Whirlpool DU800DWG, DU801DWG, DU805DWG, DU810DWG, DP840DWG Manual

...

CONSUMER SERVICES TECHNICAL

EDUCATION GROUP PRESENTS

1998 DISHWASHERS

Servicing and Troubleshooting

MODELS

DU800DWG DU801DWG DU805DWG

DU810DWG DP840DWG DU840DWG

KD-10

DU850DWG DU890DWG DU910PFG

DP920PFG DU920PFG GU940SCG

GU960SCG GU980SCG

JOB AID

Part No. 4322430

I

INTRODUCTION

This Job Aid,

specific information for the installation, service and repair of 1998 Whirlpool Dishwashers.

“1998 DISHWASHERS, Servicing and Troubleshooting

cent information on design, features, troubleshooting, service and repair procedures.

“1998 DISHWASHERS, Servicing and Troubleshooting

,” has been compiled to provide the most re-

,” (Part No. 4322430) provides

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair the 1998 lineup of Dishwashers.

The objectives of the Job Aid are:

The service technician will -

• Understand proper safety precautions.

• Successfully troubleshoot and diagnose malfunction.

• Successfully perform necessary repairs.

• Successfully return the dishwasher to proper operational status.

CORPORATION

WHIRLPOOL CORPORATION ASSUMES NO RESPONSIBILITY

FOR ANY REPAIRS MADE ON OUR PRODUCTS BY ANYONE

OTHER THAN AUTHORIZED SERVICE TECHNICIANS.

© 1998 Whirlpool Corporation, Benton Harbor, MI 49022

II

TABLE OF CONTENTS

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II

T ABLE OF CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . III

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IV

SECTION ONE

DURA WASH MODELS W/ SOIL SETTLER AND TELESCOPING TOWER

Model: DU800DWG, DU801DWG, DU805DWG, DU810DWG, DP840DWG,

DU840DWG, DU850DWG, DU890DWG

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Component Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Solutions to Common Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

T echnical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

SECTION TWO

POWER CLEAN FIL TER MODELS W/ TOWER W ATER FEED

Models: DU910PFG, DP920PFG, DU920PFG

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Component Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

T echnical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

SECTION THREE

POWER CLEAN FILTER MODELS W/ INTERNAL W ATER FEED

Models: GU940SCG, GU960SCG, GU980SCG

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Component Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

T echnical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

SECTION FOUR

Installation Considerations

Custom Door Panel Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Floor Mount Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

This Service Manual is accompanied by a companion video presentation,

SERVICING AND TROUBLESHOOTING

1998 DISHWSHERS

Part No. 4322329

III

-- NOTES --

IV

DURAWASH MODELS WITH

SOIL SETTLER AND TELESCOPING TOWER

THEORY OF OPERATION

Console Configuration

DU800DWG, DU801DWG, DU805

DU810DWG

Section One

DU840DWG, DP840DWG

DU850DWG

DU890DWG

1

Special Feature

Soil Settler

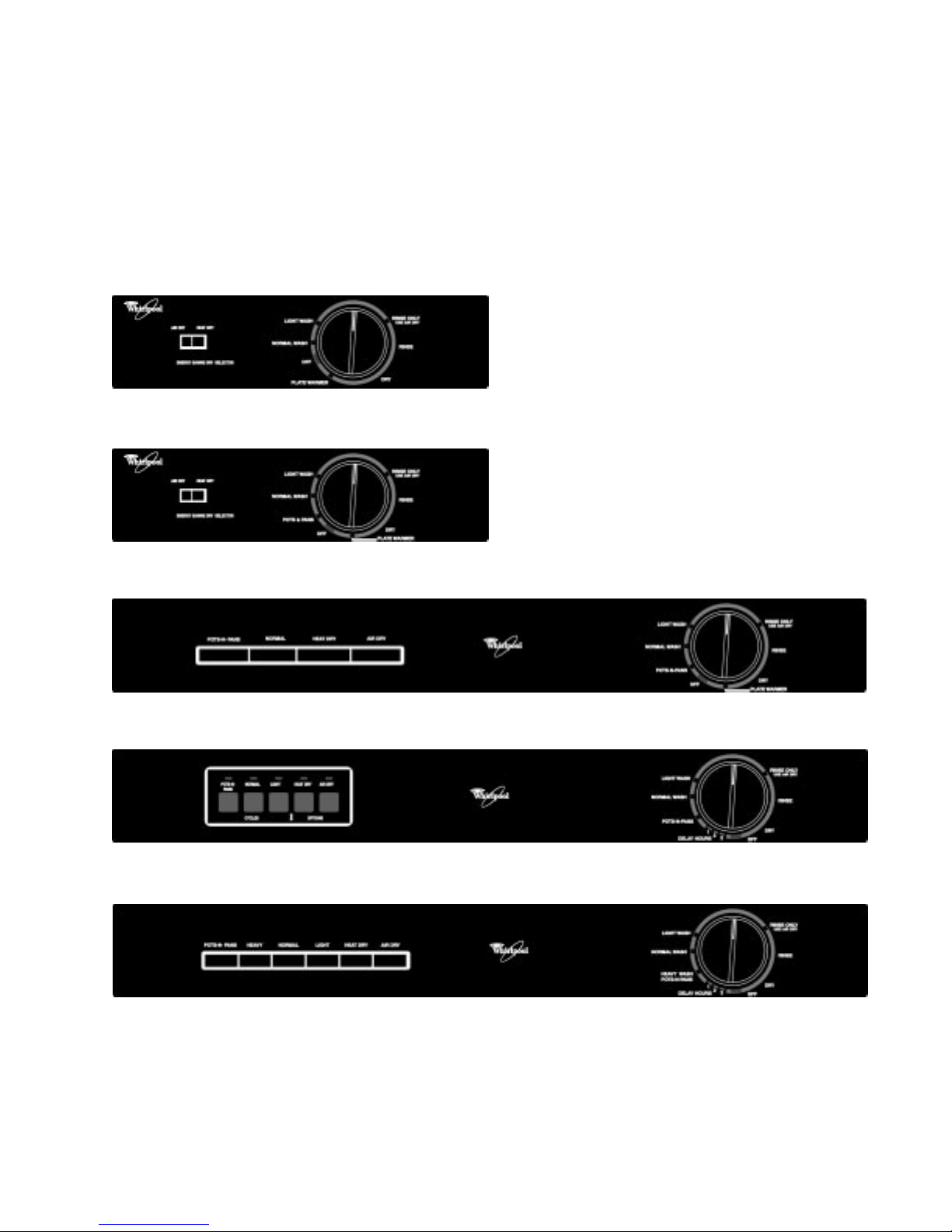

This model is equipped with a soil settler system. The inlet to the soil settler funnel is located to the

right and just behind the lower spray arm assembly.

Since this inlet is located in an area that is relatively free of water turbulence, food particles washed

from the dishes can collect in this area and fall through the funnel and accumulate in the collector .

1-2)

Food particles continue to collect as long as the dishwasher is in the Wash mode.

(Fig. 1-1)

Fig. 1-1

(Fig.

COLLECTOR

PUMP INLET

HOSE

Fig. 1-2

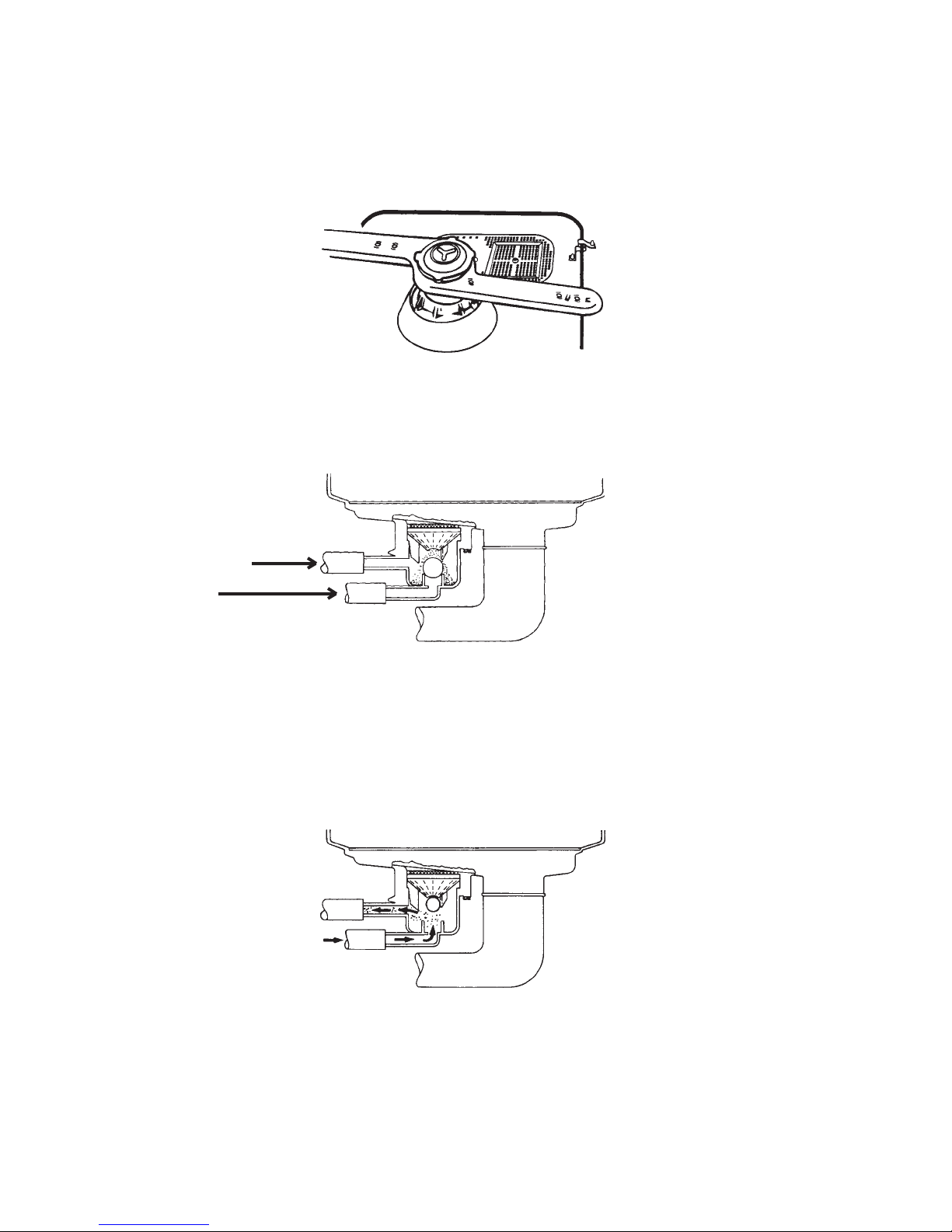

When the Wash cycle is finished, the dishwasher will reverse the direction of the motor and enter the

Drain mode. Water is pumped into the port at the bottom of the soil collector during the Drain cycle

causing the ball in the collector to rise against the opening in the bottom of the funnel. Water flows

through and out of the collector through the top port and into the drain line.

(Fig. 1-3)

Food particles

collected during the Wash cycle are carried out with the drain water. When the Drain cycle ends and

the pump stops running, the ball settles to the bottom of the collector.

Fig. 1-3

2

COMPONENT ACCESS

! WARNING

ELECTRICAL SHOCK HAZARD

Disconnect electric supply from the dishwasher before servicing.

Replace all panels before operating.

Failure to do so could result in death or electrical shock.

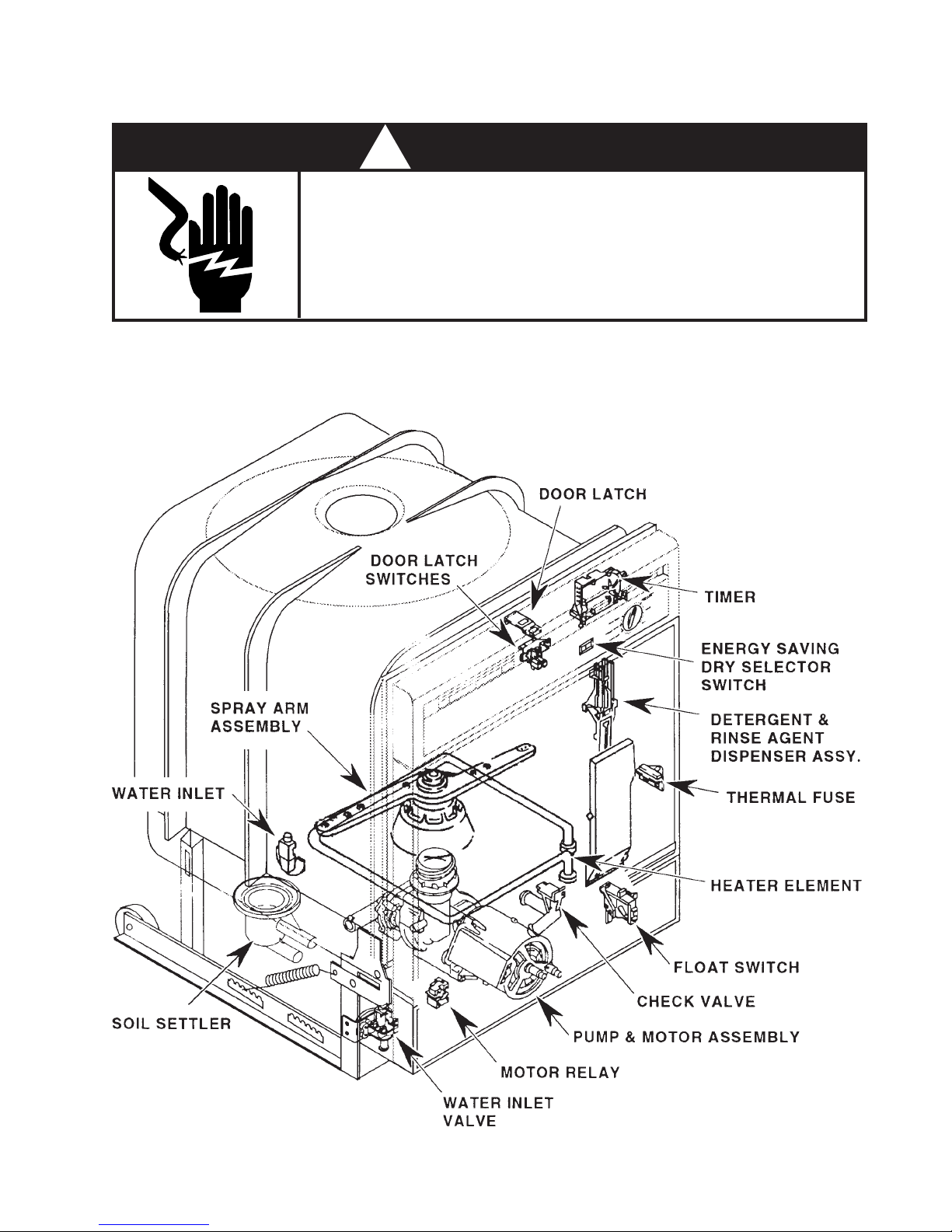

Component Location

(Bottom Right-side

Rear of Tub)

3

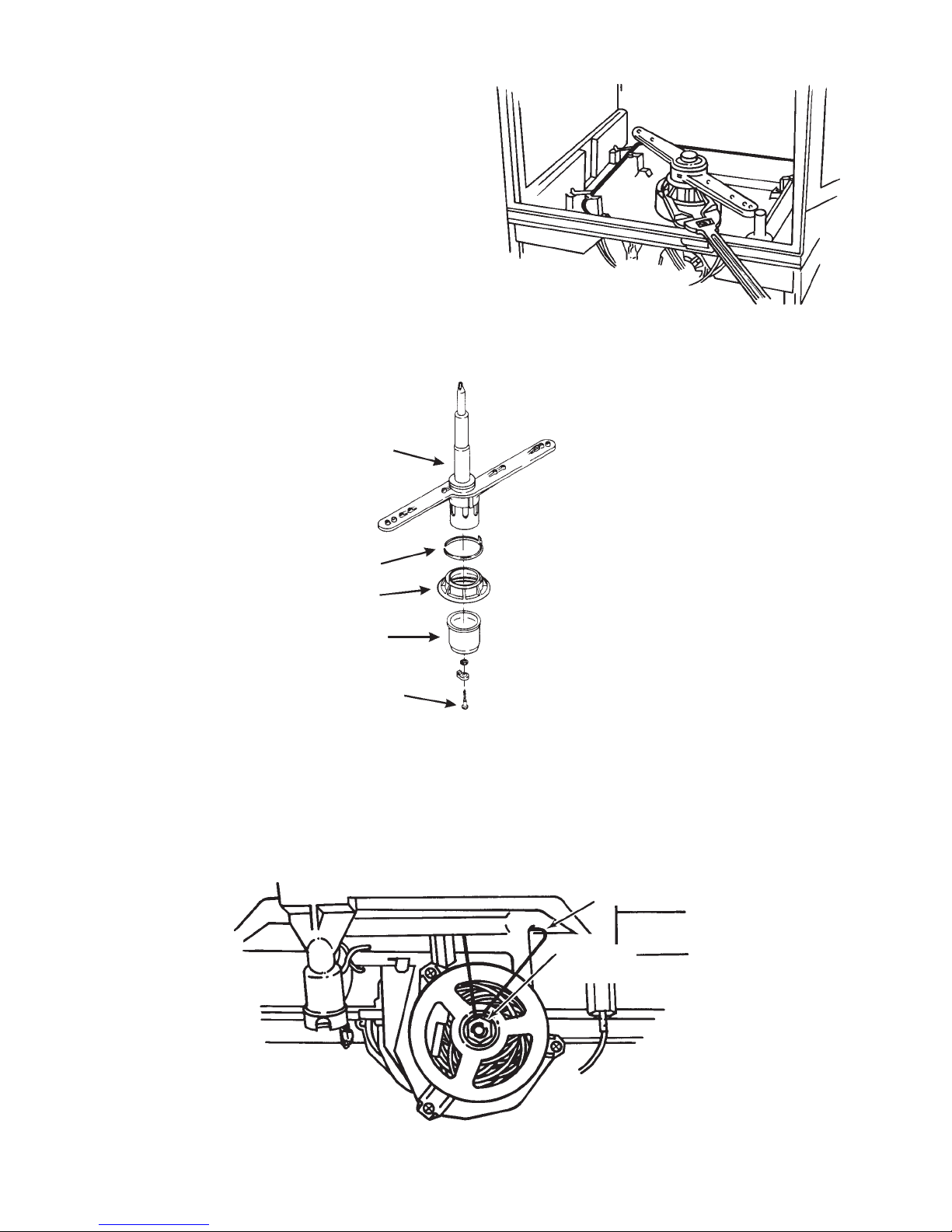

Removing the Spray Arm Assembly

1. Disconnect the dishwasher from the household electrical system.

2. Open the dishwasher door and remove the

lower rack.

3. Use an adjustable slip-nut wrench and loosen

the pump outlet nut. (Fig. 1-4)

4. Lift the spray arm assembly out of the pump fitting.

Fig. 1-4

5. The spray arm can be disassembled by removing

the retaining screw from the spray arm and removing the split-ring seal, the pump outlet nut

and the support and bearing assembly. (Fig. 1-5)

SPRA Y ARM ASSEMBLY

SPLIT RING SEAL

PUMP OUTLET NUT

SUPPORT & BEARING

RET AINING SCREW

Fig. 1-5

Removing the Pump and Motor Assembly

1. Disconnect the dishwasher from the household electrical system.

2. Lay the dishwasher on its back and disconnect the wiring harness connector from the motor.

3. Remove the motor support slip nut and remove the motor support.

MOTOR SUPPORT

SUPPORT

SPLIT NUT

Fig. 1-6

4

(Fig. 1-6)

4. Disconnect the drain hose from the drain valve by loosening the Hex-head screw on the hose

clamp. (Fig. 1-7)

5. Disconnect the pump inlet hose from the pump and motor assembly. (Fig. 1-7)

6. Remove the pump and motor assembly from the bottom of the dishwasher.

NOTE:Once the pump and mo-

tor assembly has been

PUMP INLET

HOSE

DRAIN

HOSE

removed from the tub,

the pump outlet grommet can be removed

from the inside of the

tub. Check the pump

outlet grommet for wear

or damage and replace

it if necessary.

Fig. 1-7

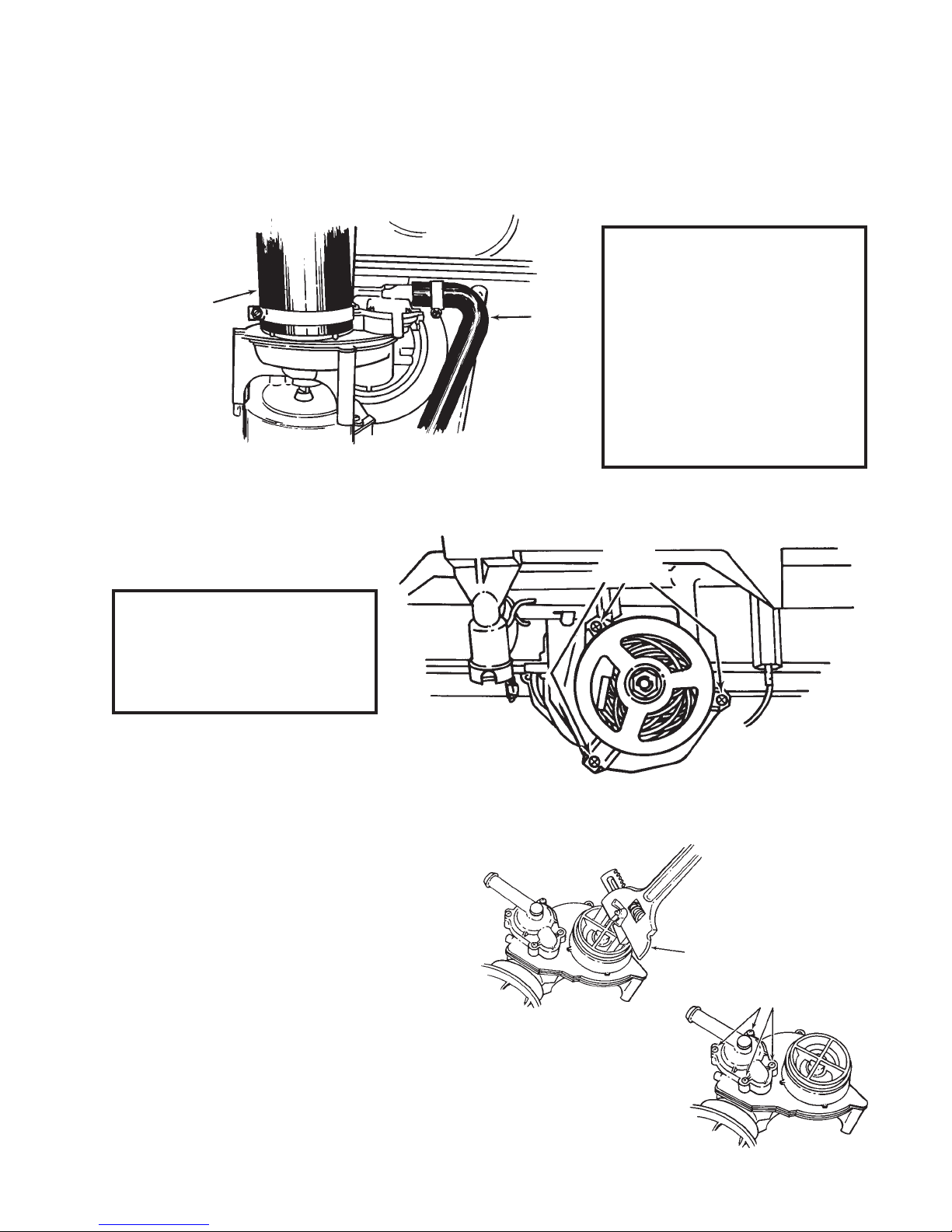

The motor can be removed from the pump assembly by removing the three T-20 Torx screws securing

the motor to the pump assembly.

(Fig. 1-8)

NOTE:When reinstalling the

motor make sure the

keyed motor shaft lines

up with the pump impeller.

Servicing the Pump Assembly

The pump impeller can be accessed by using

an adjustable slip-nut wrench to turn the

disk mount assembly counterclockwise.

Once the disk mount assembly is removed,

the impeller can be removed.

(Fig. 1-9)

SCREWS

Fig. 1-8

Fig. 1-9

TORX

SLIP-NUT WRENCH

TORX

SCREWS

The drain valve can be accessed by removing

the four (4) T-20 Torx screws securing the drain

outlet cover to the pump assembly. The drain

cover seal, diaphragm and diaphragm ring can

be removed and replaced.

(Fig. 1-10)

Fig. 1-10

5

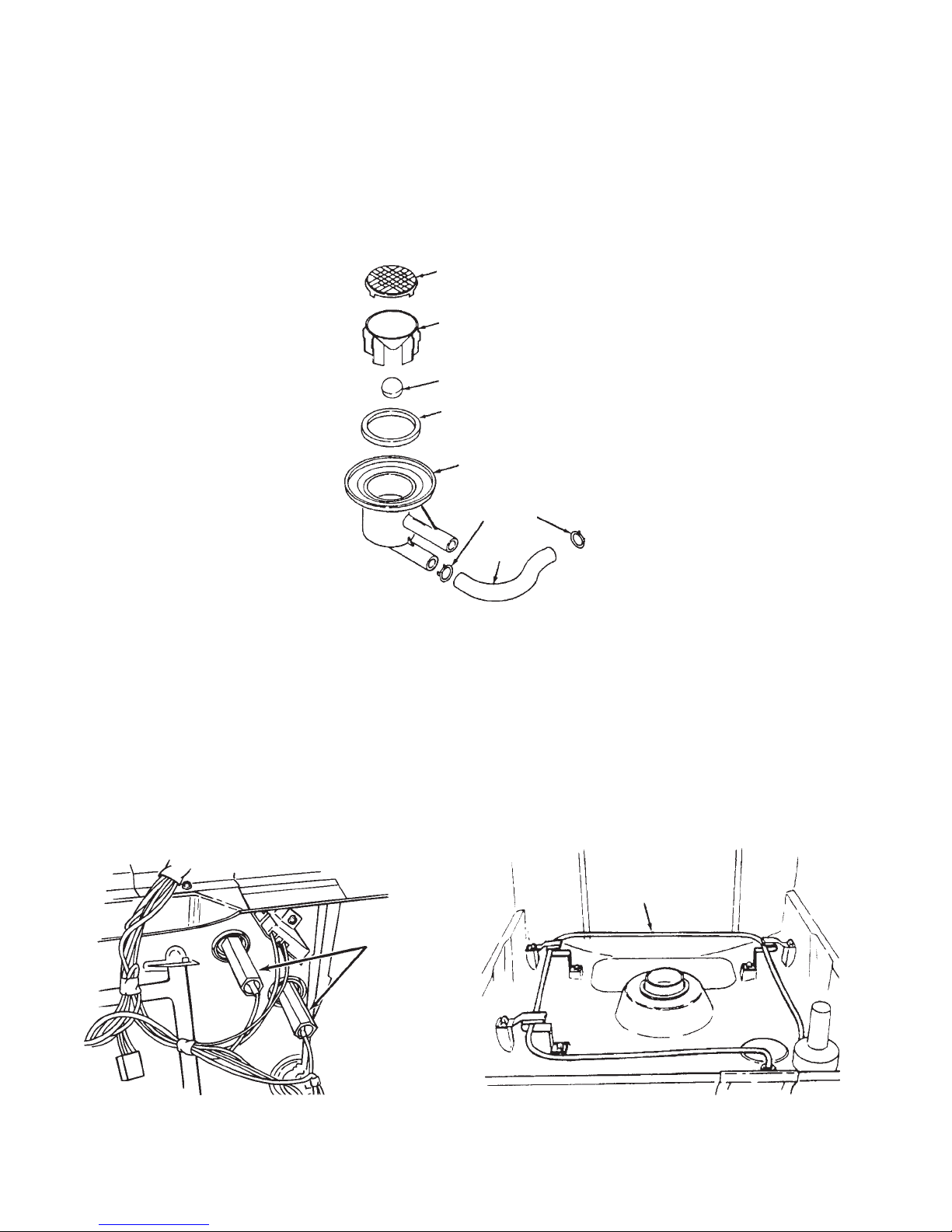

Removing the Soil Settler Assembly

1. Disconnect the dishwasher from the household electrical system and lay the unit on its back.

2. Remove the four (4) Hex-head screws securing the soil settler assembly to the tub.

3. Disconnect the two (2) hoses from the soil settler collector.

4. Remove the funnel and funnel grate, check valve ball and seal from the soil settler collector.

(Fig. 1-11)

FUNNEL GRA TE

FUNNEL

CHECK VAL VE BALL

SEAL

CLAMPS

HOSE

Fig. 1-11

Removing the Heater Element

1. Disconnect the dishwasher from the household electrical system.

2. Disconnect the wiring harness connectors from the heater element terminals with a pair of

needlenose pliers.

3. Remove the two long Hex-head nuts securing the heater element to the tub.

4. Remove the heater element from the three (3) metal clips that hold it suspended inside the tub.

(Fig. 1-13)

HEATER

ELEMENT

HEA TER

ELEMENT

RET AINING

NUTS

(Fig. 1-12)

Fig. 1-12 Fig. 1-13

6

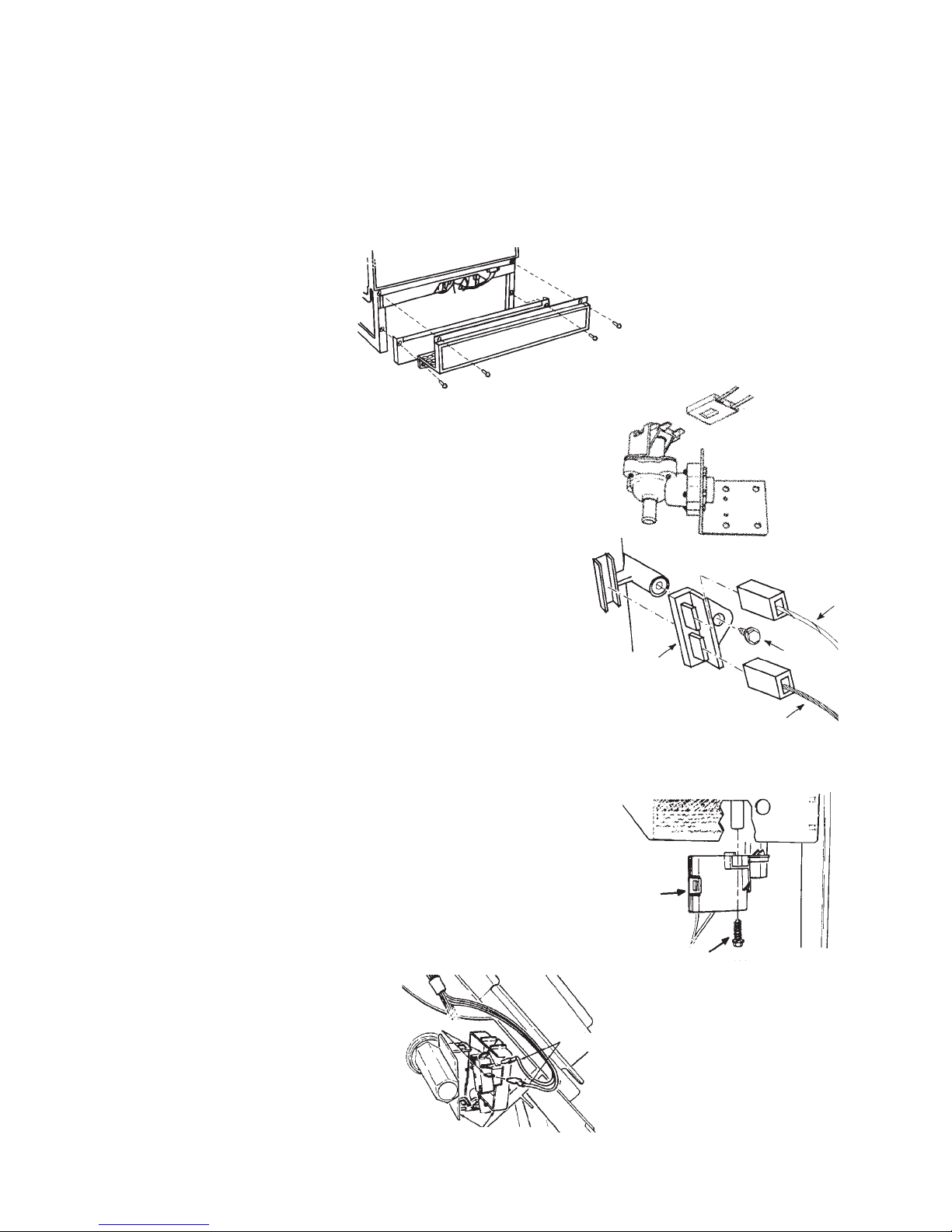

Removing the Water Inlet Valve

1. Turn off the water supply to the dishwasher.

2. Turn the timer knob clockwise to the NORMAL WASH position to energize the water inlet valve

and relieve water pressure in the line.

3. Turn the electrical supply to the dishwasher off and remove the toe panel and access panel.

(Fig. 1-14)

Fig. 1-14

4. Disconnect the wiring harness connector from the

water inlet valve terminals.

(Fig. 1-15)

5. Disconnect the water lines from the water inlet valve.

6. Remove the Hex-head screw securing the water inlet

valve to the tub support assembly.

Removing the Thermal Fuse

1. Turn the electrical supply to the dishwasher off and

remove the toe panel and access panel.

2. Disconnect the orange and white wires from the thermal

fuse terminals.

(Fig. 1-16)

3. Remove the Hex-head screw securing the thermal fuse

to the tub and remove the thermal fuse from the dishwasher.

Removing the Float Switch

1. Turn the electrical supply to the dishwasher off and

remove the toe panel and access panel.

2. Remove the Hex-head screw securing the float switch

to the tub.

3. Lift the float from the housing inside the tub.

4. Unsnap the float switch housing cover and disconnect

the two (2) wires from the terminals of the switch.

(Fig. 1-18)

(Fig. 1-17)

THERMAL

FUSE

FLOAT

SWITCH

HOUSING

RETAINING

SCREW

Fig. 1-15

Fig. 1-16

WHITE

WIRE

RET AINING

SCREW

ORANGE

WIRE

Fig. 1-17

Fig. 1-18

TERMINALS

WIRES

SWITCH COVER

7

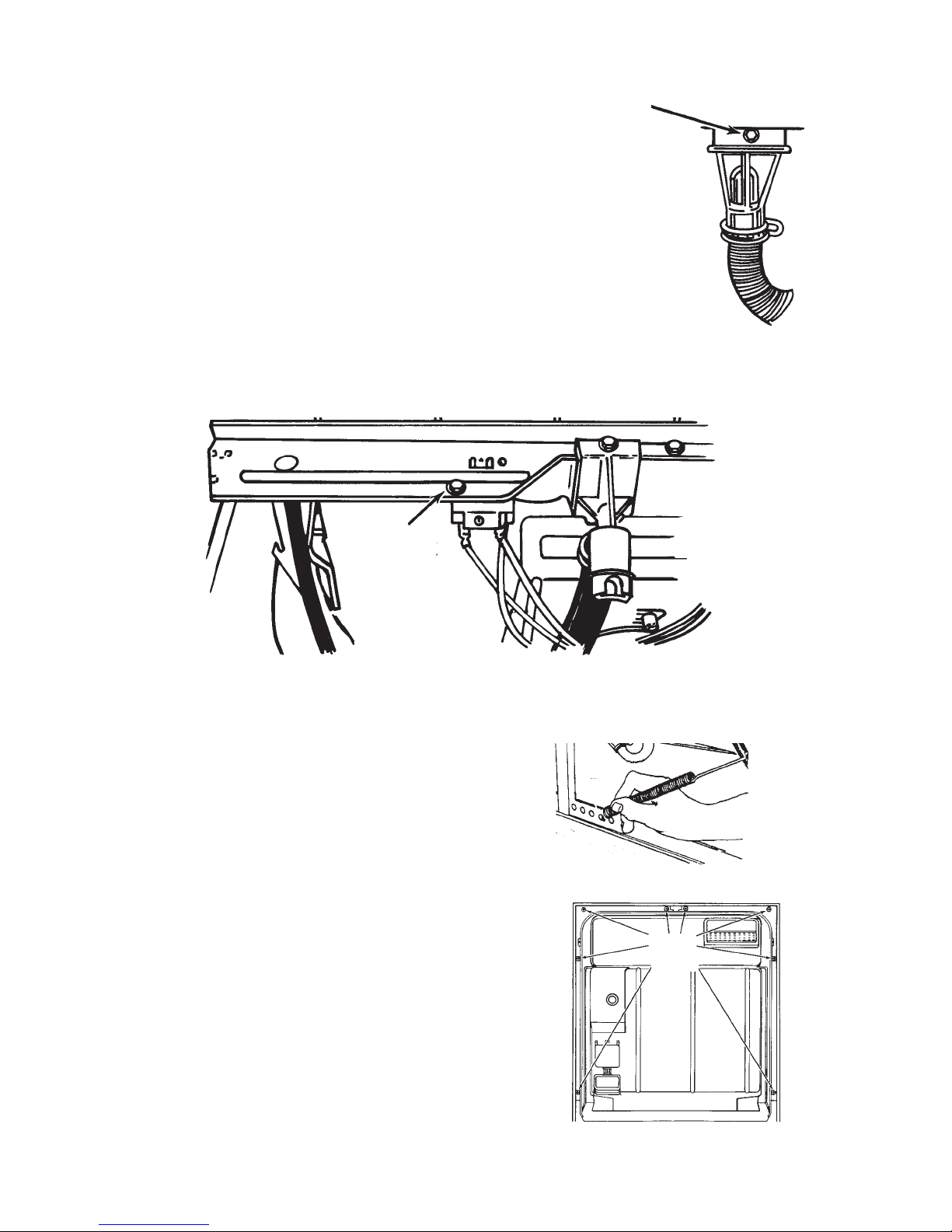

Removing the Check V alve

1. Remove the toe panel and access panel from the

bottom of the dishwasher.

RETAINING

SCREW

2. Remove the hoses from the check valve.

Fig. 1-19

3. Remove the Hex-head screw securing the check valve to

the tub support.

(Fig. 1-19)

Removing the Motor Relay

1. Disconnect the dishwasher from the electrical supply and remove

the toe panel and access panel from the bottom of the dishwasher.

2. Disconnect the three (3) wiring harness connectors from the motor relay terminals.

3. Remove the Hex-head screw securing the motor relay to the tub support.

RET AINING

SCREW

(Fig. 1-20)

Accessing Components Inside the Door

1. Disconnect the dishwasher from the electrical

supply and remove the toe panel and access

panel from the bottom of the dishwasher.

2. Disconnect the end of the door springs

from the door spring tension adjustment

holes in the frame runner. Note which

holes were used and reattach the door

springs in the same holes when the repairs

are complete.

3. Open the dishwasher door and remove the

eight (8) T-15 Torx screws securing the inner

door panel from the door frame.

4. Remove the timer cover by releasing the

two (2) retaining tabs at each end from the

door frame.

(Fig. 1-21)

(Fig. 1-22)

Fig. 1-20

Fig. 1-21

T-15

TORX

Fig. 1-22

8

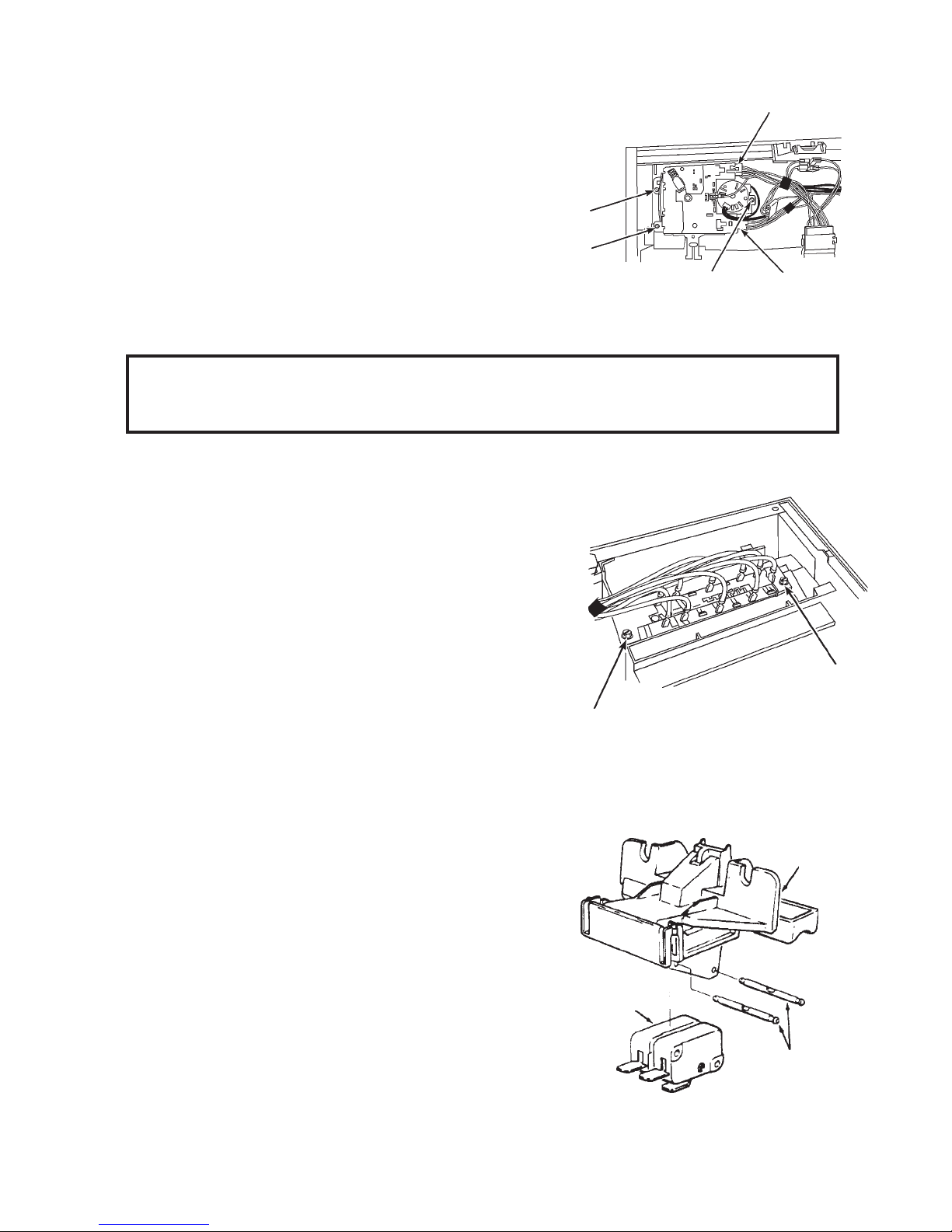

Removing the Timer

1. Disconnect the dishwasher from the electrical

supply and remove the toe panel and access

panel from the bottom of the dishwasher and

the inner door panel.

Screw

2. Disconnect the wiring harness connectors from

the timer terminals.

(Fig. 1-23)

3. Remove the three (3) Hex-head screws securing

the timer to the door frame.

(Fig. 1-23)

The timer,

Screw

Screw

Fig. 1-23

cam and cam follower can now be removed.

NOTE:When reinstalling the cam, be sure it is aligned with the keyed shaft of the timer.

When reinstalling the timer, be sure the cam follower post is positioned inside the

cam’s groove.

Removing the Switch Assembly

1. Disconnect the dishwasher from the electrical

supply and remove the toe panel and access

panel from the bottom of the dishwasher and

the inner door panel.

Wiring Harness

Connector

Wiring

Harness

Connector

2. Disconnect the harness wires from the spade

connectors on the switch assembly.

(Fig. 1-24)

3 . Remove the two (2) Hex-head screws securing

the switch assembly to the door frame.

The switch assembly can now be removed.

(Fig. 1-24)

Screw

Fig. 1-24

Removing the Door Latch Switches

1. Disconnect the dishwasher from the electrical supply and remove the toe panel and access

panel from the bottom of the dishwasher and the inner door panel.

2. Disconnect the wiring harness connectors from

the door latch switch terminals.

3. Unclip the handle and latch assembly from the

door frame.

4. To remove the switches from the handle and latch

assembly, push the two (2) retaining pins out of the

holes and remove the switches.

SWITCHES

(Fig. 1-25)

HANDLE &

ASSEMBLY

Screw

LATCH

RETAINING

PINS

Fig. 1-25

9

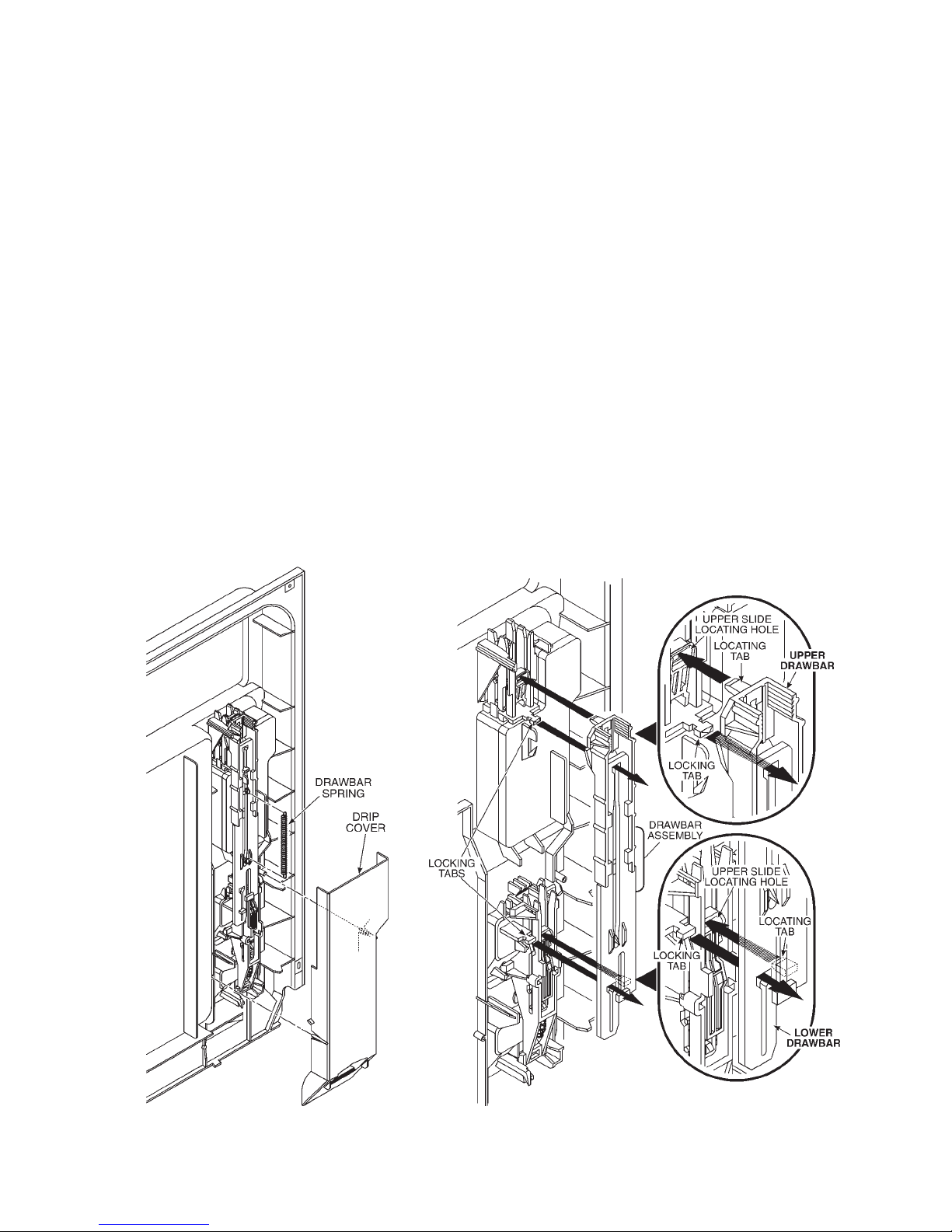

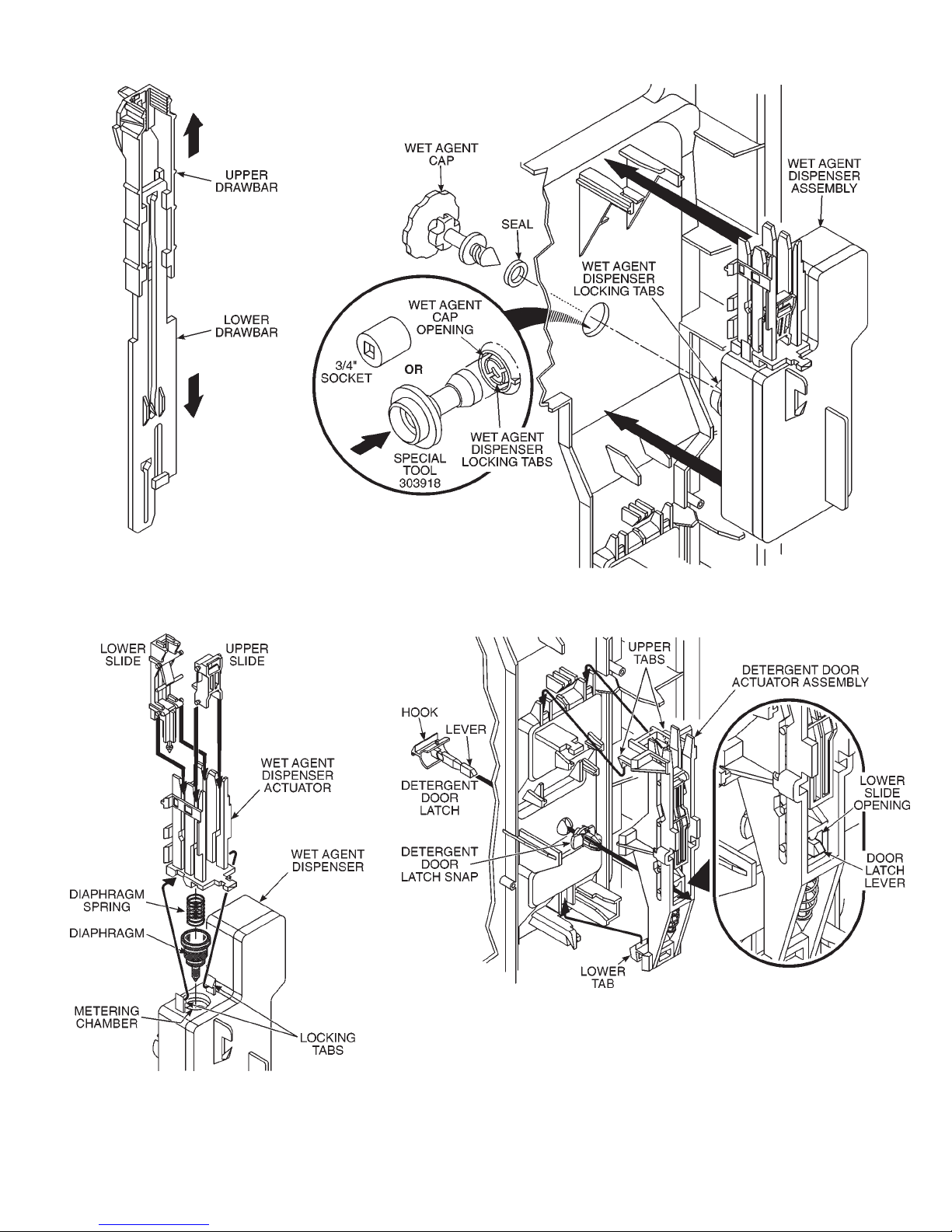

Dishwasher Dispenser Disassembly

1. Remove the drawbar spring.

(Fig. 1-26)

2. Align the lower drawbar holes with the locking tabs and remove the upper and lower drawbars.

As you do, note the locating tabs behind them and how they align with their respective locating

holes.

3. Slide the drawbars apart.

4. Turn the wet agent cap and seal assembly counterclockwise and remove it.

(Fig. 1-27)

(Fig. 1-28)

(Fig. 1-29)

5. Remove the seal from the cap.

6. Use Special Tool - Part No. 303918 or a ¾” socket to press over the attaching tabs

in the wet agent cap opening. Remove wet agent dispenser assembly.

7. Remove wet agent dispenser actuator by spreading the two (2) locking tabs.

(Fig. 1-30)

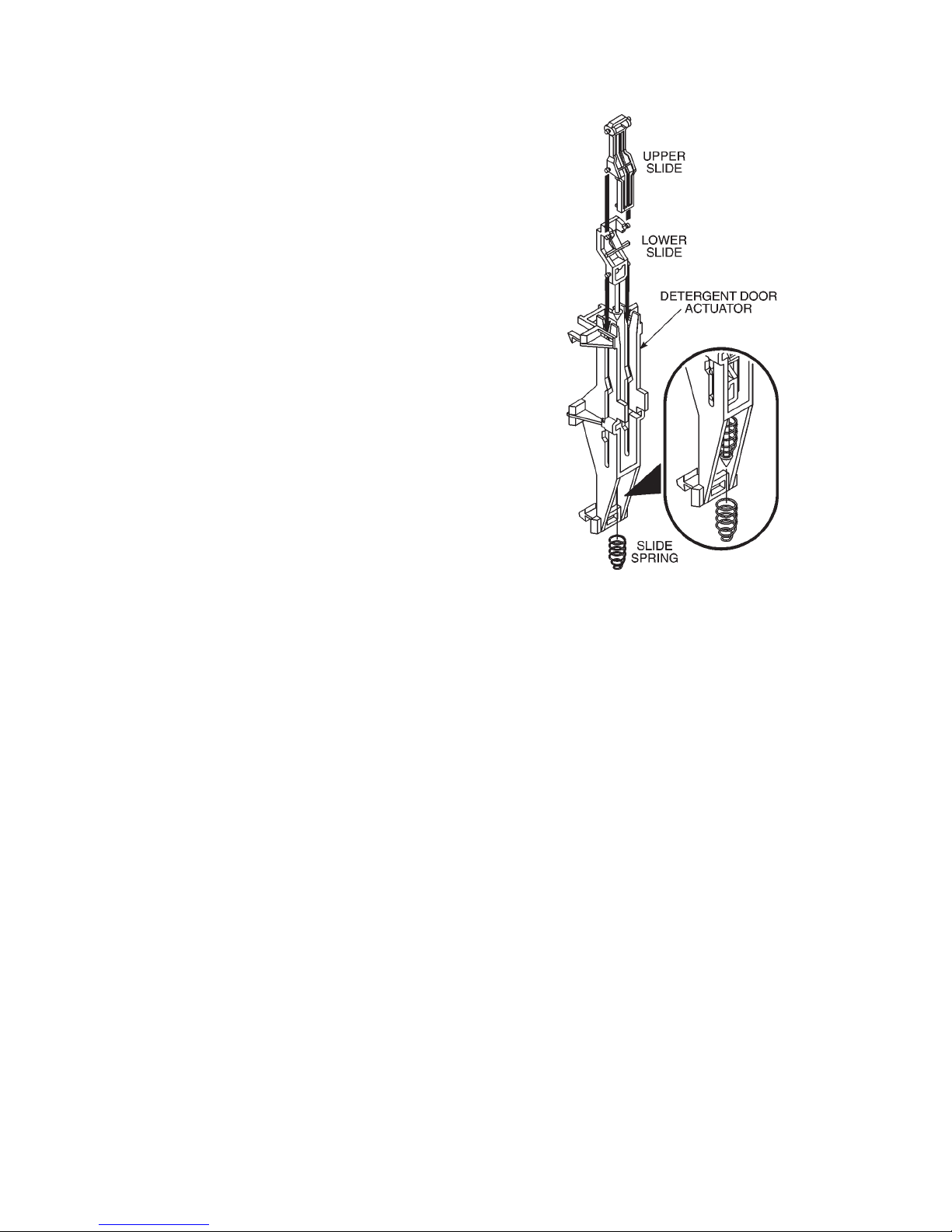

8. Remove the upper and lower slides from the wet agent dispenser actuator.

9. Remove the diaphragm spring and diaphragm.

10. Use a screwdriver to gently release the lower tab and remove the detergent door

actuator assembly. As you do, note the position of the door latch level through the hole in the

lower slide.

11. Remove the upper slide, the slide spring and the lower slide.

(Fig. 1-31)

(Fig. 1-32)

Fig. 1-26 Fig. 1-27

10

Fig. 1-28

Fig. 1-29

Fig. 1-30

Fig. 1-31

11

Dishwasher Dispenser Assembly

1. Assembly the upper slide, slide spring

and lower slide to the detergent

door actuator.

2. Pass the detergent door latch lever

through the panel making sure to turn the

hook of the latch toward the detergent

door. Snap the detergent door latch snap

onto the door latch lever.

3. The door latch lever must pass through

the opening in the lower slide. Press the

actuator assembly into position until the

upper and lower tabs engage.

4. Insert the diaphragm and diaphragm

spring into the wet agent dispenser . Seat

the diaphragm flush with the surface of

the dispenser.

5. Install the upper and lower slides into the

wet agent dispenser actuator.

6. Press the wet agent dispenser actuator

into position on the dispenser so the locking tabs engage.

(Fig. 1-32)

(Fig. 1-31)

(Fig. 1-30)

Fig. 1-32

7. Press the wet agent dispenser assembly

into position so the locking tabs engage

the wet agent cap opening. No tool is

needed for assembly.

(Fig. 1-29)

8. Install the seal on the wet agent cap.

9. Insert the wet agent cap. Turn it clockwise and close it.

10. Slide the upper and lower drawbars

together.

(Fig. 1-28)

11. Move all slides in both assemblies fully

down. Keep the drawbars slid fully together and align the drawbar holes over

the locking tabs. Look behind the draw

bars and make sure to engage the locating tabs with their respective locating

holes. Press the drawbars into position

and slide them upward behind the locking

tab ears.

12. Install the drawbar spring.

(Fig. 1-27)

(Fig. 1-26)

13. Install the drip cover by snapping it into

place.

12

SOLUTIONS TO COMMON PROBLEMS

DIAGNOSING PROBLEM COMPONENTS

PRECAUTIONS TO BE OBSERVED WHILE DIAGNOSING

PROBLEM COMPONENTS

Disconnect electric power from the dishwasher.

Voltage checks should be made by inserting meter probes beside the wires in the connector blocks with the electric power source on

and the connector block plugged in.

Resistance checks should be made on components with the electric power off and the connector blocks disconnected.

COMPONENT SCHEMATI C TESTING PROCEDURE RESULTS

Motor Start Relay

1. Disconnect the wire connectors and

remove relay from unit.

2. Set VOM meter on the Rx1 scale.

3. Set the relay upright.

4. Measure resistance between blue and

violet contacts.

5. Turn relay upside-down.

6. Measure resistance between blue and

violet contacts.

1. Relay upright - meter should read

º (infinity.)

2. Relay upside-down - meter should

read less than two (2)Ω.

Drive Motor

Thermal Fuse

Heater Element

Fill Valve

1. Disconnect the motor wiring harness

plug from the motor connector.

2. Set VOM meter on the Rx1 scale.

3. Connect one probe to the white/violet

connector.

4. Connect the other probe to the blue/

white connector.

5. Connect the meter probe to the yellow

connector.

6. Connect the probe to the grey

connector.

1. Disconnect wires connectors from the

thermal fuse terminals.

2. Set VOM meter to read Rx1 scale.

3. Measure resistance between thermal

fuse terminals.

1. Disconnect the wire connectors from

the heater element terminals.

2. Set VOM meter to read Rx1 scale.

3. Measure resistance between heater

element terminals.

1. Disconnect the wiring harness plug

from the fill valve connector.

2. Set VOM meter to read Rx1 scale.

3. Measure resistance between the

terminals of the fill valve.

1. White/violet to blue/white - meter

should read 5 - 7Ω.

2. White/violet to yellow - meter

should read 5 - 7Ω.

3. White/violet to gray - meter

should read 5 - 7Ω.

1. Meter should read 0Ω.

1. Meter should read 25 - 35Ω.

1. Meter should read approximately

700Ω.

Overfill Switch

1. Disconnect the wires connectors from

the overfill switch terminals.

2. Set VOM meter to read Rx1 scale.

3. Measure resistance between switch

terminals.

4. Block the float in the UP (full) position

and measure resistance again.

13

1. Float DOWN - meter should read

0Ω.

2. Float UP - meter should read

º (infinity).

COMPONENT SCHEMATIC TESTING PROCEDURE RESULTS

Timer Motor

1. Disconnect the Wiring harness

connector from the timer assembly.

2. Set VOM meter on the Rx1 scale.

3. Measure resistance between timer

motor terminals.

1. Meter should read 1800 - 3000Ω.

Timer

Dispenser Mechanism

1. Disconnect the wiring harness

connector from the timer assembly.

2. Set VOM meter on the Rx1 scale.

3. Connect one probe to contact 31.

(Tan)

4. Connect the other probe to the timer

contact to be tested.

5. Manually advance the timer until the

contact closes.

6. Manually advance the timer until the

contact opens.

1. Remove the front door panel.

2. Remove the drip cover.

3. Latch the detergent door closed.

4. Manually advance the timer through a

complete cycle slowly.

1. Contact CLOSED - meter should

read 0Ω.

2. Contact OPEN - meter should

read º (infinity).

1. At 12 o’clock position - Draw bars

will move upward causing the

detergent actuator assembly to

release the latch and detergent

cup should open.

2. At 4 o’clock position - Draw bars

will again move upward causing

the wetting agent actuator to

release wetting agent.

3. From the 6 o’clock position to the

8 o’clock position the draw bars

are driven down to reset the

mechanism.

14

TROUBLESHOOTING GUIDE

PRECAUTIONS TO BE OBSER VED WHILE TROUBLESHOOTING

AND DIAGNOSING PROBLEMS

Always check wiring harness and connectors before initiating any test procedures.

Disconnect electric power from the dishwasher before touching the printed circuit boards or re-seating wire connectors.

Voltage checks should be made by inserting meter probes beside the wires in the connector blocks with the electric power source on

and the connector block plugged in.

Resistance checks should be made on components with the electric power off and the connector blocks disconnected.

PROBLEM POSSIBLE CAUSES CORRECTION/TEST

Dishwasher does not run or

stops during a cycle

Dishwasher will not fill

Dishwasher will not drain

1. Door is not latching properly.

2. Child lock is "ON".

3. Wash Cycle not set properly.

4. Household fuse blown or circuit

breaker tripped.

5. Washer is not wired into a circuit with

proper voltage.

1. Overflow protection float is stuck in

"up" position.

2. Fill valve is inoperable.

3. Open timer contacts.

1. Air gap (if installed) is clogged.

2. Pump motor is inoperable.

3. Open timer contacts.

1. Check to make sure handle link

is properly seated in door latch

assembly. Check that the door

switch is opening and closing

properly.

2. Turn child lock "OFF"

3. Review setting Wash Cycles in

the Use and Care Guide.

4. Have a qualified electrician check

the circuit breaker or fuse.

5. Have customer call a qualified

electrician.

1. Check that the overflow

protection float is free to move

"up" and "down". Check that the

overfill switch in opening and

closing properly.

2. Check for continuity between

contacts on fill valve.

3. Test timer contacts.

1. Follow air gap manufacturer's

direction for cleaning.

2. Disconnect pump motor from

wiring harness and check for

continuity.

3. Test timer contacts.

Dishwasher will not

dry dishes

1. Heater element burned out.

2. Hi-limit thermostat inoperable.

3. Open circuit between timer and

heater.

15

1. Check for continuity between the

terminals of the heater element.

2. Check for continuity between

terminals of the hi-limit

thermostat.

3. Check for continuity between

timer switch contacts and heater.

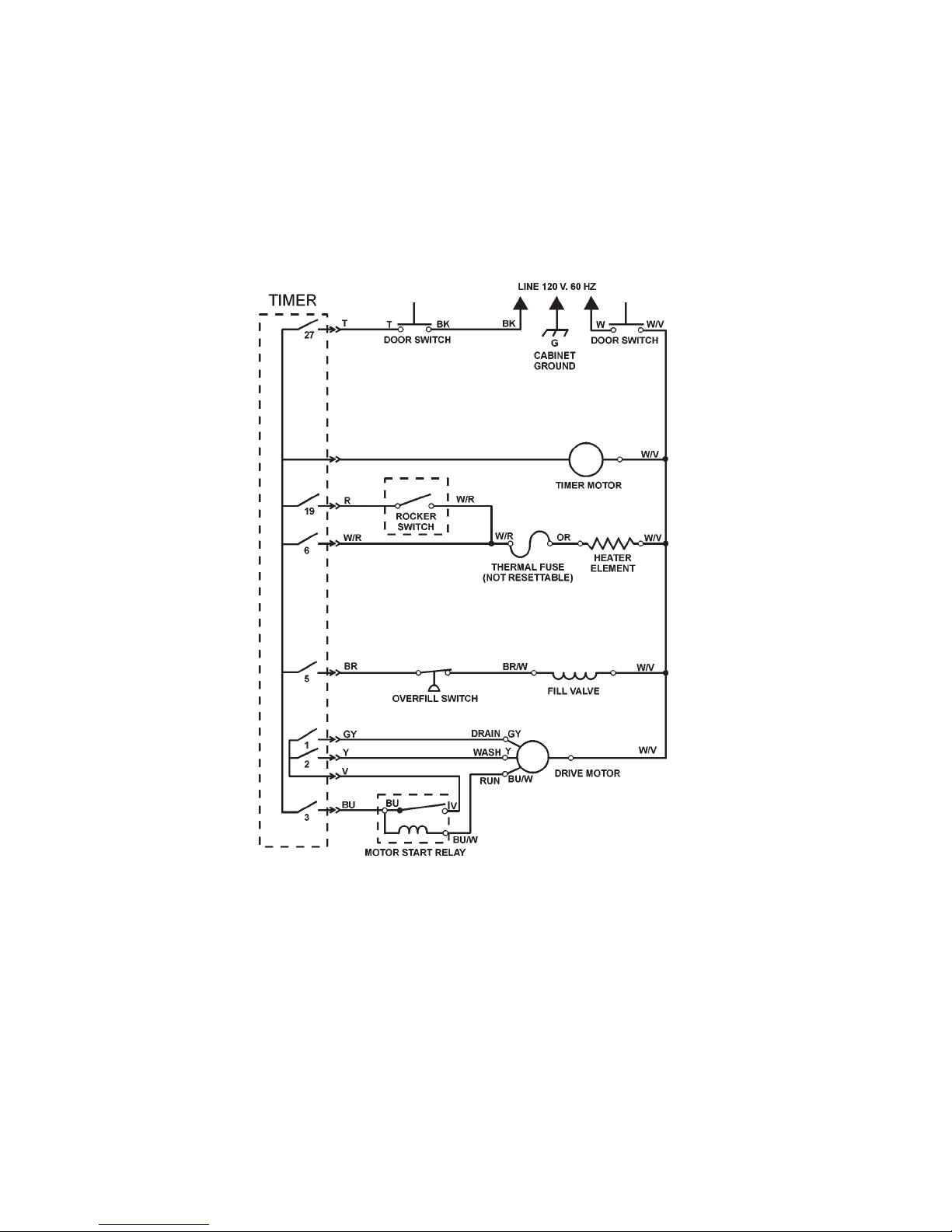

Wiring Diagram

Models DU800DWG, DU801DWG, DU805DWG

TECHNICAL INFORMA TION

SCHEMATIC SHOWN WITH DOOR SWITCHES CLOSED,

ALL CONT ACTS OPEN

16

Loading...

Loading...