Page 1

9. Llevar a cabo los pasos 1 a 8 para el sistema de

avance centrífugo si es que todavía no se ha

hecho.

10.Apagar el motor y conectar la bomba de vacío

externa al diafragma de vacío en el distribuidor o a

la computadora a bordo del vehículo.

11.Poner el control de avance de la luz de regulación

en “0”. Volver a arrancar el motor.

12. Apuntar la luz de regulación a las marcas de

regulación, pulsar el gatillo y observar la

regulación del motor.

13.Ajustar la velocidad (rpm) del motor si es

necesario, y aplicar los niveles de vacío al

diafragma de vacío del avance, como se indica en

el manual de servicio del vehículo. (Si es

necesario reajustar las rpm del motor según las

instrucciones del manual de servicio del motor,

observar nuevamente la regulación del motor

como se indica en el paso 12).

14.Girar el control de avance de la luz de regulación

hacia arriba hasta que la marca de regulación en el

motor regrese a su punto de partida, como se

observó en el paso 12.

15.Observar el avance de regulación (en grados) con

cada aplicación de vacío y comparar el resultado

con los valores dados en el manual de servicio. Si

no se logra obtener las lecturas del avance de

vacío podría significar fugas en el diafragma,

mecanismo de avance pegajoso, o ausencia de

vacío para accionar el diafragma del motor de

vacío.

16.Después de completar todas las pruebas, asegurar

de reajustar las velocidades en vacío y reconectar

las mangueras o conectores eléctricos que fueron

desconectados durante el procedimiento de

prueba.

GARANTIA COMPLETA DE UN (1) AÑO

Actron Manufacturing Company, 15825

Industrial Parkway, Cleveland, Ohio 44135,

garantiza al usuario que este equipo estará

libre de defectos en los materiales y

fabricación por un período de un (1) año a

partir de la fecha de compra original.

Cualquier equipo que llegue a fallar dentro

de este período será reparado o reemplazado

a entera discreción de ACTRON y sin cargo

cuando sea devuelto a la fábrica. ACTRON

solicita que junto con el equipo se envíe una

copia de la boleta de venta original fechada,

si el período de garantía todavía está en

efecto.

Esta garantía no cubre los daños causados

por accidente, modificaciones o el uso

inapropiado o irrazonable. Los componentes

de duración limitada, por ej., baterías,

fusibles, bombillas de luces, tubos

destellantes, quedan excluidos del amparo

de esta garantía.

ACTRONS PRODUCTS NO SE

RESPONSABILIZA POR DAÑOS

FORTUITOS O EMERGENTES DEBIDO AL

INCUMPLIMIENTO DE CUALQUIER

GARANTIA ESCRITA SOBRE ESTE

EQUIPO. Algunos estados no aceptan el

rechazo de responsabilidad por daños

fortuitos o emergentes, por lo tanto esta

negación de responsabilidad puede no servir

en el caso suyo. Esta garantía otorga

derechos legales específicos, y también

pueden existir derechos que varía de un

estado a otro.

Inductive Timing Light

Inductive Advance

INSTRUCTIONS

INSTRUCCIONES EN ESPAÑOL

Vea la pagína 9

INTRODUCTION

Precise ignition timing is essential to achieve

maximum fuel economy and performance out

of any spark ignited engine. Your timing light

provides a simple method for timing the engines used in today’s vehicles. The advance

timing light provides the additional capability

of allowing the user to check timing advance

curves of the vacuum, mechanical or computer controlled types.

Virtually all engines require that timing, both

initial and advance calibrations be set, or

checked at specific engine speeds, or in some

cases with a specific vacuum applied to the

vacuum advance diaphragm on the distributor, or on the vehicle’s on-board computer.

Your supplier offers a number of engine ana-

IMPORTANT

CONSULT THE VEHICLE SERVICE MANUAL FOR SPECIFIC TUNE-UP INFORMATION

AND TEST PROCEDURES. ALWAYS FOLLOW THE MANUFACTURER’S

SPECIFICATIONS AND TEST PROCEDURES FOR ADJUSTING DWELL ANGLE AND

IDLE SPEED, ESPECIALLY ON VEHICLES WITH MODERN ELECTRONIC IGNITION AND

EMISSION CONTROLS. DO NOT ATTEMPT TO SERVICE A VEHICLE WITHOUT THE

MANUFACTURER’S INSTRUCTIONS AND SPECIFICATIONS.

D. C. Powered Timing

lyzers which are capable of measuring engine

RPM, and vacuum pumps for application of

vacuum when required. Contact him for further

information on these instruments. In the case

of engines which are equipped with breaker

point ignition systems, it will be necessary to

check and, if necessary, adjust point dwell

before adjusting timing. Make certain that the

instrument that you have or intend to purchase

has dwell measurement capability.

Metal cased timing lights are for use on twelve

(12) volt negative (-) ground systems only.

Plastic cased timing lights may be used on six

(6) or twelve (12) volt, positive (+) or negative

(-) ground systems by following the simple

instructions in this manual.

Timing Light

Light

©1996 ACTRON MANUFACTURING CO.

0002-000-219201

PRINTED IN U.S.A.

16

15825 Industrial Parkway

Cleveland, Ohio 44135

VEHICLE MANUAL, SOURCES FOR SERVICE INFORMATION

The following is a list of publishers who have service manuals for your specific vehicle at nominal cost.

Write to them for availability and prices, specifying the make, style, and model year of your vehicle.

American Motors Corporation

Myriad

8835 General Drive

Plymouth Township, MI 48170

Chrysler Corporation

Dyment Distribution Service

Service Publication

20770 Westwood Drive

Strongsville, OH 44136

Ford Publications Department

Helm Incorporated

Post Office Box 07150

Detroit, MI 48207

Buick

Tuar Company

Post Office Box 354

Flint, MI 48501

Oldsmobile

Lansing Lithographers

Post Office Box 23188

Lansing, MI 48909

Cadillac, Chevrolet, Pontiac

Helm Incorporated

Post Office Box 07130

Detroit, MI 48207

1

OTHER SOURCES- Nonfactory

Domestic and Import Cars

Chilton Book Company

Chilton Way

Radnor, PA 19089

Cordura Publications

Mitchell Manuals, Inc.

Post Office Box 26260

San Diego, CA. 92126

Motor’s Auto Repair Manual

Hearst Company

250 W. 55th Street

New York, NY 10019

Page 2

SAFETY GUIDELINES

TO PREVENT ACCIDENTS THAT COULD RESULT IN SERIOUS INJURY

AND/OR DAMAGE TO YOUR VEHICLE OR TEST EQUIPMENT, CAREFULLY

FOLLOW THESE SAFETY RULES AND TEST PROCEDURES

SAFETY EQUIPMENT

Fire Extinguisher

Never work on your car without having a

suitable fire extinguisher handy. A 5-lb or

larger CO

gasoline/chemical/electrical fires is recommended.

Fireproof Container

Rags and flammable liquids should be stored

only in fireproof, closed metal containers. A

gasoline-soaked rag should be allowed to dry

thoroughly outdoors before being discarded.

Safety Goggles

We recommend wearing safety goggles when

working on your car, to protect your eyes from

battery acid, gasoline, and dust and dirt flying

off moving engine parts.

NOTE: Never look directly into the carburetor

throat while the engine is cranking or running,

as sudden backfire can cause burns.

or dry chemical unit specified for

2

LOOSE CLOTHING AND LONG HAIR

(MOVING PARTS)

Be very careful not to get your hands, hair or

clothes near any moving parts such as fan

blades, belts and pulleys or throttle and transmission linkages. Never wear neckties or loose

clothing when working on your car.

JEWELRY

Never wear wrist watches, rings or other jewelry when working on your car. You’ll avoid

the possibility of catching on moving parts or

causing an electrical short circuit which could

shock or burn you.

VENTILATION

The carbon monoxide in exhaust gas is highly

toxic. To avoid asphyxiation, always operate

vehicle in a well-ventilated area. If vehicle is in

an enclosed area, exhaust should be routed

directly to the outside via leakproof exhaust

hose.

SETTING THE BRAKE

Make sure that your car is in Park or Neutral,

and that the parking brake is firmly set.

NOTE: Some vehicles have an automatic re-

lease on the parking brake when the gear shift

lever is removed from the PARK position. This

feature must be disabled when it is necessary

(for testing) to have the parking brake engaged

when in the DRIVE position. Refer to your

vehicle service manual for more information.

HOT SURFACES

Avoid contact with hot surfaces such as exhaust manifolds and pipes, mufflers (catalytic

converters), radiator and hoses. Never remove the radiator cap while the engine is hot,

as escaping coolant under pressure may seriously burn you.

SMOKING AND OPEN FLAMES

Never smoke while working on your car. Gasoline vapor is highly flammable, and the gas

formed in a charging battery is explosive.

BATTERY

Do not lay tools or equipment on the battery.

Accidentally grounding the “HOT” battery terminal can shock or burn you and damage

wiring, the battery or your tools and testers. Be

careful of contact with battery acid. It can burn

holes in your clothing and burn your skin or

eyes.

When operating any test instrument from an

auxiliary battery, connect a jumper wire between the negative terminal of the auxiliary

battery and ground on the vehicle under test.

When working in a garage or other enclosed

area, auxiliary battery should be located at

least 18 inches above the floor to minimize the

possibility of igniting gasoline vapors

HIGH VOLTAGE

High voltage — 30,000 to 50,000 volts — is

present in the ignition coil, distributor cap,

ignition wires and spark plugs. When handling

ignition wires while the engine is running, use

insulated pliers to avoid a shock. While not

lethal, a shock may cause you to jerk involuntarily and hurt yourself.

JACK

The jack supplied with the vehicle should be

used only for changing wheels. Never crawl

under car or run engine while vehicle is on a

jack.

2

TWELVE (12) VOLT POSITIVE (+)

GROUND ELECTRICAL SYSTEMS

Steps 4 and 5 of LEAD CONNECTIONS below

are revised to read as follows:

4. Connect the BLACK clip to the negative (-)

battery terminal.

5. Connect the RED clip to a secure engine

ground such as the alternator/generator

bracket or engine block. For safety reasons, do not use the positive (+) battery

terminal or fuel system components as a

ground connection point.

All other instructions remain as listed.

SIX (6) VOLT ELECTRICAL

SYSTEMS

Follow the steps listed below to use your timing light on vehicles equipped with six (6) volt

electrical systems. A twelve (12) volt battery is

required. This can be any automotive, or motorcycle battery.

1. Connect the RED clip from the timing light

to the positive (+) terminal of the twelve

(12) volt battery.

2. Connect the BLACK clip from the timing

light to the negative (-) terminal of the

twelve (12) volt battery.

3. Obtain a jumper wire (minimum wire size l8

AWG).

4. Connect one end of the jumper wire to the

negative (-) terminal of the twelve (12) volt

battery.

5. Connect the other end of the jumper wire to

a clean, secure ground on the vehicle under test. The jumper wire must go to ground

on the vehicle regardless of whether the

vehicle is a positive (+) or negative (-)

ground system.

6. Connection to the number one (1) spark

plug and remaining procedures are the

same as described later in this manual.

ENGINE PREPARATION FOR

TIMING

In order for any engine to be base (initially)

timed correctly, it is important to carefully follow the instructions as shown on the Vehicle

Emission Control label. This label is located

under the hood in the engine compartment.

Some typical locations are: the underside of

the hood, the fender well, a valve cover, or in

the area of the hood latch. If the label is

missing, consult the vehicle service manual or

appropriate service literature for the engine

under test. It is important to note that preparation is specific to each engine.

NOTE

The procedures outlined below instruct the

user to connect the spark plug pickup (direct

hookup or inductive clamp style) to the number

one (1) spark plug wire. This procedure is valid

for the majority of engines in use today. There

are however, some engines which are timed

using the “averaging” method. The most popular user of this method is General Motors

where it is recommended for some of there

smaller four (4) cylinder engines beginning in

1982. Your timing light has “average timing”

capability. The only change in hookup is that

instead of connecting the spark plug pickup to

the number one (1) spark plug wire, it is connected to the coil tower wire, that is, the wire

between the ignition coil and the center of the

distributor cap. Consult your vehicle service

manual for exact procedures.

When using an advance timing light, note that

average timing is used only for initial or base

timing with the timing light’s advance control

set fully counterclockwise at “0”. Timing ad-

vance measurements must be made with the

inductive pickup clamped around the number

one (1) spark plug wire. Timing advance measurements attempted with the inductive pickup

clamped around the coil tower wire will not

produce valid results.

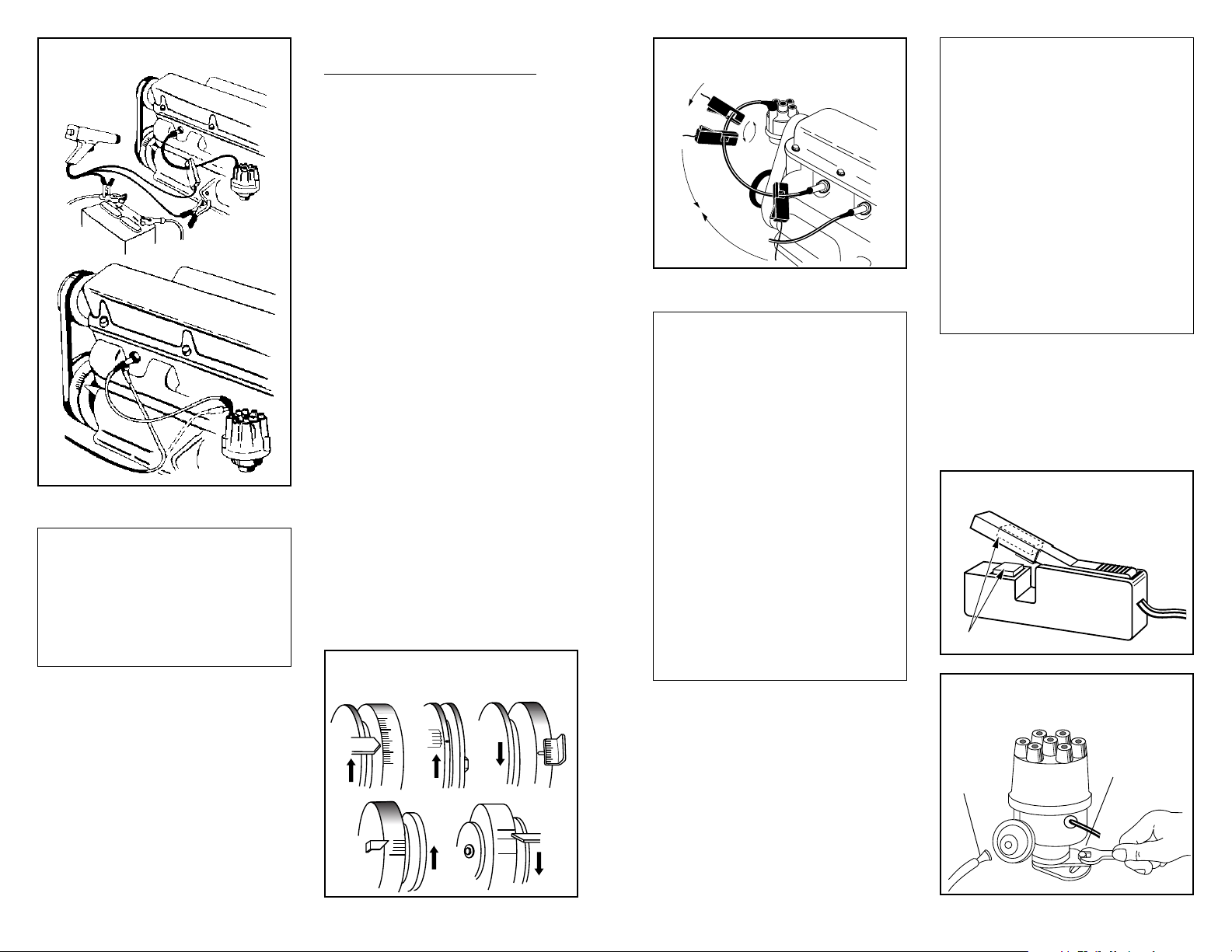

LEAD CONNECTIONS

1. Figure 1 shows the typical hookup procedure for most applications. To insure safety,

follow the hookup sequence listed below.

2. Make sure the engine is OFF, and the

ignition key is OFF.

3. (Inductive Pickup equipped timing light)

Clamp the inductive pickup around the number one (1) spark plug wire. Do not allow the

inductive pickup to touch the exhaust manifold or surrounding parts as these areas

become extremely hot and will damage the

inductive clamp.

(Direct connection equipped timing

light). Remove the number one (1) spark

wire from either the spark plug end, or the

distributor end, whichever is more convenient, but without compromising safety. See

the NOTE below.

3

Page 3

Fig. 1 - Hookup Diagram

RED

BLACK

NOTE

On some engines, the distributor may be

mounted very close to the carburetor, or

fuel injection throttle body. Since this is an

area in which there may be gasoline vapors

present, it is adviseable on these engines

to remove the number one (1) spark plug

wire only at the spark plug end.

Connect the spring adaptor and spark plug

lead between the spark plug (or distributor

cap) and the removed wire as shown in Figure

1. Route the timing light’s spark plug wire away

from the exhaust manifold and surrounding

hot areas to prevent damage.

4. Connect the RED clip to the positive (+)

battery terminal.

5. Connect the BLACK clip to a secure engine

ground such as the alternator bracket or

engine block. For safety reasons, do not

use the negative (-) battery terminal or fuel

system components as a ground connection point.

ENGINE TIMING CHECK

(Breaker point equipped engines only)

Check and, if necessary adjust dwell to specifi-

cation before proceeding with timing check.

1. Prepare the engine for timing as indicated

above in ENGINE PREPARATION FOR

TIMING.

2. Clean, and chalk if necessary, both the

rotating and stationary timing marks on the

engine. See Figure 2.

3. Start the engine and allow it to warm to

normal operating temperature (upper radiator hose is hot).

4. Check, and if necessary, adjust RPM to

specified timing speed.

5. When using an advance timing light, make

certain that the advance control is set fully

counterclockwise at “0”.

6. Aim the timing light at the crankshaft damper

(pulley) or transmission bell housing depending on the location of the timing marks

on the engine under test. See Figures 1

and 2.

7. Pull the trigger switch on the timing light

and observe the location of the rotating

mark with respect to the stationary mark. If

timing is within the tolerance as specified

by the manufacturer (typically plus or minus 2 degrees) no adjustment is necessary

and the procedure is finished. If it is not

within specifications, proceed directly to

the

INITIAL TIMING ADJUSTMENT section

below. If the timing light multiple flashes or

flashes erratically on timing lights equipped

with an inductive pickup, see NOTE below.

Fig. 2 -

Various Timing Light

Configurations

10

0

3

6

10

DC

10

TDC

UDC 1-6

16N

OP 1-6

A

O

Fig. 3 -

Positioning the Inductive

Pickup for Reliable Readings

NOTE

A defective ignition system may cause the

timing light to multiple flash or flash erratically. Low output spark voltage or a defective ignition wire may be responsible. You

may be able to steady the flash by sliding

the inductive pickup along the plug wire to

a new location or reversing the inductive

pickup as shown in Figure 3. (This may

also help even with polarity sensitive pickups). Solid copper ignition wires radiate

large amounts of radio frequency noise

through the air which may interfere with the

proper operation of the timing light and

other electronic equipment. Replace solid

copper ignition wire with resistance type

wire if only for the tests described in this

manual. Erratic flashing of the timing light

can also be caused by dirt or grease buildup

on the mating surfaces of the inductive

clamp. To maintain proper operation of the

clamp, clean and dry the inside clamp surfaces with a soft cloth when necessary as

shown in Figure 4.

8. Shut off the engine. Disconnect the timing

light leads in the reverse order from which

they were connected.

9. Re-connect any disconnected hoses or

electrical connectors which were part of

the engine's preparation for timing. Reset

the engine’s idle speed if necessary.

Timing Adjustments

l. Make certain that the engine has been

prepared for timing as indicated above in

ENGINE PREPARATION FOR TIMING.

NOTE

The following timing adjustment procedure

can be used on the majority of spark ignited engines in use today. Both General

Motors and Ford Motor Company have

introduced and used special versions of

their common electronic ignition systems

which sense ignition directly from the

engine’s crankshaft via a crankshaft sensor. These systems were introduced in the

late1970’s and were typically used only on

a few of the “high line” luxury passenger

cars. Timing is still checked with a timing

light in the standard manner, however,

timing adjustment is made at the crankshaft sensor, not by turning the distributor

as is normally done. See your vehicle service manual for exact adjustment procedures on this type system.

2. With the engine off, loosen the distributor

hold down bolt just enough so that the distributor can be turned freely. Do not loosen

the bolt beyond this point. See Figure 5.

3. Start the engine and allow it to warm to

normal operating temperature (upper ra-

Fig. 4 -

Cleaning the Inductive

Pickup

CLEAN AND DRY HERE

Fig. 5 -

Loosening the

Hold-Down Clamp

REMOVE

AND PLUG

VACUUM

HOSE IF

REQUIRED

LOOSEN

HOLD-DOWN

BOLT

4

5

Page 4

Fig. 6 -

ROTATION

Spark Advance Timing

TIMING

MARK

xya

4

2

0

2

4

xya

diator hose is hot). Adjust engine RPM to

the value specified by the vehicle manufacturer for timing purposes. If no value is

given, set the engine to curb idle.

4. Aim the timing light at the timing marks on

the engine and pull the trigger switch.

5. With the trigger switch pulled, and while

observing the timing marks, rotate the distributor slowly clockwise or counterclockwise as necessary to bring the timing into

factory specification. On most engines, a

change in timing will change engine RPM. If

this happens, reset the engine RPM as

indicated in Step 3 above and repeat Steps

4 and 5 until timing and RPM are within

factory specifications.

6. Shut off the engine. Tighten the distributor

hold down bolt securely.

7. Start the engine and recheck the timing. If it

drifted during the bolt tightening process,

readjust it as necessary.

8. Shut off the engine. Disconnect the timing

light leads in the reverse order from which

they were connected.

9. Reconnect any disconnected vacuum hoses

or electrical connectors which were disconnected as part of the engine’s preparation

for timing. Reset the engine’s idle speed if

necessary.

TIMING ADVANCE

The following instructions apply only

to advance timing lights.

The following advance system checks are general and may be used on most pre-emission

controlled vehicles. Note however, that many

vehicles have ignition and emission control systems, which may permit timing advance only

under certain operating conditions. It is therefore important on these vehicles to check your

vehicle service manual for specific instructions

on how to perform advance system checks.

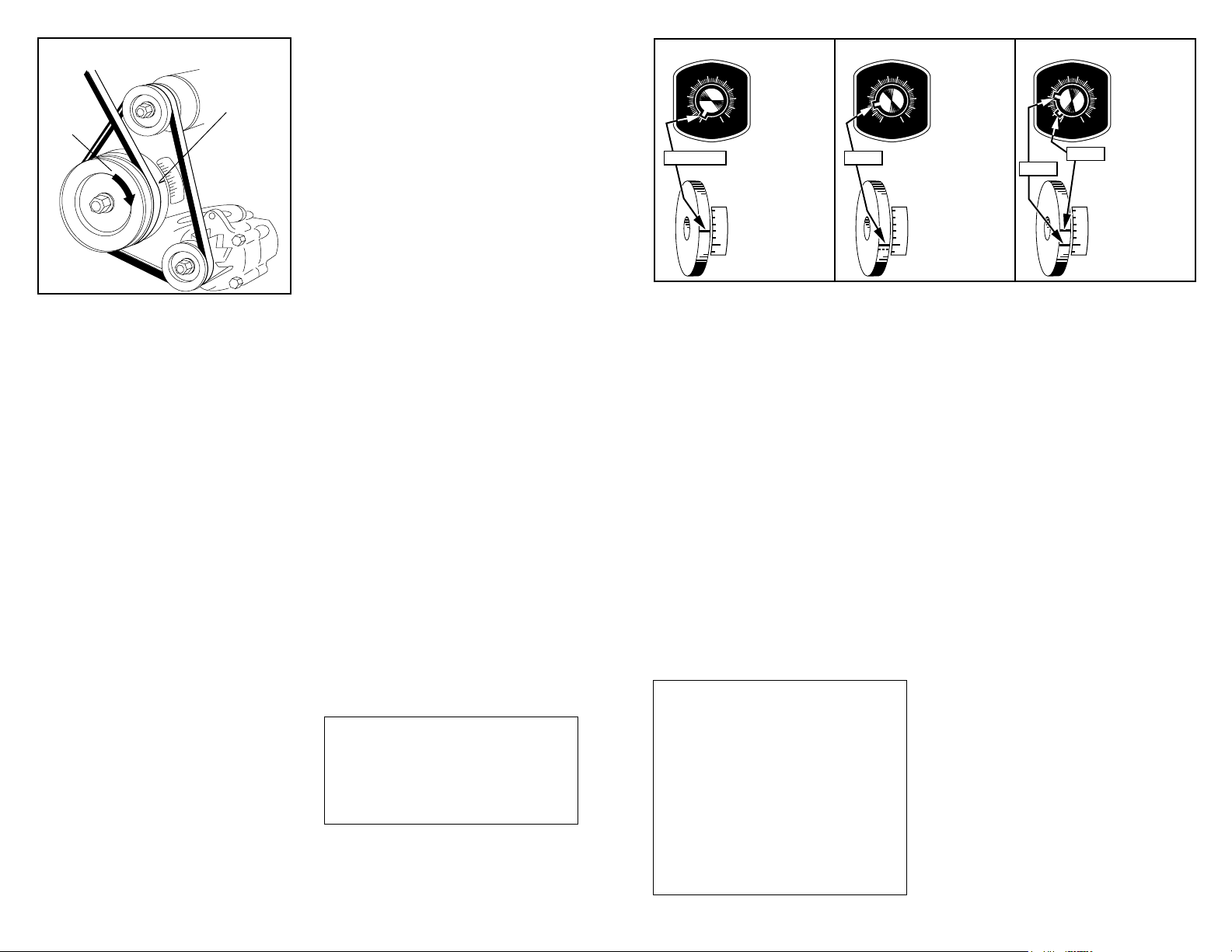

CENTRIFUGAL ADVANCE SYSTEM

Operational Test

1. Set the advance knob on the timing light to

the “0” degree position shown in Figure 7.

2. With the distributor vacuum line disconnected and plugged (Figure 5) and the

engine at curb idle, aim the timing light at

the timing marks, press the switch to operate the timing light and note the position of

the timing mark as shown in Figures 2 and

7. The timing mark or pointer should appear to be opposite one of the numbers

(initial timing) as shown.

3. Gradually increase the engine speed to

2500 RPM while observing the timing mark

position.

4. As the engine speed increases, the timing

mark should appear to move smoothly in the

opposite direction of engine rotation (the

spark advance direction). See Figure 6. As

engine speed is decreased, the timing mark

should appear to move smoothly back to the

initial timing mark noted in Step 2.

NOTE

Advance motion should be smooth. An

uneven or erratic advance motion may indicate a defective centrifugal advance system which should then be serviced as necessary, according to the vehicle

manufacturer’s instructions.

Calibration/Accuracy Test

5. Operate the engine at curb idle, direct the

timing light at the timing mark and turn the

control knob upscale until the timing mark

on the engine appears to be at “0” degrees.

(See Figure 8.) The number on the timing

light dial indicates the initial advance in

degrees, and should correspond to the

Fig. 8Fig. 7

30

35

25

40

20

15

10

5

STEPS 1 & 2

0

degrees

advance

45

55

60

25

20

15

10

5

0

5

50

READING

DAMPER

WHEEL ONLY

INITIAL

ADVANCE

IDLE RPM

VACUUM

HOSE

DISCONNECTED

number obtained in Step 2. (This step does

not apply to those engines whose initial

timing is at or after Top Dead Center,

TDC).

6. Operate the engine at 2500 RPM or as

specified by the vehicle manufacturer for

the centrifugal advance check. The timing

mark may appear to move off scale, and

beyond the highest number. This may be

normal for the RPM being used and particular vehicle under test.

7. Direct the timing light at the timing mark and

turn the control knob until the timing mark

on the engine appears to return to the

initial timing position (as noted in Step 2

above). The reading reached on the timing

light dial now indicates the amount of centrifugal advance in crankshaft or engine

degrees (Figure 9). Repeat the test as

required for various speeds as specified in

the vehicle service manual.

NOTE

Some manufacturers give advance specifications in distributor degrees and distributor RPM. Since the distributor rotates

at one half of engine or crankshaft speed,

the distributor specifications should be one

half of what is indicated on the advance

timing light dial. Vehicle test speed must

also be doubled if test speed is listed for

distributor RPM. It is therefore important to

know if the vehicle service manual is presenting specifications in “engine” or “distributor” degrees and RPM.

8. Continue to turn the control knob until the

timing mark appears at the “0” degree (TDC)

mark on the engine. The reading reached

20

15

10

5

STEP 6

25

0

30

degrees

advance

Fig. 9

30

35

40

45

55

60

25

20

15

10

5

0

5

50

READING

ADVANCE

TIMING LIGHT

DIAL

INITIAL

ADVANCE

IDLE RPM

VACUUM

HOSE

DISCONNECTED

STEP 8

35

25

40

20

15

10

5

60

0

degrees

advance

STEP 7

25

20

15

10

5

0

5

on the timing light dial now indicates the

total advance, that is, the initial advance

plus the centrifugal advance in degrees

(Figure 9).

If initial timing specification is after TDC, this

must be added to the timing light dial reading

to obtain total advance. (You may also rotate

the control knob further, to initial timing, thus

eliminating the need for calculation. Total advance will then be shown). Check the result

with manufacturer’s specifications. Repeat the

test as required for various speeds as specified in the vehicle service manual. If the reading does not meet the manufacturer’s specification, it may indicate a problem with the

centrifugal advance mechanism which should

then be corrected by repair or replacement.

VACUUM ADVANCE SYSTEM

CHECKS

Accurately checking the calibration of the

vacuum advance system requires not only the

advance timing light, but also a vacuum pump

with gauge such as described in the INTRODUCTION at the beginning of this manual.

Most vehicle service manuals will indicate specific advance in degrees for a given vacuum in

inches of mercury. See your vehicle service

manual for specific procedures. As with the

centrifugal advance system checks, note

whether specifications are in distributor or

engine degrees.

9. Perform Steps 1-8 for the centrifugal advance system if not done as yet.

l0. Stop the engine and connect your exter

nal vacuum pump to the vacuum diaphragm

on the distributor or the vehicle’s on-board

computer.

45

50

55

READING

CENTRIFUGAL

ADVANCE AND

INITIAL

ADVANCE

CENTRIFUGAL

ADVANCE

2500 RPM

VACUUM

DISCONNECTED

HOSE

6

7

Page 5

11.Set the timing light’s advance control to “0”.

Restart the engine.

12.Aim the timing light at the timing marks, pull

the trigger and note engine timing.

13.Adjust engine RPM if necessary, and apply

vacuum levels to the vacuum advance diaphragm as indicated by the vehicle service

manual. (If it is necessary to reset engine

RPM via service manual instruction, note

engine timing again as indicated in Step12).

14.Turn the timing light’s advance control up

scale until the timing mark on the engine

returns to its starting point as noted in Step

12.

15.Note the timing advance (in degrees) with

each application of vacuum and compare

the result with service manual values. Failure to obtain the vacuum advance readings

may indicate a leaky diaphragm, sticky

advance mechanism, or lack of vacuum to

drive the vacuum motor diaphragm.

16.After all testing is complete, make sure to

reset any idle speeds and reconnect any

hoses or electrical connectors which may

have been disconnected during the test

procedure.

FULL ONE (1) YEAR WARRANTY

Actron Manufacturing Company, 15825

Industrial Parkway, Cleveland, Ohio 44135,

warrants to the user that this unit will be free

from defects in materials and workmanship

for a period of one (1) year from the date of

original purchase.

Any unit that fails within this period will be

repaired or replaced at Actron’s option and

without charge when returned to the Factory. Actron requests that a copy of the

original, dated sales receipt be returned

with the unit to determine if the warranty

period is still in effect.

This warranty does not apply to damages

caused by accident, alterations, or improper

or unreasonable use. Expendable items,

such as batteries, fuses, lamp bulbs, flash

tubes are also excluded from this warranty.

ACTRON MANUFACTURING COMPANY

DISCLAIMS ANY LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES

FOR BREACH OF ANY WRITTEN WARRANTY ON THE UNIT. Some states do not

allow the disclaimer of liability for incidental

or consequential damages, so the above

disclaimer may or may not apply to you.

This warranty gives specific legal rights,

and you may also have rights which vary

from state to state.

INSTRUCCIONES

INTRODUCCION

La regulación o reglaje preciso del encendido es

esencial para lograr el máximo de economía y de

combustible y rendimiento de cualquier motor de

encendido por bujías. La luz de regulación proporciona

un método sencillo para afinar los motores de los

vehículos modernos. La luz de regulación del avance

permite además probar las curvas de regulación del

avance de los tipos controlados por vacío, mecánico o

computadora.

Casi todos los motores requieren que la regulación,

tanto las calibraciones iniciales y de avance, sea

ajustada o probada a velocidades específicas del

motor, o en algunos casos con un vacío específico

aplicado al diafragma de avance al vacío en el

distribuidor, o en la computadora a bordo del vehículo.

El proveedor ofrece una diversidad de analizadores de

Luz de regulación

inductiva

Luz de regulación

inductiva del avance

Luz de regulación

accionada por C.C.

motores capaces de medir la velocidad (rpm) del

motor, y bombas de vacío para aplicar vacío cuando se

requiera. Para más información acerca de estos

instrumentos, ponerse en comunicación con él. En el

caso de motores equipados con sistemas de

encendido de platinos, se deberá revisar y, si es

necesario, ajustar el intervalo de reposo de los platinos

antes de ajustar la regulación. Asegurar que el

instrumento utilizado es capaz de medir el intervalo de

reposo.

Las luces de regulación en caja metálica se usan en los

sistemas con negativo (-) a tierra de doce (12) voltios

solamente. Las luces con caja de plástico pueden

usarse en los sistemas con negativo (-) o positivo (+) a

tierra de seis (6) o doce (12) voltios, siguiendo las

instrucciones que se dan a continuación.

IMPORTANTE

CONSULTAR EL MANUAL DEL VEHICULO PARA LA INFORMACION ESPECIFICA ACERCA DEL AFINAMIENTO

Y PROCEDIMIENTOS DE PRUEBA. SIEMPRE RESPETAR LAS ESPECIFICACIONES DEL FABRICANTE Y LOS

PROCEDIMIENTOS DE PRUEBA PARA AJUSTAR EL ANGULO DE REPOSO Y LA VELOCIDAD EN VACIO,

ESPECIALMENTE EN LOS VEHICULOS CON ENCENDIDO ELECTRONICO MODERNO Y CONTROL DE

DESPRENDIMIENTO DE INDICACIONES Y ESPECIFICACIONES DEL FABRICANTE.

MANUAL DEL VEHICULO, FUENTES DE INFORMACION ACERCA DE SERVICIO.

La siguiente es una lista de editores que publican manuales de servicio para vehículos específicos

a por un precio nominal. Escribirles para averiguar la disponibilidad y precios, especificando la

marca, estilo y año del modelo del vehículo.

American Motors Corporation

Myriad

8835 General Drive

Plymouth Township, MI 48170

Chrysler Corporation

Dyment Distribution Service

Service Publication

20770 Westwood Drive

Strongsville, OH 44136

15825 Industrial Parkway

Cleveland, Ohio 44135

8

Ford Publications Department

Helm Incorporated

Post Office Box 07150

Detroit, MI 48207

Buick

Tuar Company

Post Office Box 354

Flint, MI 48501

Oldsmobile

Lansing Lithographers

Post Office Box 23188

Lansing, MI 48909

Cadillac, Chevrolet, Pontiac

Helm Incorporated

Post Office Box 07130

Detroit, MI 48207

9

OTRAS FUENTES-Privadas

Automóviles americanos y extranjeros

Chilton Book Company

Chilton Way

Radnor, PA 19089

Cordura Publications

Mitchell Manuals, Inc.

Post Office Box 26260

San Diego, CA. 92126

Motor’s Auto Repair Manual

Hearst Company

250 W. 55th Street

New York, NY 10019

Page 6

REGLAS DE SEGURIDAD

PARA IMPEDIR ACCIDENTES QUE PUEDAN CAUSAR GRAVES LESIONES Y/O

DAÑAR EL VEHICULO O EL EQUIPO DE PRUEBA, SEGUIR ATENTAMENTE

ESTAS REGLAS DE SEGURIDAD Y LOS PROCEDIMIENTOS DE PRUEBA.

EQUIPO DE SEGURIDAD

Extinguidor de incendios

Nunca trabajar en un automóvil sin tener a mano un

extinguidor de incendios. Se recomienda un aparato

de CO2 ó agente químico seco de 5 lbs o más grande

especificado para incendios de gasolina/químicos/

eléctricos.

Envase ignífugo

Los trapos y líquidos inflamables deben guardarse

solamente en envases metálicos cerrados e

ignífugos. Los trapos empapados en gasolina deben

dejarse secar al aire libre antes de botarlos.

Gafas protectoras

Recomendamos usar gafas cuando se trabaje en el

automóvil para protegerse los ojos contra el ácido de

la batería, la gasolina y el polvo y suciedad

desprendidos de las piezas en movimiento del motor.

NOTA: Nunca mirar directamente al interior del cuello

del carburador mientras el motor está girando o

funcionando, pues el petardeo puede causar

quemaduras.

ROPA SUELTA Y CABELLO LARGO (PIEZAS MOVILES)

Tener cuidado de no tener las manos, cabello o ropa

cerca de las piezas móviles como las aspas del

ventilador, correas y poleas o varillaje del acelerador

y transmisión. Nunca usar corbata o ropa suelta

cuando se trabaje en el automóvil.

JOYAS

Nunca usar reloj pulsera, anillos u otras joyas cuando

se trabaje en el automóvil. Se evitará la posibilidad de

engancharse en las piezas móviles o causar un

cortocircuito que podría electrocutar o quemar.

VENTILACION

El monóxido de carbono en los gases de escape es

sumamente tóxico. Para evitar asfixia, siempre hacer

funcionar el vehículo en un lugar bien ventilado. Si el

vehículo está en un lugar encerrado, instalar una

manguera a prueba de fugas en el tubo de escape

para expulsar los gases al exterior.

FRENO

Asegurar que el vehículo esté en PARK o punto

muerto y que el freno de estacionamiento esté

aplicado.

NOTA: Algunos vehículos tienen desconexión

automática en el freno de estacionamiento cuando se

saca la palanca de cambio de la posición PARK. Se

deberá inhabilitar esta características cuando sea

necesario (para pruebas) con el fin de tener el freno de

estacionamiento aplicado cuando la palanca esté en

DRIVE. Para más información al respecto, consultar el

manual de servicio del vehículo.

SUPERFICIES CALIENTES

Evitar el contacto con las superficies calientes como

múltiples y tubo de escape, silenciadores (catalíticos),

radiador y mangueras. Nunca quitar la tapa del radiador

mientras el motor esté caliente, pues el escape de

refrigerante a presión puede causar graves quemaduras.

CIGARRILLOS Y LLAMAS EXPUESTAS

Nunca fumar mientras se trabaje en el automóvil. El

vapor de gasolina es muy inflamable, y el gas emitido

por una batería en carga es explosivo.

BATERIA

No apoyar las herramientas o el equipo encima de la

batería. La conexión a tierra imprevista del borne “HOT”

(VIVO) de la batería puede electrocutar o quemar y

dañar los cables, la batería o las herramientas y

probadores. Tener cuidado de no tocar el ácido de la

batería. Puede quemar y agujerear la ropa y quemar la

piel o los ojos.

Cuando se haga funcionar un instrumento de prueba

desde una batería auxiliar, conectar un cable puente

entre el borne negativo de la batería auxiliar y tierra en

el vehículo que se esté probando. Cuando se esté

trabajando en un garage u otro ugar bajo techo, situar

la batería auxiliar a por lo menos 18 pulgadas del suelo

para reducir al mínimo la posibilidad de inflamar los

vapores de gasolina.

ALTO VOLTAJE

Hay alto voltaje—30.000 a 50.000 voltios— en la

bobina de encendido, tapa del distribuidor, cables del

encendido y bujías. Para mover los cables del

encendido mientras el motor está funcionando, hacerlo

con alicates aislados para evitar electrochoque. Aunque

no es mortal, un electrochoque puede causar una

sacudida involuntaria y lastimadura.

GATO

El gato que se suministra con el vehículo debe usarse

solamente para cambiar las ruedas. Nunca meterse

debajo de un automóvil o motor funcionando mientras

el vehículo esté apoyado en el gato.

10

SISTEMAS ELECTRICOS CON POSITIVO

(+) A TIERRA DE DOCE (12) VOLTIOS

Los pasos 4 y 5 siguientes de las conexiones de

conductores han sido revisados como sigue:

4. Conectar la pinza NEGRA al borne negativo (-) de la

batería.

5. Conectar la pinza ROJA a una buena tierra en el

motor, como el soporte del alternador/generador o

bloque del motor. Por razones de seguridad, no usar

el borne positivo (+) de la batería o componentes del

sistema de combustible como un punto de conexión

a tierra.

Todas las demás instrucciones no han sido

modificadas.

SISTEMAS ELECTRICOS DE SEIS (6)

VOLTIOS

Seguir los pasos indicados a continuación para el uso

de la luz de regulación con caja de plástico en vehículos

equipados con sistemas eléctricos de seis (6) voltios.

Se requiere una batería de doce (12) voltios. Puede ser

cualquier batería de automóvil o motocicleta.

1. Conectar la pinza ROJA de la luz de regulación al

borne positivo (+) de la batería de doce (12) voltios.

2. Conectar la pinza NEGRA de la luz de regulación al

borne negativo (-) de la batería de doce (12) voltios.

3. Conseguirse un cable puente (calibre mínimo - 18

AWG).

4. Conectar una punta del cable puente a borne

negativo (-) de la batería de doce (12) voltios.

5. Conectar la otra punta del cable puente a un puesta a

tierra limpia y firme en el vehículo que se está

probando. El cable puente debe quedar a tierra en el

vehículo sin importar si éste tiene sistema eléctrico

con negativo (-) o positivo (+) a tierra.

6. La conexión a la bujía número uno (1) y los

procedimientos restantes son iguales a los descritos

más adelante en este manual.

PREPARACION PARA LA REGULACION

DEL MOTOR

Para que cualquier motor sea regulado inicialmente en

la forma correcta, es importante seguir atentamente las

instrucciones que aparecen en la etiqueta del control de

desprendimiento de gases del vehículo. Esta etiqueta

está pegada en la parte interior del capó en el

compartimiento del motor. Algunos de los lugares

típicos son: lado interior del capó, cavidad del

guardabarros, tapa de válvula o en el lugar del pestillo

del capó. Si falta la etiqueta, consultar el manual de

servicio del vehículo o instructivo apropiado

correspondiente al motor que se está probando. Es

importante notar que la preparación es específica para

cada motor.

NOTA

Los procedimientos descritos abajo indican al

usuario que debe conectar la pinza de la bujía

(conexión directa o tipo pinza inductiva) al cable

de la bujía número uno (1). Este procedimiento es

válido para la mayoría de los motores modernos.

Sin embargo, existen algunos motores que se

regulan usando el método del “término medio”.

El usuario que más emplea este método es

General Motors, que lo recomienda para algunos

de sus motores más pequeños de cuatro (4)

cilindros a partir de 1982. La luz de regulación

tiene capacidad de “regulación promedial”. La

única diferencia en la conexión es que en lugar de

conectar la pinza de la bujía al cable de la bujía

número uno (1), se conecta al cable de la torre de

la bobina, es decir, al cable entre la bobina de

encendido y el centro de la tapa del distribuidor.

Consultar el manual de servicio del vehículo para

los procedimientos exactos.

Cuando se use una luz de regulación del avance,

notar que la regulación promedial se usa

solamente para la regulación inicial o básica con

el control de avance de la luz de regulación

puesto totalmente hacia la izquierda en “0”. Las

mediciones de regulación del avance se deben

hacer con la toma inductiva fijada alrededor del

cable de la bujía número uno (1). Si se trata de

tomar las mediciones con la pinza inductiva fijada

alrededor del cable de la torre de la bobina, los

resultados no serán válidos.

CONEXIONES DE LOS CONDUCTORES

1. La figura 1 muestra el procedimiento típico de

conexión para la mayoría de las aplicaciones. Para

seguridad, seguir la secuencia de conexión dada a

continuación.

2. Asegurar que el motor esté APAGADO y la llave de

contacto en posición OFF (desconectada).

3. (Luz de regulación equipada con pinza inductiva)

Fijar la pinza inductiva alrededor del cable de la

bujía número uno (1). No dejar que la pinza

inductiva toque el múltiple de escape o piezas

circundantes, pues esos puntos se calientan

mucho y dañarían la pinza inductiva.

(Luz de regulación equipada con conexión directa)

Desconectar el cable de la bujia numero uno (1) ya

11

Page 7

Fig. 1 -

Diagrama de conexión

ROJO

NEGRO

sea del extremo de la bujía, o extremo del

distribuidor, el que más convenga, pero sin

arriesgar la seguridad. Ver la NOTA abajo.

NOTA

En algunos motores, el distribuidor puede estar

instalado muy cerca del carburador, o cuerpo del

acelerador de inyección de combustible. Dado

que esta es un área en la cual hay mucho vapor de

gasolina presente, conviene en estos motores

desconectar el cable de la bujía número uno (1)

solamente en el extremo de la bujía.

Conectar el adaptador de resorte y conductor de la

bujía entre la bujía (o tapa del distribuidor) y el cable

sacado, como se muestra en la figura 1. Pasar el

cable de la bujía de la luz de regulación lejos del

múltiple de escape y puntos calientes circundantes,

para que no se dañe.

4. Conectar la pinza ROJA al borne positivo (+) de la

batería.

5. Conectar la pinza NEGRA a una buena tierra en el

motor, como soporte del alternador o bloque del

motor. Por razones de seguridad, no usar el borne

negativo (-) o componentes del sistema de

combustible como punto de conexión a tierra.

PRUEBA DE LA REGULACIÓN DEL MOTOR

(Motores equipados con contactos del interruptor

solamente)

Revisar, y de ser necesario, ajustar el intervalo de

reposo según especificaciones antes de proceder con

la prueba de la regulación.

1. Preparar el motor para la regulación, tal como se

indica anteriormente en PREPARACION DEL

MOTOR PARA LA REGULACION.

2. Limpiar, y marcar con tiza si es necesario, las

marcas de regulación rotativa y estacionaria en el

motor. Ver la figura 2.

3. Arrancar el motor y dejar que se caliente a la

temperatura normal de operación (manguera

superior del radiador está caliente).

4. Comprobar, y si es necesario, ajustar las rpm a la

velocidad de regulación especificada.

5. Cuando se use una luz de regulación del avance,

asegurar que el control del avance esté totalmente

hacia la izquierda en “0”.

6. Apuntar la luz de regulación a la polea del cigüeñal

o caja de la transmisión dependiendo de la

ubicación de las marcas de regulación en el motor

que se está probando. Ver las figuras 1 y 2.

7. Tirar el gatillo en la luz de regulación y observar la

ubicación de la marca rotativa con respecto a la

marca fija. Si la regulación está dentro de los

límites según lo especificado por el fabricante

(típicamente ± 2 grados) no es necesario ningún

ajuste y el procedimiento queda terminado. Si no

está dentro de lo especificado, proceder

directamente a la sección AJUSTE DE LA

REGULACION INICIAL. Si la luz de regulación

destella varias veces o lo hace erráticamente en

las luces de regulación equipadas con una pinza

inductiva, ver la NOTA a continuación.

Fig. 2 -

12

Diversas configuraciones de

marcas de regulación

10

0

3

6

10

DC

10

UDC 1-6

TDC

16N

OP 1-6

Fig. 3 -

Posición de la pinza inductiva para

obtener lecturas fiables

El procedimiento de ajuste de la regulación

NOTA

siguiente puede emplearse en la mayoría de los

motores con encendido de bujías modernos. Tanto

General Motors como Ford Motor Company han

adoptado y usado versiones especiales de sus

sistemas de encendido electrónico comunes, los

cuales detectan el encendido directamente del

cigüeñal del motor por medio de un sensor en el

cigüeñal. Estos sistemas fueron usados por

primera vez a fines de la década de los 70 y

típicamente se usaban sólo en unos pocos

automóviles de lujo. La regulación todavía se

comprueba con una luz de regulación de la manera

corriente, sin embargo, el ajuste de la regulación

se hace en el sensor del cigüeñal, y no girando el

NOTA

Un sistema de encendido defectuoso puede hacer

que la luz de regulación destelle varias veces o

erráticamente. La causa puede ser bajo voltaje de

salida de la batería o un cable de encendido

defectuoso. Se puede estabilizar el destello,

deslizando la pinza inductiva a los largo del cable

de la batería a un nuevo lugar o dando vuelta la

pinza inductiva como se muestra en la figura 3.

(Esto también a veces sirve para las pinzas

distribuidor como se hace normalmente. Ver el

manual de servicio del vehículo para el procedimiento de ajuste exacto en este tipo de sistema.

2. Con el motor apagado, aflojar el perno de sujeción

del distribuidor lo suficiente para poder girar

libremente el distribuidor. No aflojarlo más de eso.

Ver la figura 5.

3. Arrancar el motor y dejar que se caliente hasta la

temperatura de operación normal (la manguera

sensibles a la polaridad). Los cables de encendido

de cobre puro emiten gran cantidad de ruido de

radiofrecuencia por el aire el cual puede estorbar

Fig. 4 -

Limpieza de la pinza inductiva

el funcionamiento apropiado de la luz de

regulación y otros equipos electrónicos. Cambiar

el alambre de cobre puro por un alambre tipo

resistencia, solamente para las pruebas descritas

en este manual. El destello errático de la luz de

regulación también puede ser causado por

suciedad o acumulación de grasa en las

superficies adosadas de la pinza inductiva. Para

que la pinza funcione bien, limpiar y secar las

superficies interiores de la pinza con un trapo

LIMPIAR Y SECAR AQUÍ

suave, según sea necesario, como se muestra en

la figura 4.

Fig. 5 -

Aflojamiento del perno de sujeción

8. Apagar el motor. Desconectar los conductores de la

luz de regulación en orden inverso a la conexión.

A

O

9. Reconectar las mangueras o conectores eléctricos

desconectados y que formaron parte de la

preparación del motor para la regulación. Reajustar

DESCONECTAR

Y TAPAR LA

MANGUERA

DE VACIO,

SEGUN SE

REQUIERA

AFLOJAR EL

PERNO DE

SUJECION

la velocidad en vacío del motor, si es necesario.

Ajuste de la regulación

1. Asegurar que el motor haya sido preparado para la

regulación como se indica en PREPARACION DEL

MOTOR PARA LA REGULACION.

13

Page 8

Fig. 6 -

ROTACION

Regulación del avance de la

chispa

MARCA DE

REGULACION

xya

4

2

0

2

4

xya

Regulacion del avance

Las siguientes instrucciones son solamente para las

luces de regulación del avance.

Las siguientes pruebas del sistema de avance son

generales y se pueden usar en la mayoría de los

vehículos anteriores a los controles de

desprendimiento de gases. Nótese, sin embargo, que

muchos vehículos tienen sistemas de encendido y

control de desprendimiento de gases que pueden

permitir la regulación del avance solamente en ciertas

condiciones de operación. Por lo tanto, es importante

en que para esos vehículos se consulte el manual de

servicio para las instrucciones específicas sobre la

forma de realizar las revisiones del sistema de avance.

30

25

20

15

10

5

0

degrees

advance

PASOS 1 & 2

35

40

45

50

55

60

LECTURA DE LA

POLEA SOLAMENTE

AVANCE INICIAL

RPM EN VACIO

DESCONECTAR LA

MANGUERA DE

25

20

15

10

5

0

5

VACIO

Fig. 8Fig. 7

PASO 6

Fig. 9

30

35

25

40

20

15

10

5

0

degrees

advance

25

20

15

10

5

0

5

45

50

55

60

LECTURA DEL DIAL

DE LA LUZ DE

REGULACION DEL

AVANCE

AVANCE INICIAL

RPM EN VACIO

MANGUERA DE

VACIO

DESCONECTADA

20

15

10

PASO 8

5

25

0

30

degrees

advance

PASO 7

35

40

25

20

15

10

5

0

5

45

50

55

60

AVANCE INICIAL

DESCONECTADA

LECTURA DEL

AVANCE

CENTRIGUFO Y

AVANCE

CENTRIFUGO

2500 RPM

MANGUERA DE

VACIO

superior del radiador está caliente). Ajustar la

velocidad (rpm) del motor al valor especificado

por su fabricante para la regulación. Si no se da

ningún valor, ajustar el motor a velocidad en vacío

reducida.

4. Apuntar la luz de regulación a la marcas de

regulación en el motor y pulsar el gatillo.

5. Con el gatillo activado, y mientras se observan las

marcas de regulación, girar el distribuidor

lentamente en sentido horario o contrahorario

según sea necesario para dejar la regulación

según las especificaciones de fábrica. En la

mayoría de los motores, un cambio en la

regulación cambiará la velocidad (rpm) del motor.

En caso de que eso suceda, reajustar las rpm del

motor según lo indicado en el paso 3 anterior y

repetir los pasos 4 y 5 hasta que la regulación y

RPM estén dentro de las especificaciones de

fábrica.

6. Apagar el motor. Apretar el perno de sujeción del

distribuidor.

7. Arrancar el motor y volver a comprobar la

regulación. Si varió durante el apriete del perno,

reajustarla según sea necesario.

8. Apagar el motor. Desconectar los conductores de

la luz de regulación en orden inverso al empleado

en la conexión.

9. Reconectar las mangueras de vacío o conectores

eléctricos que fueron desconectados como parte

de la preparación del motor para la regulación.

Reajustar la velocidad en vacío del motor, si es

necesario.

SISTEMA DE AVANCE CENTRIFUGO

Prueba operacional

1. Poner la perilla de avance de la luz de regulación en

la posición de “0” grados, como se muestra en la

figura 7.

2. Con la manguera de vacío del distribuidor

desconectada y tapada (figura 5) y el motor a

velocidad en vacío reducida, apuntar la luz a las

marcas de regulación, pulsar el gatillo para hacer

funcionar la luz y observar la posición de las

marcas, como se muestra en las figuras 2 y 7. La

marca de regulación o índice debe aparecer

opuesta a uno de los números (regulación inicial)

como se muestra.

3. Aumentar gradualmente la velocidad del motor a

2500 rpm mientras se observa la posición de la

marca de regulación.

4. A medida que la velocidad del motor aumenta, la

marca de regulación debe moverse suavemente en

sentido contrario a la rotación del motor (dirección

de “avance de la chispa”). Ver la figura 6. A medida

que la velocidad del motor disminuye, la marca de

regulación debe moverse suavemente de vuelta a la

marca de regulación inicial, obtenida en el paso 2.

NOTA

El movimiento de avance debe ser suave. Un

movimiento irregular o errático puede significar

que el sistema de avance centrífugo está

defectuoso y será necesario repararlo, de acuerdo

a las instrucciones del fabricante del vehículo.

Prueba de calibración/exactitud

5. Hacer funcionar el motor a velocidad en vacío

reducida, apuntar la luz de regulación a la marca

de regulación y girar la perilla de control hacia

14

arriba hasta que la marca de regulación en el motor

esté en “0” grados. (Ver la figura 8). El número en

el dial de la luz de regulación indica el avance inicial

en grados, y deberá corresponder con el número

obtenido en el paso 2. (Este paso no se aplica a los

motores cuya regulación inicial está en o después

del punto muerto superior (PMS).

6. Hacer funcionar el motor a 2500 rpm o según lo

especificado por el fabricante del vehículo para la

comprobación del avance centrífugo. La marca de

regulación puede moverse fuera de la escala y más

allá del número más alto. Esto es normal para la

rpm en uso y el vehículo que se está probando.

7. Apuntar la luz de regulación a la marca de

regulación y girar la perilla de control hasta que la

marca en el motor empiece a regresar a la posición

de regulación inicial (como se obtuvo en el paso 2

anterior). La lectura obtenida en el dial de la luz de

regulación ahora indica la cantidad de avance

centrífugo en grados del cigüeñal o motor. (Figura

9). Repetir la prueba según se requiera para las

distintas velocidades como se especifica en el

manual de servicio del vehículo.

NOTA

Algunos fabricantes dan especificaciones del avance

en grados del distribuidor y rpm del distribuidor.

Dado que el distribuidor gira a la mitad de la

velocidad del motor o del cigüeñal, las

especificaciones del distribuidor deberán ser la mitad

de lo indicado en el dial de la luz de regulación del

avance. La velocidad de prueba del vehículo también

se debe duplicar si se lista la velocidad de prueba

para rpm del distribuidor. Por lo tanto, es importante

saber si el manual de servicio del vehículo se dan las

especificaciones en rpm y grados del “motor” o del

“distribuidor”.

8. Continuar girando la perilla de control hasta que la

marca de regulación aparezca en la marca de “0”

grados (PMS) en el motor. La lectura obtenida en

el dial de la luz de regulación ahora indica avance

total, es decir, el avance inicial más el avance

centrífugo en grados (figura 9).

Si la especificación de la regulación inicial es después

del PMS, éste se de sumar a la lectura del dial de la

luz de regulación para obtener el avance total.

(También se puede girar un poco más la perilla de

control, hasta la regulación inicial, eliminando así la

necesidad de hacer el cálculo. Entonces se mostrará

el avance total.) Verificar el resultado con las

especificaciones del fabricante. Repetir la prueba

según sea necesario para las distintas velocidades

como se especifica en el manual de servicio del

vehículo. Si la lectura no cumple con las especificaciones del fabricante, podría haber algún problema en

el mecanismo del avance centrífugo, el que deberá

corregirse ya sea por reparación o reemplazo.

REVISIONES DEL SISTEMA DE

AVANCE DE VACIO

Para comprobar con exactitud la calibración del

sistema de avance de vacío no solamente se requiere

la luz de regulación del avance, sino también una

bomba de vacío con manómetro como la descrita en

la INTRODUCCION al comienzo de este manual. La

mayoría de los manuales de servicio de vehículos

indican el avance específico en grados para un vacío

dado en pulgadas de mercurio. Consultar el manual

de servicio del vehículo para los procedimientos

específicos. Tal como sucede con las

comprobaciones del sistema de avance centrífugo,

observar si las especificaciones están en grados

del distribuidor o del motor.

15

Loading...

Loading...