Page 1

Instructions for

Compression Tester

Test Procedure

1. Start Engine and warm to normal

operating temperature.

2. Turn engine off

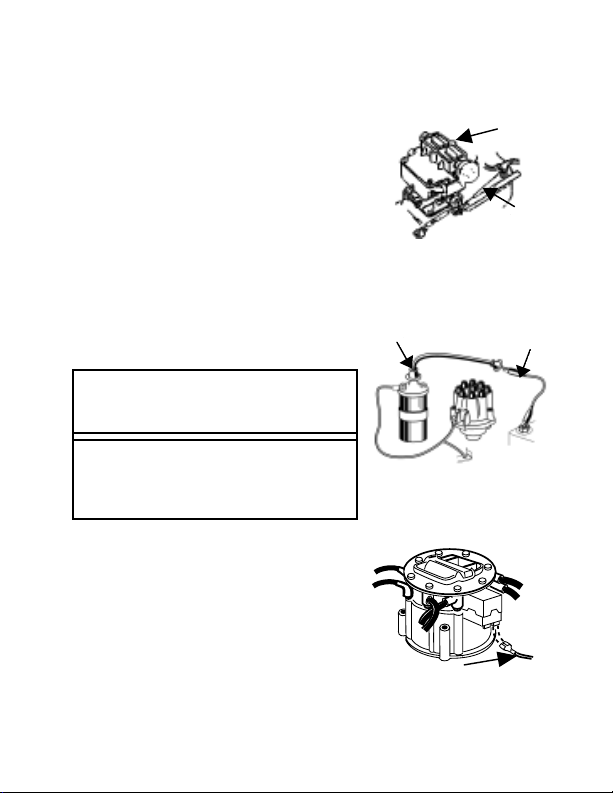

3. Remove and number spark plug wires

4. Loosen spark plugs one turn

5. Clean loose dirt and rust from and

around spark plug wells

6. Remove spark plugs and place on

clean flat surface in order removed

7. Remove air filter

8. Set carburetor throttle plate to wide

open using string.

CAUTION

Be careful not to damage linkage

or throttle body components.

CAUTION

Make sure to return

carburetor throttle plates to closed

position before starting engine.

9. Remove high tension lad from center

of distributor and connect to ground.

NOTE: To disable electronic ignition

systems, disconnect electronic ignition

module or remove primary battery

terminal from ignition coil.

NOTE: On GM HEI V-6 and V-8

disconnect primary lead from distrutor

cap.

Held Open Throttle

Plates

High Tension Lead

Ignition Disabling

Procedure

Primary Wire

GM HEI Ignition

Disabling Procedure

Carburetor

String

Jumper Wire

Page 2

NOTE: Engines with 14 mm long reach

plugs, use long reach adapter.

CAUTION

Do not use long reach adapter

on short reach holes

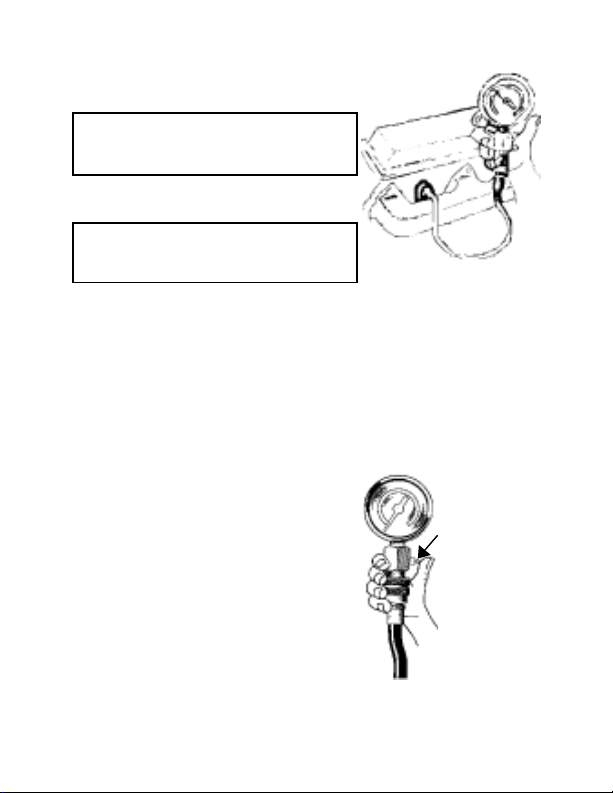

10. Hand tighten spark plug adapter

hose into a spark plug well

CAUTION

Do not use a wrench to

attach spark plug adapter hose.

11. Connect spark plug adapter hose to

gauge

NOTE: Hose adapter is attached to

gauge by pulling up on outer sleeve of

quick disconnect on gauge and allowing

sleeve to return when hose is inserted.

12. Crank engine until pressure reading

stops rising on gauge.

NOTE: Crank engine at least 4

compression strokes.

13. Record compression reading.

14. Press release valve on side of

gauge

NOTE. Repeat steps 12 through 14 on

the first cylinder

15. Remove gauge from hose.

16. Hand tighten spark plug adapter

hose into a spark plug well

17. Remove hose from spark plug well

18. Repeat steps 10 through 18 for the

rest of the remaining cylinders.

19. Refer to Test Results.

.

Installation of

Compression Gauge

Release Valve

Push Release Valve to

Relieve Pressure

Page 3

Test Results

Normal Cylinder:

Gauge needle should travel up-scale on each compression

stroke until a peak value is reached.

All cylinders should have a pressure within vehicle

manufacturers specifications.

Readings should not vary more than 10% from cylinder to

cylinder.

Needle fails to travel up gauge or remains at same value for

several strokes then climbs:

Check for a sticking valve.

Compression reading is alot higher than manufacturers

specifications

Check for carbon build-up in cylinder.

Reading on 2 adjacent cylinders is 20 pounds (or more)

lower than the other cylinders

Check for a defective head gasket.

Check for water (coolant) or oil in the 2 cylinders.

Reading are low or vary widely between cylinders

Pour teaspoon of SAE grade 30 oil into each cylinder and

retest

- If reading increases alot fault may be due to poorly

seated or worn pison rings.

- If reading remains about the same valves and associated

components are likely the problem.

Return to Original Configuration

1. Clean, regap and reinstall spark plugs or install new spark plugs.

2. Reconnect all spark plug wires

3. Remove string from carburetor throttle plates.

Make sure throttle plates return to closed position

4. Reconnect igintion system that was disconnected in step 9 of

test procedure.

CAUTION

Page 4

Compression Gauge Repair Parts

1

4

2

4

3

5

6

7

Number Part Number Description

1 31-255 Compression Gauge

1 400-1335 Replacement Bezel Only

2 180-772 Quick Disconnect Coupling & Valve Assy

3 32-109 Spark Plug Hose Assembly

4 180-775 (2 ea) Air Valve (High Pressure)

5 400-382 O-ring

6 400-381 (2 ea) O-ring

7 180-829 Deep Reach Adapter

CAUTION

Do not use automobile tire air valves as a replacement part.

©2003Actron Manufacturing Company. All rights reserved. 0002-002-1860

Loading...

Loading...