Page 1

Eliminator

GPD515/G5 Software Option (VSG114676)

Part Number: CIMR-G5MXXXXXF-015

With this factory-installed FLASH software, the

GPD515 / G5 becomes a configurable drive.

User Configurable software enhances the

standard drive software with embedded

functions. The drive may be operated as a

standard off the shelf drive or may be

configured to utilize the embedded functions.

The functions can be configured to create the

necessary control logic for many speed or

torque control applications. It is possible to

reduce the need for external control modules

and PLC’s. Whole control systems may be

integrated into a stand-alone GPD515 / G5

drive.

With this software, it is possible to read in

information and output it into other functions

from the following sources;

! All analog inputs

! All PG options

! Drive speed output

! Drive torque output

! Drive Hertz output

! Internal MOP

! Parameters

These sources can be input into the following

functions that perform operations to change

and control them. The following operations are

available;

! Add, subtract, multiply and divide

! Change polarity

(1)

XXXXX refers to the base Model Number of the drive in which the software is installed.

! Compare sources

! Absolute value

! PID

! Diameter calculator

! Scale information

! Switch between sources

The outputs from these functions can be

connected to other functions or used to control

the drive. The drive functions can be used to

write information directly to the following drive

controls;

! Analog outputs

! Speed reference

! Torque reference

! Multi-function outputs

! Digital Operator Monitors

This software provides the user the flexibility to

configure their own logic and to change it when

needed. It is one software flash that could

replace many.

To better understand what this software can do

it is necessary to understand the functions. It

is also necessary to understand how to enter

the configuration into the drive. The following

sections of this manual will explain how to use

and setup the functions.

This document is an addendum to Technical

Manual TM4515, listing the effect of this

software on the parameters in the drive and

function descriptions in the manual.

(1)

Date: 07/01/04, Rev: 04-07 Page 1 of 27 TM.G5SW.015

Page 2

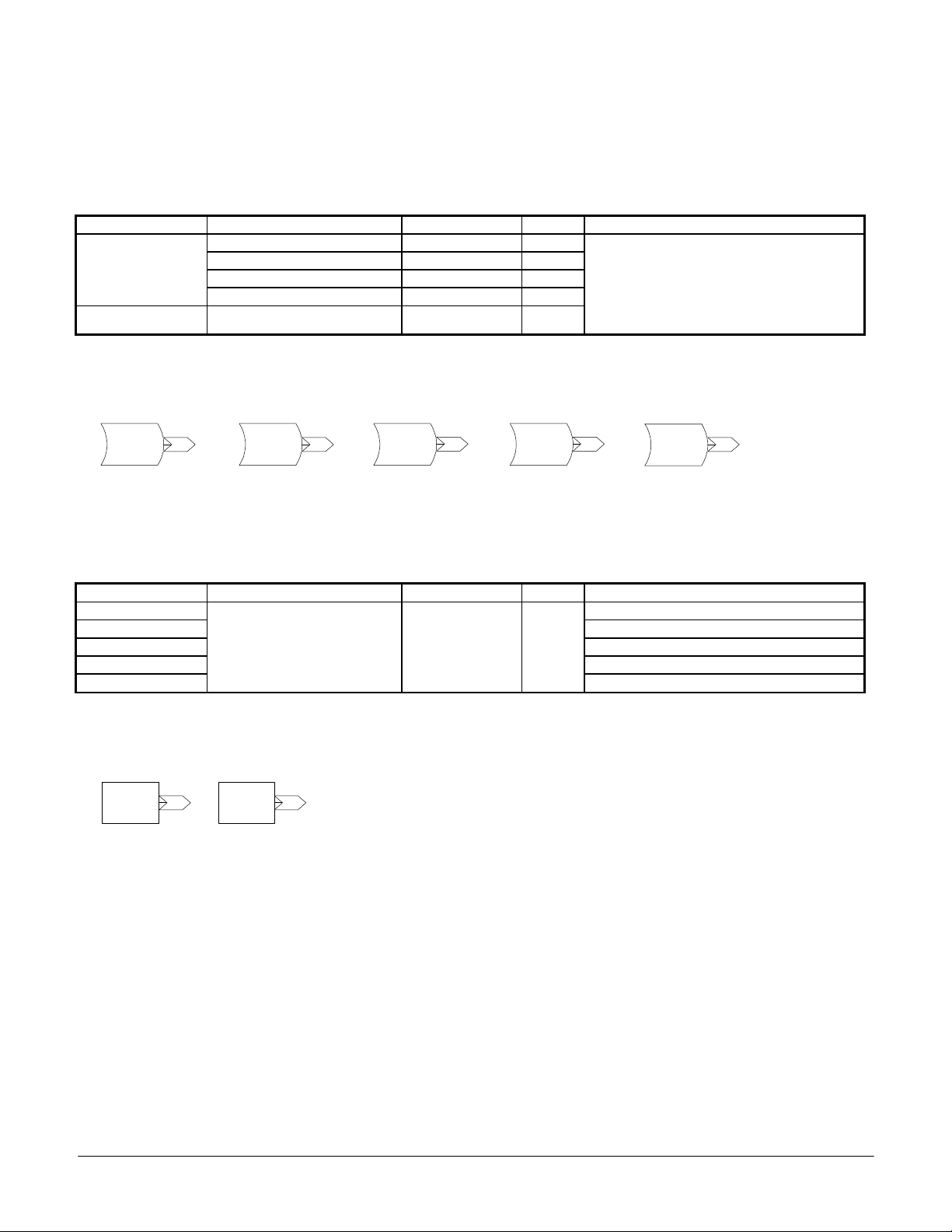

Function Blocks - Quick Reference

Source

Term 13

Analog

Input

Figure 2.1.1 Figure 2.1.2

P1-01

Number

Input

Figure 2.1.3 Figure 2.1.4

Figure 2.1.5 Figure 2.1.6 Figure 2.1.7 Figure 2.1.8 Figure 2.1.9

Read

Memory 1

Figure 2.1.A

13

9a

46

Term 14

Analog

Input

P1-02

Number

Input

0 18

Read

Memory 2

Term 16

14

9b

47

Analog

Input

P1-03

Number

Input

Drive

Output

16 MOP 25

9c

15

P1-04

Number

Input

Drive

Torque

Output

9d

1110000 12

Step

MOP

P1-05

Number

Input

Motor

Speed

26

9e

17

PG

Pulse

Input 1

PG

Pulse

Input 2

Operation

Absolute

Value

40

PID

2423

Figure 2.2.5

31

Figure 2.2.1

70

Compare

70 <= 71

71

72

73

Figure 2.2.2

20

Center

Winder

21

Figure 2.2.6

+

False

True

3230

3b

70

Compare

70 = 71

74

22

71

False

72

73

True

H1-0? = 80

01

02

Switch 1

Figure 2.2.7 Figure 2.2.8

3c3a

-

75

03

51

70

71

72

73

04

05

X

Compare

70 >= 71

False

True

H1-0? = 81

Switch 2

5250

76

Figure 2.2.3 Figure 2.2.4

06

5b

42

/

Space

10

H1-0? = 85

Hold

Number

5c5a

43

Change

Sign

41

Scale

0e

0f

6160

Drive

Drive

ff

Speed

Figure 2.3.1 Figure 2.3.2 Figure 2.3.3

U1-55

Monitor

Drive

Analog

Output 50

91

U1-50

90

Monitor

95

Figure 2.3.5

fe

96

Torque

U1-51

Monitor

Monitor

Drive

Max

U1-56

Drive

Analog

Output 51

Accel/

19

Decel

Figure 2.3.4

U1-52

92

Monitor

U1-57

97

Monitor

80

93

98

Drive

Output 40

U1-53

Monitor

U1-58

Monitor

81

94

99

Drive

Output 41

U1-54

Monitor

U1-59

Monitor

82

44

45

Figure 2.3.6

Drive

Output 42

Write

Memory 1

Write

Memory 2

Date: 07/01/04, Rev: 04-07 Page 2 of 27 TM.G5SW.015

Page 3

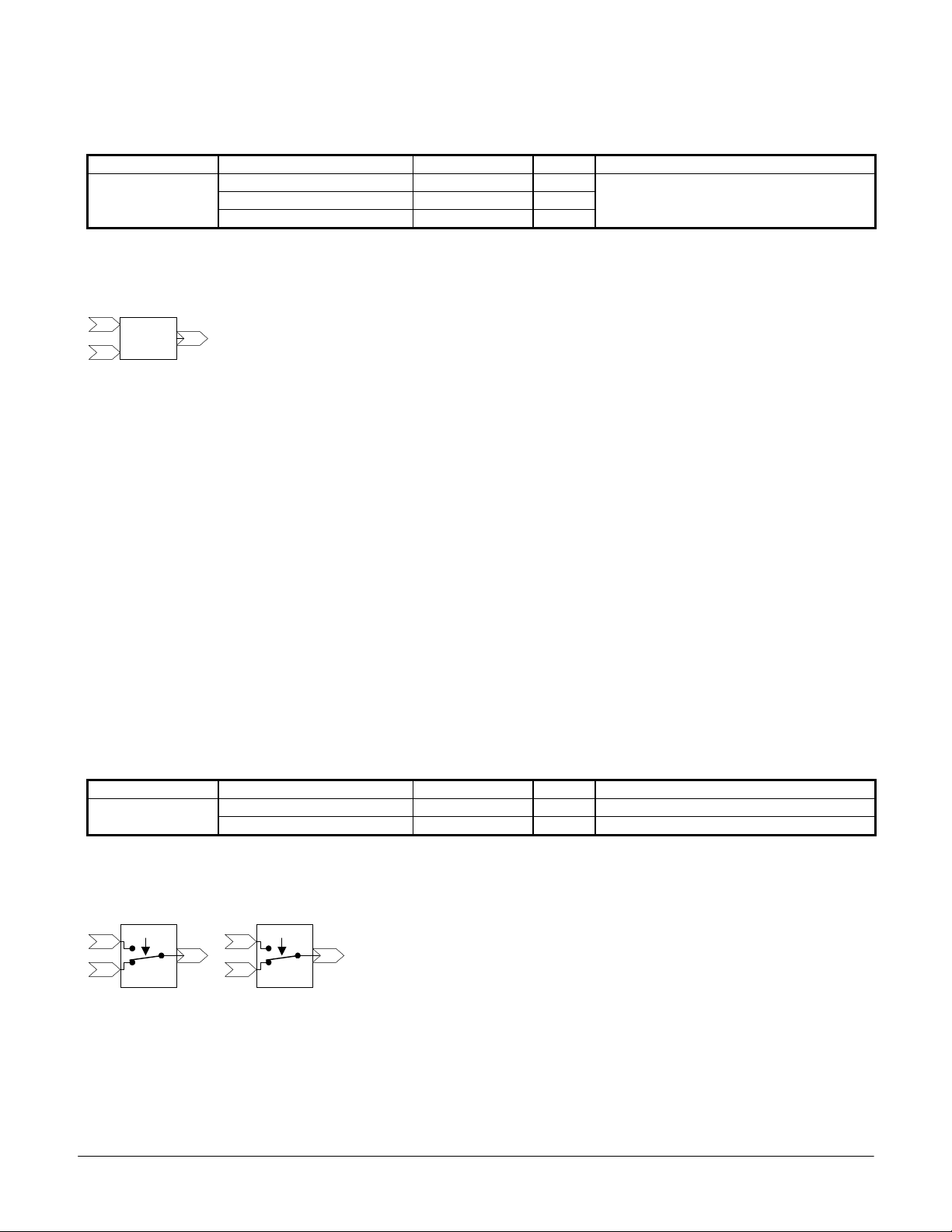

Function Block Setup - Quick Reference

Sheet 1 of 2

2.1 Sources

Figure Description Information Input Output Setup

2.1.1

Analog

Inputs

2.1.2

MOP /

Step MOP

2.1.3

Number

Inputs

2.1.4

Pulse

Inputs

2.1.5

10000

2.1.6

0

2.1.7

Drive

Output

2.1.8

Torque

Output

2.1.9

Motor

Speed

2.1.A

Read

Memory

Analog Input 13 Terminal 13 13 Terminal 13 can not be reassigned

Analog Input 14 Terminal 14 14 Terminal 14 – H3-09 = 20: Eliminator T-14

Analog Input 16 Terminal 16 16 Terminal 16 – H3-05 = 21: Eliminator T-16

P2-02 = MOP Rate / second

MOP 25

Step MOP

P1-01 Range 0 to 65535 9A

P1-02 Range 0 to 65535 9B

P1-03 Range 0 to 65535 9C

P1-04 Range 0 to 65535 9D

P1-05 Range 0 to 65535 9E

PG Channel 1

PG Channel 2

100 % Reference 10000 output value 12

0 % Reference 0 output value 18

Output Reference

Torque Reference

Motor Speed

Percentage

Read Memory 1 46 Reads Write Memory1

Read Memory 2

P2-03 = MOP Max Percent

P2-04 = MOP Min Percent

P2-05 = MOP Rst Percent

P2-06 = MOP Step Rate

F1-01 = Pulses Per Rev.

P2-01 = Pulses input at 100 %

inverter speed ( Range 0 to 65535)

Percentage of Maximum Frequency

0-10000 output value

Percentage of 100.00 Percent Torque

0-40000 output value

Available in PG and Vector modes

only

Reads the value written into memory

with the associated write memory.

2.2 Operations

Figure Description Information Input Output Information / Equation

Input Value 30

Input Value to add 31

Input Value 3a

Input Value to subtract 3b

Input Value 50

Input Value to multiply by 51

Input Value 5a

Input Value to divide by 5b

2.2.1

Math

Addition

Subtraction

Multiplication

Division

Absolute Value Same Input / Output Connector 40 Absolute Value of X

Change Sign Same Input / Output Connector 41 X times -1

Connections

H1-xx = 82: MOP UP

H1-xx = 83: MOP DOWN

H1-xx = 84: MOP RESET

26

0E PG Option Card Required (PG-X2 or PG-W2)

OF PG-W2 Option Card Required

15

11

17

47 Reads Write Memory 2

Connections

32 30 + 31 = 32

3c 3a - 3b = 3c

52 (50 x 51) / 10000 = 52

5c (5a x 10000) / 5b = 5c

Date: 07/01/04, Rev: 04-07 Page 3 of 27 TM.G5SW.015

Page 4

Function Block Setup - Quick Reference

Sheet 2 of 2

Connections

10

23 24 B5-01 PID Mode = Disabled

60 61 ((60 X P1-08) / P1-09) + P1-10 = 61

42 43 Terminal ? - H1-01 to 06 = 85: Number Hold

70 <= 71 (True: 74 = 73) (False: 74 = 72)

70 = 71 (True: 75 = 73) (False: 75 = 72)

70 >= 71 (True: 76 = 73) (False: 76 = 72)

76

P1-06 = Diameter Filter Time

22

P1-07 = Diameter Build Ratio

03 Terminal ? - H1-01 to 06 = 80: Switch 1 DI

06 Terminal ? - H1-01 to 06 = 81: Switch 2 DI

Connections

ff

fe

19

91

94

44 Number Write 1

45

E1-04: Max Frequency Limits the drive output

P2-10 = Max Torque Ref (limit)

Sets Max torque limit L7-01: Fwd = L7-02: Rev

Accel Time = (19 x C1-01) / 10000

Decel Time = (19 x C1-02) / 10000

H2-03 = 42: CONNECTION 82

H4-01 or H4-04 = 51: Case Monitor 2

Monitor Value = Input Value / 10

Number Write 2

2.2 Operations

Figure Description Information Input Output Information / Equation

1st Value 70

Compared to 1st Value 71

2.2.2

Compare

2.2.3

Space

2.2.4

PID

2.2.5

Scale

2.2.6

Center

Winder

2.2.7

Internal

Switches

2.2.8

Number

Hold

Compare input 70

to input 71

Enter Spaces

PID

23 = Error input

Scale

Calculate Diameter

with ratio output

Switch 1

Switch 2

Hold last input

value

Value if True 73

Value if False 72

Output less or equal 74

Output equal 75

Output greater or equal

Used to enter spaces into a

configuration

B5-02 PID Gain = P Gain

B5-03 PID I Time = I Bld Rate

B5-04 PID I Limit = I Limit

B5-05 PID D Time = D Rate

B5-06 PID Limit = Output Limit

P1-08 = Scale Multiplier

P1-09 = Scale Divisor

P1-10 = Scale Bias

Line Speed Ref input 20

Diameter Filter Output

Motor Speed Ref input 21

Normally Open 01

Normally Closed 02

Normally Open 04

Normally Closed 05

Outputs input value until the Hold is

activated causing it to hold the last

value read..

2.3 Drive

Figure Description Information Input Output Information / Equation

2.3.1

Drive

Speed

2.3.2

Drive Max

Torque

2.3.3

Accel /

Decel

2.3.4

Drive

Outputs

2.3.5

Analog /

Monitor

Outputs

2.3.6

Write

Memory

Frequency

Reference to Drive

Torque Reference

Accel / Decel

Contact Output 9 Connects terminal 9 to 10 80 H2-01 = 40: CONNECTION 80

Trans Output 25 Sinks terminal 25 to 27 81 H2-02 = 41: CONNECTION 81

Trans Output 26 Sinks terminal 26 to 27 82

Monitor 1 (U1-50) 90 H4-01 or H4-04 = 50: Case Monitor 1

Monitor 2 (U1-51)

Monitor 3 (U1-52) 92

Monitor 4 (U1-53) 93

Monitor 5 (U1-54)

Write a value into

the Number Read

registers

Controls the drives output frequency

Range 0 to +/- 10000

Controls the Max output torque from

the drive. Flux vector control only.

Same as changing L7-01 and L7-02.

Changes the acceleration and

deceleration time. Accel = Decel

Information can be passed to analog

output terminals 21 and 23

Store numerical data into running

memory. Two registers provided.

Date: 07/01/04, Rev: 04-07 Page 4 of 27 TM.G5SW.015

Page 5

1.0 Configuring The Function Blocks

User Configurable software allows the GPD515/G5 drive to be configured to a specific

application. This is accomplished by internal drive functions that may be connected to provide

the logic required. For the purposes of understanding and developing logic the internal

functions have been reduced to function blocks. The function block diagrams indicate how they

can be connected.

Some functions have required setup as multi-function selections to operate. Many functions

have associated parameters to provide control. Developing a configuration involves choosing

the functions required, connecting them for the required logic and setting the parameters that

control the functions.

1.1 Developing a Configuration

Function blocks are simple block diagrams that indicate their function and how they are

connected. The arrow like icons used for the input and output connectors indicate the direction

information is moving. A connector number is shown within these icons. Figure 1.1 shows the

anatomy of the three categories of functions as function blocks.

Source Operation

Source

Input

Function

#

Convert

Source

Function

##

Drive

Drive

Output

#

Function

Figure 1.1

Output

Connector

Input

Connector

Output

Connector

Input

Connector

Using function blocks provides a way to develop configurations so they may be understood.

From Figure 1.1 it is possible to see how the function blocks may be connected. Figure 1.2

demonstrates how the function blocks are connected.

04

Input

Connector

Drive

Drive

Output

Function

Source Operation

Source

Input

Function

Figure 1.2

Connection Connection

01

Output

Connector

Input

Connector

Convert

Source

Function

0302

Output

Connector

In figure 1.2 a source input function sends information to the output connector 01. The

information is passed through the connection to the input connector 02 of the operation. The

operation reads this information and converts it sending the result to the output connector 03.

The information is passed through the connection to the input connector 04. The drive output

function directs the information to control the drive. All configurations follow this example.

There can be more complex configurations with more operations but the basics are the same.

The information starts at a source. It is connected to the operations necessary to convert and

control it. The information is then passed to the drive.

Developing a configuration for a drive requires selecting a data source and directing it through

operations changing it to information that will provide the proper drive control and then

Date: 07/01/04, Rev: 04-07 Page 5 of 27 TM.G5SW.015

Page 6

connecting it to the drive function. Configurations can be complex with many sources and

operations or as simple as selecting a source reference and connecting it to the drive function.

Once a configuration has been developed using the function blocks to convert source

information, it is necessary to enter the configuration into the drive. Entering the configuration

into the drive requires generating a configuration list. This list is a record of all connections

starting with the beginning information and following the operations in the manner that they must

be executed until the information is connected to the drive functions required.

1.2 Configuring The GPD515

Using figure 1.2 a configuration list can be generated by starting at the source output connector

01 and recording the number within it. Next record the number within the input connector 02

that it connects. Follow the information path in the manner that it must be executed. This will

yield – 01,02,03,04. The configuration list of connector numbers must be entered into the drive

in this sequence.

This software reserves twenty-two User Parameters for the purpose of configuring the GPD515 /

G5 drive. The User Parameters are located under the Initialize menu option. Parameters A2-01

through A2-10 remain unchanged serving their standard function. Parameters A2-11 through

A2-32 are used for configuring the drive. Configuring the drive requires entering the

configuration list into these parameters.

To enter the configuration list into the drive start at A2-11 and enter the first two-connector

numbers or the first connection. Enter the next two-connector numbers or the second

connection in the next parameter A2-12 and continue this until the complete configuration list

has been entered.

Using the configuration list developed for figure 1.2, User Parameter A2-11 will be set to 0102,

which are the numbers of the first connection. A2-12 will be set to 0304, which are the numbers

of the second connection. When the drive is returned to operation the configuration list will be

executed in the sequence that it was entered. The sequence ends at the first 00 connector

number, which is the default number for the user parameters. The User Parameter connector

numbers are read in the sequence that they are entered. Each connector number results in an

operation. Input connectors store the information that is connected to them. Output connectors

execute a function to read the stored input connector information or to read information from the

drive then the associated function is executed converting the information sending it to the output

connector.

1.3 Setup of Functions

Some functions require being selected in the standard drive parameters before they will

function. Many functions have parameters and multi-function inputs associated with them.

Sections 2 explains the functions, their setup and controls. This information can also be found

in the quick reference information. The parameters used for these purposes should be set when

the configuration is entered into the GPD515 / G5. Only the parameters required for the current

configuration need to be setup.

Date: 07/01/04, Rev: 04-07 Page 6 of 27 TM.G5SW.015

Page 7

1.4 Configuring Examples

This software may be configured just using the quick references. The following examples will

demonstrate that it is just a matter of selecting the needed functions and connecting them

together. Once the configuration is finished just record the connector numbers in the sequence

that starts at the source information and follows it through the operations in the manner that it

must be converted util it is sent to the drive. Then input the connector numbers into the drive.

Example 1.4.1:

This configuration will provide a speed reference to the drive and a scaled display

monitor for the machine operator.

Figure 1.4.1

Terminal 13

Analog

Input

Terminal 13

Analog

Input

13

ff

13

Scale

Drive

Speed

Control

6160

94

U1-54

Monitor

Configuration List

13,60,61,94,13,ff, 00

Configure the Drive

A2-11 = 1360

A2-12 = 6194

A2-13 = 13ff

A2-14 = 00XX

XX = Don’t Care

The scaling parameters must be set to control the value displayed by the monitor.

Example 1.4.2:

This configuration uses 2 multi-function inputs to select between the 3 analog inputs to be

used as the speed reference.

Configuration List

16,04,14,05,06,01,13,02,03,

ff, 00

Configure the Drive

A2-11 = 1604

A2-12 = 1405

A2-13 = 0601

A2-14 = 1302

A2-15 = 03ff

A2-16 = 00XX

XX = Don’t Care

Terminal 16

Analog

Terminal 14

Analog

Terminal 13

Analog

Figure 1.4.2

Input

Input

Input

16

14

06

13

H1- 0x : 81

04

05

Switch 2 DI

H1- 0x : 80

01

02

Switch 1 DI

03

ff

Drive

Speed

Control

The multi-function and analog inputs must be setup. The drive will use terminal 13 as a

reference with both switches off. When switch 1 is on via the multi-function input, terminal

14 becomes the reference. When both switches are on via the multi-function inputs, terminal

16 becomes the reference.

Date: 07/01/04, Rev: 04-07 Page 7 of 27 TM.G5SW.015

Page 8

1.5 Advanced Topics / Examples

The configuration entered in the A2 User Parameters is a sequence of numbers that are read

back and executed by connector numbers. Each A2 parameter can contains one connection

point or two connector numbers. Each connector number must be two digits. When the

connector number is a single digit a 0 must be added to make it two. The leading zeros must be

entered.

When a connector is read into the drive the function it represents is executed. Upon completion

the next connector or two digit number is read and executed. This continues until a 00 is read

or until all 22 A2 parameters or all 44 connector numbers have been executed.

The connectors are always read in sequence starting at the beginning and finishing at the end.

The complete sequence is read each scan. The process starts over again on the next scan.

All operation input connectors store the connected input value without changing it. Because of

this it is possible to connect values to all operation inputs before entering the output connector

number into the sequence. When an operation output connector is read and executed the

current stored input or last read values will be used and a new value is calculated and output.

This must be considered when using an operation more than one time. Each time it is used all

the inputs must only be in the sequence one time before the output is entered. After the output

is entered it is possible to reuse the operation inputs but the output must be entered again

before the end of the configuration sequence.

It is also possible to reduce the numbers required in the sequence by only entering an output

one time when it is connected to several inputs. Once the output has been executed, the

current value that will be passed to all input connectors is unchanged until the next output is

executed. Therefore all input connectors that connect to an output may be entered into the

configuration sequence after the output and before the next output. Outputs change the current

value that will be passed. Inputs do not change the current or last output value.

Despite the flexibility provided with this software there are some configurations that may not be

possible. The following examples demonstrate what has been covered in this section.

Date: 07/01/04, Rev: 04-07 Page 8 of 27 TM.G5SW.015

Page 9

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

Example 1.5.1: This will function properly

Term 13

Analog

Input

Term 16

Analog

Input

Term 14

Analog

Input

Figure 1.5.1

Drive

13

31

16

14

3b

3230

+

3c3a

-

+

31

ff

3230

Speed

Configuration List

13,30,16,31,16,3a,14,3b,32,30,3c,31,32,ff

Configure the Drive

2-11 = 1330 A2-15 = 3230

2-12 = 1631 A2-16 = 3c31

2-13 = 163a A2-17 = 32ff

2-14 = 143b A2-18 = 00XX

XX = Don’t Care

Example 1.5.2: This w ill not function as intended

Term 13

Analog

Input

Term 16

Analog

Input

Term 14

Analog

Input

Figure 1.5.2

Drive

13

31

16

14

31

3230

+

3230

+

+

31

ff

3230

Speed

Configuration List

13,30,16,31,16,30,14,31,

Configure the Drive

2-11 = 1330 A2-15 = 3230

2-12 = 1631 A2-16 = 3231

2-13 = 1630 A2-17 = 32ff

2-14 = 1431 A2-18 = 00XX

XX = Don’t Care

In this example output 32 will provide the value from the last execution to both connected inputs.

Example 1.5.3 This will function properly

Term 13

Analog

Input

Term 16

Analog

Input

Term 14

Analog

Input

Figure 1.5.3

Drive

13

31

16

14

31

3230

+

3230

+

-

3b

ff

3c3a

Speed

Configuration List

13,30,16,31,32, 3a,16,30,14,31,32,3b,3c,ff

Configure the Drive

2-11 = 1330 A2-15 = 1431

2-12 = 1631 A2-16 = 323b

2-13 = 323a A2-17 = 3cff

2-14 = 1630 A2-18 = 00XX

XX = Don’t Care

Example 1.5.4 Figure 1.5.1 above can be reduced as shown

Reduced List Figure 1.5.1

13,30,16,31,3a, 14,3b, 32, 30, 3c, 31, 32, ff

Configure the Drive

2-11 = 1330 A2-15 = 303c

2-12 = 1631 A2-16 = 3132

2-13 = 3a14 A2-17 = ff00

2-14 = 3b32 A2-18 = XX

Figures 1.5.2 and 1.5.3 cannot be reduced. The common output 16

must be input to the addition function for each execution since a

function will use the last value input for each execution. If output 16

was connected to input 31 on both addition functions it could be

reduced since input 31 would remain the same for both executions.

32,30,32,31,32,ff

Date: 07/01/04, Rev: 04-07 Page 9 of 27 TM.G5SW.015

Page 10

2.0 Function Blocks

2.1 Source Function Blocks

Source functions are used to output information into the function block configuration. All

configurations will begin with a source. All source information is expressed as a number, which

is a percentage of their function. The normal range is from 0 to +/- 100.00 percent. The actual

value used for 100.00% is 10000. This must be understood to convert information within a

configuration.

2.1.1 Analog Inputs

Term 13

Analog

Input

Figure 2.1.1

13

Analog Input functions provide information from the analog input terminals. The source output

connectors are numbered the same as the corresponding analog input terminal. Terminals 14

and 16 must be setup. The number provided at the output connector is controlled by the

standard H3 parameters associated with analog inputs and is expressed as a percentage of the

maximum frequency. This value can be bi-polar when the analog input is set to be. With all

associated analog constants set at default values the output range is from 0 to 10000.

Term 14

Analog

Input

Term 16

14

Analog

Input

16

Function Controls Range Default Setup

Terminal 14 Analog input terminal 14 H3-09 = User Cfg Term 14

Terminal 16 Analog input terminal 16 H3-05 = User Cfg Term 16

Terminal 14 analog input is defaulted as a 4 to 20ma input. To convert this to a voltage input

jumper J1 located directly above terminal 13 on the control board must be opened.

2.1.2 MOP (Motor Operated Pot)

MOP 25

Figure 2.1.2

Step

MOP

26

MOP functions simulate a motor operated pot and can be used to control the value output. A

maximum and a minimum parameter control the range of the output limiting it to +/- 1000 % or

an actual output value of +/- 100000. Separate multi-function inputs control increasing,

decreasing and resetting the value to a preset. When the multi-function inputs have been setup

for the MOP, turning the MOP up input on will increment the output value at a definable rate.

The same is true for the MOP down except the output value decrements. The output value will

only change when the MOP multi-function input control is on. When the MOP reset input is on,

the output value will reset to a preset value.

Date: 07/01/04, Rev: 04-07 Page 10 of 27 TM.G5SW.015

Page 11

The Step MOP uses the same controls as the MOP. This function will change the output value

by a definable step for each transition from off to on of the MOP Up or MOP Down Controls. A

maintained input will only result in the output changing the value of one step. The multi-function

input control must be off for a minimum of 5ms before the next step will execute.

Function Controls Range Default Setup

P2-02 = MOP Rate / second 0.00% to 100.00% 0.00%

MOP

Step MOP P2-06 = MOP Step Rate / step 0.00% to 100.00% 0.00%

P2-03 = MOP Max Percent 0 to 1000% 100%

P2-04 = MOP Min Percent -1000% to 100% 0%

P2-05 = MOP Rst Percent -1000% to 1000% 0%

H1-xx = 82: MOP UP

H1-xx = 83: MOP DOWN

H1-xx = 84: MOP RESET

2.1.3 Number Inputs

P1-01

Number

Input

Figure 2.1.3

9a

P1-02

Number

Input

9b

P1-03

Number

Input

9c

P1-04

Number

Input

9d

P1-05

Number

Input

9e

Number Input functions output the parameter information into other functions. The value can

range from 0 to 65535. The number to input must be set in the associated P1 parameter.

Function Controls Range Default Setup

P1-01 P1-01 = Desired number

P1-02 P1-02 = Desired number

P1-03 P1-03 = Desired number

P1-04 P1-04 = Desired number

P1-05

Number output 0 to 65535 0

P1-05 = Desired number

2.1.4 Encoder Pulse Inputs

PG

Pulse

Input 2

Figure 2.1.4

0f

PG

Pulse

Input 1

0e

Encoder Pulse Input functions output information from PG option cards into a configuration.

There are two input channels. Channel 1 is available with all PG option cards. Channel 2 is

only available with a PG-W2 option card.

Channel 1 defaults to using F1-01: PG Pulses/Rev and E2-04: Motor Poles to scale the output

to the maximum frequency. The output value will range from 0 to 10000. The output is positive

regardless of encoder direction. Access to F1-01 has been enabled for open loop control. E204 remains defaulted to 4 poles and can only be changed in flux vector control mode.

Channel 2 requires a PG-W2 option card. The data from channel 2 is converted in a percentage

of the P2-01: Max Pulses In 2. The output will range from 0 to +/-10000. The output polarity

reflects the encoder direction.

Date: 07/01/04, Rev: 04-07 Page 11 of 27 TM.G5SW.015

Page 12

Function Controls Range Default Setup

PG Channel 1

PG Channel 2 P2-01: Max Pulses In 2 0 to 65535 30720 Requires a PG-W2 card

F1-01: PG Pulses/Rev. 0 to 60000 1024 Requires a PG option card

E2-02: Motor Poles 2 - 48 4 Flux Vector control only

2.1.5 10000

10000 12

Figure 2.1.5

The 10000 function outputs the number 10000 to all connected functions.

2.1.6 0

0 18

Figure 2.1.6

The 0 function outputs the number 0 to all connected functions.

2.1.7 Drive Output

Drive

Output

Figure 2.1.7

15

The Drive Output function outputs the percentage of the maximum frequency setting that the

drive is outputting. The value output can range from 0 to 10000.

2.1.8 Drive Output Torque

Drive

Torque

Output

Figure 2.1.8

11

The Drive Output Torque function outputs the percentage of the drive output torque. The value

output can range from 0 to the maximum torque setting.

Date: 07/01/04, Rev: 04-07 Page 12 of 27 TM.G5SW.015

Page 13

2.1.9 Motor Speed Reference

Motor

Speed

Figure 2.1.9

17

The Motor Speed function outputs the calculated motor speed as a percentage of the maximum

frequency setting. The value output can range from 0 to 10000.

2.1.A Read Memory

Read

Memory 1

Figure 2.1.A

46

Read

Memory 2

47

Read Memory functions output the value stored in memory by the corresponding Write Memory

function. This memory is volatile and stored values will be lost when the drive is turned off. This

may be used to retrieve old values from the previous scan when the read function precedes the

write function in the configuration. It can also be used to store a value from a function output

allowing the function to be ended and used again later in the configuration. This value can be

connected where required within the same scan.

2.2 Operations

Operation function blocks are used to change the data that is input. Some operations may be

needed more than on time in a configuration. This is only possible for the operations that

indicate it. When this is done all inputs of the operation must have the information required

present before the output is executed for each instance. This is important when several

operations are connected together.

2.2.1 Math

Absolute

Value

40

31

Figure 2.2.1

3230

+

3b

3c3a

-

51

5250

X

5b

5c5a

/

Math functions are used to convert numbers as indicated by the function blocks. These

functions may be used more than one time in a configuration. The following equations are used.

Addition: Input 30 + Input 31 = Output 32

Subtraction: Input 3a – Input 3b = Output 3c

It is important to know that the multiplication and division operations are not standard. The

scale function can be used for true multiplication and division.

Change

Sign

41

Date: 07/01/04, Rev: 04-07 Page 13 of 27 TM.G5SW.015

Page 14

Multiplication: (Input 50 X Input 51) / 10000 = Output 52

Division: (Input 5a X 10000) / Input 5b = Output 5c

Absolute Value: |Input 40| = Output 40

Change Sign: Input 41 X –1 = Output 41

2.2.2 Compare

70

Compare

70 <= 71

71

7273False

Figure 2.2.2

74

True

70

Compare

70 = 71

71

7273False

True

70

Compare

70 >= 71

75

71

7273False

True

76

Compare functions compare the value connected to input 70 to the value connected to input 71.

A true operation will output the value connected to input 73. A false operation will output the

value connected to input 72. The output number used determines the compare operation. This

operation may be used more than one time in a configuration. This function is a single function

with three possible outputs.

2.2.4 PID

PID

Figure 2.2.4

2423

The PID function is a PID controller. Input connector 23 to this function must be connected to

the error to correct for. This function can only be used one time in a configuration. It may not

be used with the standard drive PID since many of the same parameters are used for tuning.

B5-01 must be set to disabled.

Function Controls Range Default Setup

B5-02 PID Gain = P Gain 0.00 to 25.00 1.00

B5-03 PID I Time = I Bld Rate 0.00 to 360.00 sec 1.00

PID

B5-04 PID I Limit = I Limit 0.0 to 100.0 % 100.0

B5-05 PID D Time = D Rate 0.00 to 100.0 sec 0.00

B5-06 PID Limit = Output Limit 0.0 to 100.0 % 100.0

B5-01 PID Mode = Disabled

2.2.5 Scale

Scale

Figure 2.2.5

6160

The scale operation functions to scale the value input. This function uses standard

multiplication and division. It can be used for those operations and can be used more than once

in a configuration. The following equation is used;

Date: 07/01/04, Rev: 04-07 Page 14 of 27 TM.G5SW.015

Page 15

output 61 = ((input 60 X P1-08) / P1-09) + P1-10

Function Controls Range Default Setup

P1-08 = Scale Multiplier -9999 to 9999 0

Scale

P1-09 = Scale Divisor -9999 to 9999 0

P1-10 = Scale Bias -9999 to 9999

2.2.6 Center Winder

20

Center

Winder

21

Figure 2.2.6

22

The Center Winder Function calculates and outputs the ratio of line surface speed / winder

motor speed. This ratio can then be divided into the winder’s speed reference to control the

winder motor as the roll diameter increases or decreases. The actual roll diameter can be

calculated by multiplying the ratio by the core diameter. The diameter will be in the same units

as the core diameter. This is a simple center winder function and can be used only one time in

a configuration.

Input connector 20 should connect to the line speed. The line speed must be directly related to

the actual speed of the material being wound. Input connector 21 must be connected to the

winder’s motor speed. When the winder is at core input 20 should equal input 21. The

necessary adjustments must be made to make this a true statement.

The output to this function is filtered to avoid over reacting to sudden short changes in the input

information. Parameter P1-06 controls how fast the drive reacts to the diameter change.

Parameter P1-07 sets the maximum ratio that will be applied to the drive speed and is equal to

maximum roll diameter / core diameter. The ratio calculation will stop at the maximum ratio.

Function Controls Range Default Setup

Center

Winder

P1-06 = Diameter Filter Time 0.1 to 50.0 sec 0.1

P1-07 = Diameter Build Ratio 0.1 to 15.0 12.5 P1-07 = Max Roll Diameter / Core Diameter

2.2.7 Switch

H1-0? = 80

01

02

Switch 1

Figure 2.2.7

03

04

05

H1-0? = 81

06

Switch 2

The switch function provides a means to switch between two possible inputs via a multi-function

input. Switch 1 connects input 02 to output 03 when the multi-function input is off or not

configured. Switch 1 connects input 01 to output 03 when the configured multi-function input is

turned on. Switch 2 connects input 05 to output 06 when the multi-function input is off or not

Date: 07/01/04, Rev: 04-07 Page 15 of 27 TM.G5SW.015

Page 16

configured. Switch 2 connects input 04 to output 06 when the configured multi-function input is

turned on.

These functions can be used more than one time in a configuration but all instances will switch

when the associated multi-function input is activated.

Function Controls Range Default Setup

Switch 1

Switch 2

Input 01 Normally Open

Input 02 Normally Closed

Input 04 Normally Open

Input 05 Normally Closed

Terminal ? - H1-01 to 06 = 80: Switch 1 DI

Terminal ? - H1-01 to 06 = 81: Switch 2 DI

2.2.8 Number Hold

H1-0? = 85

42

Number

Figure 2.2.8

Hold

43

The number hold function will pass the input value to the output when the associated multifunction input is off. The last value read is held and output to 43 when the multi-function input is

turned on. The hold value is stored in running memory not NVRAM. It will be lost when the

drive is turned off.

Function Controls Range Default Setup

Number Hold

Input 42 connected to output 43

Terminal ? - H1-01 to 06 = 85: Number Hold

2.3 Drive

The Drive functions provide a means to direct information into the drive. Information can be

directed to all drive outputs and monitors.

2.3.1 Drive Speed

Drive

ff

Speed

Figure 2.3.1

The Drive Speed function sends the value input directly to the drive’s speed reference.

2.3.2 Drive Max Torque

Drive

Max

fe

Torque

Figure 2.3.2

Date: 07/01/04, Rev: 04-07 Page 16 of 27 TM.G5SW.015

Page 17

The Drive Maximum Torque function sets or dynamically changes the maximum forward and

reverse torque value used by the drive. This control is only available when A2-01 = 3: flux

vector control mode. The forward and reverse torque values are equal when this function is

used.

2.3.3 Accel / Decel

Accel/

19

Decel

Figure 2.3.3

The Accel / Decel function allows the acceleration and deceleration rates to be dynamically

adjusted. The change may be calculated using the following equations when the input is fixed.

Accel Time = (Input 19 x C1-01) / 10000

Decel Time = (Input 19 x C1-02) / 10000

When the input is 100.00% or 10000 the accel / decel rate will be C1-01 and C1-02.

2.3.4 Drive Output (contact and transistors)

80

Drive

Output 40

Drive

81

Output 41

82

Drive

Output 42

Figure 2.3.4

Drive Output functions provide control to the three multi-function outputs. When the value

connected to the input exceeds the associated P2 parameter level the output will close. It will

open when the input drops below the set level.

Function Information Setup

Contact Output 9 Connects terminal 9 to 10 H2-01 = 40: CONNECTION 80, P2-07: Output 9 Level

Trans Output 25 Sinks terminal 25 to 27 H2-02 = 41: CONNECTION 81, P2-08: Output 25 Level

Trans Output 26 Sinks terminal 26 to 27 H2-03 = 42: CONNECTION 82, P2-09: Output 26 Level

2.3.5 Monitor / Analog Output

U1-50

90

Monitor

95

Figure 2.3.5

U1-55

Monitor

Drive

Analog

Output 50

U1-51

91

Monitor

96

U1-56

Monitor

Drive

Analog

Output 51

U1-52

92

Monitor

U1-57

97

Monitor

U1-53

93

Monitor

U1-58

98

Monitor

U1-54

94

Monitor

U1-59

99

Monitor

Monitor functions provide a means to monitor values within a configuration. They can be used

at any time. Monitor functions do not require setup. The value input into a monitor is divided by

10, to increase the range of the monitor’s display.

Date: 07/01/04, Rev: 04-07 Page 17 of 27 TM.G5SW.015

Page 18

The drive’s analog outputs can be connected to monitor U1-50 and U1-51. This feature must be

setup. The displayed value will be sent to the associated analog output. Setting the connected

analog output gain to 10 will provide the actual value connected to the monitor. The analog

output will operate within the defined range. The gain and bias parameters can be used to scale

the analog output.

Function Information Setup

Monitor 1 (U1-50) H4-01 or H4-04 = 50: Case Monitor 1

Monitor 2 (U1-51)

Information can be passed to analog output terminals 21

and 23

H4-01 or H4-04 = 51: Case Monitor 2

2.3.6 Write Memory

45

Figure 2.3.6

Write

Memory 2

44

Write

Memory 1

Write Memory functions allow values to be stored into memory. The last value input is stored in

running memory not NVRAM. This number can be read using the corresponding Read Memory

function. This function serves as a means to end and store the final value of a function’s output.

This number value can be reintroduce into the control logic where needed by using the Read

Memory function. If the input of the Read Memory function is used before the corresponding

Write Memory function in the configuration sequence the value read will be from the previous

scan. This feature can be used to determine the change from scan to scan.

Date: 07/01/04, Rev: 04-07 Page 18 of 27 TM.G5SW.015

Page 19

3.0 Parameter Changes

3.1 Group A User Parameters

The user parameters are located within the “Initialize” menu selection. When the GPD515/G5

drive has been flashed with this software A2-11 through A2-32 constants are converted to the

parameters used to configure the drive.

3.2 Group b Applications – Function b1 Sequence

Display Constant Setting Display Description

Reference Source b1-01 05 Eliminator Ref Enables the Eliminator Software

3.3 Group H Terminal - Function H1 Digital Inputs

Display Constant Setting Display Description

80 Switch 1 DI Switch function with a common output to a NO and NC input

Terminal 3 Sel

Terminal 4 Sel

Terminal 5 Sel

Terminal 6 Sel

Terminal 7 Sel

Terminal 8 Sel

H1-01

H1-02

H1-03

H1-04

H1-05

H1-06

81 Switch 2 DI Switch function with a common output to a NO and NC input

82 MOP UP Increases the MOP value

83 MOP DOWN Decreases the MOP value

84 MOP RESET Resets the MOP value to the default value set in parameter P2-05

85 Number Hold Holds the last value input until de-activated

86 CASE DI 7 Reserved

87 CASE DI 8 Reserved

3.4 Function H2 Digital Outputs

Display Constant Setting Display Description

Terminal 9 Sel

Terminal 25 Sel

Terminal 26 Sel

H2-01

H2-02

H2-03

40 CONNECTION 80 Switch function with a common output to a NO and NC input

41 CONNECTION 81 Switch function with a common output to a NO and NC input

42 CONNECTION 82 Increases the MOP value

3.5 Function H4 Analog Outputs

Display Constant Setting Display Description

Terminal 21 Sel

Terminal 23 Sel

H4-01

H4-04

50 Case Monitor 1 Links the value in U1-50 to the selected analog output

51 Case Monitor 2 Links the value in U1-51 to the selected analog output

3.6 Group F Options

Constant F1-01, Pulses Per Rev is enabled in all control methods

Date: 07/01/04, Rev: 04-07 Page 19 of 27 TM.G5SW.015

Page 20

4.0 Startup Procedure

1. Develop a configuration list.

2. Connect all external devices.

3. Perform the appropriate procedure for a standard drive startup.

4. Enter the configuration list into the User Parameters starting at A2-11.

5. Set the reference source to “Eliminator Ref” (b1-01 = 5).

6. Test the configuration using care to prevent damage to connected loads.

Date: 07/01/04, Rev: 04-07 Page 20 of 27 TM.G5SW.015

Page 21

5.0 Custom Software Parameters

5.1 New Program Group

Group P

Eliminator Parms

5.2 New Program Function

Function P1

Eliminator P1

Select Eliminator P1 to access parameters P1-01 to P1-10.

Function P2

Eliminator P2

Select Eliminator P2 to access parameters P2-01 to P2-10.

5.3 New Program Parameters

Parameter 1

P1-01 = 0

P1-01 Parameter 1 B B B B

This parameter is provided for user input. Refer to section 2.1.3.

Parameter 2

P1-02 = 0

P1-02 Parameter 2 B B B B

This parameter is provided for user input. Refer to section 2.1.3.

Setting Range: 0 to 65535

Factory Default: 0

Modify During Run: Yes

Modbus Address: 0580H

Setting Range: 0 to 65535

Factory Default: 0

Modify During Run: Yes

Modbus Address: 0581H

Date: 07/01/04, Rev: 04-07 Page 21 of 27 TM.G5SW.015

Page 22

Parameter 3

P1-03 = 0

P1-03 Parameter 3 B B B B

This parameter is provided for user input. Refer to section 2.1.3.

Parameter 4

P1-04 = 0

P1-04 Parameter 4 B B B B

This parameter is provided for user input. Refer to section 2.1.3.

Parameter 5

P1-05 = 0

P1-05 Parameter 5 B B B B

This parameter is provided for user input. Refer to section 2.1.3.

Diam Filter Time

P1-06 = 0.1 sec

P1-06 Diameter Filter Time B B B B

The Diam Filter Time controls the rate of change within the winder filter. Refer to section 2.2.6.

Diam Bld Ratio

P1-07 = 0.1

P1-07 Diameter Build Ratio B B B B

The Diam Build Ratio is the number equal to the ratio of core diameter to maximum roll

diameter. Refer to section 2.2.6.

Example: Core Diameter = 4”

Max Roll Diameter = 48”

Set P1-07 = 48” / 4”‘or 12

Setting Range: 0 to 65535

Factory Default: 0

Modify During Run: Yes

Modbus Address: 0582H

Setting Range: 0 to 65535

Factory Default: 0

Modify During Run: Yes

Modbus Address: 0583H

Setting Range: 0 to 65535

Factory Default: 0

Modify During Run: Yes

Modbus Address: 0584H

Setting Range: 1 to 50 sec

Factory Default: 0.1 sec

Modify During Run: No

Modbus Address: 0585H

Setting Range: 0.1 to 50

Factory Default: 0.1

Modify During Run: No

Modbus Address: 0586H

Date: 07/01/04, Rev: 04-07 Page 22 of 27 TM.G5SW.015

Page 23

Scale Multiplier

P1-08 = 0

P1-08 Scale Multiplier B B B B

The Scale Multiplier number is multiplied times the value of input 60. Refer to section 2.2.5.

Scale Divisor

P1-09 = 0

P1-09 Scale Divisor B B B B

The Scale Divisor is the number divided into the product of the scale multiplication. Refer to

figure 2.2.5.

Scale Bias

P1-10 = 0

P1-10 Scale Bias B B B B

The Scale Bias is the number that will be added to the value of the scale calculation to offset the

value of output 61 up or down. Refer to section 2.2.5.

Max Pulses In

P2-01 = 30720

P2-01 Max Pulses Input B B B B

The Max Pulses In is the number that equals the input pulse rate per second that will result in

100 % inverter output. Refer to section 2.1.4.

Example: 30720 = (1800 rpm X 1024 encoder pulses per rev) / 60 sec (30720 is the default)

MOP Rate / Sec

P2-02 = 0.00 %

P2-02 MOP Rate / Second B B B B

The MOP Rate / Sec sets the rate of MOP change for output 25. This number will be added to

or subtracted from the current value of output 25 when the multi-function input assigned to 82

Setting Range: -9999 to 9999

Factory Default: 0

Modify During Run: Yes

Modbus Address: 0587H

Setting Range: -9999 to 9999

Factory Default: 0

Modify During Run: Yes

Modbus Address: 0588H

Setting Range: -9999 to 9999

Factory Default: 0

Modify During Run: Yes

Modbus Address: 0589H

Setting Range: 0 to 65535

Factory Default: 30720

Modify During Run: Yes

Modbus Address: 0590H

Setting Range: 0.01 to 100.00 %

Factory Default: 0.00 %

Modify During Run: Yes

Modbus Address: 0591H

Date: 07/01/04, Rev: 04-07 Page 23 of 27 TM.G5SW.015

Page 24

MOP UP or 83 MOP DOWN is energized for 5ms. Maintaining this input will result in output 25

changing at this rate per second. Refer to section 2.1.2.

MOP Max Percent

P2-03 = 100 %

P2-03 MOP Maximum Percentage B B B B

The MOP Max Percent sets the maximum MOP value possible for outputs 25 and 26. Refer to

section 2.1.2.

MOP Min Percent

P2-04 = 0 %

P2-04 MOP Minimum Percentage B B B B

The MOP Min Percent sets the minimum MOP value possible for outputs 25 and 26. Refer to

section 2.1.2.

MOP Rst Percent

P2-05 = 0 %

P2-05 MOP Reset Percentage B B B B

The MOP Rst Percent is the value that outputs 25 and 26 are reset to when the multi-function

input assigned to 84 MOP RESET is energized. Refer to section 2.1.2.

MOP Step Rate

P2-06 = 0.00 %

P2-06 MOP Step Rate B B B B

The MOP Step Rate is the number that will be added to or subtracted from the current value of

output 26 when the multi-function input assigned to 82 MOP UP or 83 MOP DOWN is energized

for 5ms. Each transition of either input will result in one step. Refer to section 2.1.2.

Setting Range: 0 to 1000 %

Factory Default: 100 %

Modify During Run: Yes

Modbus Address: 0592H

Setting Range: -1000 to 100 %

Factory Default: 0 %

Modify During Run: Yes

Modbus Address: 0593H

Setting Range: -1000 to 1000 %

Factory Default: 0 %

Modify During Run: Yes

Modbus Address: 0594H

Setting Range: 0.00 to 100.00

Factory Default: 0.00

Modify During Run: Yes

Modbus Address: 0595H

Date: 07/01/04, Rev: 04-07 Page 24 of 27 TM.G5SW.015

Page 25

Out 9 Level

P2-07 = 0

Setting Range: -9999 to 9999

Factory Default: 0.00

Modify During Run: Yes

Modbus Address: 0596H

P2-07 Output 9 level B B B B

The Out 9 Level sets the value that connection 80 must exceed to activate multi-function

selection 40: CONNECTION 80. It is recommended that H2-01 Terminal 9 Sel be setup as 40:

CONNECTION 80. This value is multiplied by 10 within the software. Refer to section 2.3.4

Out 25 Level

P2-08 = 0

Setting Range: -9999 to 9999

Factory Default: 0

Modify During Run: Yes

Modbus Address: 0597H

P2-08 Output 25 Level B B B B

The Out 25 Level sets the value that connection 81 must exceed to close multi-function

selection 41: CONNECTION 81. It is recommended that H2-02 Terminal 25 Sel be setup as

41: CONNECTION 81. This value is multiplied by 10 within the software. Refer to section 2.3.4

Setting Range: -9999 to 9999

Out 26 Level

P2-09 = 0

Factory Default: 0

Modify During Run: Yes

Modbus Address: 0598H

P2-09 Output 26 Level B B B B

The Out 26 Level (x10) sets the value that connection 82 must exceed to activate multi-function

selection 42: CONNECTION 82. It is recommended that H2-03 Terminal 26 Sel be setup as

42: CONNECTION 82. This value is multiplied by 10 within the software. Refer to section 2.3.4.

Max Torque Ref

P2-10 = 0.00 %

Setting Range: 0.00 to 300.00 %

Factory Default: 0.00 %

Modify During Run: Yes

Modbus Address: 0599H

P2-10 Maximum Torque Reference B B B B

The Max Torque Ref value is the limit applied to input ‘fe’ of the drive maximum torque function.

This is a bipolar limit and limits the torque output of the drive to this value. The values set in the

L7 torque limiting constants remain in effect. Refer to section 2.3.2.

Date: 07/01/04, Rev: 04-07 Page 25 of 27 TM.G5SW.015

Page 26

6.0 New Monitors

Monitor 1

U1-50 0.0

Monitor 1 will display the value / 10 of the output connected to input 90. When this monitor is

used with the analog output function the displayed number is output.

Monitor 2

U1-51 0.0

Monitor 2 will display the value / 10 of the output connected to input 91. When this monitor is

used with the analog output function the displayed number is output.

Monitor 3

U1-52 0.0

Monitor 3 will display the value / 10 of the output connected to input 92.

Range: -3276 to 3276.7 (x10)

Modbus Address: 00d0H

Range: -3276 to 3276.7 (x10)

Modbus Address: 00d1H

Range: -3276 to 3276.7 (x10)

Modbus Address: 00d2H

Monitor 4

U1-53 0.0

Monitor 4 will display the value / 10 of the output connected to input 93.

Monitor 5

U1-54 0.0

Monitor 5 will display the value / 10 of the output connected to input 94.

Monitor 6

U1-55 0.0

Monitor 6 will display the value / 10 of the output connected to input 95.

Range: -3276 to 3276.7 (x10)

Modbus Address: 00d3H

Range: -3276 to 3276.7 (x10)

Modbus Address: 00d4H

Range: -3276 to 3276.7 (x10)

Modbus Address: 00d5H

Date: 07/01/04, Rev: 04-07 Page 26 of 27 TM.G5SW.015

Page 27

Monitor 7

U1-56 0.0

Monitor 7 will display the value / 10 of the output connected to input 96.

Monitor 8

U1-57 0.0

Monitor 8 will display the value / 10 of the output connected to input 97.

Monitor 9

U1-58 0.0

Monitor 9 will display the value / 10 of the output connected to input 98.

Monitor 10

U1-59 0.0

Monitor 10 will display the value / 10 of the output connected to input 99.

Range: -3276 to 3276.7 (x10)

Modbus Address: 00d6H

Range: -3276 to 3276.7 (x10)

Modbus Address: 00d7H

Range: -3276 to 3276.7 (x10)

Modbus Address: 00d8H

Range: -3276 to 3276.7 (x10)

Modbus Address: 00d9H

Date: 07/01/04, Rev: 04-07 Page 27 of 27 TM.G5SW.015

Loading...

Loading...