Page 1

J50M

INSTRUCTIONS

CNC SYSTEM FOR MACHINING CENTERS

Before initial operation, read these instructions thoroughly, and retain for future reference

Page 2

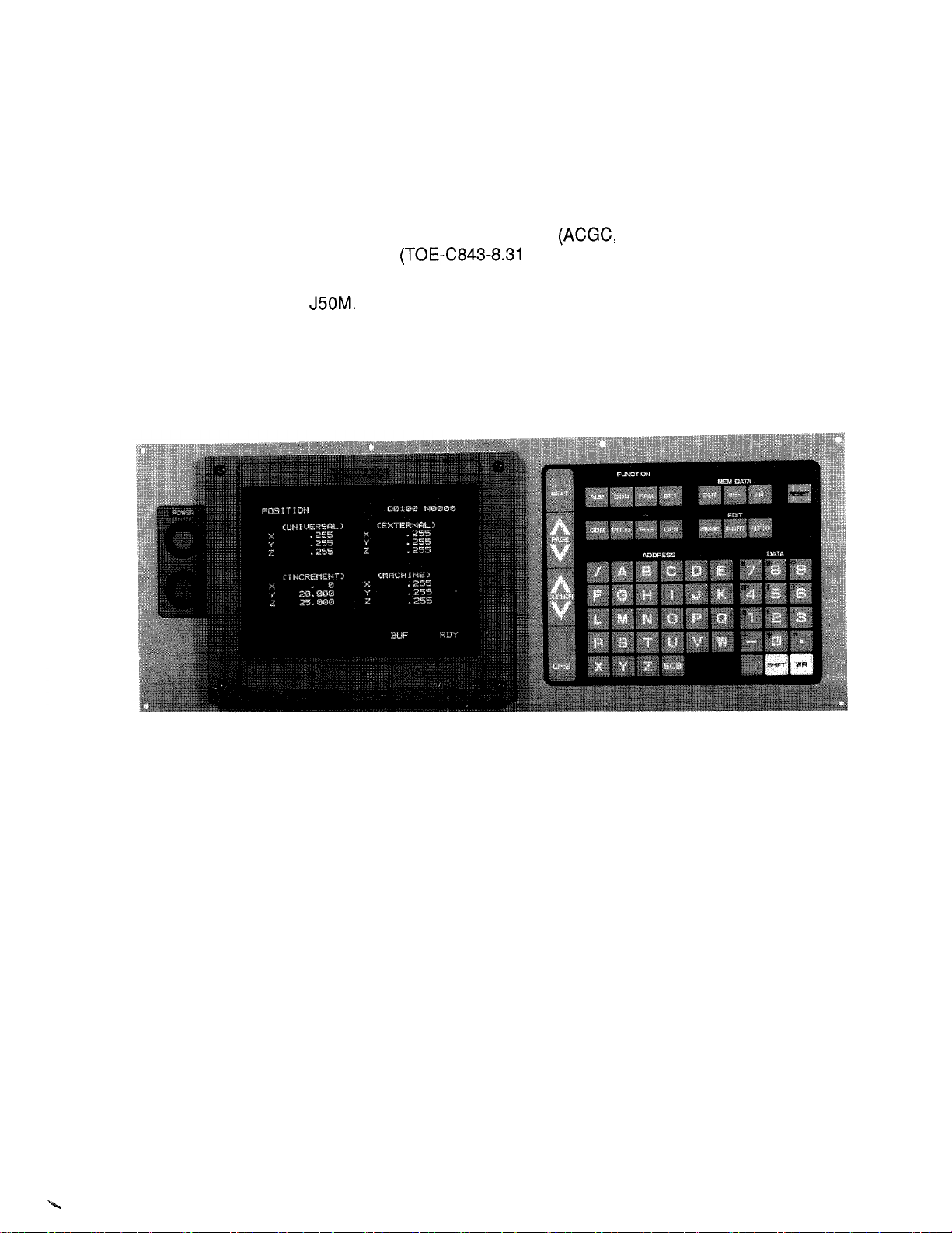

This manual is primarily intended with 9“ CRT character display to

give operators instructions for YASNAC J50M programming, operation and maintenance.

For operation of 14“ CRT character display

the instruction manual

) separately provided.

optional), refer to

This manual applies to the basic and optional features of

YASNAC

The optional features are marked with a dagger.

For the specifications of your YASNAC J50M, refer to the machine

tool builder’s manual.

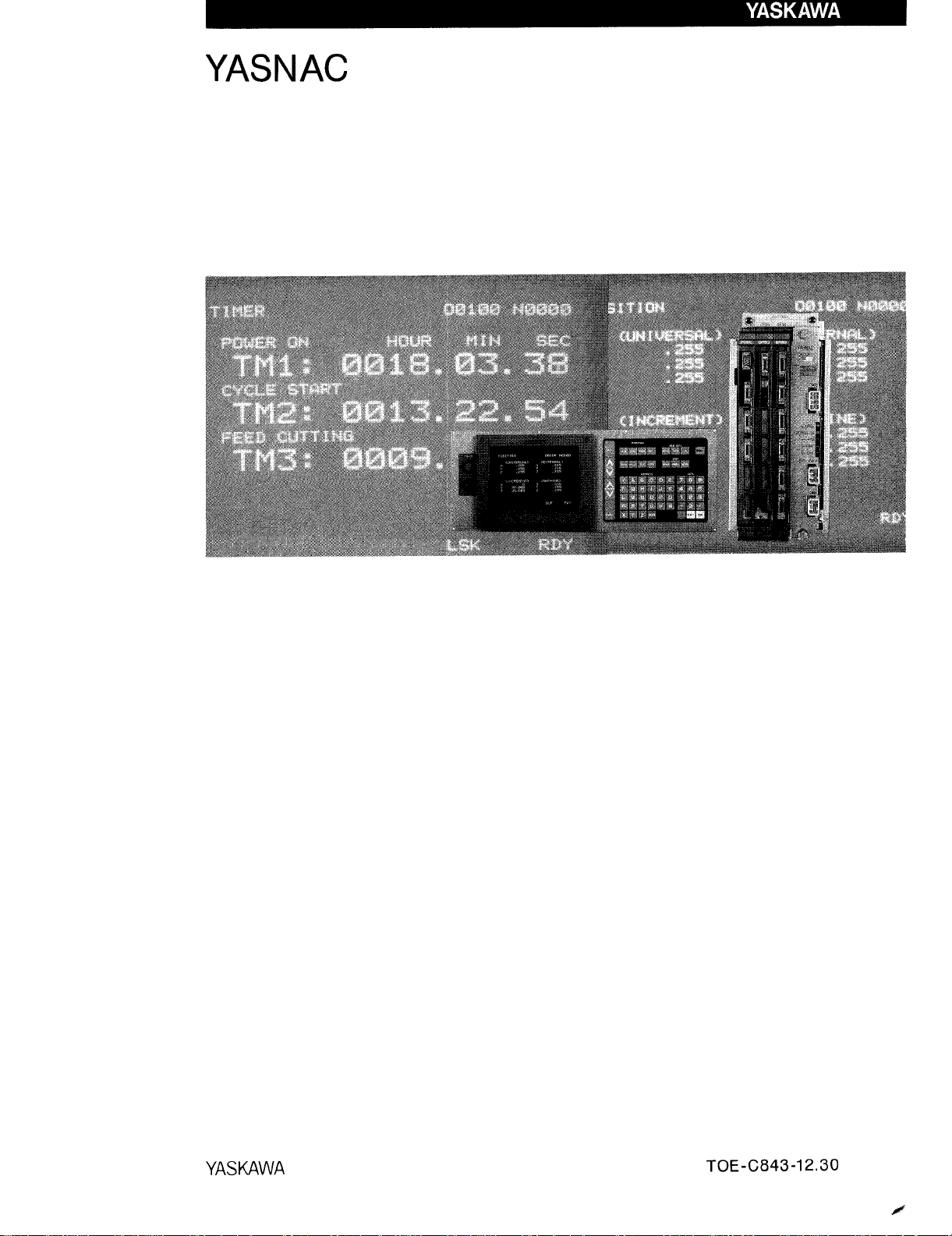

YASNAC J50M Operator’s Panel

with 9“ CRT Character Display

94-C84-123

2

Page 3

CONTENTS

Page

2.

‘PROGRAM MIN G . . . . . . . . . . . . . . . . . .

2.1

INPUT FORMAT """" """" """"

2.2

PROGRAM NUMBER AND SEQUENCE NUMBER

2.3

COORDINATE WORD

2.4

TRAVERSE AND FEED FUNCTIONS

2.5

SPINDLE-SPEED FUNCTION (S-FUNCTION)

2.6

TOOL FUNCTION (T-FUNCTION).

2.7

TOOL COMPENSATION ““”” ””-””””””””””””””””””””””””””””” ““”” ””””o ””””’””””””””””””””””””””””

2.8

MISCELLANEOUS FUNCTIONS (M-FUNCTION) ‘“ ””’”””””””””-”””””””””””””””””””’””

2.9

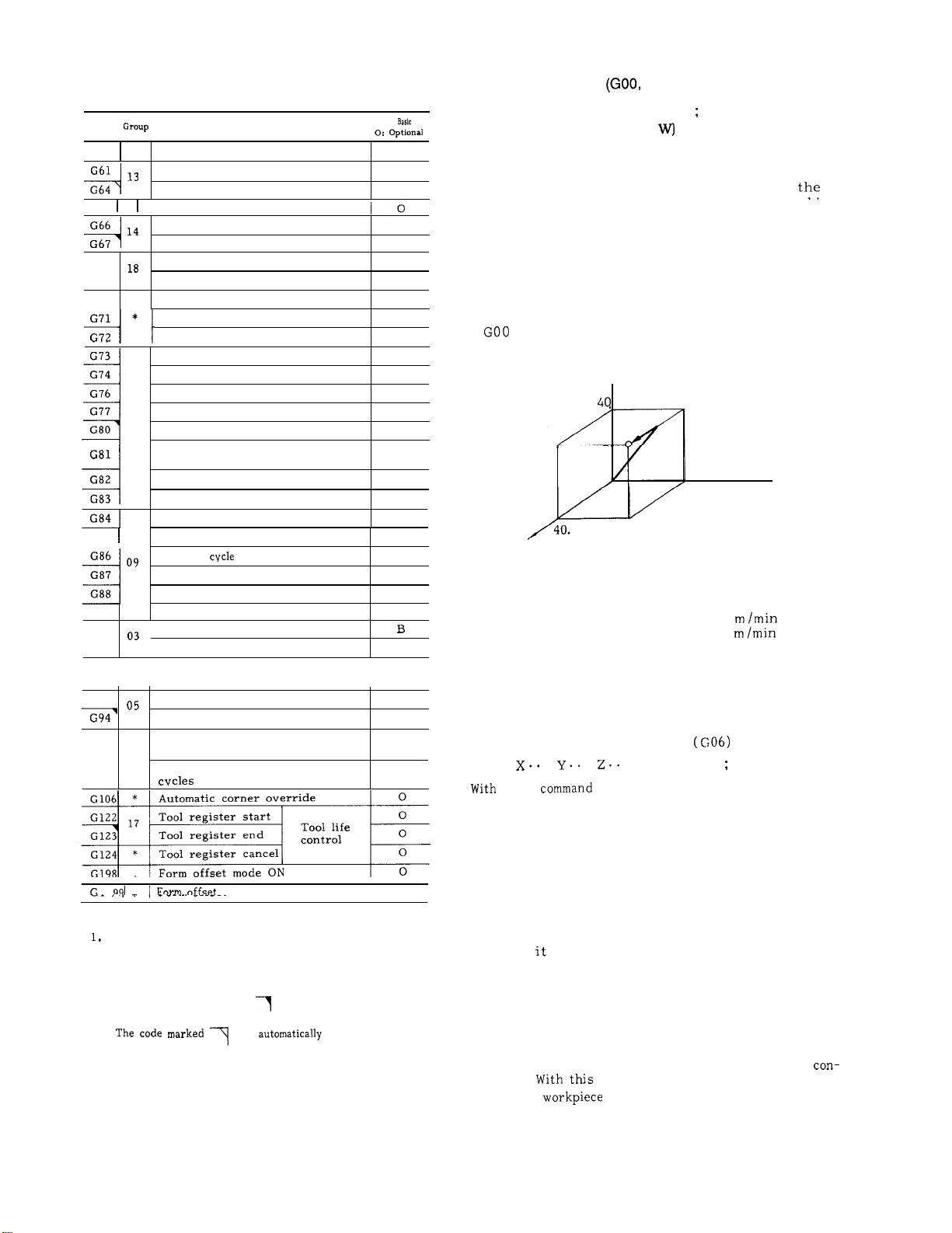

PREPARATORY FUNCTION (G-FUNCTION)

2.10

2.11 uSERMACRO (G65, G66, G67) ““.

2.12 SOLID TAP FUNCTION

2.13 AUTOMATIC CORNER OVERRIDE . . . .

2.14 HIGH-SPEED CONTOURING FUNCTION*

3.

PART PROGRAM TAPE CODING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 T~ECODE

3.2 PROGRAMMING

3.3 PART PROGRAM TAPE PUNCHING

3.4 PART PROGRAM TAPE HANDLING

4. NC

OPERATOR’S PANEL WITH 9“ CRT CHARACTER DISPLAY

4.1

PUSHBUTTONS, LAMPS AND KEYS

4.2

POWER

4.3

DISPLAY AND WRITING OPERATION

4.4

TAPE INPUT/OUTPUT OPERATIONS

4.5

LOADING PART PROGRAMS INTO MEMORY

4.6

EDIT OF PART PROGRAM

4.7

SUPPLEMENT TO DATA

4.8

TAPE VERIFYING ““”” ”””””””””””””””””””””””””””””””””

5. MACHINE CONTROL STATION

5.1

SWITCHING UNITS ON THE CONTROL STATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...164

5.2 OPERATION PROCEDURE

OPERATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1

INSPECTION BEFORE TURNING ON POWER

6.2

TURNING ON POWER

MANUAL OPERATION

6.3

PREPARATION FOR STORED LEADSCREW ERROR COMPENSATION

6.4

AND STORED STROKE LIMIT

PREPARATION FOR AUTOMATIC OPERATION

6.5

6.6

OPERATION IN TAPE AND MEMORY MODE . .

6.7

AUTOMATIC OPERATION IN MDI MODE

6.8

MDI OPERATION INTERRUPTING AUTOMATIC OPERATION

6.9

6.10

6.11 TURNING OFF POWER

7.1 ROUTINE INSPECTION SCHEDULE . .

7.2 BATTERY REPLACEMENT””””””””

7.3

7.4 THERMAL OVERLOAD RELAY OF SERVO UNIT

7.5 MOLDED-CASE CIRCUIT

7.6 TROUBLE CAUSES AND REMEDIES

OPERATION INTERRUPTING AUToMATIc opERATIoN . . . . . . . . . . . . . . . . . . . . . .

PREPARATION FOR TURNING OFF

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX-1 LIST OF SETTING NUMBERS

APPENDIX-2

STORED LEADSCREW

APPENDIX-4 LISTOFSTANDARD

OF

APPENDIX-5 LIST

ALARM

INPUT

/•

CODES

APPENDIX-6 LIST OF ADDRESS CHARACTERS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

““” -”””””””””””””””””””””””

"""" """"

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

”””””””””””””””””””””””””””””””””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

"""" """" """"

”””””””””””””””””””””””””””””””” ““”” ””””””””””””””’”””””””’”””””””””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

””””””””””””””””””””””””””””””””

”””””””””””””””””””””””’”””””””

. . . . . . . . . . . . . . . .

“””””””’”’”””’””””””””””””’”””””””

. . . . . . . . . . . . ...119

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

”””’”””””””””””””””””””””””””””””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...132

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

”””” ”””” ””””” ”””” ””””” ””””

. . . . . . . . . . . . . . . . . . . . ...133

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

““”” ”””””””””””””””””””””””””””””

INTERFAcEt ““”” ””””””””””””””””””””””””””””””””

”””””””””””””””””””””””””””””””” ““””””””””<””””161

”””””””””””””””””””””””””””””’ ““””””151

””””

. . . . . . . . . . . ...174

. . . . . . . . . . . . . . . . . . . . . . . ...191

”’””””””””””””””””””””””””””””””” ““”” ”””” ”””” ”””” ”””” ””””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

““”” ”””””””””’”””””””””””””””””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...196

““” ” ” ” ” ” ” ” ” ” ” ” ” ” ” ” ” ” ” ” ” ””””””-”” ““” ””””””””””””””””””””-””””””””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...-..........................199

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...192

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...193

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...194

””””””””””’”””””””””””””””””””

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

""""

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...196

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...198

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...202

"". """" """"

. . . . . . . . . . . . . . . . . . . . ...193

. . . . . . . . . . . ...193

. . . . . . . . . . . ...199

. . . . . . . . . . . . . . . . . . . ...239

SIGNALS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...243

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . ...282

. . . . . . . . . . ...254

1

1

5

. . . .

12

19

. . ...125

130

134

134

137

191

191

192

193

194

. . ...196

1

6

9

111

Page 4

INDEX

Subject Chapter

A ABSOLUTE/INCREMENTAL PROGRAMMING (G90,G91)

ADDING PART PROGRAM

ADDRESS AND FUNCTION CHARACTERS

ADDRESS SEARCH ------------- .

ALARM CODE DISPLAY

ALARM CODES AND REMEDIES

ALARM MESSAGE DISPLAY BY

ALARM NUMBER OF USER MACROS .

AUTOMATIC COORDINATE

AUTOMATIC CORNER OVERRIDE

AUTOMATIC OPERATION IN MDI MODE

AXIS INTERLOCK INPUT

B

BATTERY REPLACEMENT -”-----””

BEFORE MAINTENANCE CALL”--””

BUFFER REGISTER

C CABLE CONNECTOR SPECIFICATIONS

CANNED CYCLES

CIRCUIT PROTECTOR TRIP (ALARM NO. 331 TO 334)

CIRCULAR INTERPOLATION (G02, G03)

CIRCULAR PATH MODE ON/OFF ON

CIRCULAR PROJECTION COMPENSATION

CONDITIONS FOR ADDING SOLID TAP FUNCTIONS

CONSIDERATIONS AND REMARKS FOR USER MACROS

CONTROL COMMANDS

CONTROL PANEL

D

DATA KEYS

DECIMAL POINT PROGRAMMING

DELETING PART PROGRAM BLOCK (ERASE KEY)

DESCRIPTION ON PROGRAMMING

DISPLAY AND WRITE OF LOCAL VARIABLES

DISPLAY

DISPLAY IN THE

DISPLAY LOCK/MACHINE LOCK SWITCH

DISPLAY OF REGISTERED PROGRAM

DISPLAYING AND RESETTING CURRENT

DISPLAYING AND WRITING PARAMETERS

DISPLAYING AND WRITING TOOL OFFSET AND WORK OFFSET 4 -- --

DWELL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . ...-”

TOOL RADIUS COMPENSATION C(M97,

DISPLAY

CHARACTER DISPLAY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

oFFsETl-

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G74, G76, G77, G80 TO G89, G98, G99)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-- ...-..”” ““””

NUMERICAL SEnINGFUNCTION

"." . .

(SETTING) FUNCTION--”-””-”””””

”oo+”-oooo”

AND LAMP" "".

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMMAND

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

““”” ”--”

"".

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

"".

. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

POINT

--

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

””””

””””

"".

"".

””. ”.-+

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

”””’ ” ”” ” ”” ”-’-----” 5

"oo""

4””. ””.

. . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . .

-

. . . . . . . . . . . .

--

. . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

””.

””””

"".

””””

. . . .

. .

””””

. . . . . . . . . . . . . . . . . . . . . .

”””” ”””” ”””” ”””” ”””” ”””””” S

"".

"".

.""

--””-----

Par.

. . . . . . . .. 2.9.30 .”....... 85

2

. . . . . ...4.6.4

4

. . . . . . . .

2

. . . . . . . . 4.1.4

4

. . . . . ...4.3.11 . . . . . . ...150

4

. . . . . . . . 7.6.2

. . . . . ...2.10.1 . . . . . . . . . 93

2

““””””””2.11.11

””.

2

2

2

5

7

7

7

2

4

2

3

7

2

2

7

4

2

4

2

4

2

..2.9.35

2.4.5

””-” 5.2.2

. . . . . . . . 2.13

”””” 6.8

. .

. . . . . ...7.1.3

. . . . . ...7.2

. . . . . . . .

. . . . . . . . 4.7.4

. . . . . ...2.9.28 .

.02.9.9

. .

. . . . . ...2.14.3.........129

2

2

””””

. . . . . .

‘+”” $.-”

5.2.9

-”””

. . . . . ...4.1.5

. . . . . . . .

. . . . . ...4.6.2

. . . . . .

‘“”-- ””” 4.5.4

”””” 4.3.7

. . . . . . . . 2.9.6

. . . . . . . ...158

. . . . . . . . . .

. . . . . . . ...135

. . . . . . . ...199

-””-0 92

. . . . . . . ...125

. . . . . ...--196

. . . . . . . .

. . . . . . .

. . . . . . . . . .

. . . . . . . ...160

. . . . . . . ...133

3.2.3

. . .

7.4.1

2.8.6

””””

-”. -”-138

. . . . . . ...-196

. . . . . . . . . . .

. . . . . . . . . .

. . . . . . . ...135

. . . . . . . .

. . . . . . . ...157

. . .

.“”+.

4.3.4

4.3.5

. . . . . . . . . . 25

”-176

”172

26

. . .

”120

”112

”-146

”169

Page

3

96

33

5

68

22

6

6

5

iv

Page 5

INDEX (Cent’d)

Subject

E

EDIT OF PART PROGRAM

EDIT KEYS

EDIT LOCK

EXACT STOP

EXERCISES OF USER MACRO

EXTERNAL DECELERATION INPUT SIGNALSI”

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AUTO-SELECT

F

FEED HOLD PUSHBUTTON AND LAMP ““” ”””””””””””””””””””””””””””””” 5

FEED STOP FUNCTION

FEEDRATE (F-FUNCTION)

FEEDRATE 1/10 --

FEEDRATE OVERRIDE CANCEL SWITCH

FEEDRATE OVERRIDE SWITCH

FORM COMPENSATION FUNCTION

4TH AXIS CONTROL

4TH AXIS NEGLECT INPUT

G

GENERAL PART PROGRAM FORM

H

H- AND D-FUNCTION (H, DCODES)-o

HANDLE AXIS SELECT SWITCH

HANDLE DIAL

HELICAL INTERPOLATION

HIGH-SPEED CONTOURING FUNCTION*

HOLE PATTERN CYCLES

I

IMPORTANT ALARM CODES-”’””

INPUT/OUTPUT SIGNALS

INPUTTING SETTING DATA AND PARAMETER DATA . . . . . . . . . . . . . . . . . . . 4 . . . . . . . .

INPUTTING TOOL OFFSETS FROM TAPE

INSPECTION

INTERNAL TOGGLE SWITCHES

J

JOG

PUSHBUTTONS””””””--””””””

K

L

LABEL SKIP FUNCTION

LEAST INPUT INCREMENT AND LEAST OUTPUT INCREMENT

LINEAR INTERPOLATION

LIST

LIST OF ALARM CODES

LIST OF

IST OF PARAMETER NUMBERS-”--

L

LIST OF SETTING NUMBERS

LIST OF STANDARD INPUT/OUTPUT SIGNALS

LOADING PART PROGRAMS BY MDI

LOADING PART PROGRAM TAPE INTO MEMORY

LOADING PART PROGRAMS INTO MEMORY

. . . . ” ” ” ”””----””

MANUAL PULSE GENERATOR)

(SIMULTANEOUS ONE-AXIS CONTROL

OVERRIDE SWITCH

SWITCH ””-” ”---”-

ADDRESS CHARACTERS”-”””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUSHBUnON

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G64)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPEED

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SENSOR

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

----

““” ”””””””””-””””””””””-”””””””””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AND GROUPS””””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

)

. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

”””” --”” $”””””””””””””””””<””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

“’”” ”””” ”””” ””””” ”””” ”””” ””””

”’””””””””””””””””””””””””””””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

”””””””””””””-””””””””””””””””

”””””””””””-”-”””””--””””””””” “5

+.”.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

” - . ”----- ””.”---

”””-

. . . . . . . . . . .

. . . . . . . . .

”-.

Chapter

. . . . . . . . .

. . . . . . . .

o””””

AppENDIx-6

APPENDIX-5

AppENDIx-2

APPENDIX-1

. . ...<...

. . . . . ...4.6

4

. . . . . .

4

5

. . . . . . . . 3.1.2

3

5

. . . . . . . . 2.9.7

2

. . . . . .

2

5

5

. . . . . . . . 2.4.2

2

. . . . . . . . 2.4.3

2

5

5

.

2

. . .

2

5

. . . . . . . . 3.2.2 . . . . . . . . ...132

3

. . . . .

5

2

2

. . . . . . . . 7.6.3

.

4

6

. . . . . ...4.3.8

4

5

. . . . . . . . 2.1.4

2

. . . . . . . . 2.3.5

2

. . . . . . . . 2.9.3

2

. . . . . . . . 4.5.3

4

. . . . . . . . 4.5

4

Par.

. . . . . . . . ...156

. . . . . . . ...130

. . . . . . . . . . 25

. . .

”””” 2.4.4

0-’”

”””” 2.9.5

””””

””””

””””

”””

”””06.1

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . 10

5.2.7

. . . . . . . . . .

2.3.4

. . . . . . . ...165

5.1.6

. . . . . . . ...165

. . . . . . . . . . .

. . . . . . . . . .

. . . . . . . ...199

. . . . . . . ...151

. . . .

. . . . . . . ...149

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . 22

.

”””$$$”-”””

. . . . . ...4.155

. . . . . . . . ...154

. .

”115

-128

”””

.254

19

Page

10

24

66

2;

1

5

8

213

v

Page 6

INDEX (Cent’d)

Subject

M MCODESFOR

M-FUNCTION LOCK SWITCH (AUXILIARY FUNCTION LOCK)

MACHINE CONTROL STATION

MAKING ADDITION TO A PART PROGRAM

MANUAL ABSOLUTE SWITCH

MANUAL OPERATION INTERRUPTING AUTOMATIC OPERATION

MANUAL PULSE MULTIPLY SELECT SWITCH

MDI OPERATION INTERRUPTING AUTOMATIC OPERATION

MEMDATA (MEMORY DATA) KEYS

MESSAGE DISPLAY BY CONTROL-OUT

MIRROR IMAGE AXIS SELECTOR SWITCH

MIRROR IMAGE ON/OFF (M95, M94)

MISCELLANEOUS FUNCTIONS (M-FUNCTION)

MODE SELECT SWITCH

MODIFYING PART PROGRAM BLOCK (ALTER KEY)

MOLDED-CASE CRCUITBREAKERS (MCCB)o

MULTI-ACTIVE REGISTERS ON/OFF (M93, M92)

MULTI-ACTIVE REGISTERS

N

NC OPERATORS PANEL WITH 9“ CRT CHARACTER DISPLAY

NC TAPE PUNCH

“OHT’’L ED(RED)L IT . . . . . . . . . . . . . . . . . . .

0

ON-LINE SELF-DIAGNOSTICS--”””OPERATION COMMANDS ”-”” ”””-”OPERATION IN TAPE AND MEMORY MODE

OPERATION PROCEDURE

OPERATION PROCEDURE

OPERATIONS

ORG

OTHER M CODES

OUTLINE OF TOOL COMPENSATION. ““” ””-” ””””” ”””” -” ”” ” ”””” ”-”” ””--”” 2

OUTPUTTING PART PROGRAM TO PAPER TAPE

OUTPUTTING SETTING DATA AND PARAMETER DATA TO

PAPER TAPE

OUTPUTTING TOOL OFFSETS TO PAPER TAPE

OVERLOAD (ALARM NO, 351 TO 354)

OVERVIEW ”””””””””””””””””””””””” “’”” ”””” ”””” ”””” ”””” ”””” ””””

OVERVIEW OF USER MACRO BODY .

P PAGE KEYS . . . .

PAPER TAPE SELECT ----

PART PROGRAM TAPE CODING”” ““”

PART PROGRAM TAPE HANDLING

PART PROGRAM TAPE PUNCHING

. . . . . ...”.””.””””

sTOPSwITCH

KEY

PROCESS~G (M90TOM199)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POINT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DATA~PUT/OUTPUT ~TERFACE

SKIP(/l

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

""""

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

”””””---””””””””””””””””””””””

”””-”””””””””””””-”””””””””””’” “3

““” ”””””””--”-”””””””””””””-”””””” “4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

””. -.”” --”” ”””” ”””” ”””----

. . . . . . . . . . . . . . . . . . . . . . . .

"".

”””-”””””””””””””””-”””””””” “4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

-”””””””-””””-””””””””””””””””

"<"'

. . . . . . . . . . . . . . . . . . . . . . . .

"". "4"""

. . . . . . . . . . . . . . . . . . . .

"$"""

”””” ”””” ”””” ”””’

. . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . .

.o"o-

. . . . . . . . .

Chapter

""" 2

2 ‘+.+”””<

5

. . . . . . . . . . . . . . . . . . . . . . . .

5

5

. . . . . . . . . . . . . . . . . . . . . ...196

5

. . . .

6 ----

5

5

““.

2

6

2

5

. . . . . . . . 2.8.5

2

. . . . . ...2.8.”..””.””””. 14

2

. . . . . . . . 5.1.1

5

4 . . . . . . . . 4.6.3

7

. . . .

2

.

2

. . . . . . . . . . . . . . . . . . . . . ...134

4

. . .

3

. . . . . ...7.3.4

7

“7

5

. . . . . . . . . . . . . . . . . . . . . ...191

6

4 ““”

. . . . . ...4.1.9

4

2

. . . . . . . . 2.8.8

. . . . . . . . 4.4.5

4

4

. . . .

7

. . . . .

2

. . . . . .

2

. . . . . . . . 4.1.7

4

. . . . . . . . 3.3.1

3

. . . . . . . . . . . . . . . . . . . . . ...130

. . . . . . . .

3

. . . . . . . . 3.3

3

Par.

2.8.2

””.

5.2.8

”4.5.2

6.3” ”-.

6.7

5.1.7

”5.2.6

2.3.6

6.9

2.10.2

7.5”” ””””” ””””

2.1.6

””””

3,3.2

5.2

”””” 4.3.9

4.7.5 “+-.

”””

4.4.4

”””” 4.4.3

7.4.2

””””

Page

””.

. . . . . . . . . .

. . . . . . .

”4-.

. . . . . . . . . . 15

. . . . . . . ...164

. . . . . . . ...157

. . . . . . . . . .

. .

. . . . . . . . . .

. . . . . . . ...198

. . . . . . . . . .

. . .

. . . . . . . ...136

. . . . . . . . . . 19

. . . . . . . ...152

. . . . . .

. . . . . . . ...198

. . . . . . . ...136

. . . . . . . ...133

. .

. . . . . . . . ...133

””-

..171

””. ”-169

-+18:

93

-.171

15

199

6

94

97

164

5

136

vi

Page 7

INDEX (Cent’d)

Subject

“+5 V’’LED( RED)L IT””””””””” ““” ”””””””””””””””””””””””””””

P

R RAPID TRAVERSE RATE”----””””””””””””””

s S2-DIGIT

ED(RED)L IT”””””””””” ““” ”””’’””’””””””””””””””””””””

PLANE DESIGNATION

POSITIONING

POWER ON/OFF OPERATION

POWER ON/OFF PUSHBUTTONS””””

POWER SUPPLY

PREFACE

PREPARATION FOR STORED LEADSCREW ERROR COMPENSATION

PREPARATORY FUNCTION (G-FUNCTION)

PROCESS SHEET

PROGRAM NUMBER

PROGRAM NUMBER AND SEQUENCE NUMBER . . . . . . . . . . . . . . . . . . . . . . . .

PROGRAM RESTART T

PROGRAMMING

PROGRAMMING

PUSHBUTTONS, LAMPS AND KEYS

REFERENC E POINT

REGISTRATION OF USER MACROS

REMOTE POWER ON/OFF PUSHBUTTONS

ROTATION OF COORDINATES

ROUTINE INSPECTION SCHEDULE ‘“””

S 5-DIGIT PROGRAMMING .

SCALING FUNCTION

SETTING OF BAUD RATE AND OTHERS OF

SETTING

SIMULTANEOUSLY CONTROLLABLE AXES OF

SIMULTANEOUSLY CONTROLLABLE AXES OF

SKIP FUNCTION

SOLID TAP 1/0 AND ITS RELATION WITH

SOLID TAP RELATED PARAMETER” ““” ”””””””””””””””””””””””””””””””

“SOURCE” LED [GREEN] UNLIT . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AND STORED STROKE LIMIT t””””

POINT

DATAmPUT/OUTPUT INTERFACE TO

THREE-AXIS CONTROL””””””””””

TAP

SPINDLE CONTROL 1/0

TAP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RATE OVERNDE

COO

CONTROL

””””””””””””””””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(G27)~"

””””” ““” ””””””””””””””””””””””””””””””

RDINATE

G19)””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERA~ON

”””””””””-”””””””””””””””””””””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SWITCH

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G69)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i’

394) . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...7 . . . . . ...74.3 . . . . . . . ...198

SPINDLE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

--

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

".+" "". "<"""

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

””””” ”””’” ””””” ”””””’

-””””””””””””””’””-”””””””””””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

M90)T

. . . . . . . . . . . . . . . . . . . . . . 2 . . . . . . . . 2,9,31 . . . . . . . . .

”””” ”””” ”””” ”””””

. . . . . . . . . . . . . . . . . . . . . . . . . . . 5 . . . . . . . .

””””” ””””” ””””” ””””

”””” ””””” ”””” ”””” ”””””

-

. . . . . . . . . . . . . . . . . . . . . . . . . .

“

-o””””””””””””””””””””””””

. . . . . . . . . . . . . . . . . . . . . . . . . . 7 . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 4 . . . . . . . .

”””” ”””” ””””” ””””

" . . . . . . . . . . . . . . . . . . ...2 . . . . . . . .

””””” ””””” ””””” ”””””

”””-””””””-””””””””””””””” 4

. . . . . . . . . . . . . . 2 . . . . . . . .

””””

USED .." . . . ..."... 4 . . . . . . . . 4.7.2 . . . . . . . ...159

. .

. . . . . . . .

Chapter

4

1

6

6

2

3

. . . . . . . . 22

2

3

4

2

2

2

2

2

2

2

Par.

””””

. .

““.

. . . . . . . .

. . . . . . . . 2.9

””””

.

. . .

. . . . . . . . 4.1

. . . . ...” 2.11.8

””””

2

. . . . . ...2.9.33

””””

. . . . . . . . 2.5.2

. ..- . . .. 2.9.22 ”.---”--” 57

”””

”””-

. . . . . .

. . . . . . . . 7.3.1

”””2.9.10 ””’”’”””” 28

7.3” ”””” ”””” ””” 197

6.5

. . . . . . . . . . . 19

3.2.1

. . . . . . . . . . .

5.2.4

. . . . . . . . ...132

3.2

. . . . . . . . . ...134

. . . . . . . . . 35

. . . . . . . ...196

. . . . . . . .

. . . . . . . . . 9

2.3.3

. . . . . . . ...132

. . . . . . . . . .

. . . . . . . ...178

. . . . . . . . . .

. . . . . . ...168

”””

”’””

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

”””

Page

1

5

5

1

9

33

34

91

6

1

7

7

vii

Page 8

INDEX (Cent’d)

29

”””16161

-””

37

66

98

58

63

”””

Page

13

5°

26

51

9

79

94

Par.

3.4.1

4.7

--2.6.1

””””

””””

.8””

5.1.31

”””- 2.7

5.2.3

2.9.8

4.8.2

7.6”.

”””” 4.2.2

””-” 6.2”

””””

2.9.29

2.10

2923

2924

. . . . . . . ...133

. . . . . . . . ...151

“$-.

. . . . ...176

. . . . . . . . . .

. . . . . .

. . . . . . . ...137

”””” ”--191

. . . . . . . . . . 93

. . . . . . . .

s”””

Chapter

. . . . . .

5

.

5

. . . . . . . . . . . . . . . . . ...239

““.

“4

. . . . . ...4.4

4

7

5

.

5 . . . . . . . . 5.1.26 . . . . . . ...172

”””” 2.7.2

4

. . . . . ...2.9.21

2

7

. . . . . ...4.2.1

4

2

. . . . . ...2.11.2””””””””” 94

2

2

2

2

4 . . . . . . . . 4.3.3 . . . . . . . ...142

5

Subject

s

SPINDLE INDEXING FUNCTION

SPINDLE SPEED OVERRIDE SWITCH

SPINDLE-SPEED FUNCTION (S-FUNCTION) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2.5 . . . . . . . . . . .

SPLICING NC TAPE

STORED LEADSCREW ERR

STORED PART PROGRAM DISPLAY-” ““””

SUMMARY OF EDITING OPERATION

supplement To DATA INPuT/ouTPuT Interface T

SWITCHING

T

TAPE INPUT/OUTPUT OPERATIONS OF NC DATA

THERMAL OVERLOAD

3RD TO 5TH STORED STROKE

TOOL COMPENSATION-”””””””””””

TOOL FUNCTION (T-FUNCTION)”””

TOOL

TOOL LENGTH MEASUREMENT

TOOL LIFE C ONTRO L

TOOL OFFSET MEMORY”””””-”””””

TOOL OFFSET VALUE TAPE VERIFYING

TOOL POSITION OFFSET (G45 TO G48)

TRAVERSE AND FEED FUNCTIONS”

TROUBLE CAUSES AND REMEDIES

TURNING OFF POWER””-”””””””””

TURNING ON POWER . . . .

YPES AND FUNCTIONS OF INTERFACE- .0”.

T

u

UPGRADING THE CANNED CYCLE

USER MACRO (G65, G66, G67)

USER MACRO CALL COMMANDS

USER MESSAGE DISPLAY

VARIABLES '--"

VERIFYING PART PROGRAM TAPE””

W wORKCOORDINATE

WORK COORDINATE

z

Z-MIS COMMAND NEGLECT

BLOCKS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIMIT

COMPENSATION

COMPENSATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPROACH (G60)7.

---

"

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

""""

OR COMPENSATION

G23)~

CONTROL STATION . . . . . . . . . . . . . . . . . . . . . . . . 5 . . . . . . . . 5,1............164

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G123)--

-----

SETTmGC (G52To G59)~

. . . . . . . . . . . . . . . . . .

”-””

““”

‘“”” ”””””””””””””””””””””””””””””””

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(GIO)""

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

”””””-”””””””””””””””””””””””” ““.

““” ””””””’””-””””””””””””””””””””

G74, G76, G77, G80 TO

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(G52To G59)~

CONTENTS BY MDI . .

”””””””””””””””””””””””””””-””” “3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

””--”””””””””””””””-””””””””””” “2

G49)T

"o""

""o" oo-----

G59)t

+."""

o""-"

VIII

Page 9

1. PREFACE

When reading this manual keep in mind that the

information contained herein does not cover every

possible contingency which might be met during

the operation. Any operation not described in

this manual should not be attempted with the

control.

The functions and performance as NC machine are

determined by a combination of machine and the

NC control. For operation of your NC machine,

the machine tool builder’s manual shall take priority over this manual.

The illustration of machine control station should be

used for your reference in understanding the function. For detailed array of operator’s devices and

names, refer to machine tool builder’s manual.

2. PROGRAMMING

2.1

INPUT FORMAT

2.1.1 INPUT FORMAT

A variable block format conforming to JIS#B

6313 is used for

J50M.

Unless otherwise specified, the following rules

apply to the description of programming

pies shown in this manual.

Absolute Zero Point:

Reference Zero Point

(Return to reference

return) :

Dimensions : in mm

Table Z. 1

following the address characters in Table 2.1

indicate the programmable number of digits.

the input format. Numerals

zero by manual and auto-

EXAMPLE

x

Note:

A decimal point should be omitted in actual programming,

decimal points, refer to

PROGRAMMING” on page 5.

The leading zeros can be suppressed for all

dress

but all minus signs must be programmed.

In the manual, EOB (end of block) code in a program example is represented by a semicolon ( ; ) .

In actual programming, CR

(1S0 code) should be used instead of the semi-

colon ( ; ) .

# Japanese Industrial Standard

when you make a program including

+

Plus signs need not be programmed,

5

3

code) or LF/NL

Down to third decimal place

Five digits of integer inches

Sign

Address character: X

. Metric input format

. Inch input format

0N4G3

Notes:

represents X , Y , Z,

.

. P , Q , R and L are omitted in the above format

because they are used for various meanings.

in mm

or

J

B3;

Page 10

2.1.1 INPUT FORMAT (Cent’d)

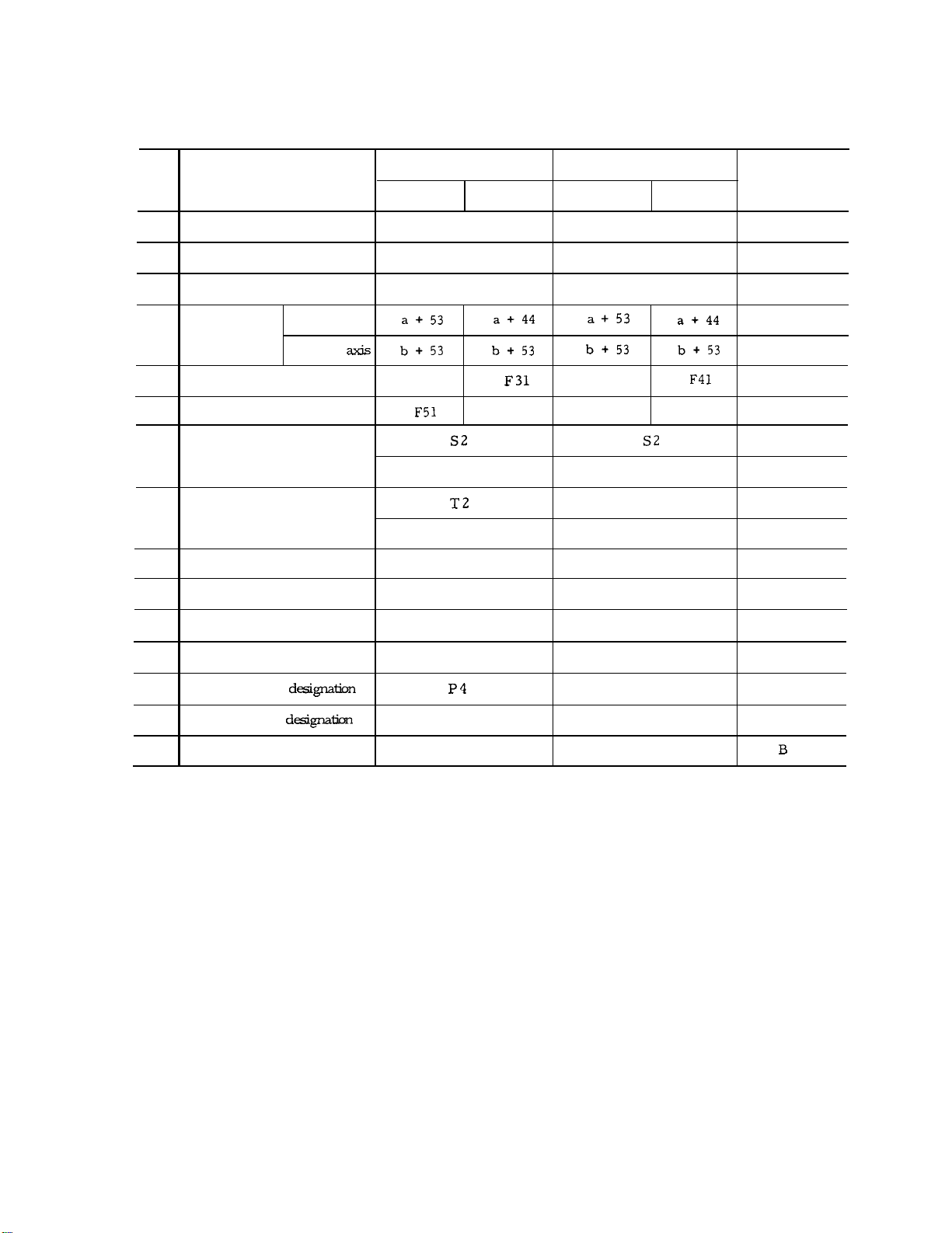

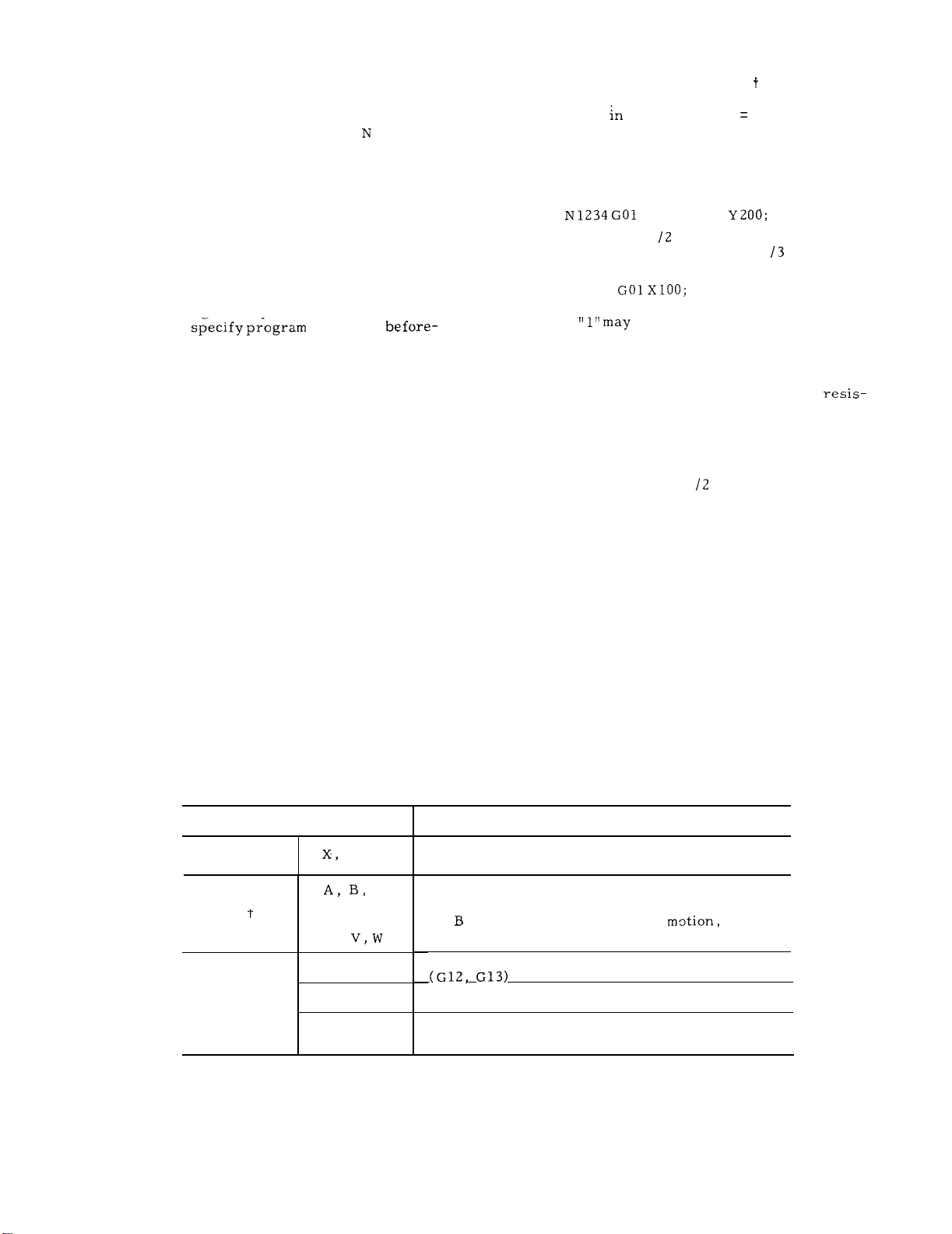

Table 2.1 Input Format

No.

1

Program No.

2

Sequence No. N4 N4

3

G function

Cordinate

4

Word

5

Feed /rein

6

Feed/rein 1/10

7

S-function,

8

T- function

M–f unction

9

Tool Offset No. H20r D2

10

Address

Linear axis

Rotary

Metric Output

Metric Input

F50

Inch Input

04 04

G3

F32

S5

T4

M3

Inch Input

Metric Input Inch Input

G3 B

F50

F51

S5

T2

T4 o

M3

H2 or D2

F42

B: Basic

O: Optional

B

B

B

o

B

B

B

o

B

B

B

B-f unction

11

12

Dwell P53 P53

Program No. d&gnation

13

Sequence No. dkgnaticm

14

15

No. of repetitions

B3

P4

L8 L8

B3

P4

o

B

B

B

Page 11

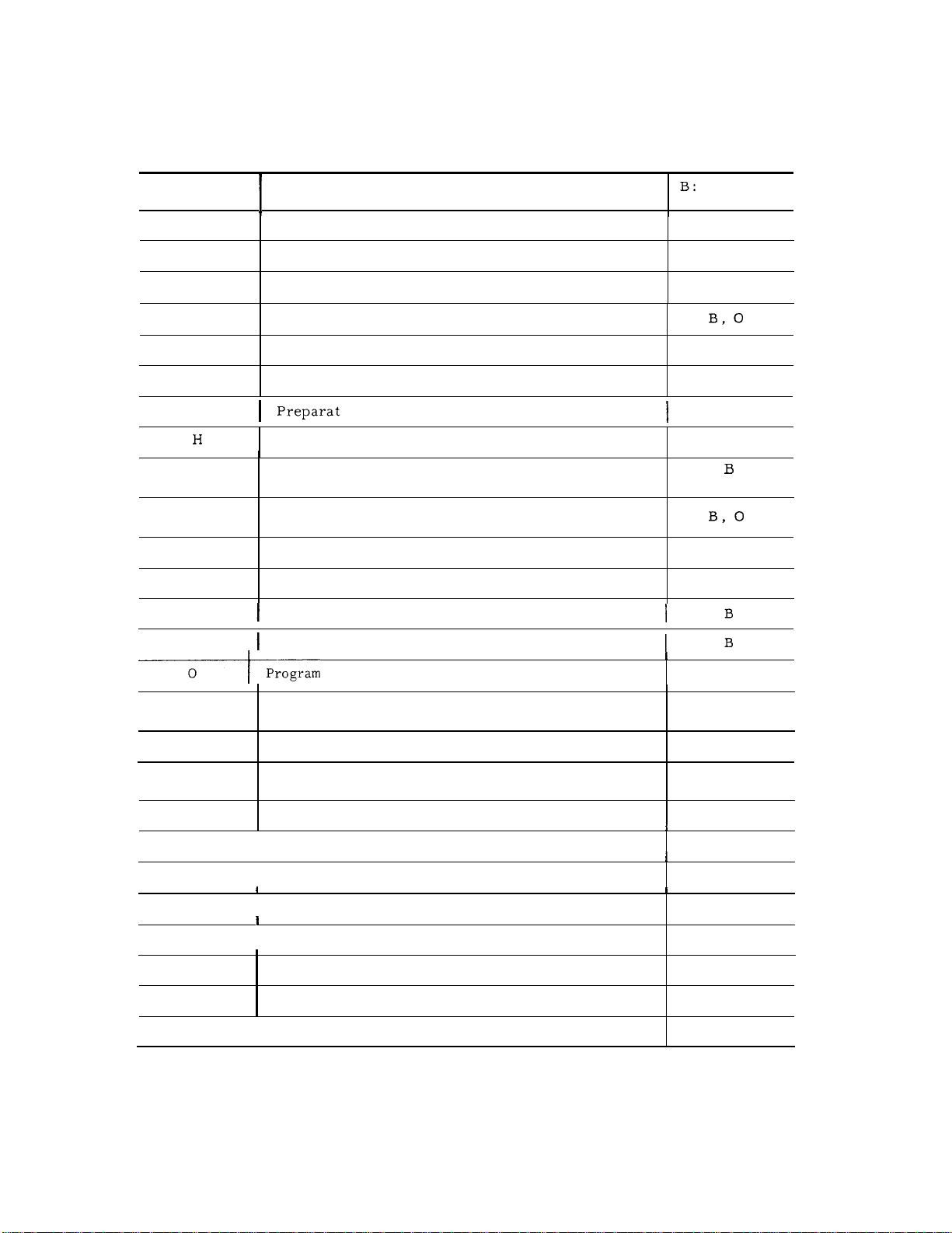

2.1.2 ADDRESS AND FUNCTION CHARACTERS

Address characters and their meanings are shown in Table 2.2.

Table 2.2 Address Characters

Address

Characters

A Additional rotary axis parallel to X-axis

B

c

D

E

F

G

I

J

K

L Number of repetitions

M

Additional rotary axis parallel to Y-axis

Additional rotary axis parallel to Z-axis

Tool radius offset number

User macro character

Feedrate

1

Tool length offset number

X-coordinate of arc center

Radius for circle cutting

Y-coordinate of arc center

Cutting depth for circle cutting

Z-coordinate arc center

Miscellaneous functions

ory function

Meanings

Basic

O: Optional

o

I

o

o

o

B

B, O

B

o

B

B, O

N

Sequence number

‘umber

P

Q

R

s

T

u Additional linear axis parallel to X-axis

v Additional linear axis parallel to Y-axis

w

x

Y

z

Dwell time, Program No. and sequence No.

designation in subprogram

Depth of cut,

Point R for canned cycles

Radius designation of a circular arc

Spindle-speed function

shift of canned cycles

I

Tool function

I

Additional linear axis parallel to Z-axis o

X-coordinate

Y-coordinate

Z-coordinate

I

B

B

o

o

O, B

B

B

o

o

I

B

B

B

3

Page 12

2.1.2 ADDRESS AND FUNCTION CHARACTERS (Cent’d)

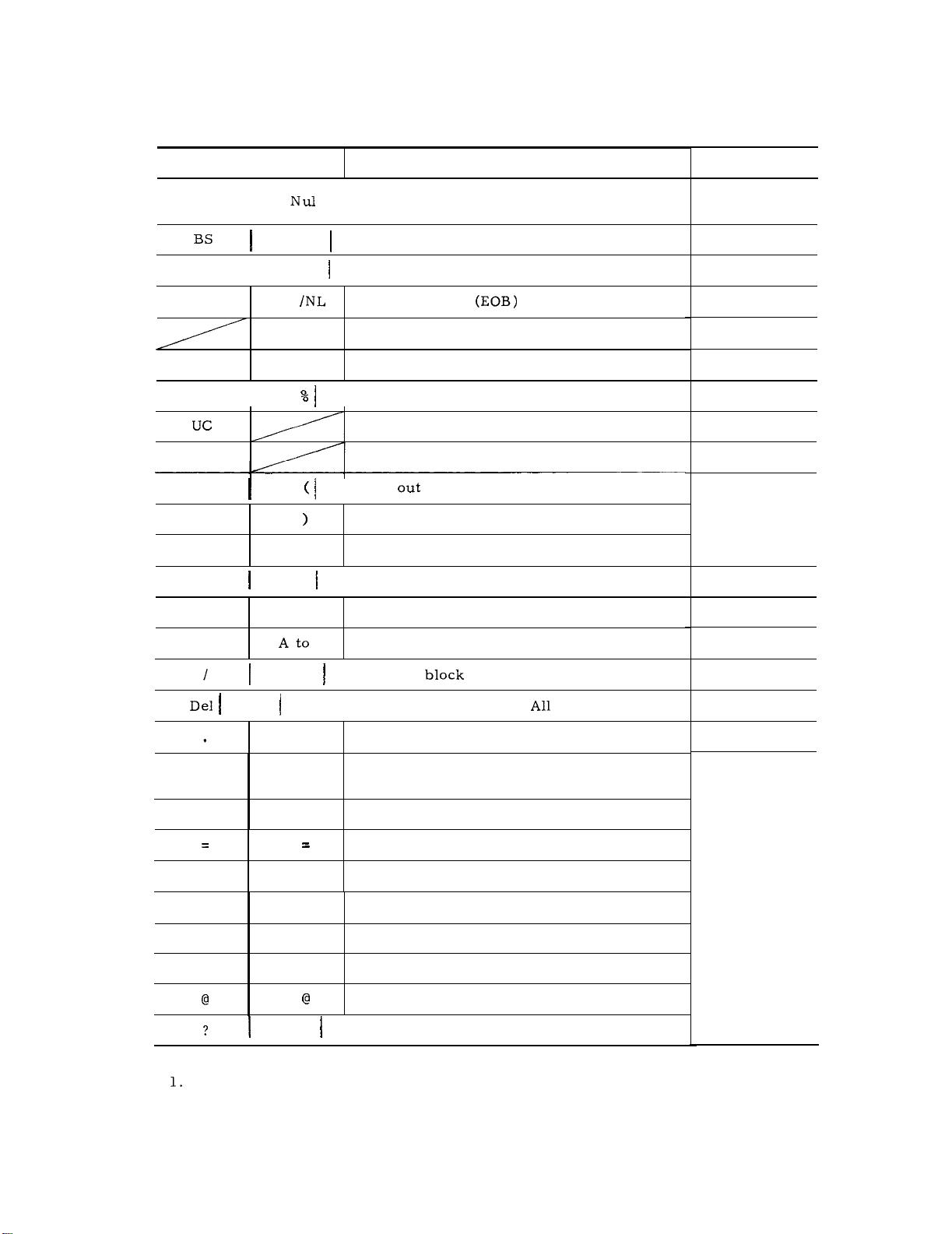

Table 2.3 Function Characters

EIA Code

Blank

Tab

CR

SP SP Space

ER

LC

2-4-5 bits

ISO Code

I

I

BS

HT

I

LF

CR Disregarded

I

I

Disregarded

Disregarded

Rewind stop

Control

2-4-7 bits

•!-

oto9

+

-

Minus sign, User macro operator

oto9

Meanings

Error in significant data area in EIA

Disregarded in ISO

End of Block

Upper shift

Lower shift

(Comment start)

Control in (Comment end)

Disregarded, User macro operator

Numerals

Remarks

EIA :

Special

code

atoz

DEL

Parameter

setting

*

[

1

o

$

Notes:

Characters other than the above cause error in significant data area.

Information between Control Out and Control In is ignored as insignificant data.

2.

Tape code (EIA or 1S0) can be switched by setting.

3.

Z

/

Optional

Disregarded (Including

#

*

[

1

$

?

User macro operator

Address characters, User macro operator

skip

Mark)

Decimal point

I

Sharp (Variable)

Astrisk (Multiplication operator)

Equal mark

Left bracket

Right bracket

User macro operator

User macro operator

User macro operator

EIA:

Special

code

4

Page 13

2.1.3 DECIMAL POINT PROGRAMMING

Numerals containing a decimal point may be used

as the dimensional data of addresses related to

coordinates (distance) , time and speed.

Decimal points can be used in the following address words.

Coordinate words: X, Y, Z, I, J, K, A, B,C,

U, V, W, Q, R

Time word: P

Feed rate word: F

EXAMPLE

[ mm]

X15. X15.000 mm

— Y20. 500 mm

– F25. O mm/min or

(for

Dwell 1.000 sec

[inch]

x15.0000 inches

or

or

5000 inches

inches/rein

(for

M code

M 92

M93

Note: When power is applied or the control is

reset, the control is in the state of M code

marked with

Inter-block stoppage can be eliminated when the

program is so made that the automatic operation

time of advance reading of 4 blocks is longer than

processing time of advance reading of next 4

blocks of data.

Note :

Advance reading is not made for every 4 blocks

but is always ready to be made up to 4 blocks in

M93 mode.

I

Multi-active register off

Multi-active register on

NUMBER AND SEQUENCE

Meaning

Normally, when data without a decimal point is

input, the control regards

(or 0.0001 inches, or 0.001 deg.).

as O. 001 mm

2.1.4 LABEL SKIP FUNCTION

In the cases named below,

becomes effective , and LSK is displayed on the

CRT.

. When the power supply is turned on.

. When the RESET key is pushed.

While the label skip function is effective, all data

on the punched tape up to the first EOB code are

neglected. When LSK is displayed on the CRT

the MEM (memory) or EDIT (editing) mode , it indicates the presence of a pointer at the leading

end of the part program.

BUFFER REGISTER

2.1.5

During normal operation ,

read in advance and compensation computing is

made for the follow-on operation.

In the tool radius compensation C

blocks of data or up to 4 blocks of data are read

in advance and compensation computing required

for the next operation is executed. One block can

contain up to 128 characters including EOB .

2.1.6 MULTI-ACTIVE REGISTERS

For the portion of part programs sandwiched in

between M93 and M92, up to

read in advance.

the label skip function

block of data is

mode, two

t

blocks of data are

2.2.1 PROGRAM NUMBER

Program numbers may be prefixed to programs

for the purpose of program identification.

Up to 4 digits may be written after an address

character

program numbers can be registered in the control, and up to 199 or 999 can be registered

employing an option.

One program begins with a program number, and

ends with M02,

placed at the ends of main programs, and M99 is

placed at the ends of subprograms.

PROGRAM WITH

PROGRAM NO. 10

ER (or

the top and end of the program.

Notes :

The blocks for optional block skip such as

of programs .

. To make the reading of M02, M30, and M99 in-

effective as a program end, and to make the

succeeding ER

program ends is possible with a parameter

change. (

as program numbers.

or M99.

PROGRAM WITH

PROGRAM NO. 1234

at ISO code) is punched on the tape at

, /M30; ,

are not regarded as ends

or % (I SO) as a sign of

and

up to 99

are

5

Page 14

2.2.2 SEQUENCE NUMBER

2.2.3 OPTIONAL BLOCK SKIP (/1 - /9)

Integers consisting of up to 4 digits may be written following an address character

numbers.

Sequence numbers are reference numbers for

blocks, and do not have any influence on the

meaning and sequence of machining processes.

Therefore, they may be sequential, non-sequen-

tial, and duplicated numbers, and also not using

any sequence number is also possible. Generally,

sequential numbers are convenient as sequence

numbers.

When searching for sequence numbers, be sure

to search or

hand.

Notes :

. When 5 or more digits are written as

number, only the digits up to the 4th from the

trailing end are effective.

. When two or more blocks have the same sequence

number, only one is retrieved and read, and

no more searching is performed.

Blocks without sequence numbers can also be

searched for with respect to the address data

contained in the blocks.

numbers

as sequence

a sequence

Those blocks

ed are neglected between In and the end of that

block, when the external optional block skip

switch for that number “n” is on.

EXAMPLE

/2

When the switch for

neglected,

block is read as if

With “ 1“ ,

Notes :

The optional block skipping process is executed

while the blocks are read into the buffer

ter.

switching on is ineffective to skip the blocks.

While reading or punching out programs, this

function is ineffective.

The optional block skip

function.

and when the switch for

N 1234

If the blocks have been read , subsequent

X1OO /3 Y20();

is on , the entire block is

XIOO; .

may be omitted.

1 - 9) is includ-

is on , this

- /9 is an option

2.3 COORDINATE WORD

Generally,

tions and commands for setting coordinate systems are called coordinate words, and coordinate

words consist of address characters for desired

axes and numerals representing dimensions of

directions.

2.3.1 COORDINATE WORD

commands for movements in axis direc-

Table 2.4 Coordinate Words

Address

Main axes

4th axis

Circular

interpolation

auxiliary

data

Y, z

or

u,

Q

R

I, J, K

C

Position or distance in X, Y or Z coordinate

direction.

These coordinate words are treated as commands

in the directions of the 4th axis.

A ,

U , V and W are used for parallel motion

Circular arc increment in circle cutting

Generally,

Generally, distances from start point to arc

center (in X , Y and Z components) .

Description

and C are used for rotary m~tion, and

G13)

radius values of circles.

6

Page 15

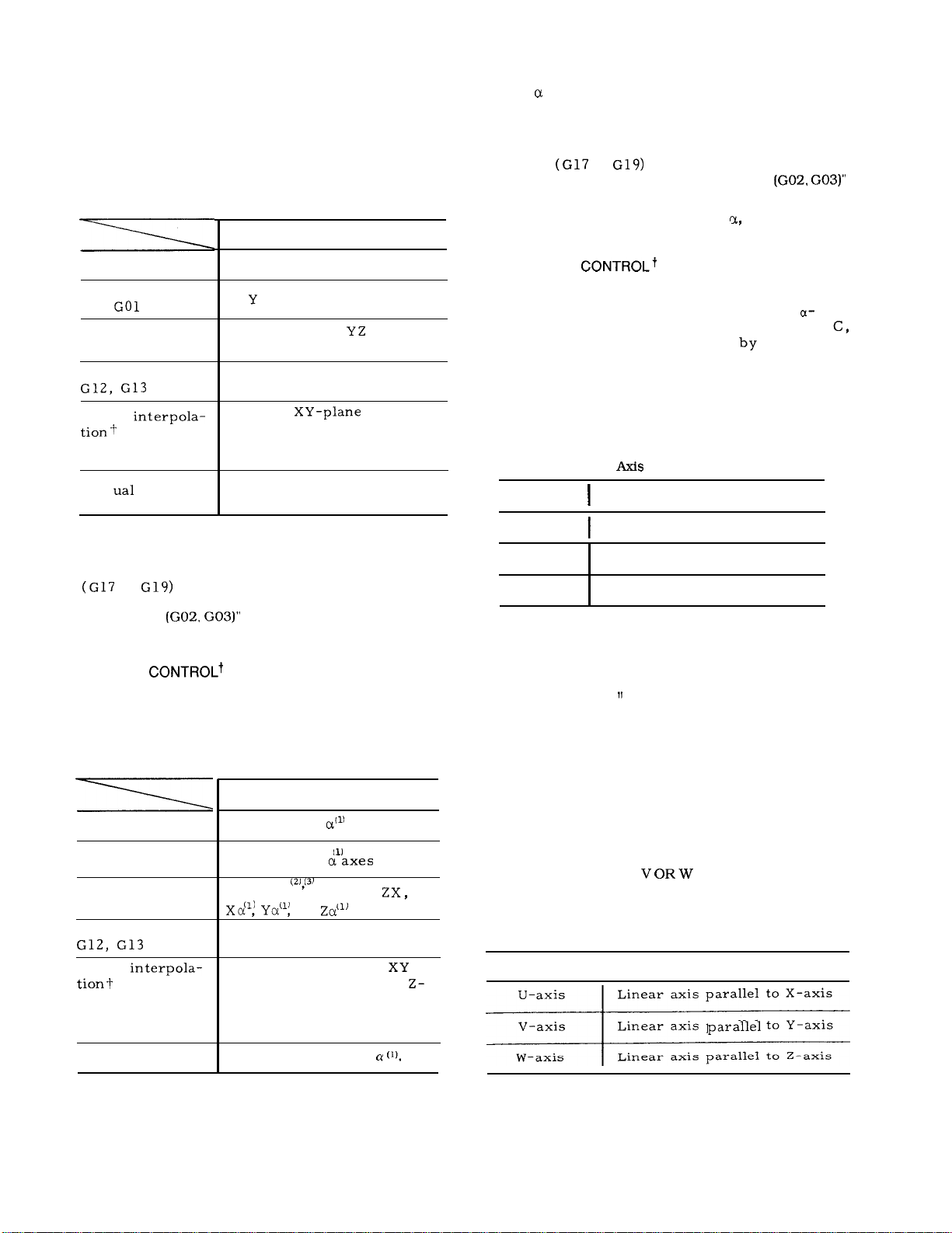

2.3.2 SIMULTANEOUSLY CONTROLLABLE AXES OF

THREE-AXIS CONTROL

Table 2. 5 shows simultaneously controllable

axes.

Table 2.5 Simultaneously Controllable Axes of

Positioning GOO

Linear interpola-

tion

Circular inter-

polation G02, G03

Circle cutting+

Helical

G02, G03

Man

Three-axis Control

Simultaneously

controllable axes

X, Y and Z axes

X,

Two axes:

Two axes: X and Y

Circle in

feed in Z-axis direction .

Refer to 2. 9.5 HELICAL

INTERPOLATION .

X. Y and Z

XY,

(see Note. )

or ZX

and linear

(1) The

U, V or W, selected as the 4th axis.

(2) Circular arc plane is determined according to

the currently effective G codes for plane desig-

nation

2.9.4, “ CIRCULAR INTERPOLATION

on page 22.

(3) For circular interpolation axis

linear axes U, V , and W should be designated.

2.3.4 4TH

An additional 4th axis can be incorporated. In

this manual, the 4th axis is referred to as

axis, and represents any of the 6 axes, A, B,

U, V and W.

#6023.

2.3.4.1 ROTARY AXIS (A, B OR C AXIS)

The rotary axis is defined as follows.

AXIS CONTROLt

Rotary axis

Address. is specified

Table 2.7 Rotary Axes for 4th

Control Table

Definition

parameter

Note:

Circular arc plane is determined according to the

currently effective G codes for plane designation.

For details, refer to 2.9.4, “ CIRCULAR INTERPOLATION

SIMULTANEOUSLY CONTROLLABLE AXES OF

2.3.3

FOUR-AXIS

Table 2. 6 shows simultaneously controllable

axes.

Table 2.6 Simultaneously Controllable Axes of

Positioning GOO

Linear interpola-

tion GO 1

Circular inter-

polation G02, G03

Circular cuttingt

Helical

G02, G03

Manual control

Four-axis Control

Simultaneously

controllable axes

X, Y, Z, and

X, Y, Z , and

Two axes,

Two axes: X and Y

Three axes :

plane and linear feed in

axis direction.

2. 9.5 HELICAL INTERPO-

LATION on page 27.

Four axes, X, Y, Z, or

XY, Yz,

circle in

-

Refer tc

A axis

B axis Rotary axis parallel to Y-axis

C axis

Note:

The unit of output increment and input increment

for B-axis is “deg.

linear axes. For the other respects, the treatments are the same as those in mm.

system)

Even when inch system is selected by parameter,

the values for the B- axis remains

The control does not convert B-axis coordinate

commands.

converted. (Refer to 2.9.3. “ LINEAR INTERPOLATION”)

2.3.4.2 LINEAR AXIS (U,

The linear axes are defined as follows.

Linear axis

Rotary axis parallel to X-axis

Rotary axis parallel to Z-axis

In this manual, any one of the three

axes, A, B and C, is referred to as

B-axis .

instead of “mm” used with

(Metric

“deg. “ unit.

However, feedrate command F is

OR

AXIS)

Table 2.8 Linear Axes

I

Linear axis parallel to X-axis

Linear axis

Linear axis parallel to Z-axis

Definition

to Y-axis

Note:

In this manual, linear axes either U, V

or W are indicated by c-axis.

7

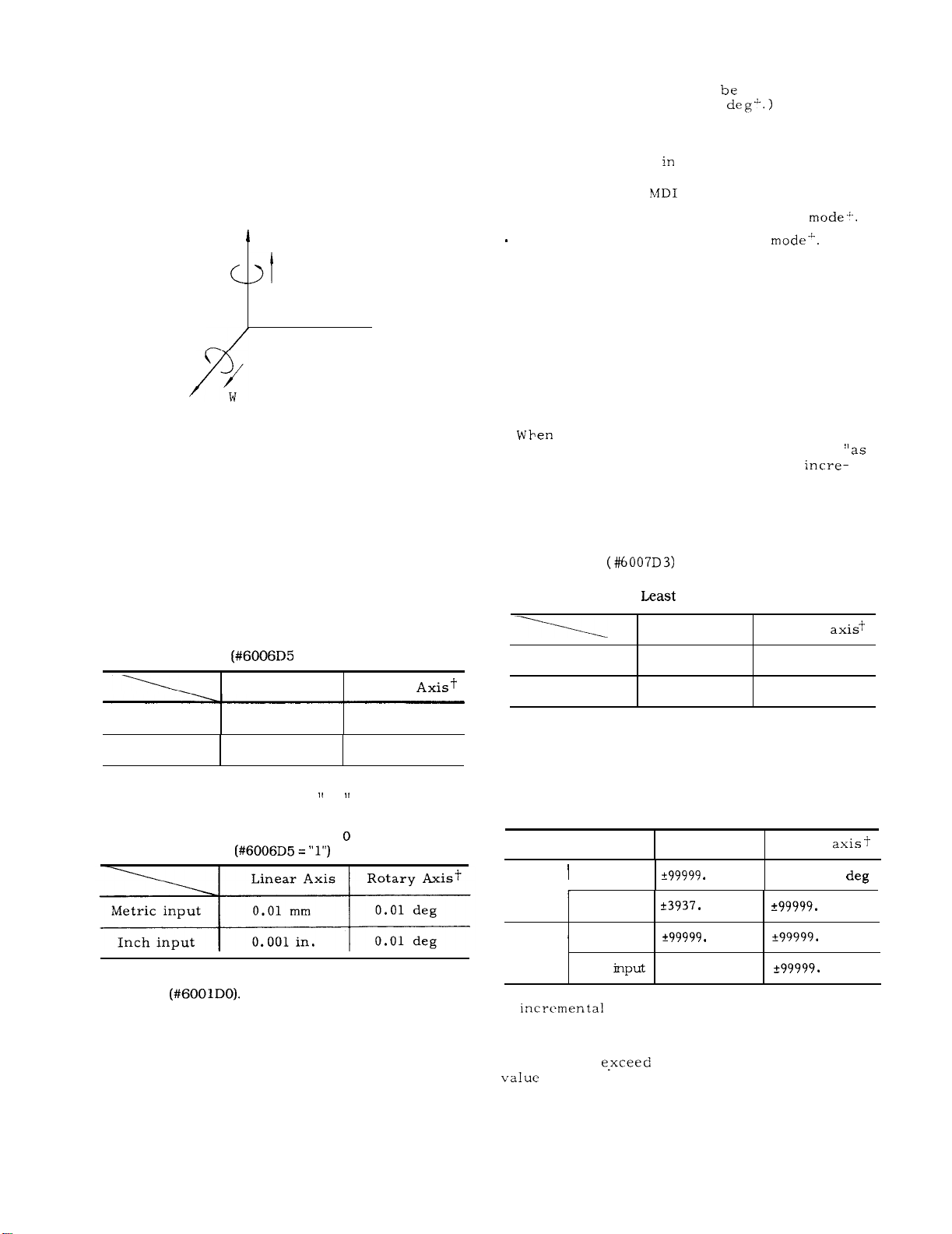

Page 16

2.3.4.2 LINEAR AXIS (U, V OR W AXIS) (Cent’d)

The unit output increment and input increment for

C-axis is the same as the other linear axes, X, Y

and Z. No discrimination is necessary.

When inch system is selected by parameter, input

values must be in inches for C–axis.

Y

v

B

—u

-x

c

A

z

Tool offset value must always

mm (or 0.0001 inch, or 0.001

is possible in these units.

In 0.01 mm increment system, the following op-

eration must be made

. Write operation in

. Programming for operation in MEMORY

Program editing operation in EDT

Notes :

If NC programs set by O. 001 mm is fed into or stored in an equipment set by 0.01 mm

increment, the machine will move ten times

the intended dimensions.

If the increment system is switched when the

contents of NC tape are stored in memory, the

machine will move by ten times or one tenth of

the commanded dimensions .

the unit of O. 01 mm.

, and offset

Fig. 2.1 4th Axis in Right-hand

Coordinate System

LEAST INPUT INCREMENT AND LEAST OUTPUT

2.3.5

INCREMENT

2.3.5.1 LEAST INPUT INCREMENT

The minimum input units that can be commanded

by punched tape or MDI are shown in Table

2.9.

Table 2.9 Least Input Increment

Linear Axis

Metric input

Inch input

Least input increment times ten can be set by

setting parameter #6006D5 at

O. 001 mm

0.0001 in

Input Increment X 1

Rotary

0.001 deg

O. 001 deg

1.

tape-’ ,

stored” regardless of switching of the

ment system.

2.3.5.2 LEAST OUTPUT INCREMENT

Least output increment is the minimum unit of tool

motion.

by parameter

Metric output

Inch output

2.3.6

Maximum programmable dimensions of move com-

mand are shown below.

Table 2.11 Maximum Programmable Dimensions

Metric

output

the stored figures are punched out

Selection of metric or inch output is made

Table 2.10

Output Increment

Linear axis

0.001 mm 0.001 deg

0.0001 in.

Rotary

0.001 deg

MAXIMUM PROGRAMMABLE DIMENSIONS

Rotary

!

*99999.999 deg

Metric input

Inch input

Linear axis

999 mm

0078 in.

999 deg

Note : Selection of metric system or inch system is made

by setting

8

Inch

output

In

not exceed the maximum programmable value.

In absolute programming , move amount of each

axis must not

Metric input

Inch

the maximum programmable

999 mm

*9999.9999 in.

999 deg

999 deg

Page 17

:

The machine may not function properly if

a move command over the maximum programmable

value is given The above maximum program-

mable values also

dresses I, J, K, R, Q

mand addresses X , Y, Z ,

The accumulative value must not exceed the maximum accumulative values shown below .

Table 2.12 Maximum Cumulative values

to distance command ad-

Table 2.13 Programmable Range of Feedrate

(Feed/rein) range

F1.-F3OOOO.O mm/min

Metric

output

Inch

output

Metric input

Inch input

Metric input

Inch

F50

FO.1-F1181.1O in. /rein

F31

F50

FO. 1-3000.00 in. /rein

F31

Feedrate

mm/min

Linear axis

Metric input

Inch input

Listed input values do not depend on metric/

inch output system.

99999.999 mm

9999.9999 in.

Rotary

99999.999 deg

99999.999 deg

2.4 TRAVERSE AND FEED FUNCTIONS

2.4.1 RAPID TRAVERSE RATE

2. 4.1.1 RAPID TRAVERSE RATE

The rapid traverse motion is used for the motion

for the Positioning

the Manual Rapid Traverse (RAPID) . The traverse rates differ among the axes since they are

dependent on the machine specification and are

determined by the machine tool builders. The

rapid traverse rates determined by the machine

are set by parameters in advance for individual

axes.

in two or three axial directions simultaneously ,

motions in these axial directions are independent

of each other, and

different times among these motions. Therefore,

motion paths are normally not straight.

For override rapid traverse rates , Fo, 25%, 50%

and 100% of the basic rapid traverse rates , are

available.

parameter ( #6231) .

2. 4.1.2 SETTING RANGE OF RAPID TRAVERSE

RATE

For each axis, rapid traverse rates can be set

at some suitable multiple of O. 001

min ) .

The maximum programmable rapid traverse rate is

30,000

have their own optimum rapid traverse rates. Refer to

the manual provided by the machine tool builder.

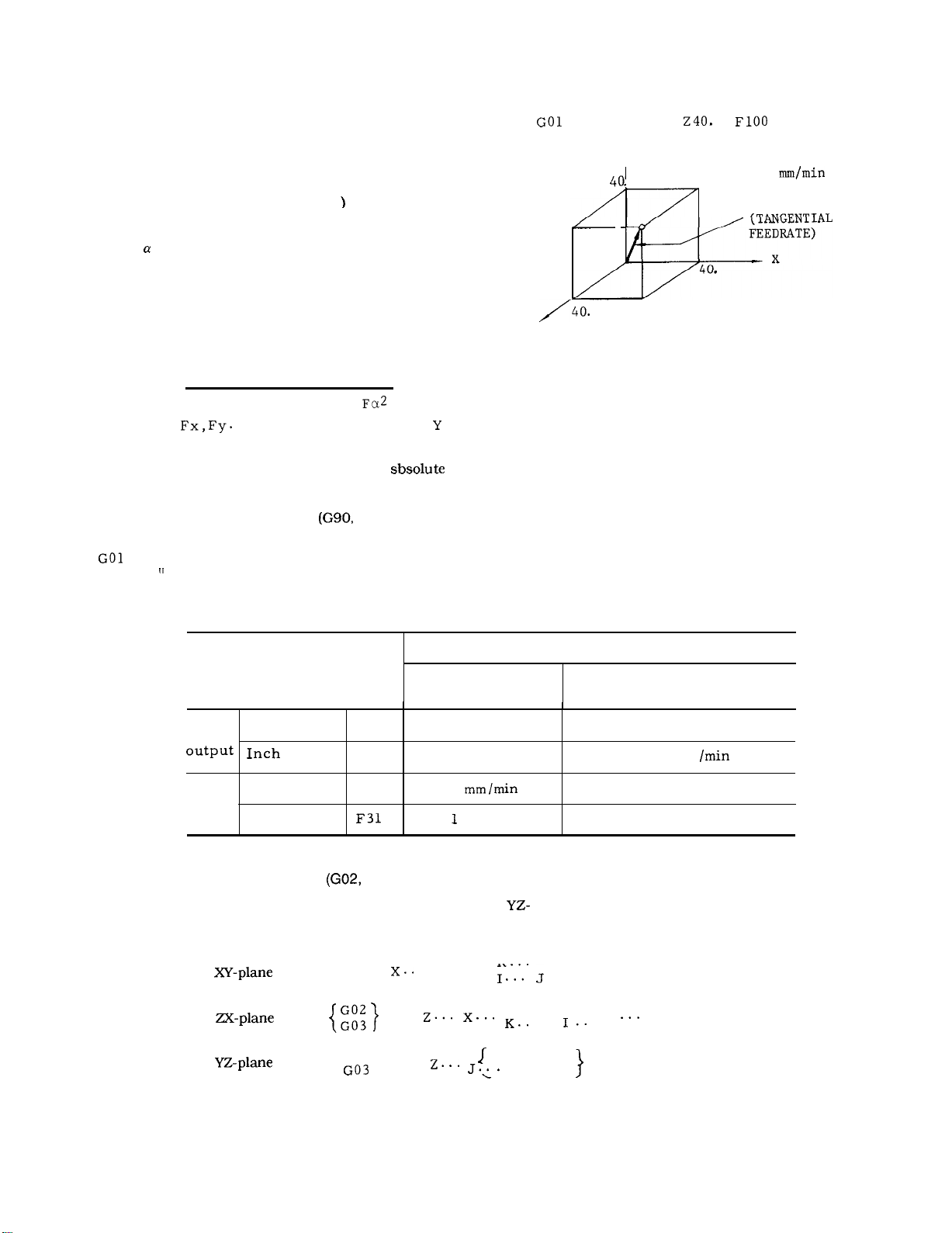

2.4.2

With five digits following an address character F,

tool feedrates per minute (mm /rein) are programmed.

The programmable range of feedrates is as follows.

When the tool is moved in rapid traverse

Fo is a constant feed rate set by a

FEEDRATE (F-FUNCTION)

and for the motion for

(or deg /

The maximum feedrate is subject to the perform-

ance of the servo system and the machine system.

When the maximum feedrate set by the servo or

machine system is below the maximum programmable feedrate given above, the former is set by

a parameter ( #6228) , and whenever feedrates

feedrate is clamped at the set maximum value.

F commands for linear and circular interpolations

involving motions in simultaneously controlled

two axial directions specify feedrates in the direc-

tion tangential to the motion path.

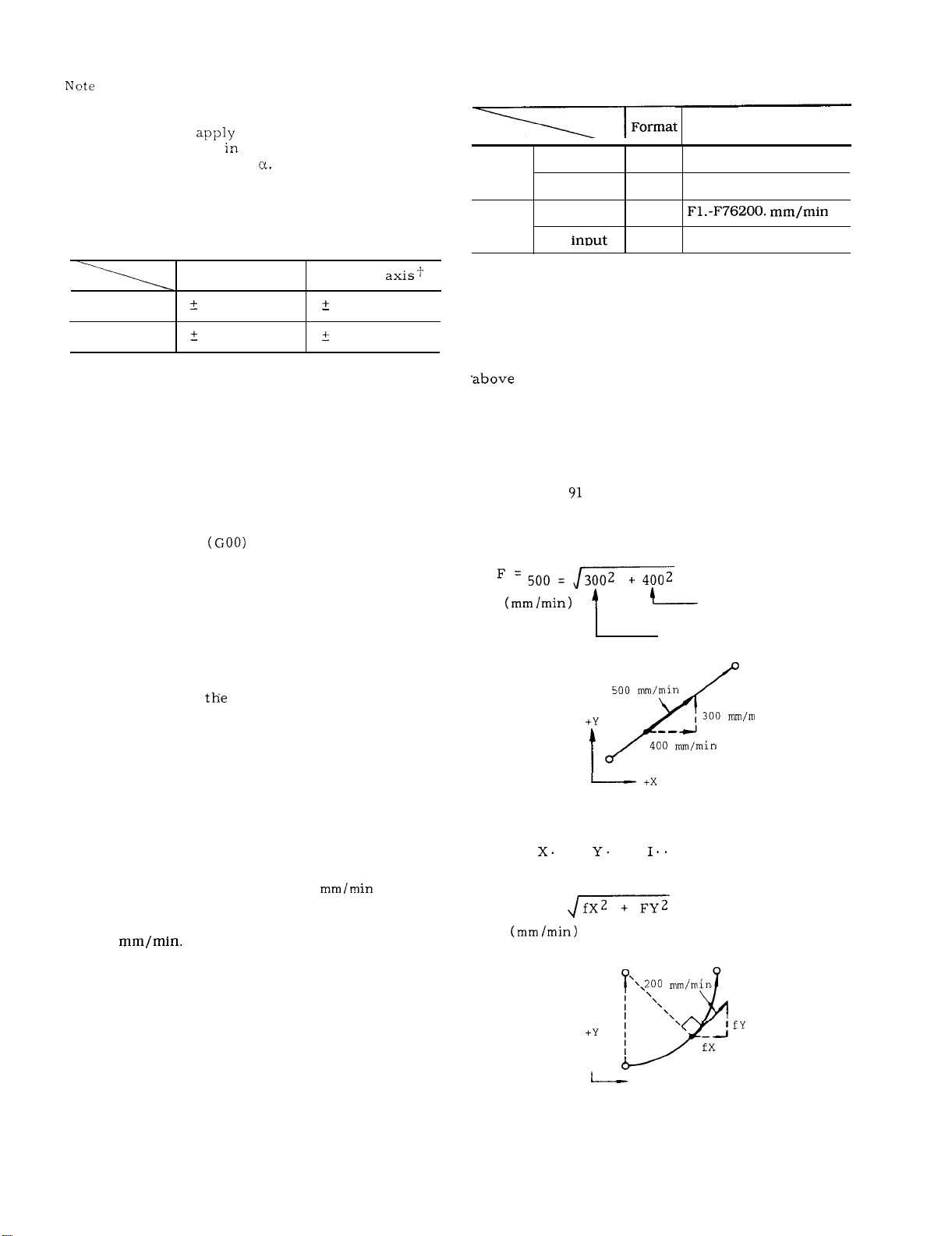

EXAMPLE G

GO1 X40.

With this command,

G03

With this command,

F = 200 =

(incremental)

Y30.

500 nun/rein

. . .

. . .

CENTER

I

F500

400

Fig. 2.2

\

.,200

I

I

l\

+x

Fig. 2.3

X component

Y component

, 300

. F200

\

in

9

Page 18

2.4.2

FEEDRATE (F-FUNCTION) (Cent’d)

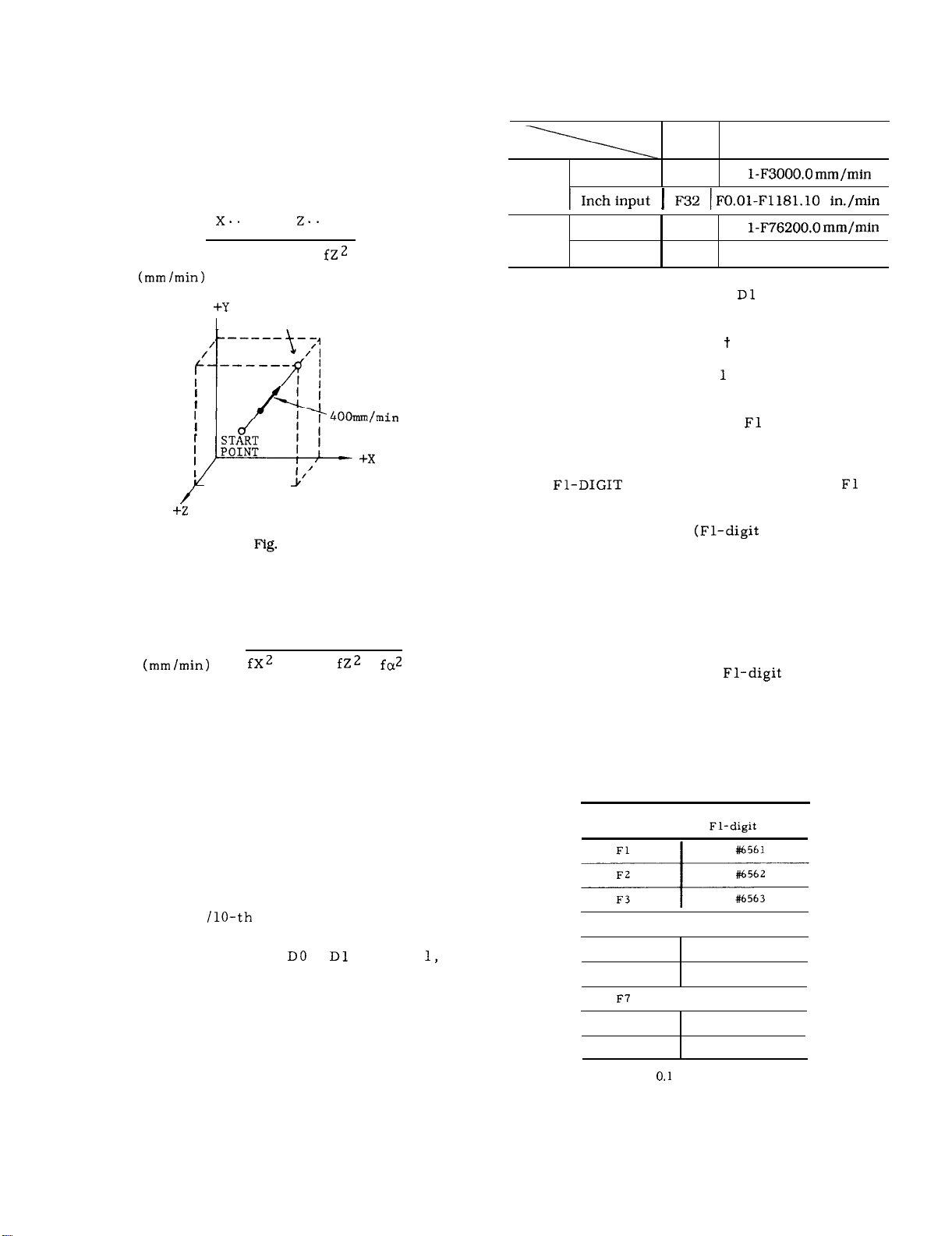

F commands for linear interpolations involving

motions in simultaneously controlled three axial

directions specify feedrates also in the direction

tangential to the motion path.

EXAMPLE

With GO1

F = 400 = fX2 + fY2 +

. Y.. .

. F400 ;

Metric

output

Inch

output

Table 2.14 Programmable Range

of 1/10 Feedrate

Format

Metric input

~nchinput

Metric input

Inch input

F51

FO.

F32 IFO.01-FI.IBI.10 in./min

F51

FO.

F32

F0.01-F3000.00 in. /rein

Feedrate

(Feed/rein) range

END POINT

—— —____

2.4

F commands for linear interpolations involving

motions in simultaneously controlled four axial

directions specify feedrates also in the direction

tangential to the motion path.

F

Notes :

. If FO is programmed, it is regarded as a data

error. (alarm code “030)

. Do not program F commands with minus numerals,

otherwise correct operation is not guaranteed.

EXAMPLE

F-250 ; . . . . . . . . wrong

+ fy2 +

+ fa2

. When parameter #6020 DO or

the feedrate range returns to normal.

is set to “O, ”

2.4.4 F 1-DIGIT PROGRAMMING

(1) Specification of a value

F selects the corresponding preset feedrate.

to 9 that follows

(2) Set the feedrate of each of F1 to F9 to the

setting number shown in Table 2.15 (a).

(3) By operating the manual pulse generator

when

digit command currently specified may be increased or decreased. Set the increment or decrement value per pulse

parameters listed in Table 2.15 (b).

As a result of this operation, the contents of the

setting number of the F1-digit feedrate are

changed.

(4) Upper Limit of Feedrate

Set the maximum feedrate of

to the following parameter. If a value greater

than the usual maximum feedrate (the contents

of #6228) is set, it is governed by the contents

of #6228.

switch is on, the feedrate of

multiply) to the

designation

Table 2.15 (a) F Command and

Setting No.

F command

Setting No. for

I

speed

-

2.4.3

FEEDRATE 1/1

The feedrate programmed by F commands can be

converted to 1

ting as follows.

. When parameter #6020

the feedrates range becomes as shown below.

O

or

is set to “

“

10

F4

F5

F6

FE

F9

Setting “ 1“ =

I

I

in. /rein or 0.01 in. /rein

#6564

#6565

#6566

#6567

#6568

#6569

Page 19

Table 2.15 (b) F Command and

Parameter No.

F

command

F5

F6

Setting

Parameter No.

a.

When this feature

1 to 9 mm /rein by the usual F function is not al-

lowed.

usually.

O.

Table 2.15 (c) Parameter No. for

Maximum Feedrate

#6226

:

Specifying

Parameter No. for

F1-digit

I

#6141

#6145

I

#6146

1

Meaning

I

Max speed of

Max speed of F5 to F9

installed, the specifying

to F4

10 mm /rein or more is allowed

b. If FO is specified, error “ 030”’ will be caused.

c. When

run is assumed.

d.

For

ride feature is invalid.

RUN switch is on, the rate of dry

specification, the feedrate over-

e. The feedrate stored in memory is retained

after the power is turned off.

For the

f.

command of micro-program

F l-digit command is possible.

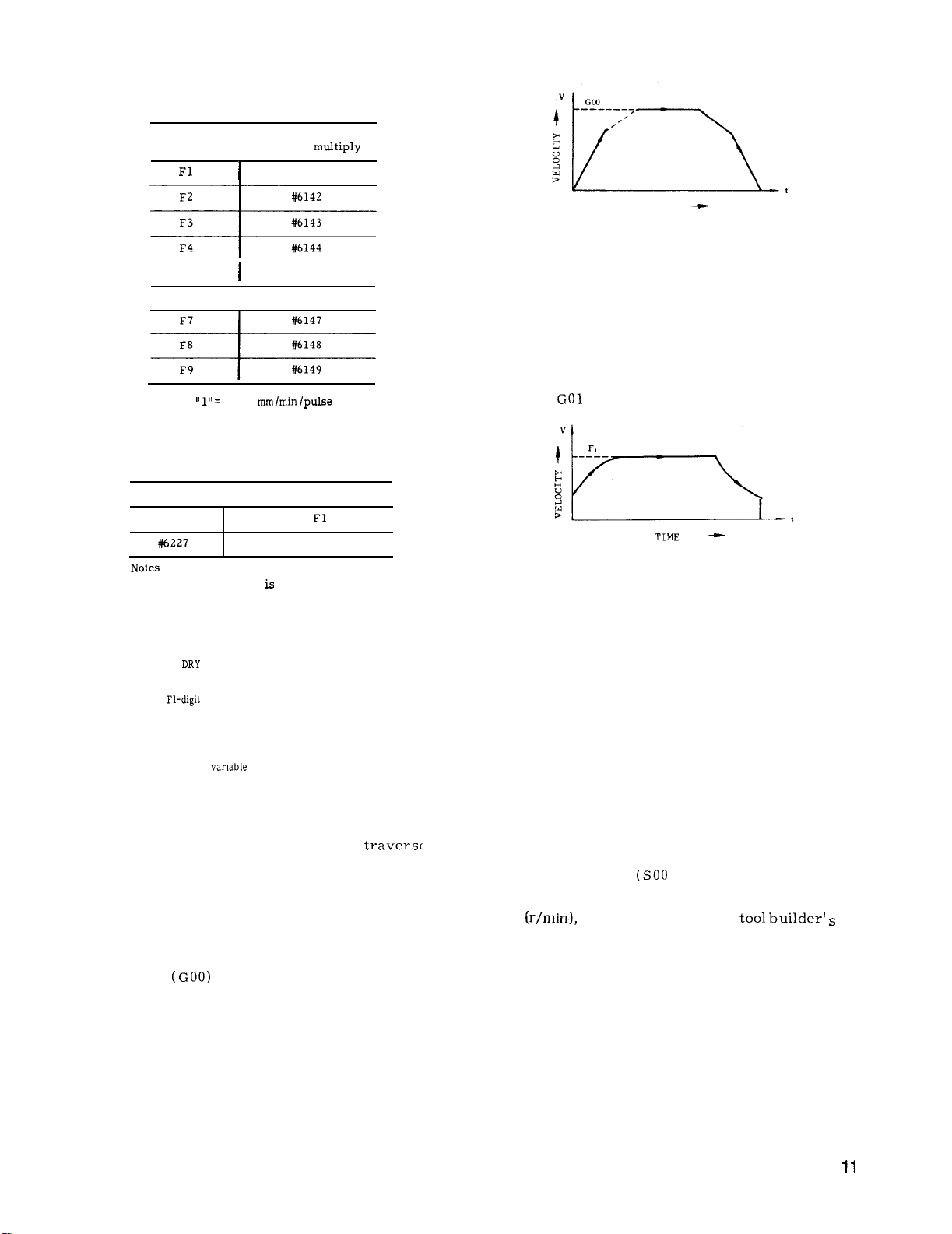

2.4.5 AUTOMATIC ACCELERATION AND DECELERATION

Acceleration and deceleration for rapid

and cutting feed are automatically performed.

2.4.5.1 ACCELERATION AND DECELERATION

OF RAPID TRAVERSE AND MANUAL FEED

In the following operation , the pattern of auto-

matic acceleration and deceleration is linear .

. Positioning

. Manual rapid traverse (RAPID)

. Manual continuous feeding (JOG)

. Manual HANDLE feeding (HANDLE)

The 2-step linear acceleration/deceleration can be speci-

fied shown in Fig. 2.5.

TIME

Fig. 2.5

Rapid traverse rate and acceleration deceleration

constant of rapid traverse rate can be set by

parameter. (#6280 to #6301)

2.4.5.2 ACCELERATION /DECELERATION OF

FEEDRATE

Automatic acceleration and deceleration of feed

motion (

Feedrate time constants and feedrate bias are

set by parameters. During tapping, another time

constants and bias other than for usual feedrate

can be set by parameters (#6406 -#6434) .

- G03) are in the exponential mode.

Fig. 2.6 Exponential acceleration

deceleration

Note:

The automatic acceleration /deceleration param-

eters are set to the optimum values for the respective machines.

unless this is required for special purposes.

Do not change the setting

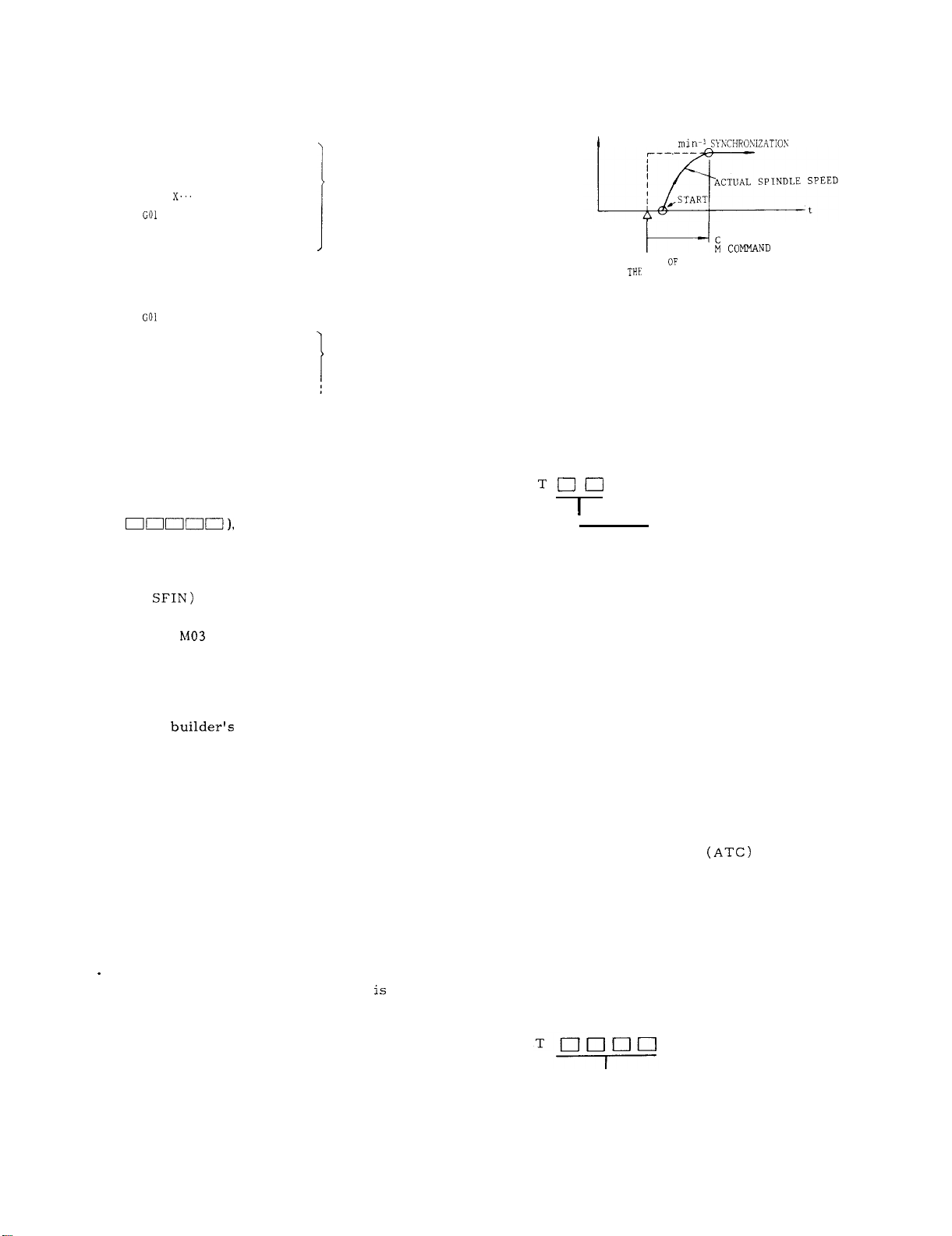

2.5 SPINDLE-SPEED FUNCTION (S-FUNCTION)

2.5.1 S 2-DIGIT PROGRAMMING

The spindle speed is specified by two digits following the address S

For each S code and its corresponding spindle

speed

manual.

When a move command and an S code are issued in the

same block, whether the S command is executed together with the move command or after the completion of tool

move depends on the machine tool builder. Refer to the

machine tool builder’s manual.

S codes are modal, remaining effective, when

once commanded, until next S code is commanded.

If the spindle is stopped by M05 (spindle stop)

command, the S command in the control is kept.

Page 20

2.5.1 S 2-DIGIT PROGRAMMING (Cent’d)

EXAMPLE

COO S11 M03 ;

. . . S command

Spindle CW

S11: Effective

Y.. . z.. . ;

Z.. . F.. . ;

GOO x.. .

Y.. . Z.. . M05 ; Spindle stop

M03 ;

x.. .

Y.. . z.. . ;

Z.. . F.. . ;

S22 ;

x.. .

Y.. . F.. . ;

Note : The two-digit BCD output is sent 10 the machine

when S two-digit command is issued.

2.5.2 S 5-DIGIT PROGRAMMING

S11: Effective

1

S22: Effective

EXAMPLE

S 1000 M03 ;

s

1000

START

BLOCK

Fig. 2.7

SPEED

COMPLETION OF

2.6 TOOL FUNCTION (T-FUNCTION)

2.6.1 T 2-DIGIT PROGRAMMING

Two digits, following the address T , specify the

tool number.

Leading zeros may be omitted.

With five digits written after an address character

S(S

commanded.

The programmed speeds become effective upon

the inputting of an S-command-comple tion-inputsignal (

When an S command is programmed in the same

block with

(spindle reverse run) ,

block starts only after the spindle speed reaches

the level specified by the S command, in most

cases. However, for exact behavior of the machine tool under consideration, refer to the machine tool

The S commands are modal, and when it is programmed once,

command is programmed.

is stopped by M05, the S command remains effective.

again with an M03 (or M04) , the spindle runs at

the speed specified by the S command.

When the spindle speed is to be changed by a

new S command after it is started with an M03 or

M04, attention must be paid to the selected spindle speed range.

Notes :

The lower limit of programmable S commands

(SO and other S commands near O)

by the spindle motor of the machine tool. Refer

to the machine tool builder’s manual.

program minus values as S commands.

Therefore, when the spindle starts

spindle speeds (rein-l) are directly

,

(spindle forward run) or M04

the execution of the next

manual.

it remains effective until another

Even when the spindle

Do not

I

The figures used for the designation of tool num-

ber are determined by the machine. Refer to

the machine tool builder’s manual.

When a move command and a T code are issued

simultaneously ,

the two commands are executed simultaneously,

or

the T command is executed upon completion of

the execution of the move command,

depending on the design of the machine.

For this, refer to the machine builder’s manual.

T codes are modal, and therefore, once they

are given , they remain effective until another

T command is given.

T code commands are generally for making

automatic tool changers

tool number to be used next. Therefore, they

can be given without regard to the G, H “or D

codes which are for offsetting for the length

or radius of the tool currently in use.

2.6.2 T 4-DIGIT

Four digits following the address T specifies the

tool number.

Leading zeros may be omitted.

PROGRAMMING

Tool number

to select the

, When the control is equipped with the S 5-digit

command function ,

is possible. That is, override speeds between

50 and 120% of the commanded spindle speed

can be obtained at intervals of 10%.

spindle speed overriding

12

L Tool number

This tool code is the same as the T 2-digit codes,

except for the increased number of digits.

Page 21

2.7 TOOL COMPENSATION

2.7.1 OUTLINE OF TOOL COMPENSATION

For the procedures of storing values into memory, refer

to 4.3.5.

SET AND WORK

“DISPLAYING AND WRITING OF TOOL OFF-

on page 144.

The tool compensation function is in the following

three modes.

. Tool length compensation

This function is for compensating the differences

in tool length, and is effective in the Z axis direction, Specified length compensation becomes

effective from the block in which G43 or G44 is

programmed together with an H code. It is

with HOO or G49.

. Tool position offset ( for simple compensation

for tool radius)

This function is for compensating for errors in

machined dimensions to be introduced by the radius

of tools. It is effective in the X, Y, and Z (4th t ) axis

directions.

G45-G48 is programmed together.

. Tool radius compensation C

for tool radius effects with complicated machining contours)

This function is for compensating for the tool

radius effect with any given machining contours.

It is effective in X-Y , Y-Z, and Z-X planes.

It becomes effective from the moment

G42 is commanded together with a D code, and

is

Not

e :

tions, refer to

It is effective only for the block in which

(for compensating

, or

by G40.

For details of these compensations func-

“PREPARATORY FUNCTION

2.7.3 H- AND D-FUNCTION (H, D CODES)

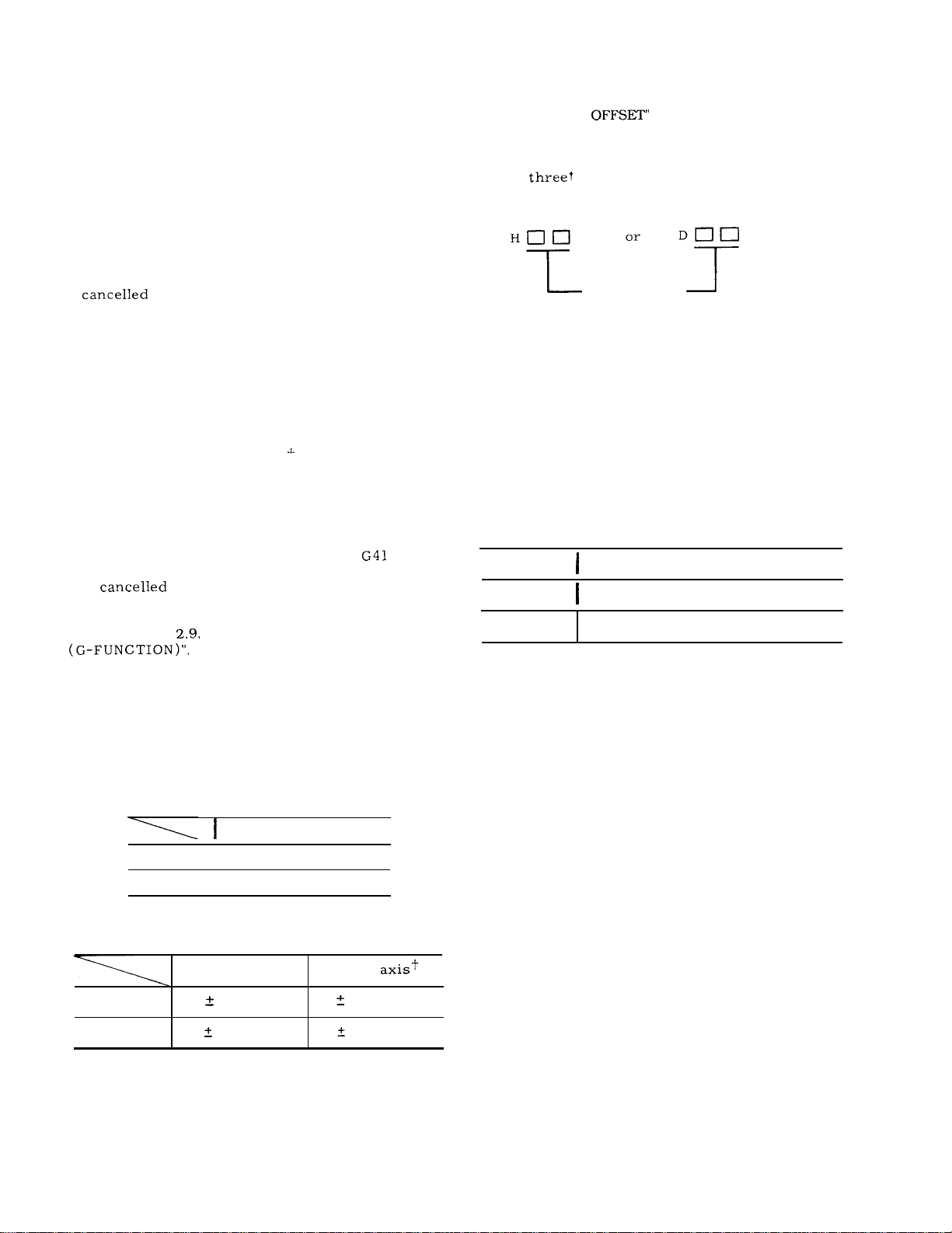

Two or

D , specify tool offset numbers.

The tool offset numbers 01 through 99 directly

correspond to the

bers.

ignated, the corresponding g offset values stored

in the offset memories will be used to offset the

tools .

Tool offset numbers 00 (HOO or DOO) have differ-

ent meanings depending on the respective offset

functions. For details, refer to the descriptions

on the respective G functions.

H- and D-codes must be used properly according

to their functions.

That is, when certain numbers are des-

Code

H code

D code

digits, following the address H or

Tool offset

number

99 offset-value memory num-

Function

Tool length offset

1

Tool position offset, Tool radius

compensation

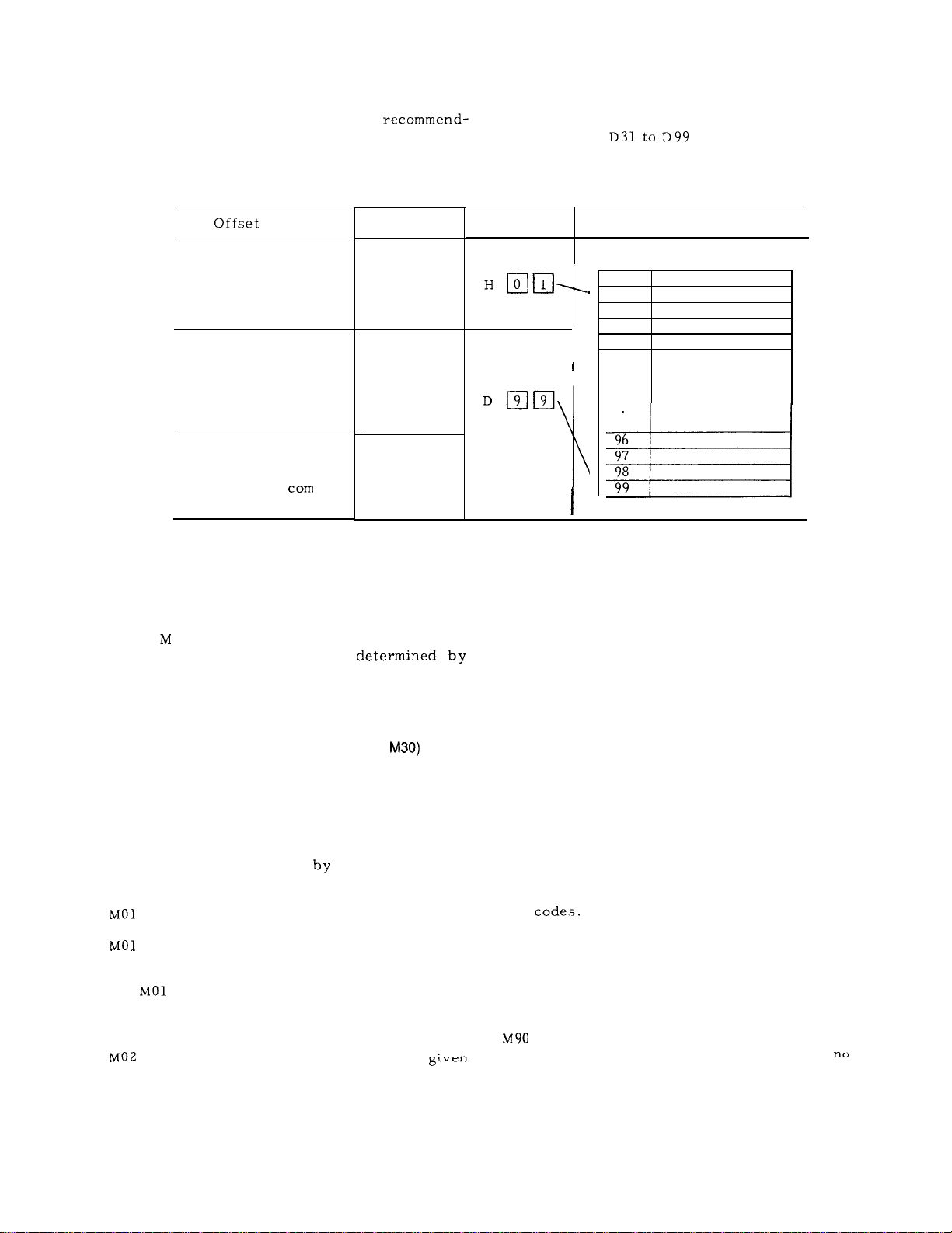

2.7.2 TOOL OFFSET MEMORY

For the three groups of offsets, all the necessary

offset values must be stored in memory before-

hand.

The following number of offset values can be

stored in the tool offset memory.

Offset Value Storage

Basic

t Optional

The setting range of offset values is as follows.

Metric input

Inch input

Listed input values do not depend on metric/

input output system.

I

I

Linear axis

999.999 mm

O -

O -

99

1199

Rotary

O-

999.999 deg

The tool offset numbers 01 through

used freely in combination with the both H and

D codes.

99 can be

13

Page 22

2.7.3 H- AND D-FUNCTION (H, D CODES) (Cent’d)

However, for programming ease, it is

ed to divide the numbers into H code part and

D code part.

Table 2.16 H or D Code and Offset Number

H codes:

D codes:

HO1 to H30

D99

method

Tool length offset

Tool position offset

Tool dia. compensation C

(Intersection

puting system)

-

G code

G43

G44

G49

G45

G46

G47

G48

G40

G41

G42

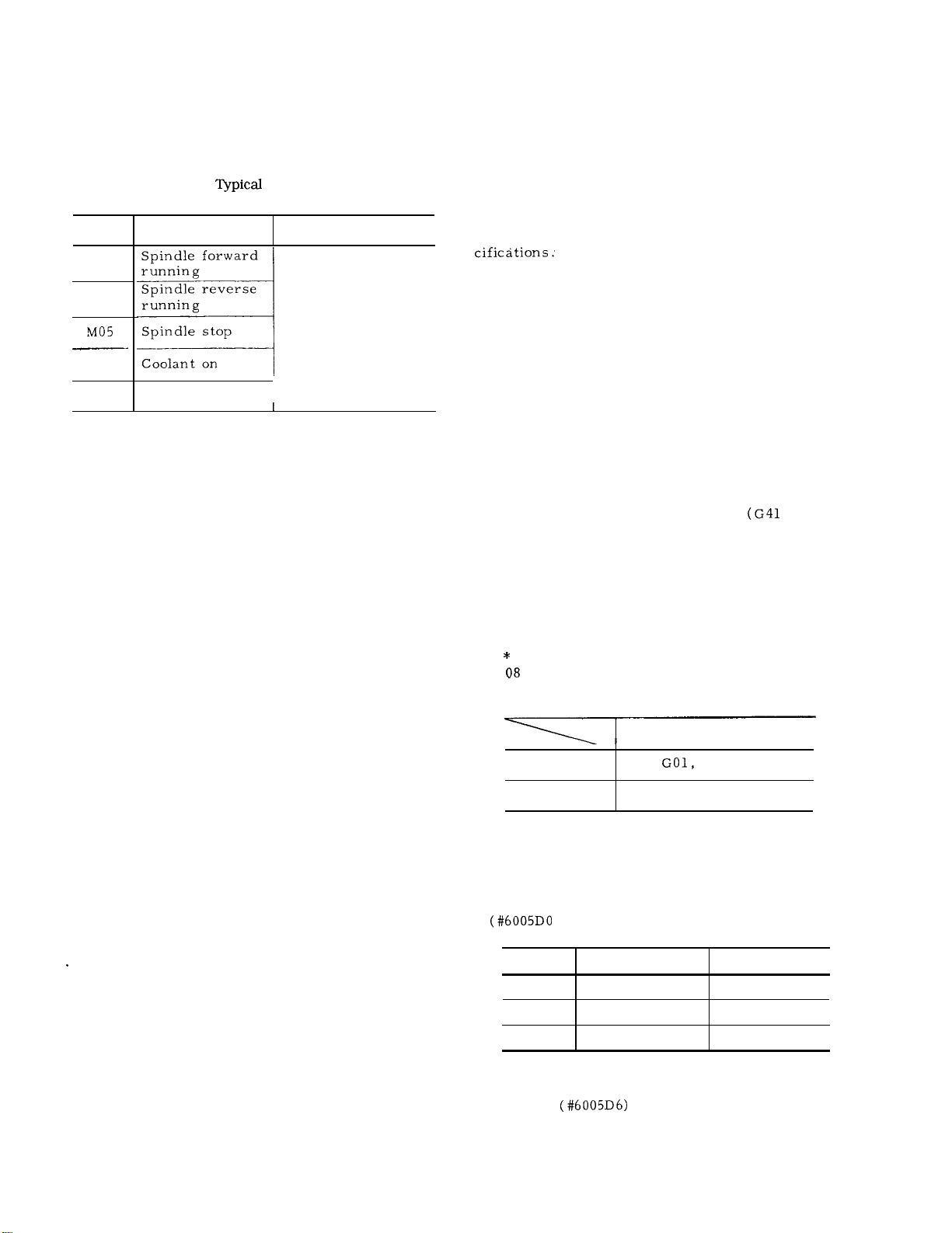

2.8 MISCELLANEOUS FUNCTIONS

(M-FUNCTION)

The miscellaneous function is specified with the

address

of each M code (MOO

the machine,

to the machine tool builder’s manual for the function of M codes except for the following M codes

concerned with the control.

2.8.1 M CODES FOR STOP (MOO, MO1 , M02,

MOO (Program Stop)

This code, when given in automatic operation

mode, stops the automatic operation after the

commands in the block containing MOO have

been completed and MOO R signal is fed. The

program may be continued

CYCLE START button.

stop MOO whenever the OPTIONAL STOP switch

is on.

the

M02 (End-of-Program)

in automatic operation

and maximum three digits. The function

to M89) is

except for several M codes.

pressing the

(Optional Stop)

performs the same function as program

When the OPTIONAL STOP switch is off,

code is disregarded.

is used at the end of program When

mode , this code stops

Refer

H or D code Offset value memory

No. Offset value

01

02

03

04

I

96

97

98

99

the automatic operation after the commands in

the block containing M02 have been completed.

Although the control is reset in most cases,

the details are determined by the machine. Refer to the machine tool builder’s manual.

M30 (End-of-Tape)

M30 is given at the end of tape. When given in

automatic operation mode, this code stops the

automatic operation after the commands in the

block containing M30 have been completed. In

addition, in most cases, the control is reset

and rewinds the memory.

are determined by the machine, refer to the

machine tool builder’s manual.

Notes :

. When MOO, MO1, M02 or M30 is given, it pre-

vents the control from reading ahead the next

block of information.

is fed in addition to the 2-digit BCD output for

M

. Whether MOO, MO1, M02 or M30 executes spin-

dle stop , coolant off or some other executions,

refer to the machine tool builder’s manual.

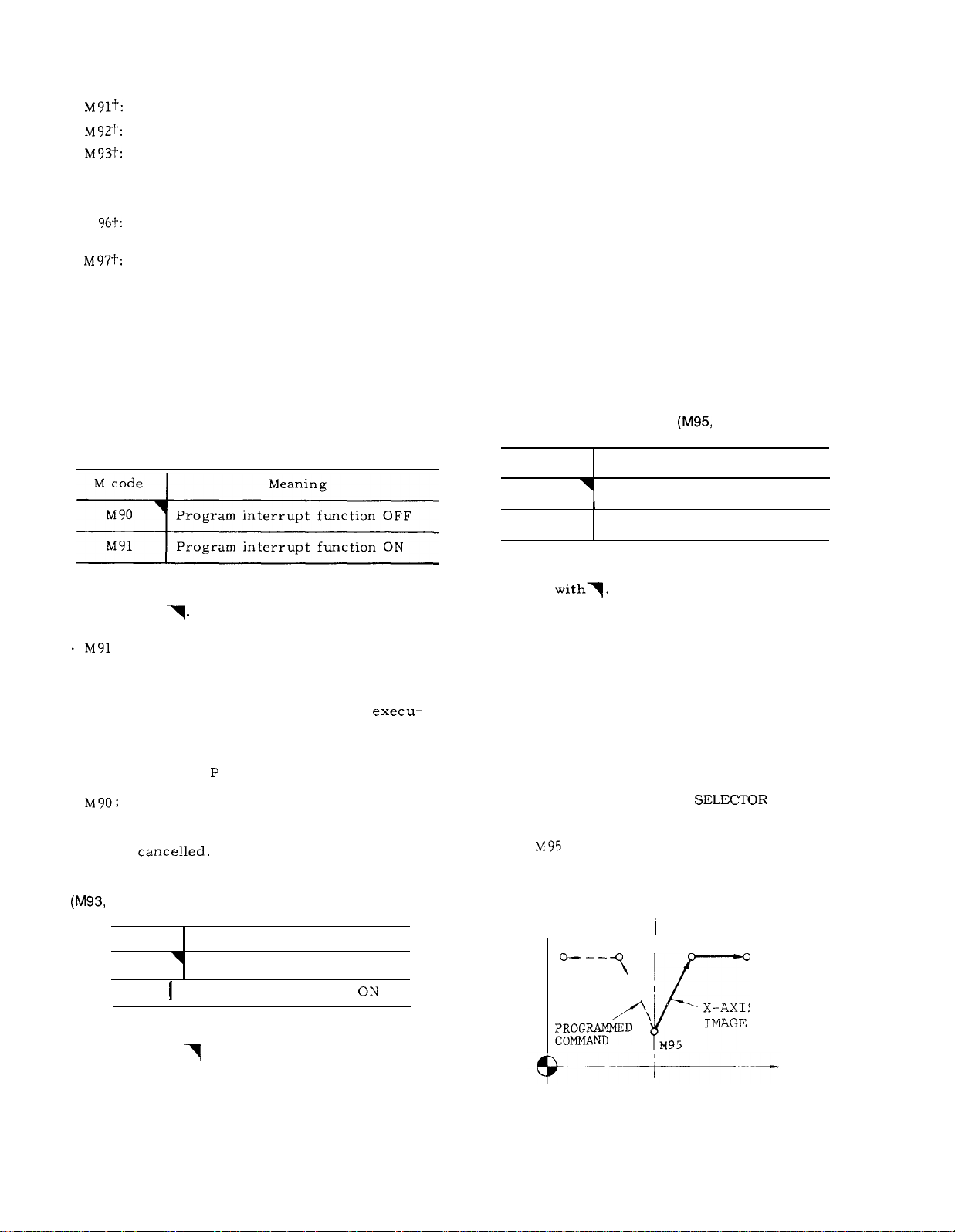

M CODES FOR INTERNAL PROCESSING

2.8.2

(M90 TO Ml 99)

through Ml 99 are used only for internal pro-

cessing.

Even when they are programmed ,

external output signal

is sent.

Since the details

The single decoded signal

(BIN and decoded output)

14

Page 23

M90t :

M94:

M95:

M

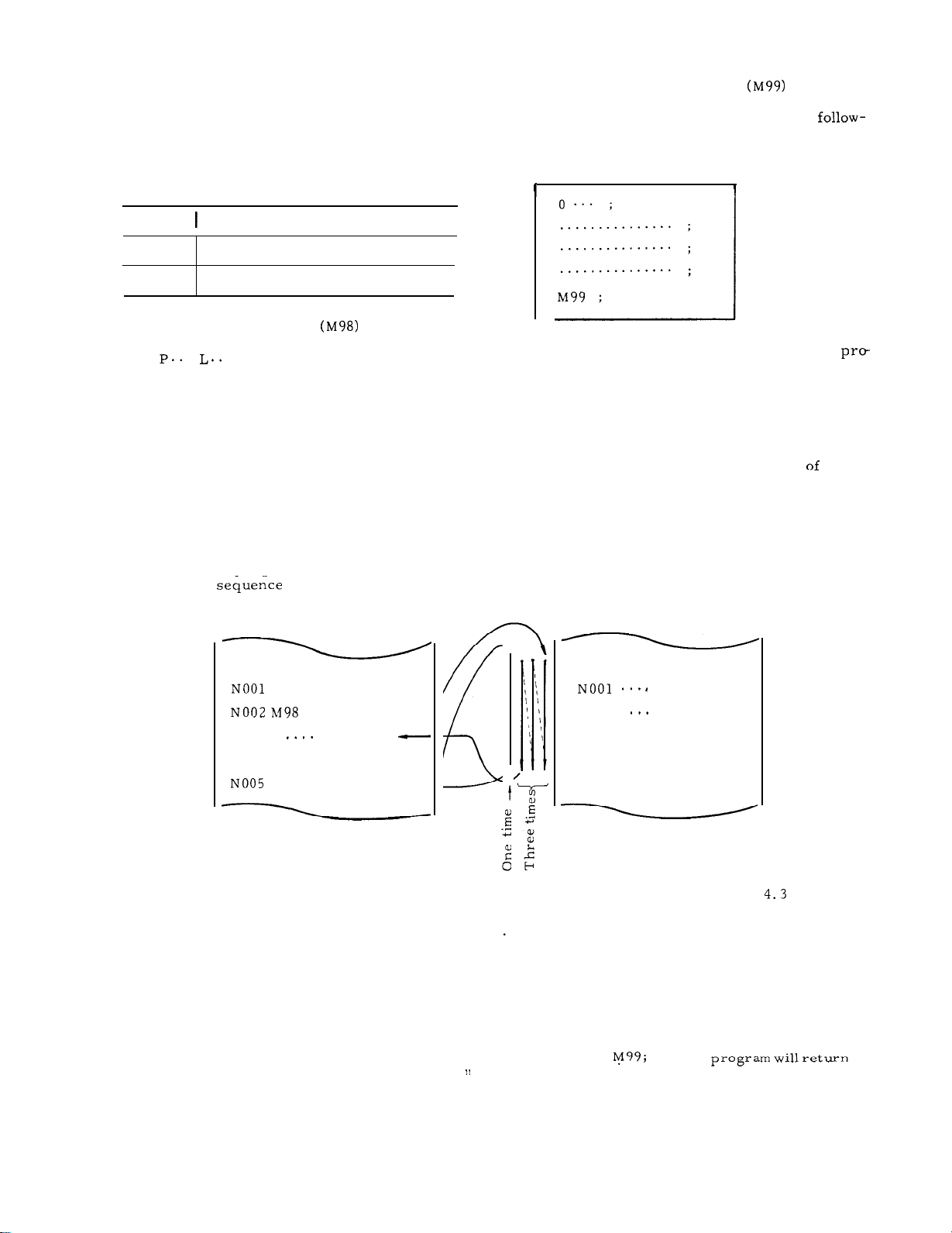

M98:

M99:

M1OO to 199: Used for enhansed codes

Program interrupt off

Program interrupt on

Multi-active register off

Multi-active register on

Mirror image off

Mirror image on

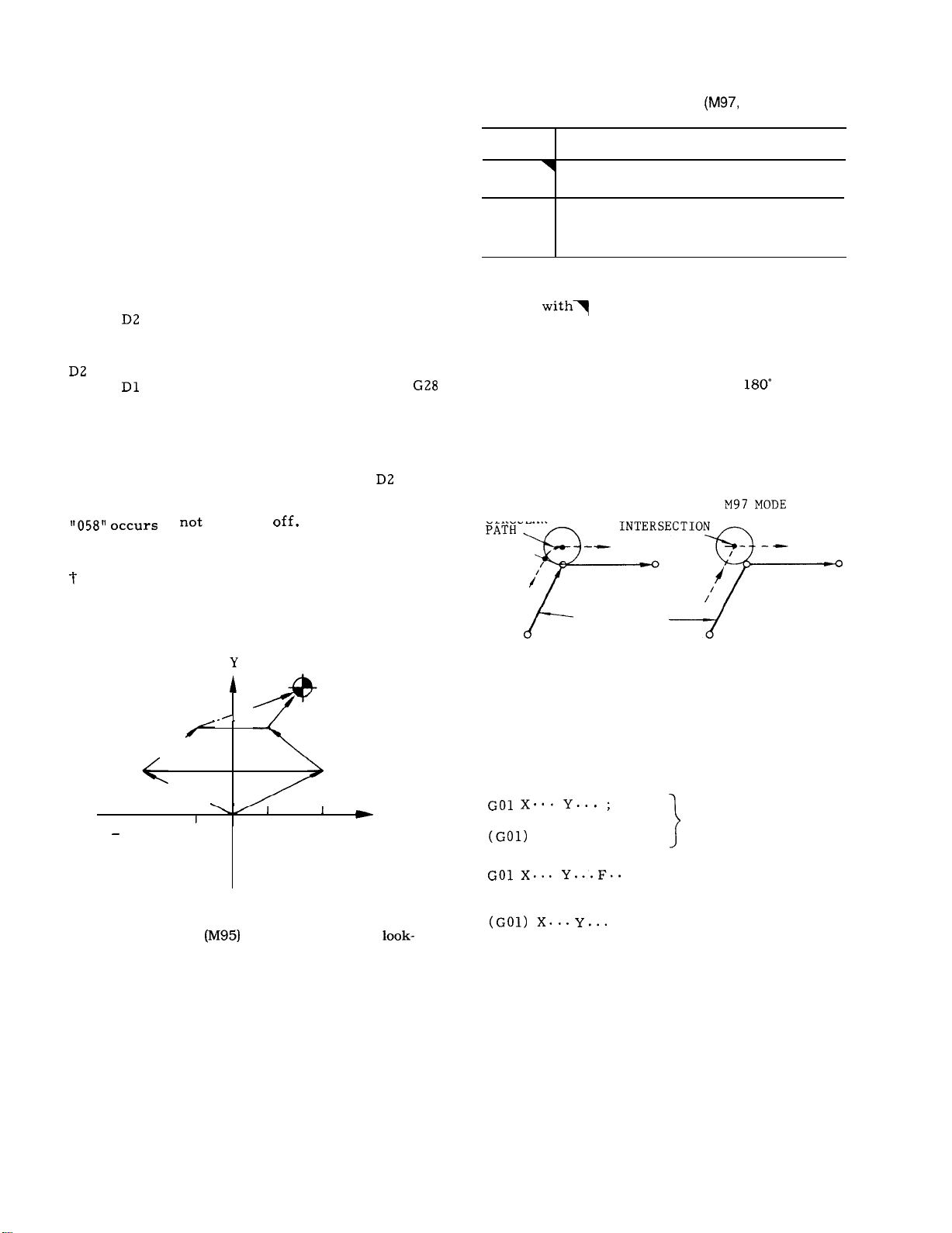

Tool radius compensation C:

circular path mode

Tool radius compensation C :

intersection computing mode

Subroutine program call

Subroutine program end

2.8.3 PROGRAM INTERRUPTION ON/OFF

(M91 , M90) t

M93:

During the time from this command to M92, the

control assumes the 4 blocks-advance-reading

mode.

in advance for the following operation.

the program is so made that the operation time

of advance reading of 4 blocks is longer than

processing time of advance reading of next 4

blocks of data.

M92:

This command cancels 4 blocks-advance -reading

mode.

Note :

blocks without move command can be contained( up to

two blocks ) .

cluding the two blocks, may be read in advance.

Namely, up to 4 blocks of data are read

Inter-block stoppage can be eliminated when

In tool radius compensation C mode, the

Under this condition, 6 blocks, in-

The following M codes are used for the program

interruption function .

Program interrupt function OFF

Note:

reset, the control is in the state of M code

marked with

.

When power is applied or the control is

P. . . . . . ;

During the time from this command to an M90

command, whenever a program interruption

signal is received, the program under

tion is interrupted (if the machine is in motion,

it is stopped after deceleration) , and the a jump

is made to the program the number of which is

written after the

With this command, the program interrupt func-

tion is

2.8.4 MULTI-ACTIVE REGISTERS ON/OFF

M92) t

M code

Meaning

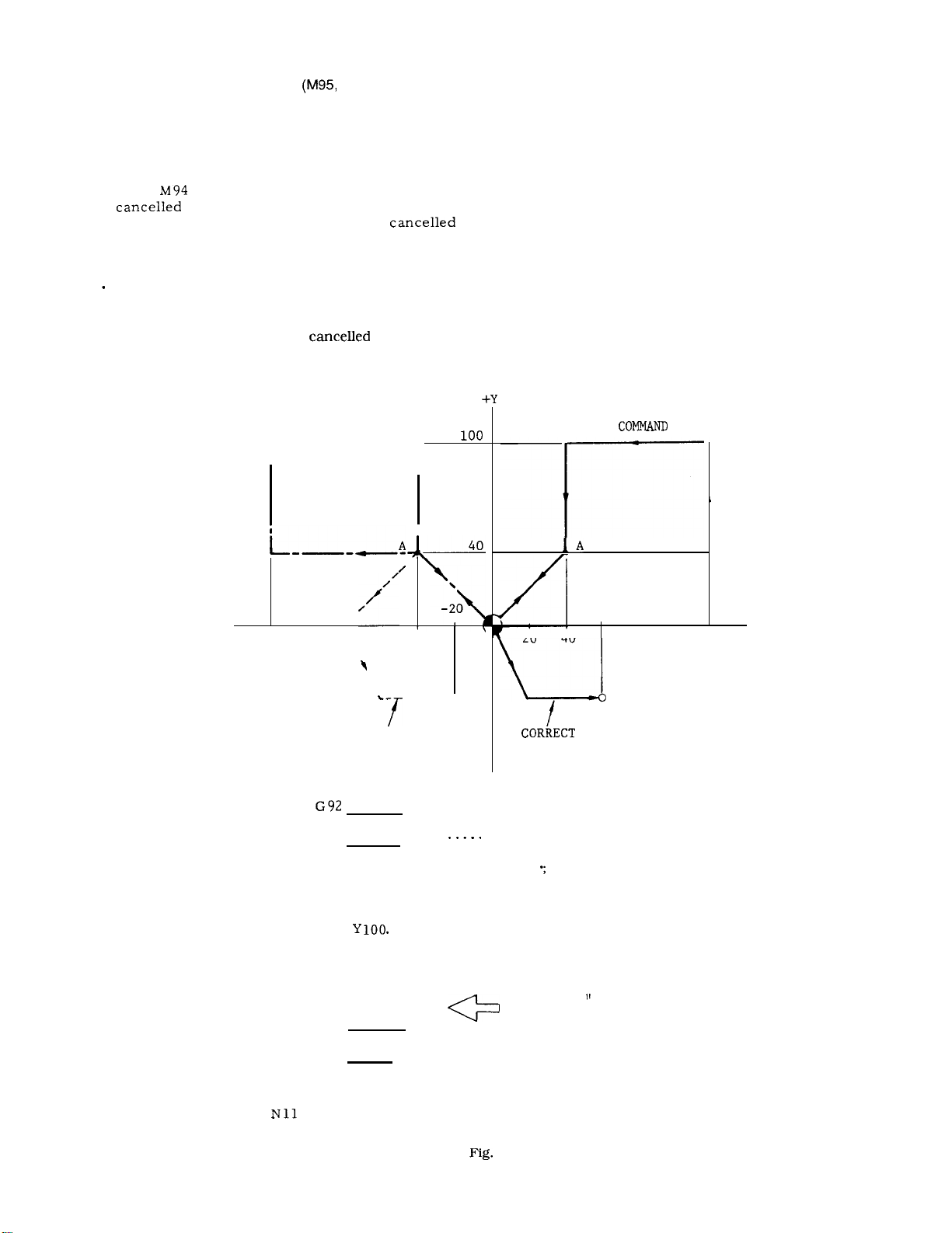

MIRROR IMAGE ON/OFF

2.8.5

M code

M94

M95

Note: When power is applied or the control is

reset, the control is in the state of M code

marked

With these codes,

be started and stopped at any desired point in

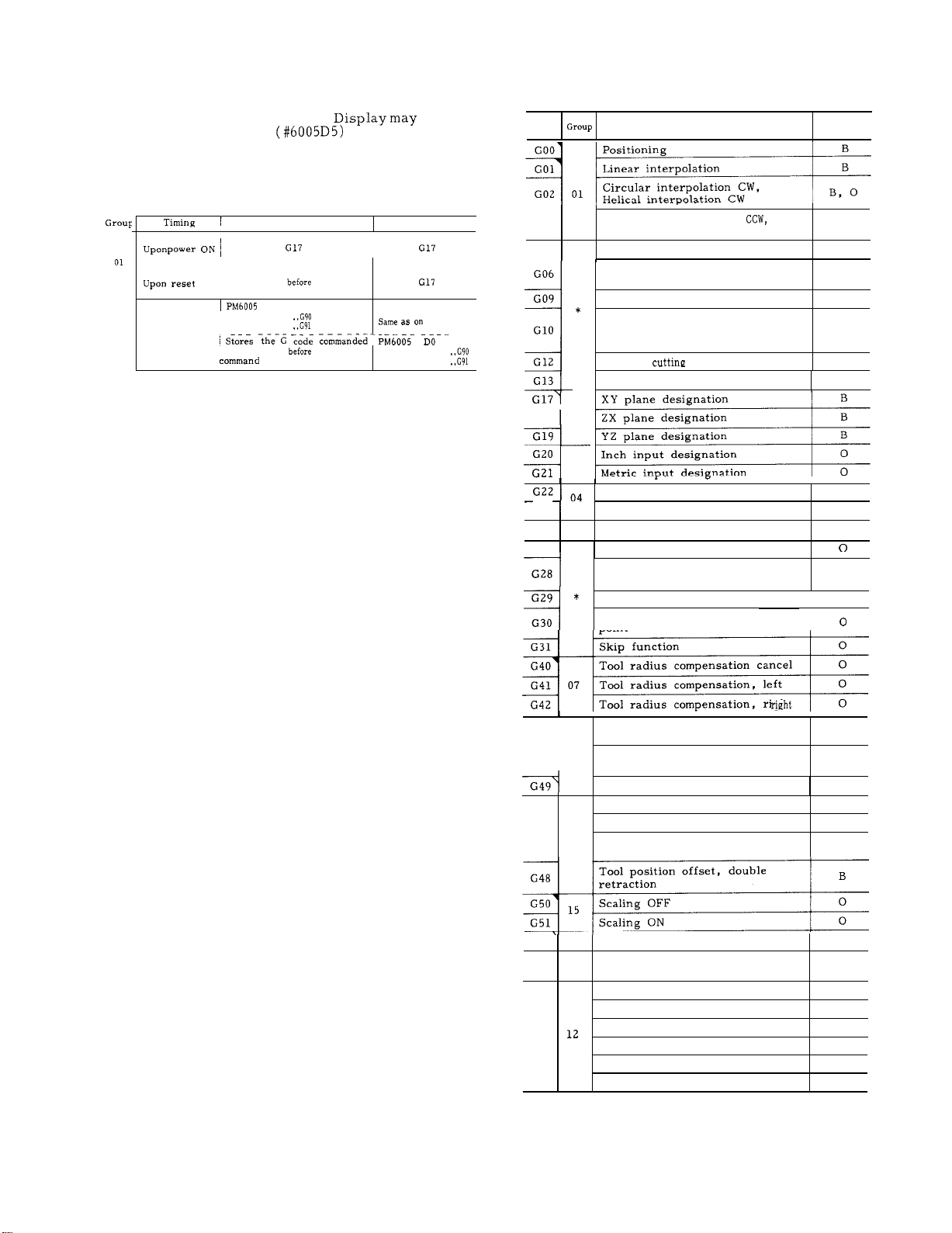

the program.