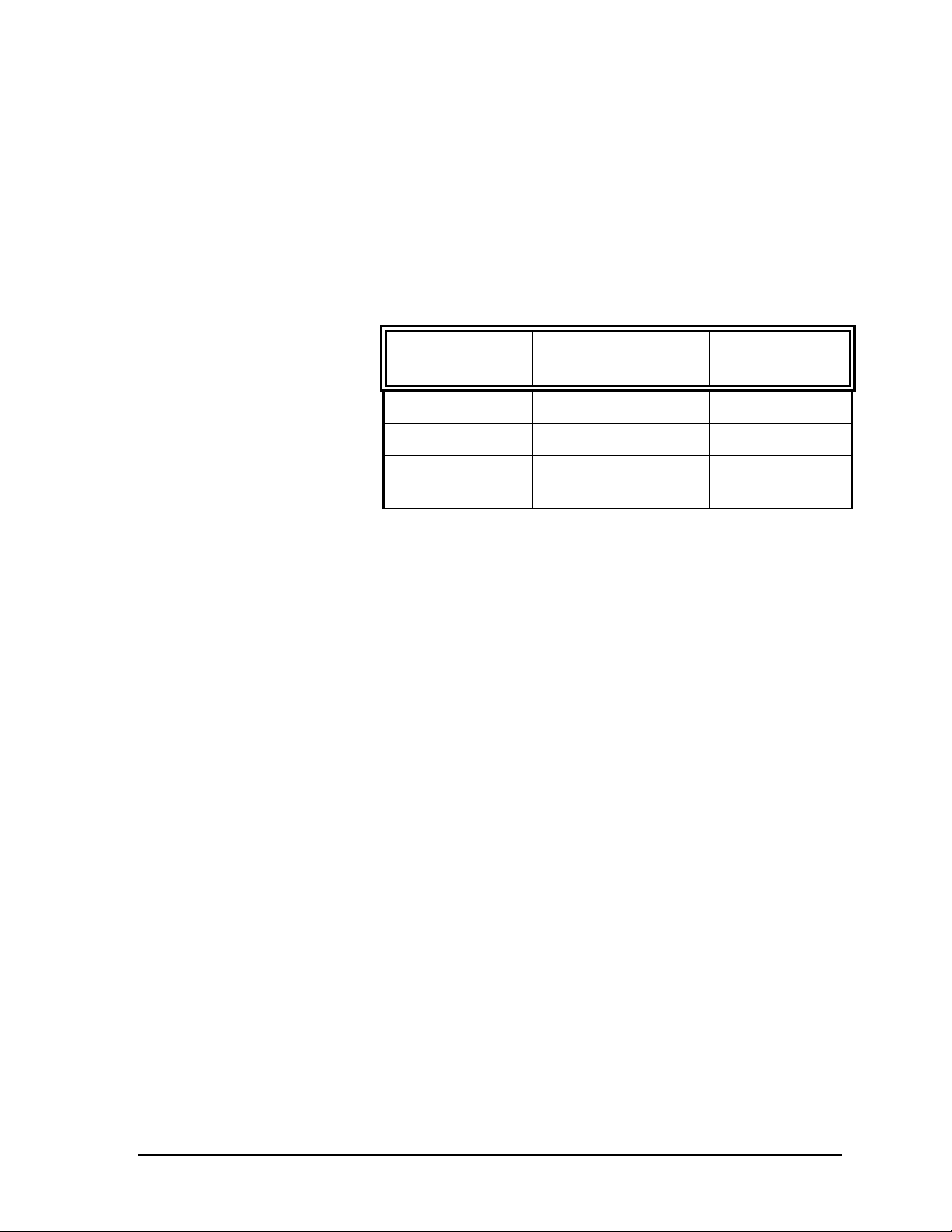

Logic Analyzer USB Analysis

Comment

Probe

Master POD 1 Header 1 State analysis

POD 2 Header 2 State analysis

POD 3 Header 3 Timing

analysis

The USB Analysis Probe can be installed in any

segment of the Universal Serial Bus. However, to

view all packets from the Host the USB Analysis

Probe must be placed between the Host and the USB

Hub or USB device. The following steps explain how

to install the USB Analysis Probe onto the Universal

Serial Bus.

1. Install the logic analyzer cables as described in

the previous section.

2. Plug the USB Analysis Probe IN cable to the

upstream Host or Hub. The USB Analysis

Probe OUT connector can be connected down

stream to either a Hub or device or it can be

left unconnected.

3. Turn on the logic analyzer on so that the VCC

and READY LEDs on the USB Analysis Probe

are lit.

NOTE: Connect the USB Analysis Probe to

the USB wire as described in step 2 prior to

powering up the logic analyzer.

11

Page 12

Setting up the Analyzers installed in the 16500 mainframe.

The logic analyzer can be configured for USB analysis

by loading the USB configuration file. Loading this file

will load the Universal Serial Bus inverse assembler

and configure your logic analyzer for USB analysis.

1. Install the 16500 USB Analysis Probe Software

for the FS4100 flexible diskette in the disk drive

of the logic analyzer.

2. Configure the menu to “Load” the analyzer with

the appropriate configuration file (see table

below).

Logic Analyzer File name

16555, 16710/1/2 USB555

166x USB660

16550 USB550

3. Execute the load operation to load the file into

the target logic analyzer. NOTE: Do not select ALL

or SYSTEM as the target of the load operation,

select the logic analyzer that is connected to the

USB Analysis Probe.

Setting up the 167xx Analyzer

The 16600/16700 requires a special install procedure

to install the FS4100 software. To accomplish this,

insert the diskette labeled 16700/702 Installation

disk for the FS4100 into the 16700/702 diskette

drive. From the SYSTEM ADMINISTRATION TOOLS

select INSTALL under SOFTWARE. From the

SOFTWARE INSTALL screen select the FLEXIBLE

DISK and APPLY. The package FS4100 will now

appear. Select it and then select INSTALL. This

procedure does not need to be repeated. It only

needs to be done the first time the USB Analysis

Probe is used.

When this has completed restart the logic analysis

session and either invoke the Setup Assistant from

the logic analyzer screen or load the appropriate

configuration file from the

Configs/FuturePlus/FS4100 directory. The Setup

Assistant will guide you in configuring the logic

analyzer. Select FuturePlus from the list on the left of

the Setup Assistant screen and then USB from the list

that then appears. If you prefer to load the

12

Page 13

configuration file yourself, see table below for a list of

analyzers and corresponding configuration files.

Note: The Logic Analysis System’s Operating System

must be version A.01.40.00 with patches 034 and 035

or higher to be compatible with the software provided

on the installation diskette for the 167xx.

The 1680/90/900 Analyzer is a PC based application

that requires a PC running the Windows OS or a

16900 frame.

Setting up the 1680/90/900 Analyzer

1680/90/900 licensing

Before installing the protocol decoder for the USB

protocol on a PC you must install the Agilent logic

analyzer software. Once the Agilent logic analyzer

software is installed, you can install the FS4100

protocol decoder by placing the CD-ROM disk into the

CD-ROM drive of the target computer or Analyzer and

executing the .exe setup program that is contained on

the disk. The .exe setup file can be executed from

within the File Explorer PC Utility. You must navigate

to the .exe file on the CD-ROM disk and then double

click the .exe file name from within the File Explorer

navigation panel.

The installation procedure does not need to be

repeated. It only needs to be done the first time

the Analysis Probe Adapter is used.

The USB Inverse Assembler is a licensed product that

is locked to a single hard drive. The licensing process

is performed by Agilent. There are instructions on this

process on the SW Entitlement certificate provided

with this product.

Loading 1680/90/900 configuration files

13

When the software has been licensed you should be

ready to load a configuration file. You can access the

configuration files by clicking on the folder that was

placed on the desktop. When you click on the folder it

should open up to display all the configuration files to

choose from. If you put your mouse cursor on the

name of the file a description will appear telling you

what the setup consists of, once you choose the

configuration file that is appropriate for your

configuration the 16900 operating system should

execute. The protocol decoder automatically loads

when the configuration file is loaded. If the decoder

does not load, you may load it by selecting tools from

Page 14

the menu bar at the top of the screen and select the

decoder from the list.

After loading the configuration file of choice, go into

the format specification of the configuration by

choosing Setup from the menu bar and then selecting

Bus/Signal in the drop down menu. When the format

specification appears press Define Probes at the

bottom of the screen. The Define Probes feature will

describe how to hook the analyzer cards to the

connections on the target. The following figure shows

what the Define Probes screen looks like. The figure

below may differ from your display; this is an example

of how the display looks in general.

Note: In the above picture under Logic analyzer pods, the first

pod goes to the Odd pod and the second goes to the Even pod

of the termination adapter (e.g. Pod B1 goes to odd termination

adapter pod and B2 goes to the even termination adapter pod).

14

Page 15

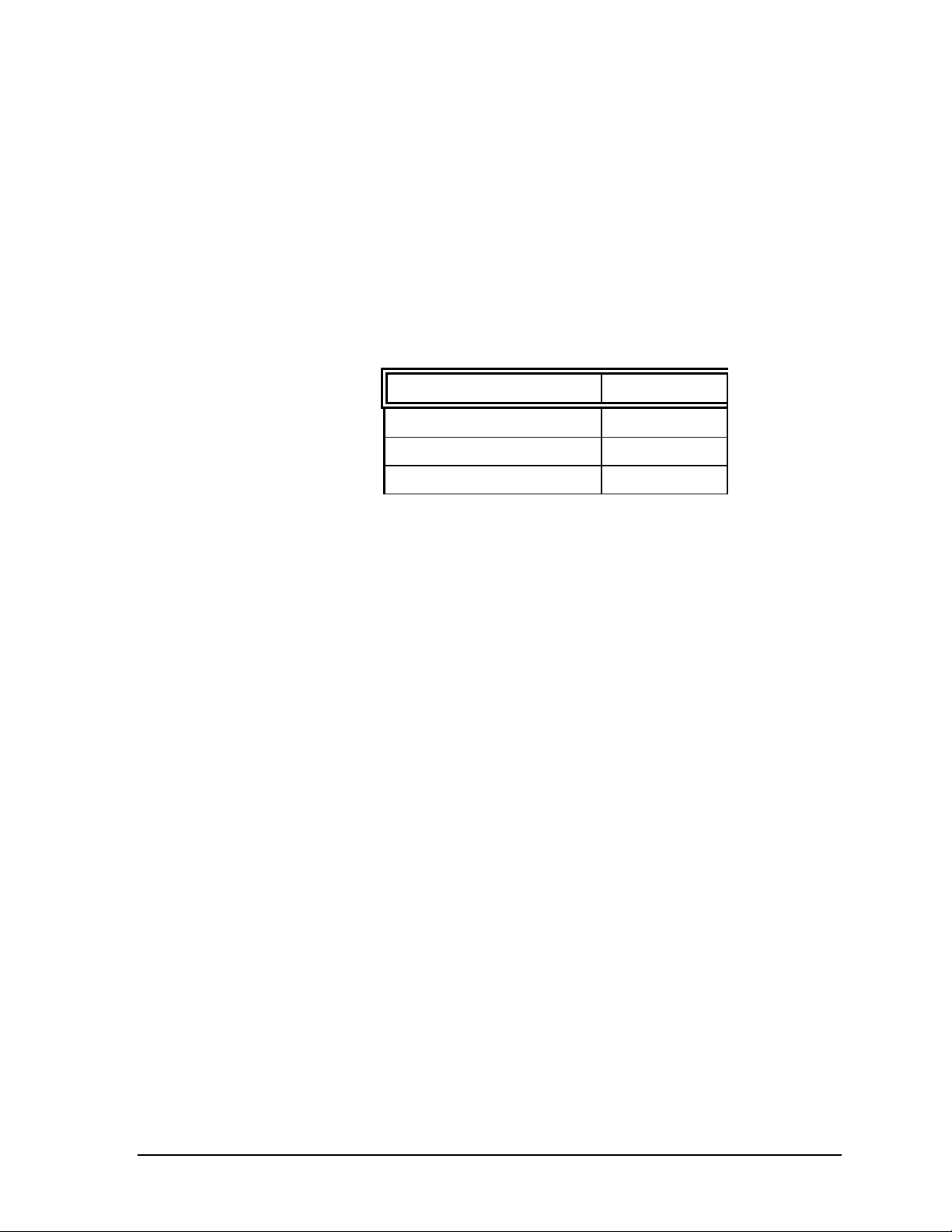

1680/90/900, 167xx Configuration files

167xx Analyzer 169xx Analyzer File Name

16550 / 16710/1/2 CUSB41_1

16555/6/7 CUSB41_2

16715/6/7, 1674x, 1675x CUSB41_3

1680/90 (State) 1680/90, 16750/1/2,

1680/90 (Timing) 1680/90, 16750/1/2,

Offline Analysis

CUSB41_6

1691x (State)

CUSB41_7

1691x (Timing)

Data that is saved on a 167xx analyzer in fast binary

format, or 16900 analyzer data saved as a *.ala file,

can be imported into the 1680/90/900 environment for

analysis. You can do offline analysis on a PC if you

have the 1680/90/900 operating system installed on

the PC, if you need this software please contact

Agilent.

Offline analysis allows a user to be able to analyze a

trace offline at a PC so it frees up the analyzer for

another person to use the analyzer to capture data.

If you have already used the license that was included

with your package on a 1680/90/900 analyzer and

would like to have the offline analysis feature on a PC

you may buy additional licenses, please contact

FuturePlus sales department.

In order to view decoded data offline, after installing

the 1680/90/900 operating system on a PC, you must

install the FuturePlus software. Please follow the

installation instructions for “Setting up 1680/90/900

analyzer”. Once the FuturePlus software has been

installed and licensed follow these steps to import the

data and view it.

From the desktop, double click on the Agilent logic

analyzer icon. When the application comes up there

15

Page 16

will be a series of questions, answer the first question

asking which startup option to use, select Continue

Offline. On the analyzer type question, select cancel.

When the application comes all the way up you

should have a blank screen with a menu bar and tool

bar at the top.

For data from a 1680/90/900 analyzer, open the .ala

file using the File, Open menu selections and browse

to the desired .ala file.

For data from a 16700, choose File -> Import from the

menu bar, after selecting import select “yes” when it

asks if the system is ready to import 16700 data.

After clicking “next” you must browse for the fast

binary data file you want to import. Once you have

located the file and clicked start import, the data

should appear in the listing.

After the data has been imported you must load the

protocol decoder before you will see any decoding.

To load the decoder select Tools from the menu bar,

when the drop down menu appears select Inverse

Assembler, then choose the name of the decoder for

your particular product. The figure below is a general

16

Page 17

picture; please choose the appropriate decoder for

the trace you are working with.

After the decoder has loaded, select Preferences if

required, from the overview screen and set the

preferences to their correct value in order to decode

the trace properly. This is a general requirement,

some decoders do not have preferences, if this is the

case then no preference setting is necessary.

17

Page 18

The Format Menu

The USB Analysis Probe diskette sets up the format

menu as shown in the following table. This format is

the same for both Timing and State Analysis. Pods 1

and 2 are for STATE analysis and POD 3 is useful for

Timing analysis.

Label Pod 4 Pod 3 Pod 2 Pod 1

STAT

ADDR

DATA

ADR

ENDPNT

PID

CTLCMD

MCLK

15:11 16

10:0

15:0 15:0

10:4

3:0

15:11 16

15:11 16:8

16

CLK12

MDATA

SOFTIC

EOP2_1

LBC3_0

RESRVD

FEOPR

FEOSYN

LSDET

UNUSED

VP

VM

RCV

16

15

14

13:11

10:7

6:4

3

2

1

0

2

1

0

18

Page 19

The STAT variable

The ADDR and DATA variables

The STAT variable is used by the USB inverse

assembler to decode USB transactions. It should not

be changed or deleted from the format menu.

The ADDR variable is the address and endpoint as

decoded from the USB serial bit stream. The DATA

variable is the Data associated with a Data0 or Data1

packet.

For ease of triggering the address and endpoint seen

in the token packets Setup, In and Out are latched by

the USB Analysis Probe and held through the

reporting of the data for the DATA0 and DATA1

packets.

The PID variable

The PID variable describes the PID and various errors

detected by the USB Analysis Probe. This variable is

most effectively used for triggering and are available

to be used in combination with any other variable

defined in the FORMAT menu.

Symbol Binary Code Comment

IDLE 000000 IDLE STATE

SETUP 000001 SETUP

IN 000010 IN

OUT 000011 OUT

SOF 000100 START OF FRAME

DATA0 0X0101 DATA0

CTL DATA0 1X0101 CTL_DATA0

DATA1 0X0110 DATA1

CTL DATA1 1X0110 CTL_DATA1

CRC DATA 000111 CRC DATA

PRE 011000 PREAMBLE

ACK 011001 ACKNOWLEDGE

NCK 011010 NO ACKNOWLEDGE

STALL 011011 STALL

USB RESET 111111 USB RESET

19

Page 20

Symbol Binary Code Comment

RESET END 111001 RESET DEASSERTS

INVALID 011101 INVALID PID

RECEIVED

BAD PID 011110 BAD PID RECEIVED

SUSPEND 111110 SUSPEND CONDITION

DETECTED

RESUME 111101 RESUME CONDITION

DETECTED

KEEP ALIVE 111011 KEEP ALIVE

SETUP SBS

ERROR

001001 SETUP PACKET WITH

SERIAL BIT STUFFED

ERROR DETECTED

IN SBS ERROR 001010 IN PACKET WITH

SERIAL BIT STUFFED

ERROR DETECTED

OUT SBS

ERROR

001011 OUT PACKET WITH

SERIAL BIT STUFFED

ERROR DETECTED

SOF SBS

ERROR

001100 START OF FRAME

SERIAL BIT STUFFED

ERROR DETECTED

DATA0 SBS

ERROR

001101 DATA0 PACKET WITH

SERIAL BIT STUFFED

ERROR DETECTED

DATA1 SBS

ERROR

001110 DATA1 PACKET WITH

SERIAL BIT STUFFED

ERROR DETECTED

CRC DATA

SBS ERR

001111 CRC DATA WITH

SERIAL BIT STUFFED

ERROR DETECTED

SETUP CRC

ERROR

010001 SETUP PACKET WITH

CRC ERROR

DETECTED

IN CRC ERROR 010010 IN PACKET WITH CRC

20

Page 21

Symbol Binary Code Comment

ERROR DETECTED

SOF CRC

ERROR

010100 START OF FRAME

PACKET WITH CRC

ERROR DETECTED

OUT CRC

010011 OUT PACKET WITH

CRC ERROR

ERROR

CRC DATA

CRC ERR

010111 CRC DATA WITH CRC

DETECTED

ERROR DETECTED

ANY ERROR 111000 ERROR SUMMARY BIT

SLOW SOF 011111 SOF TOKEN

DETECTED AT SLOW

SPEED

RESUME SE0 111100 SE0 SENT AT END OF

RESUME SIGNALING

RESUME

JSATE

111010 JSTATE SENT AT END

OF RESUME

SIGNALING

The CTLCMD variable

POSSIBLE BAD

EOP

110111 DETECTED

INCORRECT J STATE

AS EOP SIGNALING AT

SLOW SPEED.

The CTLCMD variable decodes the Setup Data into

the appropriate command.

Standard Device Requests

GET_STATUS

CLEAR_FEATURE

SET_FEATURE

SET_ADDRESS

GET_DESCRIPTOR

SET_DESCRIPTOR

21

Page 22

Standard Device Requests

GET_CONFIGURATION

SET_CONFIGURATION

GET_INTERFACE

SET_INTERFACE

SYNCH_FRAME

COMBINATION MODE

Bad EOP Detection

The default mode set up by the software shipped with

the Analysis Probe is the following configuration.

If the FS4100 operating in full speed mode, detects a

valid SE0 for at least 60ns but a valid J_STATE does

not follow, it will do the following.

1. Detect an end of packet (FEOPR TRUE in Timing

mode).

2. Pass the packet up to the logic analyzer.

3. Pass a “ POSSIBLE BAD EOP” status to the

analyzer.

If the FS4100 operating in slow speed mode, detects

a valid SE0 for at least 300ns but a valid J_STATE

does not follow, it will do the following.

1. Detect an end of packet (FEOPR TRUE in Timing

mode).

2. Pass the packet up to the logic analyzer.

22

Page 23

3. Pass a “POSSIBLE BAD EOP” status to the

Analyzer.

A status of “POSSIBLE BAD EOP” should be treated

as cautionary and the user would be advised to view

the received signals in timing mode by doing the

following.

1. Attach POD 3 of the analyzer to POD 3 of the USB

Analysis Probe.

2. Attach a flying lead set to stake pins RCV, VP and

VM.

3. In state mode trigger on PID “ POSSIBLE BAD

EOP”. Using the arming control trigger the timing

Analyzer from the State Analyzer.

4. Once the State Analyzer Triggers switch to Timing

Analyzer Waveform 2.

Low Speed/High Speed detection

The USB Analysis Probe can switch automatically

from high speed to low speed upon the detection of

the Preamble PID. The Analysis Probe then detects

only low speed traffic. Upon the receipt of a low

speed acknowledge or an internal time-out (greater

than 16 low speed bit times). The Analysis Probe will

switch back to high speed. The following explains in

more detail the sequences the Analysis Probe looks

for in making the decision whether to switch from high

speed to low speed and back.

Sequence 1

1. Detection of a PREAMBLE - switch to low speed

2. Look for SETUP or OUT packet in low speed then

switch back to high speed.

3. Look for PREAMBLE - upon detection switch to

low speed.

4. Look for a single DATA packet or handshake or

time-out.

5. On receipt of a DATA packet look for a handshake

or time-out .

6. On receipt of a handshake or the occurrence of a

time-out the pre-processor switches back to high

speed.

23

Page 24

Sequence 2

1. Detection of a PREAMBLE - switch to low speed

2. Look for IN packet and a following DATA packet

and then switch back to high speed. If a DATA

packet is not received within the time-out period

(18 bit times), the Analysis Probe will switch back

to high speed.

3. In high speed look for PREAMBLE and handshake

If the Analysis Probe is placed on a low speed only

segment the low speed only switch must be placed in

the on position (LED lit). This is because on a low

speed only segment the Host or Hub will not send a

Preamble PID. NOTE: The low speed only switch

need only be placed in the ON position if the

Analysis Probe is placed on a LOW SPEED ONLY

SEGMENT (no high speed traffic present).

If users are on a mixed high speed/low speed

segment and suspect that low speed/high speed USB

specification protocol is not being adhered to, the

following steps should be taken.

1. Acquire USB traffic with the Analysis Probe Low

Speed only switch in the OFF position.

2. Acquire USB traffic with the Analysis Probe Low

Speed Only switch in the ON position.

3. Note any differences and refer to timing mode to

determine any out of specification conditions.

24

Page 25

State Analysis

This chapter explains how to configure the USB

Analysis Probe to perform state analysis on the

Universal Serial Bus. The configuration software on

the flexible diskette sets up the format specification

menu of the logic analyzer for compatibility with the

USB Analysis Probe. The next chapter explains how

to configure the USB Analysis Probe to perform timing

analysis.

Installation Quick Reference

The following procedure describes the major steps

required to perform measurements with the USB

Analysis Probe module.

The following explains how to connect the logic

analyzer to the USB Analysis Probe for state analysis:

1. Remove the probe tip assemblies from the

logic analyzer cables.

2. Plug the logic analyzer cables into the USB

Analysis Probe cable headers as shown in the

following table.

Logic Analyzer USB Analysis

Probe

Master POD 1 Header 1 State analysis

POD 2 Header 2 State analysis

Comment

(USB_ST)

(USB_ST)

3. Plug the USB Analysis Probe IN cable to the

upstream Host or Hub. The USB Analysis

25

Page 26

Probe OUT connector can be connected down

stream to either a Hub or device or it can be

left unconnected.

4. Turn on the logic analyzer so that the VCC and

READY LEDs on the USB Analysis Probe are

lit. NOTE: Connect the USB Analysis Probe

to the USB wire as described in step 2 prior

to powering up the logic analyzer.

5. Load the USB Analysis Probe software for the

appropriate logic analyzer

The logic analyzer is now ready for STATE analysis.

Acquiring Data

State Display

The

Touch RUN and as soon as there is activity on the

bus, the logic analyzer will begin to acquire data. The

analyzer will continue to acquire data and will display

the data when the analyzer memory is full, the trigger

specification is TRUE or when you touch STOP.

The logic analyzer will flash “Slow or Missing Clock” if

the USB Analysis Probe provided master clock signal

is not being detected by the logic analyzer. This will

occur if the USB is IDLE or in an extended suspend

state. To accurately determine the state of the USB

refer to the Timing analysis chapter in this manual.

Captured data is as shown in the following figure.

The following figure displays the state listing after

disassembly. The inverse assembler is constructed

so the mnemonic output closely resembles the actual

commands, status conditions, messages and phases

specified in the Universal Serial Bus specification.

Symbols on the PID variable have also been defined

to help aid in analysis. The non-disassembled state

listing displays USB mnemonics in addition to data.

All data, address, endpoint and frame number fields

are displayed in hex.

26

Page 27

Analysis Probe related error messages

The following Analysis Probe related error messages

are reported by the USB inverse assembler.

FAILED TO IDENTIFY PID

This error will be reported by the inverse assembler if

the USB Analysis Probe hardware reports a status

code that is undefined. If this error occurs please

contact the FuturePlus Systems factory.

USB CRC and Serial Bit Errors

27

By design the USB Analysis Probe will detect and

report CRC and serial bit stuffed errors. The PID

variable chart details the CRC and serial bit stuff

errors detected.

It is a protocol violation to omit the stuffed zero when

the last 6 bits of a packet are ones although the

packet data is correct and complete. The Analysis

Probe may not indicate that a serial stuffed bit error

occurred in this scenario.

Page 28

The USB Analysis Probe will also detect invalid PIDS,

bad PIDS and SOF tokens sent at slow speed. The

Analysis Probe implements an error summary status

called ANY ERROR, this status will be sent to the

Analyzer if any of the above error conditions is

detected by the Analysis Probe.

28

Page 29

Timing Analysis

Pod 3 of the USB Analysis Probe contains signals that

describe in more detail the actual state of the USB

wire.

Installation Quick Reference

The following procedure describes the major steps

required to perform timing analysis measurements

with the USB Analysis Probe module.

1. After removing the probe tip assemblies, plug

2. Plug the USB Analysis Probe IN cable to the

logic analyzer header 3 into Analysis Probe

header 3.

upstream Host or Hub. The USB Analysis

Probe OUT connector can be connected down

stream to either a Hub or device or it can be

left unconnected.

3. Position the LOW SPEED ONLY switch to the

ON position (LED lit) if the USB Analysis Probe

is on a low speed only segment. Position the

LOW SPEED ONLY switch to the off position

(led doused) if the USB Analysis Probe is on a

full speed link.

4. Turn on the logic analyzer so that the VCC and

READY LEDs on the USB Analysis Probe are

lit.

NOTE: Connect the USB Analysis Probe to the

USB wire as described in step 2 prior to powering

up the logic analyzer.

29

Page 30

Acquiring Data

POD 3 Description

Touch RUN and the logic analyzer will begin to

acquire data. The analyzer will continue to acquire

data and will display the data when the analyzer

memory is full, the trigger specification is TRUE or

when you touch STOP.

The logic analyzer will flash “Waiting for Trigger” or

“occurrences remaining in level x” where x is number

of the unsatisfied trigger level if the trigger condition is

not satisfied.

Pod 3 was included in the USB Analysis Probe to give

the user a detailed look at the USB wire. The USB

Analysis Probe interface contains its own fully

compliant USB serial interface engine (SIE). The

state bits for the USB state machines for this SIE are

available on POD 3. In addition the recovered clock,

recovered data, start of frame, end of packet, end of

sync and low speed/high speed detect signals are

available. These signals are useful for :

• Shadowing the state of the target USB SIE when

that SIE state is unavailable.

• Comparing the state of the target USB SIE with

that of the Analysis Probe SIE.

• Making accurate time measurements of USB

events.

• Accurate USB protocol violation detection.

• Accurate USB signaling violation detection.

POD 3 channel Signal Name Description

16 CLK12 Recovered

Clock

15 MDATA Recovered

Serial Data

30

Page 31

POD 3 channel Signal Name Description

14 SOFTIC Start of Frame.

1 millisecond

timer generated

from recovered

start of frame

13:11 EOP2_0 End of Packet

state machine

10:7 LBC3_0 Load Byte State

Machine

6:4 RSRVD Reserved

3 FEOPR End of packet

2 FEOSYN End of Sync

End of Packet State Machine

1 LSDET Low Speed

Detect

0 unused

The end of packet state machine state encodings are

as follows:

State Name State Encoding Description

IDLE 000 Idle state

SEO_FIRST 100 First sample of

the single ended

zero condition

SEO_SECOND 010 Second sample

of the single

ended zero

condition

SEO_THIRD 110 Third or more

sample of the

single ended

zero condition

31

Page 32

State Name State Encoding Description

EOPR_STATE 001 J state transition

detected. Valid

end of packet

SLOW_SEO_FI

RST

SLOW_SEO_S

ECOND

BAD_EOPR_ST

ATE

101 First slow speed

single ended

zero condition

detected

011 First slow speed

single ended

zero condition

detected

111 Incorrect

transition for

single ended

zero detected.

NOTE: FEOPR

will be

generated in this

case so that the

next packet can

be detected.

Users can look

for this state if

they suspect a

bad end of

packet condition

occurring on the

USB.

Load Byte Count State Machine

32

The load byte count state machine is encoded as

follows.

State Name State Encoding Description

IDLE 0000 IDLE

PID 0001 Have received

end of sync and

currently

receiving PID

State Name State Encoding Description

Page 33

DELAY_1 0010 State delayed

by one clock tic

DELAY_2 0011 State delayed

by two clock tics

SOF_OR_ADR 0100 Receiving

address for

token packet or

Frame number

SOF_OR_EP 0101 Receiving

endpoint for

token packet or

the remainder of

the frame

number for start

of frame

CRC 0110 Receiving CRC

data

PRE_DATA 0111 About to receive

data

USB Analysis Probe Test Points

DATA 1000 Receiving data

D+, D-, VP, VM, RCV, USB Power and GND are

available to be viewed with spare probes from the

logic analyzer or a scope probe.

The format menu has been configured to include

POD4. Pod 4 allows the user by means of attaching a

flying led set to the stake pins to view the signals that

33

Page 34

POD 4 Description

the transceiver is generating in response to the USB

traffic.

POD 4 channel Signal Name Description

0 RCV Differential data

signal from the

USB transceiver

1 VM VM Signal from

the USB

transceiver

2 VP VP Signal from

the USB

transceiver.

The Waveform Display

Captured data is displayed as shown in the following

figure.

34

Page 35

General Information

This chapter provides additional reference information

including the characteristics and signal connections

for the USB Analysis Probe module.

Characteristics

Standards Supported

Power Requirements

Logic Analyzer Required

Number of Probes Used

Supported speeds

Signal loading

The following operating characteristics are not

specifications, but are typical operating characteristics

for the USB Analysis Probe.

The Universal Serial Bus Specification Revision 1.0

The USB Analysis Probe does not draw power from

the USB wire. All power is provided by the logic

analyzer.

166x, 167x, 1655x

USB State Analysis - 2 PODS

USB Timing Analysis - 3 PODS

The USB Analysis Probe supports both full speed and

low speed operation.

The USB Analysis Probe presents one USB

transceiver load onto the USB. The Analysis Probe

IN and OUT connectors (D+, D-, GND and VCC) are

daisy chained so that the USB traffic is not

interrupted.

All signal etch length, trace velocity and impedance is

within specification.

Operations

35

All Universal Serial Bus operations supported.

Page 36

Environmental Temperature

Altitude

Humidity

Testing and Troubleshooting

Servicing

Operating: 0 to 55 degrees C (+32 to +131 degrees F)

Non operating:-40 to +75 degrees C (-40 to +167

degrees F)

Operating: 4,6000m (15,000 ft)

Non operating: 15,3000m (50,000 ft)

Up to 90% non condensing. Avoid sudden, extreme

temperature changes which would cause

condensation on the Analysis Probe module.

There are no automatic performance tests or

adjustments for the USB Analysis Probe module. If a

failure is suspected in the USB Analysis Probe

contact the factory or your FuturePlus Systems

authorized distributor.

The repair strategy for the USB Analysis Probe is

replacement. However, if parts of the USB Analysis

Probe module are damaged or lost contact the factory

for a list of replacement parts.

Signal Connections

The USB Analysis Probe module monitors signals for

both state and timing analysis. The below figure

displays how the cable headers are numbered.

39 37 35 33 31 29 27 25 23 21 19 17 15 13 11 9 7 5 3 1

40 38 36 34 32 30 28 26 24 22 20 18 16 14 12 10 8 6 4 2

The following tables list the USB Analysis Probe cable

headers and the corresponding Universal Serial Bus

signals.

36

Page 37

Analysis Probe

Cable Header and

Pin number

Logic Analyzer

channel number

USB Analysis

Probe Signal

name

Header 3 pin 3 CLK/16 CLK12

5 no connect

7 15 MDATA

9 14 SOFTIC

11 13 EOP<2>

13 12 EOP<1>

15 11 EOP<0>

17 10 LBC<3>

19 9 LBC<2>

21 8 LBC<1>

23 7 LBC<0>

25 6 Reserved

27 5 Reserved

29 4 Reserved

31 3 FEOPR

33 2 FEOSYN

35 1 LSDET

37 0 unused

37

Page 38

Analysis Probe

Cable Header and

Pin number

Logic Analyzer

channel number

USB Analysis

Probe Signal

name

Header 2 pin 3 CLK/16 MCLK

5 no connect

7 15 STAT4

9 14 STAT3

11 13 STAT2

13 12 STAT1

15 11 STAT0

17 10 ADR06

19 9 ADR05

21 8 ADR04

23 7 ADR03

25 6 ADR02

27 5 ADR01

29 4 ADR00

31 3 ENDPNT03

33 2 ENDPNT02

35 1 ENDPNT01

37 0 ENDPNT00

38

Page 39

Analysis Probe

Cable Header and

Pin number

Logic Analyzer

channel number

USB Signal name

Header 1 pin 3 CLK/16 STAT5

5 no connect

7 15 D15

9 14 D14

11 13 D13

13 12 D12

15 11 D11

17 10 D10

19 9 D09

21 8 D08

23 7 D07

25 6 D06

27 5 D05

29 4 D04

31 3 D03

33 2 D02

35 1 D01

37 0 D00

39

Loading...

Loading...