Page 1

Instructions for Vacuum

Gauge/Pressure Tester

Cranking Vacuum Test For

Engine Condition

1. Start Engine and warm to normal

operating temperature.

2. Turn engine off and disable ignition.

3. Remove air filter and back out idle

speed screw counting turns until

throttle valve is closed.

NOTE: If carburetor is equipped with an idle

air bleed screw, turn clockwise, counting

number of turns until screw bottoms lightly.

NOTE: If vehicle is equipped with an

idle stop solenoid, disconnect electrical

wires at base of solenoid under rubber

boot or at connector.

NOTE: If vehicle is equipped with a PCV

(Positive Crankcase Ventilation) system,

remove valve at engine rocker arm cover

and plug valve on bottom with tape.

4. Using hose supplied, connect Vacuum

Gauge to fitting on carburetor below

throttle plate or a fitting on intake

manifold.

5. Crank engine and note Vacuum

Gauge reading.

6. Return adjustment screws to original

positions.

Test Results

3 possible gauge readings are:

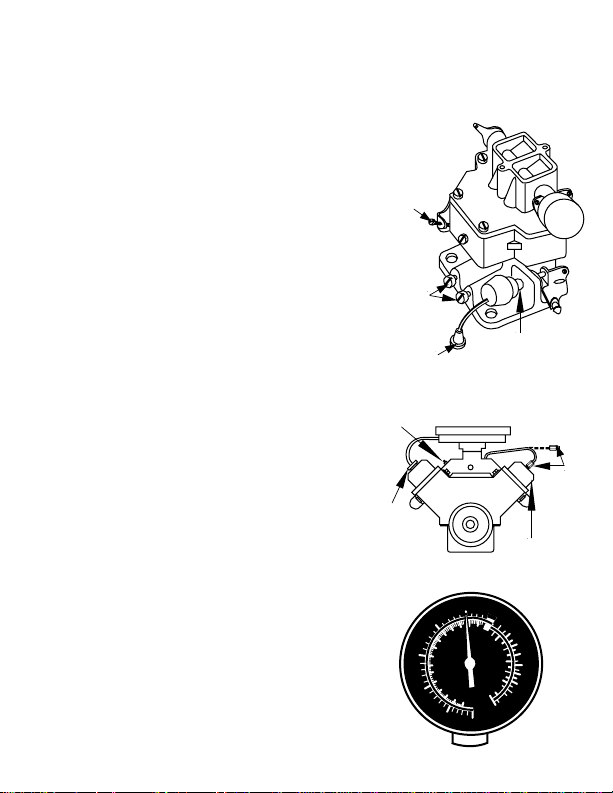

A.Steady vacuum reading of the following

indicates correct engine vacuum:

4 inches or more on emission

controlled engines.

10 inches or more on non-emission

controlled engines

Idle

Speed

Screw

Idle

Mixture

Screw

Electrical

Connector

Manifold

Closed

Breather

Air Cleaner

Vacuum

Cap

10

Engine

Vacuum

15

20

25

Steady Vacuum of 4

inches or more

5

0

Fuel

Pump

7

30

Idle Stop

Solenoid

Rocker Arm

Valve Cover

0

1

2

3

1

2

4

3

5

psi

4

6

5

6

7

8

9

10

PCV

Valve

Page 2

NOTE: See Manufacturers Specifications.

B.Really low, steady vacuum check for:

Leaking carburetor flange gasket

Worn carburetor throttle shaft

Leaking vacuum lines

Improper valve timing

Slow engine cranking due to:

- Battery or cable connections

- Defective starter motor

Mechanical drag in engine due to:

- Tight fitting pistons in rebuilt engine

- Thickened oil due to excessive

oxidation

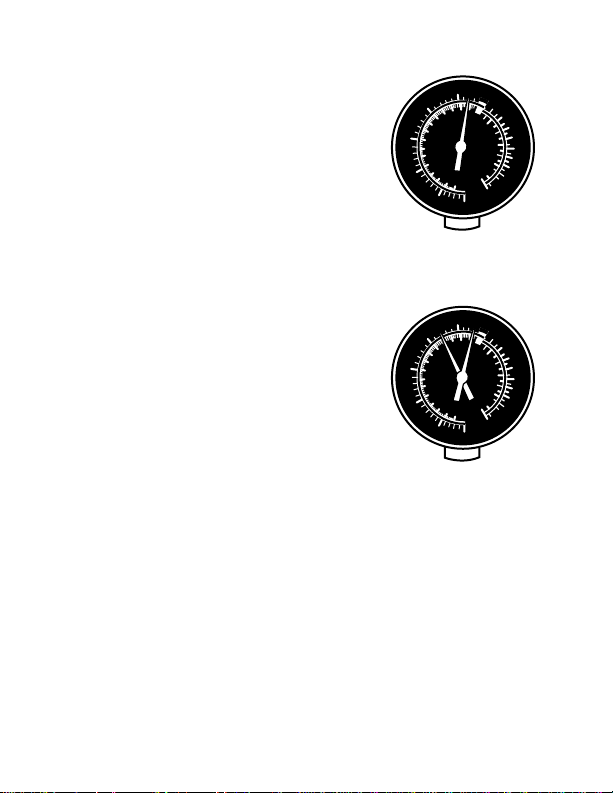

C.Pulses unsteady indicates a leaky

condition that affects one or more

cylinders check for:

Burned or stuck valve

Intake manifold leak at a cylinder

Worn intake valve guide

Broken piston or piston rings

NOTE: A certain amount of even pulsing

is normal, notably on 4 and 6 cylinder

engines, and does not necessarily

indicate a leaky condition.

Running Vacuum Test For

Engine Condition

NOTE: It is possible to get a different gauge

reading than obtained during the Cranking

Vacuum Test For Engine Condition.

1. Using hose supplied, connect

Vacuum Gauge to fitting on

carburetor below throttle plate.

2. Start Engine and let idle until at

normal operating temperature.

Test Results

2 possible gauge readings are:

5

0

10

Engine

Vacuum

15

20

25

1

0

1

2

3

Fuel

Pump

4

5

6

7

10

30

Steady low vacuum

5

0

10

Engine

Vacuum

15

20

25

1

0

1

2

3

Fuel

Pump

4

5

6

7

10

30

Unsteady vacuum

2

3

4

5

psi

6

7

8

9

2

3

4

5

psi

6

7

8

9

Page 3

A. Steady vacuum reading between 15

and 20 inches indicates a mechanically

sound engine.

B.If unsteady reading increase engine

speed to 2000 RPM:

If evens out check:

- Ignition and/or timing

- Carburetor mixture adjustments at idle

If pointer sweeps get larger check for

- Weak or broken valve springs

If pointer sweeps become smaller

and more rapid check for:

- Carburetor or intake manifold leaks

- Sticky valves

Exhaust Restriction Test

1. Make sure vacuum gauge is connected.

2. Increase engine speed to 2000 RPM

and keep.

3. Note vacuum gauge reading.

4. Look for slowly decreasing vacuum

reading.

If vacuum decreases check for a

partially blocked muffler or tailpipe.

Positive Crankcase Ventilation

(PCV) Valve Test

1. Unplug PCV valve that was plugged

with tape.

2. Crank engine

If vacuum drops to half the noted

vacuum then the PCV valve is good.

If vacuum reading is much lower than

one-half the problem is usually

excessive flow which could upset the

proper carburetor air/fuel ratio causing

rough idling and burned valves.

If vacuum does not change the PCV

valve is usually clogged.

5

0

10

Engine

Vacuum

15

20

25

Steady vacuum between

15 and 20 inches

10

Engine

Vacuum

15

20

25

1

2

0

3

1

2

4

3

Fuel

5

psi

Pump

4

6

5

6

7

7

8

9

10

30

5

0

1

2

0

3

1

2

4

3

Fuel

5

psi

Pump

4

6

5

6

7

7

8

9

10

30

Unsteady vacuum reading

5

0

Engine

1

2

0

3

1

2

4

3

Fuel

5

psi

Pump

4

6

5

6

7

7

8

9

10

30

10

Vacuum

15

20

25

Vacuum Drops half the

noted vacuum

Page 4

3. Return idle screw and idle air bleed

screws to original positions, if required.

4. Re-enable the ignition system

5. Reconnect wire to idle stop solenoid.

6. Reconnect all hoses and vacuum lines.

7. Reinstall PCV valve.

Idle

Speed

Screw

Distributor Vacuum Advance

Mechanisms

1. Disconnect hose from distributor

2. Insert a tee connector in line with

hose and another back to distributor.

3. Connect gauge to the tee connector.

4. Start engine and note vacuum at idle.

5. Slowly increase RPM noting vacuum

pressure.

Test Results

2 possible results are:

A. Vacuum manifold pressure should

drop as engine speed is increased

per vehicle manual

B. If vacuum manifold pressure does not

change or changes very little check for:

Vacuum hose being opened or

cracked

Diaphragm in advance mechanism

punctured.

NOTE: Vacuum reading can appear

normal during the above test but still

have a bad advance mechanism that is

frozen due to corrosion or dirt.

Fuel Pump Testing

Fuel Pump Testing can be done using

the 0-10 psi scale on the gauge. Make

sure to follow manufacturers

instructions exactly and follow all safety

precautions.

©2004 Actron Manufacturing Company. All rights reserved. 0002-003-1862

Idle

Mixture

Screw

Electrical

Connector

Manifold

Closed

Breather

Air Cleaner

Vacuum

Cap

5

10

Engine

Vacuum

15

20

25

30

Using Fuel Pump Scale

Rocker Arm

Valve Cover

0

1

0

1

2

3

Fuel

Pump

4

5

6

7

10

Idle Stop

Solenoid

2

3

4

5

psi

6

7

8

9

PCV

Valve

Loading...

Loading...