John Deere AT-3106-J User Manual [en, es, fr]

1/2-Inch Pistol Impact Wrench Operator's Manual 1

CAUTION

RISK OF INJURY!

READ MANUAL BEFORE OPERATING!

THIS MANUAL IS AN IMPORTANT PART OF THE IMPACT WRENCH

AND SHOULD REMAIN WITH THIS UNIT WHEN YOU SELL OR RENT IT.

AT-3106-J

1/2-INCH PISTOL

IMPACT WRENCH

2 1/2-Inch Pistol Impact Wrench Operator's Manual

Congratulations on the purchase of your new John Deere 1/2-Inch Pistol Impact Wrench!

You can be assured your impact wrench was constructed and designed with quality and

performance in mind. Each component has been rigorously tested to ensure the highest

level of acceptance.

The John Deere 1/2-Inch Pistol Impact Wrench is designed for a wide variety of

applications where access to recessed areas is required. This unit features a built-in-power

regulator for convenient output adjustment and a ring type socket retainer for quick and

easy socket removal.

This operator's manual was compiled for your benefit. By reading and following the simple

safety, installation, operation, maintenance and troubleshooting steps described in this

manual, you will receive years of trouble-free operation from your new heavy duty impact

wrench. The contents of this manual are based on the latest product information available

at the time of publication. The manufacturer reserves the right to make changes in price,

color, materials, equipment, specifications or models at any time without notice.

Once the unit has been removed from the box, immediately write in the serial number of your

unit in the space provided below.

SERIAL NUMBER_________________________________

Inspect for signs of obvious or concealed freight damage. If damage does exist, file a claim

with the transportation company immediately. Be sure that all damaged parts are replaced

and that the mechanical problems are corrected prior to operation of the unit. If you require

service, contact your Customer Service.

Mi-T-M

®

Corporation, 8650 Enterprise Drive, Peosta, IA 52068

1-877-JD-KLEEN / (1-877-535-5336) Fax 563-556-1235

Monday - Friday 8:00 a.m. - 5:00 p.m. CST

Please have the following information available for all service calls:

1. Model Number

2. Serial Number

3. Date and Place of Purchase

Introduction

1/2-Inch Pistol Impact Wrench Operator's Manual 3

Table of Content

INTRODUCTION ..................................................................................................... 2

TABLE OF CONTENTS ..........................................................................................

3

SAFETY ..................................................................................................................4-6

RECOGNIZE SAFETY INFORMATION ..................................................4

UNDERSTAND SIGNAL WORDS ...........................................................4

READ OPERATING INSTRUCTIONS ....................................................

4

ALWAYS WEAR APPROVED EYE PROTECTION .................................

5

HEARING PROTECTION IS RECOMMENDED .....................................5

WEAR RESPIRATORY PROTECTION .. ............................................... 5

AVOID PROLONGED EXPOSURE TO VIBRATION ..............................6

90 PSIG MAXIMUM ................................ ...............................6

USE ONLY IMPACT SOCKETS AND ACCESSORIES ...........................

6

INSTALLATION .......................................................................................................

7

RECOMMENDED AIR LINE SET-UP ......................................................7

OPERATION ...........................................................................................................

8

MAINTENANCE ......................................................................................................8

TROUBLESHOOTING ............................................................................................9

SPECIFICATIONS ...................................................................................................

9

STATEMENT OF WARRANTY ...............................................................................10-11

FRENCH ..................................................................................................................12-21

SPANISH .................................................................................................................

22-31

4 1/2-Inch Pistol Impact Wrench Operator's Manual

READ OPERATING INSTRUCTIONS

Always become familiar with all the instructions and

warnings before operating any pneumatic tool.

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol on

your pneumatic tool or in this manual, be alert to the potential

for personal injury.

Follow recommended precautions and safe operating prac-

tices.

UNDERSTAND SIGNAL WORDS

A "DANGER, WARNING or CAUTION" safety warning will be

surrounded by a "SAFETY ALERT BOX." This box is used to

designate and emphasize Safety Warnings that must be fol

-

lowed when operating this tool.

Accompanying the Safety Warnings are "signal words" which

designate the degree or level of hazard seriousness. The

"signal words" used in this manual are as follows:

DANGER

: Indicates an imminently hazardous situation

which, if not avoided, WILL result in

death or

serious injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, COULD result in

death or

serious injury.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided MAY result in minor or

moderate injury.

ALWAYS PROVIDE A COPY OF THIS MANUAL TO

ANYONE USING THIS EQUIPMENT. READ ALL

INSTRUCTIONS BEFORE OPERATING THIS TOOL

AND ESPECIALLY POINT OUT THE "SAFETY

WARNINGS" TO PREVENT THE POSSIBILITY OF

PERSONAL INJURY TO THE OPERATOR.

Safety

1/2-Inch Pistol Impact Wrench Operator's Manual 5

ALWAYS WEAR APPROVED EYE PROTECTION

Impact resistant eye protection should meet or ex-

ceed the standards as set forth in the United States

ANSI Z87.1, Occupational and Educational Eye and

Face Protection. Look for the marking Z87.1 on your

eye protection to insure that it is an approved style.

For further information, ANSI Z87.1, Occupational

and Educational Eye and Face Protection, is avail-

able from the American National Standards Institute,

Inc., 11 West 42nd Street, New York, NY 10036.

HEARING PROTECTION IS RECOMMENDED

Hearing protection should be used when the noise

level exposure equals or exceeds an 8 hour time-

weighted average sound level of 85 dBA. Process

noise, reflective surfaces, other tools being operated

nearby, all add to the noise level present in your

work area. If you are unable to determine your noise

level exposure, we recommend the use of hearing

protection.

WEAR RESPIRATORY PROTECTION

It is advisable, when using this tool for extended

periods of time, to wear a protective mask. This will

help prevent the inhalation of the fine dust produced

while using this tool. Prolonged breathing of dust

particles may lead to future respiratory problems.

Some dust created by power sanding, sawing,

grinding, drilling and other construction activities

contain chemicals known to cause cancer, birth

defects or reproductive harm. Some examples of

these chemicals are:

• Lead from lead-base paints

• Crystalline Silica from bricks, cement and other

masonry products.

• Arsenic and Chromium from chemically treated

lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals, work in a well

ventilated area and work with approved safety

equipment such as those dust masks that are

specially designed to filter out microscopic particles.

WARNING

6 1/2-Inch Pistol Impact Wrench Operator's Manual

AVOID PROLONGED EXPOSURE TO VIBRATION

Pneumatic tools can vibrate during use. Prolonged exposure

to vibration or very repetitive hand and arm movements, can

cause injury. Stop using any tool if discomfort, tingling feeling

or pain occurs. You should consult your physician before

resuming use of the tool.

90 PSIG MAXIMUM

Designed to operate at an air pressure of 90 pounds per square

inch gauge pressure (90 PSIG) maximum, at the tool. Use of

higher air pressure can, and may cause injury. Also use of higher

air pressure places the internal components under loads and

stresses they were not designed for, causing premature tool

failure.

NOTE: The air supply should be clean and dry, preferably

lubricated. For best results drain the moisture from your

compressor daily.

USE ONLY IMPACT SOCKETS AND ACCESSORIES

Only use sockets designated "For Use With Impact Wrenches."

Hand tool sockets can break creating a hazard from flying

pieces. Always check sockets, retainers and drives regularly for

wear or damage and replace when necessary.

WARNING

CAUTION

1/2-Inch Pistol Impact Wrench Operator's Manual 7

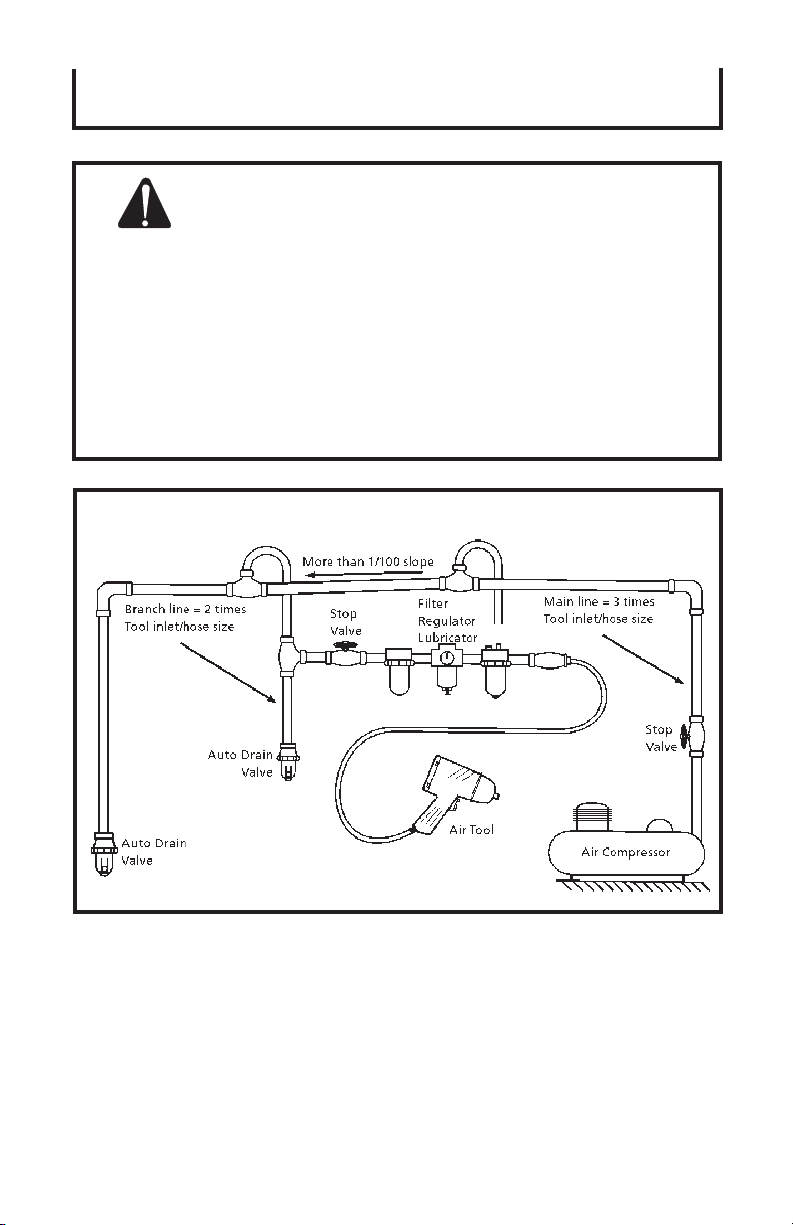

Always use clean dry air. Excessive moisture and dirt will greatly reduce the life of any

air motor. We recommend the installation of an in-line filter-regulator-lubricator as close

to the tool as possible.

A 3/8" air hose is required up to a length of 8 ft. If more length is required a 1/2" air

hose should be connected to the 3/8" hose to ensure the tool has the necessary air

supply. Be sure all hoses and fittings are the correct size and tightly secured.

Designed to operate on 90 PSIG, lower pressure (below

90 PSIG) will reduce performance of the tool while higher air

pressure (over 90 PSIG) raises the performance of the tool

beyond its rated capacity and could cause serious damage

to tool and user.

Installation

RECOMMENDED AIR LINE SET-UP

8 1/2-Inch Pistol Impact Wrench Operator's Manual

Maintenance

LUBRICATION:

An automatic in-line filter-regulator-lubricator is recommended as it increases tool life

and keeps the tool in sustained operation. The in-line lubricator should be regularly

checked and filled with air tool oil. Proper adjustment of the in-line lubricator is

performed by placing a sheet of paper next to the exhaust ports and holding the throttle

open approximately 30 seconds. The lubricator is properly set when a light stain of oil

collects on the paper. Excessive amounts of oil should be avoided.

The oil reservoir in the anvil housing should be checked every 40 hours of operation.

Remove the oil plug from the housing and hold tool so the oil port is lower than the anvil

housing. Drain oil. Measure and refill with approximately 1 oz. (30 ml) of John Deere

AT-4003 oil. Never overfill the anvil mechanism or excessive pressure will be created

reducing tool speed and power. If the tool becomes sluggish after adding oil, remove a

small amount of oil and check performance again.

In the event that it becomes necessary to store the tool for an extended period of time

(overnight, weekend, etc.), it should receive a generous amount of lubrication at that

time. The tool should be run for approximately 30 seconds to ensure oil has been

evenly distributed throughout the tool. The tool should be stored in a clean and dry

environment.

Recommended lubricants: Use John Deere AT-4003 air tool oil or any other high

grade turbine oil containing moisture absorbent, rust inhibitors, metal wetting agents

and an EP (extreme pressure) additive.

Operation

PRE-OPERATION:

Before the tool is connected to the air supply, clear the air hose of accumulated dust

and moisture. Before removing a tool for service or changing sockets, make sure the

air line is shut-off and drained of air. This will prevent the tool from operating if the

throttle is accidentally engaged.

OPERATION:

This impact wrench has a built-in-power regulator, which can be adjusted by turning

the valve counter-clockwise to increase and clockwise to decrease. The numbers on

the dial are only for reference and does not note a specific power output.

Once a bolt or fastener is seated, impacting for longer than five seconds will cause

excessive wear and damage to the impacting mechanism. If it takes longer than five

seconds to tighten your bolt or fastener, we recommend the use of a larger size impact

wrench.

CAUTION: ONLY USE SOCKETS DESIGNED FOR IMPACT

TOOLS. USING HAND TOOL SOCKETS CAN BE

HAZARDOUS AND MAY RESULT IN PERSONAL

INJURY. ALWAYS CHECK ACCESSORIES FOR

WEAR, CRACKS AND OTHER DEFECTS BEFORE

USE.

THE DESIGN OF THIS TOOL REQUIRES THAT

EXTRA CARE MUST BE TAKEN WHEN USING THE

WRENCH IN TIGHT AREAS. HANDS AND FINGERS

SHOULD NOT BE HELD BETWEEN TOOL AND

WORK SURFACE. PERSONAL INJURY MAY

RESULT.

1/2-Inch Pistol Impact Wrench Operator's Manual 9

Troubleshooting

Specifications

ITEM

Drive -----------------------------------------------------1/2"

Free Speed ---------------------------------------------10,000 RPM

Impacts per minute -----------------------------------1,700 IPM

Max. Torque range ------------------------------------

700 ft./lbs.

Length ---------------------------------------------------7"

Weight ---------------------------------------------------4 1/2 lbs.

Air inlet --------------------------------------------------1/4" NPT

Average air consumption ------------------- 18 CFM

Maximum operating pressure ----------------------90 PSI

Recommended Hose Size --------------------------3/8" I.D.

Loss of Power

1. Check air supply. For rated

performance, 90 PSI air

pressure is required at the

tool, with tool operating

2. Check for wet or dirty air.

Wet air tends to wash lubri

-

cant away. Dirt or foreign

matter will impede the action

of the motor. If dirt or water

has entered the tool, flush

with John Deere AT-4003.

3. Contact your customer

service.

1. Low air pressure

2. Improper lubrication or

dirt build up

3. Worn motor parts, or

other problems

Problem

Symptom

Solution

10 1/2-Inch Pistol Impact Wrench Operator's Manual

Limited Warranty

John Deere Two-Year Limited Warranty. John Deere Wrench,

Models covered in this manual, are warranted by John Deere to the

original user against defects in workmanship or materials under nor-

mal use for two years after date of purchase. Any part which is de

-

termined to be defective in material or workmanship and returned to

an authorized service location, as John Deere designates, shipping

costs prepaid, will be, as the exclusive remedy, repaired or replaced

at John Deere’s option. For limited warranty claim procedures,

see PROMPT DISPOSITION below. This limited warranty gives

purchasers specific legal rights which may vary from jurisdiction to

jurisdiction.

Limitation of Liability. To the extent allowable under applicable

law, John Deere’s liability for consequential and incidental damages

is expressly disclaimed. John Deere’s liability in all events is limited

to and shall not exceed the purchase price paid.

Warranty Disclaimer. John Deere has made a diligent effort to pro

-

vide product information and illustrate the products in this literature

accurately; however, such information and illustrations are for the

sole purpose of identification, and do not express or imply a warranty

that the products are merchantable, or fit for a particular purpose,

or that the products will necessarily conform to the illustrations or

descriptions.

Except as provided below, no warranty or affirmation of fact,

expressed or implied, other than as stated in the “LIMITED WAR

-

RANTY” above is made or authorized by John Deere.

Loading...

Loading...