Page 1

z

YASNAC

CJ3

DESCRIPTIVE

D

c1

J50M

m

INFORMATION

YASKAWA

CNC

SYSTEM

dMppMH

lliilil

MfliffiB

iTseiis

IfiEE

FOR

llfl!

wSm

MACHINING

pi

mSm

a

CENTERS

llfliils

m

SMBEM

Bl|§Hf§iff

1M

55-

1

1

4»-;,,%lj

s

m

I

Si

i

Bp

i

YASKAWA

SIE-C843-12.30

Page 2

1 INTRODUCTION

The YASNAC J50M is a high-performance CNC for the simultaneous control of

2 or 3 axes of a driven machine, with emphasis placed on high-speed machining, and programming capability.

FEATURES

1.

Ultra-high-speed Performance

“High-speed, computing system”

processor in the YASNAC J50M.

2.

Significant Downsizing (Miniaturized)

YASNAC J50M is significantly downsized because it has surface mounted

devices and customized gate arrays.

This manual explains both basic and optional features of YASNAC J50M as

well as the servo system.

You can determine your own hardware requirements after carefully reading

this manual.

is achieved by installing a 32-bit micro-

This manual is subject to change without

notification due to product improvements,

model changes, etc.

Page 3

1 INTRODUCTION i

2 BASIC FEATURES 1

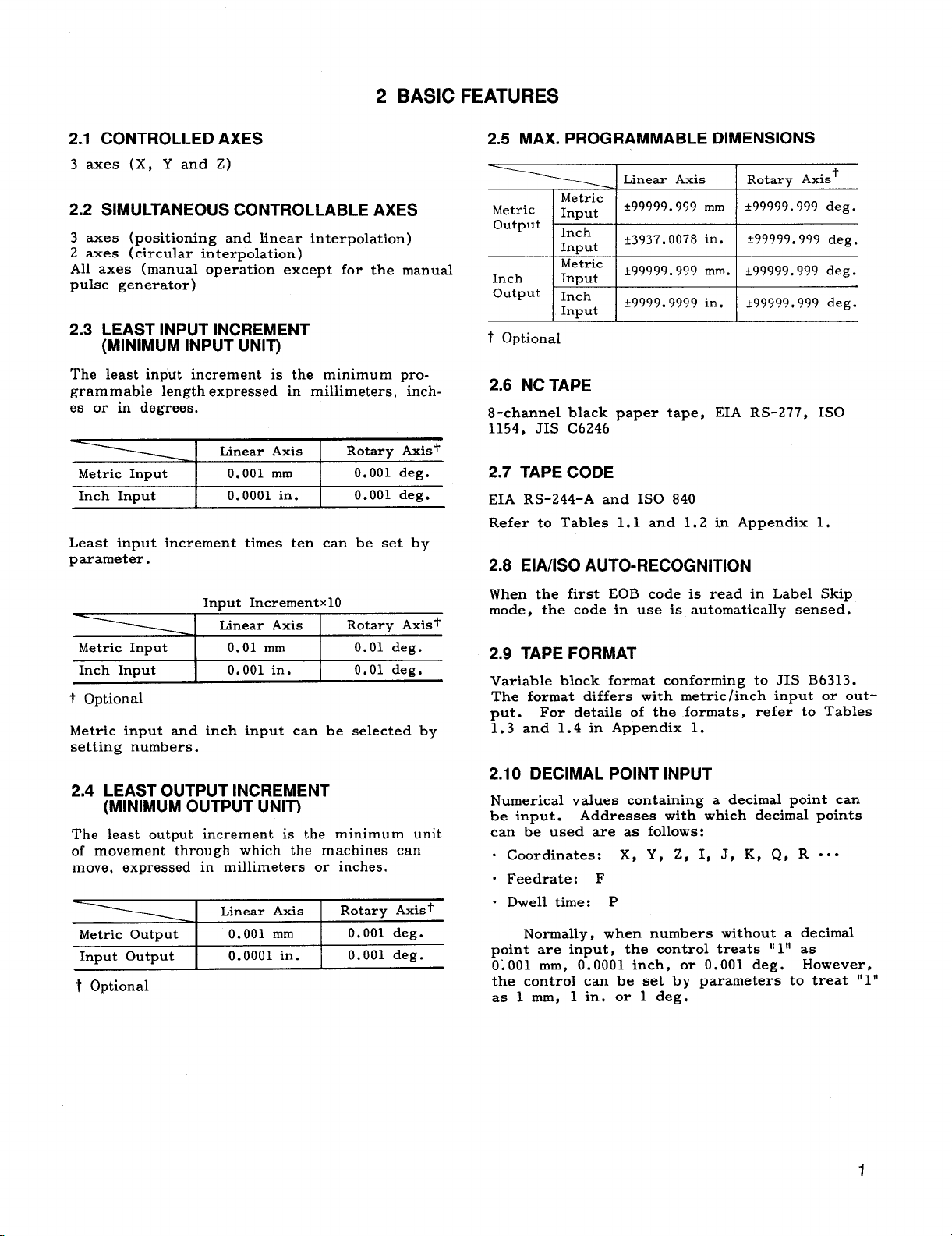

2.1 CONTROLLED AXES 1

2.2 SIMULTANEOUS CONTROLLABLE AXES 1

2.3 LEAST INPUT INCREMENT

(MINIMUM INPUT UNIT) 1

2.4 LEAST OUTPUT INCREMENT

(MINIMUM OUTPUT UNIT) 1

2.5 MAX. PROGRAMMABLE DIMENSIONS 1

2.6 NC TAPE 1

2.7 TAPE CODE 1

2.8 EIA/ISO AUTO-RECOGNITION 1

2.9 TAPE FORMAT 1

2.10 DECIMAL POINT INPUT 1

2.11 BUFFER REGISTER 2

2.12 RAPID TRAVERSE RATE 2

2.13 FEEDRATE RANGE 2

2.14 AUTOMATIC ACCELERATION /

DECELERATION 2

2.15 FEED FUNCTION (F-FUNCTION) 2

2.16 FEEDRATE OVERRIDE AND

FEEDRATE OVERRIDE CANCEL 2

2.17 PREPARATORY FUNCTIONS

(G-FUNCTION) 2

2.18 ABSOLUTE/INCREMENTAL

PROGRAMMING (G90/G91) 2

2.19 PROGRAMMING OF

ABSOLUTE ZERO POINT (G92) 2

2.20 POSITIONING (GOO, G06) 3

2.21 LINEAR INTERPOLATION (GO1) 3

2.22 CIRCULAR INTERPOLATION (G02, G03) 3

2.23 DWELL (G04) 3

2.24 EXACT STOP CHECK (G09, G61, G64) 3

2.25 MISCELLANEOUS FUNCTION

(M-FUNCTION) 4

2.26 SPINDLE-SPEED FUNCTION

(S-FUNCTION) 4

2.27 TOOL FUNCTION (T-FUNCTION) 4

2.28 TOOL LENGTH COMPENSATION

(G43, G44, G49) 4

2.29 TOOL POSITION OFFSET

(G45 THROUGH G48) 4

2.35 SUBROUTINE PROGRAM (M98, M99) 5

2.36 PARAMETER SETTING 6

2.37 SETTING FUNCTION 6

2.38 INTERNAL DATA TAPE INPUT 6

2.39 OPERATION TIME DISPLAY 6

2.40 ADDRESS SEARCH 6

2.41 PROGRAM NUMBER 6

2.42 LABEL SKIP 6

2.43 CONTROL IN/OUT 6

2.44 TV CHECK 6

2.45 SEQUENCE NUMBER BREAK POINT 6

2.46 SINGLE BLOCK 6

2.47 OPTIONAL STOP 7

2.48 OPTIONAL BLOCK SKIP 7

2.49 DRY RUN 7

2.50 MACHINE LOCK 7

2.51 DISPLAY LOCK 7

2.52 Z-AXIS COMMAND NEGLECT 7

2.53 AUXILIARY FUNCTION LOCK 7

2.54 MANUAL ABSOLUTE ON/OFF 7

2.55 MIRROR IMAGE 7

2.56 INTERNAL TOGGLE SWITCHES 7

2,57 ORIGIN KEY 7

2.58 INTERLOCK 7

2.59 START LOCK AND EDIT LOCK 7

2.60 AUTOMATIC COORDINATE SYSTEM

SETTING 7

2.61 FEED HOLD 8

2.62 EMERGENCY STOP 8

2.63 OVERTRAVEL 8

2.64 REMOTE RESET 8

2.65 REMOTE POWER ON/OFF 8

2.66 MACHINE READY INPUT SIGNAL 8

2.67 NC READY OUTPUT SIGNAL 8

2.68 NC ALARM OUTPUT SIGNAL 8

2.69 NC RESET OUTPUT SIGNAL 8

2.70 RS-232C INTERFACE 8

2.71 ON-LINE DIAGNOSTICS 8

2.72 POSITION DETECTOR INTERFACE 8

2.73 INPUT/OUTPUT CONNECTORS 9

2.74 POWER INPUT A 9

2.30 OFFSET MEMORY 5

2.31 TOOL OFFSET VALUE 5

2.32 BACKLASH COMPENSATION 5

2.33 MANUAL FEED 5

2.34 PROGRAM STORAGE AND EDITING 5

2.75 AMBIENT CONDITIONS 9

2.76 PAINT COLOR AND DIMENSIONS 9

ii

Page 4

CONTENTS (Cent’d)

3 BASIC OPTIONS 9

3. I AC SERVO CONTROL UNITS 9

3.2 AC SERVOMOTORS 9

4 OPTIONS 10

4.1 NC OPERATORS STATION 10

4.2 TAPE READER 10

4.3 TAPE READER WITH REELS 10

4.4 F1-DIGIT COMMAND 10

4.5 S5-DIGIT PROGRAMMING WITH

12-BIT OUTPUT 10

4.6 T4-DIGIT PROGRAMMING 10

4.7 ADDITIONAL OFFSET MEMORY 10

4.8 ADDITIONAL PART PROGRAM STORAGE 10

4.9 ADDITIONAL PROGRAM NUMBER

REGISTRATION 10

4.10 4TH AXIS CONTROL 10

4.11 MANUAL PULSE GENERATOR FOR ONE AXIS

AT A TIME 11

4.12 REFERENCE POINT RETURN

(G27, G28, G29) 11

4.13 2ND, 3RD, AND 4TH REFERENCE POINT

RETURN 11

4.14 EXTERNAL DECELERATION 11

4.15 TOOL LENGTH MEASUREMENT 11

4.16 OPTIONAL BLOCK SKIP B 12

4.17 2ND AUXILIARY FUNCTION

(B-FUNCTION) 12

4.18 JOG FEEDR4TE OVERRIDE 12

4.19 PROGRAM COPY 12

4.20 HELICAL INTERPOLATION (G02, G03) 12

4.21 CIRCLE CUTTING B (G12, G13) 12

4.22 INCH/METRIC DESIGNATION BY

G CODE 13

4.23 UNIDIRECTIONAL APPROACH (G60) 13

4.24 WORK COORDINATE SYSTEM SETTING A

(G52 TO G59) 14

4.25 WORK COORDINATE SYSTEM SETTING B

(G54J TO G59J) 14

4.26 TOOL RADIUS COMPENSATION C

(G40 TO G42) 14

4.27 OUTPUT FOR EXTERNAL MOTION

(G80, G81) i5

4.28 CANNED CYCLES (G73, G74, G76, G77, G80

TO G89) 15

4,29 HOLE PATTERN CYCLES

(G70, G71, G72) 22

4.30 SCALING FUNCTION 22

4.31 MACRO PROGRAM (G65, G66, G67) 22

4.32 EXTERNAL DATA INPUT 23

4.33 SKIP FUNCTION (G31) 23

4.34 STORED STROKE LIMIT (G22, G23) 23

4.35 STORED LEADSCREW ERROR

COMPENSATION 23

4.36 USER MESSAGE DISPLAY 24

4.37 PROGRAM RESTART 24

4.38 PROGRAM INTERRUPTION (M90, M91) 24

4.39 PLAYBACK FUNCTION 24

4.40 EXTERNAL INPUT, COLLATION, AND

OUTPUT 24

4.41 TOOL LIFE CONTROL (G122, G123) 24

4.42 COORDINATE ROTATION 24

4.43 LOCAL COORDINATE SYSTEM SETTING 25

4.44 AUTOMATIC OPERATION MODE HANDLE

OFFSET 25

5 BUILT-IN TYPE PROGRAMMABLE CONTROLLER

(PC) 25

APPENDIX 1 LIST OF DATA 26

APPENDIX 2 DIMENSIONS in mm (inch) 31

...

111

Page 5

INDEX

Subject

A

ABSOLUTE/INCREMENTAL PROGRAMMING (G90/G91) ~ . . . . . . . 2 . . . . . 2.18 . . . . 2

AC SERVO CONTROL UNITS. . . . . . . . . . . . . . . . . . . . . . . . . - 3 . . ...3.1... .9

AC SERVOMOTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..3.....3.2 . ...9

ADDITIONAL OFFSET MEMORY ...00.0.....s..o...... .4 °.O” .4.7 OO. O1O

ADDITIONAL PART PROGRAM STORAGE . . . . . . . . . . . . . ...-4.. . ..4.8 . ...10

ADDITIONAL PROGRAM NUMBER REGISTRATION . . . . . . . . . . 0 . 4 . . . . . 4.9 . . + . 10

ADDRESS SEARCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..24 ..”” 2.40. ““6

AMBIENT CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 . . . . . 2.75....9

AUTOMATIC ACCELERATION/DECELERATION . . . . . . . . . . . . . . 2 . . 0 . . 2.14 . . . . 2

AUTOMATIC COORDINATE SYSTEM SETTING . . . 0 . . . . . . . . . . . 2 . . . . . 2.60 “ . “ “ 7

AUTOMATIC OPERATION MODE HANDLE OFFSET . . . . . . . . . . . 4 . . . . . 4.44 . . . . 25

AUXILIARY FUNCTION LOCK.. . . . . . . . . . . . . . . . . . . . . . . . . 2 . . . . . 2.53....7

B

BACKLASH COMPENSATION.. . . . . . . . . . . . . . . . . . . .. . . . - . 2 . . . . . 2.32....5

BASIC FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ,..2 . . . . . . . . . . . ..”1

BASIC OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3...”..” ““”””””9

BUFFER REGISTER . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2.....2.11. ..2

BUILT-IN TYPE PROGRAMMABLE CONTROLLER(PC) . c o 0 . . . . . . 5 . . . . . . . . . . . “ “ .25

CANNED CYCLES (G73, G74, G76, G77, G80TOG89) . . . . . - . . . 4 . . . . . 4.28 . . . 15

c

CIRCLE CUTTING B(G12, G13) ..o...,o........... . . ...4.....4.21.. ..12

CIRCULAR INTERPOLATION (G02, G03) . . . . . . . . . .””..”... 2“””-” 2.22”””” 3

CONTROLIN/OUT . . . . . . . . . . . . . . . . ...-.....””. ““2 ””. ””2.43”””6

CONTROLLED AXES . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2.....2.1 .$”- 1

COORDINATE ROTATION”. .“”.”.”””””.”.””””” ““” ”” 4”. ”” .4.42””- .24

DECIMAL POINTINPUT . . . . . . . . . . . . . . . . . . . . . . . . . . ...2.....2.10. . . . 1

D

DIMENSIONS inmm (inch). . . . . . . . . . . . . . . . . . . . . . .. APPENDIX2” ”””” ““”””31

DISPLAY LOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2.....

DRYRUN O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 . . ...2.49 . ...7

DWELL (G04] . . . . . . . . . . ....”””””.”””.”””””. “.” .” 2.”” ”. 2.23.”. “3

EIA/ISOAUTO-RECOGNITION . . . . . . . . . . . . . . . . . . . . . ...2.....2.8 . . . . 1

E

EMERGENCY STOP..... . . . . .. . . . . . . . . . . . . . . . . . . . . ..2. .” ..2.62 “.””8

EXACT STOP CHECK(G09, G61, G64) . . . . . . . . . . . . . . . ..- 2.”””” 2.24 ””””3

EXTERNAL DATAINPUT. . . . . . . . . . . . . . . . . . . . . . . . . . ..4” .””” 4.32. ““.23

EXTERNAL DECELERATION ........4......”””” .“”””””4””””” 4.14” ‘+”11

EXTERNAL INPUT, COLLATION, AND OUTPUT . . “ “ “ “ “ “ . “ - . “ . 4 “ “ “ “ “ 4.40 “ “ “ “ 24

F1-DIGITCOMMAND . . . . . . . . . . . . . . . . . . . . . . . . . . . ...4.... .4.4 .“””10

F

FEED FUNCTION (F-FUNCTION) . -...........”.””” ““. ”2””””” 2.15.”” 2

FEED HOLD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..2” .”2.61 ““””8

FEEDRATE OVERRIDE AND FEEDRATE OVERRIDE CANCEL . . 0 0 . 2 . - . - .

FEEDRATER4NGE . . . . . . . . . . . . . . . . . . . . . . . “.” ”” ”””. 2”. ”.”2.13 ““””2

4TH AXIS CONTROL -... . . . . . . . . . . . . . . . . . . . . . . . . . ..4” ””” ’4.10 ““””lo

HELICAL INTERPOLATION (G02, GOD)....””.”.””..””” ““” 4“””” 4.20 ””.”12

H

HOLE PATTERN CYCLES (G70, G71, G72) . . . . . . ...”.” ““.”. 4“””.” 4.29 ”..”22

I

INCH/METRICDESIGNATION BYGCODE40”oo o-o-” ““””””” 4“”””” 4.22 .””.13

INPUT/OUTPUTCONNECTORS ......”.”.”.”””””” . .. ”.”2””””” 2.73” ““”9

INTERLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ”.. ”2. .”. ”2.58 ‘“””7

INTERNAL DATATAPEINPUT . . . . . . ” . - .”.”.”-”- ““. ”””” 2””” ”.2.38 ““””6

INTERNALTOGGLE SWITCHES . . . .$-””.””””””””” .“. .””2”” ”-.2.56. ““”7

INTRODUCTION . . . . . . . ........,......”oo ““’””””””1””””””” ““”””’”i

JOG FEEDRATEOVERRIDE . . . ...”..””””””””” “.” ”.”” 4””” ”.4.18 ““””12

J

Chapter

Section Page

2.51 . ...7

2.16 . ...2

iv

Page 6

INDEX (Cent’d)

Subject

LABEL SKIP . . . . . . . . . . . . . .......””””””””””.””.” 2’. ”.”2.42”””.6

L

LEAST INPUT INCREMENT (MINIMUM INPUT UNIT) . . . . . - “ . “ . 0 2 “ . “ “ “ 2.3 “ “ “ “ 1

LEAST OUTPUT INCREMENT (MINIMUM OUTPUT UNIT) . “ . “ . “ “ “ 2 “ “ “ “ “ 2.4 “ “ “ “ 1

LINEAR INTERPOLATION (GO1). . . . . . . . . . . . . . . . . ...”.”- 2“””””2.21”” ..3

LIST OF DATA . . . . . ...!... O“. ”oco”. .”. o”o. .o”s APPENDIX 1.””””..o.”26

LOCAL COORDINATE SYSTEM SETTING . “”.”.”.”””””””””” 4“”””” 4.43 ”.””25

M MACHINE LOCK . . . . . . . . . . . . . . . . . .. O..-.’”’””” O“. .2 °00-e2.50””-”7

MACHINE READY INPUT SIGNAL ““”””””””...””””””””” ““2” ”””” 2.66 ”””.8

MACRO PROGRAM (G65, G66, G67) . . . . . . . . . . . . . . . ..”. ”4 ‘“”o- 4.31 ”. ..22

MANUAL ABSOLUTE ON/OFF. . . . . . ...””””””””””””” ““”2”$-””2.54””””7

MANUAL FEED . . . . . . . . . . . . . . . . ” . ” ” ” ” .”.”””.”” ““”2”””. ”2.33. ””5

MANUAL PULSE GENERATOR FOR ONE AXIS AT ATIME “ “ - 0 “ o 0 4 “ “ “ - “ 4.11 “ “ “ “ 11

MAX. PROGRAMMABLE DIMENSIONS ““””””””””””””””””””2 ““”” ”. 2.5 ““”” 1

MIRROR IMAGE . . . . . . . . . . .....”.””.””.”””””” ““.2 ”””. 2.55” ”””7

MISCELLANEOUS FUNCTION (M-FUNCTION) “ “ . “ “ o “ o “ “ “ “ “ “ “ 2 “ “ “ “ “ 2.25 “ “ ‘ “ 4

NNCALARM OUTPUT SIGNAL” ““””.”””””””.””””.”””” ““2” ”””” 2.68 ””””8

NC OPERATORS STATION . . . .......”.”.”””””.”.”” ““”4””””” 4.1 ““””lo

NC READY OUTPUT SIGNAL.” ““””””””o”””””””””””” ““”2”””””2.67””””8

NC RESET OUTPUT SIGNAL”” ““”r”””.”””””””””””” ““”2”””””2.69””””8

NCTAPE . . . . . . . . . . . ......”””””.”””.”- ““” .” ”.”. 2”<. ””2.6 ““”” 1

O OFFSETMEMORY ”””” ““”””””””””””””””””” ““” ”” ”’”2””””” 2.30 ““””5

ON-LINE DIAGNOSTICS.” ““.””””””””..”.” .“. ”. ”””. 2””” ””2.71 “.””8

OPERATION TIME DISPLAY” .O...””oo”””o”””o.o .. ”. ””2°-’” 02.39’ ‘“”6

OPTIONAL BLOCKSKIP ””” “-”.””””””””””””””” ““” .” ”.2”””. ”2.48” ““”7

OPTIONAL BLOCKSKIPB. ..””””””””””.””.”’” .“”. .”.4”””” .4.16” “’”12

OPTIONAL STOP”’”’”””’” 4.--”-”””’”.”-”””””” ““” ”. 2-”” ”” 2.47””” “7

OPTIONS ””-” o”””-””” ““”””-””””””””””””” ““”””””4””””””””” ““””10

ORIGIN KEY...””..””” “.” .” ”-”. .”” $”.””” .“”””. .2”” ”” ’2.57< ““”7

OUTpUTFOR EXTERNALMOTION (G80, G81) ” . ” ” ”””..”.-” . . 4 . . . . . 4.27 . ...15

OVERTRAVEL ””””””””” ““””””””’”””””””””” ““” ”” ””24”. ”.2.63” ““”8

P PAINT COLORANT DIMENSIONS . “.”””””””””””””””” .“””2””””” 2.76””” “9

PARAMETER SETTING””” ““”””””””””””””””” ““” ”” ”””” 2””” ””236 ““””6

PLAYBACK FUNCTION ..” ..”””””..”o..””.”. ““” ”” ”””” 4”” ’””4.39 ““””24

POSITION DETECTORINTERFACE ““”c””””.””””””””” ““2 ”””” ”2 .72”””” 8

POSITIONING (GOO, G06)”” ““””””””””””””””””” ““” ”” ””2””””” 2.20” ““”3

POWERINPUTA ”””””” ‘“ .” 8--” ”.”. ””0””” “’”” ”” ”””2””””” 2.74 ““””g

PREPARATORY FUNCTIONS (G-FUNCTION) . . . . . . . . . . . . . . . . 2 . . . . . 2.17 . . . . 2

PROGRAM COPY””’””””” ““””””””””””””””””” ““” ”” ”-4” ”’”” 4.19” ““”12

PROGRAM INTERRUPTION (M90, M91) ””’””.””””””””” “-”.4””””” 4.38 ””””24

PROGRAM NUMBER”””” ““””””””””’””””””” ““” ”” ”””” 2””” ””2.41 “’””6

PROGRAM RESTART”.” ““o’.”-”-”’””””””” “’” ’” ’””” 4””” ””4.37 ““””24

programming oFABSOLUTE ZEROPOINT(G92) . . . . . . . . . . 2 . . . . . 2.19 . . . 2

PROGRAM STORAGEAND EDITING ““”””.”.”””””””””” ““” 2””” ”” 2.34”””” 5

R RAPID TRAVERSE RATE”” C.””’”””””””””’”””” ““” ”” ””2” ’’”” 2.12” ““”2

REFERENCE POINTRETURN(G27, G28, G29) . . . . . ~ . . . . . . . . 4 . . . . . :::: . . . . 11

REMOTEPOWERON/OFF . . ...””””””””””””” ““”””””””2”””””

REMOTERESET. .$””” . “.-””””””””””””” .“”””0”2””””” 2.64 ““””8

RS-232C INTERFACE””” “’”””””””””””””””” ““” ”” ”””” 2””” ””2.70 ‘“””8

S S5-DIGIT PROGRAMMING WITH 12-BITOUTPUT . . . . . . 0 . . . . . . 4 . . . . . 4.5 . . . . 10

SCALING FUNCTION””””” ““.’”’””””””””””””” ““” ”” ””4””””” 4.30’ ““”22

2ND AUXILIARY FUNCT10N@FuNcTION) . . . . . . . . . . . . . . . . 4 . . . . 4.17 . . . . 12

2ND, 3RD, AND 4TH Reference POINT RETURN . . . . . . . . . . . . 4 . . . . . 4.13 . . . . 11

SEQUENCE NUMBERBREAK POINT”””””””””””” ““”””””””2”””””

Chapter Section

. . . .

2.45 . ...6

Page

8

Page 7

INDEX (Cent’d)

Subject

SETTING FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2 . . . . . 2.37....6

S

SIMULTANEOUS CONTROLLABLE AXES . . . . . . . . . . . . . . ...2 .4 ...2.2 . . . . 1

SINGLE BLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 . . ...2.46 . ...6

SKIP FUNCTION (G31) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 . . . ..4.33... .23

SPINDLE-SPEED FUNCTION (S-FUNCTION) . . . . . . . . . . . . . . . . 2 . . . . . 2.26 . . . 0 4

START LOCKAND EDITLOCK . . . . . . . . . . . . . . . . . . . . . . . . 2 . . ...2.59 . ...7

STORED LEADSCREWERROR COMPENSATION . . . . . ~ . . . . . . . 4 . . . . . 4.35 . . . . 23

STORED STROKELIMIT(G22, G23) . . . . . . . . . . . . . . . . . . ...4..... 4.34....23

SUBROUTINE PROGRAM (M98, M99)............-... . . . . 2 . . . ..2.35... 5

Chapter

T T4-DIGIT PROGRAMMING.. .. . . . . . . . . . . . . . . . . . . . . . ...4.....

TAPECODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2.....

TAPEFORMAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2.. . . .

TAPEREADER . . . . . . . . . . ...!..... . . . . . . . . . . . . ...4.. . . .

TAPE READERWITHREELS . . . . . . . . . . . . . . . . . . . . . . ...4.....

TOOL FUNCTION (T-FUNCTION) . . . . . . . . . . . . . . . . . . . . . ..2.....

TOOL LENGTH COMPENSATION (G43, G44, G49) . 0 “ < “ “ “ . . . . . 2 . “ “ . .

TOOL LENGTH MEASUREMENT . . . . . . . . . . . . . . . . . . . . ...4.....

TOOL LIFECONTROL(G122, G123). o.o. o.o. .o..o . . . . ...4.....

TOOLOFFSETVALUE . . . . . . . . . . . . . . . . . . . . . . . . . . ...2...-.

TOOL POSITION OFFSET(G45 THROUGHG48) . . . . . . . . . . . . . 2 . . . . .

TOOL RADIUS COMPENSATION C(G40TOG42) . c . . . . . . . . . . . 4 . . . . .

TVCHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2.....

u UNDIRECTIONALAPPROACH (G60) . . . . . . . . . . . . . . . . . . . . . 4 . . . . .

USER MESSAGE DISPLAY. . . . . . . . . . . . . . . . . . . . . . . . ...4.....

W WORK COORDINATE SYSTEM SETTING A(G52TOG59) . . . . . . . . 4 . . . . .

WORK COORDINATE SYSTEM SETTING B(G54JTOG59J) . . . . . . 4 . “ . . “

Z Z-AXIS COMMAND NEGLECT . . . . . . . . . . . . . . . . . . . - . . ...2.-...

Section

4.6 . ...10

2.7 . . . . 1

2.9 . ...1

4.2 . ...10

4.3 . ...10

2.27 . . . . 4

2.28 ...4

4.15....11

4.41....24

2.31 . ...5

2.29 . ...4

4.26....14

2.44 . ...6

4.23,...13

4.36....24

4.24....14

4.25....14

2.52 . ...7

Page

vi

Page 8

2 BASIC FEATURES

2.1 CONTROLLED AXES

axes (X, Y and Z)

3

2.2 SIMULTANEOUS CONTROLLABLE AXES

axes (positioning and linear interpolation)

3

axes (circular interpolation)

2

All axes (manual operation except for the manual

pulse generator)

2.3 LEAST INPUT INCREMENT

(MINIMUM INPUT UNIT)

The least input increment is the minimum programmable lengthexpressed in millimeters, inch-

es or in degrees.

Linear Axis

mm

Metric Input

Inch Input

Least input increment times ten can be set by

parameter.

0.001

0.0001 in.

Rotary Axisf

0.001 deg.

0.001 deg.

2.5 MAX. PROGRAMMABLE DIMENSIONS

Inch

output

t Optional

Metric

Input

Inch

Input

+99999.999

f9999. 9999 in.

mm.

*99999.999 deg.

t99999. 999 deg.

2.6 NC TAPE

8-channel black paper tape, EIA RS-277, ISO

1154, JIS C6246

2.7 TAPE CODE

EIA RS-244-A and 1S0 84.0

Refer to Tables 1.1 and 1.2 in Appendix 1.

2.8 EIA/lSO AUTO-RECOGNITION

Input Increment X10

Linear Axis

Metric Input 0.01

mm 0.01 deg.

Rotary Axis f

Inch Input 0.001 in. 0.01 deg.

t Optional

Metric

input and inch input can be selected by

setting numbers.

2.4 LEAST OUTPUT INCREMENT

(MINIMUM OUTPUT UNIT)

Ths least output increment is the minimum unit

of movement through which the machines can

move, expressed in millimeters or inches.

Rotary Axis+

0.001 deg.

0.001 deg.

Metric Output

hmut OutPut

t Optional

Linear Axis

0.001 mm

0.0001 in.

When the first EOB code is read in Label Skip

mode, the code in use is automatically sensed.

2.9 TAPE FORMAT

Variable block format conforming to JIS B6313.

The format differs with metric /inch input or out-

put .

For details of the formats, refer to Tables

1.3 and 1.4 in Appendix 1.

2.10 DECIMAL POINT INPUT

Numerical values containing a decimal point can

be input.

can be used are as follows:

“ Coordinates: X, Y, Z, I, J, K, Q, R

“ Feedrate: F

“ Dwell time: P

Normally, when numbers without a decimal

point are input, the control treats “ 1“ as

01001 mm, 0.0001 inch, or 0.001 deg. However,

the control can be set by parameters to treat “ 1”

as 1 mm, 1 in. or 1 deg.

Addresses with which decimal points

● . .

1

Page 9

2.11 BUFFER REGISTER

During normal operation, one block of data is

read in advance and compensation is computed

for the follow-on operation.

In the tool radius compensation~ C mode, two

blocks of data or up to 4 blocks of data are read

in advance and compensation computing required

for the next operation is executed. One block

can contain up to 128 characters including EOB.

Feedrate (Feed/Minute)

Range

F1. - F30000 mm/min

FO.1 -F1181.10in. /rein

Metric Input

output

Metric

Inch

Input

Format

F40

F31

“’UHH==

2.12 RAPID TRAVERSE RATE

Up to 30,000 mm/min, or 1181.10 in. /rein, as set

by parameters, is programmed independently for

each axis.

2.13 FEEDRATE RANGE

Feedrate is programmable between 1 and 30,000

mm/min, or between 0.1 and 2400 in. /min.

upper limit can be set by parameters according

to the machine.

The

2.14 AUTOMATIC ACCELERATION /

DECELERATION

(1) In positioning and manual feeding, motion can be

automatically accelerated and decelerated linearly. Twostage linear acceleration/deceleration can also be set as

shown below, independently for each axis.

v

Note:

1/10 by parameters.

Minimum input values can be reduced to

2.16 FEEDRATE OVERRIDE AND FEEDRATE

OVERRIDE CANCEL

Rapid traverse rate override

(1)

Rapid traverse rates can be reduced to FO, 25%,

50% or 100% of the original traverse rate. FO is

set by parameters.

(2) Feedrate override

The feedrates programmed by F codes can be

modified between O% to 200% in 10% increments.

(3) Feedrate override cancel

When this switch is turned on, any feedrate

override ef feet is cancelled, and the tool moves

at the originally programmed feedrates.

2.17 PREPARATORY FUNCTIONS

(G-FUNCTION)

G codes consisting of address G plus up to 3

digits, specify work for the respective blocks.

For details of the G codes, refer to Table 1.5 in

Appendix 1.

t

(2) Feed acceleration is exponential, and is

applled commonly to all the axes.

v

The time constants for the above curves are set

by parameters.

2.15 FEED FUNCTION (F-FUNCTION)

Tool feedrates are selected within the following

ranges by F codes.

2

(1) Ordinary G codes include non-modal G-codes

marked with*, and modal G-codes belonging to

groups 01 through 15.

long to division B are basic G-codes.

(Z) G1OO through G199 are expansion G-codes.

They are used ~o call G-codes for

option, etc.

The G-codes which be-

user macro

2.18 ABSOLUTE/lNCREMENTAL

PROGRAMMING (G90/G91 )

With the following G-codes, the tool movement

can selectively be programmed either in absolute

values or in increments:

G90 :

G91: incremental designation

absolute designation

2.19 PROGRAMMING OF ABSOLUTE ZERO

POINT (G92)

With a command “G92 X... Y.. . Z. ..:,” an absolute coordinate system is established with the

current tool position having the specified coordinate values.

Page 10

2.20 POSITIONING (GOO,G06)

(1] GOO X... Y... Z... ;

With this command, the tool moves at the rapid

traverse rate to the specified coordinate position,

moving independently in each coordinate direction.

The motion after positioning will be in the ERROR

DETECT ON mode. GOO is a 01 group modal G

code. The ERROR DETECT OFF mode can be

entered by parameters.

180”OR OVER

(2) G06 X... Y... z... ;

with this command, after executing. a positioning

similar to GOO, the program advances to the next

block in the ERROR DETECT OFF mode. G06 is

non-modal, and is effective only in the programmed block.

Note:

In the ERROR DETECT ON mode, the

command of the next block is executed only after

the servo-lag pulses in the current block are

reduced to a permissible number. The ERROR

DETECT OFF mode is where the command of the

next block is executed immediately after the distribution of the pulses in the current block, regardless of the servo–lag pulses. In this mode,

the corners of the workplaces are slightly

rounded.

2.21 LINEAR INTERPOLATION (GOI)

GOI X... Y... Z... F... ;

With this command, the tool moves along the

specified straight line at a feedrate specified by

the F code.

2.22 CIRCULAR INTERPOLATION (G02, G03)

START POINT

G02 X... Y.., Rt... F... ;

(3) G02 (G03) I... J... F... Ln;

This command moves the tool around a

designated complete circle n times. When L is

not programmed, the tool moves only once

around the circle.

(4) G codes for plane designation (G17 to G19)

The plane for programming circular interpolation

is specified by the following G codes:

G17:

G18:

G19:

XY plane

2X plane

YZ plane

Note :

1. Circular interpolation is possible over two or

more quadrants.

2. Circular interpolation is also possible with

respect to the optional 4th linear axis.

2.23 DWELL (G04)

(1) G02 (G03) X... Y... I... J... F... ;

These commands move the tool along the specified circular path at feedrate specified by the F

code.

X and Y specify the end point of the circular motion, and I and J specify the center of

the circular path in XY plane. With the proper

selection of address, similar circular interpolation

is programmed also in the XY and ZX planes.

G02 is for clockwise motion, and G03 is for

counterclockwise motion.

(2) G02 (G03) X... Y... R... F... ;

Circular interpolation is also possible by desig-

nating the radius R with the above command.

When R > 0, a circular path with a center angle

smaller than 180° is programmed, and when R c

O, the center angle of the circular path is larger

than 180°.

G04 P...;

With this command, the tool remains motionless

for the duration of time specified by the P code.

The minimum and the maximum programmable

dwell times are 0.001 and 99999.999 seconds,

respectively.

2.24 EXACT STOP CHECK (G09, G61 , G64)

This function is effective only in the blocks of .

feedrate which is controlled by interpolation.

(1) Exact stop (G09)

A block containing G09 is executed in the

ERROR DETECT ON mode.

is required to be machined with a sharp corner,

this code is programmed.

is effective only in the programmed block.

(2) Exact stop check mode (G61)

When G61 is programmed, all the subsequent

blocks are executed in the ERROR DETECT ON

mode until G64 is programmed.

When the workpiece

G09 is non-modal, and

3

Page 11

2.24 &W#TOP CHECK (G09, G61 , G64)

(3) Exact stop check mode cancel (G64)

This code is for canceling the G61 command.

In either output mode, spindle speed

override can be accomplished.

permits overrides by steps of 10% within a range

of 50 to 120% to the spindle output command.

(Input points: 3)

This function

Note:

1. When the power supply is turned on, the

status corresponding to G64, that is, the

ERROR DETECT OFF mode, is on.

2. Rapid traverse motion is controlled by GOO

and G06, and not influenced by these exact

stop G codes.

2.25 MISCELLANEOUS FUNCTION

(M-FUNCTION)

Miscellaneous functions are programmed with address M and up to these digits. The M codes

are grouped in the following three categories:

(1) M codes for internal processing, decode sig-

nal outputting, and 3-digit BCD outputting.

MOO:

MO1:

M02:

M30:

(2) M

M90t:

M91~:

M92t:

M93t:

M94:

M95:

M96t :

M97+:

M98:

M99:

M1OO to 199: - f indicates options.

(3) M codes exclusively for outputting 3-digit

BCD signals are those other than the above.

Program stop

Optional stop

Program end (reset)

Tape end (reset and rewind)

codes only for internal processing

Program interrupt off

Program interrupt on

Multi-active register off

Multi-active register on

Mirror image off

Mirror image on

Tool radius compensation C; circular path

mode

Tool radius compensation C; intersection

calculation mode

Subroutine program call

Subroutine program end

2.26 SPINDLE-SPEED FUNCTION (S-FUNCTION)

Instead of this function, S5-digit

programming with 12-bit output is selected. It

outputs 12-bit binary signal without a sign

(4095 maximum) .

2.27 TOOL FUNCTION (T-FUNCTION)

Tool numbers are specified by two digits following the address T.

are sent in 2-digit BCD.

Note:

output is available as an option.

T4-digit programming with T4-digit BCD

Commands to the machine

2.28 TOOL LENGTH COMPENSATION

(G43, G44, G49)

This is a tool position offset function only effective in the Z-axis direction. With G43 ( G44)

Z H...

. . .

offset by the value stored in the tool offset

memory specified by the H code in plus (+) or

minus (-) direction, with respect to the point of

the Z-axis movement.

G Code

G43

G44

G49

Note: When power is applied, the control is in

the state of G code marked with

; or G43 (G44) H. . . ; the tool is

Meaning

Tool length compensation in plus (+]

direction

Tool length compensation in minus (-)

direction

1

Tool length compensation command

cancel

1“

2.29 TOOL POSITION OFFSET

(G45 THROUGH G48)

These tool position offsets are used mainly for

compensating for the radius differences when

machining simple rectangular workplaces.

The following output mode can be selected.

S 5-digit programming, analog output (Basic

option). Outputs analog voltage of t10 V max

as D /A converter.

The control outputs spindle gear ratio change

commands (4 max) when it receives the RPM

value specified program.

analog voltage corresponding to the changed

gear ratio.

changed gear ratio. Speed ranges for

individual gear ratio are set by parameter.

Speed ranges corresponding to the

It then outputs

4

G01G45 (G46) X... D... F... ;

With this command, the feed lehgth of the tool in

the specified axis is extended or retracted by

the length stored in the specified tool offset

memory.

G Code

G45

G46

G47

G48 I Double retraction

I

Extension

Retraction

I

Double extension

I

Meaning

Page 12

These G codes are non-modal, and are effective

only in the block in which they are programmed.

When circular interpolation is included in the

same block in which a tool position offset is pro–

grammed, the radius and the end point are extended also.

In this case

~ proper compensation

for tool radius is possible only for machining

1/4, 3/4 and 414 circles.

2.30 OFFSET MEMORY

The two digits following the address H or D are

called tool offset numbers, and these numbers

are assigned to the 99 tool offset values stored

in the tool offset memory.

set value can be designated with the tool length

compensation command (specified by the H code)

or the tool position offset command (specified by

the D code among the stored values.

Note: The 99 tool offset values can also be used

with the tool radius compensation C function

(option).

Up to 299.

Tool offset memories can be expanded

Any desired tool off-

(3) Step feed (STEP)

Each time the desired JOG button is pushed, the

tool moves through the distance specified by the

MANUAL PULSE MULTIPLY switch. The distance are in the following multiples of pulses:

x 1,

x 100, x 1000, x 10,000, x 100,000.

x 10,

2.34 PROGRAM STORAGE AND EDITING

Part program can be loaded into memory for

tapeless operation and for editing.

(1) Memory capacity is equivalent to 40 meters of

tape. (Note 1)

(2) Part program, added with a program number

of 4-digit numerals, can be stored in memory

(from paper tape or MDI).

up to 99 program numbers can be stored in memory.

(Note 2)

(3) The stored part program can be edited by

ERASE, INSERT, and ALTER keys. Editing is

done in one to several words at a time.

In the basic mode,

2.31 TOOL OFFSET VALUE

The range of tool offset value that can be

written in the tool offset memory is as follows:

Metric Input

Inch Input O to +99. 9999 inches

O to t999. 999 mm

2.32 BACKLASH COMPENSATION

This function is for compensating for the

backlash in the driving system of the

machines, Backlashes between O and +8191 P

can be compensated independently in each axes

(p representing the minimum output unit).

The desired compensation values are preset by

parameters.

2.33 MANUAL FEED

Manual feed is possible in the following three

modes, simultaneously in all three axes.

(1) Manual rapid traverse (RAPID)

The tool moves at the rapid traverse rate, in-

dependently in all three axes.

(2) Manual JOG feed (JOG)

After setting the JOG FEEDRATE switch at he

desired speed (32 available) , the tool will move

at that feedrate while any of the JOG buttons is

depressed.

(4) The OUT, VER, and IN keys are used to

output the stored part programs to external

equipment (option) , to collate them with punched

cards, and store them from tape readers.

(Note

3)

(5) Address search function permits the specified program number to be searched for the pur-

pose of an automatic operation (MEM mode).

Note:

Optionally, the part program storage may

1.

be extended to 320 meters.

2. Optionally, the number of stored programs

may be extended to 999.

3. To output the part program to an external

equipment, the optional 11data input/output

interface

11is required.

2.35 SUBROUTINE PROGRAM (M98, M99)

Subroutine programs with program numbers can

be retrieved and executed as many times as de-

sired.

(1) Retrieving subroutine programs (M98)

M98 P... L... ;

With this command, the subroutine program with

the number designated by P is retrieved and

executed L times.

the subroutine program is executed only once.

The retrieved subroutine program may also retrieve further subroutine programs up to four

nestings.

When no L-digit is defined,

5

Page 13

2.35 ~W~:)UTINE PROGRAM (M98, M99)

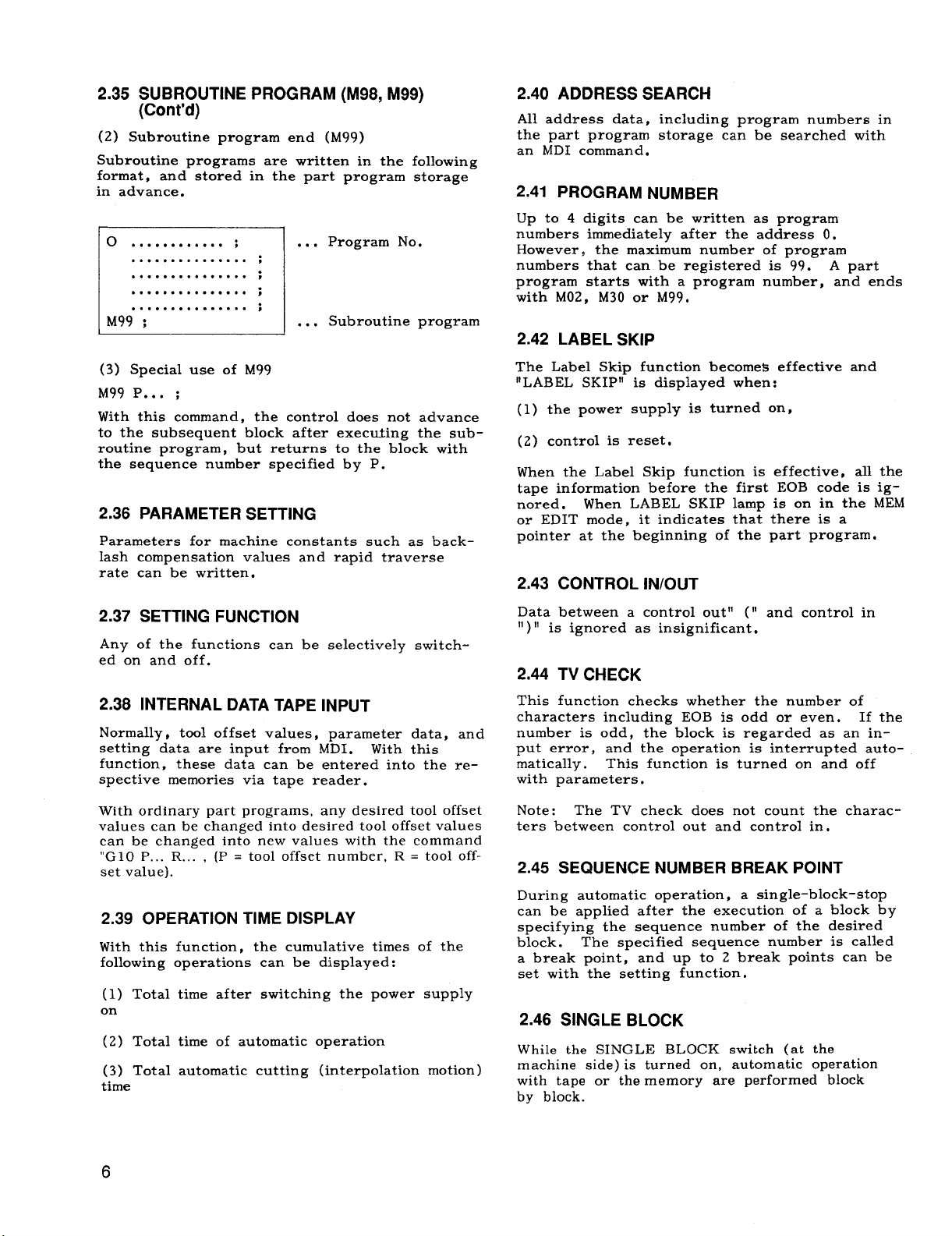

(2) Subroutine program end (M99)

Subroutine programs are written in the following

format, and stored in the part program storage

in advance.

o

. . . . . . . . . . . .

. . . . . . . . . . . . . . .

.*. .*...*. . . . . .

i

..

I

..0...... ● .**

. . . . . . . . . . . . . . .

M99 ;

;

1

:

:

;

:

Program No.

. . .

I

I

Subroutine program

. . .

I

2.40 ADDRESS SEARCH

All address data, including program numbers in

the part program storage can be searched with

an MDI command.

2.41 PROGRAM NUMBER

Up to 4 digits can be written as program

numbers immediately after the address O,

However,

numbers that can be registered is 99.

program starts with a program number, and ends

with M02, M30 or M99.

the maximum number of program

A part

2.42 LABEL SKIP

(3) Special use of M99

M99P... ;

With this command, the control does not advance

to the subsequent block after executing the sub-

routine program, but returns to the block with

the sequence number specified by P.

2.36 PARAMETER SETTING

Parameters for machine constants such as back-

lash compensation values and rapid traverse

rate can be written.

2.37 SETTING FUNCTION

Any of the functions can be selectively switch-

ed on and off.

2.38 INTERNAL DATA TAPE INPUT

Normally, tool offset values, parameter data, and

setting data are input from MDI.

function, these data can be entered into the re-

spective memories via tape reader.

With ordinary part programs, any desired tool offset

values can be changed into desired tool offset values

can be changed into new values with the command

“G1O P... R... ,

set value).

(P = tool offset number, R = tool off-

With this

2.39 OPERATION TIME DISPLAY

With this function, the cumulative times of the

following operations can be displayed:

(1) Total time after switching the power supply

on

(2) Total time of automatic operation

Total automatic cutting (interpolation motion)

(3)

time

The Label Skip function becomes effective and

LABEL SKIPII is displayed when:

!!

(1) the power supply is turned on,

(2) control is reset.

When the Label Skip function is effective, all the

tape information before the first EOB code is ignored. When LABEL SKIP lamp is on in the MEM

or EDIT mode, it indicates that there is a

pointer at the beginning of the part program.

2.43 CONTROL iN/OUT

Data between a control out” (11 and control in

‘1)” is ignored as insignificant.

2.44 TV CHECK

This function checks whether the number of

characters including EOB is odd or even. If the

number is odd, the block is regarded as an in-

put error, and the operation is interrupted auto-

matically.

with parameters.

Note: The TV check does not count the characters between control out and control in.

This function is turned on and off

2.45 SEQUENCE NUMBER BREAK POINT

During automatic operation, a single-block-stop

can be applied after the execution of a block by

specifying the sequence number of the desired

block .

a break point, and up to 2 break points can be

set wit h the setting function.

The specified sequence number is called

2.46 SINGLE BLOCK

While the SINGLE BLOCK switch (at the

machine side) is turned on, automatic operation

with tape or the memory are performed block

by block.

6

Page 14

2.47 OPTIONAL STOP

While the OPTIONAL STOP switch (at the

machine side ) is on, operation stops automatically

after executing a block including MOI.

OPTIONAL BLOCK SKIP

2.48

2.55 MIRROR IMAGE

Mirror image axis for symmetrical machining can

be specified with switches (for X, Y or the 4th~

axis).

tool path between M95 and M94 on the program

with respect to the specified axis.

Mirror image control is applied to the

While the OPTIONAL BLOCK SKIP switch (at

the machine side) is on, a command block

starting with “/” is neglected.

2.49 DRY RUN

With this function, the feedrates for automatic

operation are converted into manual operation

feedrates for convenience during dry-run. While

the DRY RUN switch (at the machine side) is

on, the following feedrates are available,

DRY RUN On

Feed

Rapid

Traverse Feed (Parameter Selection )

Feedrate for Manual Continuous Feed

Rapid Traverse or Manual Continuous

2.50 MACHINE LOCK

This function allows NC commands to be execut-

ed, with M, S, and T functions functioning normally, and the current positions to be continuously updated and displayed, with the machine

standing still.

2.56 INTERNAL TOGGLE SWITCHES

With this function, the toggle switches for the

function described in paragraph 2.47 SINGLE

BLOCK through 2.56 MIRROR IMAGE can be

eliminated at the machine control station, and

the necessary setting can be performed from the

NC operator’s station.

2.57 ORIGIN KEY

The ORG key designates the current tool

position designated at point “O. ” Each axis is

controlled independently.

2.58 iNTERLOCK

Tool movement for control axes can be locked

during motion with this function. When interlock is applied, the tool stops after deceleration,

and when interlock is cleared, the tool resumes

the motion.

When interlock is applied during an interpolation covering two or more axes, the interpolation motion is stopped.

DISPLAY LOCK

2.51

With this function, the POS-EXTERNAL display

Is locked while the machine is operated under

automatic or manual control.

2.52 Z-AXIS COMMAND NEGLECT

While Z-AXES NEGLECT switch is on, the

machine motion only in the Z–axis is locked.

2.53 AUXILIARY FUNCTION LOCK

While this switch is on, no BCD code

for M, S, and T (and BY) functions.

MANUAL ABSOLUTE ON/OFF

2.54

While this switch is on, manual movement dis-

tances are added to the absolute register, and

the coordinate system remains unchanged. While

the switch is off, manual movement distances are

not added, and the coordinate system is shifted

in parallel with the movement.

is output

2.59 START LOCK AND EDIT LOCK

The following functions can be turned on and

off by switches.

(1) START LOCK

When this function is on, the CYCLE START

key is made ineffective.

(2) EDIT LOCK

When the EDIT LOCK is on, editing and storing

of part programs are inhibited.

2.60 AUTOMATIC COORDINATE SYSTEM

SEITING

With this function, a new coordinate system

having coordinate values set by parameters in

advance is automatically set up at the reference point after executing manual return to

reference point. The coordinate system

established by this function is equivalent to

the one set by G92.

7

Page 15

2.61 FEED HOLD

The feedhold function interrupts tool feed temporarily during automatic operations.

Feedhold operation is disregarded during

threading.

2.62 EMERGENCY STOP

This function makes all the commands ineffective.

The servo power supply is turned off, and all

moving members of the machine are stopped by

dynamic brake.

2.63 OVERTRAVEL

With this function, the tool motion is stopped

upon receipt of a stroke-end signal from the

machine. When the machine is stopped by this

function, the machine member must be moved

backward by manual feed.

REMOTE RESET

2.64

With this function, the NC is reset with an

external signal. When the NC is reset, all the

commands become ineffective, and tool motion is

stopped immediately.

2.65 REMOTE POWER ON/OFF

2.69 NC RESET OUTPUT SIGNAL

While RESET key or REMOTE RESET key is depressed, an NC reset signal is output to the

machine.

RS-232C INTERFACE

2.70

RS-232C interface is provided in order to connect

with tape puncher, external tape reader or other

external devices.

Interface Type

Communication Speed

Connector I DB-25S

Maximum Cable Length 15 m

outmt from Memorv Possible

Storage in Memory

Tape Mode Opertion Possible

Note :

The following are the data items which are

objects for output from memory and storage in memory.

Part program

(a)

Offset data, machine tool coordinate data, machine

(b)

tool abrasion data

(c)

Setting and parameter data

Serial Voltage Interface

110 to 4800 baud

I Possible

In addition to the POWER ON/OFF keys on the

NC Operatoris station, the control is provided

with input terminals for receiving remote power

onloff signals.

2.66 MACHINE READY INPUT SIGNAL

When the machine is ready for operation, this

signal is transmitted from machine to control.

When this signal is received with the control in

the “NC ready” condition, operation may be

started immediately.

When this signal drops off during operation,

IImachine errorll status occurs, and all the functions become ineffective.

2.67 NC READY OUTPUT SIGNAL

When the NC is correctly energized, and is

ready for control function, an “NC ready” signal

is output to the machine.

2.68 NC ALARM OUTPUT SIGNAL

When one or more alarm states are present, an

NC alarm signal is output to the machine. When

the cause is eliminated and the reset procedure

is followed, this signal is stopped.

2.71 ON-LINE DIAGNOSTICS

During operation, the following self-diagnoses are

made online:

(1) 3-digit Alarm Code and Alarm Message Display.

System

(2

System memory total check.

a.

b.

RAM check (when power is input).

Watchdog timer.

c.

Diagnosis

(3) Input /Output Signal Diagnosis

2.72 POSITION DETECTOR INTERFACE

Position detected by feedback signal from the

rotary-type pulse generator.

rotation of the pulse generator is varied by the

number of pulses from the pulse generator as

shown below.

Pulse

Generator

Metric

OutPut ] ~ooCI p/rev I 2, 3, 4, 6, 8 mm

5000 plrev

5000 plrev

Inch

output 6000 plrev

2.5, 5, 10

0.25, 0.5

0.2, 0.3, 0.4,

0.6. 0.8

The motion per

Motion per Rotation

of Pulse Generator

mm

in

in

8

Page 16

The motion per rotation of the pulse generator

of X-axis becomes one-half of the above values.

Note: Pulse multiplication can be set by servo

unit or NC.

2.73 lNPUT/OUTPUT CONNECTORS

The control is connected with the machine control

circuit via “Half pitch connectors. ”

(2) Relative humidity: 10 to 90% R. H.

(3) Vibration: 4.9 m/s2max

Note: When the ambient conditions do not con–

form to the above requirements, or when organic

solvent or other fumes are present in high concentration we offer special measures.

2.76 PAINT COLOR AND DIMENSIONS

2.74 POWER INPUT A

Standard input

200/220/230 VAC +10%, –15%, 3-phase, 50/60 Hz,

~1 Hz

2.75 AMBIENT CONDITIONS

Ambient temperature:

(1)

for operation: O°C to 45°C (32°F to 113QF)

for storage: -20°C to +65°C’ (-4°F to +149°F)

3 BASIC OPTIONS

The optimal servo components are available for

selection to meet the requirements of the machine

being controlled.

3.1 AC SERVO CONTROL UNITS

Transistorized PWM AC servo control units are

further miniaturized to be available for use in

either or the following systems:

(1) NC board built-in system: Free standing

type.

(2) External system: Supplied in unit.

Connection cable should be 10 m max.

Servo capacity is as follows:

Series Motor

No Maximum Continuous

11

2 60

3

4

5

6

F

Torque

kg . cm

30

90

120 CACR-SR20SB1 •l F

230 CACR-SR30SB1

380

SERVOPACK Type

\ CACR-SR05SB1

CACR-SRIOSB1

CACR-SR15SB1

CACR-SR44SB1

❑ F

❑ F

❑ F

❑ F

❑ F

(1) The following dimensions are available for the

selection to suit the machine to be controlled.

‘ Control unit

150 (W) X350 (H) X185 (D) mm

5.90 (W) X13.78 (H) X7.28 (D)

(2) Paint Color

o NC operator’s station: Munsell N1. 5 (gray)

“ Enclosure inner louter surface: Munsell

4Y7.7/l.2 (light gray)

3.2 AC SERVOMOTORS

The following AC servo motors that incorporate

the feedback unit, consisting of position-detecting

pulse generator ( PG ) and speed-detecting tacho-

meter generator (TG ).

No Maximum Continuous

* According to the type of detector, either A or B is

F Series Motor

Torque

kg . cm

1

2

3

4

5

6 380

entered in

A : 6000 p/rev

B : 5000 p/rev

30

60

90

120

230

❑l.

SERVOMOTOR Type

I

USAFED-06FO*

USAFED-09F ❑

USAFED-13F •1

USAFED-20F

USAFED-30F •1

USAFED-44F •1

❑

9

Page 17

4 OPTIONS

4.1 NC OPERATOR’S STATION

The separate stations are available

rations :

. Keyboard on right side of CRT

See Fig. A2.2.

. Keyboard below CRT

See Fig. A!Z3.

in three configu-

4.2 TAPE READER

The tape reader unit specified below can be provided

as an independent unit or incorporated in a freestanding cabinet. For connections of the tape reader, RS-232C interface is used.

. Read speed :

“ Reading system : LED-photoelectric

200 char. /see

4.3 TAPE READER WITH REELS

Free-standing type cabinets can be provided with

the following tape reader with reels. Tape reel

unit can be provided as an independent unit.

(1) 6-inch reel

Reel diameter:

Tape length:

(2) 8-inch reel

Reel diameter:

Tape length: 180 m (590 ft. )

150 mm (6 inches)

80 m (262 ft. )

200 mm (8 inches)

4.6 T4-DIGIT PROGRAMMING

Instead of the basic T 2-digit programming, tool

numbers can be programmed with 4 digits following the address T.

sponding 4-digit BCD code.

The control outputs corre-

4.7 ADDITIONAL OFFSET MEMORY

Basic offset memory capacity of 99 can be

expanded up to 1199.

4.8 ADDITIONAL PART PROGRAM STORAGE

Instead of the basic part program storage of tape

length 40 m (131 ft. ) the following are available.

1

11

21

31

Tave Length

80 m (262 ft. )

160 m (524 ft. )

320

m (1049 ft. )

4.9 ADDITIONAL PROGRAM NUMBER

REGISTRATION

Either of the following number of registrable

programs can be selected to replace the basic

number of 99.

The indicated tape lengths are for tapes with

0.108 mm (4 inches) thickness. The following

are common to both reader.

Read speed: 200 char. /see

Rewind speed: 200 char. /see

Reading system: LED photoelectric

4.4 F1-DIGIT COMMAND

With this function, feedrates can be programmed

by one digit following an address F (Fl through

F9).

through F9 are preset by parameters.

mm/min commands of the ordinary F-function

(direct designation of feedrates in mm/min) can-

not be used.

The actual feedrates corresponding to F1

When this function is adopted, 1 through 9

4.5 S5-DIGIT PROGRAMMING WITH

12-BIT OUTPUT

S 5-digit programming with 12-bit output S

5-digit programming analog output can replace

S 5-digit programming 12-bit output specification.

The output is made by 12-bit binary (4095

maximum) signal.

10

2

I

Note that if the optional ‘1additional program

number registration”

capacity for the part program is reduced by the

following amount.

Additional Number Reduced

of Registered Programs

199

999

999

is adopted, the storage

Storage Capacity

2 m (6.6 ft. )

18 m (59 ft. )

4.70 4TH AXIS CONTROL

Any one out of the three rotary axes A, B and

C and linear axes, U, V and W, can be

controlled as 4th axis in addition to the three

basic axes.

are possible.

.

Simultaneous controllable 4 axes:

Positioning (GoO, G06, G60)

Linear interpolation (GO1 )

Manual feed except by manual pulse generator

The following simultaneous controls

Page 18

.

Simultaneous controllable 2 axes:

Circular interpolation (G02, G03)

●

For linear 4th axis, stored stroke limit can

be set at 1st prohibit area only.

✎

Program Restart, User Macro, Stored Leadscrew Error Compensation are effective with

the 4th axis.

✎

Tool Length Compensation, Tool Compensation

C, High-~peed Cutting are ineffective ‘with the

4th axis.

4.11 MANUAL PULSE GENERATOR FOR ONE

AXIS AT A TIME

With the manual pulse generator, the machine

can be moved in response to the manual turning

of the pulse generator by handle.

The generator has a dial graduated into 100, and the

travel distance per graduation can be set to 1,

10 and 100 pulses. The controlled axes are

selected with the select switch, and the tool is

controlled only in the selected axial direction.

4.12 REFERENCE POINT RETURN

(G27, G28, G29)

AH of the following methods for returning the

tool to the reference point are possible.

(1) Manual return to reference point

After the ZERO RETURN switch is turned

on, the tool can be returned to the reference

point by manuztl operation. The approach speed

and the traverse distance are set by parameters,

RATIO TRAVERSE RATE

v

h---J-/

i

APPROACH SPEED 1

APPROACH SPEED 2

(3) Autcxmtic return to reference point (G28)

X... Y.. . Z.. . ;

G28

With this command, the tool first moves to the

specified intermediate position, and from there,

automatically returns to the reference point.

(4) Return from reference point (G29)

G29 X... Y... Z... ;

With this command, the tool starts from the re-

frence point, moves through the intermediate

point specified by G28 previously, and finally

moves to the position specified by G29.

(5) Rapid return to reference point

The manual and automatic reference point return

motions can be made in rapid return mode by

specif yin g in the specifications.

In this rapid

return mode, the tool does not follow the deceleration sequence started by decelerations LS, but

moves directly to the reference point as if the

tool were moving in the GOO positioning mode.

This rapid return mode becomes effective,

however, only after the tool has been once

returned to the reference point in all axes in

the

normal mode.

4.13 ;JD, AND 4TH REFERENCE POINT

G30Pn X,,. Y... Z.. .

With this command, the tool is returned to the

2nd, 3rd, or 4th reference point after position-

ing in the specified intermediate position.

P2 :

2nd reference point

P3 :

3rd reference point

P4 : 4th reference point

The reference points can be set by parameters.

; (Pn = P2, P3, and P4)

4.14 EXTERNAL DECELERATION

‘---~ZERO POINT SIGNA

(2) Reference point check (G27)

G27 X... Y... Z... ;

With this command, the programmed point is

checked for coincidence with the reference point.

If the programmed point does not coincide with

the reference zero point even in one axial direc–

tion, this is regarded as an error.

When an external deceleration limit switch is

tripped, the tool speed, both, rapid traverse and

feed, are reduced to the levels set by parameters.

This switch can be installed in both directions on

all axes.

TOOL LENGTH MEASUREMENT

4.t !5

With an actual tool mounted on the machine

spindle, the tip of the tool is brought to the

base position for the Z-axis by manual operation,

and RETRACT button is pushed.

Then, the

control executes the following operations:

(1) Automatic storing of the distance from the

home position in the Z-axis to the current position in the tool offset memory at the specified

tool offset number.

11

Page 19

4.15 TOOL LENGTHMEASUREMENT (Cont’d)

(Z) Increasing the tool offset number by “l” in

preparation for the next write operation.

(3) Returning the tool to the Z-axis home posi-

tion.

Note:

1, Instead of “moved distance, “ “remaining dis-

tancell can be stored by parameters.

2. Instead of pushing the RETRACT button, the

appropriate key on the NC Operator?s Station

may be depressed for tool length measurement.

The tool does not return to the home position.

W

MODE

DISTANCE

% T.

RETURN

[

a

HOME POSITION

BASE POSITION

4.19 PROGRAM COPY

G25

P,...,, Q,.l,,...I,... ,L

pl p2 ql q2

This command executes any

sequence p2 of program

program ql, L times.

the program one time.

the copied program. Nesting up to 4th level can

be applied.

During canned cycles, program copy

can be commanded.

.*.

;

program from

pi to sequence q2 of

Omission of L executes

G25 can be commanded in

4.20 HELlCAL INTERPOLATION (G02, G03)

Circular interpolation in any desired plane can

synchronously combined ‘with a linear inter-

be

polation perpendicular to the plane of circular

interpolation. For example, with G02 ( G03) X. . .

Y I.. . J... Z.. . F...

. . . ; , circular interpolation

in the XY plane is combined with linear interpolation in the Z–axis.

4.16 OPTIONAL BLOCK SKIP B

In addition to the ordinary block skip (programmed with

built into the control.

grammed with codes “ /2” through “ /9, ” and when

the respective switches are on, these blocks

are skipped.

H /II or fl / 1 II ) , !3 skip functions may be

These functions are pro-

4.17 2ND AUXILIARY FUNCTION (B-FUNCTION)

2nd auxiliary function command can be used with

three digits following address B.

outputs the corresponding 3-digit BCD code to

the machine.

Note:

the control, the B-axis for 4th axis or 5th axis

control cannot be adopted.

When this B function is incorporated in

The control

4s18 JOG FEEDRATE OVERRIDE

This function permits overrides in 21 steps of

10% per step within a range of O to 200% in

relation to the jog feedrate.

OVERRIDE switch serves as the FEEDRATE

OVERRIDE switch.

JOG FEEDRATE

Note:

Instead of I, J and K, arc center can be

1.

specified by radius R.

2. Helical interpolation is also possible with a

4th axis which is a linear axis.

3. Tool radius compensation C is effective only

on the circle projected on the plane of

circular motion.

4.21 CIRCLE CUTTING B (Gl 2, GI 3)

With this function, all the motions involved in

cutting a circle can be programmed in one block.

(1) Rapid approach distance designation R

G12 (G13) 1... R... D... F... ;

With this command, the circle cutting operation

shown below is executed.

distance is specified by R.

The rapid approach

12

Page 20

Y-AXIS

OOL

With this command, the tool moves along a spiral

path as shown below to cut a circle. For the

sake of simplicity, an imaginary tool with the

radius D = O is shown.

X-AXIS

Tool path

G12: 1—2—3—4—5—6

G13: 6—5—4—3—2—1

(D) indicates tool offset value specified.

G12 is for CW and G13 is for CCW.

I: radius of finished circle (with sign, incre-

mental)

R: rapid approach distance (with sign, incremental)

D: tool offset number

F: feedrate

(2) Automatic calculation of rapid approach dis-

tance

G12 (G13) I... J... D... F... ;

When the cutting depth is designated incrementally by the address J, instead of three distance

R, the rapid approach distance just short of the

tool contact point ot the stock surface is

automatically calculated.

Note:

Y-AXIS

This function incorporates the tool radius

G12: 1 *2-3-4-

A

w

5+6

INCREMENT OF

RADIUS

X-AXIS

K: RADIUS OF

FINISH CIRCLE

compensation function.

4.22 lNCH/METRIC DESIGNATION BY G CODE

With the following G codes, metric and inch input

system are selectively designated.

=

Y-AXIS

1

s

P

J : CUT

.—,

I

(3) Repetition of circular motion by L

G12 (G13) I.. D.. . J... L.. . F... ;

With this command, the circular motion is re–

peated L times.

(4) Spiral circular cutting by Q and

G12 (G13 ) I.. . D.. . J.. . K.. . Q.. . L... F... ;

K

These G codes are written at the beginning of a

program in a single block.

Note:

1. G20 and G21 commands rewrite inch/metric

selecting parameter.

of G20 or G21 at power switch-on time depends

on the parameter.

2. The inch/metric selection by parameter set-

ting is a basic function.

Therefore, the condition

4.23 UNIDIRECTIONAL APPROACH (G60)

G60 X... Y... z.. . ;

With this command, the tool is brought to the

specified position. However, in the direction

specified by parameter only the tool first over-

runs and returns to the specified position.

The

overrun distance is set by parameters.

This G60 command is effective to stop the tool

with high accuracy.

13

Page 21

4.24 WORK COORDINATE SYSTEM SETTING A

(G52 TO G59)

With this function, tool motion can be programmed in the following coordinate system, in addition to the basic coordinate system set up by the

G92 command.

4.26 TOOL RADIUS COMPENSATION C

(G40 TO G42)

This function is for automatically offsetting the

tool path to the right or to the left of the programmed path by a distance equal to the radius

of the tool used.

(1) When any of the G codes from G54 through

G59 is programmed, a new coordinate system

which is shifted from the basic coordinate system

by a preset amount for the selected G code is

established.

system is referred to as a work coordinate

system, and thereafter, the tool is controlled on

the work coordinate system.

coordinate systems can be set up for use.

(Z) Return to the basic coordinate system ( G52)

G52 ;

With this command, the current work coordinate

system is can celled, and the basic coordinate

system is re-established.

(3) Temporary shift to machine coordinate sys-

tem (G53)

During the execution of programs on a work

coordinate system or on the basic coordinate sys–

tern, the tool may temporarily be shifted to the

position (X,

system with a command G53 GOO X.. . Y.. . Z.. . ;.

G53 is a non-modal G code. The machine coordinate system is one in which the origin is the reference point.

This newly established coordinate

Up to 6 work

Y, Z) on the machine coordinate

Yw

YM

I

(1) The meaning of these G codes is as follows.

G Code ! Meaninz

G40

G41

G42

Note: When power is applied or the control is

reset, the control is in the state of G code

marked with 1 .

TOOL

(2) D code for tool radius designation

Tool offset numbers are specified by two digits

following address

values are stored in the tool offset memory corresponding to these tool offset numbers.

maximum tool radius that can be set is as

follows :

+999.999 mm

?99. 9999 in.

Cancel tool radius compensation

7

Tool radius compensation , left

I Tool radius compensation, right

G40

G41

/’

\’ \

\\

/“. - “,

G42

‘\

%

b

CENTER

The actual tool radius

D.

PROGRAM

COMMAND

The

-x.

1)

BASE COORDINATE SYSTEM

(

)

ABSOLUTE ZERO POINT

4.25 WORK COORDINATE SYSTEM SETTING B

(G54J TO G59J)

This is the expansion function of work coordinate

system setting A. Up to 30 types of work coordinate

systems can be set with expansion of the work coordinate systems of specification A (6 types) by using

commands J1 to J5 at the same time as G54 to G59.

The five axes X, Y, Z, a, L?can be set since G54 to

G59 and G54J1 to G59J1 are the same. In com-

mands J2 to J5, only three axes (X, Y, Z) can be set

but the 4th axis cannot be set. The other functions

are the same as work coordinate system setting A.

14

TOOL

—-

‘)

/

/’

i??

/

M96 MODE M97 MODE

(CIRCULAR ARC)

%7

/

(CALCULATION

OF INTERSECTION)

—

,/’

/

Page 22

4,27 OUTPUT FOR EXTERNAL MOTION

(G80, G81)

G81 X... Y... L... ;

With this command, the control outputs an exter-

nal motion signal to the machine.

The L digit

specifies the number of repeated positioning

motions. G81 is modal, and remains effective on

all the motion commands until it is cancelled by

G80. G81 may selectively be used for this function or for the canned cycle 1 depending on parameter setting.

4.28 CANNED CYCLES

(G73, G74, G76, G77, G80 TO G89)

Canned cycles are simplified programs for specific

sequential movements covering several blocks by single-

block commands. The following 13 canned cycles are

available. G80 is for canceling these canned cycles.

G

Code

Plunging

G73

Wwd-

pecker _

feed deep hole

Feed Spindle

G74

Feed Spindle

G76

G77

Spindle

Orientation+

shift+

Rapid

traverse

+Shift

+Feed

G8 O

G81

At Hole

Bottom

forward

running after

after

dwell

Orientation+

Shift

>well

Retrac- Appli-

Rapid High

traverse

Spindle

reversing

feed

Rapid Boring

traverse

+Shift ,

spindle

start

Rapid

traverse

+Spindle

orientation

—

Shift+

Rapid

traverse

+Shlft

tion

cation

speed

drilling

Reverse

tapping

Back

boring

G82 Feed

G83 Wood-

pecker

feed

G84 Feed

Feed

G85

G86

Feed

Feed Spindle

G87

Feed

G88

Feed

G89

Dwell

Spindle Spindle

reversing forward

after - running

dwell

Spindle

stop

stop

Spindle

stop

after

dwell

Dwell

Rapid

traverse

—

—

Rapid

traverse

after feed

Feed

Rapid Boring

traverse

+Spin dle

start

Manual Boring

retraction

+Spindle

start

Manual

retraction

+Spindle

start

Feed Boring

spot

facing

Deep hole

drilling

Tapping

Boring

Boring

15

Page 23

4.28 CANNED CYCLES (G73, G74, G76, G77, G80 TO G89) (Cent’d)

Command Format

~G code for canned cycles

cd

.*.

x

.

,*.

Yt. .. J

o..

—.

F

LL

Dwell at hole bottom

——Point R coordinate command

— Point Z coordinate command

—hilling position X,

Q

START

POINT

Operations 1 through 4 are executed in one cycle

with the commands shown above.

@ Positioning the drill (position X, Y)

@ Rapid traverse to print R

@ Drilling to point Z

@ Return to point R or to initial point

‘-17 ~

~1~4

3,

k

/

INITIAL POINT

POINT R

POINT Z

(HOLE BOTTOM)

Y coordinate command

~Cutting feedrate

L

No. of

Drilling pitch

The number of repetitions is specified by the

address L, and when no number is specified, the

cycle is executed only once.

grammed, only positioning to (X, Y) is exe- cuted.

The shift direction is G76 and G77 can be

specified at any angle by parameters.

turn position in the Z-axis direction after execuing canned cycles can be specified by the following G codes.

repetitions

for G73, G83 Shift for G76, G77

When L = O is pro-

The re-

16

Note: When power is

applied or the control is

reset, the control is in

the state marked with

1.

Page 24

With G99 ( return to R)

With G98 ( return to initial point)

G73

Fixed

(

pitch )

High

speed

deep

hole

drilling

G73

Variable)

(

High

speed

deep

hoie

drilling

G73 X... Y.. . Z.. . R.. . Q.. . L.. .

c1

t:

Setting data

G73 X... Y.. . Z.. . R.. . 1.. . J,. .

c1

Setting data

(x,Y)

--7

I

R

Q

Q

Q

“&

(x,Y)

‘-Y I : Initial value

I-J

I-2J

m

K

8

1

81

i!

k

i J : Reducing value

K: Final value

J

1’

JI

I

I

L

z

R

z

F,. . ;

---

Q -~

J : Setting data

(.. . L.. . F.. . ;

I-2J

J : Setting data

(x,Y)

!

IR

d

I

I-J

*I

I

‘E

K

1

INITIAL

POINT

R

z

z

G74

Reverse

tapping

—

G74 X... Y.. . Z.. . R.. . P.. . L.. .

c1

SPINDLE FORWARD

AFTER DWELL

(x,Y)

---5’

I

E

/

/R

SPINOLE

REVERSE

z

F.. . ;

0

SPINDLE FOiWARD

AFTER DWELL

(x,Y)

‘- —’~POINT

D

START

11

SPINDLE

REVERSE

/’

R

z

17

Page 25

4.28 CANNED CYCLES (G73, G74, G76, G77, G80 TO G89) (Cent’d)

G76

Boring

G77

Back

boring

With G99 (return to R)

G76 X.., Y.. . Z.. . R.. . Q.. . L.. .

---?

(x,Y)

h

SPINDLE

START

‘/

-R

r

q&---z

Q

SPINDLE

INDEXING STOP Q

G77 X,.. Y... Z... R.. . Q.. . L.. .

NOT USED

1

F.. . ;

With G98 (return to initial point)

SPINDLE

START

(x,Y)

Q

SPINDLE

INDEXING

STOP

CJ

___

/

(x,Y)-–-,

-—

DWELL [ j

I

~

---l--+

+&----

---1

Q

s;,~

r

I

I

II

II

INITIAL

POINT

INITIAL

POINT

z

G80

Cancel

G81

Drilling

G80 ;

G81 X... Y.. . Z.. . R.. . L.. . F.. .

--?

(x,Y)

I

II

R

z

Q

~

SPINDLE

ORIENTATION - spl NDLE

-L

.—

0

R

START

Page 26

G 82

Tapping

With G99 ( return to R)

G82 X... Y... Z... R.. . P.. . L.. .

(x,Y)

Q

---7

I

I

DWELL ( P)

With G98 ( return to initial point)

.

R

z

“r

DWELL ( P)

G 83

Boring

G 83

Boring

G83 X... Y... Z... R.. . L.. . F.

Q

J Setting data

(x,Y)

--~

t-i-z

G83X, .. Y,., Z... R.. . L.. . F.. . ;

(2

(x,Y)

‘-~ I : Initial value

; J Reducing value

~ K Final

I

1-

V~Iu~

m

(x! Y)

—.

u

Q

Q

Q

@

8: Setting data

(x:Y)

-—

Q

,1

I-J

I-2J

INITIAL

T

i

I

1 [,1

1

l!

I

POINT

!

I

I

R

,1

I

&

II

rs

8

I

t-Lz

Y

I

I

INITIAL

POINT

I

I

R

f

J

J

d : Setting data

u--z

$: Setting data

L.. -,

Page 27

4.28 CANNED CYCLES (G73, G74, G76, G77, G80 TO G89) (Cent’d)

G 84

Tapping

G85

Boring

With G99 ( return to R)

G84 X... Y... Z... R.. . P.. . L. ..’

(x,Y)

c!

-~

SPINDLE REVERSE

AFTER DWELL

G85 X... Y... Z... R.. . L.. . F.. .

Q

E

(x,Y

--~

SPINDLE

FORWARD

/

R

z

F.. . :

With G98 ( return to initial point)

(x,Y)

--7- POINT

Q

SPINDLE REVERSE

AFTER OWELL

C2

(x,Y)

‘-”—~r POINT

INITIAL

INITIAL

G86

Boring

i

II

G86 X... Y... Z...

c1

SPINDLE STOP

(x,Y)

--~

‘ /s’:’

L

R

z

R.. . L.. . F

SPIN DLE

I

z

Q+’ (

/’z

SPINDLE STOP

I

II

II

I

I

I

I

L

R

z

SPINDLE

START

INITIAL

POINT

R

20

Page 28

With G99 ( return to R)

With G98 ( return to initial point)

G87

Boring

G88

Boring

G87 X... Y... Z... R.. . Q.. . L.. . F.. . ;

(x, Y)

C2

‘-~ SPINDLE

I

START

/,

MANUAL

~ RETRACTION

II

SPINDLE STOP

G88 X... Y... Z... FL.. P.. . L..

Q

SPINOLE STOP

AFTER DWELL ( P )

/=

(x, Y)

----9

I

‘ / ;TART

1--1-

L-L

/’

F,, . ;

SPINOLE

MANUAL

z RETRACTION

Q ‘x’: ,/::L

II

F-

I.i

SPINDLE STOP

(y:;) ,/::L

SPINDLE STOP

AFTER OWELL ( P )

/’

II

E

SPINDLE

POINT

I

R

I

MANUAL

lZRETRACTION

SPINDLE

POINT

IR

I

MANUAL

‘ ~ RETRACTION,

z

G89

Boring

G89 X,.. Y... Z... R.. . P.. . L.. .

(x, Y)

Q

--~

I

R

II

/=

DWELL (P)

F.. . ;

Q

––~

DWELL ( P)

(x, Y)

/

I

I

INITIAL

— START

—R

—z

21

Page 29

4.29 HOLE PATTERN CYCLES (G70, G71 , G72)

4.30 SCALING FUNCTION

This function,

cycles, permits simple drilling of holes in

specific position patterns. G70, G71 and G72

automatically calculate the hole locations in

specific patterns using the auto-programming

technique.

(1) Bolt hole circle (G70)

G70 X... Y... I... J.. . L... ;

This command specifies the locations equally

dividing the circumference into L parts.

START POINT, ‘ ,

used in combination with canned

‘2

I L: NO. OF CIRCLE

6-1

END POINT

5

CENTER (x, Y)

INDEXES

Y d4

i

*

3

#r -–

/

x

-+-

(2) Arc (G71)

G71 X... Y... I... J... K... L... ;

This command specifies L locations on an arc.

With this function, geometrical shapes specified

by part programs can be enlarged or reduced in

any desired ratio.

(1) G511... J... K... P... ;

With this command, the program is executed on

an enlarged or reduced stale with the scale ratio

specified by P, and the center of scaling specified by I, J, and K.

(2) G50: Command cancels the scaling mode.,

(3) The enlarging and reducing scales can be

selected within the following range.

Enlarging and reducing range: 0.000001 -

99.999999

PROGRAM COMMAND

Y

SCALE PATCH

M

t--x CENTER(”‘)

END

POINT 4=L3

IK

/’

/’

w

d

START-

POINT

(3) Line-at-angle (G72)

This command specifies L locations on any

straight line.

Note: When executing drilling cycles with G70

to G72, the canned cycle with- L “= O (G73, G76,

G77, G81 to G89) should in principle be pro-