Yamaha RX-V4600, DSP-AX4600 Service Manual

AV RECEIVER/AV AMPLIFIER

DSP-AX4600

RX-V4600/

RX-V4600/DSP-AX4600

SERVICE MANUAL

IMPORTANT NOTICE

This manual has been provided for the use of authorized YAMAHA Retailers and their service personnel.

It has been assumed that basic service procedures inherent to the industry, and more specifically YAMAHA Products, are already

known and understood by the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal

IMPORTANT: The presentation or sale of this manual to any individual or firm does not constitute authorization, certification or

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and

service departments of YAMAHA are continually striving to improve YAMAHA products. Modifications are, therefore, inevitable

and specifications are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, please

contact the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have

IMPORTANT: Turn the unit OFF during disassembly and part replacement. Recheck all work before you apply power to the unit.

injury, destruction of expensive components, and failure of the product to perform as specified. For these reasons,

we advise all YAMAHA product owners that any service required should be performed by an authorized

YAMAHA Retailer or the appointed service representative.

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

accumulated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

■ CONTENTS

TO SERVICE PERSONNEL .......................................... 2

FRONT PANELS ............................................................ 3

REAR PANELS .......................................................... 3~6

REMOTE CONTROL...................................................... 7

SPECIFICATIONS / 参考仕様 .................................. 8~10

INTERNAL VIEW ......................................................... 11

DISASSEMBLY PROCEDURES / 分解手順.......... 12~15

UPDATING FIRMWARE/

ファームウェアの書き込み..................................... 16~21

SELF DIAGNOSIS FUNCTION (DIAG)/

自己診断機能(ダイアグ)..................................... 22~52

100952

AMP ADJUSTMENT/アンプ部調整 ........................... 53

DISPLAY DATA ........................................................... 54

IC DATA ................................................................. 55~58

BLOCK DIAGRAM ................................................. 59~60

PIN CONNECTION DIAGRAM .............................. 61~62

PRINTED CIRCUIT BOARD .................................. 63~83

SCHEMATIC DIAGRAM ...................................... 85~100

PARTS LIST ....................................................... 101~140

REMOTE CONTROL.......................................... 141~143

2005 All rights reserved.

P.O.Box 1, Hamamatsu, Japan

'05.05

RX-V4600/DSP-AX4600

RX-V4600/

DSP-AX4600

■ TO SERVICE PERSONNEL

1. Critical Components Information

Components having special characteristics are marked s

and must be replaced with parts having specifications equal

to those originally installed.

2. Leakage Current Measurement (For 120V Models Only)

When service has been completed, it is imperative to verify

that all exposed conductive surfaces are properly insulated

from supply circuits.

● Meter impedance should be equivalent to 1500 ohms

shunted by 0.15µF.

WALL

OUTLET

EQUIPMENT

UNDER TEST

INSULATING

TABLE

● Leakage current must not exceed 0.5mA.

● Be sure to test for leakage with the AC plug in both polarities.

AC LEAKAGE

TESTER OR

EQUIVALENT

“CAUTION”

“F1, F2: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME TYPE 10A,

125V FUSE.”

CAUTION

F1, F2: REPLACE WITH SAME TYPE 10A, 125V FUSE.

ATTENTION

F1, F2: UTILISER UN FUSIBLE DE RECHANGE DE MEME TYPE DE 10A, 125V.

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or plastic (where

applicable) components may also contain traces of chemicals found by the California Health and Welfare Agency (and

possibly other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose

eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before

handling food.

About lead-free solder / 無鉛ハンダについて

The P.C.B.s installed in this unit are soldered using the

following solder.

Side A / A面

DSP P.C.B.

FUNCTION P.C.B.

OPERATION P.C.B.

MAIN P.C.B.

POWER PC.B.

INPUT P.C.B.

CONTROL P.C.B.

DUAL P.C.B.

IBOC P.C.B.

Side A

Side B

Lead Solder / 鉛入りハンダ

Lead Solder / 鉛入りハンダ

–

–

–

Lead Solder / 鉛入りハンダ

Lead Solder / 鉛入りハンダ

Lead Solder / 鉛入りハンダ

Lead Solder / 鉛入りハンダ

SMT

Solder Dip

MI

Among some types of lead free solder currently available,

it is recommended to use one of the following types for the

repair work.

• Sn + Ag + Cu (tin + silver + copper)

• Sn + Cu (tin + copper)

• Sn + Zn + Bi (tin + zinc + bismuth)

本機に搭載されている基板のハンダ付けに使用されている

ハンダは下記の通りです。

REFLOW

FLOW

Process

無鉛ハンダにはいくつかの種類がありますが、修理時には

下記のような無鉛ハンダの使用を推奨します。

・Sn+Ag+Cu(錫+銀+銅)

・Sn+Cu(錫+銅)

・Sn+Zn+Bi(錫+亜鉛+ビスマス)

Lead Free Solder / 無鉛ハンダ

Side B / B面

Lead Free Solder / 無鉛ハンダ

Lead Free Solder / 無鉛ハンダ

Lead Free Solder / 無鉛ハンダ

Lead Free Solder / 無鉛ハンダ

Lead Free Solder / 無鉛ハンダ

Lead Free Solder / 無鉛ハンダ

Lead Free Solder / 無鉛ハンダ

Lead Free Solder / 無鉛ハンダ

Process

Caution:

1. As the melting point temperature of the lead free solder

is about 30°C to 40°C (50°F to 70°F) higher than that of

the lead solder, be sure to use a soldering iron suitable

to each solder.

2. If lead solder must be used, be sure to remove lead free

solder from each terminal section of the parts to be

replaced and from the area around it completely before

soldering, or make sure that the lead-free solder and

lead solder melt together fully.

2

注意:

① 無鉛ハンダの融点温度は通常の鉛入りハンダに比べ30

〜40℃程度高くなっていますので、それぞれのハンダ

に合ったハンダごてをご使用ください。

② 鉛入りハンダを使わざるを得ない場合は、あらかじめ交

換する部品端子部やその周辺部の無鉛ハンダをすべて取

り除くか、あるいは無鉛ハンダと鉛入りハンダが十分に

溶けた状態となるようにハンダ付けしてください。

■ FRONT PANELS

RX-V4600/DSP-AX4600

RX-V4600 (U, C, R, T, K, A, B, G, L models)

DSP-AX4600 (J model)

DSP-AX4600

RX-V4600/

■ REAR PANELS

RX-V4600 (U model)

3

RX-V4600/

DSP-AX4600

RX-V4600/DSP-AX4600

RX-V4600 (C model)

RX-V4600 (R model)

RX-V4600 (T model)

4

RX-V4600 (K model)

RX-V4600 (A model)

RX-V4600/DSP-AX4600

DSP-AX4600

RX-V4600/

RX-V4600 (B model)

5

RX-V4600/

DSP-AX4600

RX-V4600/DSP-AX4600

RX-V4600 (G model)

RX-V4600 (L model)

DSP-AX4600 (J model)

6

■ REMOTE CONTROL

RX-V4600/DSP-AX4600

RX-V4600 (U, C, R, T, K, A, L models)

DSP-AX4600 (J model)

RX-V4600 (B, G models)

DSP-AX4600

RX-V4600/

RX-V4600 (U model) RX-V4600 (C, R, T, K, A, B, G, L models)

7

RX-V4600/

DSP-AX4600

RX-V4600/DSP-AX4600

■ SPECIFICATIONS/参考仕様

■ Audio Section / オーディオ部

Minimum RMS Output Power (Power Amp. Section) / 定格出力(パ

ワーアンプ部) (20 Hz to 20 kHz)

FRONT L/R

U, C, R, T, K, A, B, G, L models (0.04% THD, 8 ohms)

J model (0.06% THD, 6 ohms) ............................... 130W + 130W

CENTER

U, C, R, T, K, A, B, G, L models (0.04% THD, 8 ohms) ..... 130W

J model (0.06% THD, 6 ohms) ............................................ 130W

SURROUND L/R

U, C, R, T, K, A, B, G, L models (0.04% THD, 8 ohms)

J model (0.06% THD, 6 ohms) ............................... 130W + 130W

SURROUND BACK L/R

U, C, R, T, K, A, B, G, L models (0.04% THD, 8 ohms)

J model (0.06% THD, 6 ohms) ............................... 130W + 130W

Maximum Power / 実用最大出力 (EIAJ, 1kHz, 10% THD)

FRONT L/R

R, T, K, L models (8 ohms) ..................................... 180W + 180W

J model (6 ohms) .................................................... 180W + 180W

CENTER

R, T, K, L models (8 ohms) .................................................. 180W

J model (6 ohms) ................................................................. 180W

SURROUND L/R

R, T, K, L models (8 ohms) ..................................... 180W + 180W

J model (6 ohms) .................................................... 180W + 180W

SURROUND BACK L/R

R, T, K, L models (8 ohms) ..................................... 180W + 180W

J model (6 ohms) .................................................... 180W + 180W

Dynamic Power Per Channel / ダイナミックパワー (IHF)

U, C, R, T, K, A, L models (8/6/4/2 ohms) ........ 165/205/260/340W

DIN Standard Output Power Per Channel/DINパワー [B, G models]

(1 kHz, 0.7% THD, 4 ohms)

FRONT L/R ................................................................190W + 190W

CENTER ................................................................................. 190W

SURROUND L/R ....................................................... 190W + 190W

SURROUND BACK L/R ............................................ 190W + 190W

Dynamic Headroom / ダイナミックヘッドルーム

U, C, R, T, K, A, L models (8 ohms) .................................... 1.03dB

IEC Power / IECパワー[B, G models] (1 kHz, 0.04% THD, 8 ohms)

FRONT L/R ................................................................140W + 140W

Damping Factor / ダンピングファクタ

20 Hz to 20 kHz, SPEAKER-A, 8 ohms ....................... 140 or more

Input Sensitivity / Input Impedance(入力感度/入力インピーダンス)

PHONO (MM) ................................................... 3.5 mV / 47 k-ohms

CD, etc. ............................................................ 200 mV / 47 k-ohms

MULTI CH INPUT

FRONT L/R, CENTER, SURROUND L/R, SUB WOOFER

.................................................................... 200 mV / 47 k-ohms

Maximum Input Signal Level / 最大許容入力

PHONO (MM) (1 kHz, 0.1% THD) .......................... 100mV or more

CD, etc. (1 kHz, 0.5% THD) ........................................ 2.4V or more

Output Level / Output Impedance(出力電圧/出力インピーダンス)

REC OUT ........................................................ 200 mV / 1.2 k-ohms

PRE OUT (FRONT L/R, CENTER, SURROUND L/R, SURROUND

BACK L/R) .......................................................... 1.0 V / 500 ohms

SUB WOOFER ..................................................... 2.0 V / 500 ohms

[U, C, A, B, G models]

ZONE 2 OUT .................................................... 1.0 V / 1.2 k-ohms

ZONE 3 OUT .................................................... 1.0 V / 1.2 k-ohms

Headphone Jack Rated Output / Impedance(ヘッドフォン出力/出

力インピーダンス)

CD, etc. (1 kHz, 40 mV, 8 ohms) ..................... 150 mV / 100 ohms

Frequency Response / 周波数特性

CD, etc. to FRONT L/R (10 Hz to 100 kHz) ..................... +0/-3.0dB

RIAA Equalization Deviation / RIAA偏差

20 Hz to 20 kHz, PHONO (MM) ......................................... 0±0.5dB

Total Harmonic Distortion / 全高調波歪率(20Hz to 20kHz)

PHONO (MM) to REC OUT (1V) ................................ 0.02% or less

CD, etc. (STEREO) to FRONT L/R SP OUT (65W, 8 ohms)

Signal to Noise Ratio / 信号対雑音比 (IHF-A network)

PHONO (MM) (Input shorted) to SP OUT

U, C, R, T, K, L models (5mV) ................................. 86dB or more

A, B, G models (5mV) ..............................................81dB or more

J model (2.5mV) ....................................................... 80dB or more

CD, etc. (Input shorted, STEREO) to SP OUT

250mV .................................................................... 100dB or more

Residual Noise / 残留ノイズ (IHF-A network)

FRONT L/R SP OUT ................................................. 150µV or less

Channel Separation / チャンネルセパレーション (STEREO)

PHONO (Input shorted, 1 kHz/10 kHz)

CD, etc. (Input 5.1 k-ohms shorted, 1 kHz/10 kHz)

..............

..... 130W + 130W

..... 130W + 130W

..... 130W + 130W

....... 0.04% or less

60dB or more/55dB or more

....

60dB or more/45dB or more

Tone Control Characteristics / トーンコントロール特性

BASS

Boost/Cut .................................................................. ±6dB (50Hz)

Turnover Frequency ............................................................ 350Hz

TREBLE

Boost/Cut ................................................................ ±6dB (20kHz)

Turnover Frequency ........................................................... 3.5kHz

Filter Characteristics / フィルター特性

FRONT, CENTER, SURROUND, SURROUND BACK SP Small (H.P.F.)

.................... fc=40/60/80/90/100/110/120/160/200Hz / 12dB oct.

SUBWOOFER (L.P.F.)

.................... fc=40/60/80/90/100/110/120/160/200Hz / 24dB oct.

■ Video Section / ビデオ部

Video Signal Type / ビデオ信号方式

Wall Paper

U, C, R, K, J models ............................................................ NTSC

T, A, B, G, L models ............................................................... PAL

Video Conversion

U, C, R, T, K, A, B, G, L, J models ...................................... NTSC

R, T, A, B, G, L models ........................................................... PAL

Composite Video Signal Level / コンポジットビデオ信号

.............................................................................. 1 Vp-p / 75 ohms

S-Video Signal Level / Sビデオ信号

Y ............................................................................ 1 Vp-p / 75 ohms

C .....................................................................0.286 Vp-p / 75 ohms

Component Video Signal Level / コンポーネントビデオ信号

Y ............................................................................ 1 Vp-p / 75 ohms

Pb/Pr .................................................................. 0.7 Vp-p / 75 ohms

Video Maximum Input Level / ビデオ最大許容入力

.............................................................................. 1.5 Vp-p or more

Video Signal to Noise Ratio / ビデオ信号対雑音比

................................................................................... 60 dB or more

Monitor Out Frequency Response / モニターアウト周波数帯域

Composite Video Signal, S-Video Signal ..... 5 Hz to 10 MHz, -3 dB

Component Video Signal, D4-Video Signal (J model)

.................................................................... 5 Hz to 60 MHz, -3 dB

■ FM Section / FM部

Tuning Range / 受信周波数範囲

U, C models ........................................................ 87.5 to 107.9 MHz

R, L models ............................ 87.5 to 108.0 / 87.50 to 108.00 MHz

T, K, A, B, G models ....................................... 87.50 to 108.00 MHz

J model ................................................................. 76.0 to 90.0 MHz

50dB Quieting Sensitivity / 50dBSN感度 (IHF) (1kHz, 100% MOD.)

Mono ..................................................................... 2.0 µV (17.3 dBf)

Stereo..................................................................... 25 µV (39.2 dBf)

Usable Sensitivity / 実用感度 (IHF)

Mono ..................................................................... 1.0 µV (11.2 dBf)

Selectivity / 選択度

at 400 kHz ............................................................................... 70 dB

Signal to Noise Ratio / 信号対雑音比 (IHF)

HD (U model) .......................................................................... 80 dB

Mono / Stereo (C, R, T, K, A, B, G, L, J models) ....... 76 dB / 70 dB

Harmonic Distortion / 歪率 (1 kHz)

HD (U model) ........................................................................ 0.03 %

Mono/Stereo (C, R, T, K, A, B, G, L, J models) ............. 0.2 / 0.3 %

Stereo Separation / ステレオセパレーション (1 kHz)

HD (U model) .......................................................................... 70 dB

Stereo (C, R, T, K, A, B, G, L, J models) ............................... 42 dB

Frequency Response / 周波数特性

(20 Hz to 18 kHz)

HD (U model) .............................................................. +0.5 / -3 dB

(20 Hz to 18 kHz)

Stereo/Mono (C, R, T, K, A, B, G, L, J models) ......... +0.5 / -2 dB

Antenna Input / アンテナ入力

........................................................................ 75 ohms unbalanced

■ AM Section / AM部

Tuning Range / 受信周波数範囲

U, C models .......................................................... 530 to 1,710 kHz

R, L models ................................... 530 to 1,710 / 531 to 1,611 kHz

T, K, A, B, G, J models ......................................... 531 to 1,611 kHz

Usable Sensitivity / 実用感度

.......................................................................................... 300 µV/m

Signal to Noise Ratio / 信号対雑音比 (IHF)

HD (U model) .......................................................................... 80 dB

Harmonic Distortion / 歪率 (1 kHz)

HD (U model) ........................................................................ 0.03 %

8

Stereo Separation / ステレオセパレーション (1 kHz)

HD (U model) ....................................................................... 70 dB

Frequency Response / 周波数特性 (20 Hz to 12.5 kHz)

HD (U model) .............................................................. +0.5 / -3 dB

Antenna / アンテナ入力

................................................................................. Loop Antenna

■ General / 総合

Power Supply / 電源電圧

U, C models ........................................................... AC 120 V, 60 Hz

R model ................................ AC 110/120/220/230-240 V, 50/60 Hz

T model ..................................................................AC 220 V, 50 Hz

K model ..................................................................AC 220 V, 60 Hz

A model ..................................................................AC 240 V, 50 Hz

B, G models ........................................................... AC 230 V, 50 Hz

L model .............................................. AC 220/230-240 V, 50/60 Hz

J model ............................................................. AC 100V, 50/60 Hz

Power Consumption / 消費電力

U, C models ............................................................ 500 W / 630 VA

R, T, K, A, B, G, L models ..................................................... 500 W

J model .................................................................................. 440 W

Standby Power Consumption (reference data) / 待機時消費電力(参考値)

U, C, J models ............................................................ 0.2 W or less

R model (AC 240, 50 Hz) ......................................... 0.33 W or less

T, K, A, B, G, L models ............................................. 0.15 W or less

Maximum Power Consumption / 最大消費電力 (6ch Drive, 10% THD)

R model ................................................................................ 1100 W

AC Outlets / ACアウトレット

2 switched outlets

U, C models ............................ 100 W max. total / 0.8A max. total

R, L models .......................................................... 50 W max. total

T, G, J models .................................................... 100 W max. total

1 switched outlet

A, B models ......................................................... 100W max. total

Dimensions / 寸法 (W x H x D)

......................... 435 x 171 x 438.5 mm (17-1/8" x 6-3/4" x 17-1/4")

Weight / 質量

RX-V4600 ................................................... 18.0 kg (39 lbs. 11 oz.)

DSP-AX4600 ............................................... 19.0 kg (41 lbs. 14 oz.)

Finish / 仕上げ

Gold color .......................................................... R, T, K, L, J models

Black color ....................................................... U, C, R, A, J models

Titanium color ........................................................... B, G, L models

Accessories / 付属品

Remote Control, Batteries (Alkaline Dry), Indoor FM Antenna, AM

Loop Antenna, Antenna Adapter PAL (B model), Power Cable,

Speaker Terminal Wrench, Optimizer Microphone

* Specifications are subject to change without notice due to product

improvements.

※ 参考仕様および外観は予告なく変更されることがあります。

U .......... U.S.A. model C ...... Canadian model

R .......... General model T ....... Chinese model

K .......... Korean model A ...... Australian model

B .......... British model G ...... European model

L ........... Singapore model J ....... Japanese model

“Circle Surround II”, “Dialog Clarity”, “TruBass”, “SRS” and the

symbol are trademarks of SRS Labs, Inc. Circle Surround

II, Dialog Clarity and TruBass technology are incorporated

under license from SRS Labs, Inc.

CircleSorroundII、SRSと 記号はSRSLabs,Inc.の商標です。

“DTS”, “DTS-ES”, “Neo:6” and “DTS 96/24” are trademarks of

Digital Theater Systems, Inc.

DTS、DTS-ESExtendedSurround、Neo:6およびDTS96/24はデジ

タルシアターシステムズの登録商標です。

The THX logo is a trademark of THX Ltd. which may be

registered in some jurisdictions. All rights reserved.

THXとTHXロゴはTHXの登録商標です。不許複製。

“HDMI”, the “HDMI” logo and “High-Definition Multimedia

Interface” are trademarks or registered trademarks of HDMI

Licensing LLC.

HDMI、HDMIロゴおよびHigh-DefinitionMultimediaInterfaceは、

HDMILicensingLLCの商標または、登録商標です。

“i.LINK” and the “i.LINK” logo are trademarks of Sony

Corporation.

i.LINKおよびi.LINKロゴ は、ソニー株式会社の商標です。

AACロゴマーク はドルビーラボラトリーズの商標です。

• DIMENSIONS/寸法図

Initialize

NO / YES

Presence L Level Presence R Level

Sur. Back Level

Initialize

Dialogue Lift

0 / 100 / 1 % 0 / 5 / 1 NO / YES

0 / 250 / 1 ms

Rev. Time Rev. Deley Rev. Level

1.0 / 5.0 /0.1 ms

SB Room Size

SB Init. Deley

Sur. Room Size

Sur. Init. Deley

RX-V4600/DSP-AX4600

Initialize

SB Liveness Dialogue Lift

SB Room Size

SB Init. Deley

(Setting can be made when PL II Music, Pro Logic II x is selected / PLIIMusic、ProLogicIIx選択時 設定可)

(Setting can be made when Neo:6 Music is selected / Neo:6Music選択時 設定可)

}

Sur. Liveness

Sur. Room Size

Manufactured under license from Dolby Laboratories.

“Dolby”, “Surround EX”, and the double-D symbol are

trademarks of Dolby Laboratories.

ドルビーラボラトリーズからの実施権に基づき製造されています。

「ドルビー」、「PROLOGIC」、「SurroundEX」およびダブルD記号

は、ドルビーラボラトリーズの商標です。

“SILENT CINEMA” is a trademark of YAMAHA

CORPORATION.

「サイレントシネマ/SILENTCINEMA」はヤマハ株式会社の登録商標

です。

HD RadioTM technology manufactured under license from

iBiquity Digital Corporation. “iBiquity Digital” and the “HD Radio”

and “HD” symbols are registered trademarks of iBiquity Digital

Corporation. U.S. and Foreign Patents.

0301.05-------(0)NO

0151.05----1.61209(0)NO

Surround L Level Surround R Level

0 / 100 / 1 % 0 / 100 / 1 % 0 / 100 / 1 % 0 / 100 / 1 % 0 / 100 / 1 % 0 / 100 / 1 %

Center Level

7ch Stereo 100 100 100 35 (33) (33) NO

STEREO 2ch Stereo - - ----NO

Sound Serect Min./Max./Step 最小/最大/Step

Main Menu Parameter

• SOUND/SURROUND SELECT MENU

DSP Level Init. Deley Room Ssize Liveness

-6 / +3 / 1 dB 1 / 99 / 1 ms 0.1 / 2.0 / 0.1 0 / 10 / 1 1 / 49 / 1 ms 0.1 / 2.0 / 0.1 1 / 49 / 1 ms 0.1 / 2.0 / 0.1

Decode Type

Vienna 0 30 1.0 5 -------(0)NO

Freiburg 0 95 1.0 3 ----4.013070(0)NO

MUSIC Munich 0 30 1.0 5 -------(0)NO

Surround Serect Min./Max./Step 最小/最大/Step

Pop/Rock 21 1.0 --------(0)NO

The Roxy Theater

The Bottom Line

0281.0--------(0)NO

Disco 0 26 - 5 ----2.71204(0)NO

Game 0 36 1.0 - 15 1.0 (15) (1.0) - - - (0) NO

TV Sports 0 10 1.0 - 30 1.0 (15) (1.0) 1.6 100 4 (0) NO

Classical/Opera

ENTERTAINMENT

Spectacle Pro Logic 0 13 1.0 - 23 1.0 (15) (1.0) - - - (0) NO

Mono Moive 0 69 1.0 3 - - - (1.0) 2.5 160 2 (0) NO

MOVIE THEATER

Pro Logic II 0 13 1.0 - 32 1.0 (15) (1.0) - - - (0) NO

Neo : 6

[Pro Logic]

Setting value ([ ] Initial value) / 設定値([ ]初期値)

Neo : 6 0 13 1.0 - 32 1.0 15 1.0 - - - (0) NO

Pro Logic II x 0 13 1.0 - 32 1.0 15 1.0 - - - (0) NO

Sci-Fi Pro Logic 0 16 1.0 - 20 1.0 (15) (1.0) - - - (0) NO

Pro Logic II 0 16 1.0 - 2 1.0 (15) (1.0) - - - (0) NO

Neo : 6 0 16 1.0 - 2 1.0 15 1.0 - - - (0) NO

Pro Logic II x 0 16 1.0 - 2 1.0 15 1.0 - - - (0) NO

Adventure Pro Logic 0 15 1.0 - 20 1.0 (15) (1.0) - - - (0) NO

Pro Logic II 0 15 1.0 - 30 1.0 (15) (1.0) - - - (0) NO

Neo : 6 0 15 1.0 - 30 1.0 15 1.0 - - - (0) NO

Pro Logic II x 0 15 1.0 - 30 1.0 15 1.0 - - - (0) NO

General Pro Logic 0 15 1.0 - 20 1.0 (15) (1.0) - - - (0) NO

Pro Logic II 0 15 1.0 - 26 1.0 (15) (1.0) - - - (0) NO

Pro Logic II x 0 15 1.0 - 26 1.0 15 1.0 - - - (0) NO

Neo : 6 0 15 1.0 - 26 1.0 15 1.0 - - - (0) NO

Decode Type

THX Cinema

Main Menu Sub Menu Parameter

[Pro Logic]

Pro Logic II

Pro Logic II x

Decode Type

Standard

SURROUND

PL II Music

PL II Movie

PL II Game

PL II x Movie

PL II x Music

PL II x Game

Neo : 6 Music

Neo : 6 Cinema

Panarame [OFF] / ON

Sur. Init. Deley

0.0 / 1.0 / 0.1 [0.3]

DSP Level

Initialize [NO] / YES

Dimension -3 / +3 / 1 [STD]

Center Width 0 / 7 / 1 [3]

Decode Type

Center Image

Parameter

-6 / +3 / 1 dB 1 / 49 / 1 ms 0.1 / 2.0 / 0.1 1 / 5 / 1 1 / 49 / 1 ms 0.1 / 2.0 / 0.1 1 / 5 / 1 0 / 5 / 1 NO / YES

Pro Logic II 0 19 1.0 3 (15) (1.0) (5) (0) NO

Enhanced Pro Logic 0 20 1.0 3 (15) (1.0) (5) (0) NO

Neo 6 0 19 1.0 3 15 1.0 5 (0) NO

Pro Logic II x 0 19 1.0 3 15 1.0 5 (0) NO

STRAIGHT

9

RX-V4600/DSP-AX4600

• SET MENU TABLE / セットメニュー

AUTO SETUP

MAIN MENU PARAMETER

SETUP AUTO

EQ

START PUSH +

MANUAL SETUP

MAIN MENU SUB MENU PARAMETER SETTING VALUE ([ ] INITIAL VALUE)

BASIC

1

SOUND

2

INPUT

3

FLAT / FRONT / [NATURAL]

A

SPEAKER SET

B

SPEAKER DISTANCE

C

SPEAKER LEVEL

D

TEST TONE

E

THX SET

A

LFE LEVEL

B

DYNAMIC RANGE

C

TONE CONTROL FRQ

D

AUDIO OPTION

A

I/O ASSIGN

FRONT

CENTER

SURROUND LR

SURROUND BACK

PRESENCE

BASS OUT

Cross Over

SWFR PHASE

UNIT

FRONT L

FRONT R

CENTER

SURROUND L

SURROUND R

SURROUND BACK L

SURROUND BACK R

SWFR

PRESENCE L

PRESENCE R

FRONT L

CENTER

FRONT R

SURROUND L

SURROUND BACK L

SURROUND BACK R

SURROUND R

SWFR

PRESENCE L

PRESENCE R

SB SPEAKER DIST.

SPEAKER

HEADPHONE

SPEAKER

HEADPHONE

BASS

TREBLE

AUDIO MUTE

AUDIO DELAY

PR/SB SELECT

DUAL MONO (

C.V (A)

C.V (B)

C.V (C )

OUT (1)

OUT (2)

IN (3)

IN (4)

IN (5)

J model

LARGE / [SMALL]

LARGE / [SMALL] / NONE

LARGE x1 / SMALL x1 / [SMALL x2] / LARGE x2 / NONE

YES / [NONE]

[SWFR] / FRONT / BOTH

40 / 60 / [80 (THX)] / 90 / 100 / 110 / 120 / 160 / 200 Hz

[NORMAL] / REVERSE

Meters (m) / Feet (ft)

0.30 ~ 24.00m, 0.1m step [3.00m] / 1.0 ~ 80.0ft, 0.5ft step [10.0ft]

-----ll----- -10.0 ~ +10.0dB 0.5dB step [0dB]

[OFF] / ON

Under 0.3m / [0.3-1.2m] / Over 1.2m, Under 1ft / [1-4ft] / Over 4ft

-20dB ~ ±0.0dB, 0.5dB step [±0.0dB]

[MAX] / STD / MIN

Freq 125 / [350] / 500Hz, Gain -6.0dB ~ +6.0dB, 0.5dB step [±0.0dB]

Freq 2.5k / [3.5k] / 8.0kHz, Gain -6.0dB ~ +6.0dB, 0.5dB step [±0.0dB]

[MUTE] / -20dB

0 ~ 240ms, 1ms step [0ms]

[SURROUND BACK] / PRESENCE

[MAIN] / SUB / ALL

)

DVD

DTV

CBL/SAT

MD/TAPE

CD-R

CD

DVD

DTV

MAIN MENU SUB MENU PARAMETER SETTING VALUE ([ ] INITIAL VALUE)

CBL/SAT

CD

DVD

DVR/VCR2

-6.0dB ~ +6.0dB, 0.5dB step [±0.0dB]

[AUTO] / LAST

[AUTO] / LAST

Input is possible to 8 characters / 8文字まで入力可能

Input possible Character type / 入力可能文字

CAPITAL / 英大文字 A to Z

SMALL / 英小文字 a to z

FIGURE / 数字 0 to 9

Space / 空白

MARK / 記号 # * + , - . / : < > ? etc.

カタカナ ア〜ー(J model)

[6CH] / 8CH

[DVD] / DTV / CBL/SAT / VCR1 / DVR/VCR2 / V-AUX

DVD / DTV / [CBL/SAT] / VCR1 / DVR/VCR2 / V-AUX

RX-V4600 / OTHER

[<---> PLAYER] / ----> PLAYER / <---- PLAYER / --X-- PLAYER

-4 ~ 0, 1 step [0]

NONE / [YES] / GRAY BACK

OFF / [ON]

[OFF] / ON

[MAIN] / ZONE B

[VAR] / FIX

[OFF] / EXT / INT

[VAR] / FIX

4

HDMI

5

i.LINK

6

OPTION

INPUT TRIM

B

AUDIO SELECT

C

DECODER MODE

D

INPUT REMANE

E

MULTI CH INPUT

F

INPUT ASSIGN

A

SUPPORT AUDIO

B

INPUT ASSIGN

A

AUTO PLAY

B

DISPLAY SET

A

MEMORY GUARD

B

SURR. INI

C

ZONE TEST

D

ZONE2 TEST

E

(U, C, R, T, K, A,

B, G, L models)

ZONE3 TEST

F

(U, C, R, T, K, A,

B, G, L models)

IN (6)

IN (7)

IN (8)

IN (9)

DVD

PHONO

TUNER

CD

MULTI CH

V-AUX

CBL/SAT

MD/TAPE

CD-R

DTV

VCR1

DVR/VCR2

DVD

PHONO

TUNER

CD

MULTI CH

V-AUX

CBL/SAT

MD/TAPE

CD-R

DTV

VCR1

DVR/VCR2

IN 1

IN 2

DIMMER

WALL PAPER

SHORT MESSAGE

VIDEO CONV.

PRESS DSP key

SPEAKER B

OUT VOL.

ZONE2 AMP.

OUT VOL.

10

■ INTERNAL VIEW

RX-V4600/DSP-AX4600

RX-V4600 (U, C, R, T, K, A, B, G, L models)

23 4 567 8 9 C D0 A B

1

P

Q

NMLO

RS T U

E

F

G

H

I

J

K

POWER (5) P.C.B.

1

POWER (4) P.C.B. (R, L models)

2

MAIN (1) P.C.B.

3

MAIN (5) P.C.B.

4

POWER (7) P.C.B.

5

POWER (6) P.C.B.

6

MAIN (3) P.C.B.

7

FUNCTION (1) P.C.B.

8

INPUT (1) P.C.B.

9

FUNCTION (2) P.C.B.

0

FUNCTION (5) P.C.B.

A

FUNCTION (4) P.C.B.

B

INPUT (2) P.C.B.

C

DUAL P.C.B.

D

I BOC P.C.B. (U model)

E

TUNER (C, R, T, K, A, B, G, L models)

FUNCTION (6) P.C.B.

F

FUNCTION (3) P.C.B.

G

MAIN (2) P.C.B.

H

OPERATION (5) P.C.B.

I

DSP P.C.B.

J

CONTROL P.C.B.

K

POWER (3) P.C.B.

L

POWER (1) P.C.B.

M

OPERATION (3) P.C.B.

N

MAIN (4) P.C.B.

O

OPERATION (8) P.C.B.

P

OPERATION (6) P.C.B.

Q

OPERATION (4) P.C.B.

R

OPERATION (1) P.C.B.

S

OPERATION (7) P.C.B.

T

OPERATION (2) P.C.B.

U

DSP-AX4600

RX-V4600/

DSP-AX4600 (J model)

2345678 BC9 0 A

1

N

O

PRQS

POWER (5) P.C.B.

1

MAIN (1) P.C.B.

2

MAIN (5) P.C.B.

3

TUNER

4

POWER (6) P.C.B.

D

E

F

G

H

I

LKJM

5

MAIN (3) P.C.B.

6

FUNCTION (1) P.C.B.

7

INPUT (1) P.C.B.

8

FUNCTION (2) P.C.B.

9

FUNCTION (5) P.C.B.

0

FUNCTION (4) P.C.B.

A

INPUT (2) P.C.B.

B

DUAL P.C.B.

C

FUNCTION (6) P.C.B.

D

FUNCTION (3) P.C.B.

E

MAIN (2) P.C.B.

F

OPERATION (5) P.C.B.

G

DSP P.C.B.

H

CONTROL P.C.B.

I

POWER (3) P.C.B.

J

POWER (1) P.C.B.

K

OPERATION (3) P.C.B.

L

MAIN (4) P.C.B.

M

OPERATION (8) P.C.B.

N

OPERATION (6) P.C.B.

O

OPERATION (4) P.C.B.

P

OPERATION (1) P.C.B.

Q

OPERATION (7) P.C.B.

R

OPERATION (2) P.C.B.

S

11

RX-V4600/DSP-AX4600

■ DISASSEMBLY PROCEDURES/分解手順

RX-V4600/

DSP-AX4600

(Remove parts in the order as numbered.)

Disconnect the power cable from the AC outlet.

1. Removal of Top Cover

a. Remove 2 screws (1), 4 screws (2) and 5 screws (3).

(Fig. 1)

b. Slide the Top Cover rearward to remove it. (Fig. 1)

2. Removal of Front Panel

Remove 6 screws (4) and then remove the Front Panel

forward. (Fig. 1)

2

4

(番号順に部品を取り外してください。)

AC電源コンセントから、電源コードを抜いてください。

1. トップカバーの外し方

a.1のネジ2本、2のネジ4本、3のネジ5本を外しま

す。(Fig.1)

b. トップカバーを後方へスライドさせ、取り外します。

(Fig.1)

2. フロントパネルの外し方

4

のネジ6本を外し、フロントパネルを前方に外します。

(Fig.1)

3

1

Top Cover

トップカバー

3

4

3. Removal of Sub Chassis

a. Remove 4 push rivets (5) and then remove the Side

Plates L/R. (Fig. 2)

b. Remove 1 screw (6), 2 screws (7) and 3 screws (8) .

(Fig. 2)

c. Remove CB461, CB507, CB508, CB514, CB516,

CB905 and CB906. (Fig. 3)

d. Remove the Sub Chassis forward. (Fig. 2)

4. Removal of DSP P.C.B.

a. Remove 4 screws (9) and then remove the 2 Support

P.C.B.s. (Fig. 2)

b. Remove 5 screws (0) and then remove the Bracket.

(Fig. 2)

c. Remove 1 screw (A). (Fig. 2)

d. Remove 16 screws (B). (Fig. 4)

e. Remove CB502 (DSP P.C.B.), CB502 (CONTROL

P.C.B.), CB503, CB506 and CB510. (Fig. 3)

f. Remove the DSP, DUAL P.C.B.s and Shield Case

upward.

2

Front Panel

フロントパネル

Fig. 1

3. サブシャーシの外し方

a.5のプッシュリベット4本を外し、サイドプレートL/R

を取り外します。(Fig.2)

b.6のネジ1本、7のネジ2本、8のネジ3本を外します。

(Fig.2)

c. CB461、CB507、CB508、CB514、CB516、CB905、

CB906を外します。(Fig.3)

d. サブシャーシを前方に取り外します。(Fig.2)

4. DSP、DUALP.C.B.の外し方

a.9のネジ4本を外し、サポートP.C.B.2個を取り外しま

す。(Fig.2)

b.0のネジ5本を外し、ブラケットを取り外します。(Fig.

2)

c.Aのネジ1本を外します。(Fig.2)

d.Bのネジ16本を外します。(Fig.4)

e. CB502(DSPP.C.B.)、CB502(CONTROLP.C.B.)、

CB503、CB506、CB510を外します。(Fig.3)

f. DSP、DUALP.C.B.とシールドケースを上方に取り外し

ます。

12

RX-V4600/DSP-AX4600

5. Removal of FUNCTION (3) P.C.B.

a. Remove 1 screw (C) and then remove the Support

Top. (Fig. 2)

b. Remove 1 screw (D).

c. Remove CB527, CB529, CB532, CB534 (U model)

and CB537 (C, R, T, K, A, B, G, L models). (Fig. 3)

d. Remove the FUNCTION (3) P.C.B. which is connected

directly to the lower P.C.B. with connectors. (Fig. 2)

Side Plate L

サイドプレートL

5

7

Sub Chassis

サブシャーシ

Support TOP

サポートトップ

5

6

7

8

5. FUNCTION(3)P.C.B.の外し方

a.Cのネジ1本を外し、サポートトップを外します。(Fig.

2)

b.Dのネジ1本を外します。(Fig.3)

c. CB527、CB529、CB532、CB515を外します。(Fig.

3)

d. FUNCTION(3)P.C.B.を取り外します。

但し、FUNCTION(3)P.C.B.は、下方のP.C.B.と直接

コネクター接続されています。(Fig.2)

D

C

0

A

5

Side Plate R

サイドプレート

5

FUNCTION (3) P.C.B.

Shield Case

シールドケース

DUAL P.C.B.

DSP P.C.B.

0

R

Support P.C.B.

サポート

9

0

9

0

Bracket

ブラケット

0

U, C, R, T, K, A, B, G, L models

J model

CB44

CB515

CB527

(J model)

CB461 CB905CB906CB40

CB532 CB534

CB529

Fig. 2

Fig. 3

(U model)

CB537

(C, R, T, K, A, B, G, L models)

CB502

(CONTROL P.C.B)

CB502

(DSP P.C.B)

CB503

CB506

CB504

CB510

CB505

CB553

CB508

CB507

CB514

CB516

6. Removal of CONTROL, FUNCTION (1), (2), (4) ~ (6),

INPUT (1), (2), IBOC (U model) P.C.B.s and Tuner (C,

R, T, K, A, B, G, L models)

a. Remove 25 (U model) / 23 (C, R, T, K, A, B, G, L

models) screws (E). (Fig. 4)

b. Remove 2 jack screws (F). (Fig. 4)

c. Remove CB40, CB44, CB504, CB505 and CB553. (Fig.

3)

d. Remove CONTROL, FUNCTION (1), (2), (4) ~ (6),

INPUT (1), (2), IBOC (U model) P.C.B.s and Tuner (C,

R, T, K, A, B, G, L models).

Fig. 4

6. CONTROL、FUNCTION(1)、(2)、(4)〜(6)、

INPUT(1)、(2)P.C.B.、チューナーの外し方

a.Eのネジ24本を外します。(Fig.4)

b.Fのジャックスクリュー2本を外します。(Fig.4)

c. CB40、CB44、CB504、CB505、CB553を外します。

(Fig.3)

d. CONTROL、FUNCTION(1)、(2)、(4)〜(6)、

INPUT(1)、(2)P.C.B.、チューナーを取り外します。

13

RX-V4600/DSP-AX4600

When checking the P.C.B.:

• Put the Rubber Sheet and a Cloth over the equipment.

Then place the P.C.B. upside down on the Cloth and

check it. (Fig. A)

• Reconnect all cables (connectors) that have been

disconnected.

Be sure to use the extension cable for servicing for the

following section.

CONTROL P.C.B. CB506 – OPERATION (5) P.C.B. CB553:

MF127500 (27P 500mm)

CONTROL P.C.B. CB508 – OPERATION (1) P.C.B. CB904:

MF124500 (24P 500mm)

CONTROL P.C.B. CB514 – OPERATION (2) P.C.B. CB903:

MF115500 (15P 500mm)

CONTROL P.C.B. CB507 – OPERATION (3) P.C.B. CB908:

MF113500 (13P 500mm)

CONTROL P.C.B. CB516 – OPERATION (3) P.C.B. CB907:

MF107500 (7P 500mm)

CONTROL P.C.B. W502 – OPERATION (3) P.C.B. CB906:

WD635400 (3/4P 180mm)

• When connecting the cable, use care for the polarity.

• In this unit, the ground of P.C.B.s shown below is

connected to the rear panel. When these P.C.B.s are

removed from the rear panel, connect the ground to

the rear panel or chassis, using a lead wire or the like.

(Fig. B)

DSP P.C.B. : PJ501 (DIGITAL INPUT)

DUAL P.C.B. : CB2 (iLINK)

CONTROL P.C.B. : PJ511 (CONPONENT VIDEO)

INPUT (1) P.C.B. : PJ301 (MULTI CH INPUT)

INPUT (2) P.C.B. : JK701 (MONITOR OUT)

FUNCTION (1) P.C.B.: PJ509 (PRE OUT), CB514

(RS – 232C Terminal)

FUNCTION (2) P.C.B.: PJ505 (DVR IN/OUT)

Earth (lead wire)

アース(リード線)

FUNCTION (6) P.C.B.

P.C.B.チェックをする場合には

・ 本機の上にゴムシートと布を敷き、その上にP.C.B.を

裏返しに置いてチェックします。(Fig.A)

・ 外したケーブル(コネクター)をすべて接続します。

ただし次の区間は、サービス用延長ケーブルを使用し

てください。

CONTROLP.C.B.CB506−OPERATION(5)P.C.B.CB553:

MF127500(27P500mm)

CONTROLP.C.B.CB508−OPERATION(1)P.C.B.CB904:

MF124500(24P500mm)

CONTROLP.C.B.CB514−OPERATION(2)P.C.B.CB903:

MF115500(15P500mm)

CONTROLP.C.B.CB507−OPERATION(3)P.C.B.CB908:

MF113500(13P500mm)

CONTROLP.C.B.CB516−OPERATION(3)P.C.B.CB907:

MF107500(7P500mm)

CONTROLP.C.B.W502−OPERATION(3)P.C.B.CB906:

WD635400(3/4P180mm)

・ ケーブルを接続する際、極性に注意してください。

・ 本機では下記P.C.B.のアースがリアパネルに接続され

ています。これらのP.C.B.をリアパネルより取り外し

た場合は、リード線等でアースをリアパネルまたは

シャーシに接続してください。(Fig.B)

DSPP.C.B. :PJ501(DIGITALINPUT)

DUALP.C.B. :CB2(iLINK)

CONTROLP.C.B. :PJ511(CONPONENTVIDEO)

INPUT(1)P.C.B. :PJ301(MULTICHINPUT)

INPUT(2)P.C.B. :JK701(MONITOROUT)

FUNCTION(1)P.C.B. :PJ509(PREOUT)、CB514

(RSー232C端子)

FUNCTION(2)P.C.B. :PJ505(DVRIN/OUT)

Earth (lead wire)

アース(リード線)

Earth (lead wire)

アース(リード線)

Ground Point

アース箇所

7. Removal of Fan

a. Remove 4 push rivets (G) and then remove the Cover.

(Fig. 5)

b. Remove 2 screws (H) and 2 screws (I). (Fig. 5)

c. Remove CB20.

d. Remove the Fan together with the frame by lifting them

up. (Fig. 5)

8. Removal of OPERATION (5) P.C.B.

a. Remove 2 screws (J). (Fig. 5)

b. Remove CB542, CB131. (Fig. 5)

c. Remove the OPERATION (5) P.C.B. which is

connected directly to the lower P.C.B. with

connectors. (Fig. 5)

9. Removal of Amp Unit

a. Remove 2 push rivets (K) and then remove the Duct.

(Fig. 5)

b. Remove 4 screws (L) and 4 screws (M). (Fig. 5)

c. Remove the Amp Unit. (Fig. 5)

G

G

Cover

カバー

I

Ground Point

アース箇所

Frame

フレーム

7. ファンの外し方

a.Gのプッシュリベット4本を外し、カバーを外します。

(Fig.5)

b.Hのネジ2本、Iのネジ2本を外します。(Fig.5)

c. CB20を外します。(Fig.5)

d. ファンをフレームといっしょに上方に取り外します。

(Fig.5)

8. OPERATION(5)P.C.B.の外し方

a.Jのネジ2本を外します。(Fig.5)

b. CB542を外します。(Fig.5)

c. OPERATION(5)P.C.B.を取り外します。下方のP.C.B.

と直接コネクター接続されています。(Fig.5)

9. アンプユニットの外し方

a.Kのプッシュリベット2本を外し、ダクトを外します。

(Fig.5)

b.Lのネジ4本、Mのネジ4本を外します。(Fig.5)

c. アンプユニットを取り外します。(Fig.5)

OPERATION (5) P.C.B.

POWER (7) P.C.B.

(U, C, R, T, K, A, B, G, L models)

CB131

L

H

Fan

ファン

CB542

Amp Unit

アンプユニット

CB20

L

L

M

J

M

14

CONTROL P.C.B.

DUAL P.C.B.

DSP P.C.B.

MF113500

MF107500

MF124500

MF115500

Fig.A

WD635400

FUNCTION (5) P.C.B.

FUNCTION (4) P.C.B.

Tuner

チューナー

(Jmodel)

Rubber Sheet and Cloth

ゴムシートと布

Ground Point

アース箇所

FUNCTION (1) P.C.B.

FUNCTION (3) P.C.B.

FUNCTION (2) P.C.B.

INPUT (1) P.C.B. INPUT (2) P.C.B.

Fig.B

CONTROL P.C.B.

I BOC P.C.B.

(U model)

Tuner

チューナー

( C, R, T, K, A, B, G, L models

K

Duct

ダクト

Fig. 5

)

RX-V4600/DSP-AX4600

When checking the Amp Unit:

• Put the Amp Unit together with the heat sink upright

on the art base and check them. (Fig. C)

• Reconnect all cables (connectors) that have been

disconnected.

Be sure to use the extension cable for servicing for the

following section.

CONTROL P.C.B. CB506 – OPERATION (5) P.C.B. CB553:

MF127500 (27P 500mm)

• When connecting the flat cable, use care for the

polarity.

Amp Unit

OPERATION (5) P.C.B.

CB553

アンプユニット

アンプユニットをチェックする場合には

・ アンプユニットはヒートシンクといっしょに、アート

ベースの上に立ててチェックします。(Fig.C)

・ 外したケーブル(コネクター)をすべて接続します。

ただし次の区間は、サービス用延長ケーブルを使用し

てください。

CONTROLP.C.B.CB506−OPERATION(5)P.C.B.CB553:

MF127500(27P500mm)

・ フラットケーブルを接続する際、極性に注意してくだ

さい。

DSP-AX4600

RX-V4600/

MF127500

Fig. C

CB506

CONTROL P.C.B.

Cloth

布

15

RX-V4600/DSP-AX4600

■ UPDATING FIRMWARE/ファームウェアの書き込み

RX-V4600/

DSP-AX4600

After replacing the following service parts, be sure to

perform writing of the firmware.

•CONTROL P.C.B.

•IC503 (CONTROL P.C.B.)

•DUAL P.C.B.

•IC318 (DUAL P.C.B.)

Make sure to use the following procedure for firmware

writing.

Step.1 Writing of MAIN

Step.2 Writing of HDMI

Step.3 Writing of i.LINK

Performing these 3 stezps completes the writing

procedure.

Equipment required

• PC with RS-232C serial port (OS: Windows98/2000/

Me/XP)

•

Firmware

• Firmware

V46xxxxx_U.mot (U model)

V46xxxxx.mot (C, R, T, K, A, B, G, L models)

• RS-232C cross cable "D-Sub 9-pin Female".

writing

program (DSP_FLASHER_V2.x.x.exe)

Pin No.2 RxD Pin No.2 RxD

Pin No.3 TxD Pin No.3 TxD

Pin No.5 GND Pin No.5 GND

Pin No.7 RTS Pin No.7 RTS

Pin No.8 CTS Pin No.8 CTS

Preparations

Download the firmware loading program and firmware

from the specified download sources to the same directory

of the PC for writing the firmware.

Firmware updating procedure

Step.1 Writing of MAIN

a. With the power turned off, connect the RS-232C cross

cable between the PC and the RS-232C port of the unit

as shown below. (Fig. 1)

下記のサービス部品を交換した場合、ファームウェアの書

き込みを行ってください。

・CONTROLP.C.B.

・IC503(CONTROLP.C.B.)

・DUALP.C.B.

・IC318(DUALP.C.B.)

ファームウェアを書き込む場合は、必ず下記の手順で行っ

てください。

Step.1MAINの書き込み

Step.2HDMIの書き込み

Step.3i.LINKの書き込み

Step.3まで実施して書き込みが完了となります。

必要なツール

・ RS-232Cシリアルポート付きPC(OS:Windows98/

2000/Me/XP)

・ ファームウェア書き込み用プログラム

(DSPFLASHERV2.x.x.exe)

・ ファームウェア(V46xxxxx.mot)

・ RS-232CクロスケーブルD-sub9pinメス

(仕様)PinNo.2RxD PinNo.2RxD

PinNo.3TxD PinNo.3TxD

PinNo.5GND PinNo.5GND

PinNo.7RTS PinNo.7RTS

PinNo.8CTS PinNo.8CTS

準備

ファームウェア書き込み用プログラムおよびファームウェ

アを指定のダウンロード先からバージョンアップ用PCの

同じディレクトリにダウンロードしてください。

操作

Step.1MAINの書き込み

a. パワーオフ状態で、RS-232CクロスケーブルをPCと本

機のRS-232Cポートに接続します。(Fig.1)

16

Fig. 1

RX-V4600/DSP-AX4600

b. Execute DSP FLASHER. (Fig. 2)

c. Select the COM port to use and press the [connect]

button, and the Com Port Status changes to

"connected". (Fig. 3)

Fig. 2

d. Select the model name of the receiver and press the

[RDY] button. (Fig. 4)

b. DSPFLASHERを実行します。(Fig.2)

c. 使用COMポートを選択し[connect]ボタンを押します。

ComPortStatusがconnectedに変わります。(Fig.3)

Fig. 3

d.

レシーバのモデル名を選択し、[RDY]ボタンを押します。

(Fig.4)

DSP-AX4600

RX-V4600/

e. While pressing the "STRAIGHT/EFFECT" key of the

main unit, press the "STANDBY/ON" key to turn on the

power. (Fig. 5)

Fig. 4

e. 本体のSTRAIGHT/EFFECT キーを押しながら、

STANDBY/ONキーを押して電源を入れます。(Fig.5)

Fig. 5

17

RX-V4600/DSP-AX4600

RX-V4600/

DSP-AX4600

f. While pressing the "SPEAKERS A" key of the main unit,

turn the "PROGRAM" knob until "Upgrade Main" is

displayed. (Fig. 6)

g. While pressing the "MULTI CH INPUT" key of the main

unit, press the "STRAIGHT/EFFECT" key. (Fig. 7)

Immediately after releasing above two keys("MULTI CH

INPUT" key and "STRAIGHT/EFFECT" key), press and

hold the "MULTI CH INPUT" key until "232C BOOT

xxxx" is displayed. (Fig. 7)

f. 本体のSPEAKERSAキーを押しながらPROGRAM

ツマミを回しUpgradeMainをディスプレイに表示させ

ます。

(Fig.6)

Fig. 6

本体のMULTICHINPUTキーを押しながらSTRAIGHT/

g.

EFFECTキーを押します。

(Fig.7)

2つのキー(MULTICH INPUT キー、STRAIGHT/

EFFECTキー)を離してすぐに、MULTICHINPUTキー

を押し、ディスプレイに232CBOOTxxxxと表示され

るまで押しつづけます。

(Fig.7)

Then DSP FLASHER is ready for operation (the button

function is available). (Fig. 8)

18

Fig. 7

DSPFLASHERがReady状態(ボタンが有効)になります。

(Fig.8)

Fig. 8

RX-V4600/DSP-AX4600

h. Drag and drop the file of the firmware to be written or

select the file using the [OPEN] button. (Fig. 9)

i. Pressing the [EPS] button will start writing. (Fig. 10)

h.

書き込むファームウェアのファイルをドラッグアンドド

ロップするか、[OPEN]ボタンでファイルを選択します。

(Fig.9)

Fig. 9

i. [EPS]ボタンを押すと書き込みが始まります。(Fig.10)

DSP-AX4600

RX-V4600/

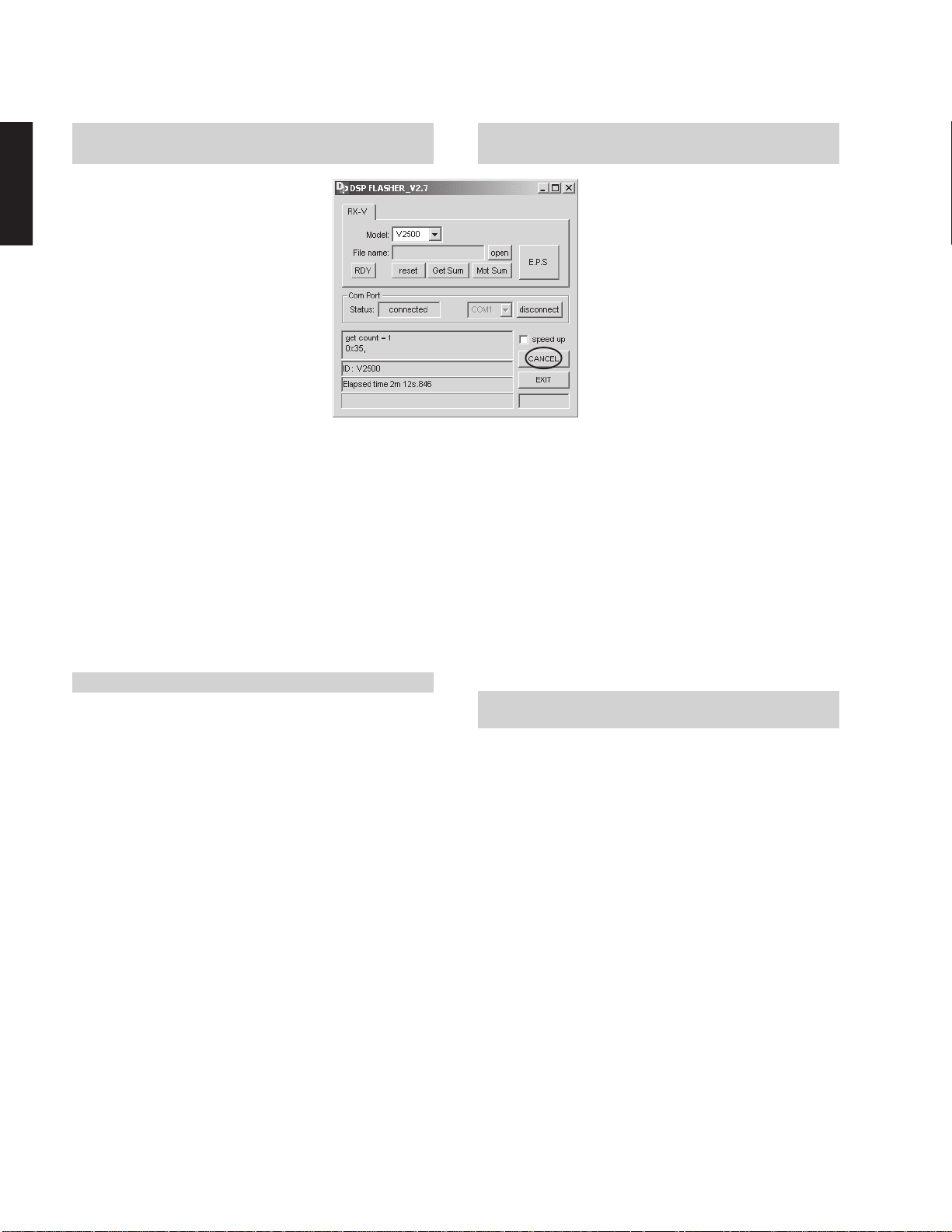

j. When writing is completed, the checksum is displayed

in the box located at the lower left of "CheckSum result"

(F : XXXX). (Fig. 11)

Start the DIAG function of the main unit and check that

the checksum value (F : After boot area) is the same.

* If there is a difference, perform the procedure again

starting from step "b. Execute DSP FLASHER".

Fig. 10

j. 書き込みが完了するとCheckSumresultの左下BOX

にチェックサムが表示されます(F:XXXX)。(Fig.11)

本体のダイアグを起動しチェックサムの値(F:Afterboot

area)と同じであることを確認します。

※ 値が違っている場合は、もう一度手順b.DSP

FLASHERを実行しますからやり直してください。

Fig. 11

19

RX-V4600/DSP-AX4600

RX-V4600/

DSP-AX4600

k. Press the [EXIT] button of DSP FLASHER. This

completes the writing procedure. (Fig. 12)

* Perform "Step.2 Writing of HDMI" without turning off

the power to the main unit.

Step.2 Writing of HDMI

a. While pressing the "SPEAKERS A" key of the main unit,

turn the "PROGRAM" knob until "Upgrade HDMI" is

displayed. (Fig. 13)

k. DSPFLASHERの[EXIT]ボタンを押して終了します。

(Fig.12)

※ 本体の電源は切らずにStep.2HDMIの書き込みを行

います。

Fig. 12

Step.2HDMIの書き込み

a.

本体のSPEAKERSAキーを押しながらPROGRAM

ツマミを回しUpgradeHDMIをディスプレイに表示させ

ます。

(Fig.13)

b. Press the "STRAIGHT/EFFECT" key of the main unit.

(Fig. 14)

"HDMI Writing ···" is displayed and writing is started.

c. When writing is finished, "HDMI Write OK" is displayed.

Then perform "Step.3 Writing of i.LINK".

* When writing is not successful, "HDMI Write NG" is

displayed.

Then perform "Step.2 Writing of HDMI" all over again.

Step.3 Writing of i.LINK

a. While pressing the "SPEAKERS A" key of the main unit,

turn the "PROGRAM" knob until "Upgrade i.LINK" is

displayed. (Fig. 13)

b. Press the "STRAIGHT/EFFECT" key of the main unit.

(Fig. 14)

"i.LINK Pre Check" is displayed and writing is started.

c. When writing is finished, "i.LINK Write OK" is displayed.

* When writing is not successful, "i.LINK Write NG" is

displayed.

Then perform "Step.3 Writing of i.LINK" all over again.

d. Press the "STANDBY/ON" switch of the main unit to

turn off the power.

本体のSTRAIGHT/EFFECTキーを押します。

b.

(Fig.14)

ディスプレイにHDMIWriting・・・が表示され、書き込

みが始まります。

c. 書き込み終了後、ディスプレイにHDMIWriteOKが表

示されます。

本体の電源は切らずにStep.3i.LNKの書き込みを行

います。

※ 書き込みに失敗した場合、ディスプレイにHDMIWrite

NGが表示されます。

Step.2HDMIの書き込みを最初からやり直してくだ

さい。

Step.3i.LNKの書き込み

a.

本体のSPEAKERSAキーを押しながらPROGRAM

ツマミを回しUpgradei.LINKをディスプレイに表示させ

ます。

(Fig.13)

本体のSTRAIGHT/EFFECTキーを押します。

b.

(Fig.14)

ディスプレイにi.LINKPreCheckが表示され、書き込

みが始まります。

c. 書き込み終了後、ディスプレイにi.LINKWriteOKが表

示されます。

※ 書き込みに失敗した場合、ディスプレイにi.LINKWrite

NGが表示されます。

Step.3i.LNKの書き込みを最初からやり直してくだ

さい。

d. 本体のSTANDBY/ONキーを押して電源を切ります。

20

RX-V4600/DSP-AX4600

DSP-AX4600

RX-V4600/

Fig. 14Fig. 13

* If writing is not successful or the power cannot be

turned on after writing, it is possible to enter the

updating mode by using "FORCED BOOT MODE" and

execute writing again.

Preparation

• Perform Steps a to d of MAIN writing procedure.

• Remove the "VOLUME" knob from the front panel of the

main unit.

• Connect the power plug to the AC outlet.

• Prepare a flatblade screwdriver.

1. While pressing the "MULTI CH INPUT" key of the main

unit, press the "RESET SWITCH" key using a flatblade

screwdriver.

2. Immediately after releasing above two keys ("MULTI

CH INPUT" key and "RESET SWITCH" key), press and

hold the "MULTI CH INPUT" key until "232C BOOT

xxxx" is displayed.

※ 書き込みの途中で失敗したり、書き込み終了後に電源が

入らない場合、「強制BOOTモード」で書き込みモードに

入ることができ、再度書き込みを行うことができます。

準備

・ MAINの書き込み手順a〜dを行なっておきます。

・ 本体前面のVOLUMEノブを外しておきます。

・ 電源プラグをACコンセントに接続します。

・ マイナスドライバーを用意します。

1. 本体のMULTICHINPUTキーを押しながらマイナス

ドライバーを使いRESETSWITCHキーを押します。

2. 2つのキー(MULTI CH INPUT キー、RESET

SWITCHキー)を離してすぐに、MULTI CH INPUT

キーを押し、ディスプレイに232CBOOTxxxxと表

示されるまで押しつづけます。

RESET SWITCH

If the display remains unchanged from "Upgrader xxxx",

start all over from Step 1.

When "232C BOOT xxxx" is displayed, go to Step h of

MAIN writing procedure and continue the procedure.

Flatblade Screwdriver /

マイナスドライバー

Upgraderxxxxのまま表示が切り替わらない場合は、も

う一度手順1からやり直します。

ディスプレイに232CBOOTxxxx と表示されたら、

MAINの書き込み手順hから作業を続けます。

21

RX-V4600/DSP-AX4600

■ SELF DIAGNOSIS FUNCTION (DIAG)/自己診断機能(ダイアグ)

There are 26 DIAG menu items, each of which has submenu items. Listed in the table below are menu items and

sub-menu items.

ダイアグメニューは26個あり、そのそれぞれにサブメ

ニューがあります。下表はメニュー一覧です。

RX-V4600/

DSP-AX4600

No DIAG MENU SUB MENU

1 DA60Y-YSS930 1. YSS 0dB

2. YSS FULL BIT

2 BYPASS 1. ANALOG BYPASS

2. DSP BYPASS

3 RAM THROUGH 1. RAM 0dB

2. FRONT ATT

4 PRO LOGIC / NEO6 1. PRO LOGIC I

2. PRO LOGIC II

3. NEO: 6

5 SPEAKERS SET 1. FRONT: SMALL 0dB

2. CENTER: NONE

3. LFE/BASS: FRONT

4. PRESS MIX: 5ch

5. SURROUND B: MUTE

6. SURROUND LR: MUTE

7. SURROUND LR: NONE

6 EXTERNAL INPUT 1. 6CH INPUT_6OHMS

SP Impedance Check 2. 6CH INPUT_8OHMS

3. 8CH INPUT_6OHMS

4. 8CH INPUT_8OHMS

5. TEMP TEST

7 MIC CHECK MIC CHECK

8 DISPLAY CHECK 1. VFD CHECK (Initial display /

2. VFD DISP OFF (All segments OFF /

3. VFD DISP ALL (All segments ON 100% /

4. VFD DIMMER (All segments ON 50% /

5. CHECKED PATTERN (ON in lattice /

初期表示)

全セグメント消灯)

全セグメント点灯100%)

全セグメント点灯50%)

格子状点灯)

9 MANUAL TEST 1. TEST ALL

2. TEST FRONT L

3. TEST CENTER

4. TEST FRONT R

5. TEST SURROUND R

6. TEST SURROUND BACK R

7. TEST SURROUND BACK L

8. TEST SURROUND L

9. TEST LFE

10. TEST PRESENCE L

11. TEST PRESENCE R

10 RS-232C 1. TxD/RxD DATA

2. HARD FLOW

11 FACTORY PRESET 1. PRESET INHIBIT (memory initialization inhibited / メモリーの初期化禁止)

2. PRESET RESERVED (memory initialized /

メモリーの初期化)

22

Loading...

Loading...