Page 1

OPMI Vario

®

Retrolux® System

Instructions for use

G-30-1721-en

Issue 1.0

Printed on 12. 03. 2008

Page 2

2

Key to symbols

Different symbols used in this manual draw your attention to safety aspects and useful tips. These symbols are explained in the following.

Warning!

The warning triangle indicates potential sources of danger which may

constitute a risk of injury for the user or a health hazard.

Caution:

The square indicates situations which may lead to malfunction, defects,

collision or damage of the system.

Note:

The hand indicates hints on the use of the system or other tips for the

user.

®

OPMI

GmbH

and Retrolux® are registered trademarks of Carl Zeiss Surgical

.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 3

Contents

3

– Key to symbols 2

Functions at a glance 7

– OPMI® VARIO 8

– S88 floor stand 10

Safety 13

– Notes on installation and use 15

– Phototoxic retinal injury in eye surgery 21

– Safety devices of the suspension systems 26

– Warning labels and notes 32

Description 37

OPMI Vario Retrolux System 38

– Intended use 38

– Components of the OPMI Vario Retrolux System 38

Components of the surgical microscope 40

– Controls, displays, connections 42

– Binocular tubes and eyepieces 50

– Retrolux illumination module 54

Components of the S88 floor stand 56

– Description of the modules 57

– Design 58

– Display field with control keys 60

– Lamp housing with xenon light source 62

– Suspension arm 68

– Stand base with column 70

– Connector panel 72

– Instrument tray (option) 74

– Video monitor (option) 76

Foot control panel (option) 84

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 4

4

– Intended use 84

– Design 84

– Foot control panel with 14 functions 86

– Foot control panel with 8 functions 87

Preparations 89

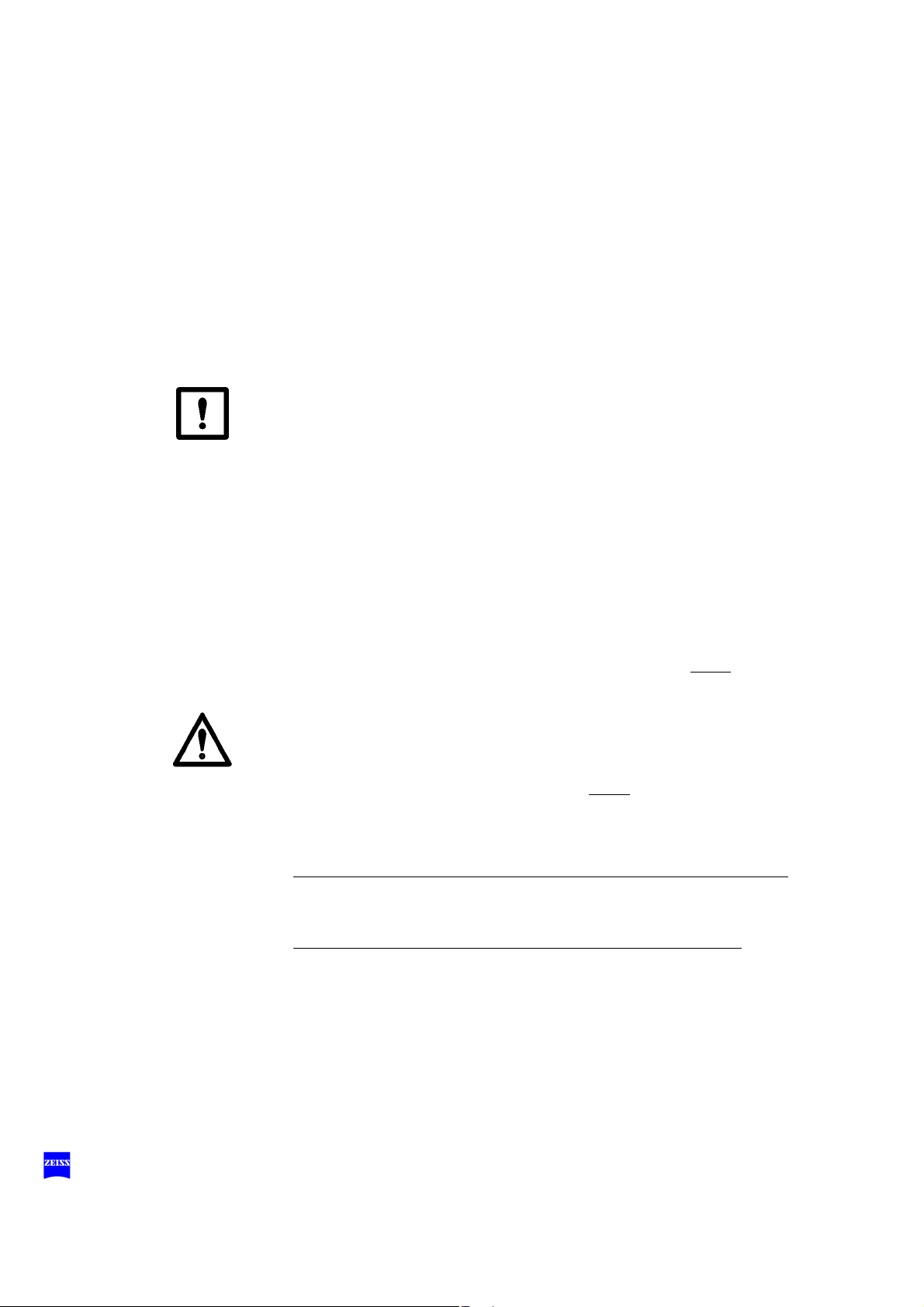

Attaching the equipment 90

– Mounting the surgical microscope 90

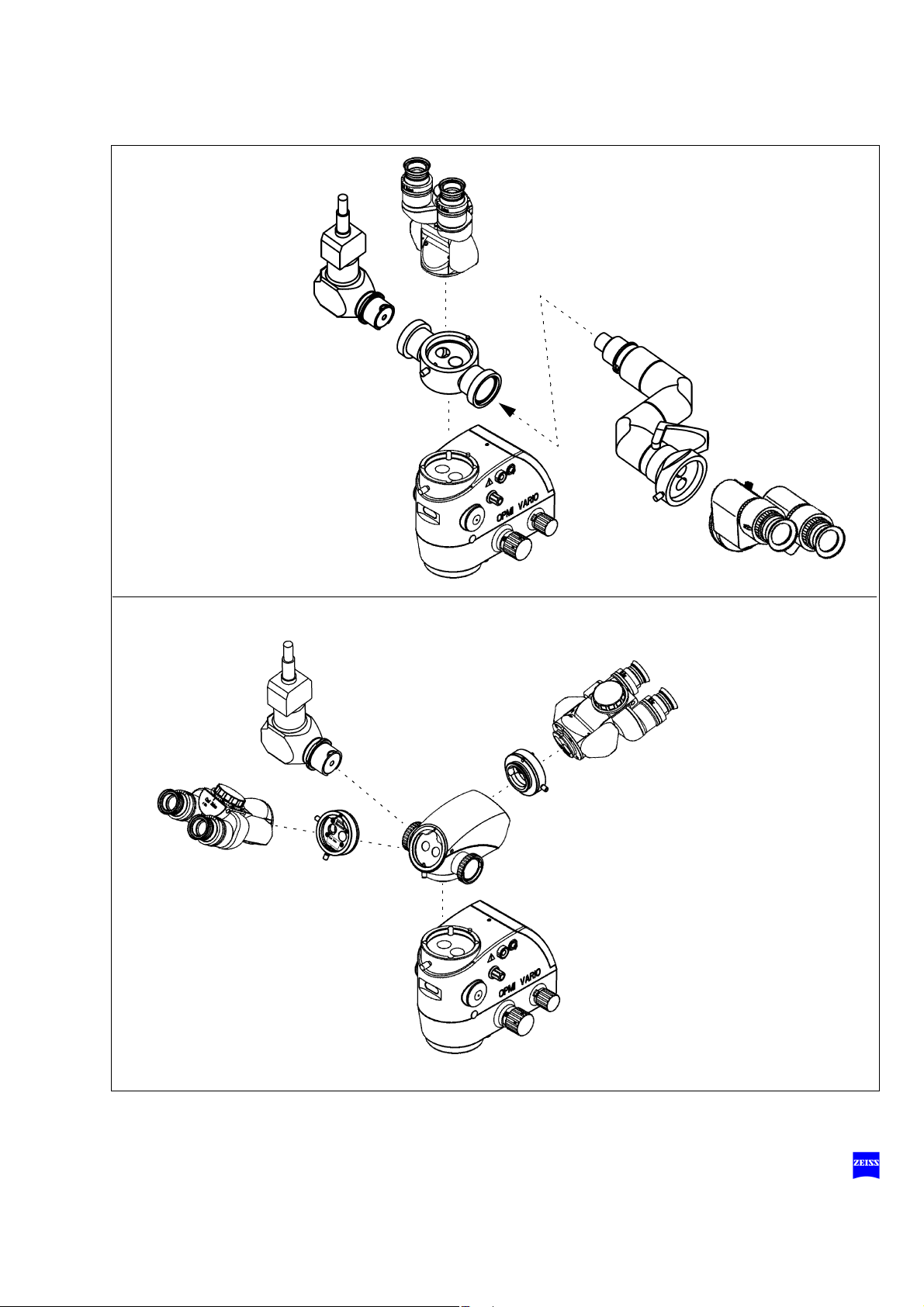

– Attaching accessories 92

– Mounting the tube and eyepieces 94

– Mounting the Retrolux illumination module 96

– Bringing the Retrolux illumination module into its standby position

100

– Attaching the fundus imaging system to the illumination module 102

Connections 104

– Connecting the surgical microscope 104

– Mounting the light guide 104

– Aligning the X-Y coupling 108

– Strain relief device on S88 floor stand 110

– Connecting the S88 floor stand 112

Adjusting the supension system 114

– Adjusting the balance setting of the suspension arm 114

– Adjusting the limit of downward movement 116

Balancing the surgical microscope 118

Settings on the control and display panel 120

– Adjusting the suspension system 120

Adjusting the surgical microscope 121

Surgical microscope with a laser micromanipulator 123

Relocating the system 126

Operation 129

Checklist 130

Positioning the S88 floor stand 134

Using the display and key field 136

– General functions 136

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 5

– OPMI Vario on the suspension system, user interface

with SpeedFokus option 140

Procedure 160

What to do in an emergency 162

– Failure of a xenon lamp 162

– Failure of lamp control 164

– Failure of the zoom function 165

– Failure of the focusing function 166

– Failure of magnetic brakes 167

Maintenance / Further information 169

– Trouble-shooting 170

– Changing the xenon lamp module 178

5

– Adjusting the monitor arm 180

– Magnifications / Fields of view 182

– Care of the unit 184

– Sterilization 185

– Disinfecting the control keys 186

– Ordering data 188

– Spare parts 190

– Accessories 191

– Disposal 193

Technical data 195

– Technical data of OPMI VARIO 197

– Technical data of S88 floor stand 198

– Ambient requirements 205

– CE conformity 205

– Changes to the system 205

Index 207

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 6

6

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 7

Functions at a glance 7

Functions at a glance

OPMI® VARIO 8

S88 floor stand 10

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 8

8 Functions at a glance

OPMI® VARIO

1 Adjusting the eyecup and the prescription page 52

2 Adjusting the interpupillary distance page 50

3 Adjusting the friction of vertical adjustment page 42

4 Recentering the X-Y coupling page 48

5 Adjusting the friction of the OPMI® axis of rotation page 48

6 Manual zoom setting page 44

7 Manual focusing page 44

8 Manual setting of the illuminated field diameter page 44

9 Connecting the light guide page 104

10 Balance setting of the microscope's

front-to-back tilt

11 Balance setting of the microscope's

lateral tilt

12 Motorized focusing page 46

13 Motorized zoom setting page 46

14 Display of the magnification factor of

the zoom system

15 Releasing the magnetic brakes page 46

16 Programmable release buttons page 46

17 Switching off the electrical drive of the

focusing system

18 Connecting the mouth switch page 42

page 42

page 42

page 42

page 44

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 9

Functions at a glance 9

5

186

1 23 4

78 11 12 13 14 15 16 17910

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 10

10 Functions at a glance

421 53

S88 floor stand

Xenon illumination system

1 Selecting a filter page 64

2 Manual activation of backup lamp page 62

3 Resetting the counter page 64

4 Opening the lamp module page 64

5 Red segment is lit - backup lamp is in use page 62

6 Control panel page 66

7 Lamp housing of xenon illumination system page 62

8 Unlocking the magnetic brakes of the suspension

system

9 Limiting the suspension arm's downward movement page 116

10 Removing/mounting the coupling for the

surgical microscope

11 Balance setting page 68

12 Locking the stand in position page 70

13 Locking the suspension arm in its horizontal position page 68

14 Connecting the foot control panel or hand switch,

connecting the remote control connector

15 Rated voltage display page 72

16 Connector panel page 72

17 Turning on the suspension system page 72

page 68

page 68

page 72

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 11

Functions at a glance 11

67 98

10 11

12 9 13 14 15, 16, 17

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 12

12 Functions at a glance

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 13

Safety

Safety 13

Notes on installation and use 15

Phototoxic retinal injury in eye surgery 21

Safety devices of the suspension systems 26

Warning labels and notes 32

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 14

14 Safety

The device described in this manual has been designed and tested in accordance with Carl Zeiss safety standards as well as German and international standards. This guarantees a high degree of instrument safety.

The system described in this user manual has been designed in compliance with the requirements of:

–EN –IEC –UL –CSA

In accordance with Directive 93/42/EEC for medical devices, the complete quality management system of the company Carl Zeiss Surgical

GmbH, 73446 Oberkochen, Germany, has been certified by DQS Deutsche Gesellschaft zur Zertifizierung von Managementsystemen GmbH, a

notified body, under registration number 250758 MP23.

– As per Directive 93/42/EEC, the unit is a Class I instrument.

– For USA: FDA classification Class I.

We would like to provide you with information about safety aspects which

must be observed when handling this device. This chapter contains a

summary of the most important information concerning matters relevant

to instrument safety.

Important safety information has been incorporated in this manual and is

marked with a warning triangle accordingly. Please give this information

your special attention.

The correct use of the system is absolutely vital for safe operation. Please

make yourself totally familiar with the contents of this manual prior to startup of the instrument. Please also observe the user manuals of any additional equipment. Further information is available from our service department or from authorized representatives.

• Please observe all applicable accident prevention regulations.

• The instrument must be connected to a special emergency backup

line supply in accordance with the regulations or directives which apply in your country.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 15

Safety 15

Notes on installation and use

Safe working order

• Do not operate the equipment contained in the delivery package in

– explosion-risk areas,

– the presence of inflammable anesthetics or volatile solvents such

as alcohol, benzine or similar chemicals.

• Do not station or use the instrument in damp rooms. Do not expose

the instrument to water splashes, dripping water or sprayed water.

• Switch off the unit at the power switch if you notice any smoke, sparks

or unusual noise. Do not use the unit until it has been repaired by our

service team.

• Do not place any fluid-filled containers on top of the instrument. Make

sure that no fluids can seep into the instrument.

• Do not force cable connections. If the male and female parts do not

readily connect, make sure that they are appropriate for one another.

If any of the connectors are damaged, have our service representative

repair them.

• Potential equalization: The instrument can be incorporated into potential equalization measures. For this purpose, contact our service department.

• Do not use a mobile phone in the vicinity of the equipment because

the radio interference can cause the equipment to malfunction. The effects of radio interference on medical equipment depend on a number

of various factors and are therefore entirely unforeseeable.

• Modifications and repairs on these instruments or instruments used

with them may only be performed by our service representative or by

other authorized persons.

• The manufacturer will not accept any liability for damage caused by

unauthorized persons tampering with the instrument; this will also forfeit any rights to claim under warranty.

• Over longer distances (e.g. removal, return for repair, etc), the instrument may only be transported in the original packaging or in special

return packaging. Please contact your dealer or the Carl Zeiss service

team.

• Use this instrument only for the applications described.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 16

16 Safety

• Only use the instrument with the accessories supplied. Should you

wish to use other accessory equipment, make sure that Carl Zeiss or

the equipment manufacturer has certified that its use will not impair

the safety of instrument.

• Only personnel who have undergone training and instruction are allowed to use this instrument. It is the responsibility of the customer or

institution operating the equipment to train and instruct all staff using

the equipment.

• Keep the user's manuals where they are easily accessible at all times

for the persons operating the instrument.

• Never look at the sun through the binocular tube, the objective lens or

an eyepiece.

• Do not pull at the light guide cable, at the power cord or at other cable

connections.

• This instrument is a high-grade technological product. To ensure optimum performance and safe working order of the instrument, its safety

must be checked once every 12 months. We recommend having this

check performed by our service representative as part of regular maintenance work.

If a failure occurs which you cannot correct using the trouble-shooting

table, attach a sign to the instrument stating it is out of order and contact our service representative.

• Observe the labels showing the symbol "Risk of crushing“!

Notes on EMC (electromagnetic compatibility)

The system meets the EMC requirements of IEC 60601-1-2. During use

of the system, the precautionary measures concerning EMC listed below

must be observed.

Only use accessories that have been approved by Carl Zeiss for this

system.

Do not use any portable or mobile high frequency communication devices

in the vicinity of the system, as this may lead to an impairment of its function.

The system complies with the limits for a Class A device concerning radio

frequency emission. However, the possibility of interference to high frequency receiving devices (e.g. TV sets or radios) being used in the surroundings cannot be ruled out. If interference of this type occurs, please

inform your Carl Zeiss Service.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 17

Safety 17

Connection of a laser micromanipulator

The link-up of a laser micromanipulator with the OPMI results in a medical

system for which the system manufacturer must meet the necessary requirements (approval, qualification, laser protection, etc.). Please note

the user manuals provided by the laser micromanipulator manufacturer

and laser manufacturer. Further information is available from our service

department or from authorized representatives.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 18

18 Safety

Connection of navigation systems (option)

The Carl Zeiss components "Surgical microscope on suspension system"

can be integrated into an external navigation system. An optional navigation interface is available.

• The manufacturer of the external navigation system (system supplier)

is responsible for the following:

– Confirmation that his navigation systems have been tested and

– Meeting all requirements (approval, qualifications, etc.) for the

– Provision of all accompanying documents required.

certified for operation with the respective Carl Zeiss surgical microscope on a suspension system in accordance with the requirements specified in the Carl Zeiss interface description "Navigation

Interface for Carl Zeiss Surgical Microscopes".

medical system created through coupling via the navigation interface.

– Ensuring that the navigation system is only connected by person-

nel who have undergone appropriate training and instruction.

– Contacting the local Carl Zeiss representative for any inquiries that

may arise.

– Implementation of a procedure that guarantees the calibration of

the surgical microscope which is absolutely vital for the use of the

Carl Zeiss components "Surgical microscope on suspension system" in combination with a connected navigation system.

This allows the calibrated surgical microscope combined with the

navigation system to be used like an optical pointer with a variable

length (corresponds to the working distance).

– Conducting complete functional testing, alignment and calibration

(landmark test) of the navigation system after every subsequent installation or exchange of navigation system components

– Incorporation of a regularly changing icon in the data injection dis-

play of surgical microscopes equipped with a data injection system, i.e. the "heartbeat" of the navigation system must be

constantly visible for the user to permit data transmission errors to

be immediately detected.

• To check the accuracy of the overall system, perform the test specified

by the navigation system manufacturer, e.g. the landmark test, also

using the surgical microscope. This allows you to ensure that the stereotactic data has been correctly generated and transmitted to the navigation system without errors.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 19

Safety 19

• Do not use any rotatable tube dovetail mounts when operating the surgical microscope with a connected navigation system. If mounts of this

type have been attached to the microscope, they must be carefully

locked in their central positions (tighten the knurled screw for rotation).

Requirements on the antenna design (non-Zeiss antennas)

• The antenna manufacturer must confirm that his antenna has been

tested and certified for operation with the respective Carl Zeiss surgical microscope on a suspension system in accordance with the requirements specified in the Carl Zeiss interface description

"Navigation Interface for Carl Zeiss Surgical Microscopes".

• The following requirements, in particular, apply to the antenna:

– The surgical microscope with accessories and the antenna must

not exceed the admissible total weight (see label or the chapter

"Technical data").

– The antenna must not project over the bottom edge of the micro-

scope body in the direction of the surgical field.

– The antenna must neither obstruct the movement and adjustability

of the accessories which can be used on the surgical microscope

(usually a stereo coobservation tube, a camera adapter, a face-toface tube for spinal surgery, a laser micromanipulator) nor collide

with these accessories.

– The antenna configuration must be implemented in such a way

that the localizer camera can always "see" the diodes or trackballs

when the surgical microscope and its accessories are in their usual

positions.

– When the system's internal antenna wiring is used, the EN60601-

1-2 standard (electromagnetic compatibility) must be complied

with.

– The output power of the LEDs or infrared LEDs (IRED) must al-

ways comply with the IEC 60825 laser safety standard, even in the

event of cable defects.

– The failure of one or several LEDs of the antenna may impair nav-

igation or lead to navigation failure. Take the necessary precautions.

Requirements for operation

• Our service representative or an expert authorized by us will install the

system. Please ensure that the following requirements are met for further operation:

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 20

20 Safety

– All connecting components (details in the user's manual) which are

– All cables and plugs are in perfect condition.

– The voltage set on the instrument corresponds to the rated line

– The power cord has been plugged into a power outlet which has a

– The power cord being used is the one designed for use with this

Before every use and after re-equipping the instrument

• Make sure that all ”Requirements for operation” are fulfilled.

• Go through the checklist.

relevant to system safety have been properly connected, and the

screw connections have been firmly tightened.

voltage on the site of installation.

properly connected protective ground contact.

system.

• Re-attach or close any covers, panels or caps which have been removed or opened.

• Pay special attention to warning symbols on the instrument (triangular

warning signs with exclamation marks), labels and any parts such as

screws or surfaces painted red.

• Do not cover any ventilation openings.

For every use of the instrument

General

• Never operate the system unattended.

• Avoid looking directly into the light source, e.g. into the microscope objective lens or a light guide.

• When the illumination is on, the light guide must be connected at both

ends. Otherwise there is a risk of fire or burn injuries.

• Make sure that the instrument has been switched off before you

change the xenon lamp module. When switched on, the ignition system generates high voltage.

• The xenon illumination system is a high-intensity light source which if used improperly - can cause thermal injury to skin or tissue. Keep

the exposed tissue moist and provide sufficient irrigation. Carefully

monitor the effects of the illumination on the tissue, in particular in the

following cases:

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 21

Safety 21

– during prolonged procedures on skin and tissue using objective

lenses with a short focal length (short working distance),

– during procedures on tissue with a low blood supply,

– with high brightness settings of the xenon lamp.

Warning!

Due to the high luminance of the xenon lamp and its light spectrum, which

resembles that of natural daylight, its use in ophthalmic applications is

only permissible in combination with the Retrolux illumination module.

• Any kind of radiation has a detrimental effect on biological tissue.This

also applies to the light illuminating the surgical field. Please therefore

reduce the brightness and duration of illumination on the surgical field

to the absolute minimum required.

• Using the locking pedal on the base, secure the stand in position.

Make sure that the stand is stable and cannot roll away.

After every use of the instrument

• Always use the main power switch of the instrument to turn it off.

• The main power switch must always be turned off when the instrument

is not in use.

Phototoxic retinal injury in eye surgery

General

1)-5)

Several papers

surgery have been published. A comprehensive review of these publications reveals five aspects of particular concern:

– Illumination characteristics (spectral composition)

– Illumination intensity

– Angle of illumination

– Focus of the light source

dealing with the problem of phototoxicity in ophthalmic

– Exposure time to light

In the following, comments on these aspects are given and a description

of how Carl Zeiss, as a manufacturer, makes allowance for them in its

systems.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 22

22 Safety

Illumination characteristics (spectral composition)

Studies on the exposure of the eye to light of varying spectral composition

date back to the early 1950s. These studies suggest that the potential

hazard of phototoxic injury to the patient's retina can be reduced by

blocking out the blue and ultraviolet light below a wavelength of 475 nm.

An important point to note here, however, is that the use of filters will inevitably change the perceived color of the light. For this reason, the physician may initially have to get used to the changed appearance of the anatomical structures.

Illumination intensity

The majority of researchers suggest that the surgeon should use the

lowest light intensity required at the patient's eye to guarantee good

viewing during surgery.

Carl Zeiss has addressed this aspect by providing its systems with a device for continuously varying the brightness of the light source. This permits the surgeon to optimally adapt the light intensity at the patient's eye

to the conditions existing in each case.

Angle of illumination

1)-4)

A number of publications

suggest that the microscope should be

tilted to reduce the exposure of the macula to direct illumination.

Carl Zeiss ophthalmic surgical microscopes are therefore equipped with

the following:

– Tilting mechanism for the microscope body

Focus of the light source

Studies show that injuries are likely to occur if the filament of the light

source is imaged on the patient's retina. The peak intensity of a filament

is considerably higher than that of an even and extended light source

such as a light guide.

This is the reason why Carl Zeiss uses fiber optic illumination in its surgical microscope systems.

Exposure time to light

According to some publications, the phakic and aphakic eye should not

be exposed to the light source longer than a few minutes. In all surgical

cases, the retinal exposure time depends on the type and duration of the

procedure and possible case complications. It is therefore recommended

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 23

Safety 23

in ophthalmic surgery to keep the light intensity as low as possible, or to

use a device which prevents the light from entering through the patient's

pupil. It is alsorecommended to make sure that the patient's eye is not additionally exposed to the light of surrounding light sources. This problem

has been solved by Carl Zeiss by the use of a retinal protection device that

can be swung into the illumination beam path of the Retrolux illumination

module.

Brightness control

The brightness control scale of our systems has a linear structure with

values ranging from 1 to 10. The stipulations of standard ISO/DDIS

15004-2:2006(E) result in maximum radiation exposure times for the different illumination configurations as specified in the table "Maximum radiation exposure times".

The microscope light source - like any bright light source - may present a

hazard to the patient's eye both in the form of immediately visible thermal

damage to the retina as well phototoxic chemical reactions which may

lead to photoretinitis. The factors which play an important role in determining the phototoxic risk are:

– Lamp brightness.

– Spectral distribution of the light (UV and blue are more dangerous

that longer wavelengths).

– Duration of direct exposure.

– Pupil size.

– Clarity of ocular media (infants and young children, for example,

may be at a higher risk).

– Phakic status of the eye (aphakic and pseudo-aphakic eyes with-

out UV and blue filtering IOLs are at a higher risk).

– Previous exposure to bright light such as retinal photography, es-

pecially within the last 24 hrs.

The following table is intended to provide the surgeon with a guideline in

determining the potential hazard. The data has been calculated for a

worst-case scenario of direct, uninterrupted exposure of an aphakic eye

with an 8 mm dilated pupil. The calculations are based on the recom-

6)

mended occupational health daily exposure limits as defined in

. A

safety factor of 10 has been used in determining these limits.

During cataract procedures, factors such as lenticular material, instruments such as the phaco handpiece, and movement of the eye provide

interruption of the exposure and would be expected to significantly

lengthen the time before photoretinits might be expected to occur.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 24

24 Safety

A prospective study 7) of the effects of microscope illumination during surgery did not reveal any phototoxic retinal injuries for procedure times of

up to 30 minutes if the calculated maximum recommended exposure time

was 150 seconds. However, it was also found that at the same brightness

setting, phototoxic retinal injury could be expected after approximately

100 min.

Carl Zeiss recommends the following measures in order to minimize phototoxic risk:

• Always use the lowest possible brightness setting.

• When working on the exterior eye, use the retinal protection device to

prevent light from entering the pupil, especially when the pupil is dilated.

• Turn off the microscope illumination system or cover the patient's eye

during pauses in surgery.

The following table shows the maximum radiation exposure to the xenon

illumination.

Maximum radiation exposure times

Illumination display scale Max. exposure time

2,5 3.4 minutes

5,0 1.5 minutes

7,5 1.0 minutes

10 0.8 minutes

Warning!

This exposure time must not be exceeded, as serious eye injury could

otherwise be caused by the xenon illumination.

Note:

A UV blocking filter is contained as a standard feature in the Retrolux illumination module on the microscope side.

This helps the surgeon to reduce the risk of phototoxic retinal injury in the

patient.

List of references

1)

H. Stiller, and B. Rassow, "Light hazards to the patient's retina from

ophthalmic instruments," Applied Optics-OT 30, 2187-2196 (1991).

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 25

Safety 25

2)

American Conference of Governmental Industrial Hygienists, "Documentation of the Threshold Limit Values for physical agents. 7th Edition,"

(American Conference of Governmental Industrial Hygienists, Cincinnati,

2001).

3)

S. G. Khwarg, F. A. Linstone, S. A. Daniels, S. J. Isenberg, T. A.

Hanscom, M. Geoghegan, and B. R. Straatsma, "Incidence, risk factors,

and morphology in operating microscope light retinopathy," Am. J. Ophthalmol. 103, 255-263 (1987).

4)

G. Kleinmann, P. Hoffman, E. Schechtman, and A. Pollack, "Microscope-induced retinal phototoxicity in cataract surgery of short duration,"

Ophthalmology 109, 334-338 (2002).

5)

ISO/FDIS 15004-2:2006(E) Optical instruments -- Fundamental requirements and test methods -- Part 2: Light hazard protection

6)

David Sliney, Danielle Aron-Rosa, Francois DeLori, Franz Fankhauser,

Robert Landry, Martin Mainster, John Marshall, Bernard Rassow, Bruce

Stuck, Stephen Trokel, Teresa Motz West, and Michael Wolffe, Adjustment of guidelines for exposure of the eye to optical radiation from ocular

instruments: statement from a task group of the International Commission

on Non-Ionizing Radiation Protection (ICNIRP) APPLIED OPTICS Vol.

44, No. 11, p 2162 (10 April 2005)

7)

Byrnes, G.A., Antoszyk, A.N., Mazur, D.O., Kao, T.C., Miller, S.A.,

Photic maculopathy after extracapsular cataract surgery. A prospective

study, 1992/05/01 Ophthalmology, VL - 99, IS - 5, SP - 731, EP - 737,

PB - Elsevier

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 26

26 Safety

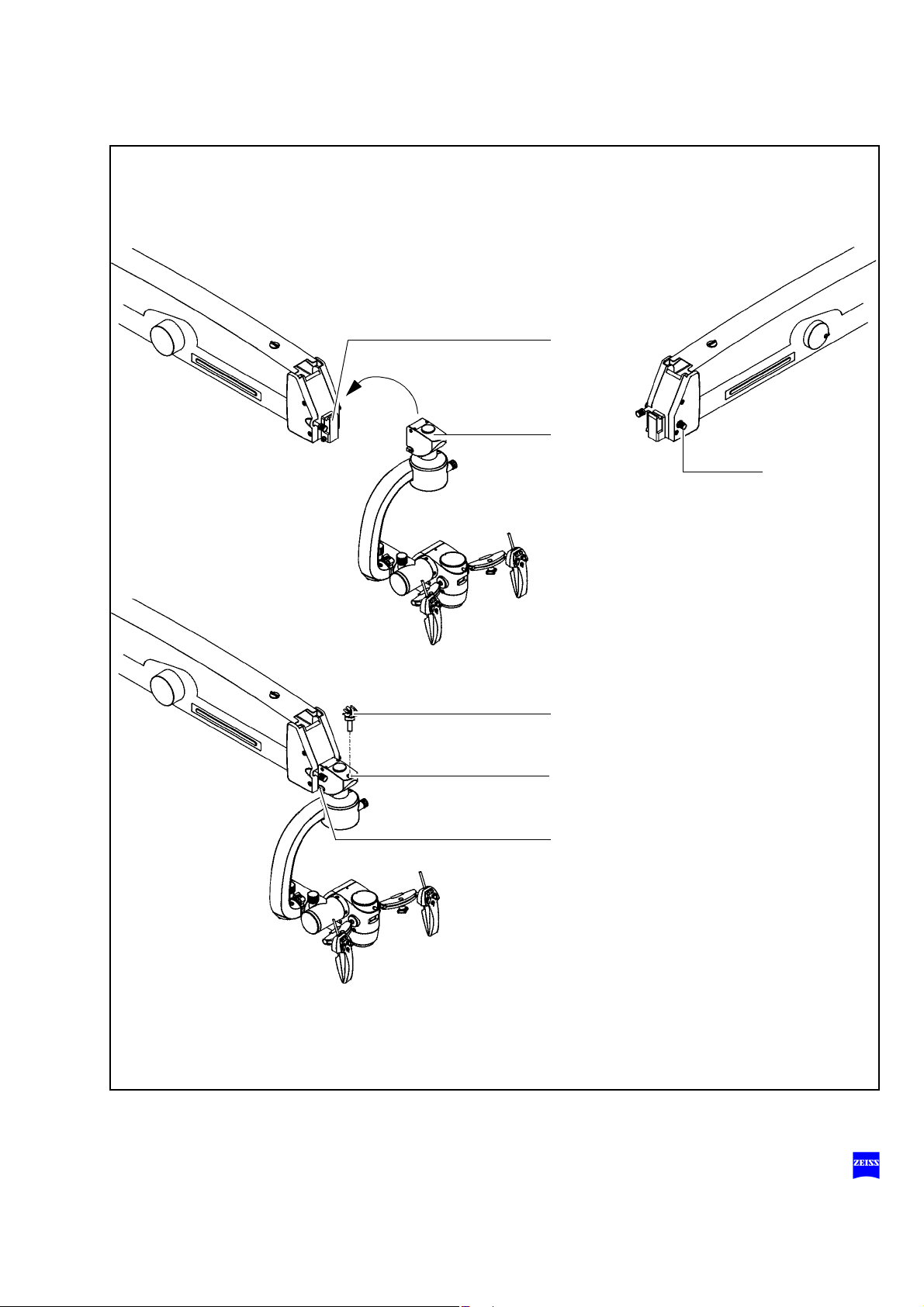

Safety devices of the suspension systems

1 Release bar

Allows non-sterile persons to release the magnetic brakes of the suspension system.

2 Adjustment screw for limiting the downward travel

Use this screw to set the minimum vertical distance (working distance)

from the surgical field. Check this setting before

dure.

3 Locking knob

for locking the suspension arm in its horizontal position.

Before removing or attaching a unit (microscope, tube, etc.), move the

suspension arm into a horizontal position. Pull out the locking knob

and turn it clockwise or counterclockwise through 180°, while slightly

moving the suspension arm up and down until the lock engages.

When locked, the suspension arm can no longer suddenly spring upward when insufficient weight is attached. After attaching a unit, perform the balancing procedure.

each surgical proce-

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 27

Safety 27

1

1

2

3

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 28

28 Safety

Xenon illumination system

Warning!

The xenon lamp has a limited service life of 500 h.

If used beyond its maximum service life, the xenon lamp may explode.

• Replace the xenon lamp in good time.

• Reset the service hour counter to "0" after replacing the lamp.

1 Switching to the backup bulb

The lamp module contains two xenon bulbs. The second bulb is used

as a backup bulb which must be swung into the illumination beam path

if the first bulb fails.

• If the xenon bulb fails, open the lamp module as follows: Press

button (7). The lamp module is slightly ejected.

• Pull out the lamp module as far as it will go.

• Turn knob (1) 180° until it snaps in place. This moves the backup bulb

into the illumination beam path.

• Push the lamp module all the way back into the lamp housing.

• Reset service hour counter (6) to "0". Use a pointed object and press

it into the recess of reset button (5).

2 Indicator: backup bulb is in use

When the red segment in the knob (1) lights up, the backup bulb is in

use.

Note:

If the first bulb has failed and the backup bulb is in use, make sure to

have a backup lamp module at hand as a precaution.

3 Yellow indicator lamp

Lights when the bulb has failed, or if the lamp module is defective.

After activation and ignition of the backup bulb, the yellow indicator

lamp turns off again.

4 Manual function

When the manual function has been activated, all electrical control

systems are disabled. The bulb brightness is automatically adjusted to

a fixed setting.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 29

Safety 29

3

4

7

1

2

25 6

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 30

30 Safety

Manual function

1 Manual key

The Manual key permits you to switch to manual operation. The motorized control functions of the surgical microscope are deactivated.

The lamp brightness is automatically adjusted to a fixed setting, the

value being shown in the first display section.

When the manual mode is activated, the yellow LED is lit and the word

"MANUAL" blinks in the third display section.

The surgical microscope can no longer be operated via the foot control

panel, the handgrips or the display and key field.

In the manual mode, you can only switch the illumination on and off on

the foot control panel and release the magnetic brakes by pressing the

appropriate key on the surgical microscope.

The manual mode is retained even if you turn the power switch of the

instrument off and on again.

Press the Manual key once again to reactivate electronic control; the

display in the display and key field then returns to the basic mode.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 31

Safety 31

1

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 32

32 Safety

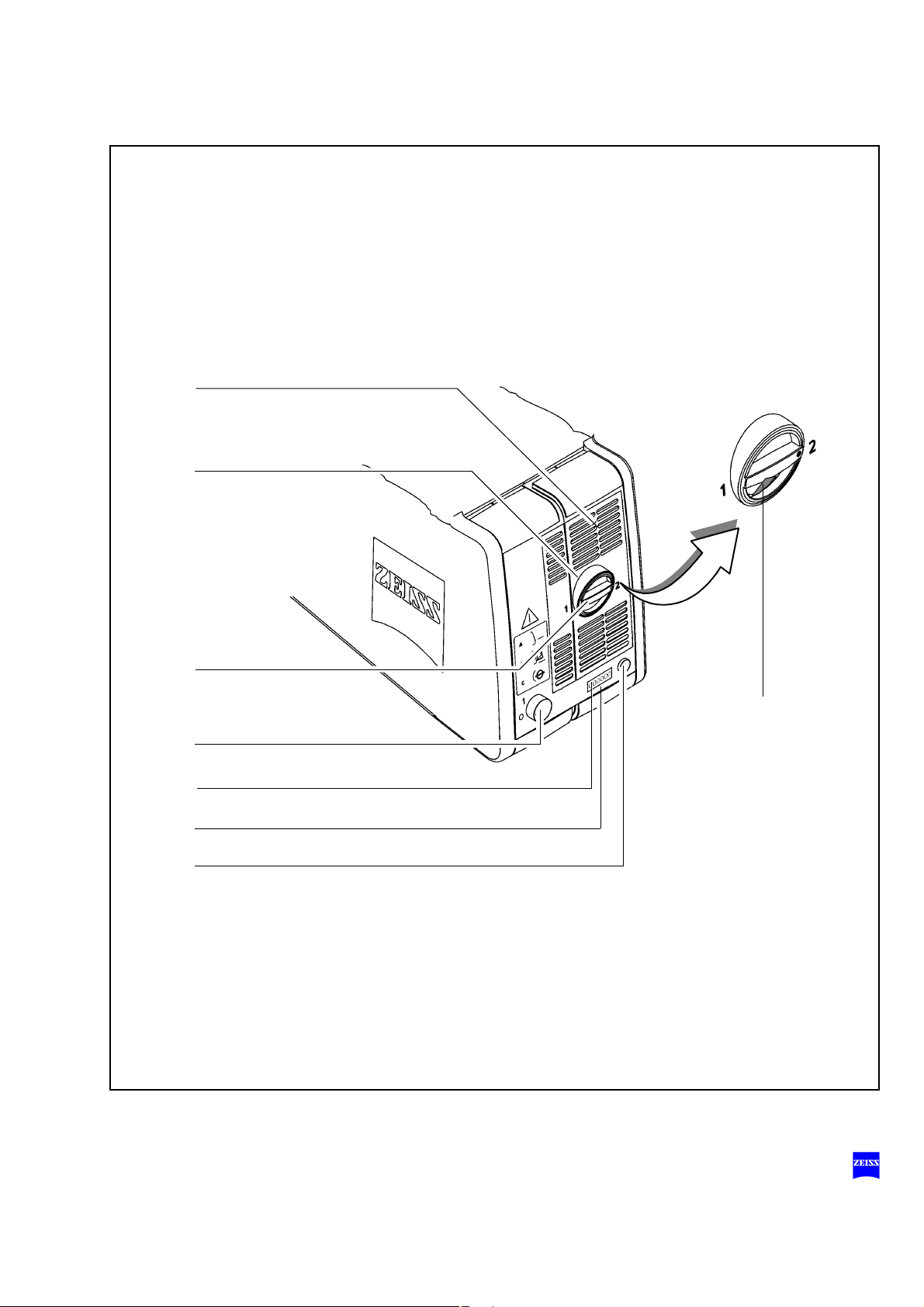

Warning labels and notes

Caution:

Observe all warning labels and notes!

If any label is missing on your instrument or has become illegible, please

contact us or one of our authorized representatives. We will supply the

missing labels.

OPMI VARIO

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 33

000000-0000-000

Safety 33

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 34

34 Safety

1

Suspension systems - xenon illumination system

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 35

Safety 35

176164

S88 floor stand

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 36

36 Safety

S88 floor stand with instrument tray option

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 37

Description

Description 37

OPMI Vario Retrolux System 38

Intended use 38

Components of the OPMI Vario Retrolux System 38

Components of the surgical microscope 40

Controls, displays, connections 42

Binocular tubes and eyepieces 50

Retrolux illumination module 54

Components of the S88 floor stand 56

Description of the modules 57

Design 58

Display field with control keys 60

Lamp housing with xenon light source 62

Suspension arm 68

Stand base with column 70

Connector panel 72

Instrument tray (option) 74

Video monitor (option) 76

Foot control panel (option) 84

Intended use 84

Design 84

Foot control panel with 14 functions 86

Foot control panel with 8 functions 87

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 38

38 Description

OPMI Vario Retrolux System

Intended use

The OPMI® VARIO Retrolux System is a surgical microscope designed

for reconstructive and plastic surgery, for neurosurgery and multidisciplinary use. In combination with the Retrolux illumination module, it can also

be used for ophthalmic procedures.

The S88 floor stand powers and controls the motorized functions of the

surgical microscope. The hallmarks of the S88 floor stand are its superb

mobility and easy operation. Four steerable casters on the stand base

permit easy positioning in the OR. The motorized functions of the surgical

microscope can be controlled using a foot control panel.

The system has been designed for use in hospitals, clinics or other human

medicine institutions.

The system must only be operated by physicians, nurses and other OR

staff who have undergone appropriate training and observe the instructions of the user's manual. The installation conditions and the use of the

system must meet microsurgical requirements:

– low vibration

– clean environment

– avoidance of extreme mechanical stress.

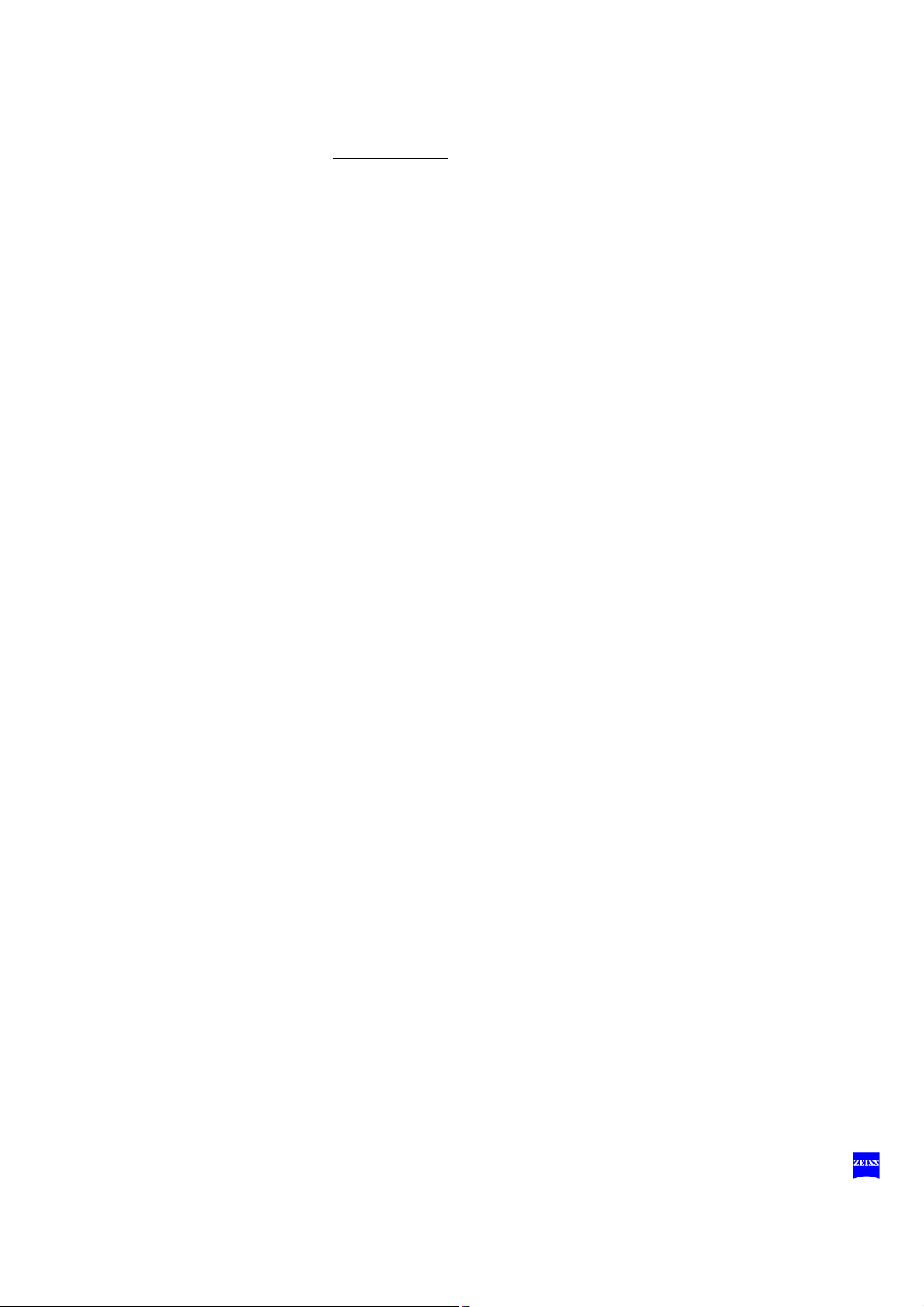

Components of the OPMI Vario Retrolux System

1 Surgical microscope

2 Coupling

3 S88 floor stand

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 39

Description 39

3

2

1

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 40

40 Description

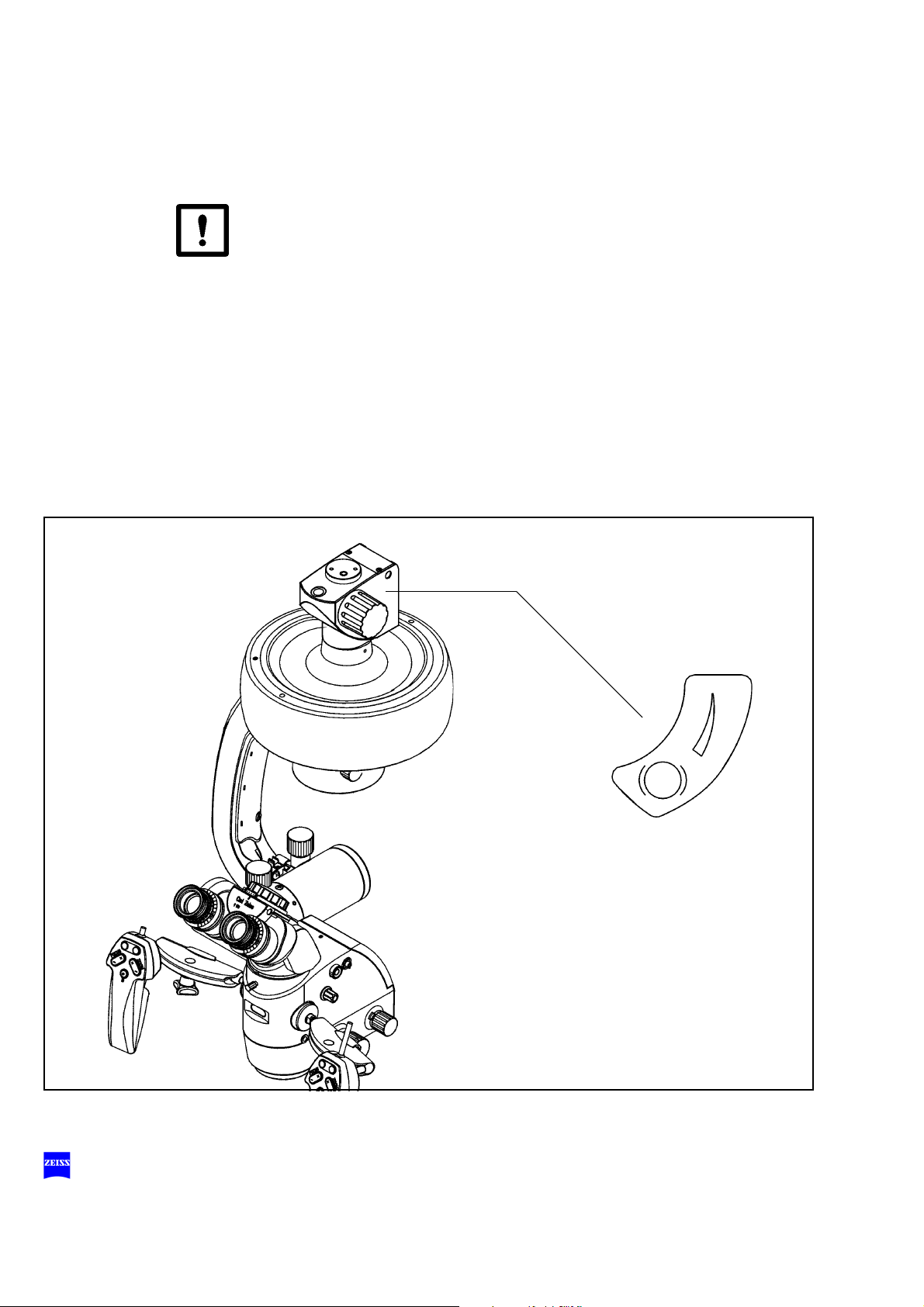

Components of the surgical microscope

The surgical microscope comprises the following modules:

1 Coupling

for mounting the surgical microscope on the suspension system.

2 Support arm for surgical microscope

3 Balancing system including magnetic brakes

This system allows balancing of the surgical microscope. When the

magnetic brakes are unlocked, the surgical microscope can be positioned almost effortlessly.

4 Handgrips

for moving the surgical microscope. The buttons on the handgrips permit you to control major microscope functions such as unlocking/locking the magnetic brakes, focusing, zooming.

5 Microscope body

The apochromatic optics of the microscope provide superb optical

quality. The microscope image displays optimum contrast and excellent detail recognition along with a large depth of field. The 1:6 ratio

zoom system allows the magnification of the overall system to be set

as required by the surgical procedure.

6 Magnetic brake

for the vertical axis.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 41

Description 41

1

2

3

4

6

3

5

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 42

42 Description

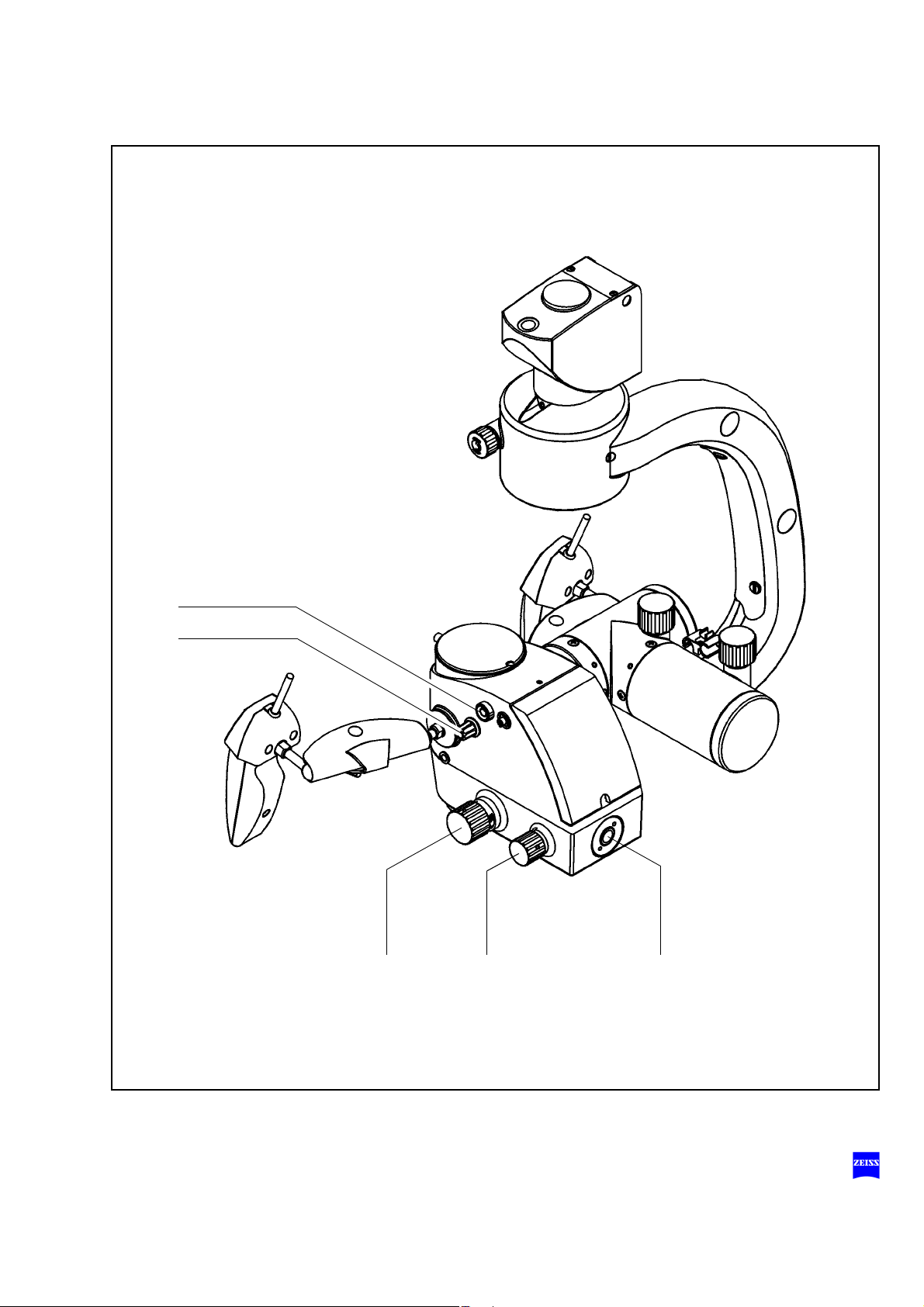

Controls, displays, connections

1 Friction adjustment of the vertical axis

Use this knob to adjust the friction of the vertical axis as required.

2 Balance setting of the lateral tilt motion

Use this knob to adjust the balance setting of the lateral tilt motion.

3 Balance setting of the front-to-back tilt motion

Use this knob to adjust the balance setting of the front-to-back tilt motion.

4 Dust cover

5 Mouth switch socket

You can use the mouth switch to release or lock the magnetic brakes

of the suspension system used.

6 Display window

for reading off the magnification factor γ of the zoom system.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 43

Description 43

6

1

3

4

2

5

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 44

44 Description

7 Focus stop button

This button permits you to deactivate the electrical drive of the focusing system. After you have pressed the focus stop button, you can

only focus manually on the surgical field using knob (9). The focus

stop button is lit. To release the stop, press the focus stop button again

(light in the button goes out).

The use of a micromanipulator for laser applications is described in

the section "Surgical microscope with laser micromanipulator", page

123.

8 Zoom knob

Use this knob for manual setting of the magnification.

9 Focusing knob

for manual setting of the image definition (focus, working distance)

10 Illuminated-field knob

for manual setting of the illuminated-field diameter.

11 Socket for S light guide

Insert the S light guide into the socket until it snaps in.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 45

Description 45

7

8

910 11

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 46

46 Description

12 Freely programmable release buttons

Specific functions of the suspension system can be assigned to these

buttons, e. g.: increasing / reducing brightness etc.

13 Zoom release button

for setting the magnification factor from 0.4x 2.4x.

14 Focus release button

for continuous focusing within the working distance of 200 to 415 mm.

15 Release button for magnetic brakes

The magnetic brakes of the surgical microscope and suspension

system are released for as long as you press this button.

16 Locking the handgrips in position

Using this screw, you can lock each handgrip in almost any position.

You can swing the handgrips backward by 180° to permit a second

surgeon to operate the microscope in the 180° position.

17 Cable holder

Warning!

To permit almost effortless guidance of the surgical microscope, the microscope and the floor stand must be correctly balanced.

If the system is in an extremely unbalanced state, the unit can move uncontrollably out of position. For this reason, hold the surgical microscope

tightly at its handgrips before unlocking the magnetic brakes.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 47

Description 47

12

14

15

13

16

17

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 48

48 Description

X-Y coupling (option)

Note:

• The OPMI® VARIO can be equipped (and also retrofitted) with an X-Y

coupling (2). Our service team or an authorized person will install the

X-Y coupling for you.

The X-Y coupling allows motorized fine positioning of the surgical microscope in a horizontal plane. The range of travel is 40 mm x 40 mm. The

speed of travel can be set on the display field of the suspension system.

The X-Y coupling is provided with a recentering mechanism. When you

press button (3), the X-Y coupling moves back into its center position.

You can also trigger the recentering function using the freely programmable buttons on the handgrips or foot control panel.

Knob (1) permits you to adjust the friction of the microscope's rotary axis.

See also: Preparations for use / Aligning the X-Y coupling, page 108.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 49

Description 49

2

3

1

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 50

50 Description

Binocular tubes and eyepieces

180° tiltable tube

1 PD adjustment knob

The correct position has been reached when the two eyepiece images

merge into one. You can read off the interpupillary distance set on the

adjustment knob.

2 180° tiltable tube

3 Eyepiece mount

45° inclined tube

4 45° inclined tube

5 PD adjustment knob

The correct position has been reached when the two eyepiece images

merge into one. You can read off the interpupillary distance set on the

adjustment knob.

6 Eyepiece mount

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 51

Description 51

4

5

1

2

3

6

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 52

52 Description

Widefield eyepieces with magnetic coupling

Note:

When you remove these eyepieces from the tube, please note that they

are fitted with a magnetic coupling. When mounted, the eyepieces display

a very weak magnetic field, so that the usual rules for the handling of magnets must only be observed with eyepieces which have not been mounted

on the microscope:

• Do not place the eyepieces close to instruments where there is any

risk of magnetization.

• Do not place the eyepieces on sensitive electronic units such as infusion pumps, cardiac pace-makers, measuring instruments or magnetic data carriers such as disks, audiotapes and videotapes, or credit

cards.

• Always store eyepieces not used in their original packaging.

1 Eyecup

Always adjust the eyecups in such a way that you can see the full field

of view.

– Viewing with eyeglasses: Screw in the eyecups all the way.

– Viewing without eyeglasses: Screw out the eyecups until you

see the full field of view.

2 Diopter adjustment ring

The eyepieces provide ametropia compensation between -8 D and

+5 D. Eyeglass wearers who perform surgery wearing their glasses

set the diopter adjustment ring to 0 D. Turn the ring until you have obtained the optimum setting. An integrated brake holds the ring in the

position set.

3 Diopter scale

for reading the prescription set.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 53

Description 53

1

2

3

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 54

54 Description

Retrolux illumination module

1 Retrolux illumination module

enables the use of the OPMI Vario for ophthalmic procedures.

2 Switch for swinging the retinal protection device into position

prevents light entering the patient's eye and therefore offers additional

protection against phototoxic injury.

3 Dovetail

for the attachment of a fundus imaging system.

4 Dovetail

for the attachment of the Retrolux illumination module

5 Light guide connector

for the attachment of the light guide.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 55

Description 55

1234

5

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 56

56 Description

Components of the S88 floor stand

The S88 floor stand is a carrier system for the surgical microscope. It is

used to power and control the motorized functions of the surgical microscope. The hallmarks of the floor stand are its superb mobility and easy

operation. Four steerable casters on the stand base permit easy positioning in the OR. The motorized functions of the surgical microscope can

be activated using a foot control panel.

Further useful functions include, for example:

– magnetic brakes for almost effortless positioning,

– brightness control via a foot control panel,

– reset of X-Y coupling, focus and zoom,

– user-defined basic settings for a maximum of nine users:

– speeds for focus, zoom and X-Y coupling

– and configurable buttons on the foot control panel for focus mem-

ory, XY inversion, camera release, swinging SDI in/out, triggering

an AUX signal.

Warning!

The use of OPMI Vario for ophthalmic procedures is only permissible in

combination with the Retrolux illumination module.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 57

Description 57

Description of the modules

The floor stand comprises an articulated arm, a stand column and a stand

base. The articulated arm comprises a carrier arm and a suspension arm.

The carrier arm contains the control unit with all electrical supply systems

required for the control of a motorized surgical microscope. These motorized functions can be activated using a foot control panel.

The suspension arm permits almost effortless positioning of the surgical

microscope. The spring force of the suspension arm can be varied in a

range from 8 to 20 kg, permitting reliable balancing of the microscope

even with heavy accessory equipment. The downward movement of the

suspension arm can be limited as required.

A maneuvering handle attached to the stand column is used to move the

stand and to attach the foot control panel. The stand column is provided

on its left and right with cable supports for winding up cables before the

unit is relocated. Four steerable casters on the stand base permit easy

positioning near the operating table. The stand base has been designed

in such a way that high stability is ensured even with unfavorable loading

of the stand. A locking pedal is provided to lock the floor stand quickly and

reliably into position.

Caution:

As the stand is very easy to maneuver, there is a tendency to underestimate its considerable weight. Therefore, move the stand slowly and carefully!

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 58

58 Description

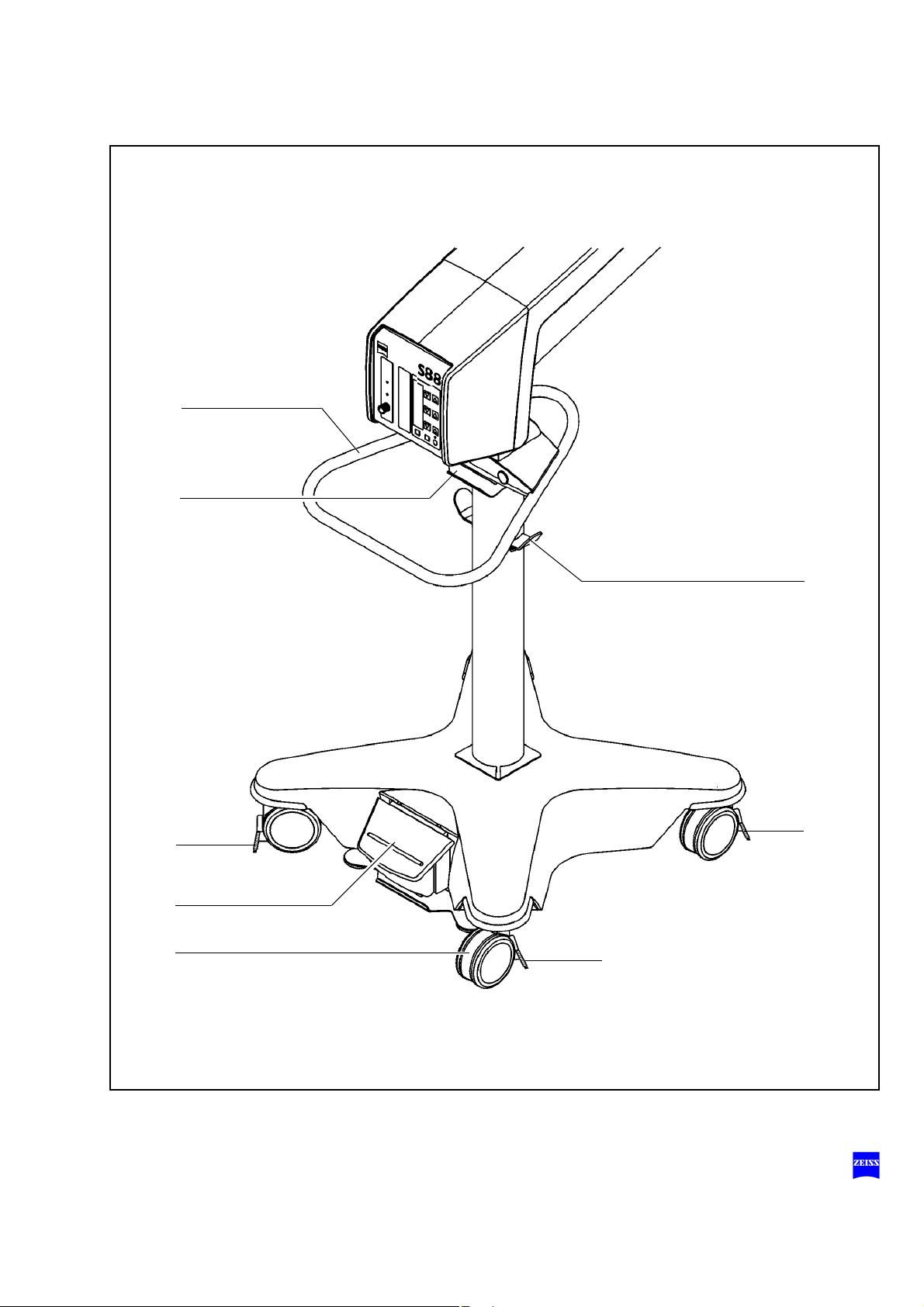

Design

1 Control panel

2 Carrier arm

3 Xenon illumination system, see page 62

4 Suspension arm

5 Stand base

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 59

Description 59

1

3

2 4

5

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 60

60 Description

MODE

STORE MANUAL

USER

1

1

1.5

Xe

Basic mode

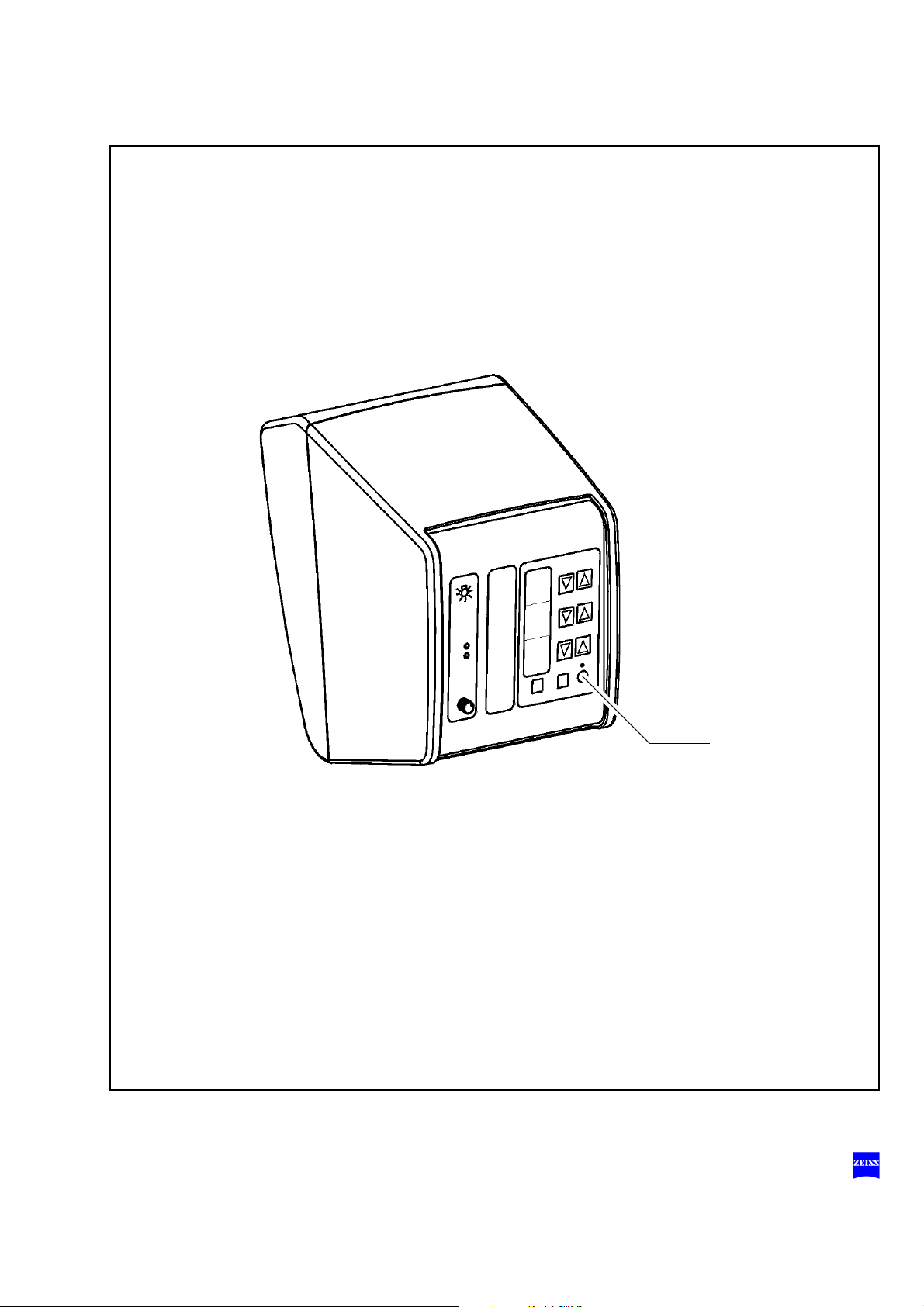

Display field with control keys

The display and control panel is integrated in the control unit.

The surgical microscope on the suspension system can be controlled either manually or electronically. The control software required for electronic control is installed in the electronics box of the suspension system.

You operate the software via the control and display panel, where you can

read off and reconfigure the current settings.

The control and display panel is structured as follows:

– Three display fields (LCD) with the associated keys "∇" and "Δ".

– One row of keys comprising the MODE, STORE and MANUAL keys,

and a yellow LED above the MANUAL key.

User interface

The user interface of the suspension system comprises three display

fields and keys located beside and below them.

A pair of keys "∇" and "Δ" has been assigned to every display field for

making the appropriate settings.

The control functions have been combined in several modes (menu

pages). The basic mode is always displayed in the normal operating

status.

The following is displayed in the basic mode:

– the current lamp brightness of lamp 1 (xenon) in the upper display

field,

– Xe for xenon in the middle display field,

– the current user ID in the lower display field.

Key row

Three keys and an LED are provided below the display fields.

Use the "MODE", "STORE" and "MANUAL" keys to select the different

control functions (modes).

"MODE" key and "STORE" key

The "MODE" and "STORE" keys permit you to access the different modes

of the user interface. For details, please see the chapter "Operation".

"STORE" key

Use the "STORE" key to save the current focus and zoom settings.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 61

Description 61

"MANUAL" key

The "MANUAL" key permits you to switch to manual operation. For details, please see the chapter "Operation".

Yellow LED above the "MANUAL" key

The yellow LED is lit when you have switched to the manual mode.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 62

62 Description

Lamp housing with xenon light source

Warning!

The use of OPMI Vario for ophthalmic procedures is only permissible in

combination with the Retrolux illumination module.

The suspension system is equipped with a xenon illumination system for

fiber illumination. The xenon lamp generates light whose spectrum resembles that of natural daylight. Regardless of the brightness setting, the

color temperature of the light always remains the same. Normal daylight

film without any additional conversion filters can therefore be used for

photographic documentation. The lamp housing contains two xenon

lamps. The second lamp is used as a backup lamp which must be swung

into the illumination beam path should the first lamp fail.

Ventilation grid

Do not cover the ventilation grid! For example, drapes could be covering

the grid. This can cause the lamp modules to overheat and lead to lamp

failure.

1 Lamp module

2 Manual activation of the backup bulb

• If the xenon bulb fails, open the lamp module as follows: Press

button (7). The lamp module is slightly ejected.

• Pull out the lamp module as far as it will go.

• Turn knob (2) 180° until it snaps in place. This moves the backup bulb

into the illumination beam path.

• Push the lamp module all the way back into the lamp housing.

• Reset service hour counter (5) to "0". Use a pointed object and press

it into the recess of reset button (6).

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 63

Description 63

2

4

3

1

6

3

7

5

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 64

64 Description

Note:

When inserting a new lamp module, make sure that the knob (2) is set

to "1“. If the first lamp fails, switch to the second lamp in logical sequence.

3 Indicator: backup lamp is in use

When the red segment in the knob (2) lights up, the backup lamp is in

use.

4 Filter selector knob

The filter knob has two positions:

0 No filter

1 Filter swung in

(No integrated filter in the standard configuration)

5 Counter

The counter records the service hours of the xenon light source.

• Change the xenon lamps after about 500 hours of operation to prevent

them from exploding. Then reset the counter to "0" by pressing reset

button (6).

6 Reset button

The reset button resets the service hour counter to "0".

7 Opening the lamp module

When you press this button, the lamp module is slightly ejected.

• To change the lamp, pull out the lamp module as far as it will go. Turn

the knob (2) through 180° until it snaps in place. This moves the backup lamp into the illumination beam path.

Warning!

The xenon lamp has a limited service life of 500 h.

If used beyond its maximum service life, the xenon lamp may explode.

• Replace the xenon lamp in good time.

• Reset the service hour counter to "0" after replacing the lamp.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 65

Description 65

2

4

3

1

6

3

7

5

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 66

66 Description

8 Brightness control

You can adjust the brightness using the two control keys on the control

panel.

Note:

The brightness of the xenon lamp can also be adjusted by pressing

the appropriate buttons on the foot control panel.

9 Yellow indicator lamp

Lights when the lamp has failed, or if the lamp module is defective.

After activation and ignition of the backup lamp, the yellow indicator

lamp goes out again.

Note:

If the first lamp has failed and the backup lamp is in use, make sure to

have a backup lamp module ready at hand as a precaution.

10 Green indicator lamp

Lights when the illumination has been switched on.

11 Selector switch:

Illumination is off.

Illumination is on.

Illumination can be switched on/off on the left-hand side of

the foot control panel.

Illumination can be switched on/off on the right-hand side of

the foot control panel.

Note:

You can adjust the selector in such a way that you can switch the illumination on/off on the right-hand and left-hand sides of the foot control

panel.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 67

Description 67

8

11

9

10

0

,

7

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 68

68 Description

Suspension arm

1 Lock of the cable duct

– For opening, turn a quarter turn clockwise or counterclockwise.

– For closing, press down and turn a quarter turn clockwise or coun-

terclockwise.

2 Adjustment screw for limiting downward movement

Use this screw to set the minimum vertical working distance from the

surgical field. Bring the surgical microscope into its working position.

Turn the adjustment screw for limiting downward movement clockwise

as far as it will go. Adjust the downward movement limitation before

each surgical procedure.

3 Balance setting screw

After mounting the surgical microscope including all

just the balance setting of the suspension arm using this screw. Balance setting is described in detail in chapter “Operation“.

accessories, ad-

4 Securing screw

®

for securing the OPMI

coupling.

5 Locking screw

for locking the suspension arm in a horizontal position for mounting

the surgical microscope. This prevents the suspension arm from uncontrollably moving upward when insufficient weight is attached.

6 Release bar

Allows non-sterile persons to unlock the magnetic brakes of the suspension system.

Magnetic brake release buttons

The magnetic brake release buttons are located on the surgical microscope. For as long as you press one of these buttons, you can move

the articulated arm in all directions. When you let go of the button, the

magnetic brakes will lock all axes in position at the same time.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 69

Description 69

12

5

3

4

6

6

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 70

70 Description

Stand base with column

1 Handle

for moving the stand.

2 Support

for hanging up the foot control panel during transport.

3 Cable support (2x)

for winding up the power cord and the cable of the foot control panel.

4 Cable deflectors

are provided to prevent cables on the floor from being run over and

damaged.

5 Locking pedal

Press once to lock the stand in position.

Press a second time to release the locking pedal.

6 Steerable casters

The four steerable casters on the stand base permit easy positioning

in the OR.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 71

Description 71

1

2

5

6

3

4

4

4

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 72

72 Description

Connector panel

1 Remote control socket

for triggering an AUX signal, e.g. to switch on/off an external device

operating at max. 24V/0.5A.

2 Connector for switching component

Connection possibility for: a foot control panel, a hand control panel or

an operating chair with an appropriate foot switch.

3 Potential equalization bolt

4 Indicator window for rated voltage

The voltage shown here must correspond to the rated line voltage provided on the site of installation. You can adjust the sliding switch using

a suitable tool.

Warning!

Please observe the maximum current consumption of two power outlets

(4) and (5). Only connect medical devices approved by us to outlets (4)

and (5). When using other instruments, make sure that safety is guaranteed regarding admissible ground leakage currents. The admissible limit

value of the ground leakage current present in the suspension system's

power cord must not exceed 500 µA in compliance with EN60601-1/IEC

60601-1. CSA/US certification in compliance with UL 60601-1 only allows

a maximum ground leakage current of 300 µA.

5 Power outlet socket

for medical devices with a maximum current consumption of 2 A.

Note:

The current of this power outlet is switched on/off using power

switch S2 (7).

6 Power outlet socket

for medical devices with a maximum current consumption of 5 A.

7 Power inlet socket

8 Power switch S2

When the stand is on, the green indicator light in the switch is lit.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 73

Description 73

S2

4

5

6

7

8

2

3

9

1

9 Strain relief device

The strain relief device prevents inadvertent unplugging of the following electrical connections:

– power cable,

– connecting cable for foot control panel, hand control panel or op-

erating chair with appropriate footswitch.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 74

74 Description

Instrument tray (option)

The S88 floor stand can be equipped or retrofitted with an instrument tray

(1). In the case of retrofitting, our service staff or an authorized person will

install the instrument tray on your suspension system.

The instrument tray (1) can carry a maximum load of 13 kg. The tray has

been designed, for example, for mounting MediLive Trio from Zeiss:

MediLive Trio is attached to the instrument tray with the aid of two stud

bolts. (The four receptacles supplied with the instrument tray are not required for mounting MediLive Trio.)

A second MediLiveTrio or other accessory equipment can be mounted on

the instrument tray using the strap provided. Please note the instrument

tray's maximum load capacity of 13 kg.

Warning!

• Make sure that the accessory equipment is positioned as securely as

possible on the instrument tray.

• Mount MediLive Trio on the instrument tray using the two stud bolts.

• If required, secure further accessory equipment on the tray using the

strap provided.

• Do not

• Remember there is a risk of collision and crushing when suspension

arm (2) is folded to its moving position. A "Risk of crushing" warning

label is therefore attached on the left and right of suspension arm (2).

• Please read the relevant user manual before starting up the accessory

equipment.

• Never pull or push at the accessory equipment (3) in order to move the

S88 floor stand. Always use handle (4) to move the S88 floor stand.

place a load of more than 13 kg on instrument tray (1).

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 75

Description 75

1

3

4

2

1

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 76

76 Description

Video monitor (option)

The S88 floor stand can be equipped or retrofitted with a TFT monitor (1).

In the case of retrofitting, our service staff or an authorized person will install the TFT monitor on your suspension system.

The TFT monitor (1) features a 15" screen and permits the scrub nurse

and other OR staff to follow the surgical procedure. For optimum viewing,

the TFT monitor can be precisely positioned using flexible arm (2).

Warning!

Risk of injury due to lowering of the TFT monitor!

• Ageing processes may lead to the loss of gas in the gas pressure

spring of the monitor's suspension arm, causing the TFT monitor to

move downward of its own accord.

• Compensate for the loss of gas by readjusting the gas pressure spring

as described on page 180.

If the TFT monitor continues to move downward, the gas pressure spring

is defective.

• Notify our service representative.

Warning!

Do not use the stored video sequences, video clips (cut sequences) and

single images for diagnostic purposes, as the video cameras and the

monitor have not been calibrated. The visualized images may therefore

include deviations in scale, color and shape.

This applies in particular if the sequences, clips or images are viewed on

a monitor outside the OR, as the transmission to a different monitor may

lead to changes in the display.

Note:

The background illumination of the LCD display has a limited service life.

If you notice that the display is getting darker or starts to flicker, contact

your Zeiss dealer.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 77

Description 77

2

1

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 78

78 Description

Components

The principal component of the TFT monitor is the 15" screen which delivers flawless, sharp images even at low frame rates of 50 Hz.

The connectors and controls are located under cable cover (2) on the

back of the TFT monitor. To access the connectors and controls, proceed

as follows:

• Remove two screws (3) from cable cover (2) by turning them counterclockwise.

• Remove cable cover (2) by pushing it upward.

Controls

1 Auto Adjust button

The Auto Adjust function permits automatic image adjustment of the

TFT monitor to obtain a sharp, optimally positioned image. Perform

the automatic adjustment when initially starting up the TFT monitor or

after making any changes to the system.

Note:

– The Auto Adjust function can only be executed if a VGA signal

source is connected.

– Always use a normal camera image for automatic image adjust-

ment. Do not use the test image which is displayed directly after

power-on or when no camera head is connected.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 79

Description 79

32 3

1

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 80

80 Description

Connector panel

2 Power supply

for power and voltage supply of the device.

Caution:

Only operate the device with the power cable included in the delivery

package.

3 DVI connector

DVI stands for Digital Video Interface and is the latest technology for

digital data transmission. The cable length for this connector must not

exceed 4.5 m.

Note:

We recommend the DVI connector for the connection of a camera, as

it delivers optimum image quality with minimum flicker. The DVI cable

is included in the delivery package.

4 VGA connector

VGA stands for Video Graphics Array and is an analog interface for

video data transmission between graphics cards and display devices.

5 S-Video connector

S-Video - also known as separate video or Y/C - is an analog interface

that transmits brightness and color information as separate signals.

This standard provides higher video image quality than Composite

Video. The maximum cable length for this connector should not exceed 10 m. For longer cables, please use the Composite Video connector.

6 Composite Video connector (1x cinch)

This is an analog interface that transmits the composite video signal

via a single channel (yellow cinch connector). This connector is particularly suitable for transmitting video signals over long distances.

7 Component connector (3x cinch)

This is an analog interface that transmits the component video signal

via three channels (red, yellow, green cinch connector). Each channel

transmits one of the primary colors.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 81

Description 81

2 3 4 5 67

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 82

82 Description

Powering on the TFT monitor

To facilitate the operation of the TFT monitor, it is automatically activated

when the suspension system is switched on.

During the power-on process, the TFT monitor executes a power-on sequence in which the signals on the connectors (DVI, VGA, S-Video, Composite and Component) are checked. After detection of the signal available, the correct screen resolution and frame rate are set automatically.

Note:

If a signal source is present at the VGA connector, the image settings can

be optimized using the Auto Adjust function as described on page 78.

Aligining the video monitor

The best visualization is obtained when you are looking straight at the

screen of the TFT monitor.

• Swivel the monitor's carrier arm (1) and suspension arm (2) into the

horizontal position required.

Caution:

Take care not to damage the video cable!

Do not swivel the suspension arm beyond ±120°.

• Tilt the suspension arm (2) upward or downward until the required

height has been reached.

• Hold the upper corners of the TFT monitor and adjust it to the required

angle via ball joint (3).

Warning!

Risk of injury due to lowering of the TFT monitor!

• Ageing processes may lead to the loss of gas in the gas pressure

spring of the monitor's suspension arm, causing the TFT monitor to

move downward of its own accord.

• Compensate for the loss of gas by readjusting the gas pressure spring

as described on page 180.

If the TFT monitor continues to move downward, the gas pressure spring

is defective.

• Notify our service representative.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 83

±90°

360°

90°

45°

2

1

3

Description 83

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 84

84 Description

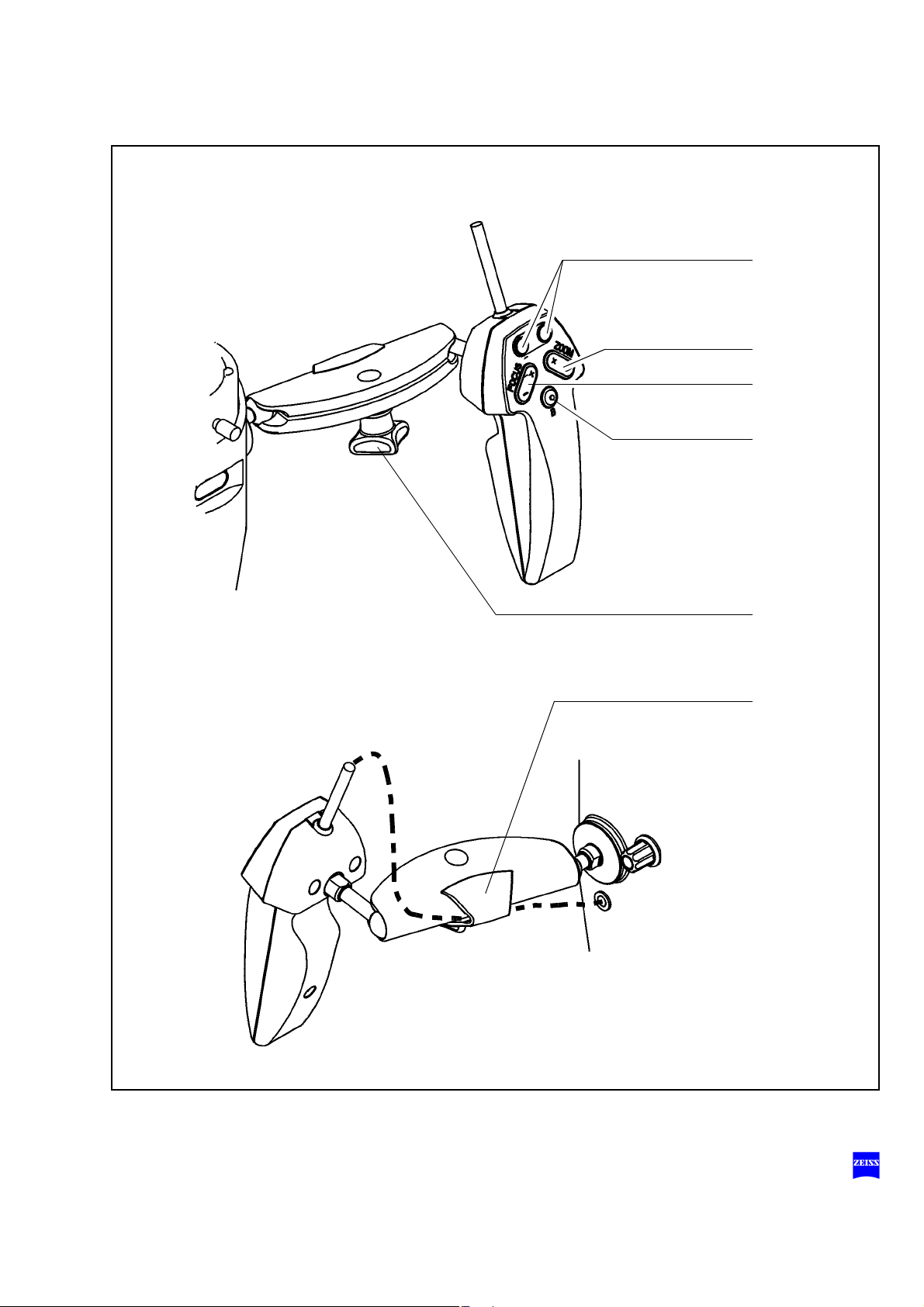

Foot control panel (option)

Intended use

The foot control panel permits you to operate various functions of a suspension system or surgical microscope. The assignment of functions to

the controls on the foot control panel is described on the next page. Only

functions provided in the system configuration used (suspension system,

surgical microscope) can be controlled.

Design

The 8-function and 14-function foot control panels feature two rocker

switches (1) which are used to control the ”Zoom” and ”Focus” functions.

The switches for these functions are located on one side, allowing you to

control both directions of a function using toe/heel movement without

having to shift your foot. Bridge (3) between two rocker switches (1)

serves as a support to rest your foot on.

Connector (2) is used to connect the foot control panel to the appropriate

connector on a suspension system or a wall-mounted control panel.

The foot control panel is provided with a waterproof rubber cover.

The illustration shows the 14-function foot control panel. Depending on

the configuration involved, an 8-function foot control panel can also be

connected.

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 85

Description 85

2

1

3

1

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 86

86 Description

11

10

9

8

7

2

3

4

5

6

1

A

B

D

C

Foot control panel with 14 functions

The illustration shows the standard assignment of functions to the foot

control panel with 14 functions. The focus/zoom assignment can be

changed by our service staff, on request.

1 Control of an X-Y coupling (if installed)

2 Button A: Reducing the lamp brightness

3 Button C: Function as assigned in configuration mode 1

4 ZOOM : Reducing magnification, increasing the field of view

(alternatively FOCUS : Increasing the working distance)

5 ZOOM : Increasing magnification, reducing the field of view

6 Illumination on/off

7 Illumination on/off

8 FOCUS : Increasing the working distance (alternatively ZOOM :

Reducing magnification, increasing the field of view)

9 FOCUS : Reducing the working distance

10 Button D: Function as assigned in configuration mode 1

11 Button B: Increasing the lamp brightness

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 87

Description 87

10

9

8

7

6

1

2

3

4

5

D

C

Foot control panel with 8 functions

The illustration shows the standard assignment of functions to the foot

control panel with 8 functions.

The focus/zoom assignment can be changed by our service staff, on request.

1 Reducing the lamp brightness

2 No function

3 ZOOM : Reducing magnification, increasing the field of view

(alternatively FOCUS : Increasing the working distance)

4 ZOOM : Increasing magnification, reducing the field of view

5 Button C: Function as assigned in configuration mode 1

6 Button D: Function as assigned in configuration mode 1

7 FOCUS : Increasing the working distance (alternatively ZOOM :

Reducing magnification, increasing the field of view)

8 FOCUS : Reducing the working distance

9 No function

10 Increasing the lamp brightness

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 88

88 Description

G-30-1721-en OPMI® VARIO Retrolux System Issue 1.0

Printed on 12. 03. 2008

Page 89

Preparations

Preparations 89

Attaching the equipment 90

Mounting the surgical microscope 90

Attaching accessories 92

Mounting the tube and eyepieces 94

Mounting the Retrolux illumination module 96

Bringing the Retrolux illumination module into its standby position 100

Attaching the fundus imaging system to the illumination module 102

Connections 104

Connecting the surgical microscope 104

Mounting the light guide 104

Aligning the X-Y coupling 108

Strain relief device on S88 floor stand 110