Cub Cadet 53AH8ST5050, 53AH8ST3050 User Manual

Hydrostatic Zero-Turn

Commercial Riding Mower

Professional Turf Equipment

Tank Recon

48” Fabricated Deck

60” Fabricated Deck

OPERATOR’S AND SERVICE MANUAL

TABLE OF CONTENTS

Foreword. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Safety Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

A.Danger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

B. Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

C.Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

A. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

B. Related to Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

C.Related to Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

D. When Mowing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

E. Towing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

F.Operator Protection System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

G.Suspension Seat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

A. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

B. Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

C.Initial Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

D. Zero Turn Break-In and Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . 13

E. Mower Cutting Blades. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Maintenance and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

A. Cleaning your Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

B. Mower Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

C.Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

D. Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

E. Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

F.

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

G.Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

H.Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Performance Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

A. High Speed Tracking Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

B. Engine RPM Check and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

C.Deck Corner Ball Wheel Roller Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

D. Deck Center Anti-Scalp Roller Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

E Lap Bar Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

F Deck Leveling Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Slope Gauge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Warranty

This product may be covered by one or more of the following patents:

D409,208; 5,946,894; 6,070,690; 6,301,864; 6,662,538 Pending

2

FORWARD

The Tank Recon Hydrostatic Zero-Turn Commercial Riding Mower provides superb maneuverability, mid-mount cutting capability for professional landscapers, commercial lawn service

companies, professional turf managers and golf course superintendents. The machine incor

porates many safety features that should be studied by all operators and maintenance personnel before use. The list of safety precautions should receive particular attention.

This manual presents all of the operating and maintenance instructions necessary to keep

your mower at peak efficiency. If operated and maintained properly, your mower will give

dependable service.

CAUTION:

Only thoroughly trained persons should operate and maintain this mower. This

machine can cause serious injury to anyone who misuses it and does not understand

its operation. For their personal safety, all operators and maintenance personnel are

required to read this entire manual before operating the mower.

Hazard control and accident prevention are partially dependent upon the design and

configuration of the equipment. Notwithstanding, these factors are also dependent

upon the awareness, concern, prudence and proper training of the personnel involved

in the operation, transport, maintenance and storage of the equipment.

-

WARNING

• The engine exhaust, some of its constituents, and certain vehicle components contain or emit chemicals

known to the State of California to cause cancer, birth defects or other reproductive harm.

• This unit is equipped with an internal combustion engine and should not be used on or near any unimproved

forest-covered, brush-covered, or grass-covered land unless the engine’s exhaust system is equipped with a

spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

• In the State of California, the above is required by law (Section 4442 of the California Public Resources

Code). Other States may have similar laws. Federal laws apply to federal lands. A spark arrester muffler

may be available.

NOTE: The engine manufacturer is responsible for all engine-related issues with

regards to performance, power-rating, specifications, warranty and service.

Please refer to the engine manufacturer’s owner’s/operator’s manual,

packed seperately with your unit, for more information.

MODELS LISTED IN THIS MANUAL

23HP 48” Tank Recon, 25HP 60” Tank Recon,

53AH8ST3050 53AH8ST5050

3

GENERAL SAFETY

OPERATIONS

A. DANGER

1. Do not operate machine in confined areas

where exhaust gases can accumulate.

2. Do not operate machine without mower chute

deflector in place and operational.

3. Do not carry passengers.

4. Do not operate nor store machine in areas

where open flames, electrical switches and

circuit breakers are present.

B. WARNING

1. Do not operate machines under the influence

of alcohol or drugs.

2. Do not operate machines without all guards

and safety devices in place and functional.

3. Do not start machines if there are fuel or oil

leaks or spillage — clean it up.

4. Do not operate machines near spilled or leaking fuels.

5. Do not stop or park machine over dry leaves,

grass, debris, etc. that could be combustible.

6. Use extreme care when backing up.

7. Do not operate machine on slopes greater

than 15 degrees (27%).

8. Do not operate machines on slopes when

traction is reduced (wet grass, ice, soft

ground, loose ground, leaves, pine needles,

debris, etc.).

9. Avoid turning downhill if possible, go slowly

and use extra care when turning downhill.

10. Do not operate machines during reduce visibility (low light, fog, rain, etc.).

11. Do not operate machines with non-approved

attachments.

12. Do not operate machines that are dam-

aged.....have machine repaired.

13. Do not operate machines that have not been

properly maintained.

14. Use only replacement parts that are the same

or equivalent to the original equipment.

15. Do not modify machines or any of their components, especially the engine governor!

16. Do not operate machine for more than 2 hours

without hearing protection.

C. CAUTION

1. Use proper protective equipment when operating machine (gloves, boots, and hearing

protection are recommended).

2. Read entire machine Operator’s Manual.

3. Make sure operators are fully trained in the

safe use of the machine.

4. Follow all safety instructions when using the

machine.

5. Keep all safety signs legible and properly

installed.

6. Do not check for hydraulic leaks with any part

of the body.

7. Do not add fuel to a machine when the engine

is running and/or the exhaust system is hot.

8. Keep machine clean and free of debris, grass,

leaves, oil, grease, etc.

9. Place lap bars in neutral/start position, set

park brake, disengage P.T.O., turn engine off,

and remove ignition key before you dismount

from machine.

10. Use machines laterally or diagonally across

slopes, avoid going downhill when possible.

11. Go slowly and use extra care when descending slopes.

12. Disengage P.T.O. when crossing surfaces

such as asphalt, concrete, loose ground,

sand, gravel, etc.

13. Use extra care when loading and unloading

machines from trucks or trailers.

14. Equipment driven on public roads must comply with state & local ordinances, SAE J137,

and ANSI/ASABE S279.

SAFETY PRECAUTIONS

A. General

1. Read this Operator’s Manual before starting

the mower. Study the controls and learn the

proper sequence of operation.

2. Do not allow anyone to operate or maintain

this machine who has not read this manual.

Never permit children to operate this machine.

3. Never carry passengers.

4. Do not remove any shields, guards or safety

devices. If a shield, guard or safety device is

damaged or does not function, repair or

replace it before operating the mower.

5. Always wear safety glasses and safety shoes

when operating or maintaining this mower. Do

not wear loose-fitting clothing.

6. Disconnect the spark plug wires and remove

the key from the ignition to prevent the engine

from accidentally starting before performing

any maintenance on this mower.

7. Never run the engine indoors without adequate ventilation. Exhaust fumes are deadly.

8. To avoid serious burns, do not touch the

engine, exhaust pipe or muffler while the

engine is running or until it has cooled after it

has been shut off.

9. The liquid in the battery is dilute sulfuric acid.

Always wear safety glasses and rubber gloves

when working on the battery. Do not overfill

the battery.

10. Lead-acid batteries generate hydrogen and

oxygen gases which form an explosive mix

ture. Keep sparks and flames away at all

times.

-

4

11. When looking for oil leaks, never run your

hand over hydraulic hoses, lines or fittings.

Never tighten or adjust hydraulic hoses, lines

or fittings while the system is under pressure.

If high-pressure oil penetrates the skin, the oil

must be removed within a few hours by a doc

tor familiar with this form of injury or serious

complications may result.

B. Related to Fuel

1. Fuel is highly flammable and its vapors can

explode if ignited. Please respect it.

2. Do not smoke or permit others to smoke

while handling fuel.

3. Always use approved containers for fuel and

fill slowly to decrease the chance of static

electricity buildup and spillage.

4. Store fuel in well ventilated and unoccupied

buildings away from sparks and flames.

5. When dispensing gasoline into approved containers, place the container on the ground

when refueling to avoid a possible static elec

tricity ignition of fuel vapors.

6. Do not fill containers while it is inside a vehicle, trunk, the bed of a pickup or floor of a

trailer.

7. Always shut off the engine and permit it to

cool before removing the fuel tank cap.

8. Always fill the fuel tank outdoors away from

sparks and flames and any other ignition

source.

9. If the fuel container spout will not fit inside the

fuel tank opening, use a funnel.

10. When filling the fuel tank, stop when the fuel

reaches one inch from the top. This space is

necessary for fuel expansion.

11. Wipe up any spilled fuel.

12. Do not use gasoline fuel classified above

E-10 (I.E., E-15 through E-85) as it could

cause severe damage to the engine and fuel

system.

13. Do not re-fuel or store machine inside buildings where open flames, sparks or ignition

sources may be present, such as water

heater and furnaces.

Do not overfill

.

C. Related to Batteries

Batteries are stored electrical energy devices that

may be serviceable with removable caps (the electro

lyte levels can be checked), or may be non-serviceable (no attempt should be made to open the vents).

Batteries may contain lead (Pb) and sulfuric acid,

and they must be re-cycled and not disposed of nor

abandoned. Sulfuric acid can cause severe burns,

and in the event of contact, the areas should be

flushed with water and a physician contacted. Bat

tery cases should not be punctured. Lead is poison-

-

ous and is contained within the positive and negative

terminals as well as within the battery’s internal gridwork of plates and active materials.

Explosive gases are generated when batteries are

re-charged, so sparks, flames and heat sources

should be avoided. Loose connections at the battery

terminals can produce sparks and heat...connections

to the terminals must be kept tight, and the terminals

and battery surfaces kept clean of acids and corro

sion. If batteries are re-charged or “jumped” from

external sources, make sure that the connections are

made properly and in the correct sequence...connect

to the positive terminal of the good battery first, then

connect that to the positive terminal of the weak bat

tery. The third connection should be to the negative

terminal of the good battery, followed by the negative

terminal of the weak battery. If sparks are observed

or heating of the wiring or connectors is detected,

disconnect in reverse order (I.E., the negative termi

nal of the weak battery first). Batteries should be recharged at a constant voltage...generally 14.5 +/- 0.5

-

volts DC for a nominal 12 volt DC battery.

D. When Mowing

1. Keep adults, children and pets away from the

area to be mowed.

2. When operating this mower in the forward

direction, DO NOT allow the steering levers to

return to the neutral position on their own.

Always maintain a firm grip on the levers,

operate them smoothly and avoid any sudden

movements of the levers when starting or

stopping.

3. If the mower is equipped for side discharge,

never use the mower without the discharge

chute installed and placed in the down position.

4. Always remove debris and other objects from

the area to be mowed.(

grass will reduce traction.)

5. Mow only in daylight.

6. Watch for holes, sprinkler heads and other

hidden hazards.

7. Avoid driving too close to trees, creeks,

ditches, sand traps and other obstacles.

8. Before backing up, check behind you and

watch where you’re going.

9. Always reduce speed when making a turn,

and when grass is wet.

-

10. Always mow laterally or diagonally across

slopes, never up and down the slope. Do not

operate on steep slopes and slow down

before turning.

11. Be careful when crossing gravel paths or

roadways. Always turn off the blade clutch

switch and wait until the blades stop rotating

and raise the cutting deck to the transport

Note

: debris and loose

-

-

-

5

position. Always allow other vehicles to have

the right-of-way.

12. If you hit a solid object while mowing, turn off

the blade clutch switch, place the left and right

steering levers in the neutral position, move

the throttle to slow, set the parking brake, shut

off the engine and take the key from the igni

tion switch. Inspect for damage. Repair any

damage. Make sure the blades are in good

condition and that the blade bolts are tight

before restarting the engine.

13. Never leave the mower unattended without:

turning off the blade clutch switch; placing the

left and right steering levers in the neutral

position; moving the throttle to slow; setting

the parking brake; shutting off the engine and

taking the key from the ignition switch.

14. Never walk or stand on the discharge side of a

mower with the engine running. Turn off the

blade clutch switch if another person

approaches while you are operating the

mower.

15. Never attempt to operate the traction unit

without the mowing deck attached.

16. Keep the mower and especially the engine

and hydraulic components clean and free of

grease, grass and leaves to reduce the

chance of fire and to permit proper cooling.

E. Towing

1. Tow only with a machine that has an approved

hitch designed for towing. Do not attach towed

equipment except at the hitch point.

2. Follow the manufacturers recommendation for

weight limits for towed equipment and towing

on slopes.

3. Never allow children or others in or on towed

equipment.

4. On slopes, the weight of the towed equipment

may cause loss of traction and loss of control.

Note:

5. Travel slowly and allow extra distance to stop.

5 degrees (9%) maximum slope.

F. Operator Protection System

1. This machine is equipped with an Operator

Protective System (OPS), which includes:

a. A Roll Over Protective Structure (ROPS) or

Operator Protective Device (OPD) of the

fixed configuration

b. Seat belt assembly with retractable function

2. ROPS and OPDs are structures designed to

provide a crush-resistant space for the oper

ator when properly seat-belted within the

designated seating area of the machine in

the event of a machine tip-over or roll-over.

DANGER:

Damaged ROPS and OPDs must be replaced prior

to operator use!

3. Seat belts shall be used and shall be prop-

-

erly fastened about the operator’s waist at all

times, except when the ROPS or OPDs are:

a. not properly installed and/or not properly

secured onto the machine

b. damaged in such manner that their struc-

tural integrity has been compromised

4. Seat belts are attached to the movable portion of the seat when suspension seats are

utilized, and therefore the seat-mounting

base must be secured to its pivot means and

the pivot means latched to the frame of the

machine.

DANGER:

If ROPS and OPDs are missing, seat belts shall not

be fastened. Worn or damaged seat belt assem

blies must be replaced prior to operator use.

5. The ROPS and seat belt are integral parts of

this machine and should not be tampered

with, modified in any manner, or removed.

6. The ROPS extends behind the operator position, and therefore the operator must be

aware of potential contact of the ROPS with

items such as trees, buildings, doorways,

clothes lines, utility wires, etc., that could

cause the machine to upset or rollover....use

caution in (or avoid) areas where the ROPS

could come in contact with any structures,

trees, etc.

7. The ROPS and seat belt add additional mass

that elevates the machine’s Center of Gravity

(C.G.) which negatively affects the machine’s

stability and traction....use extra caution when

operating on slopes.

8. Inspect the ROPS and seat belt assemblies

on a regular basis for damage and improper

operation....replace all components that are

damaged or are not functioning properly with

authorized replacement parts.

9. Failure to use the seatbelt properly could

result in serious injury or death if an acciden

tal overturn occurs. In order for the ROPS to

be effective, the seat belt must be securely

fastened around the operator at all times

-

when the operator is on the machine. Contact

with the ROPS during an overturn could

cause serious injury or death.

10. The ROPS will not prevent the machine from

upsets or roll overs.

11. Only approved attachments should be used

on this machine.

-

-

6

G. Suspension Seat

1. This unit is equipped with a heavy-duty vinyl

fabric-covered seat incorporating adjustable

armrests, an adjustable seatback, an adjust

able fore/aft track, a weight/ride adjustable

mechanical suspension system, and an

Operator Presence Control (OPC).

2. An OPC in the form of a switch, is integrated

into the seat bottom and is connected to the

machine electrical system. The weight/ride

adjustment lever is located on the right side

of the seatback and incorporates three set

tings: light = 110 lbs, medium = 195 lbs, and

heavy = 286 lbs. Lever up is light and down is

heavy. Weight adjustment should be made

without the operator sitting in the seat. The

seatback recline adjustment is also on the

right side between the seat back and seat

bottom, and it provides up to 10 degrees.

3. The fore/aft single-locking adjustment tracks

operate on roller-bearings for smooth and

almost effortless operation. The lever for seat

track actuation is near the right front corner

of the seat bottom, and allows fore/aft adjust

ment of 4”.

4. The seat is attached to pivotal brackets,

which allow the seat assembly to pivot for

ward onto the foot platform area.

-

-

-

-

Note: The seat base must be secured by

properly latching to the frame, otherwise, the

seat assembly could tilt forward. The Operator

Presence Control must be connected to the

electrical wiring harness.

7

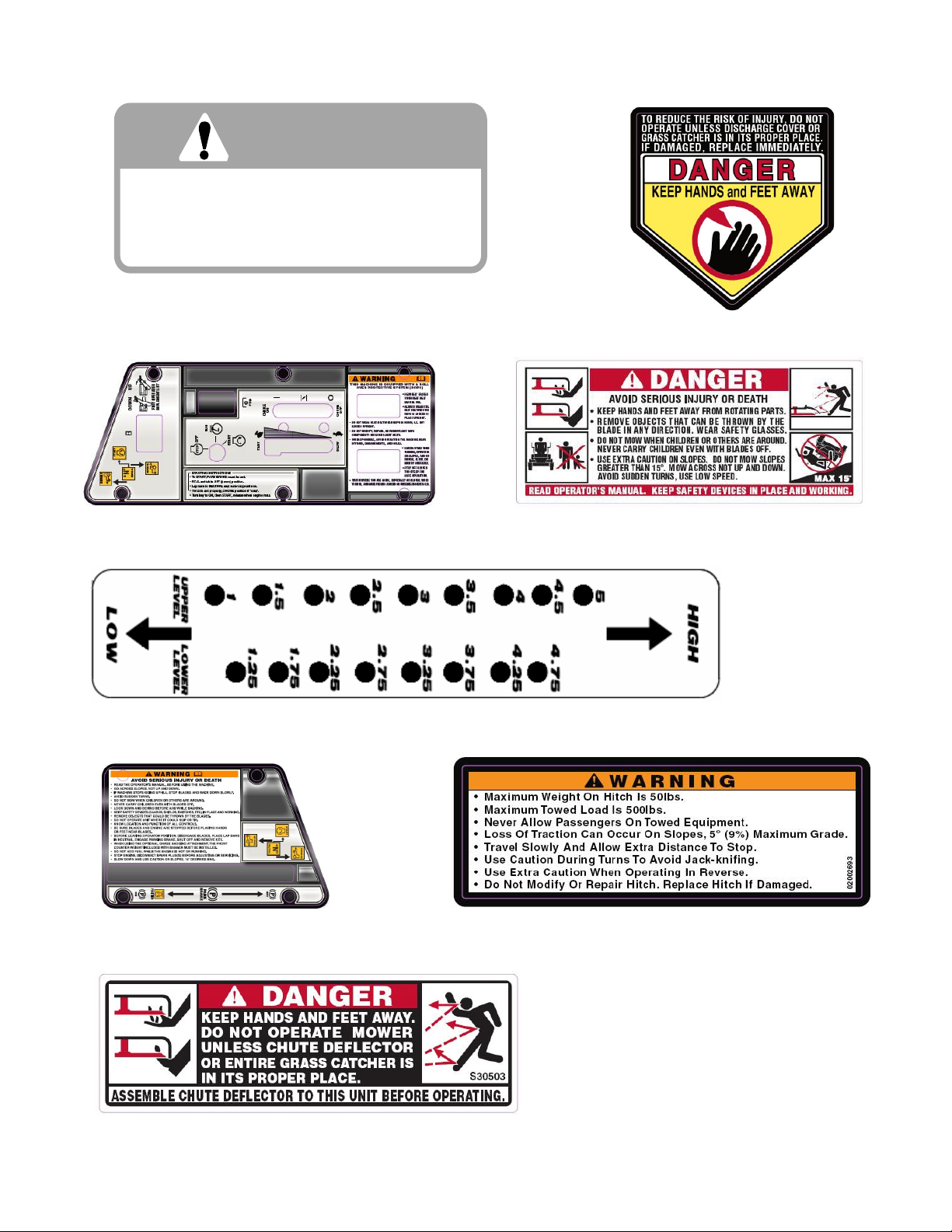

SAFETY DECALS AND LABELS

WARNING

SHIELD MISSING

DO NOT OPERATE

Part Number: 00030635

Part Number: 01002166

Part Number: 777S32801

Part Number: 02005146

Part Number: 777S32598

Part Number: 777S32797 Part Number: 02002693

Part Number: 777S30503

8

SPECIFICATIONS

GENERAL INFO.

Controls: Engine ignition and start switch; throttle; choke; left and right

steering levers; electric blade clutch switch; parking brake;

mower deck lift

Parking Brake: Mechanical linkage brake handle to internal drum brakes

Seat: Adjustable seat and armrests. 4" Adjustment (fore-aft)

Frame: 2" Steel structural tube and plate, all welded construction

Instrumentation Hour meter, Tachometer, Maintenance-minder

Front Caster Wheels: 13 x 5.0 - 6

Drive Wheels: 23 x 9.50 - 12

Tire Pressure: 8-10 psi Rear, 20-25 psi front caster

Fuel Tank: Two 5 gallon w/individual shutoff valves

Ground Speed: 0-9.5 + MPH forward. 0-4.5 MPH reverse

Net Weight: 955 lbs w/48" deck, 1035 lbs. w/60" deck

ENGINE INFO.

Engine: 23HP for 48” & 25HPKohler for 60”

Type: Vertical crankshaft air cooled V-Twin

Air Cleaner: Dual Paper Element with rain cap

Lube System: Pressurized with oil filter

Hydraulic System: In tank filter, 3 quart capacity

Starter: 12-volt electric

Blade Brake Clutch: Electric

TRACTION DRIVE INFO.

Traction Drive: DUP-10 variable-output hydraulic pump connected to individual

wheel motors

CUTTER DECK INFO.

Cutter Deck;Drive: 48", & 60" Belt Driven

Deck Lift: Foot lever w/pin lock for height adjustment

Cutting Height: 1" to 5" in 1/4” increments

No. of Blades 3, belt-driven, power take-off from engine

9

OPERATING INSTRUCTIONS

Figure. 1 Figure. 2

Engine throttle

Ignition Switch

Choke Lever

Electric Blade

Clutch Switch

Tach and

Hour Meter

A.General

1. When Mowing:

a. Keep adults, children, and pets away from the

area to be mowed.

b. When operating this mower, in the forward

direction, do not allow the steering levers to

return to Neutral on their own. Always main

tain a firm grip on the levers, operate them

smoothly and avoid any sudden movements of

the levers when starting and stopping.

c. If the mower is equipped for side discharge,

never use the mower without the discharge

chute installed and placed in the down posi

tion.

d. Always remove debris and other objects from

the area to be mowed (Note: debris and loose

grass will reduce traction).

e. Mow only in daylight.

f. Watch for holes, sprinkler heads, and other

hidden hazards.

g. Avoid driving too close to trees, creeks,

ditches, sand traps, and other obstacles.

h. Before backing up, check behind and watch

where you are going.

i. Always reduce speed when making a turn,

and when grass is wet.

j. Always mow laterally or diagonally across

slopes, never up and down the slope. Do not

operate on steep slopes and slow down

before turning. Avoid turning downhill if possi

ble, start at the bottom and work up to the top.

Use extra care and go slowly when turning

downhill. Control the speed and direction of

the zero turn machine “primarily” with the

speed/directional control (lap bar) of the

downhill side of the machine...I.E., maintain

the uphill side lap bar “essentially” in a fixed

position.

Parking Brake

k. Be careful when crossing gravel paths or

roadways. Always turn off the blade clutch

switch and wait until the blades stop rotating

and raise the cutting deck to the transport

position. Always allow other vehicles to have

the right of way.

-

-

-

l. If you hit a solid object while mowing, turn off

the blade clutch switch, place the steering

levers in the neutral position, move the throttle

to slow, set the parking brake, shut off the

engine, and take the key from the ignition

switch. Inspect for damage. Repair the dam

age. Make sure the blades are in good condition and that the blade bolts are tight before

restarting the engine.

m. Never leave the mower unattended without

observing the following: turn off the blade

clutch switch, placing the steering levers in the

neutral position, moving the throttle to slow,

setting the parking brake, shutting off the

engine and taking the key from the ignition

switch.

n. Never walk or stand on the discharge side of

the mower when the engine is running. Turn

off the blade clutch switch if another person

approaches while you are operating the

mower.

o. Never attempt to operate the traction unit with-

out having the mowing deck attached.

p. Keep the mower and especially the engine

and hydraulic components clean and free of

-

10

Loading...

Loading...