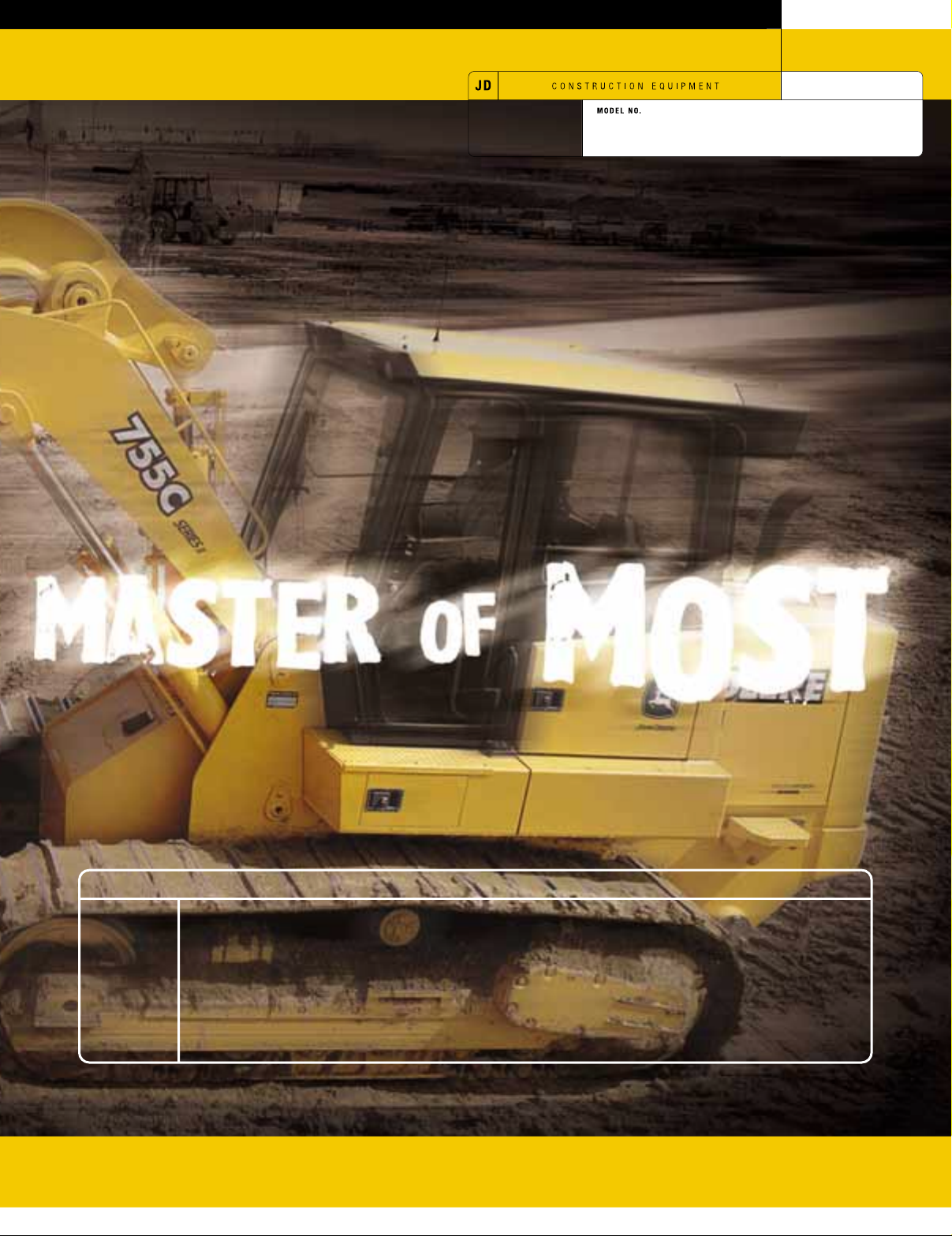

John Deere 755C-II, 655C-ll Specifications

C SERIES II

MODEL NO.

CONSTRUCTION EQUIPMENT

CRAWLER LOADERS

655C-II 755C-II

Introducing two good machines made great: the 655C and 755C Series II. These new-

and-improved loaders feature significant, contractor-driven enhancements including an

optimized power management system, more responsive steering, an increased low speed

range, and several design changes to enhance operator comfort and convenience. All of

this added to an already popular pair of hydrostatic loaders known for impressive breakout

force, tipping load capacities, and unsurpassed maneuverability. Read on for details.

2-3

KEY SPECIFICATIONS

655C-ll

755C-ll

NET HP

130

177

33,950

46,300

OPERATING WEIGHT

2.35 cu. yd.

3.14 cu. yd.

STANDARD BUCKET

27,675 lbs.

37,080 lbs

BREAKOUT FORCE

23,086 lbs.

30,418 lbs.

STATIC TIPPING LOAD

CRAWLER LOADERS

655C-II 755C-II

KEY SPECIFICATIONS

655C-ll

755C-ll

NET HP

130

177

33,950

46,300

OPERATING WEIGHT

2.35 cu. yd.

3.14 cu. yd.

STANDARD BUCKET

27,675 lbs.

37,080 lbs

BREAKOUT FORCE

23,086 lbs.

30,418 lbs.

STATIC TIPPING LOAD

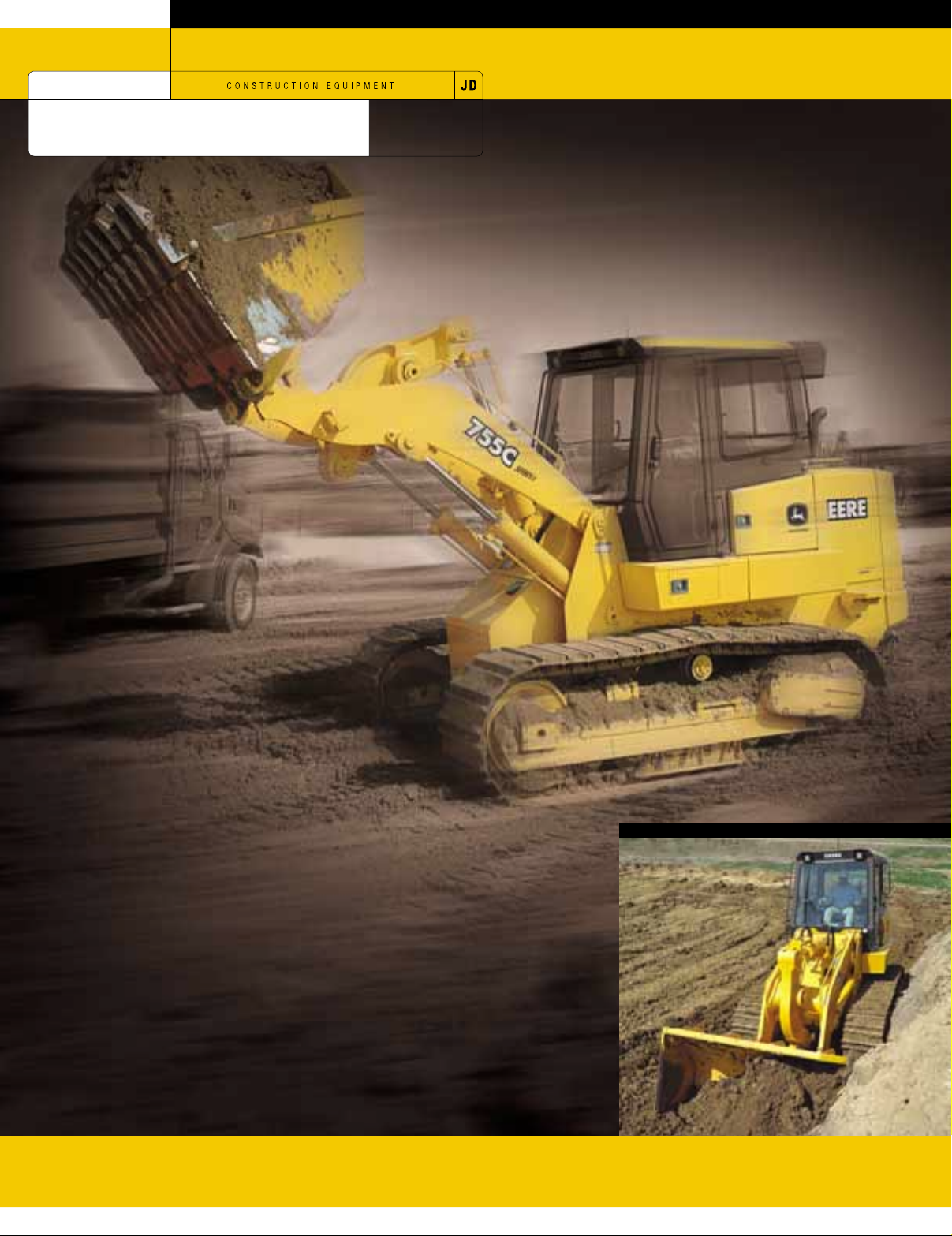

Multi-tasking

made easier

For more than 25 years, full-featured hydrostatic drivetrains have

provided John Deere crawler owners with unsurpassed operating

ease and flexibility. Now with our new optimized power management

system, you’ll feel more power when you need it, and an overall better

engine/tranmission performance match. That means track motion

remains steady while delivering strong pushing power.

We’ve enhanced hydraulic response for

faster boom, bucket cycle times, and

improved metering during fine grading.

DRIVETRAIN

CRAWLER LOADERS

Just set maximum desired ground speed

and the crawler does the rest. As the loads

change, the drivetrain responds, automatically

powering up or down to maintain peak engine

rpm and efficiency.

Innovative control system keeps

these loaders tracking straight

in either direction or on level

ground or steep slopes. Delivers

smooth, predictable turns under

full load, too.

Variable ground speeds from standstill to

6.8 mph and full power turn capability give

an operator total control

— for confidence

around critical structures.

Low-speed working range was increased to 4 mph

to allow most performance needs to be met in one

speed setting for faster cycle times.

Counterrotation is another advantage that’s especially

helpful for overcoming corner loads and for quickly

repositioning the bucket on-the-go. Or use it for

space-saving spot turns.

4-5

Loading...

Loading...