Page 1

Spindle Orientation

Document Name Document Revised Software number Part Number

TM.G5SW.021 07/01/2004 VSG114743 CIMR-G5MXXXXXF-021

A Yaskawa GPD515/G5 AC drive flashed with this software has the ability to control the stopped orientation of the

driven machine. Orientation is achieved by means of feedback from a position encoder directly coupled to the device to

be positioned. The targeted applications are for equipment that must stop in specific positions during the processing

cycle of an operation. Drive enhancements include a definable home position and 15 additional positions relative to

home that can be sequenced automatically or selected through multi-function inputs. A special serial register that does

not require accept or enter commands is provided to enable dynamic control of the stopped position via serial

communications. Drive sequence (start/stop) can come from the terminals (2 or 3 wire control), MODBUS serial

communications, or option board based serial communications (DeviceNet, Profibus, Modbus Plus, etc.). The spindle

orient function will not work in local mode or if the run command source is operator (B1-02 = 0).

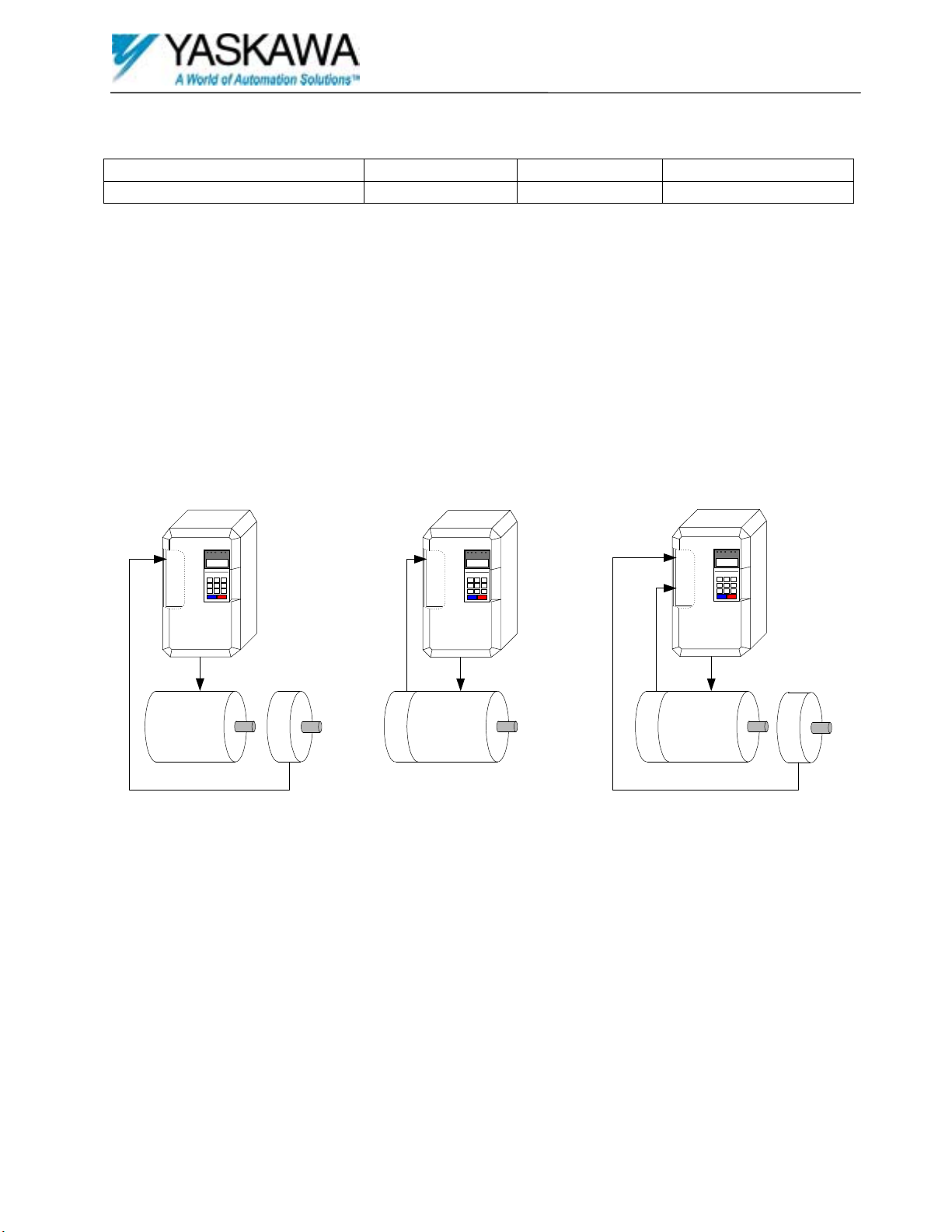

Supported Configurations

Open Loop Control

With Position Encoder

Closed Loop Control

Closed Loop Control

With Position Encoder

PG-X2

Machine

Motor

Position

Encoder

PG-X2

Machine

Motor

Encoder

Motor / Position

PG-W2

Machine

Motor

Motor

Encoder

Position

Encoder

Date: 07/01/04, Rev: 04-07 Page 1 of 14 TM.G5SW.021

Page 2

Spindle Orientation

Open Loop Control with Position Encoder

The open loop control method may be used when the motor and the device to be positioned are connected through a

drivetrain with a constant ratio. Feedback into a PG option card from the position encoder attached to the device being

positioned is required.

Closed Loop Control

The closed loop control method may be used for better speed control and positioning characteristics when the drive

motor directly drives the device being positioned.

When using this method the motor encoder is used for positioning.

Closed Loop Control with Position Encoder

Closed loop control may be used when the motor and the device to be positioned are connected through a drivetrain with

a constant ratio. Feedback from an encoder attached to the device being positioned is required. This method will

provide better performance than the open loop method.

Date: 07/01/04, Rev: 04-07 Page 2 of 14 TM.G5SW.021

Page 3

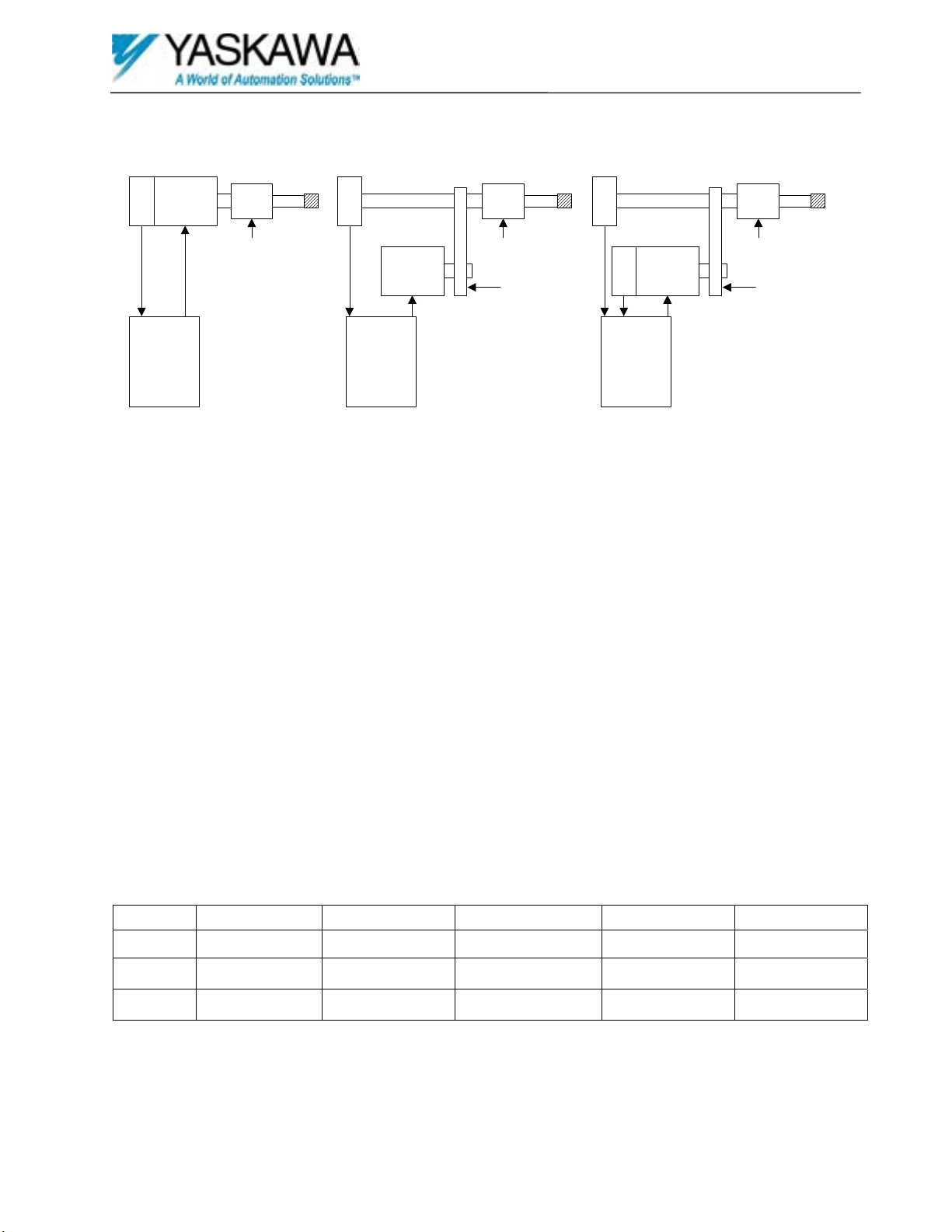

Example Applications

Example 1 Example 2 Example 3

Spindle Orientation

Encoder

Yaskawa

Drive with

PG-X2

Option Card

Motor

Tool

Tool

Chuck

Positioned Device Positioned Device Positioned Device

Encoder

Yaskawa

Drive with

PG-X2

Option Card

Motor

Tool

Chuck

Drivetrain

(Gear Ratio)

ToolSpindle Shaft

Encoder

Encoder

Yaskawa

Drive with

PG-W2

Option Card

Motor

Tool

Chuck

Drivetrain

(Gear Ratio)

ToolSpi ndle Shaft

These examples show typical applications. In these examples the encoder Z or marker pulse is used to indicate the zero

or marker position. An external switch may be used as the marker pulse to indicate this position.

Example 1

This is a direct drive system where the encoder, motor and spindle shafts are directly coupled. This system can use the

motor’s encoder for positioning and closed loop vector control of the motor to provide the best performance.

Example 2

This is an indirect drive system where the motor and the spindle shaft are connected through a drive train. The motor

and spindle speeds must have a constant ratio between them. The ratio must be entered into the drive using the provided

ratio parameters. The position encoder is coupled to the spindle shaft. Since there is no motor encoder the drive must be

set to open loop vector control. This configuration will not provide the performance of a closed loop system.

Example 3

This is an indirect drive system where the motor and the spindle shaft are connected through a drive train. The motor

and spindle speeds must have a constant ratio between them. The ratio must be entered into the drive using the provided

ratio parameters. The position encoder is coupled to the spindle shaft. The motor encoder allows for closed loop vector

control. This method will provide the best indirect positioning performance.

Required Components

The application will dictate the required configuration. The configuration will dictate the components needed. The

following table can be used to determine the components needed based on the configurations from the example.

Example Yaskawa Drive Software PG option card Position Encoder Motor Encoder

1 G5 / GPD515 VSG11474X PG-X2 512 to 2048 PPR Not Required

2 G5 / GPD515 VSG11474X PG-X2 512 to 2048 PPR Not Required

3 G5 / GPD515 VSG11474X PG-W2 512 to 2048 PPR 512 to 2048 PPR

All encoders must be quadrature encoders. The position encoder must have a Z pulse or an external switch must be used

to locate the marker position. DO NOT USE PARAMETER F1-05 TO CHANGE ENCODER PHASING WITH

THIS SOFTWARE. PLEASE SWAP ENCODER SIGNALS A+ AND A- INSTEAD.

Date: 07/01/04, Rev: 04-07 Page 3 of 14 TM.G5SW.021

Page 4

Spindle Orientation

How it Works

The function of this software is to provide the ability to orient the position encoder and any device connected to it to any

position within the PPR (pulses per revolution) resolution. This requires the position encoder to be directly coupled to

the device to be positioned, which is driven by the drive flashed with VSG11474X software. The position encoder must

also be connected to the drive via a PG option card.

This software has no effect on the normal drive functions and a drive flashed with it can be configured to operate as a

standard drive with a standard software flash. The software is only active when the orient input has been energized.

When that occurs the offset value is read and the drive will accelerate or decelerate to the threshold frequency. The

threshold frequency is determined by 4096 x P1-07: Stop Frequency Gain. If the output frequency of the drive is below

the threshold frequency the drive will accelerate at the rate controlled by C1-01: Accel Time 1. If the output frequency

is above the threshold frequency the drive will begin to decelerate at the rate controlled by C1-02: Decel Time 1. The

drive’s output frequency is monitored. When the output frequency is equal to the threshold frequency the PG card’s Z

pulse is monitored. When a Z pulse is detected the marker position is set and this software begins to orient the position

encoder. The output frequency is dynamically reduced as the position encoder nears the orient position. The orient

position is equal to the marker position plus any additional offset. When the position encoder is within the number of

counts set in P1-05: Position Count of the orient position the output frequency will be set to P1-04: Position Speed. The

drive will maintain this output frequency until the position encoder is within the number of counts set in P1-06: Stop

Count of the orient position where it will stop and zero servo until the orient input or the run input is de-energized. The

orient position maintained will be +/- the counts set in P1-06: Stop Count of the set orient position. This provides a

method to prevent oscillation while the position is being maintained. When this position has been acquired the orient

complete output will activate. If the run input is de-energized while the orient input remains energized the drive will

resume operation where it stopped when the run input is re-energized. The orient complete output will de-activate when

the orient input is de-energized.

The drive will orient the position encoder within two revolutions after the marker position has been set. Revolutions

may be added when needed by incrementing the marker offset value by the quadrature pulse count of the position

encoder. The maximum offset count value is 32767. If you are using a 1024 PPR position encoder the quadrature count

will be 1024 PPR x 4 or 4096 counts per revolution. Using this position encoder, for each 4096 counts added to the

offset the drive will require an additional revolution to orient.

All orientation is done relative to the marker position. The Z pulse from the position encoder or an external-switch

device is required to identify the marker position. P1- 03: Marker Offset parameter is provided to adjust the marker

position to the required or home position. All subsequent offset positions are relative to the home position. The stop

position or orient position is equal to the marker-offset or home position plus the current offset.

To set P1- 03: Marker Offset and identify the home position it is necessary to run the drive and perform an orient by

energizing the orient input. After the drive has stopped and holding position de-energize the run and orient inputs. The

device connected to the position encoder may be rotated into the required or the desired home position. This operation

may be done by hand or by reducing the frequency reference to the drive and using the run inputs to jog the device into

position. When the device is in position the value shown at monitor U1-50: Marker Offset must be entered into P1- 03:

Marker Offset. Monitor U1-50: Marker Offset contains the number of counts past the marker position that the position

encoder has rotated. It is a rolling counter and will restart at zero after the count has exceeded P1-02: Spindle PPR x 4.

(Rolling counter range = 0 to quadrature count –1)

There are four orient control selections. Parameter P1-10: Control Select can be used to select from the following.

0 – Marker Offset – The drive will only use P1- 03: Marker Offset as the orient position when the orient input is

energized. This is the home position.

1 – Sequenced Offset – The drive will automatically increment to the next sequence offset when the orient input is

energized. Parameters P2-01: Offset 1 to P3-05: Offset 15 are used to set the sequence offset values. These

parameters provide 15-sequenced steps. Each step can contain an offset value. When the offset value read is 0 the

sequence step will reset to 0, which is the home position. A sequence-reset input is provided and will reset the step

to 0 or the home position when energized. A home position multifunction output will activate when the sequence is

Date: 07/01/04, Rev: 04-07 Page 4 of 14 TM.G5SW.021

Page 5

Spindle Orientation

at the home position. After the sequence-reset has reset the sequence step to 0 the next orient input will increment it

to 1 pointing to offset value stored at P2-01 as the first step.

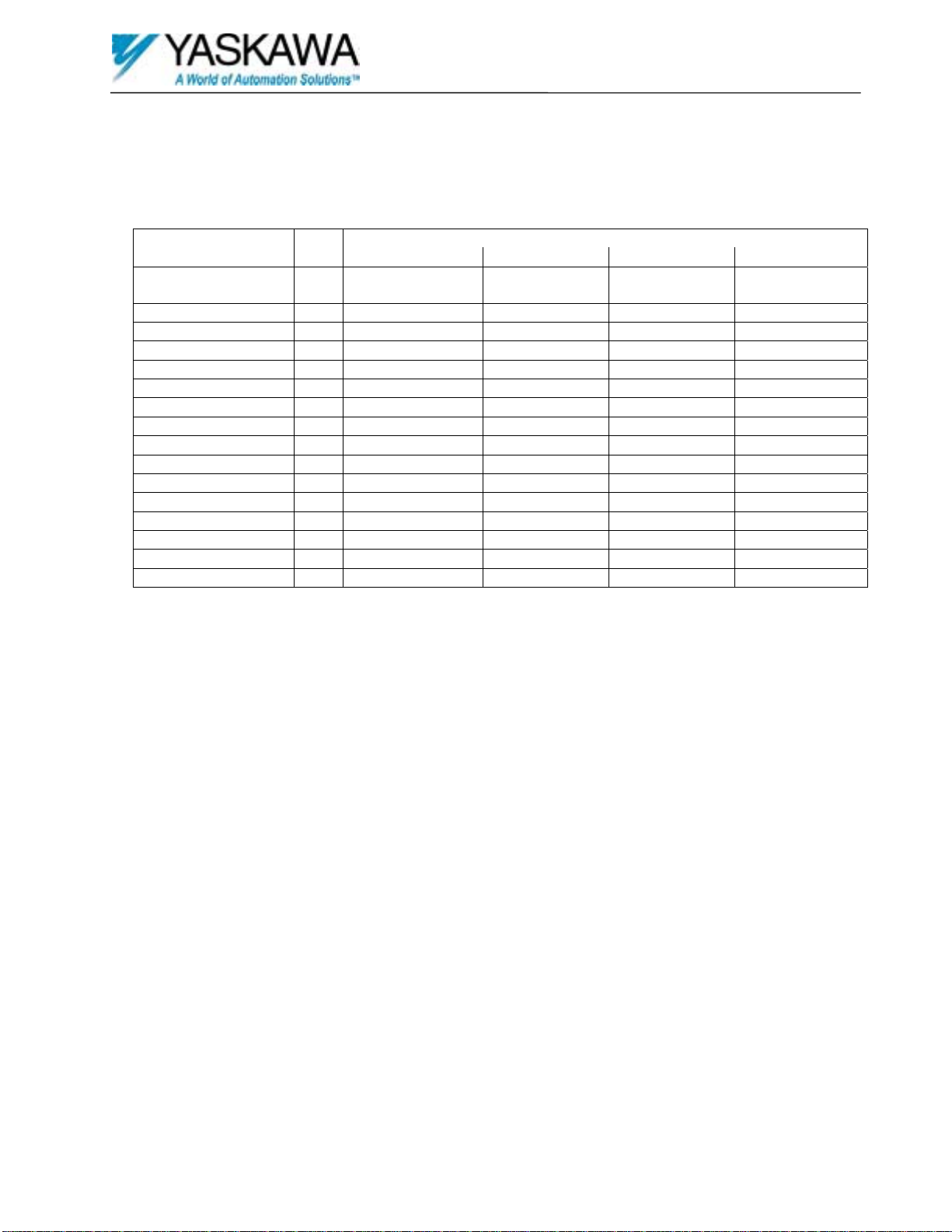

2 – Selected Offset – The offset value to be used can be selected via multifunction inputs. The following selection table

will illustrate how steps can be selected.

Selection Table

Number

P1-03: Marker

Step

84: Select MSB 4 85: Select Bit 3 86: Select Bit 2 87: Select LSB 1

0 Off Off Off Off

Offset

P2-01: Offset 1 1 Off Off Off

P2-02: Offset 2 2 Off Off

P2-03: Offset 3 3 Off Off

P2-04: Offset 4 4 Off

P2-05: Offset 5 5 Off

P2-06: Offset 6 6 Off

P2-07: Offset 7 7 Off

P2-08: Offset 8 8

P2-09: Offset 9 9

P2-10: Offset 10 10

P3-01: Offset 11 11

P3-02: Offset 12 12

P3-03: Offset 13 13

P3-04: Offset 14 14

P3-05: Offset 15 15

On

On

On

On

On On

On On

On On On

On On On On

To select step 6 requires multifunction inputs 85: Select 3 and 86: Select 2 to be energized. Multifunction inputs

84:Select MSB 4 and 87: Select LSB 1 must be off or de-energized. The sequence steps are bit mapped to the

multifunction inputs. If the 4 inputs are read as a 4 bit binary number its decimal equivalent is the sequence step.

The selection can be made anytime prior to energizing the orient input. Changing the selection while the orient input

is energized will have no affect until the next orient input.

3 – Serial Offset – The offset value will be read from U1-59: Serial Offset. U1-59: Serial Offset can be written to via

serial communications. The serial offset can be written to anytime prior to energizing the orient input. Changing the

serial offset while the orient input is energized will have no affect until the next orient input. U1-58: Sequence Step

will be set to 99 when this method is used and the serial offset is greater than 0.

The value of the offset entered into an offset parameter is controlled by P3-06: Count or Degree. P1- 03: Marker Offset

is not affected by this parameter and always remains as a count value. P3-06: Count or Degree has the following

selections.

0 – Count – The value entered into the offset parameters are in quadrature encoder counts. (PPR x 4) The number of

counts entered will be used as the offset. This can result in more than one revolution during an orient since 32767

counts can be entered.

1 – Degree – The value entered into the offset parameters are in degrees ranging from 0 to 360 degrees. If the value

entered is greater than 360 it will be reduced to then equivalent position within one revolution. (380 = 20)

All offset counts are measured in the counter-clockwise direction facing the position encoder shaft. All offset degrees

are measured in the clock-wise direction. Because of this increasing the offset count will result in the orient position

moving counter-clockwise and increasing offset degrees will result in the orient position moving clockwise. Either

selection provides for absolute orientation regardless of running direction. If the position encoder’s PPR is 1024, the

marker offset places the home position at 12 o’clock and the offset value is 1024 counts the position encoder will orient

at 1024 counts counter-clockwise past the home position. This is the 9 o’clock position. If the home position is set to

12 o’clock and the offset value is 270 degrees the orient position will be at the 9 o’clock position. Both these statements

are true regardless of running direction.

Multifunction Inputs Parameter

On

On

Off

On On

On

On

On On

Off Off

Off

On

Off

On On On

Off Off Off

Off Off

Off

Off

On

On On

On

Off

Off Off

Off

On

Off

Date: 07/01/04, Rev: 04-07 Page 5 of 14 TM.G5SW.021

Page 6

Wiring

Speed Ref

Open Loop Control

GPD515/G5

L1

Flashed with

L2

L3

G114741 Software

1 FWD Run

2 REV Run

3 Orient

4 Reset

5 MSBit 4

6 Bit 3

7 Bit 2

8 LSBit 1

11 Common

12 GND

13 Input 0-10V

14 Input 4-20mA

15 Supply +15V@20mA

16 Input 0-10V

17 Supply Common

33 Supply -15V@20mA

9

10

18

19

20

25

26

27

23 Analog Output +/- 10 VDC

24 Analog Output +/- 10 VDC

25 Analog Output Comm on

40: Orientated

41: Home Position

Spindle Orientation

Flux Vector Control

Motor/Position

T1

T2

T3

MGL

Red 5-15VDC

1

Black Common

2

3

Blue +A

4

Gray -A

5

Green +B

6

Yellow -B

7

Orange +Z

8

Violet -Z

9

1

2

3

TA2 TA1 (Channel 1)

4

PG-X2 Option Card

5

6

Shield

TA3

Marker

Switch

IM

Motor

Position

Encoder

T1

T2

T3

MGL

PG-W2 Option Card

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Red 5-15VDC

Black Common

Blue +A

Gray -A

Green +B

Yellow -B

Orange +Z

Violet -Z

Marker

Switch

IM

Motor

Encoder

Flux Vector Control

with Position Encoder

T1

T2

T3

MGL

Red 5-15VDC

1

Black Common

2

Blue +A

3

Gray -A

4

Green +B

5

Yellow -B

6

7

8

9

Blue +A

10

Gray -A

11

Green +B

12

Yellow -B

13

Orange +Z

14

Violet -Z

15

16

17

PG-W2 Option Card

18

19

20

Position Encoder - Requires an external

21

22

23

24

power supply

IM

Motor

Motor

Encoder

Marker

Switch

Position

Encoder

Using a Switch for the Marker

The PG option card’s Z pulse inputs require a line driver type output. A line driver output will toggle the +Z and –Z

inputs from +5-12 VDC on the +Z input and –5 to 12 VDC on the –Z input to –5-12 VDC on the +Z input and +5-12

VDC on the –Z input. This transition constitutes a pulse. The following diagram shows how conventional sourcing or

sinking switches can be used to trigger the marker pulse. The switch should be powered by an external power supply.

SinkingSourcing

Switch

+Z Input

-Z Input +12 vdc

+Z Input

-Z Input -Z Input

Switch

1K 1/8 W

1K 1/8 W

- Com

+Z Input

-Z Input

+Z Input

Switch

1K 1/8 W

1K 1/8 W

Switch

- Com

+12 vdc

Marker

Pulse

Marker

Pulse

Date: 07/01/04, Rev: 04-07 Page 6 of 14 TM.G5SW.021

Page 7

Spindle Orientation

Special Programming Notes

This software document is only a supplement to the Magnetek GPD515 instruction manual. All parameters and features

not mentioned in this document are not changed.

New Constant Default Settings

Group C Tuning – Function C2 S-Curve Acc/Dec

C2-01 = 0

C2-02 = 0

C2-03 = 0

Group H Terminal

H1-01 = 80: Orient

H1-02 = 81: Reset to Home

H1-03 = 84: Select MSB 4

H1-04 = 85: Select Bit 3

H1-05 = 86: Select Bit 2

H1-06 = 87: Select LSB 1

Group H Terminal

H2-02 = 40: Orient Complete

H2-03 = 41: Home Position

New Multi-Function Digital Input Settings

For Constants H-01 through H-06

Setting Display Description

80 Orient Causes the drive to orient the position encoder to the current offset

81 Reset to Home Resets the current offset to the home position (P1-03: Marker Offset)

84 Select MSB 4 Most Significant Bit 4 of the Select bit map (decimal value = 8)

85 Select Bit 3 Bit 3 of the Select bit map (decimal value = 4)

86 Select Bit 2 Bit 2 of the Select bit map (decimal value = 2)

87 Select LSB 1 Least Significant Bit 1 of the Select bit map (decimal value = 1)

New Multi-Function Digital Output Settings

For Constants F5-01 & 02 and H2-01 through H2-03

Setting Display Description

40 Orient Complete Activates when the orientation command is complete

41 Home Position Activates when the sequence step is 0 or the home position

– Function H1 Digital Inputs

– Function H2 Digital Outputs

Date: 07/01/04, Rev: 04-07 Page 7 of 14 TM.G5SW.021

Page 8

New Parameters

New Program Group

Group P

Spindle Orientation

Orient Constants

New Program Group Functions

Function P1

Orient Settings

Function P2

Seq Offset 1-10

Function P3

Seq Offset 11-15

New Program Group Function P1

PG Channel

Channel 1

P1-01 PG Channel

Either channel 1 or 2 may be used for positioning. Set this to the channel that is connected to the positioning encoder.

When a PG-X2 option card is used this setting must be 1. Channel 2 is only available with a PG-W2 option card. DO

NOT USE PARAMETER F1-05 TO CHANGE ENCODER PHASING IN THIS SOFTWARE. PLEASE SWAP

ENCODER SIGNALS A+ AND A- INSTEAD.

Pos. Encoder PPR

P1-02= 1024 PPR

P1-02 Position Encoder Pulses Per Revolution

The position encoder PPR is the actual pulse resolution or single output PPR of the position encoder used. The

quadrature pulse rate will be 4x this rate. 1024 PPR = 1024 x 4 or 4096 quadrature pulses per revolution.

Setting Range: 0 or 1

Factory Default: 0

MODBUS Address: 0x580

Q Q Q Q

Setting Range: 1 to 32767 PPR

Factory Default: 1024 PPR

MODBUS Address: 0x581

Q Q Q Q

Date: 07/01/04, Rev: 04-07 Page 8 of 14 TM.G5SW.021

Page 9

Spindle Orientation

Marker Offset

P1-03= 0

P1-03 Orient offset distance

The marker offset contains the number of quadrature pulses or counts offset past the marker position that the shaft will

travel before stopping at the orient position. When this value is 0 the shaft will stop at the marker position. The desired

value may be found by running the drive and energizing the orient input. When the drive stops de-energize the run and

orient inputs. Rotate the shaft to the desired position by hand or by jogging the drive using the run inputs. Read the

value of U1-50: Marker Offset and enter it here.

The value of U1-50 is a rolling counter ranging from 0 to the number of quadrature counts per revolution. The direction

of rotation is irrelevant. The value indicates an absolute position to the marker position and is the same in either

direction.

This value may also be used to add counts to the positioning algorithm. Adding the number of positioning encoder

quadrature counts per revolution increases the stopping distance by one revolution.

Position Speed

P1-04= 0.10 HZ

P1-04 Position Speed

The position speed is the minimum speed that may be used during positioning. This speed is also used when the shaft is

within the number of quadrature counts set in P1-05: Position Count of the orient position. If this speed is set to high the

drive will oscillate when trying to hold the orient position. The positioning algorithm will decrease the speed until zero

speed is reached at the orient position or this speed is reached and maintained until the orient position.

Setting Range: 0 to 32767

Factory Default: 0

MODBUS Address: 0x582

Q Q Q Q

Setting Range: 0.00 to 10.00 HZ

Factory Default: 0.10 HZ

MODBUS Address: 0x583

Q Q Q Q

Position Count

P1-05= 0

P1-05 Position Count

The position count is the number of quadrature counts before the orient position that the drive will hold the speed set in

P1-04: Position Speed. This may be used to prevent overshooting the orient position. If this count is set to high the

drive will slow down to soon and cause extended positioning times.

Stop Count

P1-06= 0

P1-06 Stop Count

The stop count is the number of quadrature counts before and after the actual orient position that will not result in a

correction. This creates a stop range that prevents oscillation while the drive is in zero servo. The effect of this is

dependent on the position encoder’s resolution.

Setting Range: 0 to 4096

Factory Default: 0

MODBUS Address: 0x584

Q Q Q Q

Setting Range: 0 to 100

Factory Default: 0

MODBUS Address: 0x585

Q Q Q Q

Date: 07/01/04, Rev: 04-07 Page 9 of 14 TM.G5SW.021

Page 10

Spindle Orientation

Stop Spd Gain

P1-07= 1

P1-07 Stop Speed Gain

The stop speed gain controls the threshold frequency where the positioning algorithm takes control of stopping the drive.

It is based on a minimum threshold of 4.096 Hz with a 1 setting. The minimum threshold is multiplied by this value to

achieve a maximum threshold of 40.96 Hz. This value also controls the rate of deceleration. The positioning algorithm

will bring the drive to a stop in the orient po sition within 2 revolutions after initiated. The number of revolutions

required to stop may be extended by the marker offset used.

Motor Ratio Num

P1-08= 1

P1-08 Spindle Ratio Numerator

The motor ratio numerator is the numerator for the motor ratio equation P1-08: Spindle Ratio Numerator / P1-09:

Spindle Ratio Div. The proper drivetrain ratio between the driven device connect to the position encoder and the motor

must be set for positioning to function properly.

Motor Ratio Div

P1-09= 1

P1-09 Spindle Ratio Divisor

The motor ratio divisor is the denominator for the motor ratio equation P1-08: Spindle Ratio Numerator / P1-09:

Spindle Ratio Div. The proper drivetrain ratio between the driven device connect to the position encoder and the motor

must be set for positioning to function properly.

Control Select

Marker Offset

P1-10 Control Select

The control select constant sets how the orient control of the drive. The selections are:

0 – Marker Offset – The orient position is maintained as the marker offset or home position.

1 – Sequence Offset – The orient position is incremented to the next sequence step (0 to 15) and new orient position.

2 – Selected Offset – The orient position is selected from the 16 available positions via multifunction inputs.

3 – Serial Offset – The orient position is read from U1-59: Serial Offset.

When using a 1 or 2 selection parameters P2-01 to P3-05 are used to set the orient positions.

Setting Range: 0 to 10

Factory Default: 1

MODBUS Address: 0x586

Q Q Q Q

Setting Range: 0 to 10

Factory Default: 1

MODBUS Address: 0x587

Q Q Q Q

Setting Range: 0 to 10

Factory Default: 1

MODBUS Address: 0x588

Q Q Q Q

Setting Range: 0 to 3

Factory Default: 0

MODBUS Address: 0x589

Q Q Q Q

Date: 07/01/04, Rev: 04-07 Page 10 of 14 TM.G5SW.021

Page 11

Spindle Orientation

New Program Group Functions P2 - P3

Offset xx

PX-XX = 0

P2-01 to P3-05 Offset 1 to 15

Offset 1 to 15 are provided for use when P1-10 is set to 1: Sequence or 2: Select. When P1-10 is set to 1: Sequence,

energizing the orient input will increment to the next parameter and read the offset value. If the offset value is 0 the

sequence step is reset to 0 or P1-03: Marker Offset or the home position. When P1-10 is set to 2: Select, energizing the

orient input will read the bit mapped multifunction inputs to see if they are energized and use the parameter offset

indicated by the table below. If none of the inputs are energized the drive will orient at the home position. P1-03:

Marker Offset controls this position.

Constant

P2-01

P2-02

P2-03

P2-04

P2-05

P2-06

P2-07

P2-08

P2-09

P2-10

P3-01

P3-02

P3-03

P3-04

P3-05

Description

Offset 1 0x0590 1 Off Off Off

Offset 2 0x0591 2 Off Off

Offset 3 0x0592 3 Off Off

Offset 4 0x0593 4 Off

Offset 5 0x0594 5 Off

Offset 6 0x0595 6 Off

Offset 7 0x0596 7 Off

Offset 8 0x0597 8

Offset 9 0x0598 9

Offset 10 0x0599 10

Offset 11 0x05a0 11

Offset 12 0x05a1 12

Offset 13 0x05a2 13

Offset 14 0x05a3 14

Offset 15 0x05a4 15

MODBUS

Address

Seq.

Step

84: Select

Setting Range: 0 to 32767

Factory Default: 0

MODBUS Address: see chart

Q Q Q Q

Multifunction Inputs

85: Select Bit 3 86: Select Bit 2 87: Select

MSB 4

On

On On

On

On

On On

On On On

On

On

On

On

On On

On On

On On On

On On On On

Off Off Off

Off Off

Off

Off

Off Off

Off

On

On On

Off Off

Off

LSB 1

On

Off

On

Off

On

Off

On

Off

Count or Degree

Offset Degrees

P3-06 Count or Degree

The count or degree parameter is used to determine the value of parameters P2-01 to P3-05.

0 – Offset Counts – Parameters P2-01 to P3-05 are interpreted as counts.

1 – Offset Degrees – Parameters P2-01 to P3-05 are interpreted as degrees. Entering a number greater than 360 results

in only the integer remainder from the equation number entered / 360 being used. If the number entered is 32767 the

remainder from the equation is 7. The offset is 7 degrees. (360 * 91 = 32760, 32767 – 32760 = 7)

Date: 07/01/04, Rev: 04-07 Page 11 of 14 TM.G5SW.021

Setting Range: 0 to 1

Factory Default: 1

MODBUS Address: 0x05a5

Q Q Q Q

Page 12

Spindle Orientation

Mtr 2 ASR Param

Normal (Fixed)

P3-07 Motor 2 ASR Parameter Mode Selection

This parameter changes the source of the ASR Proportional and Integral adjustments when Motor 2 is selected via multifunction input.

0 – Normal (Fixed) – The factory default values (based on control mode) of C5-01 ~ C5-04 are used to set the

proportional gain and integral time when Motor 2 is selected. The values are fixed and cannot be changed. This is

identical to the function of standard software.

1 – Use P3-08/P3-09 – Parameters P3-08 and P3-09 are used to set the proportional gain and integral time when Motor 2

is selected.

Mtr 2 ASR P Gain

P3-08 = 20.00

P3-08 Motor 2 ASR Proportional Gain

P3-08 adjusts the proportional gain of the ASR when Motor 2 is selected.

NOTE: The default P3-08 setting of 20.00 is optimized for Flux Vector control mode. Unstable operation may

occur with this setting in other control modes.

Mtr 2 ASR I Time

P3-09 = 0.500 Sec

P3-09 Motor 2 ASR Integral Time

P3-09 adjusts the integral time of the ASR when Motor 2 is selected.

NOTE: The default P3-09 setting of 0.500sec is optimized for Flux Vector control mode. Unstable operation may

occur with this setting in other control modes.

Setting Range: 0 to 1

Factory Default: 0

MODBUS Address: 0x05a6

A A A A

Setting Range: 0 to 300.00

Factory Default: 20.00

MODBUS Address: 0x05a7

A A A A

Setting Range: 0 to 10.000sec

Factory Default: 0.500sec

MODBUS Address: 0x05a8

A A A A

Date: 07/01/04, Rev: 04-07 Page 12 of 14 TM.G5SW.021

Page 13

New Monitors

Spindle Orientation

Marker Offset

U1-50 = 2303 cts

Display Range: 0 to 32767 cts

MODBUS Address: 0x00d0

U1-50 Marker Offset Q Q Q Q

Displays the number of quadrature encoder counts the shaft is past the marker pulse. This is a rolling pulse counter with

a range from 0 to the quadrature PPR rating of the position encoder. (Quad PPR = P1-02: Pos. Encoder PPR x 4) The

drive must be orientated after energizing to identify the marker pulse position. This monitor will display the offset count

from the last marker pulse. A 1024 PPR encoder has a quadrature count of 1024 X 4 or 4096. Using this encoder this

value will increment from 0 to 4095 in the forward direction. It will decrement from 4095 to 0 in the reverse direction.

The 0 indicates the marker position.

Shaft Angle

U1-51 = 0.0

Display Range: -180.0 to 179.9

MODBUS Address: 0x00d1

U1-51 Shaft Angle Q Q Q Q

Displays the angle between the position encoder and the home position. The display will indicate 0 to 179.9 degrees

then change to –180.0 to 0 degrees when rotated in the clockwise direction. Counter clockwise rotation will result in 0

to –180.0 then it will change to 179.9 and count down to 0.

Shaft Angle Deg

U1-52 = 0.0

Display Range: 0.0 to 359.9

MODBUS Address: 0x00d2

U1-52 Shaft Angle Degrees Q Q Q Q

Displays the angle between the position encoder and the home position. The display will indicate 0 to 359.9 degrees

when the position encoder is rotated clockwise.

Seq Offset

U1-57 = 0

Display Range: 0 to 32767

MODBUS Address: 0x00d7

U1-57 Sequence Offset Q Q Q Q

Displays the last read offset value pointed to by the sequence step. The value is read when the orient input is energized.

The sequence offset is used as the offset to the home position. The readable values are set in the P2-01 to P3-05

parameters. When the sequence step is 0 the P1-03: Marker Offset will be read. The actual value of the sequence offset

is controlled by P3-06: Count or Degree. (Quadrature PPR counts or 360 degrees = 1 revolution)

Date: 07/01/04, Rev: 04-07 Page 13 of 14 TM.G5SW.021

Page 14

Spindle Orientation

Sequence Step

U1-58 = 0

U1-58 Sequence Offset

Displays the last sequence step used. The sequence step will increment upon energizing the orient input when P1-10:

Control Select is set to 1: Sequenced Offset or 2: Selected Offset. The drive is in the home position when the sequence

step is 0. When P1-10 is set for serial offset and its value is greater than 0 the sequence step is set to 99. When the

value of the serial offset is 0 the sequence step will be at the home position o r 0.

Serial Offset

U1-59 = 0

U1-59 Sequence Offset

Displays the last serial offset written to this register. This monitor has been modified to allow writes. It is a volatile

register that will be lost upon shutdown. This register does not require enter or accept commands. P1-10: Control Select

must be set to 3: Serial Offset to use this register as the offset value. The value must be written to this register prior to

energizing the orient input.

Display Range: 0 to 15

MODBUS Address: 0x00d8

Q Q Q Q

Display Range: 0 to 32767

MODBUS Address: 0x00d9

Modified: Write to

Q Q Q Q

Date: 07/01/04, Rev: 04-07 Page 14 of 14 TM.G5SW.021

Loading...

Loading...