Page 1

MicroTrac Gateway - Remote I/O

Part No. 46S03196-0010

02/01/01

RD 3196-10

Warranty. Standard products manufactured by the Company are warranted to be free from defects in workmanship and

material for a period of one year from date of shipment and any products which are defective in workmanship or material will

be repaired or replaced, at the Company's option, at no charge to the Buyer. Final determination as to whether a product is

actually defective rests with the Company. The obligation of the Company hereunder shall be limited solely to repair or replace,

at the Company's discretion, products that fall within the foregoing limitations, and shall be conditioned upon receipt by the

Company or written notice of any alleged defects or deficiency promptly after discovery and within the warranty period, and in

the case of components or units purchased by the Company, the obligations of the Company shall not exceed the settlement that

the Company is able to obtain from the supplier thereof. No products shall be returned to the Company without its prior

consent. Products which the Company consents to have returned shall be shipped prepaid f.o.b. the Company's factory. The

Company cannot assume responsibility or accept invoices for unauthorized repairs to its components, even though defective.

The life of the products of the Company depends, to a large extent, upon the usage thereof, and THE COMPANY MAKES NO

WARRANTY AS TO FITNESS OF ITS PRODUCTS FOR THE SPECIFIC APPLICATIONS BY THE BUYER NOR AS

TO PERIOD OF SERVICE UNLESS THE COMPANY SPECIFICALLY AGREES OTHERWISE IN WRITING AFTER

THE PROPOSED USAGE HAS BEEN MADE KNOWN TO IT.

This warranty does not apply to experimental or developmental products for which NO warranty is made or given and Buyer

waives any claim thereto.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY WARRANTY OF MERCHANTABILITY OR OF FITNESS FOR

A PARTICULAR PURPOSE AND BUYER HEREBY WAIVES ANY AND ALL CLAIMS THEREFORE.

Limitation Of Liability. IN NO EVENT SHALL THE COMPANY BE LIABLE FOR LOSS OF PROFIT, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL DAMAGES WHETHER ARISING OUT OF WARRANTY, BREACH OF

CONTRACT OR TORT.

MicroTrac Gateway

to

Allen-Bradley PLC-5

™

and PLC-3

®

For use on MicroTrac®Local Area Network

Page 2

Table of Contents

i

Table of Contents

12/22/94

Page

INTRODUCTION ............................................................................................. 1

HARDWARE ..................................................................................................... 1

JARC Board Setup ........................................................................................ 3

JARC Board Jumper Selections .................................................................... 3

JARC Board DIP Switch .............................................................................. 3

JARC Board LED Operation ........................................................................ 5

SmartMUX™ Board Setup ........................................................................... 6

SmartMUX™ Board Baud Rate / Last State ................................................ 6

SmartMUX™ Board Rack Address ............................................................. 7

SmartMUX™ Board LED Operation ........................................................... 8

Local I/O Racks ............................................................................................. 8

Terminating the Remote I/O Link ................................................................. 9

GENERAL OPERATION .............................................................................. 10

MicroTrac to PLC (LOGO) ........................................................................ 11

PLC to MicroTrac (LOGI) .......................................................................... 12

MicroTrac to PLC (NUMO) ....................................................................... 13

PLC to MicroTrac (NUMI) ......................................................................... 14

PLC

©

Access to Drive Setup Parameters ................................................... 16

PLC Block Trasfer ...................................................................................... 17

PAC Considerations .................................................................................... 20

TROUBESHOOTING – JARC BOARD ..................................................... 22

TROUBLESHOOTING – SmartMUX™ BOARD .................................... 23

TROUBLESHOOTING – A-B PLC-5™ or PLC-3

®

.................................. 23

PCDU TERMINAL OPERATION ............................................................... 24

Block 0 – Gateway Set-Up ......................................................................... 25

Information Block 1 – Digital Read ........................................................... 25

Information Block 2 – Digital Read ........................................................... 25

Information Block 3 – Digital Write ........................................................... 26

Information Block 4 – Digital Write ........................................................... 26

Information Block 5 – PLC Block Read .................................................... 26

Information Block 6 – PLC Block Read .................................................... 27

Information Block 7 – PLC Block Write .................................................... 27

Information Block 8 – PLC Block Write .................................................... 27

Information Block 9 – MicroTrac Logic Input Allocation ......................... 28

Information Block 10 – MicroTrac Logic Output Allocation .................... 28

Information Block 11 – MicroTrac Numeric Input Allocation .................. 28

Information Block 12 – MicroTrac Numeric Output Configuration ......... 29

Page 3

List of Illustrations

Figure

Number Title Page

1 JARC Interface Board ............................................................................... 1

2 SmartMUX Board ....................................................................................... 2

3 Local I/O Interface Board ........................................................................... 9

3a Local I/O Interface "Plug-In" Modules ...................................................... 9

4 PAC Logic Output to PLC ....................................................................... 11

5 PAC Logic Input from PLC ..................................................................... 12

6 PAC Numeric Output to PLC ................................................................... 13

7 PLC to PAC Numeric Input ..................................................................... 14

8 PLC Initialization Hardware and Signal Flow ..........................................15

9 Sample PAC Diagram .............................................................................. 16

10 Sample PLC Ladder Diagram .................................................................. 19

11 Sample PAC Diagram .............................................................................. 20

List of Tables

Table

Number Title Page

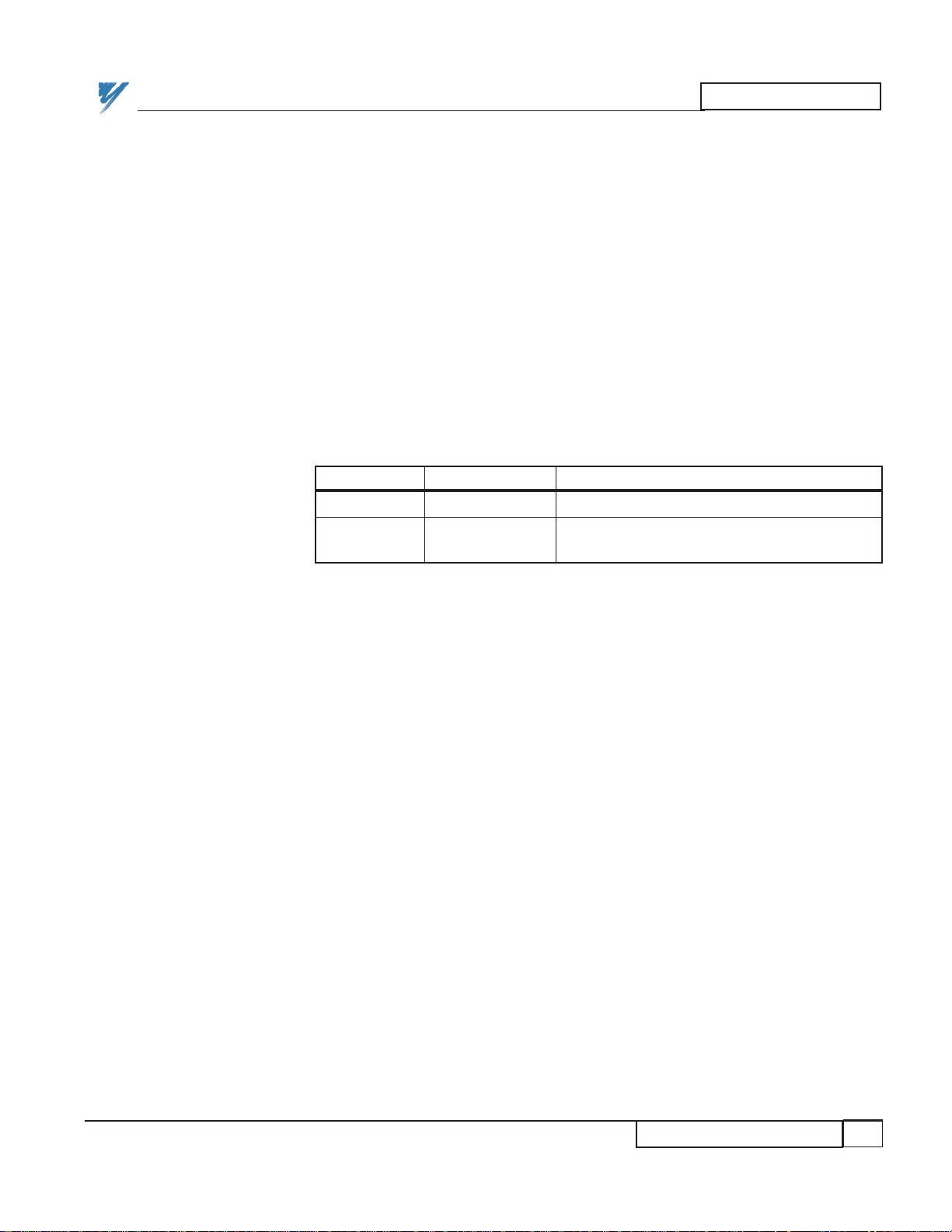

1 JARC Jumper Selection .............................................................................. 3

2 JARC Board SW1 DIP Switch, Positions 1-8 ........................................... 4

3 JARC Board SW1 DIP Switch, Positions 9-11 ......................................... 4

4 JARC Board SW1 DIP Switch, Position 12 ............................................... 5

5 JARC Board LED Operation ...................................................................... 5

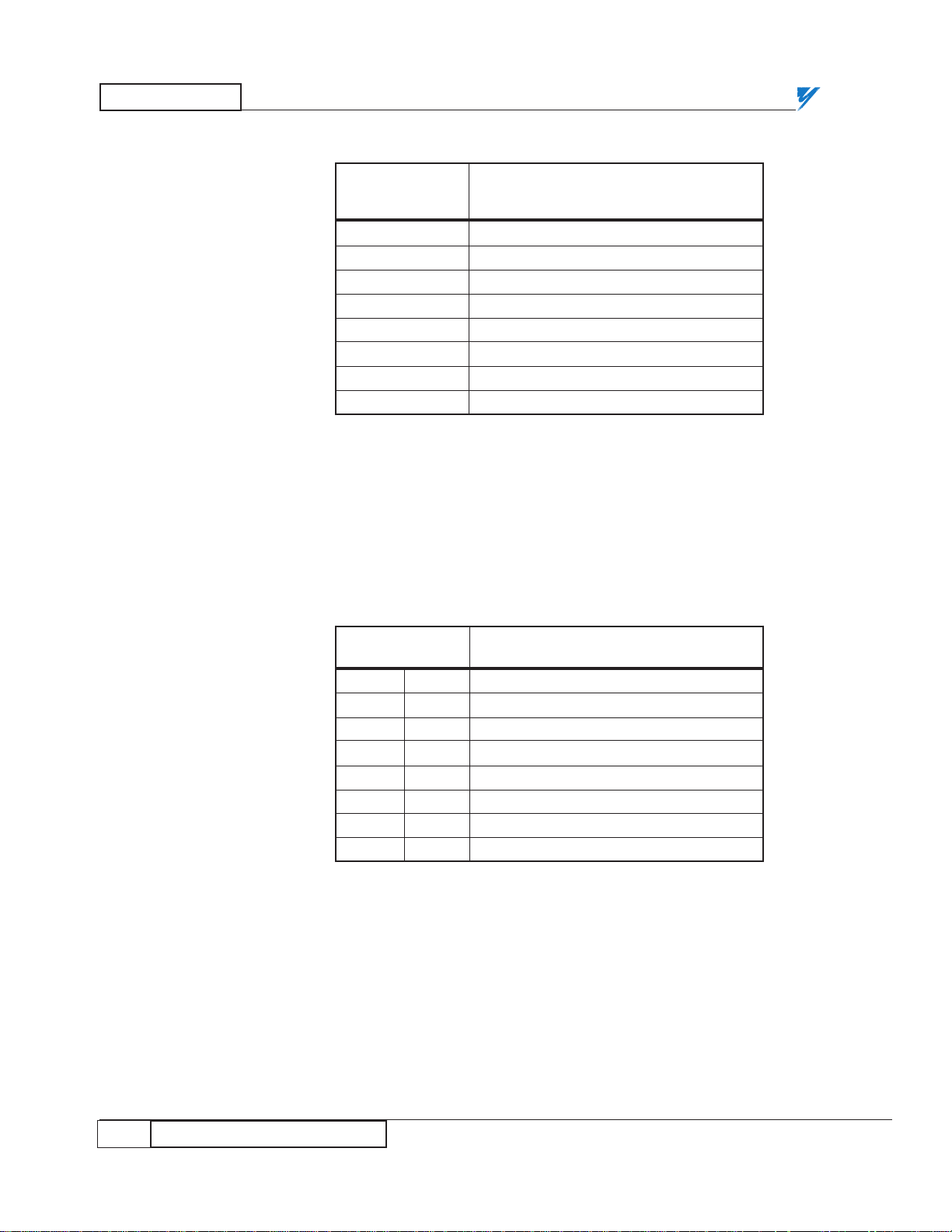

6 SmartMUX Board Baud Rate Switch ........................................................ 6

7 SmartMUX Board Last I/O Group Switch ................................................ 6

8 SmartMUX Board Last State Switch ......................................................... 7

9 SmartMUX Board Watchdog Switch ........................................................ 7

10 SmartMUX Board Rack Adddress Selection ............................................. 7

11 SmartMUX Board LED Operation ............................................................ 8

12 Troubleshooting the JARC Board ............................................................ 20

13 Troubleshooting the SmartMUX Board ................................................... 21

14 Troubleshooting the PLC ......................................................................... 21

Table of Contents

ii

Table of Contents

12/22/94

Page 4

INTRODUCTION

1

INTRODUCTION

2/17/95

INTRODUCTION

HARDWARE

The Allen-Bradley Programmable Logic Controller (PLC) Remote I/O

Gateway allows any drive on the MicroTrac

®

LAN to communicate with an

Allen-Bradley PLC-5 or PLC-3 through the 1771 I/O Network. Both logic

and numeric information can be transferred.

CAUTION

The gateway must be properly grounded. Use star washers that

will cut into the metal of the gateway box when mounting to

ensure proper earth ground.

The Allen-Bradley PLC gateway is a self-contained unit with one JARC

interface board, one SmartMUX interface board, one eight-point local I/O

interface board, and a power supply. The NEMA 1 enclosure contains the

electronics with internal connections for AC power, digital I/O points, and

external connections for the MicroTrac LAN. The initial setup is factory

configured, but depending on the application, the following electronic boards

may require setup.

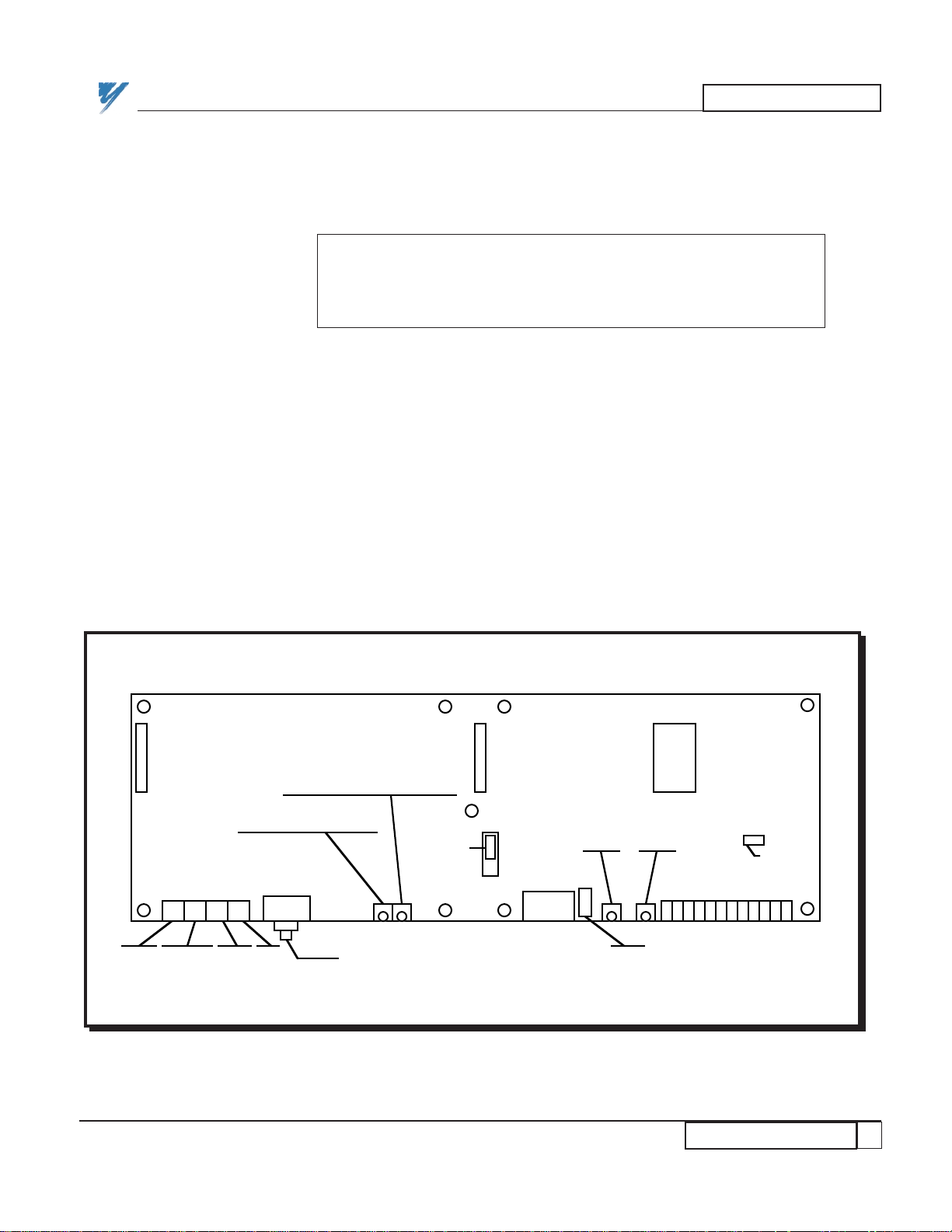

1. The JARC board is the interface board which provides the LAN

connection and communicates with the SmartMUX board through dual port

memory contained on the JARC board. A 12-position DIP switch on the

JARC board, labeled SW1, sets the LAN node address (default = 200) and the

rack address (default = 1). Refer to Figure 1.

Figure 1. JARC Interface Board

J5J6EPROM

J7

+5 V

Ground

–5 VPEJ1

• 128K

• 512K

Jumper

J9

XMIT LED D3 (Red)

RECON LED D4 (Yellow)

J3

PCDU

Connection

Fuse

PGM

LED

SW1

1

12

PWR

LED

F1

LAN

Connection

J8

CTS • • • GRD

Jumper

•

Page 5

HARDWARE

2

HARDWARE

12/22/94- RD 3196-10

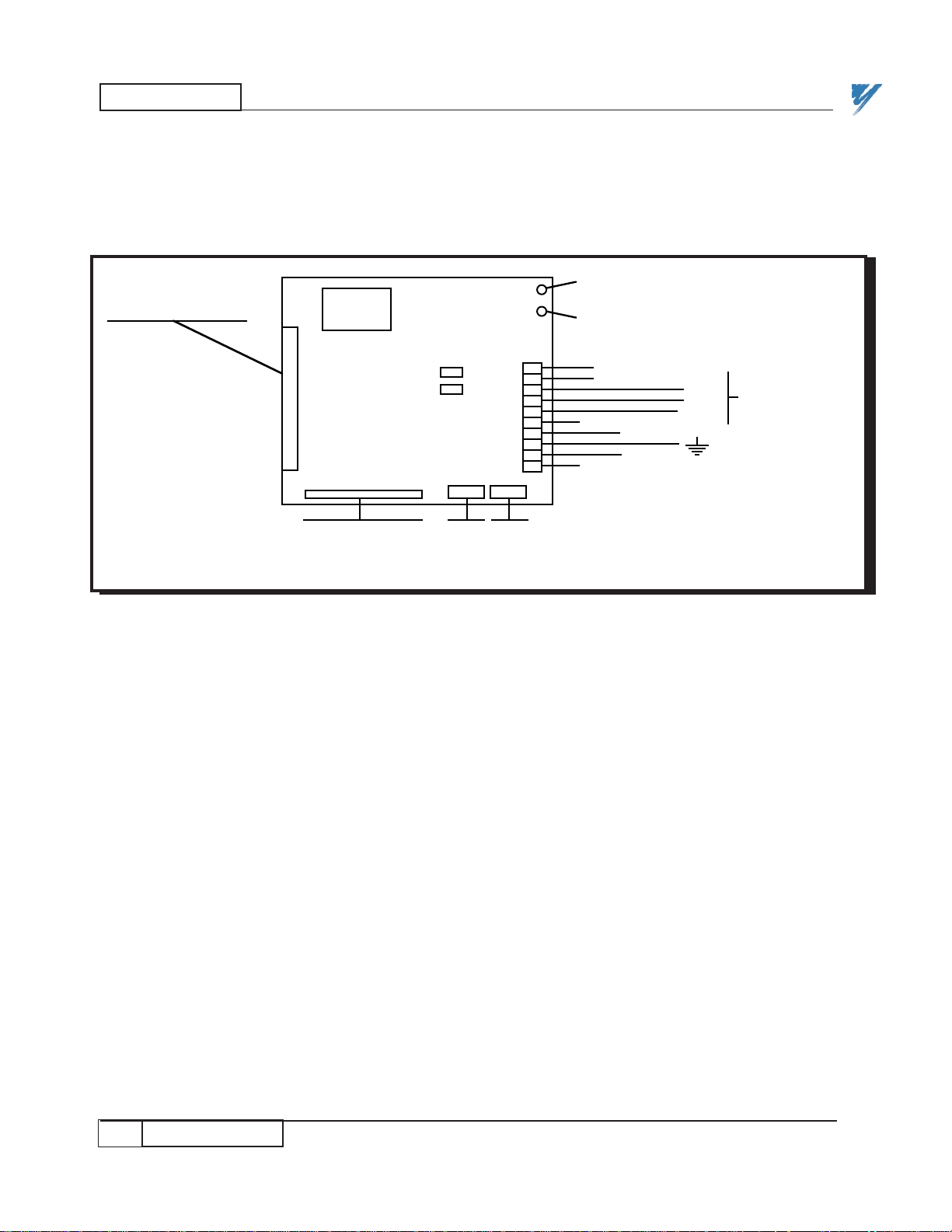

2. One SmartMUX board is attached to the JARC board using screws and a

pluggable 17-pin header. Two 6-position DIP switches on the SmartMUX

board, labeled SW1 and SW2, set the rack address and the baud rate for the

communications. Refer to Figure 2.

Figure 2. SmartMUX Board

J1

EPROM

I/O Rack Connector

J2

PWR LED (Red – for Power)

LED (Green – for Communications)

Connector

to

JARC J5 or JARC J6

SW1

SW2

110RST

ALE

CLR

SHD

BLUE

GND

CCL

CGD

+5V

Connections to

A-B 1771 I/O

Network

Page 6

HARDWARE

3

JARC Board Setup

12/22/94- RD 3196-10

The JARC board has jumpers and one 12-position DIP switch that are user

configurable.

NOTE: The JARC board only reads the DIP switch settings on

power-up.

The proper version of EPROM must be placed in the EPROM socket.

The jumpers located on the JARC board are described in Table 1, with the

defaults shown.

NOTE: On revision "C" and later JARC boards, J1 is an ARCNET

BNC connector and J2 does not exist.

NOTE: If the hand held Portable Command/Display Unit (PCDU)

does not operate properly after plugging into the JARC board J3

RS-232 connector, check the F1 fuse. This fuse protects the +5V

power to the PCDU.

Positions 1 through 8 of DIP switch SW1 determine the LAN node address.

Usually this address is set for 200, when the system has only one PLC gateway.

The address of the second PLC gateway is typically set to 201. Enter the node

ID in binary notation, choosing either a "0" or a"1" for each bit. The least

significant bit is position 1, and the most significant bit is position 8. The

standard gateway addresses are listed in Table 2. The JARC board switches use

pull-down logic, so a closed switch is a logic 0.

JARC Board

Setup

JARC Board

DIP Switch

JARC Board

Jumper

Selections

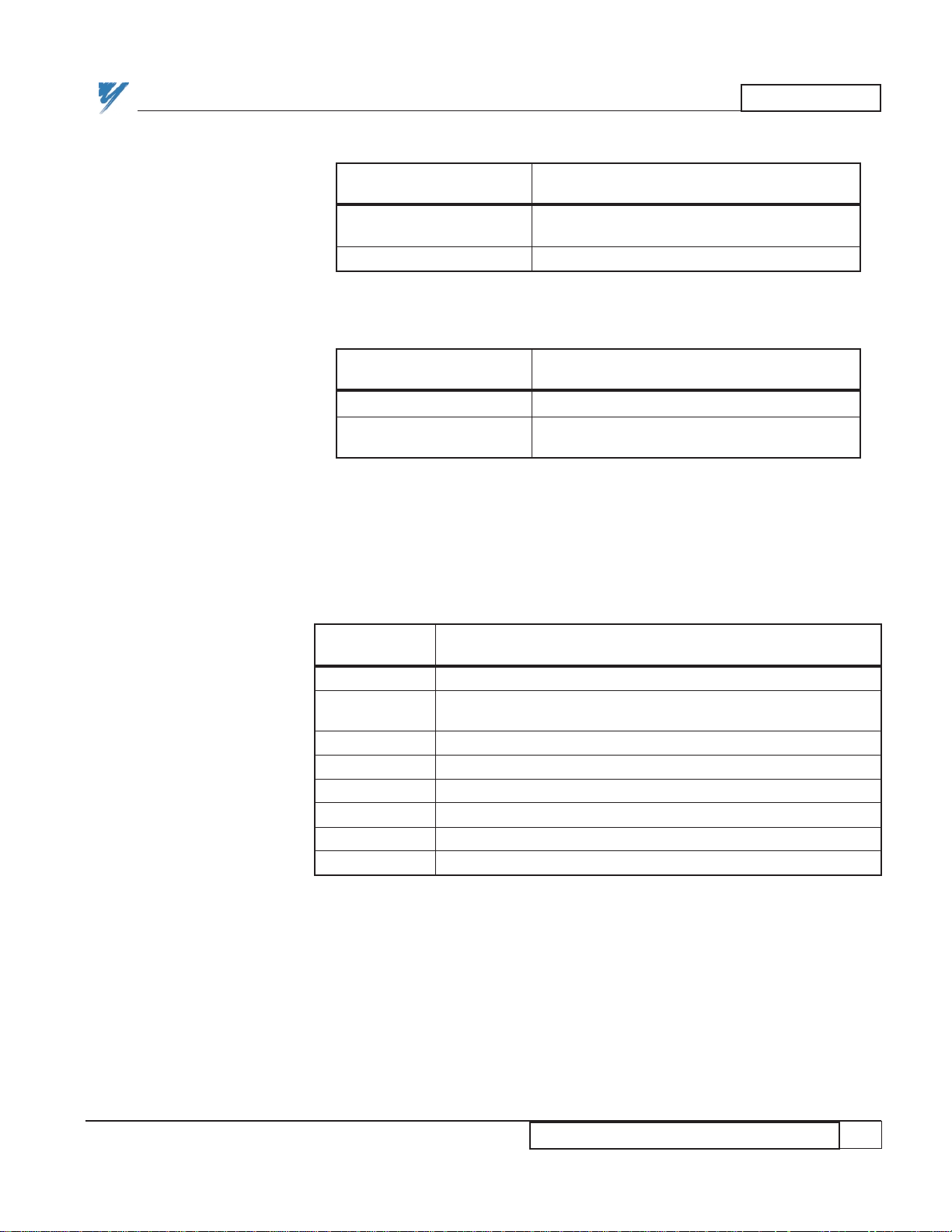

Table 1. JARC Jumper Selection

JUMPER DEFAULT DESCRIPTION

J8 Center - GND 1-2 CTS (Clear to Send for RS-232)

J9 128K - Center 1-2 RAM_CE2 (Internal selection for

128k static RAM chip)

Page 7

HARDWARE

4

12/22/94- RD 3196-10

JARC Board DIP Switch

Positions 9, 10, and 11 of DIP switch SW1 determine the starting rack number

for the JARC board to accept on the network (see Table 3). This rack number

must match the lowest rack number selected on the SmartMUX board. The

SmartMUX board is usually wired to JARC board connector J5. Rack 0 is only

valid for a PLC-3.

Table 2. JARC Board SW1 DIP Switch, Positions 1-8

MICROTRAC SW1 DIP Switch Position

LAN

LSB MSB

ADDRESS

1 2 3 4 5 6 7 8

200 X X X O X X O O

201 O X X O X X O O

202 X O X O X X O O

203 O O X O X X O O

204 X X O O X X O O

205 O X O O X X O O

206 X O O O X X O O

207 O O O O X X O O

X = Closed = Logical 0 = Switch ON

O = Open = Logical 1 = Switch OFF

Table 3. JARC Board SW1 DIP Switch, Positions 9 - 11

RACK

SW1 DIP Switch Position

J5 J6 9 10 11

0 1 X X X

1 2 O X X

2 3 X O X

3 4 O O X

4 5 X X O

5 6 O X O

6 7 X O O

7 N/A O O O

X = Closed = Logical 0 = Switch ON

O = Open = Logical 1 = Switch OFF

Page 8

HARDWARE

5

12/22/94- RD 3196-10

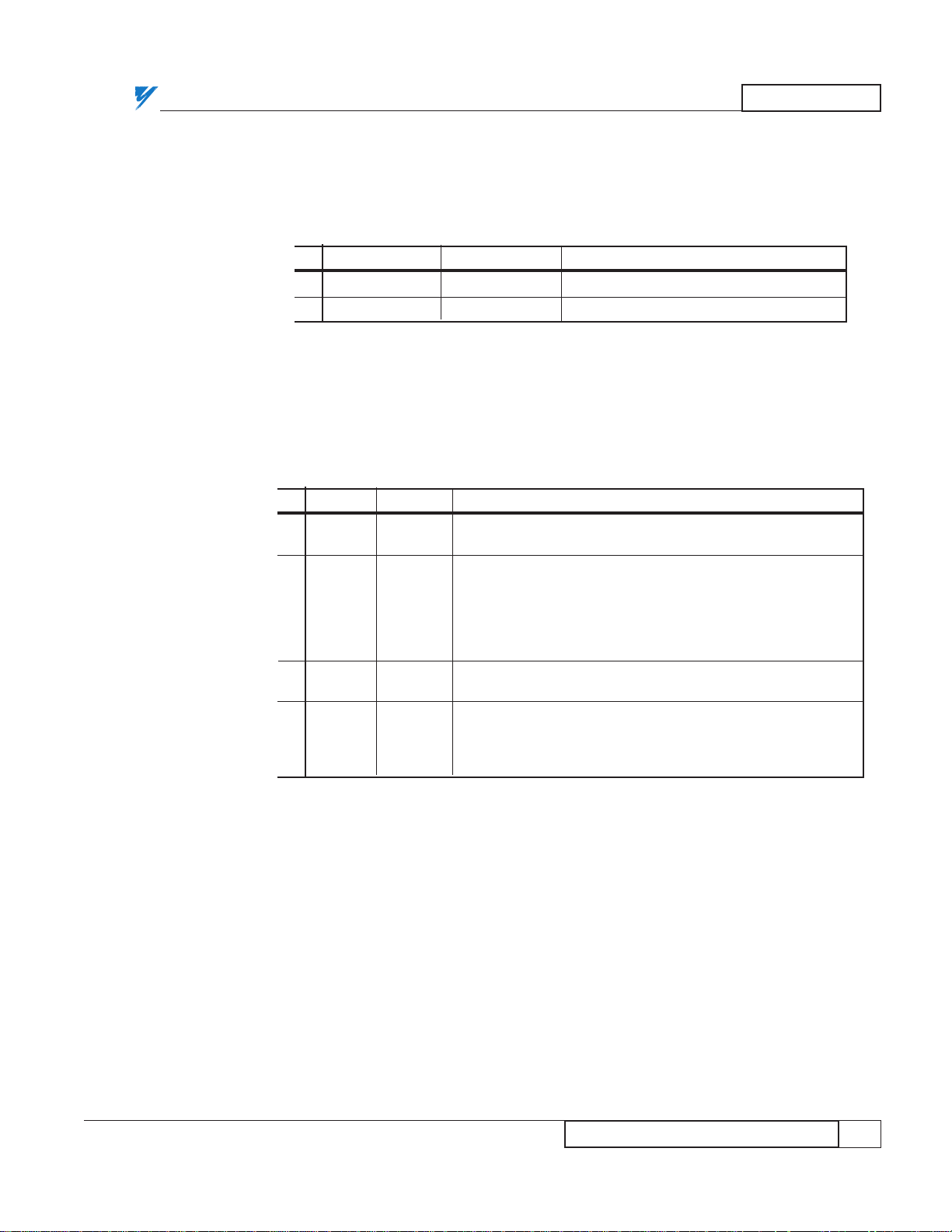

JARC Board LED Operation

Position 12 of DIP switch SW1 enables or disables the hardware watchdog (see

Table 4). The hardware watchdog resets the JARC board if a hardware or

software failure occurs. This feature should be enabled for all installations.

There are four LEDs on the JARC interface board; one power LED and three

user indication LEDs. The placement of the LEDs is shown in Figure 1.

Table 4. JARC Board SW1 DIP Switch, Position 12

WATCHDOG Position 12 DESCRIPTION

ON O Enable Watchdog (DEFAULT)

OFF X Disable Watchdog

X = Closed = Logical 0 = Switch ON

O = Open = Logical 1 = Switch OFF

Table 5. JARC Board LED Operation

LED COLOR DESCRIPTION

PWR RED ON when the JARC board has proper +5V power from the

power supply. The power LED should always be ON.

RECON YELLOW ON when a LAN reconfiguration occurs. Each time a node

enters or leaves the network, a reconfiguration occurs. If the

reconfiguration completes and the network is stable, the

RECON LED will turn OFF after about 1-2 seconds. If this

LED is ON constantly or blinks frequently, a network problem

is likely.

XMIT RED ON when the JARC board is communicating on the network.

This LED is normally on all the time.

PGM RED The PGM LED is used to indicate hardware error conditions.

If this LED is ON, turn off the power to the PLC gateway and

then turn the power back on. If this LED remains ON, then a

hardware problem has been detected with the JARC board.

JARC Board

LED Operation

Page 9

HARDWARE

6

SmartMUX Board Setup

12/22/94- RD 3196-10

SmartMUX

Board Setup

SmartMUX

Board Baud

Rate / Last

State

The SmartMUX board resides on top of the JARC board and is screwed in

place. The SmartMUX board requires four screws to attach it to the JARC

board.

There are two jumper positions on the SmartMUX board, labeled J1 and J2.

These jumpers are used for EPROM functions which are not required by this

implementation of the SmartMUX board, so these jumpers are not installed.

The SmartMUX board has two 6-position DIP switches, labeled SW1 and

SW2, to select the rack address and baud rate. The rack address must be

consecutive between zero and seven (inclusive), and must match the rack

address set on the JARC board.

The first DIP switch, SW1, controls the baud rate, last I/O group, last state,

and watchdog (see Tables 6-9), and one bit of the rack address. The "Baud

Rate" and "Last State" should be the only switches that require modification.

Table 6. SmartMUX Board Baud Rate Switch

DIP Switch SW1

BAUD RATE

Position 1 Position 2

57.6K X X

(DEFAULT)

115.2K O X

230.4K X O

230.4K O O

X = Closed switch = Switch ON

O = Open switch = Switch OFF

Table 7. SmartMUX Board Last I/O Group Switch

DIP Switch SW1

LAST I/O GROUP

Position 3

NOT LAST X

LAST O

(DEFAULT)

X = Closed switch = Switch ON

O = Open switch = Switch OFF

Page 10

HARDWARE

7

SmartMUX Board Rack Address

12/22/94- RD 3196-10

SmartMUX

Board Rack

Address

The following DIP switch settings represent the SmartMUX board connected

to the JARC board via the J5 connector.

Table 8. SmartMUX Board Last State Switch

DIP Switch SW1

LAST STATE

Position 4

RESET ALL X

(DEFAULT)

HOLD ALL O

X = Closed switch = Switch ON

O = Open switch = Switch OFF

Table 9. SmartMUX Board Watchdog Switch

DIP Switch SW1

WATCHDOG

Position 5

DISABLE WATCHDOG X

ENABLE WATCHDOG O

(DEFAULT)

X = Closed switch = Switch ON

O = Open switch = Switch OFF

Table 10. SmartMUX Board Rack Address Selection

DIP Switch / Position

RACK ADDRESS

SW1-6 SW2-1 SW2-2 SW2-3 SW2-4 SW2-5 SW2-6

00 X X X X X X X

01 X X X X O X X

(DEFAULT)

02 X X X O X X X

03 X X X O O X X

04 X X O X X X X

05 X X O X O X X

06 X X O O X X X

07 X X O O O X X

X = Closed switch = Switch ON

O = Open switch = Switch OFF

Page 11

8

HARDWARE

SmartMUX Board LED Operation

12/22/94- RD 3196-10

SmartMUX

Board LED

Operation

There are two LEDs on the SmartMUX board; one status LED and one

communications LED. The function of these LEDs is listed in Table 11.

The placement of the LEDs is shown in Figure 2.

The PLC gateway has local I/O connection points. The SmartMUX board connects

to a local I/O interface board which has 8 logic inputs or logic outputs that can be

either AC or DC. The local interface I/O are always assigned to module group 0,

slot 1 of the rack being simulated by the SmartMUX board. These I/O can be

accessed by the PLC directly, but not by devices on the drive network.

The addresses of the 8 I/O points range from: I:XX0/10 to I:XX0/17 for inputs,

and O:XX0/10 to O:XX0/17 for outputs, where XX is the Gateway rack number

(octal). These I/O must be all inputs or all outputs.

Table 11. SmartMUX Board LED Operation

LED COLOR DESCRIPTION

STATUS RED When the SmartMUX board has proper +5V power from the

(PWR) power supply, this LED will flash once or twice and then turn

OFF. If the LED flashes once, then this node is an odd rack

address. If the LED flashes twice, then this node is an even

rack address.

COMM GREEN When the Allen-Bradley PLC establishes communications with

(LED1) the SmartMUX board, this LED will flash or be ON. A flashing

LED means the PLC is in program mode. A solid or ON LED

means the PLC is in run mode and information is being

transferred. Proper operation with the PLC in run mode

results in this LED being ON.

Local I/O Racks

Page 12

HARDWARE

9

Terminating the Remote I/O Link

12/22/94- RD 3196-10

MagneTek Part Description

Number

05P00090-0327 AC Output Module

05P00090-0328 AC/DC Input Module

05P00090-0329 DC Output Module

05P00090-0330 DC Input Module

05P00090-0331 SPST Relay Output Module

The SmartMUX board is an Allen-Bradley Pyramid Solution product.

Therefore, it must meet Allen-Bradley wiring and communication

specifications. Terminating the remote I/O link is part of the specification the

SmartMUX board must meet. A user must place a terminating resistor on both

physical ends of a remote I/O link to ensure proper operation.

NOTE: Refer to Allen Bradley’s 1785 PLC-5 Family Programmable

Controllers, Hardware Installation Manual, Publication 1785-6.6.6

June 1993 or later, page 7-10 for proper terminating resistor

installation instructions.

Figure 3. Local I/O Interface Board

Figure 3a. Local I/O Interface "Plug-In" Modules

8 LEDs (0 - 7)

+ –

1A Fuse

0123456

7

1

16

Fuse

5A

Spare

5A Fuse

Terminals

Terminals

for power

Input or Output (AC or DC) modules

SmartMUX

Edge

Connector

Terminating the

Remote I/O Link

Page 13

GENERAL OPERATION

10

GENERAL OPERATION

2/17/95- RD 3196-10

GENERAL

OPERATION

The PLC gateway is normally mounted and wired on a Yaskawa drive panel.

The gateway, however, can be mounted remotely by the customer. In this case,

special consideration must be given to the 120 VAC power source for the

gateway power supply. DO NOT connect the gateway power cord directly into

a wall outlet. Instead, use an isolation transformer and tie one side of the

secondary to the nearest earth ground (the steel structure of the building is

usually a good choice). The ground studs on the MicroTrac drive panels or

cabinets must also be connected directly to a solid earth ground in order to

assure that the gateway enclosure and the drive panels are at the same potential.

Improper grounding may cause erratic operation of the LAN.

The PLC gateway, when connected to the A-B 1771 remote I/O cable, is treated

as a remote I/O rack by the PLC. From a PLC-5 the selected rack number can

be between 1 and 7 (inclusive). From a PLC-3 the rack number can be between

0 and 7. Note that the PLC gateway is configured as a rack on the remote I/O

link, and cannot be the same rack number as any other rack on the remote I/O

link. If local racks are to be used, the rack number assigned to the PLC

gateway must be greater than the last local rack number.

The baud rate of the A-B 1771 remote I/O link is determined by the PLC. A

DIP switch on the SmartMUX board selects the A-B 1771 link speed. The

acceptable baud rates are 57.6K, 115.2K, and 230.4K.

A gateway uses one entire remote rack with the following capacity:

— 64 numerics PLC to MicroTrac in group 0, slot 0.

— 64 numerics MicroTrac to PLC in group 0, slot 0.

— 8 local logics (8 inputs or 8 outputs) in group 0, slot 1.

— 112 logics PLC to MicroTrac in groups 1-7.

— 112 logics MicroTrac to PLC in groups 1-7.

CAUTION

The gateway must be properly grounded. When mounting, use star washers

that will cut into the metal of the gateway box to ensure proper earth ground.

.

Page 14

GENERAL OPERATION

11

MicroTrac to PLC

12/22/94- RD 3196-10

MicroTrac to

PLC (LOGO)

Logic outputs from a PAC schematic to a PLC can be visualized as shown in

Figure 4. Logic output (LOGO) PAC blocks send a logic value from the drive

to the remote device specified by the node, channel, and sub channel defined

for that block. The node number for a single PLC gateway is typically 200.

These logics utilize groups 1-7 for a maximum total of 112 (7 x 16) MicroTrac

to PLC logic bits.

The LAN channel number is in octal notation and corresponds directly with

the A-B PLC rack and group number for the associated simulated A-B input.

In addition, the number will have a 100's prefix digit of 1 that can be

associated with the A-B PLC input "I" notation. Thus:

LAN CHANNEL 124 = INPUT RACK 2, GROUP 4 or I:24

LAN CHANNEL 127 = INPUT RACK 2, GROUP 7 or I:27

The sub channel number will also be in octal, and will directly correspond to

the bit number of the simulated output. Thus, the 16 possible bits are:

LAN SUB CHANNEL 00 = BIT 00

: : :

LAN SUB CHANNEL 07 = BIT 07

LAN SUB CHANNEL 10 = BIT 10

: : :

LAN SUB CHANNEL 17 = BIT 17

Each PLC logic input bit can be addressed by no more than one drive. If more

than one drive attempts to initialize the same bit (sub channel) in a given

group, a “Logic Output Allocation Error” message will be sent to the drive

over the LAN.

NOTE: LAN traffic throughput may significantly improved if all logic

values for a particular drive are grouped together and not needlessly

divided between multiple PLC groups.

Figure 4. PAC Logic Output to PLC

TYPICAL LOGO

103-D

LOGO

Node Chan. Sub

200 136 3

LAN Cable

Logic Bits

PLC Gateway

Remote

I/O Cable

PLC Ladder

Logic

I:36/03

Page 15

GENERAL OPERATION

12

PLC to MicroTrac

12/22/94- RD 3196-10

PLC to

MicroTrac

(LOGI)

Logic inputs to a PAC schematic from a PLC can be visualized as shown in

Figure 5. Logic input (LOGI) PAC blocks receive a logic value sent to the

drive from the remote device specified by the node, channel, and sub channel

defined for that block. The node number for a single PLC gateway is typically

200. These logics utilize groups 1-7 for a maximum of 112 (7 x 16) PLC to

MicroTrac logic bits.

The channel number is in octal notation. The first digit is a 0, and can be

associated with the A-B PLC output "O" notation. The 2nd and 3rd digits

represent the rack number and the group number. Thus:

LAN CHANNEL 015 = OUTPUT RACK 1, GROUP 5 or O:15

The sub channel number will also be in octal, and will directly correspond to

the bit number of the simulated input. Thus, the 16 possible bits are:

LAN SUB CHANNEL 00 = BIT 00

: : :

LAN SUB CHANNEL 07 = BIT 07

LAN SUB CHANNEL 10 = BIT 10

: : :

LAN SUB CHANNEL 17 = BIT 17

Any drive can request logic inputs from any rack and group of the PLC that

has outputs defined for that location. The Drive Kernel software will select the

appropriate bit and send it to the appropriate LOGI block.

NOTE: LAN traffic throughput may significantly improved if all logic

values for a particular drive are grouped together and not needlessly

divided between multiple PLC groups.

Figure 5. PAC Logic Input from PLC

TYPICAL LOGI

101-D

LOGI

Node Chan. Sub

200 015 2

LAN Cable

Logic Bit

PLC Gateway

Remote

I/O Cable

PLC Ladder

Logic

O:015/02

Page 16

GENERAL OPERATION

13

MicroTrac to PLC

5/2/95- RD 3196-10

MicroTrac to

PLC (NUMO)

Numeric outputs from a PAC schematic to a PLC can be visualized as shown in

Figure 6. Numeric output (NUMO) PAC blocks send a numeric value from the

drive to the remote device specified by the node, channel, and sub channel defined

for that block. The node number for a single PLC gateway is typically 200.

The channel number here has a similar meaning to that discussed above for the

logic function, except that the leading digit must be a 1. The SmartMUX board

only supports Numeric block transfers to slot 0 and group 0. Thus:

LAN CHANNEL 130 = RACK 3, GROUP 0

The PAC block’s sub channel number will be in decimal, and will normally range

from 0 through 63. This number represents the location of the numeric output data

in the Block Transfer Read data file. Up to 64 values may be processed in one

Block Transfer operation.

Every numeric value exchanged between the drive system and the PLC must have

a unique value for channel and subchannel.

Figure 6. PAC Numeric Output to PLC

TYPICAL NUMO

104-D

NUMO

Node Chan. Sub.

200 110 19

LAN Cable

DATA

PLC Gateway

Remote

I/O Cable

PLC Ladder

Logic

FF

Block

Transfer

Read

Page 17

GENERAL OPERATION

14

PLC to MicroTrac

12/22/94- RD 3196-10

PLC to

MicroTrac

(NUMI)

Numeric inputs to a PAC schematic from a PLC can be visualized as shown in

Figure 7. Numeric input (NUMI) PAC blocks receive a numeric value sent to

the drive from the remote device specified by the node, channel, and sub

channel defined for that block. The node number for a single PLC gateway is

typically 200.

The channel number here has the same meaning as the numeric outputs, except

that the leading digit is always 0. The SmartMUX board only supports

Numeric block transfers to slot 0 and group 0. Thus:

LAN CHANNEL 030 = RACK 3, GROUP 0

The PAC block’s sub channel number will be in decimal, and will normally be

between 0 and 63. This number represents the location of the numeric input

data in the Block Transfer Write data file. Up to 64 values may be processed

in one Block Transfer operation. Only one BTW can be used for each

Gateway.

Figure 7. PLC to PAC Numeric Input

TYPICAL NUMI

102-D

NUMI

Node Chan. Sub.

200 010 39

LAN Cable

DATA

PLC Gateway

Remote

I/O Cable

PLC Ladder

Logic

FF

Block

Transfer

Write

Page 18

GENERAL OPERATION

15

PLC Access to Drive Setup Parameters

12/22/94- RD 3196-10

PLC Access to

Drive Setup

Parameters

The PLC can be used to change the value of drive setup parameters. In the

example illustrated in Figures 8 & 9, the PLC can modify a parameter called

“Master Line Speed”. This parameter is also accessible from the Standard

Control Display Unit (SCDU), the Portable Control Display Unit (PCDU), and

potentially from a Remote Display Unit (RDU) or a personal computer

TracView display. The subsequent programming techniques make sure that a

change from one device is reflected at the other device and establish when one

device takes precedence over the other.

Within the PAC program, the PLC initialization commands coordinate the

multiple source parameter exchange. The PLC software must also help

coordinate this multiple source exchange.

Figure 8. PLC Initialization Hardware and Signal Flow

PLC

1771 Remote I/O Cable

PLC Gateway

(Node 200)

RS232

PCDU

MicroTrac SCDU

(Node 1)

Remote Display

Controller

(Node 103)

RDU

RDU

RDU

RS485

PAC Initialization

Definitions

MicroTrac

LAN Cable

Page 19

GENERAL OPERATION

16

PLC Access to Drive Setup Parameters

12/22/94- RD 3196-10

There are two types of PAC blocks which can be used with the PLC

initialization command. These are the GETN and RDCI blocks which allow

the programmer to define drive setup parameters, each of which has a unique

"function" number. The vaules of these setup functions can be changed from

the drive, and can also be accessed by devices on the drive network such as the

PLC gateway.

Figure 9 shows the relationship between an RDCI PAC block and the PLC

initialization table. A GETN block would be handled the same way. The PLC

initialization table refers to this RDCI by its function number (115).

Figure 9. Sample PAC Diagram

300-E

TO OTHER CIRCUITS IN THIS

DRIVE'S PAC DIAGRAM

F# 115 MASTER LINE SPD

RDCI

FCTN

115

0 0

DESC

UNIT

MAX

MIN

DFLT

TYPE

BLCK

SCANDPP

S

REMOTE DISPLAY LIST

Node Chan Menu

No. No. Item

103 5 6 115 MASTER LINE SPD 0 RDCI

FCTN DESCRIPTION DP

Block

Type

PLC INITIALIZATION

PLC PLC In PLC In PLC Out PLC Out FCTN DP DESCRIPTION

Node Chan Item Chan Item

200 120 1 020 1 115 0 MASTER LINE SPD

HEADER

PAC SOURCE HEADER

LAN ID:

DRIVE NAME:

PRODUCT CLASS

SCAN A RATE

1

LEAD DRIVE

312_V9_R1

0.0

Greeting1:

THIS MAGNETEK DSD (DIGITAL SYSTEMS DRIVE) IS POWERED UP AND READY

Greeting2:

THERE ARE NO FAULTS TO REPORT AT THIS TIME

MASTER_LINE_SPD

FPM

10000

0

1000

RDCI

300

E

Page 20

GENERAL OPERATION

17

PLC Block Transfer

12/22/94- RD 3196-10

PLC Block

Transfer

The PLC INITIALIZATION table can be described as follows:

1. The PLC INITIALIZATION channel number establishes the rack and

word of the block transfer. The channel designation follows the same

conventions as the NUMI and NUMO channel conventions described above.

The "PLC IN" and "PLC OUT" headings on the PLC Table are from the PLC

Viewpoint. The "PLC OUT" column corresponds to the BTW and the "PLC

IN" corresponds to the BTR.

2. The PLC INITIALIZATION item number designates the position of

the parameter in the PLC block transfer data file.

3. The PLC INITIALIZATION table requires both input and output

channel and item numbers. Sensible PLC programming technique dictates that

the input and output channel and item numbers be grouped consecutively, and

that the input and output item numbers be equal. The programmer can then

take full advantage of the high level data manipulation techniques.

4. When the PLC gateway detects a change in data from the PLC, the

appropriate drive is updated with the new data. The data transition initiates

this exchange. This new value is returned to the PLC as confirmation of a

successful update. When this parameter is changed from the drive, the

gateway updates the PLC with the new value and expects the new value to be

returned as confirmation of the exchange.

Power-up presents a special condition. There are two locations of nonvolatile

memory for the same parameter, the drive and the PLC. The drive memory is

chosen as the default on a power-up condition. To insure proper initialization

of the RDCI or GETN blocks during power-up, the PLC gateway will inhibit

transfers from the PLC until the drive data confirmation is returned from the

PLC on power-up.

A sample ladder diagram is shown in Figure 10. It illustrates the technique

used to satisfy the above requirements. The first rung moves data from the

PLC into the write transfer buffer. The second rung moves data from the read

transfer buffer into the write transfer buffer. This is conditioned by a transition

of data from the last PLC scan. The third rung executes the write to the PLC

Page 21

GENERAL OPERATION

18

PLC Block Transfer

12/22/94- RD 3196-10

gateway. The fourth rung moves the latest data from the drive into a buffer for

the transition detector of rung 2. The fifth rung executes the read from the

PLC gateway. All 64 words can be handled with block transfers in the PLC

Ladder, if the words are consecutive.

Normally, numeric transfers (inputs and outputs) will use one 16 bit word in a

PLC data file. This word should be in 2’s complement binary format (signed

integer). If the physical input to the PLC is from Binary Coded Decimal

(BCD) thumbwheel switches, then the PLC ladder logic diagram must convert

the BCD number to 2’s complement format before putting it in the appropriate

word of the Block Transfer data file.

The thumbwheel switch assembly may have a decimal point (i.e. two digits

may exist to the right of the decimal point, allowing numeric inputs to 0.01

precision). Since the 2’s complement number put into the Block Transfer file

will be an integer, not an integer plus fraction, there must be some way of

knowing where the decimal point is located. This is accomplished in the PAC

blocks with the decimal point (DP) parameter. As shown in Figure 10, the DP

for the pertinent NUMI block must be specified as 2.

In some cases, a 16 bit signed integer (+/– 32,768) may not be sufficient for

the required range. For increased range, the IEEE floating point conversion in

the PLC should be used, and the results stored in two consecutive 16 bit words

in the Block Transfer data file. In order for the PLC gateway to expect this

number format, the DP of the appropriate PAC blocks should be specified as

255 (0FFH). Again, note that two consecutive words are used for format, and

only 32 values (0 to 32) can be specified as sub-channels.

To avoid confusion, a single Block Transfer cannot mix integer and IEEE

floating point formats. If the application must use both formats, two Block

Transfer operations are needed, one for the integer numeric and one for the

floating point numeric.

This would then require two gateway racks, since a maximum of one (1) Block

Transfer Write and one (1) Block Transfer Read can be accommodated in each

gateway rack. As with LOGI, multiple drives can be specified to have NUMI

blocks obtaining data from the same data block in a given Block Transfer

Write.

NOTE: In organizing the 64 words of the BTW, group all PLC

initialization values separate from logical inputs for optimal

communication.

Page 22

GENERAL OPERATION

19

Sample PLC Ladder Diagram

5/2/95- RD 3196-10

Figure 10. Sample PLC Ladder Diagram

ABBREVIATION KEY

DSD_INT = Drive network interface to the PLC.

DSDTOPLC = Data transferred from the drive to the PLC.

DSDTOPLC_OLD = Temporary storage of DSDTOPLC for detection of changes in value.

LOAD_PLC = True indicates the value stored in the PLC is to be transferred to the drive.

PLC_DATA = Data to be moved into the PLCTODSD register when the LOAD_PLC bit is true.

PLCTODSD = Data transferred from the PLC to the Drive.

LOAD_PLC —MOV—————————

0 ——| |—————————————————————————————–———— Move — —–

Source: PLC_DATA

0

Dest: PLCTODSD

0

————————————

—NEQ——————– —MOV—————————

1 – Not Equal (A<>B) —————————————————————————– Move ——–

A: DSDTOPLC Source: DSDTOPLC

0 0

B: DSDTOPLC_OLD Dest: PLCTODSD

0 0

—————————–- ———————————–-

Data Moves to

DSD_INT

CW C_W —BTW———————————————

2 ——————| / |———————– | / |——————————–- .Block Transfer Write –—(EN)—–

EN EN Mod Type: 1771-??

Other BLK XFER Module –—(DN)

Rack: 2

Group: 0 –—(ER)

Module: 0

Control Block: CONTROLWORD

Data File: PLCTODSD

Length: 64

Continuous: N

——————————————————–

—MOV————————–

3 ————————————————————————————————————– Move ——–

Source: DSDTOPLC

0

Dest: DSDTOPLC_OLD

0

————————————

Data Reads from

DSD_INT

C_W CW —BTR———————————————

4 ——————| / |———————– | / |——————————–- Block Transfer Read –—(EN)—–

EN EN Mod Type: 1771-??

Other BLK XFER Module –—(DN)

Rack: 2

Group: 0 –—(ER)

Module: 0

Control Block: CONTROL_WORD

Data File: DSDTOPLC

Length: 64

Continuous: N

——————————————————–

5 ———————————————————————————–————————————————————-(END)—

Page 23

GENERAL OPERATION

20

PAC Considerations

12/22/94- RD 3196-10

PAC

Considerations

PLC initialization can access both RDCI and GETN blocks. The only

difference between these blocks is the way each uses the battery backed up

memory (NVRAM – nonvolatile random access memory). The RDCI block

immediately writes directly to nonprotected NVRAM. The GETN block does

not automatically write to NVRAM. Changes made to GETN values will be

lost on drive power down unless a "save to NVRAM" procedure is executed

(function 994). GETN values are saved to "protected" NVRAM. A hardware

slide switch on the DSD board must be on to allow this save. See the DSD

manual for more information. VCD 703 drives do not have "protected"

NVRAM, so the execution of F994 would save all GETN values to

"nonprotected" NVRAM.

The PAC programmer will need to know how PLC initializations fit into the

overall handling of drive setup parameters in the PAC diagram. Just as the

PLC initialization table allows the PLC to access drive setup parameters

(function number values), the RDU initialization table allows an RDU access

to these functions. Figure 11 expands the Figure 9 example to show a remote

display (RDU) initialization table.

Figure 11. Sample PAC Diagram

300-E

TO OTHER CIRCUITS IN THIS

DRIVE'S PAC DIAGRAM

F# 115 MASTER LINE SPD

RDCI

FCTN

115

0 0

DESC

UNIT

MAX

MIN

DFLT

TYPE

BLCK

SCANDPP

S

REMOTE DISPLAY LIST

Node Chan Menu

No. No. Item

103 5 6 115 MASTER LINE SPD 0 RDCI

FCTN DESCRIPTION DP

Block

Type

PLC INITIALIZATION

PLC PLC In PLC In PLC Out PLC Out FCTN DP DESCRIPTION

Node Chan Item Chan Item

200 120 1 020 1 115 0 MASTER LINE SPD

HEADER

PAC SOURCE HEADER

LAN ID:

DRIVE NAME:

PRODUCT CLASS

SCAN A RATE

1

LEAD DRIVE

312_V9_R1

0.0

Greeting1:

THIS MAGNETEK DSD (DIGITAL SYSTEMS DRIVE) IS POWERED UP AND READY

Greeting2:

THERE ARE NO FAULTS TO REPORT AT THIS TIME

MASTER_LINE_SPD

FPM

10000

0

1000

RDCI

300

E

Page 24

GENERAL OPERATION

21

PAC Considerations

12/22/94- RD 3196-10

PAC tables dealing with setup function 115 are partially shown in FIgure 11.

The attributes of function blocks are summarized on sheet 11 of the PAC

diagram in the CDU table. The RDU table is usually also placed on sheet 1.

The RDU or PLC table size can easily be expanded as required, using the

"duplicate" command in the schematic editor. A single function number (a

single setup parameter) can be programmed to multiple RDUs and therefore

may appear in the RDU table several times. There would be no need for a

single function number to appear twice in a PLC table unless there are two

PLCs that wish to access a single function. Each PLC would require its own

gateway.

The RDU table and the PLC table can be compared as follows:

1. The RDU table node number selects the Remote Display

Controller PCB, which is usually between 100-110. The PLC table

node number selects the gateway node number, which is usually 200,

but could be 200-210.

2. A decimal location is independently assigned in each row.

The SCDU, PCDU, RDU, and PLC can each have different decimal

locations.

3. The PAC channel in the RDU table is entered once per function.

It selects one of several possible RDUs at that node. The PAC channel

in the PLC table is entered twice per function. It selects the PLC rack

number. The "PLC in" channel should always have a 1 in the hundreds

position. The "PLC out" channel should always have a 0 (or no digit)

in the hundreds column. The PLC BTW and BTR must be at group 0,

slot 0.

4. The PAC item number (subchannel) in the RDU table is entered

once per function. It selects the RDU menu number. In Figure 11,

function 115, "Master Line Speed", will appear as the 6th parameter on

the 5th RDU. The PAC channel in the PLC table is entered twice per

function. It selects the PLC BTW and BTR word number (0-63). The

PLC item (word) numbers for a single parameter should be kept

identical so that PLC block move operations can be easily done.

5. The description columns in both the PLC and RDU tables are

for reference only and do not change the drive code.

Page 25

TROUBLESHOOTING

22

TROUBLESHOOTING – JARC Board

12/22/94- RD 3196-10

TROUBLE-

SHOOTING –

JARC Board

If the hand held PCDU terminal does not operate properly after plugging into

the JARC board J3 RS-232 connector, unplug it and try again. If it still does

not show any display, then check the F1 fuse on the JARC board. This fuse

protects the +5V power to the PCDU terminal.

Table 12. Troubleshooting the JARC Board

LED COLOR DESCRIPTION

PWR RED When the JARC board has proper +5V power from the power

(D1) supply, this LED will turn ON and remain ON. If the LED is

OFF, then the power supply is bad, or the connection between

the power supply and the JARC board is bad. The four

position Phoenix connector, J7, is used to connect the ±5V,

common and GND.

RECON YELLOW The yellow RECON LED is used for displaying the occurrence

(D3) of a network reconfiguration. A reconfiguration occurs when-

ever a new node enters the network. During power-up, startup, or initialization of any node on the network this LED will

turn ON for approximately 1 second and then turn OFF. If

several nodes are powering up at the same time, then the LED

may be on for 2-5 seconds. In the normal operating state, the

RECON LED must be off. If the RECON LED is always ON,

then the JARC board is the only node on the network, or one

of the other nodes has a network interface hardware problem.

XMIT RED The XMIT LED is used to show that the JARC board is

(D4) enabled to transmit on the network and that the board is

transmitting network tokens. The XMIT LED should be ON

during normal operation.

PGM RED The PGM LED is used to display errors during initialization.

(D2) The normal state of this LED is OFF. If this LED is ON, first

reapply power to the JARC board by powering down and then

powering up. If the LED remains ON, a hardware problem with

the JARC board has been detected and service is required.

Page 26

TROUBLESHOOTING

23

TROUBLESHOOTING – SmartMUX Board

12/22/94- RD 3196-10

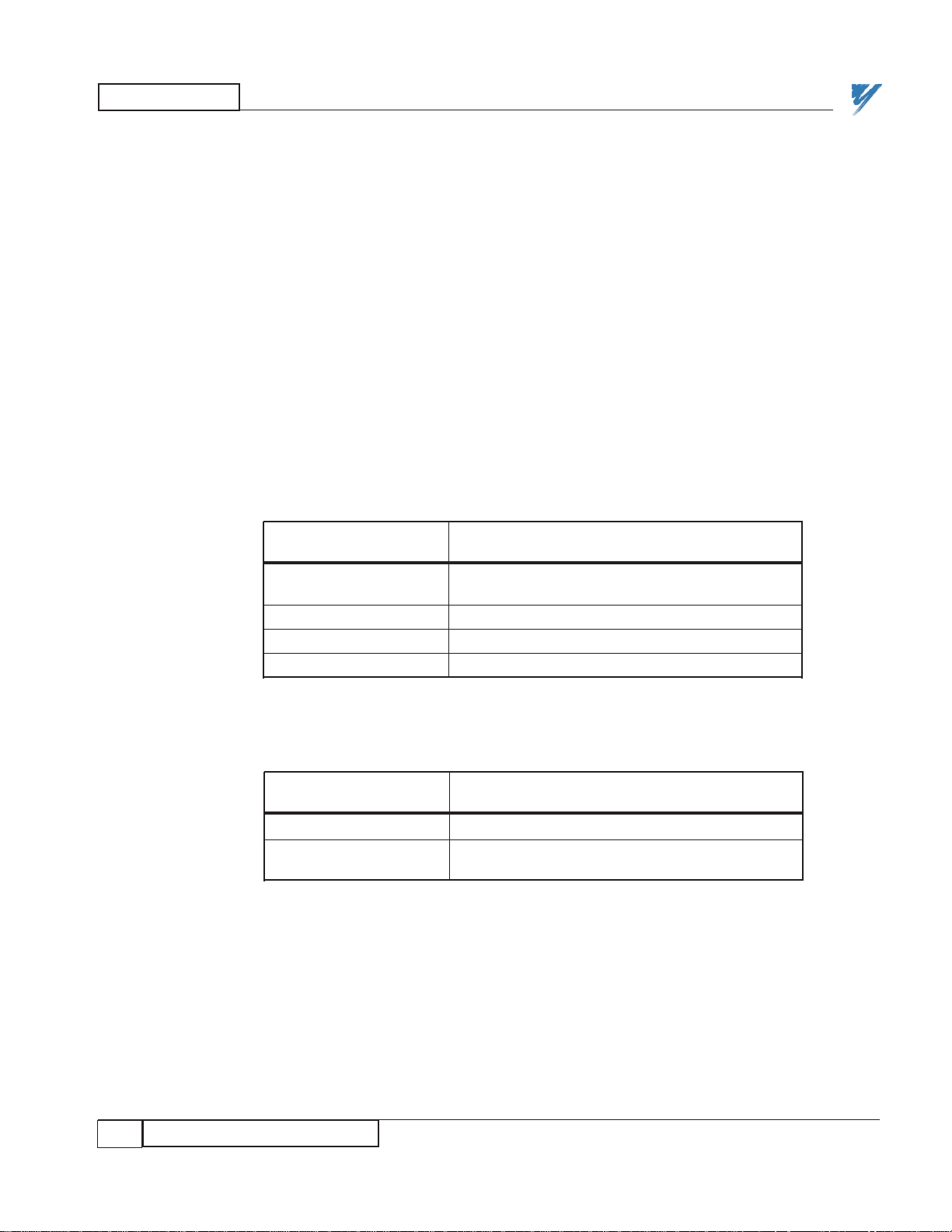

TROUBLESHOOTING –

SmartMUX

Board

TROUBLESHOOTING –

A-B PLC-5 or

PLC-3

Esure that the PLC I/O status screen does not indicate this rack is inhibited.

Table 13. Troubleshooting the SmartMUX Board

LED COLOR DESCRIPTION

STATUS RED When the SmartMUX board has proper +5V power from the

(PWR) power supply, this LED will flash once if the node is an odd

rack address or twice if the node is an even rack address.

COMM GREEN When the Allen-Bradley PLC establishes communication with

(LED1) the SmartMUX board, this LED will flash or be ON. A flashing

COMM LED means the PLC is in program mode. A solid or

ON COMM LED means the PLC is in run mode and

information is being transferred. During proper operation with

the PLC in run mode, this LED is ON.

Table 14. Troubleshooting the PLC

LED COLOR DESCRIPTION

GREEN STEADY

Communication is OK.

Remote I/O RED STEADY

No Communication.

GREEN/RED BLINK

Communication OK with some remote racks,

but not with all specified racks.

Page 27

PCDU TERMINAL OPERATION

24

PCDU TERMINAL OPERATION

12/22/94- RD 3196-10

PCDU

TERMINAL

OPERATION

NOTE: Refer to the Numeric Inputs and Numeric Ouptuts

sections (pages 13 & 14).

The same hand-held PCDU terminal that is used with the drives can be

plugged into the RS-232 connector labeled J3 on the JARC board for gateway

diagnostics. When plugged into the JARC board, the PCDU displays

information about JARC board switch settings, Yaskawa drive I/O, and Allen

Bradley PLC I/O. This is a useful tool for diagnosing network problems, as the

transmission and reception of data can be confirmed at a point between the

PLC network and the drives network. The values for the PLC and the drives

are displayed separately, which allows the technician to isolate the cause of

any data loss.

When the PCDU is used as a diagnostic tool for the gateway, only three keys

are valid to move through the different areas of information: INC (up arrow),

DEC (down arrow), and ENT (enter). The diagnostic information is a circular

list. This display can be changed by pressing the INC or DEC keys. Pressing

the INC key displays the next line of information and pressing the DEC key

displays the previous line of information. The INC, DEC, or ENT key can also

move into the next block after reaching the end of the current block.

For ease of access, the displays are further organized into blocks of

information. When the PCDU is connected, the initial display begins with

block 0, the gateway set-up information. Within each block there are multiple

lines of information that can be displayed. Pressing the ENT key moves the

display to the top of the current block. If the display is already at the top of the

block when the ENT key is pressed, the display is changed to the next

consecutive block.

The diagnostic information is designed to support a two-rack version of this

gateway even though this gateway version supports the simulation of only one

rack. Diagnostic information regarding the second rack, indicated in the

examples below as “Y”, may be ignored, but are shown because they appear in

actual operation.

Page 28

PCDU TERMINAL OPERATION

25

Block 0 – Gateway Set-Up

12/22/94- RD 3196-10

Information

Block 1 –

Digital Read

Information

Block 2 –

Digital Read

This block contains the version number of the JARC firmware, and the

node address and rack selection as set by DIP switch SW1 on the

JARC board. The node address is the node number for the MicroTrac

network. The rack selection is the rack number to be simulated by the

gateway on the Allen-Bradley 1771 Remote I/O network.

JARC VERS V.VV Where: V.VV is the version number of

Node Addr: NNN the JARC firmware

Rack Addr: X,Y NNN is the node number

X is the simulated rack number and

Y is X+l

This block displays the digital (logic) data read by the PLC from the

remote I/O rack simulated by this gateway. This is shown by the

abbreviation “Dig. Rd” followed by the rack and group number, a dash,

and the sixteen-bit digital value displayed in hexadecimal

representation.

Dig.Rd X0-???? Where: X is the simulated rack number

Dig.Rd X1-???? ???? is the data

Dig.Rd X2-????

Dig.Rd X3-????

Dig.Rd X4-????

Dig.Rd X5-????

Dig.Rd X6-????

Dig.Rd X7-????

This block displays the digital (logic) data read by the PLC from the

gateway’s second rack if it was enabled. This is shown by the

abbreviation “Dig. Rd” followed by the rack and group number, a dash,

and the sixteen-bit digital value displayed in hexadecimal

representation.

Dig.Rd Y0-???? Where: Y is the unused rack number

Dig Rd Y1-???? ???? is the data

Dig.Rd Y2-????

Dig.Rd Y3-????

Dig.Rd Y4-????

Dig.Rd Y5-????

Dig.Rd Y6-????

Dig.Rd Y7-????

Block 0 –

Gateway

Set-Up

Page 29

PCDU TERMINAL OPERATION

26

Information Block 3 – Digital Write

12/22/94- RD 3196-10

This block displays the digital (logic) data written by the PLC to the

remote I/O rack simulated by this gateway. This is shown by the

abbreviation “Dig. Wr” followed by the rack and group number, a dash,

and the sixteen-bit digital value displayed in hexadecimal representation.

Dig.Wr X0-???? Where: X is the simulated rack number

Dig.Wr X1-???? ???? is the data

Dig.Wr X2-????

Dig.Wr X3-????

Dig.Wr X4-????

Dig.Wr X5-????

Dig.Wr X6-????

Dig.Wr X7-????

This block displays the digital (logic) data written by the PLC to the gateway’s

second rack if it was enabled. This is shown by the abbreviation “Dig.Wr”

followed by the rack and group number, a dash, and the sixteen-bit digital

value displayed in hexadecimal representation.

Dig.Wr Y0-???? Where: Y is the unused rack number

Dig.Wr Y1-???? ???? is the data

Dig.Wr Y2-????

Dig.Wr Y3-????

Dig.Wr Y4-????

Dig.Wr Y5-????

Dig.Wr Y6-????

Dig.Wr Y7-????

This information block displays the data elements read by the PLC in the last

block transfer from the gateway’s simulated I/O rack. This is shown by the

abbreviation “Blk.Rd” followed by the rack number, a dash, the element

number within the block, a dash, and the sixteen-bit value displayed in

hexadecimal representation. A block transfer contains 64 elements.

Blk.Rd X-00-???? Where: X is the rack number

Blk.Rd X-01-???? ???? is the data

Blk.Rd X-02-????

....

Blk.Rd X-62-????

Blk.Rd X-63-????

Information

Block 4 –

Digital Write

Information

Block 5 –

PLC Block

Read

Information

Block 3 –

Digital Write

Page 30

PCDU TERMINAL OPERATION

27

Information Block 6 – Information Block Read

12/22/94- RD 3196-10

This information block displays the data elements read by the PLC in the last

block transfer from the gateway’s second I/O rack if it was enabled. This is

shown by the abbreviation “Blk.Rd” followed by the rack number, a dash, the

element number within the block, a dash, and the sixteen-bit value displayed in

hexadecimal representation.

Blk.Rd Y-00-???? Where: Y is the unused rack number

Blk.Rd Y-01-???? ???? is the data

Blk Rd Y-02-????

....

Blk.Rd Y-62-????

Blk.Rd Y-63-????

This information block displays the data elements written by the PLC in the

last block transfer to the gateway’s simulated I/O rack. This is shown by the

abbreviation “Blk.Wr” followed by the rack number, a dash, the element

number within the block, a dash, and the sixteen-bit value displayed in

hexadecimal representation. A block transfer contains 64 elements.

Blk.Wr X-00-???? Where: X is the rack number

Blk.Wr X-01-???? ???? is the data

Blk.Wr X-02-????

....

Blk.Wr X-62-????

Blk.Wr X-63-????

This information block displays the data elements written by the PLC in the

last block transfer to the gateway’s second I/O rack if it was enabled. This is

shown by the abbreviation “Blk.Wr” followed by the rack number, a dash, the

element number witbin the block, a dash, and the sixteen-bit value displayed

in hexadecimal representation.

Blk.Wr Y-00-???? Where: Y is the unused rack number

Blk.Wr Y-01-???? ???? is the data

Blk.Wr Y-02-????

....

Blk.Wr Y-62-????

Blk.Wr Y-63-????

Information

Block 6 –

PLC Block

Read

Information

Block 7 –

PLC Block

Write

Information

Block 8 –

PLC Block

Write

Page 31

PCDU TERMINAL OPERATION

28

Information Block 9 – MicroTrac Logic Input Allocation

6/28/94- RD 3196-10

Each logic input element (LOGI) of the PAC language allocates a

memory space in the source remote node. This information block of the

diagnostic displays shows the LOGI memory allocations in this

gateway. This is logic data to be written from the gateway to the drive

indicated by the node number. The channel number agrees with the

channel specified by the LOGI element.

LOGI NN-CCC-???? Where: NN is the node number of the

LOGI NN-CCC-???? MicroTrac Drive in hexadecimal

....

CCC is the channel number

???? is the data in hexadecimal

Each logic output element (LOGO) of the PAC language allocates a

memory space in the destination remote node. This information block

of the diagnostic displays shows the LOGO memory allocations in this

gateway. This is logic data to be written to the gateway from the drive

indicated by the node number. The channel number agrees with the

channel specified by the LOGO element.

LOGO NN-CCC-???? Where: NN is the node number of the

LOGO NN-CCC-???? MicroTrac Drive in hexadecimal

....

CCC is the subchannel number

???? is the data in hexadecimal

Each numeric input element (NUMI) of the PAC language allocates a

memory space in the source remote node. This information block of the

diagnostic displays shows the NUMI memory allocations in this

gateway. This is numeric data to be written from the gateway to the

drive indicated by the node number. The channel number agrees with

the channel specified by the NUMI element.

NUMI NN-CCC-???? Where: NN is the node number of the

NUMI NN-CCC-???? MicroTrac Drive in hexadecimal

....

CCC is the subchannel number

???? is the data in hexadecimal

Information

Block 9 –

MicroTrac

Logic Input

Allocation

Information

Block 10 –

MicroTrac

Logic Output

Allocation

Information

Block 11 –

MicroTrac

Numeric Input

Allocation

Page 32

PCDU TERMINAL OPERATION

29

Information Block 12 – MicroTrac Numeric Output Configuration

12/22/94- RD 3196-10

Each numeric output element (NUMO) of the PAC language allocates a

memory space in the destination remote node. This information block of the

diagnostic displays shows the NUMO memory allocations in this gateway.

This is numeric data to be written to the gateway from the drive indicated by

the node number. The channel number agrees with the channel specified by

the NUMO element.

NUMO NN-CCC-???? Where: NN is the node number of the

NUMO NN-CCC-???? MicroTrac Drive in hexadeicmal

CCC is the subchannel number

....

???? is the data in hexadecimal

Information

Block 12 –

MicroTrac

Numeric Output

Configuration

Page 33

Data subject to change without notice. DSD, MicroTrac and PAC are trademarks of Yaskawa Electric America, Inc.

PLC-5, PLC-3 and PLC are registered trademarks of the Allen-Bradley Company, Inc. SmartMUX is a trademark of Western Reserve Controls, Inc.

Yaskawa Electric

16555 W. Ryerson Road

New Berlin, Wisconsin 53151

(800) 541-0939, (262) 782-0200, FAX (262) 782-1283,

www.drives.com, www.yaskawa.com

RD 3196 -10 © 2001 Yaskawa Electric America, Inc. 02/01/01

MicroTrac Gateway User Reference

Loading...

Loading...