Page 1

HI400

Owner’s Guide

Page 2

About Xantrex

Xantrex Technology develops, manufactures, and markets advanced power

electronic products. The company’s products convert raw electrical power from

any source into high-quality power required by electronic and electrical

equipment.

Trademark

Xantrex is a registered trademark of Xantrex Technology Inc.

Other trademarks, registered trademarks, and product names are the property of

their respective owners and are used herein for identification purposes only.

Notice of Copyright

HI400 Owner’ s Guide © January 2002 Xantrex International. All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX

TECHNOLOGY INC. (“XANTREX”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR

SUITABILITY OF ANY TECHNICAL OR OTHER INFORMATION PROVIDED IN

ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE,

WHETHER DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH

MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY

SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision

January 2002, Revision 2

Part Number

445-0151-01-01

Contact Information

Web: www.xantrex.com

Email: techhelp@xantrex.com

Phone: 1-800-446-6180

Fax: 1-360-925-5143

Page 3

Contents

Important safety information

General precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - v

Explosive gas precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - vi

Precautions when working with batteries - - - - - - - - - - - - - - - - - vii

Precautions for using rechargeable appliances - - - - - - - - - - - - viii

1Introduction

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

HI400 features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Materials list - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

2 Installation

Preparing for installation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Installation codes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Installation tools and mate rials - - - - - - - - - - - - - - - - - - - - - - - 9

Installation features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Installing the HI400 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Designing your installation- - - - - - - - - - - - - - - - - - - - - - - - - 11

Choosing a location- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Mounting your inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Permanently connecting (hardwiring) the AC output- - - - - - - - 17

Installing the ignition lockout wiring - - - - - - - - - - - - - - - - - - 18

Connecting the DC cables - - - - - - - - - - - - - - - - - - - - - - - - - 19

Connecting the battery to the DC input- - - - - - - - - - - - - - - - - 20

Connecting the DC ground - - - - - - - - - - - - - - - - - - - - - - - - - 21

i

Page 4

Contents

Connecting the AC input cord- - - - - - - - - - - - - - - - - - - - - - - 22

Checks prio r to initial power-up - - - - - - - - - - - - - - - - - - - - - 23

Starting up and testing your installation - - - - - - - - - - - - - - - - 23

3Operation

Operation features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 26

Inverter on and off - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 26

Ground fault circuit interrupter (GFCI) protection - - - - - - - - - 26

Alternate AC source - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

Ignition lockout - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

Low battery condition - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

Inverter loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Operating several loads at once - - - - - - - - - - - - - - - - - - - - - - 28

Problem loads- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Turning the inverter off between charges - - - - - - - - - - - - - - - 29

Battery charging frequency- - - - - - - - - - - - - - - - - - - - - - - - - 29

4 Maintenance and Troubleshooting

Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 32

Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 32

Common problems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 32

Buzz in audio equipment - - - - - - - - - - - - - - - - - - - - - - - - - - 32

Television interference- - - - - - - - - - - - - - - - - - - - - - - - - - - - 32

Troubleshooting reference- - - - - - - - - - - - - - - - - - - - - - - - - - - 33

A

Specifications

Electrical - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

Physical - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

B Battery Types and Sizes

Battery types- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

Automotive starting batte ries - - - - - - - - - - - - - - - - - - - - - - - 38

Deep-cycle lead-acid batteries- - - - - - - - - - - - - - - - - - - - - - - 38

Battery size- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

ii

Page 5

Contents

Estimating battery requirements- - - - - - - - - - - - - - - - - - - - - - - 40

Battery sizing example- - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

Battery sizing worksheet - - - - - - - - - - - - - - - - - - - - - - - - - - 42

Using multiple batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

Two batteries connected in parallel - - - - - - - - - - - - - - - - - - - 43

Two separat e battery banks- - - - - - - - - - - - - - - - - - - - - - - - - 43

Battery tips - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 44

C

Warranty and Product Information

Warranty information- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 48

Returning a product - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 49

Out-of-warranty service - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50

Contacting Xantrex Customer Service- - - - - - - - - - - - - - - - - - - 51

Other Xantrex products- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 51

Index - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 53

iii

Page 6

iv

Page 7

Important safety information

Important: Before installing and using your HI40 0

Inverter, be sure to read and save these safety instructions.

General precautions

1. Before installing and using the inverter, read all

appropriate sections of this guide and any cautionary

markings on the inverter and batteries.

2. Do not operate the i nverter if it has rece ived a sharp bl ow ,

been dropped, or otherwise damaged. If the unit is

damaged, see “Service during warranty” on page 48 and

“Returning a product” on page 49.

3. Do not disassemble the inverter; it contains no user

serviceable parts. Attempting to service the unit yourself

could cause electrical shock or fire. Internal capacitors

remain charged after all power is disconnected. See

“Warranty information” on page 48 for instructions on

obtaining service.

4. To reduce the risk of electrical shock, disconnect both

AC and DC power from the inverter before working on

any circuits connected to the inverter. Turning off the

front panel On/Off Switch will not reduce this risk.

5. Protect the inverter from rain, snow, spray, and bilge

water.

6. To reduce the risk of overheating or fire, keep the

ventilation openings clear, and do not install the inverter

in a zero-clearance compartment.

v

Page 8

Explosive gas precautions

Explosive gas precautions

WARNING: Explosion hazard

.

1. Batteries generate explosive gases during normal

operation. Be sure you follow all relevant instructions

exactly before installing or using your inverter.

2. This equipment contains components which tend to

produce arcs or sparks. To prevent fire or explosion, do

not install the inverter in compartments containing

batteries or flammable materials or in locations that

require ignition-protected equipment. This includes any

space containing gasoline-powered machinery, fuel

tanks, as well as joints, fittings, or other connections

between components of the fuel system.

vi

Page 9

Precautions when working with batteries

Precautions when working with batteries

WARNING: Explosion and fire hazards

1. Follow all instructions published by the battery

manufacturer and the manufacturer of the equipment in

which the battery is installed.

2. Make sure the area around the battery is well ventilated.

3. Never smoke or a llow a spar k or fla me near the engi ne or

battery.

4. Use caution to redu ce the risk o f drop ping a metal tool on

the battery. It could spark or short circuit the battery or

other electrical parts and could cause an explosion.

5. Remove metal items li ke rings, bracelets, and watches

when working with lead-acid batteries. These batteries

produce a short-c ircuit curre nt high en ough to weld a r ing

or the like to metal and cause a severe burn .

6. If you need to remove a battery, always remove the

positive terminal from the battery first. Make sure all

accessories are off so you don’t cause an arc.

vii

Page 10

Precautions for using rechargeable appliances

Precautions fo r u sing rechargeable

appliances

Most rechargeable battery-operated equipment uses a

separate charger or transformer that is plugged into an AC

receptacle and produces a low voltage charging out.

Some chargers for rechargeable batteries can be damaged if

connected to the HI400 Inverter.

Do not use the following with the HI400 Inverter:

• Small battery-o perated a ppliance s like f lashli ghts, raz ors,

and night lights that can be plugged directly into an AC

receptacle to recharge.

• Some chargers for battery packs used in hand power

tools. These affected chargers display a warning label

stating that dangerous voltages are present at the battery

terminals.

viii

Page 11

Introduction

Chapter 1 “Introduction” describes the main

operating features of the HI400 Inverter.

1

Page 12

Introduction

Introduction

The HI400 Inverter is a modified sine wave (MSW) inverter

providing power for a variety of AC loads, such as TVs,

VCRs, laptops, camcorders and other small AC devices.

They are CSA certified for use in recreational vehicles.

The HI400 is available in two versions:

• “HI400 with hardwire” is designed for permanent

hardwired installation.

• “HI400 with hardwire and GFCI outlet” has a GFCI

receptable on the front and a hardwire compartment. It

provides easy access for plugging a load directly into the

output of the unit. The hardwire compartment allows the

unit to be installed permanently.

HI400 offers the following inverter features:

• Ability to run many of the entertainment loads that you

use at home.

You can operate TVs, stereos, VCRs, computers and

even small battery chargers. You can run multiple loads

up to 400 watts in total.

• Surge capability

HI400 will surge up to 550 watts peak.

• Low voltage shutdown

The inverter shuts off when your batteries discharge to

less than 10 volts.

When the battery voltage recharges to above 12.5 volts,

the inverter automatically restarts. Thi s feature prevents

the inverter from draining the batteries if it is left on

without a load.

• Ground fault circuit interrupter (GFCI)

As well as providing for per manent hard wire i nstallat ion,

the GFCI model provides a receptacle for plugging in a

load.

2

Page 13

Introduction

This receptacle has a “gro und fault circuit interrupter” to

reduce shock hazards on loads connected to both the

receptacle and hardwire outputs.

• Ignition lock out

Ignition lockout prevents the inverter from operating

while the engine is running. It allows the user to turn the

inverter on and off remotely.

• Transfer switch

Automatically connects the loads on the receptacle and

hardwire outputs to the external AC source when one is

available. Upon discon nection, or los s of the exter nal AC

source, the transfer switch automatically transfers the

load circuits over to inverter power.

3

Page 14

HI400 features

HI400 features

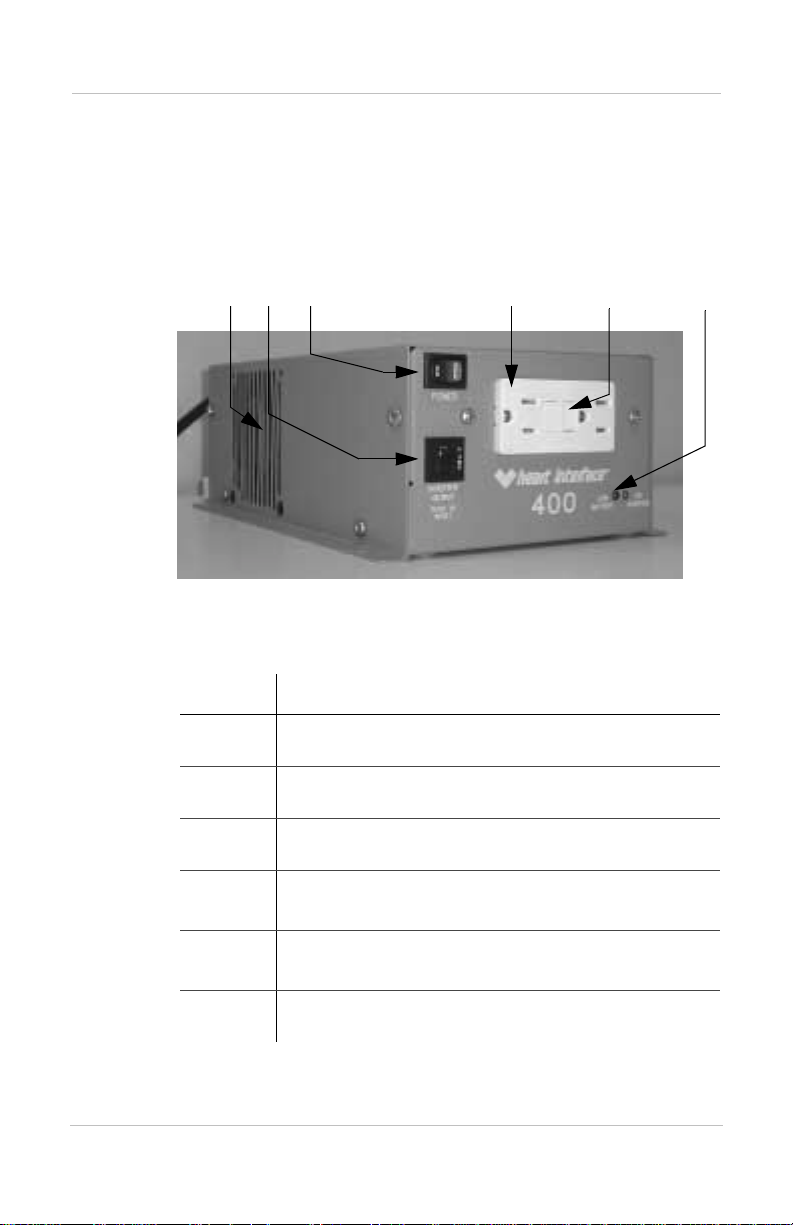

Figure 1 below, and Figure 2 opposite, show the front and

back panels of the HI400. Table 1 and Table 2 list the

respective panel parts.

➀➁

Figure 1 Front Panel - “Hardwire with GFCI” version.

Table 1 Front panel features

Feature Description

➀

➁

➂

➂

Fan vents

Output circuit protector

ON/OFF power switch

➃

➄

➅

➃

➄

➅

4

Dual AC receptacle (on the GFCI outlet and hardwire

version only)

GFCI test and reset buttons (on the GFCI outlet and

hardwire version only)

“On inverter” and “low battery status” LEDs

Page 15

HI400 features

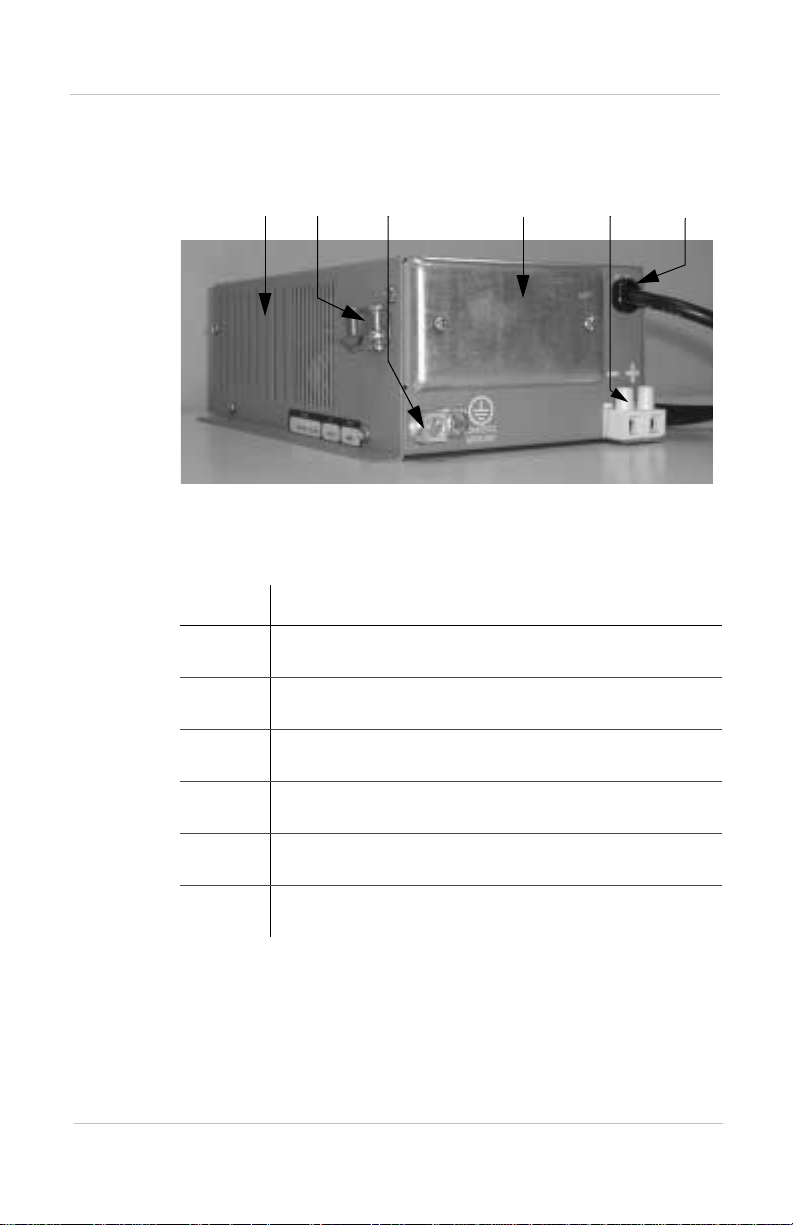

➀

➁

Figure 2 Back panel

p

T able 2 Back panel features

Feature Description

➀

➁

➂

Air vents

Cable clamp

Chassis grounding lug

➂

➃

➄

➅

➃

➄

➅

AC hardwiring compartment (with cover on)

DC input terminals

AC input cord

5

Page 16

Materials list

Materials list

Your HI400 inverter package includes the items listed below:

❐ Inverter with hardwire (80-04 01-12) or

Inverter with hardwire and GFCI outlet (80-0400-12)

❐ Owner’s Guide

6

Page 17

Installation

Chapter 2 “Installation” provides complete

information for installing the HI400 Inverter.

Specifically, this section describes:

• safety instructions and installation codes

that must be observed during installation.

• installation tools and materials.

• appropriate locations and environments

for mounting the inverter.

• AC cabling, DC cabling, and ground

information.

• detailed installation procedures.

7

Page 18

Preparing for installation

Preparing for installation

Prior to beginning your installation, review the “Important

Safety Instructions” on page v, and read the entire

“Installation” section so you can plan your installation from

beginning to end.

WARNING: Electrical shock and fire

hazards

Xantrex recommends all wiring be done by qualified

personnel. Disconnect all AC and DC power sources to

prevent accidental shock. Disable and secure all AC and

DC disconnect devices and automatic generator starting

devices.

It is the installer’s responsibility to ensure compliance

with all applicable installation codes and regulations.

CAUTION

Be sure to read all instructions before installing and

operating this inverter.

Installation codes

Applicable installation codes vary depending on the specific

location and application of the installation. Some examples

are:

• T he U.S. National Electrical Code (NEC)

• The Canadian Electrical Code (NEC)

• NEC, Canadian Standards Association (CSA), and RV

Industry Association (RVIA) requirements for

installation in RVs.

It is the installer’s responsibility to determine which codes

apply, and to ensure that all applicable installation

requirements are met.

8

Page 19

Installation tools and materials

You will need the following tools and materials to install the

inverter:

❐ #2 Phillips screwdriver

❐ Wire stripper

❐ 4 mounting screws or bolts and appropriate tools

❐ 3/8” wide slot screwdriver for DC input and chassis

ground terminals

❐ 3-conductor (2-conductor-plus-ground cable) AC output

cable sized appropr iate ly for l oad accor ding to ap plicab le

installation code(s). In the NEC, CEC and RV

applications, this is No. 14 AWG.

❐ Crimp connectors and appropriate crimping tool for AC

output wiring and ignition lockout wiring (if twist-on

wire connectors are not appropriate for your installation).

❐ DC cable, sized appropriately for load per the applicable

installation code(s). In NEC, CEC and RV applications,

this is No. 8 AWG if copper conductors rated 60 °C –

90 °C are used.

Preparing for installation

❐ Terminals for connecting the DC cables to the battery, as

well as appropriate tools for those terminals (for

example, crimping tool, hex-key, etc.).

❐ AC and DC disconnects and over-current protective

devices.

9

Page 20

Preparing for installation

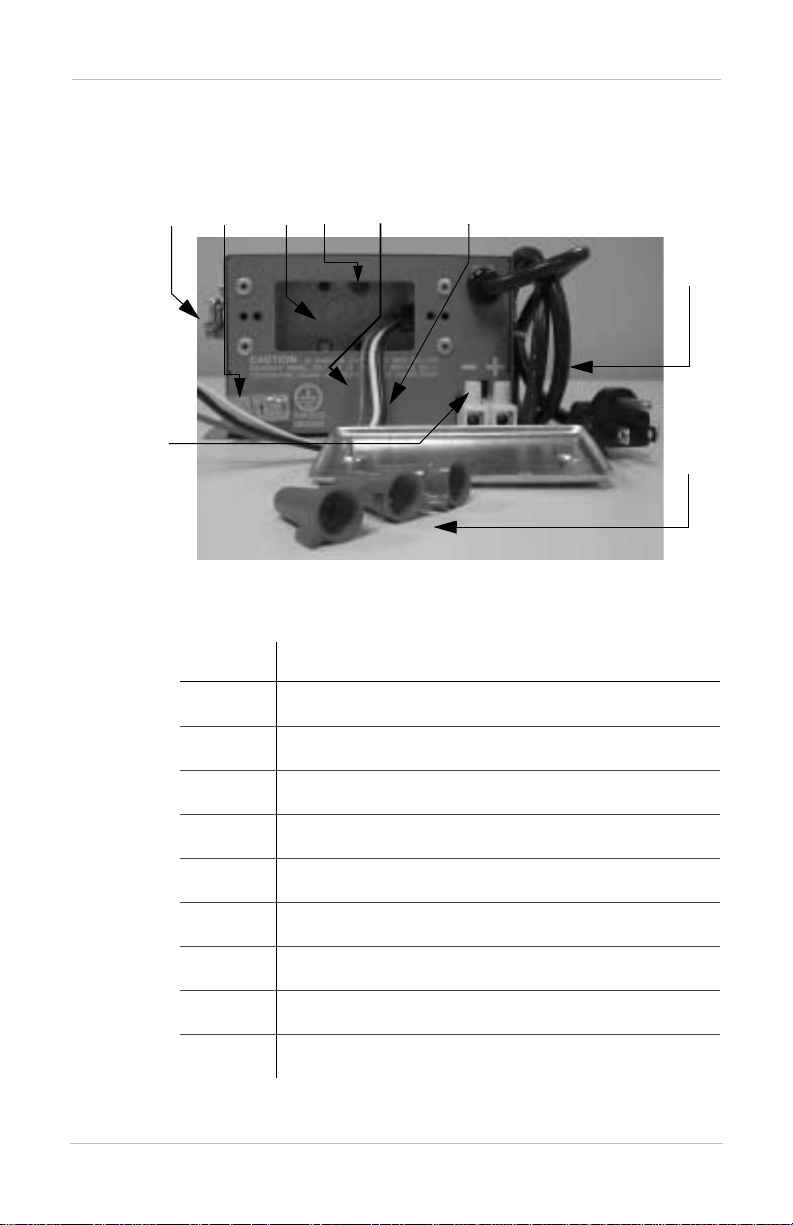

Installation features

Figure 3 and Table 3 below, list the installation features of

your HI400 inverter.

➁

➂

➃

➄

➅

➆

➀

Figure 3 Installation features: back view

T able 3 Installation features: back view

Feature Description

➀

➁

➂

DC input terminals

Cable clamp

Chassis grounding lug

➇

➈

10

➃

➄

➅

➆

➇

➈

AC Hardwire compartment

Ground screw for AC output ground

Ignition lockout wire (red)

AC output wiring (blac k, white)

AC input cord

Wire connectors (3)

Page 21

Installing the HI400

Overview

This section provides detailed installation information. The

overall procedure is divided into nine main steps:

Installing the HI400

Step 1

Step 2

Step 3

Step 4

Designing your installation (page 11)

Choosing a location for your inverter (page 15)

Mounting your inverter (page 16)

Permanently connecting the AC output wiring

(page 17)

Step 5

Step 6

Step 7

Step 8

Step 9

Installing the ignition lockout wiring (page 18)

Connecting the DC cables (page 19)

Connecting the AC input cord (page 22)

Checks prior to initial pow er-up (page 23)

Starting up and testing your installation

(page 23)

Designing your installation

This section provides information about AC wires, DC

cables, AC disconnects and over protection devices, GFCIs,

and batteries which you must supply as part of the

installation.

AC shorepower

A source of 120 volt, 60 Hz alternat ing curr ent (AC) power is

needed if it is desired to power the loads connected to the

inverter from a source other than the inverter. Typically, this

source will be utility grid (power company) power provided

at an RV park or campground, or an AC generator.

11

Page 22

Installing the HI400

Note:

AC input power from a utility grid, generator, or other source.

AC disconnects and over- current protection devices

Throughout this manual, the term “s horepower” r efers t o

To meet electrical code requirements, you must provide the

inverter with over-current protection (such as a circuit

breaker or fuse) and a disconnect device as follows:

AC Input: The circuit breaker or fuse used to protect the

HI400 inverter must be rated no more than 15 A and must be

approved for use on 120 Vac branch circuits.

AC Output: The circuit breaker or fuse must be rated at no

more than 15 A and must be approved for use on 120 Vac

branch circuits.

Disconnect devices: Each system requires a method of

disconnecting each AC circuit. If the over-current protection

device is a circuit breaker, it will serve as a disconnect

switch. If fuses are used, separate AC disconnect switches

will be needed between the source of power and the fuses.

AC output wiring

The type and size of the wires between the inverter output

and the loads varies with the installation type and applicable

codes. For many RV applications, flexible multi-strand wire

is required. Installation codes may specify solid or stranded,

overall size of the conductors, and type and temperature

rating of the insulation around the wire.

12

The AC output wiring must be sized to match the current

rating of the circui t breaker or fuse you pr ovide on AC outpu t

circuits. The size must be in accordance with the electrical

codes or regulations applicable to your installation. In most

NEC, CEC, and RV installations, the wire size will be

required to be No. 14 AWG, 3-conductor (line and neutral,

plus ground).

Page 23

AC output neutral bonding

The neutral conductor of the inverter’s AC output circuit is

automatically connected (“bonded”) to the safety ground

whenever the inverter is running and AC utility shorepower

is not present. When AC shorepower is present, this

connection is automatically lifted, as that same bonding

connection will b e presen t in the AC shorepower source. This

system automatically conforms to electrical code

requirements that neutral conductors are to be bonded to

ground at all times, but only in one place at a time.

CAUTION: Damage to unit

Do not connect AC output to any AC load circuit in which

the neutral conductor is connected to ground (earth) or to

the negative of the DC (battery) source. Doing so will

damage the unit.

DC disconnects and over-current devices

The DC circuit from the battery to the inverter must be

equipped with over-current protection (such as a circuit

breaker or fuse) and a disconnect device. This usually

consists of a DC-rated circuit breaker, a “fused-disconnect,”

or a separate fuse and DC disconnect. Do not confuse AC

circuit breakers with DC circuit breakers — they are not

interchangeable. The current rating of the fuse or breaker

must be matched to the size of the DC cables used in

accordance with the applicable installation codes. The

breaker or disconnect and fuse should be located as close as

possible to the battery, in the positive cable. Applicabl e codes

may limit how far the protection can be from the battery.

Installing the HI400

For No. 8 AWG DC cable, the fuse or circuit breaker is

required to be rated 40 Adc max. Use a sl ow-blow f use to ge t

the maximum surge performance from the inverter.

13

Page 24

Installing the HI400

DC cabling

This includes the DC cables between the battery, the DC

disconnect and over-current protection device, and the

inverter. For copper cable rated 60 °C, 75 °C, or 90 °C, the

minimum size cable allowed in NEC, CEC, or RV

installations is No. 8 AWG (assuming a 40 Adc fuse or

breaker is used).

Batteries

Every HI400 inverter requires a 12 V deep-cycle battery or

group of batteries to provide the DC current that the inverter

converts to AC. Deep-cycle batteries are intended to be

repeatedly cycled partly or fully discharged, and then

charged. Automotiv e-type st arting o r “cranking” batteri es are

not recommended, except for temporary emergency use,

since deep-cycle use will severely limit their useful life.

Ground fault circuit interrupters (GFCIs)

GFCIs are intended to protect people from electrical shocks

and are usually required in wet or damp locations. A regular

circuit breaker cannot provide this type of protection.

14

Installations in recreational vehicles require GFCI protection

of branch circuits connect ed to the AC output of the inverter .

The HI400 comes in two versions. In the version with the

integral GFCI receptacle, the GFCI protects both the

receptacle’s output and the hardwire output. In the version

without the integra l GFCI receptacl e, the hardwir e output has

no GFCI protection, and it is up to the installer to provide it.

Compliance with UL standards requir es tha t Xantre x test and

recommend specific GFCIs for use with the HI400 inverter.

Xantrex has tested the GFCI-p rotected 15 A recepta cles listed

in Table 4, and found they function properly when connected

to the AC output of the HI400.

Note:

instructions for testing and resetting your GFCI.

You should test your GFCI monthly. See page 26 for

Page 25

Table 4 Tested GFCI models

Manufacturer Model number

Leviton 6599

Pass & Seymour 1591

Hubbell GF 5252GYA

Choosing a location

WARNING: Risk of fire or explosion

This equipment contains components that tend to

produce arcs or sparks. To reduce the risk of fire or

explosion, do not install this equipment in compartments

containing batteries or flammable materials, or in

locations that require ignition-protected equipment. This

includes any space containing gasoline-powered

machinery, fuel tanks, or joints, fittings, or other

connections between components of the fuel system.

Installing the HI400

WARNING: Fire hazard

Do not cover or obstruct the ventilation openings. Do

not install this equipment in a zero-clearance

compartment. Overheating may result.

The inverter should only be installed in locations that meet

the following requirements:

Dry Do not allow water or other fluids to drip or

splash on the inverter. Do not expose to rain,

snow or splashing water.

Cool Normal air temperature should be between

32 °F and 77 °F (0 °C and 40 °C) — the

cooler the better within this range.

15

Page 26

Installing the HI400

Ventilated See the warning on page 15. Allow at least 5

Safe See the warning on page 15. Do not install

inches of clearance on each size of the

inverter for air flow. Do not allow the

ventilation openings on the unit to become

obstructed. Make sure the compartment in

which the inverter is installed allows airflow

through the compartment.

the inverter in the same compartment as

batteries or in any compartment capable of

storing flammable liquid s like gasoline.

Close to battery

compartment

and the AC

source and load

Protected from

battery acid and

gases

Mounting your inverter

The HI400 inverter must be mount ed f la t (f or exampl e, o n or

under a horizontal surface) in order to comply with safety

agency requirements.

To mount your HI400 inverter:

1. Turn the On/ O ff switch on the inverte r t o the off position.

2. Fasten the inverter to the mounting surface, using four

#10 pan head steel wood screw (5/8” long minimum) or

#10 bolts inserted through the mounting holes in the

flanges (running along the sides of the inverter).

Avoid excessive cable lengths (these reduce

input and output power due to wire

resistance). It is preferable to have lengthier

AC cables than DC cables, as the AC current

is far lower than the DC. Use the

recommended cable sizes.

Never allow battery acid to drip on the

inverter or its wiring when filling or reading

its specific gravity. Do not mount the unit

where it will be exposed to gases produced

by the batteries. These gases are corrosive

and prolonged exposure will damage the

inverter.

16

Page 27

Installing the HI400

Permanently connecting (hardwiring) the AC output

WARNING: Fire, shock, and energy

hazards

Make sure wiring is disconnected from all electrical

sources before handling. All wiring must be done in

accordance with local and national electrical wiring

codes. Do not connect the output leads of the inverter to

any incoming AC source.

To hardwire t he AC output connections:

1. Remove the AC hardwire compartment cover. Three

wires are located inside the w iring compartment as

follows:

• Black – the AC output line conductor

• White – the AC output neutral conductor

• Red – the ignition lockout conductor (page 18)

WARNING: Shock hazard

Do not connect the ignition lockout wire (red) to AC

circuits. See instructions for connecting on page 18.

2. Run No. 14 AWG 2-conductor-plus-ground cable

through the cable clamp and into the AC wiring

compartment.

3. Strip about 2 inches off the jacket of the AC cable.

4. Strip approximately ½ inch off the insulation of the black

and white wires from the AC cable (if using the twist-on

wire connectors provi ded). If you are p roviding your own

connectors, follow the manufacturer’s recommendations

regarding strip length and use of the connectors.

17

Page 28

Installing the HI400

5. Connect the bl ack and white ( line and neutral ) wires from

6. Connect the ground wire (bare or green) from the AC

7. Connect the load end of the AC cable to your system’s

the AC cable to the black and white wires located in the

HI400 hardwire compartment. Be sure to connect black

to black and white to white. Chec k to make sure the wir es

are making a good connection, and secure the twist-on

wire connectors with electrical tape.

cable to the green-headed screw on the back wall of the

hardwire compartment. Use a crimp-on ring terminal if

the AC input ground wire is stranded. Solid wire can be

secured directly under the head of the screw.

AC output circuit breaker, or the load distribution panel

depending on your system design.

WARNING: Shock hazard, risk of damage

Do not connect the HI400 Inverter output to AC

distribution wiring powered by any other source. Shock

hazard and damage may result.

Installing the ignition lockout wiring

The ignition lockout system turns the inverter off when the

ignition is on. The system is designed so that when a userapplied 12 V signa l is pr esent on the red i gnition lockout wi re

in the hardwire c ompartment, the inverter tu rns off . This 12 V

signal is normally obtained by connecting a wire to circuits

downstream from the vehicle ignition switch, so that 12 V is

present when the ignition is on, and not present when the

ignition is off. The circuit selected should be protected by a

fuse rated maximum 5 Adc.

To install the ignition lockout wiring:

1. Connect a min. No. 18 AWG wire to an appropriate,

fused 12 V ignition-switched circuit. In the following,

this wire is referred to as the “lockout signal wire.”

18

Page 29

Installing the HI400

2. Route the lockout signal wire through the cable clamp

and into the hardwire compartment.

3. Strip approximately ½ inch off the insulation of the red

ignition lockout wire an d the lockout sig nal wire (if usi ng

the twist-on wire connectors provided). If you are

providing your own connectors, follow the

manufacturer’s recommendations regarding strip length

and use of the connectors.

4. Connect the lockout signal wire to the re d ignition

lockout wire provided in the hardwire compartment.

Check to make sure the wires are making a good

connection, and secure the twist-on wire connector with

electrical tape.

5. Re-install the hardwire compartment cover plate.

6. Tighten the cable clamp so that the AC output cable and

ignition lockout wiring are secured. Check to make sure

the clamp is securing the overall jacket of the AC output

cable (not the individual conductors), and that no wiring

is being pinched in the corners of the clamp.

Connecting the DC cables

CAUTION

Before making the final DC connection, check cable

polarity at both the battery and the inverter. Positive (+)

must be connected to positive (+); negative (–) must be

connected to negative (–).

Reversing the positive (+) and negative (–) battery

cables will damage the inverter and void your warranty.

This type of damage is easily detected.

WARNING: Fire hazard

Use only appropriately sized copper wire. Make sure all

DC connections are tight. Loose connections will

overheat.

19

Page 30

Installing the HI400

Follow the procedures given below to connect the battery to

the DC input terminals. The cables should be as short as

possible and large enough to handle the required current, in

accordance with the electri cal codes or regula tions appl icable

to your installation. As noted above, the recommended cable

size is No. 8 AWG for compliance with NEC, CEC, and RV

codes (assuming a 40 amp DC fuse).

To ensure maximum performance from the invert er, do no t

route your DC cable s through a DC di stributio n panel, batt ery

isolator, or other device that will cause additional voltage

drops.

Connecting the battery to the DC input

To make the DC connections:

1. Cut the DC cables to the correct length with enough

insulation stripp ed off so you can prop erly install the type

of terminals you will be using at the battery end. At the

HI400 end, strip the wire 3/8 inch.

2. Assign one cable to be positive (+) and one cable to be

negative (–). Mark both ends of each cable to avoid

confusion during installation.

20

3. Switch the On/Off switch into the off position (if you

have not already done so).

4. Route the DC ca bles f rom the batt ery ba nk to t he inv erter.

5. Install a DC breaker or a fuse and disconnect in the

positive side of the circuit, as close as possible to the

battery. Turn off the breaker or open the disconnect

switch.

6. Attach the negative (–) cable to the negative (–) battery

terminal (or to the current shunt if a shunt is used) using

whatever connector you have selected. Tighten the

connection according to the manufacturer’s

recommendation.

Page 31

Installing the HI400

7. Insert the other end of the negative (–) cable into the

negative (–) terminal on the HI400 and tighten the

terminal screw. Ensure all strands of wire are inside the

connector (no stray st rands). The termi nal manufacturer’ s

recommended tightening torque is 21 inch-pounds.

8. Attach the positive (+) cable to the breaker or fuse and

disconnect combination installed on the battery positive

(+) terminal in step 5. Tighten the connection according

to the manufacturer’s recommendations.

9. Insert the other end of the positive (+) cable into the

positive (+) terminal on the HI400 and tighten the

terminal screw. Ensure all strands of wire are inside the

connector (no stray st rands). The termi nal manufacturer’ s

recommended tightening torque is 21 inch-pounds.

10. Verify the polarity of the DC connections is correct:

positive (+) on the inverter connected to the positive (+)

on the battery, and negative (–) connected to the

negative (–).

When you are ready to oper at e the inve rt er, close the DC

circuit breaker or disconnect switch to supply DC power

to the inverte r.

Connecting the DC ground

The chassis ground lug on the DC end of the inverter is used

to connect the chassis of the inverter to your system’s DC

grounding point as required by installation codes for some

installations.

Use copper wire that is either bare or provided with green

insulation. Do not u se t he DC gr oun d lug for your AC output

grounding wire (see the AC wiring instruc tions on page 12 in

this sectio n).

To connect the DC ground:

➢ Connect a No. 8 AWG copper wire between the HI400’s

chassis ground lug and the DC grounding point for your

system.

21

Page 32

Installing the HI400

In an RV or vehicle installation, this will usually be the

vehicle chassis or a dedicated DC ground bus.

Connecting the AC input cord

WARNING: Shock hazard

Connect the AC input cord only to a properly grounded

standard 120 Vac, 15 A receptacle. If the correct type of

receptacle is not available, have an electrician install

one.

To connect the AC input cord:

➢ Plug the AC input cord (loc ated at the bac k of the

inverter) into a properly grounded 120 Vac, 15 A

receptacle connected to an external shorepower source

such as a utility grid or a generator.

22

Note: Connecting the AC input cord to the AC output

receptacle on the HI400 GFCI version will not power loads and

will cause the unit to malfunction. There should not be any

damage.

When the shorepower AC source is supplied, the HI400 will

transfer the loads to the shorepower source and turn off the

inverter.

When the shorepower AC so urc e i s di sc onnected or fails, the

HI400 will automatically tur n on the inver ter and trans fer the

loads to inverter power.

Page 33

Checks prior to initial power-up

Before powering up your in verter , ensure these condit ions are

met:

❐ On/Off power switch is in the off position.

❐ Positive (+) battery cable is conn ect ed to the

positive (+) battery terminal.

❐ Negative (–) battery cable is connected to the

negative (–) battery terminal.

❐ Battery voltage is within the proper range for this unit

(10.0 – 15.0 Vdc).

❐ DC Fuse is intact (not blown).

Starting up and testing your installation

WARNING

The front panel power switch does not disconnect DC or

AC input power to the unit.

Installing the HI400

To turn on the HI400:

1. Turn the On/Off power switch on the fro nt panel to the on

position. The green ON INVERTER LED indicator

illuminates.

2. Plug a load into the GFCI receptacle on the front panel.

Apply a load of 400 watts or less.

3. Test the transfer feature by plugging the AC input cord

into the shorepower source receptacle.

The inverter will transfer with the power switch in either

the on or off position.

23

Page 34

24

Page 35

Operation

Chapter 3 “Operation” explains how to

operate the HI400 Inverter.

25

Page 36

Operation features

Operation features

CAUTION

Read all operating instructions before operating the

HI400.

Inverter on and off

The On/Off power switch on the front panel turns the HI400

inverter on or off:

• In the On position, the green inverter On LED indicator

illuminates and the unit begins inverting if AC

shorepower is not present . The HI4 00 is now operational

and you can apply a load requiring less than 400 watts.

• In the Off position, the inverter AC output is turned off,

but if AC shorepower is present, the hardwire and GFCI

outputs will be en ergi zed and l oads wil l operat e. W ith the

switch in the Off position, the unit does not draw any

battery power, except as required to run the fan until the

unit cools off.

Ground fault circuit interrupter (GFCI) protection

The GFCI with hardwire version contains a GFCI receptacle

that protects the hardwire output and the receptacle output

against a ground fault.

Correcting a ground fault

When a fault condition is detected, the reset button on the

GFCI receptacle pops out and power to the load is

interrupted.

To resume normal operation, determine and correct the

ground fault, then push the reset button in.

26

Page 37

Monthly testing

Once a month, with either AC shorepower or inverter power

present, press the test button on the GFCI receptacle. The

reset button should pop out. Push it to reset the GFCI, and

continue normal operation. This should be completed on a

monthly basis.

If the reset button does not pop out, the GFCI may have

failed. Disconnect AC and DC power to the unit and have a

qualified service person look at it.

Alternate AC source

An AC input cord is pro vided a t the back of the unit a llowing

for alternate source AC power. Plug the input cord on the

back of the HI400 into a shorepower receptac le. The load can

be run from the alternate source when it is present.

When the shorepower source is not present, the internal

transfer relay will automatically trans fer the load to in verter

power. This transfer relay functions whether the power

switch is in the on or off position.

Operation features

Ignition lockout

The inverter automatically shuts off when the ignition

lockout is engaged. This occurs when the power switch is in

the On position and a 12 vol t signa l (not t o exceed 16 Vdc) is

applied to the ignition lockout wire. Refer to page 18 for

details.

Low battery condition

When the low battery red LED light illuminates, the battery

voltage has dropped below 10.5 Vdc. When the battery

voltage drops below 10.0 Vdc, the inverter turns off to

prevent further discharging of the battery by the HI400.

27

Page 38

Inverter loads

Inverter loads

The HI400 will operate most AC loads within its power

rating (400 watts/3.3 amps).

Typical loads that can be used on the HI400 are as follows:

•Laptops

•Small TVs

• Handheld computing devices

• VCRs

• Camcorders

• Other light duty AC devices

Operating several loads at once

If you are going to operate se veral loads fr om the HI400, turn

them on separately af ter you ha ve turned t he inv erter on. Thi s

ensures that the inverter does not have to deliver the starting

current for all the loads at once. The HI400 can handle

several loads as long as they do not exceed 400 watts in total.

Problem loads

Some appliances may be damaged if they are connected to

the HI400:

• Electronics that modulate RF (radio frequency) signals

on the AC line will not work and may be damaged.

• Speed controllers found in some fans, kitchen app liances,

and other loads may be damaged.

28

CAUTION: Modified sine wave (MSW)

Some appliances may be damaged by the HI400’s MSW

output.

Page 39

• Some chargers for battery packs used in power hand

tools. These affected chargers display a warning label

stating that dangerous voltages are present at the battery

terminals.

If you are unsure about powering any load with the HI400,

contact the appliance manufacturer.

Turning the inverter off between charges

When the power switch is on but no power is being supplied

to a load, the inverte r id les and dr aws l ess than 400 mΑ from

the battery.

Because of this current draw, the battery may need to be

recharged after a few days. If you are not usi ng your inv erter,

turn it off.

Battery charging frequency

When possible, recharge your batteries when they are about

50% discharge d or bef ore. This gives t hem a much l onger li fe

cycle than recharging when they are almost completely

discharged. For mo re i nfo rmat ion about battery chargers, see

our web site at www.xantrex.com

Inverter loads

29

Page 40

30

Page 41

Maintenance and Troubleshooting

Chapter 4 “Maintenance and

Troubleshooting” will help you identify

common problems that can occur with the

HI400 Inverter.

Read this chapter before calling Xantrex

Customer Service.

If you cannot solve the problem, record the

information asked for on page 51. This will

help our Customer Service Representatives

to assist you better.

31

Page 42

Maintenance

Maintenance

WARNING: Shock hazard

Disconnect all sources of AC and DC power before

doing any routine maintenance.

Minimal maintenance is required to keep your HI400

operating properly.

Periodically you should

• clean the exterior of the unit with a damp cloth to prevent

the accumulation of dust and dirt.

• ensure the DC cables are secure at both the HI40 0 and the

battery.

Troubleshooting

Common problems

Buzz in audio equipment

Some inexpensive stereo systems have inadequate internal

power supply filtering and buzz slightly when powered by

the HI400. The best solution is to use an audio system with a

good quality filter.

Television interference

The HI400 is shielded to minimize interference with TV

signals. If TV signals are weak, you may see interference in

the form of lines scroll ing across the screen. Try one of the se

suggestions to minimize or eliminate the problem:

• Use an extension cord to increase the distance between

the HI400 and the TV, antenna, and cables.

32

Page 43

• Adjust the orientation of the HI400, television, antenna,

and cables.

• Maximize TV signal strength by using a better antenna;

use a shielded antenna cable where possible.

• Try a different TV. Different models vary considerably in

their susceptibility to interference.

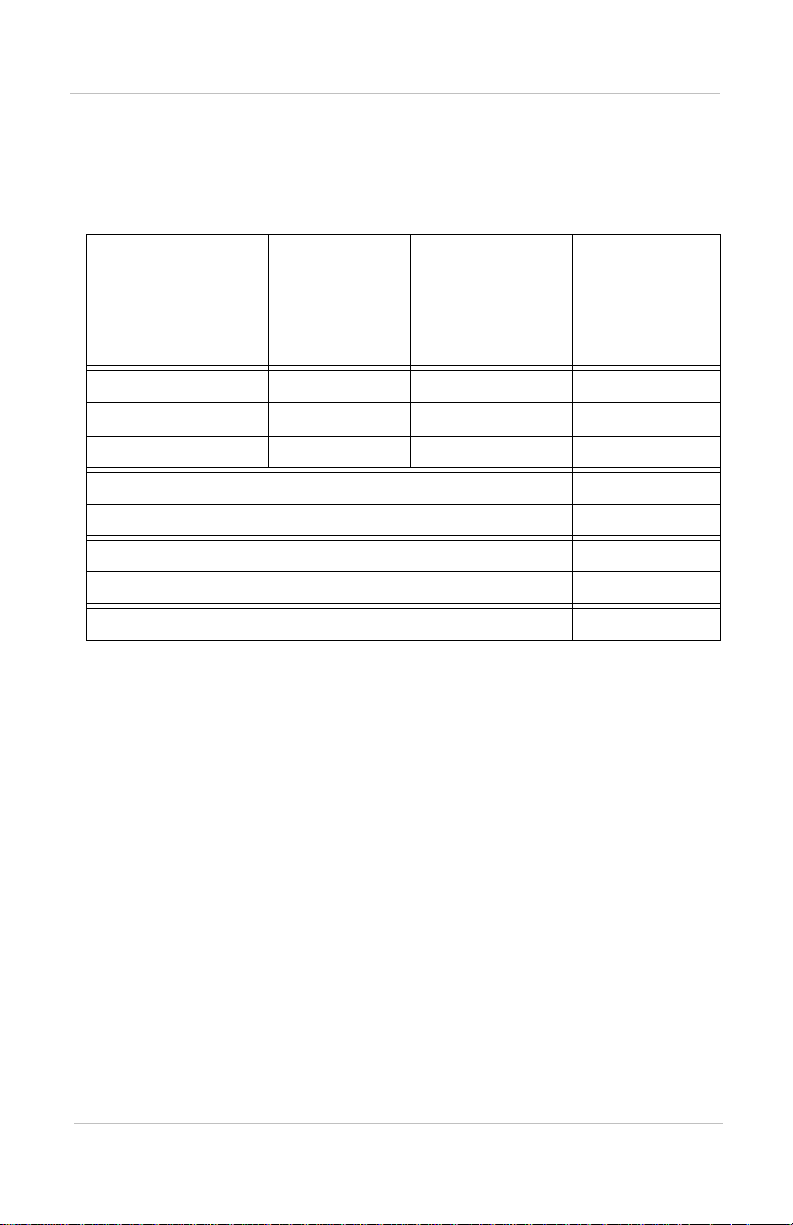

Troubleshooting refe re nce

Four common problems with the HI400 are as follows:

• Low battery

• Thermal shutdown

• Electronic shutdown

• No AC output

WARNING: Electric shock hazard

Do not remove the cover or disassemble the HI400. It

does not contain any serviceable parts and attempting to

service the unit yourself could result in electrical shock

or burn.

Troubleshooting reference

Table 5 Troubleshooting reference

Problem Possible Cause Solution

Low battery

shutdown

(Low battery

LED

illuminated red)

Thermal

shutdown

(No LED

illuminated)

Battery under

voltage

Over temperature Inverter automatically restarts when

Check battery voltage:

• If the voltage is low, charge the

battery.

• If the voltage is normal, check for

loose battery connection.

the temperature of components

decreases. Remove some loads. Be

sure there is adequate air flow to both

sides of the unit for proper cooling.

33

Page 44

Troubleshooting reference

Table 5 Troubleshooting reference

Problem Possible Cause Solution

Electronic

shutdown

(No LED

illuminated)

No AC output

(No LED

illuminated)

High battery

voltage, overload,

short circuit

Output circuit

breaker or tripped

GFCI

High battery

Open (blown)

battery fuse

Turn power switch off. Disconnect all

loads and then turn power switch on

Check the circuit breaker and GFCI.

Push in the GFCI button to reset.

Wait for battery voltage to drop. Reset

the inverter.

Check battery fuse.

34

Page 45

Specifications

Appendix A “Specifications” contains

electrical and physical specifications for the

HI400 Inverter.

35

Page 46

Electrical

Electrical

Output power

• continuous

• surge capacity

Output voltage 120 Vac RMS ±5%

Output fre quency 60 Hz nomin al

Output wave form Modified sine wave

Transfer switch 4 Amp AC

High battery shutdown 15.0 V

Low battery shutdown 10.0 V

Efficiency Approximately 80-90%

No load current draw (switch on) Less than 400mA

400 W

550 W

Physical

Specifications are subject to change without notice.

36

Length 9.7 inches (24.6 cm)

Width 6.5 inches (16.5 cm)

Height 3.5 inches (8.9 cm)

Weight 4 lb (1.8 kg)

Page 47

Battery Types and Sizes

Appendix B contains “Battery Types and

Sizes.” The batteries you use strongly affect

the performance of the HI400 Inverter. It is

important to connect the inverter to the

correct size and type of battery.

The information in this appendix will help

you select, connect, and maintain batteries

that are most appropriate for your

application.

37

Page 48

Battery types

Battery types

Automotive starting batteries

The lead-acid battery you are most familiar with is probably

the starting battery in your automobile. An automotive

starting battery is designed to deliver a large amount of

current for a shor t peri od of ti me (s o it can start your eng ine).

Only a small portion of the battery’s capacity is used when

starting the engine and it is quickly recharged by the running

engine.

This type of battery is not des igned for repeat ed cycles where

the battery is almost completely discharged and then

recharged. If it is used in this kind of deep discharge service,

it will wear out very rapidly.

Deep-cycle lead-acid batteries

Deep-cycle lead-acid batteries are designed for deep

discharge service where they will be repeatedly discharged

and recharged. They are marketed for use in recreational

vehicles, boats, and electric golf carts — so you may see

them referred to as RV batteries, marine batt er ies, o r g olf ca rt

batteries.

38

For most applications of the HI400, Xantrex recommends

you use one or more deep-cycle batteries that are separated

from the vehicle’s starting battery by a battery isolator.

A battery isolator is a solid -state el ectronic circuit tha t allows

equipment to be operated from an auxiliary battery without

danger of discharging the vehicle’s starting battery. During

vehicle operation, the battery isolator automatically directs

the charge from the alternator to the battery requiring the

charge.

Battery isolators are available at marine and RV dealers and

most auto parts stores.

Page 49

Battery size

Battery size or ca pacity is as important as the battery type f or

efficient operation of your loads. Xantrex recommends that

you purchase as much battery capacity as possible.

A number of different standards are used to rate battery

energy storage capacity. Automotive and marine starting

batteries are normally rated in cranking amps. This rating is

not relevant to an inverter which runs continuous loads.

Deep-cycle batteries use a more suitable rating system, either

“amp-hours” (“Ah”) or “reserve capacity” in minut es.

Battery reserve capacity Battery reserve capacity is a

measure of how long a battery ca n deliver a certai n amount of

current—usually 25 amps. For example, a battery with a

reserve capacity of 180 minutes can deliver 25 amps for 180

minutes before it is completely discharged.

Battery size

CAUTION

The HI400 must only be connected to batteries with a

nominal output voltage of 12 volts. The HI400 will not

operate from a 6 volt battery and will be damaged if

connected to a 24 volt battery.

Amp-hour ( A h) capacity Amp-hour capacity is a measure of

how many amps a battery c an deliv er for a specifi ed lengt h of

time — usually 20 hours. For example, a typical marine or

RV battery rated for 100 Ah can deliver 5 amps for 20 hours

(5 A x 20 hours = 100 Ah).

This same battery can deliver a higher or lower current for

less or more time, limited approximately by the 100 Ah

figure (for example, 50 A for 2 hours, or 200 A for ½ hour),

but usually the capacity figure given is only accurate at the

specified rate (20 hours).

39

Page 50

Estimating battery requirements

To calculate the battery capacity you require, read

“Estimating battery requirements” and “Battery sizing

example” on page B–41, and then complete the “Battery

sizing worksheet” on page B–42.

Estimating battery requirements

To determine how much battery capacity you need:

1. Determine how many watts are consumed by each

appliance you will operate from the HI400. You can

normally find this on a label on the product. If only the

current draw is gi ven, multiply it by 115 to get the power

consumption in watts.

2. Estimate how many hours each appliance will be

operating each day.

3. Calculate the daily watt-hours needed for each appliance.

4. Add the total number of watt-hours needed for all the

appliances and mul tiply it by the number of days betwee n

charges.

40

5. Divide the total watt-hours of AC load between charges

by 10. This gives the battery Ah used between charges.

6. Double the total Ah used between charges to get the

recommended battery size in Ah.

See the battery sizing example that follows on the next page.

Page 51

Estimating battery requirements

Battery sizing example

This battery sizing example illustrates a typical calculation,

assuming an opportunity to charge the batteries every three

days.

Daily watt-

Appliance

19” Color TV 100 W 2 hours 200 Wh

Power drill 400 W 1 hours 400 Wh

Computer system 300 W 2 hours 600 Wh

Total daily watt-hours of AC load 1200 Wh

x Number of days between charges 3

= Total watt-hours of AC load between charges 3600 Wh

Battery Ah used between charges (divide by 10) 360 Ah

Recommended Battery Bank Size in Ah (multiply by 2) 720 Ah

(A) Power

consumption

(B) Operating

time per day

hours needed

for this

appliance

(= A x B)

This example illustrates how quickly your battery needs can

escalate. To reduce the required battery size, you can

recharge more frequently or conserve energy by eliminating

or reducing the use of some loads.

When sizing your battery, resist the temptation to skip the last

step of this calculation (multiplying by 2). More capacity is

better since you will have more reserve capacity, be better

able to handle large loads and surge loads, and your battery

won't be discharged as deeply. Battery life is directly

dependent on how deeply the battery is discharged. The

deeper the dischar ge, the shorter th e battery lif e. Most batte ry

manufacturers recommend limiting the “depth of discharge”

to 50% of the battery capac ity.

41

Page 52

Estimating battery requirements

Battery sizing worksheet

Use the following worksheet to calculate your battery needs.

To ensure sufficient battery capacity, be generous when

estimating the operating time per day for each of your loads.

(A)

Appliance

Power

consumption

Daily watt-

(B)

Operating time

per day

W hours Wh

W hours Wh

W hours Wh

W hours Wh

W hours Wh

W hours Wh

W hours Wh

hours

needed for

this

appliance

(= A x B)

W hours Wh

Total daily watt-hours of AC load Wh

x Number of days between charges

= Total watt-hours of AC load between charges Wh

Battery Ah used between charges (divide by 10) Ah

Recommended Battery Bank Size in Ah (multiply by 2) Ah

42

Page 53

Using multiple batteries

As your power requirements increase, you may need to use

more than one battery to obtain sufficient capacity. Read

“Two batteries connected in parallel” and “Two separate

battery banks” to determine whether two batteries or two

battery banks are more appropriate for your applications.

Two batteries connected in parallel

Two identical batteries can be connected (positive (+) to

positive and negative (–) to negative) in a parallel system. A

parallel syst em doubl es cap acity an d maint ains the vo ltage of

a single battery.

CAUTION

Do not connect the following in parallel: batteries made by

different manufacturers, different types of batteries,

batteries that have different Ah ratings. Decreased battery

life and improper charging will result.

Using multiple batteries

Two separate battery banks

If you need more than two batteries (or are using different

makes or models of batter ies), Xantrex recommends that you

install two separate battery banks and a battery selector

switch.

By installing a battery selector switch, you can select

between the two battery banks, use both banks in parallel, or

disconnect both banks from the load. Battery selector

switches are available at marine and RV dealers.

43

Page 54

Battery tips

Battery tips

Note: Review “Precautions when working with batteries” on

page vii, before working with the batteries in your system.

Temperature sensitivity The capacity of lead-acid batteries

is temperature sensitive. Battery capacit y is rated at 77 ºF

(25 ºC). At 0º F (–20 ºC), the Ah capacity is about half the

rated capacity. You should consider temperature when

designing your system.

WARNING: Explosive/corrosive gases

Lead-acid batteries may emit hydrogen, oxygen, and

sulphuric acid fumes when recharging. To reduce the risk

of explosion:

• Vent the battery compartment to prevent the

accumulation of gases.

• Do not install electronic or electrical equipment in the

battery compartment.

• Do not smoke or use an open flame when working

around batteries.

44

Low temperatures If extremely low temperatures are

expected where the inve rter is goi ng to be locat ed, you should

consider a heated equipmen t room. If the syst em is loca ted in

an unheated space, an insulated battery enclosure is

recommended.

High temperatures The batteries should also be protected

from high temperatures. These can be caused by high

ambient temperatures, solar heating of the battery enclosure,

or heat released by a nearb y engine or generator. High battery

temperatures shorten battery life and therefore you should

ventilate the enclosure and use shade and insulation as

appropriate.

Page 55

Battery tips

Discharged batteries Do not leave batteries in a discharged

state for more than a day or two. They will undergo a

chemical process (s ulfation) tha t can permanently da mage the

battery. As well, batteries self-discharge over a period of

three to six months, so they should be recharged periodically

even if they are not being used.

Electrolyte level If your batteries are not the “maintenance-

free” type, check the electrolyte level at least once a month.

Excessive fluid loss is a sign of overcharging. Replenish the

electrolyte using dis ti ll ed wate r o nly.

Battery connections Connections to battery posts must be

made with permanent connectors that provide a reliable, lowresistance connection. Do not use alligator clips. Clean the

connections regularly and prevent corrosion by using a

protective spray coating or vaseline.

Battery state of charge You can measure battery state of

charge with a hydrometer or, more easily, with a voltmeter.

Use a digital voltmeter than can display tenths or hundredths

of a volt when mea sur in g 10 t o 3 0 vo lt s. The batteries should

be tested with no load or charge source (batteries

disconnected) and sho uld be open circ uit f or a t least one hour.

The following table gives approximate state of charge for a

lead-acid deep-cycle battery at 77 ºF (25 ºC):

Battery voltage State of charge

12.7–13.0 100%

12.5–12.6 80%

12.3–12.4 60%

12.1–12.2 40%

11.9–12.0 20%

45

Page 56

46

Page 57

Warranty and Product Information

Appendix C “Product and System

Information” contains the warranty and

return information for the HI400 Inverter.

47

Page 58

Warranty information

Warranty information

What does this warranty cover? Xantrex manufactures its

products from parts and components that are new or

equivalent to new, in accordance with industry standard

practices. This warranty covers any defects in workmanship

or materials.

How long does the coverage last? This warranty lasts for one

(1) year from the date of purchase. Implied warranties of

merchantability and fitness for a particular purpose are

limited to one y ear from date of purchase. Some j u ri sd ic ti ons

do not allow limitations on how long an implied warranty

lasts, so the above limitation may not apply to you.

What does this warranty not cover? This warranty will not

apply where the product has been misused, neglected,

improperly installed, physically damaged or altered, either

internally or exte rnally, or damaged from improper use or us e

in an unsuitable environment. Xantrex does not warrant

uninterrupted operation of its products. Xantrex shall not be

liable for damages, whether direct, incidental, special, or

consequential, or economic loss even though caused by the

negligence or fault of Xantrex. Some jurisdictions do not

allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion

may not apply to you.

48

What will Xantrex do? At its option, Xantrex will repair or

replace the defective product free of charge. Xantrex will,

also at its option, use new and/ or reconditioned parts made by

various manufacturers in performing warranty repair and

building replacement products. If Xantrex repairs or repl ac es

a product, its warranty term is not extended. Xantrex owns all

parts removed from repaired products.

Service during warranty? In order to qualify for the

warranty, a dated proof of purchase must be pro vided and the

product must not be disassembled or modified without prior

authorization by Xantrex. If your product requires warranty

Page 59

service, please return it to the place of purchase along with a

copy of your dated proof of purchase. If you are unable to

contact your merchant, or the merchant is unable to provide

service, contact Xantrex directly:

Web: www.xantrex.com

Email: techhelp@xantrex.com

Phone: 800-446-6180 (toll free)

Fax: 360-925-5143

Returning a product

You must obtain a Return Material Authorization (RMA)

number from Xantrex before returning a product directly to

Xantrex.

When you contact Xantrex to obtain service, be prepared to

supply the following information:

Retur ning a product

• Serial number of your inverter

• Date of purchase

• Information about the installation and use of the inverter

If you are returning a product from the USA or Canada:

1. Obtain an RMA number and a shipping address from

Xantrex. Products returned without an RMA number or

shipped collect will be refused.

2. Package the inverter safely, preferably using the original

packing materials. Include the following with your

shipment:

3. The RMA number

4. A copy of your dated proof of purchase

5. A return address where the repaired unit can be shipped

6. A contact telephone number

7. A brief description of the problem

49

Page 60

Out-of-warranty service

8. Ship the inve rter to the addr ess provid ed in Ste p 1, freight

prepaid. Xantrex recommends that you obtain proof of

delivery.

How other laws apply This warranty gives you specific legal

rights, and you may also have other rights which vary from

jurisdiction to jurisdiction.

For our Canadian customers When us ed herein “implied

warranties of merchantability and fitness for a particular

purpose” includes all warranties and conditions, express or

implied, statutory or otherwise, including without limitation

implied warranties and conditions of merchantability and

fitness for a particular purpose.

Out-of-warranty service

If the warranty period f or y our HI400 Inverter has expired, if

the inverter was damaged by misuse or incorrect installation,

if other conditions of the war ranty have not been met, or if no

dated proof of purchase is available, your inverter may be

serviced or replaced for a flat fee.

50

To return your HI400 for out of warranty service, contact

Xantrex Customer Service for a Return Material

Authoriza t ion (RMA) number and follow the other steps

outlined in “Warranty information” on page C–48.

Payment options such as credit card or money order will be

explained by the Customer Service Representative. In cases

where the minimum flat fee does not apply, as with

incomplete inverters or inverters with excessive damage, an

additional fee will be charged. If applicable, you will be

contacted by Customer Service once your inverter has been

received.

Page 61

Contacting Xantrex Customer Service

Contacting Xantrex Customer Service

If none of the troubleshooting suggestions work, you will

need to call Xantrex Customer Service. If possible, note the

circumstances surrounding the failure below. This will assist

the service technician in diagnosing the problem quickly.

How long have you had

the inverter?

Serial number

Battery types and sizes

Entertainment

equipment running at

shutdown

Were the LEDs flashing

and if so, what pattern

(slow blinks? fast

blinks?)

Was the ambient

temperature extremely

hot or cold?

W ere any DC appliances

affected?

Has this happened

before?

Other Xantrex products

T o see the range of invert ers and char gers o f fered by Xantrex,

visit our web site at www.xantrex.com

51

Page 62

52

Page 63

Index

A

AC disconnects 11

AC input cord

AC load circuit

AC output cable, 3-cond uctor

AC shorepower

Ah. See amp-hour capacity .

alternating current

amp-hour (Ah) capacity

appliances

battery-operated

current draw

power consumption

rechargeable

22, 23

13

11

11

39

viii

40

40, 42

viii

B

batteries

amp-hour (Ah) capacity

automotive starting

charging frequency

connecting two in parallel

deep-cycle lead-acid

depth of discharge

discharged

electrolyte level

golf cart

marine

45

45

38

38

39

38, 39

29

38

41

43

reserve capacity

RV

38

self-discharge

temperature sensitivity

tips

9

44

using multiple

using two battery banks

battery ban k

battery banks, describe d

battery connections

battery isolator

battery isolator, using

battery packs

battery reserve capacity

battery selector switch

battery size

estimating example

estimating worksheet

estimating your needs

battery types

39, 41

45

44

43

43

20

43

45

20

38

viii

39

43

41

42

39, 40

38

C

chassis ground lug 21

copper conductors

crimp connectors

CSA (Canadian Standards Association)

certification

9

9

2

53

Page 64

Index

D

DC cable 9

DC circuit breaker

DC distribution panel

DC ground bus (dedicated)

DC grounding point

DC input terminals

DC input wiring

depth of discharge (DOD)

disconnect switch

21

20

21

21

19

20

41

21

E

electrical code requirements 12

electrolyte level

explosive gases

45

vi

F

features

back panel

front panel

ground fault circuit interrupter

ignition lockout

low voltage shutdown

multiple loads

surge capability

transfer switch

flanges

(GFCI)

16

5

4

2

3

2

2

2

3

H

hydrometer 45

Canadian Electrical Code (NEC)

Canadian Standards Association

(CSA)

8

RV Industry Association (RVIA)

U.S. National Electrical Code (NEC)

8

installation features

AC input cord

cable clamp

chassis grounding lug

DC input terminals

designing your installation

ground fault circuit interrupters

(GFCIs)

tested GFCI models

flying leads

ground screw

hardwire compartment

ignition lockout wire

wire connectors

installation procedures

choosing a location

connecting ("hardwiring") the AC

output

connecting the AC input cord

connecting the DC cables

connecting the battery to the DC

input

connecting the DC ground

designing your installation

AC disconnects and over-current

protection devices

AC output neutral bonding

AC output wiring

AC shorepower

10

10

10

10

10

14

15

10

10

10

10

10

15

17

22

19

20

21

11

12

13

12

11

8

8

I

ignition lockout wire 10, 17, 18

installation codes

54

8

Page 65

Index

batteries 14

DC cabling

DC disconnects and over - current

mounting inverter

devices

14

13

16

L

lockout signal wire 18

M

malfunction 22

materials list

mounting screws

MSW (modified sine wave)

6

9

N

neutral conductor 13

No. 14 AWG

No. 18 AWG

No. 8 AWG

9, 17

18

9

O

On inverter LED (green) 23

On/Off power switch

operating features

AC input cord

air vent

5

alternate AC source

chassis grounding lug

circuit breaker

dual AC receptacle

fan vent

GFCI protection

GFCI reset button

low battery

4

23

4

5

27

5

4

4

26

4

4

negative and positive cabling

terminals

On inverter

On/Off switch

problem loads

strain relief

typical loads

wiring compartment plate panel

operation features

problem loads

electronics that modulate RF

(radio frequency)

speed controllers

over-current protection

5

4

4

28

5

28

5

28

28

12

2

P

polarity of DC connections 21

power-up check

preparing for installation

AC cabling, DC cabling and grou nd

detailed installation procedures

installation tools and materials

locations and environments for

safety instructions and installation

23

8

information

mounting the inverter

codes

7

7

7

7

7

R

reserve capacity 39

Return Material Authorization number

(RMA)

49

routine maintenance

cleaning your unit

securing DC cables

32

32

55

Page 66

Index

S

safety information v

serial number

starting batteries

state of charge

49

39

45

T

tools and materials 9

transfer feature

troubleshooting

buzz in audio equipment

common problems

electronic shutdown

low battery

no AC output

thermal shutdown

possible causes

possible problems

reference table

solutions

television interference

23

33

33

33

33

33

33

33

U

utility grid power 11

33

33

33

32

32

W

warranty 48

Canadian customers, for

contacting Xantrex customer service

51

legal rights under warranty

length of coverage

not covered under warranty

out-of-warranty service

returnin g a product

service during warranty

what does it cover

what will Xantrex do

wide slot screwdriver

wire stripper

9

50

50

48

48

50

49

48

48

48

9

X

Xantrex

contact information

web site

51

49

V

vehicle chassis 21

ventilation

ventilation openings

versions

hardwire and GFCI outlet

hardwire only

voltage drop

voltmeter

56

44

v

2

20

45

2

Loading...

Loading...