Page 1

GA

011459

19990301-148000

SERVICE MANUAL

HAMAMATSU, JAPAN

2.02K-186 Printed in Japan '99.02

GUITAR AMPLIFIER

CONTENTS

SPECIFICATIONS····································································· 3

PANEL LAYOUT········································································ 4

CIRCUIT BOARD LAYOUT······················································· 5

BLOCK DIAGRAM····································································· 6

DISASSEMBLY PROCEDURE·················································· 6

LSI PIN DESCRIPTION····························································· 9

IC BLOCK DIAGRAM ······························································ 12

CIRCUIT BOARDS·································································· 14

TEST PROGRAM···································································· 18

ERROR MESSAGES······························································· 21

MIDI IMPLEMENTATION CHART··········································· 22

PARTS LIST

Page 2

DG80-112

2

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or plastic (where

applicable) components may also contain traces of chemicals found by the California Health and Welfare Agency (and possibly

other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON

WHAT SO EVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose eyes

to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before handling

food.

LITHIUM BATTERY HANDLING

This product uses a lithium battery for memory back-up.

WARNING: Lithium batteries are dangerous because they can be exploded by improper handling. Observe the following

precautions when handling or replacing lithium batteries.

Leave lithium battery replacement to qualified service personnel.

Always replace with batteries of the same type.

When installing on the PC board by soldering, solder using the connection terminals provided on the battery cells.

Never solder directly to the cells. Perform the soldering as quickly as possible.

Never reverse the battery polarities when installing.

Do not short the batteries.

Do not attempt to recharge these batteries.

Do not disassemble the batteries.

Never heat batteries or throw them into fire.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering. Udskiftning må kun ske med batteri af samme fabrikat og type. Levér det

brugte batteri tilbage til leverandøren.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens instruktion.

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

The following information complies with Dutch Official Gazette 1995. 45; ESSENTIALS OF ORDER ON THE COLLECTION OF

BATTERIES.

•Please refer to the diassembly procedure for the removal of Back-up Battery.

•Leest u voor het verwijderen van de backup batterij deze beschrijving.

IMPORTANT NOTICE

This manual has been provided for the use of authorized Yamaha Retailers and their service personnel. It has been assumed that

basic service procedures inherent to the industry, and more specifically Yamaha Products, are already known and understood by

the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal

injury, destruction of expensive components and failure of the product to perform as specified. For these

reasons, we advise all Yamaha product owners that all service required should be performed by an authorized

Yamaha Retailer or the appointed service representative.

IMPORTANT: This presentation or sale of this manual to any individual or firm does not constitute authorization, certification,

recognition of any applicable technical capabilities, or establish a principal-agent relationship of any form.

The data provided is belived to be accurate and applicable to the unit(s) indicated on the cover. The research engineering, and

service departments of Yamaha are continually striving to improve Yamaha products. Modifications are, therefore, inevitable and

changes in specification are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist,

please contact the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have

accumulated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this

buss.)

IMPORTANT: Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the

unit.

WARNING

Components having special characteristics are marked and must be replaced with parts having specification equal to those

originally installed.

Page 3

SPECIFICATIONS

DG80-112

3

Digital Section

Complete Digital Signal Processing

Internal 8 Channel Preset

Digital Reverb (SPRING, HALL, PLATE)

Digital Tape Echo

Speaker Simulator (LINE OUT)

Analog Section

80 W (8 Ω) Solid State Power Amp

30 cm Speaker (Celestion G12H100) x 1

MIDI Function

Receive : Program change, Control Change (No. 7, 91, 94), Bulk In

Transmit : Bulk Out, Merge Out

Controller/Switch

Front Panel : TRIM, OUTPUT, GAIN, MASTER, TREBLE, HIGH

MID, LOW MID, BASS (TIME), PRESENCE (FEED

BACK), REVERB (LEVEL)

Rear Panel : LINE OUT volume, EFFECT BLEND

Switch : AMP SELECT (LEAD1, LEAD2, DRIVE1, DRIVE2,

CRUNCH1, CRUNCH2, CLEAN1, CLEAN2),

REVERB, MODE, , , STORE, RECALL

Display

AMP SELECT display LED x 8

MODE display LED x 3

REVERB type display x 3

7 segment LED x 2 digits

Indicator

Trim Level Display LED (Green)

Trim Clip Display LED (Red)

Connection Jacks

INPUT HIGH/LOW: Standard Phone Mono Jack

SPEAKER x2: Standard Phone Mono Jack

EFFECT SEND/RETURN: Standard Phone Mono Jack

LINE OUT: Cannon Jack

MIDI IN, MIDI OUT: 5 pin DIN

A/D Converter 20 bit

D/A Converter 20 bit

Sampling Frequency 48 kHz

Memory Number 128

Input Level/Impedance

INPUT HIGH: -30 dBm (THRU)/1 MΩ

INPUT LOW: -20 dBm (THRU)/1 MΩ

EFFECT RETURN: 0 dBm/120 kΩ

Output Level/Impedance

SPEAKER: 80 W RMS/8 Ω, 100 W RMS/4 Ω

LINE OUT: +4 dBm/600 Ω

EFFECT SEND: 0 dBm/2.2 kΩ

Power Requirements

U.S. and Canadian models : 120 V, 60 Hz

General model : 230 V, 50 Hz

Power Consumption 100 W

Dimensions (W x H x D) 542 x 510 x 284 mm (21.3” x 20.1” x 11.2”)

Weight 25.0 kg (55 lbs 2 oz)

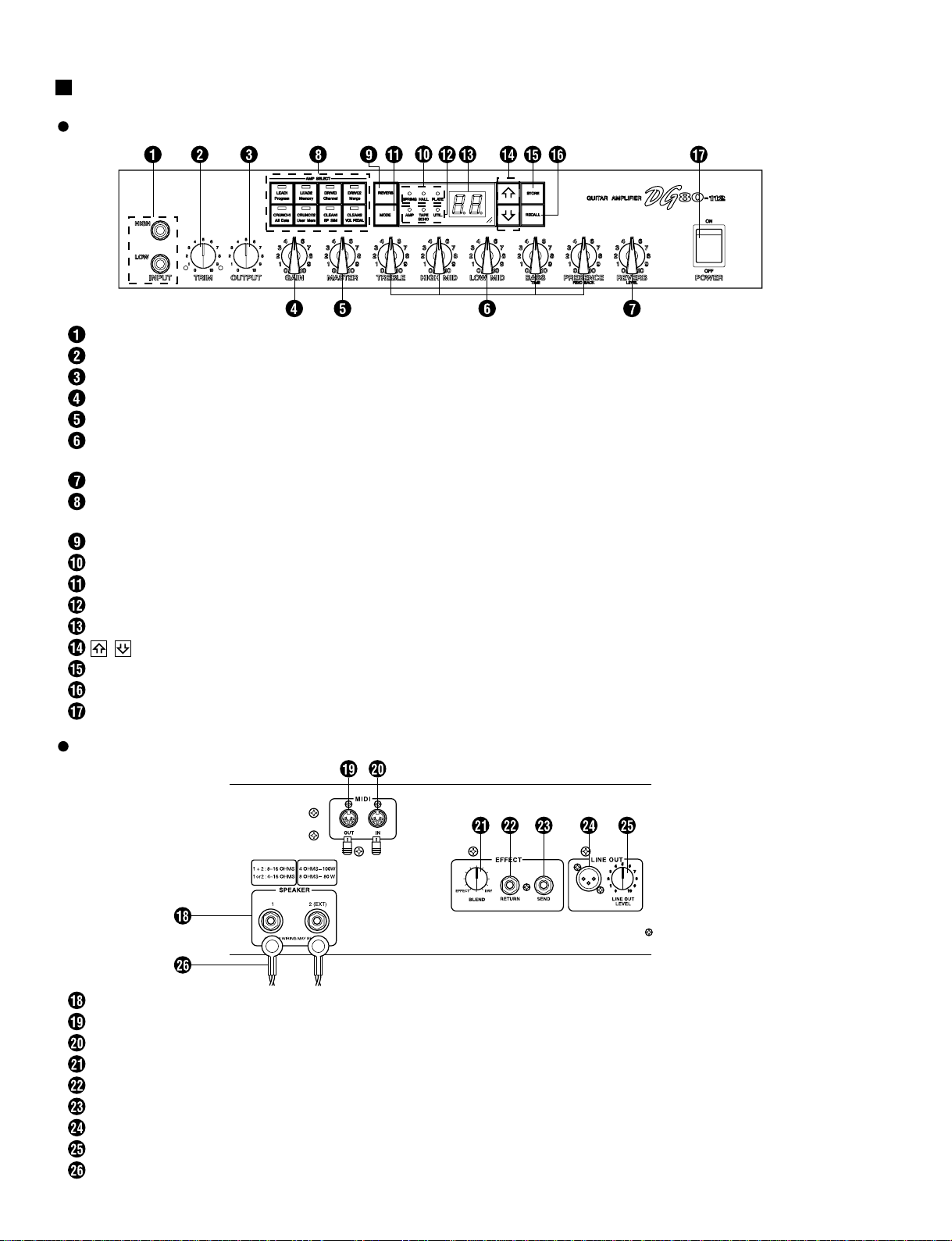

Page 4

Input Jacks (INPUT HIGH, LOW)

Trim Control (TRIM)

Output Level Control (OUTPUT)

Gain Volume (GAIN)

Master Volume (MASTER)

Tone Controls

(TREBLE, HIGH MID, LOW MID, BASS, PRESENCE)

Reverb Volume (REVERB)

Amp Select Button/Amp Select Display

(LEAD 1, 2/DRIVE 1, 2/CRUNCH 1, 2/CLEAN 1, 2)

Reverb Type Select Button (REVERB)

Reverb Type Display Lamp (SPRING, HALL, PLATE)

Mode Select Button (MODE)

Mode Display Lamp (AMP/TAPE ECHO/UTIL.)

Display

/ Buttons

Store Button (STORE)

Recall Button (RECALL)

Power Switch (POWER)

Speaker Jacks (SPEAKER1, 2 (EXT) )

MIDI OUT Jack

MIDI IN Jack

Effect Blend Control (EFFECT BLEND)

Effect Return Jack (EFFECT RETURN)

Effect Send Jack (EFFECT SEND)

Line Out Jack (LINE OUT)

Line Out Level Control (LINE OUT LEVEL)

Speaker Plug

DG80-112

4

PANEL LAYOUT

Front Panel

Rear Panel

Page 5

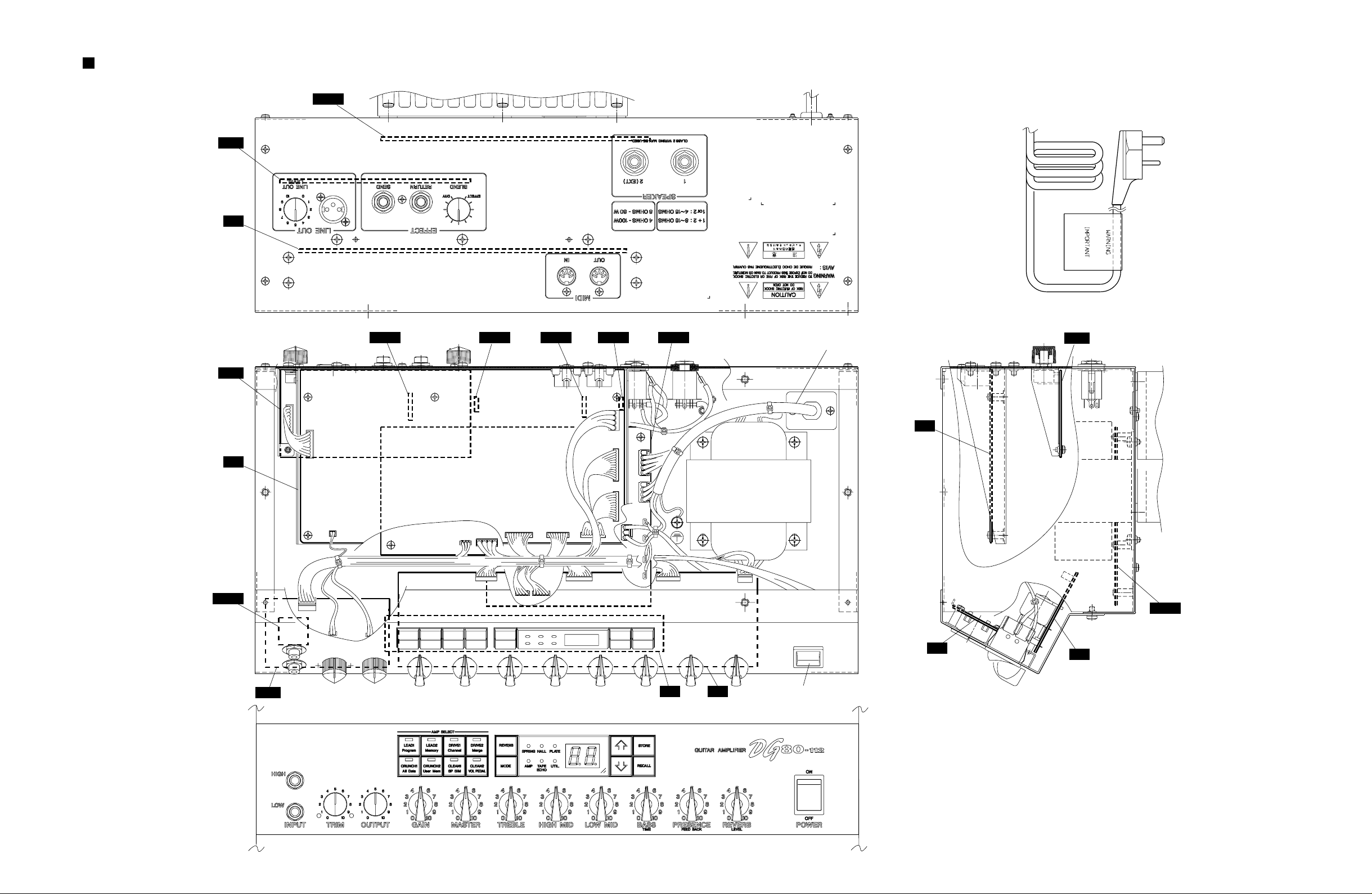

DM

ANR

ANF2

1/5MAIN

AC cord

Power

Transformer

Power Switch

ANR

ANR

ANF

5/5MAIN 4/5MAIN 3/5MAIN 2/5MAIN 1/5MAIN

1/5MAIN

DM

DM

VR

VR

PN

PN

DG80-112

5

CIRCUIT BOARD LAYOUT

Page 6

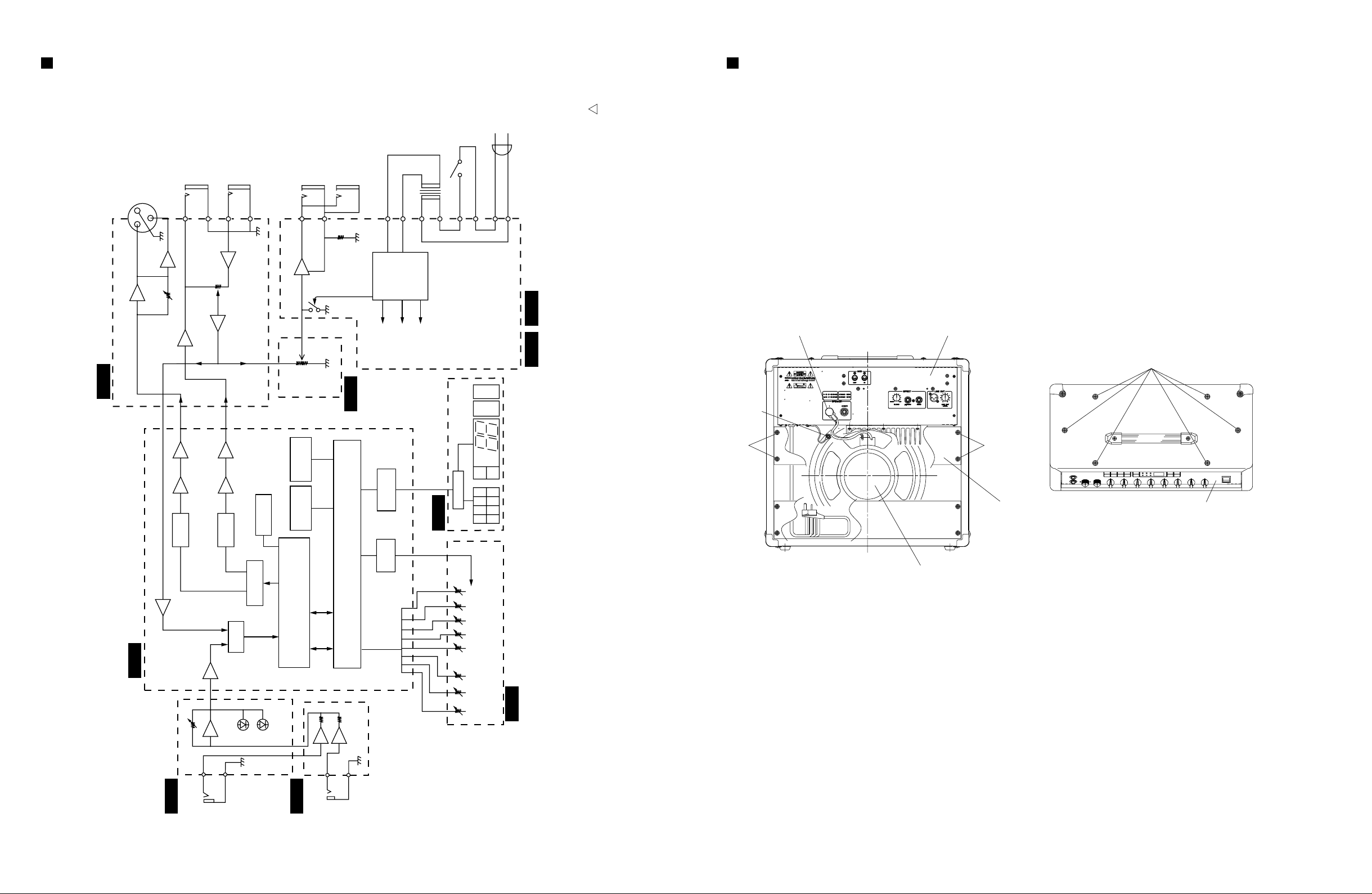

BLOCK DIAGRAM DISASSEMBLY PROCEDURE

DG80-112

6

INPUT LOW

JK501

INPUT HIGH

JK701

TRIM

VR

IC501

RED

GREEN

INPUT LEVEL

INDICATOR

IC701

ANF2

ANF

DM

IC104

IC105

IC118

IC119

IC3

IC8,11

IC2

IC123

IC125

I/V

IC122

IC124

IC403

IC34

IC13

IC21,27 IC36

I/V

D/A

D/A

DRAM

F-ROM

IC12,14

75

1

2

75

5721

6157

57

31

16

5721

31

2

1

27

S-RAM

DSP

CPU

D•FF

D•FF

BUFF

A/D

DF

PN

VR

G

A

I

N

M

A

S

T

H

•

M

I

D

L

•

M

I

D

BAS

S

T

R

E

PRE

PRV

MOTOR

DRIVE

PS PW

ANF

ANR

AC IN

POWER SW

TRANS

MUTING

POWER

SUPPLY

+HB

+/-15V

+/-5V

OUTPUT

VR

POWER AMP

SP JACK

LOAD:

(EXT)

4~8

RETURN

SEND

JK403

IC402

IC401

JK402

JK401

EFECT

LEVEL

LINE OUT LEVEL

LINE OUT

KEC-54160

1

[60]: Hexagonal Nut 5.0 MFC2BL

(20040400)

[

30A

]: Oval Head Screw 5.0X35 MFC2BL

(VP104600)

[70]: Oval Head Tapping Screw-1 4.0X30 MFC2BL

(EN240090)

(Fig. 1) (Fig. 2)

[70]

[

60A

]X4

Connector assembly (speaker)

Speaker

Back board(U)

Pre-main unit

Pre-main unit

[70]

[

30A

]

1. Pre-Main Unit

1-1 Remove the four (4) screws marked [70]. The

back board (U) can then be removed. (Fig. 1)

1-2 Remove the plug of the connector assembly

(speaker) located on the rear panel and the six

(6) screws marked [30A]. The pre-main unit

can then be removed by sliding it backward.

(Fig. 1, Fig. 2)

2. Speaker

2-1 Remove the pre-main unit. (See Procedure 1.)

2-2 Remove the four (4) hexagonal nuts with

flanges marked [60A]. The speaker can then be

removed. (Fig. 1)

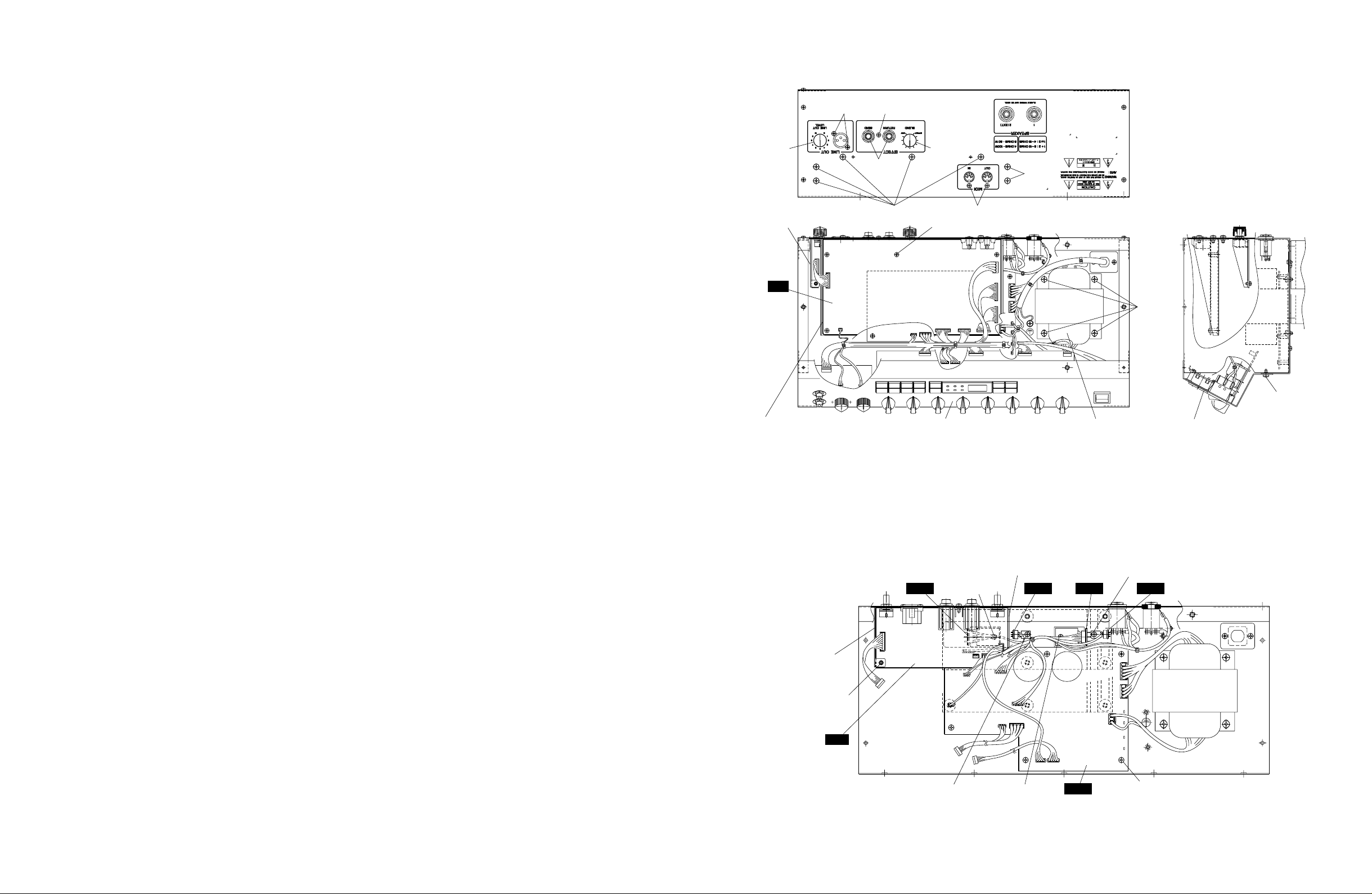

3. Front Panel Assembly

3-1 Remove the pre-main unit. (See Procedure 1.)

3-2 Remove the five (5) screws marked [30B]. The

front panel assembly can then be removed.

(Fig. 3)

Page 7

[

30B

]: Bind Head Screw A4.0X8 MFZN2BL (VP156800)

[

30C

]: Bind Head Screw A3.0X8 MFZN2BL (VP156700)

[40]: Bind Head Tapping Screw-B 3.0X8 MFZN2BL (EP600190)

[

40c

]: Bind Head Tapping Screw-B 3.0X6 MFZN2BL (EP600230)

[50]: Bind Head Screw A4.0X8 MFZN2BL (VP156800)

[80]: Bind Head Screw A4.0X8 MFZN2BL (VP156800)

[

20d

]: Pan Head Screw SP3.0X8 MFZN2Y (EK400500)

[

60C

]: Bind Head Tapping Screw-B 3.0X6 MFZN2BL (EP600230)

[

150A,B

]:Bind Head Tapping Screw-B 3.0X8 MFZN2BL (EP600190)

[

150B-E

]:Pan Head Screw SP3.0X12 MFZN2Y (EL200070)

(Fig. 3)

(Fig. 4)

Sub angle(R)

Sub angle(L)

Front panel assembly Front panel assemblyDM circuit board assembly

ANR circuit board assembly

ANR

DM

Power transformer

MAIN 5/5

[40]

[50][

150A

]

[

30C

]

[A]

[

60B

]

[

40C

] X 6

[

30B

] X 5

[

150E

]

[

60B

]

[50]

[80]

[

60C

] X 6

[

20d

] X 2

MAIN 4/5

MAIN 1/5

MAIN 3/5 MAIN 2/5

[

150B

]

[

150C

][

150D

]

DG80-112

7

4. DM Circuit Board

4-1 Remove the pre-main unit. (See Procedure 1.)

4-2 Remove the two (2) screws marked [150A] and

the six (6) screws marked [40c]. The DM

circuit board can then be removed. (Fig. 3)

5. Power T ransformer

5-1 Remove the pre-main unit. (See Procedure 1.)

5-2 Remove the four (4) screws marked [80]. The

Transformer can then be removed. (Fig. 3)

6. ANR Circuit Board

6-1 Remove the pre-main unit. (See Procedure 1.)

6-2 Remove the two (2) screws marked [150A] and

the seven (7) screws marked [50]. The DM circuit

board assembly can then be removed. (Fig. 3)

6-3 Remove the screw marked [30C], the two (2)

screws marked [40], the two (2) knobs marked

[60B] and the two (2) hexagonal nuts marked

[A]. The ANR circuit board assembly can then

be removed. (Fig. 3)

6-4 Remove the two (2) screws marked [20d]. The

ANR circuit board can then be removed from

the ANR circuit board assembly. (Fig. 3)

7. Main (1/5-2/5) Circuit Board

7-1 Remove the pre-main unit. (See Procedure 1.)

7-2 Remove the front panel assembly.

(See Procedure 3.)

7-3 Remove the DM circuit board assembly.

(See Procedure 6-2.)

7-4 Remove the ANR circuit board assembly.

(See Procedure 6-3.)

7-5 Each circuit board can then be removed in its

manner as below.

Main 1/5 Circuit Board

Remove the six (6) screws marked [60C]. The

main 1/5 circuit board can then be removed.

(Fig. 4)

Main 2/5 Circuit Board

Remove the screw marked [150B]. The main

2/5 circuit board can then be removed. (Fig. 4)

Main 3/5 Circuit Board

Remove the screw marked [150C]. The main

3/5 circuit board can then be removed. (Fig. 4)

Main 4/5 Circuit Board

Remove the screw marked [150D]. The main

4/5 circuit board can then be removed. (Fig. 4)

Main 5/5 Circuit Board

Remove the screw marked [150E]. The main

5/5 circuit board can then be removed. (Fig. 4)

Page 8

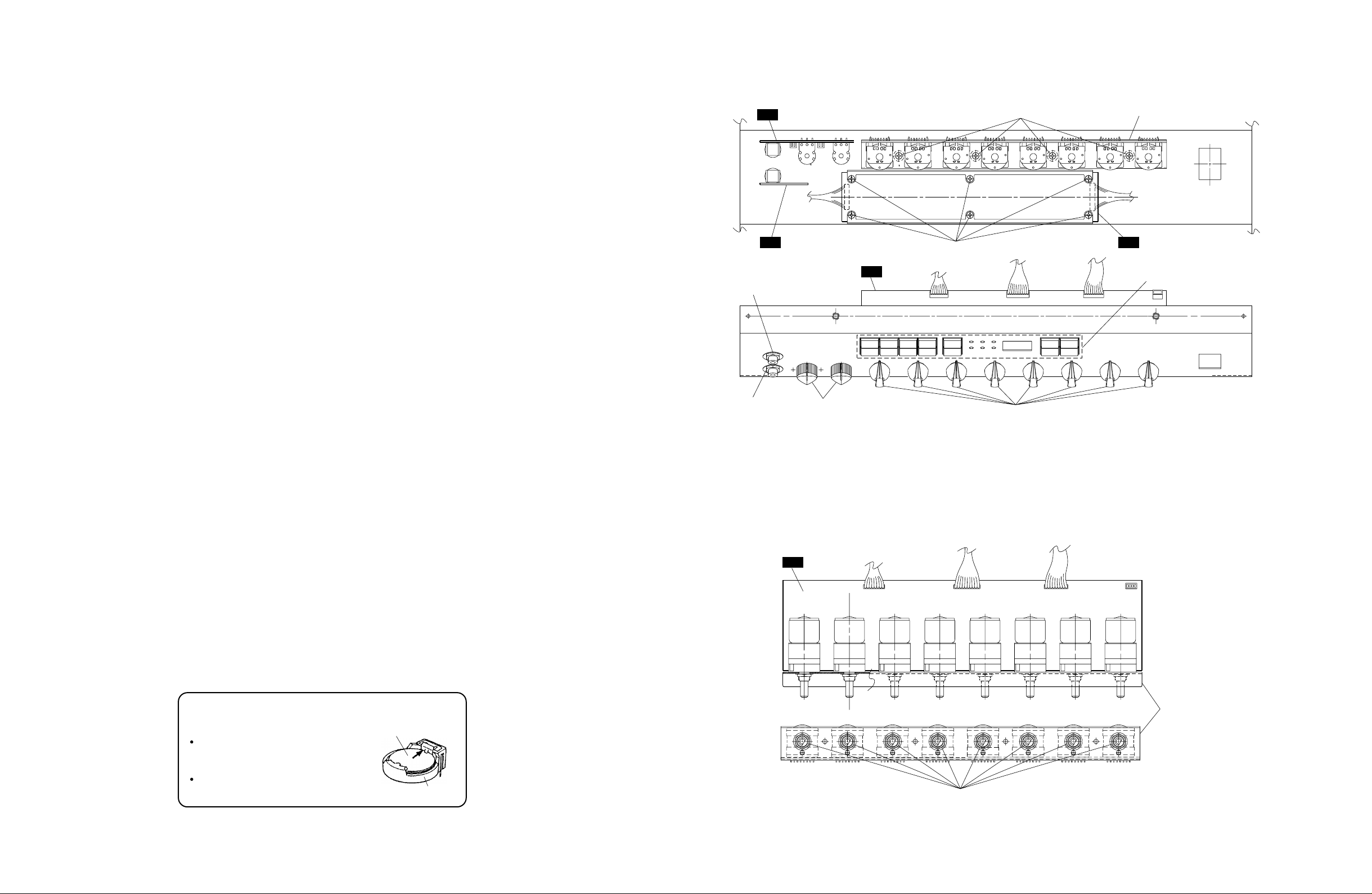

8. PN Circuit Board

8-1 Remove the pre-main unit. (See Procedure 1.)

8-2 Remove the front panel assembly.

(See Procedure 3.)

8-3 Remove the six (6) screws marked [90]. The

PN circuit board assembly can then be removed.

(Fig. 5)

8-4 Remove the seven (7) top cap assemblies from

the PN circuit board assembly.

9. ANF Circuit Board

9-1 Remove the pre-main unit. (See Procedure 1.)

9-2 Remove the front panel assembly.

(See Procedure 3.)

9-3 Remove the two (2) knobs marked [110], the

two (2) hexagonal nuts marked [B] and the

hexagonal nut marked [120A]. The ANF circuit

board can then be removed. (Fig. 5)

10. ANF2 Circuit Board

10-1 Remove the pre-main unit. (See Procedure 1.)

10-2 Remove the hexagonal nut marked [120B]. The

ANF2 circuit board can then be removed. (Fig. 5)

11. VR Circuit Board

11-1 Remove the pre-main unit. (See Procedure 1.)

11-2 Remove the front panel assembly.

(See Procedure 3.)

11-3 Remove the eight (8) knobs marked [100] and

the four (4) screws marked [30D]. The VR circuit

board assembly can then be removed. (Fig. 5)

11-4 Remove the eight (8) hexagonal nuts marked

[C]. The VR circuit board can then be removed

from the VR circuit board assembly. (Fig. 6)

12. Replacement of The Lithium Battery

12-1 Remove the pre-main unit. (See Procedure 1.)

12-2 The lithium battery marked [D], on the DM

circuit board, can be replaced.

DG80-112

8

Battery [D]

Battery VS246400

VS246300(Battery holder for VS246400)

Notice for back-up battery removal

Push against the holder hook, then the

battery will pop up.

Druk tegen de houder, de batterij springt

dan naar voren.

Battery holder

[30D]: Bind Head Tapping Screw-B 3.0X6 MFZN2BL (EP600230)

[90]: Bind Head Tapping Screw-B 3.0X6 MFZN2BL (EP600230)

[120A,B]:Hexagonal Nut 9.0X12X2 MFNI33 (LX200060)

(Fig. 5)

(Fig. 6)

[

120B

]

[

120A

]

[90]

[

100

]

Top cap assemblies

VR circuit board assembly

[

110

], [B]

ANF2

ANF

[C]

Angle,motor volume

[

30D

]

PN

VR

VR

Page 9

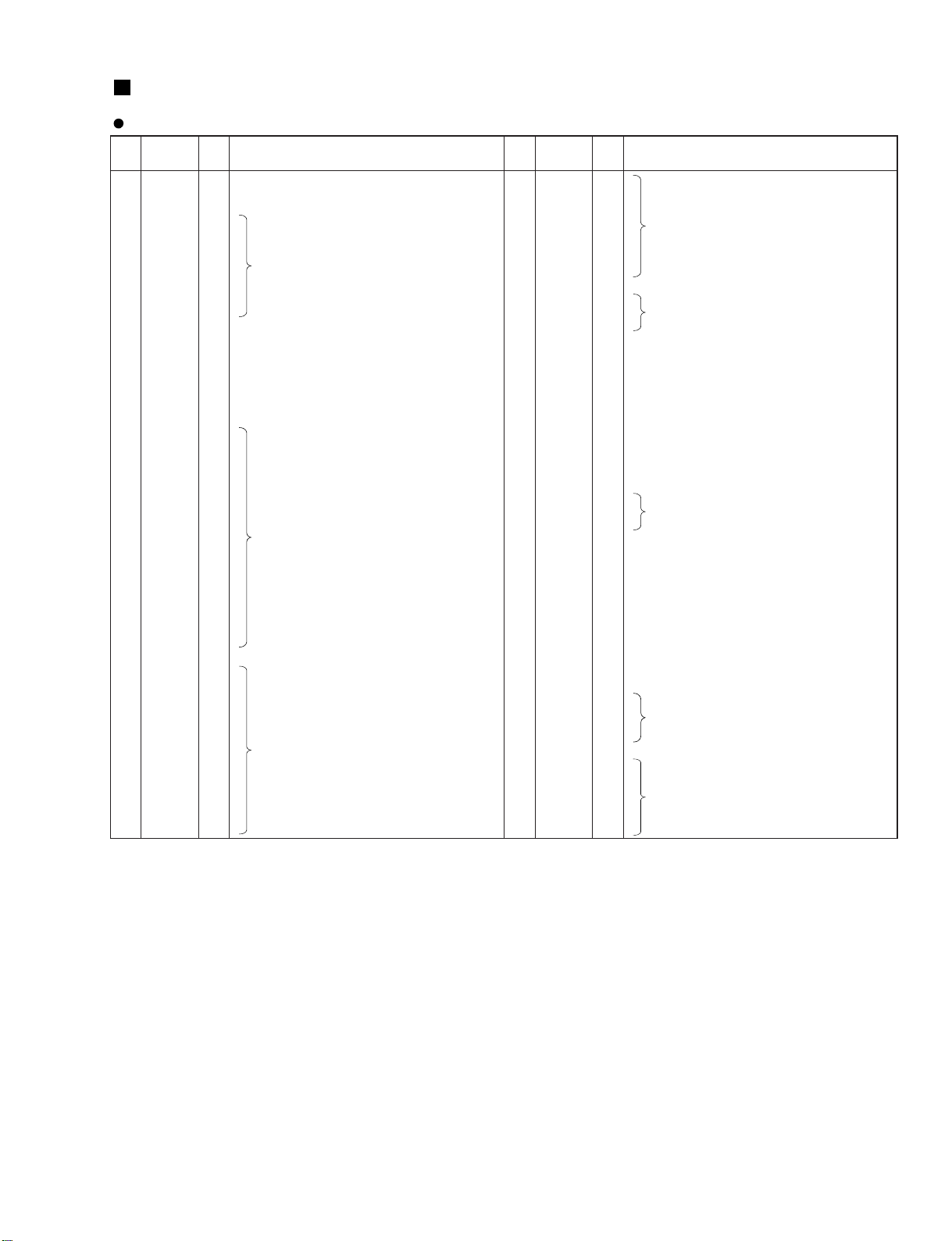

DG80-112

9

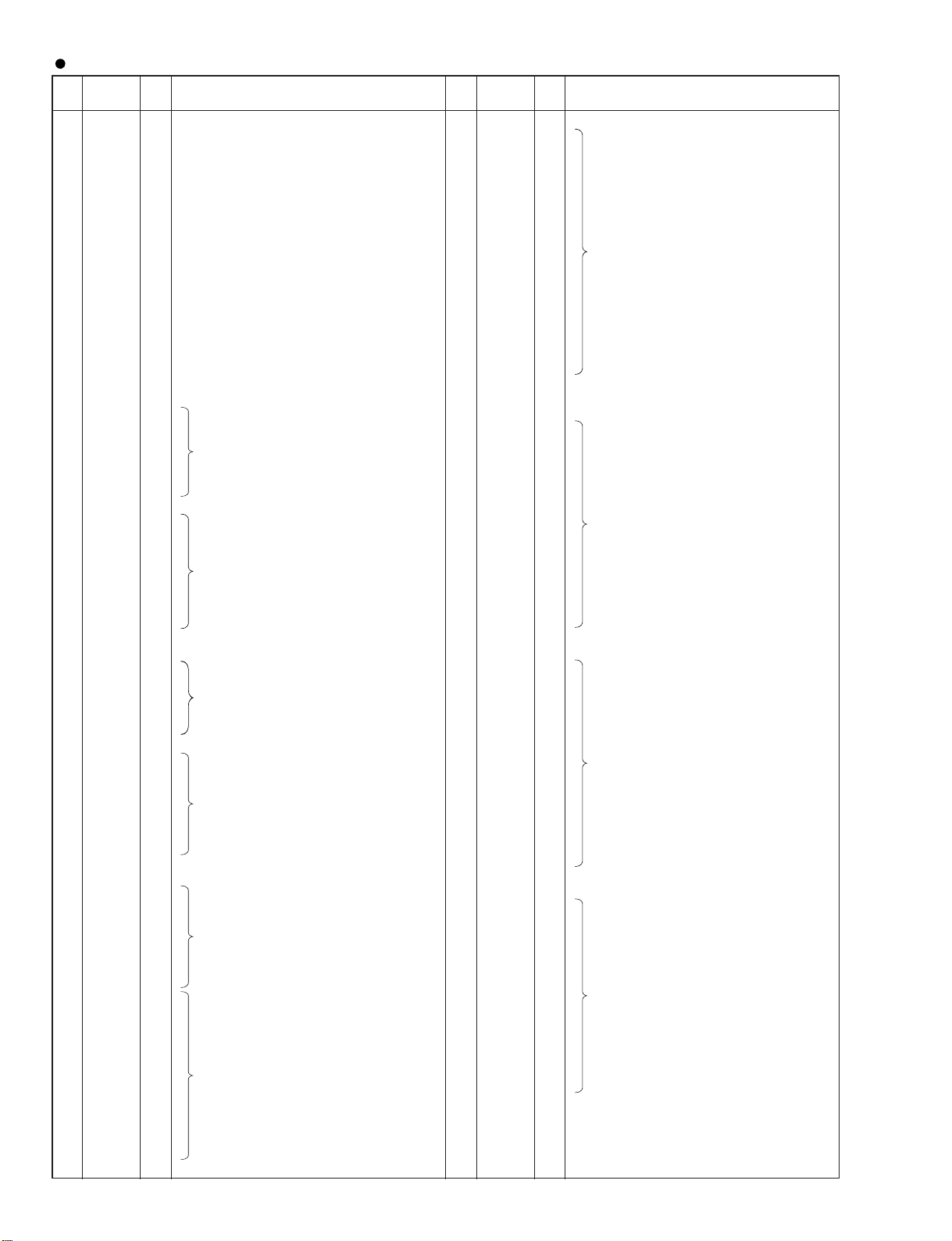

LSI PIN DESCRIPTION

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

I/O

O

O

I

I

I

I

I

I

I

I

O

O

O

I

I

O

I

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

O

O

O

O

O

O

O

O

O

O

O

O

PA6

PA7

VCC

PB0

PB1

PB2

PB3

PB4

PB5

PB6//DREQ0

PB7//DREQ1

/RESO

VSS

P90/TXD0

P91/TXD1

P92/RXD0

P93/RXD1

P94/SCK0

P95/SCK1

P40/D0

P41/D1

P42/D2

P43/D3

VSS

P44/D4

P45/D5

P46/D6

P47/D7

D8

D9

D10

D11

D12

D13

D14

D15

VCC

A0

A1

A2

A3

A4

A5

A6

A7

VSS

A8

A9

A10

A11

NAME

Port A

Address bus

Power supply

Port B

Reset

Ground

Transmit data (MIDI OUT)

KSN-ACK

Receive data (MIDI IN)

KSN-RX

Port 9

Port 9

(Ground)

Data bus

Power supply

Address bus

(Ground)

FUNCTION

PIN

NO.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

I/O

O

O

O

O

O

O

O

O

I

I

I

O

I

I

I

I

O

O

O

O

O

I

I

I

I

I

I

I

I

I

I

I

I

O

O

O

O

O

I

I

I

O

O

O

A12

A13

A14

A15

A16

A17

A18

A19

VSS

P60//WAIT

P61//BREQ

P62//BACK

Ø

/STBY

/RES

NMI

VSS

EXTAL

XTAL

VCC

/AS

/RD

/HWR

/LWR

MD0

MD1

MD2

AVCC

VREF

P70/AN0

P71/AN1

P72/AN2

P73/AN3

P74/AN4

P75/AN5

P76/AN6

P77/AN7

AVSS

P80

P81//CS3

P82//CS2

P83//CS1

P84//CS0

VSS

PA0

PA1

PA2

PA3

PA4

PA5

NAME

Address bus

Ground

Port 6

Ø out

Stand-by mode signal

Reset

Non-maskable interrupt

Ground

Clock

Clock

Power supply

Address strobe

Read strobe

Write strobe (High)

Write strobe (Low)

Mode select

Analog power supply

Reference voltage

Analog data input (EQ)

Analog input (EQ)

Analog data input

Analog input (CS)

Analog data input (BEND)

Analog input (MOD)

Analog input (FC)

Analog input (BAT)

Analog ground

Port 8

Chip select

Ground

Port A

FUNCTION

HD6413002FP16 (XQ375A00) CPU <H8/3002> DM : IC13

Page 10

DG80-112

10

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

I/O

I

I

O

I

O

I

I

I

I

I

I

O

I/O

I

I

I

I

I

I

I

I

I

I

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

O

I

I

I

I

I

I

I

I

O

O

O

O

O

O

O

O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

VSS

XI

XO

VDD

/SYNCI

/SYNCO

CKI

CKO

CKSL

VSS

MCKS

/SSYNC

/IC

/TEST

BTYP

/IRQ

TRIG

VDD

VSS

/CS

/DS

R/W

CA7

CA6

CA5

CA4

CA3

CA2

CA1

CA0/CD15

CD14

CD13

CD12

CD11

CD10

CD09

CD08

CD07

CD06

VSS

VDD

CD05

CD04

CD03

CD02

CD01

CD00

/DTACK

SI0

SI1

SI2

SI3

SI4

SI5

SI6

SI7

VSS

VDD

SO0

SO1

SO2

SO3

SO4

SO5

SO6

SO7

DB00

DB01

DB02

DB03

DB04

DB05

DB06

DB07

DB08

DB09

DB10

DB11

DB12

VDD

NAME

Ground

System master clock input (60 M or30 MHz)

System master clock input (60 M or30 MHz)

Power supply

System synch. input

System synch. output

System clock input (30 MHz)

System clock output (30 MHz)

System master clock select (0:60 M,1:30 MHz)

Ground

Master clock for serial I/O(128 xFs)

Synch. signal for serial I/O

Initial clear

Test mode setting

CPU data bus 8/16 bit select(0:8,1:16)

Interrupt request

Trigger signal

Power supply

Ground

Chip select

Data strobe

Read/Write select

CPU address bus

CPU address/data bus

CPU data bus

Ground

Power supply

CPU data bus

DTACK signal output

Serial data input

Ground

Power supply

Serial data output

Parallel data bus

Power supply

FUNCTION

YSS228E-F (XQ962D00) DSP3 (Digital Signal Processor) DM : IC2, 3

PIN

NO.

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

VSS

DB13

DB14

DB15

DB16

DB17

DB18

DB19

DB20

DB21

DB22

DB23

DB24

DB25

DB26

DB27

DB28

DB29

DB30

DB31

TIMO/DBOE

VSS

VDD

DA00

DA01

DA02

DA03

DA04

DA05

DA06

DA07

DA08

DA09

DA10

DA11

DA12

DA13

DA14

DA15

VSS

VDD

DA16

DA17

DA18

DA19

DA20

DA21

DA22

DA23

DA24

DA25

DA26

DA27

DA28

DA29

DA30

DA31

VDD

VSS

A00

A01

A02

A03

A04

A05

A06

A07

A08

A09

A10

A11

A12

A13

A14

A15/RAS

A16/CAS

A17/CE

/WE

/OE

VDD

NAME

Ground

Parallel data bus

Timing signal/Parallel data bus control

Ground

Power supply

External memory data bus

Ground

Power supply

External memory data bus

Power supply

Ground

External memory address bus

External memory address bus/Row address strobe

External memory address bus/Column address strobe

External memory address bus/Chip enable

External memory write enable

External memory output enable

Power supply

FUNCTION

Page 11

DG80-112

11

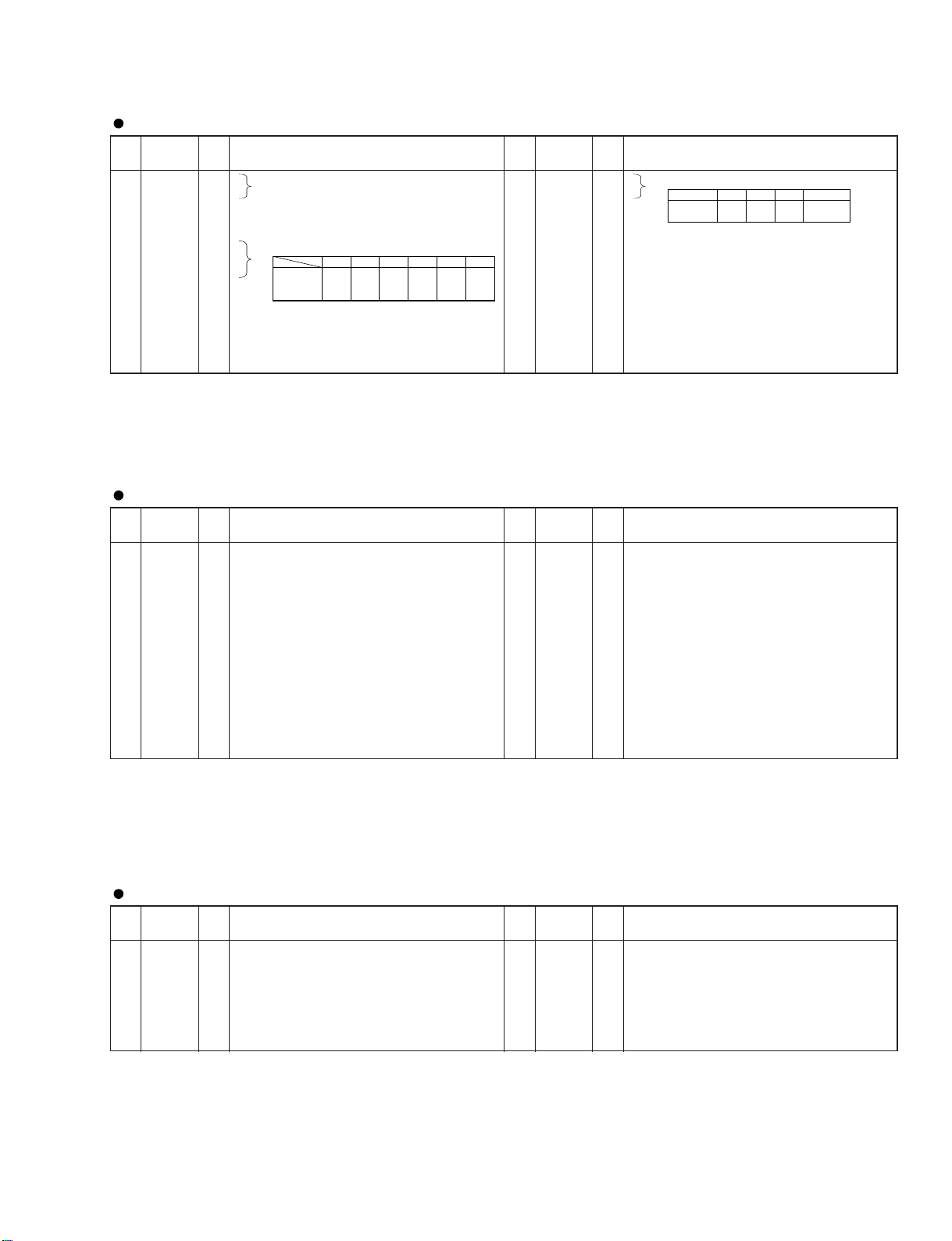

OBIT 1

OBIT 2

H

22 bit

H

L

20 bit

H

H

18 bit

L

L

no output

L

IBIT 1

IBIT 2

IBIT 3

H

22 bit

H

H

L

20 bit

H

H

H

18 bit

L

H

L

16 bit

L

H

H

AV DSP

H

L

H

MEL

H

L

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

I/O

I

I

I

I

O

I

I

I

I/O

I/O

AGND

APD

AINL+

AINLACAL

LGND

VL+

NC

DACL

DPD

CMODE

SMODE

L//R

SCLK

NAME

Analog ground

Analog signal input (L channel -)

Analog signal input (L channel +)

Analog calibration

Analog logic ground

Analog logic power supply

Digital calibration

Digital power down

Master clock select

(L: CLK=256 fs, H:CLK=384 fs)

Interface clock select

(L: slave mode, H: master mode)

Input channel select

Serial data clock

FUNCTION

PIN

NO.

15

16

17

18

19

20

21

22

23

24

25

26

27

28

I/O

O

I/O

I

O

I

I

I

O

O

SDATA

FSYNC

VD+

DGND

CLK

OCLK

NC

ICLK

VA+

VA-

AINRAINR+

VREF-

VREF+

NAME

Serial data output

Frame synch. clock

Digital power supply (+)

Digital ground

Master clock

128 fs clock output

128 fs clock input

Analog power supply (+)

Analog power supply (-)

Analog signal input (R channel -)

Analog signal input (R channel +)

Reference voltage (-)

Reference voltage (+)

FUNCTION

AK5390-VP (XQ199A00) ADC (Analog.Digita Converter) DM : IC118

PIN

NO.

1

2

3

4

5

6

7

8

I/O

I

I

I

I

DATA

CLOCK

+Vdd

DGND

-Vdd

LE

NC

NC

NAME

Serial data input

Bit clock

Digital power supply (+5 V)

Digital ground

Digital power supply (-5 V)

Latch enable

Reserved

Reserved

FUNCTION

PIN

NO.

9

10

11

12

13

14

15

16

I/O

I/O

O

I/O

I/O

+Vcc

BPO DC

I OUT

AGND

AGND

SERVO DC

REF DC

-Vcc

NAME

Analog power supply (+5 V)

BPO decouple

Current output

Analog ground

Analog ground

Servo decouple

Ref. decouple

Analog power supply (-5 V)

FUNCTION

PCM1702P (XN136A00) DAC (Digital to Analog Converter) DM : IC122, 123

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

I/O

O

I

I

I

I

I

I

I

I

XO

XI

VSS2

BCI

SDSY

IBIT1

IBIT2

IBIT3

MUTE

NC

SDI

VDD2

NAME

System clock

Ground

Bit clock

L/R select and input timing

Input bit selection

Mute

No connection

Input data

Power supply

FUNCTION

PIN

NO.

13

14

15

16

17

18

19

20

21

22

23

24

I/O

I

I

I

O

O

O

O

-

O

OBIT1

OBIT2

NC

ASY

VSS1

BCO

WCO

SHL

DRO

NC

DLO

VDD1

NAME

Output bit selection

No connection

Synchronous/Asynchronous system clock

section

Ground

Bit clock of DLO, DRO

Word clock of DLO, DRO

Deglich signal of L/R channel

Output data of R channel

No connection

Output data of L channel

Power supply

FUNCTION

YSF210-M (XK280A00) Digital Filter DM : IC119

Page 12

DG80-112

12

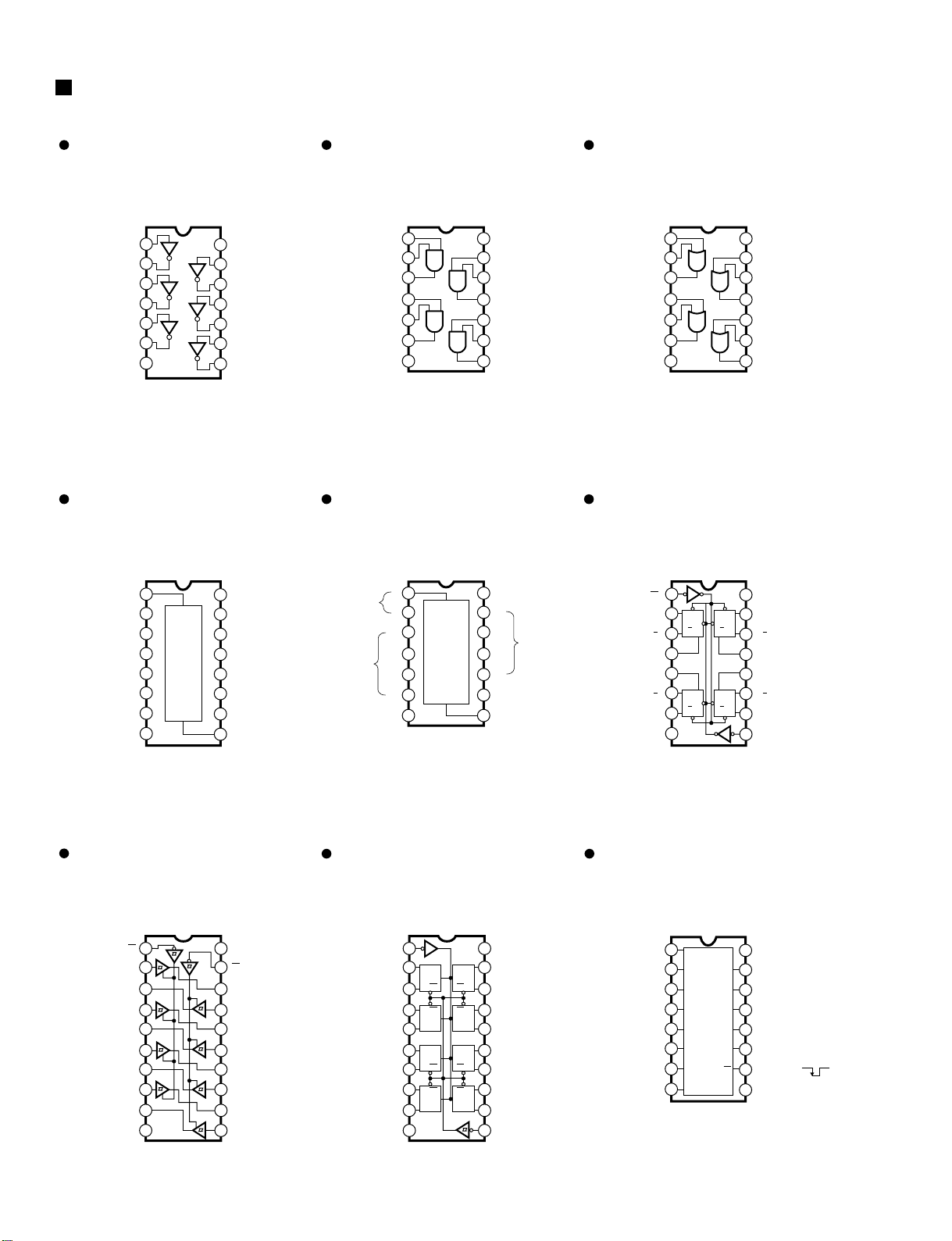

IC BLOCK DIAGRAM

Q

DCK

OE

Q

DCK

OE

Q

DCK

OE

Q

DCK

OE

OUTPUT

CONTROL

1Q

1D

2D

2Q

3Q

3D

4D

4Q

GND

1 20

2 19

3 18

4 17

5 16

6 15

7 14

8 13

9 12

10 11

TCHCU04AF-TP1(XD660A00)

Hex Inverter

SN74HC08NSR(XD831A00)

Quad 2 Input AND

1

2

31A1Y

42A

52B

62Y

7VSS

1B

14

13

12

VDD

4A

11 4Y

10 3B

93A

83Y

4B

1

2

3AQA QA

4QB QB

5QC QC

6QD QD

7GND

BB

14

13

12

VCC

QGQG

11 QFQF

10 QEQE

9 CLEARCLEAR

8 CLOCK

QH

CK

QH

1

2

31A1Y

42A

52B

62Y

7GND

1B

14

13

12

Vcc

4A

11 4Y

10 3B

93A

83Y

4B

TC74VHC32F(XN963A00)

Quad 2 Input OR

SN74HC244NSR(XD233A00)

Octal 3-State Bus Buffer

TC74HC157AF-TP1(XH603A00)

Quad 2 to 1 Multiplexer

TC74HC175AF -TP1(XD658A00)

Quad D-Type Flip-Flop

TC74HC4040F(XR684A00)

12-Stage Binary Ripple Counter

TC74HC164AF(XQ967A00)

8-Bit Shift Register

SN74HC374ANSR

(XQ042A00)

Octal 3-State D-Type Flip-Flop

Vcc

8Q

8D

7D

7Q

6Q

6D

5D

5Q

CLOCK

Q

DCK

OE

Q

DCK

OE

CK

Q

DCK

OE

Q

DCK

OE

1G

1A1

2Y4

1A2

2Y3

1A3

2Y2

1A4

2Y1

1 20

2 19

3 18

4 17

5 16

6 15

7 14

8 13

9 12

10 11

VDD (Vcc)

2G

1Y1

2A4

1Y2

2A3

1Y3

2A2

1Y4

2A1(GND) Vss

QCL

QD

CK

1

2

3

4

5

6

7

1A

1Y

2A

2Y

3A

3Y

Vss

14

13

12

11

10

9

8

VDD

6A

6Y

5A

5Y

4A

4Y

QCL

QD

CK

QCL

QD

CK

QCL

QD

CK

1

2

3

4

5

6

7

CL

1Q

1Q

1D

2D

2Q

2Q

16

15

14

13

12

11

10

VDD

4Q

4Q

4D

3D

3Q

3Q

8

Vss

9

CK

OUTPUTS

OUTPUTS

SIRIAL

INPUT

A

A

1

2

3

4

5

6

7

SELECT

1A 1A

1B 1B

1Y 1Y

2A 2A

2B 2B

2Y 2Y

16

15

14

13

12

11

10

Vcc

STROBEG

4A

S3Y

4A

4B4B

4Y4Y

3A3A

3B3B

8

GND

9

3Y

1

2

3

4

5

6

7

Q12 Q12

Q6 Q6

Q5 Q5

Q7 Q7

Q4 Q4

Q3 Q3

Q2 Q2

16

15

14

13

12

11

10

VDD

Q11Q11

Q10Q10

Q8Q8

Q9Q9

CLRCL

Input Pulses ( )

8

Vss

9

Q1Q1

DM : IC 101 DM : IC 33 DM : IC 28, 29

DM : IC 35, 36

DM : IC 110DM : IC 18

DM : IC 21, 27

DN : IC 202 – 205

DM : IC 117

DM : IC 102

Page 13

NE5532P(IG102500)

Dual Operational Amplifier

LB1641(XF494A00)

Motor Driver

MB3790PF(XR967A00)

ASSP

NJM072D(IG107000)

Dual Operational Amplifier

1A2 3 4 5 6 7 8 9

+V -IN -V

+INOUT

AAA

+V-IN

+IN OUT

BBB

-

+

B

-

+

1

2

3

4-V

8

7

6

5

Output A +V

Non-Inverting

Input A

-DC Voltage Supply

+DC Voltage

Supply

Output B

Inverting

Input B

Non-Inverting

Input B

Inverting

Input A

+-

+-

GND

IN 1 IN 2

Vz

PRE DRIVER

5

6

4

3281097

Vcc2 OUT2 P2 Vcc1OUT1P1

1

INPUT LOGIC

N.C.

V

BAT1

V OUT

V OUT

V BAT2

ALARM1

GND

CONTROL

N.C.

V

IN

V IN

V SENSE

C T

RESET

RESET

ALARM1

1

2

3

4

5

6

7

8

10

9

13

12

11

16

15

14

2

3

4

5

6

7

8

9

10

11

12

16

14

13

C

T

V

BAT2V BAT1

ALARM2

RESET

RESET

ALARM1

V OUT

V OUT

V IN

V IN

V SENSE

CONTROL

GND

-

+

-

+

-

+

590k

240k

1.24V

Reference

Voltage

Power Supply

Circuit

S

Q

R

R

CN 0.5

100

SBD

2.65V

2.37V

500

V

IN

V IN

V OUT

V OUT

3µA

V th:3V

V th:1.5V

DM : IC 104, 105, 124, 125

ANF : IC 501 ANF2 : IC 701

ANR : IC 401 – 403

DM : IC 19

VR : IC 601 – 608

DG80-112

13

Page 14

A. SET-UP

1. If no specific frequency is required, set the test

frequency at 1 kHz.

2. If no specific TRIM and OUTPUT settings are

required, set the volumes of TRIM and OUTPUT at

maximum.

3. Before turning the [POWER] switch on, set the

Idling Adjustment Volume (VR303, 470 ohms) at

minimum.

B. HOW TO ENTER THE TEST PROGRAM

While simultaneously pressing the [MODE], the

[REVERB] and the [DRIVE2] switches, turn the

[POWER] switch on. The DG80-112 will enter the

self test mode.

C. FACTORY PRESET OF RAM

While simultaneously pressing the [LEAD1] and the

[RECALL] switches, turn [POWER] switch on. The

RAM will be cleared, the factory setting data are

restored on the RAM, and the DG80-112 will enter

the normal mode.

D. PROCEEDING THROUGH THE TESTS

1. Switch Functions

Increment : test no. select upward

Decrement : test no. select downward

RECALL : start of the selected test

STORE : exit (in case of error)

LEAD1

– CLEAN2 : no effect

REVERB, MODE : no effect

2. LED Display Functions

When the DG80-112 is in the self test mode, the

LED display shows the number for the status as

below.

If the LED displays “E” and “(error no.)”, the

DG80-112 status can be changed to “test no.

selection” by pressing the [STORE] key. When the

status has been changed, the LED display shows a

next test no.

When the DG80-112 is in “test no. selection”, the

test no. can be changed by using the increment and

the decrement keys.

E. TEST PROGRAM

(Relay Check)

Check that the relay is switched ON within 2 – 3

minutes after the [POWER] switch is turned on.

(Menu of Test Program)

0. LED Check

1. Switch Check

2. Motor Drive Volume check

3. Volume Center Check

4. Battery Check

5. MIDI Check

6. SRAM Check

7. Flash Memory Erase/Write Check

8. Sound Check

9. TEST END

0. LED Check

(Test Contents)

When the DG80-112 enters the self test mode, the

LED Check is started and the LEDs light

automatically for the check in the sequence as

below.

• All the LEDs light simultaneously.

• All the LEDs go out simultaneously.

• The LEDs light one by one in the sequence as

below.

LEAD1 Program

LEAD2 Memory

DRIVE1 Channel

DRIVE2 Merge

CRUNCH1 All Data

CRUNCH2 User Mem.

CLEAN1 SP SIM

CLEAN2 VOL PEDAL

SPRING

HALL

PLATE

AMP

TAPE ECHO

UTIL.

LED display upper num. top

LED display upper num. right upper

LED display upper num. right lower

LED display upper num. bottom

LED display upper num. left lower

LED display upper num. left upper

LED display upper num. center

LED display upper num. dot

LED display lower num. top

LED display lower num. right upper

LED display lower num. right lower

LED display lower num. bottom

LED display lower num. left lower

LED display lower num. left upper

LED display lower num. center

LED display lower num. dot

DG80-112

18

TEST PROGRAM

• All the LEDs go out simultaneously

• All the LEDs light simultaneously

The LED Check is finished and the DG80-112

selects the next test no., so the LED shows a “1”.

(Error Number)

not appearing

1. Switch Check

Press the [RECALL] key when the LED display

shows “1”. The Switch Check is started and the

LED display shows the first check number “11”.

(Test Contents)

Press the keys according to the LED display guide

in the order as below.

(The Exit function of the [STORE] key is available

on the error status.)

11 LEAD1 Program Switch

12 LEAD2 Memory Switch

13 DRIVE1 Channel Switch

14 DRIVE2 Merge Switch

15 CRUNCH1 All Data Switch

16 CRUNCH2 User Mem. Switch

17 CLEAN1 SP SIM Switch

18 CLEAN2 VOL PEDAL Switch

19 REVERB Switch

1A MODE Switch

1B Increment Switch

1C Decrement Switch

1D STORE Switch

1E RECALL Switch

When all the LEDs display light simultaneously, the

Switch Check is finished. Then the DG80-112 selects

the next test no., so the LED display shows a “2”.

(Error Number)

E1 – EE

The switch corresponding to the error number has a

problem or the wrong switch was pressed.

2. Motor Drive Volume Check

Press the [RECALL] key when the LED display

shows “2”. The Motor Drive Volume Check is

started and the LED display shows the first check

number “21”.

(Test Contents)

Once the Motor Drive Check has been started, all

the volumes rotate automatically as below.

21 to the Minimum

22 to the Maximum

23 to the Center

When all the LEDs light simultaneously, the Volume

Check is finished. Then the DG80-112 selects the

next test no., so the LED display shows a “3”.

(Error Number)

E0 – E3

If a Motor Drive Volume Check operation has not

been finished in 20 seconds, the LED display shows

“E0 – “E3” by replacing “2” to “E”.

3. Volume Center Check

Press the [RECALL] key when the LED display

shows “3”, and the Volume Check is started and the

LED display shows one of the numbers from “31”

to“38”.

(Test Contents)

Select the knob that requires adjustment and turn it

until the LED display shows the next volume check

number.

33 TREBLE

34 HIGH MID

35 LOW MID

36 BASS

37 PRESENCE

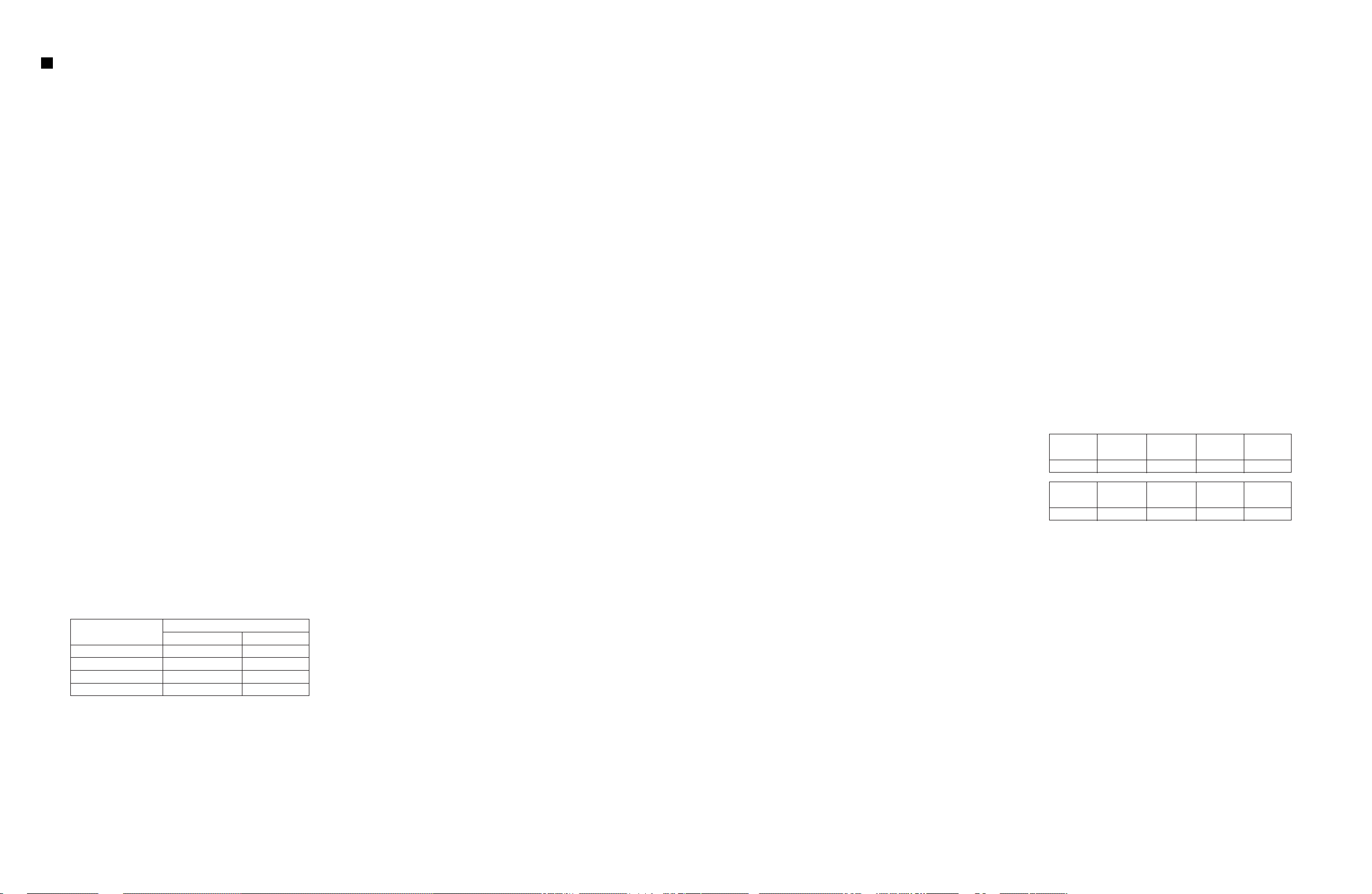

The A/D converter value is shown with binary digits

by using the AMP SELECT LEDs. Set the knob to the

center and turn the trimmer potentiometer to adjust the

AMP SELECT LEDs as shown on the list below.

If the knob data is the same as the data of the list

above, the adjustment of that knob can be passed. The

trimmer potentiometer numbers are shown below.

TREBLE : VR603

HIGH MID : VR605

LOW MID : VR607

BASS : VR609

PRESENCE : VR611

Once the required Volume Center Check has been

finished, press the [RECALL] key and the DG80112 selects the next test no., so the LED display

shows “4”.

(Error Number)

not appearing

4. Battery Check

Press the [RECALL] key when the LED display

shows "5". The Battery Check is started.

(Test Contents)

The RAM Backup Battery check is executed

automatically.

Function

(status)

test no. selection

test execution

ok

error

upper num.

(test no.)

(test no.)

8.

E

lower num.

(blank)

(check no.)

8.

(error no.)

LED display

AMP

SELECT

LED

LEAD1

Program

On

LEAD2

Memory

Off

DRIVE1

Channel

Off

DRIVE2

Merge

Off

AMP

SELECT

LED

CRUNCH1

All Data

Off

CRUNCH2

User Mem.

Off

CLEAN1

Off

CLEAN2

Off

Page 15

DG80-112

19

When all the LEDs light simultaneously, the Battery

Check is finished. Then the 80-112 selects the next

test no., so the LED display shows “5”.

(Error Number)

E0 : Battery Low (RAM DATA are kept.)

E1 : Unknown Error

E2 : Battery Low (RAM DATA are not kept.)

or Not Installed

5. MIDI Check

Connect the MIDI IN and the MIDI OUT terminals

with a MIDI cable. Press the [RECALL] key when the

LED display shows “5”. The MIDI Check is started.

(Test Contents)

The loop back MIDI check is executed automatically.

When the MIDI check is started, the LED display

shows “51” and then “52”. When all the LEDs light

simultaneously, the MIDI Check is finished. Then

the DG80-112 selects the next test no., so the LED

display shows “6”.

(Error Number)

E0 : MIDI Error

E1 : MIDI Error

6. SRAM Check

Press the [RECALL] key when the LED display

shows “6”. The SRAM Check is started.

(Test Contents)

The SRAM read/write check is executed

automatically.

When the SRAM Check is started, the LED display

shows “61” and then “62”. When all the LEDs light

simultaneously, the SRAM Check is finished. Then

the DG80-112 selects the next test no., so the LED

display shows “7”.

(Error Number)

E0 : RAM Address Error

E1 : RAM Read/Write Error

7. Flash Memory Erase/Write Check

Press the [RECALL] key when the LED display

shows “7”. The Flash Memory Erase/Write Check is

started.

(Attention)

When the result of the test number 6 has alredy been

“Error”, don't execute this test, or the DG80-112

won't set up at normal mode by the rewrited wrong

data in the Flash Memory.

Don't turn the [POWER] switch off while executing

this test, the DG80-112 won't set up at normal mode

by no data in the Flash Memory.

(Test Contents)

The Flash Memory Erase/Write check is executed

automatically.

When the check is started, the LED display shows

from “70” to “73” successively. When all the LEDs

light simultaneously, the Flash Memory Erase/Write

check is finished. Then the DG80-112 selects the

next test no., so the LED display shows “8”.

(Error Number)

E0, E1 : Flash Erase Error

E2, E3 : Flash Write Error

8. Sound Check

Before executing this sound check, the idling

adjustment, the output wave adjustment and center

voltage adjustment must be finished. the three

adjustments can be done while the LED display

shows “8”.

(Idling Adjustment)

1. Set the idling adjustment volume (VR303) at

minimum.

2. Connect the 4 ohm load to the speaker terminals.

3. Set the output volume at minimum.

4. Adjust the VR303 so that the DC voltage between

the terminals of the RA301 should be 5 +/-1 mV.

(Output Wave Adjustment)

1. After adjusting the idling adjustment, set the

OUTPUT VR at maximum.

2. When the signal of -2 dBm / 1 kHz is inputted from

the RETURN terminal, adjust the VR 301 (4.7 k

ohms) so that the wave shape should be a sine wave

symmetrical for upper and lower as below.

(Center Voltage Adjustment)

1. Adjust the VR302 so that the voltage of the output

circuit (RA301) should be 38 +/- 2 V.

* By adjusting the output adjustment and the center

voltage adjustment alternatively, search the best point.

After finishing the adjustments above, press the

[RECALL] key when the LED display shows “8”.

The Sound Check is started.

T•P

0.22X2 RA301

T•P

Adjust the VR301

to be a sine wave.

Page 16

DG80-112

20

(Test Contents)

The DG80-112 sets the conditions for the signal

Sound Check through the analogue circuit, the A/D

converter, the DSP-3 and the D/A Converter.

When the Sound Check is started, the LED display

shows “81”. The Sound Check has two conditions.

If the [RECALL] key is pressed when the LED

display shows “81”, the LED display changes to

“82” and the condition changes to the next as below.

81 : DSP3-1

82 : DSP3-2

Check the following items in each condition of “81”

and “82”.

* 0 dBm = 0.775 V Load = 4 ohms

If the Sound Check has been finished, press the

[RECALL] key when the LED display shows “82”.

The LED display shows “9”.

(Error Number)

not appearing

9. TEST END

A “9” on the LED display signals the end of the

TEST and the exit of the Test Program. Press the

[RECALL] key when the LED display shows “9”.

The mode of the DG80-112 changes to the normal

mode and all of the function data are set to the

condition of the latest program number in normal

mode. The Motor Drive Volumes rotate

automatically to the settings of that data.

Items

1. Input Sensitivity

(High)

2. Input Sensitivity

(Low)

3. RETURN Level

4. SEND Level

5. LINE OUT

Level

6. Frequency

Response

(HIGH IN)

7. Remain Noise

8. Sensitivity of

LED for Input

Level

9. Output

Conditions

1 kHz, -30 dBm

1 kHz, -20 dBm

1 kHz, 0 dBm

Condition of 1. and

100 k ohms SEND

load

Condition of 1. and

100 k ohms LINE

OUT load

-40 dBm Input

1 kHz standard

SP Output Terminal

TRIM, OUTPUT

VR MIN IHF A net

Lo Input

TRIM Vol:

maximum

OUTPUT Vol:

maximum

RETURN,10 %THD

Responses

(standards)

+28 dBm +/-2 dB

+28 dBm +/-2 dB

+28 dBm +/-2 dB

-1 dBm +/-2 dB

+3 dBm +/-2 dB

100 Hz: 0.5 +/-1 dB

10 kHz: 0.5 +/-1 dB

less than -60 dBm

Input LED

-30 dBm: no light

-20 dBm: GR only

+4 dBm: both lit

more than +28 dBm

(95 W)

Page 17

ERROR MESSAGES

DG80-112

21

If an error occurs during operation, one of the following error message numbers will appear on the display.

: Motor Drive Error

CAUSE: The volume knob has not returned to its assigned position after 20 seconds has elapsed from the start of the recall

operation or, the device does not recognize the recall command.

SOLUTION: Turn off the power and check the circuit for Motor Drive.

: MIDI Receive Buffer Full

CAUSE: Too much MIDI data is being received by the DG80-112 at one time.

SOLUTION: Try reducing the amount of data being sent or, break the data into smaller blocks.

: Communication Error

CAUSE: An abnormality is detected during MIDI communications.

SOLUTION: Check all connections, etc. and try again.

: Bulk Receive Check Sum Error

CAUSE: The check sum does not match the received MIDI bulk data.

SOLUTION: Check all connections and data, and try again.

: Bulk Receive Data Abnormality

CAUSE: An abnormality is detected in the received MIDI bulk data.

SOLUTION: Check all connections and data, and try again.

: Backup Battery Error

CAUSE: Backup battery power is depleted.

SOLUTION: Continued use of the device will result in the loss of data. Replace the battery with a new one.

Page 18

YAMAHA [ Digital Guitar Amplifier ] Date:1-Dec-1998

Model DG80-112 MIDI Implementation Chart Version : 1.0

+----------------------------------------------------------------------+

: : Transmitted : Recognized : Remarks :

: Function ... : : : :

:-------------------+----------------+----------------+----------------:

:Basic Default : x : 1 - 16, off : memorized :

:Channel Changed : x : 1 - 16, off : :

:-------------------+----------------+----------------+----------------:

: Default : x : 1,3 : memorized :

:Mode Messages : x : x : :

: Altered : ************** : x : :

:-------------------+----------------+----------------+----------------:

:Note : x : x : :

:Number : True voice: ************** : x : :

:-------------------+----------------+----------------+----------------:

:Velocity Note ON : x : x : :

: Note OFF : x : x : :

:-------------------+----------------+----------------+----------------:

:After Key's : x : x : :

:Touch Ch's : x : x : :

:-------------------+----------------+----------------+----------------:

:Pitch Bender : x : x : :

:-------------------+----------------+----------------+----------------:

: 0 - 6 : x : x : :

: 7 : x : o : Main Volume :

: 8 - 90 : x : x : :

: 91 : x : o : Reverb SW. :

: Control 92,93 : x : x : :

: 94 : x : o : Tape Echo SW. :

: Change 95 - 127 : x : x : :

: : : : :

: : : : :

: : : : :

: : : : :

: : : : :

: : : : :

:-------------------+----------------+----------------+----------------:

:Prog : x : o 0 - 127 : Program Change :

:Change : True # : ************** : : Number 1-128 :

:-------------------+----------------+----------------+----------------:

:System Exclusive : o : o : Bulk Dump :

:-------------------+----------------+----------------+----------------:

:System : Song Pos. : x : x : :

: : Song Sel. : x : x : :

:common : Tune : x : x : :

:-------------------+----------------+----------------+----------------:

:System :Clock : x : x : :

:Real Time :Commands: x : x : :

:-------------------+----------------+----------------+----------------:

:Aux :All Sound OFF: x : x : :

: :

Reset All Cntrls

: x : x : :

: :Local ON/OFF : x : x : :

: :All Notes OFF: x : x : :

:Mes- :Active Sense : o : x : :

:sages:Reset : x : x : :

:-------------------+----------------+----------------+----------------:

: :

: :

+-------------------+----------------+----------------+----------------+

Mode 1 : OMNI ON, POLY Mode 2 : OMNI ON, MONO o : Yes

Mode 3 : OMNI OFF, POLY Mode 4 : OMNI OFF, MONO x : No

DG80-112

22

Page 19

CIRCUIT BOARDS

DG80-112

14

MIDI

IN OUT

to DM-CN9

Component side

ENA-VZ77180-1/10

3

DM Circuit Board

Note : See parts list for details of circuit board

component parts.

Page 20

DG80-112

15

to DM-CN9

Pattern side

ENA-VZ77180-2/10

1

DM Circuit Board

Note : See parts list for details of circuit board

component parts.

Page 21

DG80-112

16

GAIN MASTER TREBLE HIGH MID LOW MID BASS

TIME

PRESENCE

FEED BACK

REVERB

LEVEL

Component side

Component side

Pattern side

VR : CNA-V297690-1/10

PN : CNA-V297070-1/5 ,2/5

3

11

PN Circuit Board

VR Circuit Board

Panel Layout

Note : See parts list for details of circuit board

component parts.

Page 22

DG80-112

17

LINE OUT

LINE OUT

LEVEL

Component side

Component side

Component side

Component side

LOW

INPUT

TRIM OUTPUT

HIGH

CNA-V297690-1/10

EFFECT

SEND RETURN BLEND

5/5 4/5 3/5 2/5

1/5

3

MAIN Circuit Board

ANR Circuit Board

ANF2 Circuit Board ANF Circuit Board

Note : See parts list for details of circuit board

component parts.

Page 23

CONTENTS

OVERALL ASSEMBLY

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

2

PRE-MAIN UNIT

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

4

FRONT PANEL ASSEMBLY

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

6

CHASSIS ASSEMBLY

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

8

OVERALL CABINET ASSEMBLY

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

10

ELECTRICAL PARTS

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

11 ~ 20

• The numbers in “ QTY ” show quantities for each unit.

• The parts with “ - - ” in “ PART NO. ” are not available as spare parts.

• The mark “ ” in the remarks column indicates that these parts are interchangeable.

GUITAR AMPLIFIER

PARTS LIST

A : Australian model

B : British model

C : Canadian model

D : German model

E : European model

F : French model

H : North European model

I : Indonesian model

J : Japanese model

M : South African model

O : Chinese model

Q : South-east Asia model

T : Taiwan model

U : U.S.A. model

V : General export model (110V)

W : General export model (220V)

X : General export model

Y : Export model

Notes : DESTINATION ABBREVIATIONS

WARNING

Components having special characteristics are marked and must be replaced with parts having

specification equal to those originally installed.

Page 24

DG80-112

2

OVERALL ASSEMBLY

Pre-main unit : See page 4.

Overall cabinet assembly

: See page 10.

Page 25

DG80-112

3

DESCRIPTION

OVERALL ASSEMBLY

OVERALL ASSEMBLY

OVERALL ASSEMBLY

OVERALL ASSEMBLY

Pre-main Unit

Pre-main Unit

Pre-main Unit

Pre-main Unit

Overall Cabinet Assembly

Oval Head Screw

Washer

Speaker

Hexagonal Nut

Oval Head Tapping Screw-1

Washer

Connector Assembly

Name Plate

Name Plate

Name Plate

Label, Serial Number

Connector Assembly

Bind Head Screw

Label

Toothed Lock Washer-A

REF NO.

10

10

10

10

20

30

40

50

60

70

80

90

100

102

104

110

122

132

142

152

PART NO.

- -

- -

- -

- -

- -

- -

- -

- V3063000

VP104600

EW300020

XV536A00

20040400

EN240090

VB890200

VR144600

- -

- -

- -

- -

- VP156800

VA039300

ET800070

5.0X35 MFC2BL

5S MFC2BL

G12H-100

5.0 MFZN2BL

4.0X30 MFC2BL

4S MFC2BL

L=500mm

SP frame

A4.0X8 MFZN2BL

4.0 MFZN2BL

REMARKS

DG80-112 J (V304070)

DG80-112 U (V304080)

DG80-112 E (V304090)

DG80-112 B (V304120)

J (V304030)

U (V304040)

E (V304050)

B (V304060)

J (V305380)

U (V305440)

E,B (V305510)

(CB06869)

U (V298620)

U

U

U

QTY

6

6

4

8

8

2

*

*

*

:

New Parts RANK:Japan only

RANK

01

01

01

01

06

01

01

03

01

Page 26

DG80-112

4

PRE-MAIN UNIT

100a

40b

40c

40a

DM Circuit board assembly

Chassis assembly : See page 8.

Front panel assembly : See page 6.

Power switch assembly

Power transformer

AC cord assemdly

Page 27

DG80-112

5

DESCRIPTION

PRE-MAIN UNIT

PRE-MAIN UNIT

PRE-MAIN UNIT

PRE-MAIN UNIT

Front Panel Assembly

Front Panel Assembly

Front Panel Assembly

Front Panel Assembly

Chassis Assembly

Chassis Assembly

Chassis Assembly

Chassis Assembly

Bind Head Screw

DM Circuit Board Assembly

Circuit Board

Angle Bracket, DM

Bind Head Tapping Screw-B

Bind Head Screw

Volume knob

Side Angle

Side Angle

Bind Head Screw

Power Switch Assembly

Switch

AC Cord

AC Cord Assembly

AC Cord Assembly

AC Cord Assembly

Cord Strain Relief

Cord Strain Relief

Meter Cover

Cord Holder

Bind Head Tapping Screw-B

Bind Head Screw

Label

FCC Label

Toothed Lock Washer-A

Caution Label, Cord

REF NO.

10

10

10

10

20

20

20

20

30

40

40a

40b

40c

50

60

70

80

90

100

100a

110

110

110

110

120

120

130

140

150

160

172

182

195

208

PART NO.

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

VP156800

- VZ771800

V3034500

EP600230

VP156800

VU578300

V3034600

V3034700

VP156700

- V2217000

MG000610

VZ176600

VZ971600

V2017600

CB806850

CB032840

VZ735700

CB069250

EP600190

VP156800

- -

- ET800070

VH096700

A4.0X8 MFZN2BL

DM

3.0X6 MFZN2BL

A4.0X8 MFZN2BL

S DSTA-1

Left

Right

A3.0X8 MFZN2BL

JW

2P 15A 2.1m

3P SJT VAR

3P 6A VAR

3P 10A 2.5m

SR-6N3-4

SR-5N-4

BK-1

3.0X8 MFZN2BL

A4.0X8 MFZN2BL

C.UL

4.0 MFZN2BL

REMARKS

DG80-112 J (V304030)

DG80-112 U (V304040)

DG80-112 E (V304050)

DG80-112 B (V304060)

J (V303830)

U (V303840)

E (V303850)

B (V303860)

J (V303990)

U (V304000)

E (V304100)

B (V304200)

(V303800)

BLEND, LINE OUT LEVEL

(V225770)

POWER switch

J

U

E

B

J,U

E,B

U,E,B

U (V306440)

U (V222070)

U,E,B

B

QTY

5

6

7

2

8

8

2

*

*

*

*

:

New Parts RANK:Japan only

RANK

01

52

01

01

04

01

07

06

07

08

09

02

03

09

01

01

01

01

01

Page 28

DG80-112

6

FRONT PANEL ASSEMBLY

P90

P20

P30

P40

P80

P10

P70

20b

20a

P60

P50

P100

PN circuit board assembly

VR circuit board assembly

Page 29

DG80-112

7

DESCRIPTION

FRONT PANEL ASSEMBLY

FRONT PANEL ASSEMBLY

FRONT PANEL ASSEMBLY

FRONT PANEL ASSEMBLY

Front Panel

VR Circuit Board Assembly

VR Circuit Board Assembly

VR Circuit Board Assembly

VR Circuit Board Assembly

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Angle, Motor Volime

Bind Head Tapping Screw-B

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Toothed Lock Washer-A

Toothed Lock Washer-A

PN Circuit Board Assembly

Stay

Bind Head Tapping Screw-B

Knob, VOLUME(CH)

Knob, VOLUME(S)

Hexagonal Nut

Flat Washer

Circuit Board

Circuit Board

Circuit Board

Circuit Board

PN Circuit Board Assembly

Circuit Board

Top Cap Assembly

Top Cap Assembly

Top Cap Assembly

Top Cap Assembly

Top Cap Assembly

Top Cap Assembly

Top Cap Assembly

PH Connector Assembly

PH Connector Assembly

REF NO.

10

20

20

20

20

20a

20a

20a

20a

20b

30

40

40

40

40

50

60

70

80

90

100

110

120

130

140

140

140

140

P10

P20

P30

P40

P50

P60

P70

P80

P90

P100

PART NO.

- -

- -

- -

- -

V3034300

- -

- -

- -

- V2979400

V2979500

V2979600

V2979700

VZ736100

EP600230

V2978000

V2978100

V2978200

V2978300

ET800080

ET800150

- V3034800

EP600230

VV945400

VU578300

LX200060

VL802300

V2978400

V2978700

V2978800

V2978900

- V2970700

VV374000

VV374100

VZ739800

VZ739900

VV374500

VV374600

V2134000

- -

- -

VR

VR

VR

VR

3.0X6 MFZN2BL

ANF

ANF

ANF

ANF

7.0 MFZN2Y

9.0 MFZN2Y

3.0X6 MFZN2BL

DSTA-1

9.0 12X2 MFNI33

9X14 0.5 FNM3

ANF2

ANF2

ANF2

ANF2

PN

11P L=300 C&C

12P L=300 C&C

REMARKS

DG80-112 J (V303830)

DG80-112 U (V303840)

DG80-112 E (V303850)

DG80-112 B (V303860)

J (V305940)

U (V305950)

E (V305960)

B (V305970)

J

U

E

B

J

U

E

B

(V305930)

GAIN,....,REVERB

TRIM, OUTPUT

J

U

E

B

(V305930)

LEAD1/CRUNCH1

LEAD2/CRUNCH2

DRIVE1/CLEAN1

REVERB/MODE

cursor(up/down)

STORE/RECALL

DRIVE2/CLEAN2

(VZ97520)

(VZ97530)

QTY

4

2

2

2

6

8

2

2

2

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

:

New Parts RANK:Japan only

RANK

05

01

01

01

01

05

04

01

01

06

06

06

06

06

06

06

Page 30

DG80-112

8

CHASSIS ASSEMBLY

ANR circuit board assembly

20c

20b

20a

20d

Page 31

DG80-112

9

DESCRIPTION

CHASSIS ASSEMBLY

CHASSIS ASSEMBLY

CHASSIS ASSEMBLY

CHASSIS ASSEMBLY

Chassis

ANR Circuit Board Assembly

ANR Circuit Board Assembly

ANR Circuit Board Assembly

ANR Circuit Board Assembly

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Sub Angle

Sub Angle

Pan Head Screw

Bind Head Screw

Bind Head Tapping Screw-B

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Bind Head Tapping Screw-B

Power Transformer

Power Transformer

Power Transformer

Bind Head Screw

Bush Plate

Bush Plate

Bind Head Screw

Heat Sink

Heat Sink

Bind Head Screw

Spacer, Heat Sink

Sheet

Pan Head Screw

Phone Jack

Spacer, Speaker Out

Hexagonal Nut

Flat Washer

Earth Mark

Connector Assembly

Cord Holder

REF NO.

10

20

20

20

20

20a

20a

20a

20a

20b

20c

20d

30

40

50

50

50

50

60

70

72

74

80

90

95

100

110

115

120

130

140

150

160

170

180

190

205

210

220

PART NO.

- -

- -

- -

- -

V3034400

- -

- -

- -

- V2977400

V2977500

V2977700

V2977900

VZ746600

VZ746500

EK400500

VP156700

EP600190

V2979000

V2979100

V2979200

V2979300

EP600230

XU118A00

XU295A00

XU296A00

VP156800

VZ735900

VZ736000

VP156600

VZ739200

V0029700

VP156900

VZ736400

VK196000

EL200070

LB201120

VL786300

LX200060

VL802300

CA060690

- CB069250

ANR

ANR

ANR

ANR

Left

Right

SP 3.0X8 MFZN2Y

A3.0X8 MFZN2BL

3.0X8 MFZN2BL

MAIN

MAIN

MAIN

MAIN

3.0X6 MFZN2BL

A4.0X8 MFZN2BL

A3.0X6 MFZN2BL

A4.0X12 MFZN2BL

BFG-20ADH-6 22X29

SP 3.0X12 MFZN2Y

JL2B X-G7639

SR400B300G

9.0 12X2 MFNI33

9X14 0.5 FNM33G

UL1672 RE WH

BK-1

REMARKS

DG80-112 J (V303990)

DG80-112 U (V304000)

DG80-112 E (V304100)

DG80-112 B (V304200)

J (V303760)

U (V306410)

E (V306420)

B (V306430)

J

U

E

B

J

U

E

B

J

U

E,B

J,U

E,B

J,U

E,B

SPEAKER1, 2(EXT)

U,E,B

(V306910)

QTY

2

2

6

4

2

6

6

2

4

2

4

2

2

2

*

*

*

*

*

*

*

*

*

*

:

New Parts RANK:Japan only

RANK

04

04

01

01

01

01

16

16

16

01

04

04

01

15

17

01

03

01

01

03

04

01

01

01

01

Page 32

DG80-112

10

DESCRIPTION

OVERALL CABINET ASSEMBLY

Cabinet Assembly

Vinyl

Corner

Round Head Wood Screw

Handle Assembly

Front Board Assembly

Name Plate

Trus Head Tapping Screw-1

Foot

Flat Head Wood Screw

Back Board

Shield Sheet

REF NO.

10

20

30

31

40

50

50a

50b

60

61

70

80

PART NO.

V3063000

- -

- AA809050

EX808230

NB812640

V3062900

V2237300

V3623800

CB023200

03702420

V3063300

V3053400

BL

3.5X16 FNM33G

3.0X10 MFZN2BL

BL

3.5X25 MFZN2BL

REMARKS

DG80-112

(V306280)

(V306320)

QTY

6

12

2

4

4

2

*

*

*

*

*

:

New Parts

RANK

05

07

09

01

RANK

:Japan only

OVERALL CABINET ASSEMBLY

50b

50a

Front board assembly

Handle assembly

Page 33

DG80-112

11

DESCRIPTION

ELECTRICAL PARTS

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Circuit Board

Battery Holder

Lithium Battery

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Electrolytic Cap.

Electrolytic Cap.

Electrolytic Cap.

Electrolytic Cap.

Electrolytic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Semiconductive Cera. Cap.

Semiconductive Cera. Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Monolithic Ceramic Cap.

Electrolytic Cap.

Electrolytic Cap.

REF NO.

BT1

BT1

C1

C3-6

C13

C24

C25

C27

C30

C34

C37

C40

C42

C44

C50

C53

-55

C58

C59

C60

C61

C63

C64

C66

C67

C68

C69

C71

C74

C77

C78

-81

C82

C83

C84

C85

C91

-96

C97

C98

C101

C102

C103

C104

C105

PART NO.

VZ771800

V2979400

V2979500

V2979600

V2979700

V2978000

V2978100

V2978200

V2978300

V2978400

V2978700

V2978800

V2978900

V2977400

V2977500

V2977700

V2977900

V2979000

V2979100

V2979200

V2979300

V2970700

VZ771800

VS246300

VS246400

UB245100

UB245100

UB245100

UB245100

UB245100

UB245100

UB245100

UB245100

UB245100

UB245100

UB245100

UB245100

UB245100

UB245100

UB245100

UB051120

UB051120

UB245100

UB245100

UB245100

UB245100

UB245100

UB245100

UB044100

UB044100

UB245100

UB245100

UB245100

UR828100

UR828100

UR848220

UR847100

UR847100

UB245100

UB245100

UB245100

VD930900

VD930900

VJ899000

VJ899000

UB245100

UR847100

UR847100

DM

VR

VR

VR

VR

ANF

ANF

ANF

ANF

ANF2

ANF2

ANF2

ANF2

ANR

ANR

ANR

ANR

MAIN

MAIN

MAIN

MAIN

PN

DM

CR2450BH

CR2450

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

SL 12P 50V J

SL 12P 50V J

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.010 50V Z

F 0.010 50V Z

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

100.00 10.0V

100.00 10.0V

220.00 25.0V

10.00 25.0V

10.00 25.0V

F 0.100 25V Z

F 0.100 25V Z

F 0.100 25V Z

0.1000 25V M

0.1000 25V M

CH 5P 50V C

CH 5P 50V C

F 0.100 25V Z

10.00 25.0V

10.00 25.0V

REMARKS

DG80-112

(XU331B0)

J (XU365C0)

U (XU365C0)

E (XU365C0)

B (XU365C0)

J (XU365C0)

U (XU365C0)

E (XU365C0)

B (XU365C0)

J (XU365C0)

U (XU365C0)

E (XU365C0)

B (XU365C0)

J (XU365C0)

U (XU365C0)

E (XU365C0)

B (XU365C0)

J (XU365C0)

U (XU365C0)

E (XU365C0)

B (XU365C0)

(XV485A0)

(XU331B0)

QTY

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

:

New Parts

RANK

52

52

03

03

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

ELECTRICAL PARTS

RANK:Japan only

Page 34

DG80-112

12

DESCRIPTION

Monolithic Ceramic Cap.

Electrolytic Cap.

Electrolytic Cap.

Electrolytic Cap.-BP

Electrolytic Cap.-BP

Monolithic Ceramic Cap.

Ceramic Capacitor-SL