Page 1

YASNAC LX3

CNC SYSTEM FOR TURNING APPLICATIONS

MAINTENANCE

Before initial OF

)eration read these instructions thoroughly, and retain for future reference

YASUAVVA

Page 2

This manual is primarily intended to give operator’s maintenance instruc-

tions for YASK!”ICLX3.

The information contained in manual does not provide all details to be

met. concerning maintenance and troubleshooting.

If uncertainties be

encountered for particular maintenance operation, refer to the following

YASNACLX3documents for additional information:

. YASNACLX3/llX3PC SYSTEM(TOE-C843-9.1)

. YASNACLX3SPECIFICATIONS(sIE-C843-9.20)

. YASNACLX3OPERATOR’S MANUAL(TOEC843-9. 20)

. YASNACLX3CONNECTINGMANUAL(TOE-C843-9. 22)

a ---- .

YASNAC1,X3OPllRfiTOR’SSTATION

Page 3

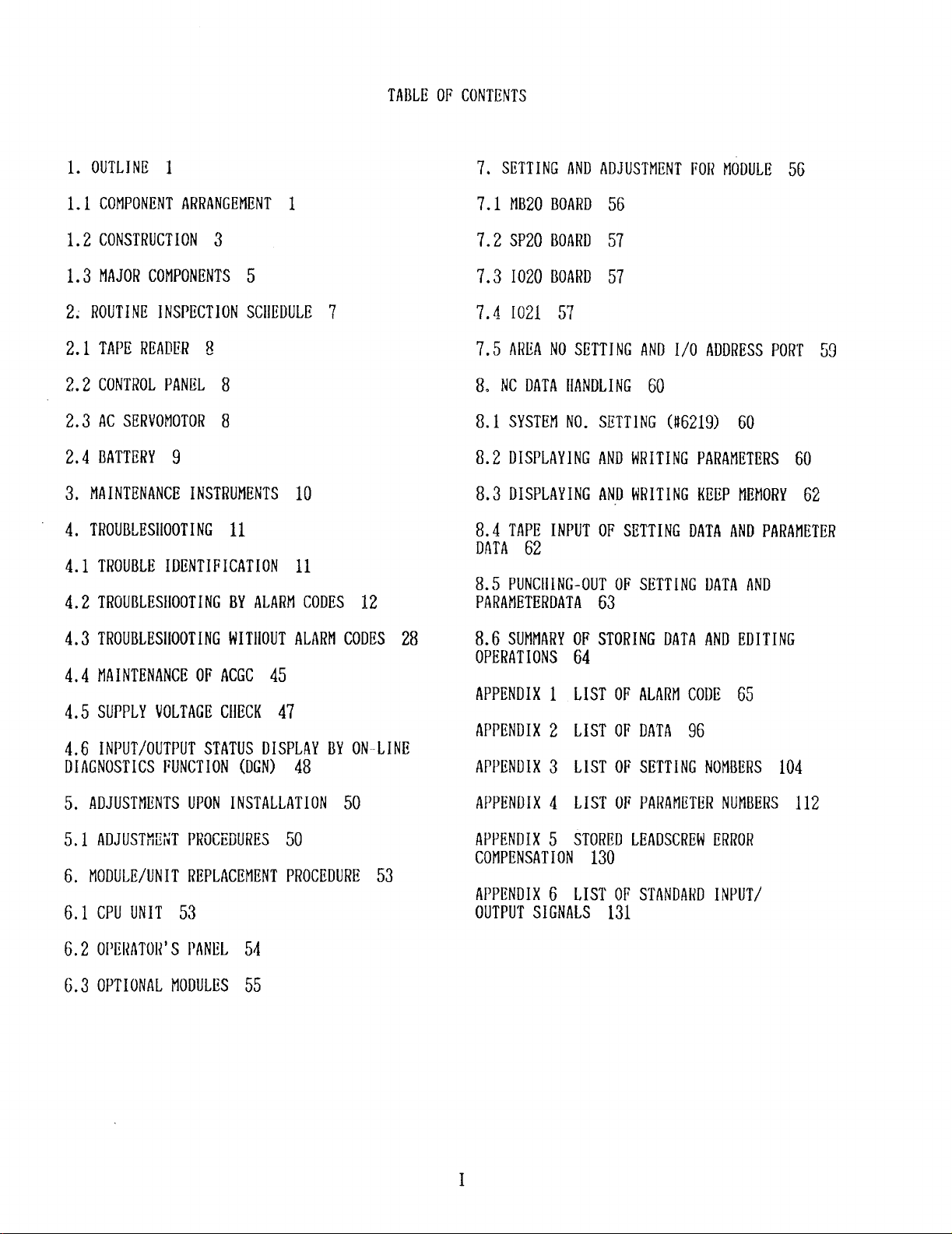

TABLEOF CONTENTS

1. OUTLINE1

1.1 COMPONENTARRANGEMENT1

1.2 CONSTRUCTION3

1.3 MAJORCOMPONENTS5

2. ROUTINEINSPECTIONSCHEDULE7

2.1 TAPEREADER8

2.2 CONTROLPANEL 8

2.3 ACSERVOMOTOR8

2.4 BATTERY9

3. MAINTENANCEINSTRUMENTS10

4. TROUBLESIIOOTING11

4.1 TROUBLEIDENTIFICATION11

4.2 TROUBLESBOOTINGBYALARMCODES 12

7. SETTINGANDADJUSTMENTFORMODULE56

7.1 MB20BOARD56

7.2 SP20 BOARD57

7.31020 BOARD57

7.4 1021 57

7.5 AREANOSETTINGAND1/0 ADDRESSPORT 5!3

8. NCDATABANDLING60

8.1 SYSTEMNO. SETTING(#6219) 60

8.2 DISPLAYINGANDWRITINGPARAMETERS60

8.3 DISPLAYINGANDWRITINGKEEPMEMORY62

8.4 TAPEINPUTOF SETTINGDATAANDPARAMETER

DATA62

8.5 PUNCBING-OUTOF SETTINGDATAAND

PARAMETERDATA63

4.3 TROUBLESHOOTINGWIT11OUTALARMCODES 28

4.4 MAINTENANCEOF ACGC 45

4.5 SUPPLYVOLTAGECIIECK 47

4.6 INPUT/OUTPUTSTATUSDISPLAYBYON-LINE

DIAGNOSTICSFUNCTION(DGN) 48

5. ADJUSTMENTSUPONINSTALLATION50

5.1 ADJUSTKIH{TPROCEiNRES50

6. MODULE/UNITREPLACEMENTPROCEDURE53

6.1 CPUUNIT 53

6.2 OPERATOR’S PANEL 54

6.3 OPTIONALMODULES55

8.6 SUMMARYOF STORINGDATAANDEDITING

OPERATIONS64

APPENDIX1 LIST OF ALARMCODE 65

APPENDIX2 LIST OF DATA 96

APPENDIX3 LIST OF SETTINGNOMBERS104

APPENDIX4 LIST OF PARAMETERNUMBERS112

APPENDIX5 STOREDLEADSCREWERROR

COMPENSATION130

APPENDIX6 LIST OF STANDAKDINPUT/

OUTPUTSIGNALS 131

Page 4

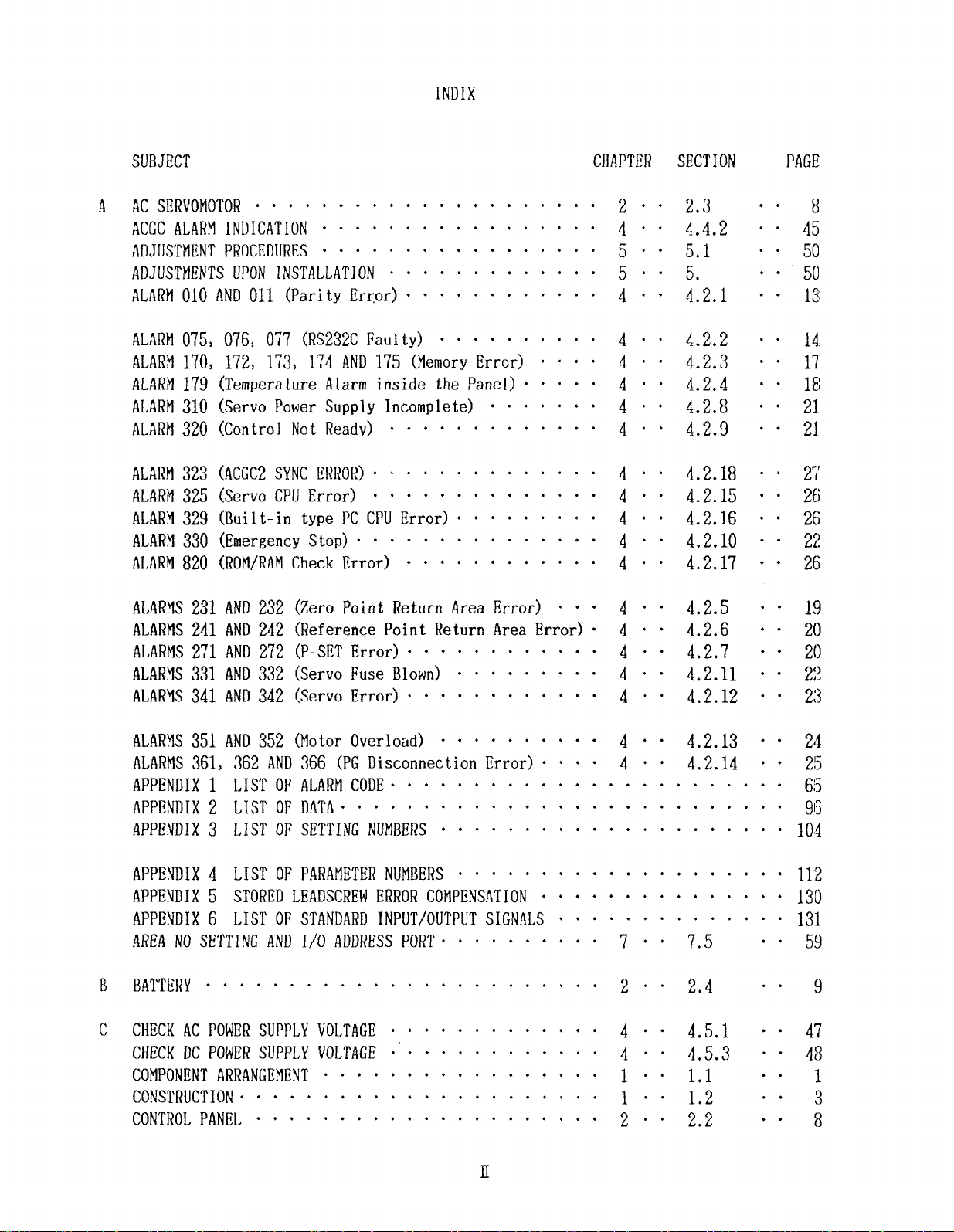

INDIX

SUBJECT CHAPTER SECTION

AACSERVOMOTOR ”” S”.+.”*’ “.0” .”000””2. ”2.30 .8

ACGCALARMINDICATION*O” O* OOO*

ADJUSTMENTPROCIIDURES”+””. ”0

ADJUSTMENTSUPONINSTALLATION* “ “ “ . . “ o 0 0 “ + o 5 “ s 5.

ALARMO1OANDO1I (Parity Error)

● “ “ ● ‘ “ ● s “ ● “ “ 4 “ “ 4.2.1 “ “ 12

●o*{oco *4*04.4.20*45

●*””O”OO” 05..5.1” “50

● “ 50

ALARM075, 076, 077 (RS232C Faulty) “ . . “ “ “ . 0 “ “ 4 “ . 4.2.2 s “ 14

ALARM170, 172, 173, 174 AND175 (MemoryError) . “

ALARM179 (Temperature Alarm inside the Panel)

● “ “ ● “ 4 “ “ 4.2.4 ● “ 18

ALARM31O(Servo Power Supply Incomplete) “ . . “ “

ALARM320 (Control Not Ready)

ALARM323(ACGC2SYNC ERROR)”*”” O”

ALARM325 (Servo CPUError) .

● “ ● “ “ ● “ “ “ o “ . “ 4 “ ● 4.2.9 s “ 21

● *”. oQ”” 4.” 4.2.18 ““ 27

● ● ● ● ● ● “ . . c o “ ● 4 . “ 4.2.15 ● “ 26

ALARM329 (Built-in type PC CPUError)” + “ o “ “ “ .

ALARM330 (Emergency Stop)” “

ALARM820 (ROM/RAMCheckError) “ .

● ● “ ● . + o “ “ “ . * ● 4 ‘ “ 4.2.10 “ “ 22

● ● “ ● ● ● “ ● ● “ 4 ● o 4.2.17 ● ● 26

ALARMS231 AND232 (Zero Point Return Area Error)

● ‘ 4 . “ 4.2.3 “ . 17

● “ 4 . 0 4.2.8 ● o 21

● 4 “ o 4.2.16 . 0 26

● “ ● 4 “ “ 4.2.5 ● o 19

ALARMS241 AND242 (Reference Point Return Area Error) “ 4 “ “ 4.2.6 “ “ 20

ALARMS271 AND272 (P-SET Error)* “ “ “

ALARMS331 AND332 (Servo Fuse Blown) . .

ALARMS341 AND342 (Servo Error)

● . ● ● ● ● ● ● “ ● ● ● 4 “ ● 4.2.12 ● ● 23

● “ o “ “ ‘ “ ● 4 “ . 4.2.7 “ + 20

● ● “ ● . + ‘ 4 “ . 4.2.11 ● “ 22

PAGE

ALARMS351 AND352 (Motor Overload) “ + “ “ “ “ “

ALARMS361, 362 AND366 (PG Disconnection Error) . . “ . 4 s

● “ “ 4 ● “ 4.2.13 0 . 24

● 4.2.14 . “ 25

APPENDIXILISTOF ALARMCODE”* “*0””00”0*””.”*”0 ““””” 65

APPENDIX2LISTOFDATA” *”’” ““”””’””’”””””””” “’”””915

APPENDIx3LIsToF sETTrNGNuMBERs ““””’””’”’””””””” ““””104

APPENDIX4 LIST OF PARAMETERNUMBERS“

APPENDIX5 STOREDLEADSCREWERRORCOMPENSATION“

APPENDIX6 LIST OF STANDARDINPUT/OUTPUTSIGNALS + +

● . 0 “ . + “ “ ● “ “ o “ + o “ . ● + 112

● “ ‘ o “ “ . ● ● “ o . . . 130

● . “ ● . 0 c o “ “ “ “ lQl

AREANOSETTINGAND1/0 ADDRESSPORT” “ “ . . “ . + “ “ 7 “ o 7.5

BBATTERY”*.so”””.””.” “..””””.o”+2.”2,4

C CHECKACPOWERSUPPLYVOLTAGEo

● “ ● “ . ● + . “ ● ● ● 4 0 “ 4.5.1

CHECKDCPOWERSUPPLYVOLTAGE.“. . “ s “ “ “ “ . . “ “ 4 “ - 4.5.3

COMPON!3NTARRANGEMENT””O” “+”.””0.”*””” 1“” 1.1

CONSTRUCTIONO. “ “ “ “ “ “ “ “. + “ “ “ o 0 “ “ “ “ “ 1 “ “ 1.2

CONTROLPANEL “

● ● “ “ ‘**” ““ . 0 .* o “ “ ● “ ● 2 “ “ 2.2

II

. .

. .

. .

. .

. .

. .

. .

101

59

9

47

48

1

3

8

Page 5

INI)IX

SUBJIK1’

c

DISPLAYINGANDWRITINGKEEPMEMORY

D

● ● “ “ “ ● ● “ “ ● ● 8 “ o

DISPLAYINGANDWRITINGPARAMETERSs “ o ● “ ● o + “ “ ● 8 “ o

E

EDIT DOESNOTFUNCTION”QO*”O O“”OO””OS”O 4+”

FAULTSNOTDISPLAYEDACGCALARMINDICATION”

F

● o ● ● ● “ 4 “ +

H

INDICATIONLAMPOF POWERSUPPLYUNIT” “

I

● “ ● “ o 0 0 “ 4 0 0

INITIAL DIAGNOSTICERRORDISPLAYATI’OWERAPPLICATION“ 4

INPUT/OUTPUTSTATUSDISPLAYBYON-LINEDIAGNOSTICS

FUNCTION(DGN)O****OO*” *O””

●00*0 ”” *4”*

1020 BOARD””””””””””””””” ““””””””7””

10210.”000.o”””ooc”**. 0“”0”0”*7+0

CHAPTER

SECTION

4.3.3

6.1

4.3.4

4.3.9

8.3

8.2

4.3.13

4.4.3

4.3.5

4.5.2

4.3.2

4.6

7.3

7.4

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

PAGE

29

53

30

35

62

60

40

45

30

48

29

48

57

57

MAINTENANCEINSTRUMENTS

M

● ● ● “ ● + s ● ● ● o “ ● ● ● ● 3 + ●

tlAINTENANCEOF ACGC*””” 00 O+” ● *””” 0.0”40s

MAJORCOMPONENTS””” O” DO Q”~OQ ““O OO” C”l SO

MANUALJOG MODEOPERATIONFAULTY*+ “ +

● “ ● ● ● ● ● “ 4 Q ●

MANUALRAPIDMODEOPERATIONFAULTY“ ● ● ● ● ● “ ● “ o “ 4 “ ●

MANUALZERORETURNOPERATIONFAULTY● “ o + “ “ ● ● ● ● 4 “ “

MB20BOARD””””””””””””””” ““””””””7””

MODULE/UNITREPLACEMENTPROCEDURE

● ● + ● c ● ● “ “ “ c 6 “ ●

NCDATAIIANDLING*”” BOO.”**** “*”00”0”80*

9* CRTSCREENIS DARK””””””””” ““””””””4””

OPERATINGPROCEDURETO DISPLAYINPUT/OUTPUTSIGNALS

o

● ● 4 ● ●

OPERATIONIS NOTAVAILABLEWITHGO1, G02 ORG03 “ ● o ● 4 0 ●

OPERATIONIS NOTAVAILABLEWITHG32, G76 ORG92 “ “ ● ● 4 . c

OPERATOR’SPANELO

OPTIONALMODULES*

● + . “ “ ““ “ o ● OO ● “ “ ● o ● “ 6 “ “

● ● ● “ “ ● + ● ● ● + ● ● ‘ ● s ● ● ● 6 “ o

3.

4.4

1.3

4.3.6

4.3.7

4.3.8

7.1

6.

8.

4.3.12

4.6.2

4.3.10

4.3.15

6.2

6.3

1.

4.6.1

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

10

45

5

32

33

34

56

53

60

39

49

36

42

54

55

1

48

RI

Page 6

INDIX

SUBJECT

CHAPTER SECTION

PAGE

P PARAtlETERDATADISPLAY”””*” ““.”’”~””0”” 8“” 8.2.2 ““ 61

PA[{AHETERTYPES ”O” OO”. ”O ””* ““”” ”””’ 8”08.2.1*”61

POWERC8NNOTBESUPPLIED”O”. .O”” .“”””.”. 4.* 4,3.1 “O 28

PUNCHING-OUTOF SETTINGDATAANDPARAMETERDATB “ “ “ ‘ 8 “ Q 8.5 e

o 63

R RUCOGNI’rIONOF NCSYSTEM”.O.” “’””+””””~” 4“. 4.1.2 .. 11

RECOGNITIONOF TROUBLESTATUS “ . 0 . “ s . s “ o “ “ . 4 “ “ 4.1.1 “ “ 11

ROUTINEINSPECTIONSCHEDULEo . “ “ “ “ “ “ “ “ “ “ . 0 2 0 s 2. “ “ 7

Rs232C DOESNOTFUNCTIONWELL“ “ “ . “ “ “ “ “ “ “ . “ 4 “ “ 4.3.14 0 “ 41

S SETTINGANDADJUSTMINTFORMODULE.

● . “ “ “ “ “ . “ “ 7 . s 7. 0 “ 56

SKIP FUNCTION(G31) OPERATIONFAILURE o . “ . 0 “ “ . “ 4 “ “ 4.3.16 . “ 43

SOFTWAREVERSIONINDICATION. “

● . 0 0 “ “ o “ o “ “ “ 4 0 s 4.4.4 0 “ 46

SP20BOARD””O. .OS”” O”” *-O ““”” ”0”07”.7.2””57

SPINDLEDOESNOTROTATE”””. “.”””..””””” 4.” 4.3.11 .“ 37

SUMMARYOF STORINGDATAANDEDITINGOPERATIONSo

● “ “ . 8 “ “ 8.6 “ . 64

SUPPLYVOLTAGECliECK” **”””” “..00””””*~4””4.5 ‘.47

SYSTEMNO. SETTING(#6219) ”OO” O”0 ““O”OOCS 8.” 8.1 .“ 60

T TAPEINPUTOF SETTINGDATAANDPARAMETERDATA “ “ “ ~ Q 8 “ “ 8.4 “ “ 62

TAPEMODEDOESNOTFUNCTION00 ””” +. ”.”””.” 40~ 4.3.17 “* 44

TAPEREADERo

● “ . 0 + . “ o “ “ ● ● “ “ Q “ o 0 “ . “ 2 . “ 2.1 ““ 8

TROUBLEIDENTIFICATION”””” .0”00 ““00.+”” 4“” 4.1 “O 11

TROUIILESliOOTING*”. .O”””” O*O 0“.”0”.*40.4.””

TROUBLESHOOTINGBYALARMCODES“ . .

TROUBLESHOOTINGSERVICEOF ACGC

0 . “ . * . “ “ o “ 4 “ . 4.2 “ “ 12

● “ “ “ + . “ “ - “ “ ● 4 0 ● 4.4.1 “ o 45

TROUBLESHOOTINGWITHOUTALARMCODES o “ “ “ “ s “ . “ “ 4 “ “ 4.3 “ “ 28

W WI{ITINGPARAMETERDATA””’”” .-”.””’’”... 8“. 8.2.3 “- Cl

N

Page 7

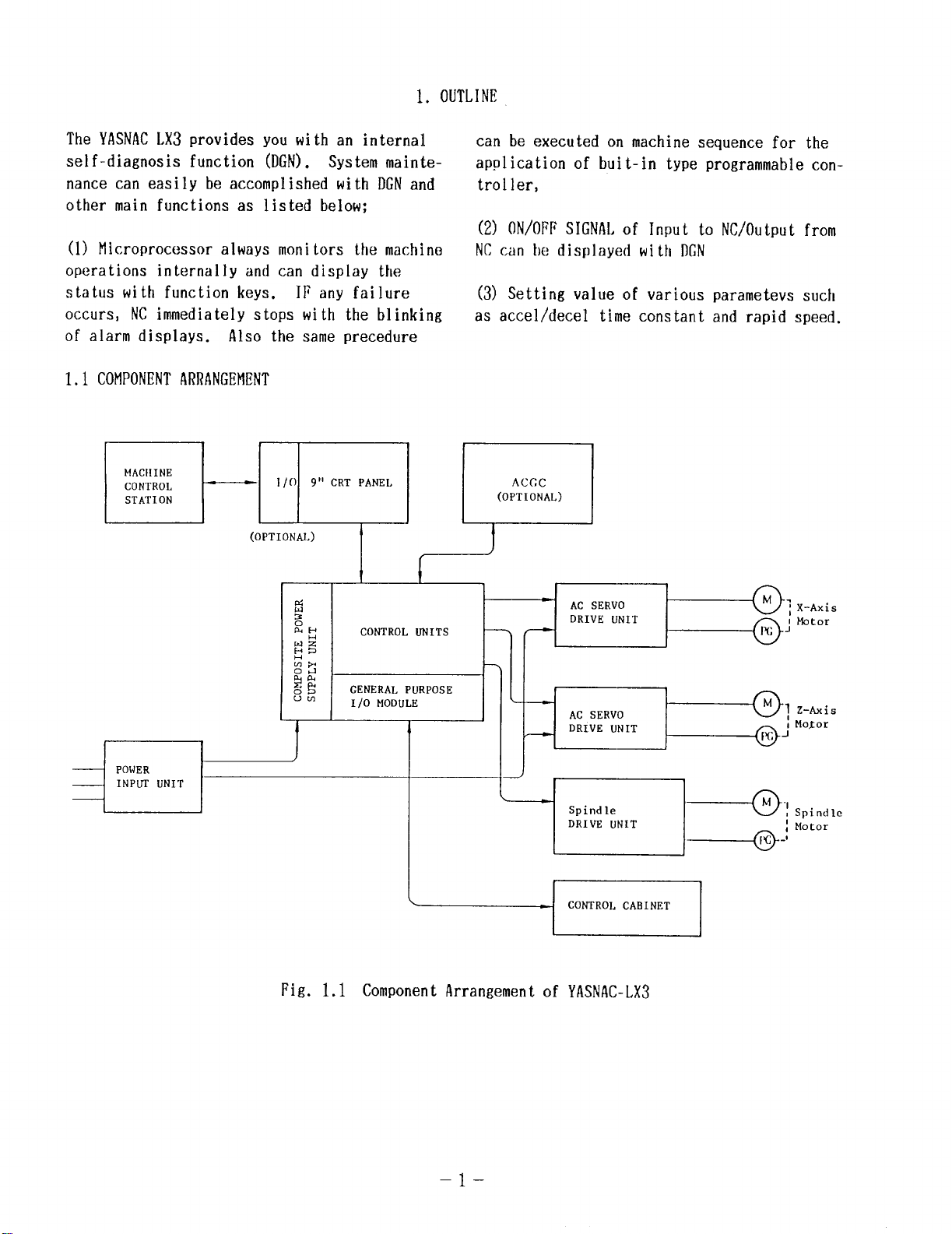

1. OUTLINE

The YASNACLX3provides you with an internal

self-diagnosis function (DGN). System maintenance can easily be accomplished with DGNand

other main functions as listed below;

(1) Microprocessor always monitors the machine

operations internally and can display the

status with function keys. IF any failure

occurs, NCimmediately stops with the blinking

of alarm displays. Also the same precedure

1.1 COMPONENTARRANGEMENT

MACNINE

CONTROL

STATION

1/()

9’sCRT PANEL

D’

(OpTIONAL)

v

d

2

EEJ

Ia.lz

w=

H

~g

Ucn

I

CONTROL UNITS

GENERAL PURPOSE

1/0 MODULE

be executed on machine sequence for the

can

ication of buit-in type programmable con-

apo

ler,

tro

ON/OFFSIGNALof Input to NC/Output from

(2)

NCcan be displayed with DGN

(3) Setting value of various

as accel/decel time constant

parameters such

and rapid speed.

ACCC

(OPTIONAL)

)

.

AC SERVO

DRIVE UNIT

f---

7

---

[

AC SERVO

DRIVE UNIT

—

1

X-Axis

kbtor

I

+ CONTROL CABINET I

Fig. 1.1 Component Arrangement of YASNAC-LX3

–l–

Page 8

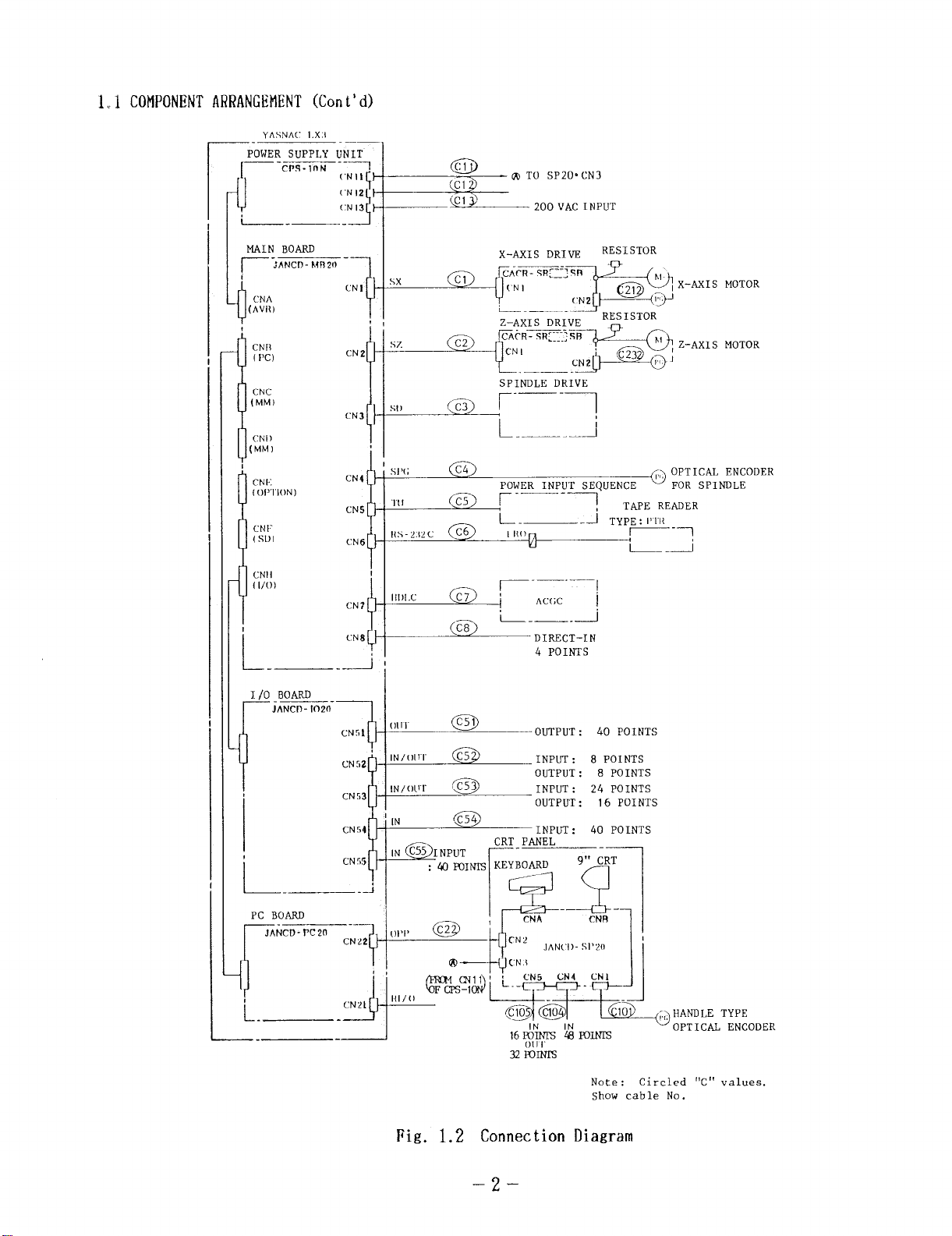

1~1 COMPONENTARRANGEMENT(Cont’ d)

YASNA(’ 1.X:1

—.

POWER SUPPLY UNIT

~-cPs.,”t4 --1

u

-.

NAIN BOARD

~-;ANCt3- kmzo -

CNA

(AVN)

0

,

CNI{

PC)

(

.

f-

CNC

(MM)

u

CNI)

(MM)

(1

1

CNI;

( OP”I”ION” )

CNl(Sl))

(’Nil

(’N12

(’N13

-J

CNl

1+

CN z

CN 4

CN5

(’N 6

1

cNII

( 1/[))

/.., *

G,. ,

!

i

L

c’N 8

-~ ,

<

+

5X

,1

ST

&

1

S1’(i

‘Ill

NS-2.i2C

111)1.c

r+I

!--L

!1

@

‘cl

@l

cl

C2

~

~

C6

\c7J j

@j

m TO

SP20. CN3

200 VAC INPUT

X-AXIS DRIVE

Fr;w$x-mlsMOTOR

~;%%y’- Z-A’IS MOTOR

k’--,-’

SPINDLE DRIVE

poWER INPUT SEQu_OpTIcM ENCODER

~.—

L-. _~

1

lto~

AC(; C

RESISTOR

FOR SPINDLE

“1

TAPE READER

TYP; :III’1{ ~

1

L _ti

]

L-_. -J

DIRECT-IN

4 POINTS

I/0 _BOARD

JANCD - 1020-

[

—-

cN51

CN52

cN53

CN54

0111”

m

OUTPUT : 40 POINTS

INPUT :

OUTPUT : 8 POINTS

INPUT : 24 POINTS

OUTPUT :

CRT PANEL

32 Fonm

8 POINTS

16 POINTS

40 POINTS

Note :

Show cable No.

Fig. 1.2 Connection Diagram

OPTICAL ENCODER

Circled “C” values.

–2–

Page 9

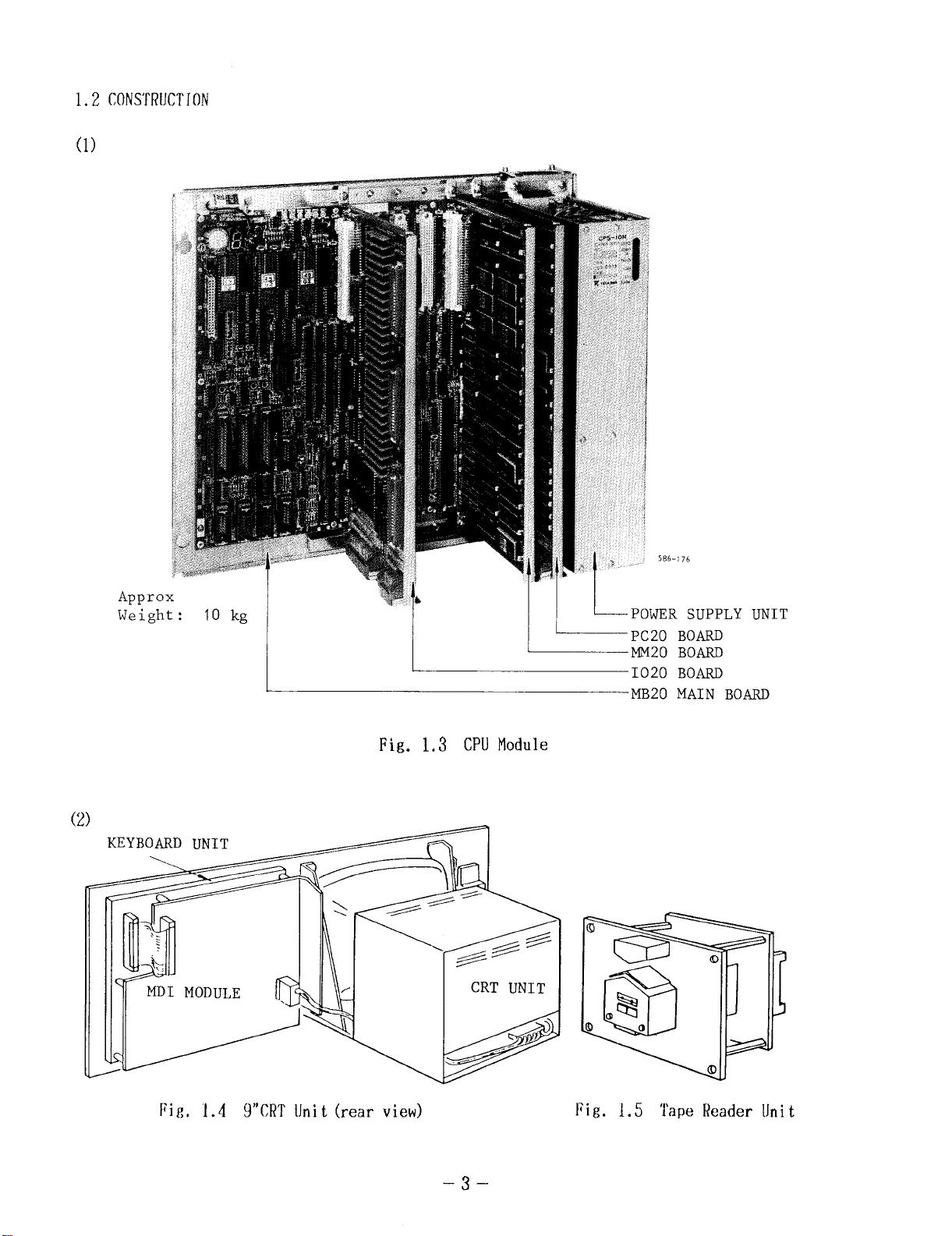

1.2 CONSTRUCTION

(1)

(’2)

Appr(

Weigl

-176

SUPPLY

L

BOARD

BOARD

I

BOARD

MB20 MAIN BOARD

UNIT

Fig. 1.3 CPUModule

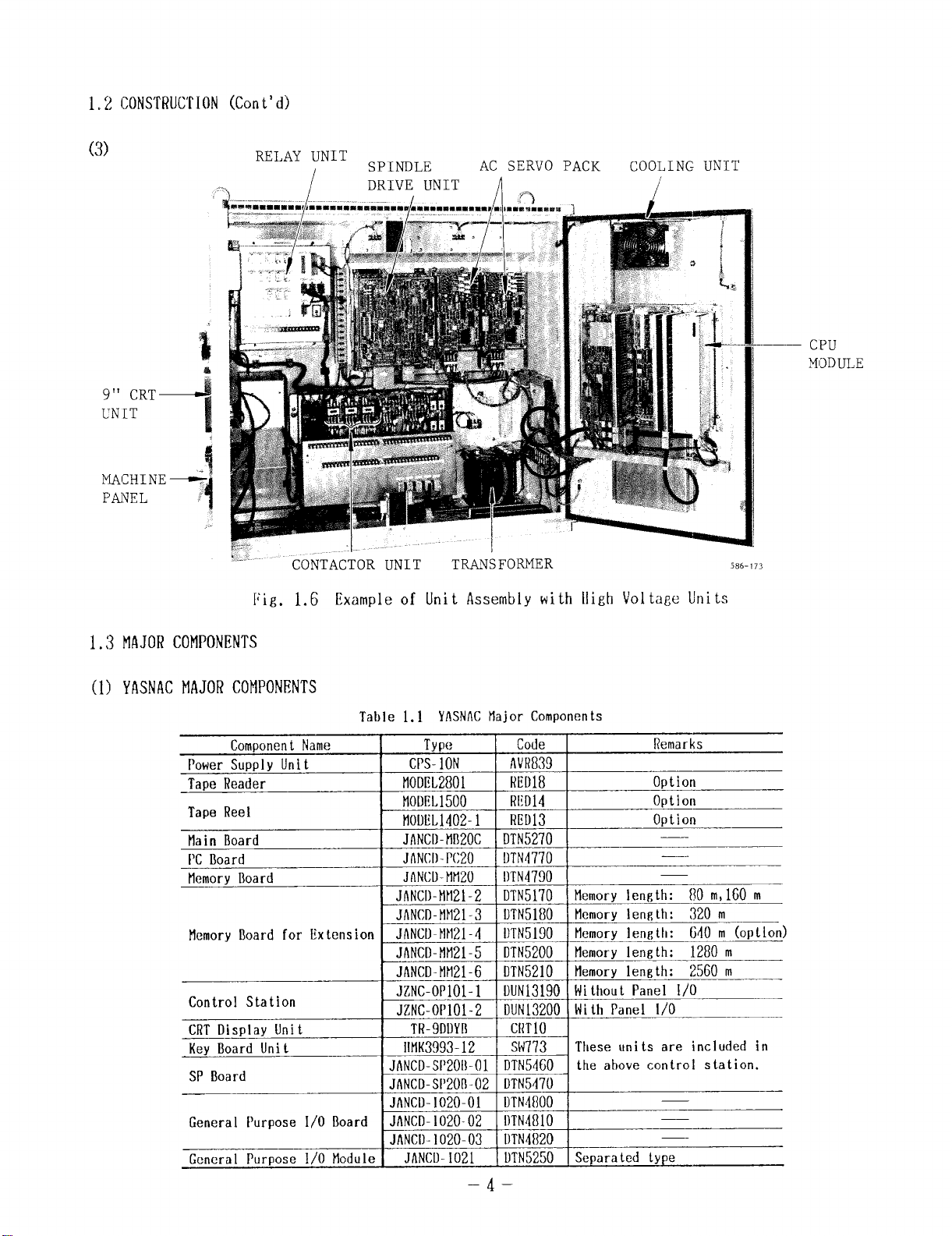

Fig. 1.4 9“CRT Unit (rear view)

Fig. 1.5 Tape Reader Unit

–3–

Page 10

1, z CONSTRUL’TION(Cont’ d)

(3)

RELAY UNIT

:.-

J

/

CONTACTOR UNIT

SPINDLE

DRIVE UNIT

Fig. 1.6 Example of Un

AC SERVO PACK

J ..> /

TRANSFORMER

COOLING UNIT

t Assembly with High Voltage Units

— CPU

M,~I)lJLE

586-173

MAJORCOMPONENTS

1.3

YASNACMAJORCOMPONENTS

(1)

ComponentName

PowerSupply Unit

TapeReader

Tape Reel

tfain Board

PCBoard

tlemoryBoard

MemoryUoardfor Extension

Control Station

CRTDisplay Unit

KeyLtoardUnit

SP Board

General Purpose 1/0 Board

General Purpose 1/0 Module

Tahte 1.1 YASNACHajor Components

Type

CPS-1ON I I

MODEL2801

t10DflL1500

t10tIEL1402-1

Code

AVRKN

RED18

RLD14

RED13

I

Remarks

Option

OptIon

Option

JANCI)-MB20CDTN5270

JANCI)-PC20

JANCD-MM20

DTN4770

OTN4790

JANCI)-MM21-2DTN5170 Memorylength: [?0m,160m

JANCD-MM21-3DTN5180 Memorylength: 320 m

JANCI.-NN21-4

DTN5190 Memorylength: 640 m (option)

JANCD-MM21-5DTN5200 Memoryleneth: 1280m

JANCD-tlH21-6DTN521OMemorylength: 2560m

JZNC-OP1O1-1DUN13190Without Panel 1/0

JZNC-OP1O1-2DUN13200\With Panel 1/0

TR-9D+T,0 ,

These units are included in

the ahove control station.

JANCD-102O-OI

DTN4800

JANCD-1020-02 DTN481O

JANCO-102O-O3OTN4820

JANCD-1021

DTN5250

Separated type

–4–

Page 11

(2) ACGCMajor Components

Table 1.2 ACGCMajor Components

14” CRTUnit

Keyboard Unit

Keyboard Unit BMK-2293-03

Keyboard Unit

Power Supply Unit

CPUModule

Graphic Module

MemoryModule

MemoryUnit

Battery Unit

(3) ACServo Units

Name Type

C-5470YE CRT6 Main Key

HMK-9993-02

HMK-9993-20

VST-5-522/ST AVR738

JANCD-CGOID

JANCD-CG02

JzNc-Mu::;::: - ~:;

JANCD-CG03 DTN51OO

JANCD-CG04

JANCD-CG05 DTN5120 These units are incorJANCD-CG06 DTN5130

JANCD-CG09

JZNC-BAT02 DUN13060

Code No.

SW677

Main Key

SW678 Soft Key

SW679

DTN5390

DTN4290

DTN511O

porated into memory module.

DTN551O

Remarks

Servopack

Type

CACR-SR05SB1AF

CACR-SR05SB1BF

CACR-SR05SB1DP

CACR-SR1OSB1AF

CACR-SRICISBIBF

CACR-SR1OSB1DF

CACR-SR15SB1AF

CACR-SR15SB1BF

CACR-SR15SBIDF

CACR-SR20SB1AF

CACR-SR20SB1BF

CACR-SR20SB1DF

CACR-SR30SB1AF

CACR-SR30SB1BF

CACR-SR30SB1DF

CACR-SR44SB1AF

CACR-SR44SB1BF

CACR-SR44SB1DF

Table 1.3 ACServo Units

Applied Motor

Code No.

DUA15920

DUA16020

DUA16120

DUA15940

DUA16040

DUA16140

DUA15950

Motor Type

USAFED-05FA1

USAFED-05FB1

USAPED-05FDI

usAiED-09FAl

USAFED-09FBI

USAFED-09FD1

USAFED-13FA1

DUA16050 USAFED-13FB1

DUA16150

DUA15960

DUA16060

DUA16160

DUA15970

DUA16070

DUA16170

DUA15980

DUA16080

DUA16180

USAFED-13FD1

USAFED-20FA1

USAFED-20FB1

USAFED-20FD1

USAFED-30FA1

USAFED-30FB1

_USAFED-30FD1

USAFED-44FA1

USAFED-44FB1

USAFED-44FD1

Optical Encoder

p/rev

6000

5000

4000

6000

5000

4000

6000

_

5000

4000

6000

5000

4000

6000

_

5000

4000

6000

5000

4000

–5–

Page 12

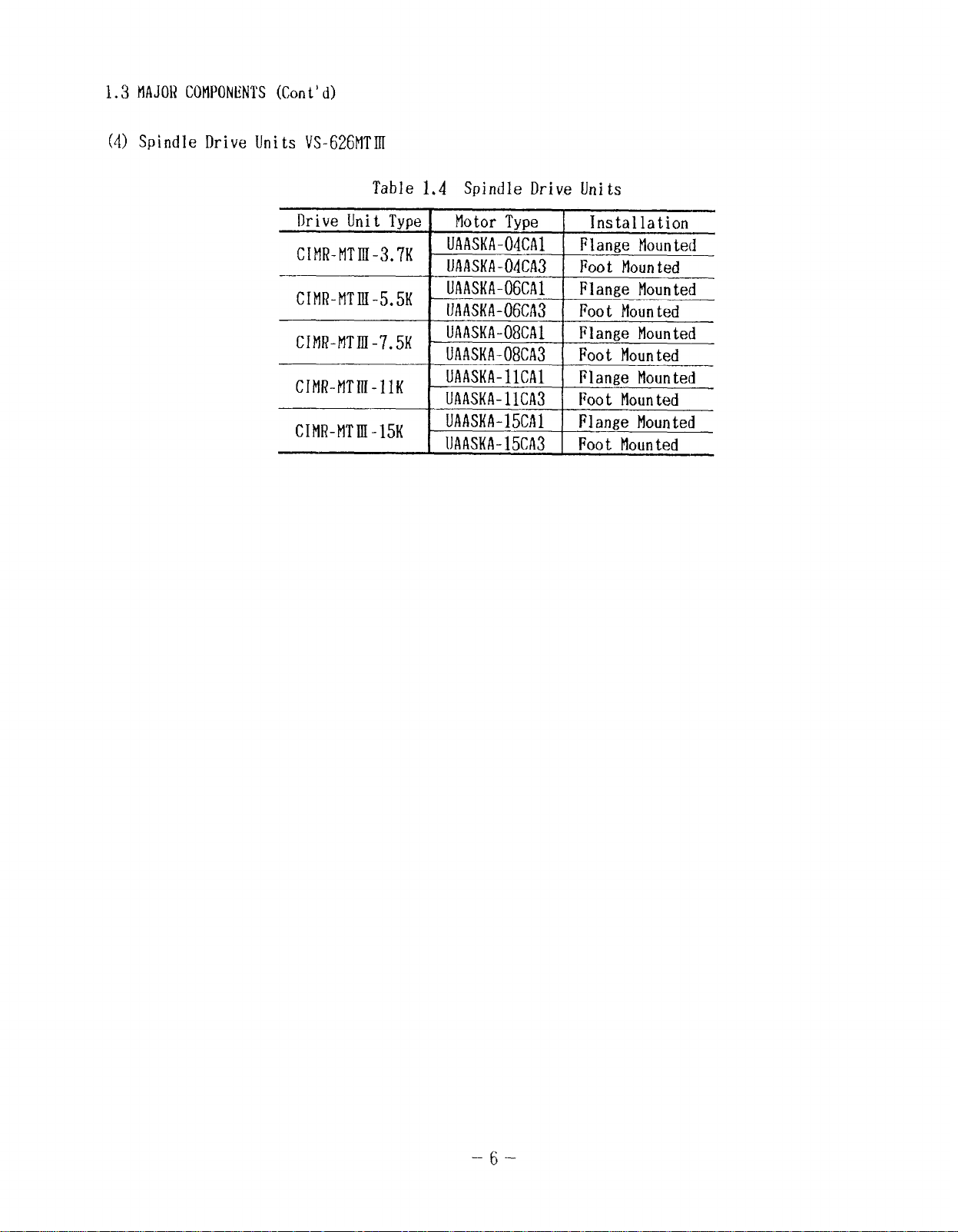

1.3 MAJORCOMPONENTS(Cont‘ d)

(4) Spi nd

e Drive Units VS-626FITIR

Table 1.4 Spinal e Drive Units

Drive Unit Type Motor Type Installation

cIMR-MTm-3.7K

CIMR-MTIII-5.5K

cIMR-MTnI-7.5K

CIMR-MTIR-llK

CIMR-MTUI-15K

UAASKA-04CA1 Flange Mounted

UAASKA-04CA3 Foot Mounted

UAASKA-06CA1 Flange Mounted

UAASKA-06CA3

UAASKA-08CA1

UAASKA-08CA3 Foot Mounted

UAASKA-llCA1 Flange Mounted

UAASKA-11CA3 Foot Mounted

UAASKA-15CA1 Flange Mounted

UAASKA-15CA3 Foot Mounted

Foot Mounted

Flange Mounted

-6-

Page 13

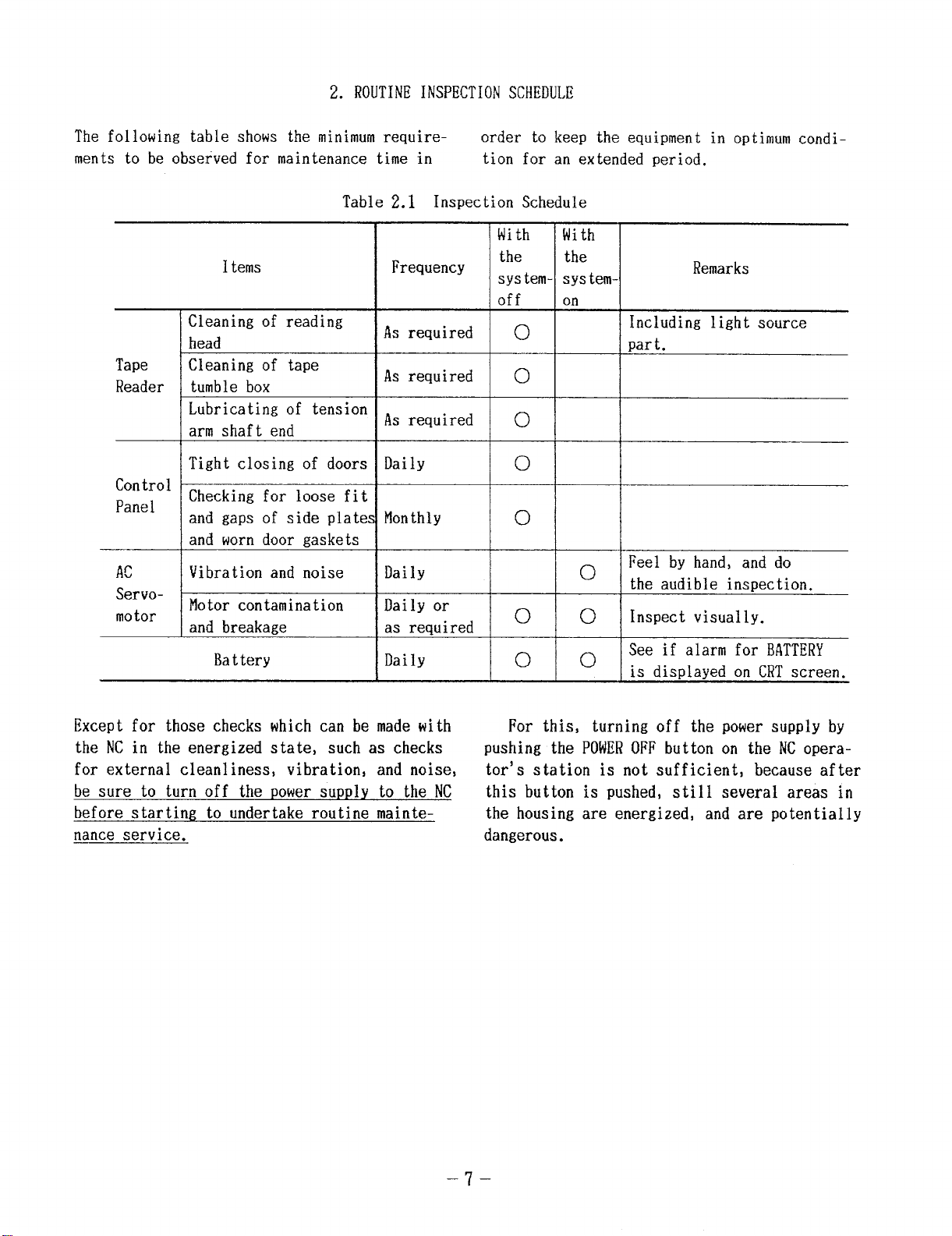

2. ROUTINEINSPECTIONSCHEDULE

The following table shows the minimumrequirements to be observed for maintenance time in

Table 2.1 Inspection Schedule

I terns

Cleaning of reading

head

Tape Cleaning of tape

Reader tumble box

Lubricating of tension

arm shaft end

Tight closing of doors Daily

Control

Panel

AC

Servo-

motor

Checking for loose fit

and gaps of side plates

and worn door gaskets

Vibration and noise

Motor contamination

and breakage

Battery

Frequency

As required o

As required o

As required o

MonthlY

Daily

Daily or

as required

Daily

order to keep the equipment in optimum condi-

tion for an extended period.

With

the

system- systemOff on

o

o

o 0

o 0

With

the

o

Remarks

Including light source

part.

Feel by hand, and do

the audible inspection.

Inspect visually.

See if alarm for BATTERY

is displayed on CRTscreen.

Except for those checks which can be made with

the NCin the energized state, such as checks

for external cleanliness, vibration, and noise, tor’s station is not sufficient, because after

be sure to turn off the power supply to the NC

before starting to undertake routine mainte-

nance service.

For this, turning off the power supply by

pushing the POWEROFF button on the NCopera-

this button is pushed, still several areas in

the housing are energized, and are potentially

dangerous.

–7–

Page 14

2.1. ‘TAPEREADER

(1) [Cleaning the tape reader head (Dai

(a) Removetape rubbish and dust from the

glass with a blower brush. If the glass is

stained with oil or oily dust, wipe it using

agauze or soft cloth with absolute alcohol.

Also clean the tape guide and the tape

retainer.

(b) Remove the dust, if any, on LED (light

source) on top with a blower brush.

(2) Cleaning of tape tumble box (Weekly)

Clean the braided nylon leading tape with a

clean, soft cloth.

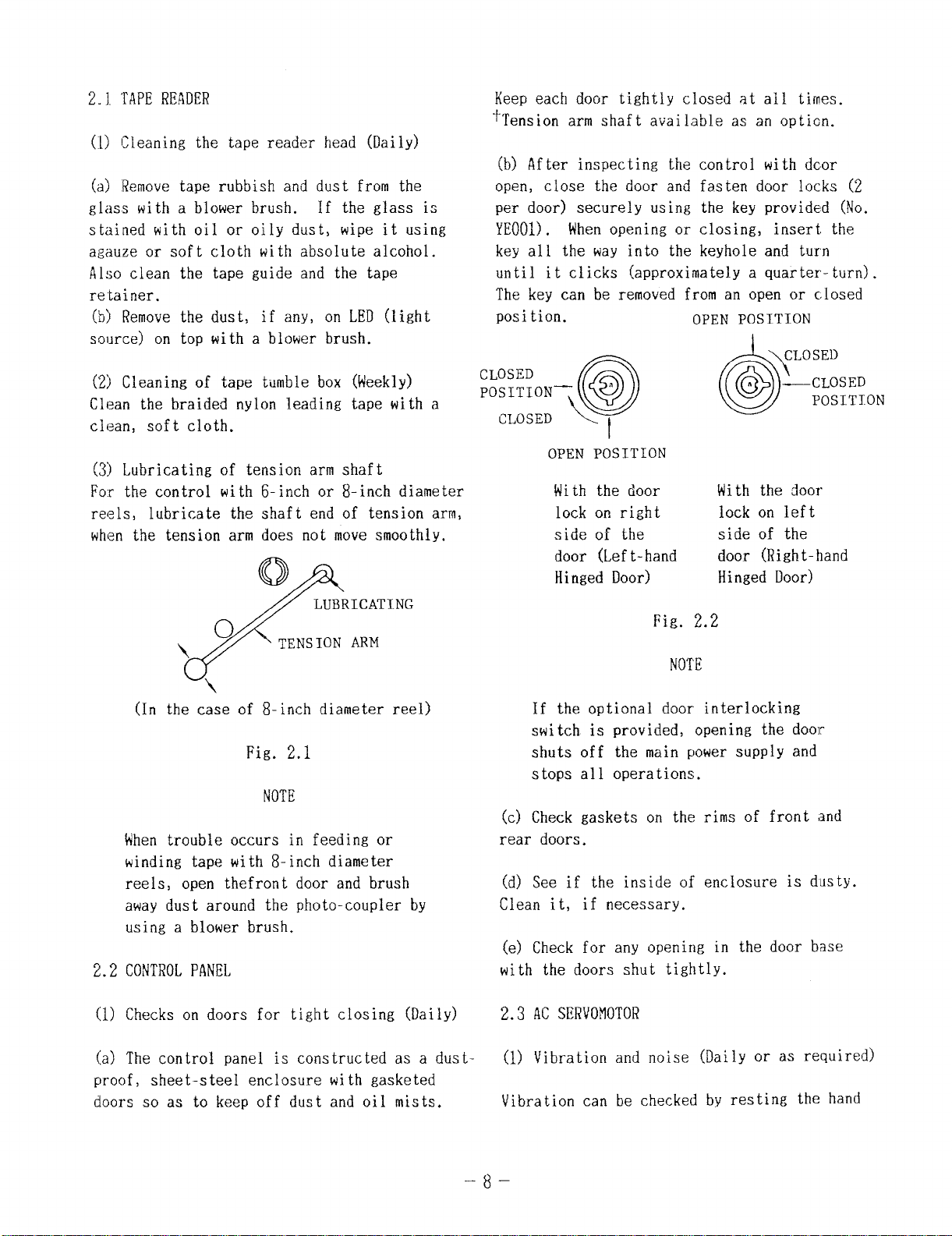

(3) Lubricating of tension arm shaft

Fo:r the control with 6-inch or 8-inch diameter

reels, lubricate the shaft end of tension arm,

when the tension arm does not move smoothly.

lY)

Q

LUBRICATING

o

\

/

\

(In the case of 8-inch diameter reel)

Whentrouble occurs in feeding or

winding tape with 8-inch diameter

reels, open thefront door and brush

away dust around the photo-coupler by

using a blower brush.

CONTROLPANEL

2.2

TENSION ARM

Fig. 2.1

NOTE

Keep each door tightly closed at all times.

~Tension arm shaft available as an option.

(b) After inspecting the control with dcor

open, close the door and fasten door locks (2

per door) securely using the key provided (No.

YEOOI). Whenopening or closing, insert the

key all the way into the keyhole and turn

until it clicks (approximately a quarter-turn).

The key can be removed

position.

CLOSED

POSITION—

CLOSED L

OPEN POSITION

If the optional door interlocking

switch is provided, opening the door

shuts off the main power supply and

stops all operations.

(c} Check gaskets on the rims of front and

rear doors.

(d) See if the inside of enclosure is dusty.

Clean it, if necessary.

(e) Check for any opening in the door base

with the doors shut tightly.

a

Q

t

with the door

lock on right

side of the

door (Left-hand

Hinged Door)

from an open or closed

OPEN POSITION

\

r,

d=

6

With the door

lock on left

side of the

door (Right-hand

Hinged Door)

Fig. 2.2

NOTE

CLOSED

—CLOSED

POSITION

Checks on doors for tight closing (Daily)

(1)

(a)

The control panel is constructed as a dustproof, sheet-steel enclosure with gasketed

doors so as to keep off dust and oil mists.

2.3 ACSERVO!lOTOR

(1) Vibration and noise (Daily

Vibration can be checked by resting the hand

–8–

or as required)

Page 15

on the motors, and for noise, using a listen-

ing stick is recommended.

If any abnormality

is found, contact maintenance personnel imme-

diately.

(2) Motor contamination and impairment (Dai

or as required)

Check the motor exterior visually. If dirt

damage should be observed, inspect the motor

by removing the machine cover. Refer to the

machine tool builder’s manual.

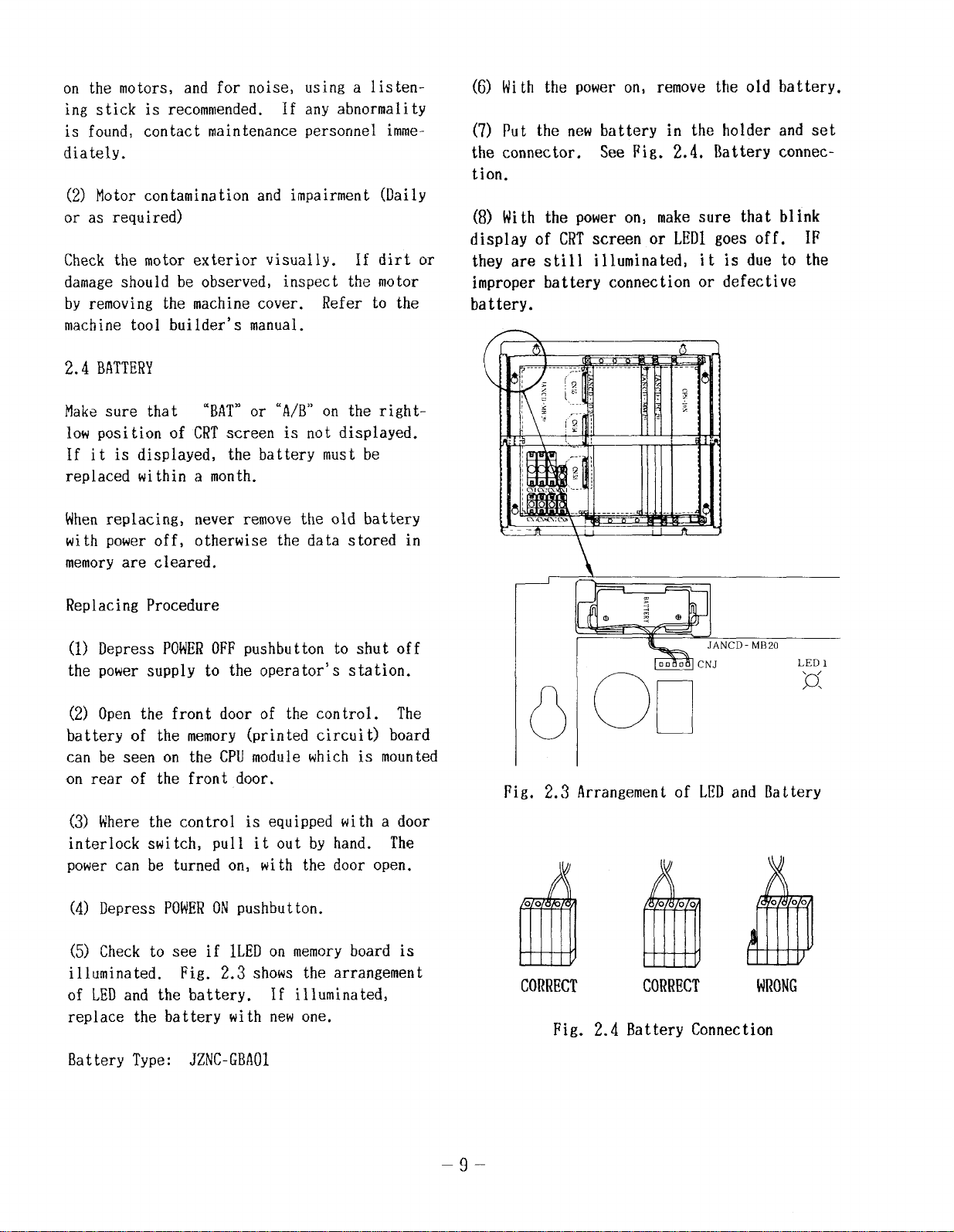

2.4 BATTERY

Make sure that ‘BAT”or ‘A/B” on the right-

low position of CRTscreen is not displayed.

If it is displayed, the battery must be

replaced within a month.

(6) With the power on, remove the old battery.

(7) Put the new bat tery in the holder and set

the connector.

See Fig. 2.4. Battery connec-

tion.

Y

(8) With the power on, make sure that b] ink

display of CRTscreen or LED1goes off. IF

or

they are still illuminated, it is due to the

improper battery connection or defective

battery.

—

\

*\

,+

A -1

Whenreplacing, never remove the old battery

with power off, otherwise the data stored in

memoryare cleared.

Replacing Procedure

(1) Depress POWEROFFpushbutton to shut off

the power supply to the operator’s station.

(2) Open the frent door of the control. The

battery of the memory (printed circuit) board

can be seen on the CPUmodule which is mounted

on rear of the front door.

(3) Where the control is equipped with a door

interlock switch, pull it out by hand. The

power can be turned on, with the door open.

(4) Depress POWERONpushbutton.

(5) Check to see if lLED on memoryboard is

illuminated. Fig. 2.3 shows the arrangement

of LEDand the battery.

If illuminated,

replace the battery with new one.

A \

L

I

Fig. 2.3 Arrangement of LEDand Battery

CORRECT

Fig. 2.4 Battery Connection

CORRECT

WRONG

Battery Type: JZNC-GBAO1

–9-

Page 16

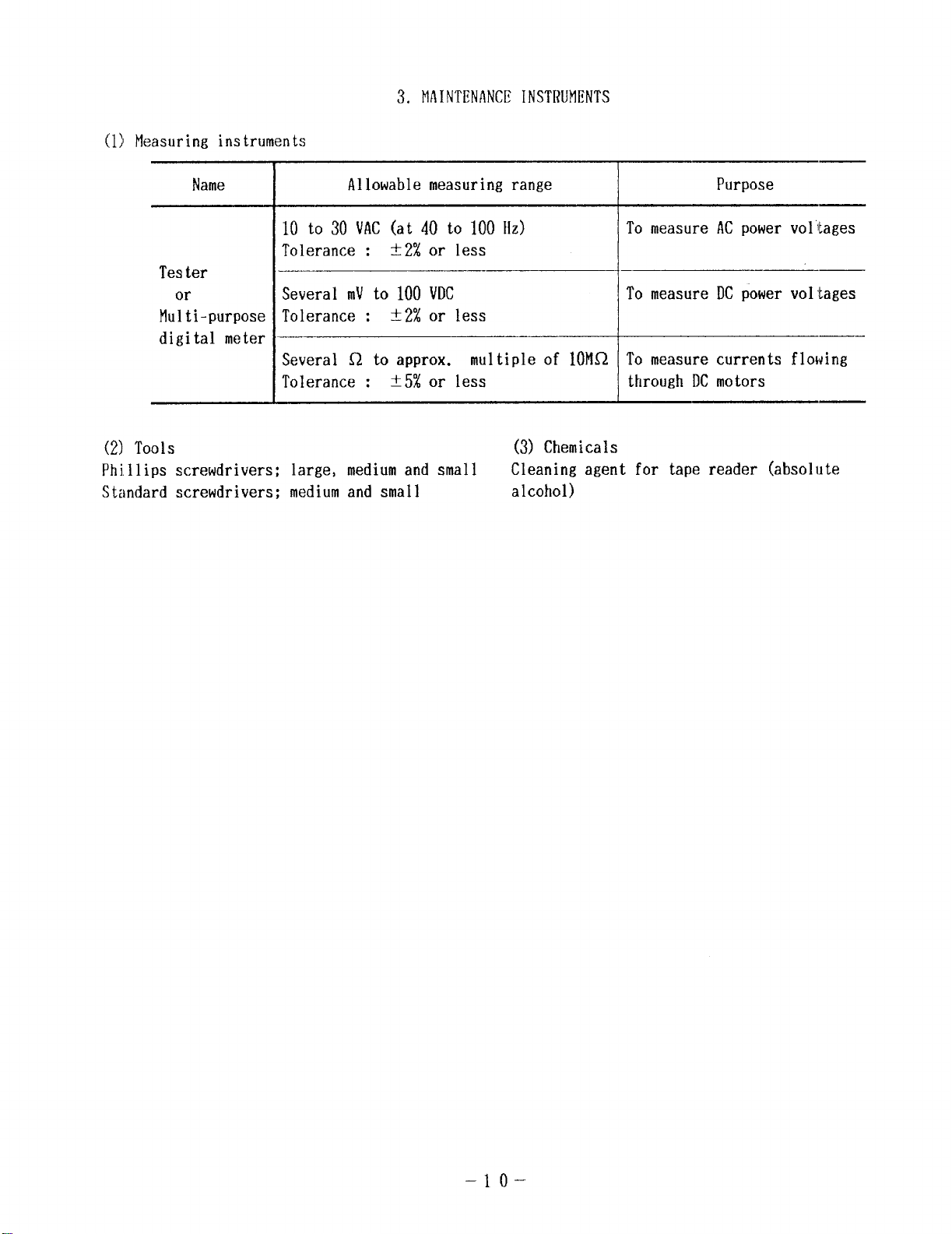

(1) Measuring instruments

3. MAINTENANCEINSTRUMENTS

Name

10 to 30 VAC(at 40 to 100 Hz)

Tolerance :

Tester

or

Multi-purpose

digital meter

(2) Tools

Phillips screwdrivers; large, medium and small

Standard screwdrivers; medium and small

Several mVto 100 VDC

Tolerance :

Several Q to approx.

Tolerance :

Allowable measuring range

~~~ or less

~~~ or less

*5% or less

Purpose

To measure ACpower voltages

To measure DCpower voltages

multiple of 10MQ

(3) Chemicals

Cleaning agent for tape reader (absolute

alcohol)

To measure currents flowing

through DCmotors

–lo-

Page 17

4. TROUBLESHOOTING

4.1 TROUBLE

Try to fully

which the trouble occurred. This is necessary

for identifying the trouble and/or for having

the YASNACservice personnel called in to

correct the trouble.

points will minimize

system:

4.1.1 RECOGNITIONOF

(1) What operation w

(Is other opera t ion performed normal lY?)

(2) Whendoes the trouble occur: every time

or frequently?

(3) Was there no external disturbance such as

power interruption or lightning when trouble

occurred?

(4) Did it occur during or after operation of

mode switches such as EDITor memory, or func-

tion such asm(parameter) or~(diagnose)

or key switch on CRTpanel?

(5) Ensure the fol lowing points if the trouble

occurred as related to feed and/or spindle

operation:

. Check of LEDon the drive unit

. ON/OFFcheck of fuse or MCCB

“ Time of trouble occurrence such as

power application.

at

at

acceleration.

at

deceleration.

at

steady-state running.

(6) Does it depend on part program?

If so, record also part program, offset and

coordinate system settings.

DENTIFICATION

analyze the circumstances in

Verifying the following

the down time of your

TROUBLESTATUS

11 cause the trouble?

recognize the status of

regardless of the detai

The NCunit is provided

switch. When the operator opens the door, the

NCunit power supply is tripped by MCCBand

the interlock switch is released.

Do not start the check operation until the

interlock switch is released.

(1) Nameof

(2) Time of

(3) Nameand type of machine

(4) Nameand type of NCunit and others

(Example)

NCunit

Servo drive : CACR-SR053SB

Servo motor : USAFED-05MA

Spindle drive

Spindle motor

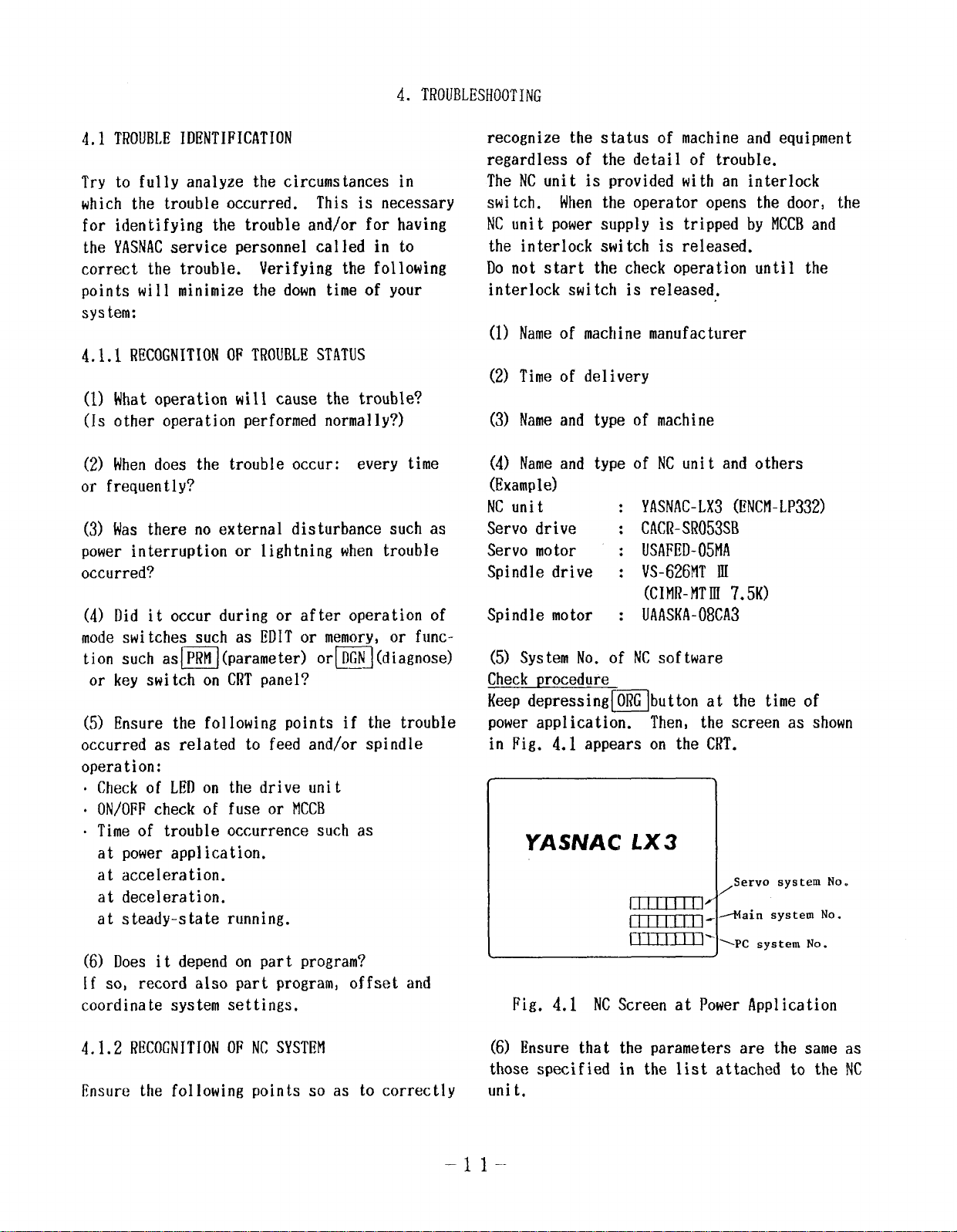

(5) SYStem No. of NCsoftware

Check procedure

Keep depressing~button at

power application. Then, the

in Fig. 4.1 appears on the CRT.

Fig. 4.1 NCScreen at Power Application

machine manufacturer

delivery

: YASNAC-LX3(ENcM-LP332)

: VS-626MTIII

: UAASKA-08CA3

Lx 3

IrrImn Lain sy~tem No

uuuln!nnnn’

1

machine and equipment

of trouble.

with an interlock

(CIMR-MTIII7.5K)

the time of

screen as shown

\

I

Servo system No.

.

~PC system No.

4.1.2 RECOGNITIONOF NCSYSTEM

Ensure the following points so as to correctly

(6) Ensure that the parameters are the same as

those specified in the list attached to the NC

unit.

–11--

Page 18

4+~ TR~U~LESj]()()’TINGBy ALAf/MCODES

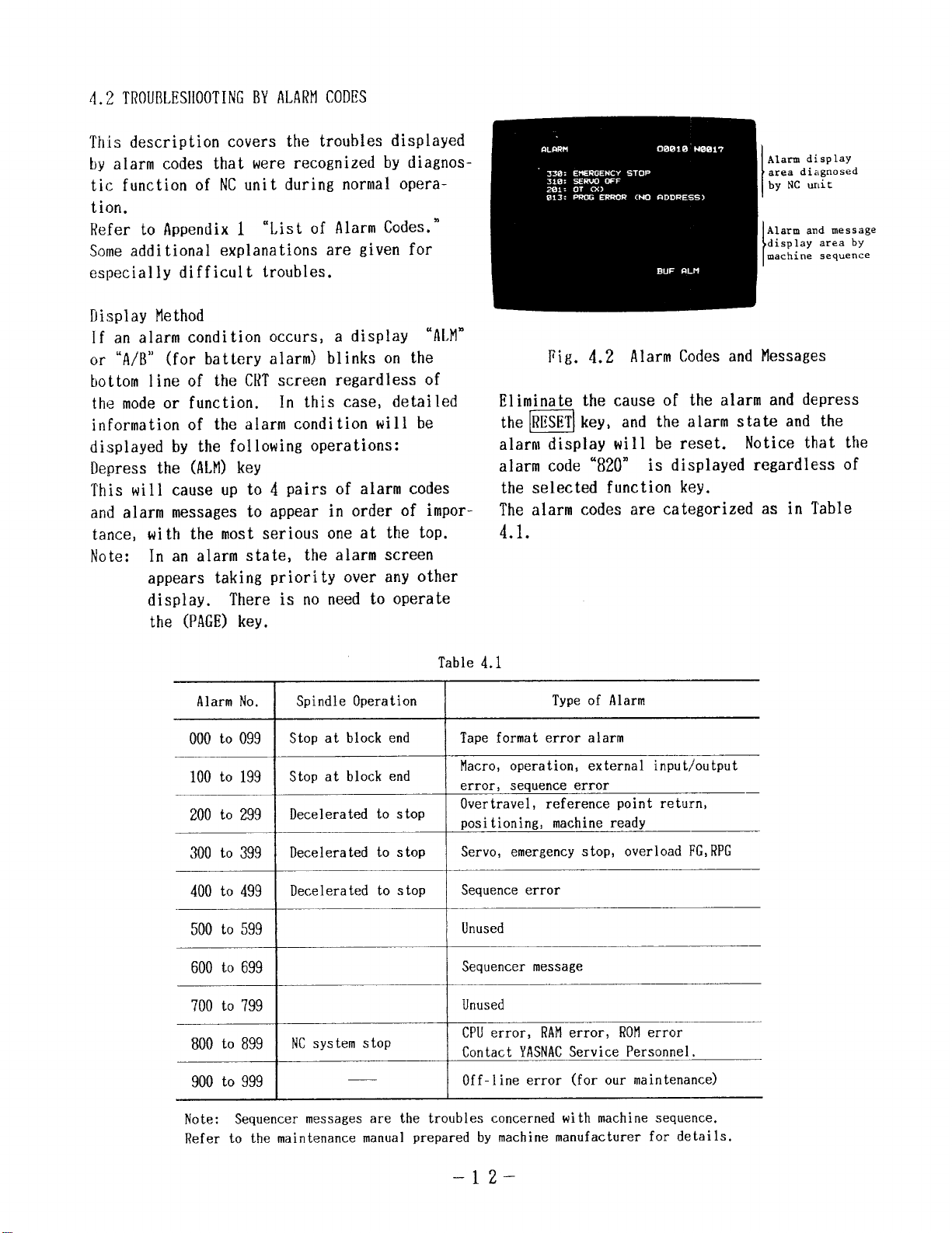

This description covers the troubles displayed

by alarm codes that were recognized by diagnos-

tic function of NCunit during normal operation.

Refer to Appendix 1

“List of Alarm Codes.”

Some additional explanations are given for

especially difficult troubles.

Display Method

If an alarm condition occurs, a display “ALM”

or “A/B” (for battery alarm) blinks on the

bottom line of the CRTscreen regardless of

the mode or function.

In this case, detailed

information of the alarm condition will be

displayed by the following operations:

Depress the (ALM)key

This will cause up to 4 pairs of alarm codes

and alarm messages to appear in order of impor-

tance,

Note:

with the most serious one at the top.

In an alarm state, the alarm screen

appears taking priority over any other

display.

There is no need to operate

the (PAGE)key.

Alarm di splay

area diagnosed

by NC unit

Alarm and message

display area by

machine sequence

Fig. 4.2 Alarm Codes and Messages

Eliminate the cause of the alarm and depress

the=l key, and the alarm state and the

alarm display will be reset. Notice that the

alarm code ‘820”

is displayed regardless of

the selected function key.

The alarm codes are categorized as in Table

4.1.

AlarmNo.

000 to 099

100 to 199

200 to 299

300 to 399

400 to 499

500 to 599

600 to 699

700 to 799

800 to 899

900 to 999 I

Table 4.1

Spindle Operation Typeof Alarm

Stop at block end Tape format error alarm

Stop at block end

Decelerated to stop

Decelerated to stop

Decelerated to stop

I

I

Macro, operation, external input/output

error,

sequence error

Overtravel, reference point return,

positioning, machineready

Servo, emergency stop, overload FG,RPG

Sequence error

I

Unused

i

Sequencermessage

,

I

NCsystem stop

1

Unused

I

CPUerror, RAMerror, ROMerror

Contact YASNACService Personnel.

] Off-line error (for our maintenance)

Note:

Refer to the maintenance manual prepared by machine manufacturer for details.

Sequencer messages are the troubles concerned with machine sequence.

–12-

Page 19

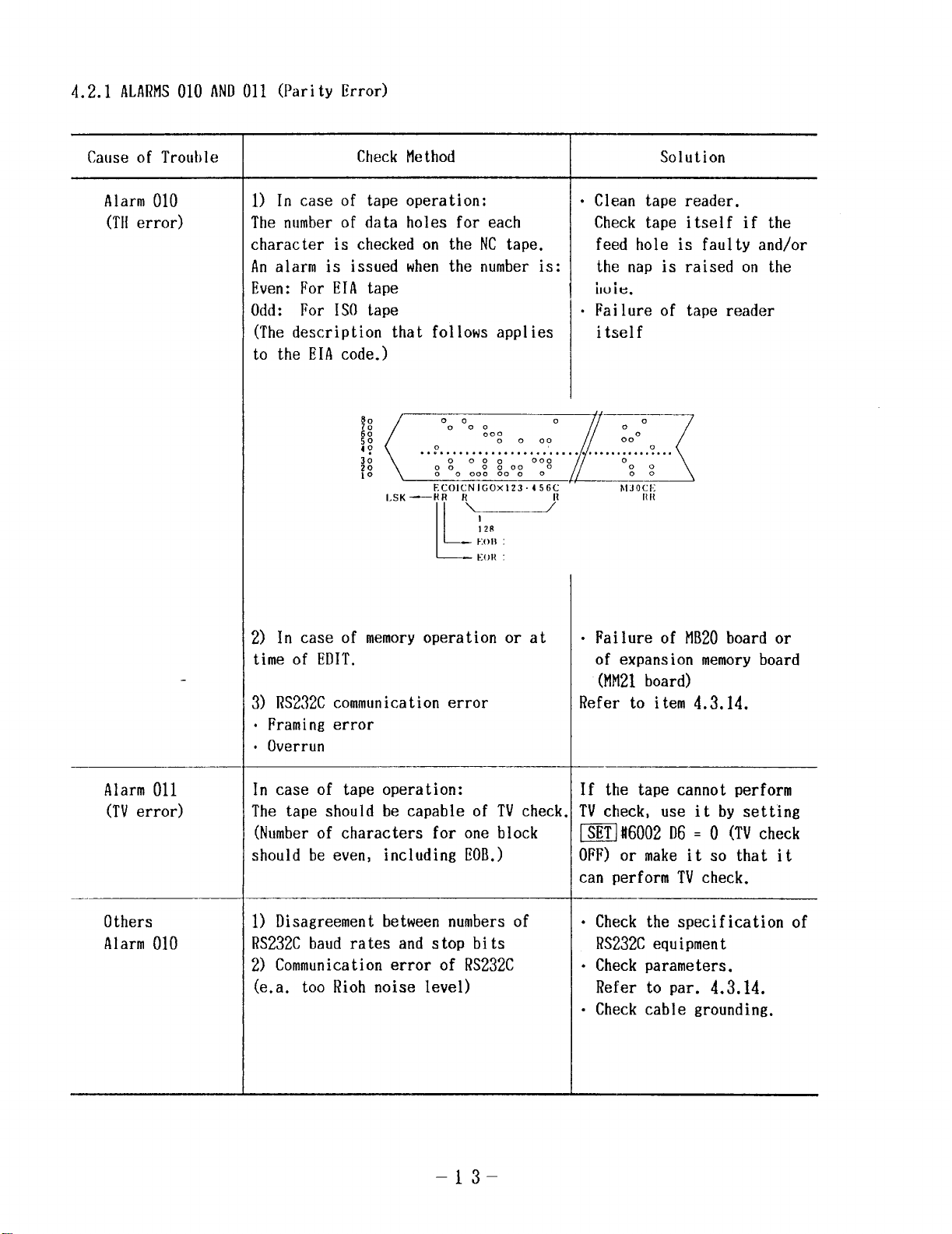

4.2.1 ALARMS010 ANDO1l (Parity Error)

Cause of Trouble

Alarm 010

(THerror)

Check Method

1) In case of tape operation:

The number of data holes for each

character is checked on the NC tape.

An alarm is issued when the number is:

Even: For EIA tape

Odd: For 1S0 tape

(The description that follows applies

to the EIA code.)

!Wr,ca

LSK-RR R

Ec01cNIGox123.456c hlJOCl;

II +

128

ton :

k

E(JR :

Solution

● Clean tape reader.

Check tape itself if the

feed hole is faulty and/or

the nap is raised on the

iluie.

. Failure of tape reader

itself

Tn

HII

Alarm 011

(TVerror)

Others

Alarm 010

2) In case of memoryoperation or at

time of EDIT.

3) RS232C communication error

● Framing error

. Overrun

In case of tape operation:

The tape should be capable of TVcheck

(Number of characters for one block

should be even, including llOB.)

1) Disagreement between numbers of

RS232Cbaud rates and stop bits

2) Communicantion error of RS232C

(ea. too Rioh noise level)

.

Failure of MB20board or

of expansion memory board

(MI121board)

Refer to item 4.3.14.

If the tape cannot perform

TVcheck, use it by setting

m ft6002 D6 = O (TVcheck

OFF) or make it so that it

can perform TVcheck.

● Check the specification of

RS232Cequipment

● Check parameters.

Refer to par. 4.3.14.

“ Check cable grounding.

–13-

Page 20

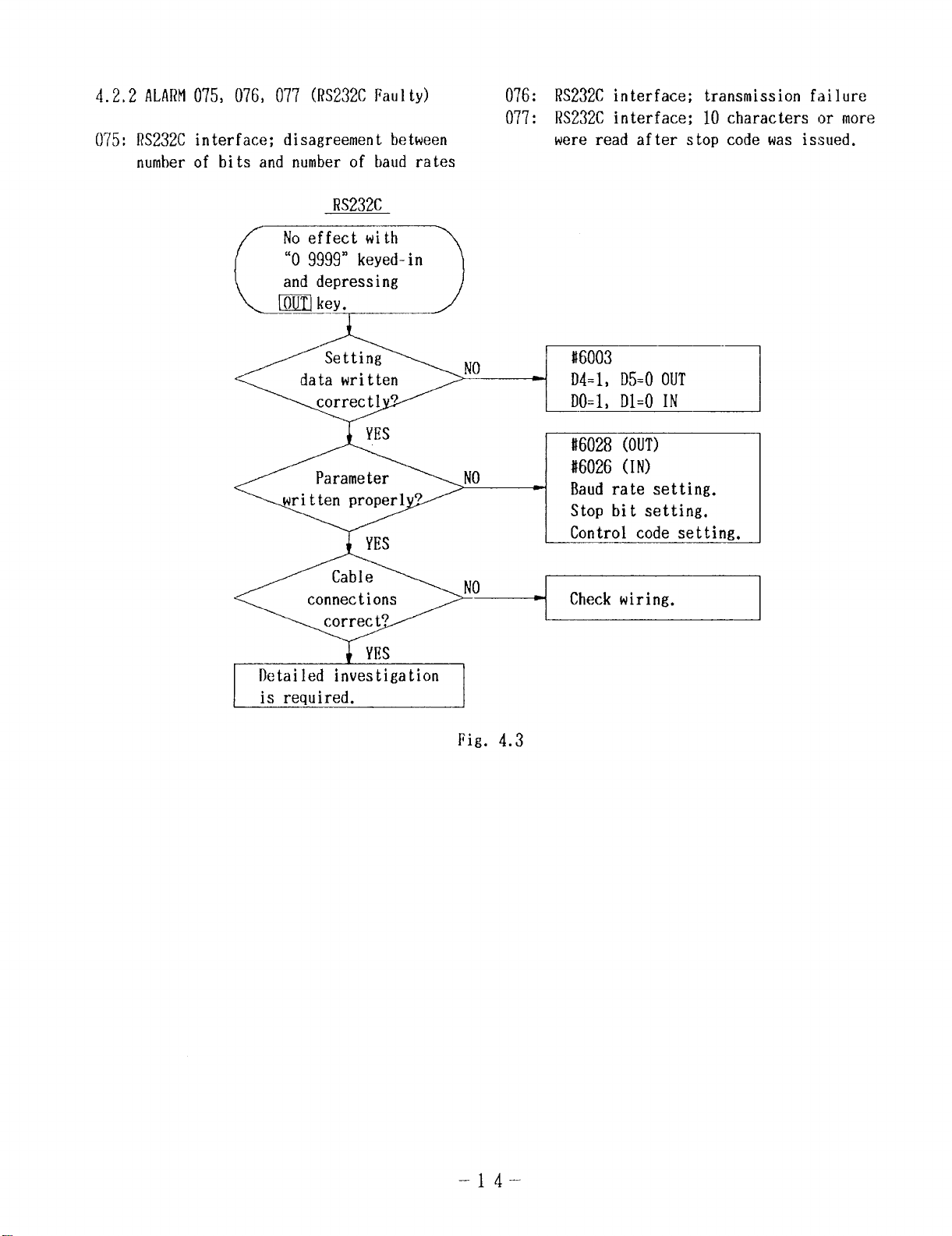

4.2,2 ALARM075, 076, 077 (RS232CFaulty)

075: RS232C interface; disagreement between

number of bits and number of baud rates

RS232C

076: RS232C interface; transmission fi~ilure

077: RS232C interface; 10 characters or more

were read after stop code was issued.

~llkey. ~

—

Setting

data written

~No “ __!ti

correctl 9

NO

\- “-

Fig. 4.3

#6028 (OUT)

#6026 (IN)

Baud rate setting.

Stop bit setting.

Control code setting.

Check wiring.

–14-

Page 21

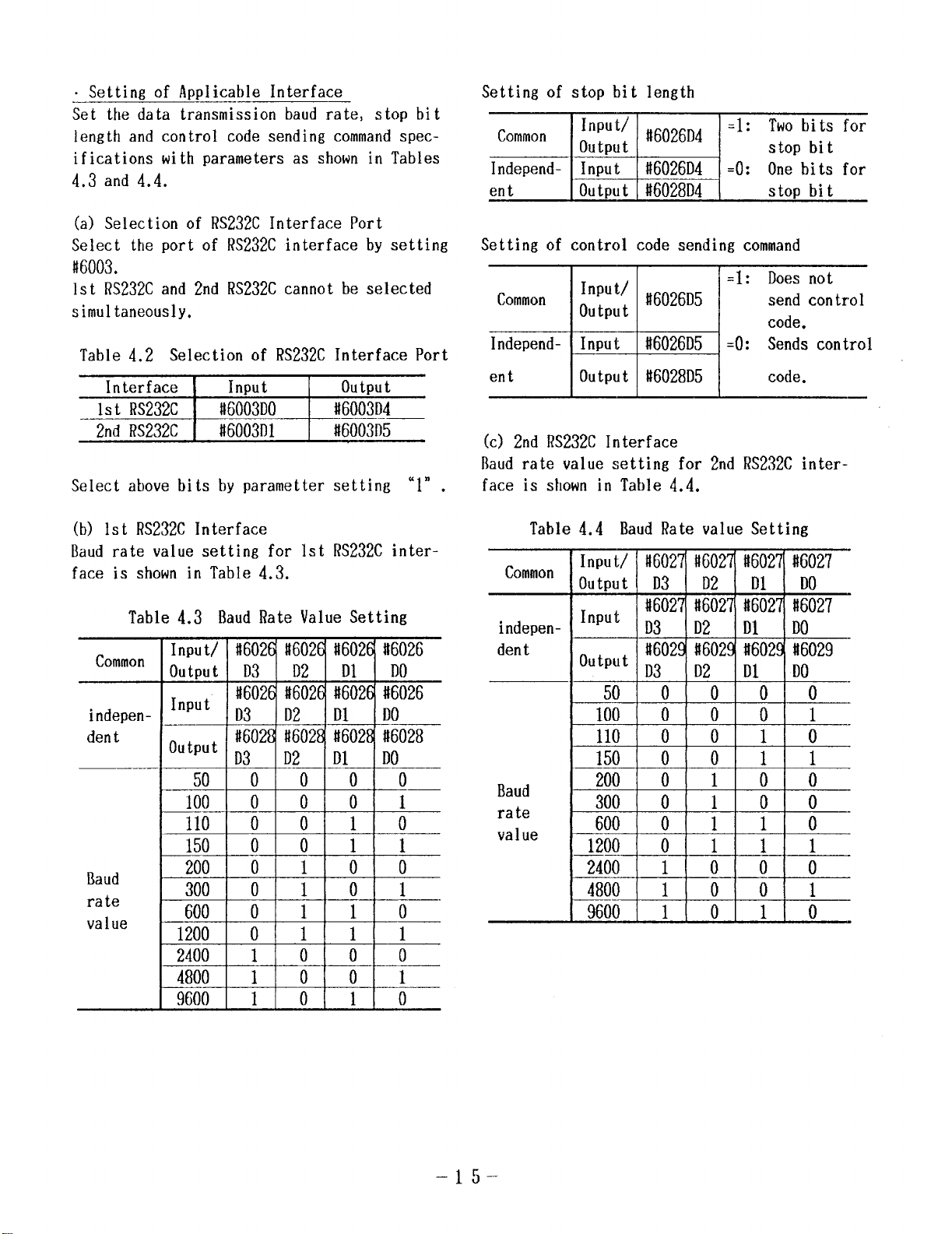

o Settin~ of Amlicable Interface

Set the data transmission baud rate, stop bit

length and control code sending commandspecifications with parameters as shown in Tables

4.3 and 4.4.

(a) Select ion of RS232C Interface Port

Select the port of RS232C interface by setting

#6003.

1st RS232Cand 2nd RS232Ccannot be selected

simultaneously.

Table 4.2 Selection of RS232CInterface Port

Interface

1st RS232C

2nd Rs232C

Select above bits by parameter setting ‘1” .

Input

#6003D0 #6003D4

#6003f)l

Output

#6003D5

Setting of stop bit length

Setting of control code sending command

I

Common

Independentt

(c) 2nd RS232C Interface

Baud rate value setting for 2nd RS232C inter-

face is shown in Table 4.4.

input’#6026D5

output

Output #6028D5

I

=1: Does not

send control

code.

=0: Sends control

code.

(b) Ist RS232C Interface

Baud rate value setting for 1st Rs232C inter-

face is shown in Table 4.3.

Table 4.3 Baud Rate Value Setting

Common

indepen-

dentt

Baud

rate

value

Input/

output

‘nput

‘u ‘Put

Jo

110

150

200

300

600

#6026 li6026 it602E it6026

D3 D2 D1 DO

#6026 #6026 #6026 #6026

D3 D2 D1 DO

#602/?’#6028 #6028 #6028

D3 D2 D1 DO

50

0 0 0 0

o 0

0 0 1 0

0 0 1 1

0 1 0 0

0 1 0 1

0 1 1 0

0 1

Table 4.4 Baud Rate value Setting

Common

indepen-

dentt

Baud

rate

value

Input/

Output

Input

output

100

110

150

200

300

600

1200

2400

4800

9600

t1602~#602~ #602~ #6027

—

50

#&i&

iEHEk

–lrj _

Page 22

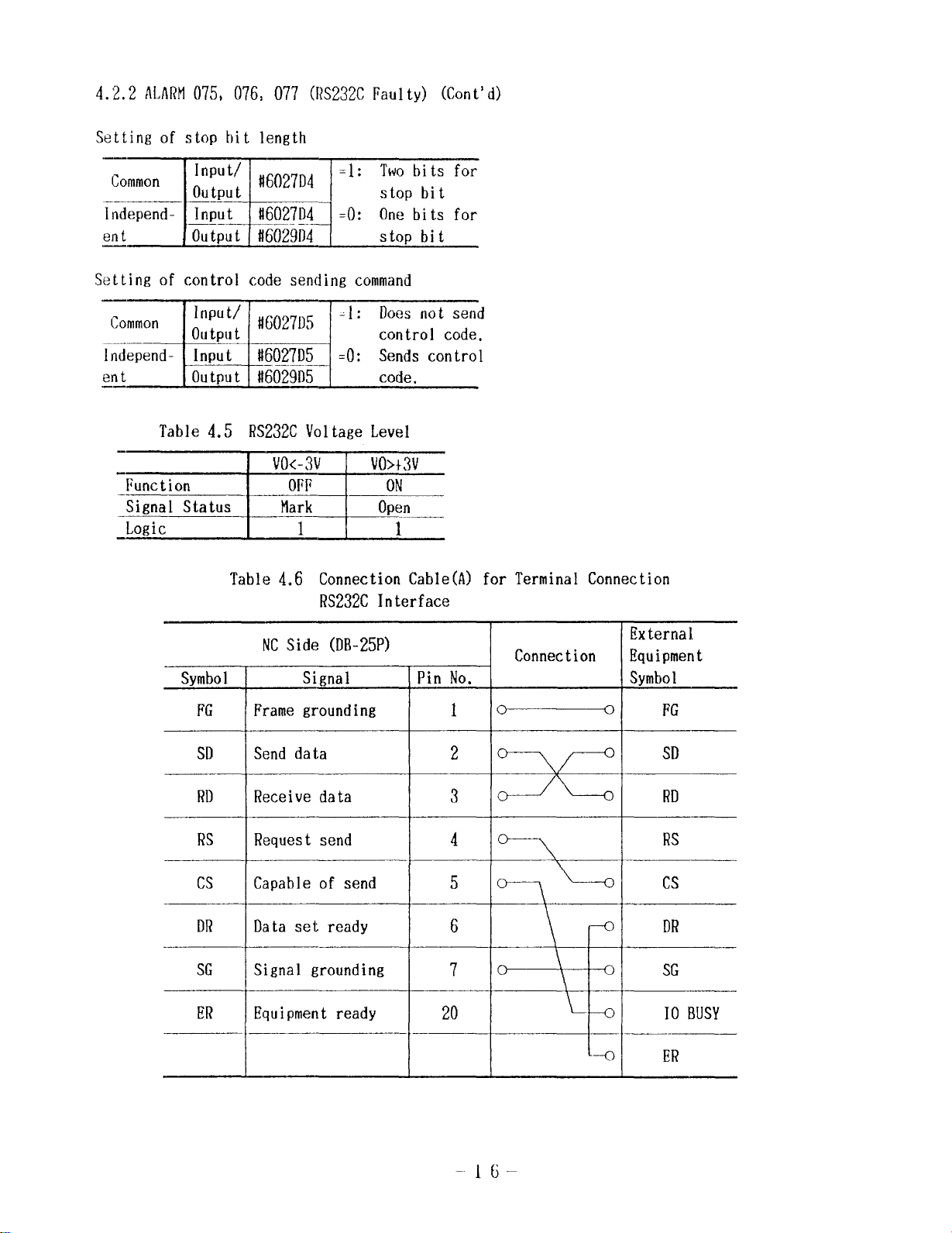

4.2.2 ALARM075, 076, 077 (RS232CFaulty) (Cont’ d)

Setting of stop bit length

—

Common

lndepend- Input !16027D4 =0: One bits for

ent Out;ut

Setting of control code sending command

Function

‘Signal Status

—

_Logic

input’ #6027D4

output

#6029D4 stop bit

Table 4.5 RS232CVoltage Level

VO<-3V VO>+3V

I

OFF ON

Mark Open

I

=1: Twobits for

1 -[

stop bit

1“

Table 4.6 Connection Cable (A:

RS232C Interface

NCSide (DB-25P)

Symbol

FG Frame grounding

SD

RD Receive data

RS Request send

Cs Capable of send

DR Data set ready

SG Signal grounding

ER

I

Send data

Equipment ready

Signal

\

Connection

External

o

*

— ..—.

+

for Termina

Connection Equipment

]Pin No. Symbol

1~

I

2

3

4

5

6

7

20

—,—

0

FG

SD

RD

RS

SG

10 BUSY

ER

16

Page 23

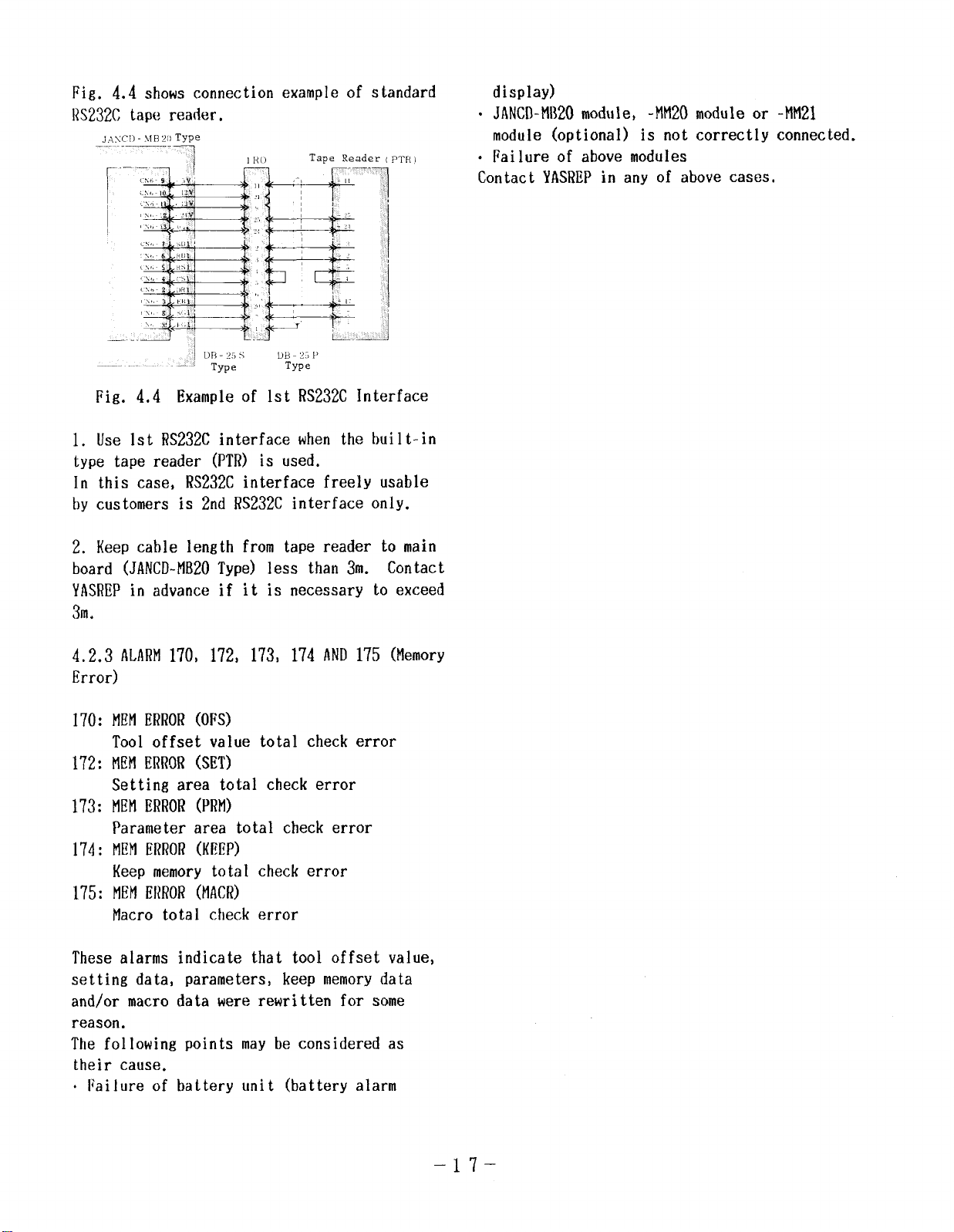

Fig. 4.4 Example of 1st RS232C Interface

1. Use 1st RS232Cinterface when the built-in

type tape reader (PTR) is used.

In this case, RS232Cinterface freely usable

by customers is 2nd RS232C interface only.

display)

“ JANCD-MB20module,

-MM20module or -MM21

module (optional) is not correctly connected.

● Failure of above modules

Contact YASREPin any of above cases,

2. Keep cable length from tape reader to main

board (JANCD-MB20Type) less than 3m. Contact

YASREPin advance if it is necessary to exceed

3m.

4.2.3 ALARM170, 172, 173, 174 AND175 (Memory

Error)

HEMERROR(OFS)

170:

Tool offset value total check error

MEtlERROR(SET)

172:

Setting area total check error

MEMERROR(PRM)

173:

Parameter area total check error

MEMERROR(KEEP)

174:

Keep memory total check error

MEMERROR(MACR)

175:

Macro total check error

These alarms indicate that tool offset value,

setting data, parameters, keep memorydata

and/or macro data were rewritten for some

reason.

The following points may be considered as

their cause.

. Failure of battery unit (battery alarm

–17-

Page 24

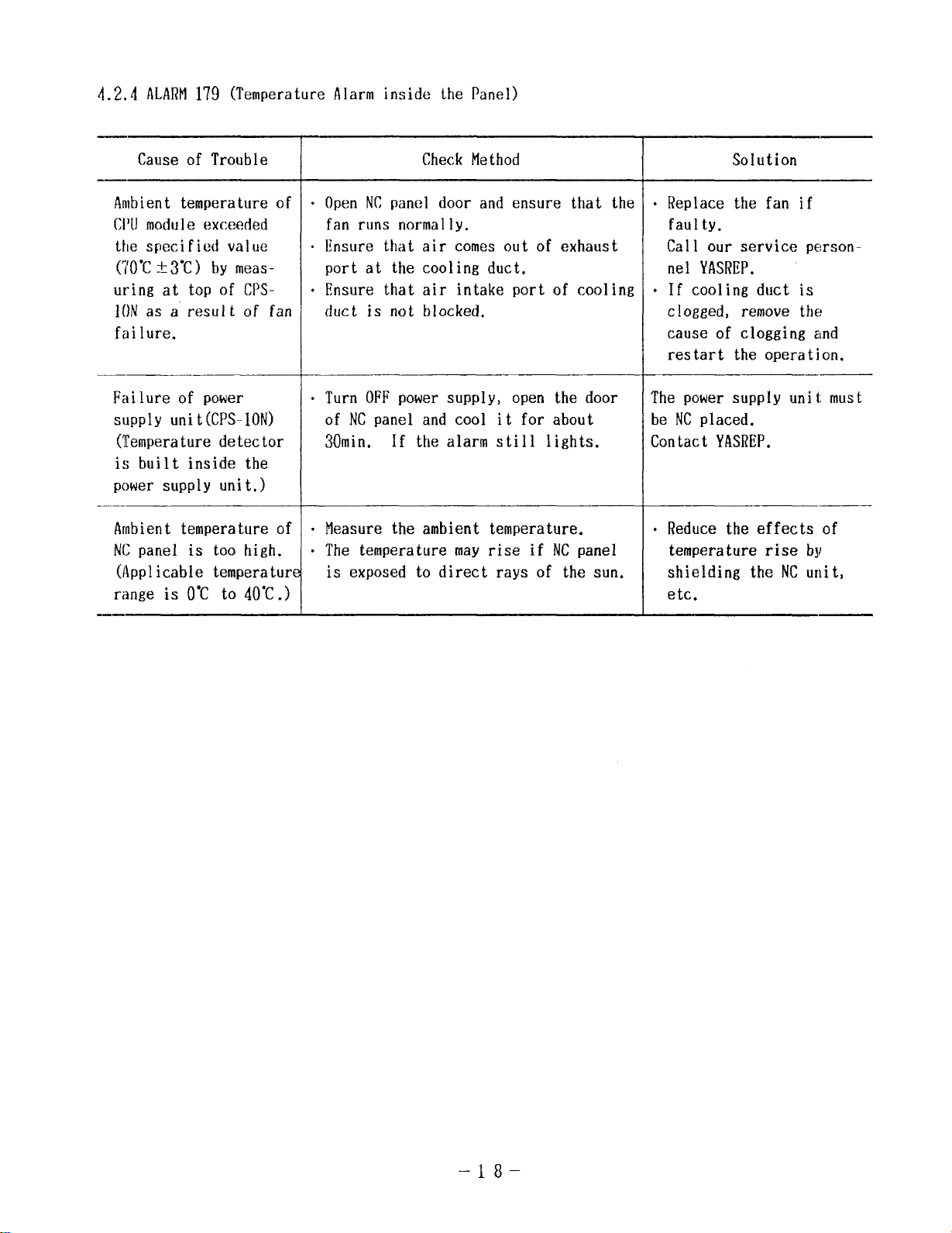

4.2.4 flLARtl179 (Temperature Alarm inside the Panel)

Cause of Trouble

Ambient temperature of

CI)Umodule exceeded

the specified value

(70”Ct3”C) by meas-

uring at top of CPS10N as a result of fan

failure.

Failure of power

supply unit(CPS-10N)

(Temperature detector

is built inside the

power supply unit.)

_——

Ambient temperature of

NCpanel is too high.

(Applicable temperature

range is O-C to 40”C.)

Check Method

.

Open NCpanel door and ensure that the

fan runs normally.

.

Ensure that air comes out of exhaust

port at the cooling duct.

.

Ensure that air intake port of cooling

duct is not blocked,

—

“ Turn OFF power supply, open the door

of NCpanel and cool it for about

30min.

If the alarm still lights.

“ Measure the ambient temperature.

“ The temperature may rise if NCpanel

is exposed to direct rays of the sun.

Solution

o Replace the fan if

faulty.

Call our service personnel YASRllP.

● If cooling duct is

clogged, remove the

cause of clogging and

restart the operation.

The power supply unit must

be NCplaced.

Contact YASREP.

o Reduce the effects of

temperature rise by

shielding the NCunit,

etc.

–18–

Page 25

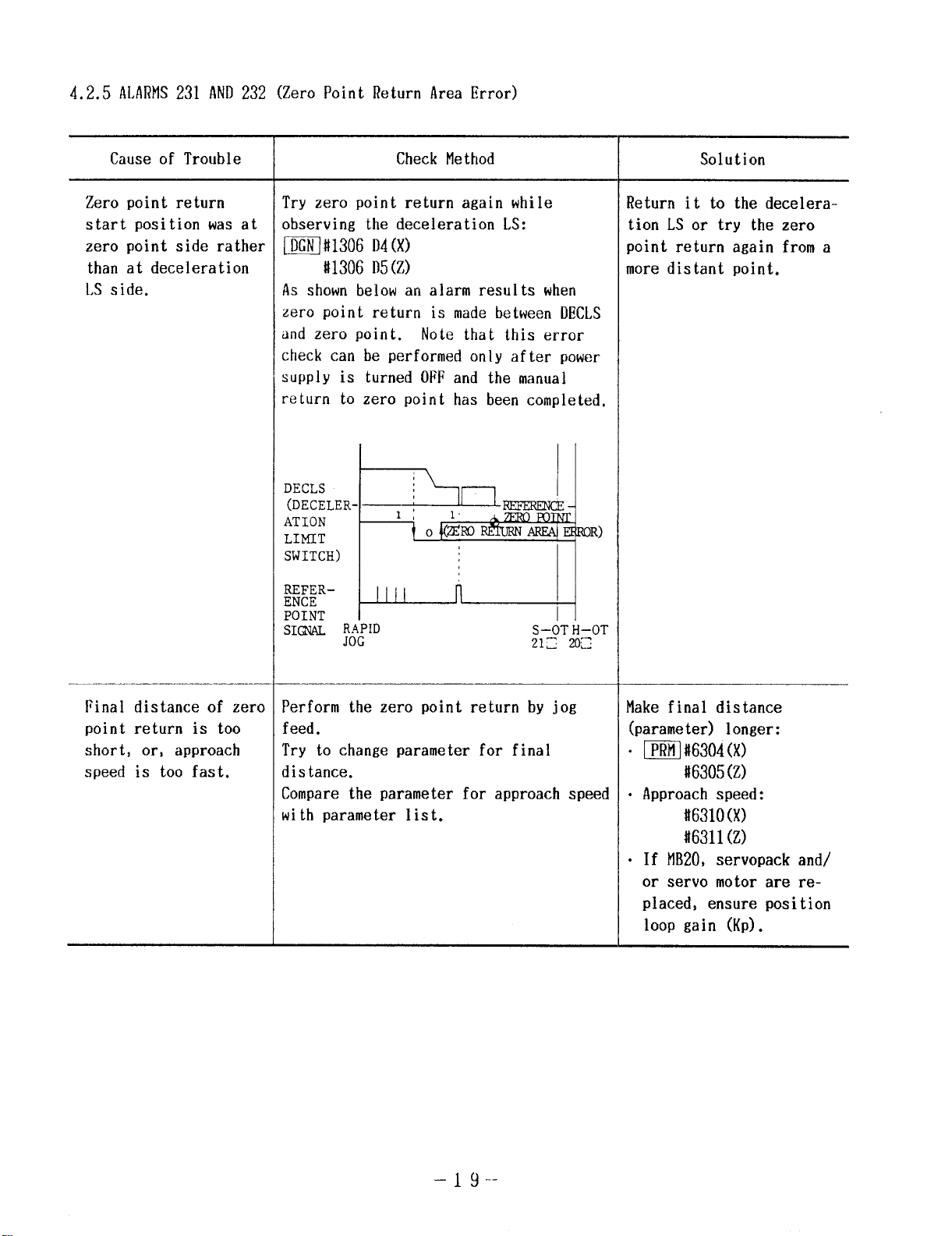

4.2.5 ALARM231 AND232 (Zero Point Return Area Error)

Cause of Trouble

Zero point return

start position was at

zero point side rather

than at deceleration

LS side.

Check Method

Try zero point return again while

observing the deceleration LS:

~#1306 D4(X)

#1306 D5(Z)

As shown below an alarm results when

zero point return is made between DECLS

and zero point.

Note that this error

check can be performed only after power

supply is turned OFFand the manual

return to zero point has been completed.

SWITCH)

Solution

Return it to the decelera-

tion LS or try the zero

point return again from a

more distant point.

Final distance of zero

point return is too

short, or, approach

speed is too fast.

!%!:-L-L

SI@J& R#D

S–OT

212. ;

Perform the zero point return by jog

feed.

Try to change parameter for final

distance.

Compare the parameter for approach speed

with parameter list.

Make final distance

(parameter) longer:

. m#6304(X)

116305(Z)

● Approach speed:

#6310(X)

+16311(Z)

● If MB20,servopack and/

or servo motor are replaced, ensure position

loop gain (Kp).

–l(J._

Page 26

4.2,6 ALARMS241 AND242 (Reference Point Return Area Error)

Cause of Trouble

This type of alarm

results when reference

point return performed

manually.

It also occurs by

reference point return

at low speed due to

DECLSchattering.

Observe DECLSchattering: Adjustment or replacement

DGN#1306 D4 (X-axis) of LS

#1306 D5 (Z-axis)

Observe reference point pulse: PCB

DGN#1288 D6 (X-axis) Replace ACservo.

X1289 D6 (Z-axis) Replace MB20B.

Check Method

I

● Failure of 1020 or 1021

Solution

Replace ACmotor.

PG cable failure

Occurs at high speed

by error of reference

point pulse

The alarm occurs also

In case of G28 Same as above

at automatic reference

point return.

4.2,7 ALARMS271 AND272 (P-SET Error)

In case of G27 Check the program.

(Z-axis) at the time of completing positioning

with GOO,G27, G28, G29 and G30.

[)-Set Error results when difference between Check is also required at the time of ERROR

commandposition and machine position does not DETECTON (~#1304 D5=1) and G4 (dowell).

fall within parameters #6056 (X-axis) or X6057

Cause of Trouble Check Method

Miichine runs too heavy. Measure the load current. Observe

torque motor in case of ACservo.

Servo error pulse

exceeds setting range.

Check error pulse.

Refer to par. 3.3.4.8

Display Number of Servo Lag Pulses in

Operator’s Manual.

-20–

Solution

Lighten machine load,

Adjust zero point of servo.

If it cannot be adjusted,

replace MB20or Servo Pack.

Contact YASREP.

Page 27

4.2.8 ALARM310 (Servo PowerSUPPlYNot APP1ied)

Cause of Trouble

Secondary power supply

is not applied.

In caseof automatic

servo power applic-

ation 1/0 input specification is not activated by secondary

power supply.

Emergencystop input.

Secondary powersupply

was tripped by other

alarm.

Check Method

This is a normal result whendepressing

NCRESETafter initial ~r application

or resetting emergency stop alarm, etc.

Ensure that it is set to

~#1322 D7=l.

Chwk if ALht330displays, or~l!ll?lll

Dl=l.

Check for other alarm display.

Solution

Depress IWERONbutton

again.

Check wiring and sequence.

Reset emergency stop input.

Take corrective action

according to alarm code.

4.2.9 ALARM320 (Control Not Ready)

This ty~of alarm results whenposition lag

Cause of Trouble

Faulty zero point

adjustment of servo.

Machine is running.

PCsignal keeps feeding.

MIMIfailure.

Wctm!%219=4, then, ERRORPULSE

iisplay screen from~display and

wad the values of X- and Z-axes.

Check Method

does not fall within therangeofmM056

and it6057 after powr application and selfdiagnosis,

Solution

Perform zero Wint adjust-

ment of servo.

This isaproblmof the

machine side rather than

failure of NCunit.

Contact machine manufac-

turer.

Replace FCor servo.

Contact YASREP.

Replace MB20. Contact

YASREP.

–21-

Page 28

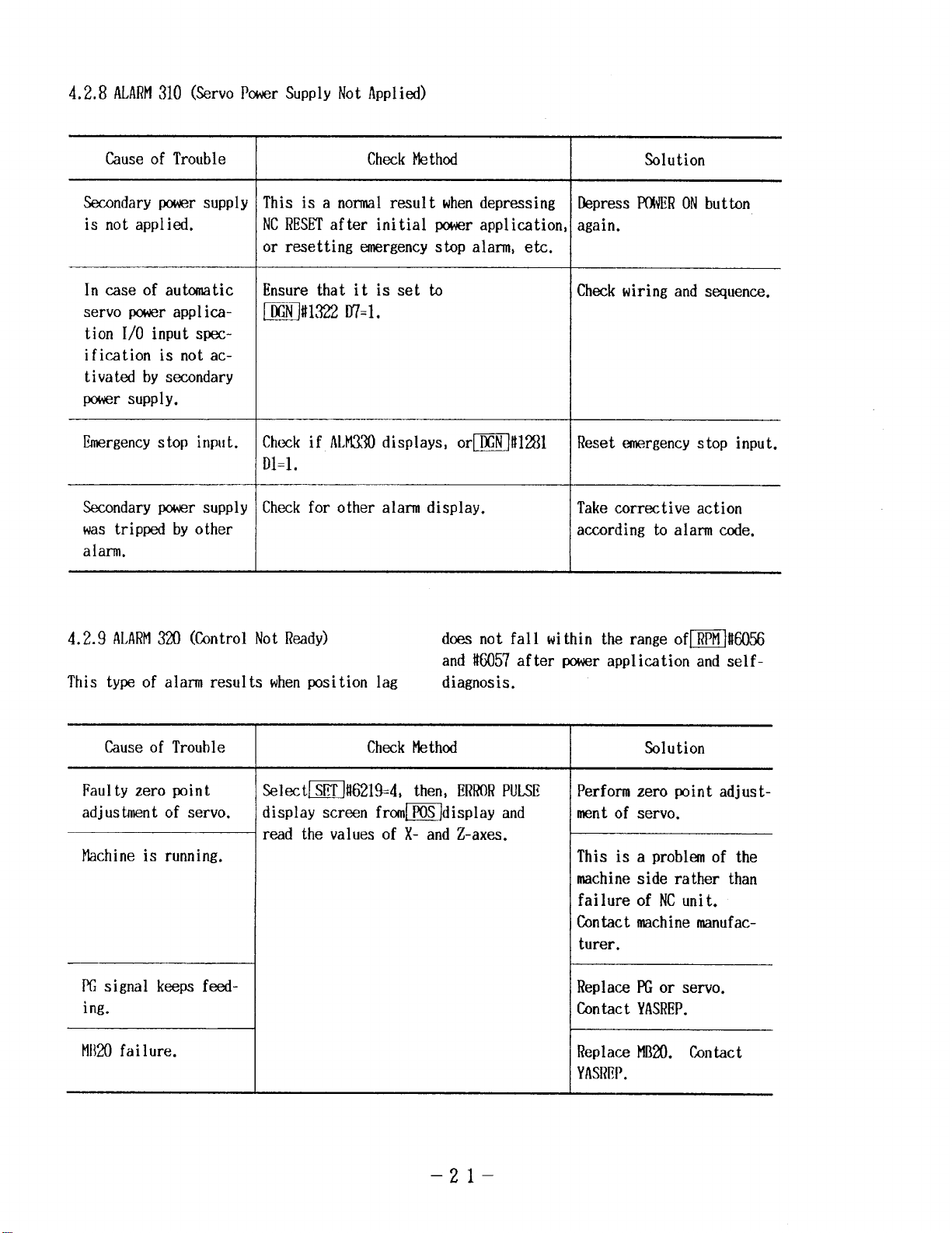

4.2.10 ALARM330 (EmergencyStOP)

——

Cause of Trouble

CheckMethod

Solution

Emergencyshp button

depressed, or, machine

end L-Sis out of place

Failureof MIMI

!fter ensurinm#1281 D1=O(during

anergency stop), check continuity of

mergency stop button or nnchine end LS

shown below. For correct connection,

refer to connection diagram prepared

by math ne manufacturer.

MB20

1

ESP

Machine End LS

“ m

L--%--J

Machine End Release

Exampleof EmergencyStop Connection

This is MB2Qfailure if alarm 330 lights

even amgli%l=l.

Reset the emergency stop

button. Release itfrcrn

machine end LS according

to instruction manual

prepared by machine manu-

facturer.

I

Replace HB20.

Contact YASREP.

Drop of +24V power

Check +24 VDCpower. If thevolt.age is

below +20V, it indicates pmsible

trouble.

4.2.11 ALARMS331 AND332 (.ServoFuseBlown)

Cause of Trouble

Servopack fuse is

bl.wn or~B tripped.

I

m#1288 Dl=l X-axis alarm

#1289 D1-1 Z-axis alarm

Check Methcxl

Alarm3!%)(servoPack alarm) should also

be displayed simultaneously.

IXN#1’281D2=l

Erroneous wiring

Check if CN1-43and/or CN2-43drop to

o vi

Replace CPS-10N(power

supply unit).

Contact YASREP.

Solution

Turn off power supply to

mathine.

Check if servopack fuse is

blcm or KB tripped.

Contact YASREP.

Gm-ect wiring according

toconnection f’lanualitem

12. Servo Unit Feed Ca-mction

–22–

Page 29

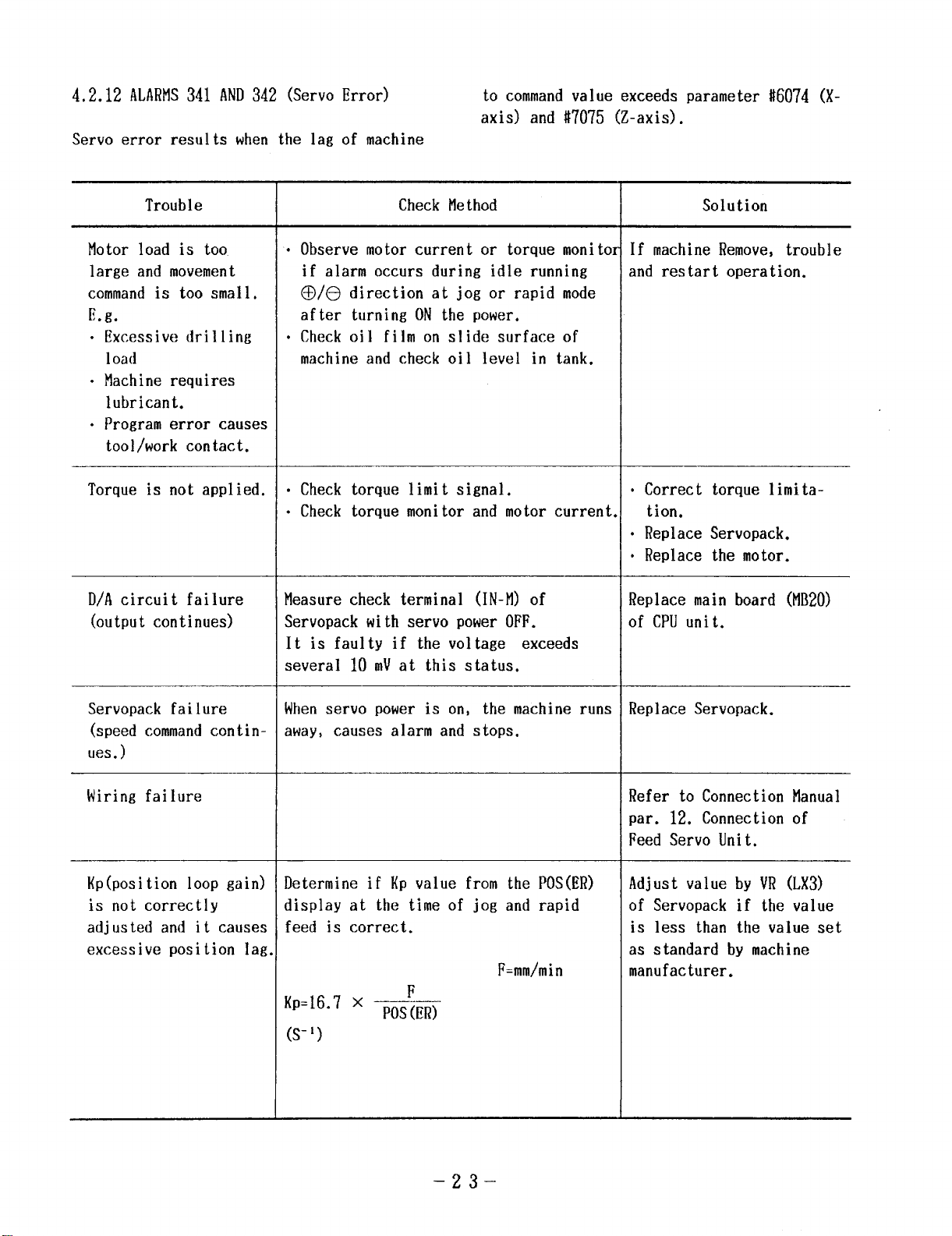

4.2.12 ALARMS341 AND342 (Servo Error)

Servo error results when the lag of machine

to commandvalue exceeds parameter #i6074 (X-

axis) and #7075 (Z-axis).

Trouble

Motor load is too

large and movement

commandis too small.

E.g.

“ Excessive drilling

load

● Machine requires

lubricant.

“ Program error causes

tool/work contact.

Torque is not applied.

D/A circuit failure

(output continues)

Check Method

.

Observe motor current or torque monito;

if alarm occurs during idle running

@/t3 direction atjogor rapid mode

after turning ONthe power.

.

Check oil film on slide surface of

machine and check oil level in tank.

—

● Check torque limit signal.

● Check torque monitor and motor current

Measure check terminal (IN-M) of

Servopack with servo power OFF.

It is faulty if the voltage exceeds

several 10 mVat this status.

Solution

If machine Remove, trouble

and restart operation.

● Correct torque limita-

tion.

● Replace Servopack.

“ Replace the motor.

Replace main board (MI120)

of CPUunit.

Servopack failure

(speed commandcontin-

ues. )

Wiring failure

Kp(position loop gain)

is not correctly

adjusted and it causes

excessive position lag

Whenservo power is on, the machine runs

away, causes alarm and stops.

Determine if KP value from the POS(ER)

display at the time of jog and rap’

d

feed is correct.

F=mm/min

F

‘P=16”7 x POS(ER)

(s-’)

Replace Servopack.

Refer to Connection Manual

par. 12. Connection of

Feed Servo Unit.

Adjust value by VR (LX3)

of Servopack if the va

is less than the value

ue

set

as standard by machine

manufacturer.

–23–

Page 30

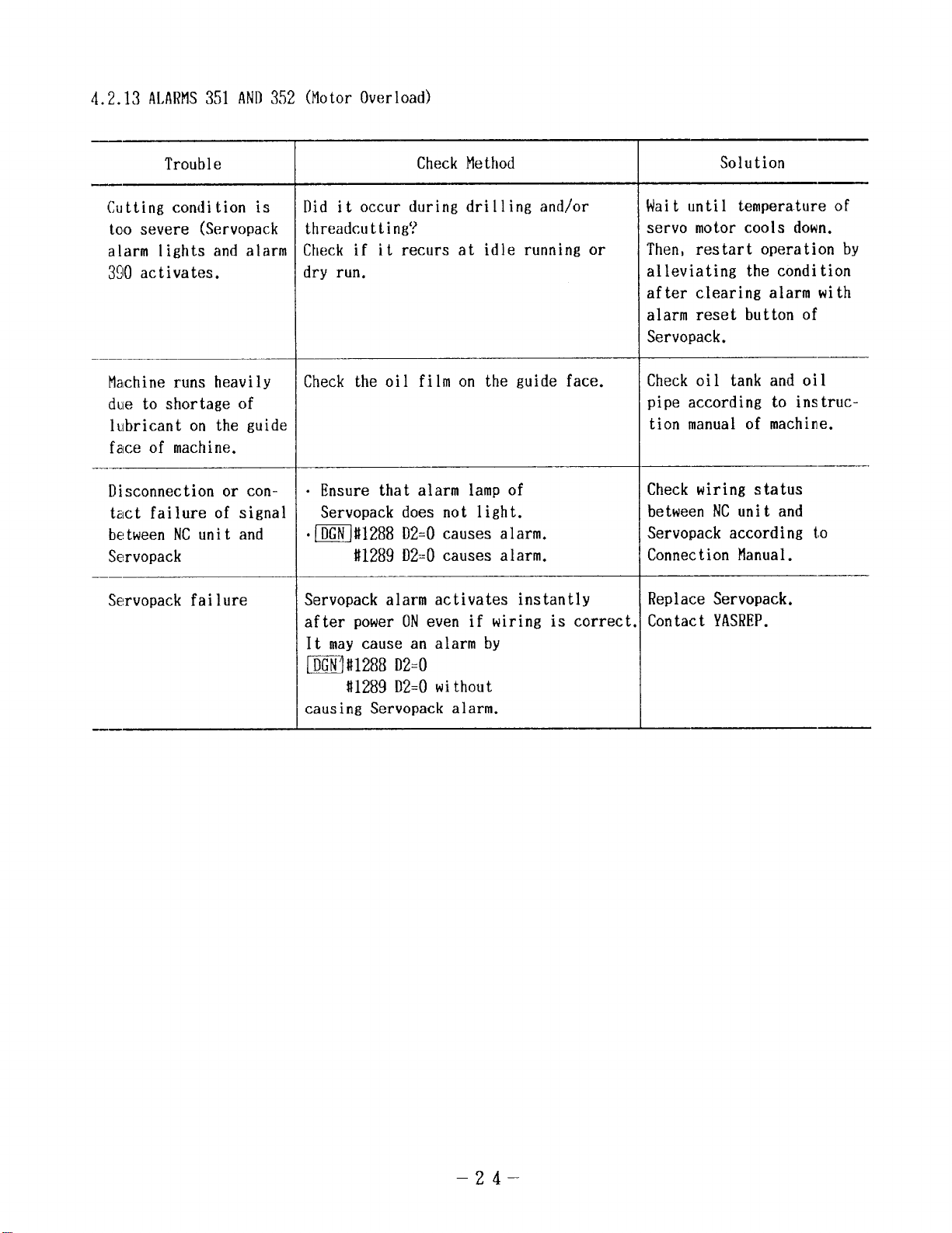

4.2.13 ALARMS351 AND352 (Motor Overload)

Trouble

Cutting condition is

too severe (Servopack

alarm lights and alarm

390 activates.

Ma(chineruns heavily

due to shortage of

lubricant on the guide

face of machine.

———

Disconnection or con-

tact failure of signal

between NCunit and

Servopack

!%!rvopack failure

Check Method

Did it occur during drilling and/or

threadcutt.ing?

Check if it recurs at idle running or

dry run.

Check the oil film on the guide face.

“ Ensure that alarm lamp of

Servopack does not light.

.~#1288D2=0 causes alarm.

#1289 D2=0 causes alarm.

Servopack alarm activates instantly

after power ONeven if wiring is correct

It may cause an alarm by

m#1288 D2=0

#1289 D2=0 without

causing Servopack alarm.

Solution

Wait until temperature of

servo motor cools down.

Then, restart operation by

alleviating the condition

after clearing alarm with

alarm reset button of

Servopack.

Check oil tank and oil

pipe according to instruc-

tion manual of machine.

Check wiring status

between NCunit and

Servopack according to

Connection Manual.

Replace Servopack.

Contact YASREP.

–24–

Page 31

4.2.14 ALARMS361, 362 AND366 (PG Disconnection Error)

They perform 2 types of checkup: Signal wire

disconnection check of A, B and C phases from

PG and check by PG input comparison at the

time when TGONsignal from Servopack turns ON.

Trouble

Disconnection or

contact failure of

signal wire between NC

unit and servopack

Failure of PG detector

circuit connection

No shorting plug connector even without

spindle PG.

Servopack failure

Check Method

.

Check for looseness and removal of

MB20board’s connectors CN1 (X-axis),

CN2(Z-axis), CN3(spindle) and/or

CN4(spindle PG).

.

Check looseness and removal of

Servopack connectors.

.

Perform wiring check according to

Connection Manual.

—

This type of alarm results when main

power is applied though result of check

for above item 1 is normal.

Shorting plug connector to CN4at CPU

module is required for such specifica-

tions without spindle PG.

● Check if

m#1288 D7=1

(X-axis TGON)

#1289 D7=1

(Z-axis TGON)

occur at motor stop.

“ If alarm occurs above the speed to

turn ONTGONsignal, it may be PG

output signal failure of Servopack.

Solution

● Correct looseness and/or

removal of connectors.

“ Correct wiring as neces-

sary.

Replace MB20.

Contact YASREP.

Mount shorting plug

connector.

Replace Servopack.

PG failure

Setting failure of

TGONsignal detect

level for Servopack

(Abnormal case)

“ If alarm occurs above the speed to

turn ONTGONsignal, it may be failure

of PG.

This type of alarm results when position

detector PPS is low. Motor may reach

running speed at TGONsignal detect

level in case of a large speed change

ratio with an external detector (such as

Inductosyn, linear scale).

–25–

Replace PG

This is a rare case.

But, change TGONsignal

detect level of servopack

to 12%from the standard

~.

Page 32

4.2.15 ALARM325 (Servo CPUError)

Trouble

Servo CPUfailure

4.2.16 ALARM329(Buil t-in type PC CPUerror)

Cause of Trouble

PC CPUfailure

4.2.17 ALARM820 (ROM/RAMCheck Error)

It performs check of ROMconstantly and RAMat

the time of power application with self-

diagnostic function of NCunit. If there is

mflfi014 D6=1 causes error.

I

m#6014 D7=1 causes error.

Check Method Solution

Check Method

Replace MB20.

Contact YASREP.

Solution

Replace PC20.

Contact YASREP.

any fault, it is displayed together with RO1l/

RAMnumber.

This is one of the major failures. After recording the alarm number, immediately contact

YASREP.

Trouble

#00 to #05 ROMin

failure

#30, #33 ROMerror MM-20 ERROR

#350 RAMerror PCURAMtiERROR

#36 ROMerror

I

IIM-20 ERROR

#ON:820

#30 :820

(#33)

$350820

MFI-20ERROR

#36 :820

Check Method

(n=O to5)

Solution

Replace ROM#00 to #05

mounted to MM20.

Replace ROM#30(#33)

mounted to MM20.

Failure of RAMmounted to

PC20

Replace PC20.

Replace ROM#36 mounted to

Mf120.

–26–

Page 33

Trouble

Check Method

Solution

#500 RAMerror

#40 error

#44, 45 error

#100 to#103 RAMfailure

#120 RAMfailure

#300 to #301 RAMfailure

#302 RAMfailure

#510 to #511, #520,

#521, #530 RAMfailure

RAMCHECKERROR

#0500 820

(#501)

PC-ROMUERROR

#40 :820

MB-20 ERROR

#44 :820

(i145)

RAMCHECKERROR

#XXX:820

RAMCHECKERROR

#XXX:820

Failure of RAMmounted to

MB20

Replace MB20.

Replace ROM#40 mounted to

PC20.

Replace ROM#44(#45)

mounted to MB20.

Replace MM20.

Replace MB20.

Replace PC20.

Replace PC20.

Replace MB20.

4.2.18 ALARM323 (ACGC2SYNCERROR)

Trouble

ACGC2CPU failure

m 116014D5=1causes error.

Check Method

–27–

Solution

Contact YASREP.

Page 34

4.3 TROUBLESHOOTINGWITHOUTALARMCODES

The following examples are instructions for

locating and correcting the troubles not indi-

4.3.1 POWERCANNOTBE SUPPLIED.

cated by alarm codes.

For further details of signal meanings expressed by the address~, refer to Section “Re-

tails of Signals” in Connection Manual.

Trouble

No power SUPP1

unit.

.——

Alarm LEDof CPS-ION

lights.

d to NC

Check Procedure

Ensure that SOURCELED(green) of DC

power SUPP1Y(CPS-1ON)inside CPUmodule

lights.

CPS-IONLEDDisplay

Signal

Naw

Pwer

Norma 1

Trouble

Display

supply

status

Pn+er on

status

v

+5

Trouble

+12 v

Trouble

-12 v

Trouble

+2.4 v

Trouble

External

trouble

Note:

LEDlights for external trouble (EXT) when CN13

connector batwen 4 and 7 short-circuits.

i LED

Display !

IWER ON Grsen

+5 v,

*12

+24v

Color

,

SOURCE ~ Green

Rad

v

Red

EXT Red

Func t ion &

Cause

Lights when AC

pouer is on, out

when owr is

Lights i+hen SOURCE

input above 170

VAC at NC!IXCN.

Lights at +5 V

over- vo 1 tage or

overcurrent.

Lights at +12 V

overvoltage or

–

12 V under-

vol tsge.

Lights at

over- vo 1 tage

overcurren t.

or

Lights with

external EXALtl

signal.

off.

+24 V

Solution

Check molded-case circuit

breaker or NCpanel and

also connector CN13of

CPS-1ON.

When trouble in Table on

the left is displayed by

LED, correct the trouble,

then, turn on power again.

If the trouble is not

corrected by this procedure,

trouble mey be in the power

unit. Contact your YASKAWA

representative(YASREP).

Power ON/OFFSwitch is

not set properly.

SW5

)

i

I0 =

10 I o ~ 12- POF(invalid/valid)

u

(Set at factory

Prior tO

shirment)

I

i 3+ ’14 ‘Cn’y cm)

Use panel (POF)

only

lo~3

~

SW5

7~09

10 o= 12

SW5Setting(for 9 ‘CRT)

1

Use external

device (EOF)

only

000 G

El

I

I

–28–

Use both

Set correctly shorting

plug SW5at left corner on

MB20PCB.

3

6

9

12

Page 35

4.3.2 INITIALDIAGNOSTICERRORDISPLAYATPOWERON

Trouble !

Error identified by

initial diagnostics at

power ON.

4.3.3 “CPUERROR”DISPLAY(Without Alarm Codes)

Trouble

“CPUERROR”only is

displayed on CRT

screen.

Both diagnostic items passed and

diagnostic item lead up to error are

displayed and NCunit stops.

I

CPUcannot function normally and this is

major failure. The main system shuts

off th6 servo power, but, depress the

emergency stop and power OFF buttons to

make check for proper AC input voltage

and ensure power is OFF.

Check Procedure

Check Procedure

I

Record the diagnostic item

lead up to NCunit stop,

turn on power again and

contact your YASKAWArepresentative of its results.

I

Removeany noise source

near the NCunit.

Turn on the main power

under emergency stop

condition.

YASKAWArepresentative

immediately if it is “CPU

ERROR”.

If normal, start operation

after ensuring correct

parameters, settings, offsets and programs.

Solution

Solution

Contact our

–29-

Page 36

4.3.4 CRTSCREENDOESNOTDISPLAY

CRTscreen may not display any data as a result

of trouble of CRTunit itself, display circuit

and/or connection cable.

If there is no display on the screen even after

the NCunit power is applied, check to ensure

4.3.5 HANDLEMODEOPERATIONFAULTY

that the wire is properly connected to the NC

operator’s station, connectors are not loose,

or fuse inside CRTunit is not blown(refer to

Par. 4.3.12, “ 9“ CRTSCREENIS DARK”).

Contact YASREP,if the trouble can not be lo-

cated even after the above procedure,

Trouble

Handle mode not selec-

tion,

——

Axis not selection.

Magnification not se-

lection.

Check Procedure

~#1300 D,

m#1302 D, (X-axis)

m#1302 D, (Z-axis)

Handle Magnification Setup

#1302 D,

MP3

0

0

0

0

1

#1302 Do

#1302 D7

MP2 MP1 cation

0

0

1 0

1 1

Either Oor 1

is acceptable.

Solution

Check wiring for Proper

mode.

Select the axis.

Check wiring.

llagnifi-

Check sequence.

0

1

xl

x 10

x 100”

Check wiring.

x 100”

x 100

No power to handle PG.

No pulse generated by

turning handle.

Check that +5 V is supplied on

terminal of handle PG.

Also check the signal wiring.

Hanual pulse monitor~#1282 DOto D7

Does this DGNchange by turning handle?

–30-

Correct wiring according

to Connecting Manual(TOE-

c843-9.22) .

Same as above

Page 37

Trouble

Check Procedure

Solution

Parameter not set correctly.

SW1of SP20 not set to

ENB.

m#6222

Max.

1: Magnification to be set with~

0: Magnification XIOO

SW1setup is shown below.

1 HPGpower is fixed to +5 V.

2 SW1on SP20 board is set as below by

speed at handling(Reference)

m#6009 D4

#6223 at handlex 100

specification of manual pulse

generator.

(Swl)

1

Em”

000

4

000

7

000

10

Simultaneous 1 axis manual

pulse generator

3

6

9

12

Set parameter according to

YASNACLX3Operator’s

Manual(TOE-C843-9.20)

Specification for simultaneous 1 axis manual pulse

generator. (Use this

terface.)

–31–

Page 38

4.3.6 MANUALJOG MODEOPERATIONFAULTY

Trouble

Jclg mode not selected

Axial direction not

specified.

Jcg override not enter

ed

_——

Check Procedure

mti1300 D,

+xmIt1302

IIz

–X~~#1302 D3

i-Z~#1302 D4

–z~#1302 D5

Feed override/Hanual JOG feed rate Selection

=

r !6238 Setting speed_

r #6239 Setting speed

110; 0101 80% lPar.ame~r__~241 Setting speed

araaeter t6240

100’0

-+ t--

.1 0-

~o..

.~

l_olo

t

1 ,–03

;-~$+-{--

‘~ 1-::

-f~, ~~

-:”–:7-

-fi+- 1#+-

1

kote: 1: close O: open

g

‘--

0

0 1 170%

_~ j. _

1 1 190 ~

o 0 203%

-;- -;-

-t-

.1-+.1

7—

0

.O+O. Para~ter ~6261 Setting sgeed

,,

1

160 %_

@%__ Para~ter #6251 SettingspSed

araweter

Parawter t6249 %ttings~ed

Parameter #6250 Setting speed

Parameter 16252 %tting speed

Paraweter t6253_%tting speed

Parameter #6254_%tt i ng_s~_ed _

Parawter t6255 Setting sp~d

Pa:?~_tg~

Parameter~Setting speed..

Para~ter t6258 Setting speed

o% Paramter $6259 Setting :_@ed

~- ‘--”-”-”

Parawter

Para.~t::.#6&2.Setting sq?ed_

~a~~m~er *6263 Set t i ng_spwd

, Paramter

Settings&ed

~42 Setting sy@

t6243SettinS_>@

t6244Setting sqd

r

r t6245 .%-

r

t6246Settingj.~d.

r

ffi247 Setting speed

t6248Setting speed

$62EfjSetti “g speed

t62?XlSettig~_:peed

#6264Setting speed

S&_@

Solution

Select the mode.

Check wiring.

Select axial directicm.

Check wiring.

Set jog

value o

Check w

override to move

her

han O.

re.

Parameter not set correctly.

Not at machine lock.

Ensure thatmlt6233 to #6264 are set

according to Table 4.9.

m#1303 D,

–32–

Set parameter

Check the switch to ensure

thatm#6000Dl is at 1.

Page 39

4.3.7 MANUALRAPIDMODEOPERATIONFAULTY

Trouble

Rapid mode not selected.

Axial direction not

specified.

Rapid override not

entered.

Check Procedure

m#1300 DO

+X~#1302 Dz

–X~#1302 DS

+Zm#1302 D4

–Zm#1302 D5

Input status and Rapid feedrate

MNSlzol

Inputstatus

Rapidfeedrate

ROV2Rovl Xaxis Zaxis

; ; [SF+ r!F+

0,’ ,E!ng lx+ [=n’1“+

0 [01 F. (*6231 Setting speed)

Notes: 1) 1: close O: open

2) The following table is applied for rapid

override at 6 step specification.

(6 step specification: Parameter u6018 Dz=l)

Input status

ROV4 ROV2 ROV1

1

1

o

0 1 100% 100%

0 0

1

o 1 A

o 0 1

o 0

1: close O: open

0 FO

Rapid feedrate

X axis Z axis

50% 50%___

25%

10%

5%

(!6231 Setting speed) --

25% _

lo%__

L—+

Solution

Select the mode.

Check wiring.

Select axial direction.

Check wiring.

Select rapid override and

set the parameter.

Parameter not set correctly.

Not at machine lock.

Check following parameters for correct

setting as shown in the above table.

#6280 X-axis rapid feedrate

#6281 Z-axis rapid feedrate

#6231 Rate at FO specification

~#1303 DI

–33–

Check the switch.

iTliiJt6000D, notatl.

Page 40

4.3,8 MANUALZERORETURNOPERATIONFAULTY

Trouble

Modenot set to zero

return.

Rapid or jog mode not

selected.

-—_

Axial direction not

specified.

Deceleration LS not in

order of 1 to O to 1?

Parameter not set correctly?

Check Procedure

RAPID~#1300 Do

JOG ~#1300 D,

+X~#1302 Dz

–X~#1302 Ds

+Z~#1302 D4

–Zm#1302 Ds

X-axis m#1306 D.4

Z-axis~ #1306 D5

Manual feed

(#6233 to #6264)

Speed Rapid feed

(I)6 80, //6281)

t

k-n

Solution

Select the mode.

Check wiring.

Select the rapid or jog

mode at the time of ,zero

return on sequence.

Select axial direction.

Check wiring.

Check the limit switch.

Check wiring.

Set parameter correctly,

Approach speed 1

(#6310, //6311)

Approach speed 2

(//6316. //6317)

1 Traverse distance

I

L J,

Jlnmuui

.--Zero point pulse

Reference point return

control 1/0 signals

Approach speed 1

X-axis m#6310

Z-axism #6311

Approach speed 2

X-axis m #6316

Z-axis m#6317

Final traverse distance

X-axismfi6034

Z-axis ~#6305

Decel LS signal

(*Dcx, *DCZ)

–34–

Page 41

Trouble

Check Procedure

Solution

Motor run slips one

turn.

Position slips at

random.

4.3.9 CYCLESTARTFAILURE

Trouble

No start signal.

—

Feed hold signal is

fed.

Move from zero point to deceleration LS

direction, read the point where~

#1306 Dd(X-axis) and DS (Z-axis) turn to

O and ensure the positional relation

between zero point pulse position and

deceleration LS position.

● Ensure that coupling and dog are not

loose.

c Check to ensure that the wire is

shielded.

Check Procedure

:heck ifm#1304 Do becomes 1.

;heck ifw#1304 DI is set to 1 (norms

if it is set to 1).

Locate the point where

deceleration LS turns to 1

from O to the medium of

zero point pulses.

Solution

!elease the interlock with

‘eference to instruction

Ianual of machine manufacturer. Check the sequence

md also ensure to be cor‘ectly wired.

;heck that feed hold but;on is not depressed and

;hat wiring is not disconnected. If there is any

[ault, correct it.

Mode is erroneous.

Reset signal is fed.

System number switch

set erroneously.

Monitor on PROGscreen if the mode is

set to MEH,TAPEand MDI.

Check if~#1202 D) is set to 1 (normt

if it is set to O).

Normal ifm#6219 is at O or 4,

Normal is the system number switch on

MB20is set toO or 4.

–35–

Check the mode switch.

Refer to #1300 in ~

table.

Check that external reset

input of #1305 DZ is set

to o.

Correct setting.

Page 42

4.3.10 OPERATIONIS NOTAVAILABLEWITIIGO1, G02 or 03.

Trouble

Spindle stops at feed

per revolution.

Spindle revolution is

checked by feed per

minute.

Cutting feed override

is set to O%.

Manual jog feedrate is

nt;t set correctly at

dry run status.

Check Procedure

;heck on~ylscreen if the mode is S(

to G!19.

;heck ifmti6006 Dq is at 1 (spinal

revolution is checked if it is at 1)

;AGR#1306 117

Insure if~#1301 DOto Dq is set

:orrectlyo

~~edoverride/~anua1JOGfeedrate Selection

Solution

~urn the spindle. Make

;ure of revolution by~

;pindle revolution display.

——

(Spindle PG monitor~l~

41287

D4, D5)

hrn the spindle.

[f it is at dry run, make

spindle revolution nclt be

:hecked by setting #fiO06

)4=0,

I’urn the override switch.

;orrect wiring if discon~ected.

;heck parameter setting.

Interlock signal is

entered.

——

Servo system is erroneously set.

Check if~]i!1305 Ds is at 1 (norms

it is O).

Check if manual spindle feed is work

(check its function by manual mode).

–36-

Release interlock with

reference to instruction.

Manual of machine manufac-

turer. Refer to the item

for manual feed.

Page 43

4.3.11 SPINDLEDOESNOTROTATE

Trouble

Program failure

● No Scommand.

● No start flcode(e.g.

M03, M04).

No start signal.

Spindle speed command

is not given.

S2 digit specification

S4 digit specification

A.

S4 digit specification

B.

Check Procedure

Check on PROGscreen and~screen.

Check the output signal on~screen

(numbers in *11OO).

Check instruction voltage with spindle

unit.

Check #1216, #1217, #1323 and #1324 on

D1211Jscreen.

Solution

Modify the program.

Release the interlock with

reference to instruction

manual of machine manufac-

turer.

Correct wiring and sequence

properly to apply instruc-

tion voltage to the spindle

unit.

Spindle drive is at

alarm.

Combination of SSTP,

GRSand GSCinputs is

erroneous.

O is enterd to parame-

ters #6270 and #6275.

Check the alarm of spindle drive unit.

Ensure DGN#1307 by the following table.

SSTP, GRS&GSC Inputs And S4 Digit

CommandAnalogue Voltage

mm #1307

D. I D, ] D6

GRS \ GSC S4 Digit Couand

SsTP

Input Input

Input

o 0

0

o 1

o

1

1

1

1

Note: 0: contsct open

1: contact close

0

1

0

0

1

1

0“ Ov

0

1

0

0

1

1

1

Analog Voltage by

The voltage to wet with

spinalIe WA to NCprogram

This csubination causes c~nd

voltage at O V and the spindle

does not run.

The spindle does not run if

O is set.

Ov

. Be careful for SSTP to cause reverse

input if 1 is set to parameter SSTPAB

(#16020D,) .

Remove the cause of alarm

for spindle drive unit.

It may be caused by failure

of limit switch or sequencer. Adjust input signal

with reference to instruc-

tion manual of machine

manufacturer.

Also refer to item 8.2

SpindleS commandInput...

in Connecting Manual(TOE-

c843-9. 22)

Set the correct value to

parameters it6270 and

f16275.

–37–

Page 44

4.3.

SPINDLEDOESNOTROTATE(Cont’ d)

Cause of Trouble

Parameters for spindle

function are erroneous

#1307 Do

ti1307 D,

#1307 I),

#1307 D3

GR1

GR2

GR3

GR4

Check Procedure

?otation command

for spindle revolution

-—-— -—-— -—

.(2\

—

L:6Z71

~j~)

(MACCR1) (MACGR21

L

— z 6276

[MICGR 1 )

L $6272

E= L’::}&”’

~ ,s~,

Z

(MICGR 2 )

6277

II

,,

(MACCR3)

(MICGR 3 )

Solution

Correct setting.

–38-

Page 45

4.3.12 9“ CRTSCREENIS DARK.

Cause of Trouble

Power voltage is too

low.

Escutcheon is dirty.

Check Procedure

Check it with CN3on SP20 board at rear

side of 9* CRTunit.

—

Check visually if the surface of

escutcheon and section between escutcheon

and CRTare dirty.

Solution

.

If the voltage drops at

power cable, replace the

cable.

●

If CPS-1ONoutput voltage

is also low, it may be

caused by failure of CPS-

10N.

Call our service personnel if it is so.

tlean up CRTdisplay and

:scutcheon.

Brightness is not proproperly adjusted.

Hardware failure

/

coN”rRAsT

V-HOI.D

HEiGHT

(Trouble other than above)

‘FOCLIS

Do not perform setup

change of CRTas a

[

rule.

10, perform adjustment

!ith VR1(BRIGIIT)on SP20

}oard.

/eplace CRTunit or SP20

]oard.

~all our YASREP.

1

–39–

Page 46

4.3.13 EDIT DOESNOTFUNCTION

Trouble

Failure of input sigr

!lode input) is n[

cc,rrect.

Edit lock is input.

Parameter setting

Connection & materia

failure

Check Procedure

~#1300 D, should be 1 and all #1300

Do to Db should beO.

#1303 D~ should he O and SET

116000DTshould be O.

Operator tries to edit number O that

cannot edit data.

08000 to 08999m

#6002 Dd: Edit interlock

#6004 Dz: Edit, display and output

interlock

09000 to 090000m

#6002 DFj:Edit interlock

#6021 D~: Edit, display and output

interlock

Alarm 010 lights if operator tries to

edit.

The program characters registered turn

to other characters.

Key entry is not made correctly.

Key entry turns to other characters.

Solution

Check mode input rotary

switch, etc.

Release edit lock input.

Release

ting.

Release

ting and

Failure of CMOSmemory

Replace MB20.

Replace MM21in case of

mass storage.

Failure of keyboard

Failure of SP20

Plug-in failure of S1’20

flat cable

nterlock for set-

nterlock for setparameter.

Ol,her failures

The trouble caused by exceeding memory

capacity or by exceeding number of

registered programs.

Check the number of characters left and

number of registered programs by alarm

directory screen.

–40–

Erase the program with

Oxxxxplilg

Page 47

4.3.14 RS232CDOESNOTFUNCTIONWELL

Trouble

Cable failure

Parameters

Check Procedure

Refer to connection examples of

connecting Manual.

The cable is too long.

Check if lstand 2nd RS232CSand 1/0

settings can make proper selection.

Ensure the value of m#6003.

Check if baud rate, stop bit and

control codes are properly set.

]s t RS232C

2nd RS232C

1st RS232C

2nd RS232C

input 116026DO to Ds

input #i6027 DOto Ds

output #6028 Do to D5

output #6029 Do to D5

#6021 Do

Solution

Readjust cable wiring.

Limitable length to within

15nl.

DI u,

Status

o 0 It does not

o operate

Input ‘o

o

1 Ist RS-232C

1 0 2nd RS-232C

1 1 Unsettable

DS D4 Status

o 0 lt does not

0 opera te

Output o

o

1 1st RS-232C

1 0 2nd RS-232C

1 1 Unsettable

Regard M02, M30and M99as

end of program.

Noise

tt6021 D,

#6021

D,

#6021 D5

it6022 Dz

#6022 D3

If TNerror, framing error and/or

overrun error occur, connecting

equipment may require noise solution.

Regard NXXXXas OXXXX.

Ensure DR(data set’ ready).

Turn ON/OFFRS signal (request

for sending) by%.

—

Disregard or not disregard

1S0 parity at the time of ~

operation.

Output or not output ISO

parity at the timeofm

operation.

Install a line filter in AC

input line of connecting

equipment.

–41–

Page 48

4.3.15 OPERATIONIS NOTAVAILABLEWITHG32, G76 ORG92

—

Cause of Trouble

Check Method

Solution

Pulse of spindle encoder does not return.

Unevenness of starting

point pulse(C phase)

Slip of chuck or spindle

Servo response

Staggering of spindle

revolution

—

Failure of thread

cutting bias or acceleration/deceleration

setting

;heck POSS on POS screen(failure of A

~nd/or B phase).

;an be observed by~#1287 if at low

speed revolution such as manual

rota+tion.

0 phase is faulty if GOl(mm/rev) is

proper and G32 is faulty.

Occurs when thread is shifted.

Occurs when thread pitch is shifted,

Ensure the servo response with TG-M,

Check if POS S staggers on the POS

screen.

m #6306 X-axis acceleration/dece lera-

tion at thread cutting

#6307 Z-axis acceleration/decelera-

tion at thread cutting

~ailure of encoder, loosen

:able, timing belt or con~ector, or PG interface

railure of MB20.

——

ieplace the spindle PG.

:heck wiring.

;heck the function of

nachine.

\djust KP(L-GAIN).

~ailure of spindle clrive

mit, spindle drive unit,

spindle motor, DAoutput

of MB20, or noise

Adjust parameters.

Spindle speed X F

(pitch) exceeds maximu

rating of machine.

#6308 X-axis bias at thread cutting

X6309 Z-axis bias at thread cutting

Check the program.

–42–

Reduce the commandfor

spindle speed.

Page 49

4.3.16 SKIP FUNCTION(G31) OPERATIONFAILURE

Trouble

Input failure of skip

signal

Parameters

Others

Check Procedure

Check~ #1280 DO.

● Chattering must be eliminated.

GSignal should exceed 5 m Sec.

m#6232(G31F) value is not set.

#6031 Dd setting

+24V

Ov

Case O

J

‘1’

Case 1

#6032 setting

D, only should beat 1, but all Do, Dz

and Dx should be at O.

Optional

Solution

● Replace LS and/or proxim-

ity switch.

● Check noise level.

Change wiring route.

Correct parameter settings.

Contact machine manufac-

turer.

–43–

Page 50

4.3,17 TAPEMODEDOESNOTFUNCTION

Trouble

Failure of input signa

Mcldeinput(T) is not

correct.

TAPEmode does not

s tart.

..— —

Parameters failures

such as baud rate, sto

bit and control code

Tape reader setting

failure

Check Procedure

mM1300D.i should bel, but

#1300 Do to D, and DS to D?

should be O.

TAPEshould appear on PRGscreen,

Refer to Par. 4.3.9

Refer to Par. 4.3.14, “RS232CDoes Not

Function Well”.

Tape Reader Setting

DIP Wtch (OS)

For

For

Tm.nsa13-

Pm

SFe=d :;: ,:_

Input

Cuitml

SeIw-

J I I I

For

sOlf Cnezkiq (cAar/s) Ewd rata Checking

I

Read Tram.is-

- sion

NJlu

sOll-

Solution

Check setting status of

tape reader Model 2801B-2

according to the table at

lrwt

COstrol

the left column and set it

correctly again.

C13nnection failure

Failure of tape reader

Others

* standard setting

Dip switch arrangement) -- standard setting

0

—

.

Check the wiring status of RS232C

~ :T:.’2C!::1

UFF‘L-T–

[[ 1

ON

_l#L :. :

cable according to the Connecting

Manual.

.

Check for looseness of connector.

.

Tape does not work even by depressing

tape feed switch.

.