Page 1

MS2000 Sine Wave Inverter/Charger

MS2000

Installation Guide

Page 2

Page 3

MS2000 Sine Wave Inverter/Charger

Installation Guide

Page 4

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with products from

50 watt mobile units to one MW utility-scale syste ms for wind, solar, batt eries, fuel cells, microturbines, and backup

power applications in both grid-connected and stand-a lone systems. Xantrex products include inverters, battery

chargers, programmable power supplies, and va riable speed drives that convert, supply, control, clean, and distribute

electri cal pow er.

Trademarks

MS2000 Sine Wave Inverter/Charger is a trademark of Xantrex International. Xantrex and Xanbus are registered

trademarks of Xantrex Internationa l.

Other trademarks, registered trademarks, and produc t nam es are the property of their respective owners and are used

herein for identi fication purposes only .

Notice of Copyright

MS2000 Sine Wave Inverter/Charger Installati on Guide © August 2004 Xantrex Inte rnational. All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMAT ION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBIL ITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL , WHICH MIGHT ARISE OUT OF THE USE OF SUCH

INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision

August 2004 Rev A

Part Number

975-0126-02-01

Contact Information

Telephone: 1 800 670 0707 (toll free North America)

1 360 925 5097 (direct)

Fax: 1 800 994 7828 (toll free North America)

1 360 925 5143 (direct)

Email: customerservice@xantrex.com

Web: www.xantrex.com

Page 5

About This Guide

Purpose

The MS20 00 Sin e Wave Inverte r/Charger Installation Gui de describ es the

procedure for instal ling the MS2000 Sine W ave Inverter/Charger

(MS2000).

Scope

The Installation Guide pr ovides safety guidelines, detailed planning and

setup information, and procedures for installing the inverter/charger. It

does not provide information on ope ration, configuration,

troubleshooting, and warranty and product information. Refer to the

MS2000 Sine Wave Inverter/Charger Operation Guide.

This guide does not provide detai ls about particular brands of batteries.

You need to consult individual battery manufacturers for thi s information.

Audience

The Installation Guide is inte nded for qualified installers who need to

install the MS2000. Installers should be certified technicians or

electricians.

975-0126-02-01 i

Page 6

About This Guide

Conv en t io n s Used

The following conventions are used in this guide.

WARNING

Warnings identify conditions or practices that could resu lt in personal injury or

loss of life.

CAUTION

Cautions i dentif y co ndit ions o r pra ctic es th at cou ld res ult in dama ge t o the u nit or

other equipment.

Symbols Used

Important:

but is not as critical as a caution or warning.

The following symbols are used on the product labels or in this guide.

&

(

%

These notes cont ain i nformat ion tha t i s importa nt for you to k now,

In this guide: Important information, warnings or cautions.

On the product: Important information, warnings or cautions

with further expla nation in the product guides.

AC – Alternating current

DC – Direct current

Warning: Hot surface. Do not touch.

DC ground connection point

AC safety ground connection point from incoming AC source

AC safety ground connection point for AC output (to AC loads)

Abbreviat i ons and Acronyms

For a listing of abbreviations a nd acronyms, refer to the MS2000 Sine

Wave Inverter/Charger Operation Guide.

ii 975-0126-02-01

Page 7

Relat ed Inf o rmation

For related materials on this Xanbus-enabled product and its available

accessori es, se e also:

MS2000 Sine Wave Inverter/Charger Operation Guide (975-0125-02-01)

Automatic Generator Start Owner’s Guide (975-0082-01-01)

System Control Panel Owner’s Guide (975-0083-01-01)

Xanbus System Installation Guide (975-0136-01-01)

More information about Xantr ex Technology Inc. as well as its products

and services, including a complete list of Xanbus-en abl ed devices, is

available at www.xantrex.com

Contact Informatio n

Telephone: 1 800 670 0707 (toll free North America)

Fax: 1 800 994 7828 (toll free North America)

Email: customerservice@xantrex.com

About This Guide

1 360 925 5097 (direct)

1 360 925 5143 (direct)

Web: www.xantrex.com

iii 975-0126-02-01

Page 8

iv 975-0126-02-01

Page 9

Important Safety Instructions

READ AND SAVE THESE INSTRUCTIONS

The MS2000 Sine Wave Inverter/Charger Installation Guide contains

important safety ins tructions.

Before you install and use your MS2000 Sine Wave Inverter/Charger, be

sure to read, understand, and save these safety instructions and those in

the other product guides.

Read all caut ionary mar kings on the i nverter/c har ger, the ba tterie s, and all

appropriate sections of this guide.

WARNING: Risk of injury or loss of life

The MS2000 Sine Wave Inverter/Charger shall not be used in connection with

life support systems or other medical equipment or devices.

WARNING

The following warnings identify conditions or practice s that could result in

personal injury or loss of life.

1. Use of accessories not recommended or sold by Xantrex Tec hnology,

Inc. may result in a risk of fire , elect ri c shock, or injury to perso n s.

2. The inverter/charger is designed to be perm anently connected to your

AC and DC electrical systems. Xantrex recommends that all wiring

be done by a cert ified technician or electrician to ensure adherence to

the local and national ele ctrical codes applicable in your application.

3. To avoid a risk of fire and ele ctric shock, make sure that the existing

wiring is in good c ondition a nd that t he wir e is not und ersi zed. Do not

operate the inverte r/charger with damaged or substandard wiring.

4. To reduce risk of damage and injury, charge only rechargea ble

lead-acid batt eries: flooded, gel, or absorbed glass mat (AGM) types.

Other types of batterie s may burst , causing personal injury and

damage.

5. Do not operate the inverter/charger if it has received a sharp blow,

been dropped, or otherwise damaged in any way. If the unit is

damaged, see the Warranty and Product Information section in the

MS2000 Sine Wave Inverter/Charger Operation Guide.

975-0126-02-01 v

Page 10

Safety

6. Do not disassemble the inverter/char ger; it does not contain userserviceable p arts. Take it to a qu al ified se rvice per son when servi ce or

repair is required. Incorrect reassembly may result in a risk of

electrical shock or fire. Internal capacitors remain charged after all

power is disconnected. For instructions on obtaining service, see the

section in the MS2000 Sine Wave Inverter/Charger Operation Guide.

7. Do not expose the inverter/charger to rai n, snow, or splashing bilge

water.

8. To reduce the risk of electric shock, disconne ct all sources of AC and

DC power from the inverter/char ger before attempting any

maintenance or cleani ng. Turning off controls will not reduce this

risk.

9. The inverter/charger must be provided with equipment grounding

conductors connect ed to the AC input ground and chassis ground

terminals.

CAUTION

Cautions i dentif y co ndit ions o r pra ctic es th at cou ld res ult in dama ge t o the u nit or

other equipment.

T o reduce the risk of overheati ng, keep the ventilation openings clear and

do not install the inverter/charger in a compartment with limited airflow

or inadequate cleara nces around the unit. Refer to “Step 1: Choosing a

Location for the Invert er/Charger” on page 16 for required clear ance.

vi 975-0126-02-01

Page 11

Explosiv e Gas Precaut ions

WARNING: Risk of explosive gases

Working in the vicinity of a lead-acid battery is dangerous. Batteries generate

explosive gases during normal battery operation. For this re ason, it is of utmost

impor t an c e th at each tim e be f o re s er v icing eq u ip m e n t in the vic in i ty of the

battery, you must read this guide and fol low the instructions closely.

1. To reduce the risk of battery explosion, follow these instructions and

those published by the battery manufacturer and the manufacturer of

any equipment you intend to use in the vicini ty of a batt ery. Review

the cautionary markings on these products and on the engine.

2. This equipment contains components which tend to produce arcs or

sparks. To prevent fir e or exp losion , do not inst all the inve rter/cha rge r

in compartments containing batteries or flammable materials or in

locations that requi re ig nition-p rotected e quip ment. This i nclude s any

space containing gasol ine-power machinery, fuel tanks, as well as

joints, fittings, or other connections between components of the fuel

system.

Safety

Personal Precautions When Working With Batteries

1. Someone should be within range of your voice or close enough to

come to your aid when you work near a lead-acid battery.

2. Have plenty of fresh water and soap nearby in case battery acid

contacts your skin, clothing, or eyes.

3. Wear complete eye protection and clothing protection. Avoid

touching your eyes while working near batteries.

4. If battery acid contacts your skin or clothing, wash i mmediate ly with

soap and water. If acid enters your eye, immediately flood the eye

with running cold water for at least ten minutes and get medical

attention immediat ely.

5. Never smoke or allow a spark or flame in the vicini ty of the battery or

engine.

6. Be extra cautious to reduce the risk of dropping a metal tool onto a

battery. It might spark or short-circuit the battery or other electrical

parts that may cause an explosion.

975-0126-02-01 vii

Page 12

Safety

7. Remove personal metal items such as rings, bracelets, necklaces, and

watches when working with a lead-acid battery. A lead-acid battery

can produce a short-circuit current high enough to weld a ring or the

like to metal, causing a severe burn.

8. Never charge a frozen battery.

9. If it is necessary to remove a battery, always remove the grounded

terminal from the b at tery first. M ak e sure all the accessories are off,

so as not to cause an arc.

10. Be sure the area around the battery is well ventilated.

11. Clean the battery terminals. Be careful to keep corrosion from coming

in contact with your eyes.

12. Study all batte ry manufacturer’s specific precautions such as

removing or not removing the cell caps while charging and the

recommended rates of char ge .

13. For refillable (flooded) batteries, add distilled water in each cell until

the battery acid reaches the level specified by the battery

manufacturer. This helps to purge excessive gas from cells. Do not

overfill. Carefully follow the manufacturer’s recharging instructions.

FCC Information to the User

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful

interference when the equipment is operated in a residentia l enviro nment.

This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction guide,

may cause harmful interf erence to radi o communications . However, there

is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment of f and on,

the user is encouraged to try to correct the interference by one or more of

the following measures:

• Reorient or relocate the rece iving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outl et on a circu it different from that

to which the receiver is connected.

• Consult the dealer or an experie nced r adio/TV technician for help.

viii 975-0126-02-01

Page 13

Contents

Important Safety Instructions

Explosive Gas Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vii

Personal Precautions When Working With Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - vii

FCC Information to the User - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

Installation

Installation Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

Before You Begin the Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

Installation Codes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

About the Xanbus System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

Xanbus Enabled - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

System Accessories - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Planning the Installation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Two Key Performance Factors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Size and Length of DC Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Mounting Location of the MS2000 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

AC, DC, and Network Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

AC Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

AC Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Disconnect and Over-Current Prote ction Device - - - - - - - - - - - - - - - - - - - - - - - - 8

Distribution Panels - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

AC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

AC Output Neutral Bonding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

DC Components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

DC Disconnects and Over-Current Devices - - - - - - - - - - - - - - - - - - - - - - - - - - 11

DC Cabling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

DC Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Unpacking and Inspecting the Inverter/Charger - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Materials List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Installation Tools and Materials - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

Installing the Inverter/Charger- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Step 1: Choosing a Location for the Inverter/Charger - - - - - - - - - - - - - - - - - - - - - - 16

Step 2: Mounting the Inverter/Charger - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Step 3: Connecting the AC Input and AC Output Wires - - - - - - - - - - - - - - - - - - - - - 20

975-0126-02-01 ix

Page 14

Contents

General AC Wiring Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

Connecting AC Input Wires - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

Connecting the AC Output Wires - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Step 4: Connecting the Main DC Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 23

DC Connection Precaution - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 23

Recommended Cable Sizes and Lengths and Fuse Size - - - - - - - - - - - - - - - - - - - 23

Preparing the Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 23

Guidelines for Routing the DC Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 24

Connecting the DC Cables to the Inverter/Charger - - - - - - - - - - - - - - - - - - - - - - 25

DC Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Step 5: Connecting the Echo Charger - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

DC Connection Precaution - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

Preparing the Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

Connecting the Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 31

Step 6: Connecting the Batter y Temperature Sensor (BTS) - - - - - - - - - - - - - - - - - - - 31

Mounting Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 32

Mounting to the Negative Battery Terminal - - - - - - - - - - - - - - - - - - - - - - - - - - - 32

Mounting to the Side of the Battery Case - - - - - - - - - - - - - - - - - - - - - - - - - - - - 34

Step 7: Connecting to the Network - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

Step 8: Perform ing Ch ec k s Prior t o Ini tia l Start-U p - - - - - - - - - - - - - - - - - - - - - - - - 36

Step 9: Testing Your Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

Testing in Invert Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

Testing in Charge Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

Testing in AC Bypass Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

Testing the Echo Charger - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

Inverter/Charger Physical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

Battery Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Terminology - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Battery Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

Starting Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

Deep Cycle Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

Sealed Gel-Cell - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 42

Environment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 42

Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 42

Enclosures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

Temperature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

Battery Bank Sizing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 44

Estimating Battery Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 45

Battery Bank Sizing Example - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

Battery Bank Sizing Worksheet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 47

x 975-0126-02-01

Page 15

Contents

Monthly Battery Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -48

Preparation for Cleaning Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -49

Clothing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -49

Tools - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -49

Equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -49

Supplies - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -49

Maintaining and Cleaning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -50

Battery Enclosure and Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -50

Terminals & Lugs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -50

Battery Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -51

Cabling & Hook-up Configuratio ns - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -52

Parallel Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -52

Series Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -53

Series-Parallel Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -54

Index

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -55

975-0126-02-01 xi

Page 16

xii

Page 17

Figures

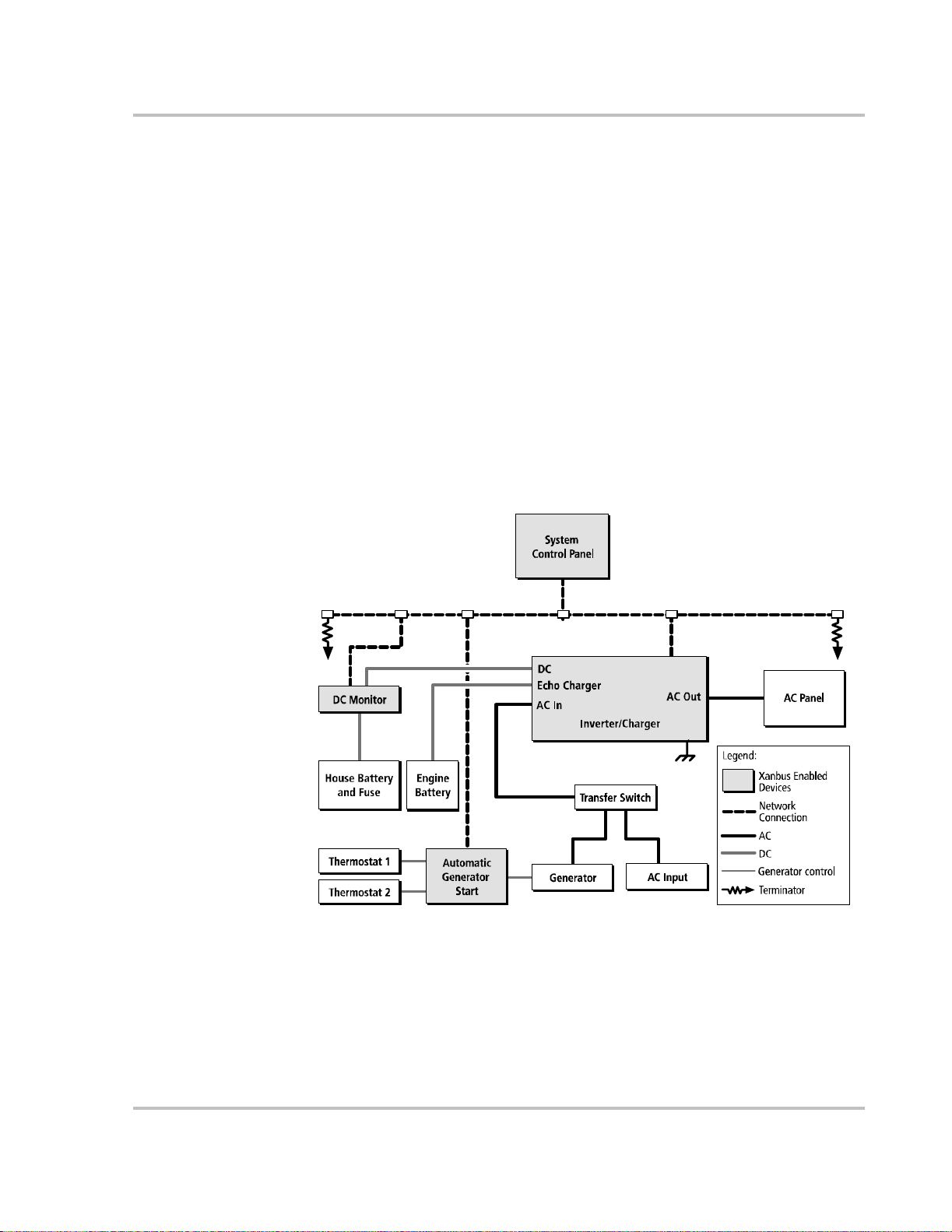

Figure 1 Typical Xanbus System Diagram- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

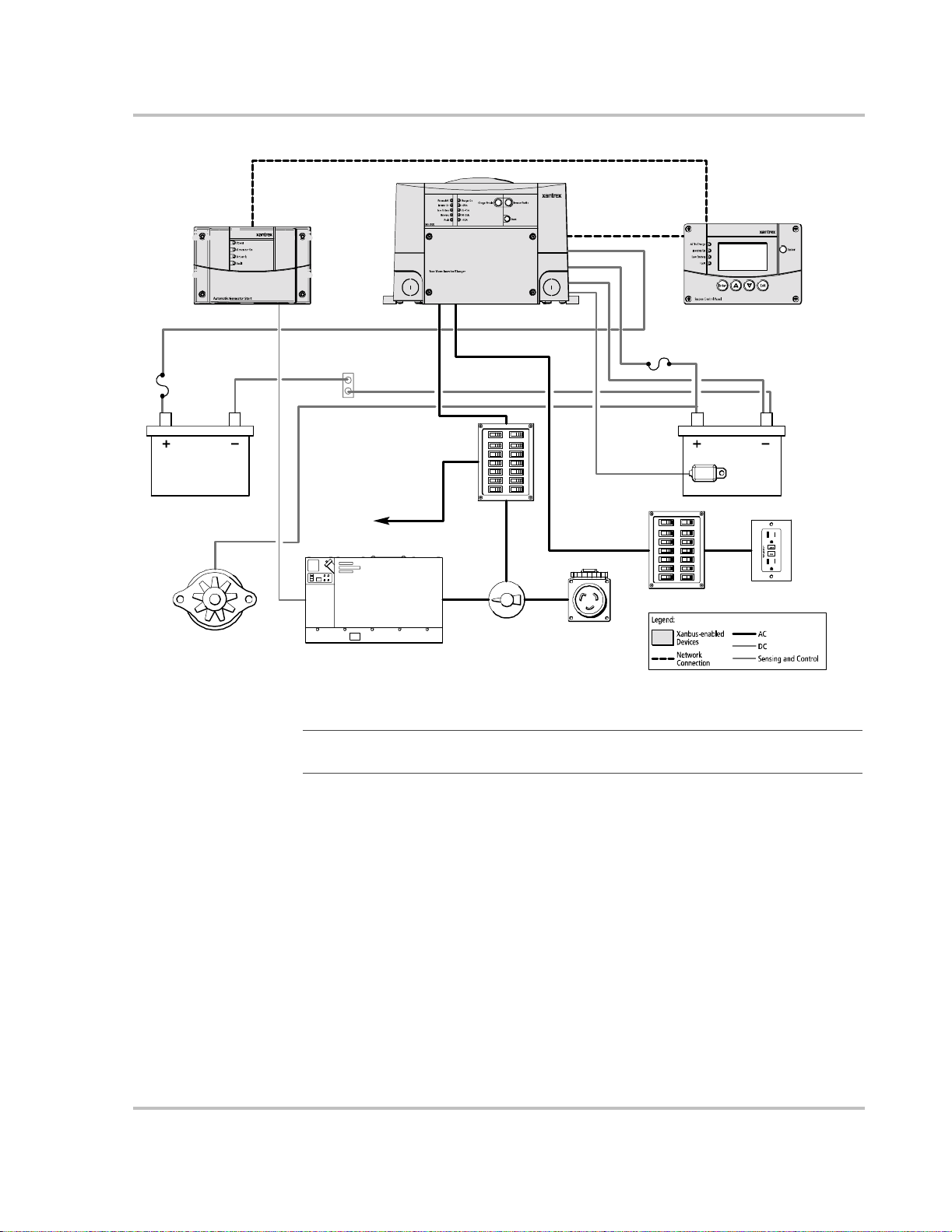

Figure 2 Typical Marine Electrical System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Figure 3 MS2000 Hardware Materials as Shipped - - - - - - - - - - - - - - - - - - - - - - - - 13

Figure 4 Approved Mounting Orientations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Figure 5 Front Panel with Wiring Compartment - - - - - - - - - - - - - - - - - - - - - - - - - - 20

Figure 6 AC In and AC Out: Hardwiring Completed- - - - - - - - - - - - - - - - - - - - - - - 22

Figure 7 DC Cable Connections- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 26

Figure 8 DC Terminal Covers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 26

Figure 9 Completed DC Wiring- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

Figure 10 Completed DC Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Figure 11 Echo Charger Port- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

Figure 12 Inserting Cable into the Echo Charger Connector- - - - - - - - - - - - - - - - - - - 30

Figure 13 BTS with Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 31

Figure 14 BTS Mounted on the Negative Battery Terminal - - - - - - - - - - - - - - - - - - - 32

Figure 15 Connecting the BTS Cable to Battery Temp. jack- - - - - - - - - - - - - - - - - - - 33

Figure 16 BTS Mounted on the Battery Case- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 34

Figure 17 Connecting to a Network Jack- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

Figure 18 Inverter/Charger Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

Figure 19 Batteries Connected in Parallel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 52

Figure 20 Batteries Connected in Series - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 53

Figure 21 Batteries in Series-Parallel Connections - - - - - - - - - - - - - - - - - - - - - - - - - 54

975-0126-02-01 xiii

Page 18

xiv

Page 19

Installation

The Installation Guide provides detailed information for installing the

MS2000 Sine Wave Inverter/Charger, Echo Charge r, and the battery

temperature sensor.

The MS2000 is a Xanbus®-enabled device that typically powers the

Xanbus system. For information on installing the Xanbus system, see

the Xanbus System Installation Guide, which is available for

download at www.xantrex.com.

This Installation Guide provides:

• safety instructions that must be observed during installation

• a diagram of a typical Xanbus system

• information on additional AC and DC components required

• a list of installation tools and materials

• detailed procedures for a typical installation

• installation testing procedures

• battery information

For information on operating the MS2000, see the MS2000 Sine Wave

Inverter/Charger Operation Guide.

Page 20

Installation

Installation Information

Before You Begin t he Installation

Before beginning your installation:

• Read the entire Installa tion Guide so you can plan the installation from

beginning to end.

• Read the Xanbus System Installation Guide to plan your network

requirements.

• Assemble all the tools and materials you require for the installation.

• Review the Important Safety Instruc tions on page v.

• Be aware of all safety and electrical codes which must be met.

WARNING: Electrical shock and fire hazards

Xantrex® recommends all wiri ng be done by qualified personnel. Disconnect all AC and

DC power sources to preve nt accidental shock. Disable and secure all AC and DC

disconnect devices and automatic generator starting devices.

Installation Code s

It is the in s taller’s responsibility to ensure co mpliance with all appli cable installation

codes and regulations.

Applicable instal lation codes vary depending on the specific location and

application of the ins tal l ation . Som e exam p le s are:

• The U.S. National Electrical Code (NEC)

• The Canadian Ele ct rical Co de (CE C )

• Canadian Standards Association (CSA) and American Boat and Yacht

Council (ABYC) standards for insta llation on boats.

External co nne ct ions to the in ve rter/ charger shall comply with the U nited State s

Coast Guard electrica l regulations (33CFR 183, Sub Part 1).

2 975-0126-02-01

Page 21

About the Xanbu s Sy stem

The Xanbus system includes the MS2000 Sine Wave Inverter/Charger and other

Xanbus-enabled devices, as shown in Figure 1, “Typical Xanbus System

Diagram”. Each Xanbus-enabled devic e interacts and communicates with the

other devices on the network, creating a power system that can be precisely

configured to your needs.

The MS2000 is the device that typica lly provides power in a Xanbus system. The

System Control Panel provide s configuration and monitoring capability for each

device conn ected to t he Xa nbus sys tem, such as the Autom at ic G en era tor Start

and the MS2000.

In Figure 1, network connec tions ar e represente d by dotted li nes and conve ntional

electrical connections are represented by solid lines. No attempt has been made to

show polarity of electric al connections. Your system requir ements may be more

complex than the basic instal lation shown in Figure 1. Xantrex recommends that

you consult a qualified insta ller or electrician to customize your installation to

meet your requirements.

Installation

Figure 1

975-0126-02-01 3

Typical Xanbus System Diagram

Page 22

Installation

Xanbus Enabled

The Xanbus-enabled designa tion means that this product will work on a Xanbus

network. Xanbus-enabled products are:

• Easy to use. The Xanbus network simplifies operation and automate s routine

• Reliable. Software control eliminates errors due to analog signalling.

• Accurate. Digital information is less susceptible to interference and line loss.

• Upgradeable. Firmware upgrades mean your purchase will remain up to date.

For detailed instructions and a complete list of Xanbus-ena bled devices, visit the

website at www.xantrex.com

System Accessor ies

System accessories currently available that are Xanbus-enabled include the

System Control Panel and Automatic Generator Start. These system accessories

are available from any authorized Xantrex dealer or at www.xantrex.com Please

provide the part number of the acces sor y to the dealer.

Other Xanbus-enabled dev ices will become available in the future.

tasks.

4 975-0126-02-01

Page 23

Planning the Installation

This section provides information to help you plan for a basic installation of the

MS2000.

As your system configuration is de termined, record the details in Information

About Your Syste m on page WA-4 of the MS2000 Sine Wave Inverter/Charger

Operation Guide.

Two Key Performance Factors

T wo key factors in particular will have a major impact on system performance.

Size and Length of DC Cables

To select the appropriate size and length of DC cables, see “DC Cabling” on

page 11.

The DC cables should be as short as possible and large enough to handle the

required current, in accordance with the electrical codes or regulations applicable

to your installation. If battery cables are in excess of 10 feet each (10 feet for the

positive cable and 10 feet for the negative cable) or not of sufficient size, the

voltage drop across the cables will have a negative impact on overall system

performance.

Installation

Mounting Location of the MS2000

T o choose an appropriate location for mounting the inverter/charger, see

“Step 1: Choosing a Location for the Inverte r/Charger” on page 16.

975-0126-02-01 5

Page 24

Installation

AC, DC, and Network Components

For a successful installation, you need to plan for AC, DC, and network

components of the power system. The AC and DC components are describe d in

this section and illustrated in Figure 2, “Ty pical Marine Electrical System” on

page 7.

AC compone n ts inclu d e:

• Sources of AC input

• AC wiring

• Over-current protection and disconnect devices

• AC distribution panels

DC compone n ts inclu d e:

• Sources of DC power (batteries, for example)

• DC cables

• DC over-current protection and disconnect devices

Network considerati ons include:

• Cables, connectors, network connectors, and terminators for the System

Control Panel and Automatic Gener at or Start, if installing. See Figure 1.

Detailed information on planning and installing your network is available in

the Xanbus System Installation Guide. Refer to the system guide to deter mine

the type of network layout to install, as well as guidelines for installing the

network. This guide is available for download at www.xantrex.com

6 975-0126-02-01

Page 25

Sine Wave Inverter/Charger

Installation

Engine Battery

Alternator

Automatic Generator Start

Non-Inverter Loads

Engine Negative

Terminal/Bus

Generator

AC In

AC Main Panel

AC Out

Transfer Switch

Echo Charger +

DC -

AC Inpu t

(Shore Powe r)

DC +

DC Fuse

Battery Temperature

Sensor

Inverter AC Panel

System Control Panel

House Battery

GFCI

RESET

TEST

Figure 2

Typical Marine Electrical System

Important:

In Figure 2, “Typical Marine Ele ctrical System” on page 7, no attempt has

been made to show all required grounding or overcurrent protection.

975-0126-02-01 7

Page 26

Installation

AC Components

AC Input

A source of 120 volts AC single-phase, 60 Hz alternating current is needed to

provide energy fo r charging batteries and to pass through to AC loads. AC input

can be supplied from an AC source like the utili ty grid (power company), from a

generator, or from the output of a transfer switch. These sources must have their

neutral conductors bonded to ground. See “AC Output Neutral Bonding” on

page 9.

Disconnect and Over-Current Protection Device

T o meet CSA, UL, and electrical code requirements, the AC inputs and outputs of

the inverter/ch arger must be provided with over-current protection such as a

circuit breaker or fuse and a disconnect device on both the AC input and output.

Refer to your applicable installation codes and the following requirements:

AC Input Protection

The circuit bre aker or f use us ed to pr otect the MS2000 must be rated no more than

30 amps and must be approved for use on 120 VAC branch circuits. I f the AC

input power rating is more than 30 amps, you need to add an additional 30 amp

breaker or fuse at the electri c al panel to which the MS2000 AC input is wired.

AC Output

The circuit breaker or fuse must be rated at no more than 30 amps and must be

approved for use on 120 VAC branch circuits.

GFCI Requirements

A GFCI (ground fault circuit int errupter) is a device that deenergizes a circuit

when a current to ground exceeds a specified value that is less than that required

to blow the circuit breaker. GFCIs are intended to protect people from electric

shocks and are usually requi red in wet or damp locations.

Installation in rec reational vehicles requires GFCI protection of certain branch

circuits. Consult all applicable codes .

Tested GFCIs

Compliance with UL standar ds requir es that Xantrex test a nd recommend spe cifi c

GFCIs for use on the output of the inverter. Table 1 lists models that have been

tested and will function pr operly when connected to the AC output of the

MS2000.

8 975-0126-02-01

Page 27

Installation

T ab le 1

Manufacturer Model Number

Hubbell GFR5252WA

Leviton 8599-GY

Pass & Seymour 1594-W

Tested GFCI Models

Disconne ct Dev i ces

Each system requires a method of disconnecting the AC circuits. If the overcurrent protecti on devic e is a circui t breake r, it will also serve as the discon nect. I f

fuses are use d, separate AC disconnect switches will be needed a head of the fuses.

Distribution Panels

Some systems incorporate distribution panels both ahead of the inverter/charger

(the AC source panel) and between the inverter/charger and the loads (the AC

load panel). AC source panel includes a main circuit breaker, which serves as

over-current protection for the panel. Additional circuit breakers serve individual

circuits, one of which serves the inverter/charger.

AC Wiring

Definition AC wiring include s all o f the wires an d conne ctors bet ween the AC source and the

inverter/cha rger input and all of the output wiring between the inverter/cha rger

and the AC load panels, circuit breakers, and loads.

T ype The type of wiring req uired varies according to the electric al codes or regulat ions

applicable to your insta llation. For marine applications, this may be solid wire in

multi-conductor cables, but stranded wire is required if single conductors are

used. All wiring must be rated 90 °C or higher.

Size Wire size has to be coordinated with the overcurrent protection provide d ahead of

the wire involved, in accordance with the electrical codes or regulations

applicable to your insta llation. The wiring used between the AC input circuit

breaker and the inverter/charger input must be sized to match the input breaker

rating. The wiring used between the AC output of the inverter /charger and the AC

output breaker must also be size d to match the input br eaker rating. The wiring

used between the AC output breaker and your loads must be sized to match the

output breaker. Typ ically, No. 10 AWG is required for the 30A breakers required

to be on the MS2000 input and output.

AC Output Neutral Bonding

Bonding system The MS2000 provides a system that autom atically connects the neutral conductor

of the inverter’s AC output circuit to safety ground (“bonding” it) during inver ter

operation, and disconnects it (“unbonding” it) when the inverter/charger is

connected to exte rnal AC or generator power. This system is desig ned to conform

to installation codes that require single-phase AC sources such as inverters and

975-0126-02-01 9

Page 28

Installation

generators to have their neutra l conductor s tied t o ground at the s ource of p ower i n

the same way that the neutral conductor from the utility is tied to ground. These

same codes specify that the neutr al can only be connected to ground in one place

at any one time.

Suitability This automatic neutral- to-ground bonding system is suited for installations in

which the AC input source is known to have a bonded neutral. This will be the

case in most situations: in a utility feed, at an external AC hook-up, or a generator

with a bonded neutral. If not, have an electrician look into bonding the source’s

neutral to ground. See also “AC Input and Output Isola tion” on page 20.

10 975-0126-02-01

Page 29

Installation

DC Components

Batteries

The MS2000 can be installed to operate with two different battery systems—a

house battery and an engine batte ry. Each system may be a single battery or a

bank of several batteries connected in series, parallel, or series-parallel.

House battery The house battery is the lar ge capacity, deep cycle battery that is connected to the

inverter/charger ’s main DC terminals. The MS2000 requires the house battery to

provide the DC current that the inver ter converts to AC power. The house battery

is a 12 volt, lea d-acid deep-cycl e ba ttery or group of ba tteries , all of a flood ed, gel,

or AGM type.

Engine battery The engine bat tery is the battery connect ed to the Echo Charger output. Typica lly,

this will be an engine starti ng battery or an auxiliary battery for loads other than

the inverter.

For general information about batteries, see “Battery Information” on page 40.

For detailed information about specific brands of batteries, you’ll need to consult

individual battery manufacturers.

DC Disconnects and Over-Current Devices

The DC circuit from each battery to the inve rt er/charger must be equipped with a

disconnect and over -current protection device. (Refer to your applic able

installati on code.) This usually consists of a circuit breaker, a “fused-disconnect,”

or a separate fuse and DC disconnect. Do not confuse AC circuit breakers with

DC circuit breakers. They are not interchangeable. The rating of the fuse or

breaker must be matched to the size of cables used in accordance with the

applicable installation codes. The breaker or fuse and disconnect should be

located as close as possible to the battery in the positive cable. Applicable cod es

may limit how far the protection can be from the battery. For recommended fuse

sizes, see Table 2 on page 12.

DC Cabling

DC cabling inc ludes all of the ca bles a nd connec tors betwe en the batt eries, the DC

disconnect and over -current protection device, and the inverter/c harger. All

installations require multi-strand insulated cables as well as disconnect and overcurrent devices. DC cable sizes are indicated by AWG notation. Under the AWG

standard, a larger gau g e num ber indicates a sma ller size d iame te r. Wire size is

usually marked on the cables.

Important:

performance.

A void excessive cable lengths to ensure optimum system

See Ta ble 2 for required DC cable size and required fuse size for the MS2000.

The DC cables must be copper and must be rated 90 °C minimum.

975-0126-02-01 11

Page 30

Installation

DC Grounding

T ab le 2

Maximum DC Cable Length (one way)

Maximum Total Length (two way)

Minimum Recommended Ca bl e Size No. 4/0 AWG

Maximum Batter y Fuse or Breaker

Required DC Input Cable (copper) and Fuse Size

From MS2000 to

house battery bank

10 feet (3 meters) 20 feet (6 meters)

20 feet (6 meters) n/a

300 A class T 15 A DC

From Echo Charger

to engine battery

14 AWG

The inverter/charger DC (chassis) ground terminal needs to be connected to the

boat’s DC grounding bus by a minimum No. 1/0 AWG copper conductor , which is

either rated 90 °C or is bare copper1.

1. Per ABYC E-11, which requires No. 2/0 AWG DC supply conductors for the

MS2000, but allows a DC grounding conductor one size smaller than the DC supply

conductors. The larger No. 4/0 AWG cable size for DC supply conductors shown in

Table 2 is recommended for inverter performance.

12 975-0126-02-01

Page 31

Unpacking and Inspecting the Inverter/Cha r ger

WAR NING: Heavy load

The MS2000 Sine Wave Inverter/Charger weighs approximately 67 lbs (30 kg). The unit

is too heavy for one person to safely lift and mount. Xantrex recommends that two people

lift and m ount the unit. Always use proper lifting techniques during installation to prevent

personal injury.

Materials List

Contents The following materials are in the shipping box:

• MS2000 Sine Wave Inverter/Charger

• DC terminal covers (one red, one black) and four screws

• Bag containing DC terminal hardware:

• Tw o fla t washers

• Tw o lock wash ers

• Two 3/8" bo l ts

• Battery temperatur e sensor

• MS2000 Sine Wave Inverter/Charger Installation Guide

• MS2000 Sine Wave Inverter/Charger Operation Guide

Installation

Figure 3

To unpack and inspec t:

1. Unpack the unit and check the materials list. If anything is missing from the

2. Record the serial number of the MS2000 and other purchase information in

975-0126-02-01 13

MS200 0 Hardware Ma terials as Shipped

shipping box, contact Xantrex Customer Service. See “Contact Information”

on page iii.

the “Warranty and Product Information” section of the MS2000 Sine Wave

Inverter/Charger Operation Guide. You will be asked for this product

information if you need to call Xantrex Customer Service.

Page 32

Installation

3. Save your purchase receipt to use as proof-of-purchase, especially for

warranty servi ce. This is r equire d if the inve rte r/char ge r should nee d warranty

service.

4. Save the original shipping carton and packing materi als. If the inverter/

charger needs to be returned for service, it should be shipped in the original

carton. This is also a good way to protect the inver ter/charger if it ever needs

to be moved.

Installation Tools and Materials

Tools You will need the following tools to install the MS2000 and the battery

temperature sensor.

❐ Wire stripper

❐ Crimping tools for fastening lugs and terminals on DC cables

❐ Phillips screwdriver: #2

❐ Slot screwdriver (1/4" wide blade max.) for AC terminals

❐ Slot screwdriver (1/8" wide blade max.) for Echo Charger connector

❐ Needle-nose pliers

❐ Wrench for DC terminals: 7/16"

❐ Wrench for DC grounding connection: 5/16"

Materials You will need the following materials to complete your installation:

❐ Strain-relief clamp(s) for AC cables: 3/4" and/or 1"

❐ DC battery cables sized according to Table 2 on page 12

❐ Terminals and/or crimp connectors for DC cables (for 3/8" stud size)

❐ Copper wire for DC grounding sized according to Table 2 on page 12

❐ Terminal or crimp connector for DC grounding cable (for 1/4" stud size)

❐ AC and DC disconnect switches and over-current protec tive devices and

connectors as required

❐ Cables for AC input and output wiring

❐ Six ¼"–20 1.25" length steel screws or bolts to mount the MS2000

For a list of tools and material s required to insta ll the networ k, refer to the Xanbus

System Installation Guide, which is available for downl oad at www.xantrex.com.

14 975-0126-02-01

Page 33

Installing the Inverter/Charger

Overview

This section provides detailed information on installing the MS2000. The overall

procedure is divided int o nine steps:

1. Choosing a location

2. Mounting the inverter/charger

3. Connecting the AC input wires and AC output wires

4. Connecting the DC cables

5. Connecting the Echo Charger

6. Connecting the battery temperature sensor

7. Connecting to the network

8. Performing checks prior to initial start- up

9. Testing your installation

Installation

975-0126-02-01 15

Page 34

Installation

Step 1: Choosing a Location for the Inverter/Charger

WARNING: Risk of fire or explosion

This equipme nt is not igniti on p rote cted, and c ontain s com ponents that could produc e arc s

or sparks. To reduce the risk of fire or explosion, do not install this equipment in

compartments containing flammable materials, or in locations that require igniti onprotected eq uipment. This includes any space containing gasoline-powered machinery,

fuel tanks, or joints, fittings, or other connections between components of the fuel sys tem.

WARN ING: Fire hazard

Do not cover or obstruct the ventilation openings. Do not install this equipment in a

compartment with limited airflow. Overheating may result.

The location of the inverte r/charger is a key factor in system performance.

Allow sufficie nt clearance around the unit and install in a well-ventilated

compartment to prevent overheating and premature shutdown of the inverter/

charger.

The inverter should only be installed in a location that meets the following

requirements:

Ventilated Do not operate the inverter/charger in a closed-in area or

restrict ventila tion in any way . The invert er/char ger requires

air circulation to maintain optimum operating temperature

and provide best performanc e. If the unit has inadequate

ventilation, it may shut down due to overheating.

The air vented thr ough t he open ings s hould a lso ha ve a pa th

to circu l ate away from the inverter/ch arger.

Dry Do not allow water or other fluids to drip or splash on the

inverter. Do not expose to rain, snow or water.

Cool Normal air temperature shou ld be between 32 °F and

122 °F (0 °C and 50 °C)—the coo ler the better within this

range.

Clearance Allow as much space around the inverter/charger as

possible. Xantrex recom me nds that other objects and

surfaces be at least 3 inches (76 mm) away from the

ventilation openings for best performance.

Safe Locate the inverter/charger away from battery in a separate

well-ventilated compartment . Do not install the inverter /

charg er in any compartment containing flammable gases or

liquids like gasoline.

16 975-0126-02-01

Page 35

Installation

Close to

battery

compartment

The length and size of your DC cables will affect

performance. Use the DC cables recommended in Table 2

on page 12. The unit should not be installed in the battery

compartment due to th e pos sible presence of explosive

hydrogen gas from the batteries.

Protected

from battery

acid and gase s

Never pl ac e th e inver te r /c h arg er d irectly ab o ve th e

batteries—gases from battery will corrode and damage the

inverter/charger. Never allow battery acid to drip on the

inverter/charger or its wiring when filling the bat teries or

reading their specific gravity.

Orientation To meet regulatory require ments, the MS2000 must be

mounted in an approved mounti ng ori entat ion. S ee Fi gure 4

on page 19. These orientation restrictions are designed to

stop dripping wate r, due to condensation in damp marine

environments, from get ting inside the MS2000.

975-0126-02-01 17

Page 36

Installation

Step 2: Mounting the Inverter/Charger

Considerations

Before mounting the MS2000, take the following two factors into account.

1. The weight of the inverter/charger requires two people to install it.

2. Mounting considerations are shown in Figure 4 on page 19 and described in

Table 3 on page 19.

WAR NING: Heavy load

The MS2000 Sine Wave Inverter/Charger weighs approximately 67 lbs (30 kg). The unit

is too heavy for one person to safely lift and mount. Xantrex recommends that two people

lift and m ount the unit. Always use proper lifting techniques during installation to prevent

personal injury.

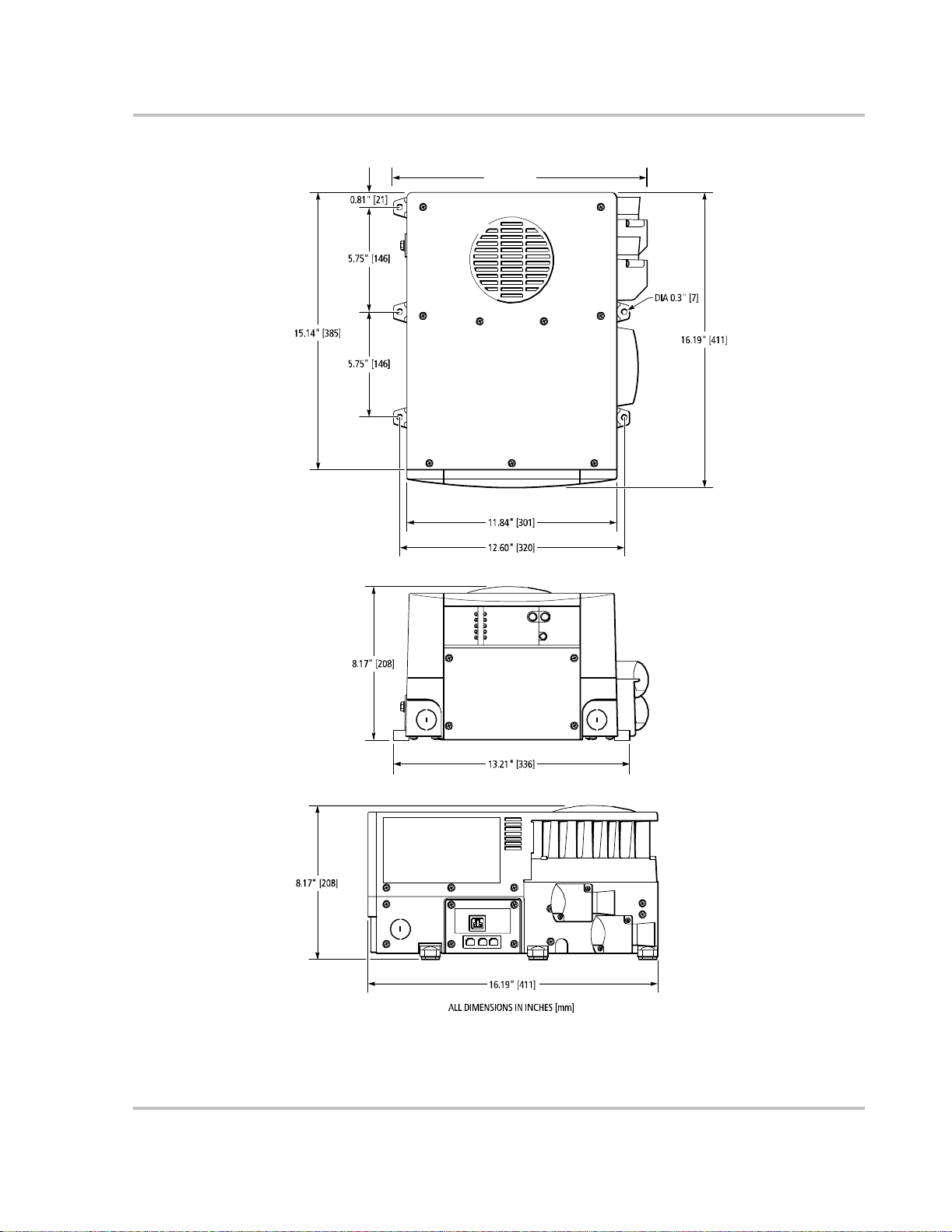

The MS2000 dimensions and location of the mounting holes are provided in

Figure 18 on page 39.

Mount your inverter/cha rger before you connect any wires or cables.

To mount the inverter/charger:

1. Remove the inverter/charger from its shipping container.

The inverter/charger is shipped on a packaging board which can also serve as

a template.

2. Remove the four screws that attach the inverter/charger to the packaging

board. Use the box handles provided to move the unit.

Important:

the uni t. See “Installation Tools and Materials” on page 14 for recommended screw size.

3. Verify that all components are present, and record relevant product

informatio n on fo rm WA-4 i n the MS2000 Sine Wave Inverter/Charger

Operation Guide.

4. Select an appropriate mounting location and orientation. To meet regulatory

requirements, the MS2000 must be mounted in one of the two orientations

shown in Figure 4.

5. Use the packaging board as a template to mark the position of the mounting

screws or refer to Figure 18 on page 39.

6. Pilot drill the six mounting holes.

7. Fasten the inverter/charge r to the mounting surface with the six ¼"–20 steel

screws or bolts.

Do not use the four screws that at ta ch the un it to the te mp late for mounti ng

18 975-0126-02-01

Page 37

Installation

1 - Desktop mount

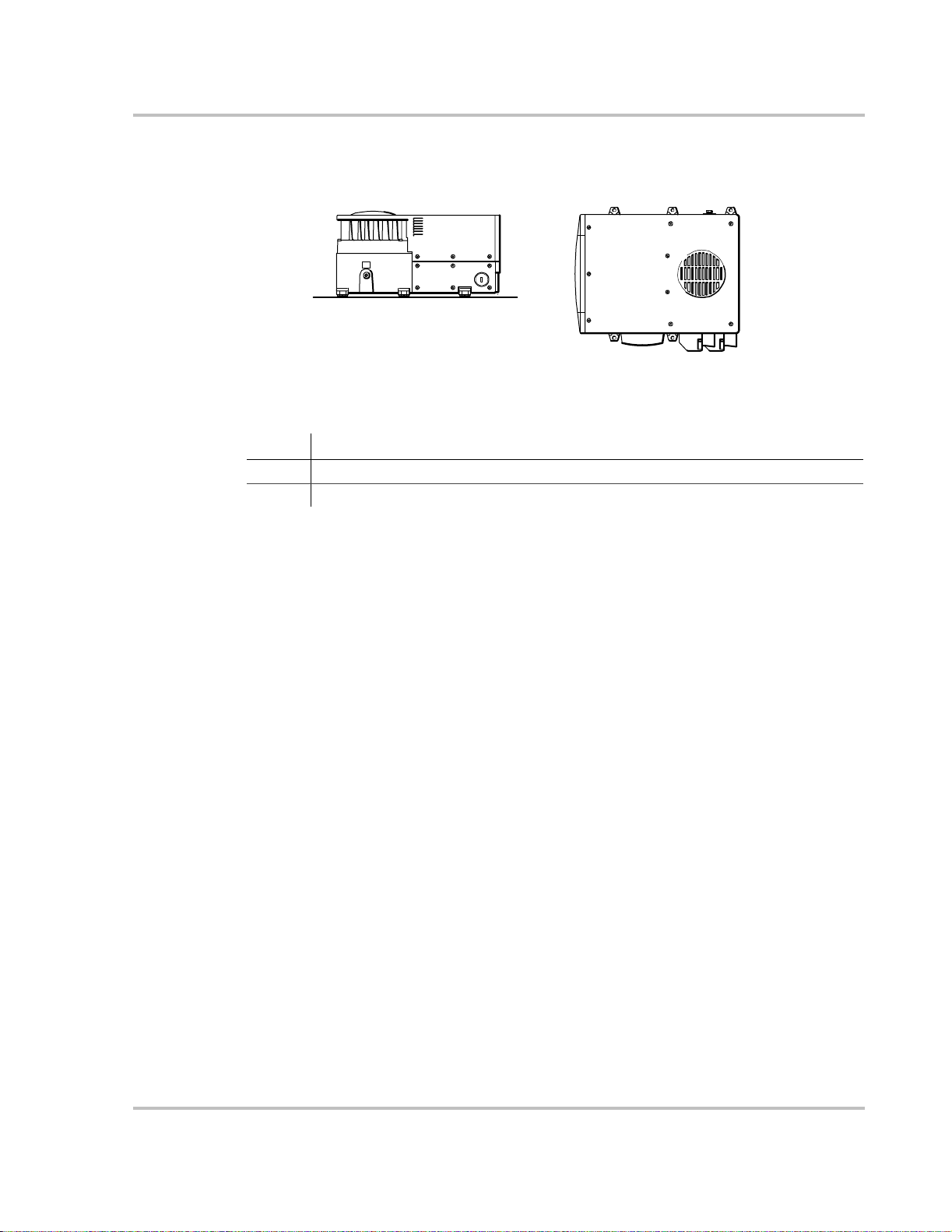

Figure 4

T ab le 3

Number Approved Mounting Orientation

Description of Approved Mounting Orientations

1Desktop

2 Wall mount orientation, on a vertical surface with DC terminals facing down.

Approved Mounting Orientations

2 - Wall mount

975-0126-02-01 19

Page 38

Installation

Step 3: Connecting the AC Input and AC Output Wires

WARN ING: Fire, shock, and energy hazards

Make sure wiring is disc onnected from all electrical sources before handling. All wiring

must be done in accordance with local and national electrical wiring codes.

General AC Wiring Considerations

AC and DC Wiring Separation Do not mix AC and DC wiring in the same conduit or panel. Consult the applicable installation code for details about DC wiring and AC wiring in vicinity to each other.

AC Input and Output Isolation The AC input and output circuits of this inverter/cha rger are isolated from each other when in invert mode to ensure safe operation. This isolation must be maintained in the installation, by being sur e not to connect AC input and output wiring to a common point. For example, do not route the AC input and output neutrals to a common neutral bus.

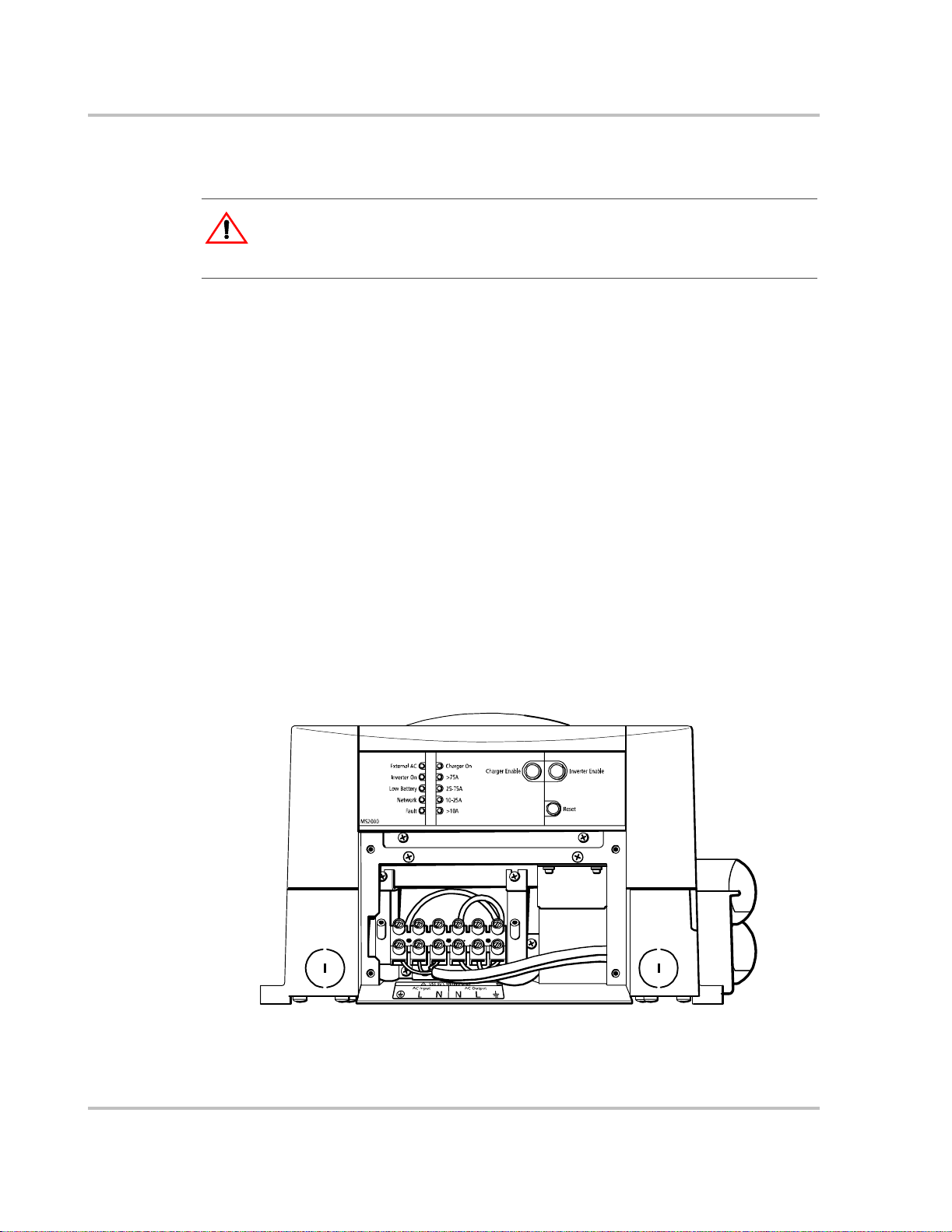

AC Wiring Compartment For your reference, the AC wiring compartment is shown in Figure 5.

AC Knockouts There are two 3/4" trade-size knockouts on the front panel for AC wiring, as show n in Fig ure 5 . For eas i er wi ri ng acc es s, the re are al so knockouts on either side of the unit ( not shown). The side knockouts are 1" trade size knockouts. Use the same trade size of strain relief as the trade size of the knockout (s) you are using.

AC Wiring Terminals The AC wiring terminals accept cables of a specific size. See “AC Wiring” on page 9 for required sizes.

Figure 5

20 975-0126-02-01

Front Panel with Wiring Compartment

Page 39

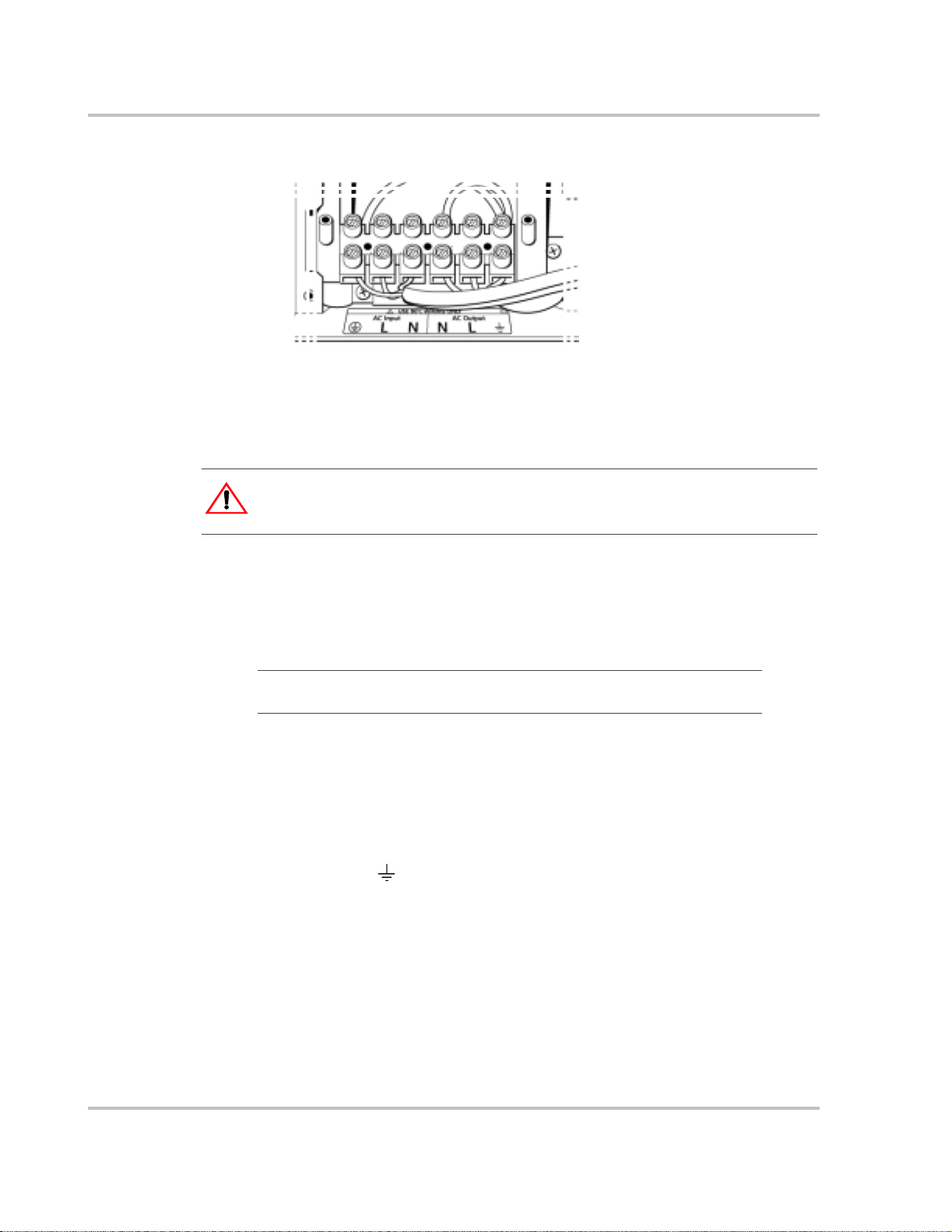

Connecting AC Input Wires

A detailed view of the MS2000 wiring compartment with the AC compartment

panel removed is shown in Figure 6. The terminal block is used to hardwire the

AC input and AC output connections.

CAUTION: Equipment damage

The terminal blo ck is sp lit into INPUT and OUTPUT sections. Damage may occur if the

unit is wired incorrectly.

Do not remove or loosen factor y ins talled wiring.

When making the AC input an d AC output connections, observe the correct color

code for the appropriate AC wire, as described in Table 4.

Installation

T ab le 4

Color AC Wire

Black Line

White Neutral

Green or bare copper Ground

Color Codes for Typical AC Wiring

To make the AC input connections:

1. Locate the wiring compartment cover panel and remove the four screws.

2. Remove the cover panel from the unit to access the wiring compartment.

3. Remove one of the AC knockouts from the front or side of the unit. Do not

leave the knockout inside the wiring co mpartment.

4. Install a strain-relief clamp in the AC knockout.

5. Run the AC wiring through the strain-relief clamp.

6. Strip approximately 2 inches (50 mm) off the jacket from the AC cable and

sepa r ate th e th r ee wires.

7. Using the 1/4" blade slot screwdriver, loosen the wire attachment screws on

the terminals. Do not remove the screws.

8. Insert the line wire into "L", the neutral wire into "N", and the ground wire

into ground (

), as shown in Figure 6 on page 22. Observe the color codes

described in Table 4.

9. Tighten the wire attachment screws. Leave some slack wire inside the wiring

box.

10. Secure the strain-relief clamp on the AC input cable ja cket.

975-0126-02-01 21

Page 40

Installation

Figure 6

Connecting the AC Output Wires

CAUT ION: Risk of equipment damage

Do not connect the output of the inverter to any incoming AC source.

To make the AC output wi ring co nn ect ions:

1. Remove one of the AC knockouts from the front or side of the unit. Do not

leave the knockout inside the wiring co mpartment

2. Install a strain-relief clamp in the AC knockout.

Important:

input and AC output wiring through the same AC knockout.

3. Run the AC wiring through the strain-relief clamp.

4. Strip approximately 2 inches (50 mm) off the jacket from the AC cable and

sepa r ate th e th r ee wires.

5. Using the 1/4" blade slot screwdriver, loosen the wire attachment screws on

the AC output terminals. Do not remove the screws.

AC In and AC Out: Hardwiring Completed

The applicable installation code may not allow you to run the AC

6. Insert the line wire into "L", the neutral wire into "N", and the ground wire

into ground (

T able 4.

7. Tig hten the wire attachment scre ws. Leave so me slack wire inside the wiring

box.

8. Secure the strain -re lief clamp on the AC outp ut cabl e ja cket .

9. Attach the wiring compartment cover panel and tighten the four screws.

10. Connect the outgoing AC wires to an AC load panel equipped wit h circ uit

breakers.

22 975-0126-02-01

), as shown in Figure 6. Observe the color codes described in

Page 41

Step 4: Connecting the Main DC Cables

DC Connection Precaution

WARNING: Energy hazard

Connect and disc onnect DC wiring onl y after ope ning the discon nect switc hes or bre akers

at all AC and DC sources.

Recommended Cable Sizes and Lengths and Fuse Size

For the best load starting sur ge performance, the DC cables should be as short as

possible and lar ge enough to handle the required current, in accordance with the

electrical code s or regul ations applicable to your installation. Avoid excessive

cable lengths. The DC cables must be copper and must be rated 90 °C

minimum.

For recommended DC cables and fuse size, see Table 2, “Required DC Input

Cable (copper) and Fuse Size” on page 12. Using a longer or smaller gauge cable

may cause the inverter to shut down under heavy load.

Installation

Preparing the Cables

To prepare the DC cables:

1. Cut the negative and positive cable to the required lengt h. S trip off enough

insulation so you can instal l the terminals you will be using.

Xantrex recomm ends the use of crimp connectors. The connector should be

designed for a 3/8" s tud s ize to c onnect to the MS2000 . If a cr imp connecto r i s

used, it should be crimped using the tool indicated by the connector

manufacturer.

2. Cut the DC ground cable to the required length. Strip of f enough insula ti on so

you can install the terminals you will be using.

Xantrex recomm ends the use of crimp connectors. The connector should be

designed for a 1/4" s tud s ize to c onnect to the MS2000 . If a cr imp connecto r i s

used, it should be crimped using the tool indicated by the connector

manufacturer.

3. Attach the connectors to the ends of all cables. Make sure no stray wire

strands protrude from the connectors.

975-0126-02-01 23

Page 42

Installation

Guidelines for Routing the DC Cables

Follow these guidelines to en sure maximum performance.

WARNING: Fire and shock hazard

Route the cabl es away from sharp edges that might damage the insulation. Avoid sharp

bends in the cable.

• Do not attempt to use the chassis in place of the main bank battery negative

connection for groun ding. The inverter requires a reliable return path directly

to the battery.

• T o reduce the chance of radio frequency interference, keep the positive and

negative cables close together—ideally, held togethe r by straps, loom, or

insulated clamps at regular intervals.

• To ensure maximum performance from the inverter, do not route your DC

cables through a DC distribution panel, battery isola tor, or other device that

will cause additional voltage drops. The exception is the DC fuse and

Disconnect or the DC circuit brea ker which is required at the batte ry to

protect the DC w iri ng.

• T o help avoid damage caused by reverse polarity battery connection, it is a

good idea to mar k each end of each cab le t o id entify it as a pos itiv e (red ) or

negative (black) cable before routing the wiring.

24 975-0126-02-01

Page 43

Connecting the DC Cables to the Inverter/Charger

WARN ING: Fire hazard

Use only appropriately sized copper cable. Loose connections or improper connections

will overheat . Make sure the bolts supplied by Xantrex on the inve rter/charger are

tightened to a torque of 15–16 ft-lbs (20.4–21.7 Nm). Torque all other connections to the

manufacturer’s specifications. Make sure the DC cable, washers, and bolt are assembled

in the order shown in Figure 7.

CAUTION: Reverse polarity damage

Before making the fin al DC connection or closi ng the DC breaker or disconnect, check

cable polarity at both the battery and the inv er ter/char g er. Positive (+) must be connected

to positive (+). Negative (–) must be connected to negative (–).

To connect the DC cables:

1. Route the DC cables from the house battery bank to the inverter/charger.

Observe the “Guidelines for Routing the DC Cables” on page 24.

2. Install a DC fuse and disconnect switch or a DC circuit breaker between the

inverter/cha rger and the battery. They must be installed in the positive side of

the DC circuit, as close as possible to the battery.

Installation

This protects your batte ry and wiring in case of accidental shor ting. See

T able 2 on page 12 for required fuse or breaker size. Open the DC disco nnect

switch or turn off the DC circuit breaker.

3. Connect one connector on the POSITIVE (+) cable to the POSITIVE DC

terminal on th e inverter/charger, as shown in Figure 7. The connector goes on

first, then the flat w ash er (s teel ), lo ck washer (steel), and 3/8 " bo lt (bras s ).

4. Connect the other connector to the POSITIVE (+) terminal on the fuse or

breaker. Observe polarity carefully while completing the installation.

Use a wrench to tighten the bolt to a torque of 15–16 ft-lbs (20.4–21.7 Nm) at

the inverter/ch arger end. Observe the fuseholder or breaker manufacture r’s

recommendation at the other end.

5. Connect one connector on the NEGATIVE (–) cable to the NEGATIVE (–)

DC terminal on the inverter/charger, as shown in Figure 7. The connector

goes on first, then the flat washer (steel), lock washer (steel), and 3/8" bolt

(brass).

975-0126-02-01 25

Page 44

Installation

Figure 7

DC Cable Connections

6. Before proceeding, che ck that the cable polarity is correct: POSITIVE (+) on

the inverter/ch arger is connected to the POSITIVE (+) on the battery, and

NEGATIVE (–) cable is connected to the NEGATIVE (–) terminal on the

inverter/charger.

Important:

normal when this connection is made.

The next step is the last cable connection you need to make. A spark is

7. Connect the other end of the NEGATIVE (–) cable to the NEGATIVE (–)

terminal on the battery.

8. Use a wrench to tighten the bolt to a torque of 15–16 ft-lbs (20.4–21.7 Nm

) at

the inverter/charger end.

9. Attach the DC terminal covers using the screws provided to protect the DC

terminals, as shown in Figure 8.

Figure 8

26 975-0126-02-01

DC Terminal Covers

Page 45

Installation

!

Figure 9

Completed DC Wiring

975-0126-02-01 27

Page 46

Installation

DC Grounding

The Chassis Ground point on the inverte r/char ge r is used to connect the chassis of

the inverter/ch arger to your system’s DC grounding point , as req uired by

regulations for some insta llations. Use copper wire that is either bare or provided

with green insulation.

The grounding guideline given below assumes you are using the code-complia nt

DC supply cable and fuse sizes indicated in this Installation Guide. If you are

using differ ent sizes, refer to the applicable code for DC grounding detail.

To connect the chassis ground:

1. Using the appropriate wrench, loosen the bolt on the chassis ground point

shown in Figure 10.

2. Connect the DC grounding cable (No. 1/0 AWG or larger copper cable)

between the chassis ground point a nd the DC grounding point for your

system, usually the boat’s DC grounding bus.

3. Tighten the bolt to a torque of 3.5–3.8 ft-lbs (4.5–5.2 Nm).

chassis ground point

Figure 10

28 975-0126-02-01

Completed DC Grounding

Page 47

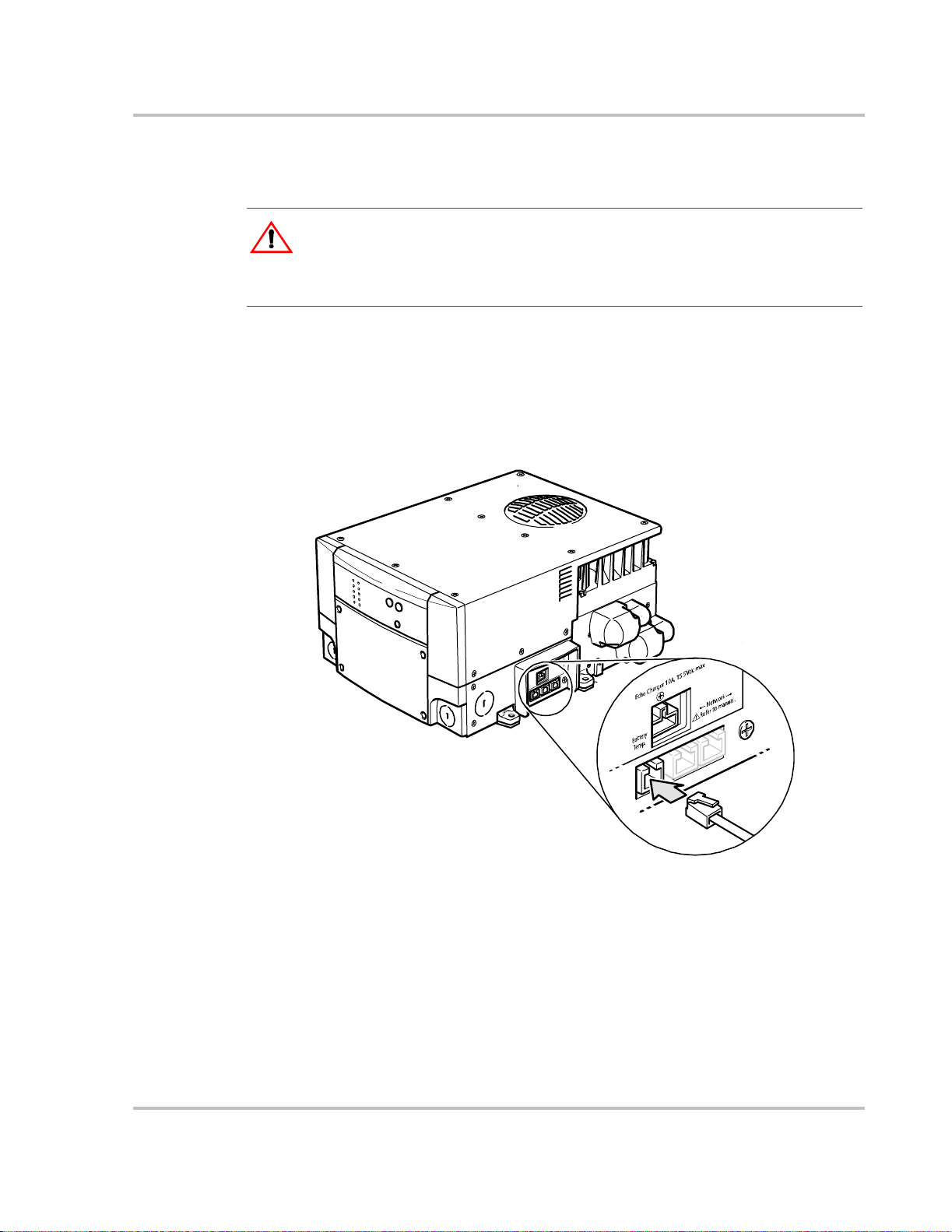

Step 5: Connecting the Echo Charger

The Echo Charge r connection is made above the net work and battery temperature

sensor jacks. See Figure 11.

Echo Charger port

Installation

!

Figure 11

The Echo Charger requir es a single positive cable connected between the Echo

Charger port on the MS2000 and the engine batter y. That battery and the house

battery bank must have their negative terminals connected to the boat’s DC

negative bus for the Echo Char ge to function (see Figure 2 on page 7).

DC Connection Precaution

WARNING: Energy hazard

Connect and disc onnect DC wiring onl y after ope ning the discon nect switc hes or bre akers

at all AC and DC sources.

Preparing the Cable

For the best charging pe rfor mance, the DC cable should be as short as possible

and large enough to handl e the required current, in accordance with the electrical

codes or regulations applicable to your installation.

Although the Echo Charger output is limited to 10 A, it is recommended to use

No. 14 AWG 90 °C cable to minimize volta ge drops.

Battery Temp. jack

Echo Charger Port

Network jacks

To prepare the Echo Charger cable:

1. Cut the cable to the required length. Strip off 1/4" insulation on the Echo

Charger connection side.

2. Remove the Echo Charger connector from the Echo Charger port on the side

of the MS2000.

975-0126-02-01 29

Page 48

Installation

3. Using the slot screwdriver with a 1/8" blade, press down on the tension cl ip

through the slot located at the top of the connector. While pressing down on

the tension clip, insert the end of the cable with insulat ion removed into the

left-side round hole at the front of the connector. See Figure 12.

OR

You can also insert the screwdriver blade into the square hole above the left-

side hole and twist the screwdri ver to press down on the tension clip before

inserting the cable .

Important:

anything internally and should not be used. If you connect the Echo Charger to the engine

battery using the right-side connector, the Echo Charger will not work.

The right-side hole on the Echo Charger connector does not connect to

4. To secure the cable, remove the screwdriver to release the tension clip.

To MS2000

Echo Charger port.

Insert screwdriver into left-side

top notch or front notch.

Figure 12

Inserting Cable into the Echo Charger Connector

5. Install the disconnect and 15 A DC over-current pr otection between the other

end of the cable and the battery positive (+) terminal, as close as possi ble to

the battery in accordance with codes.

6. Open the disconnect switch or remove the fuse.

30 975-0126-02-01

Page 49

Connecting the Cable

Installation

WARNING: Energy hazard

Connect and disc onnect DC wiring onl y after ope ning the discon nect switc hes or bre akers

at all AC and DC sources.

To connect the Echo Charger cable:

1. Route the cable from the engine battery to the Echo Charger port on the

MS2000.

2. Connect the cable to the fuse on the PO SITIVE (+) terminal of the engine

battery.

3. Plug the Echo Charger connector into the port on the MS2000.

4. If it is not already connected, connect the engine battery negative terminal to

the engine negative ter minal/bus.

This cable must be siz ed for all t he loads on the eng ine batte ry (inclu ding st art

current), not just the Echo Charger.

Step 6: Connecting the Battery Temperature Sensor (BTS)

Installing a bat tery temperature sensor (BTS) extends the life of the house battery

bank by preventi ng overch ar ging in wa rm tempera tures and under char ging i n cold

temperatures. With a BTS monitoring the battery temperature, the volt age

delivered to the house batte ry bank is adjusted according to the battery’s actual

temperature.

A 25-foot (7.6 m) cable is supplied with the BTS, as shown in Figure 13.

Figure 13

975-0126-02-01 31

BTS with Cable

Page 50

Installation

WARNING: Energy and explosion hazard

Review the “Important Safety Instructions” on page v.

Mounting Options

You can mount the BTS in one of two ways:

• Mounting the sensor to the negative post of one of the house batteries allows

the internal battery temperature to be sensed and provides the most accurate

results.

• Attaching the sensor to the side of one of the house batteries using the selfadhesive backing also provide s good results in most situations.

Mounting to the Negative Battery Terminal

To mount the sensor on the negative battery terminal :

See Figur e 14.

Figure 14

1. Select the battery to be monitored. The battery temperature sensor must be

connected to the house battery bank, which is directly connected to the

inverter/charger.

2. Switch off all devi ces operatin g from t he bat tery, or open the ba tter y switc h (if

present) to disconnect the battery.

3. Wait 10 minutes for any explosive battery gases to dissipate.

4. Remove the nut that connects the existing wir ing ring terminals to the battery

negative terminal stud.

5. Move or reorient the existing wiring ring terminals on the battery negative

terminal stud, so there is a flat surface on which to seat the battery

temperature sensor mount ing plate.

You may need to bend the r ing te rmin al cri mp and/ or wires sli ghtly downwa rd

to allow the sensor to seat flush to the top surfa ce of the upper ring terminal.

32 975-0126-02-01

BTS Mounted on the Negative Battery Terminal

Page 51

Installation

6. Mount the sensor directly on top of the ring terminal, as shown in Figure 14,

and firmly tighten the termina l nut.

WARN ING: Fire hazard

In this procedure, you must install the DC wire on the battery terminal first. Then the

sensor is insta lled on top of the DC wire. This sequence is required to provi de the best

connection to the battery and to ensure correct performance of the sensor.

7. Check to ensure that the sensor and all wires are held firmly and cannot be

moved.

8. Turn the battery switch on again ( if you opened it in Step 2).

9. Route the sensor cable to the inverter/char ger and plug it into the Battery

Temp jack, as shown in Figure 15 . Secure the cable along i ts lengt h .

Figure 15

975-0126-02-01 33

Connecting the BTS Cable to Battery Temp. jack

Page 52

Installation

Mounting to the Side of the Battery Case

To mount the sensor on the ba tt ery cas e:

See Figur e 16.

Figure 16

BTS Mounted on the Battery Case

1. Select the battery from the house battery bank to be monitored.

2. Select a side suitable for attaching the sensor.

The surface where the sensor is to be mounted must be flat and free from

reinforcing ribs or other raised features. This surface must be in direct internal

contact with the battery el ectr olyte. Do not install the sensor near the top of

the battery or on the battery’s top surface.

3. Clean the selected area thoroughly to remove any oil or grease tha t could

prevent the sensor fro m adhering to the batte ry case. Allow the battery case to

dry thoroughly.

4. Peel the protective backing from the self-adhesive strip on the rear of the

sensor.

5. Press the sensor firmly against the clean side of the battery to fix it in place, as

shown in Figure 16.

6. Route the sensor cable to the inverter/char ger and plug it into the Battery

T emp. jack, as shown in Figure 15. Secure the cable along its length.

34 975-0126-02-01

Page 53

Step 7: Connecting to the Network

For your reference, Figure 17 shows where the network connections are made on

the MS2000. The network cable can be pl ugged into ei ther one of the two ne twork

jacks on the MS2000.

CAUTION: Equipment Damage

Connect the MS2000 only to other Xanbus compatible device s.

Although t he cabling and connectors used in this network system are the same as Ethernet

connectors, this network is not an Ethernet system. Equipment damage m ay result from

attempting to connect two different systems.

Detailed information on planning and installing your network is available in the

Xanbus System Installation Guide . Refer to the this guide to determi ne the type of

network layout to instal l, a s well as guidelines for insta lling the network.

The Xanbus System Installation Guide is available for download at

www.xantrex.com

Installation

Figure 17

975-0126-02-01 35

Connecting to a Network Jack

Page 54

Installation

Step 8: Performing Checks Prior to Initial Start-Up

Before testing your insta llation, ensure these conditions are met:

❐ Chassis and AC grounds are properly installed.

❐ AC input connections and AC output connections are wired correctly on the

terminal block and not reversed.

❐ Positive (+) battery cable is connected to the house bank posit ive (+) battery

terminal through the DC fuse and disconnect switch or DC circuit breaker.

❐ Negative (–) battery cable is connected to the house bank negative (–) battery

terminal.

❐ House battery voltage is within the proper range for this unit

(10.3–15.3 volts DC).

❐ DC disconnect switch or breaker is turned off.

❐ Echo Charger disconnect switch is off or fuse is removed.

❐ Echo Charger connections are correct: posi tive (+) cable runs from the Echo

Charger to the positive terminal of the engine battery.

❐ Both the house battery and the engine battery negative terminals are

connected to the engine negative terminal/bus.

❐ AC input and output br eakers are turned off.

❐ All connections are tight.

36 975-0126-02-01

Page 55

Step 9: Testing Your Installation

WARNING: Shock hazard

The Inverter Enable button on the MS2000 and the optional accessories do not disconnect

DC or AC input power to the MS2000.

There are several tests to be performed for testing your installation. These tests

will verify that:

• The MS2000 works in invert mode.

• The MS2000 works in charge mode.

• The MS2000 works in AC bypass mode.

• The Echo Charger is functioning.

Testing in Invert Mode

To test the inverter/charger in invert mode, using a 100 watt light bulb as the

test load:

1. Close the DC disconnect switch or the DC circuit brea ker to suppl y DC p ower

to the MS2000.

Installation

2. Verify that all lights on the front panel illuminate during the initialization

3. Connect the MS2000 to the test light by closing the AC breaker that contols

Testing in Charge Mode

To test the MS2000 in charge mode:

1. Close the AC supply breaker to supply AC power to the unit.

2. After a few seconds, veri fy that the Ext ernal AC an d Char ger ON l ights on the

Important:

occurs over an extended period of time.

The unit takes 10 to 30 seconds to initial ize.

stage. If other Xanbus-enabled devices are connected, the Network light will

be illuminated. The Invert light illuminates only if the Invert Enable button

light is also illuminate d. If the unit is powered up for the first time, the

Inverter On light will be off. To turn the inverter on, press the Invert Enable

button.

the circuit that the test light is connected to.

If the light bulb illuminate s, the installation has been successful.

front panel illumina te. One of the current range lights (>75A, 25–75A,

10–25A, >10A) should also illuminate.

The charging process, whether it is three-stage or two-stage charging,

975-0126-02-01 37

Page 56

Installation

Testing in AC Bypass Mode

To test the MS2000 in transfer mode:

1. Close the AC supply breaker to supply AC power to the unit.

The transfer from invert to AC input power occurs.

2. Press the Charger Enable button to disable the charger. Verify that the Charger

Enable light is not illumina ted. AC loads will still be powered.

Testing the Echo Charger

1. Close the Echo Charger disconnect switch or replace the fuse.

2. Check the System screen on the System Control Panel and ensure the

MS2000 is in the Bulk or Absorption charge cycle.

3. From the MS2000 advanced menu on the System Control Panel, verify that