Page 1

10-Port 100BASE-FX and

20-Port 10/100BASE-TX

Fast Ethernet Layer 2

Switching Modules

Quick Start Guide

For the CoreBuilder® 9000 Enterprise Switch

Module Descriptions

Key Features

This guide describes key installation information for two

CoreBuilder

■ The 10-port 100BASE-FX Fast Ethernet Layer 2 Switching Module

(Model Number 3CB9LF10MC) has ten 100 Mbps Ethernet fiber-optic

ports with SC connectors on its front panel and two 1-Gigabit ports

on the back for connection to the chassis backplane.

■ The 20-port 10/100BASE-TX Fast Ethernet Layer 2 Switching Module

(Model Number 3CB9LF20R) has twenty 10/100 Mbps RJ-45 ports on

its front panel and two 1-Gigabit ports on the back for connection to

the chassis backplane.

Each of these FEN Switching Modules operates as a Layer 2 switch and

occupies a single switching module slot in the CoreBuilder 9000 7-slot

chassis, 8-slot chassis, or 16-slot chassis.

The 10/100BASE-TX and 100BASE-FX FEN Switching Modules support

the following key features:

■ Hot-swapping of modules

■ Management using the Administration Console

(a command line interface), the Web Management suite of

applications with an Internet browser, or SNMP-based applications

®

9000 Fast Ethernet (FEN) Switching Modules:

Page 2

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

2

For information about the software features that these modules support,

see the:

■ CoreBuilder 9000 Implementation Guide

■ Command Reference Guide

■ CoreBuilder 9000 Release Notes for the Fast Ethernet and Gigabit

Ethernet Layer 2 Switching Modules

Front Panel

Ejector handle

Module Status LED

Port Status LEDs

14

14

7

7

MOD STAT

MOD STAT

1

2

1

2

3

3

6

7

8

MOD STAT

1

2

3

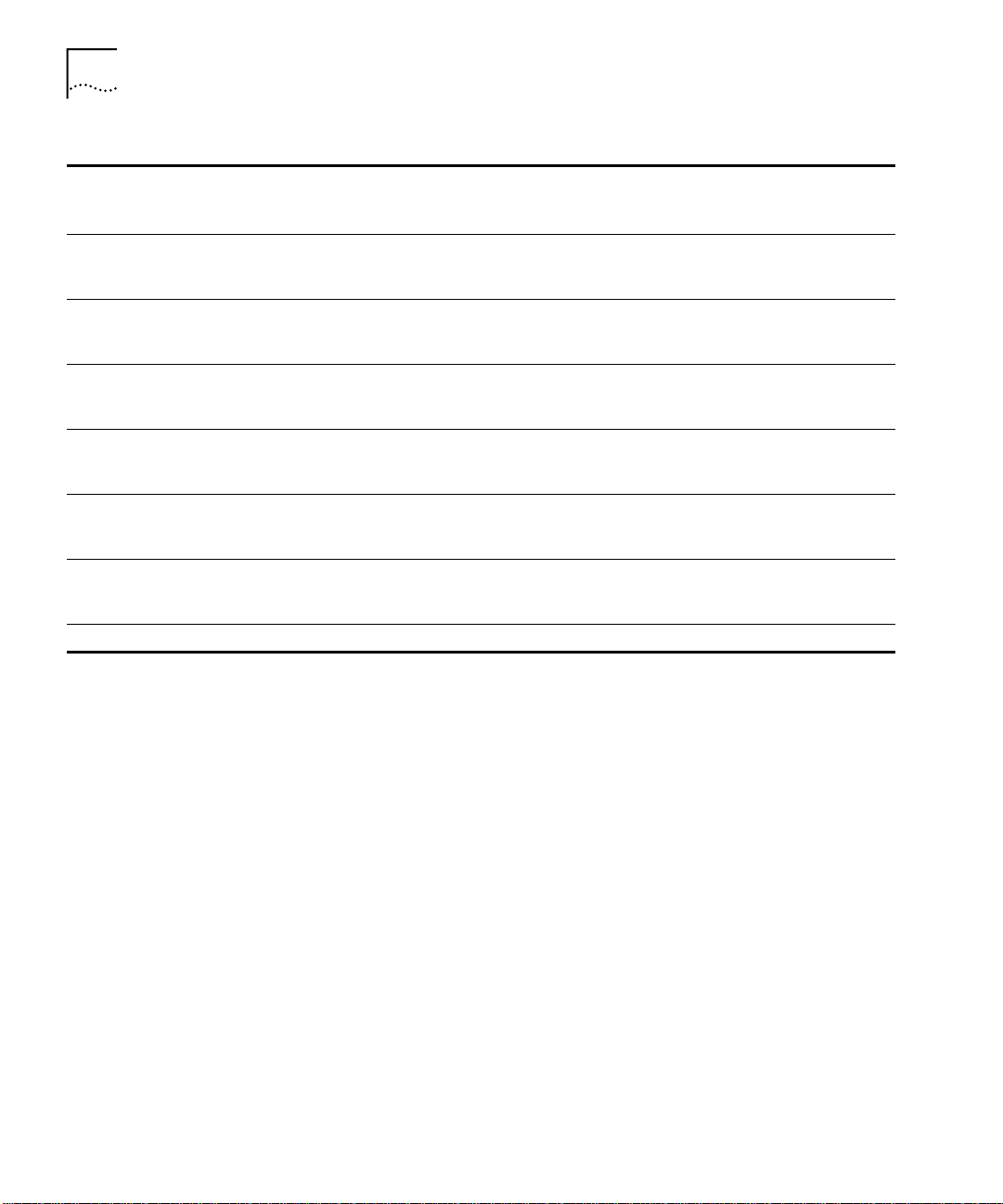

On the 10-port 100BASE-FX FEN Switching Module, the front panel ports

are numbered 1 through 10, as shown in Figure 1. The two 1-Gigabit

ports on the back of the module (not shown in Figure 1) are numbered

11 and 12.

On the 20-port 10/100BASE-TX FEN Switching Module, the front panel

ports are numbered 1 through 20, as shown in Figure 1. The two

1-Gigabit ports on the back of the module (not shown in Figure 1) are

numbered 21 and 22.

Front Panels for the 10/100BASE-TX and 100BASE-FX FEN Modules

10/100BASE-TX

RJ-45 ports

4X

4X

3X

3X

2X

2X

5X

5X

8X

8X

7X

7X

6X

6X

9X

9X

12X

12X

11X

11X

10X

10X

13X

13X

16X

16X

15X

15X

14X

14X

100BASE-FX

RX

1

RX

TX

2

RX

TX

3

RX

TX

4

RX

TX

5

RX

TX

6

RX

TX

7

RX

TX

8

Ejector handle

Model number

19X

19X

18X

18X

17X

17X

RX

TX

TX

9

6

6

4

4

5

5

0

9

1

4

5

Figure 1

1X

1X

TX

3CB9LF20R

3CB9LF20R

20X

20X

RX

10

3CB9LF10MC

Port Status LEDs

Module Status LED

In the 7-slot chassis, you install the modules horizontally with the LEDs at

the left. In the 8-slot chassis and the16-slot chassis, you install the

modules vertically with the LEDs at the top.

Fiber-optic ports

(SC connectors)

Page 3

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

3

Audience Description

Safety Precautions

This guide is intended for trained technical personnel only. Do not

attempt to install, remove, or replace the 10/100BASE-TX or 100BASE-FX

FEN Switching Modules if you have not had the proper training from

3Com. For training information in the United States and Canada, call

1-800-NET-3COM. For the numbers to call in other locations, visit the

3Com Web site:

www.3Com.com/support/

When you handle components in a CoreBuilder 9000 system, be sure

that you follow all safety precautions. To avoid electric shocks, burns, or

equipment damage, read and follow these warnings:

WARNING:

Allow only trained service personnel to install, remove, or

replace any module in the chassis.

WARNING: Hazardous energy exists within the system. Use extreme

caution when you install, remove, or replace any module in the chassis.

When the system is on:

■ Never insert metal objects such as a screwdriver or a finger with

jewelry into open module slots.

■ Do not touch any connections within the chassis with your hands or

fingers.

WARNING: To ensure optical safety when installing a FEN Switching

Module, comply with the following precaution:

Although the data communication LEDs used in this product meet the

regulatory requirements for casual exposure to the eye, as with any

source of bright light, it is advised that you do not look into the light

source.

LED Safety Information:

IEC 825 and EN60825, Class 1 LED Device. For

connection only to Class 1 LED Devices.

CLASS 1

LED PRODUCT

Page 4

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

4

ESD Safety Information

Electrostatic discharge (ESD) can damage components of the module.

ESD, which occurs when a module is improperly handled, can cause

complete or intermittent failures.

CAUTION: To prevent ESD-related damage:

■ Always wear an ESD wrist strap (not provided) when you handle a

module, ensuring that the strap makes good skin contact and is

properly grounded.

■ Keep the module in its antistatic bag until you are ready to install it.

Handling Precautions

When you handle a module, follow these precautions:

■ Always handle the module by the front panel only.

■ Do not touch the components, pins, leads, or solder connections.

■ Do not twist or otherwise force the module into the chassis when you

insert it into the module guides.

■ Before you push the module into the chassis, verify that the module

ejector handles are open.

■ When you slide the module into the 7-slot chassis, match the left and

right module guides. In the 8-slot chassis or 16-slot chassis, match the

upper and lower module guides.

For details, see “Installation Prerequisites” and “Installing the Module”

later in this guide.

Page 5

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

5

Unpacking

Instructions

Use the following procedure when you unpack a FEN Switching Module:

Verify that the module is the correct product by matching the 3C number

1

that is listed on the shipping box label to the 3C number that you ordered

(Model Number 3CB9LF10MC for the 10-port 100BASE-FX Fast Ethernet

Layer 2 Switching Module or Model Number 3CB9LF20R for the 20-port

10/100BASE-TX Fast Ethernet Layer 2 Switching Module).

Remove the module, in its antistatic bag, from the shipping box.

2

Observing the caution instructions, remove the module from its antistatic

3

bag and inspect it for physical damage.

CAUTION: Handle the module only by the front panel. Do not touch any

components, pins, leads, or solder connections.

If the module appears to be damaged, replace it in the antistatic bag, put

it back in the shipping box, and contact your network supplier.

Verify that the box also contains:

4

■ CoreBuilder 9000 Release Notes for the Fast Ethernet and Gigabit

Ethernet Layer 2 Switching Modules

■ 10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet

Layer 2 Switching Modules Quick Start Guide for the

CoreBuilder 9000 Enterprise Switch (this guide)

If the listed contents are not in your shipping box, contact your network

supplier.

All shipping boxes are reusable. After you remove the contents, replace

the packing materials in the box and store it for future use.

Page 6

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

6

Installation

Prerequisites

Before you install a module, make the following preparations:

■ Verify that the chassis is properly installed in a rack, on a table, or on a

shelf, according to the instructions in either of these guides:

7-Slot Chassis Quick Installation Guide for the CoreBuilder 9000

■

Enterprise Switch

Chassis Quick Installation Guide for the CoreBuilder 9000

■

Enterprise Switch 8-slot Chassis and 16-slot Chassis.

■ Have a flat-blade torque screwdriver available to secure the module to

the chassis after you install it.

■ Read the CoreBuilder 9000 Release Notes for the Fast Ethernet and

Gigabit Ethernet Layer 2 Switching Modules for important information

about installing and upgrading modules in an existing chassis or a new

chassis.

CAUTION: All modules in a CoreBuilder 9000 chassis must operate at

compatible software levels. You must verify the software release on all

new and existing modules in your chassis and upgrade as necessary. See

the CoreBuilder 9000 Release Notes for the Fast Ethernet and Gigabit

Ethernet Layer 2 Switching Modules for a module software compatibility

requirements table, mandatory upgrade procedures, and other important

information.

Module Placement

in the Chassis

Note the following chassis slot restrictions and recommendations when

you choose a chassis slot for the

10-port 100BASE-FX Fast Ethernet

Switching Module or the 20-port 10/100BASE-TX Fast Ethernet

Switching Module:

■ In the 7-slot chassis:

Do not install the module in slot 7. This slot is reserved for a

■

Gigabit Ethernet (GEN) Switch Fabric Module.

Install the module in slot 1, 2, 3, 4, 5, or 6.

■

■ In the 8-slot chassis:

Do not install the module in slot 7 or slot 8. These slots are

■

reserved for GEN Switch Fabric Modules.

Install the FEN Switching Module in slot 1, 2, 3, 4, 5, or 6.

■

Page 7

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

■ In the 16-slot chassis:

Do not install the module in slot 8 or slot 9. These slots are

■

reserved for GEN Switch Fabric Modules.

Install the module in slot 1, 2, 3, 4, 5, 6, 7, 10, 11, or 12.

■

3Com recommends that you do not install the module in slot 13,

■

14, 15, or 16 because these slots have only one connection to the

GEN Switch Fabric Module.

■ Table 1, Table 2, and Table 3 list the relationship between the

following:

■ 24-port GEN Switch Fabric Module (SFM) (Model Number 3CB9FG24

or Model Number 3CB9FG24T)

■ 10-port 100BASE-FX FEN Switching Module

■ Switching module slots in the 7-slot chassis, 8-slot chassis, and 16-slot

chassis, respectively

Table 4, Table 5, and Table 6 list the relationship between the following:

■ 24-port GEN Switch Fabric Module (SFM)

7

■ 20-port 10/100BASE-TX FEN Switching Module

■ Switching module slots in the 7-slot chassis, 8-slot chassis, and 16-slot

chassis, respectively

Table 7 and Table 8 list the relationship between the following:

■ 9-port GEN Switch Fabric Module (SFM) (Model Number 3CB9FG9)

■ 10-port 100BASE-FX FEN Switching Module

■ Switching module slots in the 7-slot chassis and 8-slot chassis,

respectively

Table 9 and Table 10 list the relationship between the following:

■ 9-port GEN Switch Fabric Module (SFM)

■ 20-port 10/100BASE-TX FEN Switching Module

■ Switching module slots in the 7-slot chassis and 8-slot chassis,

respectively

Use the table information to help select a slot for your module, as well as

administer the system after you have completed the installation.

Page 8

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

8

Ta b l e 1

Chassis

Slot

Number

1 4; up to 2 can be

2 4; up to 2 can be

3 4; up to 2 can be

4 4; up to 2 can be

5 4; up to 2 can be

6 4; up to 2 can be

7 Reserved for an SFM Not applicable Not applicable Not applicable

Mapping the 24-port GEN SFM and the 10-port FEN Switching Module to the 7-slot Chassis

Number of SFM

Backplane Ports

Allocated to Slot

accessed by this

module

accessed by this

module

accessed by this

module

accessed by this

module

accessed by this

module

accessed by this

module

10-port Switching

Module Backplane

Port Numbers

11

12

11

12

11

12

11

12

11

12

11

12

SFM Backplane Port

Numbers Assigned to

Chassis Slot

1

2

5

6

9

10

13

14

17

18

21

22

SFM LED Numbers

Assigned to Backplane

Port Numbers

1

2

3

4

5

6

7

8

9

10

11

12

Page 9

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

9

Ta b l e 2

Chassis

Slot

Number

1 4; up to 2 can be

2 4; up to 2 can be

3 4; up to 2 can be

4 4; up to 2 can be

5 4; up to 2 can be

6 4; up to 2 can be

7 Reserved for an SFM Not applicable Not applicable Not applicable

8 Reserved for an SFM Not applicable Not applicable Not applicable

Mapping the 24-port GEN SFM and the 10-port FEN Switching Module to the 8-slot Chassis

Number of SFM

Backplane Ports

Allocated to Slot

accessed by this

module

accessed by this

module

accessed by this

module

accessed by this

module

accessed by this

module

accessed by this

module

10-port Switching

Module Backplane

Port Numbers

11

12

11

12

11

12

11

12

11

12

11

12

SFM Backplane Port

Numbers Assigned to

Chassis Slot

1

2

5

6

9

10

13

14

17

18

21

22

SFM LED Numbers

Assigned to Backplane

Port Numbers

1

2

3

4

5

6

7

8

9

10

11

12

Page 10

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

10

Ta b l e 3

Chassis

Slot

Number

1 2 11

2 2 11

3 2 11

4 2 11

5 2 11

6 2 11

7 2 11

8 Reserved for an SFM Not applicable Not applicable Not applicable

9 Reserved for an SFM Not applicable Not applicable Not applicable

10 2 11

11 2 11

12 2 11

13 1 11 21 21

14 1 11 22 22

15 1 11 23 23

16 1 11 24 24

Mapping the 24-port GEN SFM and the 10-port FEN Switching Module to the 16-slot Chassis

Number of SFM

Backplane Ports

Allocated to Slot

10-port Switching

Module Backplane

Port Numbers

12

12

12

12

12

12

12

12

12

12

SFM Backplane Port

Numbers Assigned to

Chassis Slot

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

SFM LED Numbers

Assigned to Backplane

Port Numbers

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Page 11

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

11

Ta b l e 4

Chassis

Slot

Number

1 4; up to 2 can be

2 4; up to 2 can be

3 4; up to 2 can be

4 4; up to 2 can be

5 4; up to 2 can be

6 4; up to 2 can be

7 Reserved for an SFM Not applicable Not applicable Not applicable

Mapping the 24-port GEN SFM and the 20-port FEN Switching Module to the 7-slot Chassis

20-port Switching

Number of SFM

Backplane Ports

Allocated to Slot

accessed by this

module

accessed by this

module

accessed by this

module

accessed by this

module

accessed by this

module

accessed by this

module

Module

Backplane Port

Numbers

21

22

21

22

21

22

21

22

21

22

21

22

SFM Backplane Port

Numbers Assigned to

Chassis Slot

1

2

5

6

9

10

13

14

17

18

21

22

SFM LED Numbers

Assigned to Backplane

Port Numbers

1

2

3

4

5

6

7

8

9

10

11

12

Page 12

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

12

Ta b l e 5

Chassis

Slot

Number

1 4; up to 2 can be

2 4; up to 2 can be

3 4; up to 2 can be

4 4; up to 2 can be

5 4; up to 2 can be

6 4; up to 2 can be

7 Reserved for an SFM Not applicable Not applicable Not applicable

8 Reserved for an SFM Not applicable Not applicable Not applicable

Mapping the 24-port GEN SFM and the 20-port FEN Switching Module to the 8-slot Chassis

Number of SFM

Backplane Ports

Allocated to Slot

accessed by this

module

accessed by this

module

accessed by this

module

accessed by this

module

accessed by this

module

accessed by this

module

20-port Switching

Module Backplane

Port Numbers

21

22

21

22

21

22

21

22

21

22

21

22

SFM Backplane Port

Numbers Assigned to

Chassis Slot

1

2

5

6

9

10

13

14

17

18

21

22

SFM LED Numbers

Assigned to Backplane

Port Numbers

1

2

3

4

5

6

7

8

9

10

11

12

Page 13

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

13

Ta b l e 6

Chassis

Slot

Number

1 2 21

2 2 21

3 2 21

4 2 21

5 2 21

6 2 21

7 2 21

8 Reserved for an SFM Not applicable Not applicable Not applicable

9 Reserved for an SFM Not applicable Not applicable Not applicable

10 2 21

11 2 21

12 2 21

13 1 21 21 21

14 1 21 22 22

15 1 21 23 23

16 1 21 24 24

Mapping the 24-port GEN SFM and the 20-port FEN Switching Module to the 16-slot Chassis

Number of SFM

Backplane Ports

Allocated to Slot

20-port Switching

Module Backplane

Port Numbers

22

22

22

22

22

22

22

22

22

22

SFM Backplane Port

Numbers Assigned to

Chassis Slot

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

SFM LED Numbers

Assigned to Backplane

Port Numbers

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Page 14

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

14

Ta b l e 7

Chassis

Slot

Number

1 1 11 1 1

2 1 11 2 2

3 1 11 3 3

4 1 11 4 4

5 1 11 5 5

6 1 11 6 6

7 Reserved for an SFM Not applicable Not applicable Not applicable

Ta b l e 8

Chassis

Slot

Number

1 1 11 1 1

2 1 11 2 2

3 1 11 3 3

4 1 11 4 4

5 1 11 5 5

6 1 11 6 6

7 Reserved for an SFM Not applicable Not applicable Not applicable

8 Reserved for an SFM Not applicable Not applicable Not applicable

Mapping the 9-port GEN SFM and the 10-port FEN Switching Module to the 7-slot Chassis

Number of SFM

Backplane Ports

Allocated to Slot

10-port Switching

Module Backplane

Port Numbers

SFM Backplane Port

Numbers Assigned to

Chassis Slot

SFM LED Numbers

Assigned to Backplane

Port Numbers

Mapping the 9-port GEN SFM and the 10-port FEN Switching Module to the 8-slot Chassis

Number of SFM

Backplane Ports

Allocated to Slot

10-port Switching

Module Backplane

Port Numbers

SFM Backplane Port

Numbers Assigned to

Chassis Slot

SFM LED Numbers

Assigned to Backplane

Port Numbers

Page 15

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

15

Ta b l e 9

Chassis

Slot

Number

1 1 21 1 1

2 1 21 2 2

3 1 21 3 3

4 1 21 4 4

5 1 21 5 5

6 1 21 6 6

7 Reserved for an SFM Not applicable Not applicable Not applicable

Table 10

Chassis

Slot

Number

1 1 21 1 1

2 1 21 2 2

3 1 21 3 3

4 1 21 4 4

5 1 21 5 5

6 1 21 6 6

7 Reserved for an SFM Not applicable Not applicable Not applicable

8 Reserved for an SFM Not applicable Not applicable Not applicable

Mapping the 9-port GEN SFM and the 20-port FEN Switching Module to in the 7-slot Chassis

Number of SFM

Backplane Ports

Allocated to Slot

20-port Switching

Module Backplane

Port Numbers

SFM Backplane Port

Numbers Assigned to

Chassis Slot

SFM LED Numbers

Assigned to Backplane

Port Numbers

Mapping the 9-port GEN SFM and the 20-port FEN Switching Module to the 8-slot Chassis

Number of SFM

Backplane Ports

Allocated to Slot

20-port Switching

Module Backplane

Port Numbers

SFM Backplane Port

Numbers Assigned to

Chassis Slot

SFM LED Numbers

Assigned to Backplane

Port Numbers

Page 16

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

16

Installing the Module

To install a FEN Switching Module:

Before you start the installation process, read and follow the instructions

1

in “Safety Precautions,” “Handling Precautions,” and “Installation

Prerequisites” earlier in this guide.

Select a chassis slot for your module, following the restrictions and

2

recommendations in “Module Placement in the Chassis” earlier in this

guide.

To expose a slot for the module, remove the blank faceplate.

3

Save this faceplate in case you need it in the future. Empty slots must be

covered to ensure proper airflow and cooling in the chassis.

3Com recommends that you remove the faceplate only for the slot where

you intend to install an individual module; leave the remaining faceplates

in the chassis.

Open the module ejector handles.

4

Begin to insert the module:

5

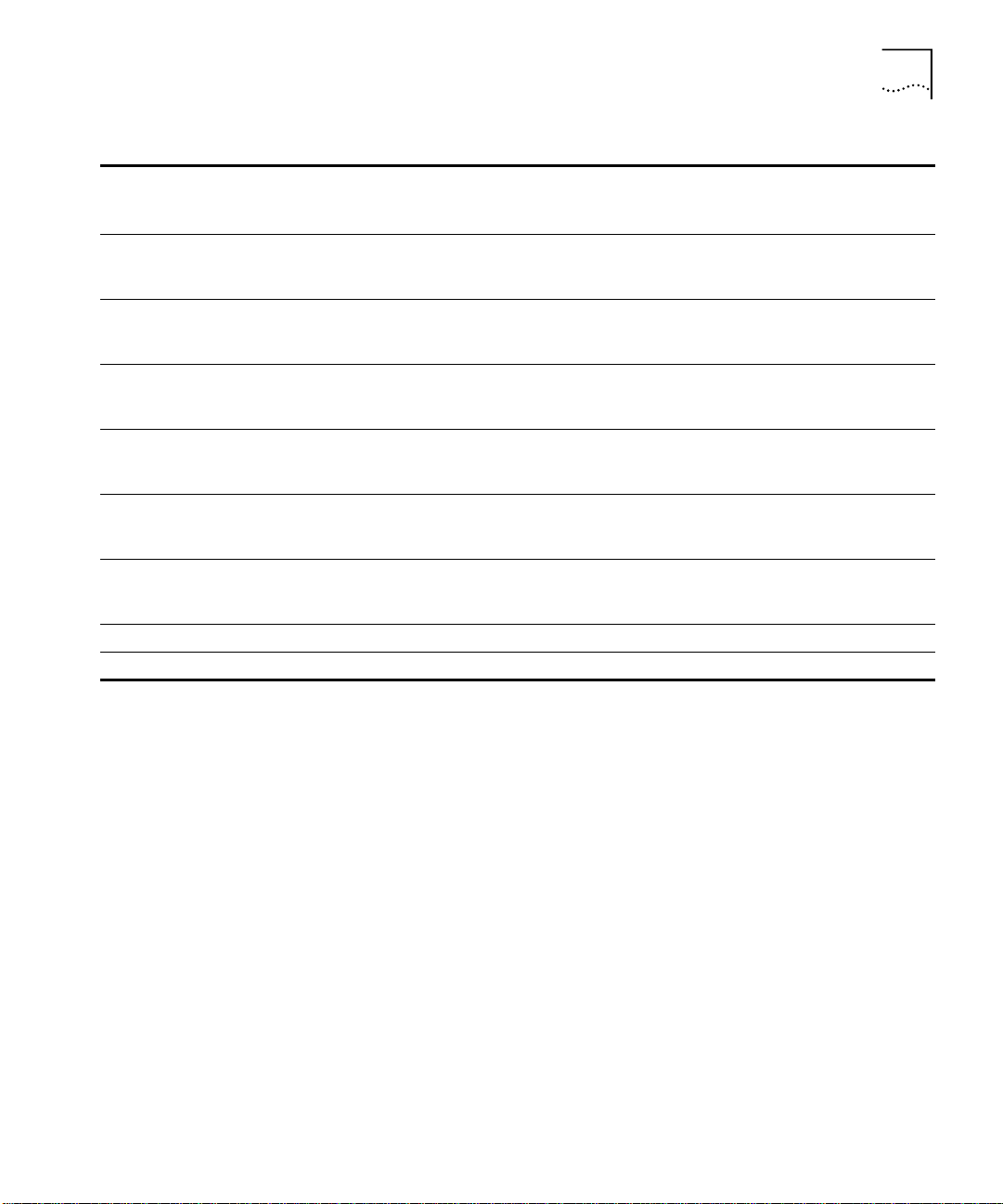

■ In the 7-slot chassis, hold the module horizontally with the LEDs to the

left and begin to insert the module using the guides on the left and

the right of the slot. Figure 2 shows the module position in a 7-slot

chassis.

■ In the 8-slot chassis and 16-slot chassis, hold the module vertically

with the LEDs at the top and begin to insert the module using the

guides on the top and the bottom of the slot. Figure 3 shows the

module position in a 16-slot chassis. The module position is the same

in an 8-slot chassis.

CAUTION: Do not twist or bend the module when you insert it.

Slide the module into the chassis by pushing firmly on the two ends of

6

the front panel near the ejector handles.

WARNING: Hazardous energy exists inside the chassis. Do not place

hands or objects into the chassis or touch any components on an inserted

module.

Page 17

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

R

3CB9FG24

PR

I

M

O

D

S

T

A

T

SE

C

123456789

10

1

1

1

2

1

3

1

4

151617181

9

2

0

2

1

2

2

2

3

2

4

3CB9FG24

PR

I

M

O

D

S

T

A

T

SE

C

123456789

10

1

1

1

2

1

3

1

4

151617181

9

2

0

2

1

2

2

2

3

2

4

3CB9FG24

PR

I

M

O

D

S

T

A

T

SE

C

123456789

10

1

1

1

2

1

3

1

4

151617181

9

2

0

2

1

2

2

2

3

2

4

1

2

3

4

5

6

7

8

CoreBuilder

®

9000

9

3CB9LF20R

1

M

O

D

S

T

A

T

2

3

4

5

6

7

1

4

1

X

2

X

3

X

4

X

5

X

6

X

7

X

8

X

9X

1

0

X

1

1

X

1

2

X

1

3

X

1

4

X

1

5

X

1

6

X

1

7

X

1

8

X

1

9

X

2

0

X

3CB9LF20R

1

M

O

D

S

T

A

T

2

3

4

5

6

7

1

4

1

X

2

X

3

X

4

X

5

X

6

X

7

X

8

X

9X

1

0

X

1

1

X

1

2

X

1

3

X

1

4

X

1

5

X

1

6

X

1

7

X

1

8

X

1

9

X

2

0

X

Spring-loaded

screws

20-port Fast Ethernet

Switching Module

17

Figure 2

Installing a FEN Switching Module into a 7-Slot Chassis

Page 18

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

18

Figure 3

Spring-loaded

screw

20-port

Fast Ethernet

Switching

Module

Spring-loaded

screw

Installing a FEN Switching Module into a 16-Slot Chassis

R

1 2 3 4 5 6 7 8 12 13 169 10 11 14 15

M

M

O

O

M

M

M

M

M

M

D

D

O

O

O

O

O

O

D

D

D

D

D

D

S

S

T

T

S

S

S

S

S

S

A

A

T

T

T

T

T

T

T

T

A

A

A

A

A

A

T

T

T

T

T

7

7

1

1

2

2

3

3

4

4

5

5

6

6

1

1

X

X

2

2

X

X

3

3

X

X

4

4

X

X

5

5

X

X

6

6

X

X

7

7

X

X

8

8

X

X

9

9

X

X

1

1

0

0

X

X

1

1

1

1

X

X

1

1

2

2

X

X

1

1

3

3

X

X

1

1

4

4

X

X

1

1

5

5

X

X

1

1

6

6

X

X

1

1

7

7

X

X

1

1

8

8

X

X

1

1

9

9

X

X

2

2

0

0

X

X

3CB9LF20R

3CB9LF20R

T

1

1

4

4

S

S

S

S

S

S

P

P

P

P

P

P

E

E

E

E

E

E

R

R

R

R

R

R

C

C

C

C

C

C

I

I

I

I

I

I

1

2

1

2

1

2

1

2

1

2

1

2

3

4

3

4

3

4

3

4

3

4

3

4

5

6

5

6

5

6

5

6

5

6

5

6

7

8

7

8

7

8

7

8

7

8

7

8

9

1

9

1

9

1

9

1

9

1

9

1

0

0

0

0

0

0

111

111

111

111

111

111

2

2

2

2

2

2

131

131

131

131

131

131

4

4

4

4

4

4

151

151

151

151

151

151

6

6

6

6

6

6

171

171

171

171

171

171

8

8

8

8

8

8

192

192

192

192

192

192

0

0

0

0

0

0

212

212

212

212

212

212

2

2

2

2

2

2

232

232

232

232

232

232

4

4

4

4

4

4

3CB9FG24

3CB9FG24

3CB9FG24

3CB9FG24

3CB9FG24

3CB9FG24

CoreBuilder

®

9000

Page 19

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

To engage the module with the backplane, use both hands to perform

7

the following steps:

Push firmly at the two ends of the front panel near the ejector handles

a

until you feel the module connectors make firm contact with the

backplane connectors.

Put your left thumb on the left or top ejector handle and your right

b

thumb on the right or bottom ejector handle. Simultaneously, push

the ejector handles in towards the front panel until each handle is

parallel with the front panel.

You feel a slight resistance as the connectors fully engage.

CAUTION: If there is too much resistance when you try to close the

ejector handles, the module backplane connector may not be aligned.

Forcing the module into place can damage the module connectors and

backplane connectors. If necessary, remove and reinsert the module,

ensuring that the connectors are properly aligned. Do not tighten the

spring-loaded screws to seat the module.

To secure the module in the chassis, tighten the spring-loaded screws to a

8

torque specification of 3 to 5 inch-pounds.

19

CAUTION: Verify that the module screws are properly aligned with the

threaded holes in the chassis. If the screws are not aligned when you

tighten them, you may strip the threads and make it impossible to secure

the module.

To ensure that you tighten screws to torque specification, use a torque

screwdriver.

WARNING: To ensure adequate cooling airflow and continued product

safety agency compliance, install blank faceplates over all empty slots.

If the chassis is powered on, the module initialization process begins.

Page 20

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

20

Verifying Module

Operation

The 10-port 100BASE-FX FEN Switching Module has 10 Port Status LEDs

and the 20-port 10/100BASE-TX FEN Switching Module has 20 Port

Status LEDs. Each module has one Module Status LED.

Watch the LEDs during the system power-on diagnostics test to verify

proper module operation:

■ On the Module Status LED, the normal power-on test sequence is

Green – Yellow – Green – Flashing Green (while running the

diagnostic test) – Green

If the Module Status LED is Yellow after the diagnostics run, the module

has failed.

■ The Port Status LEDs are tested during the diagnostic test. The normal

test sequence is Yellow – Green – Off

Table 11 describes LED colors and definitions.

Table 11

LED State or Color Definition

Module Status

Port Status

Module and Port Status LED Indicators

Green Power is on (normal operation).

Flashing Green Diagnostics or software download is in

progress.

Yellow Diagnostic failure.

Off After initial insertion or module reset, the

LED remains unlit for approximately 3

seconds. Otherwise, an unlit LED

indicates that the module is not receiving

power.

Green Port is enabled and link is up.

Flashing Green Port is receiving or transmitting packets.

Yellow Module or port is malfunctioning.

Off Port is disabled or link is down.

Page 21

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

21

Managing the

Module

You configure and manage a FEN Switching Module using several

interfaces. The following sections describe two of the interfaces.

Administration Console

The Administration Console is the embedded menu-driven command line

interface that you access from a terminal or through terminal emulation

software.

To manage the module from the Administration Console:

Log in to the EME.

1

For information about how to log in to the EME, see the CoreBuilder

9000 Enterprise Management Engine User Guide.

At the EME prompt, enter:

2

connect <slot>.1

where <slot> is the chassis slot number of the module that you want to

manage, and the number after the decimal point is a subslot number,

which is always 1.

The top level of the Administration Console menu for the module

appears.

Enter command strings to manage the module. For example, to display a

3

module baseline, enter:

module baseline display

For information about the Administration Console module commands,

see the Command Reference Guide.

Web Management

Web Management applications are an embedded part of the system.

They include WebConsole, DeviceView, and Performance monitoring

tools. Additional installable applications include online Help.

After you have set up the IP address for your system, you can access the

Web Management applications directly in your Web browser by entering

the IP address.

For information about setting up your IP address, see the Enterprise

Management Engine Quick Start Guide for the CoreBuilder 9000

Enterprise Switch. For additional information about Web Management,

see the Web Management User Guide for the CoreBuilder 9000

Enterprise Switch.

Page 22

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

22

Module

Specifications

The following tables list specifications for the 10-port 100BASE-FX and

20-port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules:

Cabling Requirements

Module Required Cable Type Maximum Segment Length

100BASE-FX

(3CB9LF10MC)

10/100BASE-TX

(3CB9LF20R)

Multimode fiber

62.5/125 micron

UTP Category 5 Up to 100 m (328 ft)

Half-duplex mode: 400 m (1312 ft

Full-duplex mode: 2 km (1.2 mi)

Environmental Requirements

Operating temperature 0 to 50 °C (32 to 122 °F)

Operating humidity 10% to 90% relative humidity, noncondensing

Storage temperature –40 to 66 °C (–40 to 151 °F)

Storage humidity 5% to 95% relative humidity, noncondensing

Physical Specifications

Module Dimensions Weight

100BASE-FX

(3CB9LF10MC)

10/100BASE-TX

(3CB9LF20R)

25.4 mm x 340.36 mm x 388.112 mm

(1 in. x 13.4 in. x 15.28 in.)

25.4 mm x 340.36 mm x 388.112 mm

(1 in. x 13.4 in. x 15.28 in.)

1.135 kg

(2.5 lb)

1.1804 kg

(2.6 lb)

Power Specifications

Module Voltage Wattage

100BASE-FX

(3CB9LF10MC)

10/100BASE-TX

(3CB9LF20R)

+5.2 V 25 W

+3.5 V 33 W

+12 V 2 W

Total Wattage

+5.2 V 28 W

+3.5 V 41 W

+12 V 2 W

Total Wattage

= 60

= 71

Page 23

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

Regulatory Compliance

23

Related

CoreBuilder 9000

Documents

Safety

CSA 22.2 No. 950

■

EN 60950

■

IEC 60950 (formerly IEC 950)

■

UL 1950

■

EN 60825 -1, -2

■

CE Mark

■

Emissions

FCC Part 15 Class A

■

ICES003 Class A

■

VCCI Class A

■

EN 55022 Class A

■

EN 50082-1

■

AS3548 (C-Tick Mark)

■

CISPR 22 Class A

■

CE Mark

■

For detailed information about using and managing the FEN Switching

Modules, see the following documents:

■ CoreBuilder 9000 Implementation Guide

■ Command Reference Guide

■ CoreBuilder 9000 Enterprise Management Engine User Guide

■ Web Management User Guide for the CoreBuilder 9000 Enterprise

Switch

For the software code installation procedure as well as known problem

information for this module, see the

the Fast Ethernet and Gigabit Ethernet Layer 2 Switching Modules

CoreBuilder 9000 Release Notes for

.

For information about installing and powering on the system, see the

following documents:

■ CoreBuilder 9000 Enterprise Switch Getting Started Guide

■ 7-Slot Chassis Quick Installation Guide for the CoreBuilder 9000

Enterprise Switch

■ Chassis Quick Installation Guide for the CoreBuilder 9000 Enterprise

Switch 8-slot Chassis and 16-slot Chassis

■ 7-Slot Chassis Power Supply Installation Guide for the

CoreBuilder 9000 Enterprise Switch

■ Power Supply Installation Guide for the CoreBuilder 9000 Enterprise

Switch 8-slot Chassis and 16-slot Chassis

Page 24

24

10-Port 100BASE-FX and 20-Port 10/100BASE-TX Fast Ethernet Layer 2 Switching Modules Quick Start Guide

You can view and print these and other current CoreBuilder 9000

documents from the following sources:

■

3Com Web site

http://support.3com.com/nav/switches.htm

■ CoreBuilder 9000 Documentation CD-ROM

This CD-ROM is included in the chassis shipping box. You can also

order the CD-ROM separately (Order Number 3CB9DB).

Page 25

3Com Corporation L

IMITED WARRANTY

10-Port 100BASE-FX Fast Ethernet Layer 2 Switching Module (Model Number 3CB9LF10MC) and 20-Port 10/100BASE-TX

Fast Ethernet Layer 2 Switching Module (Model Number 3CB9LF20R) for the CoreBuilder

H

ARDWARE

S

OFTWARE

Y

2000 W

EAR

ARRANTY

3Com warrants to the end user (“Customer”) that this hardware product will be free from defects in workmanship

and materials, under normal use and service, for one (1) year from the date of purchase from 3Com or its authorized

reseller.

3Com’s sole obligation under this express warranty shall be, at 3Com’s option and expense, to repair the defective

product or part, deliver to Customer an equivalent product or part to replace the defective item, or if neither of the

two foregoing options is reasonably available, 3Com may, in its sole discretion, refund to Customer the purchase

price paid for the defective product. All products that are replaced will become the property of 3Com. Replacement

products may be new or reconditioned. 3Com warrants any replaced or repaired product or part for ninety (90) days

from shipment, or the remainder of the initial warranty period, whichever is longer.

3Com warrants to Customer that each software program licensed from it will perform in substantial conformance to

its program specifications, for a period of ninety (90) days from the date of purchase from 3Com or its authorized

reseller. 3Com warrants the media containing software against failure during the warranty period. No updates are

provided. 3Com’s sole obligation un der this express warranty shall be, at 3Com’s option and expense, to refund the

purchase price paid by Customer for any defective software product, or to replace any defective media with software

which substantially conforms to applicable 3Com published specifications. Customer assumes responsibility for the

selection of the appropriate applications program and associated reference materials. 3Com makes no warranty or

representation that its software products will meet Customer’s requirements or work in combination with any

hardware or applications software products provided by third parties, that the operation of the software products

will be uninterrupted or error free, or that all defects in the software products will be corrected. For any third-party

products listed in the 3Com software product documentation or specifications as being compatible, 3Com will make

reasonable efforts to provide compatibility, except where the noncompatibility is caused by a “bug ” or defect in the

third party’s product or from use of the software product not in accordance with 3Com’s published specifications or

user manual.

THIS 3CO M PRODUCT MAY INCLUDE OR BE BUNDLED WITH THIRD-PARTY SOFTWARE, THE USE OF W HICH IS

GOVERNED BY A SEPARATE END-USER LICENSE A GREEMENT. THIS 3COM WAR RANTY DOES NOT APPLY TO SUCH

THIRD-PARTY SOFTWARE. FOR THE APPLICABLE WARRANTY, PLEASE REFER TO THE END-USER LICENSE

AGREEMENT GOVERNING THE USE OF SUCH SOFTWARE.

In addition to the Hardware Warranty and Software Warranty stated above, 3Com warrants that each product sold

or licensed to Customer on and after January 1, 1998, that is date sensitive will continue performing properly with

regard to such date data on and after January 1, 2000, provided that all other products used by Customer in

connection or combination with the 3Com product, including hardware, software, and firmware, accurately

exchange date data with the 3Com product, with the exception of those products identified at 3Com’s Web site,

http://www.3com.com/products/yr2000.html, as not meeting this standard. If it appears that any product that is

stated to meet this standard does not perform properly with regard to such date data on and after January 1, 2000,

and Customer notifies 3Com before the later of April 1, 2000, or ninety (90) days after purchase of the product from

3Com or its authorized reseller, 3Com shall, at its option and expense, provide a software update which would effect

the proper performance of such product, repair such product, deliver to Customer an equivalent product to replace

such product, or, if no ne of the foregoing is feasible, refund to Customer the purchase price paid for such product.

Any software update or replaced or repaired product will carry a Year 2000 Warranty for ninety (90) days after

purchase or until April 1, 2000, whichever is later.

®

9000 Enterprise Switch

O

BTAINING WARRANTY

S

ERVICE

Customer must contact a 3Com Corporate Service Center or an Authorized 3Com Service Center within the

applicable warranty period to obtain warranty service authorization. Dated proof of purchase from 3Com or its

authorized reseller may be required. Products returned to 3Com’s Corporate Service Center must be preauthorized

by 3Com with a Return Material Authorization (RMA) number or User Service Order (USO) number marked on the

outside of the package, and sent prepaid and packaged appropriately for safe sh ipment, and it is recommended that

they be insured or sent by a method that provides for tracking of the package. Responsibility for loss or damage does

not transfer to 3Com until the returned item is received by 3Com. The repaired or replaced item will be shipped to

Customer, at 3Com’s expense, not later than thirty (30) days after 3Com receives the defective product.

3Com shall not be responsible for any software, firmware, information, or memory data of Customer contained in,

stored on, or integrated with any products returned to 3Com for repair, whether under warranty or not.

Dead- or Defective-on-Arrival

workmanship within the first forty-eight (48) hours of installation but no later than thirty (30) days after the date of

purchase, and this is verified by 3Com, it will be considered dead- or defective-on-arrival (DOA) and a replacement

shall be provided by advance replacement. The replacement product will normally be shipped not later than three (3)

business days after 3Com’s verification of the DOA product, but may be delayed due to export or import procedures.

The shipment of advance replacement products is subject to local legal requirements and may not be available in all

locations. When an advance replacement is provided and Customer fails to return the original product to 3Com

within fifteen (15) days after shipment of the replacement, 3Com will charge Customer for the replacement p roduct,

at list price.

. In the event a product completely fails to function or exhibits a defect in materials or

Page 26

W

ARRANTIES EXCLUSIVE

L

IMITATION OF LIABILITY

Advance Replacement

will make commercially reasonable efforts to ship the replacement product not later than five (5) business days after

receiving the request for advance replacement, but may be delayed due to product availability or export or import

procedures. The shipment of advance replacement products is subject to local legal requirements and may not be

available in all locations. When an advance replacement is provided and Customer fails to return the original product

to 3Com within fifteen (15) days after shipment of the replacement, 3Com will charge Customer for the

replacement, at list price. This advance replacement is different from the fee-based Advance Har dware Repla cement

Service, which is available as a contracted s ervice offering.

INCLUDED SERVICES:

Telephone Support,

of purchase, on a commercially reasonable efforts basis. Please refer to the Technical Support appendix in the Getting

Started Guide for telephone numbers.

3Com’s Web and Bulletin Board Services

some software maintenance releases at no charge.

IF A 3COM P RODUCT DOES NOT OPERATE AS WARRANTED ABOVE, CU STOMER’S SOLE R EMEDY FOR BREACH OF

THAT WARRANTY SHALL BE REPAIR, REPLACEMENT, OR REFUND OF THE PURCHASE PRICE PAID, AT 3COM’S

OPTION. TO THE FULL EXTENT ALLOWED BY LAW, THE FOREGOING WARRANTIES AND REMEDIES ARE EXCLUSIVE

AND ARE IN LIEU OF ALL OTHER WARRANTIES, TERMS, OR CONDITIONS, EXPRESS OR IMPLIED, EITHER IN FACT OR

BY OPERATION OF LAW, STATUTORY OR OTHERWISE, INCLUDING WARRANTIES, TERMS, OR CONDITIONS OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, SATISFACTORY QUALITY, CORRESPONDENCE WITH

DESCRIPTION, AND NONINFRINGEMENT, ALL OF WHICH ARE EXPRESSLY DISCLAIMED. 3COM NEITHER ASSUMES

NOR AUTHORIZES ANY OTHER PERSON TO ASSUME FOR IT ANY OT HER LIABILITY IN CON NECTION WITH THE SALE,

INSTALLATION, MAINTENANCE, OR USE OF ITS PRODUCTS.

3COM SHALL NOT BE LIABLE UNDER THIS WARRANTY IF ITS TESTING AND EXAMINATION DISCLOSE THAT THE

ALLEGED DEFECT OR MALFUNCTION IN THE PRODUCT DOES NOT EXIST OR WAS CAUSED BY CUSTOMER’S OR

ANY THIRD PERSON’S MISUSE, NEGLECT, IMPROPER INSTALLATION OR TESTING, UNAUTHORIZED ATTEMPTS TO

OPEN, REPAIR, OR MODIFY THE PRODUCT, OR ANY OTHER CAUSE BEYOND THE RANGE OF THE INTENDED USE, OR

BY ACCIDENT, FIRE, LIGHTNING, POWER CUTS OR OUTAGES, OTHER HAZARDS, OR ACTS OF GOD.

TO THE FULL EXTENT ALLOWED BY LAW, 3COM ALSO EXCLUDES FOR ITSELF AND ITS SUPPLIERS ANY LIABILITY,

WHETHER BASED IN C ONTRACT OR TORT (INCLUDING NEGLIGENCE), FOR INCIDENTAL, CONSE QUENTIAL,

INDIRECT, SPECIAL, OR PUNITIVE DAMAGES OF ANY KIND, OR FOR LOSS OF REVENUE OR PROFITS, LOSS OF

BUSINESS, LOSS OF INFORMATION OR DATA, OR OTHER FINANCIAL LOSS ARISING OUT OF OR IN CONNECTION

WITH THE SALE, INSTA LLATION, MAINTENA NCE, U SE, PERFORMA NCE, FAILURE, OR INTERRU PTION OF ITS

PRODUCTS, EVEN IF 3C OM OR ITS AUTHORIZED RESELLER H AS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGE S, AND LIMITS ITS LI ABILITY TO RE PAIR, REPLA CEMENT, OR R EFUND OF THE PURCHASE PR ICE PAID, AT

3COM’S OPTION. THIS DISCLAIMER OF LIABILITY FOR DAMAGES WILL NOT BE AFFECTED IF ANY REMEDY

PROVIDED HEREIN SHALL FAIL OF ITS ESSENTIAL PURPOSE.

is provided for ninety (90) days, after which time it may be available for a specified fee. 3Com

with coverage for basic troubleshooting only, will be provided for ninety (90) days from the date

provide 3Knowledgebase, bug tracking, documentation, release notes, and

D

ISCLAIMER

G

OVERNING LAW

Some countries, states, or provinces do not allow the exclusion or limitation of implied warranties or the limitation of

incidental or consequential damages for certain products supplied to consumers, or the limitation of liability for

personal injury, so the above limitations and exclusions may be limited in their application to you. When the implied

warranties are not allowed to be excluded in their entirety, they will be limited to the duration of the applicable

written warranty. This warranty gives you specific legal rights which may vary depending on local law.

This Limited Warranty shall be governed by the laws of the State of California, U.S.A., excluding its conflicts of laws

principles and excluding the United Nations Convention on Contracts for the International Sale of Goods.

3Com Corporation

, 5400 Bayfront Plaza, P.O. Box 58145, Santa Clara, CA 95052-8145 (408) 326-5000

Page 27

E

MISSIONS COMPLIANCE

S

TATEMENTS FOR CLASS

P

RODU CTS

Federal Communications

Commission Notice

Canadian Emissions

Requirements

VCCI Class A Compliance

A

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC rul es. These limits are designed to provide reasonable protection against harmful interferen ce when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at his or her own expense.

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du

Canada.

This is a Class A product based on the standard of the Voluntary Control Council for Interference by Information

Technology Equipment (VCCI). If this equipment is used in a domestic environment, radio disturbance may arise.

When such trouble occurs, the user may be required to take corrective actions.

EMC D

S

TATEMENT

EMC Directive Compliance This equipment was tested and found to conform to the Council Directive 89/336/EEC for electromagnetic

LOW V

OLTAGE DIRECTIVE

S

TATEMENT

G

ENERAL APPROVAL

S

TATEMENT FOR

UK General Approval Statement This equipment is manufactured to the international Safety Standard EN60950 and is approved in the UK under the

A

USTRALIAN

F

RAMEWORKS STATEMENT

Australian EMC Frameworks

IRECTIVE

Low Voltage Directive

Compliance

UK

EMC

Compliance

compatibility. Conformity with this Directive is based upon compliance with the following harmonized standards:

EN 55022 Limits and Methods of Measurement of Radio Interference

EN 50082-1 Electromagnetic Compatibility Generic Immunity Standard:

Residential, Commercial, and Light Industry

Warning

: This is a Class A product. In a domestic environment, this product may cause radio interference, in which

case you may be required to take adequate measures.

This equipment was tested and found to conform to the Council Directive 72/23 /EEC for safety of electrical

equipment. Conformity with this Directive is based upon co mpliance with the following harmonized standard:

EN 60950 Safety of Information Technology Equipment

General Approval Number NS/G/12345/J/100003 for indirect connection to the public telecommunication network.

This product conforms to the EMC Frameworks and meets the Class A limits of AS3548.

Page 28

3Com Corporation

5400 Bayfront Plaza

Santa Clara, California

95052-8145

Copyright © 1999, 3Com Corporation. All rights reserved. No part of this documentation may be reproduced in

any form or by any means or used to make any derivative work (such as translation, transformation, or

adaptation) without written permission from 3Com Corporation. 3Com Corporation reserves the right to revise

this documentation and to make changes in content from time to time without obligation on the part of

3Com Corporation to provide notification of such revision or change.

3Com Corporation provides this documentation without warranty, term, or condition of any kind, either implied

or expressed, including, but not limited to, the implied warranties, terms, or conditions of merchantability,

satisfactory quality, and fitness for a particular purpose. 3Com may make improvements or changes in the

product(s) and/or the program(s) described in this documentation at any time.

3Com registered trademarks are registered in the United States and may or may not be registered in other

countries. 3Com, the 3Com logo, and CoreBuilder are registered trademarks of 3Com Corporation.

All other company and product names may be trademarks of the respective companies with which they are

associated.

http://www.3com.com/

Part No. 10013072

Published August 1999

Loading...

Loading...