Page 1

YASNAC LX3

CNC SYSTEM FOR TURNING APPLICATIONS

UPGRADING FUNCTION

Before initial operation read these instructions thoroughly, and retain for future reference.

YASUAWA

Page 2

Page 3

Specification upgrading of several functions is possible witn YASNAC

LX3 if it has a “Compact Interactive Function. ” (optional).

This manual describes these specification upgrading items and

operation.

The reader is requested to refer to the YASNAC LX3 Operator’s

Instruction Manual (TOE-C843-9.20) regarding those items that

are not covered here.

The data No. of the operator’s manual referred

to in this manual is ‘TOE-C843-9.20.

CONTENTS

1. STANDARD FUNCTION UPGRADING / 2

1.1 UPGRADING OF MULTIPLE CANNED

CYCLE FUNCTION / 2

1,2 UPGRADING AND CHANGE IN 9“

SCREEN DISPLAY ITEM / 6

1.3 UPGRADING 9“ EDIT OPERATION / 8

2. NEW TOOL SETTER FUNCTION / 9

2.1 GENERAL / 9

2.2 WRITING TOOL COORDINATE MEMORY / 9

2.3 WRITING Z-AXIS WORK COORDINATE

SYSTEM SHIFT AMOUNT / 11

2.4 OFFSET DISPLAY / 73

3. NEW COORDINATE SYSTEM

SETTING FUNCTION / 15

3.1 GENERAL / 15

3.2 DESCRIPTION FUNCTIONS / 15

3.3 PRECAUTIONS IN USING CONVENTIONAL

G 50 T*”* FUNCTION / 76

4. FS AUTO EDIT FUNCTION / 17

4.1 GENERAL / 77

4.2 INPUT AND OUTPUT / 77

4.3 DESCRIPTIONS OF FUNCTIONS / 78

4.4 PRECAUTIONS / 21

5. AUTO NOSE R FUNCTION / 22

5.1 GENERAL / 22

5.2 CONDITIONS TO MAKE AUTO NOSE

R COMPENSATION FUNCTION EFFECTIVE / 22

5.3 COMPENSATION CALCULATIONS OF AUTO

NOSE R COMPENSATION APPROACH AND

RETRACT / 23

5.4 CANCEL FUNCTION (G40, GO1) / 27

5.5 PRECAUTIONS / 27

6. Z-AXIS TOOL CHUCK BARRIER

FUNCTION / 27

6.1 GENERAL / 27

6.2 OPERATION / 27

6.3 PRECAUTIONS / 28

7. OTHER ADDITIONAL FUNCTIONS / 29

7.1 HIGH-FREQUENCY SKIP SIGNAL APPLIED FOR

MACHINE SETTER / 29

7.2 WORK SHIFT FUNCTION ADDED (G54) / 29

7.3 ABSOLUTE COORDINATE SWITCHING ADDED

WHEN MACHINE LOCK EFFECTIVE IS

SWITCHED TO INEFFECTIVE / 29

7.4 ADDITIONAL PARAMETER SWITCHING TO

AUTO NOSE R COMPENSATION AND COMMAND

T (INCLUDING G 50 T) FUNCTION / 30

7.5 HANDLE INTERPOLATION FUNCTION / 30

8. LIST OF NC PARAMETERS FOR

COMPACT INTERACTIVE FUNCTION / 31

-1-

Page 4

1. STANDARD

1.1 UPGRADING

FUNCTION UPGRADING

C)F

MULTIPLE CANNED CYCLE FUNCTION

1.1.1

Nose R compensation can be executsd with the G 70 to G 73 cycles even while

the finish profile program is being performed.

By this, G41 and G42 are added to the G codes that can be designated

by the blocks other than blocks Ns f and Nnf during finish profile program

execution.

During the rough finish and finish cycles, nose R compensation will become

effective during the finish cycle by the blocks instructed by G41 to G42.

Always instruct with the GOO or GO 1 moving command when instructing

G41/G42 to the block to start the finish profile program.

Commands with single-blocks are prohibited.

Upgrading (d) and (e) of par. 2.8.25.2, “Rules in programming” in the

YASNAC! LX3 Operator’s Instruction Manual.

.

Upgrading in (6) of par. 2.8.25.4,

tor’s Instruction Manual.

.

Upgrading in (2) of par. 2.8.25.5,

tor’s

Instruction Manual.

“NOTES” in the YASNAC LX3 Opera-

“NOTES” in the YASNAC LX3 Opera-

1.1.2

The T

during

gram become effective during the finish cycle (G70) and is disregarded during rough cutting of the external fclrm.

“ Upgrading in

YASNAC LX3 Operator’s Instruction Manual.

“ Upgrading in (1) of par. 2.8.25.4, “NOTES” in the YASNAC LX3 Operator’s

Instruction Manual.

1.1.3

A command with different start and end points in a finish profile program

can be executed during the G70 to G72 cycles.

- Upgrading in (a) of par. 2.8.25.2, “ Rules in programming “ in the

YASNAC LX3 Operator’s Instruction Manual (Condition of BA being parallel to Axis Z is lost.)

s Upgrading in par. 2.8.25.3, “Rules and cautions in programming finish

shape”

BA being parallel to Axis Z is lost.)

code command can be executed during the G70 to G73 cycles even

the finish profile program.

By thj.s, the codes F, S and T instructed during the finish profile pro-

(c) of par. 2.8.25.2,

in the YASNAC LX3 Operator’s Instruction Manual (Condition of

—

“ Rules in programming” in the

1.1.4

Execution using finish allowances lJ and W as stock removal allowances is

possible during the cycles G70 to G73 if both stock removal allowances I and

–2-

Page 5

K are omitted. Upgrading is possible with the related parameter # 6009 D1

= 1.

1.1.5

The recessing fixed cycle

(number of cutting-off stages) and Command B (cutting-off bite blade width)

to the functions G74 (end face cutting-off cycle) and G75 (outside diameter

cutting-off cycle) .

Given the following command,

(1)

- Upgrading in (1)

G 74X (U)

of par. 2.8.25.6 of the YASNAC LX3 Operator’s

.Z(W) _l_K_D_A_B _ F(E) ._ (RI);

—

I

can be executed by adding the Command A

G74 executes the cycle as shown

f ~ -

1’

~ –.—. — AMOUNT OF RETRACT ,QT

‘LEEDCOMMAND

BLADEWIDTH

(WITHOUTSIGNS)

OF CUTTING-OFF

NO,

STAGES(WITHOUT

CUT BOTTOM(wlTHOuT SIGNS)

CUTTING-OFFAMOUNT IN

z-Axis DIRECTION(wlTHOuT SIGNS)

MOVE AMOUNT

DIRECTION(WITHOUTSIGNS)

IN X-AXIS

SIGNS)

in Fig. 1.

Manual.

L

+x

R: RAPID FEED

F: F CODE FEED

d: PULL BACK AMOUNT (SETTING # 6208)

—— Z-AXISCOORDINATE

‘--— X-AXISCOORDINATEAT

NO. OF STAGES

POINT c (WITH SlGNS)

POINTB (WITH SIGNS)

AT

START POINT

WIDTH

-+2

Fig. 1 G7’4 Cycle Execution

-3-

Page 6

1.1.5 (Cent’d)

(2) Given the following command,

“ Upgrading in (1) of par.

75x(u) __ z(w)

(3

—

2.8.25.7 in the YASNAC LX3 Operator’s

_l_K__D_A_B– F(E) – (R l);

—

——– X-AXIS COORDINATE AT

(175 executes the cycle as shown

TTT

~-

~--—-—– NO. OF CUTTING-OFF

—— MOVE AMOUNT IN Z-AXIS

— CUTTING-OFF AMOUNT IN

--—

Z-AXIS COORDINATE AT

POINT B (wITH SIGNS)

POINT c (wITH SIGNS)

DIRECTION (WITHOUT SIGNS)

x-Axis DIRECTION (WITHOUT SIGNS)

,STAGES (WITHOUT SIGNS)

AMOUNT OF RETRACT AT

CUT BOTTOM (WITHOUT SIGNS)

FEED COMMAND

BLADE WIDTH

[wlTHOuT siGNs)

in Fig.2

Manual.

B

‘-T

n~

a

L

z

R: RAPID FEED

F: F CODE FEED

d: PULL BACK A!AOUNT (SETFING $ 6209)

R

F

R

R

K

w--l

BLAADE W ID,TH

A

d

START

I

POINT

U/2 I NO. OF STAGES

I

I

x

-+Z

Fig. 2 G75 Cycle Execution

–4–

Page 7

1.1.6 Upgrading of G76 Thread Cutting Cycle Function

The final nth cycle specified by L is executed by adding command L to

(1)

original G76 command.

G76X (U)_ Z (W) _

LO : Executes the

L1 : Executes the

final cycle.

Ln : Executes the

final cycle.

When n is a

cycles (n2N) , a

Zig zag cutting

(2)

adding command

G76X (U)– Z (W) -

The following plunges are obtained by command P :

Without P :

P,

P,

P3, P4, P5 ““”” :

I_ K_ D_F(E) _A_L ;

command of the final cycle.

commands in one cycle before the final cycle and the

commands from nth cycle before the final cycle to the

larger number than the number (N) of normal cutting

normal cutting cycle is executed.

with constant cutting

P to original G76 command.

I–K–D– F(E)– A_ P_;

Constant normal cutting amount, one-blade cutting

Constant normal cutting amount, one-blade cutting

Constant normal cutting amount,

Constant normal cutting amount, one-blade cutting

amount can be performed by

zig zag cutting

BLADE TIP

\\ \ iw-—

‘:!5--‘TH5iiiid

B9

Fig. 3 Constant Cutting Amount, Zig Zag Cutting

-5-

-3RD ~111111

Page 8

1.1.7 Dwell Added to G74 and G75 C:ycles

Dwell can be executed on the hole bottom by setting parameter ( # 6214) to

G74 or G75. When command A is provided (with number of’ stages) , dwell

is executed on the hole bottom of the last step.

#6214 O – – 65535 l=lms

1.1.8

Precautions in Upgrading of Multiple Canned Cycle Function

The following conditions are added to pars. 1.1.1, 1.1.2 and 1.1.3.

(1)

Upgrading becomes effective with the related parameter # 6011 D1 ==1.

(a)

This upgrading increases the maximum memory capacity of the finish

(b)

profile programs to 39 blocks.

Change in (2) of par.2.8.25.l in the YASNAC LX3 Operator’s Manual.

(2)

Precautions to G74/G75 upgrading in par.1.5.

If neither Command A nor Corr.mand B is given, the execution will be

(a)

the same as in previous G74/G’75.

If Command B only is given, blade width shifting is executed at the

(b)

beginnj.ng and end of G74/G75 as mentioned in detail below:

(i) The first motion is shifting by the blade width in the X-axis co:m-

ma.nd direction with G74 and in the Z-axis command direction with

G75 from the position of the block immediately before G74/G75.

(ii) The last motion is returning to the position of the block immedi-

ately before G74/G75 after being shifted by the blade width

amount.

If Command A only is given, o:dy retract is executed without executing

(c)

blade width shifting.

If Command A is given, the pull back amount with G74 and G75 will be

(d)

the set amount of # 6208 and 6209.

Pecking is not performed if this is

“o.”

Addition to par. 2.8.25.6,

“

Instruction Manual

Alarm 96 with the groove width < B (blade width) command.

(e)

“NOTES” in the YASN.AC LX3 Operator’s

UPGRADING AND CHANGE IN 9“ SCREEN DISPLAY ITEM

1.2

Basically, this function is upgrading of and changes in the 9” character

CRT. The same functions are obtained with the compact interactive function

also.

1.2.1 Upgrading

The program directory menu was displayed in the alarm function.

(1)

By upgrading, the menu is displayed in the program function.

Therefore, the alarm function does not show a program directory

By depressing ~ in the program function regardless of the

the program directory and program menu are shown cyclically.

m

-6-

menu.

mode,

Page 9

The program directory menu is displayed when the operation returns to the

program

another function.

The page key in the program directory menu is operated by the same

method as before.

(2) The external present value display can be changed to “O” by the opera-

function after changing from the program directory menu to

tion in the all-position menu

display can be changed to

all-position menu is displayed.

Change the value of the external current value display X-

(a) ❑ t~ axis to ()

(b) ❑ ❑

II ~~~II

(c)~\(=]”-@:

The values other than the external current values do not change.

Similar operation is possible also with the external current value menu.

:

: Change the value of the external current value display Z-

axis to “O.”

Change the values of the external current value display

X and Z axes to “O.”

~p] ~ .

“O” by the following key operation when the

The external present value

1.2.2 Changes

“R” was displayed after No.51

(1)

However, this has been deleted.

The first display when power

(2)

However,

played in the all-position display has not changed.

There were independent position increment displays. However, these dis-

(3)

plays are now eliminated.

now the first display

of the offset display.

was turned on was an alarm display.

is the all-position display. The data dis-

The displays change cyclically in the following sequence if the page

key is depressed in the position function mode:

1. All-position display

2. Program restart information display

3. Display for remaining numbers of pulses of stored stroke limit

4. Spindle PG pulse number display

5. Servo position deviation display

6. Command pulse integration register display

7. External current value display

8. Current value display

By depressing OPS

(4)

cyclically:

1. All-position display

2. Spindle PG pulse number display

3. External current value display

4. Current value display

function key the following four menus are displayed

•1

-7-

Page 10

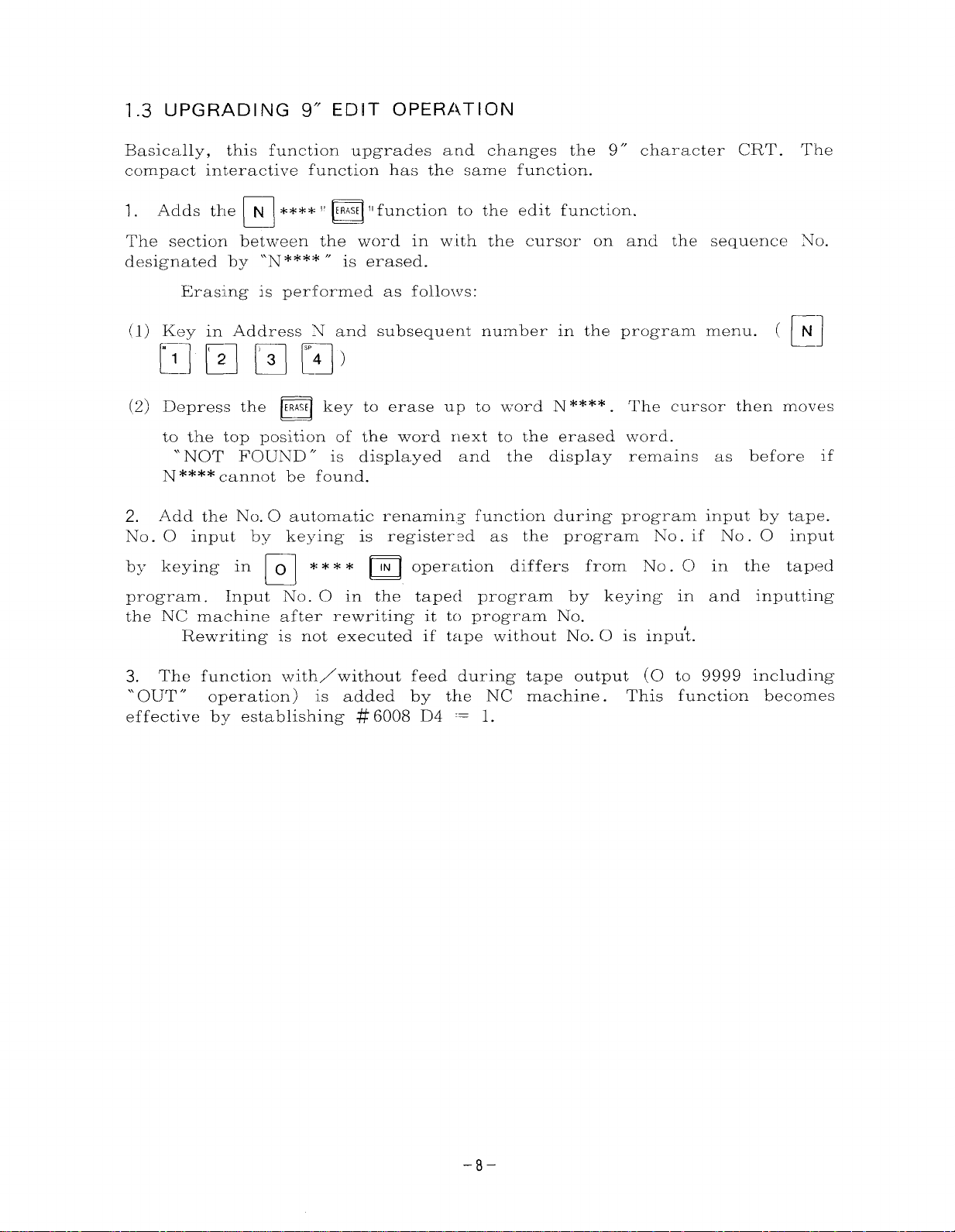

1.3 UPGRADING 9“ EDIT OPERATION

Basically, this function upgrades and changes the 9” character CRT. The

compact interactive function has the same function.

1.

Adds the ~****1~

The section between the word in with the cursor on and the sequence No.

designated by “N**** “ is erased.

Erasing is performed as follo~vs:

(1) Key in Address N and subsequent number in the program menu.

El El

(2) Depress the

to the top position of the word next to the erased word.

“ NOT FOUND “

N **** cannot be found.

2. Add the No. O automatic renamin~ function during program input by tape.

No. O input by keying is registered as the program No. if No. O input

by keying in 0

❑ rg)

ERASE key to erase up to word N****. The cursor then moves

❑

❑

program. Input .No. O in the taped program by keying in and inputting

the NC machine after rewriting it to program No.

Rewriting is not executed if tape without No. O is inpu’t.

ERASE II function to the edit function.

is displayed and the display remains

**** lN

operation differs from No . C) in the taped

n

( @

as before if

3. The function with/without feed during tape output (O to 9999 including

Ourr “ operation) is added by the NC machine.

“

effective by establishing # 6008 D4 = 1.

This function becomes

-8-

Page 11

2. NEW TOOL SETTER FUNCTION

2.1 GENERAL

Offset amounts and work coordinate system shift amounts can be written

automatically by manual operation even if the machine is not equipped with

a touch sensor.

This function simplifies setup during tool change.

This function differs from the previous tool setter function with a touch

sensor in tool coordinate memory value and in work coordinate shift amount.

The previous tool coordinate memory data was the differential distance

value between the touch sensor and the tip of the selected tool. This has

been changed to the differential distance value between the workpiece end

face and the tip of the tool.

been changed the shift amount from the projected home position to that from

the workpiece end face.

However,

function is called the new tool setter function.

the approach to the coordinate system does not change. This

2.2 WRITING TOOL COORDINATE MEMORY

Regardless of whether or not a measuring tool for a setter in the machine

exists, the tool coordinate memory amount can be written by manual operation as follows.

The tool coordinate memory amounts written in this case will be the

differential distance value between the workpiece end face and the tip position of the applicable tool.

The work coordinate system shift amount has

2.2.1 Writing Procedures

Home position return is executed by manual operation.

(1)

Mount the workpiece.

(2)

Set the tool coordinate memory value writing mode setting (6001 D6) to

(3)

\.

by this setting.

The display automatically changes to the ~~~

SHIFT) display as shown in Fig.

Select the machining tool.

(4)

The tool coordinate memory matching the tool post No. (tool post No.

input in # 1317) selected at this time is automatically selected.

tool coordinate memory No. is automatically selected, memory No. selection by the cursor or by the page key is prohibited.

cursor is moved to the tool coordinate memory No. by operating

cursor key or page key.

Make one cut of the workpiece skin.

(5)

( “PST 1” key ON in compact interaction). The write mode is set

1. “

~ function OFFSET (TOOL-

3 and the ~~s lamp blinks.

This function is effective only if parameter # 6020 D3 = 1. If the

If the tool coordinate memory No.

~

n

is not selected automatically,

the

the

–9–

Page 12

2.2.1 Writing Procedures (Cent’d)

Have the Z-axis only retract a:~d stop the spindle, keeping the X-axis

(6)

as it is.

Measure the workpiece diameter.

(7)

If the above setting is not turned on,

(8)

picture TD** Of the oFs

By inputiing the NIXnworkpiece diameter and WR

(9)

memory

(Tool coordinate memory

(10) Make one cut of the workpiece end face.

(11) Have the X-axis only retract and stop the spindle, keeping the Z-axis

as it is.

(12) Input MZ 0 and WR to automatically write in the tool coordinate

memory

(Tool coordinate memory “Z”

(13) Operate (4) to (12) for all tocls, both for X and Z axes.

(14) Set the tool coordinate memor~r value write mode setting (# 6001 D6) to

The write mode is cancelled a~d the o~s lamp stops blinking.

o

“X” is automatically written by the following calculation:

❑ n ❑

“Z” by the following calculation.

“METER 1” key OFF in compact interaction.)

“o” .

(

r7

u

a

function manually.

“X” ) = (workpiece diameter)

I = – (Position machine “Z” value)

select the tool coordinate memory

, the tool coordinate

(Position machine “X” value)

~

a

Precaution :

Tool coordinate memory value write

position return is not performed even once after turning on power.

mode setting is not effective if home

-1o-

Page 13

2.3 WRITING Z-AXIS WORK COORDINATE SYSTEM SHIFT AMOUNT

2.3.1 Writing Procedures

Home position return is executed by manual operation.

(1)

Mount the workpiece.

(2)

Set work coordinate system shift value writing mode setting (# 6001 D5)

(3)

to “l. ”

the write mode is set up.

At this time, OFFSET (WORK-SHIFT) display of the ~~~ function auto-

matically changes to TOO and the ~ function key lamp blinks.

( “PST 2“ : key ON in compact interaction. ) After this setting,

~

n

>

OFFSET(WORK-SHIFT)

~

~

02000 Noooo

d

EDIT

mmmmr==m=d

220.XOO0 20.ZOO0

I

Fig. 4 Work Coordinate System Shift

Display (Compact Interactive Function)

Make one cut of the workpiece end face.

(4)

Have the X-axis only retract, keeping the axis Z as it is.

(5)

Measure the workpiece cutting allowance.

(6)

Input

(7)

ing calculation is automatically written in the work coordinate system

shift memory “Z.”

input in # 1317.

❑ m •1

cutting allowance and WR . The result of the follow-

The tool offset memory matches the tool post No.

(Work coordinate system shift memory “Z” )

= (Cutting allowance) – (Tool coordinate memory “Z” value)

– (Position machine “Z” value)

Changing Z-axis work coordinate system shift amount.

(8)

If further shifting of the program is desired (e.g. a cutting allowance

(a)

from the workpiece end face) ,

can be rewritten for both the X and Z axes by MDI operation.

the work coordinate system shift memory

-11-

Page 14

2.3.1 Writing Procedures (Cent’d)

Calculate the shift amount, depl-ess the

value to add the value keyed in to the value presently displayed.

The code for addition is by #6018 D6.

# 6018 D 6 =

# 6018 D 6 = 1 : Workpiece shift amount – cutting allowance amount

The procedure for rewriting the work coordinate system shift memory

“X” value by

# 6018 D 6 = O : Workpiece shift amount

# 6018 D 6 = 1 : Workpiece shift amount

Normally, the ~ and numeral keys are

(b)

changes such as cutting allowance values

DE]

and

Set the writing mode setting (# 6001 D5)

(9)

shift memory value to “O.” ( “PST 2“ and

ion. ) The writing mode is cancelled and the OFS

(10) By manual home position return after changing the work coordinate

or w❑key or by inputting p

WF~again.

system shift memory,

If parameter # 6011 DO = 1 (if the tool coordinate memory No.

follows the last two digits of ‘1’ * * SS ) , refer to the Coordinate Setting

Operator’s Instruction Manual, Work coordinate system

performed in manual home position return.

O : Workpiece shift amount + cutting allowance amount

(with W code)

(with W code)

U is the same.

❑

(with code U)

(vith ‘code U)

—

❑

the work coordinate system is automatically set.

Norm

+ cutting

cutting

effective in this case. Minute

are input by adjusting by the

z?

n

~

of the work

key OFF in

~

a

key and input the

allowance amount

allowance amount

cutting allowance value

coordinate system

compact interact-

lamp

stops blinking

setting is not

Precaution :

Mode setting to write work coordinate system shift memory

effective if home position return is nob performed even once after

on.

Z-AXIS WORK

I SHIFT AMOUNT

COORDINATE

SYSTEM

,1

Z-AXIS TOOL COORDINATE

MEMORY VALUE

I

I r-

r

Fig, 5 Cc)ordinate .System

-12-

values is not

turning power

POINT)

ZERO

Page 15

2.4 OFFSET DISPLAY

The following offset display will be shown if the new tool setter function is

added.

The following displays can be changed cyclically by depressing the OFS key.

~

The

OFS key is disregarded during the PST 1 or 2 mode.

n

~

a

Fig. 6 Display No.1

Work Coordinate System

(Compact Interaction)

Fig. 7 Display No.2

Tool Offset Memory Display

(Compact Interaction)

Shift Display

OFFSET(WORK-SHIFT)

d

EDIT LSK

220.XOO0

POSITION (MAc! H&R}

x

z

Izmlmmmm

I

I OFFSET (TOOL-WEAR)

I

TX

t.:.

%!

03 : 0 :

04 . 0 .

05 . 0 .

Pos I’po N

00090 NOOOO

30.ZOO0

o

00090 .Noooo

z

o . 0:

0 . 00

0 . 00

0 . 00

0 . 00

RDY

R

EDIT

Mm=Hb_d

-13-

z

LSK

RDY

Page 16

;Z.4 OFFSET DISPLAY (Cent’d)

Fig.8 Display No.3

Tool Coordinate Memory Display

(Compact Interaction)

OFFSET(TOOL-WEAR)

00090 Noooo

-14-

Page 17

3. NEW COORDINATE SYSTEM SETTING FUNCTION

3.1 GENERAL

This function has a new approach to coordinate setting which is entirely

different from previous ones.

(a) The approach to coordinates is machine coordinate sYstem.

(b) The blade tip point can

(absolute) .

(c) Coordinate system setting is not required in programs.

3.2 DESCRIPTION OF FUNCTIONS

How and on what timing are coordinate system set?

3.2.1 Operational Expressions for Coordinates Setting

Various types of timing are used to set coordinates.

However,

coordinate system :

(X-axis coordinate value)

= (Machine position) +

(Z-axis coordinate value)

—

—

(Machine position) +

The machine position is the position machine.

(1)

Tool coordinate memory value Nos. are divided into

(2)

on whether the timing of next coordinate system

automatic.

The work coordinate system shift amount is data of

(3)

the following operational expressions are always used in setting

+ (Work coordinate system shift amount)

+ (Work coordinate system shift amount)

The features are shown below :

always be displayed as the current value

(Tool coordinate system memory value)

(Tool coordinate system memory value)

two systems depending

setting is manual or

offset T 00, X, and Z.

3.2.2 Coordinate System Setting Timing in Manual Mode

In the manual mode, coordinate system is set on timing ( a ) to mentioned

below (c) . The tool coordinate memory Nos. in this case are produced based

on tool No. binary values set from 1/0 inputs # 13174 (TP1) to # 13178 (TP8)

and are used for arithmetic operations.

Set up is performed in two modes, namely, setting up inside the NC

machine and coordinate system setting by sequencer requests. On a sequencer

request, coordinate system setting is executed and Output # 121974 (coordinate

system setting end output ) is turned on if Input # 13127 ( coordinate system

setting request input) turns on.

(a) At the tire-e of ~he home ‘position return.

(b) When the blade tip contacts the sensor with the tool setter during measure-

ment.

(c) When the turret is indexed manually.

Precaution :

Coordinate system setting in the manual mode is not performed if Parameter

#60 11 DO = 1. If the tool coordinate memory No. follows the last two digits

of T**$ $, refer to par. 2.3.

-15-

Page 18

:3.2.3 Coordinate System Setting Timing in Auto Mode

(~~ordinate

:he T code. In this case, the tool coordinate memory No. uses the turret No. or

offset No. instructed to tha command display for arithmetic operations.

Unlike the T code command b~’ the conventional

:he T code command in the coordinate system setting

as follows :

The tool coordinate memory No. can be selected to

last two digits of T4 dig-its by setting parameter # 6011

Depending on parameter setting, the execution

:setting differs as

(1) Setting first

two digits

(#”6011 DO =

Precaution :

The tool coordinate rnernory No. will be (tool No. + 50)

For this reason, select data of (tool No. + 50) as the tool coordinate memory

value.

By executing the T *‘K $$ command,

(a)

the selected tool coordinate memcry No. is set after the tool post moves by

the offset amount to the compensation No. simultaneously with turret

calling regardless of the tool post location.

T * *O O command executes turret calling and offset value cancel shift

(b)

sirnulta.neously regardless of the tool post location. Then coordinate system

is set corresponding to the selected coordinate memory No.

By this coordinate setting,

(c)

always set.

(2)

Setting last

two digits

(#6011 DO = 1)

settingis performed in the auto m~de if the turret is called by

compensation method,

specification instructs

be set in the first or

DO.

of coordinate system

o)

T** $$

L

COMPENSATION NO. (WEAR AMOUNT COMPENSATION)

01 TO 1601 T049 (B IADE TIP NOSE RI

- TOOL NO (TOOL COORDINATE MEMORY NO. )

01 TO 16/01 T049

coordinate system corresponding to

the coordinate system at the tool blade tip are

‘-- T

-—

‘-— (TOOL COORDINATE MEMORY NO )

COMPENSATION NO. (WEAR AMOUNT COMPENSATION)

—

01 T3 16/01 T049 (BLADE TIP NOSE R)

TOOL NO 01 TO 16/01 TO 49

The tool coc)rdinate memory No. will be compensation No. + 50. For this reascn,

tool coordinate m.emo]jy value will select compensation No. + 50.

the

By executing the T * * $$ command coordinate system corresponding to

(a)

the selected tool coordinate memory No. is set after moving by the offset

amount to the compensation No.

simultaneously with turret calling regardless of the tool post location.

By executing the T‘~ * 00 command moving of cancel operation of the offset

(b)

amount simultaneously with turret calling is executed regardless of the

tool post location.

By this set up, coordinate system at tool blade tip are always set.

(c)

PRECAUTIONS IN lJSING CONVENTIONAL G 50 T**** FUNCTION

3.3

Do

not issue the G 50 T * * * * command when using in the coordinate

setting specification.

Coordinate system setting is not executed at this time.

system

An error results if the command is issued.

-16-

Page 19

4. FS AUTO EDIT FUNCTION

4.1 GENERAL

This function creates optimum programs by storing effective values of feed

speed and spindle revolution speed during auto operation and feeds them back

to the NC part program.

and spindle revolution speed

In the following descriptions,

(S code) are called “FS.”

4.2 INPUT AND OUTPUT

The 1/0 signals needed in FS editing are as follows :

4.2.1 Input

FSCM (# 13134) :

(1)

feed speed (F code)

FS edit mode. Prepares for FS memory and for FS memory

ing FS editing when the signal is on.

FSMEM (# 13135) :

(2)

FS memory. Call up feed speed and spindle revolution speed

nal memory during

FSCH (# 13136) :

(3)

FS memory change.

NC PART program

FSCLR (# 13126) :

(4)

FS data clear. Clears the FS data stored when the signal is on.

4.2.2 Output

FSMD (# 12183) :

(1)

During FS edit mode. The signal shows that FSCM is on and that FS storage

and FS memory edit is ready. Feed speed and spindle revolution speed are

cancelled when the status of this signal changes from on to off.

FSCE (# 12184) :

(2)

FS memory change end.

status of FSCH becomes on and data is reflected on the NC PART program.

The status of this signal changes to off if the status of FSCH becomes off

again.

auto operation when the signal is on.

Reflects data called up in automatic operation in the

while auto operation pauses when the signal is on.

The status of this signal becomes on when the

change dur-

in the inter-

FSCLRE (# 12233) :

(3)

FS data clear end. The status of this signal becomes on if the status of

FSCLR becomes on and if the stored FS data is cleared. The status of this

signal changes to off if the status of FSCLR becomes off again.

-17-

Page 20

4.3 DESCRIPTIONS OF FUNCTIONS

Rough calculations of FS data only m--e programmed by the NC PART program and the program is optimized by feed and spindle override after cutting.

The optimum data and positions

stored in the memorY contained in the NC machine. By turning on FS

change input, the data and positions a::e reflected in the part program.

4.3.1 Operation Procedures

Set up the system ready to operate.

(1)

(2)

Search the operation program in the memory mode.

Trun on FSCM.

(3)

Check that FSM13 has been output and start memory operation.

(4)

Change the feed or spindle revolution speed for optimum value.

(5)

Make FSMEM when cptimum condition is achieved.

(6)

Execute steps (5) and (6) repetitively.

(7)

Set up the operation pause status (label skip status) .

(8)

Turn on FSCH. Put the execution values stored in FSMEM in the PART

(9)

program.

of actual cutting in the program are

memory

(10) Turn off FEFSCH.’SCE breaks.

(11) Turn off FSCM. The data stored in step (5) and (6) are cancelled.

4.3.2 Timing Chart

,Sc. ~

(PC-NC) \

FSMD

(NC+ PC)

\l

/

L

INTER=L DATA CANC’EL

-AuLJUL

(PC+ NC’

Y./

250 m sec OR MORE

FSCH

(PC-NC)

\A

FSCE ~

(NC+ PC)

FSCLR

(PC+ NC)

FSCLRE

(NC+ PC)

NC PART PROGRAM CHANGE

/ ,’4

v

DATA CLEAR

1

-18–

Page 21

4.3.3 Examples of FS Editing

The following two edit patterns are available by selecting parameter # 6008 D6.

(1) F/S is edited every time (# 6008 D6 = O)

(a) (Before editing)

1000 ;

o

N1G28UOWO;

N 2 G50 TS1OO ;

N 3 TO1O3 ;

N 4 G40 G97 G99 S1500 M08 ;

N 5 GOO X43.236 Z1O. M03 ;

N6Z1. ;

N 7 GO1 X39.216 Z–6.5 F.15 ; - F override 80% S override 110% FSMEM is

on.

N 8 X38.864 ;

N 9 G03 X18. Z–20.142 R19.85 ;

on.

N 10 GO1 Z–20.5 ;

N 11 X12. Z–22.232 ;

N 12 G40 X1O. F1. ;

.

.

.

.

.

.

.

.

- F override 50 YO S override 80% FSMEM is on.

- F override 60 YO S override 100 YO FSMEM is

(After editing)

(b)

1000 ;

o

N

1 G28 UO WO ;

2 G50 TS1OO ;

N

N

3 TO1O3 ;

4 G40 G97 G99 S1500 M08 ;

N

N

5 GOO X43.236 Z1O. M03 ;

N

6 Z1. ;

N

7 GO1 X39.216 Z–6.5 F.12 S1650 ; - F override 80% S override 110%

N

8 X38.864 ;

N

9 G03 X18. Z–20.142 R19.85 F.09 S1500 ; - F override 60 Yo S override” 100 YO

10 GO1 Z–20.5 ;

N

N

11 X12. Z–22.232 F.08 S1200 ;

N

12 G40 X1O. F1. ;

.

.

.

.

.

.

.

.

.

- F override 50 YO S override 80%

-19-

Page 22

4.3.3 Examples of FS Editing (Cent’d)

(2) F/S is edited retroactively (# 16008 D6 = 1)

In this case F/S is edited retroactive to the point where FSMEM was

last closed.

(Before editing)

(a)

1000 ;

o

1

G28 UO WO ;

N

2 G50 TS1OO ;

N

N

3 TO1O3 ;

N

4 G40 G97 G99 S1500 M08 ;

N

5 GOO X43.236 Z1O. M03 ;

N

6 21. ;

N

7 GO1 X39.216 Z-–6.5 F.15 ; - F override 80% S override 110% FSMEM

is on.

8 X38.864 ;

N

N

9 G03 X18. 2–20.142 R19.85 ; - F override 60% S override 100% FSMEM

E on.

10 GO1 2–20.5 ;

N

11 X12. Z–22.232 ; -

N

N

12 G40 X1O. F1. :

.

.

.

.

.

F overri3e 50% S override 80% FSMEM is on.

(After editing)

(b)

o

1000 ;

N

1 G28 UO WO ;

2 G50 TS1OO ;

N

N

3 TO1O3 ;

N

4 G40 G97 G99 S1200 M08 ; - S override 80% is reflected.

N

5 GOO X43.236 Z1O. M03 ;

N

6 Z1. ;

N

7 GOl X39.216 Z—6.5 F.08 ; - F override 50% is reflected.

N

8 X38.864 ;

N

9 G03 X18. 2–20.142 R19.85 ;

N

10 GO1 2–20.5 ;

N

11 X12. Z–22.232 ;

N

12 (340 X1O. F1. ;

.

.

.

.

.

.

-20-

Page 23

4.3.4 Specification Conditions for FS Editing

Conditions to store FS data in internal memory

(1)

(a) During FSMD output.

(b) During automatic operation (STL is on).

(c) Actual feed and spindle revolution speed values are stored by the rise

of FSMEM.

(d) All the data stored in (3) are cancelled by the fall of FSCM.

(e) The maximum memory cycles (the cycles to turn on FSMEM ) are

128 cycles.

(2) Conditions to reflect FS data in part program

(a) During FSMD output.

(b) During automatic operation pause. (Label skip status)

By changing the status of FSCH from off to on under this condition,

F/S data are inserted in each block in accordance with the stored

data.

4.4 PRECAUTIONS

(1) The newest feed and spindle revolution speeds become effective if the

status of FSMEM is on more than twice in one block. The FSMEM count

is not increased.

(2) FS data is inserted in the sub-program itself if the status of FSMEM is

on during a sub-program.

are also called up.

Caution must be exercised as other programs

(3) FS editing during a compound fixed cycle allows only F/S of O.D. rough

cutting cycles.

(4) Blocks in on status are changed with F if FSMEM is on in constant pe-

ripheral speed control. Blocks are not changed with S.

(5) The CYCLE START switch does not operate while FSCH is on even if

it is depressed.

(6) F/S data is stored if FSMEM is on during cutting.

(7) S data is stored if FSMEM is on during rapid feed.

(8) A warning is issued if FSMEM is on more than 128 times, and data are

not stored even if FSMED is on further.

(9) FSMD is not on even

operation.

(10) The CYCLE START switch does not operate while FSMEM is on.

if the status of FSCM is on during automatic

(11) A warning is issued if editing is performed while FSMD is on after

finishing FS editing.

-21_

Page 24

!5. AUTO NOSE R FUNCTION

5.1 GENERAL

Nose R compensation is performed b~ the nose R control point (O to 9) corr~-

mand and by G 41 and G 42. Selection of compensation side moving from a n

end face to outside diameter becomes simple. By executing the T command,

tool, as well as the nc]se R and control point corresponding to the toc,l,

a

are selected.

At this time, coordinates of the tool based on this machine coordinate

system are set. After issuing the T command,

tions are made by the control point and by G 41 and G 42.

5.2 CON DITONS TO MAKE AUTCI NOSE R COMPENSATION

FUNC1-ION EFFECTIVE

Auto nose R compensation becomes effective by four conditions, namely,

(designation of projected blade tip pcints set by compensation No., by nose R

radius, by setting of the compensation side by the G 41 and G 42 commands,

and by the T code command. They are described below.

5.2.1 Designation of Proje~ted Tool Tip Points

Projected edge point direction

(1)

nose R compensation calcul:~-

Auto nose R is determined by designating the projected tool tip point

position by using a numeral between O and 9 to regulate the shift direction. The directions a:~e shown in Fig.9 (X PIUS specification).

2 6

7

H=

3

(2)

Method to set projected

tool tip point.

Projected tool tip points

can be set using the off-

set screen. (Se; Fig. 13)

09

8

1

5

4

Fig. 9 Projected Tool Tip Point Direction

OFFSET (T OOI.-W’EAR)

[

,.

01234 NOO03

0~--12%4. 567 -12$4. 56’J 12!. 456 i

02 . 0

03 . :

(a) Select the ~ funct-

ion.

(b) Select the compensa-

tion memory of the

matching

from T 01 to 49.

(c) Input

~

I-E

are

tool

tip points.

tool

❑ , [~ a:xl

by MDI if there

three projected

No.

04 !:

05 : 0

0.

POSITION (EXTERNAL)

x–1234. 567

Z 1234.567

EDIT

LSK RDY

mmmr=w=z

\ 1

Fig. 10 Offset Display (Compact Interactive)

I

-22–

Page 25

5.2.2 Setting Tool Tip R Data Memory

(1) Setting nose R data memory

The nose R data memory can be set on the offset display as shown in Fig. 10.

(a) Select the ow function.

(b) Select the compensation memory of the corresponding to tool No. from

T 01 to T 49.

~

n

(c) Input R

8 and wR by MDI if the nose R data is 0.8 mm.

cm ❑

5.2.3 G41 and G42 Commands

The compensation direction can be instructed during cutting by the G 41 and

G 42 commands. (X plus specification)

G 40: Nose R compensation OFI?

G 41 : Left side of moving direction is nose R center.

G 42 : Right side of moving direction is nose R center.

5.2.4 T Code Commands

The T code No. (4 digit) commands select coordinates system, wear compen-

sation and nose Rs.

Refer to Sect. 3,

for details.

T**

$$

TT

‘COmpenSatiOn NO. (w EAR AMOUNT COMPENSATION)

~TOOL NO. EDGE (TOOL COORDINATE MEMORY NO. )

“ NEW COORDINATE SYSTEM SETTING FUNCTION, ”

01 TO 16/01 TO 49 (NOSE R)

01 TO 16/01 TO 49

5.3 COMPENSATION CALCULATIONS OF AUTO NOSE R COMPEN-

SATION APPROACH AND RETRACT

In auto nose R compensation,

from the conventional YASNAC LX3 nose R compensation

5.3.1

Block compensation G 00 -+ G 00 is not performed.

Positioning only is performed.

the following functions have been upgraded

function

-23-

Page 26

!5.3.2

[n approach G 00 - G 01 (G 02, G 03), a vector (wall)

set on the tool to make compensation to prevent overcutting

In recess G 01 ( G 02, G 03) - G 00, a vector (wall) is

o make compensations as follows to prevent omission in cutting.

(1) Approach G 00- G 01 or recess G 01 ~ G 00

(a) If the direction of the cutting command moving axis is larger than 45”

relative to Z-axis ( I X/2 I > I Z I ) , a vector

is theoretically erected to make compensation calculations with the cutting

moving axis.

(b) If the direction o-f the cutting command moving axis is smaller than 45[’,

or is equal, relative to Z-axis

to X-axis is theoretically erected to make compensation calculations with

the cutting moving axis. The to~l moves toward this calculated position.

See Fig

12.

The tool moves toward this calculated position. See Fig. 11.

( I X/2 I < I Z I ) , a vector (wall) parallel

./

THEORETICAL

VECTOR X

(wall) parallel to Z-axis

is theoretically

and overshock.

theoretically set

Ss

z

Fig. 11

Example : 3 tool tip points

,/” , ,

/’ ,

/’

/“ ~ ,,

)’” ,/’

/ /’

L4RGER THAN,45’

?!?2

1

,“

Fig. 12

.@/

CJ(5 “

60,,

.

,-

(PARALLEL

(G42)

GO’I

7

=., ,

%

G@J (;4;,’ .

Fig. 13 Example of 3 Tool Tip Points

/“

THEORETICAL

\/EcTo R

(vERTlcAL TO Z-AXIS)Q+’

TO Z-AXIS)

THEORETICAL

VECTOR

i

Q/

C$’

/

—

———.——

GOO(G42)

-24-

Page 27

(2) Approach GOO + G02 (G03) or recess G02 (G03) + GOO

(a) If the, vector direction of the circular arc cutting command moving axis is

larger than 45° relative to Z-axis, a vector

theoretically erected to make compensation calculations with the cutting

moving axis. The tool moves toward this calculated position. See Fig. 14.

(b) If the vector direction of the circular arc cutting command moving axis is

smaller than 450, or is equal, relative to Z-axis, a vector

to Z-axis is theoretically erected to make compensation calculations with

the cutting moving axis. The tool moves toward this calculated position.

See Fig.15.

THEORETICAL

(wall) parallel to Z-axis is

(wall) parallel

VECTOR x

LARGER THAN 45’

THEORETICAL VECTOR

%

Fig. 14

Example : 3 tool tip points

45’

z

AN

z

Fig. 15

/

/

THEORETICAL VECTOR

THEORETICAL

VECTOR

G03 (G4i~

Fig. 16 Example of 3 Tool Tip Points

-25-

45’ OR

MORE ;Z

?

#/

~>/

c+

G03 (G4;)

Page 28

5.3.3 Patterns of Auto Nose R Apprcach and Retract

0

C=3

Circular

45° or less

—

t

Linear

t

45° or more

—

/

–26-

Page 29

5.4 CANCEL FUNCTION (G40, GO1)

Auto nose R function can cancel G40 GO 1 X _ Z _ I _ K _ ; command. In addition

to cancel function of G40 GOO X _ Z —I _ K_;, GO1 has the same function.

This function makes a theoretical wall by command I or K in the block

before G40 GO1 command and executes nose R calculation.

5.5 PRECAUTIONS

(1) In G40 GOO X_Z

provided on the end point normal.

(2) In G51 independent block or G28 block, nose R complete cancel is exe-

cuted in the block immediately before G51 or G28.

(3) In G40 GOO X_ Z_ I_K_;,

indicated as

(4) When GO 1 and G41 (G42) are commanded simultaneously, the center

of nose R is provided on the normal of the starting point of the next block.

In canned cycle, the first block can be started up by GO1 G42, how-

ever, it cannnot be started up by the same command afterward.

(5) G40 GO1 X_K

as that of beveling command, however,

only when G40 command is provided.

“I” or “K” in the block immediately before G40 GOO.

_ ; or G40 independent block, the center of nose R is

node calculation is executed with vector

_ ; and G40 GO1 Z _ I _ ; have the same command format

cancel function has priority

6. Z-AXIS TOOL CHUCK BARRIER FUNCTION

Barrier for each tool in Z-axis direction is automatically set by setting the

length between absolute zero point and the barrier by extending normal

tool stored stroke limit function.

6.1 GENERAL

When # 13181 (tool range change) signal is input in the timing for changing

the tool, chuck barrier value corresponding to tool number is set in Z-axis

direction by reading the tool numbers set in # 13174 to # 13178 (TP1 to TP8) .

This function is effective when parameter # 6011 D4 = 1.

6.2 OPERATION

(1) Each tool coordinate memory value and work coordinate system shift value

is set in PST mode.

(2) A value of the length between the absolute zero point to a desired chuck

barrier in Z-axis direction is set in setting parameter (# 6573).

(3) Stored stroke limit 3 is effective. (# 6001 D2 = 1)

-27-

Page 30

6.2

OPERATION (Cent’d)

(4)

Stored stroke limit 3 setting parameter

( # 6507) in Z-axis direction is

set in the tool chan~ing timing in manual or automatic mode, by the

following operation :

# 6507 = # 6573 –- (Tool coordinate memory value +

Work coordinate system shift value)

--- —

1Z-AXIS WORK COORDINATE

SYSTEM SHIFT AMOUNT

I

Z-AXIS BARRIER(8 6507)

Z-AXIS

T(IOL

COORDINATE

=RY VALUE+

\ X-AXIS TOOL ‘

\

ABSOLUTE

ZERCI

PolN”r

Fig. 17 Coordinate System

COORDINATE

MEMORY

AMOUNT

REFERENCE ZERO

POINT

c

-

-’----+

/“-

I

6.3 PRECAUTIONS

The following conditions are required for effective functioning

(1) Stored storoke limit Z is availatlle as an option.

(~) when ~ool stored stroke limit is

value of Z-axis only can be reset.

a~~ailable, each tool stored stroke limit

-28-

Page 31

7. OTHER ADDITIONAL FUNCTIONS

7.1 HIGH-FREQUENCY SKIP SIGNAL APPLIED FOR MACHINE SETTER

When high-frequency skip signal is used together with sensor input signal

{X + OFST (#13201), X–OFST (#13202), Z + OFST (#13203), Z–OFST

(# 13204) ~, it will improve absolute accuracy of measured value.

High-frequency skip signal is switched by # 6011 D3.

X + OFST :

X–OFST[,

Z+ OFST; ~,

Z–OFST; ~\:

1 :

#6011 D3

7.2 WORK

The current

and

.,

# 6572 (Z) by G54 independent command.

Shift amount can be cancelled by G50 independent command.

.

X-axis coordinate value = Machine position

+ Tool coordinate value + Work coordinate system shift amount + # 6571

.

Z-axis coordinate value = Machine position

+ Tool coordinate value + Work coordinate system shift amount + # 6572

SHIFT FUNCTION ADDED (G54)

coordinate system can be shifted for setting amount of # 6571 (X)

Effective

0 : Ineffective

# 13201

# 13202

# 13203

# 13204

DINo (SKIP INPUT)

G54 ; Coordinate system shift effective

G~O ; Coordinate system shift ineffective

7.3 ABSOLUTE COORDINATE SWITCHING ADDED WHEN MACHINE

LOCK EFFECTIVE IS SWITCHED TO INEFFECTIVE

To prevent an error in coordinate systems when machine lock is ineffective

after drawing display at machine lock effective, absolute coordinate sYstem

is reset by the tool number currently provided when machine lock is switched

from effective to ineffective.

-29-

Page 32

“7.4 ADDITIONAL PARAMETER SWITCHING TO AUTO NOSE R

COMPENSATION AND COMIVAND T (I NcLu DING G50T)

FUNCTION

A parameter

:system setup function

command T (including G513T) function, is added.

#6011 D2 O : Auto nose R function and coordinate system setup

which switches

“by command T to normal nose R compensation and

function by cc~mmand T effective

1 : Normal nose R function and command T (including

G~OT) functi~~n effective

auto

nose R compensation and coordinate

7.5 HANDLE INTERPOLATION FUNCTION

7.5.1 General

When handle interpolation mode is commanded during program execution in

memory, tape or MDI mode, cutting speed commanded by GO1, G02 or G03 can

be controlled by turning the handle in the plus direction.

7.5.2 Operation

select handle interpolation mode to set by panel key or I / O input in

(1)

compact interactive function

monochrome display.

Setting # 6001 D4

; b~ setting parameter or I/ O input in 9”

1 : Effective

O : ineffective

1/0 Signal # 13066 1 : Effective

O : Ineffective

(2) Depress cycle start button.

“F” b links and cutting stops before executing GO1 (or G02, G03) program.

(3)

(4) The manipulator moves

and starts cutting.

The moving speed is in proportion to handle rotating speed and co:m-

mand F is overridden.

EXAMPLE : When 1 rotation/ sec = 100 Yo, the relation between rotation

speed and override is as follows :

# 6349 parameter

1 rotation/see or more

0.5 rotation/see 50%

0.01 rotation/see

0.01 rotation/see or less

(5) The manipulator stops moving

the minus direction.

(6) Turn off handle interpolation mode after cutting is completed.

while turning the handle in the plus direction

= 100 (pulse/see)

100VO

1YO

stop

when the handle is stopped or turned in

-30–

Page 33

7.5.3 Precautions

Turning the handle at 0.2 rotation / sec or more makes a constant move-

(1)

ment. If at 0.2 rotation/see or less, the movement is intermittent.

When turning off the mode during handle interpolation, the remaining

(2)

movement is executed by command F’.

In case of handle 2 axis specification,

(3)

Handle interpolation is ineffective during thread cutting.

(4)

Handle axis selection is not required for interpolation.

(5)

Handle interpolation mode is disregarded during automatic

(6)

handle offset.

Normally, the command is overridden,

(7)

ride selection switch.

In dry run,

(8)

override varies depending on feed override selection switch setting and

rapid traverse speed setting.

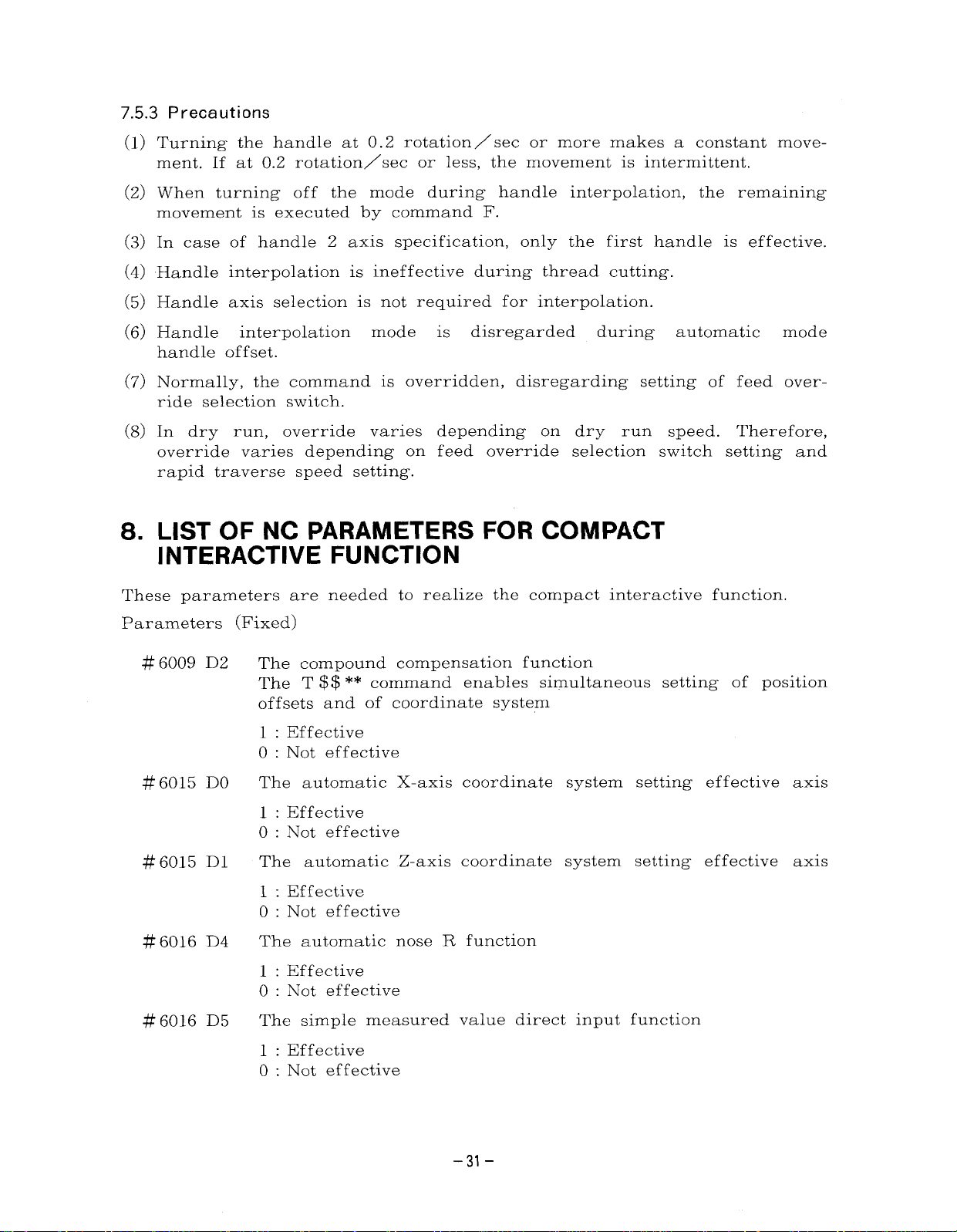

LIST OF NC PARAMETERS FOR COMPACT

8.

override varies depending on dry run speed.

only the first handle is effective.

disregarding setting of feed over-

Therefore,

INTERACTIVE FUNCTION

These parameters are needed to realize the compact interactive function.

Parameters (Fixed)

# 6009 D2

The compound compensation function

The T $$ ** command enables simultaneous setting of position

offsets and of coordinate system

mode

#6015 DO

#6015 D1

# 6016 D4

#6016 D5

1 : Effective

O : Not effective

The automatic X-axis coordinate system setting effective axis

1 : Effective

O : Not effective

The automatic Z-axis coordinate system setting effective axis

1 : Effective

O : Not effective

The automatic nose R function

1 : Effective

O : Not effective

The simple measured value direct input function

1 : Effective

O : Not effective

–31-

Page 34

8. LIST OF NC PARAMETEFIS FOR COMPACT

INTERACTIVE FIJNCTION

(Cent’d)

#

6016 D6

Parameters (Selective)

# 6008 D4

# 6008 D6

# 6009 D1

#6011 DO

The tool coordinate system setting function. The coordinate

system setting function by the T4-digit command

1 : Effective

O : hot effective

With or without feed during tape output by NC

1 : Without feed

O : With feed

During automatic FS editing

1 : F/S edited retroactively

O : F/S edited every time

U and W are used instead if I and K are not available wj th

G 71 to G 73.

1 : Effective

O : Not effective

The T *‘~ $$ command to make tool coordinate memory Nos.

1 : Lower 2 digits

O : Upper 2 digits

(Relatecl fixed parameter : # 6016 D6)

#6011 D1

#6011 D2

#6011 D3

#6011 D4

Setting Parameters

# 6001 D4

Enables the T code, G 41 and G 42 commands during com-

pound fixed cycles

1 : Effective

O : Not effective

Interlock of auto nose R function and coordinate setup

function by commancl T

1 : Effective normal nose R function and command T ( in-

O : Effective auto nose R function and coordinte system

Setter higkfrequency skip signal in machine

1 : Effective

O : Ineffective

Check barrier function for each tool

1 : Effective

O : Ineffective

Handle cc,rnpensation function

cluding G 50 T) function

setup function

1 : Effective

O : ineffective

-32-

Page 35

# 6001 D5

PST2 workpiece shift amount write request

1 : Effective

O : Not effective

# 6001 D6

# 6208

# 6209

#6210

#6211

#6212

PST 1 tool coordinate

1 : Effective

O : Not effective

G 74 recessing canned

Unit : Input unit

Set range :0 to 65535

G 75 recessing canned

Unit : Input unit

Set range :0 to 65535

G 74 recessing canned

Unit : Input unit

Set range : 0 to 65535

G 75 recessing canned

Unit : Input unit

Set range :0 to 65535

G 74/G 75 recessing

Unit : 1 == 100%

Set range : 0 to 127

system memory amount write request

cycle pull back amount

cycle pull back amount

cycle clearance amount

cycle clearance amount

canned cycle approach speed override

Enables override to F in approach speed after second recessing cycle.

#6213

#6214

# 6571

Reduces cutting amount of each cutting in units of 1 YO to

G 71 / G 72 cutting reduction override # 6004 (D 3 to D 7 )

or to cutting override. D * ( # 6004 or input override) *

(100 - (B 1) * # 6013) /100 = cutting amount of each cutting

D : Cutting amount

N : Number of cutting cycles

Unit: 1 = l%

Set range : 0 to 99

G 74, G 75 cycle hole bottom dwell time

Unit : 1 = lms

Set range : 0 to 65535

G 54 work shift function X coordinate

Unit : 1 = 0.001 mm or 0.0001 inch

Set range :

–99999999 to 99999999

NOTE : The NC machine automatically turns # 6001

when the new tool setter function is used.

Therefore, setting them is not possible.

shift amount

D5 and D6 on and off

-33-

Page 36

YASNAC LX3

19

CNC SYSTEM FOR TURNING APPLICATIONS

UPGRADING FUNCTION

TOKYO OFFICE OIWmachl Bldg, 16-1 Ohtemachl, Chlyoda-ku, Tokyo, iOO Japan

Phone (03)3284.911. Telex YASKAWAJ33530 Fax (03)3284-9034

SEOUL OFFICE 88? Floor Seoul Center Bldg 91-1 Sogong-Dong, Chung-ku, Seoul, Korea 1OC-O7O

Phone (02) ”776-7844 Fax (02)7532639

TAIPEI OFFICE Sh(m Hslang Tang Sung Chlang Bu[ldng 10F 146 Sung Chlang Road, Ta!pel Taiwan

Phone (02) 563-CO IO, -7732 Fax (02)567-4677

YASKAWA ELECTRIC AMERICA, INC.

Chicago-Corporate Headquarters 2942 MacArthur B1vd Northbrook, (L 600622028, US.A

Phone (708)291 2340 Fax (708)4982430

Chlcaao-Technmal Center 3160 MacArthu Bvd Northbrook, IL 60062-1917, USA

Phone-(708)2910411 Fax (708)291 1018

MOTOMAN INC.

805 Llocr!v Lane We;l Carroll[on, OH 45449 USA

Phone (513] 847-620C Fax (513)8476277

YASKAWAELECTRC EUROPE GmbH

Nleoerhochstadter Stta13e 73, 61476 KronbergOberhochstadt, Germany

Phorle (06173)9380 l“elex415660YASE [1 Fax (06173)68421

YASKAWA ELETRIC:O DO BRASILCOMERCIO LTDA

Rua Conoc Do IPmhztl 85°, Andar Sala51 SEP 01501 Sap PauloSP Brash

Phcme(Oll)35-’9ll Fax(Oll) 377375

YAstiWA ELECTRIC (SINGAPORE) PTE. LTD.

Head Off Ice CPF bldg, 79 Rob!nson Roacl # 1305, %gapore 0106, SINGAPORE

Phone 2211-530 Telex (87)24890 YASKAWA RS Fax 2245854

Service Center 221 Henderson Road # 17-20 Henderson Bulldlng Singapore 0315 S’NGAPORE

Phcme 276-7407 Fax 276-7406

YATEC ENGINEERING CORPORATION

Snen Hslang Taog Sung Ch!ang Bu!ldmg 10F 146 Sung Chkmg Road, Talpel, Taiwan

Phone (02)5630010 Fax (02)567-4677

Y

YASKAWA

YASKAWA ELECTRIC CORPORATION

TOE-C 843-9.23D

C printed

in Japan October

Loading...

Loading...