Page 1

YASNAC LX3

CNC SYSTEM FOR TURNING APPLICATIONS

CONNECTING MANUAL

[

f

,

,

t

6

,

Before initial operation read these instructions thoroughly, and retain for future reference.

YASUAWA

Page 2

Page 3

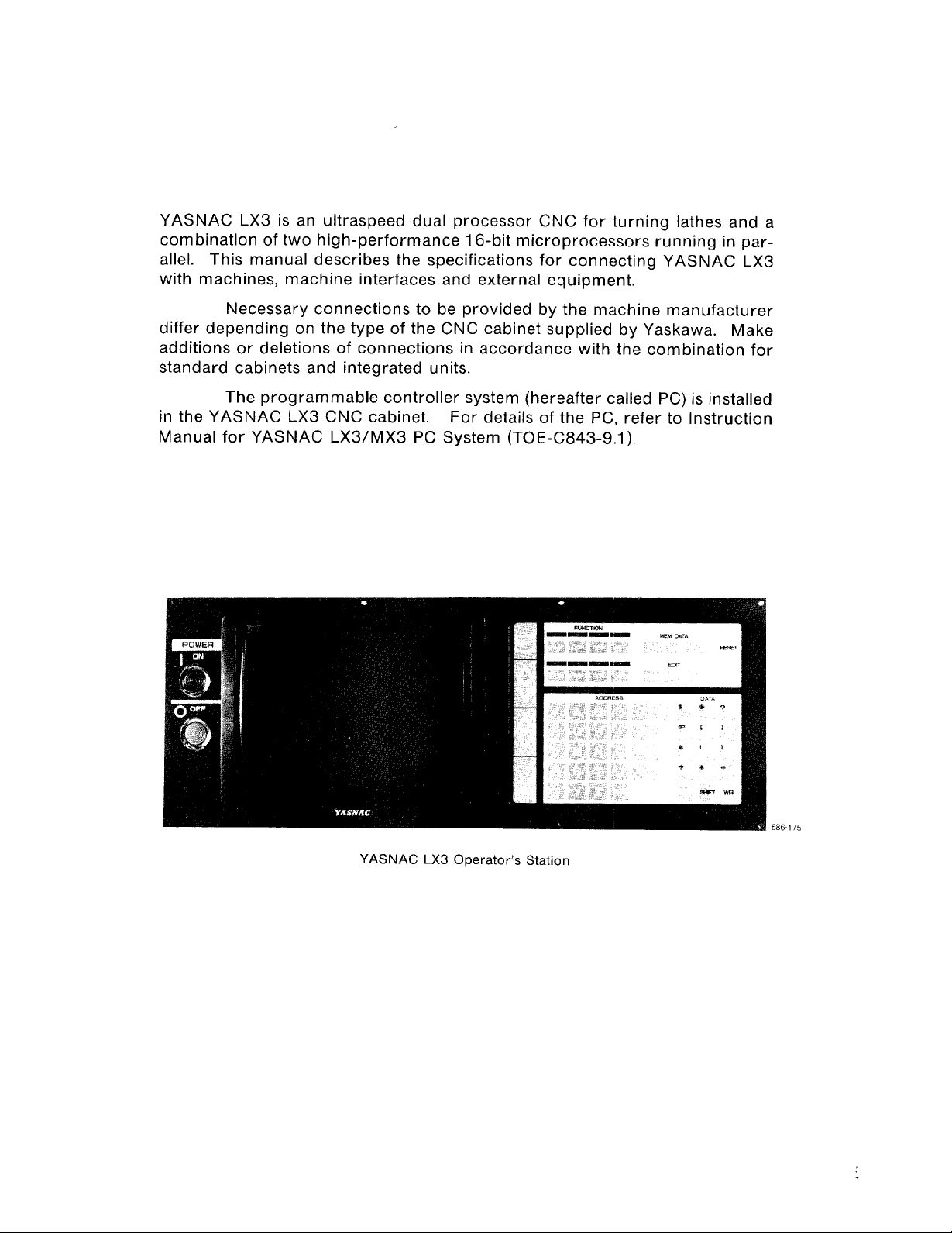

YASNAC LX3 is an ultraspeed dual processor CNC for ‘turning lathes and a

combination of two high-performance 16-bit microprocessors running in parallel. This manual describes the specifications for connecting YASNAC LX3

with machines, machine interfaces and external equipment.

Necessary connections to be provided by the machine manufacturer

differ depending on the type of the CNC cabinet supplied by Yaskawa. Make

additions or deletions of connections in accordance with the combination for

standard cabinets and integrated units.

The programmable controller system (hereafter called PC) is installed

in the YASNAC LX3 CNC cabinet.

For details of the PC, refer to Instruction

Manual for YASNAC LX3/MX3 PC System (TOE-C843-9.1 ).

YASNAC LX3 Operator’s Station

586175

Page 4

CONTENTS

1. CONFIGURATION

1.1 SYSTEM CONFIGURATION

1.2 STANDARD CABINETS AND INTEGRATED UNITS

................... . . . .......... . . . ...... . . . . . . . .......... . . ..... . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

2. Environmental coNDITloNs" """"" """""""""'"""""""""""""""""""""""""""""""""""""" 1

3. CABINET CONSTRUCTION DESIGN

4. CABINET DESIGN

4.1 SELECTION OF HEAT EXCHANGER

4.2 HEAT VALUES OF UNITS

FOR HEAT FACTORS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...... . . . .......... . . ........... . . . ......... . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.cABLE ENTRANcE "". """"" """"" """"" ""`"" """"""""""""""""""""""""""`"""""""""""""""""" 4

5.1 LAYOUT OF CABLE CONNECTORS

5.2 CLAM PINGCABLES, AN DGROUNDING CAB LESHl ELD""S. """-."• ""C.""• """" O""O""""" 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

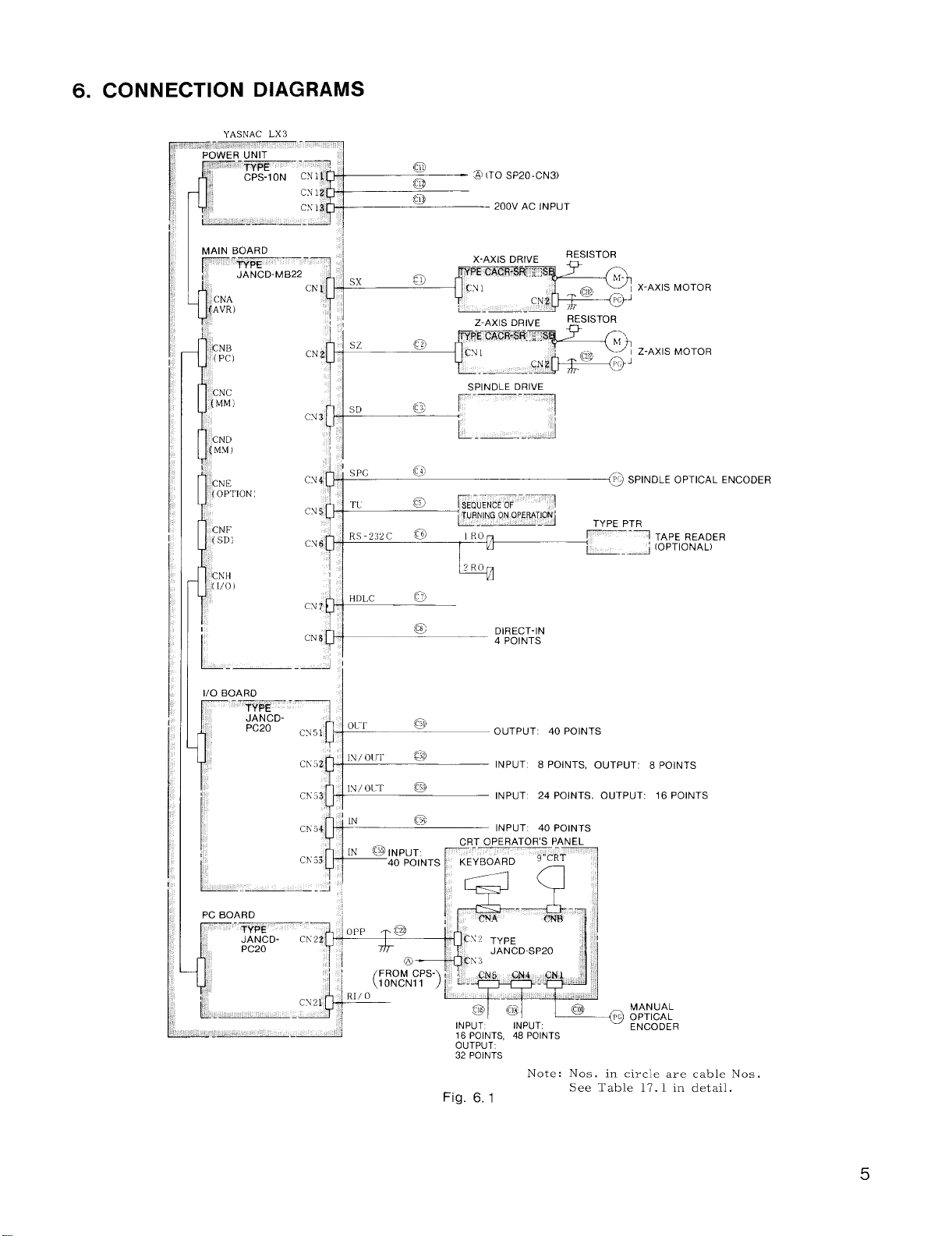

6. CONNECTION DIAGRAMS O""""`• "O""""O"C... O".O""".• """""""• """"""""• O...OO""""OOOO"5

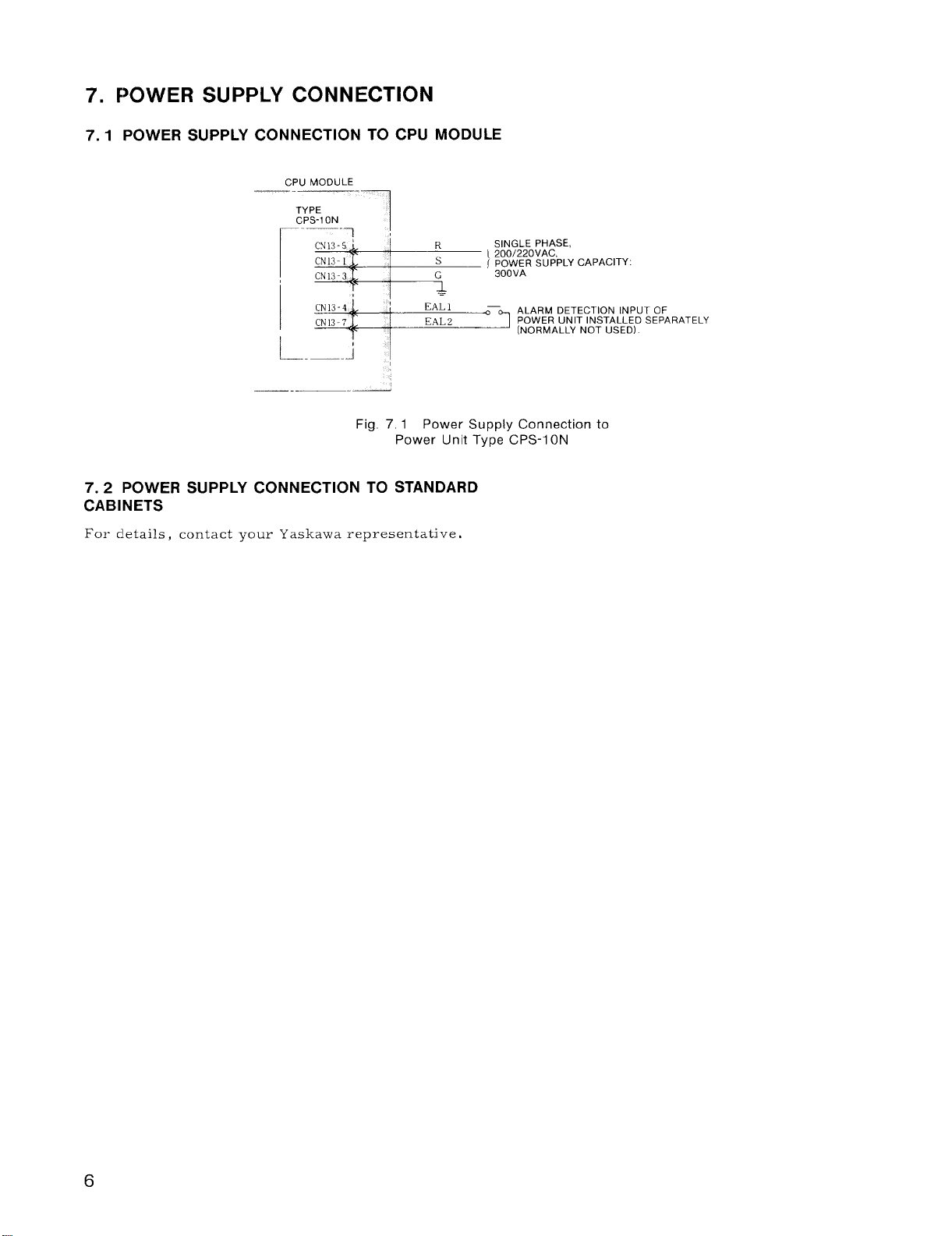

7. POwERSUPPLY Connection "O"""O"""""".".-.• """""".• O"""O"""""• "".. C"CC""""""""" 6

7.1 POWER SUPPLY CONNECTION TO CPU MODULE

7.2 POWER SUPPLY CONNECTION TO STANDARD CABINETS

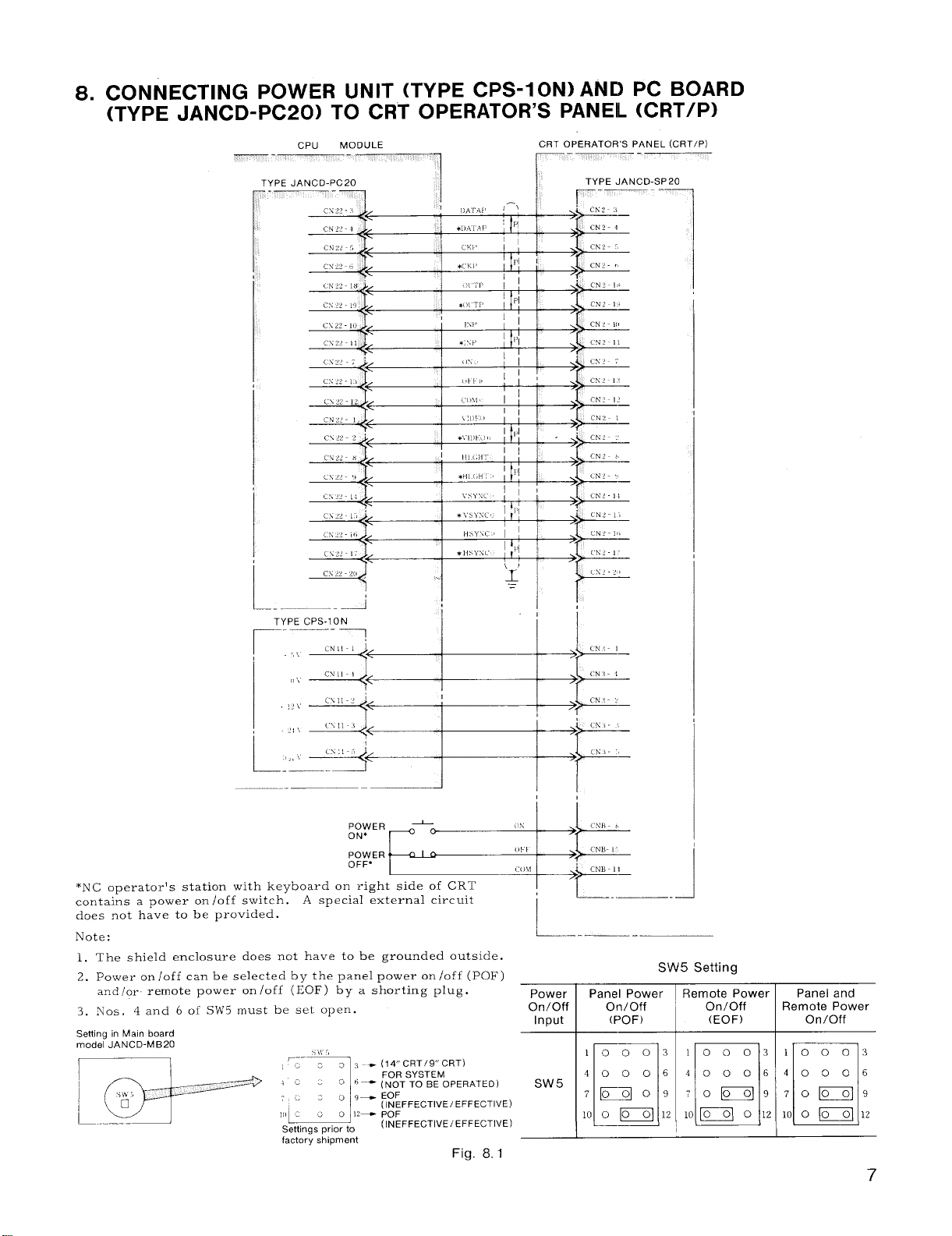

8. CONNECTING POWER UNIT (TYPE CPS-1ON) AND PC BOARD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

(TYPE JANCD-PC20) TO CRT OPERATOR’S PANEL (CRT/P) ...sos.00.. . ...0..... 7

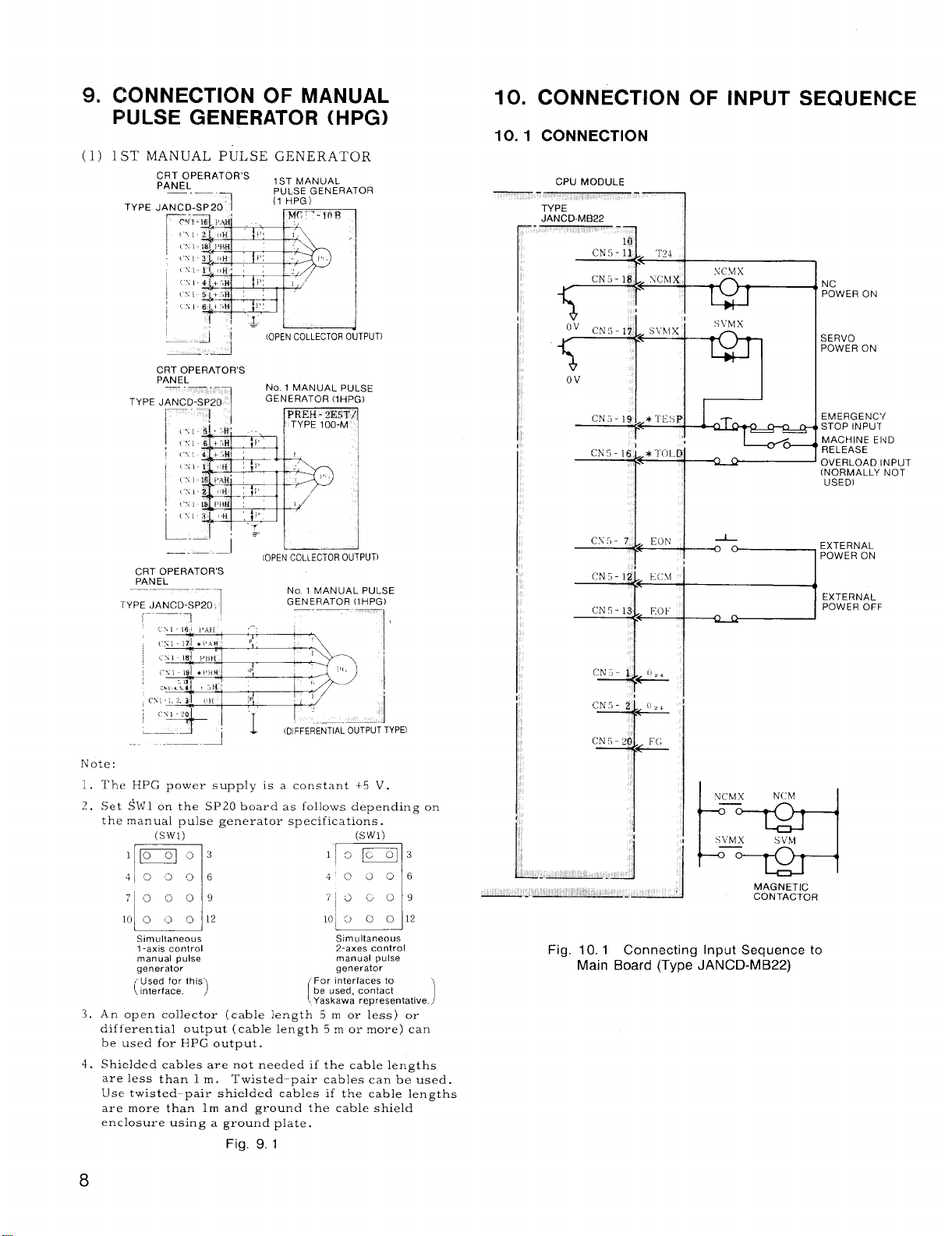

9. CONNECTION OF MANUAL PULSE GENERATOR (HPG) .00”.”.”0..”””o”””oo””””oo 8

10. CONNECTION OF INPUT SEQUENCE OO”.OO”””””” ””””” ””””” ”””.. ”””o”””o”o”””o o””” 8

10.1 CONNECTION

10.2 DETAl LSOFSIGNALS .O... O......• . . . . . . . . . . .. O"". """" ."""" "". ""S""....• ."""""".""""• 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

1

1

1

3

3

3

4

6

6

8

ll. Connection TO FEED SERVO UNITS(SVX AND SVZ)O"OO"""OO.""CO."""""""""lo

12. CONNECTION TO SPINDLE DRIVE UNIT (SDU)

.. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . .

13. CONNECTION TO SPINDLE PULSE GENERATOR (SPG)”” O””.”O””O”O”OS”.O.0””””13

14. CONNECTION TO RS-232C INTERFACE

14.1 CON NECTIONO . . .. 00 . . . . .. 000 . . . . . . . . .. O.. O... O"""" "O""" ."" O"". "" O"O.Ooo--oooo-o o---mm 13

14.2 RS-232C interface . .. O... O..................• ".. "". S."" O""" O"O""" O"" O"" SCS""O"O"""- 14

. . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . .

15. DIREcT-lN slGNALcoNNEcTloN """""""""""""""""""""""""""""""""""""""`"""""""""lo

16. CONNECTION TO GENERAL-PURPOSE 1/0 SIGNALS

16.1 l/O PORTS

16.2 l/O CIRCUITS OF l/O PORTS

16.3 1/0 SIGNAL INTERFACE

17. CABLES

17.1 LIST OF CABLES

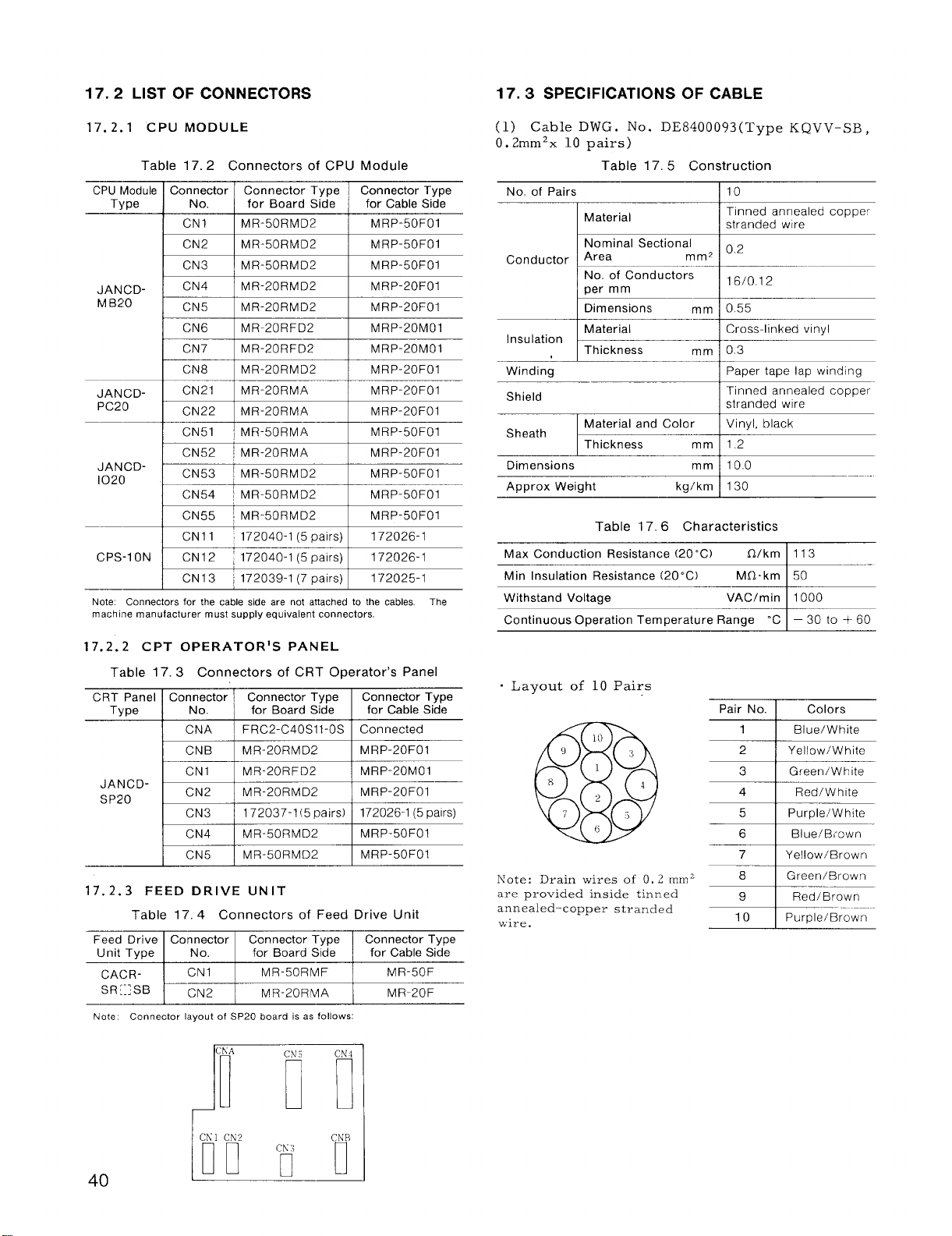

17.2 LIST OF CONNECTORS

17.3 SPECIFICATIONS OF CABLE

18. STANDARD 1/0 SIGNALS

18.1 LIST OF NC STAN DARDl/O SIGNALS . ..o . . . . . . . . . . . . . . . ..o . . . . . . . ..””.. o.””.”.”””””” 42

18.2 DETAILS OF SIGNALS . . . . . .. O........• . . . . .. O... O.""..."• """"."""• "OOOO""""C". "OOO""" 48

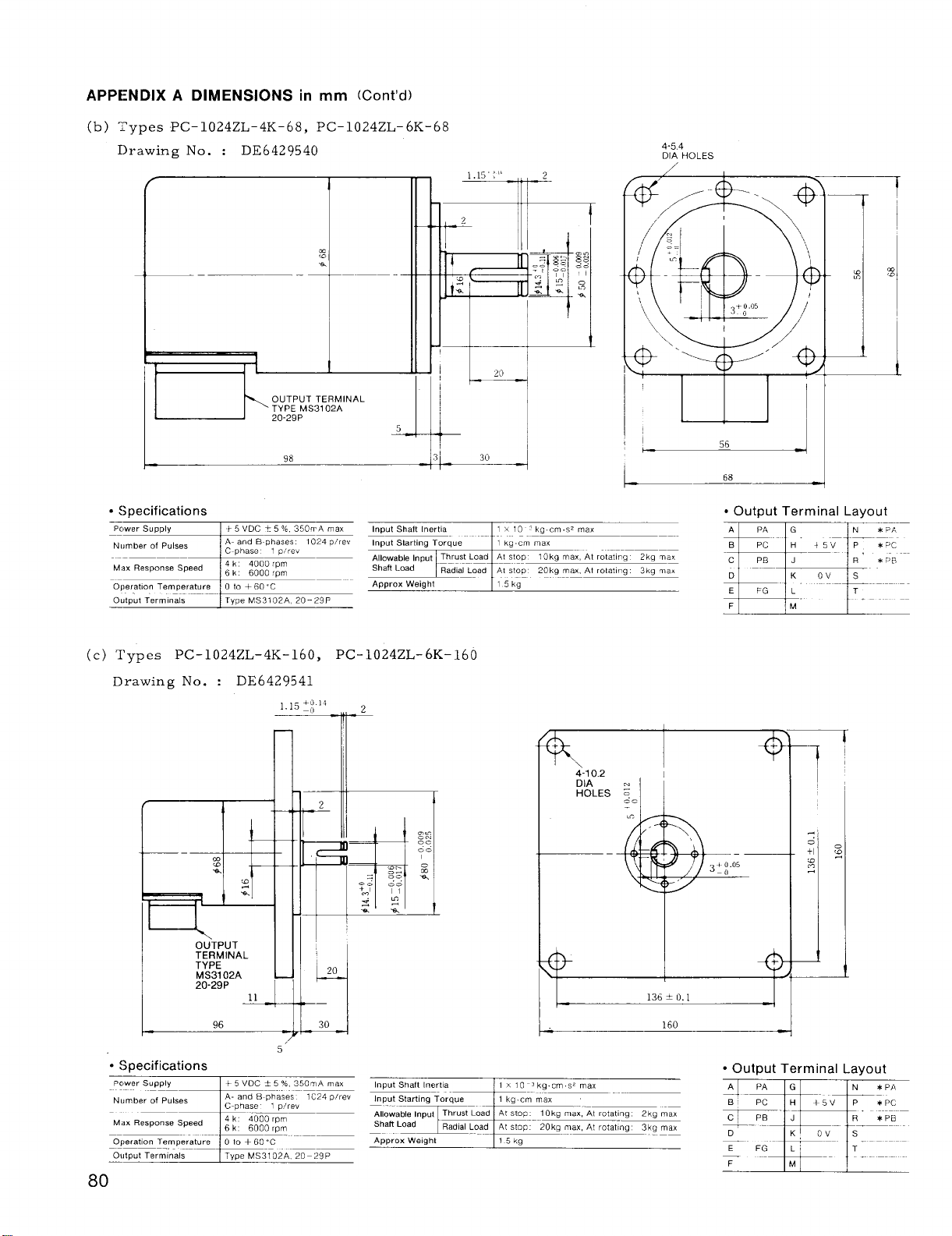

APPENDIX A DIMENSIONS in mm

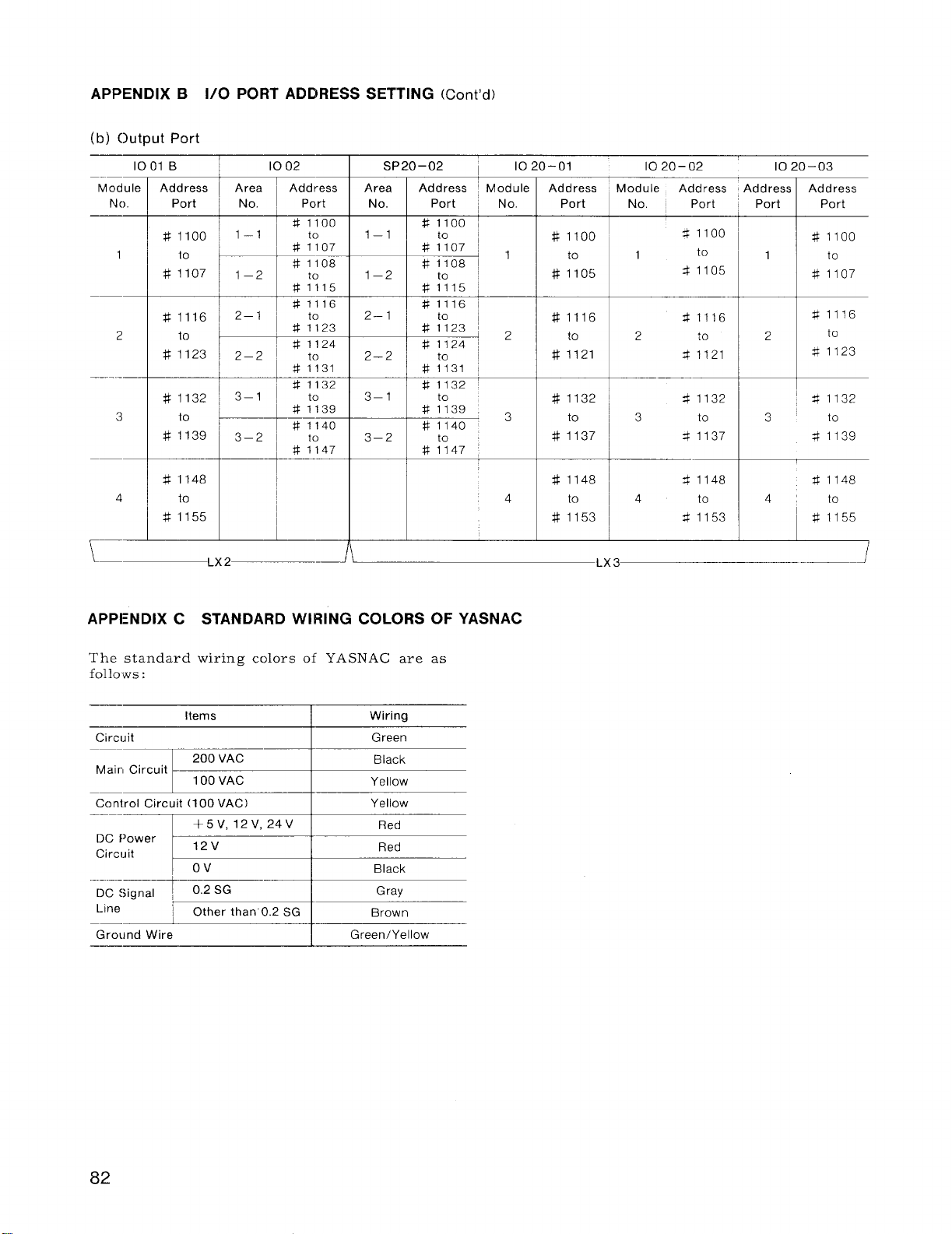

APPENDIX B 1/0 PORT ADDRESS SETTING

APPENDIX C STANDARD WIRING COLORS OF YASNAC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

12

13

17

17

17

19

39

39

40

40

42

73

81

82

Page 5

Subject Chapter Section

A Alarm andlnput Error Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 . . . . . .26. 5626 . . . ...56

Auxiliary Function Lock Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..18 . . . . ..18. 2. 18 . . . ...55

c CABINET CONSTRUCTION DESIGN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 . . . . . . . . . . . . . . . . . . . . 1

CABINET DESIGN FOR HEAT FACTORS . . . . . . . . . . . . . . . . . . . . . . . . . 4 . . . . . . . . . . . . . . . . . . . . 3

CABLE ENTRANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 . . . . . . . . . . . . . . . ----- 4

CABLES . . . . . . . . . . . . . . . . . . . . . ..-. . . . . . . . . . . . . . . . . . . . ..-- . . . . ...17 . . . . . . . . . . . . . . . . . ...39

CLAMPING CABLES, AN D GROUNDING CABLE SHIELD . . . . . . . . . . . 5 . . . . . .5. 2 . . . . . . . . . . 4

Combined Fixed Cycle Cutting Override Inputs . . . . . . . . . . . . . . . . . . . . . . 18. . . . . . 18.2. 48 . . . ...71

CON FIG URATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 . . . . . . . . . . . . . . . . . . . . 1

CONNECTING POWER UNIT AND

PC BOARD TO CRT OPERATOR’S PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 . . . . . . . . . . . . . . . . . . . . 7

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...10. . . . ..10.1 . . . . . . . . . 8

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...14.. . . ..14. 1 . . . . . . ...13

CONNECTION DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 . . . . . . . . . . . . . . . . . . . . 5

CONNECTION OF INPUT SEQUENCE . . . . . . . . . . . ...-............10.. . . . . . . . . . . . . . . . . . . 8

CONNECTION OF MAN UAL PULSE GENERATOR . . . . . . . . . . . . . . . . . . . . 9 . . . . . . . . . . . . . . . . . . . . 8

CO,NNECTION TO FEED SERVO UNITS . . . . . . . . . . . . . . . . . . . . . . . ...11.... . . . . . . . . . . . . . ...10

CONNECTION TO GENERAL-PURPOSE l/O SIGNALS . . . . . . . . . . . . . ..16 . . . . . . . . . . ..- . . . . ...17

CON NECTION TO RS-232C INTERFACE. . . . . . . . . . . . . . . . . . . . . . . . . . ..14..... . . . . . . . . . . . . ...13

CON NECTION TO SPIN DLE DRIVE UN IT. -- . . . . . . . . . . . . . . . . . . . . . . . ..l2 . . . . . . . . . . . . . . . . . ...12

CON NECTION TO SPIN DLE PULSE GENERATOR . . . . . . . . . . . . . . . . . . ..l3 . . . . . . ..- . . . . . . . . ...13

CPU Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..17......17.2.1 . . . ...40

CRT Operator’s Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...17......17.2.2 . . . ...40

Current Value Storing Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 . . . . . .18. 2. 15- . . ...54

Page

DETAILS OF SIG NABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 . . . . . .10. 2 . . . . . . . . . 9

D

DETAILS OF SIG NABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 . . . . . .18. 2 . . . . . . ...48

DIM ENSIONS in mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. APPEND Ix A . . . ...-..73

DIRECT-I N SIG NAL CONNECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...15 . . . . . . . . . . . . . ...-...16

Display Reset inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - . . . . .18 . . . . . .18. 2. 33 . . . ...59

Dry Runlnput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 . . . . . .18. 2. 14 . . . ...54

Edit Lo~k . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 . . . . . .18. 2.17..... .55

E

Emergency Stop input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . --.10 . . . ...10.2.2 . . . . . . 9

Emergency Stop On Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 . . . . . .18. 2. 23 . . . ...56

End-of -program input, Rewind input : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 . . . . . .18. 2. 32 . . . ...58

ENVIRON MENTAL CON DITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 . . . . . . . . . . . . . . . . . . . . 1

External Data lnputlnputs/Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 . . . . . .18. 2.45 . . . ...68

External Power On-Off Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..10......10.2,3

External Reset lnputand Reset On Output . . . . . . . . . . . . . . . . . . . . . . . . . . . ..18 . . . . . .18. 2. 24 . . . ...56

External Store, Match, and Output Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . -- .18 . . . . . .18. 2. 34. -....59

External Work Number Search A Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 . . . . . .18. 2. 40- . . ...52

F Feed Drive Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - . . . . . . . ..17..... .17. 2.3 . . . ...40

Feed Override/Manual Jogging Speed Selection Input . . . . . . . . . . . . . . ...18......18.2.7 . . . ...51

HEAT VALUES OF UN ITS...... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 . . . . . .4. 2 . . . ..-- . . . 3

H

High-speed Rewind and Start input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 . . . . . .18. 2. 50- . . ...72

I lnputand Output for Control Operation Modes . . . . . . . . . . ...-.........18......18.2.2 . . . ...48

input Signals for Cycle Start, Stop Output Signals . . . . . . . . . . . . . . . . . . . ...18......18.2.1 . . . ...48

interlock input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..18 . . . . . .18. 2. 25 . ...-.56

Interruption Point Return Input... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -..18......18,2.20...-..55

1020 Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...16......16.3.1 . . . ...19

l/O Board Type JANCD-1020 . . . . . . . . . . . . . . . . . . . . . . . . . . ...-........16. . . ...16.2.1 . . . ...17

l/O Board Type JANCD-SP 20.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 . . . ...16.2.2 . . . ...18

l/O CIRCUITS OFl/O PORTS.... . . . . . . . . . . . . . . . . . . ...-..........16. . . ...16.2 . . . . . ...17

l/O PORT ADDRESS SETTING . . . . . . . ..- . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. APPENDIX B. . . . . . . ...81

l/O PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...-16.. . . ..16. 1 . . . . . . ...17

l/O SIGNAL INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..16 . . . . ..16.3 . . . . . . . ..l9

. . . . . .

9

...

111

Page 6

INDEX (Cent’d)

Subject

LAYOUT OF CAB LE CONNECTORS . . . . . . . . . . . . . . . 5. ..5.1 . . . . . 4

L

LIST OF CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 . . . . 17.1 . . . . . ...39

LIST OF CON NECTARS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 . . . . 17.2 . . . ...40

LIST OF NC STAN DAR D1/O SIGNALS. . . . . . . . . . . . . . . . . . . . . . ...18. . . 18.1 . . . ...42

M, S,and TCodeslnputs/Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . .18. . . 18.2.29 . . ...57

M

Machine Lock and Display Lock Input . . . . . . . . . . . . . . . . . . . . . . . . . . 18. . . . . 18.2. 13....54

Machine-ready input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18... 18. 2.22....56

Macro Program Input/Output Function . . . . . . . . . . . . . . . . . . . . . ...18 . . . . 18.2 .44...68

Manual Absolute On/Off Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18.. . 18. 2.10 . . ...52

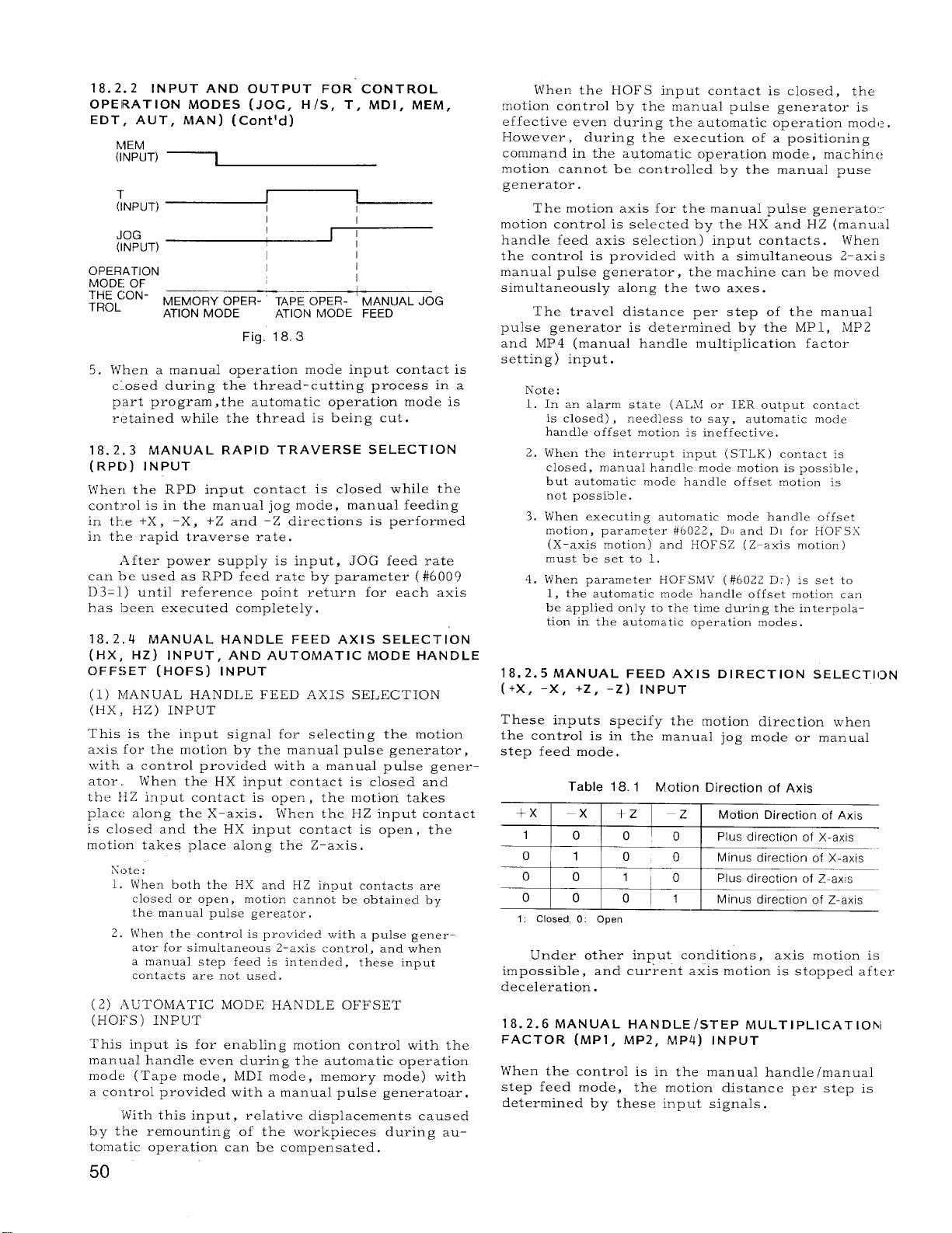

Manual Feed Axis Direction Selection Input . . . . . . . . . . . . . . . ...-18. 18.2.5 . . . ...50

Manual Handle Feed Axis Selection Input . . . . . . . . . . . . . . . . . . . ...18.. .18 .2.4 . . . ...50

Manual Handle/Step Multiplication Factor Input . . . . . . . . . . . . . ...18....18. 2.6 . . . ...50

Manual Rapid Traverse Selection Input . . . . . . . . . . . . . . . . . . . . . . . ...18. . ..18.2.3 . . ...50

N

NC Power Onand Servo Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . .10...10.2.1 . . . . . . 9

NCUnit................... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4. . . 4.2.1..... 3

Optional Block Skip Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18. . . 18 .2.12..54

o

Overload Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - . . . . . . 10.. .10.2. 4 . . . 9

Overtravel inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18. 18. 2.21 . . ...55

Positioning Completion Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . 18. . . . . . 18.2.30 . . ...58

P

POWER SUPPLY CONNECTION.. . . . . . . . . . . . . . . . . . . . . . . . . 7 . . . . . . . . . . . . . . . . 6

POWER SUPPLY CO NNECTIONTO CPU MODULE . . . . . . . . . . . . . 7, .7.1 . . . . . . 6

POWER SUPPLY CONNECTION TO STANDARD CABINETS . . . . . . . . . . 7. ..7.2 . . . . . . . . 6

Program Restart Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...18..18.2.16. . . ...55

Chapter Section

Page

R

Rapid Feedrate Override input. . . . . . . . . . . . . . . . . . . . . . . . . . . ...18......18.2.8 . . ...51

Rapid Thread ing Pull-out input.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18. . . . . . 18.2. 27..56

Reference Point Return Control l/O Signals . . . . . . . . . . . . . . . . . . . . . ...18 . ..18.2.9 . ...52

RS-232C INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1414 .2....... 14

S4-Digit Comma ndExterna10utputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 . . . . . .18. 2. 39....62

s

S4-Digit Commands inputs/Outputs . . . . . . . . . . . . . . . . . . . . . . . . .18. . . 18.2 .35....59

SELECTION OF HEAT EXCHANGER. . . . . . . . . . . . . . . . . . . . . . 4 . ...4.1 . . . . . . 3

Servo Power On Input

Servo Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4. . 4.2.2.... 3

Setup Point Return Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 . . .18. 2.19...55

Single Block input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18. . . . . 18.2.11.53

Skip Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...18...18. 2.47..71

SPECIFICATIONS OF CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . 17.17 . 3. . . . ...40

Spindle indexing Function input/Output . . . . . . . . . . . . . . . . . . . ...18 . ..18.2 .42.” ”.63

Spindle SCommand’’O,’’ Gear Shift On Input . . . . . . . . . . . . . . ...18.18. 2.36...61

Spindle Speed Override Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18. . . . . . 18. 2. 38 . . . ...61

Spindle Speed Reached input,... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18. . . . 18. 2.37 . ...61

STAN DARDCABIN ETS AN D INTEGRATED UN ITS . . . . . . . . . . . . . . . 1 . . . 1. 2. . . . . . . . . 1

STAN DARD1/O SIG NABS . . . . . . . . . . . . . . . . . . . . . . . . . . ...18 . . . . . . . . . . . . . ...42

STAN DARDWIRING COLORS OF YASNAC .................APPENDIX C.....82

Stored Stroke Limit 3by Tool inputs/Outputs . . . . . . . . . . . . . . . ...18......18. 2.43.....67

SYSTEM CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 . . . ...1.1 . . . . . 1

Time Count fnput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18.18.2. 41...,..63

T

Tool Life Control Inputs/Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18... 18. 2.46 . . ...70

Travel Onand Thread Cutting On Outputs . . . . . . . . . . . . ..- . . . . . . . . ..” 18.. . . . 18.2 .31 . . ...58

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18....18.2.49....72

x

X-axis Mirror lmagelnput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18. . . . 18.2.28 . . . ...57

Page 7

1. CONFIGURATION

3. CABINET CONSTRUCTION DESIGN

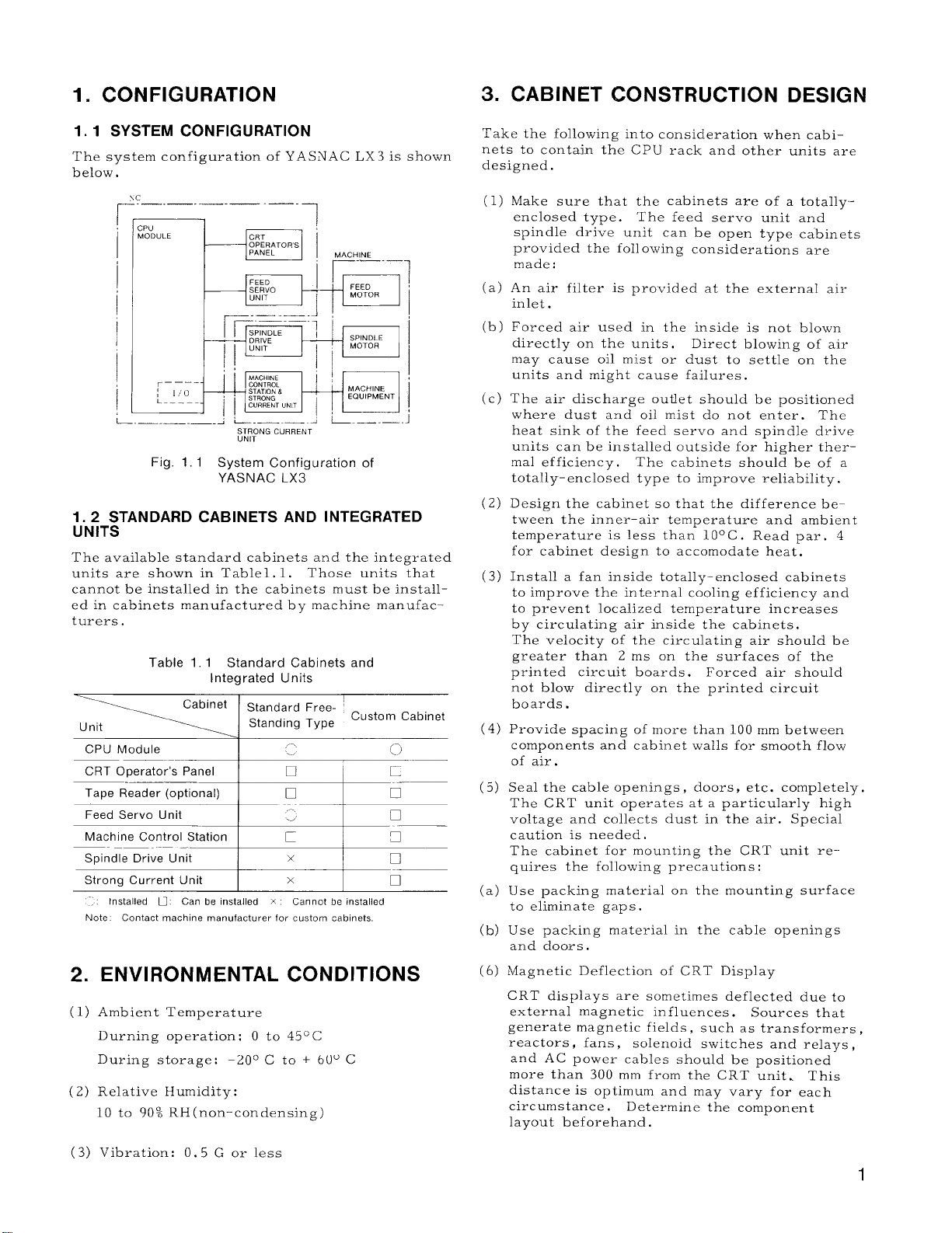

1.1 SYSTEM CONFIGURATION

The system configuration of YASNAC LX3 is shown

below.

&? —._._.

I

CPU

MODULE

Fig. 1.1 System Configuration of

—.— .=

I

YASNAC LX3

fiN;T:TANDARD CABINETS AND INTEGRATED

The available standard cabinets and the integrated

units are shown in Tablel, 1,

cannot be installed in the cabinets must be install–

ed in cabinets manufactured by machine manufac–

turers.

Table 1.1 Standard Cabinets and

Unit

CPU Module

CRT Operator’s Panel

Tape Reader (optional)

Feed Servo Unit

Spindle Drive Unit

“’’=’’O’s’-=

Strong Current Unit

Installed U. Can be installed X Cannot be installed

Note

Contact machine manufacturer for custom cabinets

ENVIRONMENTAL

2.

Ambient Temperature

(1)

Durning operation: O to

During storage:

Relative Humidity:

(2)

10 to 90% RH(non-condensing)

Integrated Units

Cabinet

Standard Free-

Standing Type

In

–20° C to + 60” C

Those units that

Custom Cabinet

-, ,x

.–.

❑ 1

I

x

CONDITIONS

45° C

‘<~

r

❑

❑

Take the following into consideration when cabinets to contain the CPU rack and other units are

designed.

(1)

Make sure that the cabinets are of a totallY-

enclosed type.

spindle drive unit can be open type cabinets

provided the foil owing considerations are

made:

(a)

An air filter is provided at the external air

inlet.

Forced air used in the inside is not blown

(b)

directly on the units, Direct blowing of air

may cause oil mist or dust to settle on the

units and might cause failures.

The air discharge outlet should be positioned

(c)

where dust and oil mist do not enter.

heat sink of the feed servo and spindle drive

units can be installed outside for higher ther–

ma] efficiency. The cabinets should be of a

totally-enclosed type to improve reliability.

(2)

Design the cabinet so that the difference between the inner-air temperature and ambient

temperature is less than 10° C . Read par. 4

for cabinet design to accommodate heat.

Install a fan inside totally-enclosed cabinets

(3)

to improve the internal cooling efficiency and

to prevent localized temperature increases

by circulating air inside the cabinets.

The velocity of the circulating air should be

greater than 2 ms on the surfaces of the

printed circuit boards. Forced air should

not blow directly on the printed circuit

boards.

Provide spacing of more than 100 mm between

(4)

components and cabinet walls for smooth flow

of air.

Seal the cable openings , doors, etc. completely,

(5)

The CRT unit operates at a particularly high

voltage and collects dust in the air. Special

caution is needed.

The cabinet for mounting the CRT unit requires the fol[owing precautions:

Use packing material on the mounting surface

(a)

to eliminate gaps.

Use packing material in the cable openings

(b)

and doors,

Magnetic Deflection of CRT Display

(6)

CRT displays are sometimes deflected due to

external magnetic influences . Sources that

generate magnetic fields , such as transformers ,

reactors, fans,

and AC power cables should be positioned

more than 300 mm from the CRT unit. This

distance is optimum and may vary for each

circumstance. Determine the component

layout beforehand.

The feed servo unit and

The

solenoid switches and relays ,

Vibration: O. 5 G or less

(3)

1

Page 8

3. CAB

((Jon

(7)

(a)

(b)

(8)

(9)

(lo)

. Example

NET CONSTRUCTION DESIGN

[’d)

TO prevent malfunction due to noise, mount

the units more than 100 mm from cables feedi:og 90 VDC or greater, AC power lines, and

other components.

should be complied with during wiring:

Separate AC and DC cables.

Separate the primary and secondary sides

of transformers, line filters, etc.

The front panels of the units that are exposed

to the cabinet surfaces, such as the CRT unit,

tape reader, and PO unit should be of a dustproof type. However, do not install them

in locations where cutting fluid may directly

splash on them.

z.round the mounting sections.

hlount the units so as to allow easy checking,

removal and reinstalling during maintenance

work.

Read the instruction manuals of the feed servo

and spindle drive units when mounting them.

Heat sink should be installed outside the

c:abinet to reduce internal thermal loss-es.

This increases the possibilities for a change

from an open type to a totally-enclosed type

and reduces the capacity of the heat exchanger.

A

The following precautions

B e sure to seal completely

(b) Allow forced air at more than 2 ms to circulate

inside the unit,

directly on the surfaces of the printed circuit

boards.

Be careful not to blow air

VENTILA1

/ DUCT

“ING

—

—

l--

(a) Good

FORCED AIR

P

BLOWN DIRECT

LY

R14D

FIN

I I

I

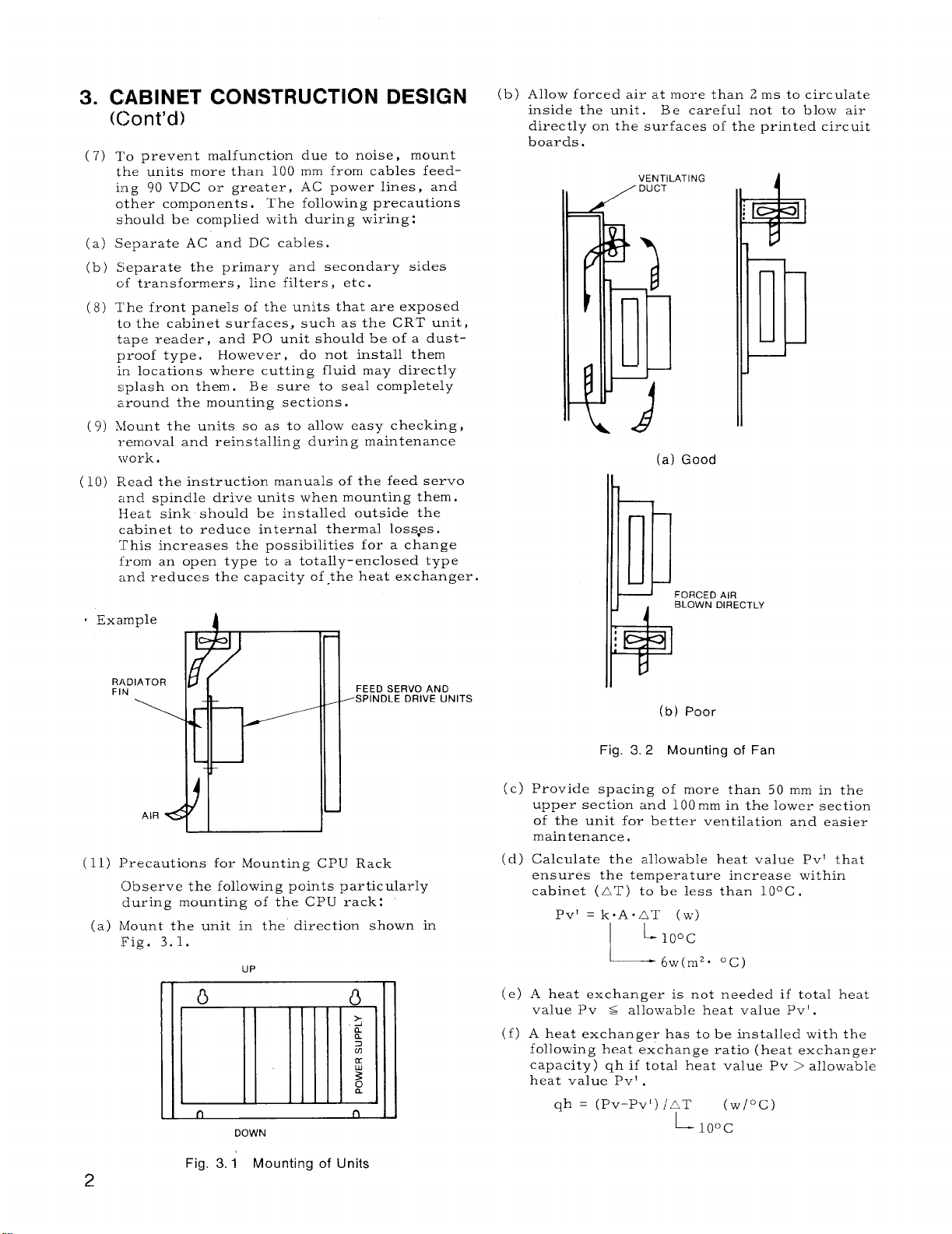

l?recautions for Mounting CPU Rack

(11)

Observe the following points particularly

during mounting of the CPU rack:

Mount the unit in the direction shown in

(a)

Fig. 3.1.

UP

n

DOWN

FEED SERVO AND

SPINDLE DRIVE UNITS

n

*

(b) Poor

Fig. 3.2 Mounting of Fan

(c) Provide spacing of more than 50 mm in the

upper sec~ion and 100 mm in the lower section

of the unit for better ventilation and easier

maintenance.

Calculate the allowable heat value Pv’ that

(d)

ensures the temperature increase within

cabinet (AT) to be less than 10° C.

pvf =k. A.~T (W)

L

10”C

L

A heat exchanger is not needed if total heat

(e)

value Pv s allowable heat value Pv’ .

(f)

A heat exchanger has to be installed with the

following heat exchange ratio (heat exchanger

capacity) qh if total heat value Pv > allowable

heat value Pv’ .

qh = (pv-pv[) /AT

6w(m2. ‘C)

L-

10”C

(w/”c)

Fig. 3.1 Mounting of Units

2

Page 9

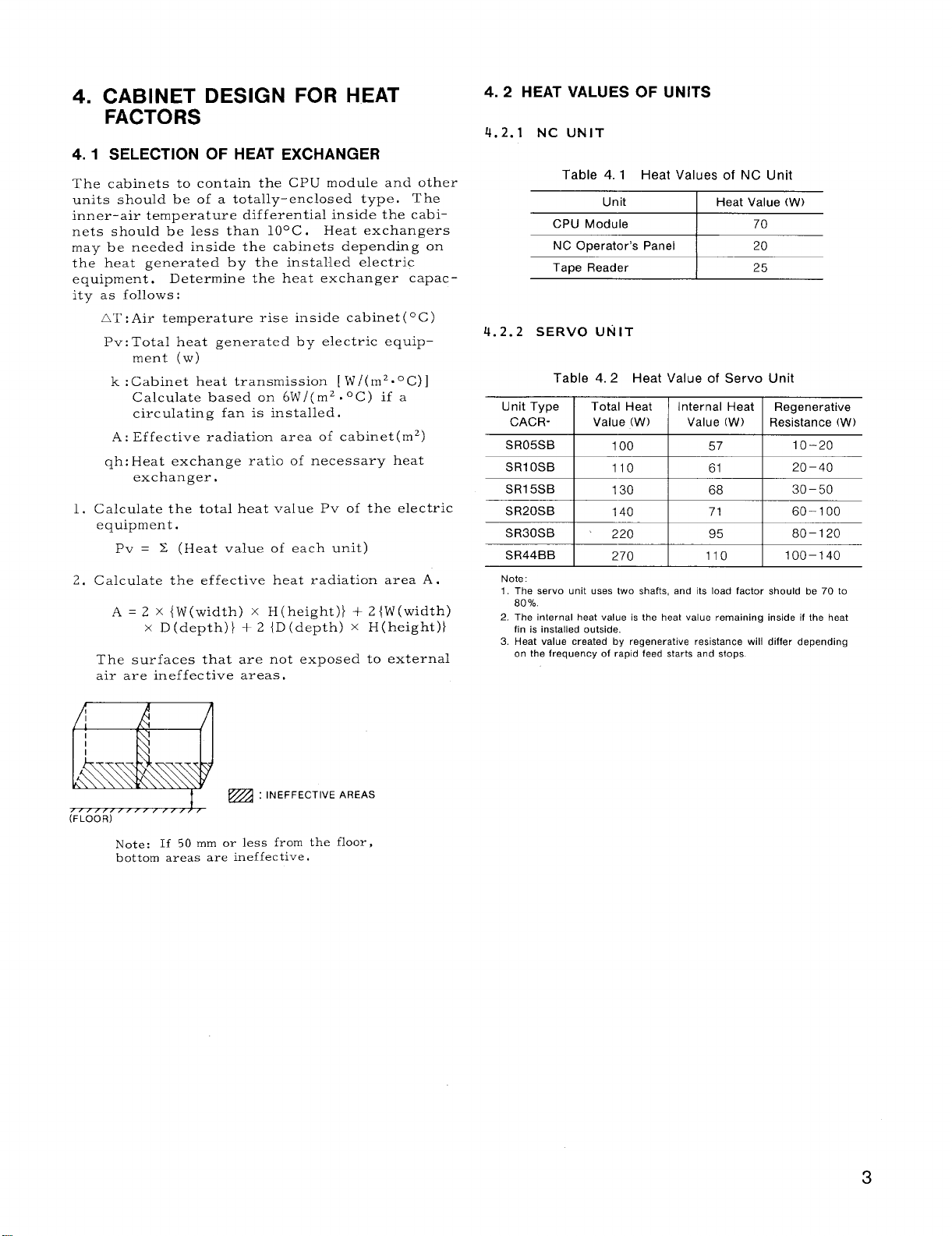

4. CABINET DESIGN FOR HEAT

FACTORS

4.1 SELECTION OF HEAT EXCHANGER

The cabinets to contain the CPU module and other

units should be of a totally–enclosed type. The

inner-air temperature differential inside the cabi–

nets should be less than 10° C.

may be needed inside the cabinets depending on

the heat generated by the installed electric

equipment.

Determine the heat exchanger capac-

ity as follows:

AT :Air temperature rise inside cabinet

Pv: Total heat generated by electric equip-

ment (w)

k :Cabinet heat transmission [ W/(m2.0C)]

Calculate based on 6W/(m2 .°C) if a

circulating fan is installed.

A : Effective radiation area of cabinet

qh: Heat exchange ratio of necessary heat

exchanger.

1. Calculate the total heat value Pv of the electric

equipment.

Pv = X (Heat value of each unit)

2. Calculate the effective heat radiation area A .

A = 2 x {W(width)

x D(depth)} + 2 {D (depth) x H(height)}

x H(height)} + 2 {W(width)

The surfaces that are not exposed to external

air are ineffective areas.

Heat exchangers

4.2 HEAT VALUES OF UNITS

4.2.1 NC UNIT

Table 4.1 Heat Values of NC Unit

Unit

CPU Module

NC Operator’s Panel

Tape Reader 25

4. 2.2 SERVO UNIT

Table 4.2 Heat Value of Servo Unit

Unit Type Total Heat Internal Heat

CACR- Value (W) Value (W)

SR05SB

SR1OSB I

SR30SB ‘

SR44BB

Note:

1. The servo unit uses two shafts, and its load factor should be 70 to

80%.

2. The internal heat value is the heat value remaining inside if the heat

fin is installed outside.

3. Heat value created by regenerative resistance will differ depending

on the frequency of rapid feed starts and stops.

100 57

110

I

220

270

Heat Value (W)

I

I

61

95

110

70

20

Regenerative

Resistance (W)

10–20

I 20-40

80–120

100–140

~ : INEFFECTIVE AREAS

(FLOOR)

Note: If 50 mm or less from the floor,

bottom areas are ineffective.

3

Page 10

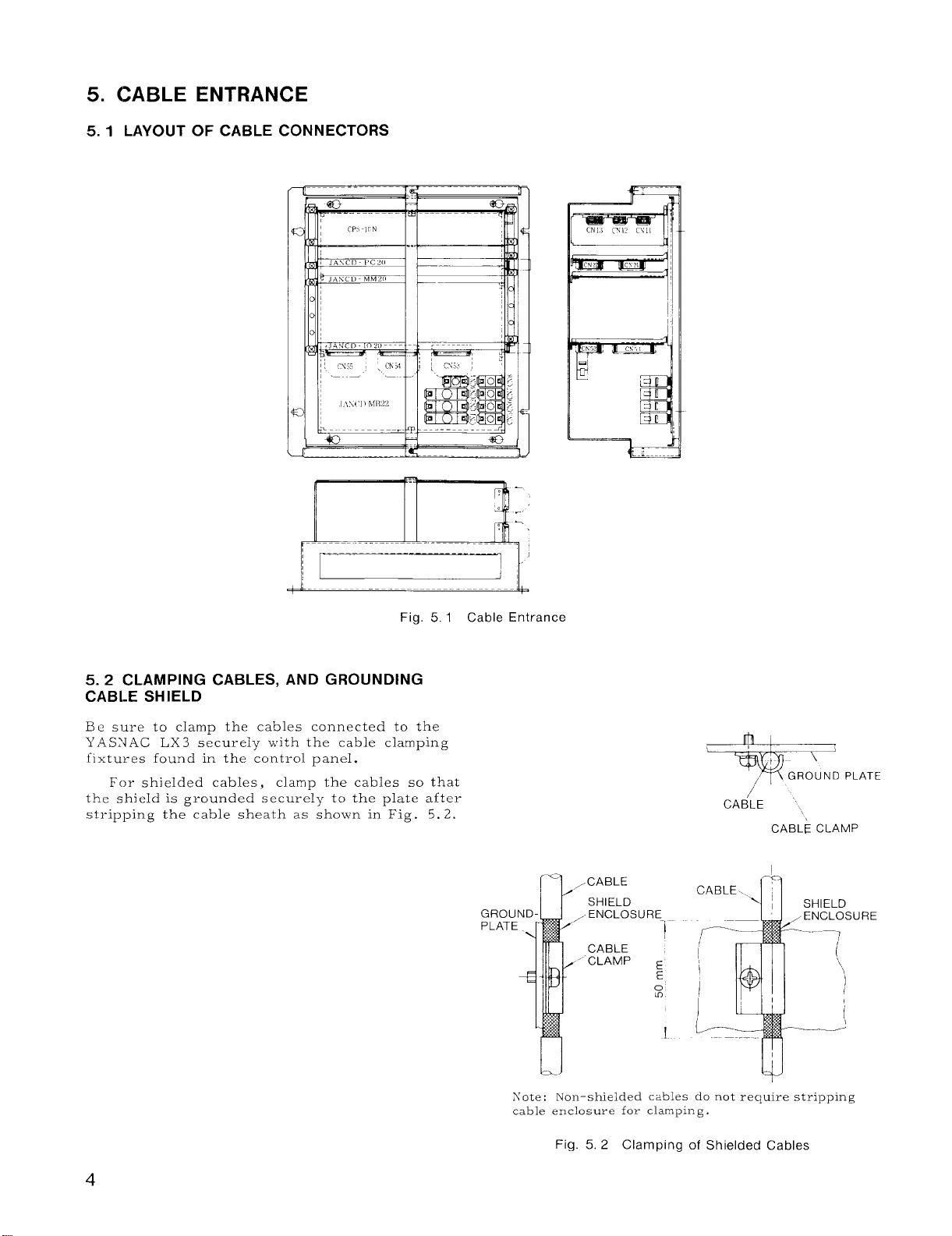

5. CABLE ENTRANCE

5.1 LAYOUT OF CABLE CONNECTORS

r d-

Fig. 5.1 Cable Entrance

5.2 CLAMPING CABLES, AND GROUNDING

CABI.E SHIELD

Be sure to clamp the cables connected to the

\’.4SNAC LX3 securely with the cable clamping

fixtures found in the control panel.

For shielded cables, clamp the cables so that

the shield is grounded securely to the plate after

stripping the cable sheath as sho~vn in Fig. 5.2.

GROU

PLATE

CABLE

SHIELD

ENCLOSURE

CABLE

CLAMP ~

I

~

\

GROUND PLATE

/

,/’

CABLE

CABLE CLAMP

-1

E

0

m

I

URE

Sote: Non-shielded cables do not require stripping

cable enclosure for clamping.

Fig. 5, 2 Clamping of Shielded Cables

Page 11

6. CONNECTION DIAGRAMS

X-AXIS MOTOR

Z-AXIS MOTOR

~@ SPINDLE OPTICAL ENCODER

TYPE PTR

~–-1 TAPE READER

‘L. _~ ‘oPTloNAL1

@

DIRECT-IN

4 POINTS

cable Nos.

detail.

5

Page 12

F)OWER SUPPLY CONNECTION

7.

7.1

POWER SUPPLY CONNECTION TO CPU MODULE

CPU MODULE

—.

TYPE

CPS-1 ON

—— .

[Sk

L_:-’:’:;’:’’’’’uTOF

——

Fig. 7.1 Power Supply Connection to

Power Unit Type CPS-I ON

POWER SUPPLY CONNECTION TO STANDARD

7.2

CABINETS

For details, contact your Yaskawa representative,

R

s

G

—

SINGLE PHASE,

I 200/220VAC,

( ~~o~~fl SUPPLY CAPACITY:

POWER UNIT INSTALLED SEPARATELY

Page 13

8. CONNECTING POWER UNIT (TYPE CPS-I ONI AND PC BOARD

(TYPE JANCD-PC20) TO CRT OPERATOR’S PANEL (CRT/P)

I

TYPE CPS-1ON

*NC operators station with keyboard on right side of CRT

contains a power on /off switch. .4 special external circuit

does not have to be provided.

Note:

1. The shield enclosure does not have to be grounded outside.

2. Power on/off can be selected

and/or

3. Nos. 4 and 6 of Sh’5 must be set open.

Setiing in Main board

model JANCD-MB20

remote power on/off (EOF) by a shorting plug.

by the panel power on/off (POF)

i!i

! ‘L-..—

L–_—–-

Power

On/Off

Input

Sw 5

Panel Power

On/Off

(POF)

—.—

SW5 Setting

Remote Power

On/Off

(EOF)

10003 1000:1

40006

70~9 70~9

lo~o12 loo~12

n❑

Remote Power

40006

Panel and

On/Off

Fig. 8, 1

7

Page 14

9.

CONNECTION OF MANUAL

PULSE GENERATOR (HPG)

(1)

1ST MANUAL PULSE GENERATOR

TYPE

10. CONNECTION OF INPUT SEQUENCE

10.1 CONNECTION

—.

CPU MODULE

-————1

NC

POWER ON

——+4

(OPEN COLLECTOR OUTPUT)

CRT OPERATOR’S

PANEL

—.— .-

TYPE JANCD-SP20

I

I

I

,.

:

,*

—1

1

! -,@,

!,,, !,

——.—

CRTOPERATOR’S

PANEL

“rYPE JAN CD-SP20.

,. —.

:p ~

Note:

1.

The HPG power supply is a constant +5 V.

?

Set ~ltil on the SP20 boardas follo~vs depending on

-.

the manual pulse generatol- specifications.

(Swl) (Swl)

No 1 MANUAL PULSE

GENERAToR (lHPG)

[OPEN COLLECTOR OUTPUT)

,-

,,

,,

I

‘M

I

No 1 MANUAL PULSE

GENERATOR (lHPG)

—.— --–, ,

1

,,,

,,

,.

(DIFFERENTIAL OUTPUT TYPEI

1

CN3-19 *1’Esp

~+

CN5- 16’ *TOLD

“4

II

-~++

CN3-IZ

CN5 -13

CN3- I

2“ ‘4 ‘

Lc\i

Eot

&

NCh4X

—

s\klx

—

NCbl

SVhl

i~=l

MAGNETIC

CONTACTOR

SERVO

POWER ON

EM ERG ENC’/

STOP INPUT

MACHINE E14D

RELEASE

OVERLOAD INPUT

(NORMALLY NOT

USED)

EXTERNAL

POWER ON

EXTERNAL

POWER OFF

1“M12 ‘~=412

Simultaneous

l-axIs control 2-axes control

manual pulse

generator generator

(:?:::::. th’s)

An open collector (cable length 5 m or less) or

3,

differential output (cable length 5 m or more) can

be used for HPG output.

Shielded cables are not needed if the cable lengths

4.

are less than 1 m.

Use twisted-pair shielded cables if the cable lengths

are more than lm and ground the cable shield

enclosure using a ground plate.

Twisted-pair cables can be used.

Simultaneous

manual pulse

For Interfaces to

be used, contact

(

Yaskawa representative 1

Fig. 9.1

8

Fig. 10.1 Connecting Input Sequence to

Main Board (Type JAN CD-MB22)

Page 15

10.2 DETAILS OF SIGNALS

10.2.1 NC POWER ON (NCMX) AND SERVO

POWER ON (SVMX)

(1) NCMX: This output is turned on when the

logic circuit of the control is energized.

(2) SVMX: This output is turned on when the

servo unit is energized.

unit, turn on the power supply when this signal

is outputted.

(3) The power supply turning on sequence is as

follows :

Close the power supply main switch for the

(a)

con.t~ol.

Either push the POWER ON button on the NC

(b)

operator’s station * or close the circuit between

EON and ECM. Then,

the servo control circuit are both energized,

and the circuit between NCMX (NC power

input and output) is closed.

With an external servo unit, design the

the servo control circuit power input

sequence so that the circuit is ener–

gized at the output of NCMX signals.

[

Again make the same power switching (pushing

(c)

the POWER ON button or closing the circuit

between EON and ECM) . Now, the servo power

supply is turned on, and the circuit between

SVMX (servo power input and output) is closed.

With an external servo unit, design

the servo power circuit power input

sequence so that the circuit is energized at the output of SVMX signals.

[

When the external circuit is ready after the

(d)

circuit between SVMX is closed, and the control

becomes ready, close the MRD (machine ready)

input of the 1/0 module. Then, RDY is dis–

played on the CRT, and operation becomes

possible.

With an external servo

the logic circuit and

1

1

10.2.2 EMERGENCY STOP(TESP) INPUT

When the circuit between emergency stop input

terminals (TESP ) is open , the control stops totally ,

the servo power supply is turned off, and the

emergency stop output (* ESPS) of general purpose

1/0 module is opened.

10. 2.3 EXTERNAL POWER ON-OFF

(EON, EOF, ECM) INPUT

The control can be switched on and off by external

input signals , in the same way as the depressing

of the POWER ON /OFF buttons on the NC operator’s

station . When the circuit between EON and ECM

is closed, the logic circuit or servo power of the

control is energized.

When the circuit between

EOF and ECM is opened, the logic circuit or servo

power of the control is deenergized.

EO-F.ECM

CONTROL

CIRCUIT

SUPPLY

CONTROL SERVO

POWER SUPPLY

Fig. 10.3

CLOSED

OPEN

LOG [C

POWER

1,

1

External Power ON-OFF

,

1

10.2.4 OVERLOAD (*TOLD) INPUT

Short-circuit T24 (CN 5- 10) if this input is not

used. (Normally this input is not used. )

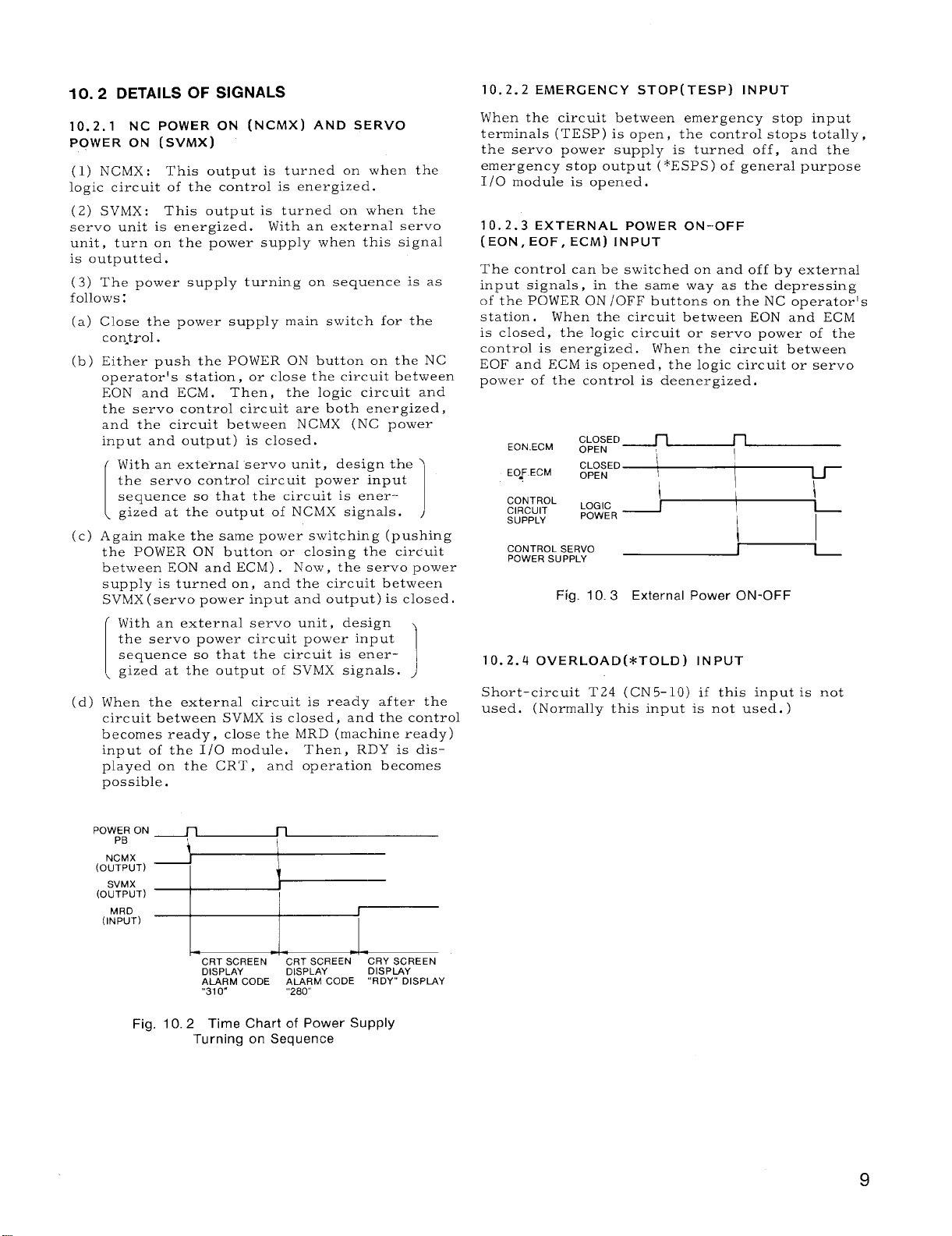

POWER ON

PB

NCMX

(OUTPUT)

SVMX

(OUTPUT)

MRD

(INPUT)

n n

i

I

I

i

l—

CRT SCREEN ~~~~~~EEN

DISPLAY

ALARM CODE ALARM CODE

‘“31o“ “280”

Fig. 10.2 Time Chart of Power Supply

Turning on Sequence

CRY SCREEN

DISPLAY

“RDY” DISPIAY

Page 16

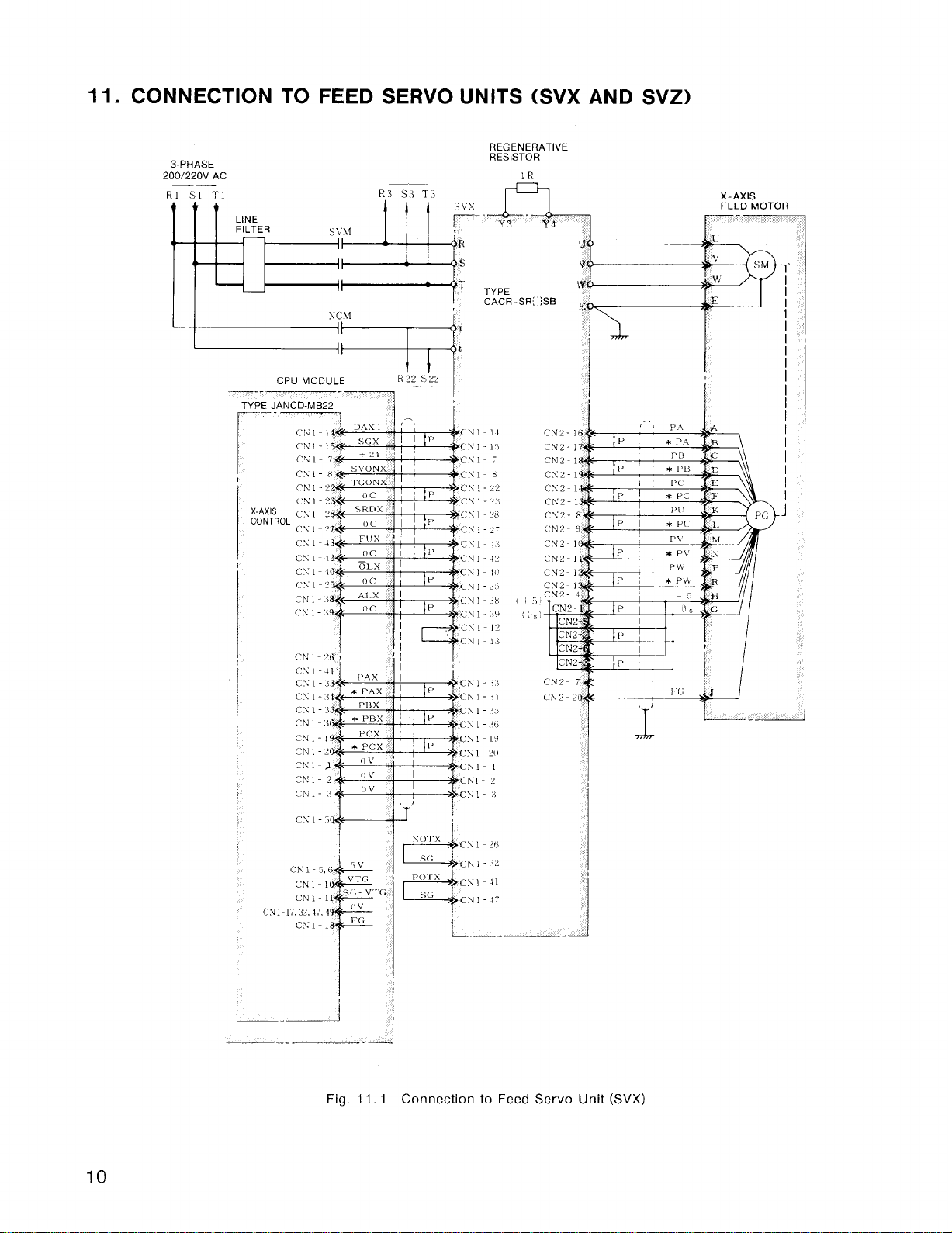

11. CONNECTION TO FEED SERVO UNITS (SVX AND SVZ)

REGENERATIVE

3-PHASE

200/220V AC

R1 S1

T1

R:3 S:3 T:]

RESISTOR

..A

Y3

Y4

TYPE

SC.M

c\ l-x

(’N 1-22

CN 1-.38

cY1-:i9

(.N 1- ?tj ,

CS 1-41

CS I-.33

CS I-3*

c\ 1-.15

II

I

TYPE JANCD-M B22

r

X-AXIS

I

CACR-SR{”;SB

r

‘~’(;:;cN2-

\

CN2-1,

CN2-)

CN2-I

CS2-1

CX2-1

CN2-1

CX2- [

~~z. ,

Chlz-1

CN2-1

CN2-1

CN2-1

CN2- 4

.

CN2

CN2

CN2

CN2

“E

CN2- 7

C12-2(

10

CN1-2

CK 1-2

CN 1-:+

CY1

.—

Fig. 11.1 Connection to Feed Servo Unit (SVX)

Page 17

REGENERATIVE

~D RESISTOR

. ..

3-PHASE

200/220V AC

R ‘+

s .1

‘r .3

13’

,-!

!IP

1P

B

,1P

II

II

Ii

1!

~

1’

1’

i)

@

J,

~.a

R

:s

T

l.,

cN 1-11

-s1-1.7

CN I-7

CNI-8

CN 1-22

‘CN1 -2”;

,CN 1-28

P

‘:CN 1-27

;CN1-t.+

‘CN1- $2

,Csl-io

P

CN1-?5

‘C N1- +8

P

:CNi-:\9

“CN1-12

‘C N1 -1{

k;N 1- .1.)

P

CN1-’3t

CNI-.I5

P

“CN 1-:<b

,’cN1-IY

P

c~l.z(,

CN 1-1

CN1- 2

‘CN1-.i

TYPE

CACR-SR; “SB

Y4

I

1

I

I

—.-

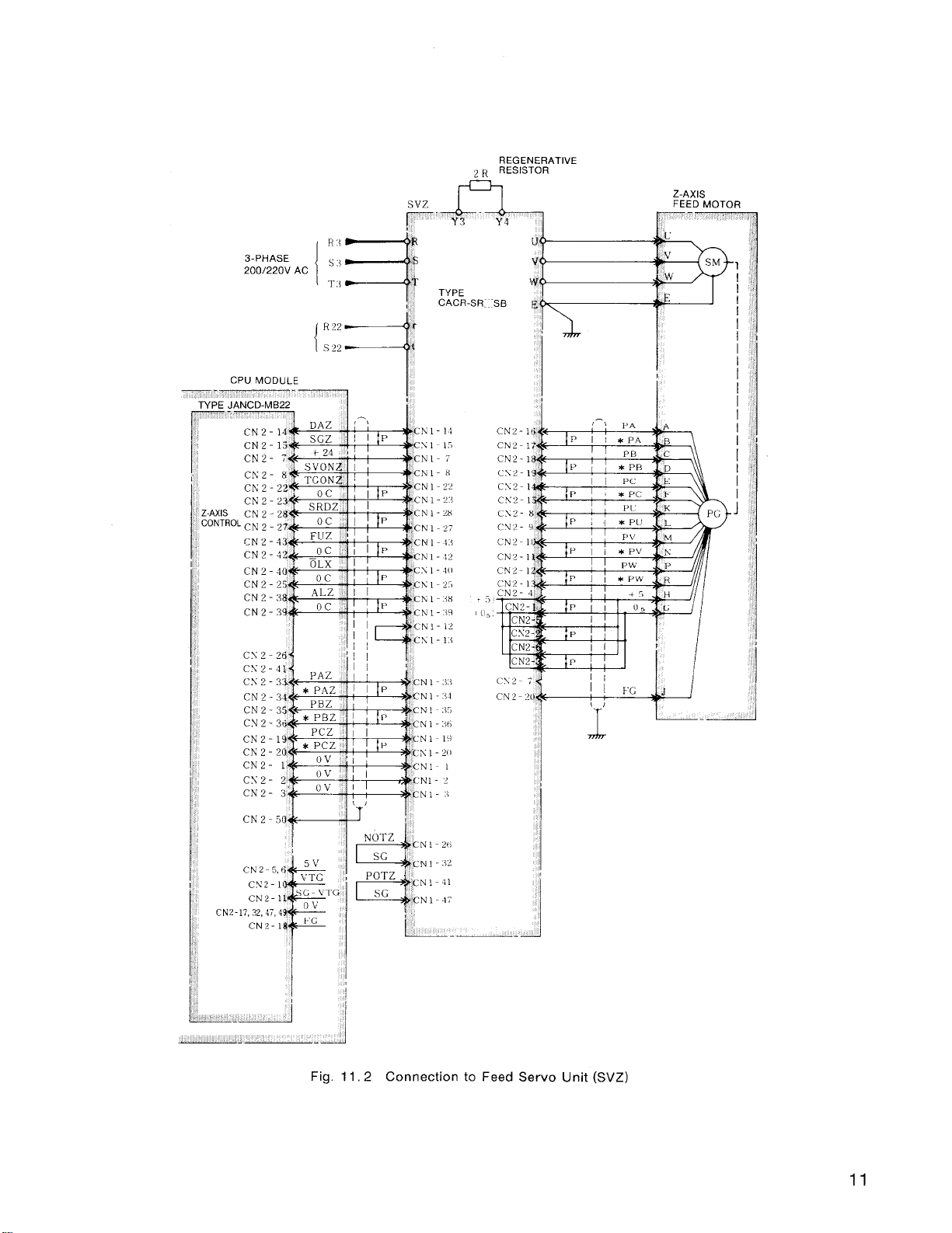

Fig. 11,2 Connection to Feed Servo Unit (SVZ)

11

Page 18

11. CONNECTION TO FEED SERVO

UNITS (SVX AND SVZ)

(1)

CONNECTION AND MOTOR ROTATING

DIR”ECTfON

Forward Connection Reverse Connection

Direction of

Motor Rotation if

“ +” moving com-

g

mancl is given.

The connection diagram shows forward connection. Connect wires as shown below for

reverse connection .

o

cc ‘vi’

FLANGE

SURFACE

OF MOTOR

(Cent’d)

o

g

Cw

Line Filter Type Current per Phase of Input Power Supply

o IOA max

LF31

LF 320

LF330

LF 340

I

I

max

20A

30A max

max

40A

(4) CONNECTION TO MOTOR WITH BRAKE

SINGLE PHASE

100/200 VAC

SVMX

@ ~ PUSHBUTTON

EMERGENCY

STOP

MOTOR BRAKE

u--” “---+-1

+2 :~-’]

L. —. —._

BRAKE POWER SUPPLY

TYPE OPR1 09A (FOR

200/220V INPUT),

TYPE OPR-109F

(FOR 100VAC INPUT)

[

.d

I

Do not short-circuit output terminals 3 and 4.

Tightly fasten terminal board screws ,

Protective devices are built-in .

tectors are not needed,

The contact making and breaking current for

terminals 5 and 6 shall be 5 to 10 times the rated

current of the brake to be used. Use DC make–

break contacts .

i-—. —

External pro-

(2) COMBINATION OF DRIVE UNIT AND REGEN-

ERATIVE RESISTOR

Servo Drive Type

CACR-

SR05SB

SR30SB

SR44SB

*Two resistors connected in parallel

LINE FILTER INSTALLATION

(3)

A line filter is installed to prevent radio inter-

(a)

ference by high frequency generated by the

servo drive unit.

Select the appropriate filter as follows depend-

(b)

ing on the current per phase of the drive

unit input power supply,

Regenerative Resistor installed

Separately

4H-AS 30W 10O-OHM

—

MRC22-250K

MRC22-250K

12

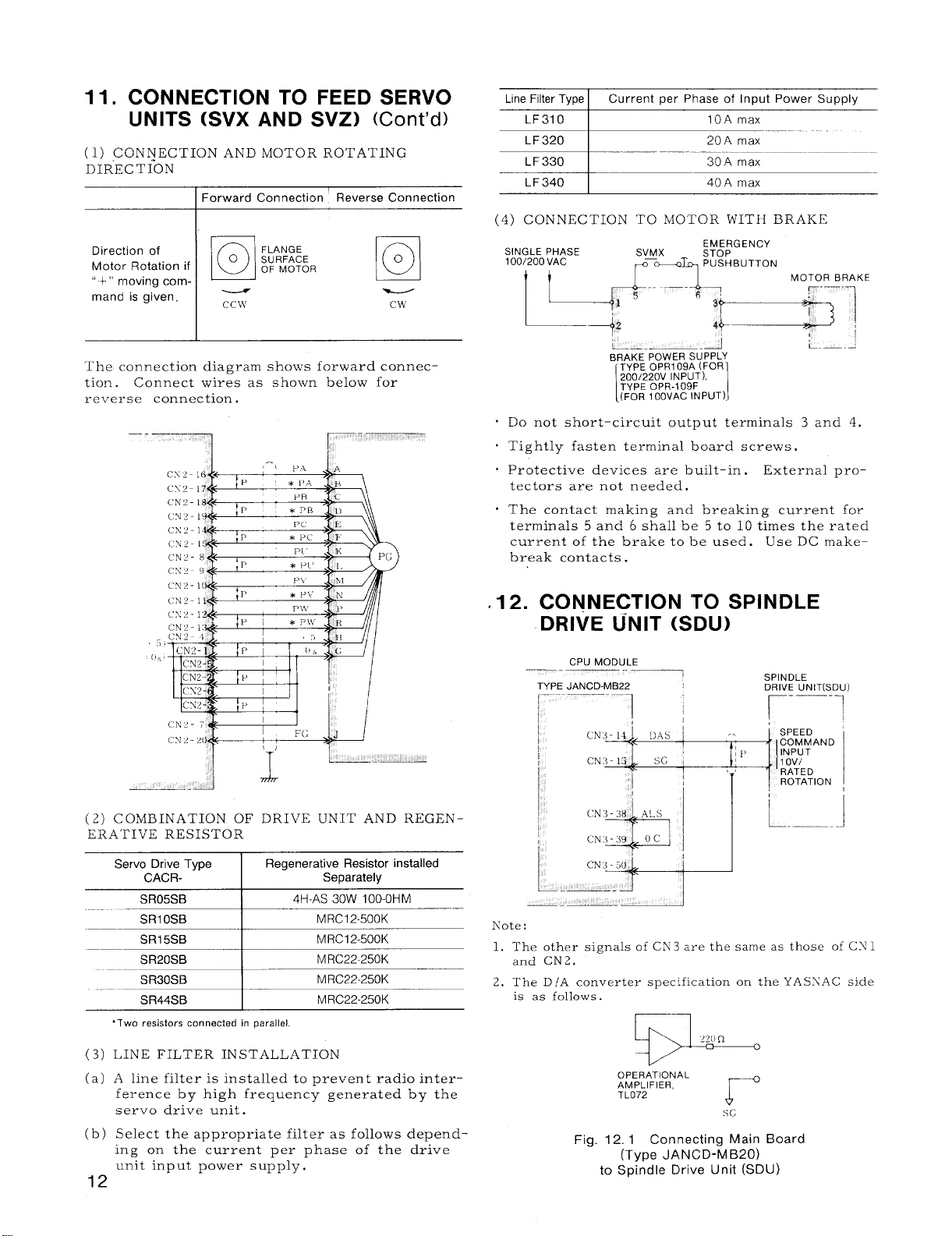

.12. CONNECTION TO SPINDLE

DRIVE UNIT (SDU)

CPU MODULE

TYPE JANCD-MB22

~_..-——.

1

Kote:

The other signals of CN3 are the same as those of CS 1

1.

and CN2.

2. The D 1A converter specification on the YASXAC side

is as follows.

*

OPERATIONAL

AMPLIFIER,

TL072

Fig. 12.1 Connecting Main Board

(Type JANCD-MB20)

to Spindle Drive Unit (SDU)

r

SPINDLE

DRIVE UN IT(SDU)

r-—-l

Page 19

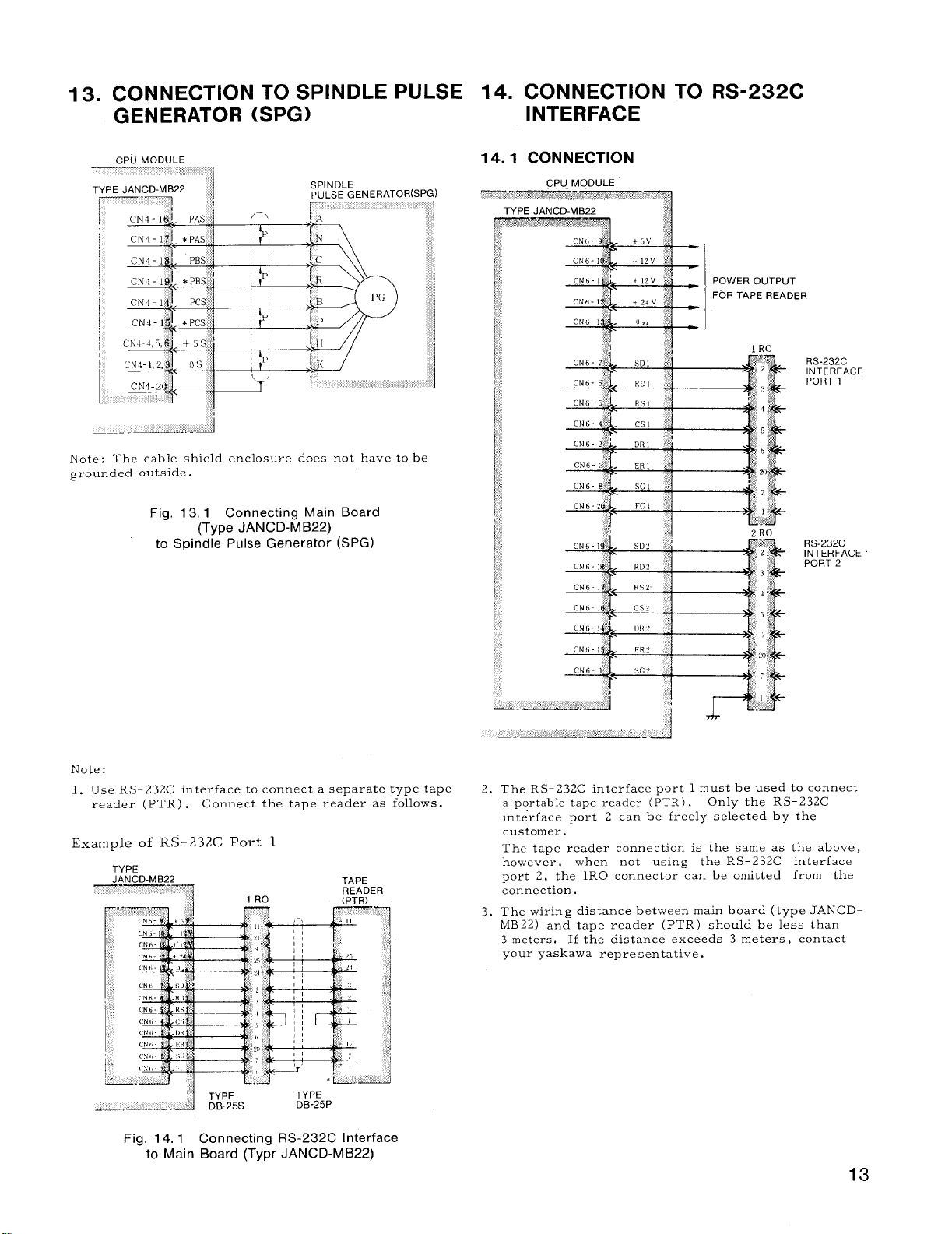

13. CONNECTION TO SPINDLE PULSE

GENERATOR (SPG)

Note: The cable shield enclosure does not have to be

grounded outside.

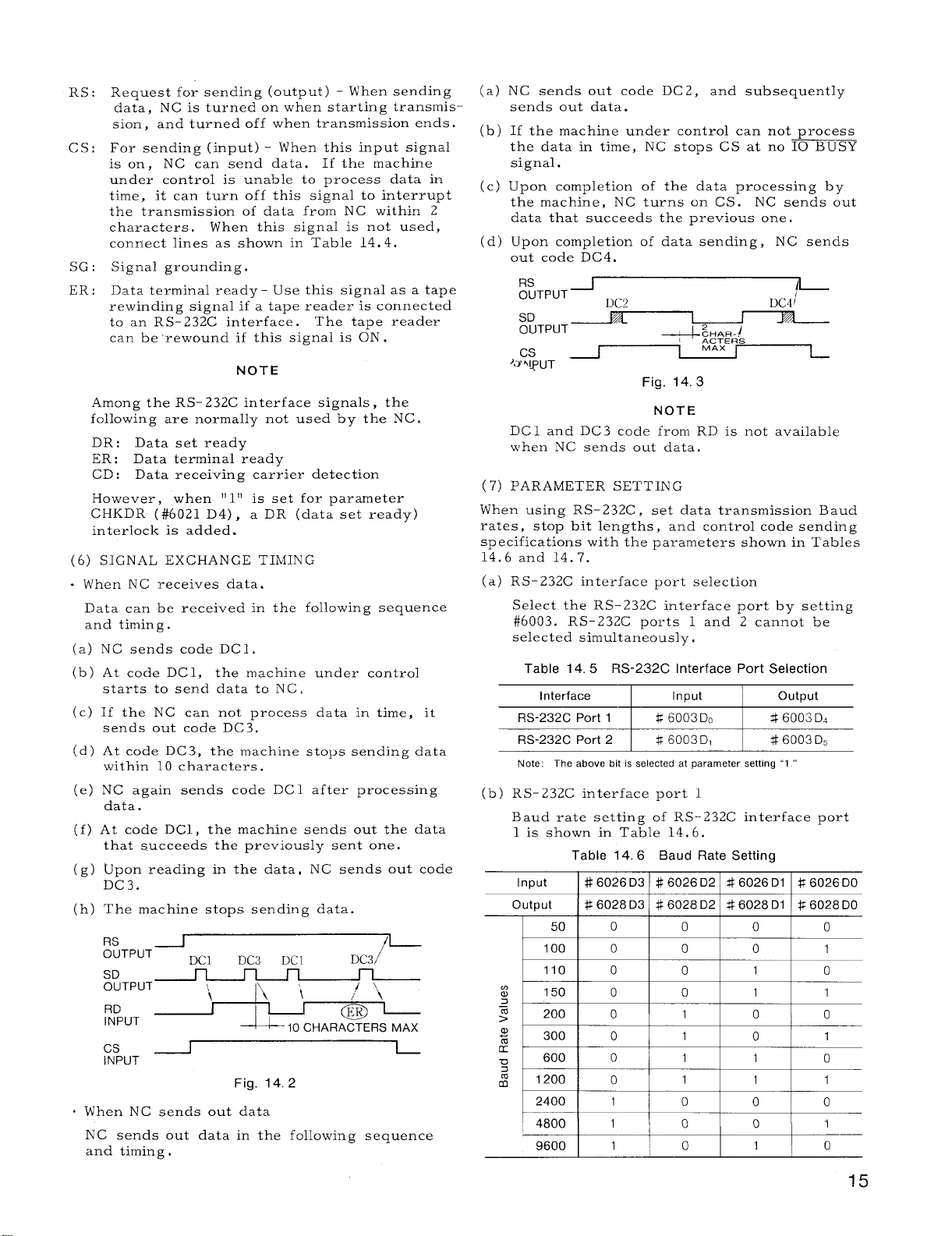

14. CONNECTION TO RS-232C

INTERFACE

POWER OUTPUT

FOR TAPE READER

Fig. 13, 1 Connecting Main Board

Note:

1. Use RS- 232C interface to connect a separate type tape

reader (PTR) .

Example of RS-232C Port 1

TYPE

(Type JANCD-MB22)

to Spindle Pulse Generator (SPG)

Connect the tape reader as follows.

2. The RS-232C interface port 1 must be used to connect

a portable tape reader (PTR) .

interface port 2 can be freely selected by the

customer.

The tape reader connection is the same as the above,

however, when not using the RS-23ZC interface

port 2, the lRO connector can be omitted from the

connection.

3. The wiring distance between main board (type JANCD-

MB22) and tape reader (PTR) should be less than

3 meters. If the distance exceeds 3 meters, contact

your yaskawa representative.

Only the RS-232C

Fig. 14.1 Connecting RS-232C Interface

to Main Board (Typr JANCD-M B22)

13

Page 20

14. :? RS-232C INTERFACE

(5) INTERCONNECTION

TRANSMISSION MODE

(1)

Starl;-stop synchronization :

preceded by a start signal,

stop signal.

A SINGLE START-STOP CHARACTER

I

ON–––’

OFF –

(2) (;ODES USED

The following two types of codes are used, and

are :selectively used by parameters (#6026D5,

#6028D5) .

0 EIA codes or 1S0 codes

EIA codes or 1S0 codes + control codes (DC 1 -

.

DC4)

To use control codes , the machine to be controlled must be able to discriminate codes DC1

th-t-ough DC4. Codes DC 1 - DC4 are as follows.

DC, Tape reader .-

5 Y

START DATA BIT

BIT

Character

start

DI D2 D3 D4 D5 D6 D7

DO

Table 14, 1

Table 14.2

8 7 65 4 ::; 32

Each data bit is

and followed by

...

.

STOP BIT

(1 OR 2 BITS)

~

{..’

Table 14.3 RS-232C Interface Connecting

Cable (A)

a

-FG I Frame grounding

SD Sending data

RD Receiving data

RS

NC outputs control codes DC1 - DC4 to start and

stop the machine, but the machine can not output

control codes to control the NC .

the machine under control is unable to process

data in time, it can control the CS signals of the

NC to halt the data outputting of the NC.

CS and RS as shown Table 14.4,

Symbol

1

/.

FG I Frame grounding

SD

RD

+

NC (DB-25P)

Connections —---—-

Signal Name

Sending data 4

fihen CS signals of the NC are not used, short

Table 14.4 RS-232C Interface Connecting

NC (DB-25P)

Signal Name

Sending data

Receiving data

~ Pin

No.

1

I 1 I ~~) FG

2

~+ ‘-

3

—

1 !

However, when

Cable (B)

Connections \

Pin

No.

I

T

I ‘ 10

--{’ME

External

Equipment

Symbol

Cl RS

I

ER

External

Equipment

~ Symbol

~, ~FG

(3) TRANSMISSION BAUD RATE

Transmission Baud rates can be selected at any

rate between 50 and 9600 Bauds with parameters.

Refer to (7) in par. 14.2.

(4) (;ABLE LENGTH

The permissible maximum cable length varies with

the machine to be controlled, Refer to the manual

of the machine builder’s manual. (Standard maximum

cable

length is 15 m, )

14

DR

Data set ready

SG

Signal grounding

ER

Data terminal ready 20

, Description of signals

FG: Safety grounding

SD: Transmission data (output)

RD :

Received data (input)

-fIl I I

I 61

+’*-P

1,, ,,

L-START

fl~DR

~sTop

Page 21

RS:

Request for sending (output) - When sending

data, NC is turned on when starting transmis-

sion, and turned off when transmission ends.

Cs:

For sending (input) - When this input signal

is on, NC can send data. If the machine

under control is unable to process data in

time, it can turn off this signal to interrupt

the transmission of data from NC within 2

characters, When this signal is not used,

connect lines as shown in Table 14.4.

SG :

Signal grounding.

Data terminal read~ - Use this signal as a tape

ER :

rewinding signal if-a tape reader–is connect;d

to an RS-232C interface.

can be rewound if this signal is ON .

NOTE

Among the RS-232C interface signals, the

following are normally not used by the NC.

DR: Data set ready

ER : Data terminal ready

CD: Data receiving carrier detection

However, when

CHKDR (#6o2l D4), a DR (data set ready)

interlock is added.

(6) SIGNAL EXCHANGE TIMING

- When NC receives data.

Data can be received in the following sequence

and timing.

(a) NC sends code DC1,

(b) At code DC1, the machine under control

starts to send data to NC.

(c) If the NC can not process data in time, it

sends out code DC3,

(d) At code DC3, the machine stops sending data

within 10 characters.

(e) NC again sends code DC1 after processing

data.

(f) At code DC1, the machine sends out the data

that succeeds the previously sent one.

Upon reading in the data, NC sends out code

(g)

DC3.

(h)

The machine stops sending data.

~RTPUT

SD

OUTPUT

RD

INPUT

Cs

INPUT

When NC sends out data

NC sends out data in the following sequence

and timing .

~

Ill!) is set for parameter

\

DC3

1’/

L“

Fig. 14.2

DC1

The tape reader

DC3

Dc 1

10 CHARACTERS MAX

/-

/ \,

o~

NC sends out code DC 2, and subsequently

(a)

sends out data.

(b)

If the machine under control can not process

the data in time, NC stops CS at no IO BUSY

signal.

(c)

Upon completion of the data processing by

the machine, NC turns on CS. NC sends out

data that succeeds the previous one.

Upon completion of data sending, NC sends

(d)

out code DC4.

~RTpUTJ

SD

ouTpuT~

Cs

‘3Nl~UT

DC1 and DC3 code from RD is not available

when NC sends out data.

PARAMETER SETTING

(7)

When using RS-232C , set data transmission Baud

rates, stop bit lengths,

specifications with the parameters shown in Tables

14.6 and 14.7.

(a)—RS-232C interface port selection

Select the RS-232C interface port by setting

#6003. RS-232C ports 1 and 2 cannot be

selected simultaneously,

Table 14.5 RS-232C Interface Port Selection

Interface Input output

RS-232C Port 1

RS-232C Port 2

Note: The above bit is selected at parameter setting “1 “

(b) RS-232C interface port 1

Baud rate setting of RS-232C interface port

1 is shown in Table 14.6.

Table 14.6 Baud Rate Setting

Input

output

I

I

I

I

I

] # 6026D3 I # 6026D2 I # 6026D1 I R 6026D0

I * 6028D3 I # 6028D2 I # 6028D1 I $ 6028D0

501 0 I o

100 IOIO

1101010

150

200

3001011

24001110

~

D~~

+;g+~R~

MAX

Fig. 14.3

NOTE

and control code sending

$ 6003Do

@f3003D1 46003 D,

I

I

I

0 0 1 1

0

1

I

I

DC4 ~

I L-

# 6003 D,

o

10

o

I

1

I

0

o

11

o

I

1

o

0

o

15

Page 22

14. 2! RS-232C INTERFACE (Cent’d)

. Stc)p bit length setting

#6026 D4 for input 1:

#6028 D4 for output O:

. Setting of control code sending

#6026 D5 for input 1:

code .

#6028 D5 for output O: Sends control code.

(c) RS-232C interface port 2

13aud rate setting of RS-232C interface port

2 is shown in Table 14.7.

Input

output

# 6027 D3

# 6029 D3

50 0 0

100 0 0

110 0 0’1

m

a 150 0 0

3

z

200 0

>

m

%

K

u

:

m

300

600

1200 0

0 1’0

0

2400 1 0!0

4800

9600

1

1

Stop bit length setting

#6027 D4 for input 1:

#6C29 D4 for output O: Sets stop bit at one bit.

Setting of control code sending

#6C127D5 for 1:

#6029 D5 for O:

does not send control code.

Sends control code.

Sets stop bit at two bits.

Sets stop bit at one bit.

Does not send control

Table 14.7

# 6027 D2 $6027 D1

# 6029 D2 * 6029 D1

0

0

1 1

1’0

11

1

1

1 1

o~o

0’1

Sets stop bit at two bits.

# 6027 DO

# 6029 DO

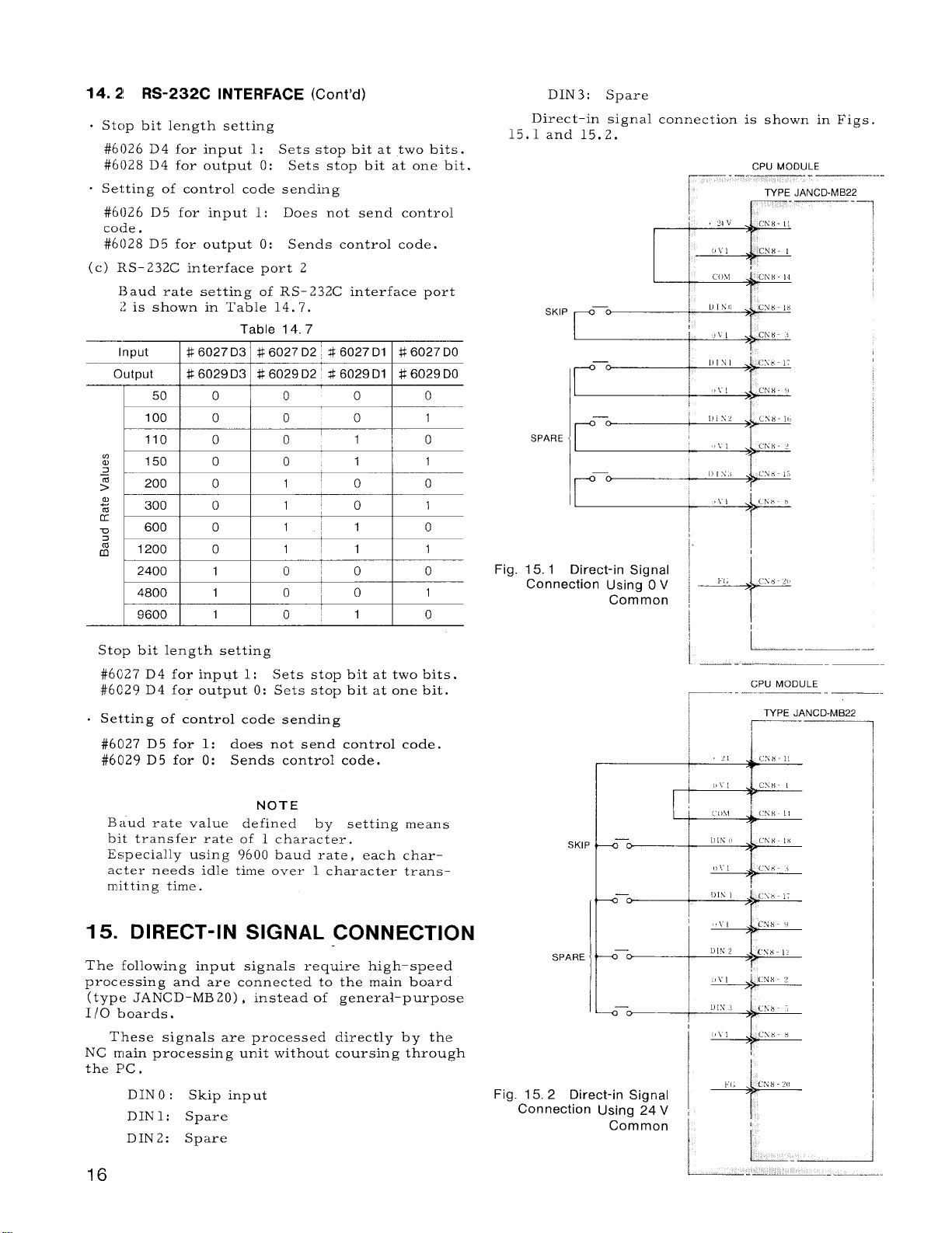

D1N3: Spare

Direct-in signal connection is shown in Figs.

15,1 and 15.2.

SKIP

r’”

0

1

0

SPARE

0

1

0

o

1

0

Fig. 15.1 Direct-in Signal

Connection Using O V

Common

I

L.—--------

.—. ——

CPU MODULE

,

I

TYPE JANCD-MB22

~-

NOTE

Baud rate value defined by setting means

bit transfer rate of 1 character.

Especially using 9600 baud rate, each character needs idle time over 1 character trans–

m.itting time.

15. DIRECT-IN SIGNAL CONNECTION

The following input signals require high-speed

processing and are connected to the main board

(type JANCD-MB 20) , instead of general-purpose

1/0 boards.

These signals are processed directly by the

NC main processing unit without coursing through

the F’C ,

DINO:

Skip input

DIN1: Spare

DIN2: Spare

16

SKII

SPARE

Fig. 15.2 Direct-in Signal

Connection Using 24 V ,

Common I

CN8 -20

+

~ “ L-_A

Page 23

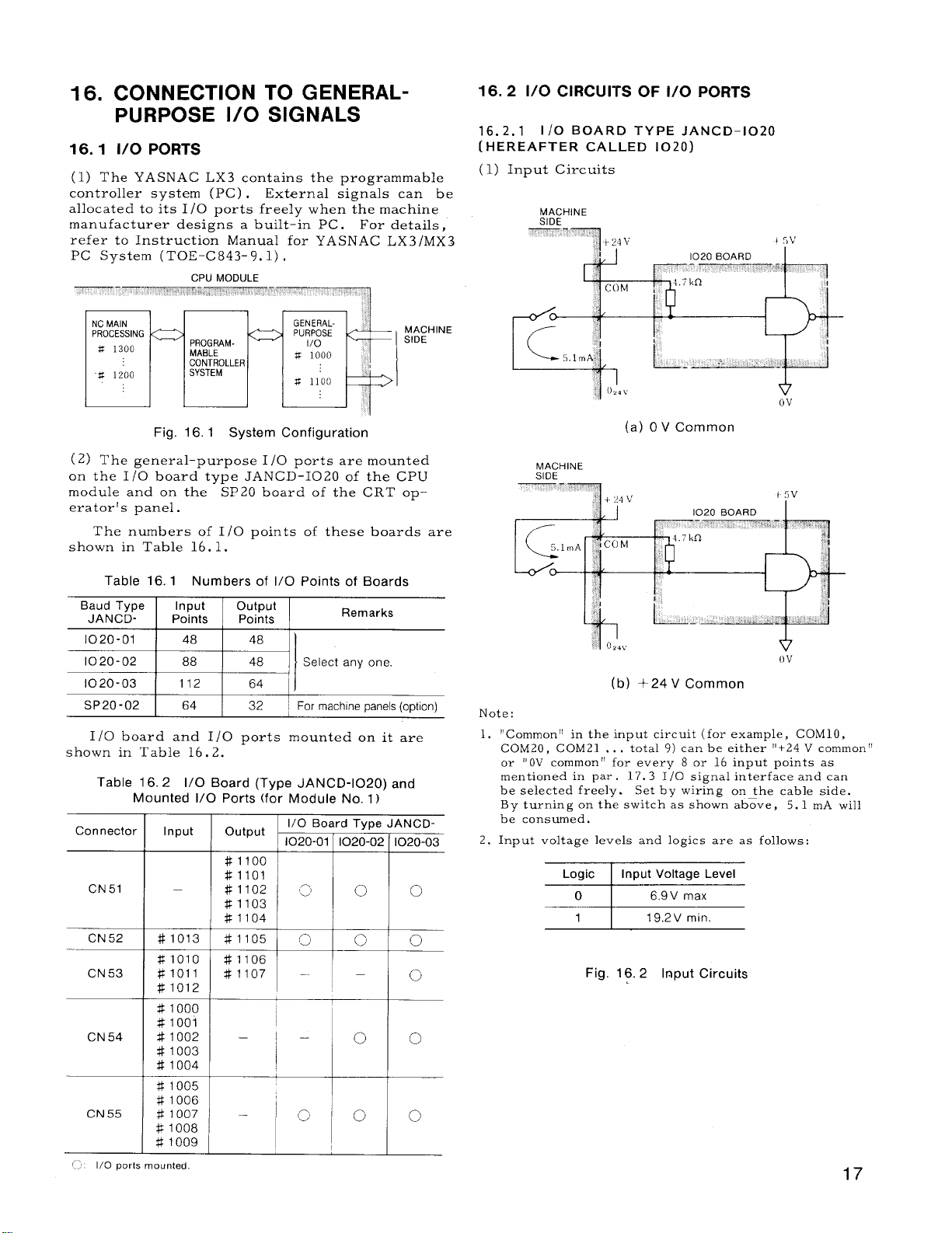

16. CONNECTION TO GENERALPURPOSE 1/0 SIGNALS

16.1 1/0 PORTS

The YASNAC LX3 contains the programmable

(1)

controller system (PC) . External signals can be

allocated to its 1/0 ports freely when the machine

manufacturer designs a built-in PC. For details,

refer to Instruction Manual for YASNAC LX3/MX3

PC System (TOE-C 843-9. 1) ,

—-

NC MAIN

PROCESSING

s 1300

CPU MODULE

,,$ ..~;,; <.> ,.,

‘““~

MACI

SIDE

m

“w 1200

I

I

16.2 1/0 CIRCUITS OF 1/0 PORTS

16. 2.1 1/0 BOARD TYPE JANCD-102O

(HEREAFTER cALLED 1020)

(1) Input Circuits

Fig. 16.1 System Configuration

(2) The general-purpose 1/0 ports are mounted

on the 1/0 board type JAN CD-1020 of the CPU

module and on the SP20 board of the CRT operator’s panel.

The numbers of 1/0 points of these boards are

shown in Table 16.1.

Table 16.1 Numbers of 1/0 Points of Boards

Baud Type

JANCD- Points

~

I /0 board and 1/0 ports mounted on it are

shown in Table 16.2.

Table 16.2 1/0 Board (Type JANCD-1020) and

Connectc

CN 51

CN52

CN53

Input output

Mounted 1/0 Ports (for Module No. 1)

Input output

—

#lo13

#lolo

#loll

#lo12

Points

~ For machine panels (option)

l/O Board Type JANCD-

1020-01

#lloo

#llol

#llo2

#llo3

#llo4

#llo5

#1106

#llo7

Remarks

I1020-02 1020-03

— —

# 1000

CN54

CN55

..

1/0 ports mounted

[,

# 1001

# 1002

# 1003

# 1004

# 1005

# 1006

# 1007

# 1008

# 1009

—

—

o

I

(a) OV Common

MACHINE

SIDE

ov

(b) +24V Common

Note:

1.

“Common “ in the input circuit (for example, COM1O,

COM20, COM21 . . .

or “ OV common” for every 8 or 16 input points as

mentioned in par . 17.3 1/0 signal interface and can

be selected freely.

By turning on the switch as shown above, 5.1 mA will

be consumed.

Input voltage levels and logics are as follows:

2.

0

~

1

total 9) can be either “+24 V common”

Set by wiring on the cable side.

19.2V min

I

0

0

Fig. 16.2 Input Circuits

0

c)

17

Page 24

16. 2.1 1/0 BOARD TYPE JAN CD-1020

(HEREAFTER CALLED 1020)

(Cent’d)

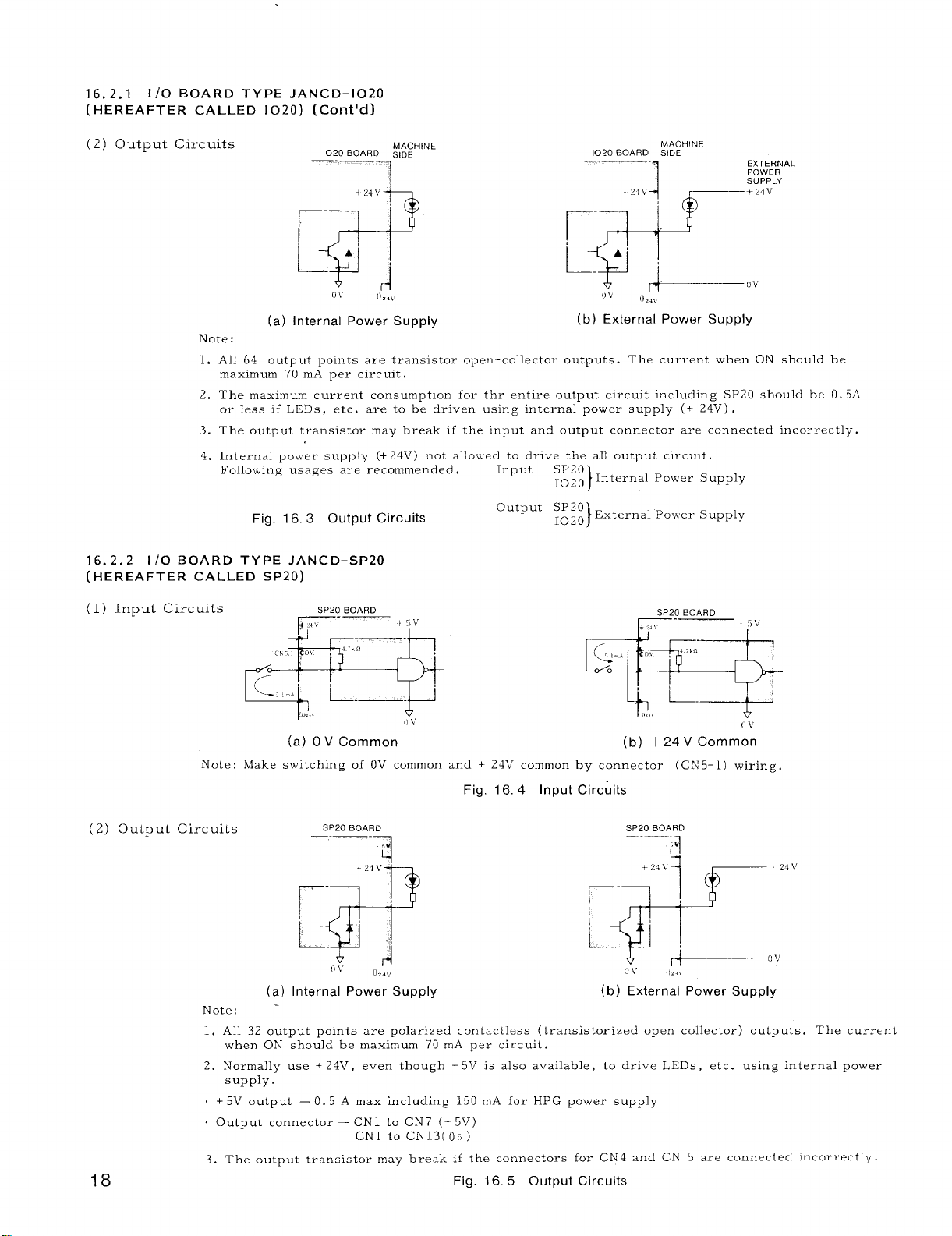

(2) C)utput Circuits

(a) Internal Power Supply

Note:

1. All 64 output points are transistor open-collector outputs. The current when ON should be

maximum 70 mA per circuit.

2. The maximum current consumption for thr entire output circuit including SP20 should be O. 5A

or less if LEDs, etc. are to be driven using internal power supply (+ 24V) .

3. The output transistor may break if the input and output connector are connected incorrectly.

4. Internal power supply (+ 24V) not allowed to dri~,e the all output circuit.

Following usages are recommended.

Fig. 16.3 Output Circuits

16. 2.2 1/0 BOARD TYPE JAN CD-SP20

(HEREAFTER cALLEt3 sp20)

1020 BOARO slDE 1020 BOARD SIDE

$ fz:

Ov

O<..

MACHINE

Input

output SP20

SP20

~ozo Internal PO\\,er Supply

~020 External Po\\er Supply

MACHINE

02.,

(b) External Power Supply

)

)

(1) Input Circuits

Note: Make switching of OV common and + 24V common by connector (CN 5

(2) Output Circuits

18

BOARD

SP20

~,.

c,, , CO,, , ‘--”

Ego

*,, .

(a) OV Common

BOARD

SP20

—-— .

~d ~~:

ov

(a) Internal Power Supply

Note:

1. All 32 output points are polarized con tactless (transistorized open collector) outputs. The current

when Oh? should be maximum 70 m.A per circuit.

2. Normally use + 24V,

supply.

. + 5V output — O. 5 A max including 150 mA for HPG power supply

. Output connector – CN1 to CN7 (+5V)

3. The output transistor may break if the connectors for CN4 and

t 5\J

.— -

(1\;

Fig. 16.4 Input Circuits

,5

1

0,.,>

(b) External Power Supply

even though + 5V is also available, to drive

CN1 to CN13(Os)

Fig, 16.5 Output Circuits

(i v

(b) +24V Common

1) wiring.

SP20 BOARD

“1

‘c

UY

LEDs, etc. using internal power

Ch’ 5 are connected incorrectly.

Page 25

16.3 1/0 SIGNAL INTERFACE

16.3.1 1/0 20 BOARDS

------ .

.i

/

1

ADDRESS BIT

No. No

#looo. o

#looo 1

2

<,

:{ 20 )

I

%

/:( 35)

‘p

z( 36)

~

‘(6)

>,

;

1;’(22) —

t,.

,,

k

#looo.

#looo 3

b

#looo 4

#looo. 5

#1000. 6

#looo. 7

#lool o

#lool. 1

#lool 2

*1 OO1. 3

#lool. 4

#lool. 5

,-,

T 1

1

I }

+, ... c

*.

f,., ~ -

L

COM 30

:<,,,:,;::<, ;i..,,; ,;,. ,,; ...,,:,.“~,,,.,,.,,.,,,,, l,, ,. .,, *$*

—

Note:

1. This connection example shows +24 V common.

O V common is also available.

Refer to par. 16.2.1,

I/0 Board Type JANCD–1020 for connection details ,

2. The addresses are those for module No. 1. The address

layouts for modules Nos.

above starting with newer addresses.

B (3) , Address Classification for details.

2 to 4 are the same as shown

Refer to Appendix

Fig. 16.6 Connection to Address and Bit Nos.

#1000,0 to #1001.7 on 1020 Board

I

—

””,. “

. . . .

19

Page 26

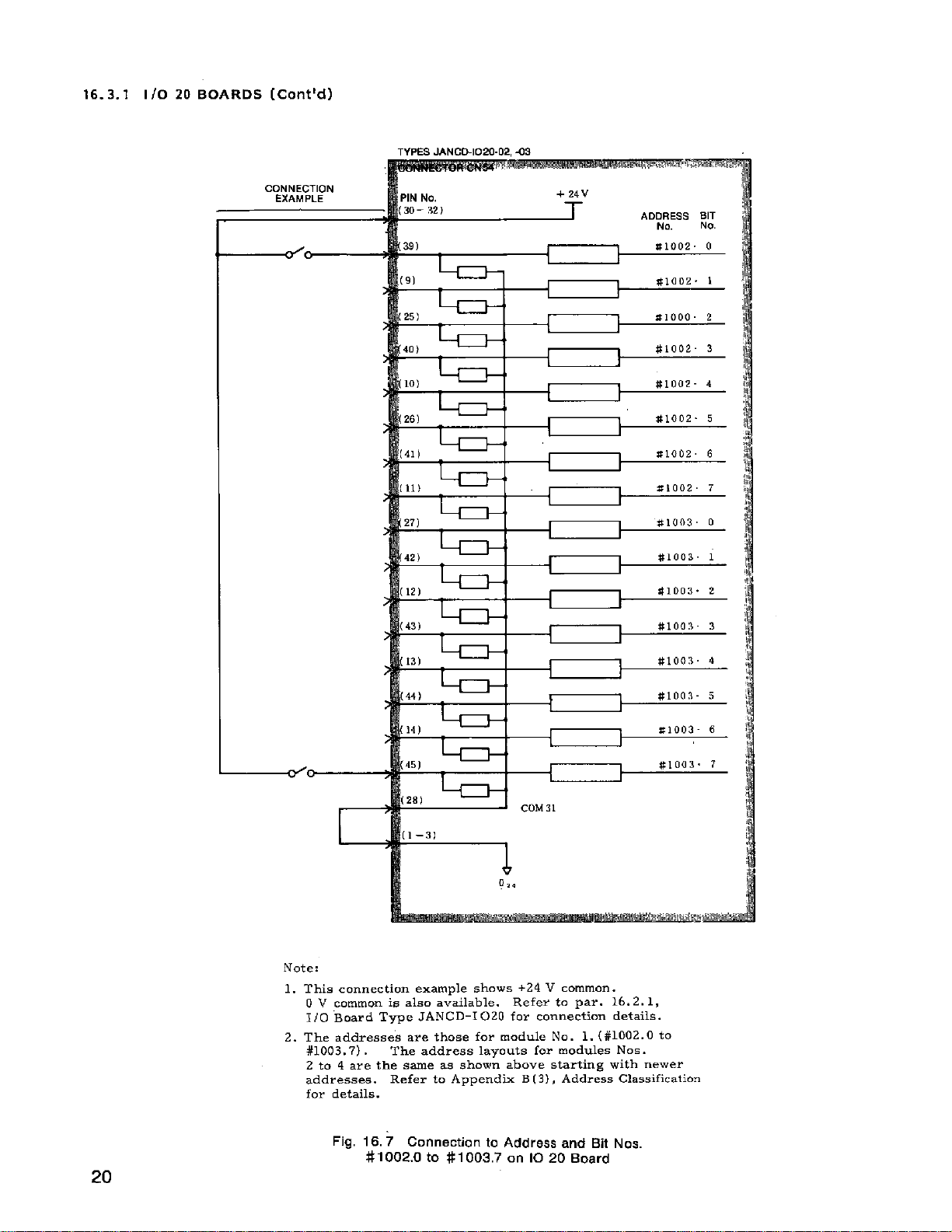

16.3.1 1/0 20 BOARDS (Cent’d)

TYPES JANCW1020 .02, -09

1-

,.,

<3!

K31

441

141

“.) —

—

[

I

I

Note:

1. This connection example shows +24 V common.

0 V common is also available. Refer to par. 16.2.1,

1/0 Board Type JANCD-I 020 for connection details.

2. The addresses are those for’ module No. 1. (#1002. O to

#loo3.7).

2 to 4 are the same as shown above starting with newer

addresses. Refer to Appendix B (3) , Address Classification

for details.

The address layouts for modules No,

$1003. 2

#l Oa:{ 3

*1 OO:3. d

U1OO3- 5

s1OO3. 6

20

Fig. 16.7 Connection to Address and Bit Nos.

#1002.O to #1 003.7 on 1020 Board

Page 27

CONNECTION

EXAMPLE

> p

5 %

> w

$

<30–321

(

( 17 )

(48)

(~L);

PIN No.

[16)

,

Cohl.12

+

+ ~ii,

ADDRESS ~[

No

#loo40

#loo41

#loo4. ?

1

M1O(I4:I

#loo4.4

1

S1OOI5

$1004{5

1

31(1017

1

E :

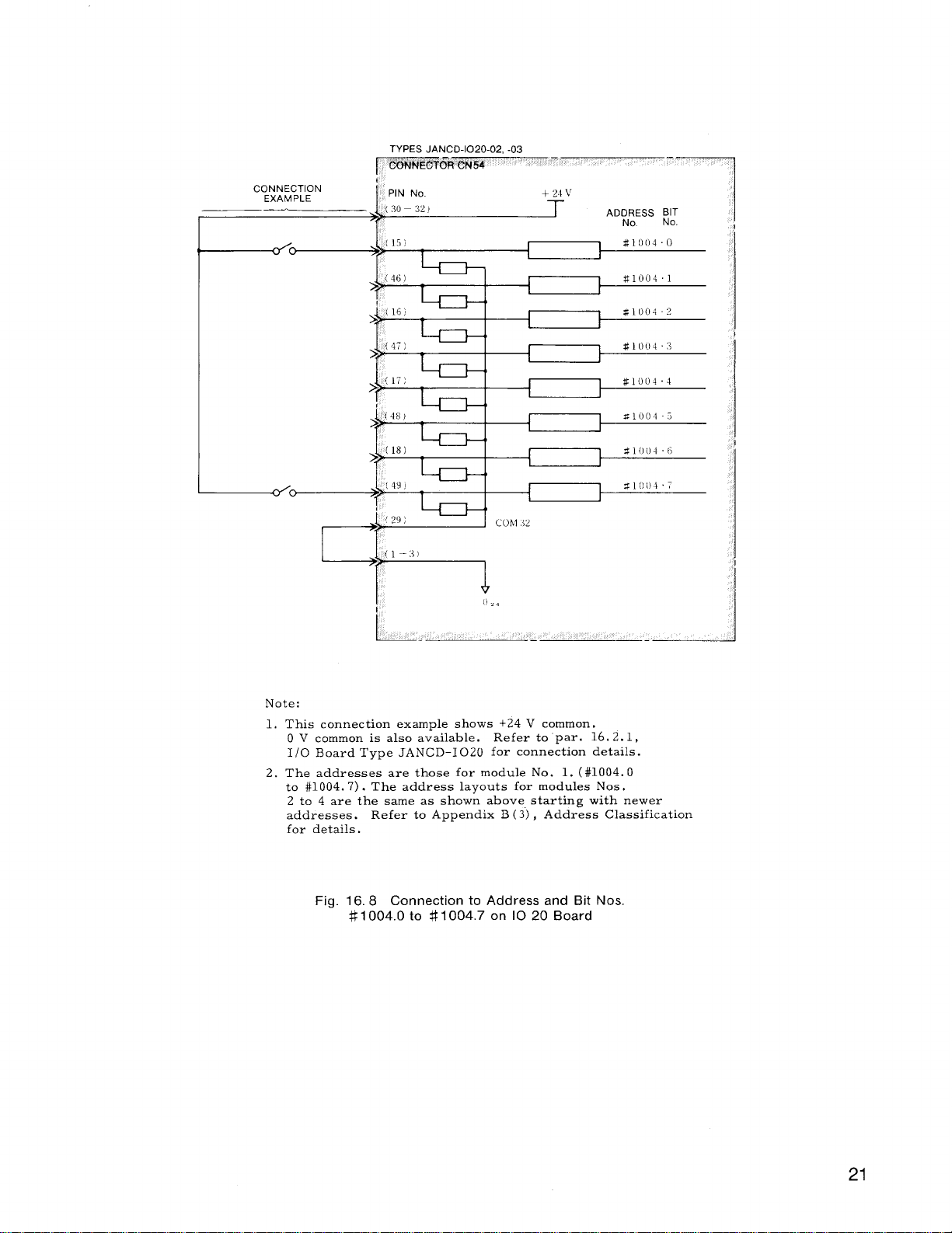

Note:

1, This connection example shows +24 V common.

0 V common is also available. Refer to par. 16.2.1,

I/0 Board Type JANCD-1020 for connection details.

2. The addresses are those for module No. 1. ( #1004. O

to #1004. 7) . The address layouts for modules Nos.

2 to 4 are the same as shown above starting with newer

addresses.

for details.

Fig. 16.8 Connection to Address and Bit Nos

{1--?)

Refer to Appendix B (3) , Address Classification

#1 004.0 to #1004.7 on 1020 Board

21

Page 28

16. 3.1 1/0 20 BOARDS (Cent’d)

[1’>. ...

\a” —aL)

r

f

1

I

ADDRESS BIT

No

No

22

Note:

1. This connection example shows +24 V common.

O V common is also available,

I/0 Board Type JAN CD-1020 for connection details,

Refer to par. 16.2.1,

2, The addresses are those for module No. 1. (#1005. O

to #1006. 7) . The address layouts for modules Nos.

2 to 4 are the same as shown above starting with newer

addresses. Refer to Appendix B (3) , Address Classification

for details.

Fig. 16, 9 Connection to Address and Bit Nos.

#1 005.0 to #1 006.7 on 1020 Board

Page 29

CONNECTION

EXAMPLE

d

,,.

<A

1

~?{16)

~~

(15)

>%

1

,,:

t’{14)

>2

r:

+24V

ADDRESS BIT

No. No.

#loo7. o

#loo7. 1

#loo7 2

1

#loo7 3

)

1

#looi’. 4

S1OO7 5

$1 OO7. 6

#loo7. 7

#1008 O

#1008 1

#1008 2

#1008. 3

~~:f41)

>?

,,’

I

,.,

...

I

~

Note:

1. This connection example shows +24 V common.

O V common is also available.

1/0 Board Type JAN CD–1020 for connection details.

2, The addresses are those for module No. 1. (#10Ct7. O

to #1008. 7) . The address layouts for modules Nos.

2 to 4 are the same as shown above starting with newer

addresses. Refer to Appendix B(3) , Address Classification

for details,

+1

o

,.

Refer topar.16. 2.1,

#1008 4

#1008 5

#1008 6

#1008. 7

Fig. 16.10 Connection to Address and Bit Nos.

#1007.O to #1008.7 on 1020 Board

Page 30

16. 3.1 1/0 20 BOARDS (Cent’d)

CONNECTION

-~ ‘0 ‘0

TYPES JAN CD-1020 -01 -02, -03

por4MEcFm CNW -

ADDRESS BIT

I

J

COLI!2

Note:

1. This connection example shows +24 V common.

O V common is also available,

1/0 Board Type JANCD-1020 for connection details.

2. The addresses are those for module No. 1. (#1009. O

to #1009. 7) . The address layouts for modules Nos.

2 to 4 are the same as shown above starting with newer

addresses.

Refer to Appendix B (3) , Address Classification

for details.

Fig. 16.11 Connection to Address and Bit Nos.

#1 009.0 to #1 009.7 on 1020 Board

Refer to par, 16.2.1,

Page 31

<0

..

r

I [39)

F

i

(9)

>%

1

(25)

i

(40)

>2

I

[41)

>>

I

(111

1,’(27)

‘1

I ADDRESS BIT

-t I

1

}

t

No.

#lolo o

#lolo. 1

#lolo 2

#lolo 3

#lolo 4

Zlolo 5

#lolo 6

#lolo 7

#loll o

#loll 1

#loll. 2

No.

~~>

E [43)

>>

!13)

>2

(44)

1

(14;,

[45)

I

!

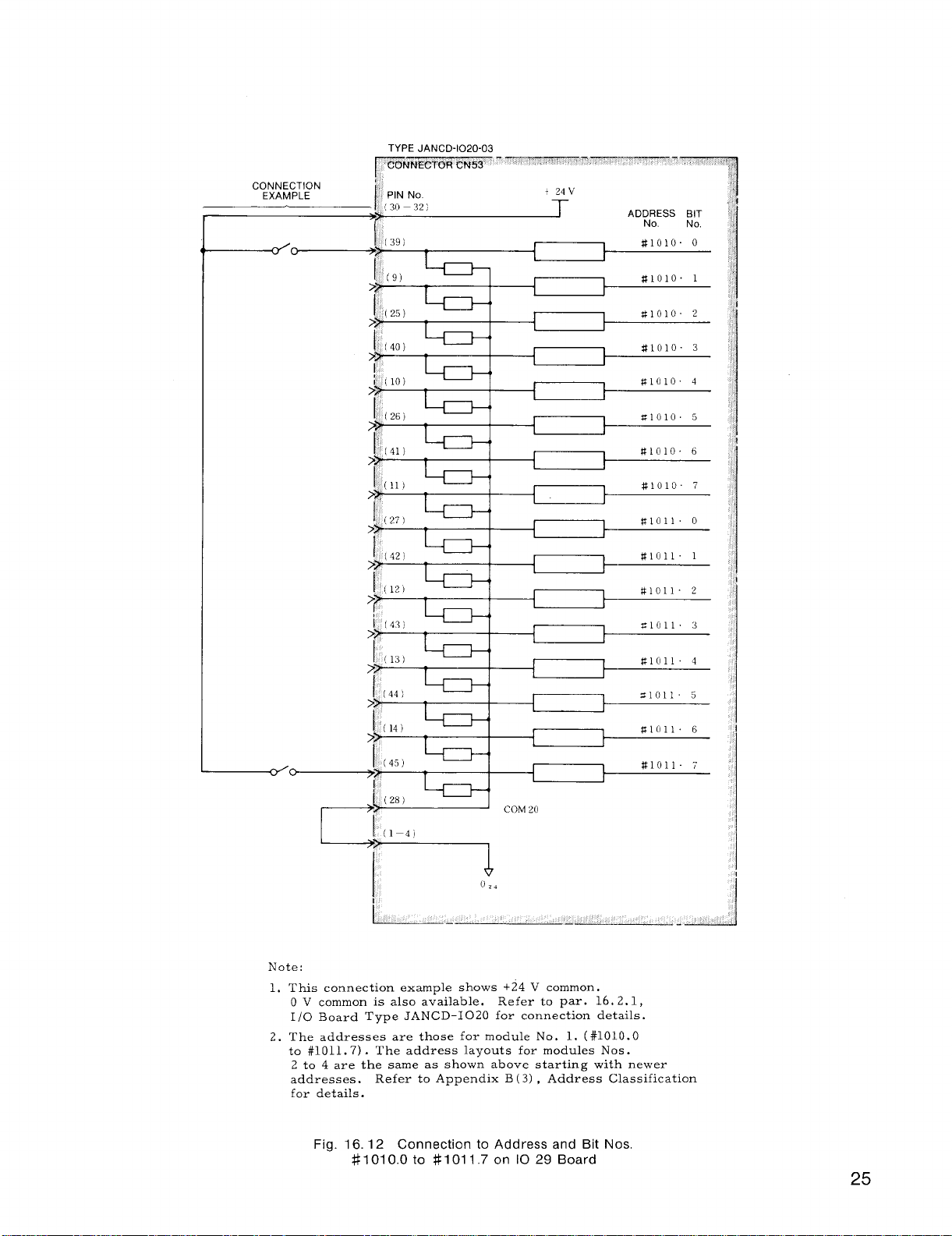

Note:

1, This

2. The addresses are those for module No. 1. (#1010. O

connection example shows +24 V common.

0 V common is also available. Refer to par. 16.2.1,

Board Type JANCD-1020 for connection details.

1/0

to #1011. 7) . The address layouts for modules Nos.

2 to 4 are the same as shown above starting with newer

addresses.

for details.

Refer to Appendix B (3) , Address Classification

-11

I

Xloll 3

flloll 4

Sloll, 5

S1OI1 6

#loll. 7

Fig. 16.12 Connection to Address and Bit Nos.

#1010.O to #101 1.7 on 1029 Board

25

Page 32

16. 3.1 1/0 20 BOARDS (Contld]

i

L_

Note :

1. This coczection exampl. she%-s -24 V cor,mon.

0 1, common is also zrvailzblc.

1/0 EwaYd T>rpc JANCI)102O for connection details.

2, The addresses are those [or

to #l 012. 7) . The address la>-outs for module, .Nos

2 to 4 are the sam,. ;is showri zbove sttirting with ne%ver

address... Refer to Appe,,clix B (3) , Addre8s Classification

for details,

Fig. 16.13 Connection to Address and Bit NOS

E1012.O to $1012.7 on 10 20 Board

Refer to.par. 16.2.1,

~,”d”l~ No. 1. (#1012. O

Page 33

~L[ 13, ~o)

f“

I ADDRESS BIT

No.

No

Note:

1.

This connection example shows +24 V common.

O V common is also available.

I/0 Board Type JANCD-1020 for connection details.

2.

The addresses are those for module No. 1. (#1013. O

to #1013. 7) . The address layouts for modules Nos.

2 to 4 are the same as shown above starting with newer

addresses. Refer to Appendix B(3) , Address Classification

for details.

3.

Connector CN52 can be used conveniently for interface with

the spindle drive unit,

Refer to par. 16.2.1,

Fig. 16.14

27

Page 34

16. 3.1 1/0 20 BOARDS (Cent’d)

TYPES JANCD-1020-01, -02, -03

ADDRESS BIT

No No

r“

+ 24 ~’

C%MN~cTOR GM31

PIN No

7

:ill :12 )

CONNECTION

EXAMPLE

1~

=11 [)().1

$11 [,1 11

=11111.1

#lllJl 1

X11(11. 5

(Zfj)I

t

I

4<

1

2’)<~

I

2:])

---i

4

I 4

’20)I

1

I

3

Note:

1. This connection example shows +24 V common.

O V common is also available.

I/0 Board Type JANCD-1020 for connection details.

2. The addresses are those for module No. 1. (#1100. O

to #1101. 7) . The address layouts for modules Nos.

2 to 4 are the same as shown above starting with newer

addresses.

for details.

Refer to Appendix B , Address Classification

Refer to par, 16.2,1,

Fig. 16.15 Connection to Address and Bit Nos

#1100.O to

#1101,7 on 1020 Board

Page 35

TYPES JANCD-1020-01 .-02. -03

#llo2. 5

#1102 6

#llo2. 7

$1103 0

#llo3. 2

*1103 5

#1103 6

#llo3 7

+1

(35}1

1~

(34)i~

I

1

(33) ~

1

’181,~

+

(16~~,

}

1’ --i

(131.’

,~

(12}~

1

]

(11)’,

}

I

m

Note:

1. This connection example shows +24 V common.

0 V common is also available. Refer to par. 16.2.1,

I/0 Board Type JANCD-1020 for connection details.

2. The addresses are those for module No. 1. (#1102. O

to #1103. 7) . The address layouts for modules Nos.

2 to 4 are the same as shown above starting with newer

addresses.

for details.

Refer to Appendix B (3) , Address Classification

Fig. 16.16 Connection to Address and Bit Nos.

#1 102.0 to #1 103.7 on 1020 Board

29

Page 36

16. 3.1 [/0 20 BOARDS (Cent’d)

Note:

1.2.This connection example shows +24 V common.

O V common is also available.

1/0 Board Type JAN CD-1020 for connection details,

The addresses are those for module No, 1. ( #1104. O

to #1104, 7) . The address layouts for modules Nos.

2 to 4 are the same as shown above starting with newer

addresses.

for details.

Refer to Appendix B (3) , Address Classification

Refer to par. 16.2.1,

Fig. 16.17 Connection to Address and Bit Nos.

#1 104.0 to #1104.7 on 1020 Board

30

Page 37

F1OO5. 2

#llo5 3

j,

[17)

I

}

‘5)2~

‘1

#llo5. 5

t

#1105 6

1

Note:

1. This connection example shows +24 V common.

O V common is also available.

1/0 Board Type JANCD-1020 for connection details.

2. The addresses are those for module No. 1. ( #1105, O

to #1105. 7) . The address layouts for modules Nos.

2 to 4 are the same as shown above starting witl~ newer

addresses.

for details.

Refer to Appendix B(3) , Address Classification

‘6;4+

j,

(12)

/

Refer to par. 16.2.1,

Fig. 16.18 Connection to Address and Bit Nos

#1 105.0 to #1 105,7 on 1020 Board

31

Page 38

16. 3.1 [/0 20 BOARDS (Cent’d)

TYPES JANCD-I020-03

32

Note:

1. This connection example shows +24 V common.

O V common is also available. Refer to par. 16.2.1,

I/0 Board Type JANCD-I 020 for connection details,

2. The addresses are those for module No.

to #1107. 7) . The address layouts for modules Nos.

2 to 4 are the same as shown above starting with newer

addresses, Refer to Appendix B (3) , Address Classification

for details.

1. (#1106. O

Fig. 16.19 Connection to Address and Bit Nos

#1106.O to #1 107.7 on 1020 Board

Page 39

16. 3.2 SP20 BOARDS

TYPE JANCD-SP20

C;;;;C;;N

‘IN No.

33)

2)

34) —

3)

19)

35)

4)

20)

36)

5:,

21)

+24V

ADDRESS BIT

No No

#looo. o

I I

1 J

I 1

L I

#looo. 1

#looo 2

#looo. 3

,

Wlooo 4

}

#looo. 5

t

#1000. 6

t

#looo. 7

—

I i

I

#lool o

J

*1 OO1. 1

I I

22)

38‘)

7)

I 1

1

J i

1

23) —

v

COLI30

Note:

1. This connectio~ example shows +24 V common.

0 V common is also available. Refer to par. 16.2.2,

I/0 Board Type JANCD-SP20 for connection details.

2. The addresses are those for module No. 1. (#1000. O

to #1001. 7) . The address layouts for modules Nos.

2 to 4 are the same as shown above starting with newer

addresses.

for details.

Refer to Appendix B (3) , Address Classification

1

1

1

#lool. 4

$1001 5

$1001 6

*1OO1. 7

Fig. 16.20 Connection of Address and Bit Nos

#1000.O to #1001.7 on SP 20 Board

Page 40

16. 3.2 SP20 BOARDS (Cent’d)

+24V

+24V

CONNECTION

EXAM PLE

11

do

o’~~

t

,<,

.,,

ADDRESS

1

I

!

1

No

#lo(12. o

#loo2 2

41002 3

$1002 4

S1OO2. 5

#loo2 6

Slooz. 7

#loo3 o

S1OO3 1

S1OO3. 2

#loo3 3

#loo3 4

#loo3 5

s1OO3, 6

#loo3 7

,’ PIN NO

/b+{

:,(39)

,.

(8) *1 OO2. 1

1(24) +

I

(40)

;?

,“

I

(411

1

j

(26)

1’

(421

COM 30

,

~

-1]

-i

+1

1

>>

[43)

>?

1>

(12)

>>

(28)

>?

i(44)

1

cOM 30

1

BIT

No.

Note:

1. This connection example shows +24 V common.

O V common is also available.

Refer to par. 16.2.2,

1/0 Board Type JANCD– SP20 for connection details.

2, The addresses are those for module No. 1. (#1002. O

to #1003. 7) . The address layouts for modules Nos.

2 to 4 are the same as shown above starting with newer

addresses.

Refer to Appendix B (3), Address Classification

for details.

Fig. 16.21 Connection of Address and Bit Nos.

002.0 to # 1003.7 on SP 20 Board

#1

Page 41

CONNECTION

EXAMPLE

I (13)

#

(29)

1

(45)

>>

I

(14)

>>

!

{30)

1

(46)

7

(15)

J (,,,

(47)

‘lb

(16)

I

(32)

>

i [4S)

>>

(17)

ADDRESS BIT

No.

No.

#loo4 o

#loo4 1

#loo4 2

1

}

t

1

1

~loo4 3

%1004. 4

#loo4 5

#loo4 6

SIO04 7

P1OO5. o

Z1OO5. 1

X1 OO5. 2

TIOO5. 3

#1005 4

-7

i

+

1

<49)

1

(18)

>>

~~> ( 50 )

Note:

1. This connection example shows +24 V common,

O V common is also available. Refer to

Board Type JANCD-SP20 for connection details,

1/0

2. The addresses are those for module No. 1. (#1004. O

to #1005. 7) . The address layouts for modules Nos.

2 to 4 are the same as shown above starting with newer

addresses. Refer to Appendix B (3) , Address Classification

for details.

Fig, 16.22 Connection of Address and Bit Nos.

k

1

#1004.O to #1 005.7 on SP 20 Board

#loo5 5

#1005 6

#1005. 7

par. 16.2.2,

Page 42

16. 3.2 SP20 BOARDS (Cent’d)

TYPE .JANCD-SP20

v

~~>

CONNECTION

EXAMPLE

PIN NO

I

I ,2,

(341

: (3,

1

[19!

>>

[

{ !35,

: (,,

121

?

!37)

>?

~ (6,

>>

(221

1381

1

COM 30

,

ADDRESS BIT

NO

#1006. O

t

#1006, 1

1

#loo6 2

1

#1006. 3

I

#1006. 4

$1006 5

I

s1OO6. 6

1

=1006. 7

$1007. 0

1

#loo7. 1

}

#loo7 2 ‘

$1007 3

#loo7. 4

1

W1OO7 5

I

No.

1,,

[23:1

~~y

Note:

1. This connection example shows +24 V common.

O V common is also available. Refer to par. 16.2.2,

1/0 Board Type JANCD-SP20 for connection details.

2. The addresses are those for module No. 1. (#1006. O

to #1007. 7) . The address layouts for modules Nos.

2 to 4 are the same as shown above starting with newer

addresses. Refer to Appendix B (3) , Address Classification

for details.

Fig. 16, 23 Connection of Address and Bit Nos.

#1006.O to #l 007.7 on SP 20 Board

I

02.

I

#1007. 6

#loo7. 7

Page 43

TYPE JANCD-SP20

ADDRESS BIT

No.

#l loo. o

~1 loo. 1

#l loo. 2

#l loo 3

#llo(o 4

#l loo 5

—

No.

+~4v

,, ,~fv, ;

~

.,.

,$,,$,<3?,

i5 J

i

ZONNEeTORcN5

7<:

.

4

:<*

~$

1

t

I

t

PIN No.

(33}

:39}

‘24)<~

:40)

125)

I

i

..

!

‘8)<+

I

‘g’<~

j,

CONNECTION

EXAM PLE

d

,

*11OO 6

#l loo 7

#llol o

#llol. 1

tilool 2

#llol 3

#llol 4

Sllol 5

#llol 6

#llol 7

l----

{

t

[ }—-----/

i 1

1

1

}

1

1

1

}

-d

I

‘41)<~

[10) ~

I

(26‘<~

‘42)<~

(11) ~

‘27}<:~

:43),

I

I12)

I

128)

1~

(44)

~~

+24V

,

4I

I

d

<

f

Note:

1. This connection example shows +24 V common.

0 V common is also available. Refer to

1/0 Board Type JANCD-SP20 for connection details,

2. The addresses are those for module No. 1. (#1100. O

to #1101, 7) . The address layouts for modules Nos,

2 to 4 are the same as shown above starting with newer

addresses. Refer to Appendix B (3), Address Classification

for details.

Fig. 16.24 Connection of Address and Bit Nos

#1100.O to #1101.7 on SP 20 Board

par. 16.2.2,

37

Page 44

SP20 BOARDS (Cent’d)

TYPE JANCD-SP20

ADDRESS BIT

No No

#llo2 1

#loo2 2

Z1102 4

S1103 1

#llo3. 2

Z1103. 3

+

PIN No :,

I

(30)I

1

{

1

1

I

1

!16]

1~

(32),.1

}

(48;’

I

<~

1

38

#1103. 3

I

N’ote:

1.2.This connection example shows +24 V common.

O V common is also available.

1/0 Board Type JANCD-SP20 for connection details.

The addresses are those for module No. 1. (#1102. O

to #1103. 7) . The address layouts for modules Nos.

2 to 4 are the same as shown above starting with newer

addresses.

for details.

Refer to Appendix B ( 3) , Address Classification

(49J

..

‘i

Refer to par. 16.2.2,

Fig. 16.25 Connection of Address and Bit Nos.

#1 102.0 to #1 103.7 on SP 20 Board

Page 45

17. CABLES

17.1 LIST OF CABLES

s

Connector Cable Type

The interface cables are furnished with or without

connectors. Those cables shown in Table 17.1

are available.

If the machine manufacturer is supplying the

cables,

prepare equivalent cables b;s~d on- the

cable specifications.

Table 17.1 List of Cables

Cable No.

Configuration

TYPES

MRP-50F01 ,

MR-50L

‘/()

)

TYPES

MR-50F01 ,

MR-50L

\

Remarks

● Servo drive unit

● Max cable length:

15m

Type KQVV-SB

. Spindle optical

encoder

s Max cable length:

15m

TypeKQVV-SB,DE8400093

0.2mmzX 10

ConnectorCN4:

TvDeMRP-20M01,MR-20LW

Dairs

● For input

sequence

Cable:

TypeKQVV,DE6428673

0,2mmzX20 cores

ConnectorCN6:

TypesMRP-20M01,MR20LW

RS-232C interface

1RO,2RO:

@

TypeDB-25S

Cable:

TypeKQVV,DE6428673

0.2mmzX20 cores

—

ConnectorCN8:

Not used

1/0

TypesMRP-20F01,MR-20LW

Cable:

TypeKQVV,DE6428673

02 mmzX20 cores

. Power supply for

CRT operator’s

TYPE