Page 1

TOE-C843-7

INSTRUCTIONS

w

25

®o§

RUS

*IK®

rag

f

initial

Before

read

these

horoughly,

future

reference

operation

instructions

and

retain

A

Jm

jfl

This

ators

not

nance

encountered

contact

manual

maintenance

The

provide

and

mssmam

"v

frm

primarily

is

information

all

details

troubleshooting.

for

your

nearest

instructions

contained

to

particular

YASNAC

intended

met

be

If

maintenance

to

for

YASNAC

in

this

concerning

uncertainties

service

give

manual

operation,

office.

oper¬

H

LX1.

does

mainte¬

be

BB

Sill

ra*j

H:

YASNAC

LX1

OPERATOR'S

Hgli

Igllil

0

e

I

0

0

I

STATION

m

Mk

Efc

s

*9

ES

582-231

Page 2

OUTLINE

1.

1.1

COMPONENT

CONTROL

1.2

SYSTEM

MAINTENANCE

1.3

ROUTINE

1.4

1.4.1

1.4.2

1.4.3

1.4.4

TROUBLESHOOTING

2.

2.1

TROUBLE

2.1.1

2.1.2

2.1.3

TROUBLESHOOTING

2.2

2.2.1

2.2.2

TROUBLESHOOTING

2.3

CODES

2.4

SUPPLY

2.4.1

2.4.2

SYSTEM

BLOCK

3

Tape

Control

Servomotor

Battery

Nature

Operations

Unit

NC

of

List

counteracting

28

Check

DC

Power

1

ARRANGEMENT

DIACRAM

INSPECTION

Reader

Panel

and

6

ISOLATION

Circumstances

and

and

Check

Alarm

VOLTAGE

power

Supply

1

OF

YASNAC

INSTRUMENTS

SCHEDULE

5

5

Motor

DC

7

7

Programming

8

BY

ALARM

Codes

Alarm

Supply

10

Codes

WITHOUT

CHECK

Voltage

Voltage

OF

CONTROL

for

Trouble

of

Checks

18

37

Check

YASNAC

4

Spindle

CODES

ALARM

37

Table

4

38

Contents

of

ON-LINE

STATUS

2.5

TICS

Output

3.

3.1

3.2

5

3.2.1

3.2.2

3.3

FUNCTION

2.5.1

2.5.2

Outline

Operating

Signals

2.5.3

(

List

ADJUSTMENTS

ADJUSTMENT

POWER

Tap

)

49

2T

Tap

DISPLAYING

DISPLAY

(DCN

of

Displays

Procedure

39

Standard

of

TRANSFORMER

Changing

Changing

BY

)

38

Input/Output

UPON

PROCEDURES

AND

INSTALLATION

Control

on

Control

on

WRITING

DIAGNOS¬

38

to

Display

Signals

47

CONNECTIONS

Transformer

Transformer

PARAMETERS

Input/

39

47

49

49

50

7

7

9

3.3.1

3.3.2

3.3.3

3.3.4

Data

3.3.5

eter

3.3.6

3.3.7

APPENDIX

Parameter

Parameter

Writing

Tape

51

Punchmg-out

Data

List

List

of

of

PENSATION

Parameter

Input

51

Setting

Parameter

STORED

69

Types

Display

Data

Settinq

of

of

Numbers

LEADSCREW

50

Data

Setting

Numbers

Data

50

50

Data

52

and

and

57

ERROR

parameter

Param¬

COM¬

Page 3

The

YASNAC

simultaneously

emphasis

tended

placed

automatic

control.

the

With

cessors

NC

and

corporates

capabilities.

semi-permanent

used

age

maximum

in

advantage

LX1

controlling

on

operation,

logic

incorporating

various

a

compact

The

and

combination

is

a

high-performance

high-speed

LSIs,

design

memory

programmable

to

2

axes

or

the

with

comprises

utilize

a

of

machining,

feedback

16-bit

YASNAC

wide

a

permanent,

software

each

CNC

lathe,

gauging

micropro¬

LX1

range

one

1.

for

with

unat¬

in¬

of

stor¬

to

OUTLINE

The

data

ed

in

interfaces

is

able

modes

distance

YASNAC

The

machine

edited

input-output

concept,

such

to

accommodate

of

operations

data

interface,

easily

and,

FACIT4070

as

such

transmission.

can

incorporate

and

from

the

interface

addition

m

requirements

the

NC

to

and

as

high-speed,

a

programmable

logic

operators

has

been

conventional

RS232C,

for

diagram

station.

expand¬

RS422

new

long¬

can

*

be

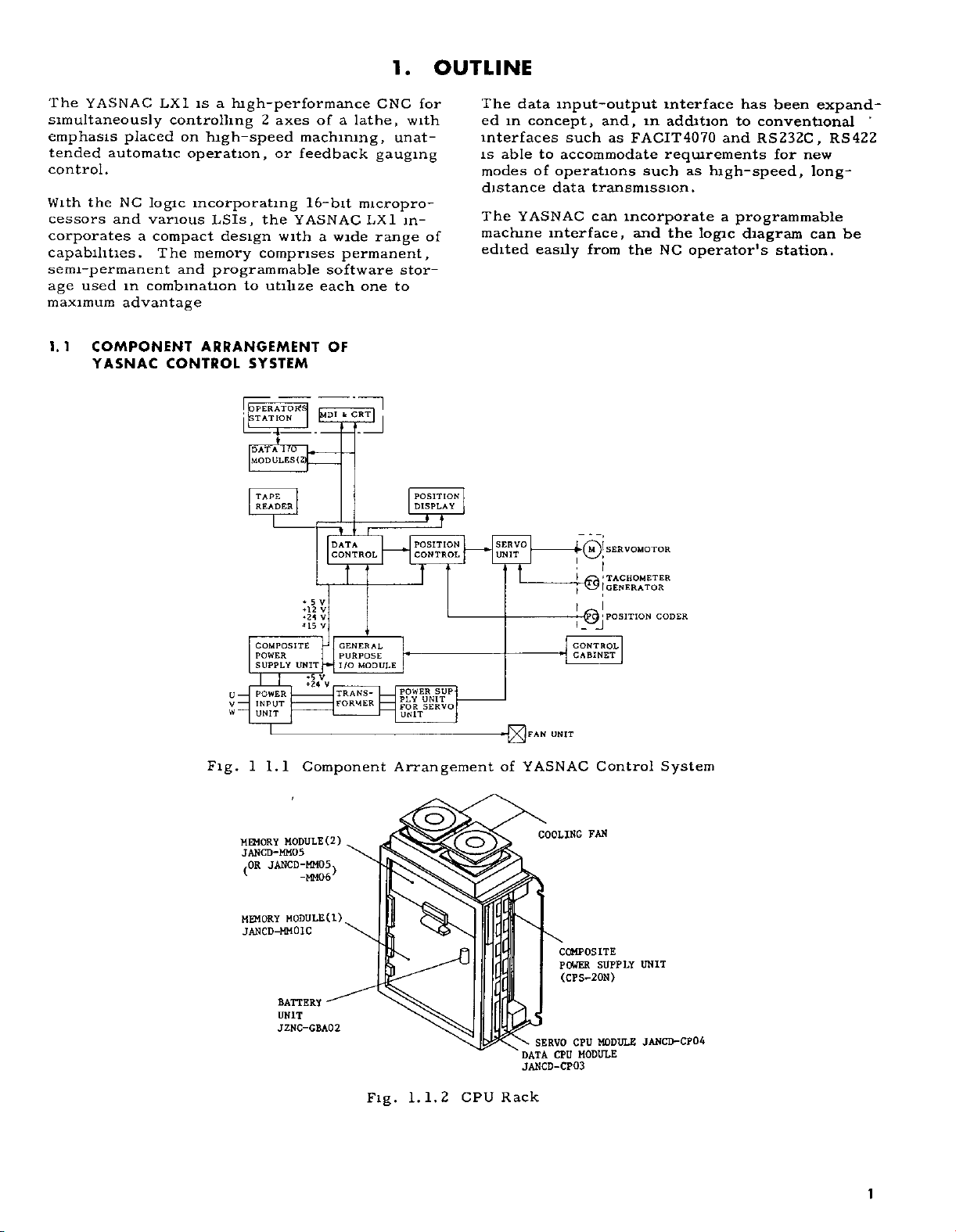

1.1

COMPONENT

YASNAC

CONTROL

ARRANGEMENT

SYSTEM

I

I

OPERATORS

!

STATION

I/O

DATA

(2)

MODULES

TAPE

READER

I

*

12

*15

COMPOSITE

POWER

UNIT

SUPPLY

POWER

U

—

INPUT

V

—

W

UNIT

—

I

1

Fig.

1.1

Component

[MDI

V

5

V

V

V

v

5

OF

«ÿ

1

DATA

CONTROL

GENERAL

PURPOSE

I/O

V

TRANS¬

FORMER

CRT|

I

MODULE

1

|

POSITION

DISPLAY

POSITION

CONTROL

POWER

UNIT

PLY

SERVO

FOR

UNIT

Arrangement

SUP

SERVO

UNIT

of

FAN

UNIT

YASNAC

i

f®

\

|

t

I

I

0j

CONTROL

CABINET

Control

SERVOMOTOR

TACHOMETE:

GENERATOR

POSITION

CODER

System

MODULE

MEMORY

JANCD-MM05

JANCD-MM05

OR

(

MEMORY

JANCD-MM01C

-MM06

MODULE

BATTERY

UNIT

JZNC-GBA02

O

(2)

)

(1)

COOLING

[

FAN

[

[C

[

COMPOSITE

SUPPLY

POWER

(CFS-20N)

UNIT

i

Fig.

\

DATA

JANCD-CP03

CPU

1.2

1.

Rack

SERVO

CPU

CPU

MODULE

MODULE

JANCTHCP04

1

Page 4

1

l

Fig

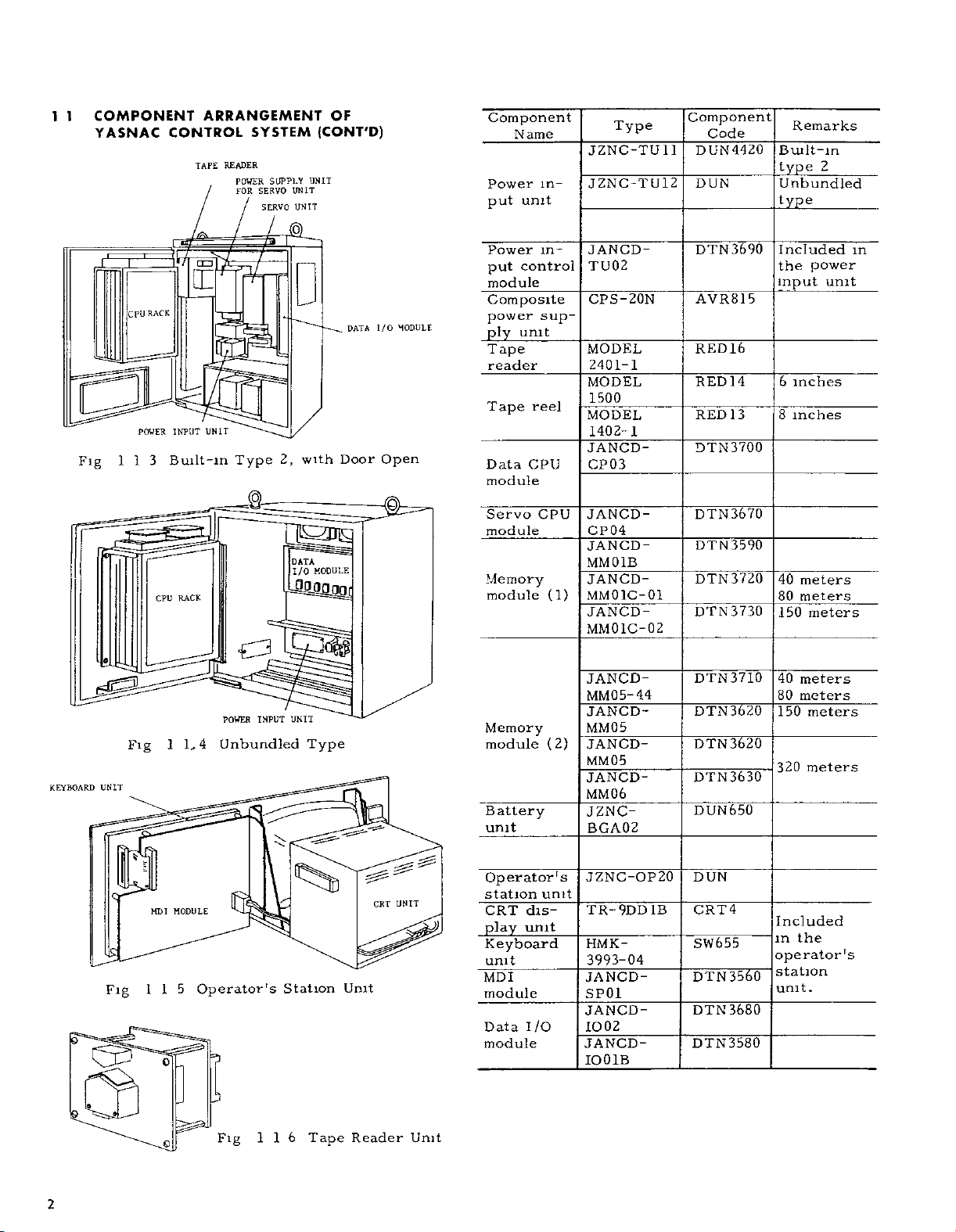

COMPONENT

CPU

RACK

POUER

CONTROL

Vf\

INPUT

Built-m

RACK

CPU

YASNAC

I

113

ARRANGEMENT

SYSTEM

TAPE

READER

SUPPLY

POWER

SERVO

FOR

SERVO

LIU

QIMPTT

UNIT

2,

Type

(q)

]]gZIIg

UNII

UNIT

UNIT

_

with

DATA

I/O

OF

(CONT'D)

DATA

Door

MODULE

I/O

Open

P

MODULE

Component

Name

Power

unit

put

Power

control

put

module

Composite

power

ply

T

sup-

unit

ape

reader

reel

Tape

CPU

Data

module

Servo

module

CPU

Memory

module

in¬

in¬

(1)

Type

JZNC-TU

JZNC-TU12

JANCD-

TU02

CPS-20N

MODEL

2401-1

MODEL

1500

MODEL

1402-1

JANCD-

CP03

JANCD-

CP04

JANCD-

MM01B

JANCD-

MM01C-01

JANCD-

MM01C-02

Component

1

1

Code

DUN

4420

DUN

3690

DTN

AVR815

RED16

RED

14

13

RED

DTN3700

DTN3670

DTN3590

3720

DTN

DTN

3730

Remarks

Built-in

type

2

Unbundled

type

Included

power

the

6

unit

inches

inches

meters

meters

meters

input

8

40

80

150

in

KEYBOARD

e

Q

UNIT

Us

Fig

iSh.

Fig

*

I

115

MDI

1

MODULE

o

o

LI

Operator's

3

Fig

INPUT

POWER

Unbundled

116

UNIT

Type

Station

Tape

Unit

Reader

CRT

UNIT

Unit

Memory

module

Battery

unit

Operator's

station

CRT

dis-

play

unit

Keyboard

unit

MDI

module

Data

I/O

module

(2)

unit

JANCD-

MM05-

JANCD-

44

MM05

JANCD-

MM05

JANCD-

MM06

JZNC-

BGA02

JZNC-OP20

TR-9DD

HMK-

3993-04

JANCD-

SP01

JANCD-

1002

JANCD-

IO01B

IB

DTN3710

3620

DTN

3620

DTN

DTN3630

DUN650

DUN

4

CRT

SW655

DTN

3560

3680

DTN

DTN3580

40

meters

meters

80

150

meters

meters

320

Included

the

in

operator's

station

unit.

2

Page 5

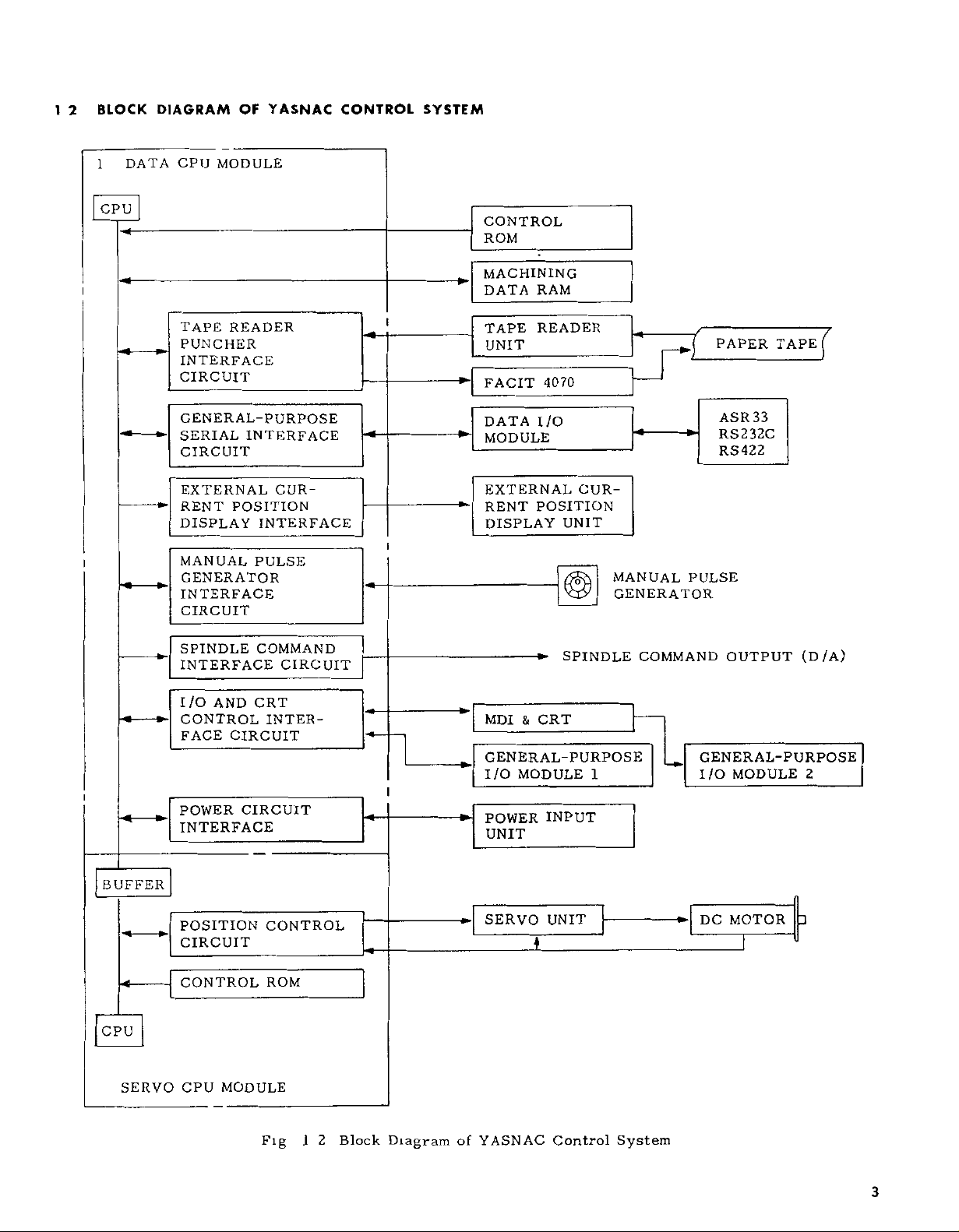

DATA

DIAGRAM

CPU

BLOCK

1

2

1

OF

MODULE

YASNAC

CONTROL

SYSTEM

CPU

CONTROL

ROM

-*ÿ

TAPE

PUNCHER

INTERFACE

CIRCUIT

GENERAL-PURPOSE

SERIAL

CIRCUIT

EXTERNAL

RENT

DISPLAY

MANUAL

GENERATOR

INTERFACE

CIRCUIT

SPINDLE

INTERFACE

READER

INTERFACE

CUR¬

POSITION

INTERFACE

PULSE

COMMAND

CIRCUIT

l

i

MACHINING

DATA

TAPE

UNIT

FACIT

DATA

MODULE

EXTERNAL

RENT

DISPLAY

RAM

READER

4070

I/O

POSITION

CUR¬

UNIT

SPINDLE

r

*ÿ

MANUAL

GENERATOR

COMMAND

PULSE

r

PAPER

ASR33

RS232C

RS422

OUTPUT

TAPE

r

(D/A)

-4

BUFFER

-<ÿ

CPU

SERVO

AND

I/O

CONTROL

FACE

POWER

CRT

CIRCUIT

CIRCUIT

INTERFACE

POSITION

CIRCUIT

CONTROL

MODULE

CPU

INTER¬

CONTROL

ROM

I

Fig

2

Block

--

I

Diagram

&

MDI

GENERAL-PURPOSE

I/O

POWER

UNIT

SERVO

CRT

MODULE

INPUT

UNIT

1

of

YASNAC

Control

1

System

GENERAL-PURPOSE

I/O

DC

MODULE

MOTOR

2

3

3

Page 6

1.3

MAINTENANCE

INSTRUMENTS

(1)

(2)

1.4

The

Measuring

Tools

Phillips

small

Standard

ROUTINE

following

instruments

Name

AC

voltmeter

DC

voltmeter

Oscilloscope

DC

ammeter

screwdriver

screwdrivers

INSPECTION

table

shows

Tape

reader

Control

panel

Servomotor

DC

and

motor

for

spindle

Capable

Tolerance

Maximum

T

olerance

(A

2-channe]

range

Maximum

Tolerance

large,

medium

SCHEDULE

the

minimum

Items

Cleaning

head

Cleaning

tumble

box

Lubricating

arm

shaft

Tight

closing

doors

Checking

gaps

and

and

worn

Vibration

Motor

contamination

and

breakage

Clearance

tion

openings

Burned

wear,

of

Roughened

tor

Dirt

motor

Battery

and

brushes

surface

m

spots

interior

digital

of

of

end

for

of

door

and

of

pressure

commuta¬

of

measuring

range

voltmeter

type

b

of

MHz

range

medium

Table

reading

tape

of

tension

of

loose

side

gaskets

noise

ventila¬

,

cracks,

of

Specifications

-2%

or

less

10

less

or

-2%

with

or

higher

10A,30

or

less

-2%

and

and

small

require-

14

Daily

Weekly

As

Daily

fit

Monthly

plates

Daily

Daily

as

Every

three

Daily

ACpower

V,

30

may

a

frequency

1

Inspection

Frequency

required

or

required

months

be

V

required

50

,

A

(3)

voltage

A

ments

order

tion

To

To

)

To

waveforms,

To

through

Chemicals

Cleaning

(absolute

to

to

for

an

Schedule

V

s:

Ife

V

=

5T

3

I!

o

o

o

o

o

o

o

o

o

o

o

o

o

oo

measure

measure

measure

measure

be

keep

extended

g

£

P

urpose

AC

DC

tape

etc

currents

DC

motors

agent

alcohol)

observed

the

Including

by

Feel

audible

Inspect

Inspect

motor

Check

the

brushes

Check

dark

and

grooving

Clean

with

See

alarm

if

is

displayed

power

power

reader

for

for

equipment

period

Remarks

light

hand,

inspection

visually

mainly

length

bar,

of

compressed

for

on

voltages

voltages

output

flowing

tape

maintenance

source

and

do

spindle

of

threading

commutator

BATTERY

CRT

screen

reader

in

part

the

DC

air

optimum

time

in

condi¬

Except

the

for

be

before

service

4

NC

externa]

sure

for

the

in

to

starting

.

those

energized

cleanliness,

turn

checks

off

to

undertake

the

which

state,

vibration,

power

can

such

supply

routine

be

made

as

checks

and

noise,

to

the

maintenance

with

NC

For

pushing

ator's

button

are

ing

this,

the

station

pushed,

is

energized,

turning

POWER

not

is

off

OFF

sufficient,

still

and

the

button

several

are

power

on

because

areas

potentially

supply

the

in

dangerous.

NC

after

the

by

oper¬

this

hous¬

Page 7

1

(

4.1

1)

A

B

(2)

A

B

(3)

TAPE

Cleaning

Remove

a

with

with

oil

soft

or

the

clean

Remove

source)

Cleaning

Clean

,

clean

Remove

112)

and

clean

with

box

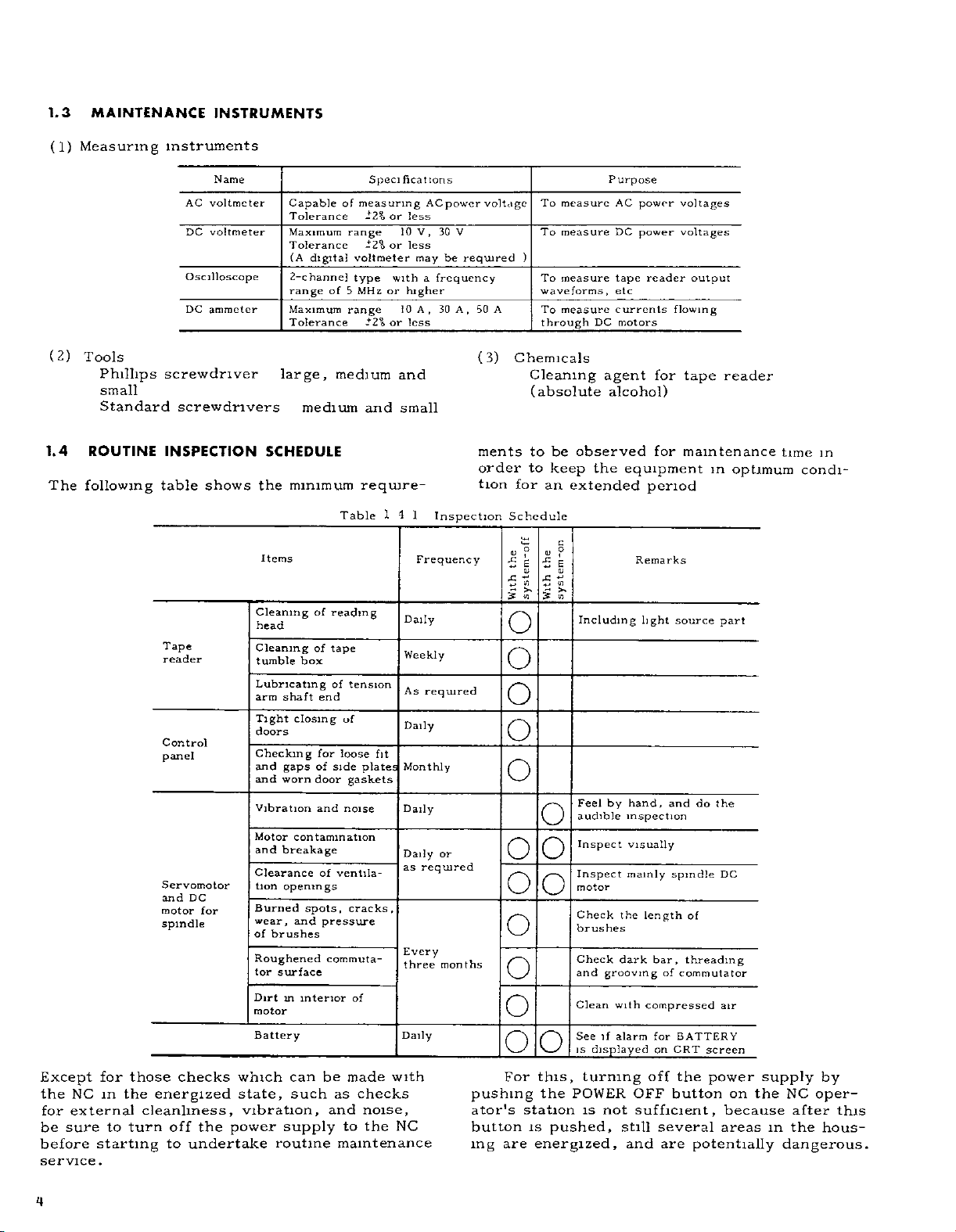

Lubricating

the

For

reels,

when

lubricate

the

READER

the

tape

blower

or

cloth

tape

the

on

of

the

braided

soft

the

loosening

by

the

cloth

control

tension

tape

rubbish

brush

dust,

oily

with

guide

dust,

withablower

top

tumble

tape

cloth

tape

bottom

or

of

tension

with

the

reader

absolute

if

any,

nylon

outlet

two

brush

6

shaft

arm

and

If

wipe

and

of

arm

inch

does

head

dust

the

it

alcohol.

the

on

box

leading

cover

mounting

the

shaft"ÿ

or

end

not

(Daily)

from

glass

using

retainer.

tape

(light

LED

brush.

(Weekly)

tape

(See

tumble

tape

inch

8

of

tension

move

the

stained

is

a

gauze

Also

with

Fig

screws

diameter

smoothly.

glass

arm,

After

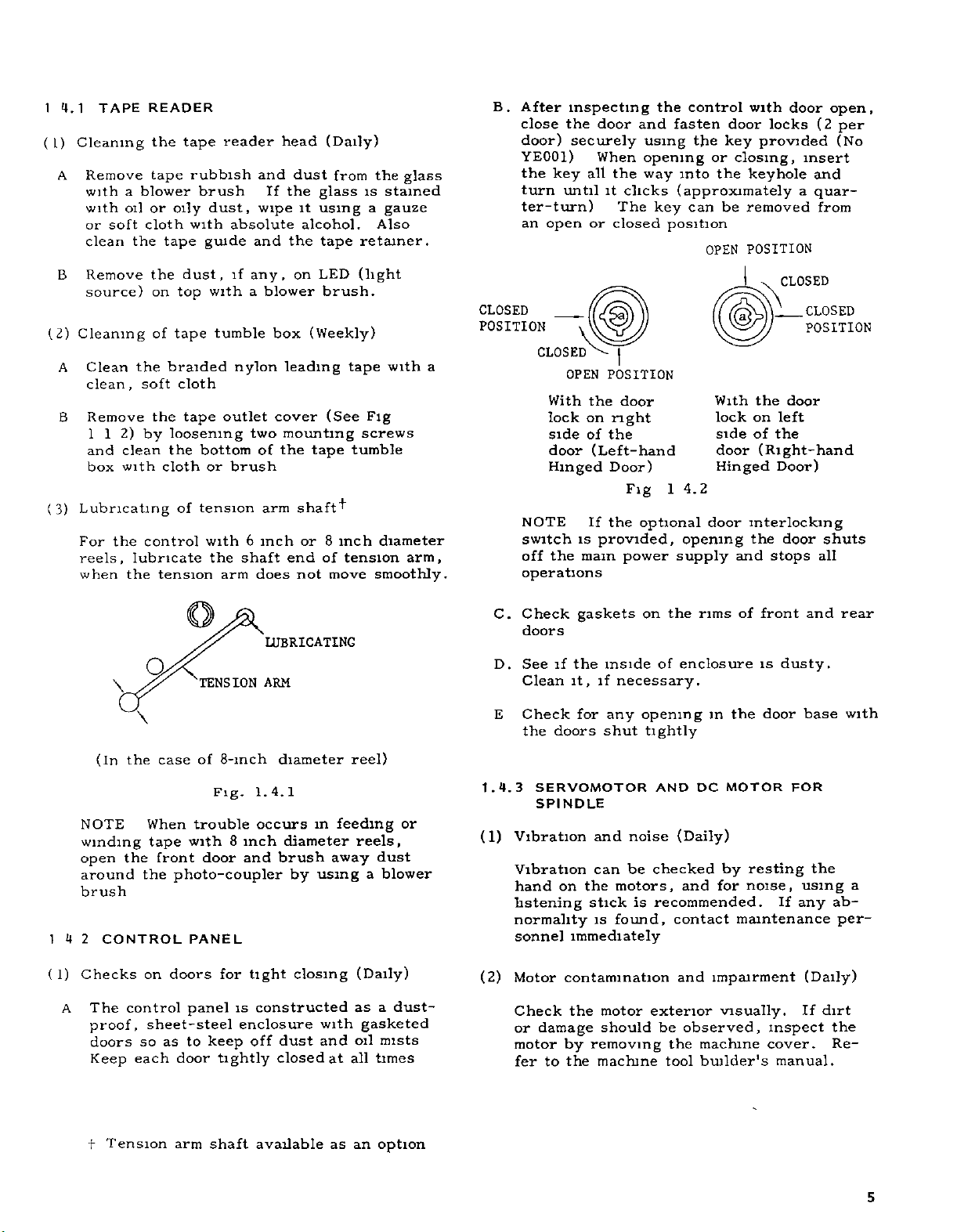

B.

CLOSED

close

door)

YE001)

the

key

turn

ter-turn)

an

open

inspecting

the

door

securely

When

all

until

it

or

POSITION

a

CLOSED

OPEN

With

lock

side

door

POSITION

the

on

of

the

(Left-hand

Hinged

NOTE

switch

the

off

operations

If

is

provided,

mam

the

the

clicks

The

closed

door

right

Door)

Fig

power

the

control

fasten

and

using

opening

into

way

(approximately

can

key

position

4.2

1

optional

opening

supply

the

door

key

or

the

be

OPEN

With

lock

side

door

Hinged

door

with

locks

provided

closing,

keyhole

removed

POSITION

CLOSED

the

on

left

the

of

(Right-hand

Door)

interlocking

the

door

stops

and

door

(2

insert

and

a

quar¬

from

CLOSED

POSITION

door

shuts

all

open,

per

(No

1

(

4

1)

A

\

(In

NOTE

winding

open

around

brush

2

CONTROL

Checks

The

proof,

doors

Keep

Q

\

the

When

tape

the

the

on

control

sheet-steel

so

each

TENSION

of

case

trouble

with

front

door

photo-coupler

PANEL

doors

panel

to

as

keep

door

8-mch

Fig.

8

for

is

enclosure

tightly

LUBRICATING

ARM

diameter

1.4.1

occurs

inch

diameter

and

brush

by

tight

closing

constructed

dust

off

closed

in

using

with

and

reel)

feeding

away

as

oil

all

at

reels,

dust

blower

a

(Daily)

dust-

a

gasketed

mists

times

or

C.

D.

E

1.4.3

(1)

(2)

Check

doors

See

if

Clean

Check

the

doors

SERVOMOTOR

SPINDLE

Vibration

Vibration

on

hand

listening

normality

sonnel

Motor

Check

or

motor

fer

contamination

damage

by

the

to

gaskets

inside

the

it,

if

necessary.

for

any

shut

and

noise

can

be

motors,

the

stick

is

found,

is

immediately

motor

the

should

removing

machine

the

of

enclosure

rims

on

opening

tightly

DC

AND

(Daily)

checked

and

recommended.

contact

and

exterior

observed,

be

the

machine

builder's

tool

of

in

the

MOTOR

by

resting

for

noise,

maintenance

impairment

visually.

front

is

dusty.

door

If

inspect

cover.

manual.

and

base

FOR

the

using

any

(Daily)

If

rear

with

a

ab¬

per¬

dirt

the

Re¬

t

Tension

arm

shaft

available

as

an

option

5

Page 8

1.4.3

SERVOMOTOR

SPINDLE

(CONT'D)

AND

DC

MOTOR

FOR

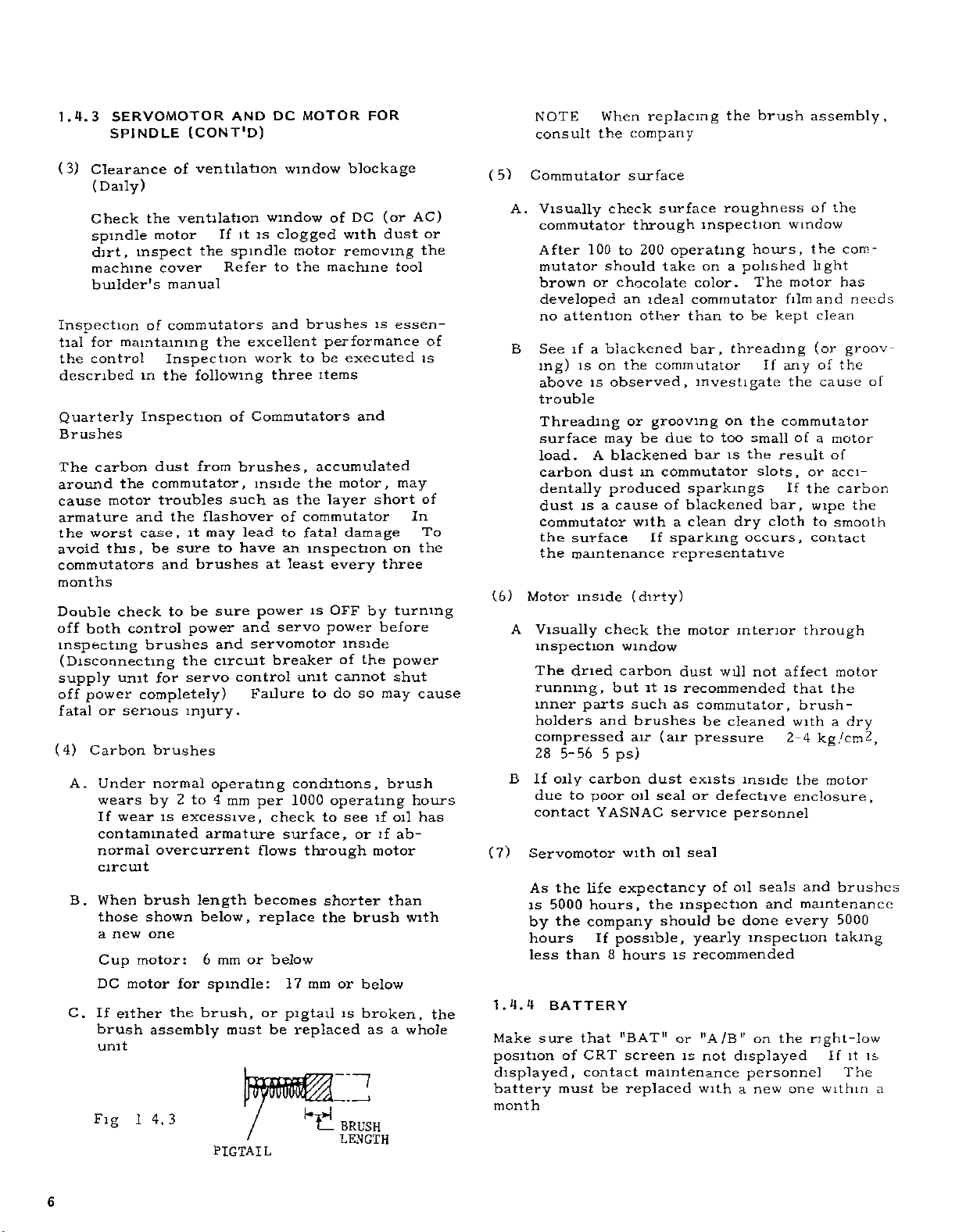

NOTE

consult

When

the

replacing

company

the

brush

assembly,

(3)

Clearance

(Daily)

Check

spindle

dirt,

machine

builder's

Inspection

for

tial

the

maintaining

control

described

Quarterly

Brushes

carbon

The

around

cause

the

motor

armature

worst

the

avoid

this,

commutators

months

both

check

control

Double

off

inspecting

(Disconnecting

power

or

Carbon

Under

unit

serious

supply

off

fatal

(4)

A.

wears

If

wear

contaminated

normal

circuit

When

B.

those

a

new

Cup

DC

motor

C.

If

either

brush

unit

Fig

14.3

ventilation

of

ventilation

the

motor

inspect

cover

manual

commutators

of

Inspection

the

dust

following

from

in

Inspection

commutator,

troubles

and

the

case,

be

and

to

it

sure

brushes

be

power

brushes

the

servo

for

completely)

injury.

brushes

normal

2to4

by

is

excessive,

overcurrent

brush

length

shown

one

motor:

for

the

assembly

it

If

the

spindle

Refer

the

of

brushes,

such

flashover

may

to

have

sure

and

circuit

control

operating

mm

armature

below,

6

mm

spindle:

brush,

must

PIGTAIL

window

window

is

clogged

motor

to

the

and

excellent

to

work

three

Commutators

inside

the

as

of

to

lead

an

at

least

power

and

servo

servomotor

breaker

unit

Failure

conditions,

1000

per

check

surface,

flows

becomes

replace

or

below

17

or

pigtail

be

replaced

blockage

DC

of

with

removing

machine

brushes

performance

executed

be

items

and

accumulated

motor,

the

layer

commutator

fatal

damage

inspection

every

OFF

is

by

power

inside

of

the

cannot

to

do

so

operating

to

see

or

through

shorter

the

brush

mm

or

below

broken,

is

as

]

BRUSH

LENGTH

(or

dust

tool

essen¬

is

may

short

on

three

turning

before

power

shut

may

brush

oil

if

ab¬

if

motor

than

a

AC)

or

the

of

is

of

In

To

the

cause

hours

has

with

whole

the

5)

(

A.

B

(6)

Motor

A

B

(7)

Servomotor

As

is

by

hours

less

1.4.4

Make

position

displayed,

battery

month

Commutator

Visually

commutator

After

100

mutator

brown

or

developed

no

attention

See

mg)

above

a

if

on

is

is

trouble

Threading

surface

load.

carbon

A

dust

dentally

is

dust

commutator

surface

the

the

maintenance

inside

Visually

inspection

The

dried

running,

inner

parts

holders

compressed

28

56

5-

oily

If

due

contact

the

5000

the

carbon

poor

to

YASNAC

life

hours,

company

If

than

BATTERY

sure

that

CRT

of

contact

must

surface

check

through

200

to

should

chocolate

an

other

blackened

the

observed,

or

be

may

blackened

m

produced

cause

a

with

(dirty)

check

window

carbon

but

such

and

brushes

air

5

ps)

oil

with

expectancy

possible,

hours

8

"BAT”

screen

be

replaced

surface

operating

take

color.

commutator

ideal

than

bar,

commutator

investigate

grooving

due

to

bar

commutator

sparkings

of

blackened

clean

a

If

sparking

representative

motor

the

dust

is

it

recommended

commutator,

as

(air

pressure

dust

exists

or

seal

service

seal

oil

the

inspection

should

yearly

recommended

is

"A/B"

or

is

maintenance

with

roughness

inspection

on

a

polished

to

threading

on

too

is

dry

occurs,

interior

will

be

cleaned

inside

defective

personnel

oil

of

be

done

not

displayed

a

window

hours,

motor

The

film

be

kept

If

any

the

the

commutator

small

the

result

slots

If

bar,

cloth

not

affect

that

with

2-4

enclosure,

seals

and

every

inspection

the

on

personnel

new

one

the

of

com¬

the

light

has

and

clean

(or

groov

of

the

cause

of

motor

a

of

,

or

acci¬

the

carbon

wipe

to

smooth

contact

through

motor

the

brush-

a

dry

kg

/cm

the

motor

and

brushes

maintenance

5000

taking

right-low

If

The

within

needs

the

2

is

it

of

,

a

6

Page 9

2.1

TROUBLE

to

Try

the

trouble

•

the

of

Type

In

In

the

NATURE

what

what

latmg

serviceman

fying

time

2.1.1

TROUBLE

(1)

operate

What

trouble

Was

positioning

Was

Was

Was

What

In

What

Does

the

Is

Is

the

(2)

Frequency

When

when

How

(3)

Recurrence

Run

trouble

the

being

able

Verify

tributed

Increase

Ask

under

fully

analyze

occurred

trouble

calledin

following

system

your

of

trouble

mode

mode(s)

7

was

occurred7

the

positioning

tool

the

the

feedrate

an

auxiliary

was

which

was

the

trouble

trouble

did

other

often

program

the

several

NC

unit

programmed.

to

external

the

values

or

the

operator

which

ISOLATION

and/or

to

points

AND

did

the

display

error,

path

the

alarm

program

sequence

the

trouble

related

associated

of

trouble

the

trouble

machines

did

it

trouble

of

times

and

disturbances

offset

being

decrease

the

the

circumstances

This

is

necessary

for

having

correct

CIRCUMSTANCES

the

does

incorrect

displayed

erroneous

will

trouble

the

of

MDI

the

minimize

system

&

position

(by

correct7

the

used7

trouble

function

number7

did

number7

a

recur

in

particular

to

tool

with

develop7

m

were

occur?

experienced

that

tape

Check

the

them

trouble

and

remaining

compare

Is

values

stored.

override

the

explain

to

trouble

the

occurred.

2.

TROUBLESHOOTING

m

for

YASNAC

the

trouble.

the

OF

occur7

normally

CRT

when

(error

axis,

values7

much)

how

occur7

changing7

feedrate7

(Did

it

operation7)

the

values

with

those

attribut¬

7

value.

circumstances

which

Veri¬

down

mode7

occur

the

dis¬

ISO-

the

m

AND

2.1.2

(

1)

OPERATIONS

Operations

Was

the

there

Was

the

Was

operator

recent

a

operator

PROGRAMMING

properly

change

well

familiar

trained7

of

operators?

with

CHECKS

the

pro¬

gram7

under

properly

coded7

before

incremental

be

selected?

function

or

erroneous

comple¬

set?

proper¬

the

7

the

absolute

the

other

the

used7

the

the

there

program

program

tool

operating

optional

tape

program

Was

tion

Was

or

•

Was

•

Can

Was

ly

Was

Was

7

•

Were

interrupted

placed

command7

compensation

block

correctly

properly

any

inadvertent

modes

skip

set7

operations7

(2)

Punched

•

Was

•

Was

•

Were

*

Was

this

Was

•

Was

Was

Programming

(3)

Is

Was

instruction

•

Did

•

Did

•

Was

the

tape

tape

the

the

tape

tapes

program

the

operation7

tape

the

the

tape

black

a

program

the

program

the

trouble

trouble

the

check

a

contaminated7

or

bent

properly

successfully

correctly

puncher

used7

tape

new?

formulated

manual7

occur

occur

list

made

crimpled?

spliced7

punched?

operating

a

in

particular

m

subprogram?

a

and

used

run

normally7

according

for

prior

tape

to

to

block?

the

verification7

(4)

Settings

adjustments

the

or

operation?

Were

made

Was

there

a

prior

fuse

any

to

starting

blown7

corrections

7

Page 10

2.1.2

(5)

(6)

OPERATIONS

(CONT'D)

•

Was

•

Was

Was

What

Was

board)

Was

Was

Was

Was

External

Was

justed

Was

usted

adj

Was

there

Is

frequency

machine,

range’

Was

there

nearby

there

Is

ed

similar

Has

the

inside

the

Has

this

Ambient

What

there

Was

Was

the

Was

there

the

in

Were

Was

the

an

emergency

the

machine

an

alarm

was

the

alarm

’

MODE

the

override

the

the

machine

the

feed

the

machine

’

the

control

’

NC

the

’

user

the

same

unit’

conditions

was

tape

immediate

there

system

the

factors

unit

any

sewing

welding

any

any

failures

NC

the

any

any

any

other

AND

stop

tool

ready

in

state

lamp

number’

lit

alarm

switch

set

to

set’

lock

set’

hold

tool

recently

cabinet

recently

source

noise

machine,

machine)

new

machine

NC

in

your

made

an

unit’

trouble

occured

temperature’

abrupt

oil

or

contaminated’

cutting

reader

area’

vibrations’

exposed

PROGRAMMING

maintained’

to

operate’

effect’

module

a

on

in

normal

position’

"0"’

repaired

recently

repaired

(e

g

repaired

,

crane,

electrical

within

interference

recently

that

has

unit

factory’

attempt

at

adjustments

previously

temperature’

change

in

splashed,

fluid

to

the

direct

CHECKS

(on

or

adjusted’

discharge

installed

develop¬

sunlight’

print

or

high

ad¬

or

with

(4)

(5)

(2)

(

3)

Was

Was

Did

interior’

Tape

•

Was

What

forms

Control

Was

Was

(Was

port

Was

Composite

Was

Were

+24

Was

•

Was

Was

•

Was

•

Was

cabinet

How

Was

voltage

Was

interlock

Is

there

amount

machine,

ing

Grounding

Was

Was

the

tape

the

unit

machining

any

reader

the

tape

were

from

unit

the

control

the

fan

the

air

normal’)

the

interior

the

input

the

output

V)

each

voltage

fuse

a

the

circuit

the

shield

the

wiring

’

much

there

any

’

the

front

m

any

current

of

grounding

the

shield

reader

operated

reader

the

characteristics

the

interior

motor

flow

power

voltage

blown’

properly

did

the

significant

or

effect)

machine

electrical

properly

grounding

chips

tape

unit

operating

from

damaged

supply

voltages

within

breaker

properly

input

rear

’

m

door

closed’

with

its

enter

contaminated’

reader’

interior

normally’

the

cooling

by

unit

normal’

normal

tolerance’

tripped’

grounded’

inside

voltage

drop

door

open

that

consumes

the

factory

discharge

connected’

proper’

door

open’

the

cabinet

of

the

wave¬

contaminated

air

corrosive

(

V

+5

the

control

fluctuate’

in

input

(with

a

(e

g

machine)’

’

exhaust

gas’

,

+12

door

large

,

weld¬

V,

2.1.3

(1)

8

NC

Control

the

Was

the

Was

UNIT

unit

MDI

tape

CHECK

exterior

CRT

&

reader

unit

kept

normal’

clean’

(6)

Cables

Were

Was

Was

Was

cable

any

any

any

connectors

internal

external

cable

cable

cable

broken

securely

damaged’

damaged’

contaminated’

or

inserted’

Page 11

(7)

Modules

(on

printed

circuit

board)

1

Depress

the

(ALM)

key

•

•

(8)

•

(9)

(10)

1.1

an

If

"A/B"

line

function.

the

lowing

all

Were

Were

plug

What

was

Were

connections

modules

&

MDI

Were

push

Was

the

Was

the

Parameters

Did

the

parameter

Interface

Were

the

installed7

ly

Was

the

Were

the

equipped

Were

the

DGN

the

TROUBLE

alarm

(for

the

of

alarm

condition

operations.

modules

connectors

the

correct7

CRT

buttons

flat

flat

actual

table

power

cable

relay,

with

I/O

(diagnostic)

SHOOTING

condition

battery

CRT

this

In

revision

unit

keyboard

cable

parameters

attached

cable

positively

solenoid,

a

noise

signals

alarm)

screen

case,

will

securely

(on

freely

free

normally

occurs,

regardless

detailed

be

installed7

properly

letter7

cable)

flat

operable7

operable

of

defects7

match

the

to

NC

and

shielded7

motor,

suppressor7

function7

BY

ALARM

display

a

blinks

information

displayed

secured7

between

7

those

NC

cable

etc

generated

CODE

on

the

the

of

by

m

unit7

separate¬

each

"ALM"

bottom

mode

fol¬

the

of

the

by

will

This

alarm

and

importance,

cause

messages

with

up

the

to

to

4

pairs

appear

most

serious

of

alarm

in

order

one

codes

of

at

the

top.

NOTE

appears

There

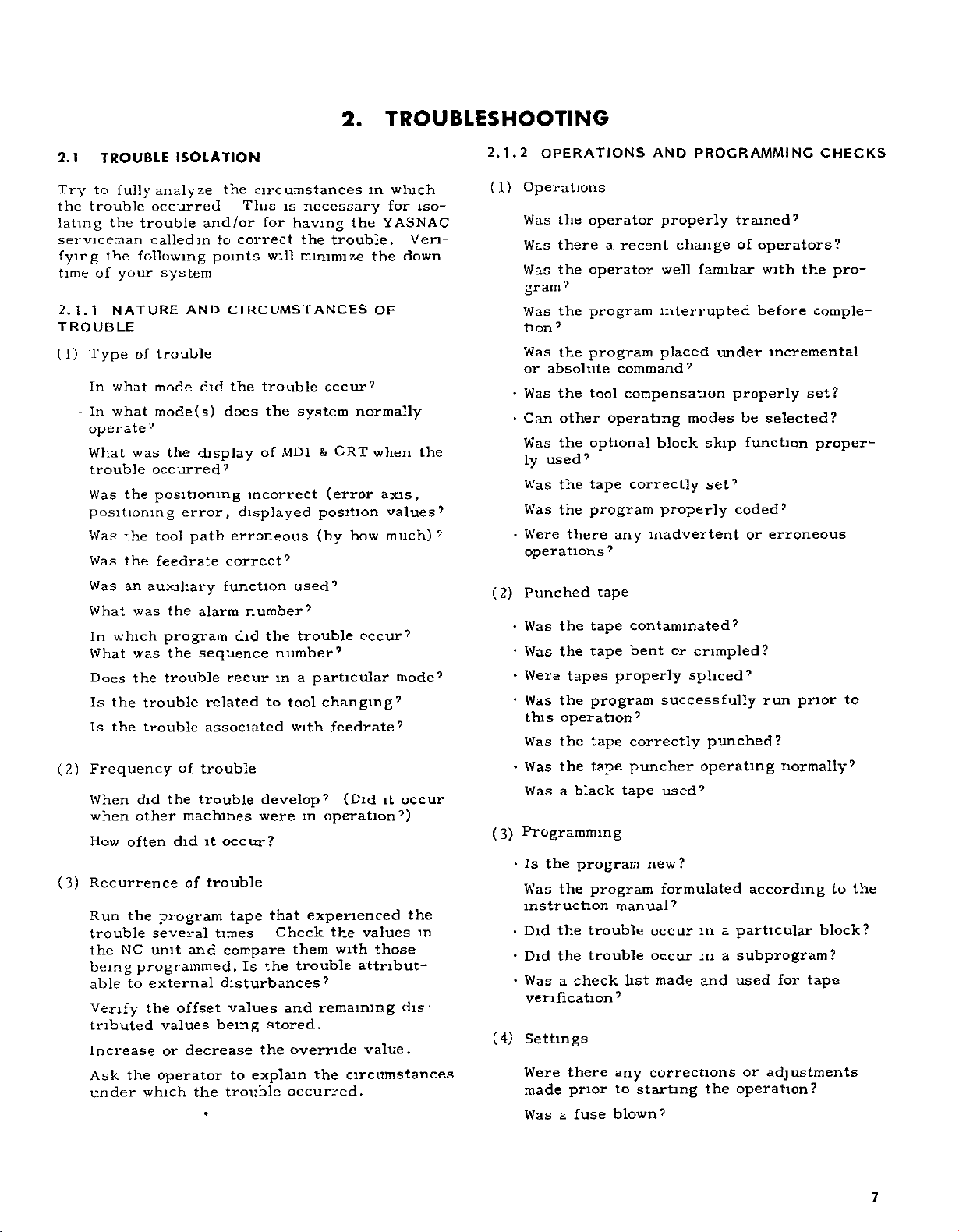

330:

310:

291:

013:

an

In

taking

need

no

is

EMERGENCY

SERVO

OO

OT

PROG

alarm

priority

to

OFF

ERROR

state

over

operate

STOP

CNO

,

the

any

the

0001

ADDRESS)

BUF

alarm

other

(PAGE)

B

N0017

ALM

screen

T

display

key

L

and

alarm

reset

alarm

it

Messages

and

state

Notice

n

820,"

as

depress

and

that

"830"

of

the

follows:

Alarm

2

RESET

alarm

alarm

"840"

2

cause

the

key,

display

codes

are

function

Fig

Eliminate

the

the

the

or

and

selected

Codes

of

and

will

"800,"

displayed

key.

the

the

be

"810,

regardless

or

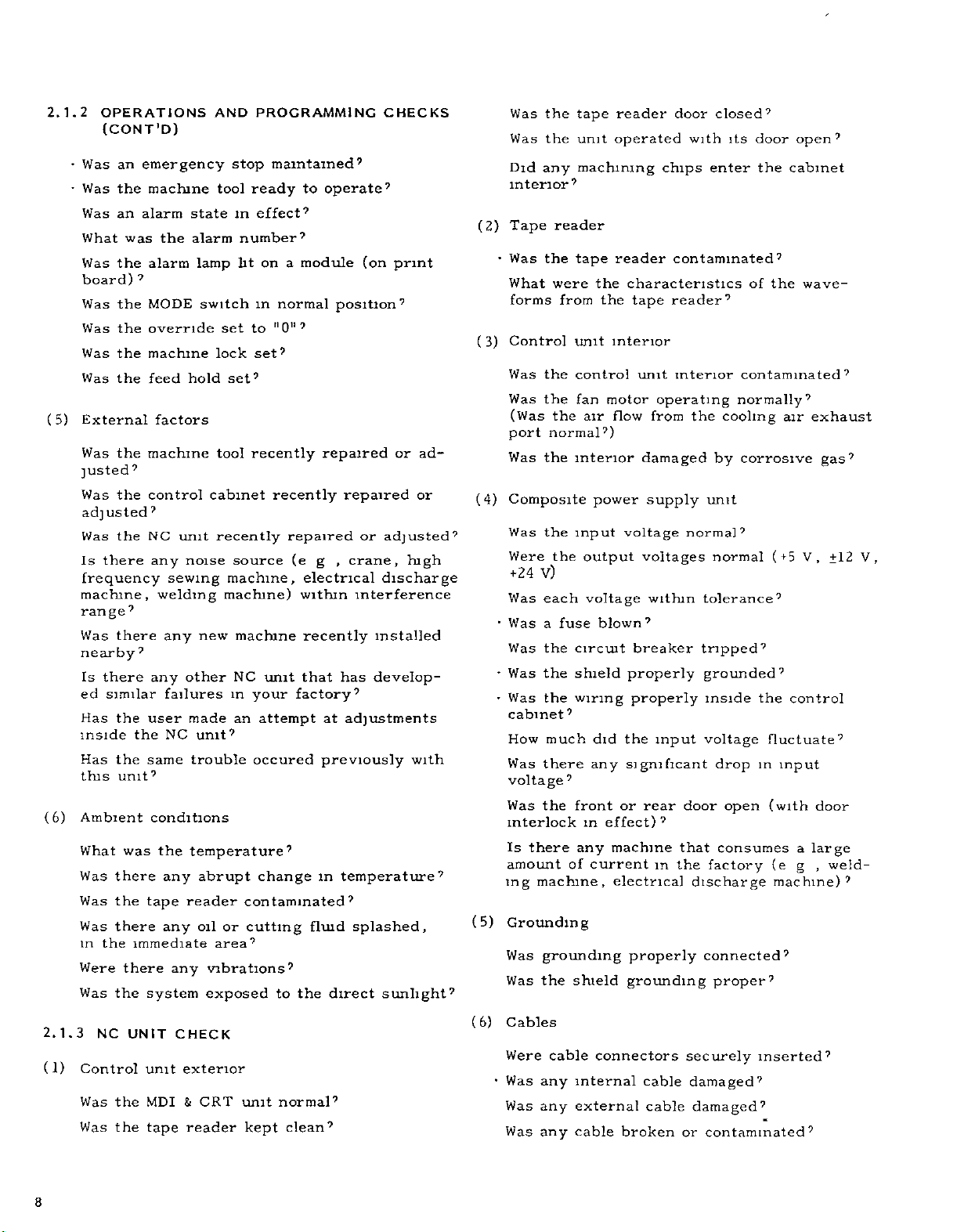

The

2.

alarm

codes

are

categorized

Alarm

000

100

200

300

400

500

600

700

800

900

Table

No

099

to

to

199

to

299

to

399

to

499

to

599

to

699

799

to

to

899

999

to

Spindle

at

Stop

at

Stop

Immediate

Immediate

Immediate

NC

system

Operation

block

block

stop

stop

stop

stop

end

end

2.2

Tape

Macro,

output

Overtravel,

positioning,

Servo,

FG,

Sequence

Sequencer

CPU

Off-line

format

operation,

error,

emergency

RPG

error,

error

Type

error

reference

machine

error

message

RAM

of

Alarm

alarm

external

sequence

stop,

(2)

error,

point

ready

input/

error

overload

ROM

(1)

return,

error

9

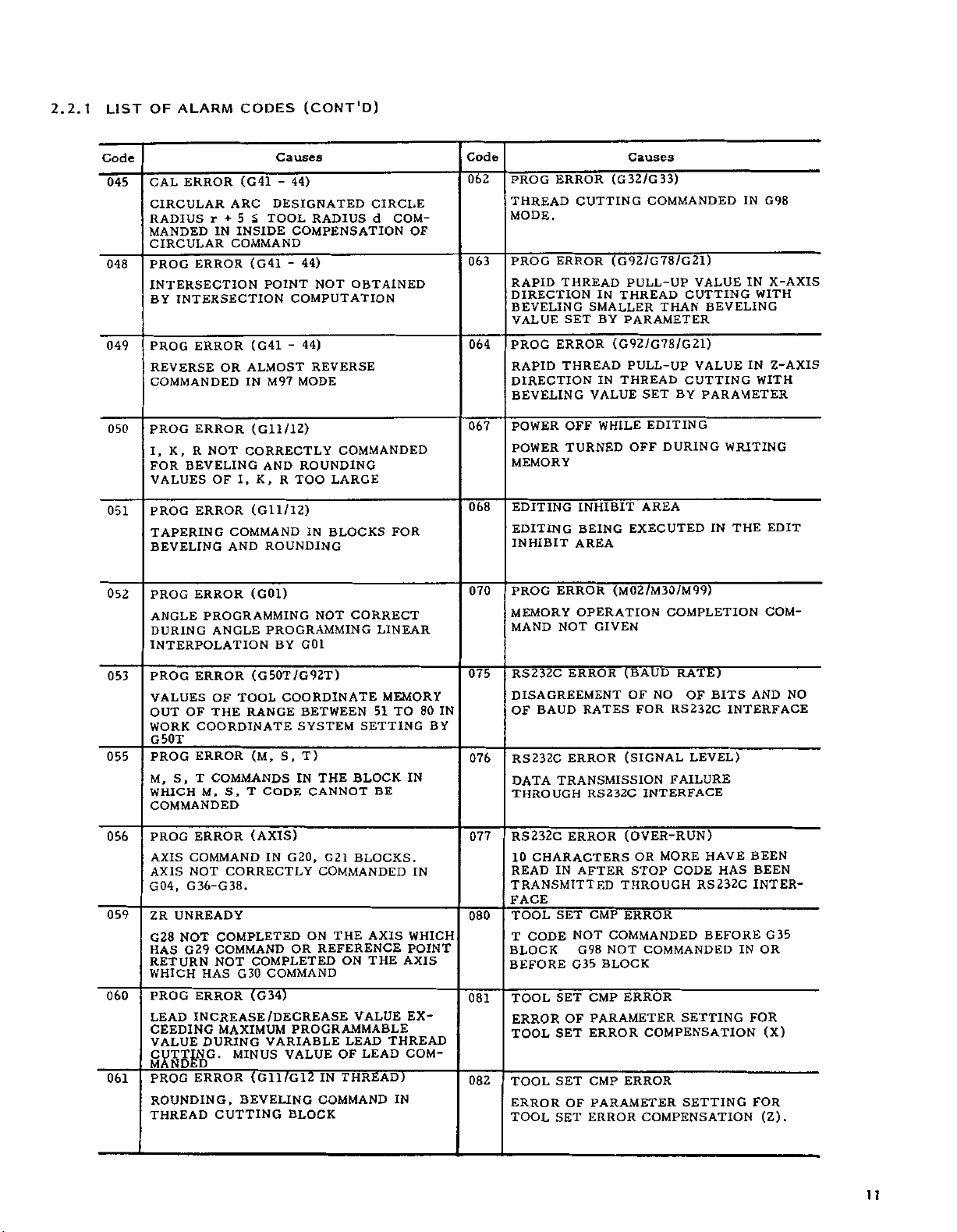

Page 12

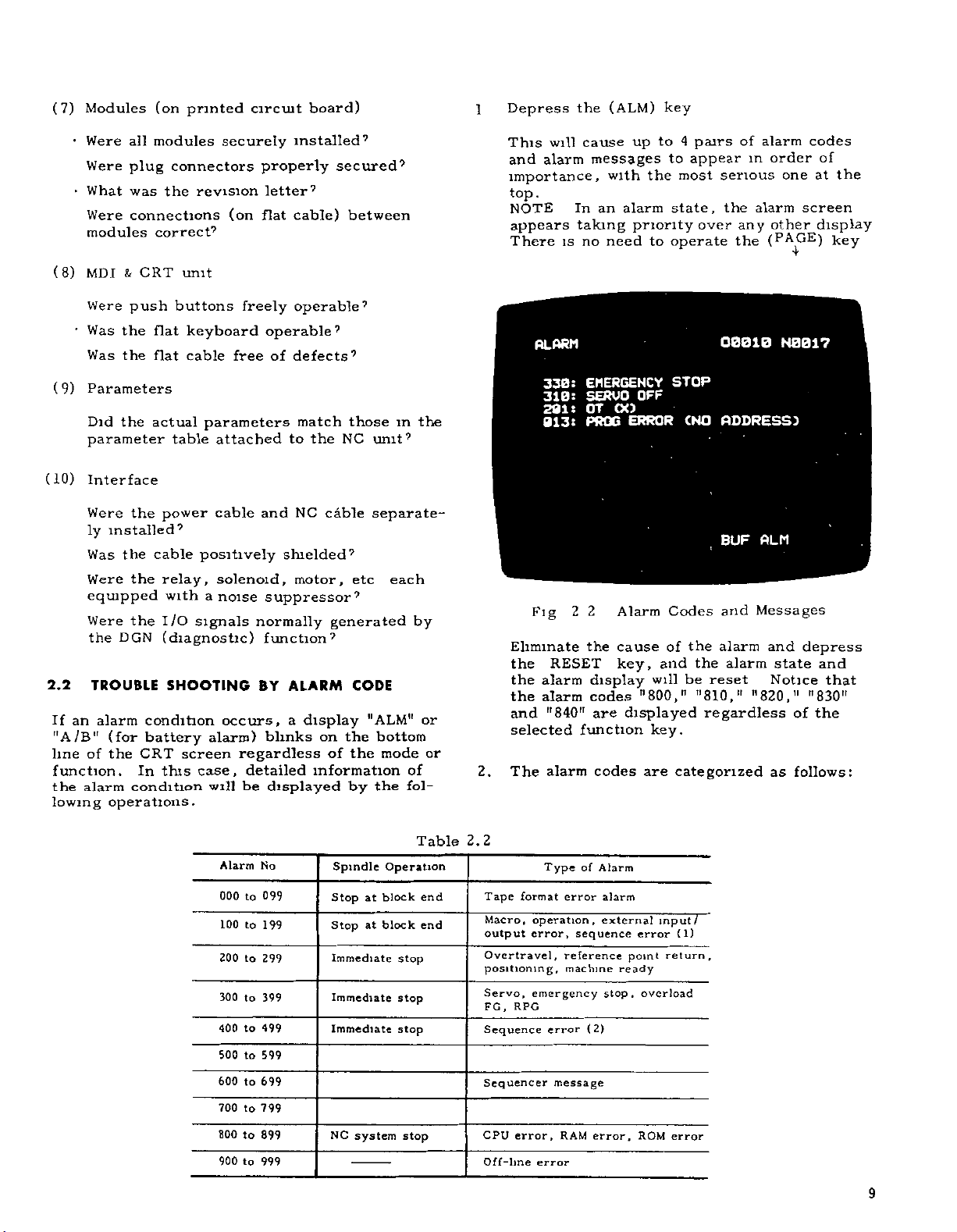

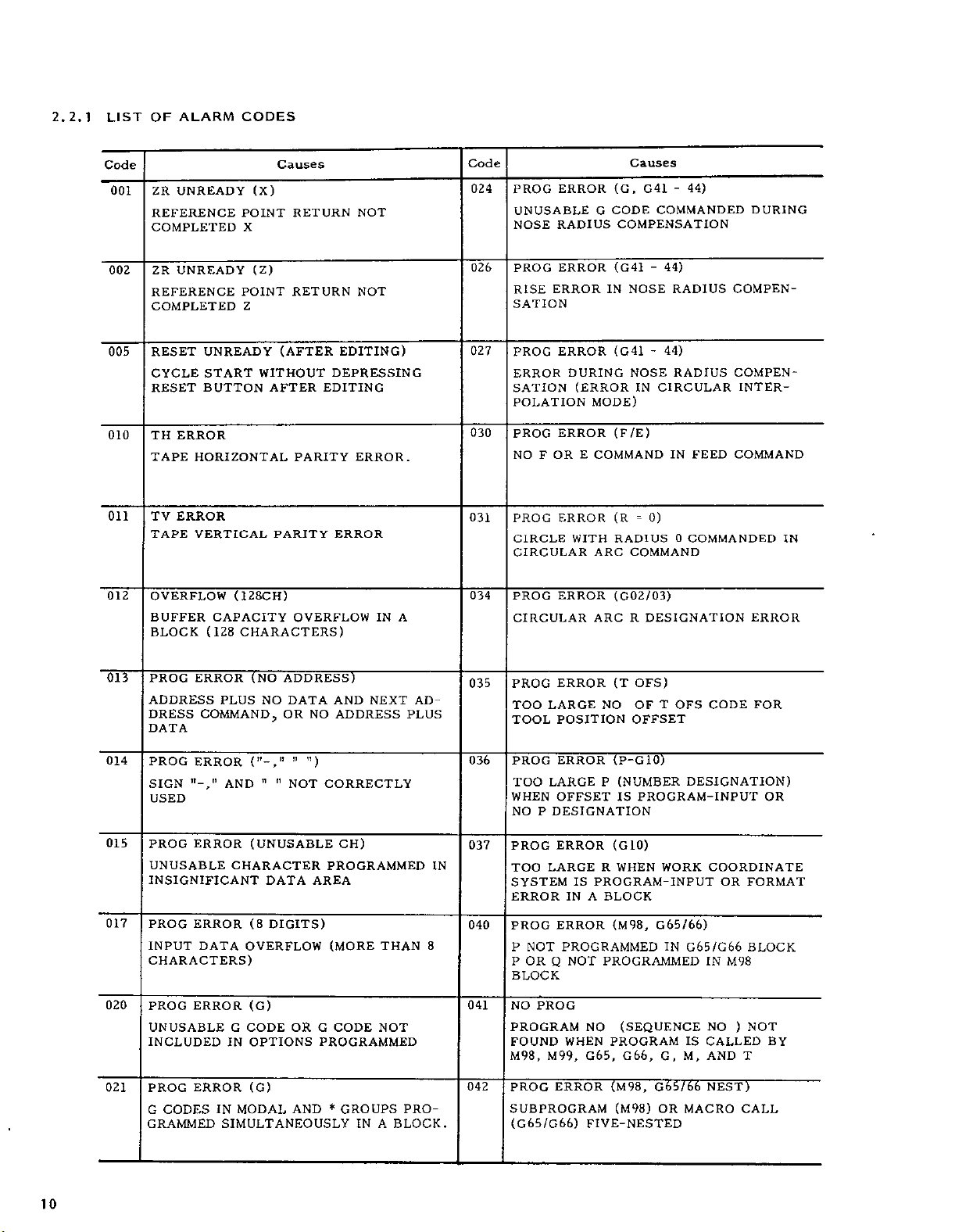

2.2,1

LIST

OF

ALARM

CODES

Code

001

002

005

010

Oil

012

UNREADY

ZR

REFERENCE

COMPLETED

UNREADY

ZR

REFERENCE

COMPLETED

RESET

CYCLE

RESET

TH

TAPE

TV

TAPE

UNREADY

START

BUTTON

ERROR

HORIZONTAL

ERROR

VERTICAL

OVERFLOW

BUFFER

BLOCK

CAPACITY

(128

Causes

(X)

POINT

RETURN

X

(Z)

POINT

Z

RETURN

(AFTER

WITHOUT

AFTER

PARITY

PARITY

(I28CH)

OVERFLOW

CHARACTERS)

NOT

NOT

EDITING)

DEPRESSING

EDITING

ERROR.

ERROR

IN

Code

024

026

PROG

ERROR

UNUSABLE

RADIUS

NOSE

ERROR

PROG

RISE

ERROR

Causes

(G

,

G41

CODE

G

COMMANDED

COMPENSATION

(G41-44)

NOSE

IN

44)

-

RADIUS

DURING

COMPEN¬

SATION

027

PROG

ERROR

ERROR

SATION

POLATION

030

031

034

A

ERROR

PROG

OR

NO

F

ERROR

PROG

CIRCLE

CIRCULAR

PROG

ERROR

CIRCULAR

(G41

DURING

(ERROR

MODE)

(F/E)

E

COMMAND

(R=0)

RADIUS

WITH

ARC

(G02/03)

ARCRDESIGNATION

44)

-

RADIUS

NOSE

IN

CIRCULAR

IN

0

COMMAND

COMPEN¬

INTER¬

COMMAND

FEED

COMMANDED

ERROR

IN

013

014

015

017

020

021

ERROR

PROG

ADDRESS

DRESS

DATA

PROG

SIGN

USED

PROG

UNUSABLE

PLUS

COMMAND

ERROR

AND

ERROR

CHARACTER

INSIGNIFICANT

PROG

ERROR

INPUT

CHARACTERS)

PROG

UNUSABLE

INCLUDED

PROG

G

GRAMMED

ERROR

CODES

DATA

G

IN

ERROR

IN

SIMULTANEOUSLY

(NO

ADDRESS)

NO

DATA

OR

C-,"

n

"

(UNUSABLE

DATA

(8

DIGITS)

OVERFLOW

(G)

CODE

OPTIONS

(G)

MODAL

AND

NO

ADDRESS

”)

"

NOT

CORRECTLY

CH)

PROGRAMMED

AREA

(MORE

OR

G

CODE

PROGRAMMED

AND

*

NEXT

THAN

NOT

GROUPS

IN

A

AD¬

PLUS

8

PRO¬

BLOCK.

IN

035

036

037

040

041

042

PROG

ERROR

TOO

LARGE

POSITION

TOOL

PROG

ERROR

TOO

LARGE

WHEN

OFFSET

NO

P

DESIGNATION

ERROR

PROG

LARGE

TOO

SYSTEM

ERROR

PROG

P

ORQNOT

P

IN

ERROR

NOT

PROGRAMMED

IS

BLOCK

PROG

NO

PROGRAM

FOUND

M98

PROG

,

M99,

WHEN

G65,

ERROR

SUBPROGRAM

(G65/G66)

OFS)

(T

T

OF

OFS

NO

OFFSET

(P-G10)

(NUMBER

P

IS

PROGRAM-INPUT

(G10)

WHEN

R

DESIGNATION)

WORK

PROGRAM-INPUT

BLOCK

A

G65/66)

(M98,

IN

G65/G66

PROGRAMMED

(SEQUENCE

NO

PROGRAMISCALLED

G66,

(M98,

(M98)

FIVE-NESTED

M,

G,

G65/66

OR

MACRO

CODE

FOR

OR

COORDINATE

OR

FORMAT

BLOCK

IN

M98

)

NOT

NO

BY

AND

T

NEST)

CALL

10

Page 13

2.2.1

LIST

OF

ALARM

CODES

(CONT'D)

Code

045

048

049

050

051

052

053

055

ERROR

CAL

CIRCULAR

RADIUS

MANDED

CIRCULAR

PROG

INTERSECTION

BY

INTERSECTION

PROG

REVERSE

COMMANDED

PROG

K,

I,

BEVELING

FOR

VALUES

PROG

TAPERING

BEVELING

PROG

ANGLE

DURING

(G41

ARC

+

5

r

INSIDE

IN

COMMAND

ERROR

ERROR

OR

IN

ERROR

R

ERROR

ERROR

CORRECTLY

NOT

I,

OF

COMMAND

AND

PROGRAMMING

ANGLE

INTERPOLATION

ERROR

PROG

TOOL

VALUES

OUT

WORK

G50T

PROG

M,

WHICH

COMMANDED

OF

THE

OF

COORDINATE

ERROR

S,

T

COMMANDS

S,

M,

Causes

44)

-

DESIGNATED

S

<G41

POINT

RADIUS

TOOL

COMPENSATION

44)

-

NOT

COMPUTATION

(G41

ALMOST

(Gll/12)

(Gll/12)

(G01)

44)

-

MODE

M97

ROUNDING

AND

K,

TOO

R

ROUNDING

REVERSE

IN

NOT

PROGRAMMING

G01

BY

(G50T/G92T)

COORDINATE

RANGE

(M,

BETWEEN

SYSTEM

T)

S.

IN

CANNOT

CODE

T

CIRCLE

d

OBTAINED

COMMANDED

LARGE

BLOCKS

CORRECT

LINEAR

51

SETTING

THE

BLOCK

BE

COM¬

OF

FOR

MEMORY

TO

80

BY

IN

IN

Code

062

PROG

THREAD

MODE

PROG

063

RAPID

DIRECTION

BEVELING

VALUE

PROG

064

RAPID

DIRECTION

BEVELING

067

POWER

POWER

MEMORY

EDITING

068

EDITING

INHIBIT

070

PROG

MEMORY

MAND

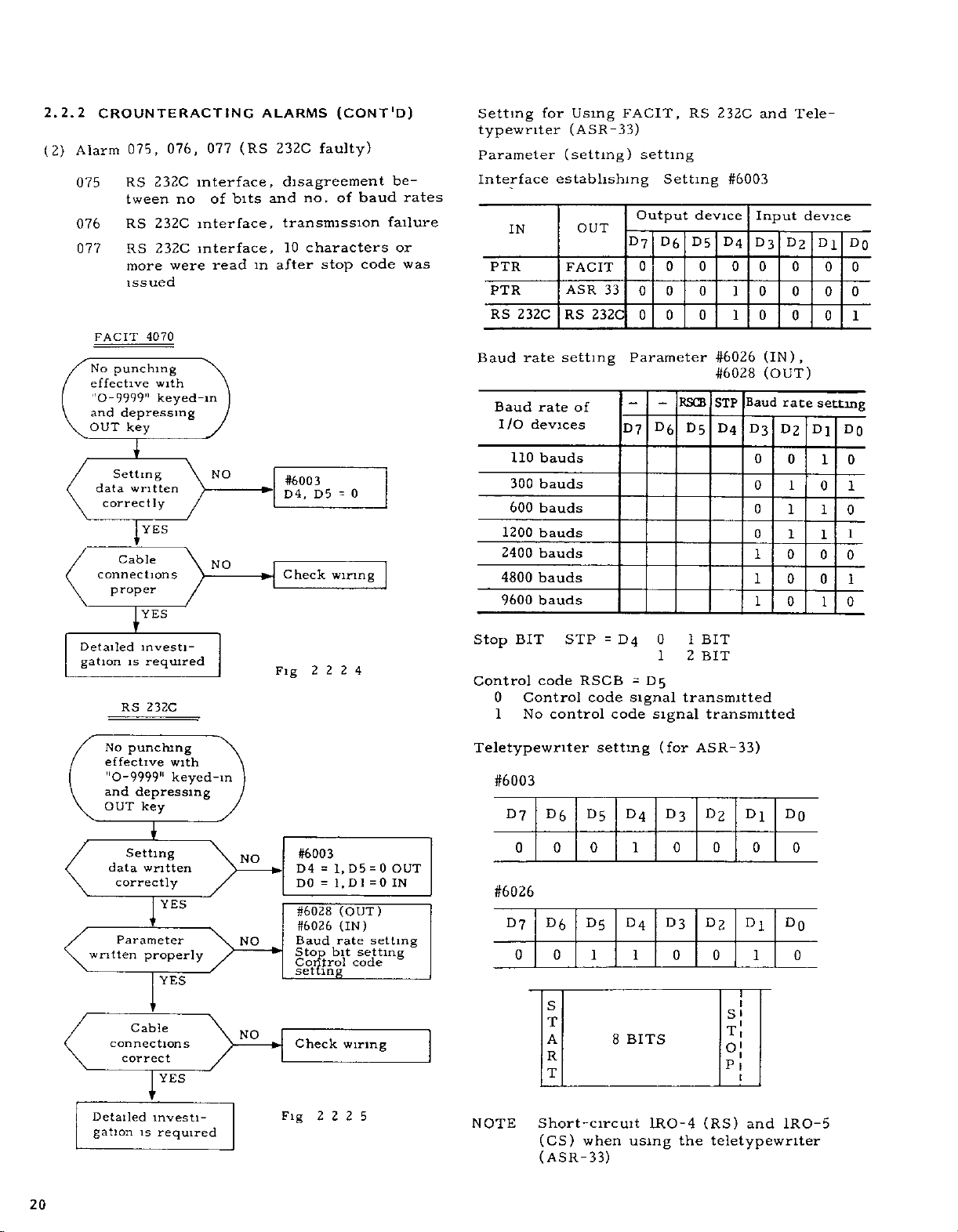

075

RS232C

DISAGREEMENT

OF

RS232C

076

DATA

THROUGH

ERROR

CUTTING

.

ERROR

THREAD

IN

SMALLER

SET

BY

ERROR

THREAD

IN

VALUE

WHILE

OFF

TURNED

INHIBIT

BEING

AREA

ERROR

OPERATION

GIVEN

NOT

ERROR

BAUD

RATES

ERROR

TRANSMISSION

RS232C

Causes

(G32/G33)

COMMANDED

(G92/G78/G21)

PULL-UP

THREAD

THAN

PARAMETER

(G92/G78/G21)

PULL-UP

THREAD

(M02/M30/M99)

BY

SET

EDITING

DURING

OFF

AREA

EXECUTED

COMPLETION

FOR

RATE)

NO

RS232C

(BAUD

OF

(SIGNAL

FAILURE

INTERFACE

VALUE

CUTTING

BEVELING

VALUE

CUTTING

PARAMETER

WRITING

IN

THE

BITS

OF

INTERFACE

LEVEL)

IN

IN

IN

G98

WITH

WITH

EDIT

COM¬

AND

X-AXIS

Z-AXIS

NO

056

059

060

061

ERROR

PROG

AXIS

COMMAND

AXIS

NOT

G04,

G36-G38.

UNREADY

ZR

NOT

G28

G29

HAS

RETURN

WHICH

PROG

LEAD

CEEDING

VALUE

CUTTING

MANDED

PROG

ROUNDING,

THREAD

HAS

ERROR

INCREASE/DECREASE

DURING

ERROR

(AXIS)

CORRECTLY

COMPLETED

COMMAND

COMPLETED

NOT

G30

(G34)

MAXIMUM

MINUS

(G11/G12

BEVELING

CUTTING

G20,

IN

G21

COMMANDED

THE

ON

REFERENCE

OR

COMMAND

PROGRAMMABLE

VARIABLE

VALUE

IN

ON

OF

THREAD)

COMMAND

BLOCK

BLOCKS.

AXIS

THE

VALUE

LEAD

LEAD

IN

WHICH

POINT

AXIS

EX¬

THREAD

COM-

IN

077

080

081

082

RS232C

10

READ

ERROR

CHARACTERS

AFTER

IN

TRANSMITTED

FACE

SET

TOOL

T

CODE

BLOCK

BEFORE

TOOL

ERROR

TOOL

TOOL

ERROR

TOOL

CMP

NOT

G98

G35

SET

CMP

OF

PARAMETER

ERROR

SET

SET

CMP

OF

PARAMETER

ERROR

SET

(OVER-RUN)

MORE

OR

STOP

THROUGH

ERROR

COMMANDED

NOT

COMMANDED

BLOCK

ERROR

COMPENSATION

ERROR

COMPENSATION

HAVE

CODE

RS232C

BEFORE

SETTING

SETTING

HAS

BEEN

BEEN

INTER¬

IN

FOR

FOR

G35

OR

(X)

(Z).

11

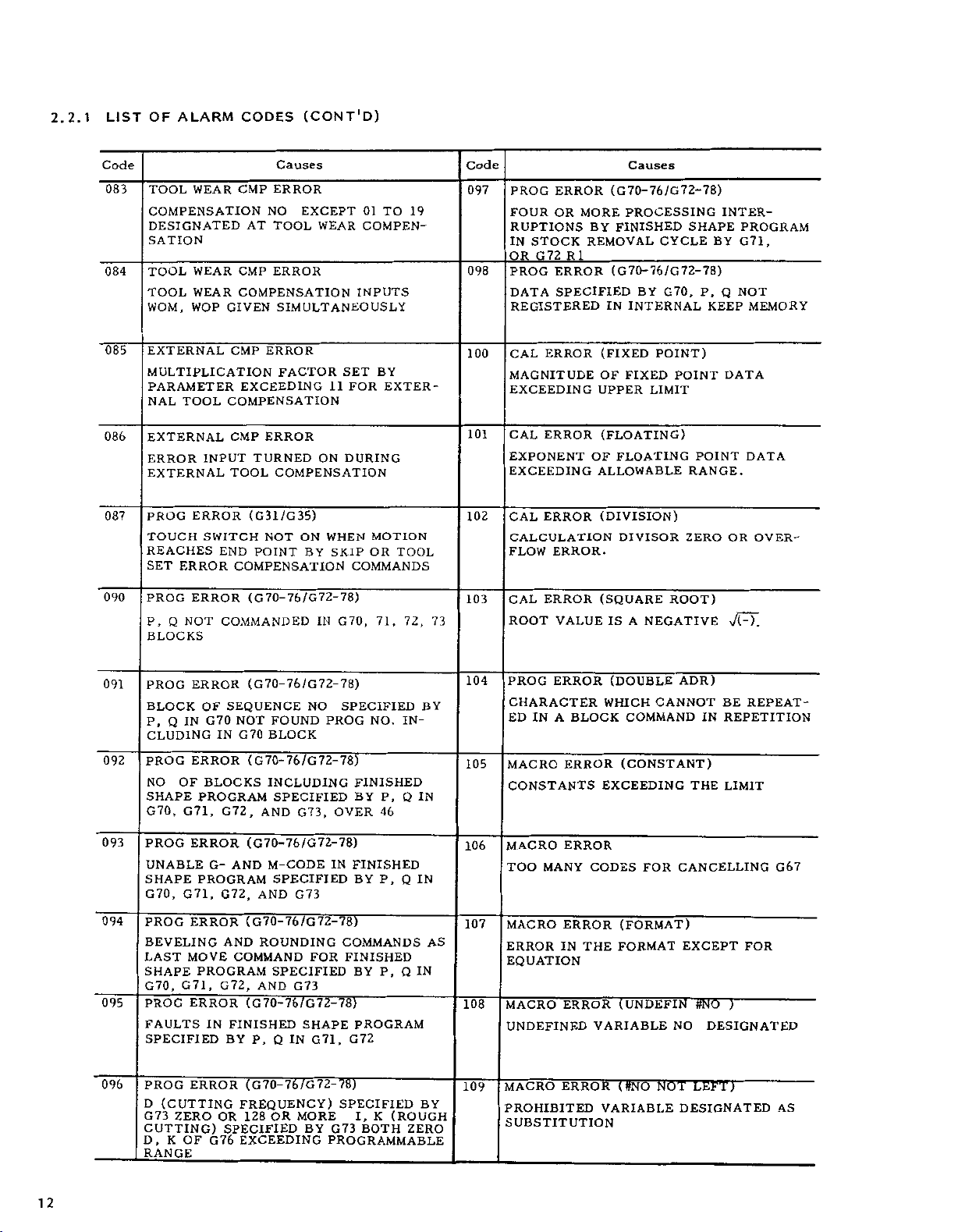

Page 14

2.2.1

LIST

OF

ALARM

CODES

(CONT'D)

Code

TOOL

083

COMPENSATION

DESIGNATED

SATION

TOOL

084

TOOL

WOM,

EXTERNAL

085

MULTIPLICATION

PARAMETER

NAL

086

EXTERNAL

ERROR

EXTERNAL

087

PROG

TOUCH

REACHES

SET

090

PROG

P,

BLOCKS

TOOL

ERROR

Q

NOT

WEAR

CMP

CMP

WEAR

WEAR

COMPENSATION

GIVEN

WOP

CMP

EXCEEDING

COMPENSATION

CMP

INPUT

TOOL

ERROR

SWITCH

END

COMPENSATION

ERROR

COMMANDED

Causes

ERROR

EXCEPT

NO

AT

TOOL

ERROR

WEAR

SIMULTANEOUSLY

ERROR

FACTOR

ERROR

TURNED

ON

COMPENSATION

(G31/G35)

WHEN

ON

NOT

POINT

(G70-76/G72-78)

BY

IN

01

COMPEN¬

INPUTS

SET

FOR

11

DURING

MOTION

SKIP

OR

COMMANDS

G70,

TO

BY

EXTER¬

TOOL

71.

19

72.

73

Code

097

098

100

101

102

103

ERROR

PROG

FOUR

OR

MORE

RUPTIONS

STOCK

IN

G72

OR

PROG

DATA

R

1

ERROR

SPECIFIED

REGISTERED

CAL

ERROR

MAGNITUDE

EXCEEDING

ERROR

CAL

EXPONENT

EXCEEDING

CAL

ERROR

CALCULATION

FLOW

ERROR.

ERROR

CAL

VALUE

ROOT

Causes

(G70-76/G72-78)

PROCESSING

FINISHED

BY

REMOVAL

_

(G70-76/G72-78)

BY

IN

INTERNAL

(FIXED

OF

FIXED

UPPER

(FLOATING)

OF

FLOATING

ALLOWABLE

(DIVISION)

DIVISOR

(SQUARE

IS

A

SHAPE

CYCLE

G70,

POINT)

POINT

LIMIT

POINT

RANGE.

ZERO

ROOT)

NEGATIVE

BY

P,

KEEP

INTER¬

PROGRAM

G71,

Q

NOT

MEMORY

DATA

DATA

OR

OVER¬

v/FT.

091

092

093

094

095

096

ERROR

PROG

BLOCK

P,

Q

IN

CLUDING

PROG

ERROR(G

OF

NO

SHAPE

G71,

G70,

PROG

ERROR

UNABLE

SHAPE

G71,

G70,

PROG

ERROR

BEVELING

LAST

MOVE

SHAPE

G70,

G71

PROG

ERROR

FAULTS

SPECIFIED

ERROR

PROG

(CUTTING

D

G73

ZERO

CUTTING)

D,

KOF

RANGE

(G70-76/G72-78)

SEQUENCE

OF

G70

NOT

G70

IN

BLOCKS

PROGRAM

G72,

(G70-76/G72-78)

G-

AND

PROGRAM

G72,

(G70-76/G72-78)

AND

COMMAND

PROGRAM

,

G72,

(G

IN

FINISHED

BY

(G70-76/G72-78)

FREQUENCY)

OR

128

SPECIFIED

G76

EXCEEDING

FOUND

BLOCK

70-

76

/G

INCLUDING

SPECIFIED

G73,

AND

M-CODE

SPECIFIED

AND

G73

ROUNDING

SPECIFIED

G73

AND

70-76/G72-78)

SHAPE

Q

P,

IN

OR

MORE

BY

SPECIFIED

NO

PROG

NO.

72-78)

FINISHED

P,

BY

46

OVER

IN

FINISHED

P,

BY

COMMANDS

FINISHED

FOR

G71,

G73

PROGRAMMABLE

P,

BY

PROGRAM

G72

SPECIFIED

(ROUGH

I,

K

BOTH

IN¬

Q

Q

Q

ZERO

IN

IN

IN

BY

BY

AS

104

105

106

107

108

109

SUBSTITUTION

PROG

ERROR

CHARACTER

ED

MACRO

IN

BLOCK

A

ERROR

CONSTANTS

MACRO

TOO

MACRO

ERROR

EQUATION

MACRO

ERROR

MANY

ERROR

IN

ERROR

UNDEFINED

MACRO

PROHIBITED

ERROR

CANNOT

FOR

CANCELLING

NO

NOT

ADR)

THE

EXCEPT

#NO

LEFT)

DESIGNATED

(DOUBLE

WHICH

COMMANDINREPETITION

(CONSTANT)

EXCEEDING

CODES

(FORMAT)

THE

FORMAT

(UNDEFIN

VARIABLE

(

#NO

VARIABLE

REPEAT¬

BE

LIMIT

G67

FOR

)

DESIGNATED

AS

12

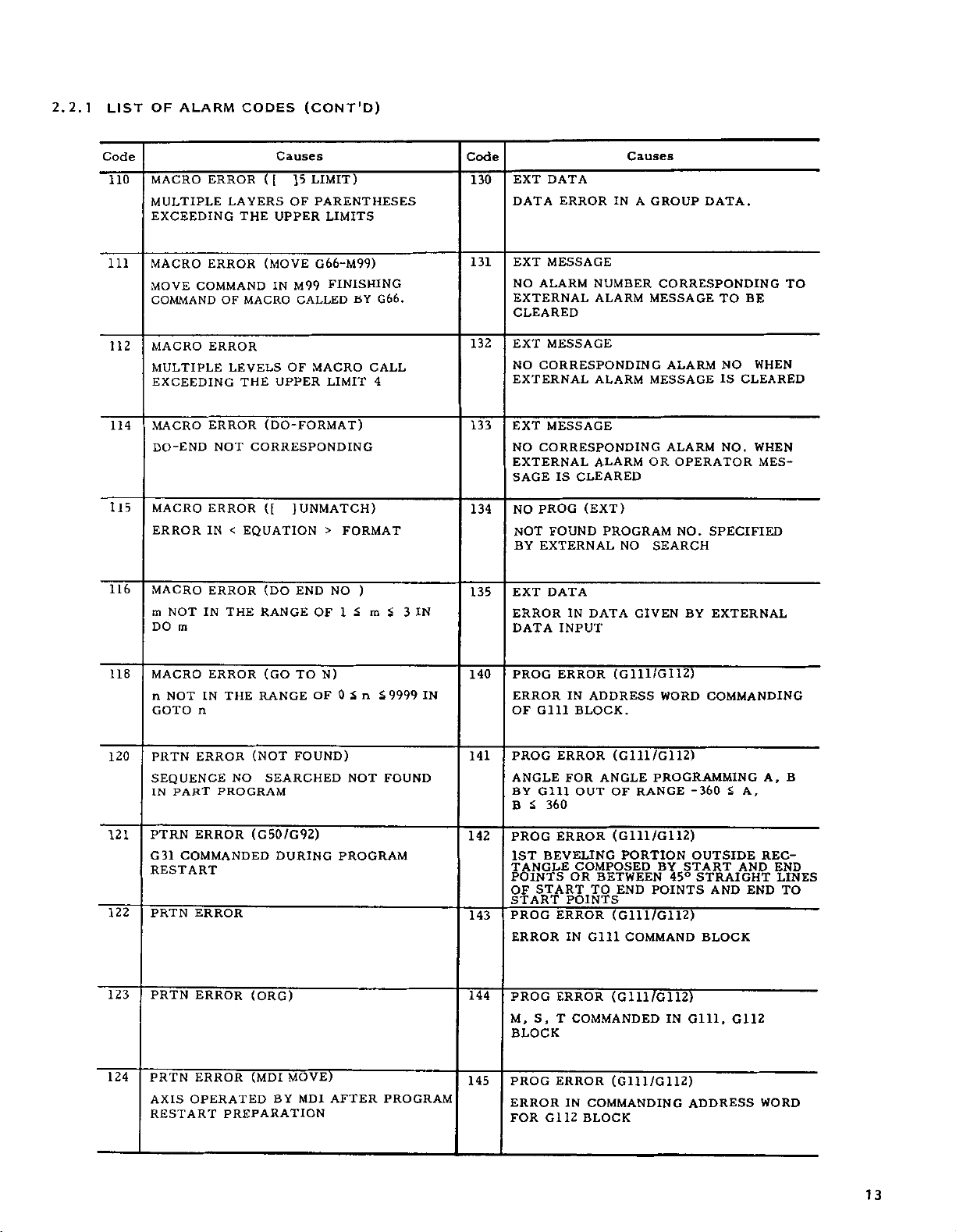

Page 15

2.2.1

LIST

OF

ALARM

CODES

(CONT'D)

Code

110

111

112

114

115

116

(

MACRO

ERROR

MULTIPLE

EXCEEDING

MACRO

MOVE

COMMANDOFMACRO

MACRO

MULTIPLE

ERROR

COMMAND

ERROR

EXCEEDING

MACRO

DO-END

MACRO

ERROR

MACRO

m

DO

NOT

m

ERROR

NOT

ERROR

IN

ERROR

IN

[

LAYERS

THE

(MOVE

IN

LEVELS

THE

(DO-FORMAT

CORRESPONDING

([

EQUATION

<

(DO

THE

RANGE

Causes

]5

OF

UPPER

M99

CALLED

OF

UPPER

UNMATCH)

]

END

LIMIT)

PARENTHESES

LIMITS

G66-M99)

FINISHING

BY

G66.

MACRO

OF

LIMIT

>

FORMAT

NO

1

£

CALL

4

)

)

m

Code

EXT

DATA

EXT

NO

DATA

ERROR

MESSAGE

ALARM

130

131

EXTERNAL

CLEARED

MESSAGE

EXT

132

CORRESPONDING

NO

EXTERNAL

133

MESSAGE

EXT

NO

CORRESPONDING

EXTERNAL

IS

SAGE

134

NO

NOT

BY

EXT

135

<

3

IN

ERROR

DATA

CLEARED

PROG

FOUND

EXTERNAL

DATA

IN

INPUT

IN

NUMBER

ALARM

ALARM

ALARM

(EXT)

PROGRAM

NO

DATA

Causes

A

GROUP

CORRESPONDING

MESSAGE

ALARM

MESSAGE

ALARM

OR

OPERATOR

NO.

SEARCH

GIVEN

BY

DATA.

BE

TO

WHEN

NO

IS

CLEARED

WHEN

NO.

SPECIFIED

EXTERNAL

TO

MES¬

118

120

121

122

123

124

MACRO

n

NOT

n

GOTO

ERROR

PRTN

SEQUENCE

IN

PART

PTRN

ERROR

G

31

COMMANDED

RESTART

ERROR

PRTN

PRTN

ERROR

ERROR

PRTN

OPERATED

AXIS

RESTART

ERROR

IN

THE

(NOT

NO

PROGRAM

(G50/G92)

(ORG)

(MDI

PREPARATION

(GO

TO

RANGE

FOUND)

SEARCHED

DURING

MOVE)

BY

MDI

N)

OF

0

PROGRAM

AFTER

n

£

NOT

£9999

IN

FOUND

PROGRAM

140

141

142

143

144

145

PROG

ERROR

Gill

OF

PROG

ANGLE

BY

Gill

360

£

B

PROG

1ST

BEVELING

TANGLE

POINTS

START

OF

START

PROG

ERROR

PROG

S,

M,

BLOCK

PROG

ERROR

G112

FOR

ERROR

ERROR

FOR

ERROR

POINTS

ERROR

IN

ERROR

T

ERROR

IN

(G111/G112)

IN

ADDRESS

BLOCK.

(G111/G112)

ANGLE

OUT

OF

(G111/G112)

COMPOSED

OR

BETWEEN

TO

(G111/G112)

Gill

(G111/G112)

COMMANDED

(G111/G112)

COMMANDING

BLOCK

WORD

PROGRAMMING

RANGE

PORTION

BY

END

POINTS

COMMAND

IN

COMMANDING

-360

OUTSIDE

START

STRAIGHT

45°

AND

BLOCK

Gill,

ADDRESS

<

A

AND

G112

,

REC¬

END

WORD

A,

END

B

LINES

TO

13

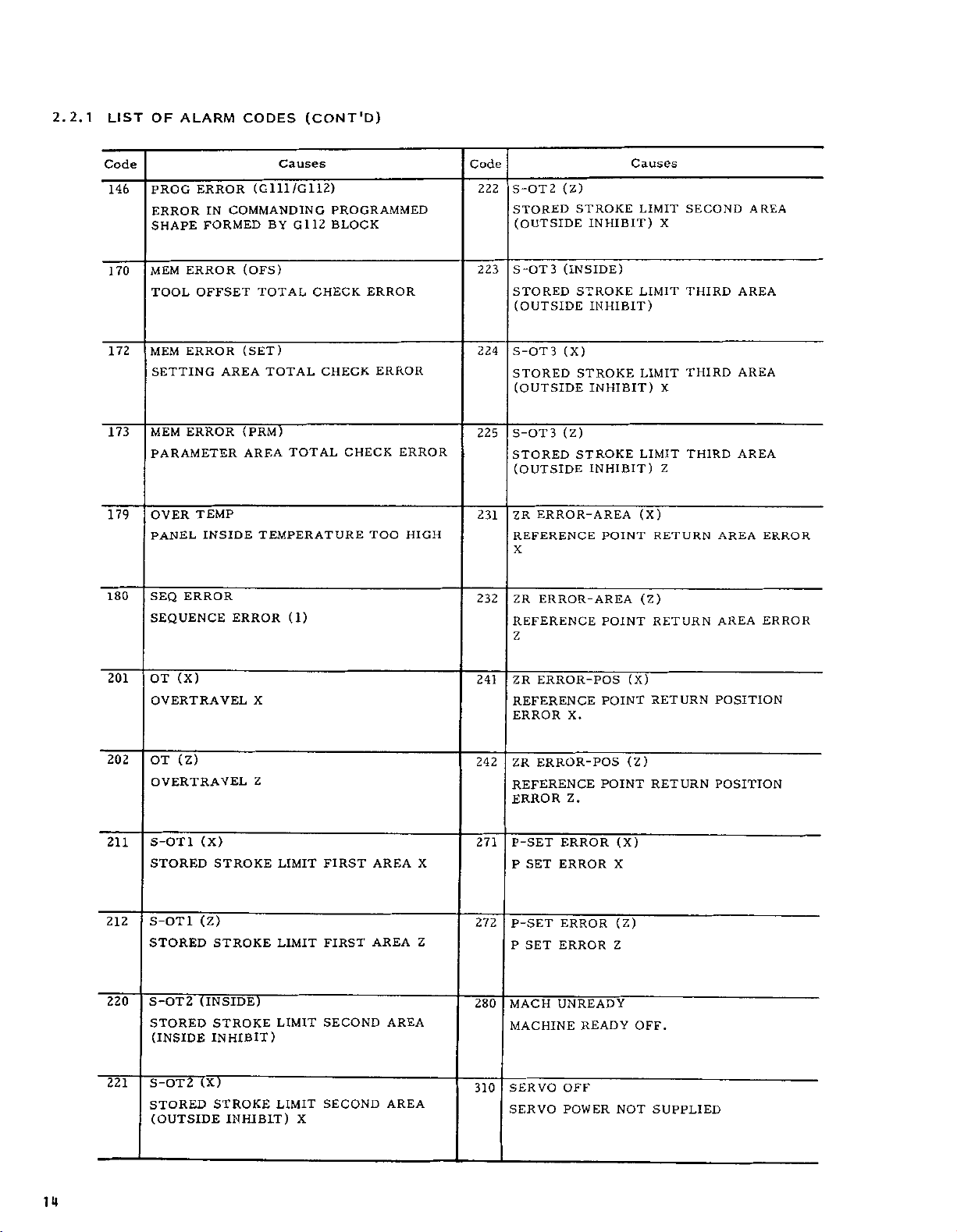

Page 16

2.2.1

LIST

OF

ALARM

CODES

(CONT'D)

Code

146

170

172

173

179

180

ERROR

PROG

ERROR

SHAPE

MEM

TOOL

MEM

IN

FORMED

ERROR

OFFSET

ERROR

SETTING

ERROR

MEM

PARAMETER

TEMP

OVER

PANEL

SEQ

SEQUENCE

INSIDE

ERROR

Causes

(G111/G112)

COMMANDING

G112

BY

(OFS)

TOTAL

(SET)

TOTAL

AREA

(PRM)

TOTAL

AREA

TEMPERATURE

ERROR

(1)

PROGRAMMED

BLOCK

CHECK

ERROR

ERROR

CHECK

CHECK

TOO

ERROR

HIGH

Code

222

223

224

225

231

232

S-OT2

(Z)

STORED

(OUTSIDE

S-OT3

STORED

(OUTSIDE

S-OT3

(INSIDE)

(X)

STORED

(OUTSIDE

S-OT3

STORED

(OUTSIDE

ZR

REFERENCE

X

ZR

(Z)

ERROR-AREA

ERROR-AREA

REFERENCE

Z

STROKE

INHIBIT)

STROKE

INHIBIT)

STROKE

INHIBIT)

STROKE

INHIBIT)

POINT

POINT

Causes

LIMIT

LIMIT

LIMIT

LIMIT

(X)

RETURN

(Z)

RETURN

X

X

Z

SECOND

THIRD

THIRD

THIRD

AREA

AREA

AREA

AREA

AREA

AREA

ERROR

ERROR

201

202

211

212

220

221

(X)

OT

OVERTRAVEL

(Z)

OT

OVERTRAVEL

S-OT1

STORED

S-OT1

STORED

S-OT2

STORED

(INSIDE

S-OT2

STORED

(OUTSIDE

(X)

STROKE

(Z)

STROKE

(INSIDE)

STROKE

INHIBIT)

(X)

STROKE

X

Z

INHIBIT

LIMIT

LIMIT

LIMIT

LIMIT

)

X

FIRST

FIRST

SECOND

SECOND

AREA

AREA

AREA

AREA

POINT

POINT

(X)

X

(Z)

Z

NOT

(X)

RETURN

(Z)

RETURN

OFF.

SUPPLIED

POSITION

POSITION

ERROR-POS

ZR

241

REFERENCE

242

ERROR

ZR

X.

ERROR-POS

REFERENCE

SET

SET

Z.

ERROR

ERROR

ERROR

ERROR

UNREADY

READY

OFF

POWER

ERROR

271

P-SET

X

Z

272

280

P

P-SET

P

MACH

MACHINE

310

SERVO

SERVO

14

Page 17

2.2.1

LIST

OF

ALARM

CODES

(CONT'D)

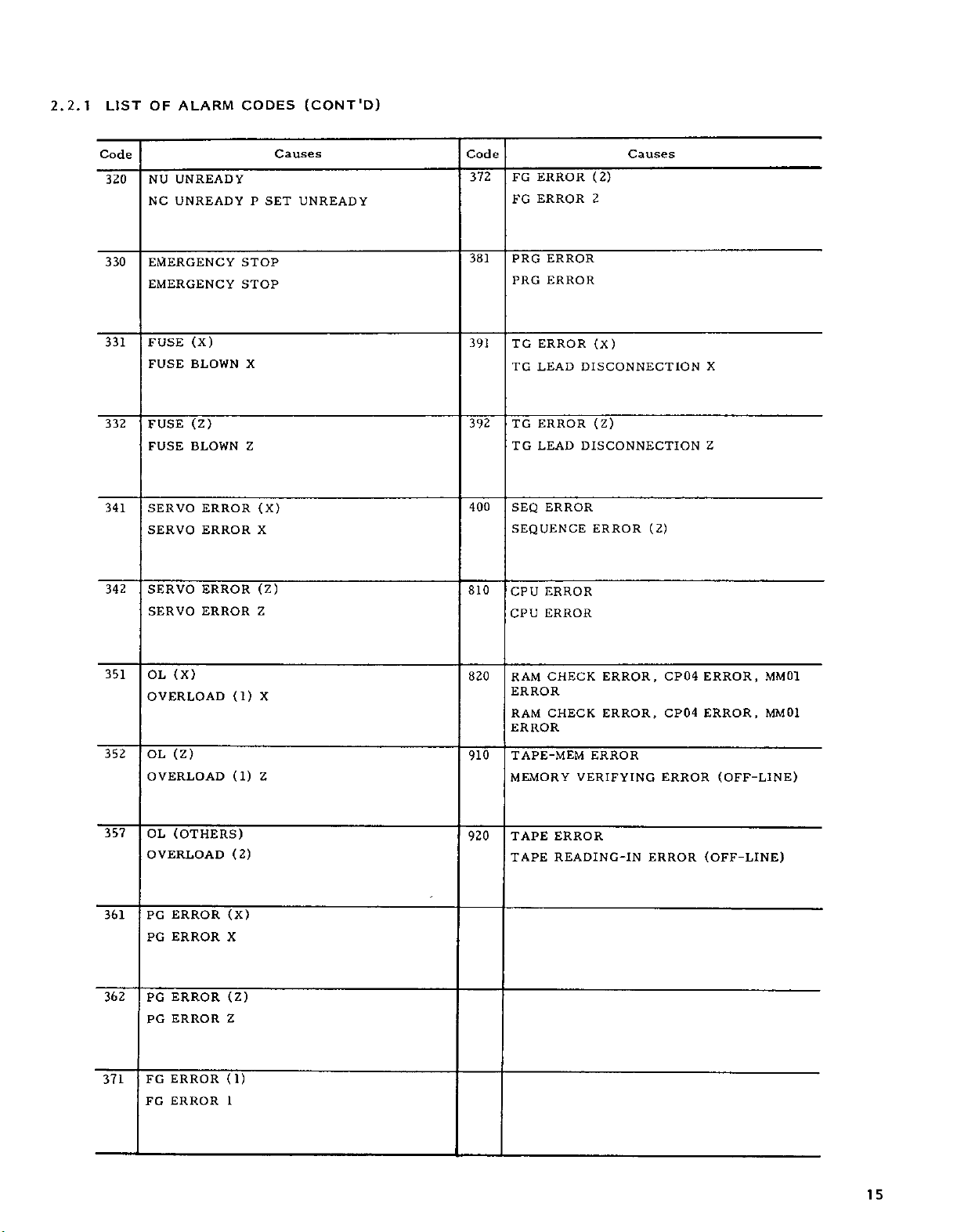

Code

320

330

331

332

341

342

NU

UNREADY

NC

UNREADY

EMERGENCY

EMERGENCY

(X)

FUSE

FUSE

BLOWN

(Z)

FUSE

FUSE

BLOWN

SERVO

SERVO

SERVO

SERVO

ERROR

ERROR

ERROR

ERROR

P

STOP

STOP

X

Z

(X)

X

(Z)

Z

Causes

SET

UNREADY

Code

372

381

391

392

400

810

ERROR

FG

FG

ERROR

PRG

ERROR

PRG

ERROR

TG

ERROR

TG

LEAD

TG

ERROR

TG

LEAD

SEQ

ERROR

SEQUENCE

CPU

ERROR

ERROR

CPU

Causes

(2)

2

(X)

DISCONNECTION

(Z)

DISCONNECTION

ERROR

(2)

X

Z

331

352

357

361

362

371

(X)

OL

OVERLOAD

(Z)

OL

OVERLOAD

(OTHERS)

OL

OVERLOAD

ERROR

PG

PG

ERROR

PG

ERROR

ERROR

PG

FG

ERROR

ERROR

FG

(X)

X

(Z)

Z

(1)

1

(1)

(1)

(2)

CP04

CP04

ERROR,

ERROR,

MM01

MM01

RAM

ERROR

RAM

CHECK

CHECK

ERROR

ERROR,

820

X

,

ERROR

TAPE-MEM

910

Z

920

MEMORY

TAPE

TAPE

ERROR

VERIFYING

ERROR

READING-IN

ERROR

ERROR

(OFF-LINE)

(OFF-LINE)

15

Page 18

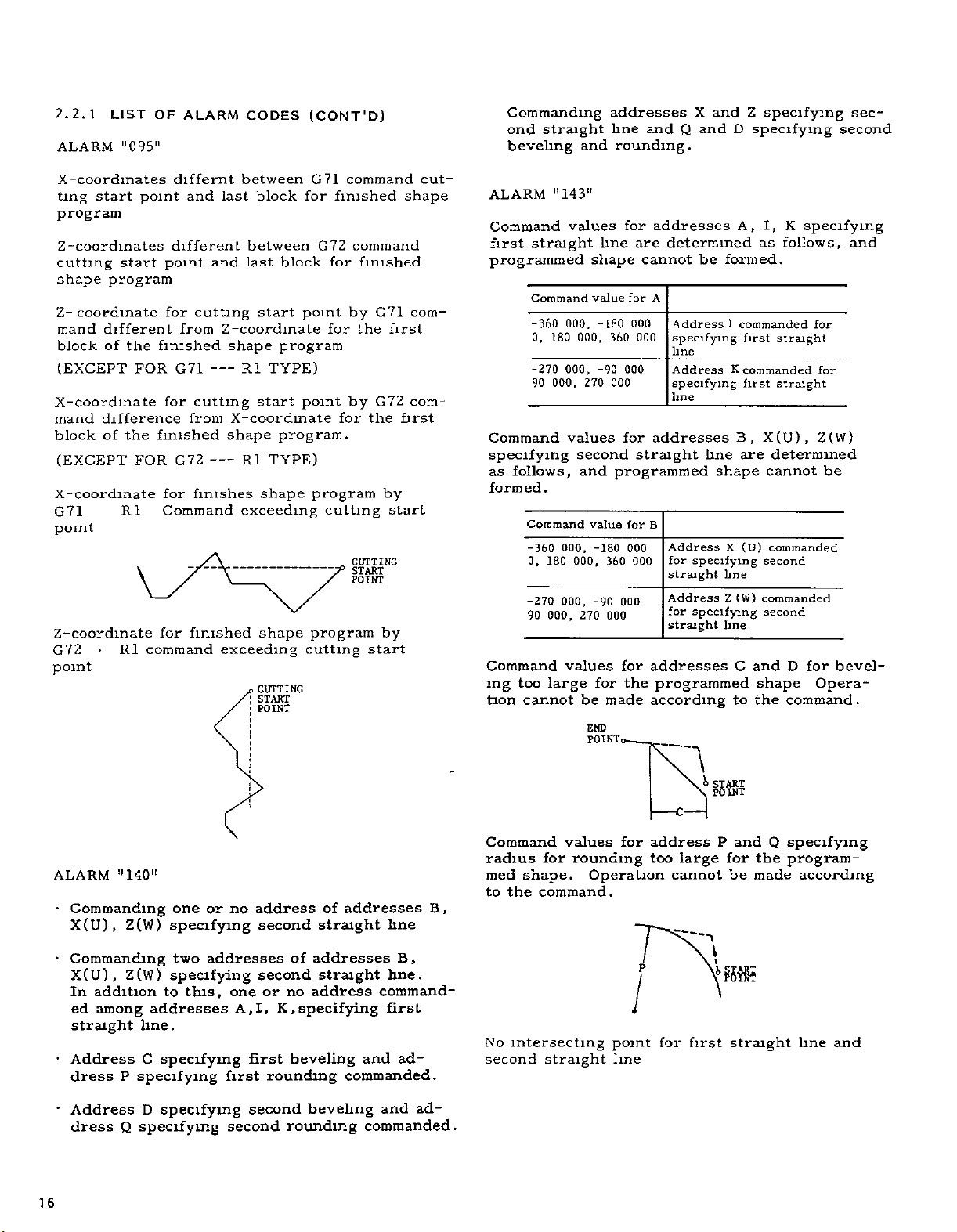

2.2.1

ALARM

LIST

"095"

OF

ALARM

CODES

(CONT'D)

Commanding

straight

ond

beveling

and

addresses

line

and

rounding.

and

X

Q

and

Z

specifying

D

specifying

sec¬

second

X-coordmates

start

ting

program

Z-coordinates

cutting

shape

Z-

mand

block

(EXCEPT

X-coordinate

mand

block

(EXCEPT

program

coordinate

different

of

difference

of

X-coordmate

G71

point

Z-coordinate

•

G72

point

start

the

FOR

the

FOR

R1

R1

diffemt

point

different

point

for

from

finished

G71

for

finished

G72

for

Command

for

command

and

and

cutting

—

cutting

from

—

finishes

finished

between

last

block

between

block

last

start

Z-coordinate

R1

program

TYPE)

shape

start

X-coordmate

R1

program.

TYPE)

shape

shape

exceeding

shape

exceeding

CUTTING

START

POINT

G71

for

finished

G72

for

point

for

point

program

cutting

program

cutting

command

command

finished

G71

by

the

by

G72

for

the

CUTTING

START

POINT

start

first

by

start

by

shape

com¬

com¬

first

cut¬

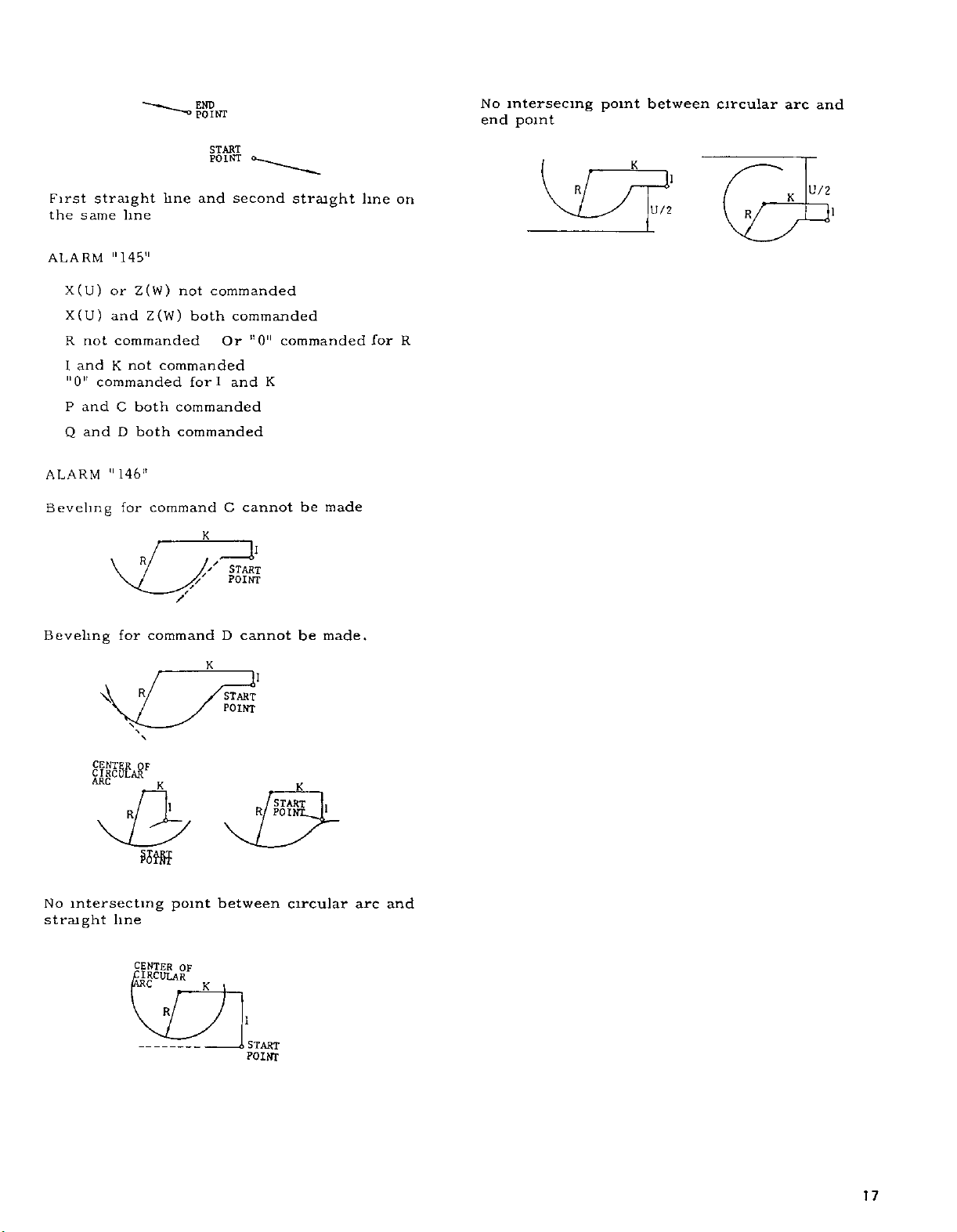

ALARM

Command

straight

first

programmed

Command

-360

0,

180

-270

90

Command

specifying

follows,

as

formed.

Command

-360

180

0.

-270

000,

90

Command

too

ing

tion

large

cannot

"143"

values

000.

000,

000,

values

second

000.

000,

000,

values

000,

270

and

270

be

line

shape

value

-180

-90

value

-180

360

-90

000

for

made

END

POINT,

360

000

for

addresses

determined

are

cannot

for

A

Address

000

000

specifying

line

000

for

Address

specifying

line

addresses

straight

programmed

for

B

Address

000

for

000

straight

Address

000

for

straight

for

addresses

the

programmed

according

’

—

be

formed.

1

K

line

shape

X

specifying

line

Z

specifying

line

C

to

i

\

!>

15®

A,

I,

follows,

as

commanded

first

straight

commanded

first

straight

X(U),

B,

are

determined

cannot

(U)

commanded

second

(W)

commanded

second

and

shape

the

K

specifying

for

for

Z(W)

be

for

D

Opera¬

command

and

bevel¬

.

ALARM

•

Commanding

X(U),

•

Commanding

X(U),Z(W)

In

ed

straight

•

Address

dress

•

Address

dress

16

"140"

Z(W)

addition

among

P

Q

one

specifying

two

specifying

this,

to

addresses

line.

C

specifying

specifying

D

specifying

specifying

or

no

addresses

one

A,

first

first

second

second

address

second

of

second

or

no

I,

K,

beveling

rounding

rounding

addresses

of

straight

addresses

straight

address

specifying

commanded.

beveling

B

line

B,

line.

command¬

first

and

ad¬

ad¬

and

commanded.

,

Command

radius

med

shape.

to

the

No

intersecting

second

values

for

rounding

Operation

command.

straight

for

point

line

address

too

P

for

large

cannot

\

first

P

for

i

\

and

the

be

made

straight

Q

specifying

program¬

according

line

and

Page 19

First

the

straight

same

line

line

END

POINT

START

POINT

and

second

straight

line

on

No

end

intersecing

point

between

point

K

R

1'

U/2

circular

R

arc

K

and

U/2

ALARM

X(U)

X(U)

not

R

and

I

"0"

and

P

Q

and

ALARM

Beveling

Beveling

"145"

Z(W)

or

Z{W)

and

commanded

not

K

commanded

C

both

both

D

"146"

for

command

R,

for

command

R/

A

not

commanded

both

commanded

fori

commanded

commanded

K

//'

'/

/

K

commanded

"0"

Or

K

and

cannot

C

START

POINT

cannot

D

l1

START

POINT

commanded

be

made

be

made.

for

R

No

intersecting

straight

R,

line

CENTER

£

K

1

point

OF

_

_

IRCULAR

R,

between

K

„

/

R

1

START

POINT

K

START

POINT.

circular

|1

arc

and

17

Page 20

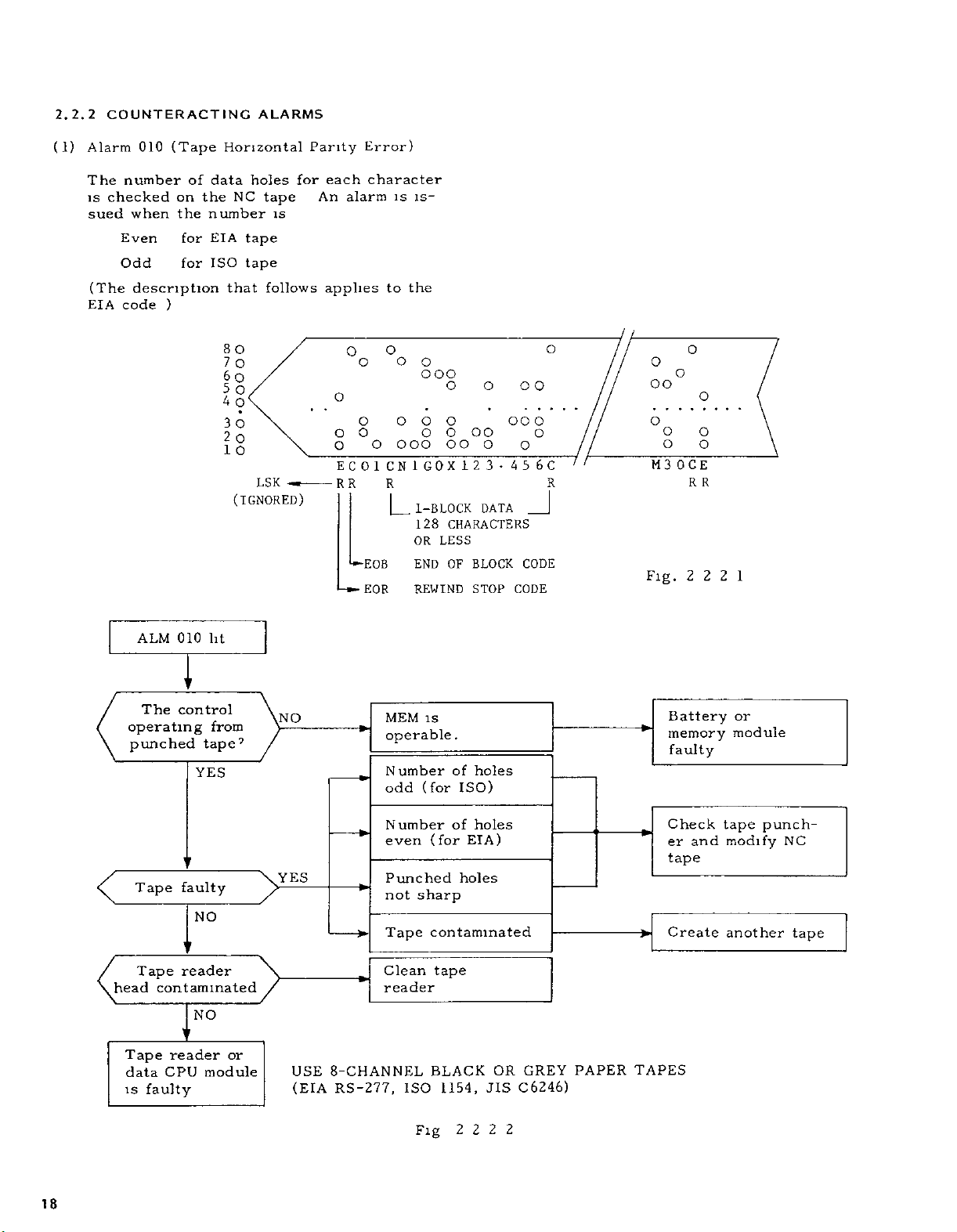

2.2.2

COUNTERACTING

ALARMS

each

An

applies

o

o

o

EC01

RR

Error)

character

alarm

O

o

o

o

EOB

EOR

o

to

O

CN

R

L

is

o

ooo

ooo

is-

the

o

ooo

o

o

o

oo

1

GOX

BLOCK

1-

CHARACTERS

128

LESS

OR

OF

END

REWIND

oo

2

1

DATA

BLOCK

STOP

o o

oo

o

•

3

4

CODE

o

o

o

o

6

5

J

CODE

O

C

R

o

oo

o

M3

Fig.

o

o

O

o

OCE

R

2221

o

o

o

R

(

1)

Alarm

The

is

sued

(The

EIA

010

number

checked

when

Even

Odd

description

code

(Tape

on

the

for

for

)

of

the

Horizontal

data

NC

number

EIA

ISO

that

80

7

O

§0

5

O

4

O

30

2

O

1

o

(IGNORED)

holes

tape

tape

LSK

Parity

for

tape

is

follows

ALM

The

operating

punched

Tape

Tape

head

Tape

data

is

010

i

r

control

tape7

YES

faulty

NO

reader

contaminated

NO

V

reader

CPU

faulty

lit

from

or

module

NO

YES

>

USE

8-CHANNEL

(EIA

*ÿ

RS-277,

MEM