York EFH018, EFH060 User Manual

036-21031-004 Rev. A (0603)

®

TECHNICAL GUIDE

STELLAR PLUS

12 SEER

SPLIT-SYSTEM HEAT PUMPS

MODELS:

E*FH018 Thru E*FH060

(1.5 THRU 5 NOMINAL TONS)

This product was manufactured

in a plant whose quality system

is certified/registered as being

in conformity with ISO 9001.

Due to continuous product improvement, specifications

are subject to change without notice.

Visit us on the web at www.york.com for the most

up-to-date technical information.

Additional rating information can be found at

www.ariprimenet.org.

TM

O

T

A

D

R

E

I

I

A

F

S

I

T

R

C

E

O

C

M

Y

R

A

T

I

N

U

E

R

T

I

F

I

C

A

R

I

S

with ARI.

P

L

Y

H

E

I

A

T

N

G

P

U

M

P

R

E

T

Q

F

N

U

E

I

P

M

O

S

N

O

I

T

A

C

E

T

S

I

0

N

O

4

2

T

D

A

R

N

A

D

R

E

R

U

T

C

A

F

U

N

A

M

C

Certification applies only

when the complete

system is listed

LISTED

DESCRIPTION

These high efficiency EFH Ser ies heat pump units are the outdoor part of a versatile sys tem designed to eco nomically heat

and cool a home or small business. The compact design of these

outdoor units make them ideal for ground or roof installation. The

units contain enough refriger ant charge for the outdoor unit, a

matched indoor coil and 15 feet of interconnecting piping.

EFH heat pumps can be custom-matched with o ne of YORK's

two lines of evaporator blower sections, each designed to serve

a specific function. Electric heaters ar e available for both, in a

variety of sizes.

For Add-On applications, the indoor coil may be applied in the

supply duct of a conventional gas, oil or electric furnace. The

heat pump will be the primary source of heat for the building with

the furnace operating only when the heating requirement

exceeds the capacity of the heat pum p.

WARRANTY

5-year limited parts warranty.

10-year limited compr es sor w ar ra nt y.

FEATURES

• QUALITY COILS - The coil is constructed of copper tube and aluminum fins.

• COIL PROTECTION - Coils are protected from damage by a polymer

mesh applied between the coil face, and a PVC coated steel coil

guard, or a polymer coil guard.

• DURABLE FINISH - Cabinet is made of pre-painted steel. The pretreated flat galvanized steel provides a better paint to steel bond,

which resists corrosion and rust creep. Special primer formulas and

glossy earth tone finish insure less fading when exposed to sunlight.

• LOWER INSTALLED COST - Installation time and costs are reduced

by the fully exposed refrigerant connections and the single panel covering of the electrical controls. The small base dimension means

smaller mou nting pa ds or less ma terial s requ ired for mou nting , lower ing installation costs.

• COMPRESSOR - 2 - 5 ton models are equipped with scroll compressors which are inte rnal l y pro te cted agai nst hig h p ress ure and t emper ature. This is accomplished by the simultaneous operation of high

pressure relief valve and a temperature sensor which protect the compressor if undesirable operating conditions occur. The compressor is

protected by a 10 year limited warranty.

• COMPLETE SYSTEM CONTROL - These heat pump units utilize the

unique YorkGuard V microprocessor control system to provide optimal

comfort control and assure reliable operation. The YorkGuard V control system continuously monitors the space environment to maintain

optimum efficiency. It initiates defrost only when necessary to further

reduce heating costs and improve reliability. Supplemental heat can

only operate below the balance point and then only upon need. In the

event of improper operating conditions (high temperature and high

pressure), the YorkGuard V will shut the system down to extend the

life of the heat pump. Rapid cycling is prevented by use of an integral

anti-recycle timer. Loss of charge protection is provided by a discharge

temperatu r e se nsor and intern a l co m p r essor overloads.

• Finally the YorkGuard V control provides system diagnostics to aid the

service technician, minimizing repair time and cost. The YorkGuard V

control even stores important information for use during servicing and

has a 5 year warranty.

• LOW OPERATING SOUND LEVEL - The discharge ai r from the top

mounted fan is blown up away from the structure and any landscaping

carrying the normal operating noise up away from the living area. The

rigid top panel effectively isolates any motor sound. Isolator mounted

compressor and the rippled fins of the condenser coil muffle the normal fan motor and compressor operat ing sounds.

• U.L. and C.U.L. listed - approved for outdoor application.

Certified in accordanc e wit h the Uni t ary Small Equipment certif icat ion pr ogram, which is based on ARI Standard 210/240.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

036-21031-004 Rev. A (0603)

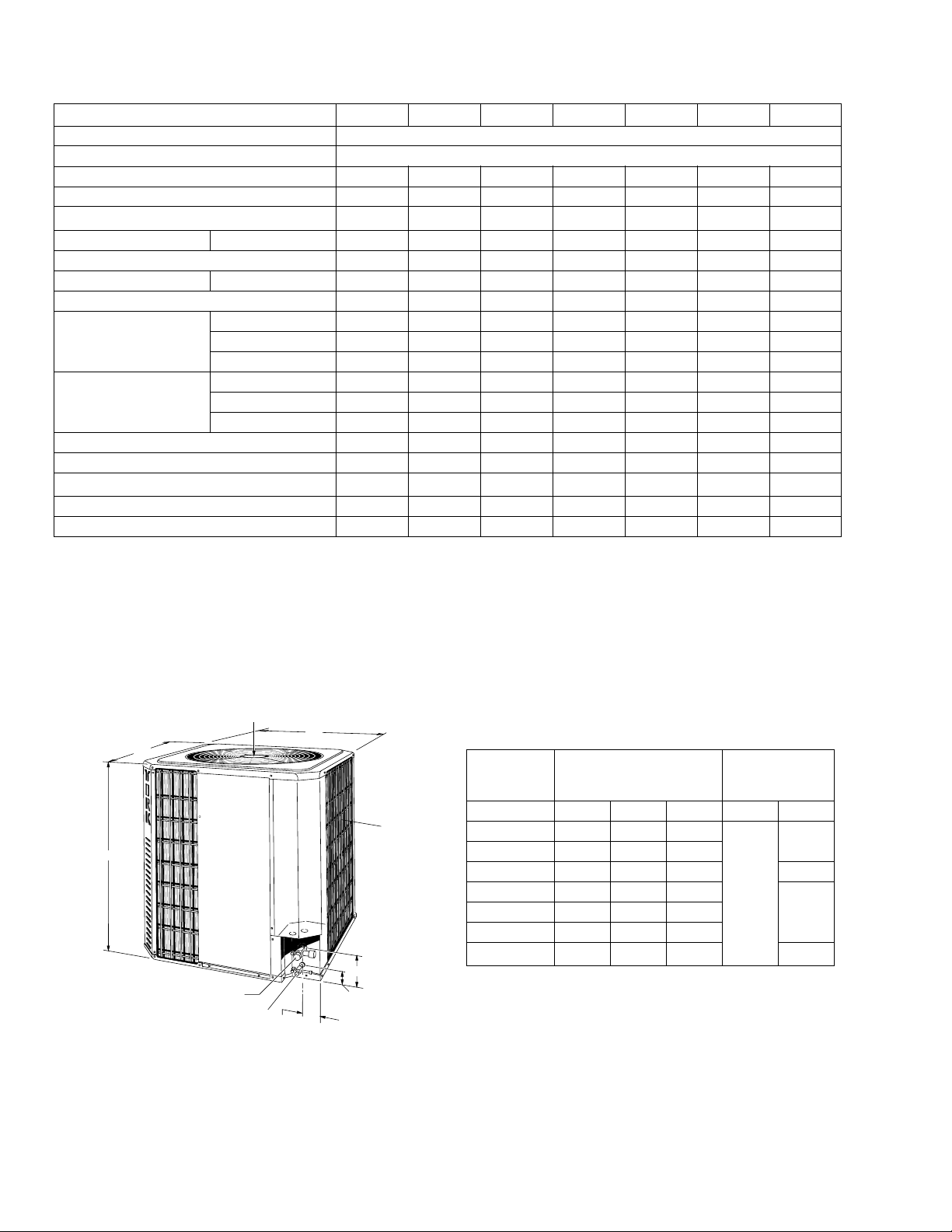

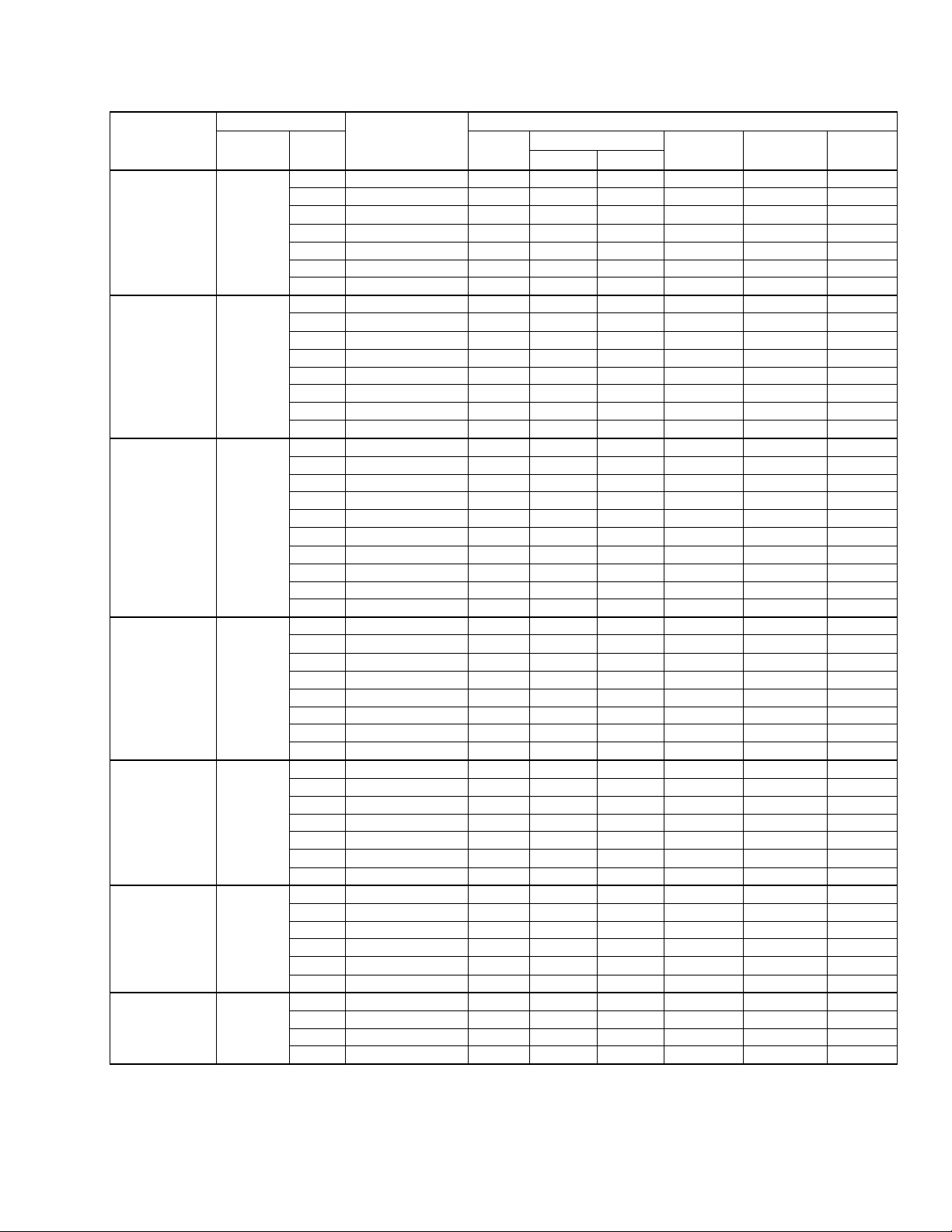

PHYSICAL AND ELECTRICAL DATA

MODEL

E4FH018 E4FH024 E4FH030 E4FH036 E4FH045 E5FH048 E4FH060

Unit Supply Voltage 208/230-1-60

Normal Voltage Range

1

187 to 252

Minimum Circuit Ampacity 9.7 16.2 16.4 22.1 25.4 33.3 37.8

Max. Overcurrent Device Amps

Compressor Type

3

2

15 25 25 35 35 50 50

Recip

Scroll

C

Scroll

C

Scroll

C

Scroll

C

Scroll

C

Scroll

C

Compressor Amps Rated Load 6.7 10.3 12.2 16.4 19 21.4 28.8

Crankcase Heater YesNoNoNoNoNoNo

Fan Motor Amps Rated Load 0.8 0.8 0.9 1.6 1.6 1.6 1.8

Fan Diameter Inches 18 18 18 24 24 24 24

Rated HP 1/12 1/12 1/8 1/4 1/4 1/4 1/3

Fan Motor

Nominal RPM 1050 1050 1075 850 850 850 1075

Nominal CFM 1500 1500 2050 3300 3400 3400 4100

Face Area Sq. Ft. 14.1 14.1 14.1 20.0 24 24 24

Coil

Rows Deep 1111112

Fin / Inches 16 16 20 16 16 16 13

Liquid Line OD 3/8 3/8 3/8 3/8 3/8 3/8 3/8

Vapor Line OD 5/8 5/8 3/4 7/8 7/8 7/8 1 - 1/8

Unit Charge (Lbs. - Oz.)

4

5 - 9 5 - 1 5 - 9 6 - 14 8 - 3 9 - 11 14 - 0

Charge Per Foot, Oz. 0.68 0.68 0 .6 8 0 .68 0 .7 0 0.70 0.70

Operating Weight Lbs. 156 148 150 212 237 272 300

1. Rated in accordance with ARI Standard 110, utilization range “A”.

2. Dual element fuses or HACR circuit breaker.

3. All scrolls listed with a superscript “B” are Bristol scrolls. All scrolls listed with a superscript “C” are Copeland scrolls.

4. The Unit Charge is correct for the outdoor unit, matched indoor coil and 15 feet of refrigerant tubing. For tubing lengths other than 15 feet, ad d or su btract the amount of refrigerant, using the difference in length multiplied by the per foot value.

48" OVERHEAD

CLEARANCE

B

A

VAPOR

CONNECTION

LIQUID CONNECTION

3-1/8

C

AIR IN

4 SIDES

5-1/2

2-3/8

without notice. Certified dimensions will be provided upon

request.

UNIT MODEL

EFH

DIMENSIONS

ABCLIQUIDVAPOR

018 30-1/8 24 24

024 30-1/8 24 24

030 30-1/8 24 24 3/4

036 30-7/8 35 35

048 37-7/8 35 35

060 37-7/8 35 35

1. Valve on 060 is 7/8 with a reducer supplied for the 1-1/8

vapor line.

REFRIGERANT

CONNECTION

LINE SIZE

5/8

3/8

7/8042 37-7/8 35 35

1-1/8

1

All dimensions are in inches. They are subject to change

2 Unitary Products Group

036-21031-004 Rev. A (0603)

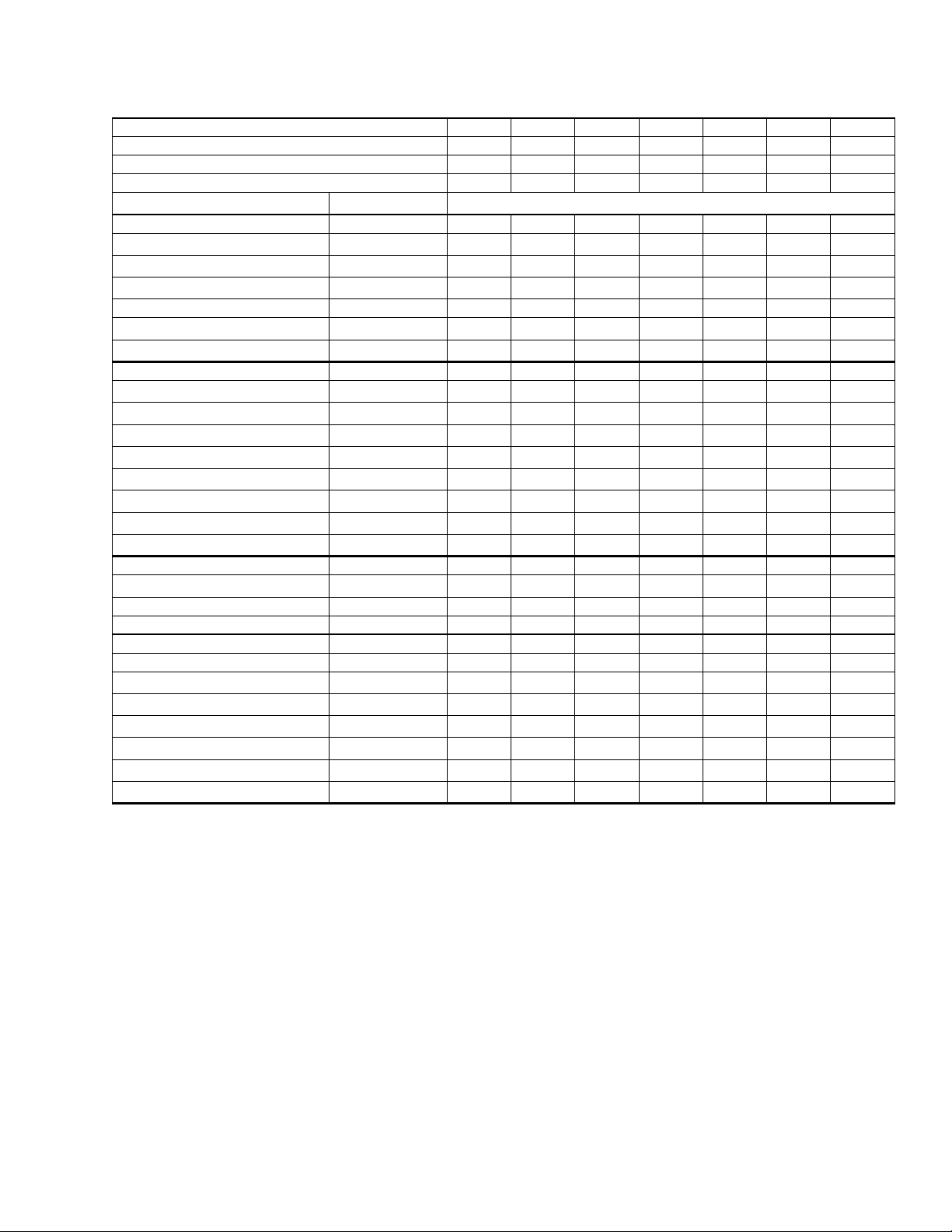

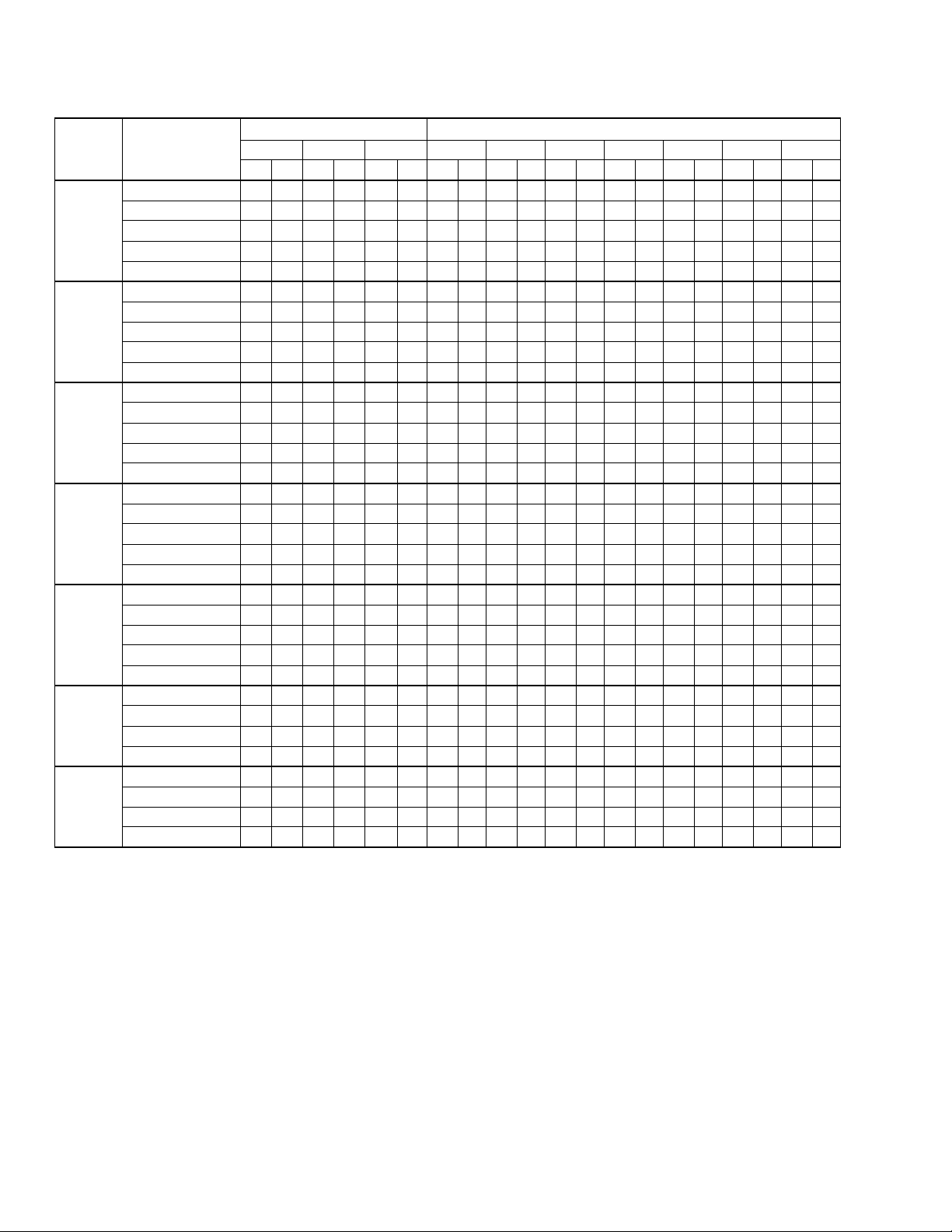

ADDITIONAL R-22 CHARGE / ORIFICE SIZE FOR VARIOUS MATCHED SYSTEMS

OUTDOOR UNIT E4FH018 E4FH024 E4FH030 E4FH036 E4FH042 E5FH048 E4FH060

Orifice in OD Distributor 37 45 49 55 65 69 76

FACTORY CHARGE, LBS. - OZ. 5 - 9 5 - 1 5 - 12 6 - 14 8 - 3 9-11 14 - 0

ID Orifice included w/Instruction Package 57 59 -- -- -- -- --

INDOOR COIL

COIL ORIFICE

1

G1FA/G1UA024S14, 17 59 57 + 4 -- -- -- -- -- -G1FA/G1UA030S14 65 57 + 6 701 + 0

G1FA/G1UA036S14 73 -- 701 + 2

G1FA/G1UA036S17 73 -- --

G1FA/G1UA048S17 84 -- -- -- -- -- -- -G1FA/G1UA048S21 84 -- -- --

G1FA/G1UA060S21, 24 90 -- -- -G2FD024S(H)14, 17 61 57 + 6 59 + 0 -- -- -- -- -G2FD030S(H)17 65

GFD035S(H)14 65 -- 59 + 2

G2FD036S(H)17 75 -- -G2FD042S(H)21 78 -- -- -G2FD046S(H)17 78 -- -- -G2FD048S(H)21, 24 84 -- -- -- -G2FD060S(H)24 90 -- -- -- -- -G2FD061SH24 9 0 -- -- -- -- -- --

G1HD024 59 -- 59 + 1 -- -- -- -- -G1HD036 69 -- -G1HD048 81 -- -- -- -- -- -- --

G1HD060 93 -- -- -- -- -- -- -F2RP/FP018 (53) (55) +0 -- -- -- -- -- -F2RP/FP024 61 57 + 6 59 + 0 -- -- -- -- --

F2RP/FP030 65 -- 59 + 2

F2RP/FP036 75 -- -F2RP/FP042 78 -- -- -F2FP048 84 -- -- -- -F2FP060 90 -- -- -- -- -F2FV060 90 -- -- -- -- --

FOOTNOTES:

1. Verify the TXV kit and the additional charge required for the specific evaporator coil in the system using the table above.

PROCEDURES:

1. Unit factory charge listed on the unit nameplate includes refigerant for the condenser, the smallest evaporator and for 15 feet of interconnecting line tubing.

2. Verify the orifice size and the additional charge required for the specific evaporator coil in the system using the table above:

3. Add additional charge for the amount of interconnecting line tubing greater than 15 feet at the rate specified in the table above.

4. Permanently mark the unit nameplate with the total system charge. Total System Charge=Base Charge (as shipped) +adder for

evaporator +adder for line set.

5. If the orifice in the evaporator was changed verify the evaporator nameplate has been marked with the correct orifice size.

REQUIRED SYSTEM ORIFICE + ADDITIONAL CHARGE, OZ.

701

1

+ 8

59 + 2

1

+ 0

701

1

+ 0

701

1

701

+ 0

7011 + 0

1

+ 0

701

1

701

+ 4 7021 + 0

1

+ 4

701

1

+ 0

701

1

+ 4 7021 + 0

701

-- -- -- --

-- -- -- --

-- -- -- --

1

+ 0 7021 + 0 7031 + 0

702

1

+ 2 7021 + 5 7031 + 5 7031 + 0

702

-- -- -- --

-- -- -- --

-- -- --

1

+ 2 7021 + 0

702

1

+ 2 7021 + 0

702

1

+ 8 7031 + 4

702

-- -- -- --

-- -- -- --

-- -- --

1

702

+ 2 7021 + 0

1

+ 8 7031 + 3

702

-- --

-- --

1

+ 5 7031 + 0

703

-- --

1

+ 5 7031 + 0

703

1

+ 5 7031 + 0

703

703

--

--

1

--

+ 8

Unitary Products Group 3

036-21031-004 Rev. A (0603)

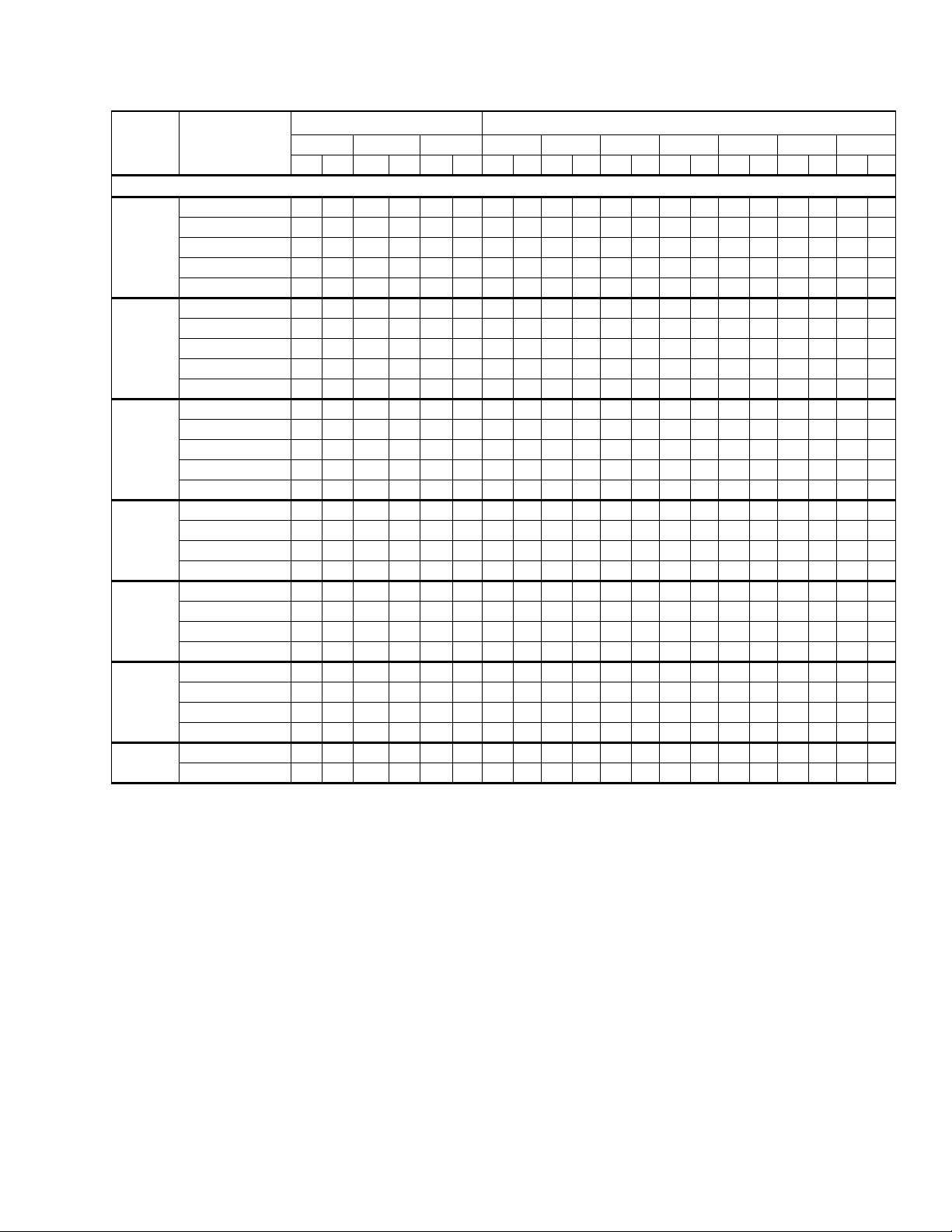

COOLING CAPACITY - With Air Handler Coils

UNIT

MODEL

MODEL

AIR HANDLER

ELECTRIC

HEAT KW

COIL MODEL

2

W

1

RATED

CFM

NET MBH

TOTAL SENS.

1 Phase 12 SEER HP / N1AH / G2FD

E4FH018

N1AHB08 2,5,7.5,10 17 G2FD024(S,H)17 650 19.0 14.3 12.05 --- 10.65

N1AHB08 2,5,7.5,10 17 G2FD030(S,H)17 650 19.4 14.6 12.15 --- 10.70

N1AHB08 2,5,7.5,10 17 G2FD024(S,H)17 800 23.4 17.6 12.10 --- 10.85

E4FH024

N1AHB08 2,5,7.5,10 17 G2FD030(S,H)17 850 23.4 17.6 12.10 --- 10.85

N1AHB08 2,5,7.5,10 14 G2FD035(S,H)14 850 23.4 17.6 12.10 --- 10.85

E4FH030 N1AHB12 5,7.5,10,15,18 17 G2FD036(S,H)17 1000 29.0 21.8 --- 12.40 10.65

E4FH036 N1AHB12 5,7.5,10,15,18 17 G2FD036(S,H)17 1200 34.6 25.6 -- 12.00 10.50

E4FH042

E5FH048

E4FH060

N1AHC16 5,7.5,10,15,20 21 G2F D042(S ,H)2 1 1400 40.0 29.6 -- 12.00 10.50

N1AHC16 5,7.5,10,15,20 21 G2F D048(S ,H)2 1 1425 41.0 30.3 -- 12.40 10.80

N1AHC16 5.7.5,10,15,20 21 G2F D048(S ,H)2 1 1600 47.5 35.6 -- 12.00 10.50

N1AHD20 5.7.5,10,15,20,25,30 24 G2FD060(S ,H)24 1620 48.0 36.0 -- 12.40 10.85

N1AHD20 7.5,10,15,20,2 5,30 24 G 2F D060(S ,H)2 4 1850 58.0 42.0 -- 12.00 10.70

N1AHD20 7.5,10,15,20,25,30 24 G2FD061H24 1875 58.5 41.5 -- 12.20 10.70

1 Phase 12 SEER HP / N1VS / G2FD

E4FH018 N1VSB12 5,7.5,10,15,18 17 G2FD024(S,H)17 650 19.4 14.3 13.3 5 --- 11.70

E4FH024 N1VSB12 5,7.5,10,15,18 17 G2FD024(S,H)17 800 24.0 18.0 14.00 --- 12.00

E4FH030

N1VSB12 5 ,7.5,10,15,18 17 G2FD030(S,H)17 1000 29.0 21.8 --- 13.00 11.20

N1VSB12 5 ,7.5,10,15,18 17 G2FD036(S,H)17 1000 29.2 21.9 --- 13.50 11.40

E4FH036 N1VSB1 2 5,7.5,10,15,18 17 G2FD036(S,H)17 1200 35.0 25.9 -- 12.80 11.20

E4FH042

E5FH048

E4FH060

E4FH018

E4FH024

E4FH030

E4FH036

E4FH042

N1VSC16 5,7.5,10,15,20 21 G2FD042(S,H)21 1400 40.5 30.0 -- 12.80 11.20

N1VSC16 5,7.5,10,15,20 21 G2FD048(S,H)21 1425 41.5 30.7 -- 13.50 11.40

N1VSC16 5.7.5,10,15,20 21 G2FD048(S,H)21 1600 48.0 36.0 --- 13.40 10.50

N1VSD20 5.7.5,10,15,20,25,30 24 G2FD060(S,H)24 1650 49.0 36.8 --- 13.80 10.80

N1VSD20 7.5,10,15,20,25,30 24 G2FD060(S,H)24 1850 60.5 42.9 -- 13.00 11.60

N1VSD20 7.5,10,15,20,25,30 24 G2FD061H24 1875 59.0 41.5 -- 12.60 11.90

1 Phase 12 SEER HP / F2RP / FP / FV

4,5

F2RP/F2FP018 5,8,10 18 -- 650 18.0 13.5 12.00 --- 10.75

F2RP/F2FP024 5,8,10 18 -- 650 19.0 14.3 12.50 --- 10.50

F2RP/F2FP024 5,8,10 18 -- 800 23.4 17.6 12.00 --- 10.35

F2RP/F2FP030 5,8,10,15 18 -- 800 23.8 17.9 --- 12.50 10.55

F2RP/F2FP030 5,8,10,15 18 --- 1035 28.2 21.2 --- 12.00 10.30

F2RP/F2FP036 5,8,10,15 21 --- 1035 29.0 21.8 --- 12.00 10.30

F2RP036 5,8,10,15 18 -- 1250 34.6 25.6 -- 12.10 10.60

F2RP042 5,8,10,15 21 -- 1250 34.6 25.6 -- 12.10 10.50

F2RP042 5,8,10,15 21 -- 1400 40.0 29.6 -- 12.00 10.40

F2FP048 10,15,20,25 24 -- 1600 41.0 30.3 -- 12.40 10.80

F2FP048 10,15,20,25 24 -- 1600 47.0 35.3 --- 12.00 10.45

E5FH048

F2V060 10,15,20,25 24 -- 1600 48.5 36.4 --- 13.00 11.60

F2FP060 10,15,20,25 24 -- 1600 47.5 35.6 --- 12.00 10.35

E4FH060

Rated in accordance with DOE test procedures (Federal Register 12-27-79 and 3-18-88) and ARI Standards 210/240.

Cooling MBH based on 80°F entering air temperature, 50% RH, and rated air flow.

EER (Energy Efficiency Ratio) is the total cooling output in BTU’s at a 95°F outdoor ambient divided by the total electric power in watt-hours at those conditions.

SEER (Seas on a l En er g y Efficiency Ratio) is t h e to tal cooling output i n BT U’s during a normal an nu a l u s ag e pe r i od fo r co o l ing d i vided by the total electric power input

in watt-hours during the same period.

1. G2FD coils availab le with a factory installed horizontal drain pan. See price pages for specific model number.

2. Single phase units require single phase 2HK heaters.

3. TXV = Use 1TV700 Series Kit.

4. To meet R=4.2 insulation requirements, substitute F2FP for F2RP, and F2FC for F2RC. models. All ratings remain the same.

5. FG8, FG9, and FL8 furnaces and F2RP / F2RC air handlers have B.O.D (Blower on Delay) standard.

- = Not applicable

F2FP060 10,15,20,25 24 -- 1850 57.0 42.2 -- 11.60 10.40

F2FV060H24 10,15,20,25 24 -- 1875 59.0 43.0 -- 13.00 11.60

COOLING

SEER

W/O TXV

SEER

+ TXV

EER

3

4 Unitary Products Group

COOLING CAPACITY - With Upflow, Downflow and Horizontal Furnace and Coils

UNIT

MODEL

FURNACE**

NOMINAL

AIRFLOW

COIL

W

MODEL

RATED

CFM

14,17 G1FA024S14,17 650 18.8 14.1 12.00 - 10.55

14 G1FA030S14 650 19.0 14.3 12.50 - 10.65

14,17 G1UA024S14,17 650 18.8 14.1 12.00 - 10.55

14 G1UA030S14 650 19.0 14.3 12.50 - 10.65

14,17 G2FD024S14,17 650 19.0 14.3 12.50 - 10.65

E4FH018S06

575

725

17 G2FD030(S,H)17 650 19.2 14.4 12.50 - 10.70

14 G2FD035(S,H)14 650 19.2 14.4 12.50 - 10.70

14 G1FA030S14 800 22.2 16.7 - 12.00 10.85

G1UA030S14 800 22.2 16.7 - 12.00 10.85

17,21 G1FA036S17,21 800 22.4 16.8 - 12.10 11.00

E4FH024S06

725

925

G1UA036S17,21 800 22.4 16.8 - 12.10 11.00

- G1HD024 820 23.6 17.7 12.10 - 10.85

17 G2FD024(S,H)14,17 820 23.6 17.7 12.10 - 10.85

17 G2FD030(S,H)17 820 23.6 17.7 12.10 - 11.00

14 G2FD035(S,H)14 820 23.6 17.7 12.10 - 11.00

14 G1FA036S14 1050 28.2 21.2 - 12.00 10.35

17,21 G1FA036S17,21 1050 28.2 21.2 - 12.00 10.35

- G1HD036 1035 28.8 21.6 - 12.00 10.30

14 G1UA036S14 1050 28.2 21.2 - 12.00 10.35

E4FH030S06

925

1175

17,21 G1UA036S17,21 1050 28.2 21.2 - 12.00 10.35

17 G2FD030(S,H)17 1050 28.2 21.2 - 12.00 10.35

17 G2FD030(S,H)17 1050 28.2 21.2 - 12.00 10.35

14 G2FD035(S,H)14 1050 28.6 21.5 - 12.00 10.35

17 G2FD036(S,H)17 1050 28.8 21.6 - 12.00 10.65

21 G2FD036(S,H)21 1050 28.8 21.6 - 12.00 10.65

17 G1FA048S17 1225 35.0 25.9 - 12.10 10.60

21 G1FA048S21 1225 35.4 26.2 - 12.50 10.70

17 G1UA048S17 1225 35.0 25.9 - 12.10 10.60

E4FH036S06

1075

1375

21 G1UA048S21 1225 35.4 26.2 - 12.50 10.70

17 G2FD036(S,H)17 1200 34.6 26.2 - 12.00 10.50

21 G2FD036(S,H)21 1200 34.6 26.2 - 12.00 10.50

21 G2FD042(S,H)21 1225 34.8 25.8 - 12.20 10.55

17 G2FD046(S,H)17 1225 35.0 25.9 - 12.10 10.60

17 G1FA048S17 1450 40.5 30.0 - 12.25 10.65

21 G1FA048S21 1450 40.5 30.0 - 12.40 10.70

17 G1UA048S17 1450 40.5 30.0 - 12.25 10.65

21 G1UA048S21 1450 40.5 30.0 - 12.40 10.70

21 G2FD042(S,H)21 1450 40.0 29.6 - 12.00 10.50

E4FH042S06

1275

1625

17 G2FD046(S,H)17 1450 40.5 30.0 - 12.25 10.65

21,24 G2FD048(S,H)21,24 1450 41.0 30.3 - 12.40 10.80

21 G1FA048S21 1600 46.5 34.9 - 12.00 10.45

21,24 G1FA060S21,24 1650 47.5 35.6 - 12.20 10.60

E5FH048S06

1400

1800

21 G1UA048S21 1600 46.5 34.9 - 12.00 10.45

21,24 G1UA060S21,24 1650 47.5 35.6 - 12.20 10.60

21,24 G2FD048(S,H)21,24 1600 47.5 35.6 - 12.00 10.50

24 G2FD060(S,H)24 1625 48.0 36.0 - 12.50 10.80

21,24 G1FA060S21,24 1850 57.0 41.0 - 11.70 10.40

E4FH060S06

1600

2100

21,24 G1UA060S21,24 1850 57.0 41.0 - 11.70 10.40

24 G2FD060(S,H)24 1800 58.0 42.0 - 12.00 10.70

24 G2FD061H24 1800 58.5 41.5 - 12.20 10.70

1. TXV = Use 1TV700 Series Kit.

* Requires a 2FD Blower Time Delay unless a standard furnace is equipped with one.

**

Refer to Quick Selection Chart for specific furnace match-up.

NET MBH

TOTAL SENS.

COOLING

SEER

W/O TXV

036-21031-004 Rev. A (0603)

1

SEER + TXV

EER

Unitary Products Group 5

036-21031-004 Rev. A (0603)

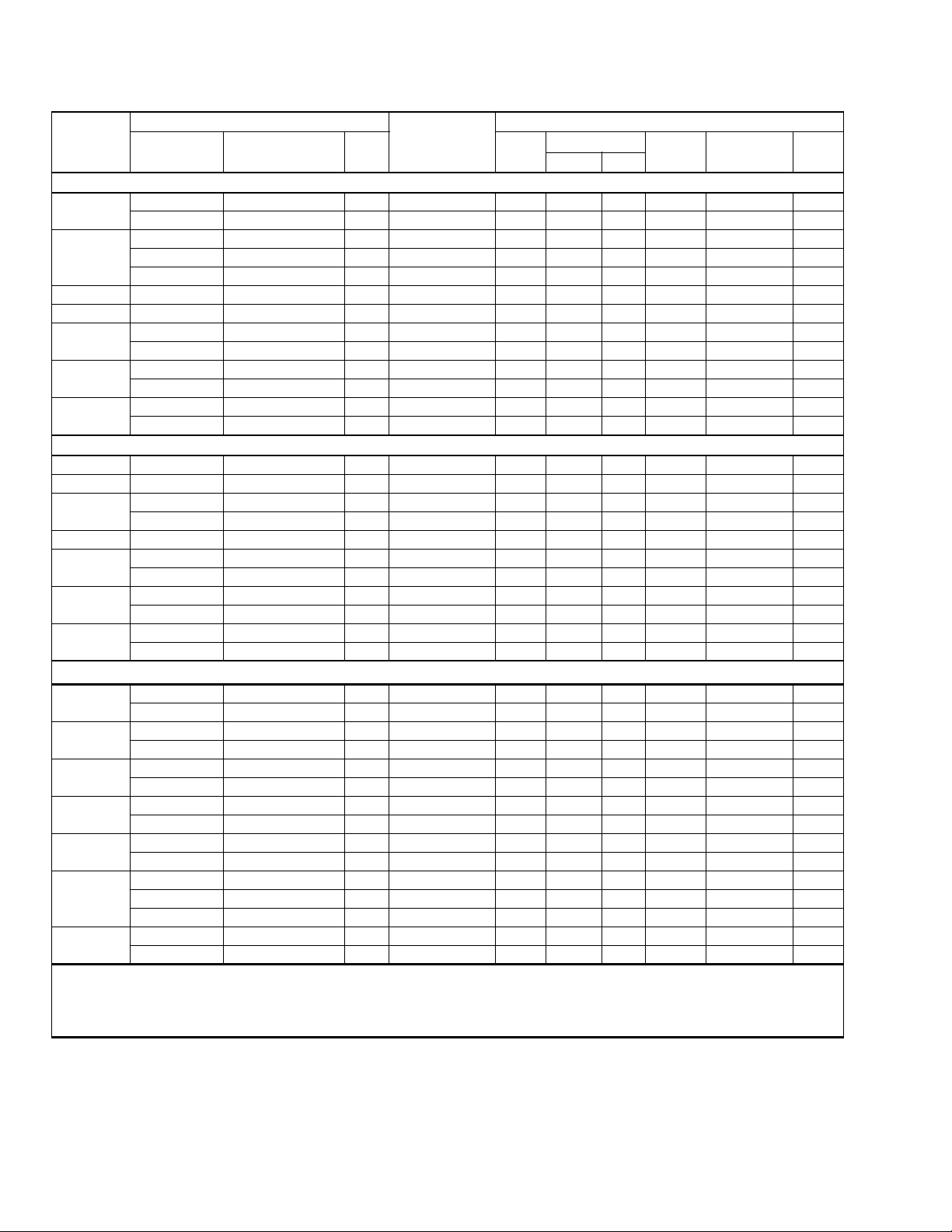

HEATING PERFORMANCE - Air Handler and Multi-position Coils

2

UNIT

MODEL

F2RP/F2FP018 17 3.00 10 2.00 6.8 -- 4 1.3 7.8 1.27 10 1.35 12.3 1.60 15.2 1.6 17 1.61 17.6 1.66

F2RP/F2FP024 19.5 3.20 11.3 2.10 7.5 -- 4.5 1.25 8 1.25 11.3 1.36 12.7 1.57 15.5 1.68 19.5 1.59 19.6 1.65

E4FH018

G2FD024(S,H)14,17 19.0 3.32 11.6 2.00 7.6 8 6 1.51 8 1.25 11.6 1.36 12.9 1.40 16.5 1.52 19.8 1.59 19.6 1.65

G2FD030(S,H)17 19.8 3.40 1.16 2.24 7.5 -- 6.2 1.52 8.2 1.23 11.6 1.69 12.8 1.38 16.4 1.5 19.8 1.79 19.6 1.63

G2FD035(S,H)14 19.8 3.40 1.16 2.24 7.5 -- 6.2 1.5 8.2 1.25 11.6 1.69 12.9 1.39 16.6 1.51 19.8 1.79 19.8 1.64

F2RP/F2FP024 24 3.32 12.9 2.20 8 -- 6.6 1.55 11 1.78 12.9 1.7 16 1.85 18.8 1.87 24 1.8 26.6 2.07

F2RP/F2FP030 24 3.32 12.9 2.20 8 -- 6.8 1.56 11.4 1.76 12.9 1.78 16.2 1.84 19 1.85 24 2.07 26.8 2.08

E4FH024

G2FD024(S,H)14,17 23.8 3.40 13.5 2.30 8 8.1 6.6 1.58 11.6 1.75 13.5 1.78 16.3 1.82 19.1 1.85 23.8 2.07 26.6 2.1

G2FD030(S,H)17 24 3.26 13.6 2.18 8 -- 6.8 1.6 11.4 1.73 13.6 1.75 16.2 1.80 19.2 1.83 24 2.08 26.8 2.08

G2FD035(S,H)14 24 3.26 13.6 2.18 8 -- 6.9 1.57 11.6 1.74 13.6 1.77 16.4 1.80 19.4 1.8 24 2.06 26.8 2.1

F2RP/F2FP030 28 3.33 17 2.33 8 -- 9.6 1.98 13.1 2.1 16.6 2.21 20.3 2.33 24.3 2.46 28 2.56 32.9 2.7

F2RP/F2FP036 28 3.33 17 2.33 8 -- 9.6 1.95 13.1 2.09 16.7 2.21 20.2 2.34 24.4 2.48 28 2.57 33 2.71

E4FH030

G2FD030(S,H)17 28 3.33 17 2.33 8 8.2 9.8 2.06 13.1 2.14 16.5 2.2 19.9 2.29 23.9 2.4 28 2.5 32.7 2.55

G2FD035(S,H)14 28 3.33 17 2.33 8 -- 9.4 2.06 13.2 2.14 16.6 2.3 20 2.31 24 2.41 28 2.6 33 2.6

G2FD036(S,H)17,21 28 3.33 17 2.33 8 8.2 9.9 2.02 13.3 2.15 16.6 2.19 21 2.41 23.8 2.4 28 2.6 33.4 2.65

F2RP/F2FP036 36.0 3.10 21.8 2.30 8.0 -- 12.5 2.36 17.1 2.57 21.8 2.78 26.5 2.99 31.7 3.21 36.0 3.40 41.4 3.56

F2RP/F2FP042 36.0 3.10 21.8 2.30 8.0 -- 12.5 2.35 17.2 2.57 21.8 2.78 26.4 2.99 31.6 3.21 36.0 3.40 41.5 3.57

E4FH036

G2FD042(S,H)21 36.0 3.38 21.8 2.26 8.0 -- 12.5 2.63 17.1 2.73 21.8 2.83 26.5 2.93 31.7 3.04 36.0 3.12 41.7 3.18

G2FD046(S,H)17 36.0 3.38 21.8 2.26 8.0 -- 12.5 2.63 17.2 2.73 21.8 2.83 26.4 2.93 31.7 3.04 36.0 3.12 41.4 3.16

G2FD036(S,H)17,21 36.0 3.40 21.8 2.28 8.0 8.1 12.5 2.60 17.1 2.70 21.8 2.80 26.5 2.90 31.7 3.02 36.0 3.10 41.7 3.16

F2RP/F2FP042 42.0 3.30 25.2 2.20 7.8 -- 13.4 3.08 19.3 3.22 25.2 3.36 31.1 3.50 37.7 3.63 42.0 3.73 48.5 3.85

E4FH042

G2FD042(S,H)21 41.5 3.40 25.0 2.26 8.0 8.1 12.5 2.94 18.8 3.09 25.0 3.24 31.2 3.39 38.2 3.55 41.5 3.58 49.6 3.73

G2FD046(S,H)17 41.5 3.40 25.0 2.24 8.0 -- 13.4 3.05 19.2 3.16 25.0 3.27 30.8 3.38 37.3 3.51 41.5 3.58 47.8 3.66

G2FD048(S,H)21,24 42.0 3.58 25.2 2.32 8.0 8.0 12.4 2.98 18.8 3.08 25.2 3.18 31.6 3.29 38.7 3.41 42.0 3.44 50.4 3.56

E5FH048

G2FD048(S,H)21,24 48 3.48 28 2.34 8.1 8.2 17 3.52 22.6 3.6 28 3.76 34.2 3.96 40 3.9 48 4.04 53.5 4.25

G2FD060(S,H)24 48.5 3.30 28.4 2.20 8.1 8.2 18 3.55 22.8 3.65 28.4 3.78 34.6 3.96 40 3.8 48.5 4.03 54 4.26

E4FH060

For Notes See Page 7.

G2FD060(S,H)24 60.0 3.50 40.0 2.50 8.2 8.3 18.9 3.94 26.0 4.21 40.0 4.48 40.0 4.75 48.1 5.05 60.0 5.39 67.8 5.61

COIL

MODEL

1

ARI HEATING

47 °F 17 °FHSPF-3 °F 7°F17°F27°F37°F47°F57°F

MBH COP MBH COP STD. V. S. MBH KW MBH KW MBH KW MBH KW MBH KW MBH KW MBH KW

F2FP048 42.0 3.58 25.2 2.32 8.0 -- 12.5 2.98 18.8 3.08 25.2 3.18 31.6 3.29 38.6 3.40 42.0 3.44 50.4 3.56

F2FP048 47.5 3.30 28.4 2.20 8.1 -- 17 3.54 22.6 3.66 28.4 3.78 34.2 3.91 39 3.76 47.5 4.03 53.5 4.13

F2FP060 47.5 3.30 28 2.20 8.1 -- 18 3.5 22.8 3.58 28 3.75 34.6 3.95 40 3.8 47.5 4.15 54 4.3

F2FP060 60.0 3.40 40.0 2.40 8.0 -- 18.7 4.08 26.1 4.44 40.0 4.80 40.7 5.16 49.0 5.55 60.0 5.94 68.6 6.25

F2FV060 60.0 3.00 40.0 2.60 -- 8.3 17.6 3.93 24.6 4.11 40.0 4.29 38.6 4.47 46.6 4.68 60.0 4.93 66.1 5.07

G2FD061H24 62.0 3.60 41.0 2.60 8.4 – 20.2 4.07 26.9 4.28 41.0 4.49 40.5 4.70 48.3 4.95 62.0 5.22 67.5 5.39

OUTDOOR TEMP

3

6 Unitary Products Group

036-21031-004 Rev. A (0603)

HEA TING PERFORMANCE - Furnace Coils

2

OUTDOOR TEMP

UNIT

MODEL

COIL

MODEL

1

ARI HEATING

47°F 17 °F HSPF -3 °F 7°F17°F27°F37°F47°F 57°F

MBH COP MBH COP STD. V. S. MBH KW MBH KW MBH KW MBH KW MBH KW MBH KW MBH KW

E*FH WITH (VAR IABLE SPEED & STANDARD) FURNACE COILS

G1HD024 18 3.08 9.9 2.00 7.1 -- 6.2 1.1 9 1.15 9.9 1.25 13.6 1.4 16 1.5 18 1.6 20 1.75

G1FA024S17 19.0 3.24 11.4 2.16 7.6 -- 6.6 1.09 9.2 1.1 11.4 1.25 13.8 1.45 16.6 1.54 19.6 1.64 22 1.74

E4FH018

G1UA024S17 19.0 3.24 11.4 2.16 7.6 -- 6.6 1.09 9.2 1.1 11.4 1.25 13.8 1.45 16.6 1.54 19.6 1.64 22 1.74

G1FA030S14 19.0 3.32 11.6 2.20 7.6 -- 6.6 1.08 9.2 1.15 11.6 1.27 14.2 1.43 16.8 1.5 19.8 1.62 22.4 1.76

G1UA030S14 19.0 3.32 11.6 2.20 7.6 -- 6.6 1.08 9.2 1.15 11.6 1.27 14.2 1.43 16.8 1.5 19.8 1.62 22.4 1.76

G1HD024 24 3.16 12.2 2.00 8 -- 7.2 1.57 10 1.67 12.2 1.76 16.4 1.9 19.6 1.95 24 2.05 27.4 2.17

G1FA030S17 23.6 3.16 13.4 2.14 8 -- 7.6 1.5 10.4 1.65 13.4 1.76 16.6 1.85 19.8 1.97 23.6 2.03 27.6 2.16

E4FH024

G1UA030S17 23.6 3.16 13.4 2.14 8 -- 7.6 1.5 10.4 1.65 13.4 1.76 16.6 1.85 19.8 1.97 23.6 2.03 27.6 2.16

G1FA036S17,21 24 3.26 13.6 2.18 8 -- 7.6 1.52 10.4 1.6 13.6 1.76 16.8 1.9 20 1.9 24 2.03 28.2 2.18

G1UA036S17,21 24 3.26 13.6 2.18 8 -- 7.6 1.52 10.4 1.6 13.6 1.76 16.8 1.9 20 1.9 24 2.03 28.2 2.18

G1HD036 28 3.33 17 2.3 8 -- 9.8 2.08 13.1 2.14 16.6 2.1 19.8 2.2 23.8 2.38 28 2.5 39.8 2.55

G1FA036S14 28 3.33 17.2 2.3 8 -- 10 2.07 13.2 2.15 16.8 2.3 19.9 2.3 23.9 2.39 28 2.5 34 2.57

E4FH030

G1UA036S14 28 3.33 17.2 2.3 8 -- 10 2.07 13.2 2.15 16.8 2.3 19.9 2.3 23.9 2.39 28 2.5 34 2.57

G1FA036S17,21 28 3.33 17.2 2.3 8 -- 10.1 2.08 13.3 2.17 17 2.4 20.1 2.4 24.1 2.4 28 2.55 34.2 2.6

G1UA036S17,21 28 3.33 17.2 2.3 8 -- 10.1 2.08 13.3 2.17 17 2.4 20.1 2.4 24.1 2.4 28 2.55 34.2 2.6

G1FA048S21 35.6 3.46 21.8 2.30 8.0 -- 12.8 2.61 17.3 2.69 21.8 2.78 26.3 2.86 31.3 2.95 35.6 3.02 41.2 3.07

E4FH036

G1UA048S21 35.6 3.46 21.8 2.30 8.0 -- 12.8 2.61 17.3 2.69 21.8 2.78 26.3 2.86 31.3 2.95 35.6 3.02 41.2 3.07

G1FA048S17 36.0 3.38 21.8 2.26 8.0 -- 12.5 2.63 17.2 2.73 21.8 2.83 26.4 2.93 31.7 3.04 36.0 3.12 41.4 3.16

G1UA048S17 36.0 3.38 21.8 2.26 8.0 -- 12.5 2.63 17.2 2.73 21.8 2.83 26.4 2.93 31.7 3.04 36.0 3.12 41.4 3.16

G1FA048S21 42.0 3.50 25.2 2.30 8.0 -- 12.5 2.98 18.9 3.09 25.2 3.21 31.5 3.33 38.5 3.47 42.0 3.52 50.3 3.66

E4FH042

G1UA048S21 42.0 3.50 25.2 2.30 8.0 -- 12.5 2.98 18.9 3.09 25.2 3.21 31.5 3.33 38.5 3.47 42.0 3.52 50.3 3.66

G1FA048S17 41.5 3.40 25.0 2.24 8.0 -- 13.4 3.05 19.2 3.16 25.0 3.27 30.8 3.38 37.3 3.51 41.5 3.58 47.8 3.66

G1UA048S17 41.5 3.40 25.0 2.24 8.0 -- 13.4 3.05 19.2 3.16 25.0 3.27 30.8 3.38 37.3 3.51 41.5 3.58 47.8 3.66

G1FA048S21 48 3.40 28 2.30 8 -- 16.1 3.23 22.1 3.41 28 3.57 34 3.72 40.6 3.91 48 4.06 54.8 4.16

E5FH048

G1UA048S21 48 3.40 28 2.30 8 -- 16.1 3.23 22.1 3.41 28 3.57 34 3.72 40.6 3.91 48 4.06 54.8 4.16

G1FA060S21,24 48 3.40 28 2.30 8 -- 16.2 3.24 22.2 3.42 28 3.55 34 3.7 40.6 3.92 48 4 54.9 4.18

G1UA060S21,24 48 3.40 28 2.30 8 -- 16.2 3.24 22.2 3.42 28 3.55 34 3.7 40.6 3.92 48 4 54.9 4.18

E4FH060

1. Rated CFM same as for cooling.

2. Heating MBH based on ARI standards of 70° DB entering i n door air, 72% RH outdoor air with 25 feet of interconnecting piping and no supplemental

3. Integrated heating capaci ties include the effect of defrost cycles in the temperature range where they occur.

G1FA060S21,24 60.0 3.40 40.0 2.40 8.0 -- 18.9 3.95 26.0 4.21 33.0 4.48 40.1 4.74 48.1 5.04 57.0 5.39 67.8 5.60

G1UA060S21,24 60.0 3.40 40.0 2.40 8.0 -- 18.9 3.95 26.0 4.21 33.0 4.48 40.1 4.74 48.1 5.04 57.0 5.39 67.8 5.60

electric heat operation.

3

COP equals MBH output divided by (total KW input x 3.412).

HSPF (Heating Seasonal Performance Factor) is the total heating output during a normal annual usage period for heating divided by the total electric

power input during the same period.

— = Not Applicable.

Unitary Products Group 7

036-21031-004 Rev. A (0603)

ACCESSORIES

Refer to Price Manual for specific model numbers.

Start Assist Kit (2SA067*)

Blower Time D elay - Available to increase efficiency when

installed. Installs on indoor section and maintains blower for

approximately one minute after cooling thermostat has been

satisfied.

Hard Start Kits - Provides required starting torque for use

with Thermal Expansion Valve Kit.

Low Temperature Cutout (2LT06700224) - Prevents heat

pump operation below -10°F ambient temperature.

Compressor Blanket - Designed to further reduce the normal operating sound.

Add-on Control (2AC02700701) - Provides interface for use

of gas and oil furnaces with the heat pump system.

Thermal Expansion Valve Kit - 1TV0700 Series TXV kit

used to improve system performance.

Outdoor Thermostat (2TD06700124) - Provides additional

staging of supplemental electric heat.

Room Thermostats - A wide selection of matching thermostats is available to provide features required for any installation.

2H/1C, manual change-over electronic non-programmable

thermostat.

3H/2C, non-programmable digital thermostat.

3H/2C, auto/manual changeover, electronic programmable,

7-day, thermostat.

* For the most current accessory information, refer to the

price book or consult factroy.

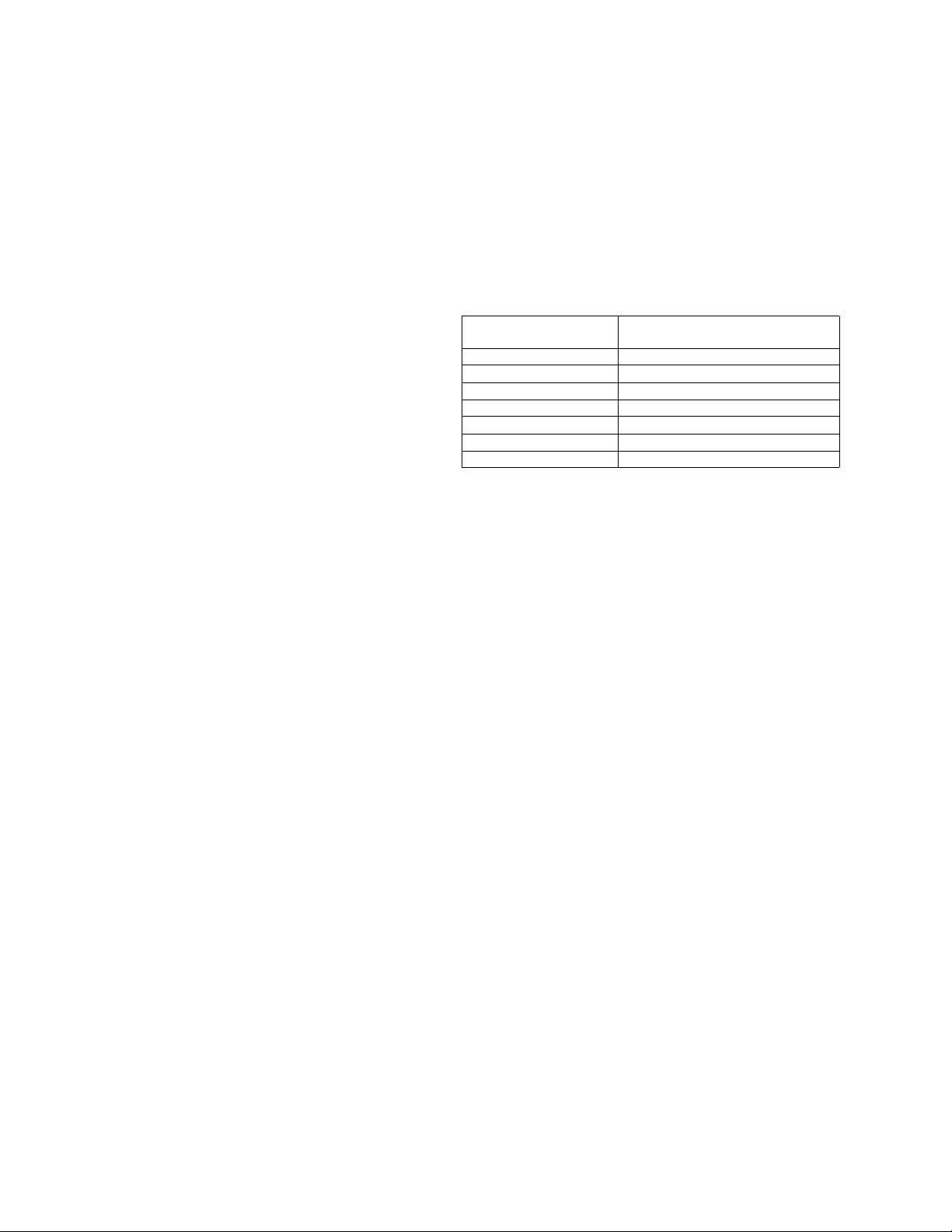

SOUND BLANKET

EFH

MODEL

018 72

024 73

030 74

036 74

042 74

048 76

060 76

*Rated in accordance with ARI Standard 270.

SOUND RATING

DECIBELS

8 Unitary Products Group

Loading...

Loading...