Page 1

'ft

'ASKAWAj

IjECTRH?

TOE-

C843-

8.22

'

•

'"tÿV

•

r,

;>

I

*

'mFJWimixvsmra!tmrpÿÿp

***ÿ“

Sitei

in

eeuie'ATioNs

ZD\

Cl

cr«|4

»

i

:«*-

HM

|

Before

read

f

thoroughly,

future

or

L,

running

opera

/rw7/a/

instructions

these

and

retain

reference

YASNAC

CNC

for

two

high-performance

C«.««

ew

Sfcr#M

fV

&

BHP*

is

an

lathes,

LX2

turning

in

//on

parallel.

«Hiÿ:

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

*20;;

m

[ÿ#«

ultraspeed

and

16-bit

This

manual

“ÿk

:

!*

*«*

-»

'>

<v

»

«

«

If*

*****

i«gp?ti®§t

dual

processor

combination

a

microprocessors

describes

the

of

specifications

machines,

quipment.

for

"?

.*

«P

=

*

\-,*

connecting

interfaces

'

=

*;

4

imi'

machine

.•ÿ

•

•

‘V?

»

v

,»

*

*

YASNAC

and

LX2

external

with

e-

I:

a

‘

5

l

U

I

-

’

1

[,

rli

K

t

c:

[•E

PDSlflOMCEXTffPudi.)

X-12345.

4585.

Z-

QOP32

US*

ND000

678

337

ildfisaa

k

I

a

B

H

G

N

M

I

s

T

Y

z

ID

!ÿ

mo

C

O

U

(

\*m\

SBC

0

El

K

J

a

P

V

W|'-

9

8

7

5

6

4

1

2

1

3

O

!i

*ÿ

'•**.

OPERATOR’S

LX

YASNAC

2

STATION

582*215

:

;

;

Page 2

r

Page 3

CONTENTS

1.

CONNECTION

1.1

TOTAL

OPERATOR'S

FACE

1.2

1

TOTAL

EXTERNAL

CRT

1

.

3

2

TOTAL

EXTERNAL

CRT

1

4

.

2

TOTAL

EXTERNAL

TOTAL

5

.

1

POWER

2.

2.

2.

CABLE

3.

4.

SUPPLY

CABLES

1

CABLES

2

CLAMPING

SHIELD

CONNECTIONS

CONNECTION

CONTROL

4.

1

CONNECTION

UNITS

4.

SERVO

4.

3

MODULE

4.

UNITS

5.

8

RECOMMENDED

2

POWER

CONNECTION

4

CONNECTIONS

9

CONNECTIONOFSERVOMOTORS

DIAGRAMS

CONNECTION

STATION

CONNECTION

NC

OPERATOR'S

CONNECTION

OPERATOR'S

NC

CONNECTION

TAPE

READER

CONNECTION

AND

AND

CABLE

3

CABLES

5

OF

WITH

UNIT

TO

SWITCHING

BETWEEN

ANDXAND

BETWEEN

OF

MACHINE

AND

OF

STATION

OF

STATION

OF

UNIT

OF

SERVOMOTOR

CLAMPS

AND

POWER

EXTERNAL

8

THE

ALL

SEQUENCE

AXES

Z

1

YASNAC

WITH

INTER¬

YASNAC

YASNAC

TO

WITH

TO

WITH

YASNAC

WITH

2

YASNAC

WITH

2

3

GROUNDING

SUPPLY

6

SERVO

SERVO-RELATED

CIRCUIT

8

SERVO

SERVO

FOR

CPU

UNITS

SERVO-RELATED

10

9”

14"

NC

TO

CONNECTIONS

6.

OPERATOR

CONNECTIONS

7.

S

OPERATOR’S

CONNECTION

8.

READER

CONNECTIONS

9.

PULSE

CONNECTIONS

10.

PULSE

CONNECTIONS

11.

UNIT

GENERATOR

GENERATOR

COMMAND

12.

CONNECTION

SERIAL

12.

1

12.

2

3

12.

13.

CONNECTION

UNITS

1

13.

13.

2

14.

CONNECTION

INTERFACE

FACIT

4070

CURRENT

RS232C

OF

LIST

DETAILS

INTERFACE

19

CONNECTION

OF

MODULE

9

LIST

2

14.

UNBUNDLED

FOR

14.

CONNECTIONS

3

UNBUNDLED

FOR

4

DETAILSOFSIGNALS

14.

RATING

1

14.

OF

CONNECTION

OF

EXTERNAL

STATION

EXTERNAL

TO

STATION

WITH

EXTERNAL

12

OF

YASNAC

YASNAC

OF

TO

S4-DIGIT

13

FACIT

TO

INTERFACE

(20

LOOP

WITH

SIGNALS

GENERAL

TO

21

CONTACTS

TYPE

BETWEEN

TYPE

WITH

WITH

12

mA)

POWER

NC

CRT

9”

NC

14”

TAPE

WITH

WITH

13

SPINDLE

INTERFACE,

14

14

INTERFACE

16

INPUT

SIGNALS

19

PURPOSE

21

SIGNALS

21

UNITS

24

31

CRT

MANUAL

SPINDLE

EXCEPT

EXCEPT

11

11

15

19

I/O

i

i

Page 4

INDEX

Subject

and

Alarm

A

Auxiliary

C

CABLES

CABLES

CLAMPING

Combined

CONNECTION

CONNECTION

CONNECTION

CONTROL

CURRENT

Current

Display

D

Door

switch

Dry

Run

Edit

E

Lock

Emergency

Emergency

End-of-

Rewind,

External

EXTERNAL

TOTAL

EXTERNAL

CONNECTIONS

EXTERNAL

TOTAL

EXTERNAL

CONNECTIONS

External

Input

Error

Function

AND

Fixed

MODULE

LOOP

Value

Reset

Input

Program

and

Data

CONNECTION

CONNECTION

Power

Lock

CABLE

CABLES

Cycle

DIAGRAMS

SIGNALS

SIGNALS,

INTERFACE

Storing

Inputs

Stop

and

Stop

on

Input,

Rewind

Inputs/Outputs

Input

NC

OPERATOR’S

NC

OPERATOR’S

TO

OPERATOR'S

NC

OPERATOR'S

NC

TO

On-Off

Outputs

CLAMPS

AND

Cutting

PALAMETERS

and

Input

GROUNDING

Override

EXCEPT

OF

LIST

....

Input

.

.

.

Machine

Output

Rewind

on

OF

OF

Input

End

Input,

Outputs

STATION

YASNAC

STATION

STATION

YASNAC

STATION

External

CABLE

Inputs

FOR

UNBUNDLED

.

.

.

High

WITH

TO

WITH

WITH

TO

WITH

Error

Speed

14"

14”

9”

9"

Detect

SHIELD.

TYPE,

CRT,

CRT,

CRT,

CRT,

Inputs

LIST

.

Chapter

. .

OF

.....

.14

14

2

2

2

14

1 1

.

.14

13

Section

14.4.26.

14.

2.

2.

14

.

.

.14.2

13.

APPENDIX

.

. .

12

14

.....

.14

.

13

14

14

.13

.....

14

.

.14

.....

14

1

7

1

6

13

12.2

14.

14.4.33.

13.

14.

14.4.

13.

14.

14.4.32.

14.

1.

1.

13.2.4

Page

No.

.

.40

4.

18

1

2

4.

52

1

4.

15

2.

2

14

4.

17

2.3

23

4.

4.

47

3

2

39

3

3

5

57

.

.

.

.21

19

.

.58

15

38

.

.43

20

38

38

.

.20

.

40

.

.42

54

2

11

2

11

20

External

EXTERNAL

External

EXTERNAL

YASNAC

EXTERNAL

External

External

F

FACIT

FACIT

Feed

Input,

G

GENERAL

I

Input

Input

During

Interlock

Interruption

Input

Reset

SERVO

Match,

Store,

TAPE

WITH

Tool

Work

4070

INTERFACE,

Override/Manual

and

Output

and

Signals

Cycle

Input

READER

TAPE

READER

Compensation

Number

INTERFACE

Feed

Override

PURPOSE

for

Cycle

for

Start

Point

Return

and

Reset

CONTROL

and

Search

SERIAL

Jogging

Cancel

MODULE,

I/O

Control

Start,

Feed

and

Input

Outputs

on

UNIT,

Output

UNIT,

UNIT,

Inputs

TOTAL

CONNECTION

Input/Outputs.

Inputs

A

INTERFACE,

Speed

Input

CONNECTION

Operation

Stop

Output

Hold

CONNECTION

CONNECTION

WITH

.

.

.

.

.

.

CONNECTION

Selection

.

Modes

.

Signals

WITH.

TO

.

OF

TO

4

14

4

14

1

.

8

.14

.

.....

14

12

12

14

14

14

.

.

.14

.

.....

.

.....

.14

14

14.

4.

14.

1.

4

14.4.43.

14.

4.41

12.1

14.4.7

14.4.2

14.4.1

14.4.25.

14.

4.

24

34

20

40

8

43

2

12

.48

.

47

14

14

.

34

21

31

.31

.

.

.

.40

39

ii

Page 5

Subject

Chapter

Section

No.

Page

M,

S,

M

N

O

P

R

and

Machine

Machine-Ready

Manual

Manual

Automatic

Manual

Manual

Manual/Absolute

NC

TOTAL

NC

Optional

Overload

Overtravel

Positioning

POWER

POWER

OF

POWER

Program

Progam

Rapid

Rapid

RATING

RECOMMENDED

SERVO

Reference

Feed

Handle

Handle/Stop

Rapid

OPERATOR

CONNECTION

Poweronand

YASNAC

Feedrate

Threading

POWER

Codes

T

Lock

and

Axis

Mode

Traverse

Block

Input

Inputs

Completion

INPUT

SUPPLY

WITH

SUPPLY,

Interrupt

Restart

OF

CONTACTS

Point

Inputs/Outputs

Display

Input

Direction

Feed

Handle

On/Off

STATION

S

Servo

Skip

Selection

Axis

Offset

Multiplication

Selection

Input

YASNAC

OF

Power

Input

. . . .

UNITS,

Input

Override

Outputs

CONNECTION

SERVOMOTOR,

AND

CONNECTIONS

Input

Input

Pull-out

SEQUENCE

SWITCHING

Return

Input

Control

Lock

Selection

Input

AND

on

and

CIRCUIT

. . .

Input.

Input

Input,

....

Factor

Input

MACHINE

WITH

WITH

TOTAL

OF

Error

FOR

Signals

I/O

.

and

Input

.

.

INTERFACE,

CONNECTION

Detect-on

Input

14.

14

14

14

14

14

.14

.

.

.

.

.

.

.

.....

.

.14

.....

.

14

1

13

14

13

14

14

13

1

3

14

14

14

.....

.

.14

14

4

14

4.

14.

4.

14.4.

4.5

14.

4.4

14.

14.4.6

14.4.3

14.4.

1.1

2.

13.

14.4.

13.2.5

14.4.21

14.

4.

1.5

4.

14.

14.

4.

14.

4.8

14.4.27.

14.1

2

4.

14.4.9

29

13

22

10

1

12

30

51

16

41

38

39

34

33

.

.

.34

.

.

.33

36

1

19

37

20

39

42

19

2

6

57

38

35

.40

.

21

8

.

35

S

RS232C

S

S

External

S

S

SERVO

INTERFACE

4-Digit

4-Digit

Inputs

4-Digit

4-DIGIT

CPU

CONNECTION

SERVO-RELATED

SERVO-RELATED

SEVOMOTORS,

Setup

Point

SIGNALS,

SIGNALS,

Single

Block

Skip

Input

Spindle

Spindle

and

Spindle

Indexing

S

Spindle

Speed

Analog

Command

Commands

Output

SPINDLE

MODULE

BETWEEN

UNITS,

UNITS,

CONNECTION

Return

DETAILS

DETAILS

Input

Function

Command

Constant

Override

Auto/Manual

External

Inputs/Outputs

COMMAND,

ANDXAND

CONNECTION

CONNECTIONS

Input

OF

OF

Input/Output

"00",

Gear

Speed

Inputs

Outputs

Input

and

CONNECTIONS

AXES

Z

OF

Shift

on

Switching

4-Digit

S

SERVO

TO

ALL

BETWEEN

...

Input,

.

.

Inputs/Outputs

TO

...

UNITS,

THE

.

12

.

14

.....

.

.

.14

.

.

.....

14

1

1

4

4

.

.

.....

4

5

14

13

14

14

.

.....

.14

14

14

14

12.3

14.4.39.

14.4.40.

14.4.35

4.3

1

4.

4.

4

19

14.4.

13.2

14.4.

11

14.

4.

14.4.49...56

4.

44

14.

36

14.

4.

14.4.38

16

.46

.

.

.47

43

13

9

8

9

10

.

39

19

.

31

37

49

45

46

iii

Page 6

INDEX

(Cont’d)

Subject

Spindle

S

T

U

Stored

Time

Tool

Tool

Tool

Travel

UNITS

Stroke

Count

Life

Set

Wear

on

EXCEPT

CONNECTIONS

User

Macro

X

X-Axis

Y

YASNAC

CONNECTIONS

YASNAC

CONNECTIONS

Speed

Limit

Input

Control

Compensation

Error

Compensation

Thread

and

Input/Output

Image

Mirror

WITH

WITH

Input

Reach

by

3

Inputs/Outputs

Cutting

UNBUNDLED

FOR

BETWEEN

Input

MANUAL

OF

SPINDLE

OF

Inputs/Outputs.

Tool

Inputs

Input

on

Function.

PULSE

PULSE

....

.

.

.

Outputs

TYPE,

.

.

.

GENERATOR,

GENERATOR,

Chapter

.14

.

.....

14

.14

.

.

.14

.14

.

.

.14

14

14

14

14

9

10.

Section

14.4.37.

4.

14.

.14.4.

4.

.14.

.14.4.50.

.14.4.53.

.14.

4.31.

14.3

14.

4.

4.

14.

45

42.

48.

.

46

28

No.

.

Page

.46

53

48

.

.55

.57

.57

42

24

54

41

12

13

iv

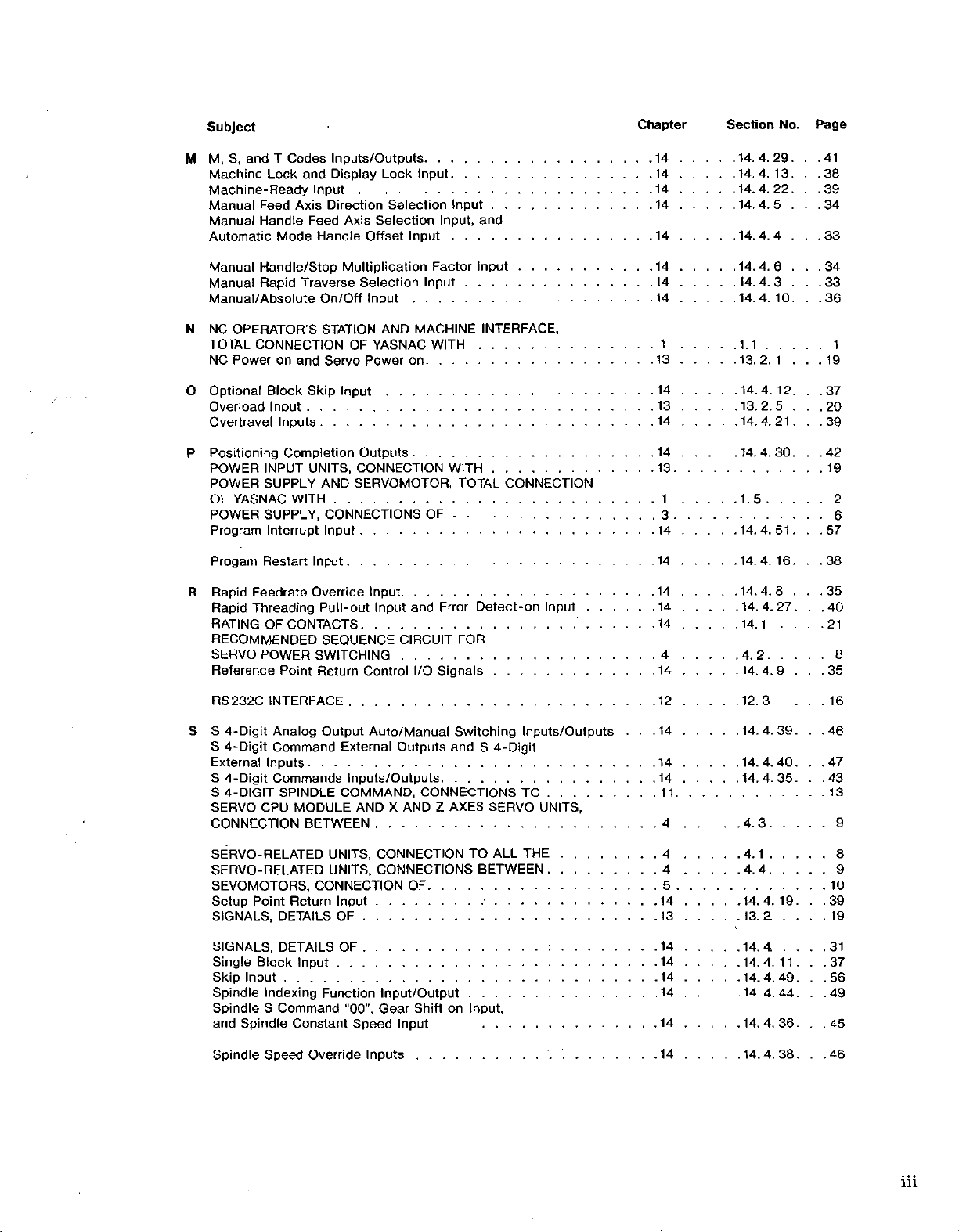

Page 7

1.

CONNECTION

LX2

shows

and

This

section

YASNAC

DIAGRAMS

connections

the

external

equipment.

between

1.

1

TOTAL

CONNECTION

OPERATOR’S

FACE

STATION

OF

AND

YASNAC

MACHINE

WITH

INTER¬

NC

YASNAC

7001-1

DATA

MODULE

I

DATA

I/O

MODULE

1001-2

CP04

|“SERVO

!

CPU

|

MODULE

r~

DATA

!

CPU

|

MODULE

CP07

JZNC-TU

POWFR

I

IMpUT

UNIT

l

LX2

(I011)

-5ib«-

02j]|-

03p»—

04.31-

05

06

31-

07D»-

08(31-

09D*

iopi-

023*

03]*-

04

31

06

07[]|-

08

pi

09

31

10

1

1

pl-

-12P*

(1012)

"[W

r

MQI-

J

LM3.5

2,

PTl.

|

©

©

©

©

©

®

I

®

I

©

i

©

©

©

©

©

j

©

PO

Jl

IROUT"'255

©

®

I

—

©

I

©

_

SCREW

TERMINAL

ECM

EOF

EON.

C

J

SCREW

M3

o

/

ASR-33

-

FACIT

RS232C

©

SCREW

-

a

SCREW

MANUAL

SIMULTANEOUS

MANUAL

FOR

MS31

TERMINAL

0

MANUAL

©

©

M3

'

TERMINAL0

---

M3

OPERATORS]

NC

STATION

MACHINE

INTERFACE

!

TERMINAL

PUNCHER

I/O

DEVICE

PULSE

PULSE

SPINDLES

29S

06820-

PULSE

GENERATOR

TWO

GENERATOR

I

1

GENERATOR

AXES

FOR

Note:The

without

type

MR

-

following

names

connector

rules

in

20

Fig,

pins,

apply

1

1.

male

to

to

1.

connectors

5.

Fig.

1.1

-

MR

connector

MR

connector

-

[I

connector

MR

|

-

20

50

50

pins,

pins,

pins,

female

male

female

1

i

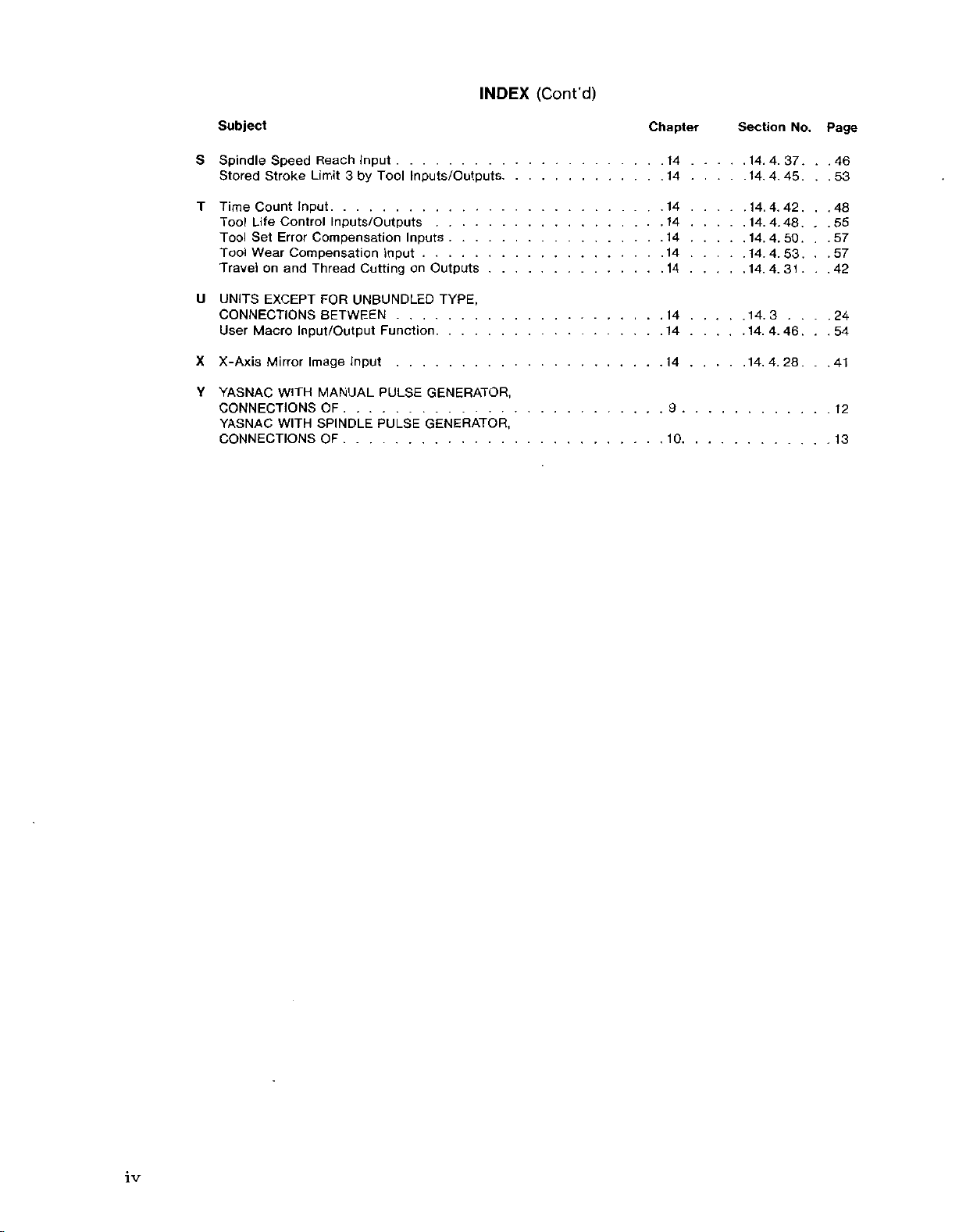

Page 8

OF

UNIT

EXTERNALLY

TAPE

1.

4

OF

CONTROL

®

SERVO

TO

ARMATURE

_TO

ARMATURE

YASNAC

READER

BASE

:

IG

TERMINAL

YASNAC

POWER

POWER

X-AXIS

Z-AXIS

SERVOMOTOR

SERVOMOTOR

WITH

PROVIDED

UNIT

WITH

4

TOTAL

1.

2

EXTERNAL

WITH

9”

YASNAC

CP07

BATA

CPU

MODULE

[JUNCTION

ITO

|CPS-2QN

CONNECTION

NC

OPERATOR

CRT

LX2

i

i

X

r

HHlCN

AMP

;

9P)

{MIC

J

OF

STATION

S

EXTERNAL

STATION

WITH

i[Cr

AMP

172026

1/002

YASNAC

NC

MODULE

u

—

J

®

1

TO

OPERATOR’S

9”

SP01

2CN

—

DAMP

?

172026

i

|

MDI

C

©

AMI

i{Mic

sp!

r'AicNn

[MINI

DATA

T

STATION

cable

MP”.

@

cable

where

I/O

i

©

I/O

MODULE

:

_

type

type

YASNAC

to

YASNAC

to

diagram

station

1.2

Fig.

junction

terminals.

unbundled

For

*

shouldbeconnected

f

For

unbundled

be

:

The

connection

employed.

is

connected

control

should

Note

the

machine

module

MACHINE

TO

CONTROL

cabinet,

cabinet,

is

shown

with

mini

T

connector

data

TOTAL

1.

EXTERNAL

TERMINAL

5

1.

TOTAL

POWER

YASNAC

JZNC-TU

fPOWER“|

INPUT

UNIT

j

_

[SERVO

I

INPUT

'POWER

[TRANS

SVX

X-AXIS

SERVO

SVZ

Z-AXIS

i

SERVO

CONNECTION

TAPE

YASNAC

LX2

BASE

TKU|||

1

!

CONNECTION

SUPPLY

LX2

rsG

Jr

j

]

L

Jr

j

M4

SCREW

TERMINAL

A.B.E

SCREW

M4

TERMINAL

A,B,E

READER

1

Fig.

AND

R,S,T,G

,

7

SCREW

M4

TERMINAL

@

SERVOMOTOR

_

©

_

@

3

TOTAL

1.

EXTERNAL

14”

CRT

YASNAC

CP07

DATA

CPU

MODULE

COMPOSITE

POWER

INPUT

UNIT

CONNECTION

OPERATOR

NC

LX2

]»

L

TB

EXTERNAL

STATION

©

©

Fig.

1.3

OF

STATION

S

TB

YASNAC

NC

OPERATOR’S

WITH

14“

CG01

D

ACGC

MODULE

TO

WITH

CRT

1

CP04

!~SERVO

CPU

MODULE

HW

JP*

MS3108B

©

-

—

-

®

Fig.

20

29S

MS3108B

20

29S

5

1.

X-AXIS

a

FEEDBACK

Z-AXIS

FEEDBACK

SERVOMOTOR

UNIT

SERVOMOTOR

UNIT

2

Page 9

2.

CABLES

AND

CABLE

CLAMPS

2.1

CABLES

The

cables

ordered

supplied

are

shall

cations

The

conform

.

Cable

1-22

23-28,

35,

48,

30,

67

37

specifications

under

1.

Specifications

listed

separately

No.

33,

43,

49,

34, 36,

the

group

44,

66

by

to

in

from

machine

the

Table

Cable

-core

Multi

mm2

0.2

(DWG.

Shield

mm2

0.2

(DWG.

Vinyl

cabtyre

2

mm2

(DWG.

Shielded

2

mm2

(DWG.

pairs

of

number,

Cable

of

the

Yaskawa.

following

1

2.

Supplied

cable

X

20

DE

No.

cable

X10

DE

No.

x

cores

5

No.

DE

composite

pairs

X2

the

(DWG.

table

tool

Cables

by

.

core

6428673)

pairs

8400093)

cable

8402398)

+0.2

DE

No.

below

builders,

Yaskawa

cable

mm2

8400094)

cables

No.

are

When

cable

Title

No.

X17

are

DE6428673)

be

to

cables

cables

specifi¬

t

2

3

4

given

Max

Conduction

Min

Insulation

Withstand

Continuous

Temperature

2.

Specifications

of

No.

Conductor

Insulation

Winding

Pairs

Table

Resistance

Resistance

Voltage

Operation

Range

Table

Material

Nominal

area

No.

mm

Per

Dimensions

Material

Thickness

3

2.

Cable

of

2.

sectional

conductors

of

Characteristics

(20'C)

£2/km

(20"C)

M£2-km

VAC/min

•c

(DWG.

4

Construction

mm2

mm

mm

113

50

1,000

-30

+60

to

DE8400093)

No.

10

Tinned

annealed

copper

stranded

wire

0.2

16/0.12

0.55

Cross-linked

vinyl

0.3

Paper

tape

winding

lap

of

Cable

No.

Conductor

Insulation

Winding

Sheath

Finished

Approx

Cable

Weight

2.

Table

Cores

Material

Nominal

area

No.

of

conductors

per

mm

Dimensions

Material

Thickness

Material

Thickness

Diameter

2

Construction

sectional

color

and

kg/km

mm2

mm

mm

mm

mm

20

annealed-

Tinned

copper

stranded

wire

0.2

16/0.12

0.55

Cross-linked

0.3

tape

Paper

winding

vinyl,

Soft

black

1.2

8.0

90

lap

vinyl

Shield

Sheath

Dimensions

Weight

Approx

Conduction

Max

(20'C)

Insulation

Min

(20‘C)

Withstand

Material

Thickness

Table

Resistance

Voltage

and

5

2.

Characteristics

Resistance

color

mm

mm

kg/km

£2/km

MQ-km

VAC/min

Tinned

copper

wire

Vinyl,

1.2

10.0

130

113

50

1,000

annealed

stranded

black

3

Page 10

1

2.

CABLES

3.

Specifications

Table

item

Conductor

Vinyl

Insulation

Stranding

Vinyl

Sheath

ELECTRICAL

•

•

•

HEAT

Vinyl

•

•

•

conduction

Max

Withstand

Min

insulation

TEST

insulator:

Testing

Heating

Heat

Remaining

Tensile

Remaining

Elongation

Operating

Allowable

30°C):

ture

Storing

(Cont'd)

of

Cable

2.6

Construction

Specification

Nominal

area

2.0

C3152

JIS"

soft-copper

37/0.26

K6723

JIS

compound

Insulation

Average

90%

or

thickness

Min

80%

or

Right

twisted

6723

JIS

K

compound

Sheath

Average

90%

or

thickness

Min

or

80%

CHARACTERISTICS

resistance:

voltage:

resistance:

Heating

±2°C

Item

Time

Temperature

Strength

temperature:

current

16

A

temperature:

(DWG.

sectional

mm2

tinned

wire

mm

vinyl

vinyl

thickness

more

more

vinyl

vinyl,

black

thickness

more

more

3000

(submerged

Vinyl

Insulator

wave

-40

No.

Characteristics

and

Thick¬

ness

(Approx)

0.8

20°C

or

VAC/min

20°C

or

48

for

hours

48

100"C

at

85%

80%

+60°

to

0

(at

ambient

+60°C

to

DE8402398)

1.9

less

in

more

hours

Vinyl

Sheath

±2'C

min

min

Outer

Diameter

(Approx)

1.8

3.4

9.2

13.0

10.2fi/km

water)

mOkm

50

at

tempera¬

100°

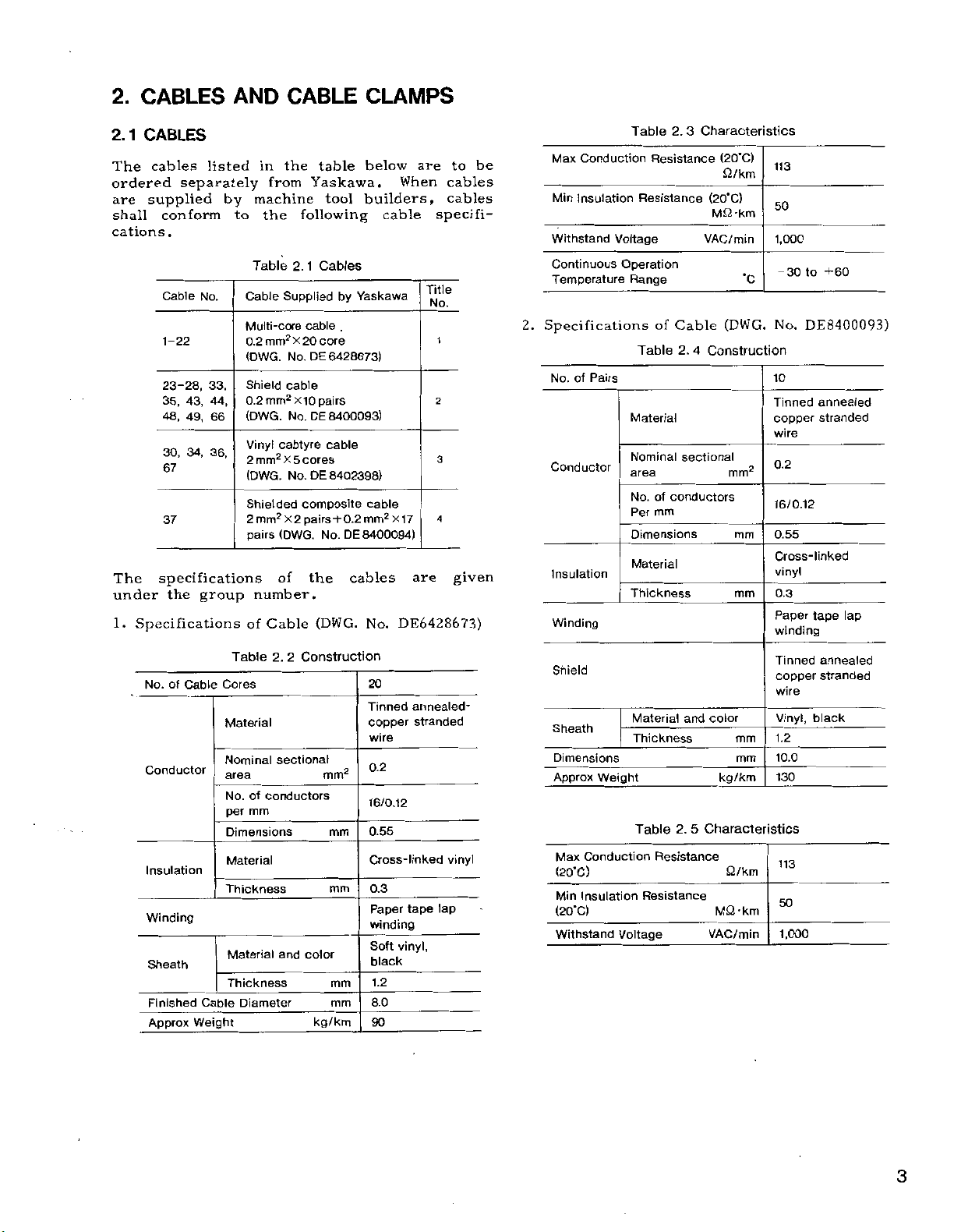

Location

Insulator

Color

VINYL

Specifications

4.

A

Lead

Lead

B

Winding

Shield

Vinyl

Sheath

Approx

Conductor

Max

(20"C)

Insulation

Min

(20"C)

Withstand

Pair

No.

1

2

3

4

5

6

7

8

9

No.

Black

VINYL

SHEATH

INCLUSION

INSULATION

CONDUCTOR

Conductor

Insulation

Conductor

Insulation

Color

thickness

Outer

Weight

Table

Item

Resistance

Voltage

Color

Blue-White

Yellow-White

Green-White

Red-White

Purple-White

Blue-Brown

Yellow-Brown

Green-Brown

-Brown

Red

1

White

of

Cable

Table

and

diameter

2.8

Resistance

Tadle

3

2

Red

LML2

4

(DWG.

7

2.

37/0.26

Vinyl,

16/0.12

Cross-linked

mm

0.3

Plastic

copper

Soft

wire

Black,

21

mm

kg

440

Characteristics

Q/km

MQ

-km

VAC/min

9

2.

Pair

No.

10

11

12

13

14

15

16

17

4

Yellow

1

:-s

3

DE8400094)

No.

mm,

Tinned

0.6mm

thick

mm,

Tinned

vinyl,

thick

lap

tape

stranded

1.5

mm

/km

A

Cable

9.81

50

1500

Color

Purple-Brown

Blue-Black

Yellow-Black

Green-Black

Red

-Black

Purple-Black

Blue-Grey

Yellow-Grey

5

Brown

winding

Cable

soft

soft

B

113

50

1000

"Japanese

4

Industrial

Standard

Page 11

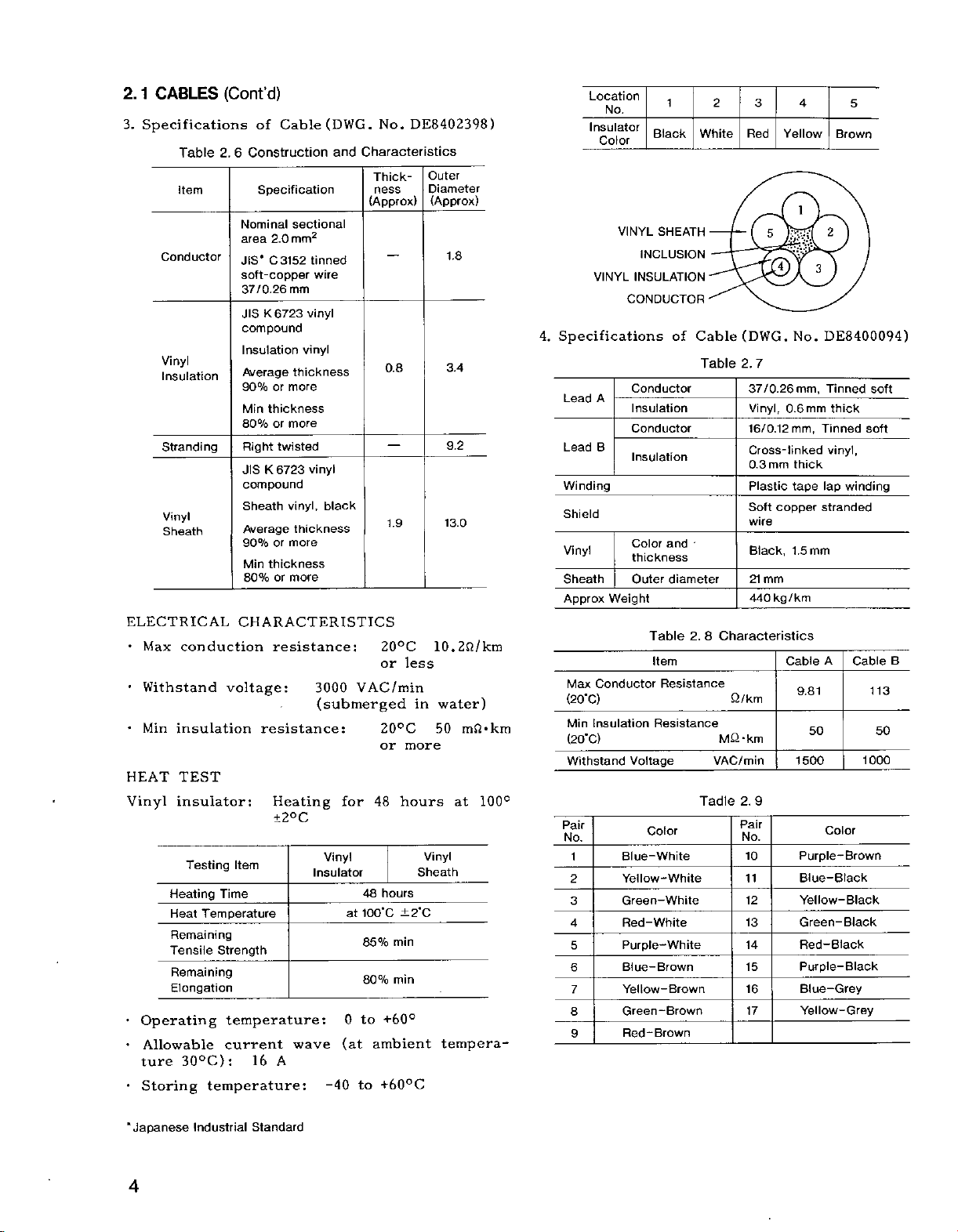

\

GROUNDPLATE

CLAMP

CABLE

SHIELD

i

ENCLOSURE

i

15

14

13

16

12

Table

11

17

\

@

[WHITE

10

2.

1

RED

BLUE

I

10

JT

9

Cable

2

3

4

7

8

Supplied

A

CABLE

INCLUSION

5

6

by

Machine

CABLE

WINDING

LAP

SHIELD

SHEATH

B

CABLE

SHIELD

B

ENCLOSURE

CABLE

CLAMP

S

E

E

GROUND-

PLATE

-E-

CABLE

CABLE

$

Builders

Specifications

No.

Cable

31,

32,

46,

47

38, 39,

57,

60

65

58,

59,

42,

41,

40,

52,

56

cable

The

pending

2

2.

CLAMPING

CABLE

Be

SHIELD

sure

YASNAC

fixtures

t

f

connected

excepted.)

are

For

the

that

after

plate

the

in

figure

55,

45,

62,

61,

53,

size

load

on

to

clamp

LX2

found

to

shielded

shield

stripping

64,

63

54,

may

duty.

CABLES,

securely

in

the

is

below.

Cable

mm2

0.3

vinyl

V

300

mm2

0.75

vinyl

V

600

cabtyre

or

2

mm2

special

V

600

cable

special

V

600

or

cable

05,

MR

MR22K

MR

37

K

V

special

600

cable

DCP

JUSP

JUSP

DCP

DCP

JUSP

be

cables

the

with

control

the

connectors

cables,

grounded

the

or

more

cable

more

or

cable

cable

more

cabtyre

08,

15

:

3.5

'

5.5

15

30

60

smaller

AND

the

clamp

cable

vinyl

or

resistant

heat

heat

resistant

cable

2

mm2

K

mm2

mm2

resistant

heat

:

mm2

2

A

A:

mm2

5.5

:

14

A

mm2

listed

than

GROUNDING

connected

the

clamping

cables

as

panel.

on

securely

sheath

cable

connector

vinyl

vinyl

vinyl

to

(Cables

to

shown

de¬

the

base

the

so

Note

enclosure

LIST

:

Non-shielded

Fig.

OF

SHIELDED

YASNAC

CP07

E

F

H

CP04

M

for

J

E

F

H

J

L

clamping.

Clamping

1

2.

LX2

MR

-

MR

-

cables

CABLE

i

s-1

3—

connector

connector

do

not

of

r

require

Shielded

CLAMPS

pins,

20

pins,

20

i

stripping

Cables

X-AXIS

male

female

COMMAND

OUTPUT

PULSE

TWO-AXIS

NC

(X)

<Z)

MOTOR

MOTOR

PULSE

PULSE

POSITION

S4-DIGJT

ANALOG

MANUAL

GENERATOR

REMOTE

CURRENT

INDICATOR

REMOTE

OPERATOR

EXTERNAL

UNIT

EXTERNAL

UNIT

FEEDBACK

Z-AXIS

FEEDBACK

MANUAL

GENERATOR

SPINDLE

GENERATOR

cable

S

STATION

SERVO

SERVO

UNIT

UNIT

NO.

2

Note

:

shield

be

madeinthe

x

Shield

grounded

is

:

Symbol

ground

cabinet.

for

should

externally,

Fig.

shielded

be

at

shield

2.

2

cable

a

single

ground

clamp

point.

should

When

not

5

Page 12

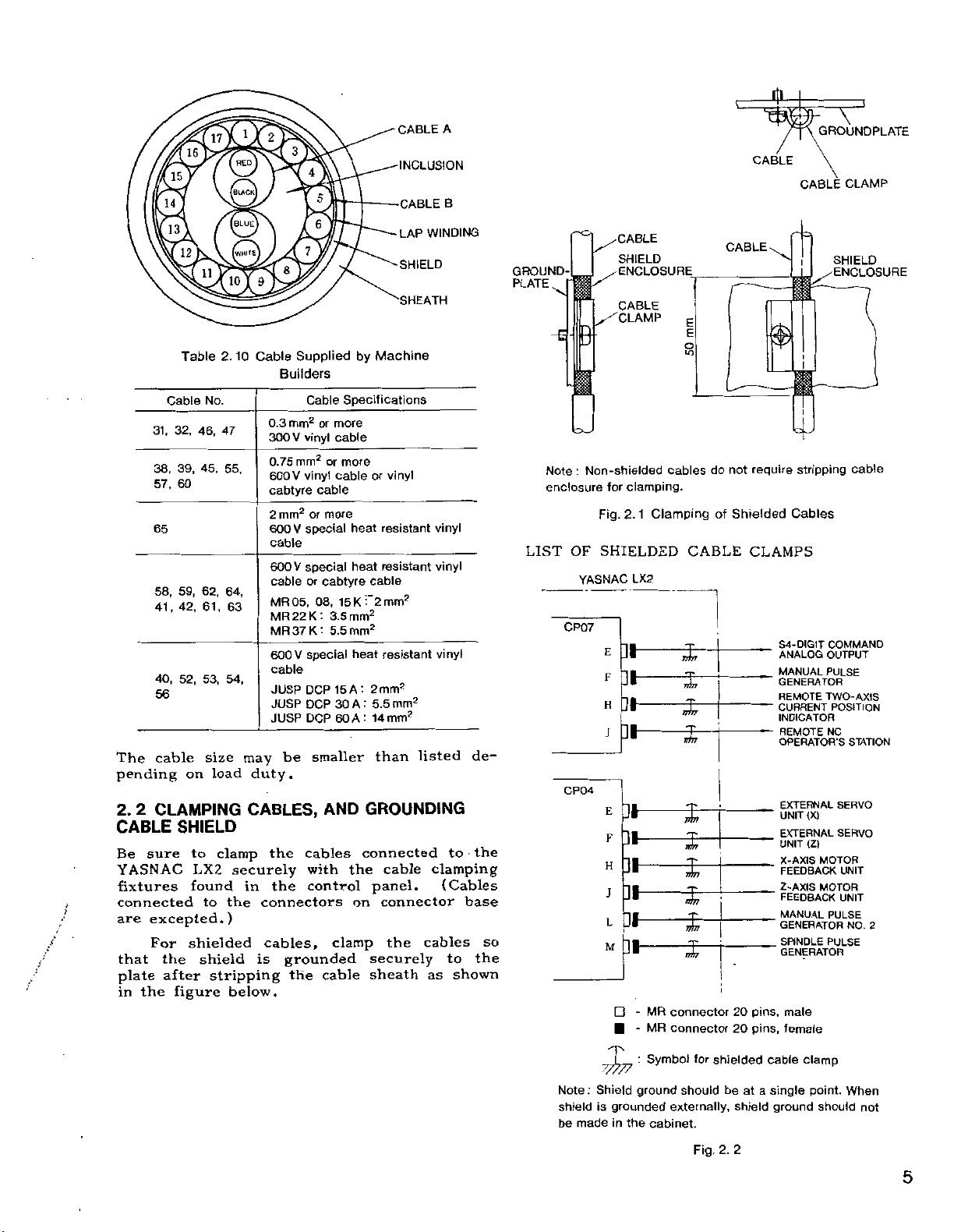

3.

CONNECTIONS

SUPPLY

Specifications

unit

are

shown

of

input

below.

OF

power

POWER

of

the

control

(2)

Input

Applicable

type,

servo

input

input

power

Power

to

provided

the

power

B.

B

for

controls

with

B

free

in

a

transformer

and

standing

the

one

for

free

unit

standing

the

for

control

the

Standard

200/220/230

Hz,

Single-phase

Input

Power

200/220

-15%,

to

•

•

Power

Power

with

following

are

Standard

and

Capacity

capacity

used

Power

The

tion

(1)

type

Applicable

the

or

type

power

feature

YASNAC

1TB-

VAC,

power:

+10%

input

B:

240/380/420/460

Hz

MR

05

08

15

22

37

four

with

for

±1

control

for

modes

the

50/60

supply

supply

Type

MR

MR

MR

MR

MR

input

attached

to

attached

the

type

controls

B.

r

to

Hz,

servo

Table

YASNAC

power

2

type

-15%,

-

at

480/550

Three-phase

unit:

units

3.1

Capacity

Power

kVA

1

1.6

3

4

6.9

of

power

LX2.

for

the

in

without

2,

1

free

free

50/60

VAC,

kVA

is

line

Hz

different

connec¬

standing

standing

the

input

±1

+10%

YASNAC

(3)

Input

Application

vided

input

(4)

with

power

YASNAC

External

YASNAC

1

S,

III

power

to

only

B.

R

S_ÿ

T

Gl,

r

f

servo

B

the

a

1

Fig.

3.

for

attached

controls

transformer

I.

Fig.

3.

unit

type

CONTROL

SIGNAL-PHASE

(STANDARD

SERVO

(INPUT

GROUNDING

2

POWER

POWER

type

in

POWER

INPUT

attached

for

SERVO

POWER

(INPUT

POWER

GROUNDING

CONTROL

(STANDARD

3

POWER

INPUT

INPUT,

POWER)

INPUT,

B)

TERMINAL

2

the

INPUT,

)

B

TERMINAL

INPUT

POWER)

pro¬

servo

%

4

Tt

Gl

CONTROL

SERVO

'

THREE-PHASE

(STANDARD

GROUNDING

X

Fig.

3.

1

AND

POWER

INPUT

TERMINAL

INPUT,

POWER)

Note:Make

terminal

1

r

s

G

3

class

larger.

mm2

3.5

or

X

grounding

Fig.

3.

CONTROL

SINGLE-PHASE

GROUNDING

4

usingaground

work

POWER

INPUT,

TERMINAL

6

Page 13

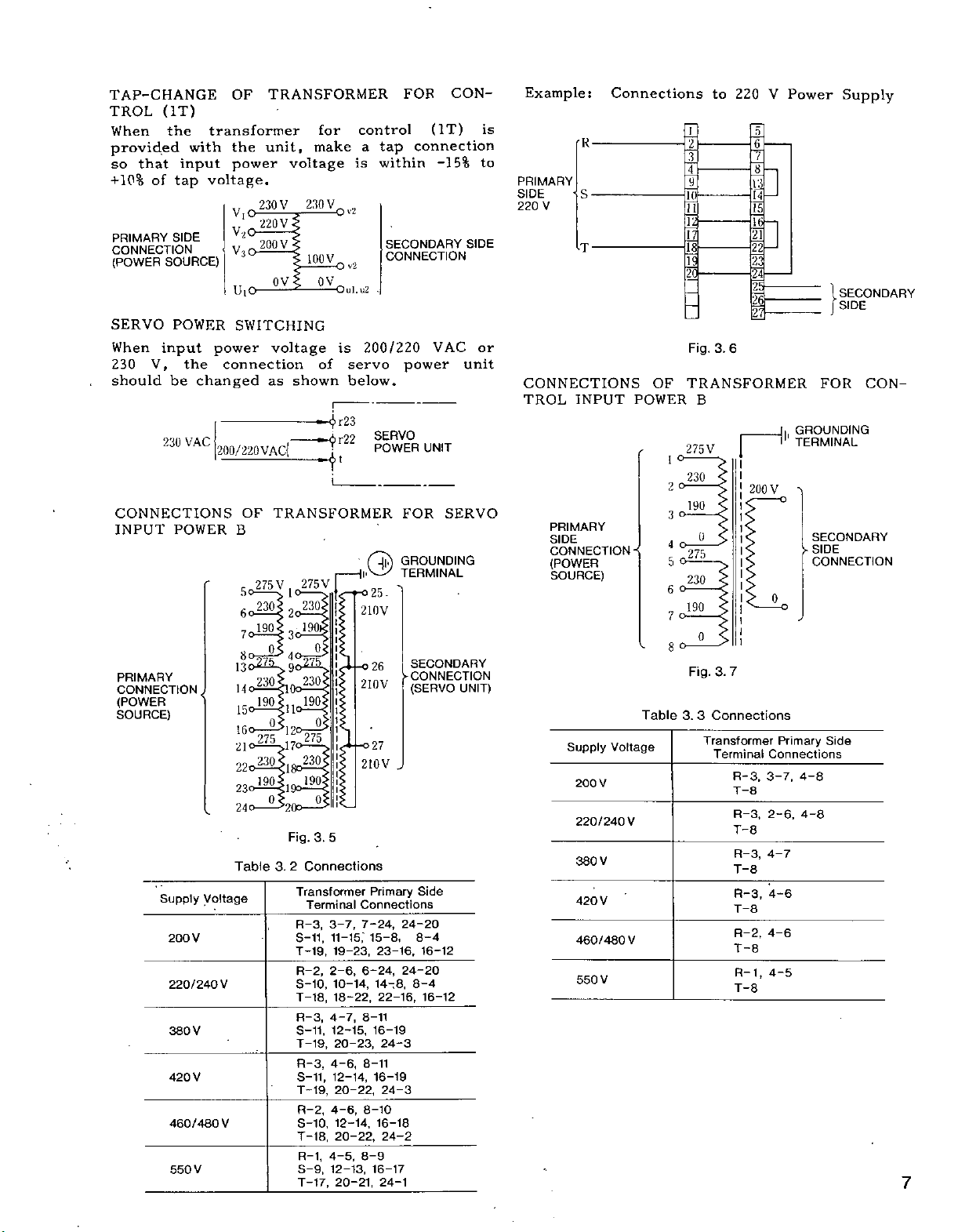

TAP-CHANGE

that

of

V,

(IT)

the

with

input

tap

SIDE

SOURCE)

POWER

input

the

be

TROL

When

provided

so

+10%

PRIMARY

CONNECTION

(POWER

SERVO

When

230

should

OF

transformer

the

power

voltage,

V,0

v2o

V30

I

uto

SWITCHING

power

connection

changed

TRANSFORMER

for

unit,

make

voltage

230

230

220

200

-

ov

voltage

V

V

V

V

100V

0

Ov2

O

V

-Oul.u2

is

of

shown

as

control

a

is

v2

.

200/220

servo

below.

tap

within

FOR

CON¬

(IT)

connection

-15%

SECONDARY

CONNECTION

VAC

power

SIDE

unit

Example:

is

to

PRIMARY

SIDE

220

or

CONNECTIONS

TROL

Connections

to

220

V

Power

Supply

[I]

R

J

S

V

1

10

H

13

ii

T

1

15

0

P

23

25

26

27

3.

6

SECONDARY

SIDE

FOR

CON¬

INPUT

OF

POWER

IS

Fig.

TRANSFORMER

B

VAC

230

CONNECTIONS

INPUT

PRIMARY

CONNECTION

(POWER

SOURCE)

POWER

Supply

200

220/240

380

420

460/480

550

.

V

V

V

V

200/220VACI

OF

TRANSFORMER

«|>r22

t

B

V

So™*

275

1

Ca230i2o230'

7Q19O|CC19Q*

o

:i

11'

gw

,17<

;n

Fig.

3.2

73

230

190:

275

i9o:

3.

5

Connections

Transformer

Terminal

3-7,

R-3,

11-15,'

S-11,

T-19,

19-23,

2-6,

R-2,

10-14,

S-10,

18-22,

T-18,

R-3,

4-7,

S-11,

12-15,

T-19,

20-23,

R-3,

4-6,

12-14,

S-11,

T-19,

20-22,

R-2,

4-6,

12-14,

S-10,

T-18,

20-22,

4-5,

R-1,

S-9,

12-13,

20-21,

T—

17,

130ÿÿ9,

230

U

190

15'

16'

275

21

22o230|igt>230

190

23

24ÿ20&_o

Table

Voltage

V

V

SERVO

POWER

FOR

GROUNDING

TERMINAL

25-

210V

SECONDARY

26

-CONNECTION

2I0V

210V

Connections

7-24,

6-24,

8-11

8-11

8-9

27

Primary

15-8,

23-16,

14-8,

22-16,

16-19

24-3

16-19

24-3

8-10

16-18

24-2

16-17

24-1

(SERVO

J

24-20

8-4

24-20

8-4

UNIT

Side

16-12

16-12

SERVO

UNIT)

PRIMARY

SIDE

CONNECTION

(POWER

SOURCE)

Supply

Voltage

V

200

220/240

V

380

420

V

460/480

V

550

V

V

-

Table

275

o

1

o

2

&

3

O

4

o

5

o

6

190

o

7

o

8

3.3

V

230

190

275

230

0

Fig.

3.

Connections

Transformer

Terminal

rH"

200

V

0

7

Connections

R-3,

3-7.

8

T—

R-3,

2-6,

T-8

R-3,

4-7

T-8

4-6

R-3,

T-8

R-2,

4-6

T-8

4-5

R-1,

T-8

GROUNDING

TERMINAL

SECONDARY

SIDE

*

CONNECTION

Primary

4-8

4-8

Side

7

Page 14

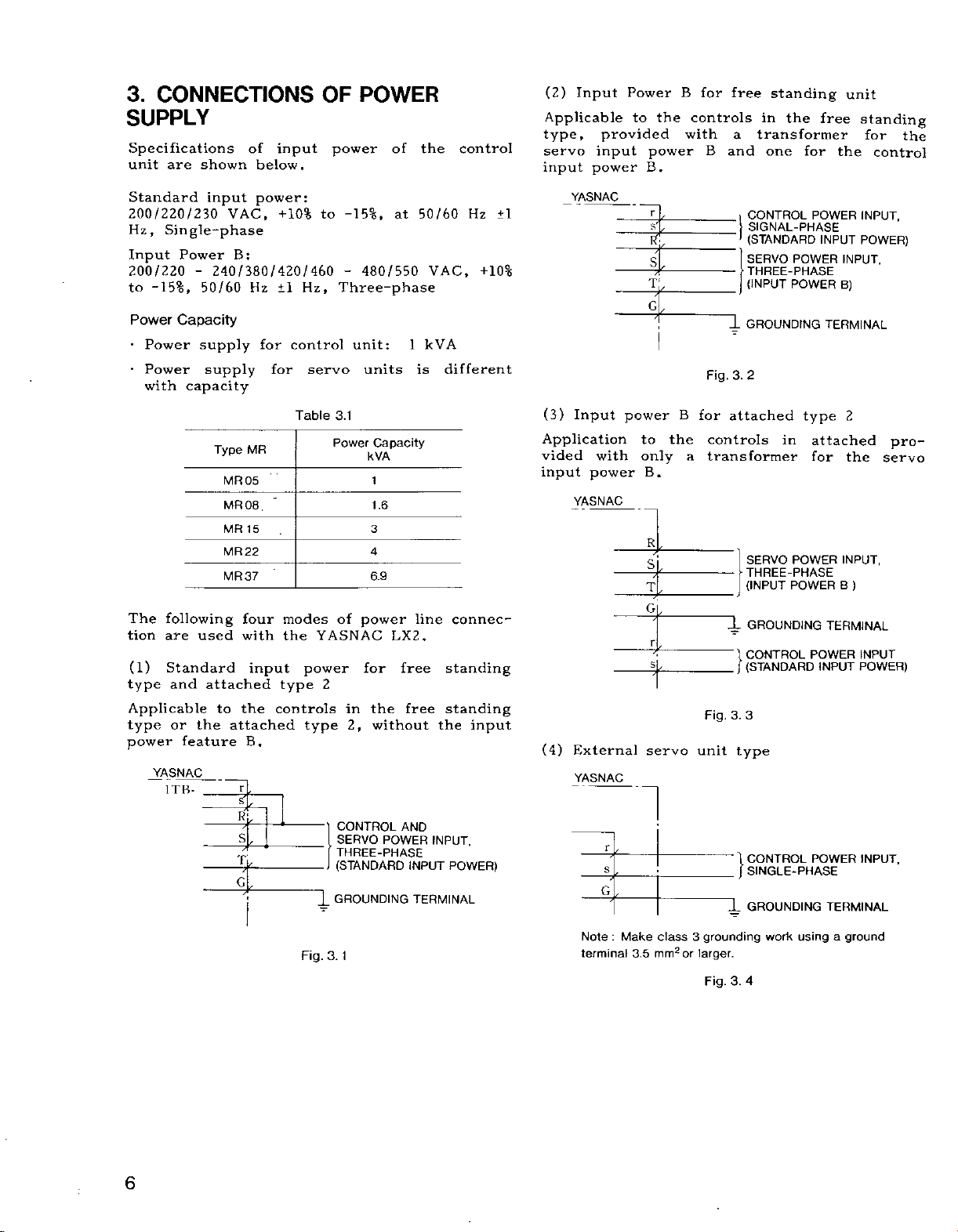

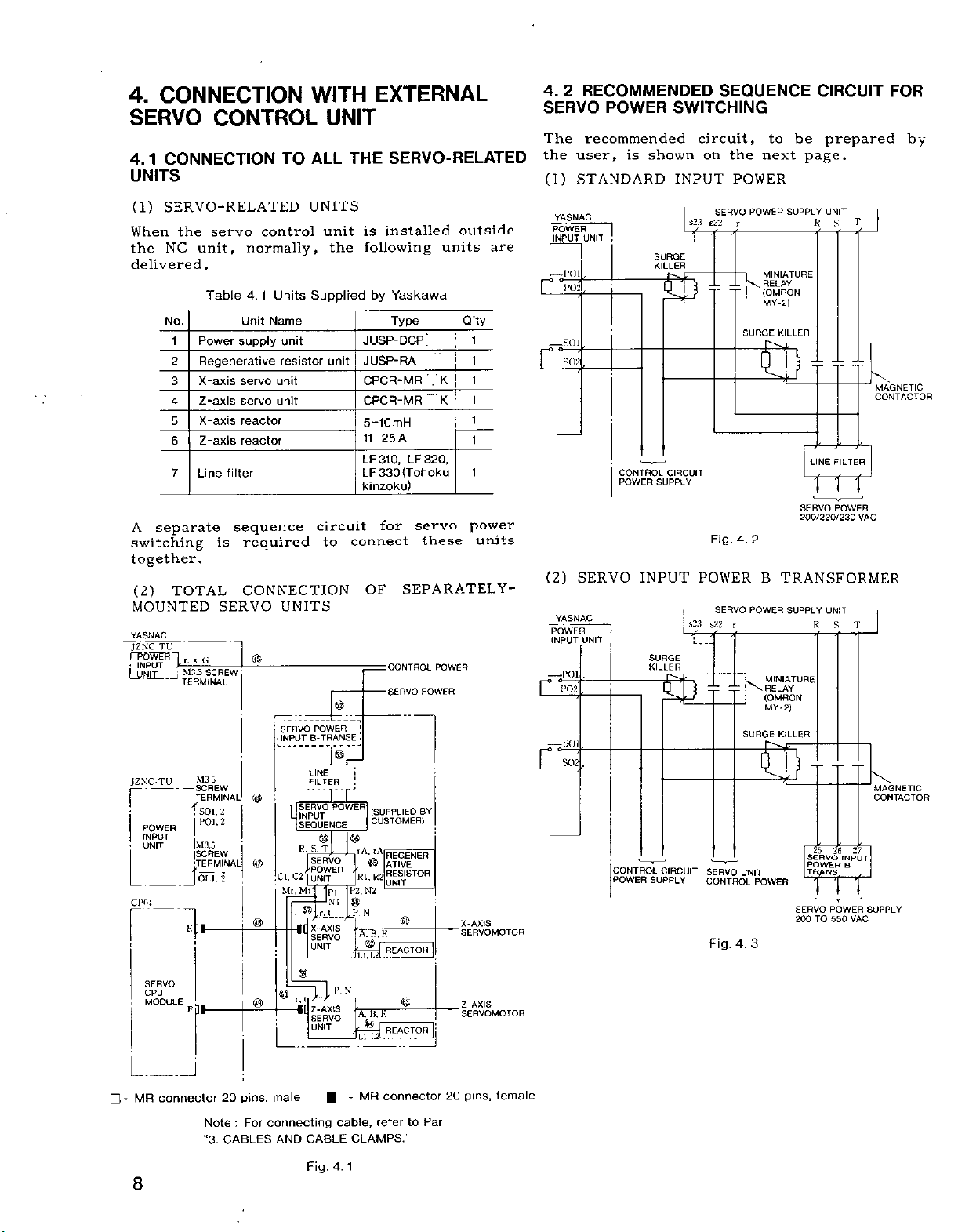

4.

CONNECTION

SERVO

4.1

CONNECTION

CONTROL

UNITS

TO

WITH

UNIT

ALL

THE

EXTERNAL

SERVO-RELATED

4.

2

RECOMMENDED

SERVO

The

the

(1)

POWER

recommended

user,

STANDARD

is

SWITCHING

circuit,

shown

on

INPUT

SEQUENCE

be

to

the

next

POWER

CIRCUIT

prepared

page.

FOR

by

(1)

SERVO-RELATED

When

the

the

NC

unit,

delivered.

Table

No.

1

Power

Regenerative

2

3

X-axis

Z-axis

4

5

X-axis

Z-axis

6

7

Line

A

separate

switching

together.

(2)

TOTAL

MOUNTED

YASNAC

TU

JZNC

fPOWEFn

•

INPUT

UNIT

L

JZNC-TU

f

POWER

INPUT

UNIT

Cl>fl4

SERVO

CPU

MODULE

(i

T.

S.

y

M3.5

TERMINAL

M3

-

SCREW

—

|

TERMINAL

SOI.

POl.

|\13.5

SCREW

0L1.

J

SCREW

servo

control

normally,

4.

1

Unit

supply

servo

servo

reactor

reactor

filter

sequence

is

required

CONNECTION

SERVO

©

3

@

2

2

®

2

j

©

©

Units

Name

unit

resistor

unit

unit

UNITS

'SERVO

.

INPUT

;

CLC2

--

Mr.

L_

UNITS

unit

Supplied

circuit

to

POWER

B-TRANSE

:ilNE

:FILTER

‘rr

SERVO

INPUT

SEQUENCE

©

S,

T

R.

SERVO

j

POWER

UNIT

Mt

]P1

|

©

r,

X-AXIS

SERVO

UNIT

©

n

r.t

|[

Z-AXIS

SERVO

I

UNIT

installed

is

following

the

by

Yaskawa

Type

JUSP-DCP

JUSP-RA

unit

CPCR-MR.

.

CPCR-MR

5-10mH

A

11-25

LF

310,LF320,

(Tohoku

330

LF

kinzoku)

servo

for

connect

OF

©

|

.

I

i

POWER

(SUPPLIED

CUSTOMER)

©

.

tA

TA.

_

©_

R1.R2

N2

P2.

NI

©

t

P

N

'

B,

A.

L1.L2

N

P.

'

A.

H.

-

©

Jini-REACTQR

these

SEPARATELY-

CONTROL

POWER

SERVO

BY

REGENER-

ATIVE

RESISTOR

UNIT

©

K

REACTOR

©

E

I

1*

li

outside

units

Q’ty

K

K

POWER

X-AXIS

SERVOMOTOR

Z-AXIS

SERVOMOTOR

are

1

1

1

1

1

1

1

power

units

POWER

INPUT

«

O

—

f—

L

—

Hi

(2)

POWER

INPUT

-

|~°

-

Hi

YASNAC

UNIT

POl

0—7

roz

SOI

SERVO

YASNAC

UNIT

POl,

P02

SOI

I

!

CONTROL

POWER

INPUT

1

CONTROL

POWER

SURGE

KILLER

SB

CIRCUIT

SUPPLY

SURGE

KILLER

£5

CIRCUIT

SUPPLY

SERVO

s2li

s22

Fig.

POWER

SERVO

s23

s22

Y72

=b

SERVO

CONTROL

Fig.

POWER

r

MINIATURE

-L

RELAY

\

--

(OMRON

MY-

--

SURGE

S5

4.

2

B

POWER

r

W

MINIATURE

\

dr

RELAY

(OMRON

MY-

SURGE

UNIT

POWER

3

4.

UNIT

SUPPLY

2)

KILLER

R

LINE

S

FILTER

T

MAGNETIC

CONTACTOR

TTT

SERVO

POWER

200/220/230

VAC

TRANSFORMER

SUPPLY

UNIT

R

S

T

2)

KILLER

MAGNETIC

CONTACTOR

25

27

26

SERVO

INPUT

POWER

B

TRANS.

TTT

POWER

VAC

SUPPLY

SERVO

200TO550

-

I

MR

8

i

connector

i

pins,

20

Note:For

"3.

CABLES

male

connecting

CABLE

AND

Fig.

MR

-

cable,

CLAMPS.”

4.1

connector

to

refer

Par.

20

pins,

female

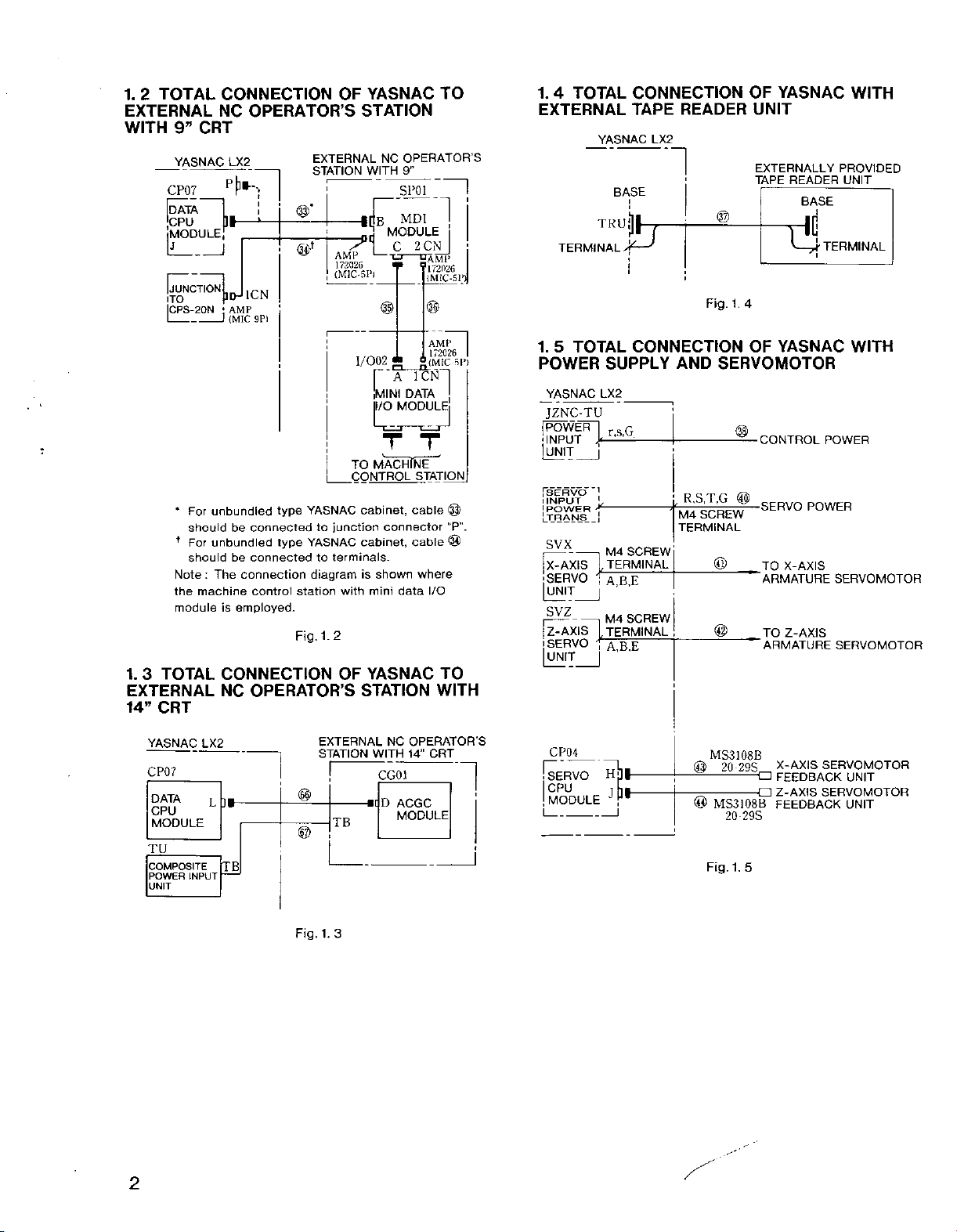

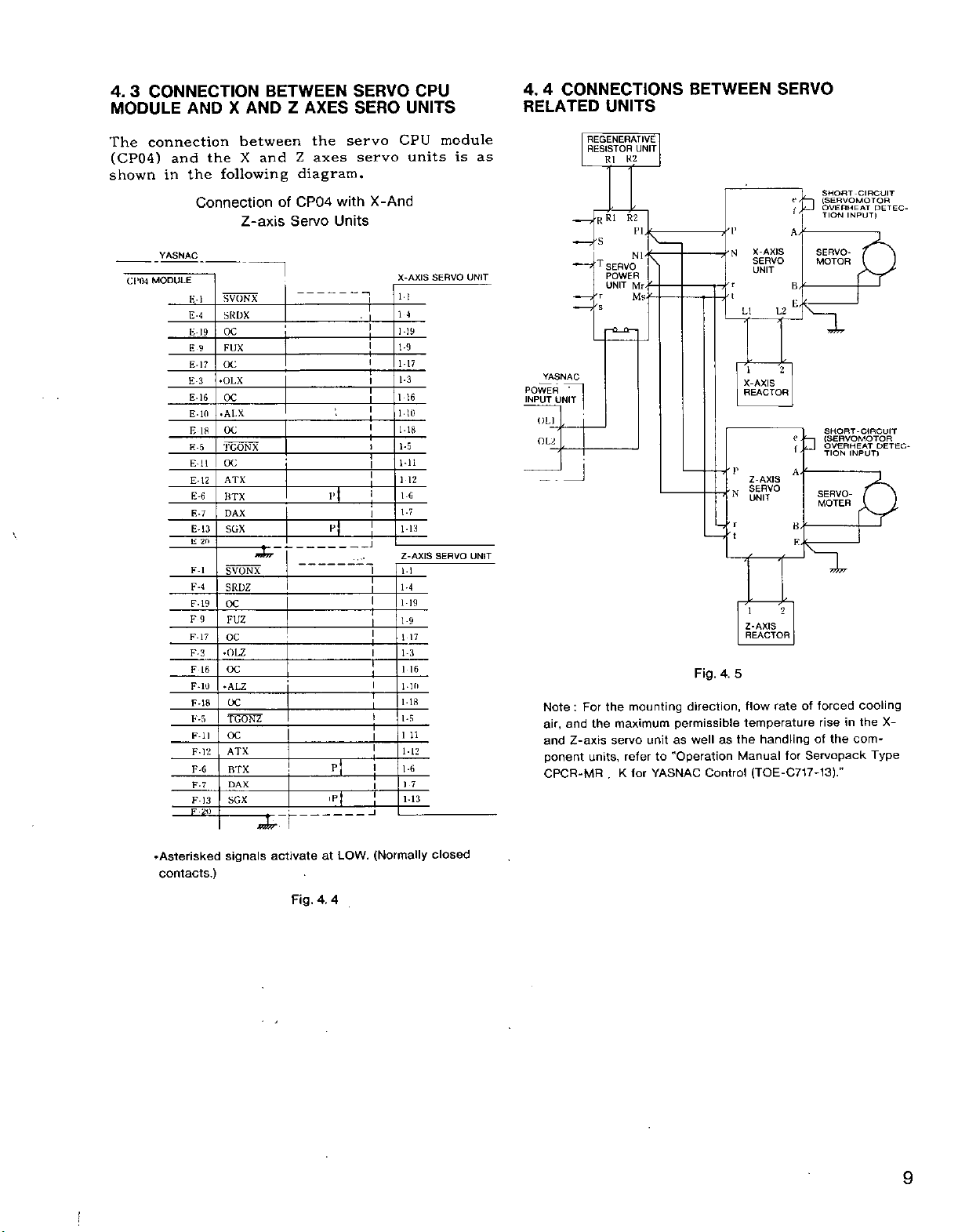

Page 15

3

4.

CONNECTION

MODULE

AND

BETWEEN

X

AND

Z

AXES

SERVO

SERO

CPU

UNITS

4

CONNECTIONS

4.

RELATED

UNITS

BETWEEN

SERVO

module

servo

X-And

-I

CPU

units

X-AXIS

11

14

1-19

1-9

1-17

1-3

l

16

110

1-18

1-5

Ml

1

12

l-G

1-7

1-13

Z-AXIS

11

1-4

1-19

1-9

17

1

1-3

16

1

110

118

1-5

1

11

1-12

1-6

17

M3

SERVO

SERVO

is

as

UNIT

POWER

]NPUT

OLl

OL

UNIT

the

The

connection

(CP04)

shown

\

CP04

and

in

VASNAC

MODULE

the

K-

E-4

E-

E

E-

E-3

E-

E10

E

E-5

E-l

E-12

E-6

E-7

E-

E

F-l

F-4

F

F

F-17

F-3

F

F-10

F-18

K-5

F-ll

F

between

the

X

following

Connection

Z-axis

SVONX

1

SRDX

OC

19

FUX

9

OC

17

OLX

•

16

OC

ALX

•

OC

18

TCP

NX

OC

1

ATX

BTX

DAX

13

SGX

20

SVONX

SRDZ

19

OC

9

FUZ

OC

OLZ

•

OC

16

•ALZ

OC

TGONZ

OC

ATX

F-12

F-6

BTX

DAX

F-7

SGX

F-

13

and

Z

diagram.

CP04

of

Servo

servo

axes

with

Units

3

jT

Tp[

REGENERATIVE

RESISTOR

YASNAC

~

1

UNIT

Note:For

air,

and

and

Z-axis

units,

ponent

CPCR-MR

K1

-RR1

'S

T

SERVO

POWER

UNIT

T

's

the

the

.

UNIT

K2

R2

PI.

Nl'ÿT

Mr--

Ms.

mounting

maximum

unitaswell

servo

refer

for

K

direction,

permissible

"Operation

to

YASNAC

Fig.

Control

X-AXIS

SERVO

UNIT

LI

1

X-AXIS

REACTOR

Z-AXIS

SERVO

VN

UNIT

r

'

Z-AXIS

REACTOR

5

4.

flow

temperature

handling

the

as

Manual

(TOE-C717-13)."

L2

2

2

rate

for

SHORT-CIRCUIT

(SERVOMOTOR

|

OVERHEAT

f

'

A/

SERVO¬

MOTOR

B/ÿ

SERV

MOTE

forced

of

rise

of

Servopack

INPUT)

TION

SHORT-CIRCUIT

(SERVOMOTOR

OVERHEAT

INPUT)

TION

O-

:R

cooling

the

in

the

com¬

DE

DE

X-

Type

TEC-

TEC-

.Asterisked

contacts.)

signals

activate

Fig.

(Normally

LOW.

at

4.

4

closed

9

Page 16

5.

CONNECTION

The

connection

shown

and

is

only

Z-axis

motors

applicable

X-

unit.

(1)

CONNECTIONS

MOTOR

AND

YASNAC

the

of

below.

where

are

OF

SERVOMOTORS

X-axis

the

servo

incorporated

BETWEEN

LX2

This

and

X-AXIS

Z-axis

connection

units

for

the

in

SERVO¬

servo¬

the

NC

(2)

CONNECTIONS

MOTOR

is

YASNAC

svz

(Z-AXIS

SERVO

UNIT)

AND

A,

YASNAC

LX2

BETWEEN

LX2

i

Z-AXIS

A(A2)

B(AI)

SERVO¬

Z-AXIS

SERVOMOTOR

SVX

(X-AXIS

SERVO

UNIT)

CP04

+

5V

OV

YASNAC

MODULE

H-

H

H-16

H

H-

H-19

H-14

H-15

H-4,

5,6

H-1,2,3

8,

12

9,

H

A.*-

10

-ll

17

18

20

LX2

if

0

0

0

if

if

if

if

if

if

0

ATX

BTX

PAX

PAX

•

PBX

PBX

•

PCX

•PCX

Tftrr

P

P

P

P

P

Fig.

;

5.1

-2-

A(A2)

X-AXIS

SERVOMOTOR

B(A1)

L

0

M

A

0

B

0

C

0

D

0

R

0

S

0

H

0

G

0

A(

B(-)

)

+

X-AXIS

SERVO-

MOTOR

>

FEEDBACK

UNIT

CP04

5V

+

0V

Note

1.

When

peel

The

2.

where

the

motor

MODULE

J

J-li

J-I6

J-17

-

J

J-

J-14

J-

J-4.5,6

J-1,2.3

9,

8,

-20

J

:

connecting

coating

the

connection

"the

output

run

10

if

if

*PAZ

if

18

if

19

*PBZ

if

0

15

*PCZ

0

0

if

12

0

motor

shaft

direction,

ATZ

BTZ

PAZ

PBZ

PCZ

T777T

Fig.

the

cabletothe

connect

and

diagram

for

indicates

runs

clockwise

motioninthe+direction.

change

P

P

P

3

P

the

*-

0

0

0

0

0

0

0

0

0

5.

2

feedback

shield

the

the

as

connection

L

;A(

M

A

B

C

D

R

s

H

G

to

connection

viewed

B(

the

+)

—

unit,

from

B

as

)|

>

be

housing.

for

the

the

For

follows.

Z-AXIS

SERVO-

MOTOR

FEEDBACK

UNIT

sure

to

the

case

rear

of

opposite

•Asterisked

contacts.)

10

signals

activate

at

LOW.

(Normally

closed

3.

Where

wiring

NC

the

SERVO

A

of

SVX/Z

of

SVX/Z

B

CP

Of

10

11

CP

of

16

of

CP

of

CP

17

18

of

CP

of

CP

19

servo

the

identical,

is

unit.

Refer

CONTROL

04,

04,

04,

04,

04,

04,

H/J

H/J

H/J

H/J

H/J

H/J

units

except

to

UNIT."

are

Para.

(A1)

B

2)

(A

A

M

feedback

of

of

feedback

L

Coffeedback

of

feedback

D

of

feedback

A

of

feedback

B

installed

that

SVX

"4.

CONNECTION

Servomotor

of

of

Servomotor

outside

SVZ

and

unit

unit

unit

unit

unit

unit

the

are

WITH

unit,

NC

located

EXTERNAL

the

outside

Page 17

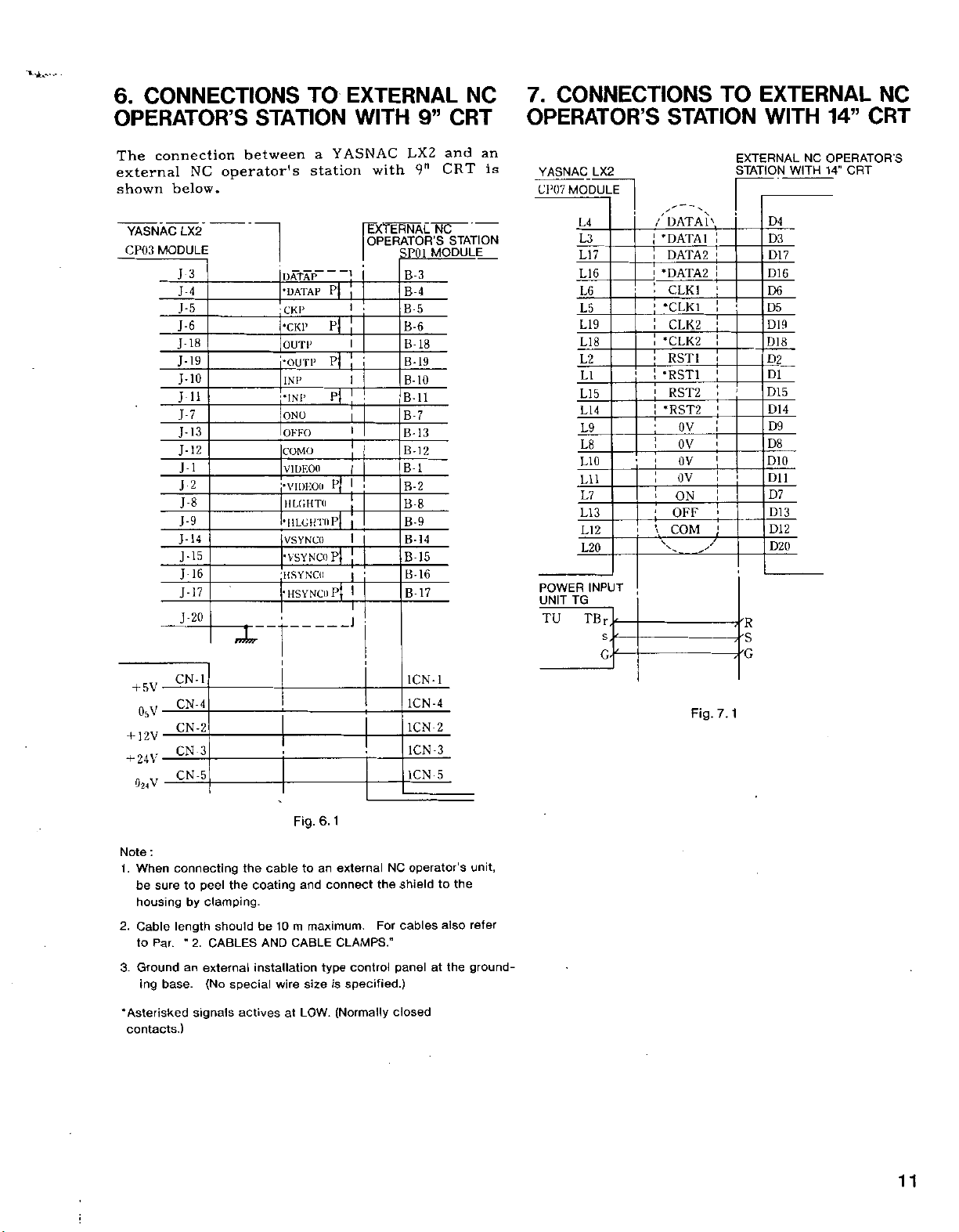

6.

CONNECTIONS

OPERATOR’S

connection

The

external

shown

NC

below.

between

operator's

TO

STATION

YASNAC

a

station

EXTERNAL

with

9”

LX2

9"

CRT

and

CRT

WITH

NC

an

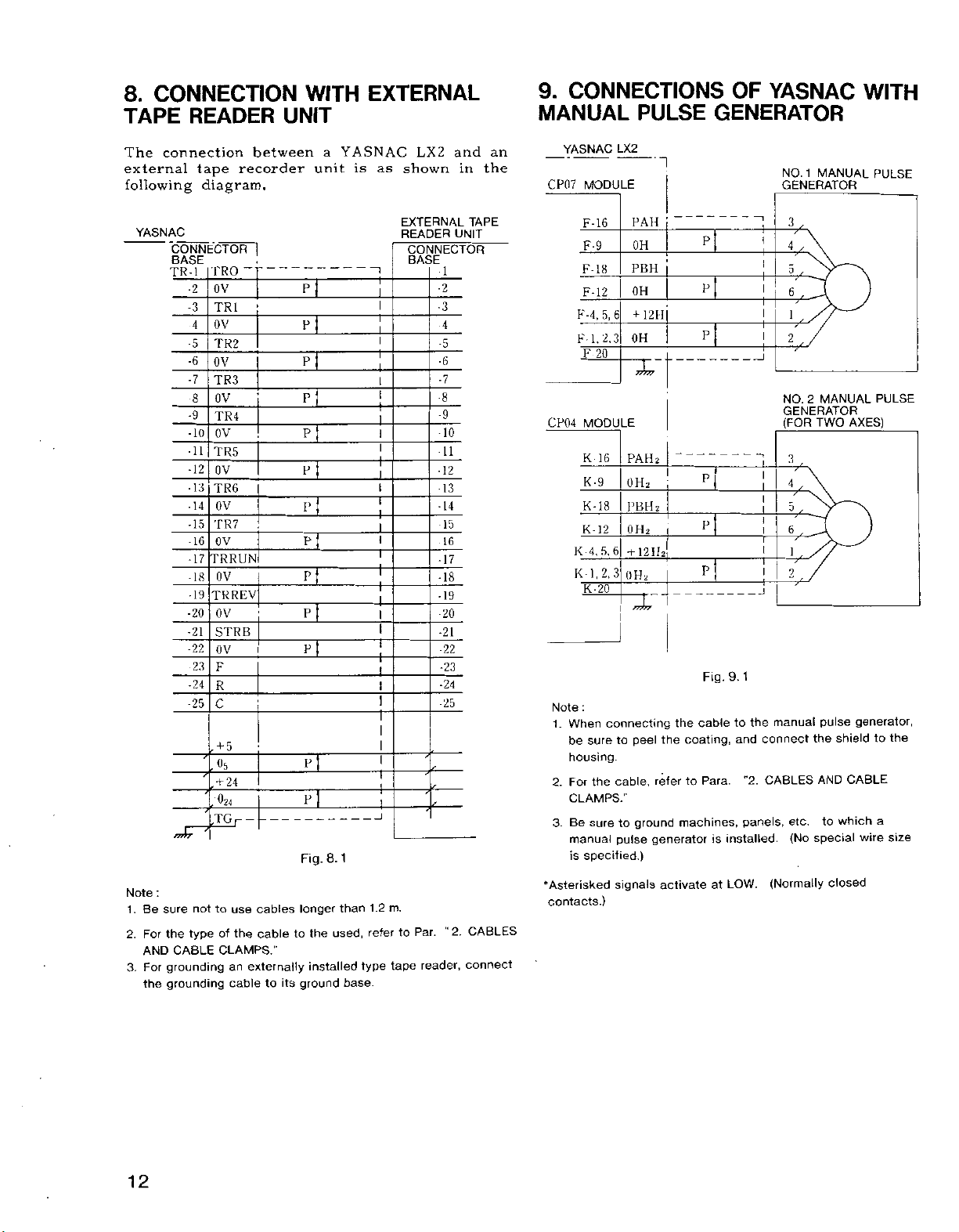

7.

CONNECTIONS

OPERATOR’S

is

YASNAC

Cl’07

MODULE

LX2

TO

STATION

EXTERNAL

STATION

EXTERNAL

NC

WITH

14”

OPERATOR

CRT

14"

WITH

NC

CRT

S

YASNAC

MODULE

CP03

LX2

3

J

J-4

J-5

J-6

J-18

19

J-

J-10

a

J

J-7

13

J-

12

J-

J-l

2

J

J-8

.1-9

14

-

J

J-15

16

J

17

J-

-

20

J

DATAP

P|

•DATAP

CKP

P

•CKP

OUTP

P|

•OUTP

1NP

ONO

OKFO

COMO

VIDKOtl

•VIDEOll

IILGHTO

wr

P

.•INI’

•ULGHTnP

VSYNCO

P

HSYNCO

•HSYNCO

P

EXTERNAL

OPERATOR'S

SPfll

B-3

B-4

B

B-6

B-

B-19

B-10

BB-7

B-

B-12

B

B-2

B-8

B-9

B-

B-15

J

5

18

11

13

1

14

B-16

17

B-

NC

STATION

MODULE

L4

_

L3

L17

L16

L6

L5

L19

L18

1,2

LI

L15

L14

L9

L8

L10

Lll

L7

LI

3

L12

L20

TU

TG

INPUT

TB

POWER

UNIT

/DATAI\

'DATA1

DATA

•DATA2

CLK1

*CLK1

CLK2

*CLK2

RST1

•RST1

RST2

•RST2

OV

OV

OV

OV

ON

OFF

+

COM

-v

*

2

D4

D3

D17

D16

D6

D5

D19

D18

D2

D1

D15

D14

D9

D8

DIO

Dll

D7

D13

D12

D20

5V

+

o,v

12V

+

24V

+

02<V

Note

:

connecting

When

1.

be

sure

housing

Cable

2.

Par.

to

3.

Ground

ing

base.

•Asterisked

contacts.)

CN-1

CN-4

CN-2

CN

CN-5

to

by

length

"

2.

an

signals

3

peel

the

clamping.

should

CABLES

external

special

(No

the

cable

coating

be

AND

installation

actives

10

wire

at

Fig.

an

to

and

maximum.

m

CABLE

size

LOW.

1

6.

external

connect

CLAMPS."

control

type

specified.)

is

(Normally

the

For

1CN-1

1CN-4

1CN-2

1CN-3

1CN

NC

shield

cables

panel

closed

5

operator's

to

also

the

at

unit,

the

refer

ground¬

Fig.

7.1

11

Page 18

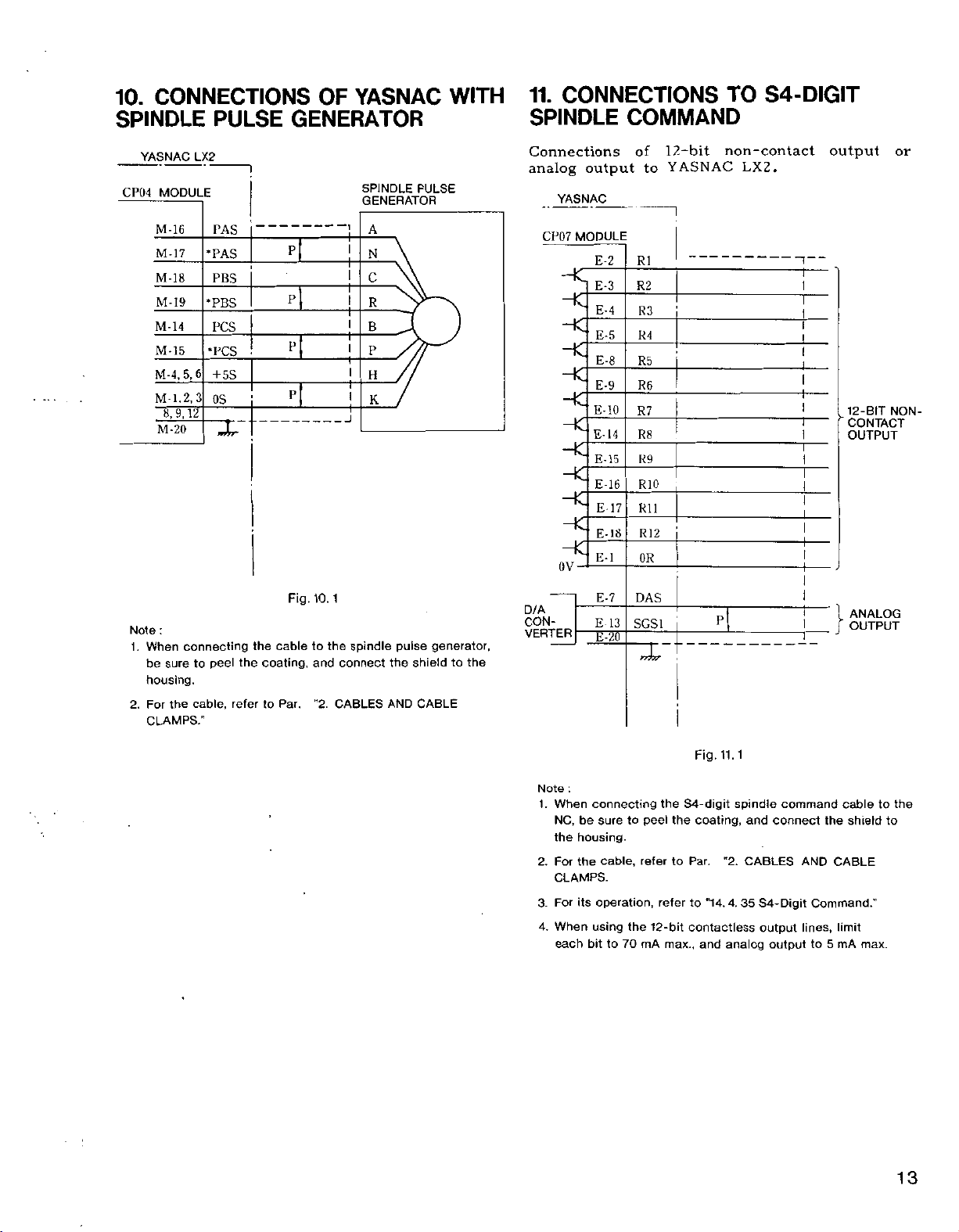

8.

CONNECTION

TAPE

READER

WITH

UNIT

EXTERNAL

9.

CONNECTIONS

MANUAL

PULSE

OF

YASNAC

GENERATOR

WITH

The

connection

external

following

YASNAC

Note

:

sure

Be

1.

the

For

2.

AND

grounding

For

3.

grounding

the

YASNAC

tape

between

recorder

unit

a

is

as

diagram.

PRO

ov

TRI

OV

TR2

OV

TR3

OV

TR4

ov

TR5

OV

TR6

OV

TR7

OV

TRRUN

OV

TRREV

0V

STRB

ov

F

R

C

5

+

I

~T

EL

n

EL

P

n

El

p

PT

n

u

EE

CONNECTOR

BASE

TR-I

I

2

3

4

5

6

7

8

9

10

11

12

13 13

14

15

16 16

17

18

19

20

21

22

23

24

25

,

El

24

,

J7nr

not

type

CABLE

+

,'0?4

-TGr

use

to

the

of

CLAMPS."

externally

an

cabletoits

cables

cable

p

Fig.

longer

the

to

installed

ground

8.

used,

1

than

base.

1.2

refer

type

m.

tape

and

LX2

Par.

reader,

1

2

3

4

5

6

7

8

9

10

11

12

14

15

17

18

19

20

21

22

23

24

25

"

in

UNIT

2.

shown

EXTERNAL

READER

CONNECTOR

BASE

to

an

the

TAPE

CABLES

connect

YASNAC

MODULE

CP07

F-16

F-9

IK

F-

F-12

K-4,

FI.

20

F

CP04

MODULE

16

K

K-9

K-18

12

K-

4,5,6

K

1,2.3

K

K-20

:

Note

When

1.

sure

be

housing.

For

the

2.

CLAMPS."

Be

sure

3.

manual

specified.)

is

•Asterisked

contacts.)

LX2

PAH

OH

PBH

OH

5,

+

6

1

2.3

OH

PAH

OH2

PBH;

OH;

+

12H2j

OH;

~X

connecting

peel

to

cable,

ground

to

pulse

signals

II

2

|

2

i

1

the

the

refer

machines,

generator

activate

P

5

P

P

P

P

Fig.

cable

coating,

Para.

to

is

at

J

9.1

to

the

and

connect

"2.

CABLES

panels,

installed.

LOW.

1

NO.

MANUAL

GENERATOR

I

5

6ÿ

l

2

MANUAL

NO.

2

GENERATOR

(FOR

TWO

3

4ÿ

D

6

1

2

pulse

manual

the

AND

to

etc.

(No

special

(Normally

AXES)

shield

CABLE

which

closed

PULSE

PULSE

generator,

the

to

a

wire

size

12

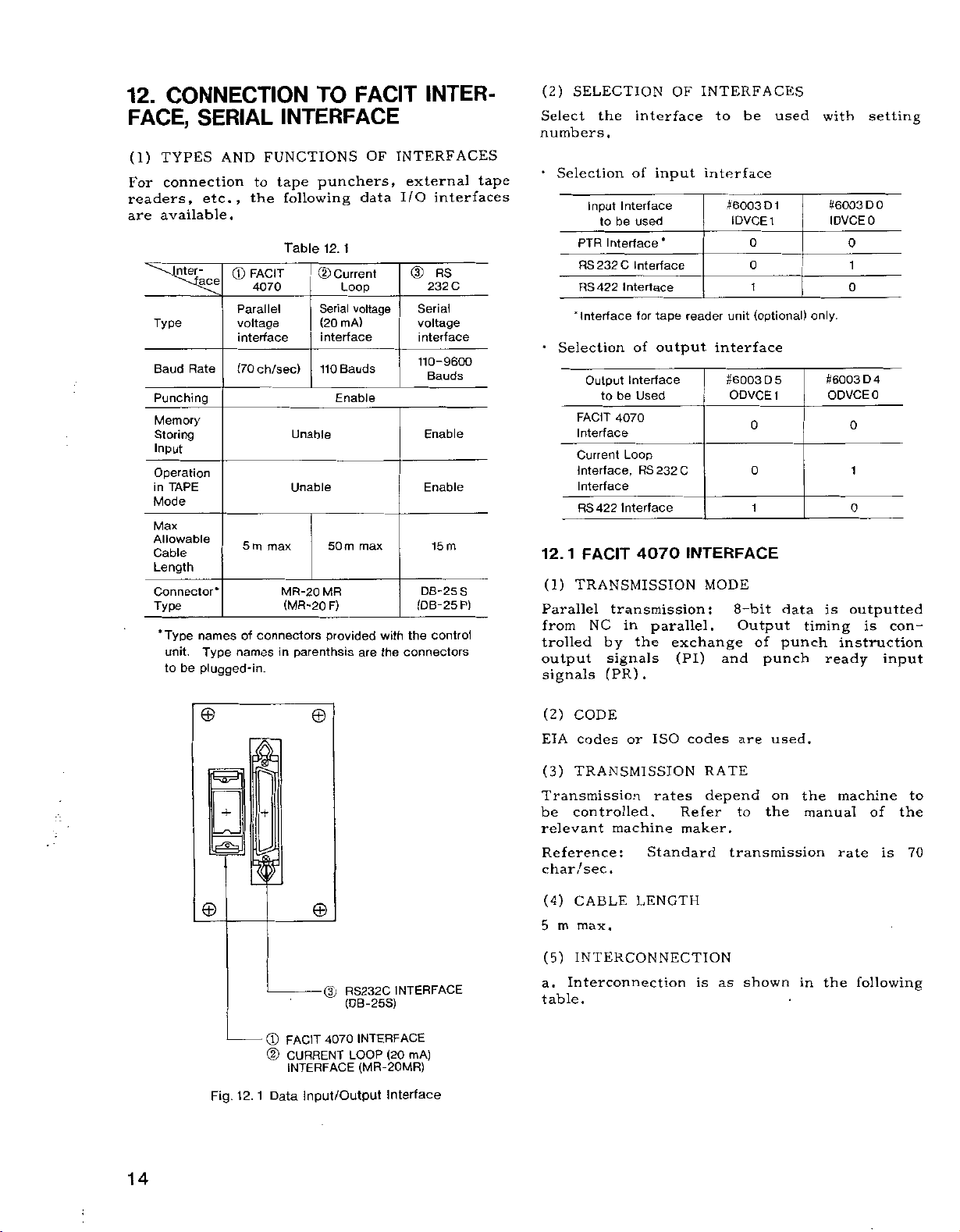

Page 19

CONNECTIONS

10.

SPINDLE

PULSE

YASNAC

OF

GENERATOR

WITH

11.

CONNECTIONS

SPINDLE

COMMAND

TO

S4-DIGIT

YASNAC

CP04

Note

When

1.

be

housing.

For

2.

CLAMPS."

MODULE

M-16

M-17

M-18

M-I9

M-14

M15

M-4,5,6

2,

M

l.

8,9,

12

M-20

:

connecting

sure

the

LX2

PAS

•PAS

PBS

•PBS

PCS

•PCS

+

3

peel

to

cable,

5S

OS

rwXr-

the

refer

the

cabletothe

coating,

Par

to

P

P

P

P

Fig.

10.

and

"2.

SPINDLE

GENERATOR

J

1

spindle

connect

CABLES

ANALOG

OUTPUT

or

NON-

l?.-bit

E-2

E-3

E-4

E-5

E-8

E-9

E-10

E-

E-15

E-16

E-17

E-18

E-l

E-7

E

E¥

14

13

of

to

R1

R2

R3

R4

R5

R6

R7

R8

R9

RIO

Rll

R12

OR

DAS

SCSI

YASNAC

Connections

analog

PULSE

A

YASNAC

CP07

output

MODULE

N

C

R

B

P

H

K

HC

HC

HC

HC

HC

HC

HC

HC

HC

HC

HC

OV

D/A

CON¬

pulse

the

AND

generator,

shield

CABLE

the

to

VERTER

non-contact

LX2.

P

output

12-BIT

”

CONTACT

OUTPUT

Note

When

1.

NC,

the

For

2.

CLAMPS.

3.

For

When

4.

each

:

be

housing.

the

its

bit

connecting

to

sure

cable,

operation,

using

the

to

70

peel

refer

12-bit

mA

the

the

to

refer

max.,

Fig.

11.1

S4-digit

coating,

Par.

"2.

to

4.

"14.

contactless

analog

and

spindle

and

CABLES

S4-Digit

35

command

connect

output

output

cable

the

CABLE

AND

Command.”

lines,

limit

5

to

mA

shield

max.

the

to

to

13

Page 20

CONNECTION

12.

FACE,

(1)

For

readers,

are

SERIAL

TYPES

connection

available.

Inter-

[ace

Type

Rate

Baud

Punching

Memory

Storing

Input

Operation

in

TAPE

Mode

Max

Allowable

Cable

Length

Connector*

Type

‘Type

names

unit.

to

be

plugged-in.

AND

etc.,

Type

FUNCTIONS

to

the

FACIT

©

4070

Parallel

voltage

interface

(70ch/sec)

5

m

max

of

connectors

names

FACIT

TO

INTERFACE

OF

punchers,

tape

following

Table

Unable

Unable

MR-20

(MR-20

parenthsis

in

1

12.

Current

CD

Loop

Serial

mA)

(20

interface

Bauds

110

Enable

50

m

MR

F)

provided

data

voltage

max

are

with

the

INTER¬

INTERFACES

externa]

I/O

©

232

Serial

voltage

interface

110-9600

Bauds

Enable

Enable

15

DB-25S

(DB-25P)

the

connectors

tape

interfaces

RS

C

m

control

(2)

SELECTION

Select

numbers.

Selection

*

Input

PTR

RS232C

RS422

'Interface

•

Selection

Output

FACIT

Interface

Current

Interface,

Interface

RS422

12.

1

FACIT

(1)

TRANSMISSION

Parallel

NC

from

trolled

output

signals

the

interface

of

input

Interface

be

to

used

Interface

Interface

for

of

Interface

be

Used

4070

Loop

RS232C

Interface

*

tape

output

Interface

to

4070

transmission:

in

parallel.

the

by

signals

(PR).

OF

INTERFACES

to

interface

#6003

1DVCE1

unit

reader

interface

#6003

ODVCE

INTERFACE

MODE

8-bit

Output

exchange

(PI)

and

be

D

0

0

1

(optional)

D

0

0

1

of

punch

used

1

5

1

data

punch

with

#6003

IDVCEO

only.

#6003

ODVCEO

is

timing

ready

setting

0

D

0

1

0

4

D

0

1

0

outputted

is

con-

instruction

input

©

+

le®3J

©

Fig.

12.

ft

+

1

®

©

Data

©

©

(3)

4070

FACIT

CURRENT

INTERFACE

Input/Output

RS232C

(DB-25S)

INTERFACE

INTERFACE

(20

LOOP

(MR-20MR)

Interface

mA)

(2)

CODE

codes

EIA

(3)

TRANSMISSION

or

Transmission

be

controlled.

relevant

Reference

char

(4)

m

5

(5)

a.

machine

:

/sec.

CABLE

max.

INTERCONNECTION

Interconnection

table.

ISO

rates

Standard

LENGTH

codes

RATE

depend

Refer

maker.

is

are

used.

on

the

to

transmission

shown

as

the

manual

the

in

machine

of

rate

following

to

the

is

70

14

;

Page 21

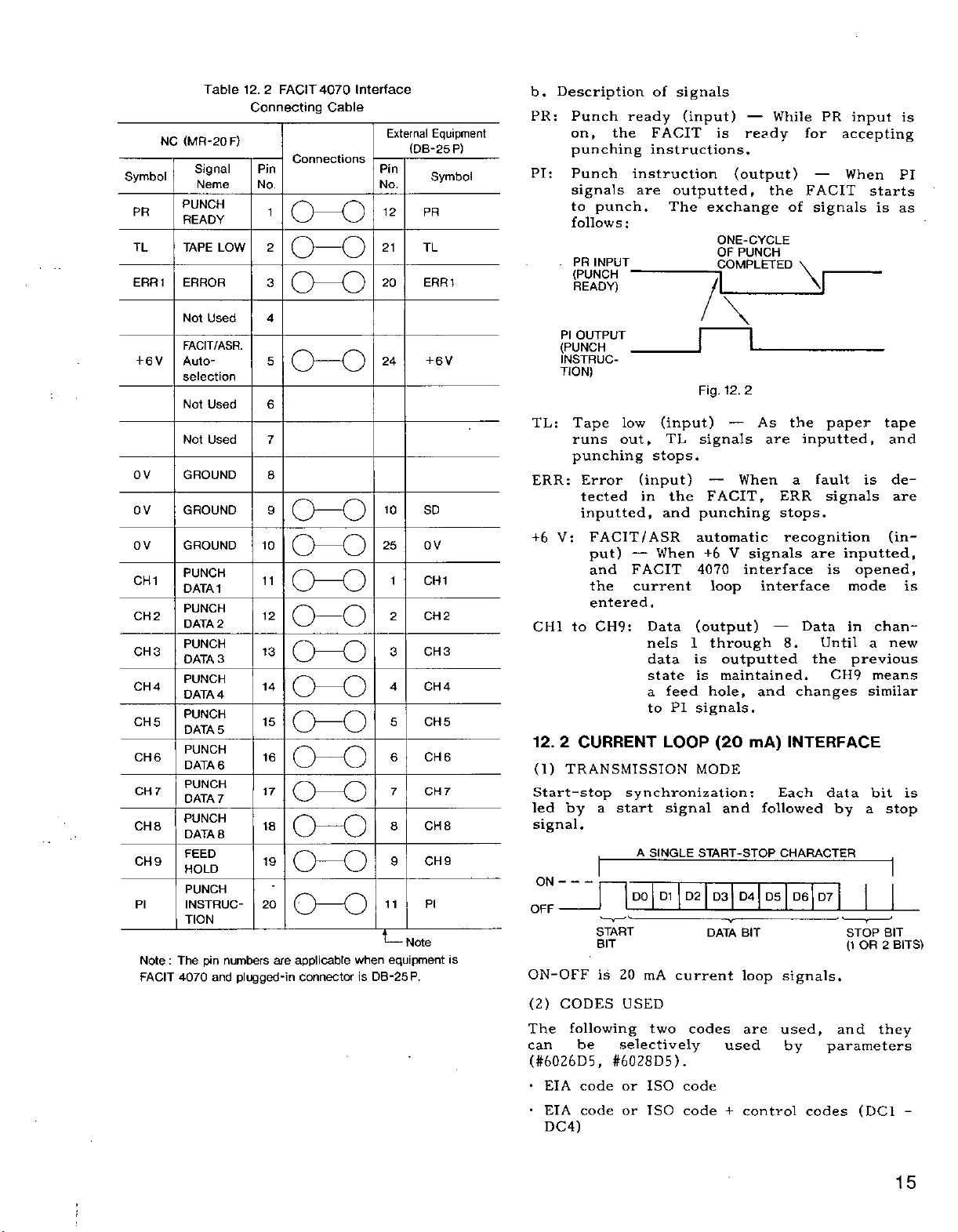

Symbol

PR

TL

ERR1

NC

Table

(MR-20

Signal

Neme

PUNCH

READY

TAPE

ERROR

F)

LOW

12.

2

FACIT4070

Connecting

Pin

No.

1

2

3

Interface

Cable

Connections

CH)

o-o

o—o

External

Pin

No.

12

21

20

Equipment

(DB-25P)

Symbol

PR

TL

ERR1

b.

Description

PR:

PI:

.

Punch

the

on,

punching

Punch

signals

to

punch.

follows

PR

INPUT

(PUNCH

READY)

of

ready

FACIT

instructions,

instruction

are

The

:

1

signals

(input)

is

outputted,

exchange

ONE-CYCLE

OF

COMPLETED

While

—

ready

(output)

the

PUNCH

of

PR

for

FACIT

signals

V

input

accepting

When

starts

is

is

PI

as

numbers

plugged-in

4

5

o-o

6

7

8

9

0-0

10

o—o

11

003

12

o—o

13

(H)

14

(K)

15

COO

16

0-0

17

oo

18

o—o

19

o—o

20

o—o

applicable

are

connector

when

is

24

10

25

1

2

3

4

5

6

7

8

9

11

Note

equipment

DB-25P.

+

SD

OV

CH

CH3

CH4

CH5

CH6

CH

CH8

CH9

PI

Not

Used

FACIT/ASR.

Auto¬

6

V

+

selection

Not

Used

Not

Used

2

3

5

PI

Note

FACIT

7

:

GROUND

GROUND

GROUND

PUNCH

DATA1

PUNCH

DATA

2

PUNCH

3

DATA

PUNCH

4

DATA

PUNCH

5

DATA

PUNCH

DATA

6

PUNCH

7

DATA

PUNCH

8

DATA

FEED

HOLD

PUNCH

INSTRUC¬

TION

The

pin

and

4070

OV

OV

OV

CH1 CH1

CH

CH

CH4

CH

CH6

CH

CH8

CH9

PI

OUTPUT

(PUNCH

6

V

2

7

INSTRUC¬

TION)

TL:

Tape

runs

punching

ERR:

Error

tected

inputted,

+6

FACIT/ASR

V:

put)

and

entered

to

CHI

2

12.

CURRENT

(1)

TRANSMISSION

Start-stop

led

by

low

out,

(input)

in

—

FACIT

the

current

CH9:

synchronization:

start

a

(input)

stops,

and

When

.

Data

nels

data

state

a

to

LOOP

signal

TL

the

feed

PI

Fig.

punching

automatic

4070

(output)

1

is

is

signals.

MODE

12.

signals

When

FACIT,

V

+6

loop

through

outputted

maintained.

hole,

(20

and

1

2

As

are

ERR

stops.

recognition

signals

interface

interface

8.

and

mA)

Each

followed

the

paper

inputted,

fault

a

is

signals

are

inputted,

is

opened,

mode

Data

in

Until

the

previous

CH9

changes

similar

INTERFACE

data

a

by

tape

and

de¬

(in¬

chan-

new

a

means

bit

stop

are

is

is

signal.

A

SINGLE

ON

-

-

OFF

is

ON-OFF

(2)

CODES

The

following

can

be

(#6026D5,

•

•

EIA

EIA

DC4)

code

code

START

BIT

is

20

USED

selectively

#6028D5)

or

or

DO

mA

two

ISO

ISO

D1

D2

current

codes

.

code

code

START-STOP

D4

D3

DATA

D5

BIT

loop

are

used

control

+

CHARACTER

D6

D7

signals.

used,

by

and

parameters

codes

STOP

(1

OR

(DC1

BIT

BITS)

2

they

-

15

;

i

Page 22

2

12.

CURRENT

(Cont'd

To

trolled

DC1

shown

(3)

The

a

(4)

The

with

the

)

control

use

must

through

below.

Character

Tape

DC1

start

Tape

2

DC

designation

Tape

3

DC

stop

_

Tape

DC

4

release

TRANSMISSION

transmission

parameter.

CABLE

LENGTH

permissible

machine

the

manual

of

Reference:

(5)

INTERCONNECTION

•

The

interconnection

Table

(MR-20

NC

V

2

1

Signal

Name

Not

FACIT/

ASR.

selection