Page 1

Electronic Lineshaft with Alignment

GPD515/G5 Software Option (VSG114713E)

Part Number: CIMR-G5MXXXXXF-046

(1)

A Yaskawa GPD515/G5 flashed with this software has the ability to electronically emulate a lineshaft connection

between 2 or more independently driven devices. In this system there will be a master device and one or more

slave drives. The slaves will follow the master device and can be automatically aligned to it by using the

alignment feature. Once aligned the relationship between the leading master device and the following slave

drives will be maintained. The gearing feature allows the slaves drives to follow the master device at a definable

ratio.

This system requires supplying the slave drive with a line driver quadrature feedback from the device to be

followed. Any electronic device that is capable of supplying the following drive with the proper signal can be used

as the master signal. The following drive will follow the master signal pulse for pulse after applying the ratio in

either direction. The following drive must be operated using closed loop or flux vector control and therefore must

have an encoder coupled to the motor.

The typical application will have a master drive and a slave drive. The equipment being driven requires two

mechanically isolated and motor driven moving parts to maintain a constant position relationship to within a few

encoder counts. The position of the moving part driven by the slave motor requires alignment to the position of

the master device.

The master drive can be operated in any control mode but master device feedback connected to the slave drive is

required. The feedback or master signal controls the follower drive. The follower drive monitors the master

signal and compares it to the feedback from the slave motor’s encoder. The follower will then compensate for

any position errors resulting by adjusting the output frequency of the slave drive. This results in near perfect

alignment between the master device and slave device. There is no accumulation of position error, so alignment

will always be maintained within a few pulses.

The slave drive has an automatic alignment feature with this software. This feature provides a means of aligning

the follower encoder to the master signal. This is accomplished by using two switches connected to the trigger

inputs of the slave drive. One switch is used to indicate the position of the master. The other switch is used to

indicate the position of the follower. When the alignment feature is active, advancing or retarding the slave motor

corrects the difference between when these switches are activated. When both encoders are activated at the

same time the master and follower are aligned. An offset feature is provided enabling fine adjustment for switch

misalignment.

This software provides a trim advance and retard input to adjust the following drive in respect to the to the master.

Adjustments can be made while running. This adjustment will change the position or phase relationship between

the drives.

When the master signal is from another GPD515/G5 it is not necessary for it to be running lineshaft software. All

follower or slave GPD515/G5 drives must be running lineshaft software.

Date: 07-01-04, Rev: 04-07 Page 1 of 15 TM.G5SW.046

Page 2

Electronic Lineshaft with Alignment

Features:

Disable Lineshaft Input – Disables the lineshaft software placing the drive back into standard control

Advance (Trim) Input – Advances the alignment position of the slave drive at a settable rate

Retard (Trim) Input – Retards the alignment position of the slave drive at a settable rate

Slave Trigger Input – Indicates the position of the slave drive when activated

Master Trigger Input – Indicates the position of the master drive when activated

Align Slave Input – Enables the automatic alignment feature

Aligned Output – Indicates the alignment procedure was performed and the following drive did align

Alignment Checking – Monitors the difference between the trigger inputs with the result controlling an output

Alignment Fault – Monitors the travel during alignment and faults the drive when the limit is exceeded

Following Alarm – Monitors the following error and provides a selectable result when it exceeds the limit

Gear Ratio – Adjust the ratio of the following drive in respect to the master

Monitors – Displays useful information to indicate how close the follower is following

The disable lineshaft input provides a means to operate the drive independent from the master drive. This feature

can be selected at any time and disables all lineshaft features when active. The position relationship between the

master and the slave drive will be lost when this input is activated. The slave drive will maintain the current

position with the master when the lineshaft disable input is deactivated.

The trim controls provide a means to adjust the position relationship between the master and the slave drives.

The trim rate is settable. The slave position can be advanced or retarded in relation to the master drive when the

slave’s run input is on. The trim can function if the run input is on.

The align slave, master and slave trigger inputs are required to perform an alignment. The alignment procedure

can be used to align the slave to the master using fixed trigger positions. This process does not control the

master drive. All correction is made by the slave drive. The amount of the correction is controlled by the

quadrature counts that are accumulated from the time when the first or leading trigger starts the process and

continues until the trailing trigger stops it. The correction will be made as soon as the trailing trigger input

becomes active. This process was intended to be performed at lower frequencies but will function if the triggers

provide a minimum of a 5 millisecond signal.

The alignment check is provided to indicate whether the trigger inputs are activated within a settable quadrature

count range. An alignment check output will be on when the triggers are within the defined range and will go off

when the range is exceeded. This output will only change after the trailing trigger has activated. This check is

always active in lineshaft mode.

The following alarm monitors the quadrature error count that exists between the master and the slave drive. If the

count exceeds the settable range a selectable action will occur.

The gear ratio provides a means to apply a ratio between the master device and the slave drive. This may be

used to correct for errors in drivetrain ratios or to apply a required ratio between the drives.

The monitors provided allow monitoring of how well the slave drive is following the master signal. The master

signal can also be monitored.

Date: 07-01-04, Rev: 04-07 Page 2 of 15 TM.G5SW.046

Page 3

1.1 Sample Application

Electronic Lineshaft with Alignment

Gear

Slave

Box

d

e

n

g

i

l

A

Master

Motor

Slave Trigger Switch

Motor

Slave Motor

Slave Encoder

PG-W2

GPD

515

Master Motor

Master Encoder

Master Trigger Switch

PG-X2

GPD

515

This example shows two pusher chains. Each chain is mechanically isolated from the other. The master

and slave trigger switches are placed in line providing an alignment position for the pushers. The pusher’s

leading edge will activate the switches as they pass.

When this line starts alignment is necessary. The “Align Slave” input must be activated and maintained to

cause the alignment feature to operate. The slave drive will align itself after the trailing pusher has

triggered. The “Aligned” output indicates that the alignment procedure was successful and that the “Align

Slave” input may be removed. If this input is not removed alignment will occur each time a pusher passes a

trigger switch. The pushers will be aligned to the associated trigger switch position.

The lineshaft software will maintain the follower’s position in respect to the master. The follower position is

monitored and if it exceeds the users set value a following fault or alarm will result. The alignment check

will also monitor the quadrature counts between the triggers. An “Alignment Check” output will remain on if

the check was within the set range.

Date: 07-01-04, Rev: 04-07 Page 3 of 15 TM.G5SW.046

Page 4

Electronic Lineshaft with Alignment

1.2 Example Configuration Diagram

to the 1

OR

OR

OR

OR

Master Source Signal

st

Slave GPD515 Drive

Master Source Signal

nd

Slave GPD515 Drive

to the 2

Master Source Signal

to the 3rd Slave GPD515 Drive

Master Source Option 1

Pulse

Generator

+A Pulse

-A Pulse

+B Pulse

-B Pulse

Master Source Option 2

Encoder

Master Source Option 3

Motor

Encoder

1.2 Example Wiring Diagram

Master Drive

T1

T2

T3

MGL

Red 5-15VDC

1

Black Common

2

3

Blue +A

4

Gray -A

5

Green +B

6

Yellow -B

7

8

9

Blue +A

1

Gray -A

2

Green +B

3

Yellow -B

TA2 TA1

4

PG-X2 PCB Option

5

6

TA3

Run

Speed Ref

L1

L2

GPD515

L3

1 FWD Run

2 REV Run

3 EXT Fault

4 Fault Reset

5 Definable

6 Definable

7 Definable

8 Definable

11 Common

12 GND

13 Input 0-10V

14 Input 4-20mA

15 Supply +15V@20mA

16 Input 0-10V

17 Supply Common

33 Supply -15V@20mA

9

10

18

19

20

25

26

27

23 Analog Output +/- 10 VDC

24 Analog Output +/- 10 VDC

25 Analog Output Common

IM

Motor

Shield

Master Source Option 4

Encoder

encoder

PG-X2

GPD

515

Any Software

Master

Motor

Encoder

Enable / Run

Disable

S Align Switch

M Align Switch

Alignment Sw

PG-W2

GPD

515

G114712

Software

Slave 1

Motor

Slave Drive

L1

GPD515

L2

G11471x

L3

1 FWD Run

2 REV Run

3 EXT Fault

4 Fault Reset

5 DisableLineshaft

6 Slave Trigger

7 Master Trigger

8 Align Slave

11 Common

12 GND

13 Input 0-10V

14 Input 4-20mA

15 Supply +15V@20mA

16 Input 0-10V

17 Supply Common

33 Supply -15V@20mA

9

10

18

19

20

25

26

27

23 Analog Output +/- 10 VDC

24 Analog Output +/- 10 VDC

25 Analog Output Common

PG-W2

GPD

515

G114712

Software

Slave 2

Motor

Encoder

T1

T2

T3

MGL

Red 5-15VDC

1

Black Common

2

Blue +A

3

Gray -A

4

Green +B

5

Yellow -B

6

7

8

9

Blue +A

10

Gray -A

11

Green +B

12

Yellow -B

13

14

15

16

+A

17

PG-W2 PCB Option

-A

18

+B

19

-B

20

21

22

Shield

23

24

To Next Drive

IM

Motor

encoder

Date: 07-01-04, Rev: 04-07 Page 4 of 15 TM.G5SW.046

Page 5

Electronic Lineshaft with Alignment

1.3 PG-W2 Terminal Description and Wiring Notes

Refer to the GPD515/G5 User’s Manual for additional information regarding encoder feedback option cards.

PG-W2

Terminal #

1 IP12 +12V supply to power encoder

2 IG12

3 +A

4 -A

5 +B

6 -B

10 +A

11 -A

12 +B

13 -B

17 +A

18 -A

19 +B

20 -B

For proper lineshaft operation the following conditions must be met:

1) A PG-W2 encoder feedback card must be installed in the follower VFD(s).

2) The pulse reference from the master device must be quadrature, differential line driver type.

3) Encoder feedback from the follower motor must be quadrature, differential line driver type.

4) When the master operates in its normal, forward direction, monitor U1-50 of the follower should display a

positive value. If it does not, it may be necessary to reverse the channel 2 pulse input A wires at

terminals 10 and 11 of the follower’s PG-W2.

5) If the follower’s U1-50 display is positive, when the drive is commanded to run via input to terminal #1, the

motor should rotate in the proper direction and the follower’s U1-05 monitor should display a positive value. If

the motor direction is incorrect, it may be necessary to reverse any two of the motor leads on the VFD output.

If the motor fails to rotate, or is unstable, it may be necessary to reverse the channel 1 pulse input A wires at

terminals 3 and 4 of the PG-W2.

6) Do not use parameter F1-05 to change encoder phasing in this software. Please swap encoder

signals A+ and A- instead.

1.4 Alignment Operation Description

The alignment operation performed by the follower drive requires three external inputs. The “Align Slave” input

enables and disables the alignment feature. The “Master Trigger” input indicates the master drive is at the

aligned position. The “Slave Trigger” input indicates that the slave drive is at the aligned position. The aligned

position is where both trigger switches are activated at the same time.

When the “Align Slave” input is activated the slave drive will monitor the trigger inputs. The slave drive will

accumulate the error count that separates the leading edges of the trigger inputs. When aligned both triggers are

simultaneous. When not aligned the leading trigger will start an error count. The following trigger will stop the

error count and the error will be corrected by advancing or retarding the slave drive at a maximum frequency of 4

Hz. The correction will occur when the leading edge of the following trigger is activated.

The recommended speed range for alignment is between 6 to 12Hz. Alignment can be performed at higher

speeds. The trigger inputs require a minimum signal of 5 milliseconds. If the alignment speed is below 4 Hz the

slave drive may run in the reverse direction to retard.

Parameter P1-02: “Align Offset” has been provided to adjust for misalignment of the trigger switches. The

adjustment allows for + / - 9999 quadrature encoder counts or approximately 2.5 motor revolutions when using a

Designation Function Remarks

Power Supply

Follower Motor

Feedback

Master

Device

Signal

Pulse Output

(Mirrors Channel 2)

0V, Common for 12V power supply

Channel 1, Pulse Input A

Channel 1, Pulse Input B

Channel 2, Pulse Input A

Channel 2, Pulse Input B

Encoder 2, Pulse Output, Channel A (5V pk)

Encoder 2, Pulse Output, Channel B (5V pk)

Date: 07-01-04, Rev: 04-07 Page 5 of 15 TM.G5SW.046

Page 6

Electronic Lineshaft with Alignment

1024 pulse encoder with a 4096 quadrature encoder count. The sign is determined in respect to the master

trigger switch.

Alignment is when both master and slave triggers are activated simultaneously. If the trigger switches are not

aligned properly the align offset can be used to correct the error. A negative offset indicates the slave drive

needs to retard. A positive offset indicates the slave drive needs to advance.

A minus offset value is indicative of the slave trigger occurring before the master resulting in the need to retard

the drive by the negative offset count set in P1-02. A positive value indicates the slave trigger occurs after the

master resulting in the need to advance the drive.

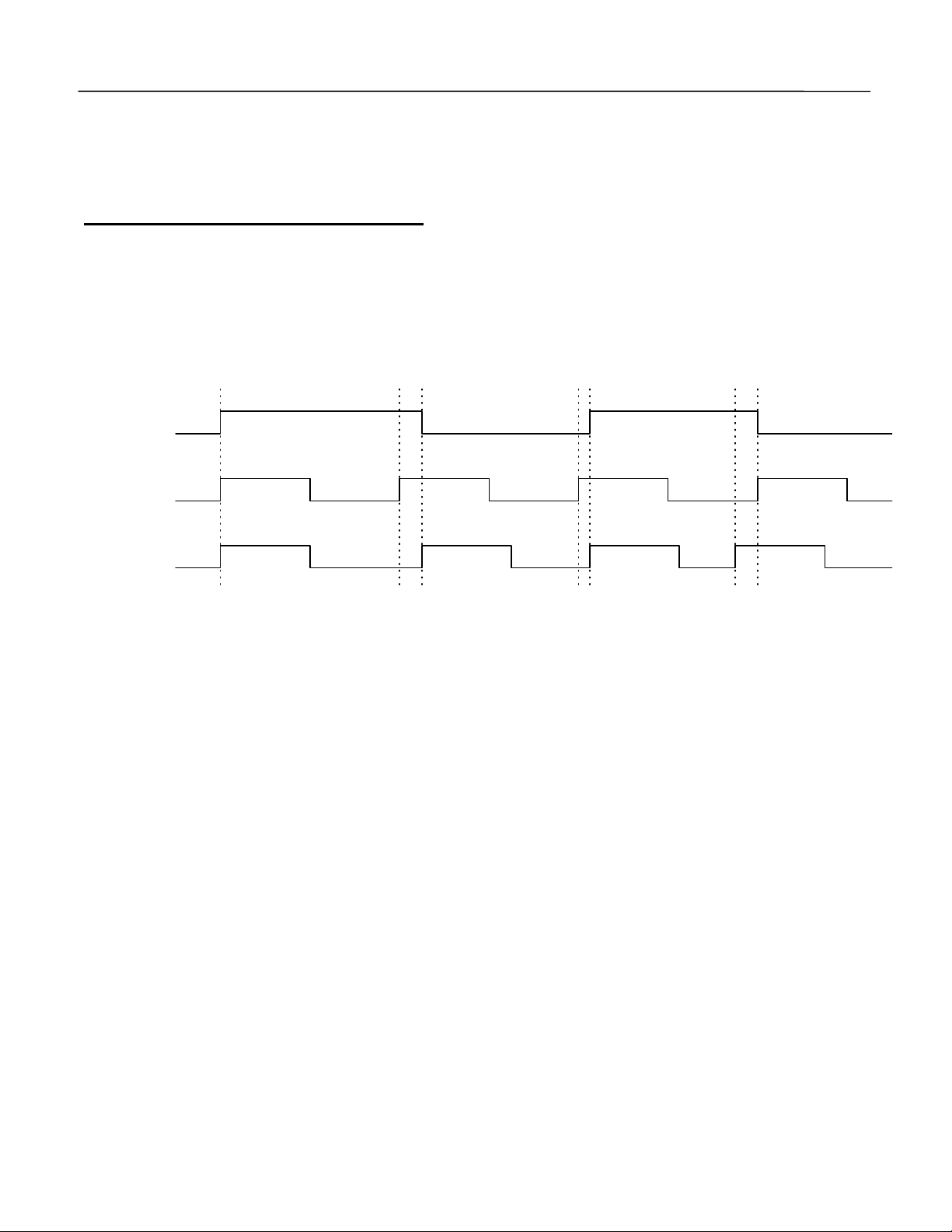

Alignment Timing Chart

Slave Run

Input Term #1

Master Run

Input Term #1

Aligned

Output

Master Trigger

Input

Slave Trigger

Input

Align Slave

Input

Alignment

Error

Slave Freq

Output

Master Freq

Output

Chart Explanation:

The slave drive is set to run. The master driver is set to run. The slave follows the master drive. The align slave

input is activated and maintained. Both master and slave triggers are activated simultaneously. No alignment

error is accumulated and no correction in alignment is made.

The master trigger is activated. The alignment error begins to accumulate. The slave trigger is activated. The

alignment error accumulation stops. The alignment error is corrected by accelerating the slave drive because the

master was leading the slave. Both triggers are deactivated.

The slave trigger is activated. The alignment error begins to accumulate. The master trigger is activated. The

alignment error accumulation stops. The alignment error is corrected by decelerating the slave drive because the

slave was leading the master. Both triggers are deactivated.

The “Aligned Output” will activate when the slave drive has corrected the position error to within 50 encoder

counts. It will not reset until the “Slave Run” input has been removed or the “Align Slave” input has been removed

and reactivated.

Date: 07-01-04, Rev: 04-07 Page 6 of 15 TM.G5SW.046

Page 7

Electronic Lineshaft with Alignment

When the run signal is removed from the master drive the slave drive will follow the master to a stop.

When the alignment process has completed the “Align Slave” input may be removed to prevent continuous

alignment. The “Aligned Output” will not reset until the “Align Slave” input has been removed and reactivated.

1.4 Alignment Check Description

When operating in lineshaft mode an alignment check is performed. This check monitors the difference in

quadrature counts that separates the trigger inputs. The alignment offset is factored into the calculation. If the

error count exceeds the value set in P1-10 the alignment check output will be off. This output will only change

states after an alignment check. When the alignment check output is on it indicates that the error count between

the master and slave trigger inputs was less than the value set in P1-10 when last checked.

Alignment Checking Chart

Alignment

Check Output

Master Trigger

Input

Slave Trigger

Input

{

Exceeds P1-10: Alignment Check Exceeds P1-10: Alignment Check

{

Within P1-10: Alignment Check

{

Date: 07-01-04, Rev: 04-07 Page 7 of 15 TM.G5SW.046

Page 8

Electronic Lineshaft with Alignment

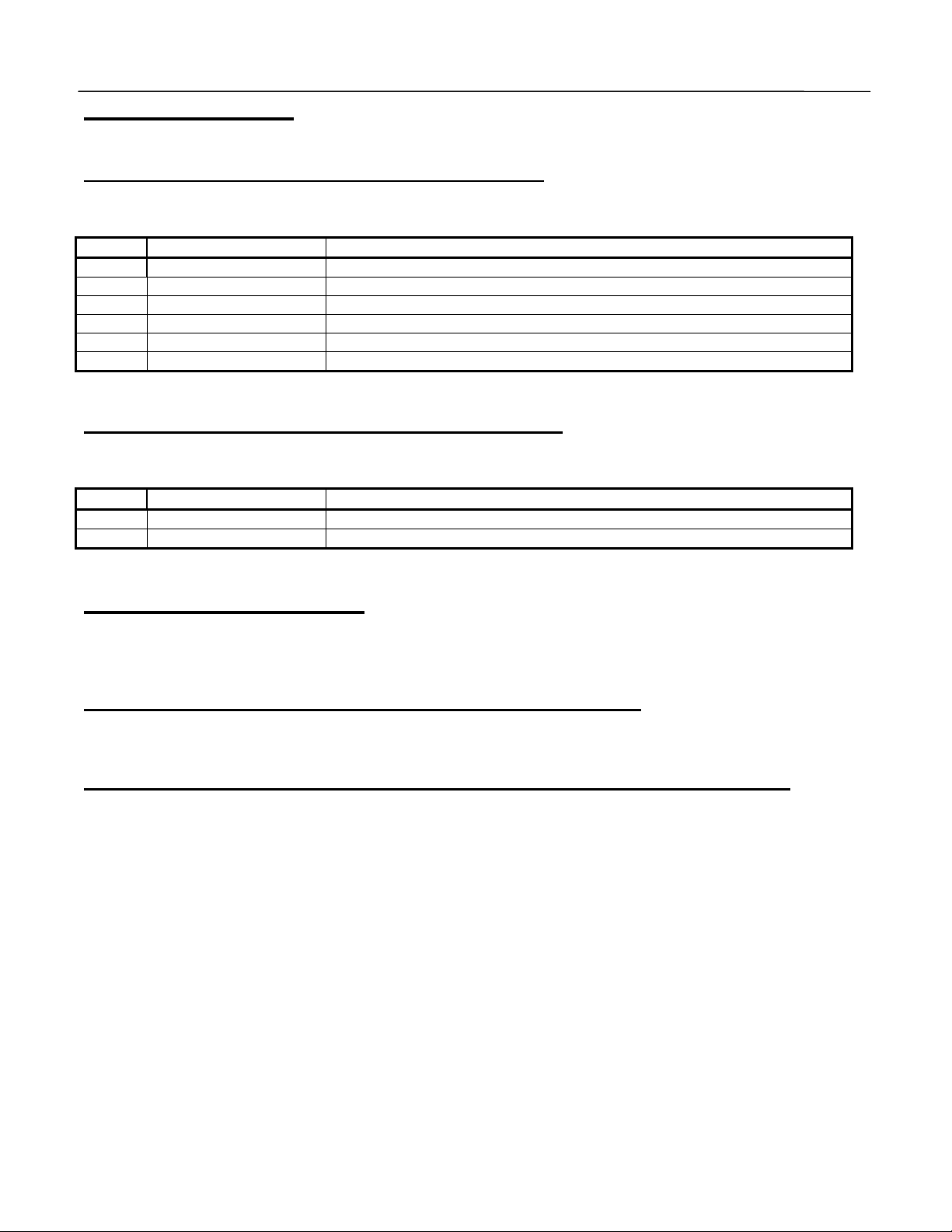

2.0 I/O Definitions

2.1 New Multi-Function Digital Input Settings

For constants H1-01 through H1-06.

Setting Display Description

80 Disable LineShft Closed: Line Shaft Mode is disabled

83 Advance Slave Closed: Slave drive will increase speed without accumulating error

84 Retard Slave Closed: Slave drive will decrease speed without accumulating error

85 Slave Trigger Closed: The slave encoder has achieved the alignment position

86 Master Trigger Closed: The master encoder has achieved the alignment position

87 Align Slave Closed: The error count between the triggers will be corrected

2.2 New Multi-Function Digital Output Settings

For constants H2-01 through H2-03.

Setting Display Description

40 Alignment Check On = The alignment has check was within the set range

42 Aligned On = The alignment function was performed successfully

3.0 Configuration Notes

This software document is only a supplement to the GPD515/G5 Series instruction manual. All parameters and

features not mentioned in this document have not changed.

3.1 Changed Factory Defaults of Standard Parameters

None

3.2 Minimum Programming Requirements for “Line Shaft” Operation

1. The follower VFD must be programmed for the Flux Vector control method, A1-02 = 3.

2. The follower’s run and reference sources, B1-01 and B1-02, must be set to 5:Line Shaft.

Date: 07-01-04, Rev: 04-07 Page 8 of 15 TM.G5SW.046

Page 9

Electronic Lineshaft with Alignment

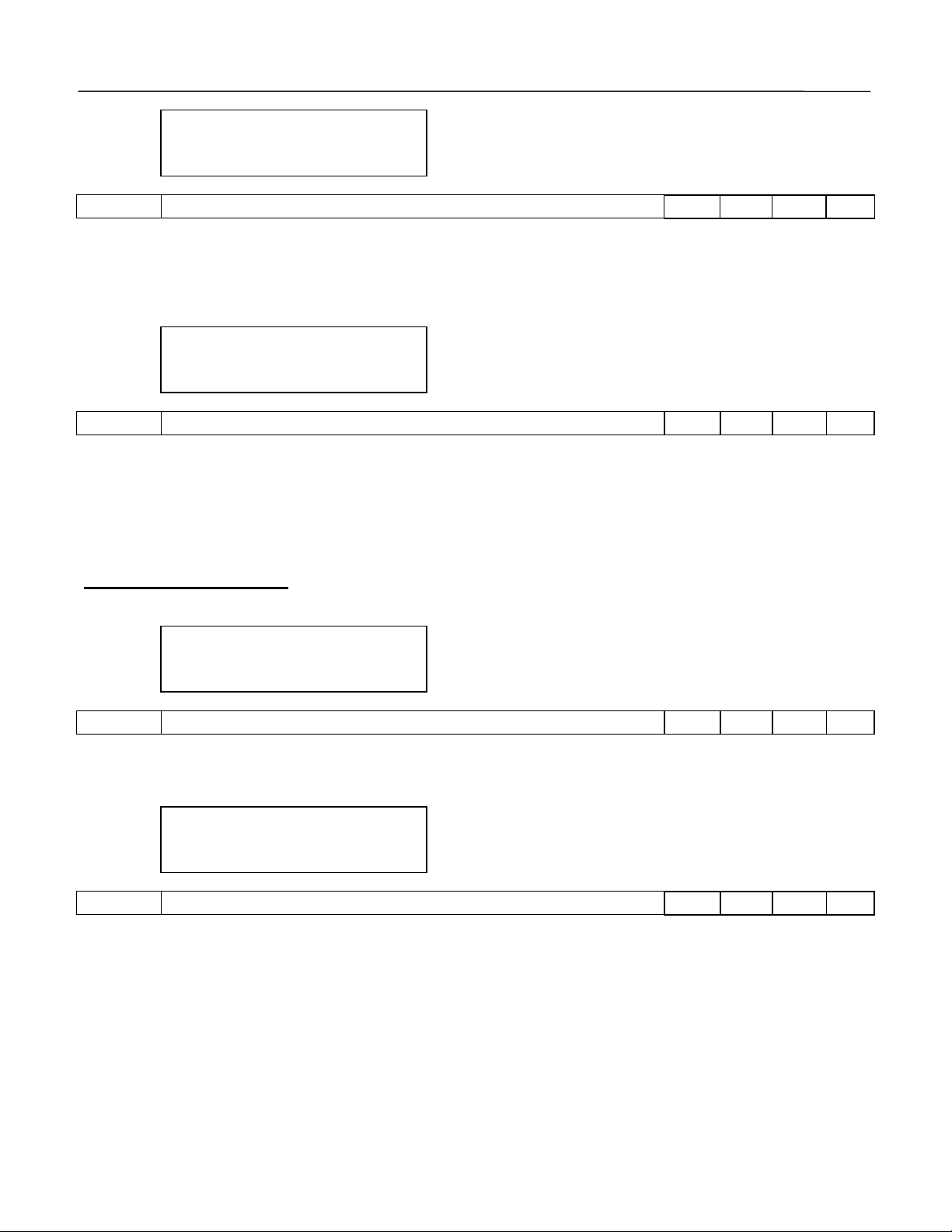

4.0 Custom Software Parameters

4.1 New Program Group

Group P

Elect Line Shaft

4.2 New Program Function

Function P1

Line Shaft Data

Function P2

Line Shaft Data

4.3 New Program Parameters

Master PPR

P1-01= 1024

P1-01 Master PPR

The number of output pulses per revolution from the master encoder. (not quadrature)

Align Offset

P1-02= 0

P1-02 Align Offset

The “Aligned Offset” is provided to correct for the misalignment of the trigger inputs preventing the need to do fine

mechanical adjustments. This value may be used as a fine tuning feature to align the slave to the master making

setup much easier. The range provides for approximately 2.5 motor revolution.

Setting Range: 0 to 10000

Factory Default: 1024

MODBUS Address: 0580H

B B B B

Setting Range: + / - 9999

Factory Default: 0

MODBUS Address: 0581H

B B B B

Date: 07-01-04, Rev: 04-07 Page 9 of 15 TM.G5SW.046

Page 10

Electronic Lineshaft with Alignment

Over Travel Lmt

P1-03= 0

P1-03 Over Travel Lmt

The “Over Travel Limit” is used during the alignment procedure and is the maximum error count permitted. The

error count is the number of encoder pulses that occurs between trigger inputs. When master and slave are

aligned the error count will be 0. If this value is exceeded an “Align_Flt” will occur and stop the drive.

Position P gain

P1-04= 10.00

P1-04 Position Error Proportional Gain

The ‘proportional gain’ adjusts the follower’s speed reference to compensate for any position error between the

master and slave. The proportional function increases speed compensation based on the magnitude of the

position error. Increasing the proportional gain makes the follower more responsive to position errors.

The maximum correction factor added by P1-04 defaults at +/- 2.000 Hz. This limit can be adjusted using P2-04

P Limit.

Setting Range: 1 to 99999

Factory Default: 0

MODBUS Address: 0582H

B B B B

Setting Range: 0.00 to 100.00

Factory Default: 10.00

MODBUS Address: 0583H

B B B B

Position I time

P1-05= 0.10 Sec

P1-05 Position Error Integral Time

The ‘integral time’ adjusts the follower’s speed reference to compensate for any position error between the

master and slave. The integral function increases speed compensation based on the amount of time a given

error exists. Decreasing the integral time makes the follower more responsive to position errors.

The maximum correction factor added by P1-05 defaults at +/- 2.000 Hz. This limit can be adjusted using P2-05 I

Limit.

TrimRate ct/10ms

P1-06= 20

P1-06 Rate of Advance/Retard at Digital Input

The follower can be advanced or retarded at the rate of P1-06 counts every 10 mSec, whenever a multifunction

digital input programmed to 83 (advance) or 84 (retard) is closed. When the digital input is removed, the follower

will maintain synchronization with the master, at the follower’s advanced (retarded) position. This feature also

functions when a gear ratio is used.

Follw.trip cnts

Setting Range: 0.00 to 100.00 Sec

Factory Default: 0.10 Sec

MODBUS Address: 0584H

B B B B

Setting Range: 0 to 1000

Factory Default: 20

MODBUS Address: 0585H

B B B B

Setting Range: 0 to 32767

Factory Default: 4096

MODBUS Address: 0586H

Date: 07-01-04, Rev: 04-07 Page 10 of 15 TM.G5SW.046

Page 11

Electronic Lineshaft with Alignment

P1-07= 4096

P1-07 Follower Trip Counts

If the position error between the master and the follower exceeds the P1-07 setting, the follower will respond

based on the P1-08 setting.

Trip Reaction

P1-08= 2

Setting Range: 0 to 2

Factory Default: 2

MODBUS Address: 0587H

P1-08 Trip Reaction

If the position error between the master and the follower exceeds the P1-07 setting, the follower responds as

selected below.

Setting Description

0 The follower continues operation without trip annunciation

1 The follower continues operation while displaying FOL_ALM

2 The follower faults, coasting to a stop, and displays FOL_FLT

Resync Property

P1-09= 1

Setting Range: 0 to 1

Factory Default: 1

MODBUS Address: 0588H

P1-09 Resync Property

The follower can be configured to respond to, or ignore, position errors when it is under power but not running.

With a setting of 0, the follower will monitor the position of both the master and the follower. If a position error

develops, via movement of the master or follower shaft, at the initiation of a run command the follower will

advance or retard accordingly, to cancel the position error. With a setting of 1, the follower sets the position error

to zero, ignoring any movement of the master or follower until a ‘run’ command is initiated.

Setting Description

0 Accumulates position error when not running. Corrects error at ‘run’

1 Holds position error at zero when not running.

Alignment Check

P1-10 = 100

Setting Range: 0 to 32767

Factory Default: 100

MODBUS Address: 0589H

P1-10 Alignment Check Counts

The alignment check counts is the number of error counts that are acceptable between the position trigger inputs.

When the error count is within this range the alignment checked output will activate. The output will only change

states after a check has been performed.

B B B B

B B B B

B B B B

B B B B

Date: 07-01-04, Rev: 04-07 Page 11 of 15 TM.G5SW.046

Page 12

Electronic Lineshaft with Alignment

Ratio Numerator

P2-01=1000

P2-01 Ratio Numerator

The ratio numerator is multiplied by the encoder feedback from the master and then is divided by the ratio

denominator. This provides the ability to use a gear ratio between the master and the slave. See P2-02.

Ratio Demomin

P2-02=1000

P2-02 Ratio Denominator

The ratio denominator is divided into the product of the ratio numerator and the encoder feedback from the

master.

Example:

Slave Speed = (Master Encoder Feedback x P2-01) / P1-02

Feedback = 10 Hz , P1-01 = 1000, P2-02 = 250

Slave Speed = (10 Hz x 1000) / 250 or 40 Hz

Feedback = 10 Hz , P1-01 = 250, P2-02 = 1000

Slave Speed = (10 Hz x 250) / 1000 or 2.5 Hz

The position relationship between the master and the slave is maintained just as if a lineshaft went through a

gearbox with the same ratio. If the ratio is unknown it may be determined by counting the motor revolutions

required to make a complete machine cycle of both the master and slave. Convert the counts into a four digit

number by multiplying or dividing both by the same number. Set P1-01 to the slave count and set P1-02 to the

master count.

Example:

Master = 10 revs., Slave = 2.5 revs., Multiply both by 100

Master = 1000, Slave = 250

P1-01 = 250, P1-02 = 1000

P Limit

P2-04=2.000 HZ

P2-04 Proportional Limit

This parameter limits the proportional part of the position regulator.

Setting Range: 0 to 9999

Factory Default: 1000

MODBUS Address: 0590H

Q Q Q Q

Setting Range: 0 to 9999

Factory Default: 1000

MODBUS Address: 0591H

Q Q Q Q

Setting Range: 0.000 to 20.000

Factory Default: 2000

MODBUS Address: 0593H

Q Q Q Q

Date: 07-01-04, Rev: 04-07 Page 12 of 15 TM.G5SW.046

Page 13

Electronic Lineshaft with Alignment

I Limit

P2-05=2.000 HZ

P2-05 Integral Limit

This parameter limits the integral part of the position regulator. This parameter should be increased when the

drive will not stay shaft-locked under heavy loads or at high speeds (above base speed). Too high of a setting

will result in instability or overshoot.

D Time

P2-06 = 0.00 sec

P2-06 Derivative Time

This parameter provides control of the derivative function of the PID speed control loop. Setting this value to zero

will remove any affect that it may have. The derivative provides a means to stabilize the position error if it is

oscillating between plus and minus. Setting this value to high will cause instability.

Setting Range: 0.000 to 20.000

Factory Default: 2000

MODBUS Address: 0594H

Q Q Q Q

Setting Range: 0.00 to 100.00

Factory Default: 0.00

MODBUS Address: 0595H

Q Q Q Q

5.0 New Monitors

Master Encoder

U1-50= 0.00 kHZ

U1-50 Master Encoder

Displays the pulse frequency of the master encoder.

Slave Reference

U1-51= 0.0 HZ

U1-51 Slave Reference

Displays the frequency reference of the follower drive prior to ratio adjustments. The follower will not exceed its

maximum output frequency based on E1-04 and D2-01.

Range: 0.00 to 327.67 kHz

MODBUS Address: 00D0H

Q Q Q Q

Range: -999.9 to 3276.7 Hz

MODBUS Address: 00D1H

Q Q Q Q

Date: 07-01-04, Rev: 04-07 Page 13 of 15 TM.G5SW.046

Page 14

Electronic Lineshaft with Alignment

Position err cts

U1-53= 0

U1-53 Position Error in Counts

Displays the error, in encoder counts, between the master and follower.

Posit.P Gain

U1-54= 0.000 HZ

U1-54 P-Gain Correction of Position Error

Displays the frequency adjustment to the follower’s speed reference, based on the proportional gain setting.

Posit.I Gain

U1-55= 0.000 HZ

U1-55 I-Gain Correction of Position Error

Displays the frequency adjustment to the follower’s speed reference, based on the integral time setting.

LineShaft Speed

U1-56= 0.00 HZ

U1-56 Line Shaft Speed Reference Output

The follower’s final speed reference derived from the “line shaft” algorithm. Includes the initial reference from the

master plus compensation due to gearing and proportion/integral adjustments.

Range: -9999 to 32767

MODBUS Address: 00D3H

Q Q Q Q

Range: -2.000 to 2.000 Hz

MODBUS Address: 00D4H

Q Q Q Q

Range: -2.000 to 2.000 Hz

MODBUS Address: 00D5H

Q Q Q Q

Range: -99.99 to 327.67 Hz

MODBUS Address: 00D6H

Q Q Q Q

Date: 07-01-04, Rev: 04-07 Page 14 of 15 TM.G5SW.046

Page 15

Electronic Lineshaft with Alignment

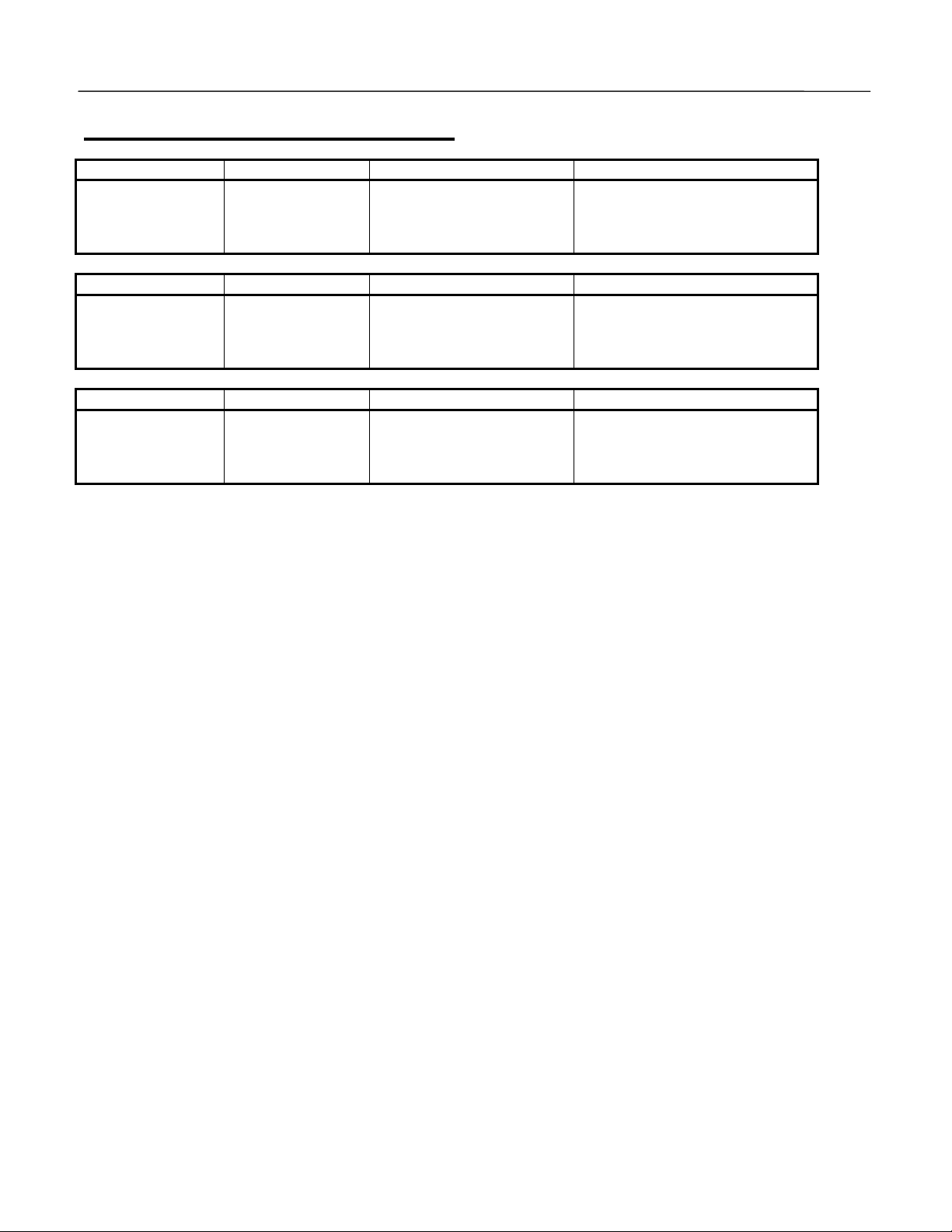

6.0 New Alarm and Fault Codes

Alarm Display Name Description Corrective Action

FOL_ALM

Following Alarm

Fault Display Name Description Corrective Action

FOL_FLT

Following Fault

Fault Display Name Description Corrective Action

ALIGN_FLT

Align Fault

Following Alarm

Following Error

Alignment Error

The position error between

the master and slave

exceeded the allowable

amount. (P1-07 – P1-08)

The position error between

the master and slave

exceeded the allowable

amount. (P1-07 – P1-08)

The error count between

the master and slave

exceeded the allowable

amount. (P1-03)

Check for physical obstruction of

slave motion.

Check for physical obstruction of

slave motion.

Check the trigger input switches.

Date: 07-01-04, Rev: 04-07 Page 15 of 15 TM.G5SW.046

Loading...

Loading...