Page 1

FuturePlus® Systems

Corporation

DDR2 DIMM HIGH SPEED PROBE

FS2334

For use with Agilent Technologies Logic Ana lyzers

FuturePlus is a trademark of FuturePlus Systems Corporation

Copyright 2006 FuturePlus Systems Corporation

Users Manual

Revision 1.1

Page 2

How to reach us.......................................................................................................................4

Product Warranty....................................................................................................................5

Limitation of warranty................................................................................................................... 5

Exclusive Remedies ....................................................................................................................................5

Assistance......................................................................................................................................... 5

Software License Agreement..................................................................................................6

License Agreement.......................................................................................................................... 6

Use of the software.......................................................................................................................... 6

Copies and Adaptations.................................................................................................................. 6

Ownership ....................................................................................................................................... 6

Sublicensing and Distribution........................................................................................................ 6

Introduction.............................................................................................................................7

Definitions........................................................................................................................................ 7

Logic Analyzer Modules..............................................................................................................................7

Logic Analyzer Machine..............................................................................................................................7

FS2334 Probe Description......................................................................................................8

Probe Technical Feature Summary .............................................................................................. 8

Probe Components.......................................................................................................................... 8

Signal Assignments on Probe Pods................................................................................................9

Signal Threshold Voltage Settings................................................................................................. 9

Connecting the DDR2 Probe to the Logic Analyzer.................................................................... 9

Test Points ..................................................................................................................................... 10

Connecting to your Target System.............................................................................................. 11

Signal Isolation on the Probe....................................................................................................... 11

Buffered signals on the probe......................................................................................................11

Recommended Logic Analyzer Card Requirements and Configuration files......................... 12

Software Requirements.........................................................................................................14

Setting up the 169xx Analyzer..................................................................................................... 14

169xx Licensing............................................................................................................................. 14

Loading 169xx configuration files and General Purpose Probe Feature................................. 14

Offline Analysis............................................................................................................................. 15

TimingZoom Analysis...........................................................................................................17

Decoding DDR Commands..........................................................................................................17

Taking a Trace, Triggering, and Seeing Measurement Results ............................................... 17

State Analysis........................................................................................................................18

2

Page 3

Overview........................................................................................................................................ 18

State Analysis Operation – Read and Writes above 667MT/s....................................................................18

State Analysis Operation – Read and Write at 667MT/s or slower............................................................19

State Analysis Operation – Read or Write at 800MT/s ..............................................................................19

The process for setting sampling positions at speeds of 800MT/s:........................................... 20

State analysis calibration procedure ...........................................................................................................21

Adjusting the sampling positions with controlled stimulus ...................................................... 24

State Display.................................................................................................................................. 26

DDR2 Protocol Checking and Performance Tool (FS1140) ..............................................27

FS1140 Installation and Licensing .............................................................................................. 27

Loading the FS1140......................................................................................................................27

Setting up the FS1140 DDR2 Tool............................................................................................... 28

Functional and Performance Analysis – NOTE: The Functional Performance portion of this

software will NOT work with 2 FRAME configurations .......................................................... 29

Statistics......................................................................................................................................................29

Errors..........................................................................................................................................................29

Export.........................................................................................................................................................30

Repetitive Run............................................................................................................................................30

Timing Analysis ............................................................................................................................ 30

Export.........................................................................................................................................................30

Appendix................................................................................................................................32

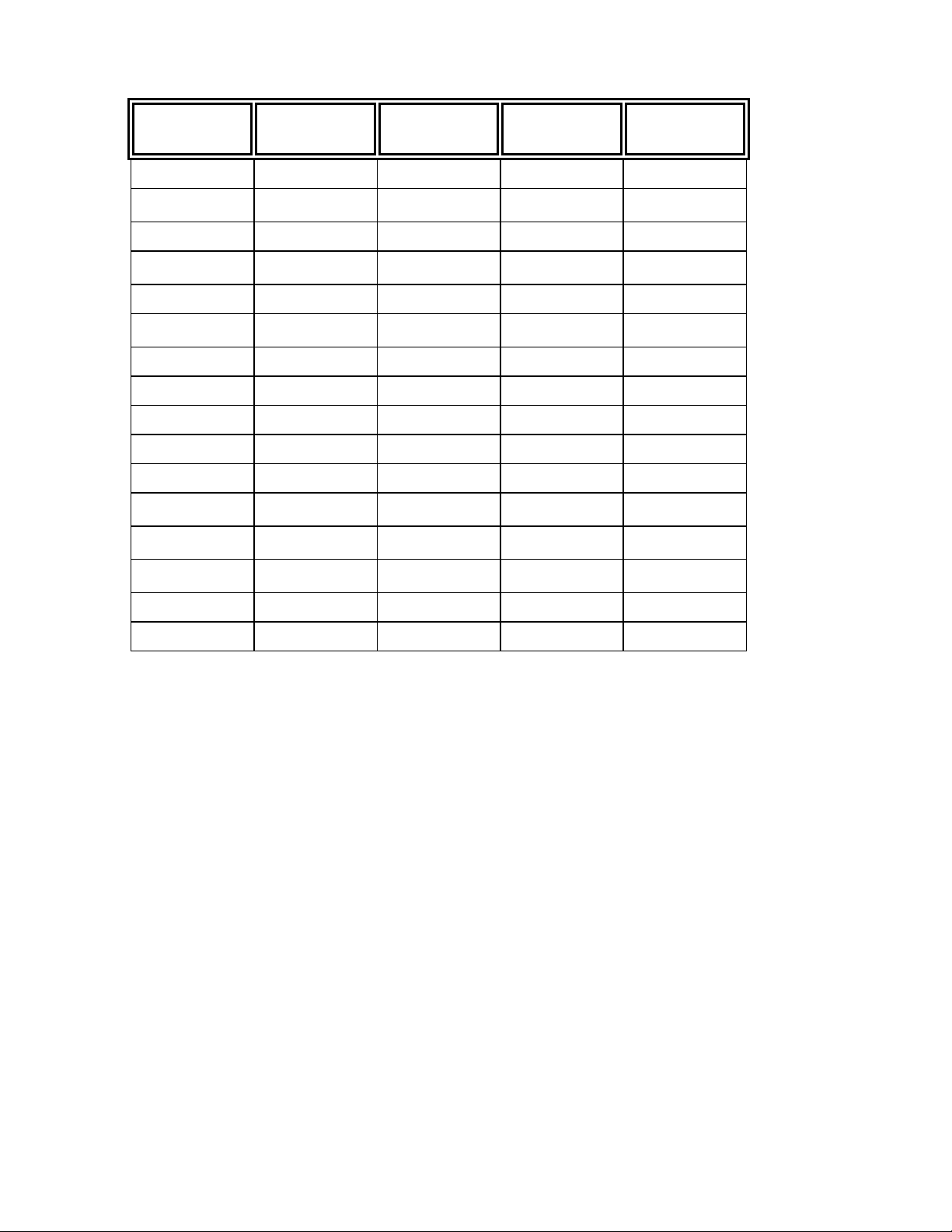

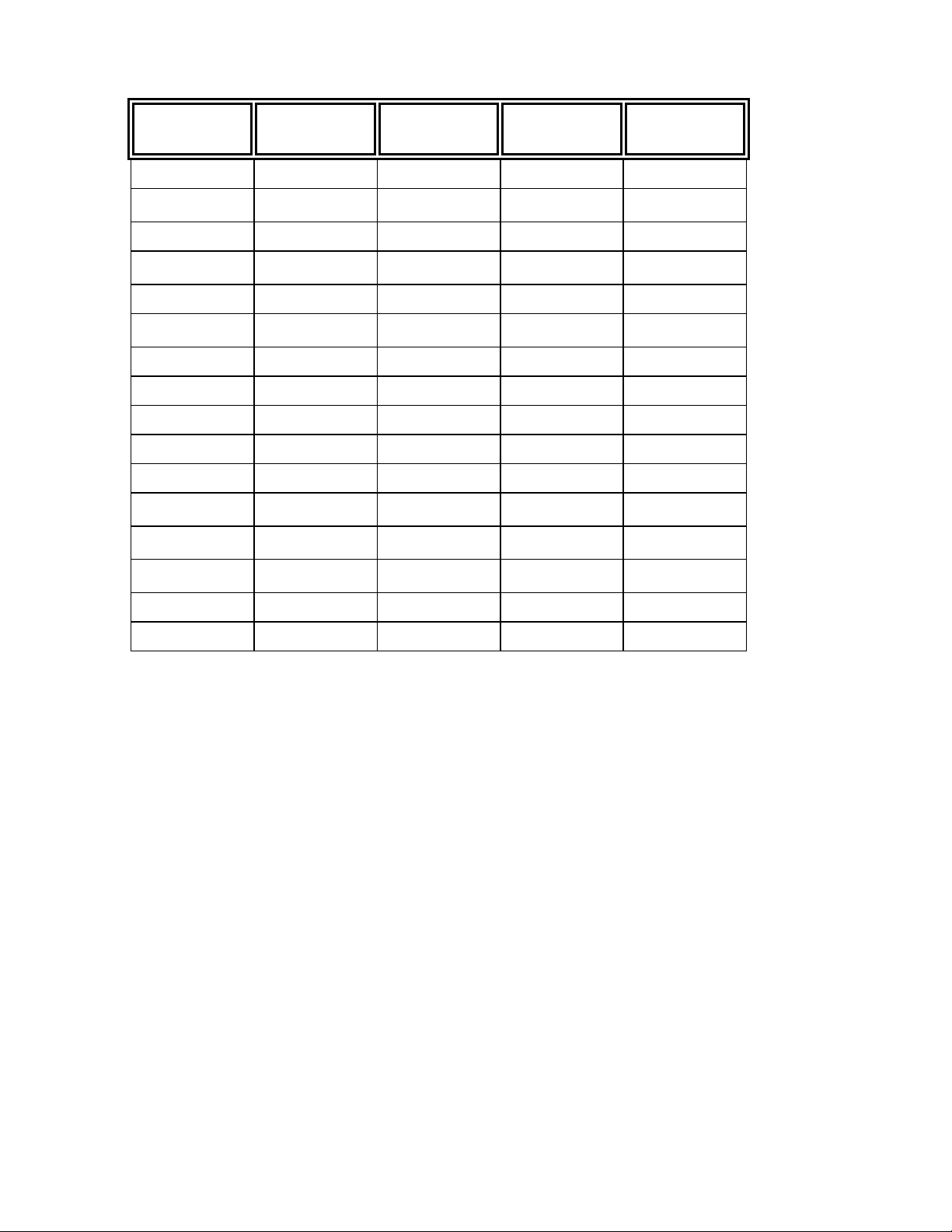

FS2334 Signal to Logic Analyzer Connector and Channel Mapping ...................................... 32

3

Page 4

How to reach us

For Technical Support:

FuturePlus Systems Corporation

36 Olde English Road

Bedford NH 03110

TEL: 603-471-2734

FAX: 603-471-2738

On the web http://www.futureplus.com

For Sales and Marketing Support:

FuturePlus Systems Corporation

TEL: 719-278-3540

FAX: 719-278-9586

On the web http://www.futureplus.com

FuturePlus Systems has technical sales representatives in several major

countries. For an up to date listing please see

http://www.futureplus.com/contact.html.

4

Page 5

Product Wa rranty

Due to wide variety of possible customer target implementations, the FS2334

DDR2 DIMM probe has a 30 day acceptance period by the customer from the date

of receipt. If the customer does not contact FuturePlus Systems within 30 days of

the receipt of the product it will be said that the customer has accepted the

product. If the customer is not satisfied with the FS2334 DDR2 DIMM probe they

may return the FS2334 within 30 days for a refund.

This FuturePlus Systems® product has a warranty against defects in material and

workmanship for a period of 1 year from the date of shipment. During the warranty

period, FuturePlus Systems will, at its option, either replace or repair products proven to

be defective. For warranty service or repair, this product must be returned to the factory.

For products returned to FuturePlus Systems for warranty service, the Buyer shall

prepay shipping charges to FuturePlus Systems and FuturePlus Systems shall pay

shipping charges to return the product to the Buyer. However, the Buyer shall pay all

shipping charges, duties, and taxes for products returned to FuturePlus Systems from

another country.

FuturePlus Systems warrants that its software and hardware designated by FuturePlus

Systems for use with an instrument will execute its programming instructions when

properly installed on that instrument. FuturePlus Systems does not warrant that the

operation of the hardware or software will be uninterrupted or error-free.

Limitation of warranty

The foregoing warranty shall not apply to defects resulting from improper or inadequate

maintenance by the Buyer, Buyer-supplied software or interfacing, unauthorized

modification or misuse, or improper site preparation or maintenance. NO OTHER

WARRANTY IS EXPRESSED OR IMPLIED. FUTUREPLUS SYSTEMS

SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE

REMEDIES. FUTUREPLUS SYSTEMS SHALL NOT BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER

BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Assistance

Product maintenance agreements and other customer assistance a greements are

available for FuturePlus Systems products. For assistance, contact the factory.

5

Page 6

Software License Agreement

IMPORTANT - Please read this license agreement carefully before opening the media

envelope. Rights in the software are offered only on the condition that the customer

agrees to all terms and conditions of the license agreement. Opening the media

envelope indicates your acceptance of these terms and conditions. If you do not agree

to the licensing agreement, you may return the unopened package for a full refund.

License Agreement

In return for payment for this product, FuturePlus Systems grants the Customer a

SINGLE user LICENSE in the software subject to the following:

Use of the software

Customer may use the software on any one Agilent mainframe logic analysis system.

• Customer may make copies or adaptations of the software.

• Customer may not reverse assemble or decompile the software.

Copies and Adaptations

• Are allowed for archival purpose only.

• When copying for adaptation is an essential step in the use of the software with the logic

analyzer and/or logic analysis mainframe so long as the copies and adaptations are used in no

other manner. Customer has no right to copy software unless it acquires an appropriate license

to reproduce from FuturePlus Systems.

• Customer agrees that it does not have any title or ownership of the software, other than the

physical media.

Ownership

• Customer acknowledges and agrees that the software is copyrighted and protected under the

copyright laws.

• Transfer of the right of ownership shall only be done with the consent of FuturePlus Systems.

Sublicensing and Distribution

Customer may not sublicensing the software or distribute copies of the software to the public in

physical media or by electronic means or any other means without the prior written consent of

FuturePlus Systems.

6

Page 7

Introduction

Thank you for purchasing the FuturePlus Systems FS2334 DDR2 DIMM Interposer

Logic Analyzer Probe. We think you will find the FS2334, along with your Agilent

Technologies Logic Analyzer, a valuable tool for helping to characterize and debug your

DDR2-based systems. This Users Guide will provide the information you need to install,

configure, and use the DDR2 Probe. If you have any questions about this Guide or use

of this probe, please contact FuturePlus Systems Corporation.

Definitions

Logic Analyzer Modules

"Module" - A set of logic analyzer cards that have been configured (via cables

connecting the cards) to operate as a single logic analyzer whose total available

channels is the sum of the channels on each card. A trigger within a module can be

specified using all of the channels of that module. Each module may be further broken

up into "Machines”. A single module may not extend beyond a single 5 card 16700

frame or 6 card 16900 frame.

Logic Analyzer Machine

"Machine" - A set of logic analyzer pods from a logic analyzer module grouped together

to operate as a single state or timing analyzer.

7

Page 8

FS2334 Probe Description

The FS2334 DDR2 Probe allows you to perform timing analysis measurements on

DDR2 DIMM busses. It also provides a Protocol Decoder with the capability of providing

State analysis of both Read and Write activity is provided by using the dual sample

mode feature available on the 169xx.

The interposer design of this probe allows any DDR2 connection to be probed while it

supports a DDR2 DIMM module.

Probe Technical Feature Summary

• Quick and easy connection between the DDR2 240 pin DIMM connector and Agilent

Logic Analyzers.

• Interposer design does not consume a DDR2 slot.

• Complete and accurate state analysis up to 800MT/s.

• Available Protocol Checking capability (VBA license required) software.

• Uses Auto Sample Position Set-up (EyeFinder) and Auto Threshold Set-up to locate

tight DDR2 data valid windows for optimal state data capture.

Probe Components

The following components have been shipped with your FS2334 DDR2 Probe:

• FS2334 DDR2 DIMM Probe

• Supplemental DC power supply.

• This Users Guide and other information on CD-ROM.

• CD-ROM with the following software install files:

• FS1136 DDR2 Protocol decoder software and configuration files for 169xx

analyzers or offline analysis of 800MT/s data traffic

• FS1117 DDR2 Protocol Decoder software and configuration files for 169xx

analyzers or offline analysis of data traffic <= 667MT/s.

• FS1140 Protocol Checking software.

• Software Entitlement Certificate for Windows based FS1136, FS1117 and FS1140

software.

• Quick Start Sheet.

8

Page 9

Signal Assignments on Probe Pods

The overlap in the bit ranges (for DQxx) signals between pods occurs because the bits

are assigned to pods in the order that they appear physically on the DDR2 DIMM

connector, which is not strictly in logical bit order. This allows the Probe layout to better

match stub lengths among all DQxx signals.

See the Appendix for a detailed list of how Logic Analyzer Channels are mapped to

signals and DDR2 pins.

Signal Threshold Voltage Settings

The standard voltage threshold for the logic analyzer pods is defined as 900mV. This is

based on the SSTL2-1.8V signaling used by the DDR2 DIMM bus. The configuration

files provided with this product set-up the threshold voltages for both the Data and

Command pods to 900mV. Design differences between target platforms or overvoltage

settings may require adjustment of the logic analyzers threshold for optimal signal

capture. The use of Eye Scan can be very helpful in determining where to set these

thresholds.

NOTE: The optimal settings may need to be defined either through trial and error

or by using Eye Scan. Accurate data capture is very dependent on optimizing

these settings and changes of as little as 50mV may have a significant effect.

Connecting the DDR2 Probe to the Logic Analyzer

The FS2334 DDR2 Probe requires up to 7 logic analyzer cards depending on whether

state (Read and Write - quadruple sampled), state (Read or Write - dual sampled), or

timing measurements are desired. See Timing and State configuration information

below.

At this time the user may find it easier to connect the logic analyzer cables to the probe

before inserting the probe into the target system. The FS2334 probe has fourteen 90 pin

pod connections which mate directly to Agilent Logic analyzer cards. Adapter cables are

not required. Once a configuration file is loaded refer to the General Purpose Probe

feature in the Agilent 1690x Overview tab for cable connections.

9

Page 10

FS2334 Frontside layout

1.25”

Header 3 Header 4 Header 5

Header14

FS2334 Backside layout

TP 5

Header 13

Header 9

TP 6 TP 4

Header1

Header2

Header6

Header 7 Header8

Header 11 Header10 Header12

TP 1,2,3,7

Test Points

There are several test point on the board.

The first set of test points are used to select which signals go to the Clk input and the

D15 input of Header 2. The shipping configuration for the FS2334 is to have S0 wired to

the Clk input, which is TP3 wired to TP2. This is done in the factory by soldering a short

wire between the 2 test points.

If CKE0 is to be used as a Clk input then TP7 is wired to TP2 and S0 is brought to the

D15 input by wiring TP3 to TP1.

DM2_DQS11 is not brought to the logic analyzer, but it can be probed at TP4

DQS5n is not brought to the logic analyzer, but it can be probed at TP5

DQS14n is not brought to the logic analyzer, but it can be probed at TP6

10

Page 11

Connecting to your Target System

To connect the probe to the DDR2 bus, select an available DDR2 slot. Remove the

DDR2 DIMM module, if present. Install the DDR2 DIMM module into the 240 pin

connector on the top of the FS2334 probe.

Install the DDR2 probe/DIMM into the target system.

Connect the supplemental power supply to the FS2334.

Connect the FS2334 Headers directly to the logic analyzer pods per the configuration

file requirements if not done prior to installing the probe. Refer to the General Purpose

Probe.

Signal Isolation on the Probe

All signals sent to the logic analyzer from the FS2334 DDR2 probe are isolated from the

DDR2 DIMM bus by a parallel RC network of 20K ohms and .3 pF. These resistors a re

placed in a manner to minimize stubs seen by the DIMM bus and to match lengths to the

DIMM module so that Data bits and their Strobe/Mask bits are matched to within 20 ps.

Buffered signals on the probe

The DDR2 DIMM bus Control signals are buffered on the probe before they are

connected to the DIMM. This includes the S0:1, CKE0:1, and ODT0:1 signals.

11

Page 12

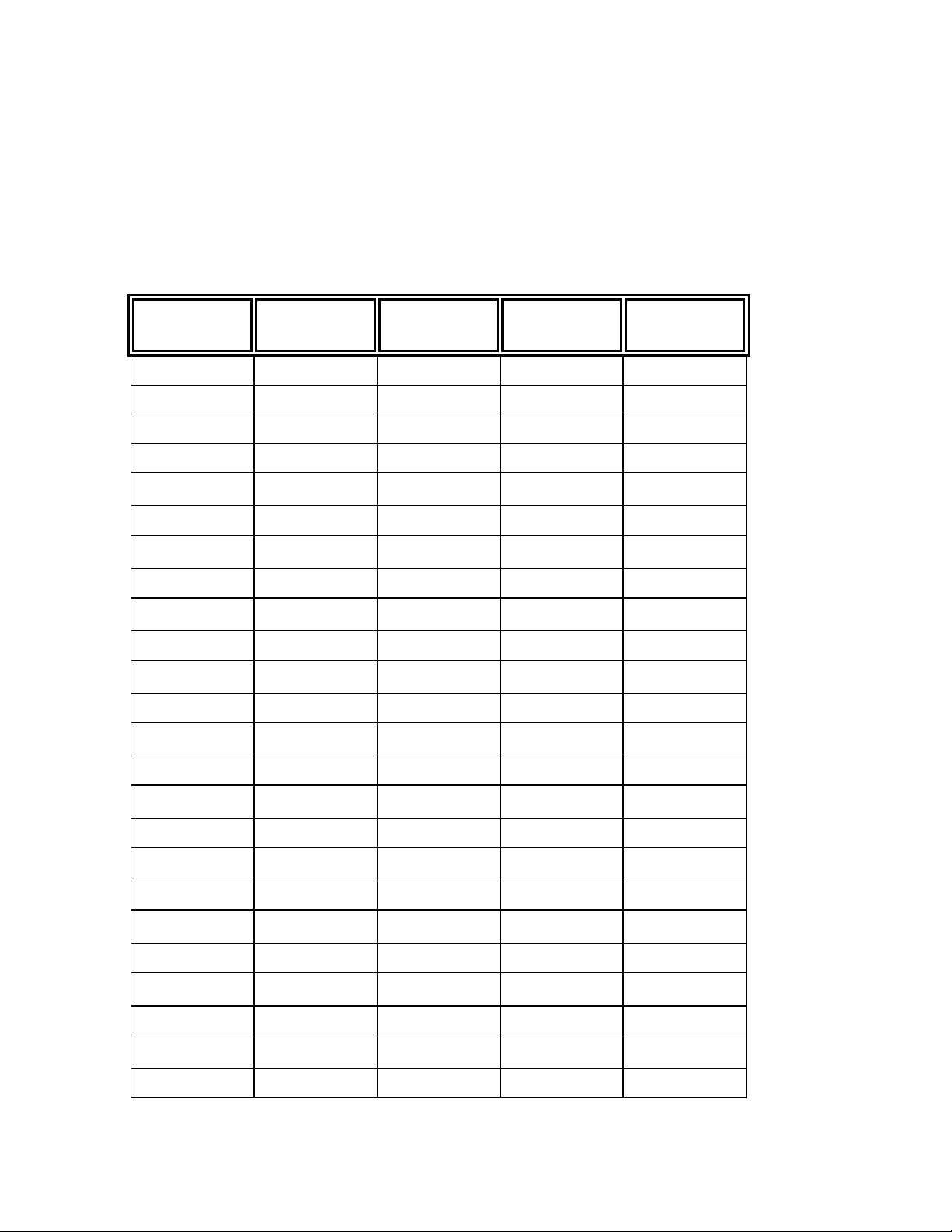

Recommended Logic Analyzer Card Requir ements a nd Config uration files

169xx Analyzer

Type

Timing Analysis State Analysis

667MT/s or slower

16753/4/5/6,

16950

800MT/s

16753/4/5/6,

16950

FS234_2 3 cards

configured as one

module, one timing

machine

FS234_2 3 cards

configured as one

module, one timing

machine

FS234_5 4 cards

configured as one logic

analyzer state machine.

Uses FS1117

FS234_1 Read and Write

analysis requires 7 cards

across 2 frames

configured as 2 logic

analyzer state machines.

Uses FS1136

FS234_3 4 card

configuration provides

Write state analysis

only Uses FS1136

FS234_4 4 card

configuration provides

Read state analysis only

Uses FS1136

FS234_32_Lower(Upper)

4 card configuration

provides Read and Write

state analysis for only 32

bits of Data, either Lower

or Upper

Uses FS1136

12

Page 13

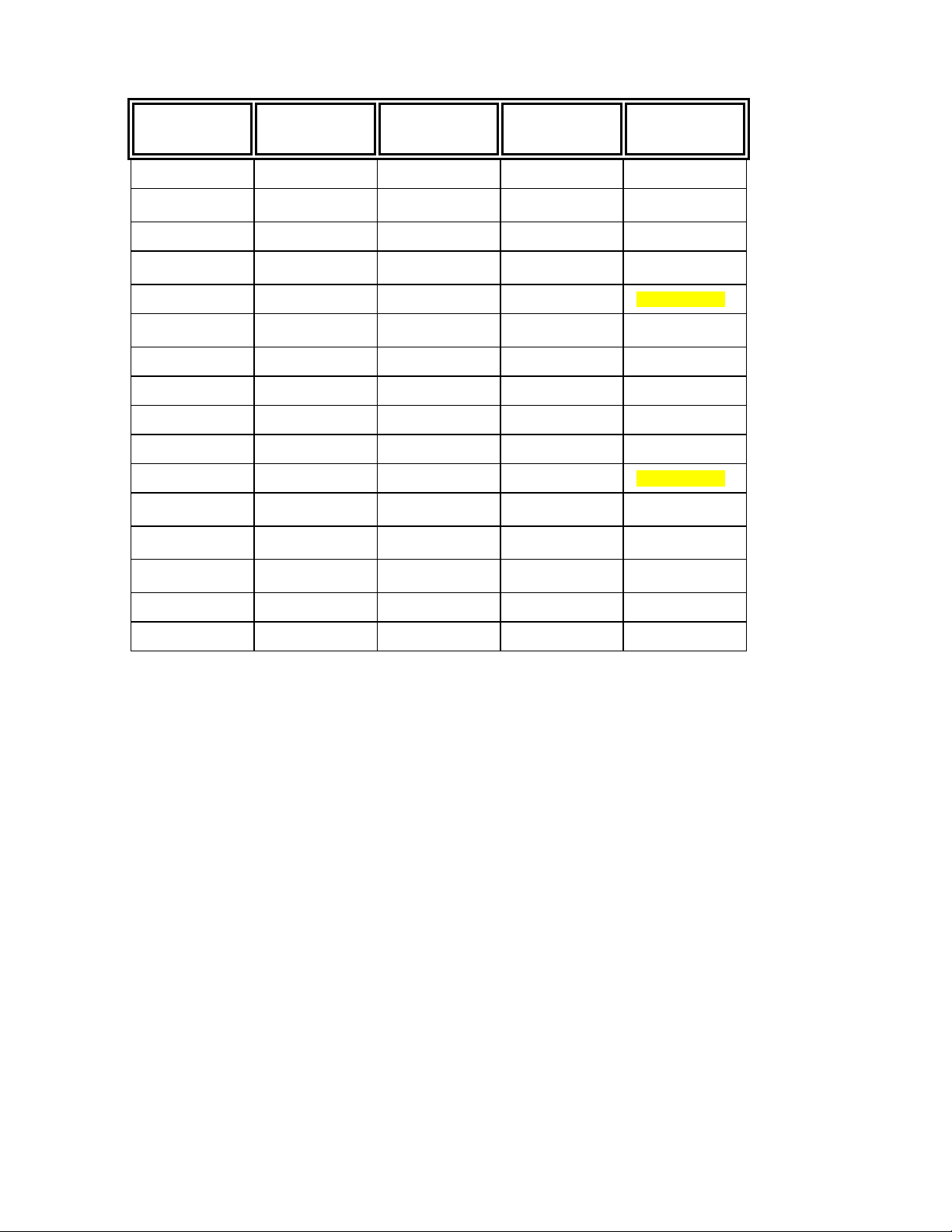

Logic Analyzer card configurations – Note: These are all for unbuffered DIMM

probing

FS234_1 2 machine, 7 Card 800MT/s

Read and Write configuration file

FS234_32_Lower(Upper) 4 card 32 bit

800MT/s Data State analysis configuration

FS234_2 Timing analysis 3 card

configuration

FS234_3 800MT/s Writes only 4 card

configuration

FS234_3 800MT/s Reads only 4 card

configuration

FS234_3 667MT/s Reads and Writes 4

card configuration

Write – Command machine 4 cards in slots A – D (B =

Master). Read machine 3 cards in slots A – C (B =

master)

4 cards in slots A – D (B = Master)

3 cards in slots A – C (B = Master)

4 cards in slots A – D (B = Master)

4 cards in slots A – D (B = Master)

4 cards in slots A – D (B = Master)

13

Page 14

Software Requirements

Setting up the 169xx Analyzer

A CD containing the 16900 software is included in the FS1136 package. The CD

contains a setup file that will automatically install the configuration files and protocol

decoder onto a PC containing the 16900 operating system or onto a 16900 analy zer

itself.

To install the software simply double click the .exe file on the CD containing the FS1136

and the FS1117 software. After accepting the license agreement the software should

install within a couple of minutes. Duplicate the process for the FS1140 Protocol

Checking software.

169xx Licensing

Once the software has been successfully installed you must license the software.

Please refer to the entitlement certificate for instructions on licensing each software

product. Please note that you are licensing 3 products, both the FS1136 and

FS1117 Protocol Decoders AND the FS1140 Protocol Checking software and all

require separate license installation on your system. The software can only be

installed on one machine. If you need to install the products on more than one machine

you must contact the FuturePlus sales department to purchase additional licenses.

Loading 169xx configuration fil es and Gener al Purpo se Probe Featur e

When the software has been licensed you are able to load a configuration file. You can

access the configuration files by clicking on the folder that was placed on the desktop.

When you click on the folder it should open up to display all the configuration files to

choose from. If you put your mouse cursor on the name of the file a description will

appear telling you what the setup consists of, once you choose the configuration file that

is appropriate for your configuration, the 16900 operating system should execute. The

protocol decoder automatically loads when the configuration file is loaded. If the

decoder does not load, you may load it by selecting tools from the menu bar at the top of

the screen and select the decoder from the list.

Once you have loaded a configuration file on the 169xx machine you can find out how to

attach the logic analyzer cables to the probe by going to the workspace and selecting

Properties on the General Purpose Probe tool icon that appears before the logic

analyzer icon. Once you click on the Properties box a new window will appear showing

which analyzer pod attaches to which probe cable.

14

Page 15

Offline Analysis

Offline analysis allows a user to be able to analyze a trace offline at a PC so it frees up

the analyzer for another person to use the analyzer to capture data.

If you have already used the license that was included with your package on a

1680/90/900 analyzer and would like to have the offline analysis feature on a PC you

may buy additional licenses, please contact FuturePlus sales department.

In order to view decoded data offline, after installing the 1680/90/900 operating system

on a PC, you must install the FuturePlus software. Please follow the installation

instructions for “Setting up a 16900 analyzer”. Once the FuturePlus software has been

installed and licensed follow these steps to import the data and view it.

From the desktop, double click on the Agilent logic analyzer icon. When the application

comes up there will be a series of questions, answer the first question asking which

startup option to use, select Continue Offline. On the analyzer type question, select

cancel. When the application comes all the way up you should have a blank screen with

a menu bar and tool bar at the top.

For data from a 16900 analyzer, open the .ala file using the File, Open menu selections

and browse to the desired .ala file.

After clicking “next” you must browse for the fast binary data file you want to import.

Once you have located the file and clicked start import, the data should appear in the

listing.

15

Page 16

After the decoder has loaded, select Preferences from the overview screen and set the

preferences to their correct value in order to decode the trace properly.

The protocol decoders, FS1136 and FS1117, require 4 parameters to be entered by the

user in order to decode valid states. To access the preferences on the 169xx select

Prefs from the graphic representation of the protocol decoder in the overview window.

The information required is generally available from the spec. sheet of the memory

device being used or by querying the BIOS of the target system.

a) Number of Chip Selects – This is either 1 or 2 based on the whether either

S0 is being probed and incorporated into the IA or both S0 and S1.

b) CAS Latency – Also defined as “CL”, or the delay from a valid Read

command to when the Read data is strobed on the bus.

c) Additive Latency – Defined by the chipset

d) Burst Length – Usually fixed at 4, or 8.

e) Additionally, the FS1136 has Preference selections for Data bit length and

number of logic machines

The input screen for this information is shown below

16

Page 17

TimingZoom Analysis

The TimingZoom feature of the 1690x logic analyzer allows for efficient timing analysis

of all the signals on the DDR2 DIMM bus.

Please refer to the “Setting up the 16900 Analyzer” section of this manual on the use of

the general purpose probe feature to determine how to attach the logic analyzer to the

probe.

Load the logic analyzer configuration file for timing, FS234_2. It doesn't matter whether

you select to load "Configs only" or "Configs and Data". You are now ready to start

making measurements.

For timing analysis operation above 600 MHz you need to use the ½ Channel Timing

Mode, which provides bandwidth to 1.2GHz. This mode makes every other pod

available to the user so 4 cards are required. These must be configured via the cables

supplied with the cards as a single logic analyzer module. Refer to the appropriate

Agilent Technologies manual for information on how to connect analyzer cards together

to create multi-card modules.

Please note that 6 of the ECC bits and their Data Strobe (DQS8) are contained on an

extra Header (#14), which will require an additional logic analyzer card in order to probe.

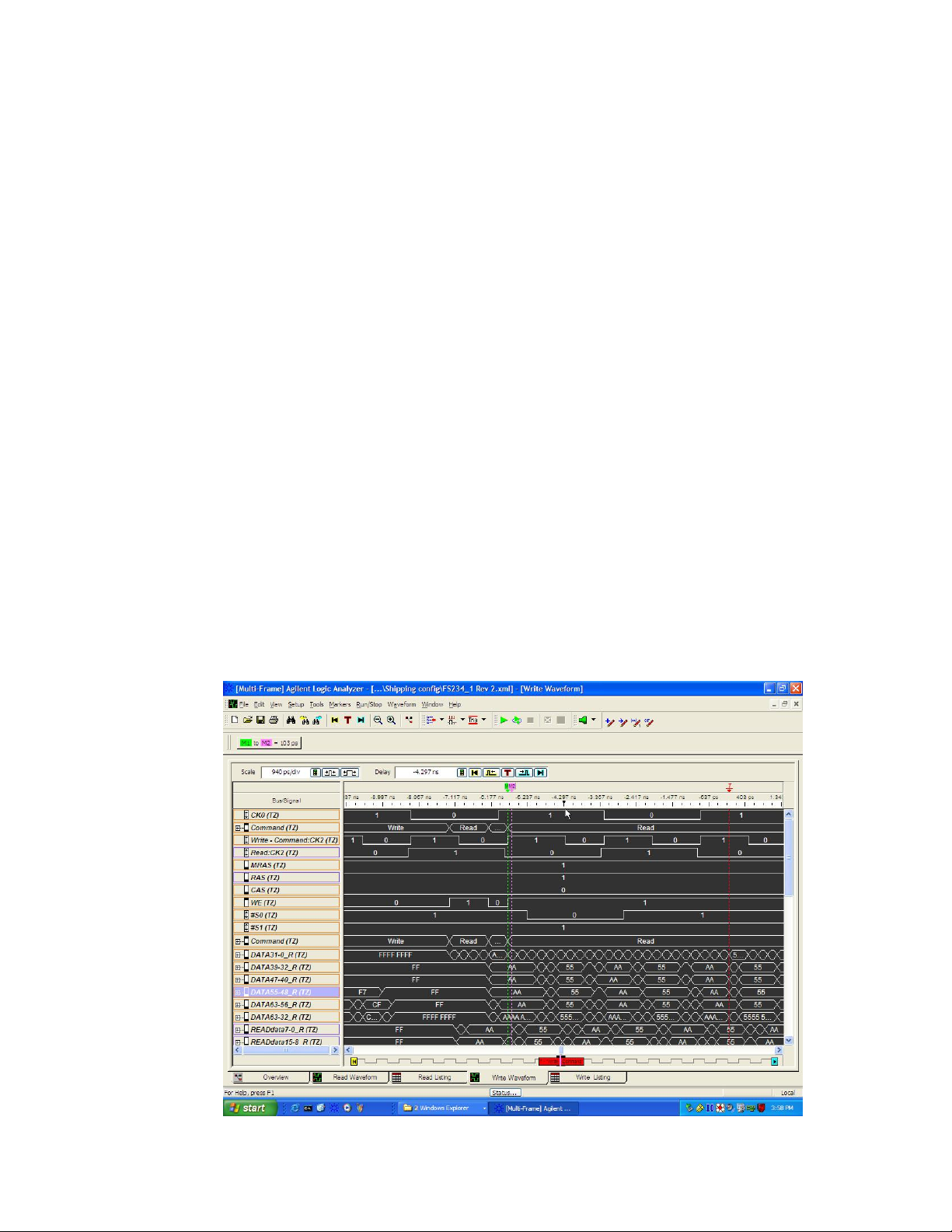

Decoding DDR Commands

No Protocol Decoder is used for timing analysis. However, symbols are pre-defined for

the DDR2 Command bus. These decode the RAS, CAS, and WE lines to display the

DDR Command as “Read”, “Write”, etc., so you don’t have to refer to the DDR chip data

sheet to see what command is being executed. These decoded values are displayed by

setting the display base (in the listing window) or the label property (in the waveform

window) to “Symbols”. The display base defaults to hexadecimal.

Taking a Trace, Triggering, and S eeing Measuremen t Results

Timing analysis is the simplest setup and there are no special factors involved in

analyzer trigger setup, initiating a trace, and viewing results. For the Command bus you

can use the pre-defined symbols to specify mnemonically the command you wish to

trigger on. These are set up by default and are accessible in the trigger tab. The default

waveform display also shows DDR Commands mnemonically.

You may setup a trigger, initiate a measurement, and view results in the usual ways via

the trigger tab, pressing the Run button, and opening the desired display window.

17

Page 18

State Analysis

Overview

There are several choices for State mode analysis using the FS2334 DDR2 probe

depending on the speed of the data bus being probed and the number of logic an alyzer

cards available to the user. At data speeds of up to 667MT/s the logic analyzer can be

triggered on BOTH edges of the clock signal used for State analysis (state clock), at a

data speed of 800MT/s ONLY the rising edge of the state clock can be used.

Because the sampling point for a data signal is at a different position relative to the state

clock edges during a Read data burst than during a Write data burst you need 2

sampling points established for each data signal, which allows the analyzer to sa mple a

data signal twice at speeds up to 667MT/s. When you only have sampling on the rising

edge of the state clock (800MT/s) you need to sample each data signal four times

because you need to account for both the 2 data states per clock and both Reads and

Writes. This is all done by the logic analyzer cards, which drives the cards requirements.

If a user is willing to sample ONLY Read OR Write bursts at 800MT/s, then you reduce

your sampling requirements by ½.

FuturePlus has provided configuration files and a set-up procedure that anticipates

these different scenarios and has described them in the following pages. Please note

that these are for DIMMs without ECC because the addition of the DQ64-72 bits would

force the user to add another card in all the configurations. These bits are available

(refer to the Appendix) if the user wants to modify the existing configuration files and/or

add an additional logic analysis card.

State Analysis Operation – Read and Writes abov e 667MT/ s

State mode capture of Reads and Writes at data rates above 667MT/s requires

quadruple sampling of the Data bits and is performed by using the rising edge of CK0.

This requires 7 cards, which means that for every Data bit there are 4 labels (or

sampling positions), Write Data rising and falling, and Read Data rising and falling. The

analyzer sample position of each channel is set as described later in this manual. The

DDR Command/Address bus is also sampled (along with the data bus) on the rising

edge of CK0.

The 7 cards are configured as 2 logic analyzer machines (Write/Command and Read) in

2 separate frames. CK signals are provided to both machines as well as MRASn and

RASn, which are 2 copies of the same signal from each logic analyzer machine that can

be used as a reference signal for intermodule skew adjustment.

The configurations are set-up with 4 cards melded together in Frame # 1 in slots C, D

(master), E and F. Frame #2 has 3 cards melded together in slots A, B (master) and C.

The frames need to be connected through the Intermodule cable and share a network

connection. More detailed information is available within the Help documentation on

your Agilent Logic analysis frame under “Multiframe operation”.

If you are using the special configurations for 32 bits of Read and Write Data de code

only, then a 4 card configuration in one frame is all that is required.

18

Page 19

State Analysis Operation – Read and Write at 667MT/s or slower

State mode capture is performed by using both edges of CK0. This double probing of

each signal is handled internally by the Agilent Logic Analyzer using the Dual Sample

mode feature. State analysis within these parameters only requires dual sampling of the

Data signals, which can be done with 4 cards in one frame. The four cards used for

state analysis must be configured as one logic analyzer machine. You may also place

the cards in slots other than described here, but must then adjust the pod connection

tables and configuration file loading instructions accordingly. The configuration file is set

up with the Master in slot D, expanders in C, E, and F.

The analyzer sample position of the channel capturing data is set via a calibration

procedure (described in this document) to the optimum value. The DDR

Command/Address bus is also sampled (along with the Data bus) on both edges of

CK0. This does not reduce triggering capability but does require additional care when

setting up triggers because the command/address bus is not valid on the falling edge of

CK0.

The Auto Sample Position Set-up function can be a more accurate means to set the

sampling position for each bit used in the State analysis, but this requires using known,

continuous data patterns of exclusive Reads and then exclusive Writes.

The logic analyzer’s TimingZoom traces can be used to set the sampling position s for

the labels as described in the following sections. Note: The label names are different

depending on whether you are doing Read and Write <= 667MT/s (FS1117 ) or doing

Read or Write at 800 MT/s (FS1136).

State Analysis Operation – Read or W rite at 800MT/s

This mode of State Analysis permits just the use of 4 cards and one logic analyzer

frame. There are 2 different configuration files provided, on for Read only and one for

Write only State analysis. These configuration files use the FS1136 Protocol Decoder

and difference between the 2 is there pre-defined sampling positions are set for one

type of data burst or the other. The State clock operates on only the rising edge of the

clock and each data signal is sampled twice.

Please note that the Protocol decoder listing will show invalid data for the type of burst

that the sampling positions are not defined for.

Setting the sampling positions is done in the same manner as for the 7 card, 800MT/s

configuration, the only difference being fewer labels to set sampling positions for.

19

Page 20

The process for setting sampling p ositions at speeds of 800MT/s :

This procedure requires the probe user to capture TimingZoom traces and use the

markers to determine the correct sampling positions. This is an iterative, trial and error

procedure where adjustments to Data signal sampling positions may need to be

adjusted several times before they provide correct State data capture on both Read and

Writes.

When operating at 800MT/s data speed and a Multi-Frame configuration. There are

several things to consider:

1) There are 4 sets of State Data. These are:

a. Write Data sampled on the rising edge of CK0 Data63-0_R

b. Write Data sampled on the falling edge of CK0 Data63-0_F

c. Read Data sampled on the rising edge of CK2 READdata63-0_R

d. Read Data sampled on the falling edge of CK2 READdata63-0_F

2) Please note within each of these 4 groups of labels there are additional labels

organized by data byte. This is because many platforms may display timing

differences between byte groups and therefore require a slightly different sampling

setting which the byte labels make easier to both measure and set.

3) At 400MHz clock speed the 16900 analyzer in this configuration will display both the

State and TimingZoom version of the State Clock signal, (CommandClk) CK0 for the

Write analyzer and CK2 for the Read analyzer, at ½ it’s actual frequency. For an

.actual representation of the state clock use Write – Command:CK2_TZ

4) Because of the logic analyzer’s pod to pod skew of +/- 1.75ns, you want to take

several timing offset measurements before setting a sampling value.

5) Both the Write and Read analyzers are clocked only on the rising edge of their State

Clocks.

6) The Intermodule Skew should not need adjustment for State analysis. This can

done if necessary by aligning the MRAS_TZ (Write analyzer) and RAS_TZ (Read

analyzer) signals, but the user will have to reset it after every trace capture.

7) Sample positions for Command, Address and Control signals are already set to

values that should allow proper State analysis. If adjustment is necessary they can

be moved using either the TimingZoom measurement procedure described here, or

by using Auto Sample positioning provided that Chip Select qualification is applied

or the system is slowed down to a DDR clock rate of 333MHz and the logic analyzer

is set to 300MHz State mode.

20

Page 21

State analysis calibration procedure

This process is in large part the same for both use in the 7 card Read and Write

configuration at 800MT/s and for the 4 card configurations. Differences are noted.

1) Start a memory test program that creates a good mixture of reads and writes in a

single TimingZoom trace. A trigger on a write may be required if the test program does

not have a mix or reads and writes in close proximity.

Note that in addition to looking for the DDR commands the #S0:1 and CKE0:1 signals are

used to determine if the command is actually addressing a memory chip. The Write –

Command:CK2_TZ signal is used to make sure the command i s sampled on the rising edge

of the DIMM clock (since that is when the DDR command bus is valid).

2) Bring up a waveform display and add the TimingZoom labels for the command

clock, chip selects, and DQS0 (Write – Command:CK2_TZ, #S0_TZ, DQS80_TZ[0]) and the data bus labels for Writes (Data63-32_R/Fand Data31-0_ R/F) in

the waveform view. Scroll the waveforms to find the start of a Write burst. You will

see this by finding where the DQS0 strobe becomes active.

Note: The 4 card configurations have only 2 sets of Data labels.

3) Now the time delay from the closest rising edge of Write – Command:CK2_TZ prior

to the center of the write data eyes can be measured. This will be the DATA_rising

point. Place a marker on that edge of the Write – Command:CK2_TZ. Place the

other marker in the center of the data valid region for the data label. You may find it

easier to identify this point by locating the point on one of the DQS signals that is

equal distances from the edges. Note the 103 ps delay between the markers as

shown below.

The 4 card config for 667MT/s will use delays measured from the nearest rising of

falling edge of the state clock.

21

Page 22

4) Repeat this procedure using the next rising edge of Write – Command:CK2_TZ and

the corresponding data burst cycle (it will be right next to the burst cycle you just

looked at). Measure the time difference from the rising edge of Write –

Command:CK2_TZ to both the center of the data eyes associated with the rising

edge of the Data strobe and then the falling edge of the Data strobe.

5) Repeat this procedure for several cycles of the burst. You may do this for other

bursts as well if you wish to cover different types of data burst patterns and account

for possible edge jitter sources. You may also find that the timing varies slightly

from Data byte to Data byte. This can be due to differences in the DIMM layout and

individual differences in the DRAMs on the DIMM. Compute the average of the

times between the rising edge of Write – Command:CK2_TZ for each byte

associated with the rising and separately for the falling labels.

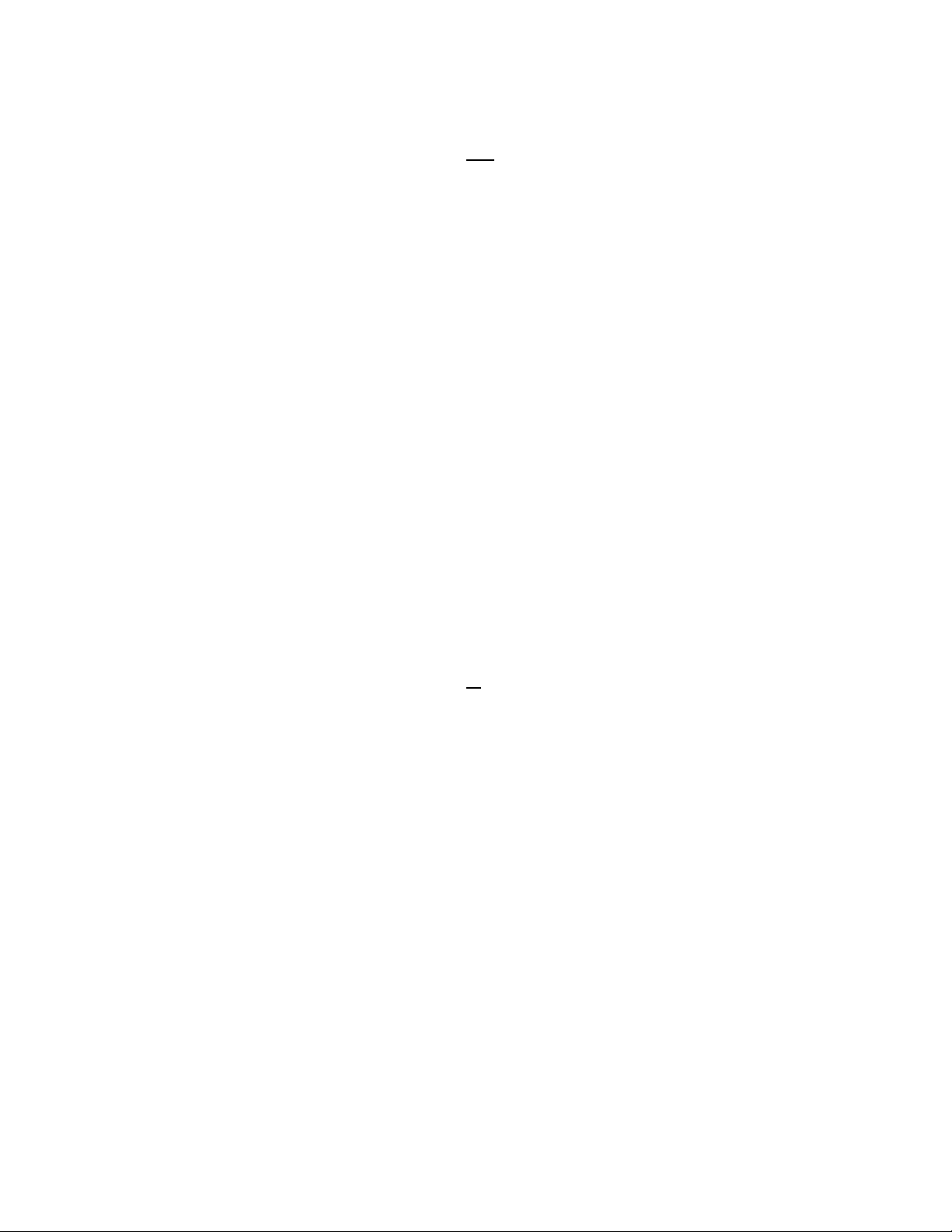

6) Now it is time to use this delay information to set the logic analyzer sample position.

From the “Sampling” tab of the “Write - Command” analyzer window click the

”Thresholds and Sampling Positions” button to bring up the sample positions for

Write data labels. (The write data labels are shown below).

7) Set the sample position to be equal to the average time you computed in step 5.

The easiest way to do this is to point to the blue vertical sample position bar with the

mouse and press and hold the left mouse button while dragging the blue bars as far

to the left side of the display as possible. This will cause all the blue bars for that

22

Page 23

label to be set to the same value. Then you can drag the blue sample position bar

back to the right to place it in the position you measured in step 5. The sample

position is indicated on the scale at the top of the display as well as on the side

under the “Sampling Position” column. The figure above shows the DATA31-0_R

label sample position set to .110 ns and DATA31-0_F sample position set to 1.59

ns. This means that a 1.59ns average delay was measured to the center of the data

eye associated with a falling data strobe edge for a Write data burst on the bus after

a valid State Clock edge.

8) After making these adjustments to the Write Data Sampling positions, go back to

step #1 and trigger on your known data pattern again. Check your Write - Command

listing for the State data values across multiple Write bursts. They should be close

to or equal to the known data written. There may be a pattern of bits that are

incorrect and those bits will need further adjustment to their sample positions

following the steps outlined above until you have the Write data sampling positions

set to values that allow for proper data capture.

This completes the procedure for the Write labels. Use the same procedure using Read

bursts and the Read data labels. Write data eyes are centered on the edge of the strobes

whereas reads straddle the DQS strobes.

You should now be ready to take state traces and be confident you will capture bus traffic

correctly. You may want to save the settings that you have either in the current configuration

or in a new one.

23

Page 24

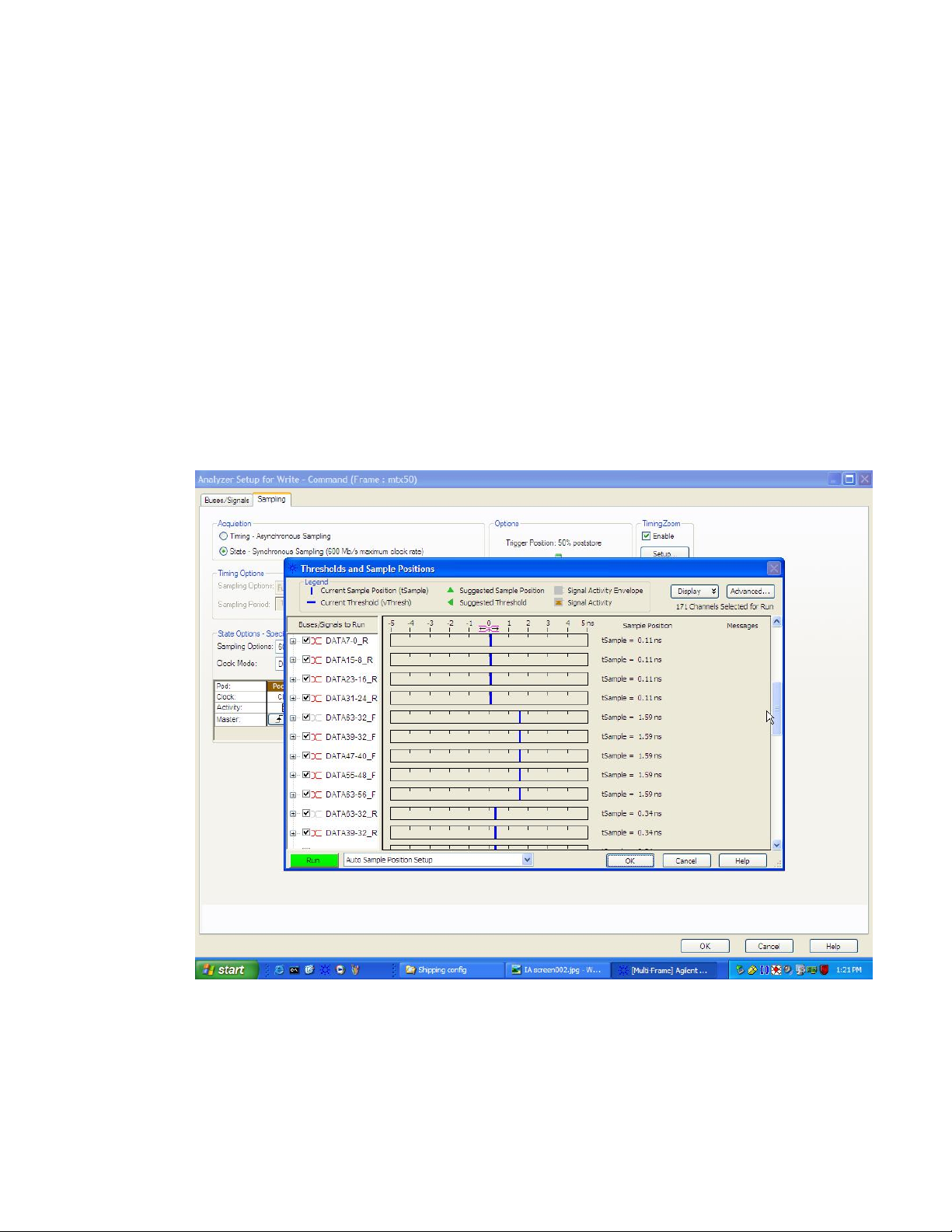

Adjusting the sampling positions wit h control led st imulus

This is a special case requiring special stimulus of the DDR2 DIMM bus. This may

involve the use of a special memory test card from Ultra-X that can create this special

stimulus

• The Auto Sample Position Setup and Auto Threshold functions of the Agilent logic

analyzer are the most precise method of determining the data valid window for signals

and then setting each logic analyzer sample position to that optimum value for state

analysis. There are several basic concepts that should be understood first. In order to

run Auto Sample Position Setup and Auto Threshold on the Data signals it is important

that the target system is programmed to generate exclusively Write or Read

traffic. This is the only way to get usable data windows to set the sampling positions of

both the Read and Write Data labels on the logic analyzer. At these speeds even ½ a

data strobe bit width of timing relationship shift between the strobe (clock) and the data

bits will eliminate the window.

• The Threshold setting for clocks and signals can have a significant effect on the size of

the eyes. At speeds of 667MT/s or higher even a 50mV change in the threshold can

make all the difference in the eye size as measured at the logic analyzer. The best way

to determine this level is through trial and error, or through use of the Auto Threshold

function.

• The Command/Address/Control signals are all qualified by Chip Select (S0:1), and

therefore one of these signals should be used as a clock qualifier when using Eyefinder

to set sampling positions. However, 600MHz State speed on the Agilent logic analyzer

does not provide clock qualification. You can set the sampling speed to 300MHz and

slow the system DDR clock down to 333MHz (667MT/s) and run Eyefinder on the

Command/Address/Control signals with the S0 clock qualification. Set the sampling

speed and system DDR clock back afterwards. Alternatively, the use of a special

memory test may provide a mode where there are continuous Chip Select qualified

commands at 800MT/s

1. To setup the sampling positions for Address, Command and Control signals.

This can be done using a Timing or State configuration as they use CK0 as the

clock input for the logic analyzer. Make sure the Clock mode is Rising edge. Set

the Sampling Options to 300MHz and select S0 as a Clock Qualifier – Low,

(refer to section on secondary Clock inputs). Generate some bus traffic and run

Auto Sample Position Setup and/or Auto Threshold as required to establish

correct Threshold settings, valid eye openings, and sample positions for these

signals. NOTE: You have to have the target system running at 667MT/s for this

process.

2. For Data signal sample positions, initiate traffic on the target system that

generates as much only Write bursts to the DIMM as possible. If there are

Read bursts contained in this traffic the positions of the Data signal edges

change relative Clock input and this will close the valid eye openings for all the

Data signals. All Clock cycles that occur without Write Data transfers will also

close down the eyes. Run Auto Sample Position Setup and/or Auto Threshold

as required to establish correct Threshold settings, valid eye openings, and

sample positions for these signals. Move the sample positions for the Data

Strobes and all the Data labels (rising and falling) to the center of the valid

windows for those labels as shown below.

3. Initiate traffic on the target system that generates only Read bursts to the

DIMM. If there are Write bursts contained in this traffic the positions of the Data

24

Page 25

signal edges change relative to the Data Strobes (clock input) and this will be

close the valid eye openings for all the Data signals. Run Auto Sample Position

Setup and/or Auto Threshold as required to establish correct Threshold settings,

valid eye openings, and sample positions for these signals. Move the sample

positions for all the Read_Data labels (rising and falling) to the center of the

valid windows.

4. Once the Sampling positions have been correctly set for all labels in the

configuration file, save the sample positions by saving the configuration file.

25

Page 26

State Display

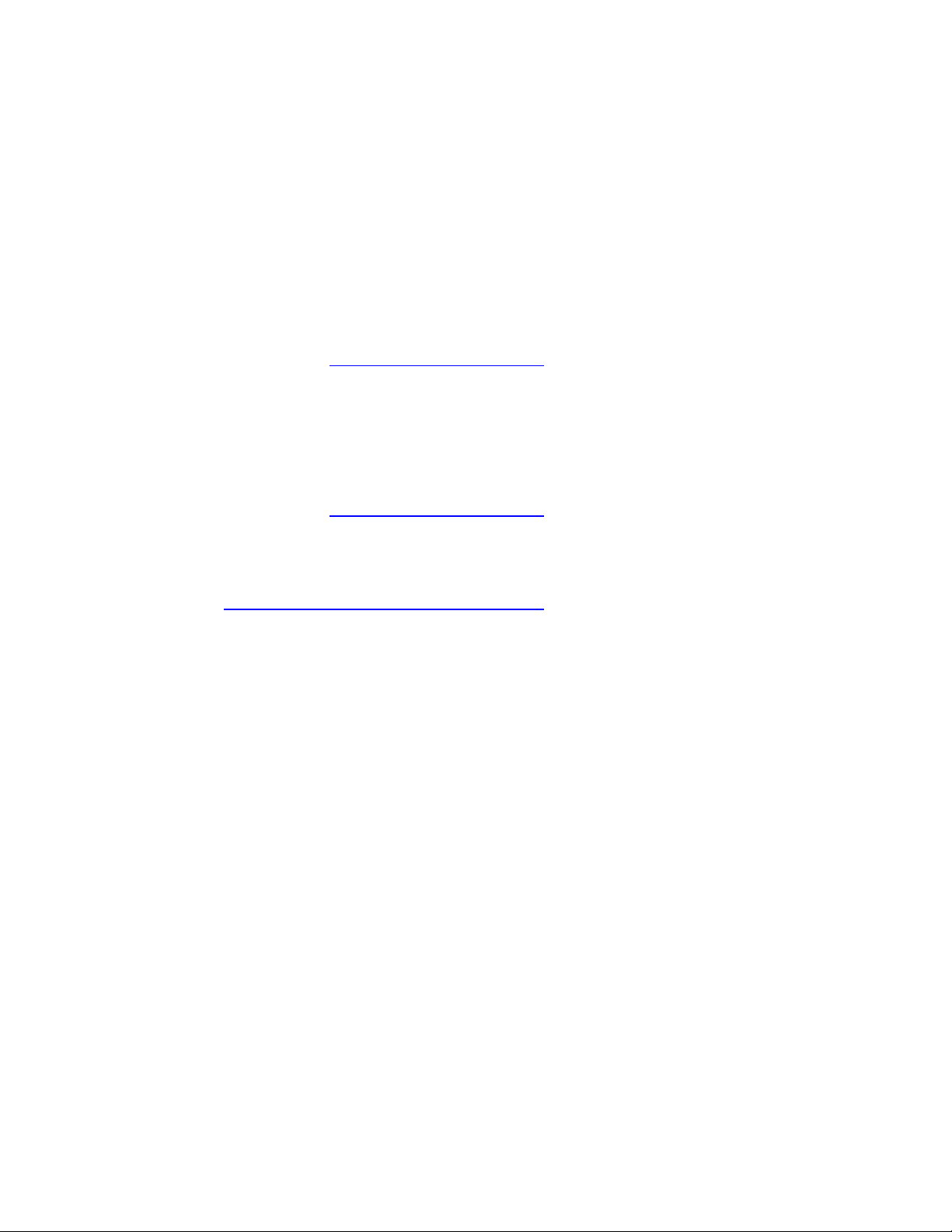

The following figure shows a typical DDR2 screen display. Because the analyzer may

sample data on both edges of the clock (FS1117) there are going to be some states that

have no commands or data associated with them. The Protocol Decoder contains a filter

that will allow post filtering of any states included Not Selected state, which is defined as

a state that has no command or data associated with it.

Symbols were created for the Command label. These symbols make searching for a

particular command in a listing easier as well as setting up triggers. These decode the

RAS, CAS, and WE lines to display the DDR Command as “Read”, “Write”, etc., so you

don’t have to refer to the DDR chip data sheet to see what command is being executed.

These decoded values are displayed by setting the display base (in the listing window)

or the label property (in the waveform window) to “Symbols”. The display base defaults

to hexadecimal.

Filtering on the 169xx is configured by the user there are no predetermined filters in the

169xx decoder. To set up a filter in the 169xx environment select tools from the menu

bar, then select filter/colorize. You can choose to filter before or after the decoder. If

you filter before the decoder, use caution to not filter any labels needed by the decoder.

If you filter after the decoder you can use the label “filter tags” created by the decoder,

change hex to symbols and use symbols to remove any command that the user does

not want to see.

26

Page 27

DDR2 Protocol Checking and Performance T ool (FS1140)

The FS1140 DDR2 Protocol Checking and Performance Tool is a separate VBA-based

application that provides a detailed analysis of a 16900 format logic analyzer trace file,

captured with an FS2334 DDR2 Interposer probe. The FS1140 is provided as a single

user, node-locked license that requires separate licensing, and the Agilent system

needs the Agilent VBA Runtime or Development license present as well.

NOTE: The Functional Performance portion of this software will NOT work with 2

FRAME configurations

The FS1140 provides 3 different types of analysis on the captured trace data.

First, it provides a flag any where there is a violation of any of 6 different DDR2 protocol

rules. These include:

1) Refresh with Active Banks

2) Write to a Bank that is not Active

3) Read from a Bank that is not Active – Not available on FS2334 probe

4) Mode Register Set with Active Banks

5) Bank not Precharged before being Activated

6) Data Burst interrupted by a Command

Second, the FS1140 provides summary statistics of the transactions captured in the

trace file. These measurements provide some indication of the performance of the

DDR2 system during the trace capture and include % of Write and Read commands, %

of Clock cycles with data activity,

Third, the FS1140 software will provide measurements of the Data Window eye width on

a bit by bit basis across all Timing Zoom data in the trace file; additionally it will identify

those signals with the smallest eye width.

FS1140 Installation and Licensing

The FS1140.exe file is on the CD used to install the FS2334 configurations and Protocol

Decoder in your Windows environment. It can be installed by simply double-clicking on

the file. Please note that you are licensing 3 products, both the FS1136 and FS1117

Protocol Decoders AND the FS1140 Protocol Checking software and they require

separate installation on your system. The software can only be installed on one

machine. If you need to install the products on more than one machine you must contact

the FuturePlus sales department to purchase additional licenses.

Loading the FS1140

After one of the State listing configuration files has been loaded, go to the “Windows”

selection on the Title bar from the Overview tab in the Logic Analyzer application. The

application can be either on or off-line at this time. From the “Windows” drop-down,

select “new VBAView” and from that list, select “DDR2 Checking and Performance”.

Once that is selected, a new window will appear providing some choice as to where the

DDR2 Diagnostic Window will attach to the DDR2 data. We recommend that the user

select to attach it directly after the logic analyzer module, so that filtering effects from the

Protocol Decoder do not impact the DDR2 Diagnostic Tool’s results.

27

Page 28

Setting up the FS1140 DDR2 Tool

The FS1140 DDR2 tool has to be set-up with the DDR2 bus parameters being used on the target

system in order to insure proper decode of the captured logic analyzer trace file. Selecting the “Setup” button from the window provides a form for this information. There are 4 DDR2 DIMM bus

parameters that have to be set in order for the FS1140 tool to work properly. These are the same

as the Preferences described on page 21.

28

Page 29

Functional and Performance Analy sis – NOTE: The Function al Perfo rmance

portion of this software will NOT work with 2 FRAME configurations

This window tab provides the ability to initiate the analysis of a trace file in either on or

off-line mode using the “Start Analysis” button. Additionally, when used in on-line mode

it can capture a trace file using the “run” command or initiate repetitive runs and additive

Tool analysis of each run.

Statistics

The performance analysis of the DDR2 DIMM bus over the entire captured trace file is

displayed in the “Statistics” section. This shows information regarding the total number

of clock cycles and Commands that are included in the analyzed trace file, as well as the

total number of errors found. The error count is based on the errors selected in the

Setup. Also, included in this display is information on the Read, Write and Data activity

occurring during the captured trace file.

Errors

This section of the tool displays comprehensive information about the location and

nature of each selected error found in the captured trace file. The user can scroll

through the error listing and either select one error by left clicking on the error to set a

“DDR” marker in the State and Waveform listings, or the user can select the “Place

Markers on All” button which will place uniquely numbered markers (DDRx) on all

identified errors.

Please note: The errors listing is limited to a maximum of 1,000 errors. Placing markers

on all with a large number of errors in the listing can take several minutes to complete,

The error markers allow the users to switch between the Tool, State, and Waveform

information easily during the analysis of the activity related to an error.

29

Page 30

Export

This function takes the data captured and exports it in .csv format to a location the user

selects.

Repetitive Run

This function allows the user to set-up the tool to trigger the logic analyzer a predefined

number of times and capture data incrementally on each run. Please note this function

does not work in Off Line mode.

Timing Analysis

This window tab provides an analysis of each Data bit’s window during every data burst

across an entire TimingZoom trace. The user can set a threshold criteria in this window

and then select whether the data windows to be identified should be equal to, greater

than or equal to, or less than or equal to that value. All Data bits during any burst

captured in a TZ trace will be listed in the Timing Analysis window.

Additionally, the tool provides some overall statistics on what was measured in the TZ

trace that was analyzed. This includes the number of Read and Write strobes analyzed,

the % of data strobes with data transitions occurring; as well as, the maximum, minimum

and average Data Bit widths across ALL bits during ALL bursts in the TZ trace.

Export

This function takes the data captured and exports it in .csv format to a location the user

selects.

30

Page 31

31

Page 32

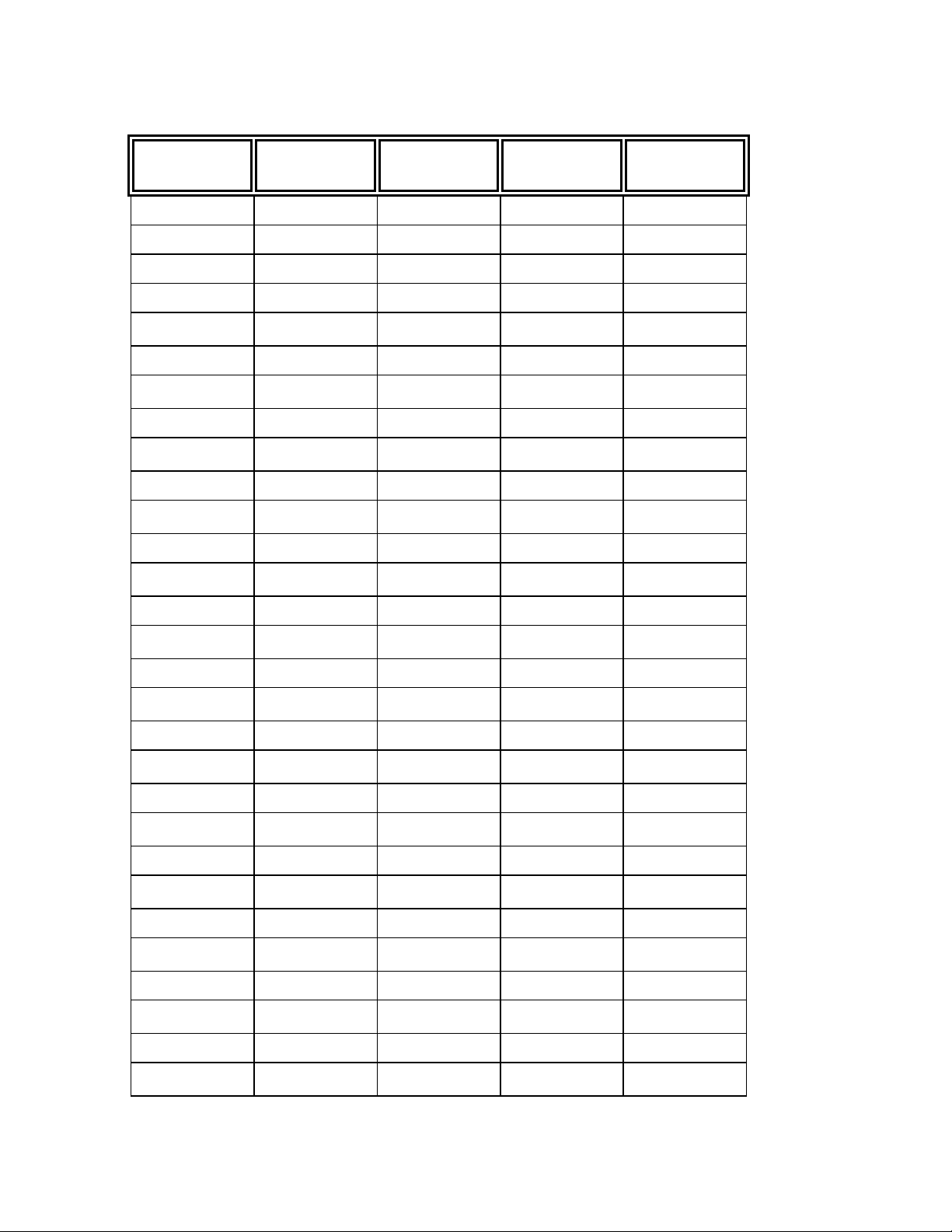

Appendix

FS2334 Signal to Logic Analyzer Connector and Cha nnel Mappin g

The following table shows how the FS2334 DDR2 Probe connects DDR2 DIMM signals

to the logic analyzer pods and channels.

Header 1 - Command

Logic Analyzer

channel

number

Ground 1 2 Ground

Ground 3 4 NC

NC 5 6 NC

Ground 7 8 D0 CKE1

20K ohm to

Ground

Ground 11 12 D1 CKE0

20K ohm to

Ground

Ground 15 16 D2 A15

20K ohm to

Ground

Ground 19 20 D3 A14

20K ohm to

Ground

Ground 23 24 D4 A16

20K ohm to

Ground

Ground 27 28 D5 NC2

20K ohm to

Ground

Ground 31 32 D6 A12

20K ohm to

Ground

Ground 35 36 D7 A9

20K ohm to

Ground

Ground 39 40 D8 A11

20K ohm to

Ground

Ground 43 44 D9 A7

20K ohm to

Ground

Ground 47 48 D10 A8

SAMTEC Pin

number

9 10 Ground

13 14 Ground

17 18 Ground

21 22 Ground

25 26 Ground

29 30 Ground

33 34 Ground

37 38 Ground

41 42 Ground

45 46 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

Signal

name/Logical

Signal Name

32

Page 33

Logic Analyzer

channel

number

20K ohm to

Ground

Ground 51 52 D11 A5

20K ohm to

Ground

Ground 55 56 D12 A6

20K ohm to

Ground

Ground 59 60 D13 A4

20K ohm to

Ground

Ground 63 64 D14 A3

20K ohm to

Ground

Ground 67 68 D15 A1

20K ohm to

Ground

Ground 71 72 NC

NC 73 74 Ground

SAMTEC Pin

number

49 50 Ground

53 54 Ground

57 58 Ground

61 62 Ground

65 66 Ground

69 70 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

Signal

name/Logical

Signal Name

Ground 75 76 NC

Ground 77 78 Ground

Ground 79 80 DP16P/ CLK CK0

20K ohm to

Ground

Ground 83 84

25K ohm to

Ground (PID)

Ground 87 88 NC

NC 89 90 Ground

81 82 Ground

DP16N/

CLKN

85 86 Ground

CK0N

33

Page 34

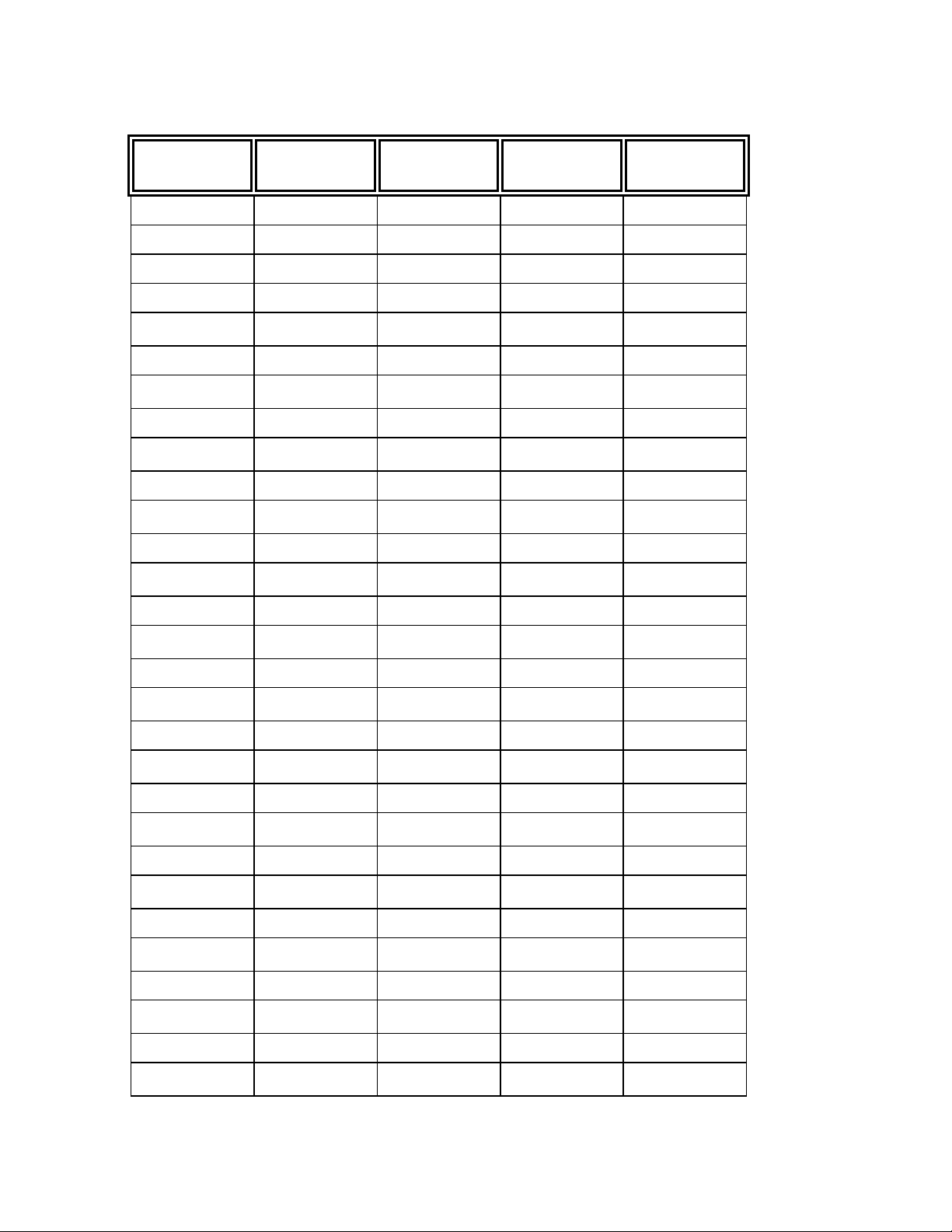

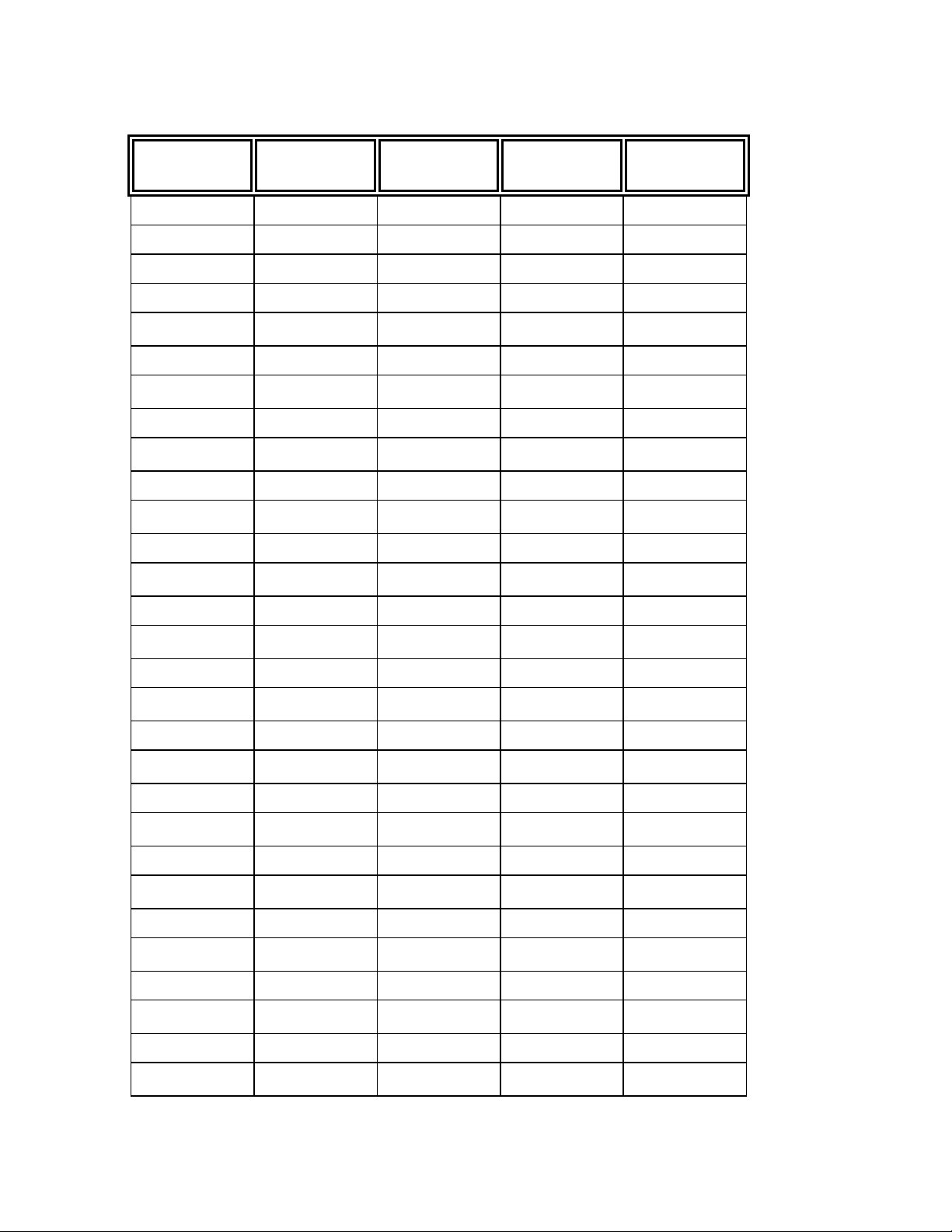

Header 2 - Command

Logic Analyzer

channel

number

Ground 1 2 Ground

Ground 3 4 NC

NC 5 6 NC

Ground 7 8 D0 ODT1

20K ohm to

Ground

Ground 11 12 D1 No connection

20K ohm to

Ground

Ground 15 16 D2 A13

20K ohm to

Ground

Ground 19 20 D3 NC4

20K ohm to

Ground

Ground 23 24 D4 S1

20K ohm to

Ground

Ground 27 28 D5 ODT0

20K ohm to

Ground

Ground 31 32 D6 CAS

20K ohm to

Ground

Ground 35 36 D7 MRAS

20K ohm to

Ground

Ground 39 40 D8 WE

20K ohm to

Ground

Ground 43 44 D9 BA1

20K ohm to

Ground

Ground 47 48 D10 BA0

20K ohm to

Ground

Ground 51 52 D11 A0

20K ohm to

Ground

Ground 55 56 D12 A10

20K ohm to

Ground

SAMTEC Pin

number

9 10 Ground

13 14 Ground

17 18 Ground

21 22 Ground

25 26 Ground

29 30 Ground

33 34 Ground

37 38 Ground

41 42 Ground

45 46 Ground

49 50 Ground

53 54 Ground

57 58 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

Signal

name/Logical

Signal Name

34

Page 35

Logic Analyzer

channel

number

Ground 59 60 D13 NC3

20K ohm to

Ground

Ground 63 64 D14 A2

20K ohm to

Ground

Ground 67 68 D15 See TP matrix

20K ohm to

Ground

Ground 71 72 NC

NC 73 74 Ground

Ground 75 76 NC

Ground 77 78 Ground

Ground 79 80 DP16P/ CLK See TP matrix

20K ohm to

Ground

Ground 83 84

25K ohm to

Ground (PID)

Ground 87 88 NC

SAMTEC Pin

number

61 62 Ground

65 66 Ground

69 70 Ground

81 82 Ground

85 86 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

DP16N/

CLKN

Signal

name/Logical

Signal Name

NC 89 90 Ground

35

Page 36

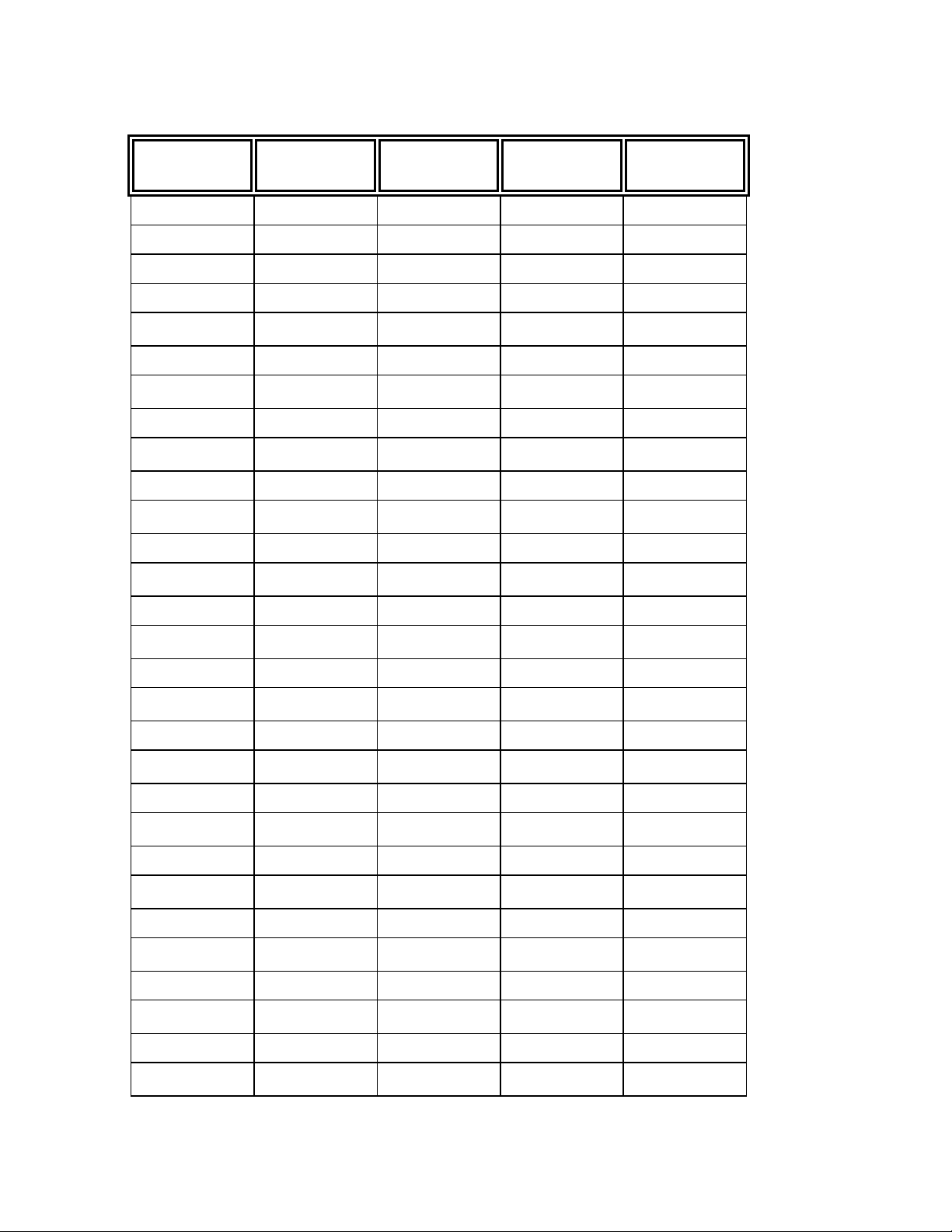

Header 3 - Write

Logic Analyzer

channel

number

Ground 1 2 Ground

Ground 3 4 NC

NC 5 6 NC

Ground 7 8 D0 DQ4

20K ohm to

Ground

Ground 11 12 D1 DQ0

20K ohm to

Ground

Ground 15 16 D2 DQ5

20K ohm to

Ground

Ground 19 20 D3 DQ1

20K ohm to

Ground

Ground 23 24 D4 DM0

20K ohm to

Ground

Ground 27 28 D5 DQS0n

20K ohm to

Ground

Ground 31 32 D6 DQS0

20K ohm to

Ground

Ground 35 36 D7 DQ6

20K ohm to

Ground

Ground 39 40 D8 DQ2

20K ohm to

Ground

Ground 43 44 D9 DQ7

20K ohm to

Ground

Ground 47 48 D10 DQ3

20K ohm to

Ground

Ground 51 52 D11 DQ12

20K ohm to

Ground

Ground 55 56 D12 DQ8

20K ohm to

Ground

SAMTEC Pin

number

9 10 Ground

13 14 Ground

17 18 Ground

21 22 Ground

25 26 Ground

29 30 Ground

33 34 Ground

37 38 Ground

41 42 Ground

45 46 Ground

49 50 Ground

53 54 Ground

57 58 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

Signal

name/Logical

Signal Name

36

Page 37

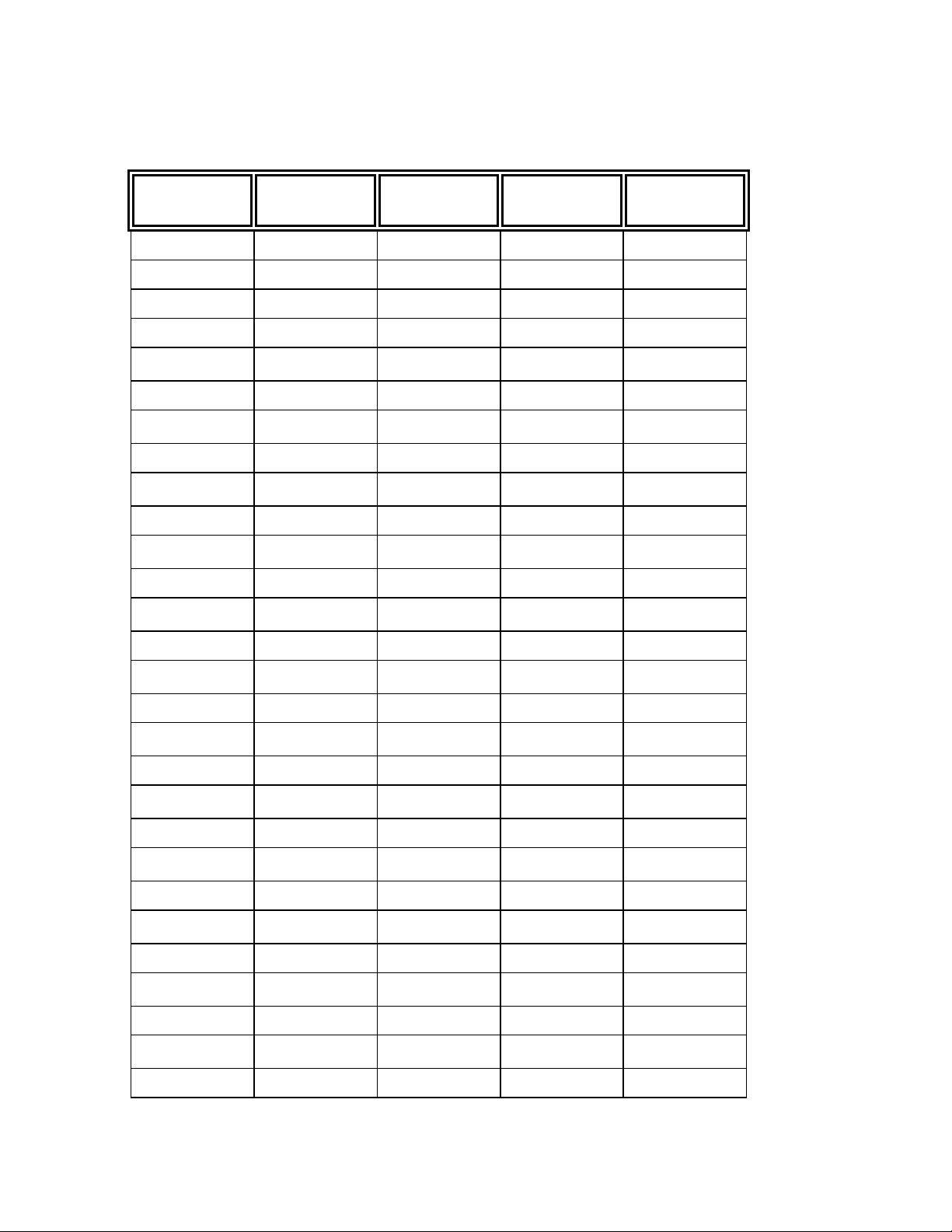

Logic Analyzer

channel

number

Ground 59 60 D13 DQ13

20K ohm to

Ground

Ground 63 64 D14 DQ9

20K ohm to

Ground

Ground 67 68 D15 DM1

20K ohm to

Ground

Ground 71 72 NC

NC 73 74 Ground

Ground 75 76 NC

Ground 77 78 Ground

Ground 79 80 DP16P/ CLK DQS1

20K ohm to

Ground

Ground 83 84

25K ohm to

Ground (PID)

Ground 87 88 NC

SAMTEC Pin

number

61 62 Ground

65 66 Ground

69 70 Ground

81 82 Ground

85 86 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

DP16N/

CLKN

Signal

name/Logical

Signal Name

NC

NC 89 90 Ground

37

Page 38

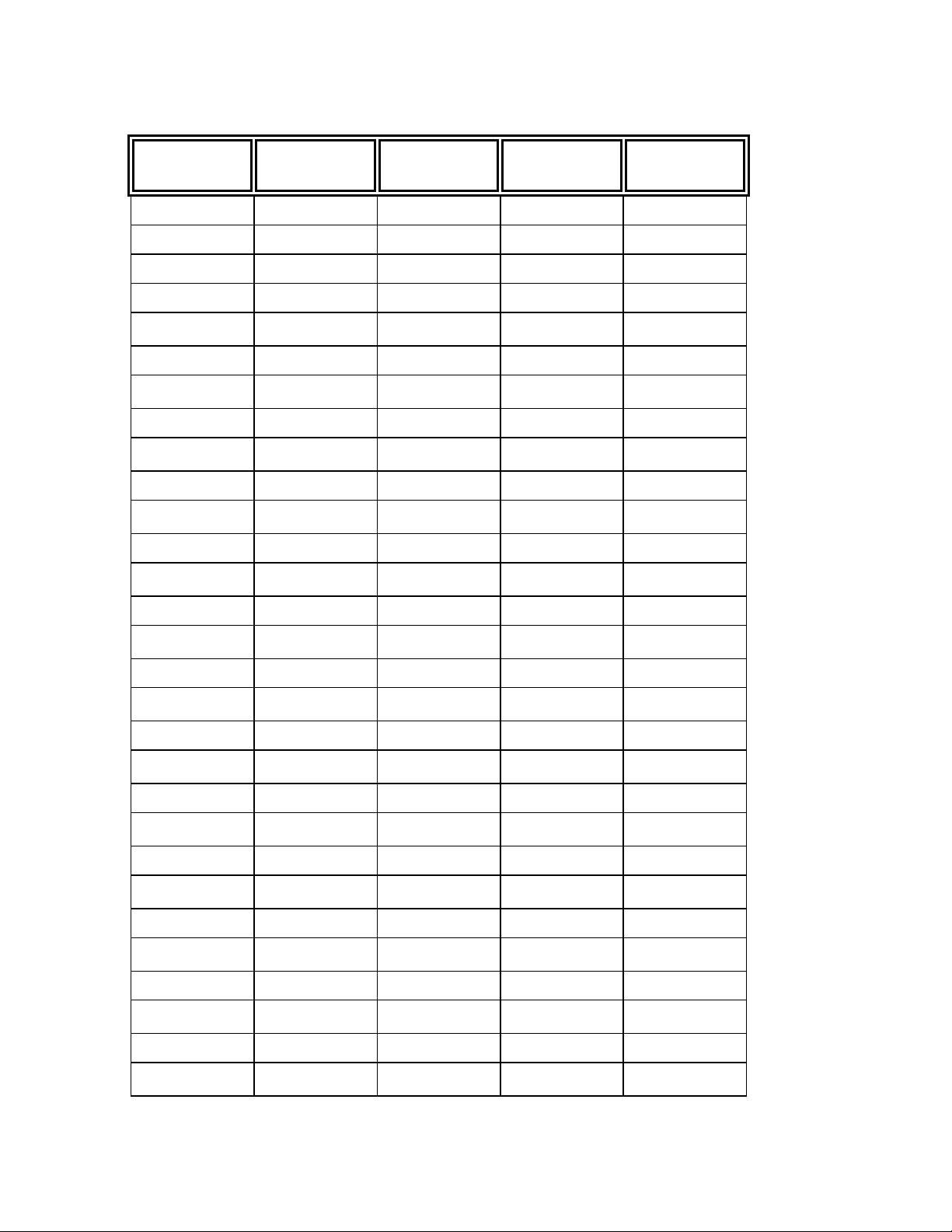

Header 4 - Write

Logic Analyzer

channel

number

Ground 1 2 Ground

Ground 3 4 NC

NC 5 6 NC

Ground 7 8 D0 CK1

20K ohm to

Ground

Ground 11 12 D1 CK1n

20K ohm to

Ground

Ground 15 16 D2 RESETn

20K ohm to

Ground

Ground 19 20 D3 DQ14

20K ohm to

Ground

Ground 23 24 D4 DQ10

20K ohm to

Ground

Ground 27 28 D5 DQ15

20K ohm to

Ground

Ground 31 32 D6 DQ11

20K ohm to

Ground

Ground 35 36 D7 DQ20

20K ohm to

Ground

Ground 39 40 D8 DQ16

20K ohm to

Ground

Ground 43 44 D9 DQ21

20K ohm to

Ground

Ground 47 48 D10 DQ17

20K ohm to

Ground

Ground 51 52 D11 DQS2n

20K ohm to

Ground

Ground 55 56 D12 DQS2

20K ohm to

Ground

SAMTEC Pin

number

9 10 Ground

13 14 Ground

17 18 Ground

21 22 Ground

25 26 Ground

29 30 Ground

33 34 Ground

37 38 Ground

41 42 Ground

45 46 Ground

49 50 Ground

53 54 Ground

57 58 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

Signal

name/Logical

Signal Name

38

Page 39

Logic Analyzer

channel

number

Ground 59 60 D13 DQ22

20K ohm to

Ground

Ground 63 64 D14 DQ18

20K ohm to

Ground

Ground 67 68 D15 DQ23

20K ohm to

Ground

Ground 71 72 NC

NC 73 74 Ground

Ground 75 76 NC

Ground 77 78 Ground

Ground 79 80 DP16P/ CLK No connection

20K ohm to

Ground

Ground 83 84

25K ohm to

Ground (PID)

Ground 87 88 NC

SAMTEC Pin

number

61 62 Ground

65 66 Ground

69 70 Ground

81 82 Ground

85 86 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

DP16N/

CLKN

Signal

name/Logical

Signal Name

NC 89 90 Ground

39

Page 40

Header 5 - Write

Logic Analyzer

channel

number

Ground 1 2 Ground

Ground 3 4 NC

NC 5 6 NC

Ground 7 8 D0 DQ19

20K ohm to

Ground

Ground 11 12 D1 DQ28

20K ohm to

Ground

Ground 15 16 D2 DQ24

20K ohm to

Ground

Ground 19 20 D3 DQ29

20K ohm to

Ground

Ground 23 24 D4 DQ25

20K ohm to

Ground

Ground 27 28 D5 DM3

20K ohm to

Ground

Ground 31 32 D6 DQS3n

20K ohm to

Ground

Ground 35 36 D7 DQS3

20K ohm to

Ground

Ground 39 40 D8 DQ30

20K ohm to

Ground

Ground 43 44 D9 DQ26

20K ohm to

Ground

Ground 47 48 D10 DQ31

20K ohm to

Ground

Ground 51 52 D11 DQS7

20K ohm to

Ground

Ground 55 56 D12 CB4

20K ohm to

Ground

SAMTEC Pin

number

9 10 Ground

13 14 Ground

17 18 Ground

21 22 Ground

25 26 Ground

29 30 Ground

33 34 Ground

37 38 Ground

41 42 Ground

45 46 Ground

49 50 Ground

53 54 Ground

57 58 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

Signal

name/Logical

Signal Name

40

Page 41

Logic Analyzer

channel

number

Ground 59 60 D13 CB0

20K ohm to

Ground

Ground 63 64 D14 CB5

20K ohm to

Ground

Ground 67 68 D15 DM8

20K ohm to

Ground

Ground 71 72 NC

NC 73 74 Ground

Ground 75 76 NC

Ground 77 78 Ground

Ground 79 80 DP16P/ CLK No connection

20K ohm to

Ground

Ground 83 84

25K ohm to

Ground (PID)

Ground 87 88 NC

SAMTEC Pin

number

61 62 Ground

65 66 Ground

69 70 Ground

81 82 Ground

85 86 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

DP16N/

CLKN

Signal

name/Logical

Signal Name

NC 89 90 Ground

41

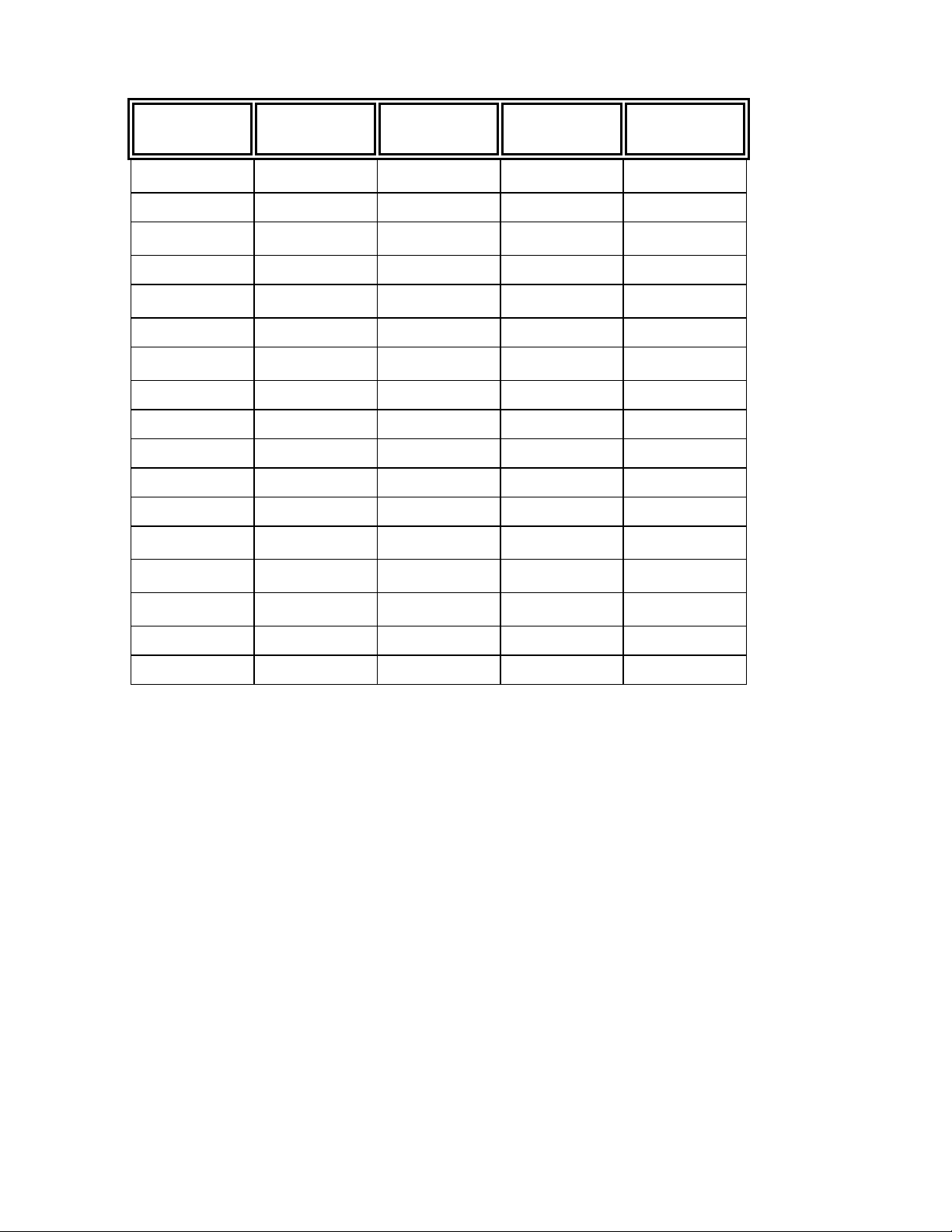

Page 42

Header 14 – ECC bits only this header is not in any config file

Logic Analyzer

channel

number

Ground 1 2 Ground

Ground 3 4 NC

NC 5 6 NC

Ground 7 8 D0 CB1

20K ohm to

Ground

Ground 11 12 D1 DQS8n

20K ohm to

Ground

Ground 15 16 D2 DQS8

20K ohm to

Ground

Ground 19 20 D3 CB6

20K ohm to

Ground

Ground 23 24 D4 CB2

20K ohm to

Ground

Ground 27 28 D5 CB7

20K ohm to

Ground

Ground 31 32 D6 CB3

20K ohm to

Ground

Ground 35 36 D7 Ground

20K ohm to

Ground

Ground 39 40 D8 No connection

20K ohm to

Ground

Ground 43 44 D9 No connection

20K ohm to

Ground

Ground 47 48 D10 No connection

20K ohm to

Ground

Ground 51 52 D11 No connection

20K ohm to

Ground

Ground 55 56 D12 No connection

SAMTEC Pin

number

9 10 Ground

13 14 Ground

17 18 Ground

21 22 Ground

25 26 Ground

29 30 Ground

33 34 Ground

37 38 Ground

41 42 Ground

45 46 Ground

49 50 Ground

53 54 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

Signal

name/Logical

Signal Name

42

Page 43

Logic Analyzer

channel

number

20K ohm to

Ground

Ground 59 60 D13 No connection

20K ohm to

Ground

Ground 63 64 D14 No connection

20K ohm to

Ground

Ground 67 68 D15 No connection

20K ohm to

Ground

Ground 71 72 NC

NC 73 74 Ground

Ground 75 76 NC

Ground 77 78 Ground

Ground 79 80 DP16P/ CLK Ground

20K ohm to

Ground

Ground 83 84

25K ohm to

Ground (PID)

Ground 87 88 NC

SAMTEC Pin

number

57 58 Ground

61 62 Ground

65 66 Ground

69 70 Ground

81 82 Ground

85 86 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

DP16N/

CLKN

Signal

name/Logical

Signal Name

No connection

NC 89 90 Ground

43

Page 44

Header 6 – Write

Logic Analyzer

channel

number

Ground 1 2 Ground

Ground 3 4 NC

NC 5 6 NC

Ground 7 8 D0 DQ36

20K ohm to

Ground

Ground 11 12 D1 DQ32

20K ohm to

Ground

Ground 15 16 D2 DQ37

20K ohm to

Ground

Ground 19 20 D3 DQ33

20K ohm to

Ground

Ground 23 24 D4 DM4_DQS13

20K ohm to

Ground

Ground 27 28 D5 DQS4n

20K ohm to

Ground

Ground 31 32 D6 DQS4

20K ohm to

Ground

Ground 35 36 D7 DQ38

20K ohm to

Ground

Ground 39 40 D8 DQ34

20K ohm to

Ground

Ground 43 44 D9 DQ39

20K ohm to

Ground

Ground 47 48 D10 DQ35

20K ohm to

Ground

Ground 51 52 D11 DQ44

20K ohm to

Ground

Ground 55 56 D12 DQ40

SAMTEC Pin

number

9 10 Ground

13 14 Ground

17 18 Ground

21 22 Ground

25 26 Ground

29 30 Ground

33 34 Ground

37 38 Ground

41 42 Ground

45 46 Ground

49 50 Ground

53 54 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

Signal

name/Logical

Signal Name

44

Page 45

Logic Analyzer

channel

number

20K ohm to

Ground

Ground 59 60 D13 DQ45

20K ohm to

Ground

Ground 63 64 D14 DQ41

20K ohm to

Ground

Ground 67 68 D15 DM5_DQS14

20K ohm to

Ground

Ground 71 72 NC

NC 73 74 Ground

Ground 75 76 NC

Ground 77 78 Ground

Ground 79 80 DP16P/ CLK No connection

20K ohm to

Ground

Ground 83 84

25K ohm to

Ground (PID)

Ground 87 88 NC

SAMTEC Pin

number

57 58 Ground

61 62 Ground

65 66 Ground

69 70 Ground

81 82 Ground

85 86 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

DP16N/

CLKN

Signal

name/Logical

Signal Name

Ground

NC 89 90 Ground

45

Page 46

Header 7 -Write

Logic Analyzer

channel

number

Ground 1 2 Ground

Ground 3 4 NC

NC 5 6 NC

Ground 7 8 D0 DQS5

20K ohm to

Ground

Ground 11 12 D1 DQ46

20K ohm to

Ground

Ground 15 16 D2 DQ42

20K ohm to

Ground

Ground 19 20 D3 DQ47

20K ohm to

Ground

Ground 23 24 D4 DQ43

20K ohm to

Ground

Ground 27 28 D5 DQ52

20K ohm to

Ground

Ground 31 32 D6 DQ48

20K ohm to

Ground

Ground 35 36 D7 DQ53

20K ohm to

Ground

Ground 39 40 D8 DQ49

20K ohm to

Ground

Ground 43 44 D9 DM6_DQS15

20K ohm to

Ground

Ground 47 48 D10 DQS6n

20K ohm to

Ground

Ground 51 52 D11 DQS6

20K ohm to

Ground

Ground 55 56 D12 DQ54

SAMTEC Pin

number

9 10 Ground

13 14 Ground

17 18 Ground

21 22 Ground

25 26 Ground

29 30 Ground

33 34 Ground

37 38 Ground

41 42 Ground

45 46 Ground

49 50 Ground

53 54 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

Signal

name/Logical

Signal Name

46

Page 47

Logic Analyzer

channel

number

20K ohm to

Ground

Ground 59 60 D13 DQ50

20K ohm to

Ground

Ground 63 64 D14 DQ55

20K ohm to

Ground

Ground 67 68 D15 DQ51

20K ohm to

Ground

Ground 71 72 NC

NC 73 74 Ground

Ground 75 76 NC

Ground 77 78 Ground

Ground 79 80 DP16P/ CLK CK2a

20K ohm to

Ground

Ground 83 84

25K ohm to

Ground (PID)

Ground 87 88 NC

SAMTEC Pin

number

57 58 Ground

61 62 Ground

65 66 Ground

69 70 Ground

81 82 Ground

85 86 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

DP16N/

CLKN

Signal

name/Logical

Signal Name

CK2na

NC 89 90 Ground

47

Page 48

Header 8 - Write

Logic Analyzer

channel

number

Ground 1 2 Ground

Ground 3 4 NC

NC 5 6 NC

Ground 7 8 D0 DQ60

20K ohm to

Ground

Ground 11 12 D1 DQ56

20K ohm to

Ground

Ground 15 16 D2 DQ51

20K ohm to

Ground

Ground 19 20 D3 DQ57

20K ohm to

Ground

Ground 23 24 D4 DM7_DQS16

20K ohm to

Ground

Ground 27 28 D5 DQS7n

20K ohm to

Ground

Ground 31 32 D6 DQS7

20K ohm to

Ground

Ground 35 36 D7 DQ62

20K ohm to

Ground

Ground 39 40 D8 DQ58

20K ohm to

Ground

Ground 43 44 D9 DQ63

20K ohm to

Ground

Ground 47 48 D10 DQ59

20K ohm to

Ground

Ground 51 52 D11 SA2

20K ohm to

Ground

Ground 55 56 D12 SA0

SAMTEC Pin

number

9 10 Ground

13 14 Ground

17 18 Ground

21 22 Ground

25 26 Ground

29 30 Ground

33 34 Ground

37 38 Ground

41 42 Ground

45 46 Ground

49 50 Ground

53 54 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

Signal

name/Logical

Signal Name

48

Page 49

Logic Analyzer

channel

number

20K ohm to

Ground

Ground 59 60 D13 SDA

20K ohm to

Ground

Ground 63 64 D14 SA1

20K ohm to

Ground

Ground 67 68 D15 SCL

20K ohm to

Ground

Ground 71 72 NC

NC 73 74 Ground

Ground 75 76 NC

Ground 77 78 Ground

Ground 79 80 DP16P/ CLK No connection

20K ohm to

Ground

Ground 83 84

25K ohm to

Ground (PID)

Ground 87 88 NC

SAMTEC Pin

number

57 58 Ground

61 62 Ground

65 66 Ground

69 70 Ground

81 82 Ground

85 86 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

DP16N/

CLKN

Signal

name/Logical

Signal Name

Ground

NC 89 90 Ground

49

Page 50

Header 12 – Read – Duplicates - only data signals

Logic Analyzer

channel

number

Ground 1 2 Ground

Ground 3 4 NC

NC 5 6 NC

Ground 7 8 D0 DQ4

20K ohm to

Ground

Ground 11 12 D1 DQ0

20K ohm to

Ground

Ground 15 16 D2 DQ5

20K ohm to

Ground

Ground 19 20 D3 DQ1

20K ohm to

Ground

Ground 23 24 D4 No connection

20K ohm to

Ground

Ground 27 28 D5 No connection

20K ohm to

Ground

Ground 31 32 D6 No connection

20K ohm to

Ground

Ground 35 36 D7 DQ6

20K ohm to

Ground

Ground 39 40 D8 DQ2

20K ohm to

Ground

Ground 43 44 D9 DQ7

20K ohm to

Ground

Ground 47 48 D10 DQ3

20K ohm to

Ground

Ground 51 52 D11 DQ12

20K ohm to

Ground

Ground 55 56 D12 DQ8

20K ohm to

Ground

SAMTEC Pin

number

9 10 Ground

13 14 Ground

17 18 Ground

21 22 Ground

25 26 Ground

29 30 Ground

33 34 Ground

37 38 Ground

41 42 Ground

45 46 Ground

49 50 Ground

53 54 Ground

57 58 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

Signal

name/Logical

Signal Name

50

Page 51

Logic Analyzer

channel

number

Ground 59 60 D13 DQ13

20K ohm to

Ground

Ground 63 64 D14 DQ9

20K ohm to

Ground

Ground 67 68 D15 No connection

20K ohm to

Ground

Ground 71 72 NC

NC 73 74 Ground

Ground 75 76 NC

Ground 77 78 Ground

Ground 79 80 DP16P/ CLK DQS1

20K ohm to

Ground

Ground 83 84

25K ohm to

Ground (PID)

Ground 87 88 NC

SAMTEC Pin

number

61 62 Ground

65 66 Ground

69 70 Ground

81 82 Ground

85 86 Ground

SAMTEC Pin

number

Logic Analyzer

channel

number

DP16N/

CLKN

Signal

name/Logical

Signal Name

No connection

NC 89 90 Ground