Whirlpool APARTMENT MAINTENANCE SERIES, 24” THIN TWIN, 27” THIN TWIN Service Manual

CONSUMER SERVICES TECHNICAL

EDUCATION GROUP PRESENTS

APARTMENT MAINTENANCE SERIES

LAUNDRY

PRODUCTS

AM-5

JOB AID

Part No. 4322616

I

INTRODUCTION

This Job Aid,

specific information for the installation, service and repair of Whirlpool Laundry products.

“AM-5, Apartment Maintenance Series- Laundry Products,”

recent information on design, features, troubleshooting, service and repair procedures.

“AM-5, Apartment Maintenance Series- Laundry Products,”

has been compiled to provide the most

(Part No. 4322616) provides

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair Whirlpool Laundry Products.

The objectives of the Job Aid are:

The service technician will -

• Understand proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the laundry product to proper operational status.

CORPORATION

WHIRLPOOL CORPORATION ASSUMES NO RESPONSIBILITY

FOR ANY REPAIRS MADE ON OUR PRODUCTS BY ANYONE

OTHER THAN AUTHORIZED SERVICE TECHNICIANS.

© 1999 Whirlpool Corporation, Benton Harbor, MI 49022

II

TABLE OF CONTENTS

INTRODUCTION .................................................................................. II

TABLE OF CONTENTS...................................................................... III

SAFETY ............................................................................................ VIII

SECTION ONE - DIRECT DRIVE WASHER

Part A

INSTALLATION CONSIDERATIONS .......................................2

Part B

THEORY OF OPERATIONTHEORY OF OPERATION

THEORY OF OPERATION

THEORY OF OPERATIONTHEORY OF OPERATION

Fill.................................................................................................................... 5

Agitation........................................................................................................... 8

Drain.............................................................................................................. 10

Spin ............................................................................................................... 12

............................................................................................................

......................................................

............................................................................................................

55

5

55

Part C

COMPONENT ACCESSCOMPONENT ACCESS

COMPONENT ACCESS

COMPONENT ACCESSCOMPONENT ACCESS

Component Location...................................................................................... 15

Accessing Component in the Console............................................................ 16

Accessing Component inside the Washer Cabinet......................................... 19

....................................................................................................................................

..................................................................

....................................................................................................................................

1515

15

1515

Part D

DIAGNOSIS AND TROUBLESHOOTINGDIAGNOSIS AND TROUBLESHOOTING

DIAGNOSIS AND TROUBLESHOOTING

DIAGNOSIS AND TROUBLESHOOTINGDIAGNOSIS AND TROUBLESHOOTING

Diagnosis and Troubleshooting Chart............................................................ 25

Component T esting........................................................................................ 27

Wiring Diagram .............................................................................................. 32

Cycle Chart.................................................................................................... 33

Model/Serial Number Designators ................................................................. 34

Reshipping Kit and Instructions........................................................................35

............................................................

..............................

............................................................

2525

25

2525

III

SECTION TWO - 22” COMPACT WASHER

Part A

THEORY OF OPERATIONTHEORY OF OPERATION

THEORY OF OPERATION

THEORY OF OPERATIONTHEORY OF OPERATION

General Information ....................................................................................... 39

Cycle Functions ............................................................................................. 42

........................................................................................................

....................................................

........................................................................................................

3939

39

3939

Part B

COMPONENT ACCESSCOMPONENT ACCESS

COMPONENT ACCESS

COMPONENT ACCESSCOMPONENT ACCESS

Washer T op Components .............................................................................. 45

Cabinet Components ..................................................................................... 49

....................................................................................................................................

..................................................................

....................................................................................................................................

4545

45

4545

Part C

TROUBLESHOOTING AND DIAGNOSISTROUBLESHOOTING AND DIAGNOSIS

TROUBLESHOOTING AND DIAGNOSIS

TROUBLESHOOTING AND DIAGNOSISTROUBLESHOOTING AND DIAGNOSIS

Troubleshooting Chart ................................................................................... 59

Diagnostic T est Program................................................................................ 61

............................................................

..............................

............................................................

5959

59

5959

Part D

TECH TIPSTECH TIPS

TECH TIPS

TECH TIPSTECH TIPS

Wiring Diagram .............................................................................................. 65

Control Sequence Chart ................................................................................ 66

Strip Circuits .................................................................................................. 67

....................................................................................................................................................

..........................................................................

....................................................................................................................................................

6565

65

6565

IV

SECTION THREE - 29” AND COMPACT

GAS AND ELECTRIC DRYERS

Part A

THEORY OF OPERATION ....................................................71

Part B

COMPONENT ACCESSCOMPONENT ACCESS

COMPONENT ACCESS

COMPONENT ACCESSCOMPONENT ACCESS

................................................................................................................

........................................................

................................................................................................................

7373

73

7373

V

SECTION FOUR - 27” GAS AND ELECTRIC

DRYERS

Part A

THEORY OF OPERATION .................................................... 81

Part B

COMPONENT ACCESSCOMPONENT ACCESS

COMPONENT ACCESS

COMPONENT ACCESSCOMPONENT ACCESS

................................................................................................................

........................................................

................................................................................................................

8585

85

8585

Part C

TROUBLESHOOTING AND DIAGNOSISTROUBLESHOOTING AND DIAGNOSIS

TROUBLESHOOTING AND DIAGNOSIS

TROUBLESHOOTING AND DIAGNOSISTROUBLESHOOTING AND DIAGNOSIS

Troubleshooting Guide .................................................................................. 95

“C” Version Electronic Dryer Control.............................................................. 96

..................................................................................

.........................................

..................................................................................

9595

95

9595

Part D

TECH TIPSTECH TIPS

TECH TIPS

TECH TIPSTECH TIPS

Wiring Diagram .............................................................................................. 97

Timer Schedule.............................................................................................. 99

Strip Circuits .................................................................................................. 99

Model/Serial Number Plate Location............................................................ 102

Model/Serial Number Designators ............................................................... 102

....................................................................................................................................................

..........................................................................

....................................................................................................................................................

9797

97

9797

VI

SECTION FIVE - 24” and 27” THIN TWIN

Part A

THEORY OF OPERATION ................................................. 105

Part B

COMPONENT ACCESS (24)COMPONENT ACCESS (24)

COMPONENT ACCESS (24)

COMPONENT ACCESS (24)COMPONENT ACCESS (24)

Washer Access............................................................................................ 107

Dryer Access ............................................................................................... 109

COMPONENT ACCESS (27)COMPONENT ACCESS (27)

COMPONENT ACCESS (27)

COMPONENT ACCESS (27)COMPONENT ACCESS (27)

Washer Access.............................................................................................11 1

Dryer Access ............................................................................................... 11 3

......................................................................................

...........................................

......................................................................................

......................................................................................

...........................................

......................................................................................

107107

107

107107

111111

111

111111

Part C

TECH TIPSTECH TIPS

TECH TIPS

TECH TIPSTECH TIPS

Timer Schedules.......................................................................................... 1 1 9

Wiring Diagrams .......................................................................................... 120

Model/Serial Number Plate Location............................................................ 122

Model/Serial Number Designators ............................................................... 122

..................................................................................................................................................................

.................................................................................

..................................................................................................................................................................

119119

119

119119

VII

SAFETY

YOUR SAFETY AND THE SAFETY OF OTHERS IS IMPORTANT

Safety messages have been provided in this manual where performing certain procedures may

cause exposure to hazards that can kill or hurt you.

This is the safety alert symbol. All safety messages will be preceded by the safety

alert symbol and the word “DANGER” or “WARNING”.

!

These words mean:

! DANGER

YOU WILL BE KILLED OR SERIOUSLY INJURED

IF YOU DON’T FOLLOW INSTRUCTIONS.

! WARNING

YOU CAN BE KILLED OR SERIOUSLY INJURED

IF YOU DON’T FOLLOW INSTRUCTIONS.

All safety messages will identify the hazard, tell you how to reduce the chance of injury, and tell

you what can happen if the instructions are not followed.

VIII

DIRECTDIRECT

DIRECT

DIRECTDIRECT

DRIVEDRIVE

DRIVE

DRIVEDRIVE

WASHERSWASHERS

WASHERS

WASHERSWASHERS

1

Section One - Part A

INSTALLATION CONSIDERATIONS

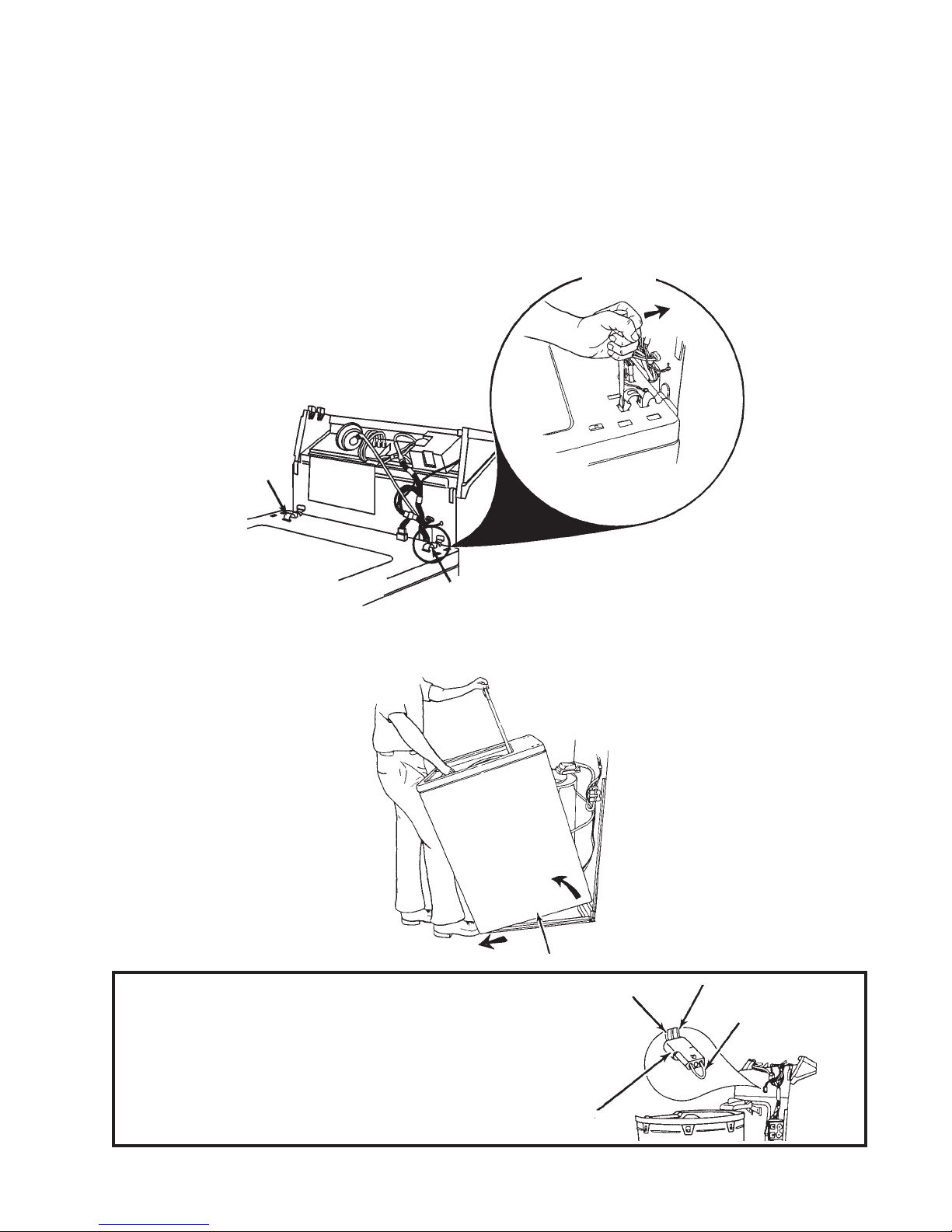

1. Carefully follow the installation instructions supplied with the washer for information related to

your product.

KEY POINTS TO REMEMBER:

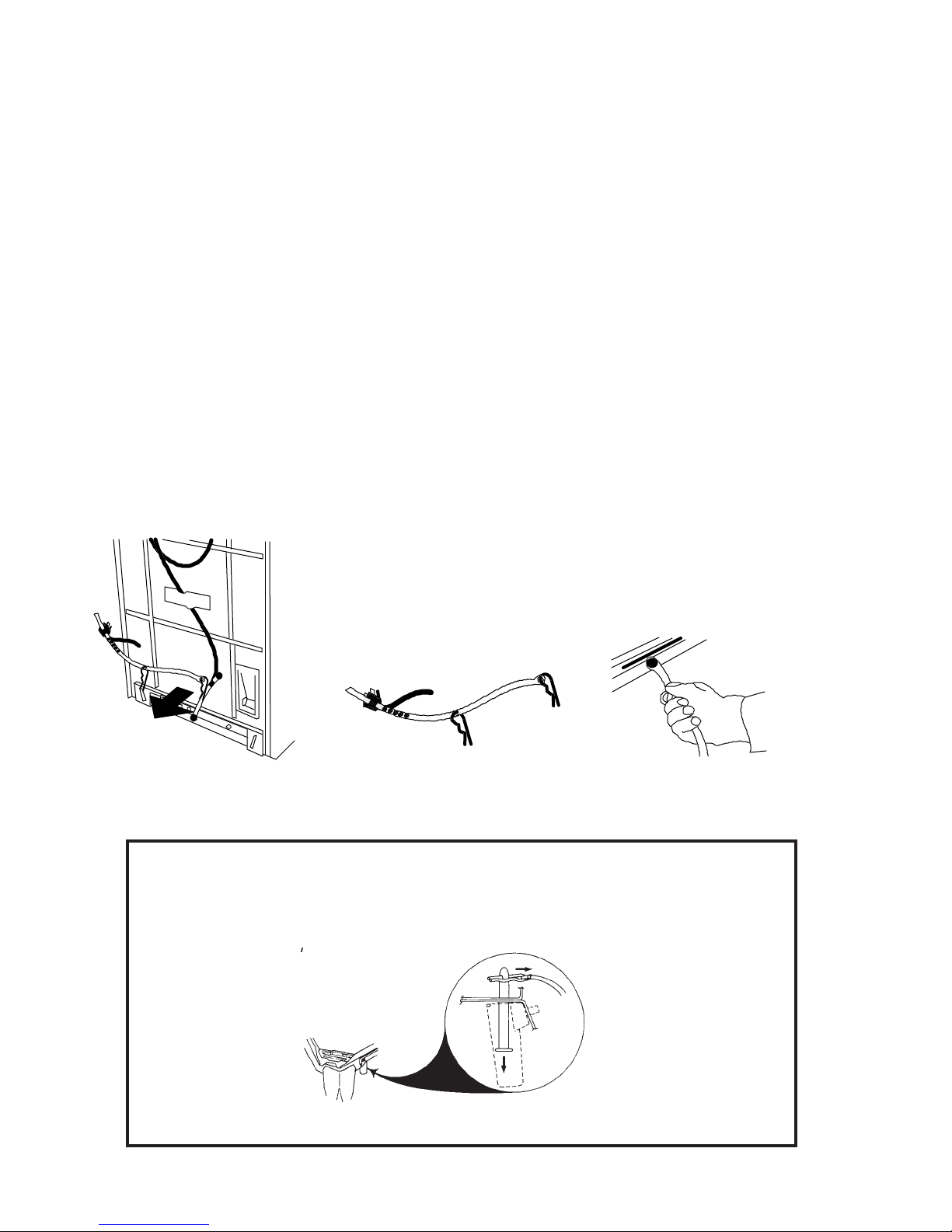

2. Remove the shipping strap as follows:

a. Carefully read, then remove the yellow label securing the power supply cord to the back of

the washer .

b. With the washer upright, pull the yellow shipping strap completely out of the back of the

washer. Be sure both cotter pins come out of the washer. Note that the power supply cord

plug will still be attached to the yellow shipping strap.

c. Firmly pull on the end of the yellow shipping strap that is attached to the bottom of the back

of the washer.

(Fig. 1-1)

(Fig. 1-3)

(Fig. 1-2)

This will release the self-leveling leg mechanism.

Fig. 1-2

Fig. 1-1

NOTE:To prevent the two (2) shipping pins from falling on the floor, two (2) plastic

holders are attached to the base.

the shipping pins fall into these holders. These pins may be left in the

holder cups.

washer.

(Fig. 1-4, INSET)

Fig. 1-4

(Fig. 1-4)

They will not interfere with the operation of the

When the cotter pins are removed,

Fig. 1-3

2

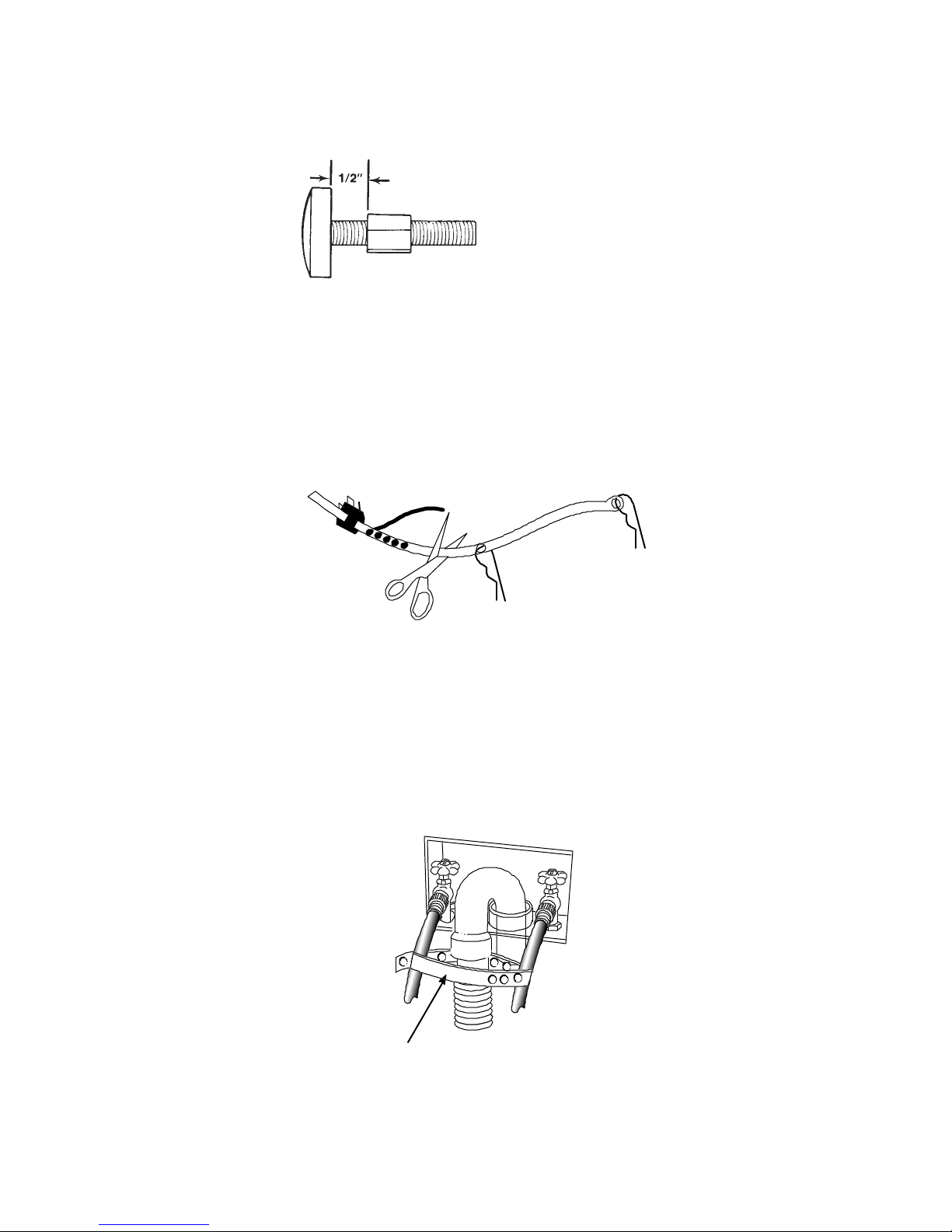

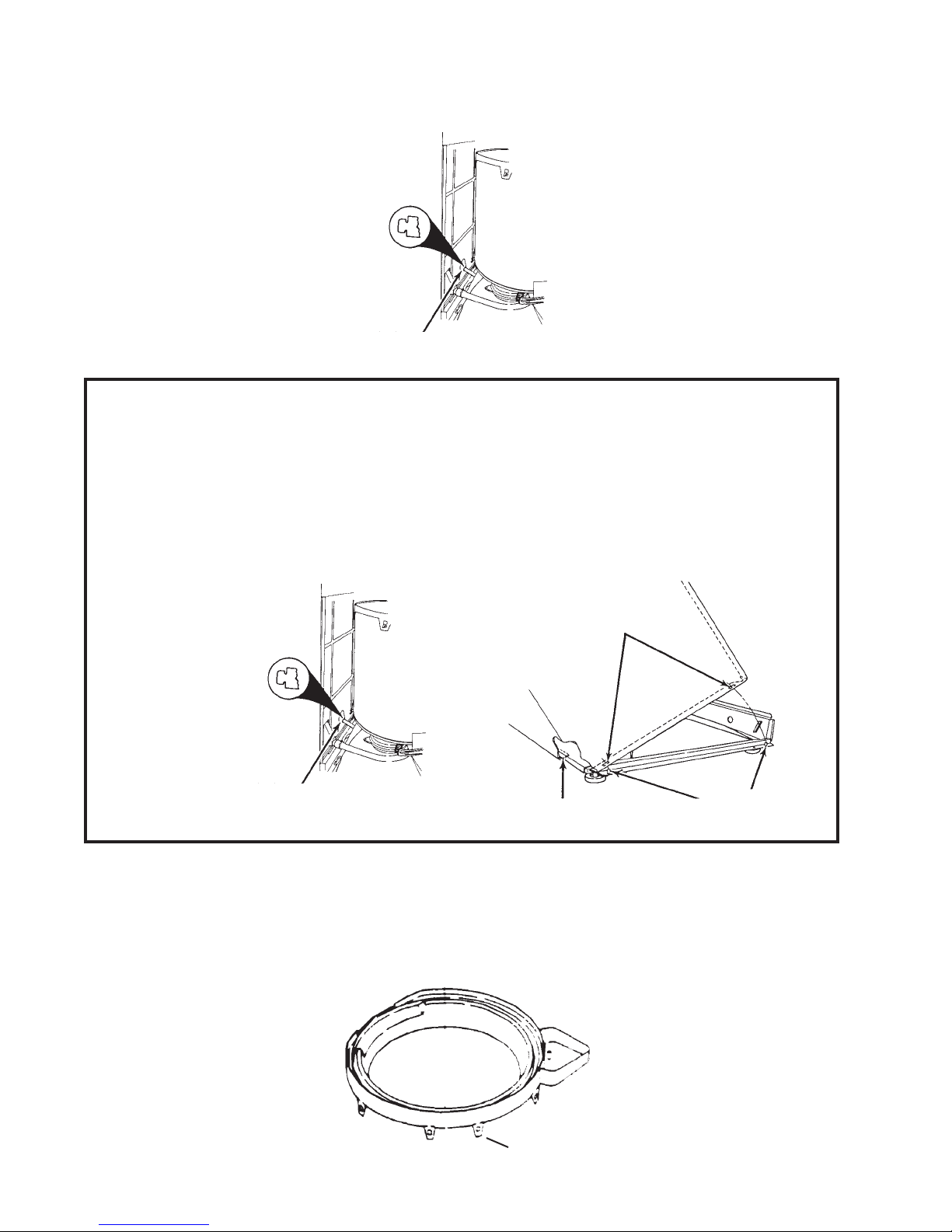

3. Screw the lock nut down to within 1/2 inch of the base of the leg.

Fig. 1-5

4. Tilt the washer forward off the floor and set back down to adjust the rear self-leveling legs.

5. Check the washer for level, both side-to-side and front-to-back. Adjust the front legs as

necessary. Tighten the locking nuts to the base of the washer with a wrench. If the nuts

are not tightened, the washer may vibrate excessively .

6. Cut the shipping strap at the words “CUT HERE” and slide it off the power supply plug.

(Fig. 1-6)

(Fig. 1-5)

Fig. 1-6

7. The hook-end of the drain hose can be installed into a stand pipe

tub,

(Fig. 1-7, C)

A

and secured with the shipping strap as shown.

B

STRAP

Fig. 1-7

C

(Fig. 1-7, A&B)

or laundry

STRAP

3

NOTE:

Laundry Drain Requirements:

Laundry Tub or Utility Sink -

1. Laundry tub or utility sink should have a minimum capacity of 20 gallons.

2. Top of tub or sink must be a minimum of 34” and not more than 72” from the

bottom of the washer.

Floor Drain -

1. Floor drain systems require a Siphon Break (Part No. 285320.) Siphon Break

must be above the high water level in the washer tub (a minimum of 28”

from the bottom of the washer.)

2. Additional drain hose will be required for a Floor Drain installation.

Standpipe Drain -

1. A minimum 2” diameter drain pipe with a minimum carry-away capacity of

17 gallons per minute is required.

2. Top of standpipe must be a minimum of 39” and not more than 72” from the

bottom of the washer.

COMMON INST ALLATION PROBLEMS

1. Water does not pump out.

Causes: a. Drain hose too high (over six feet).

b. Blockage or crimp in the drain hose.

c. Drain pipe not vented.

2. Water on the floor.

Causes: a. A leaking hose on the water inlet valve or faucet.

b. A leaking drain hose connection.

c. The drain hose is coming out of the stand pipe when draining.

d. Restricted drain pipe -- running beyond capacity.

3. The machine vibrates or “walks”.

Causes: a. Improperly installed front feet.

b. The washer is not level.

c. The shipping strap is not removed or a retaining pin is still attached to a

shipping pin on the base of the washer.

d. Floor not solid.

e. Rear leveling legs not set.

4. The machine doesn’t fill.

Causes: a. The water faucets are not turned on.

b. There is a blockage in the hose or the fill valves.

c. Drain hose siphoning -- too low or siphon break not installed.

4

Section One - Part B

THEORY OF OPERATION

All washers perform essentially the same four functions. They fill with water, agitate, drain the water

and spin the water out of the clothing.

FILL

Water Inlet

Water Level

Switch

Water

Temperature

Switch

Timer

Water Fill

Valve

Fig. 2-1

5

1. Before the washer can fill, the customer makes selections that:

• Control the length of the wash cycle by turning the timer control knob

• Control the temperature of the wash and rinse water by setting the water temperature switch.

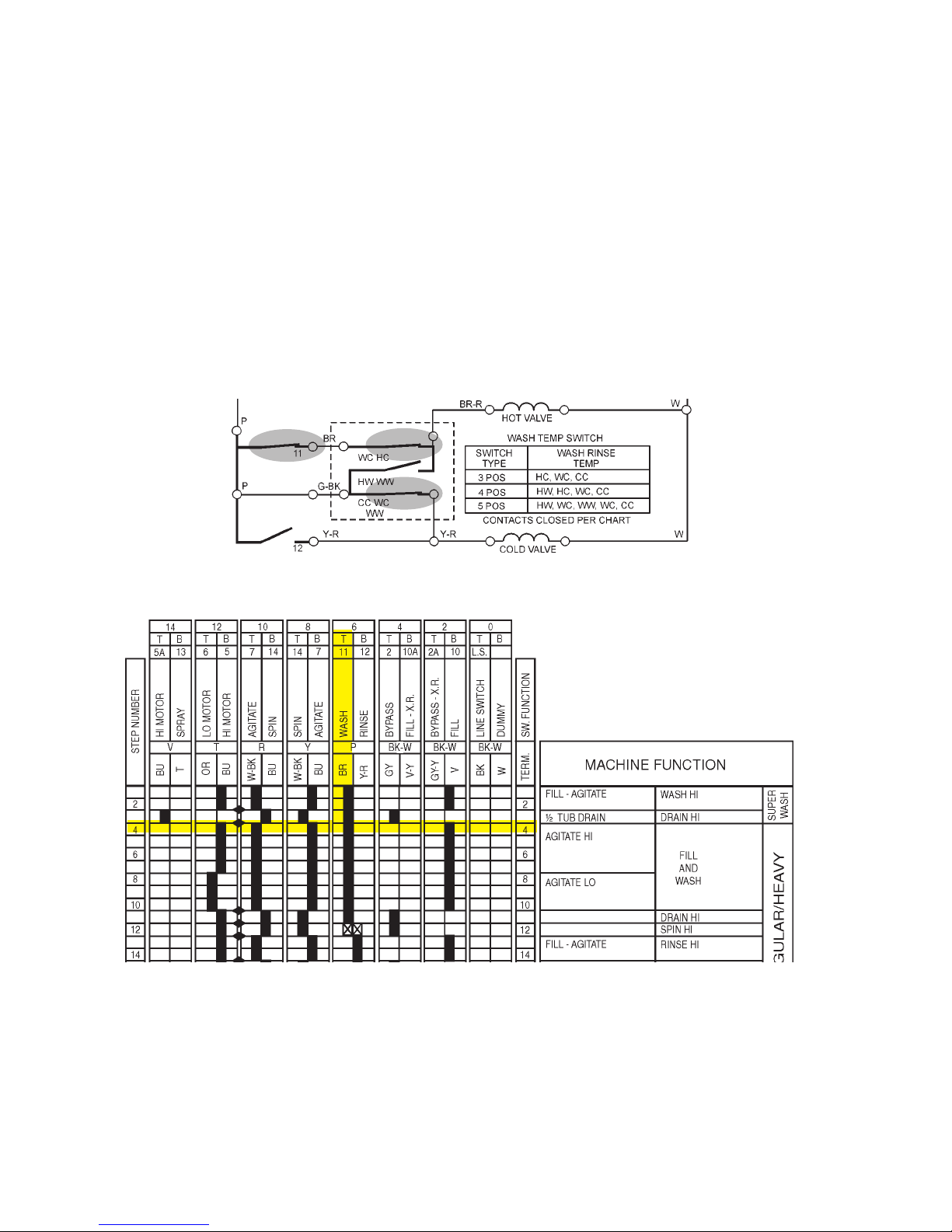

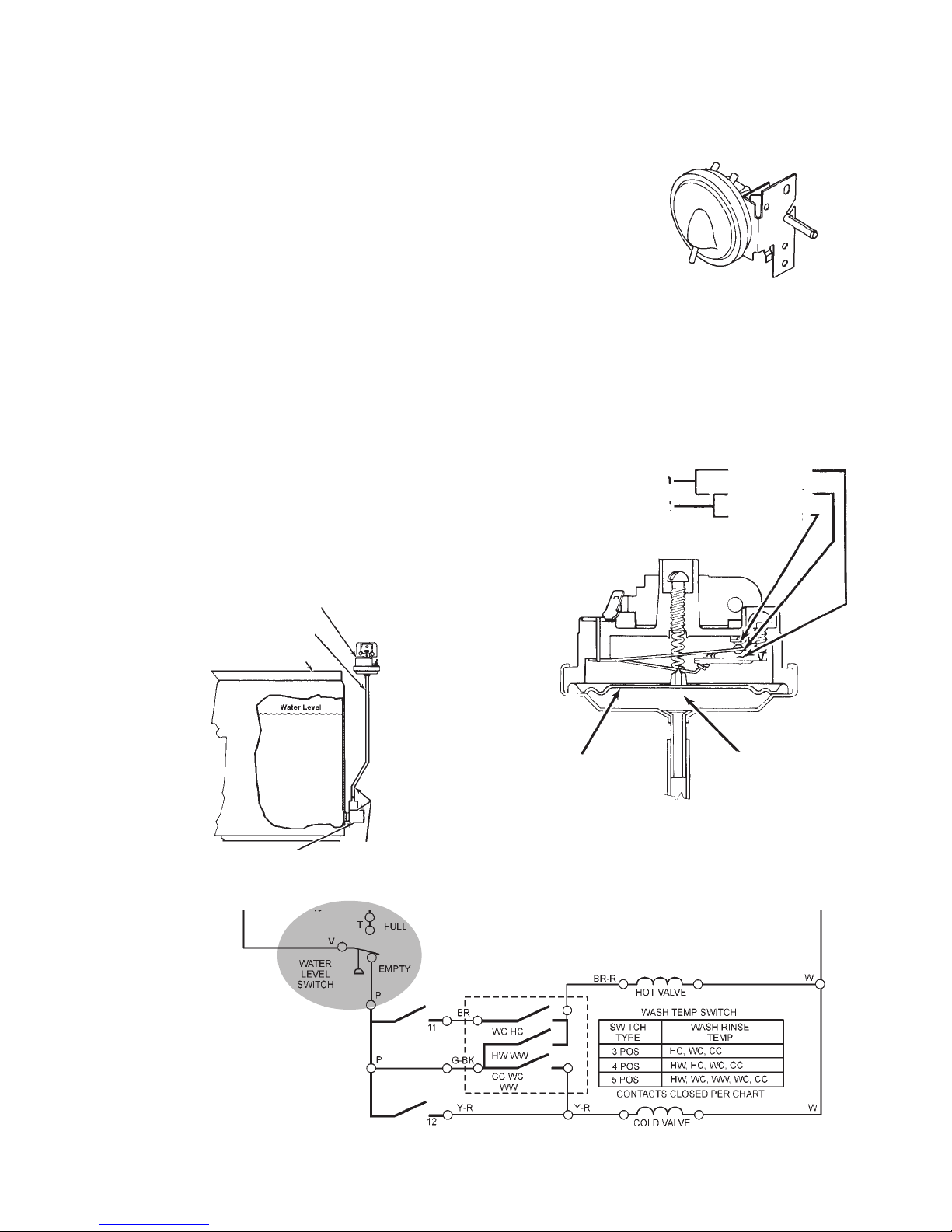

The water temperature switch is identified by the dotted box in Fig. 2-2. The wash temp switch

chart indicates three possible switches, depending on the model washer being used. The switch

letters in the chart, H W and C are the possible water temperature selections, Hot , Warm and

Cold. The first letter is the wash temperature, the second letter is the rinse temperature.

• Control the amount of water required for the amount of clothing by setting the water level or

pressure switch.

2. Once the selections are made, a series of switches are closed in the timer and water temperature

switch. If, for example, the customer selects the beginning of the REGULAR cycle, increment 4,

and a WARM wash and COLD rinse, the following switches would be closed.

Fig. 2-2

Fig. 2-3

6

The water level switch is set to move from the

EMPTY position to the FULL position depending on how much tension is set on the switch

diaphragm.

3. When the customer pulls the timer knob out,

voltage is supplied to the hot and/or cold water inlet solenoids. In the example above, both

solenoids are energized to allow water to fill

the tub.

4. As the water level rises in the tub, it causes

an increase in air pressure in the air dome

assembly mounted to the side of the tub. A

hose between the air dome and the water level

switch transfers this air pressure against the

diaphragm in the water level switch, causing

electrical contacts to move from V to P ,

(EMPTY position), to V to T, (FULL position).

The washer stops filling and the water level

switch is providing voltage to the timer motor

and the drive motor to begin agitation.

Typical Water

Level Switch

Fig. 2-4

WATER LEVEL SWITCH

AT FULL POSITION

Open

Closed

P-Contact

V-Contact

T-Contact

Fig. 2-5

Water Level Switch

Hose

Tub

Air Dome

Assembly

Trapped Air In

Hose And Air

Dome Assembly

(Air Pressure)

Diaphragm

Air Pressure

Applied To

Diaphragm

Fig. 2-6

Fig. 2-7

7

Pump

AGITATION

Water Level

Switch

Timer

Drive

Motor

Gearcase

Fig. 2-8

8

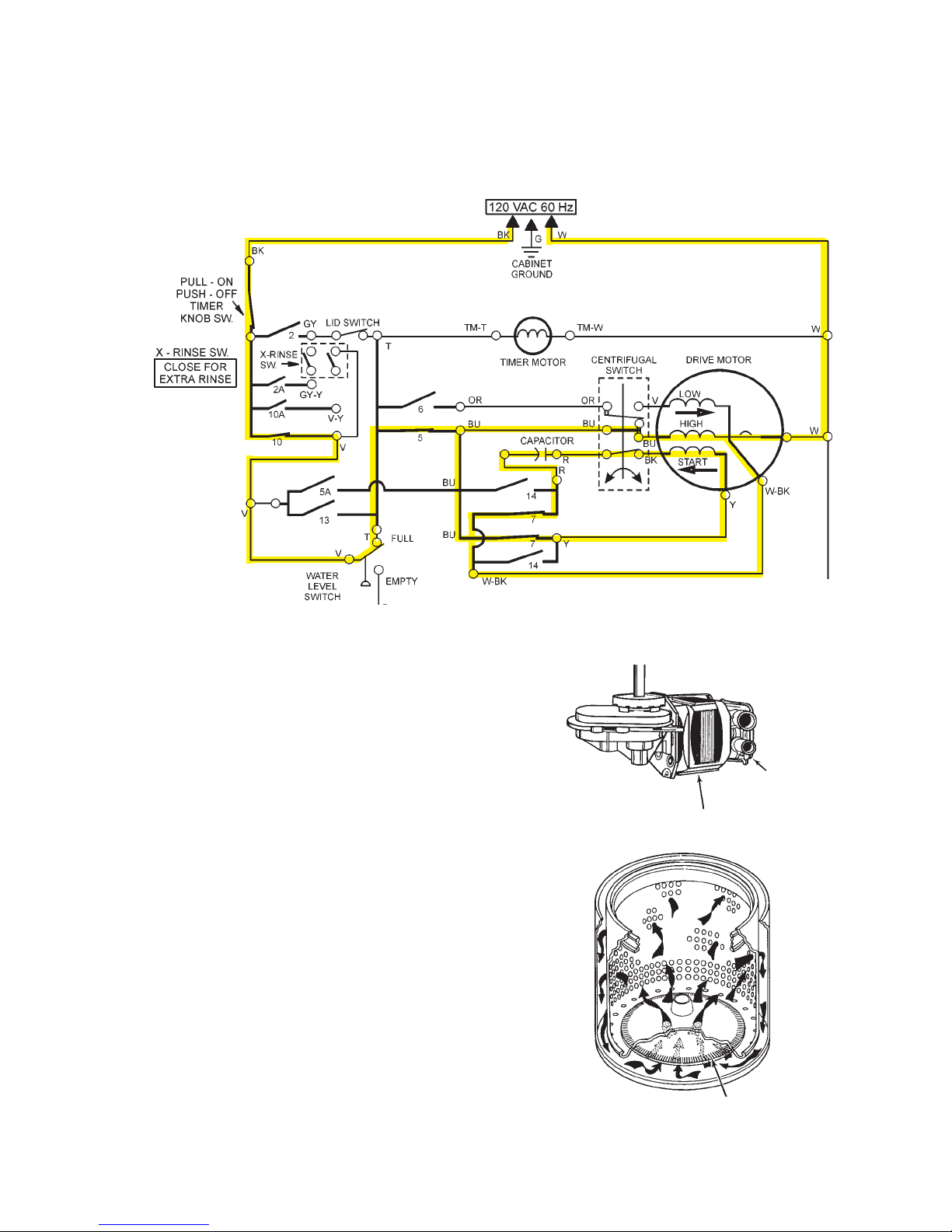

1. Once there is power to the timer motor, the timer will start to advance. The drive motor will also

begin to turn counterclockwise in the agitation direction. The direction of current through the dirve

motor start winding will determine the direction the drive motor runs. In the agitation mode, contacts 7 are closed, causing current to flow in the start winding opposite the flow in the run winding.

Fig. 2-9

2. The motor is coupled directly to the transmis-

sion and will cause the transmission shaft to

turn in the agitate direction. The agitator is

mounted directly to the transmission shaft and

is driven back and forth to provide agitation.

3. The water pump is mounted directly to the

motor and will also turn in the agitate direction. At this point the pump is running in reverse, so water does not leave the tub.

4. During the agitation cycle, the wash water is

being pulled through a basket mounted lint

filter, (if equpped), by pumping vanes molded

into the underside of the agitator. Due to the

shape of the filter, lint is captured on the filter

fins.

5. Also, during the agitation cycle, the transmis-

sion is being set up for neutral drain to provide a pump-out prior to going into spin.

Fig. 2-10

Pump

Motor

6. Once the timer has advanced to the end of

the wash cycle, contacts open in the timer

causing the drive motor to stop.

Lint Filter

Fig. 2-11

9

Pump

DRAIN

Water Level

Switch

Timer

Drive

Motor

Gearcase

Fig. 2-12

10

1. The timer advances to the next step in the process, which is the drain cycle. This time, contacts 14

in the timer are closed, energizing the drive motor to run in a clockwise direction. The current flow

in the start winding is the same as that in the run winding.

Fig. 2-13

2. The drive motor now turns the pump in the clockwise or drain direction causing the pump to drain

the dirty water out of the tub through the drain hose.

3. The weight of the water being pulled over the lint filter flushes the lint from the filter and out the

drain hose with the dirty water.

Fig. 2-14

4. After a two-minute drain, the timer contacts open momentarily , stopping the drive motor . This

momentary pause causes the transmission to reset itself for the spin cycle.

11

Pump

SPIN

Water Level

Switch

Timer

Drive

Motor

Clutch

(Spin)

Gearcase

Fig. 2-15

12

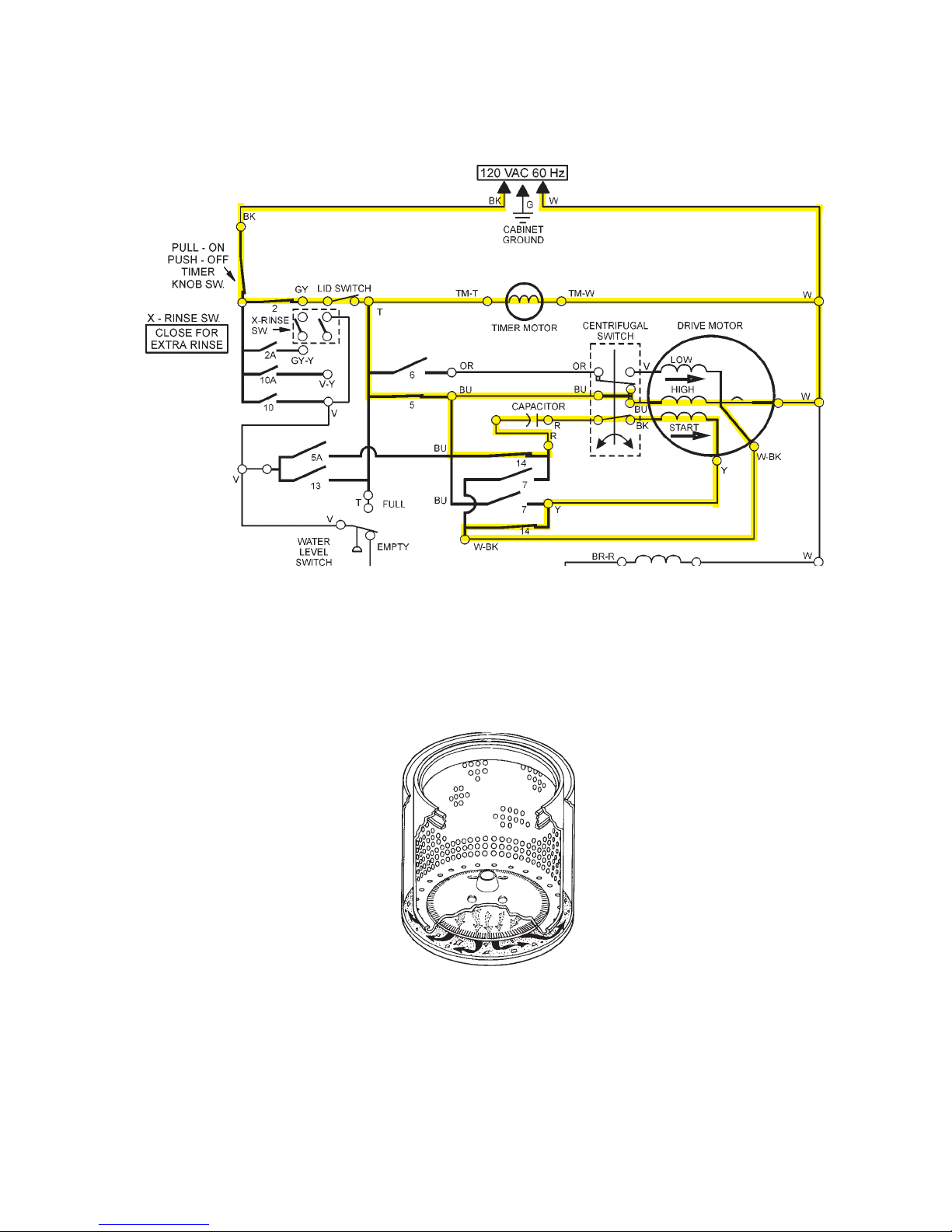

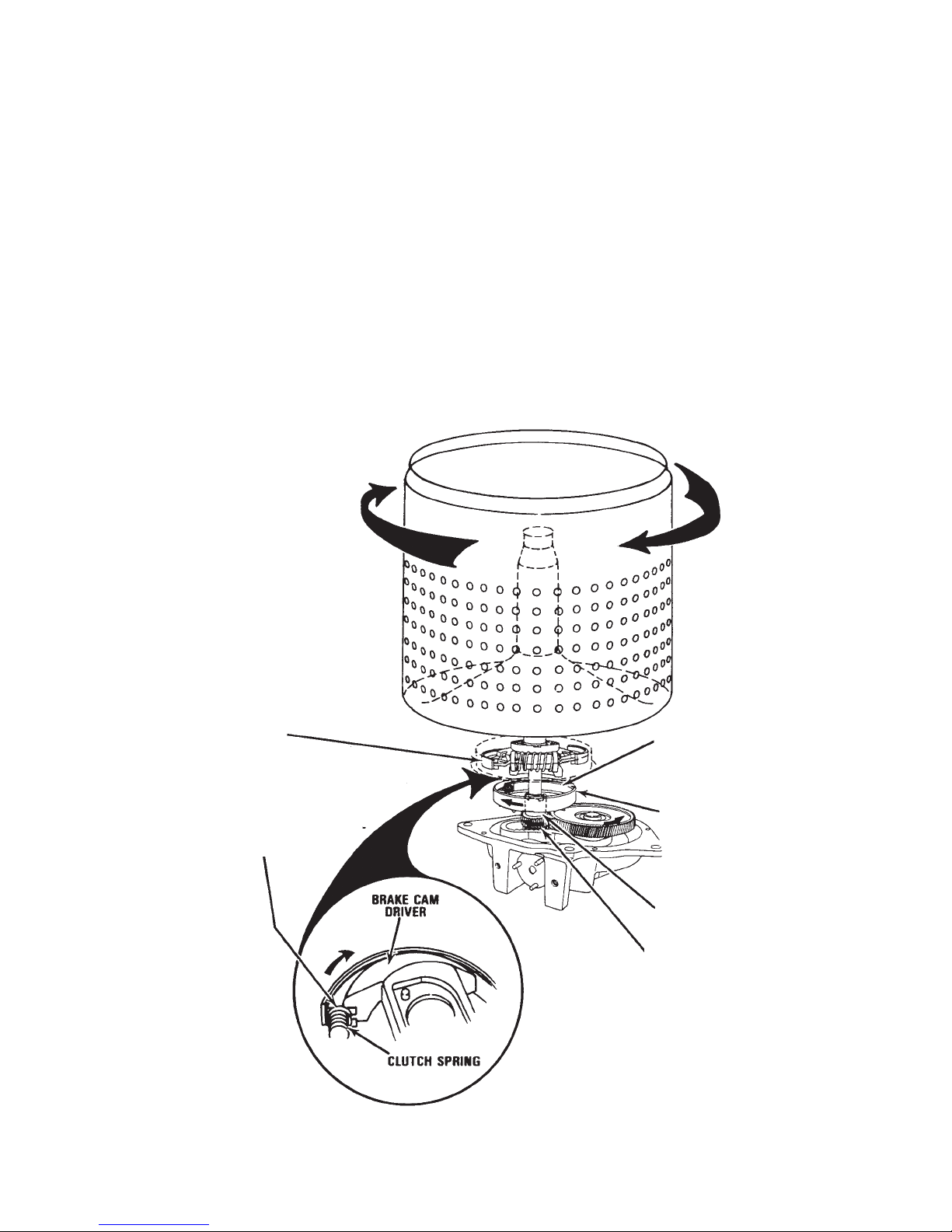

1. After the motor restarts, in the same clockwise direction, the transmission is reset for the spin

mode and the spin pinion begins to turn.

2. A clutch housing is mounted directly to the transmission spin pinion and begins to turn as well.

3. Inside the clutch housing is a clutch lining that is turned by the clutch housing by friction. The clutch

lining is an almost complete circular band that is cushioned with a spring to allow the clutch to slip

as the basket is coming up to speed. This slip prevents high torque loads on the motor and allows

the motor to bring this heavy load up to speed without overloading.

4. The clutch lining is designed to contact the basket drive brake cam which releases the basket

drive brakes during the spin cycle, allowing the basket drive to turn freely .

5. The basket drive is connected to the basket with a drive block and nut. The turning basket drive

causes the basket to begin to spin.

6. As the basket gets up to its full spin speed, the clutch slippage is gradually reduced until the clutch,

basket drive and basket are being driven as if they were one unit.

Fig. 2-16

Brake Shoe

Clutch Tab

Clutch Lining

Clutch Housing

Spin Pinion

Spin Pinion

Gear

13

-- NOTES --

14

Section One - Part C

COMPONENT ACCESS

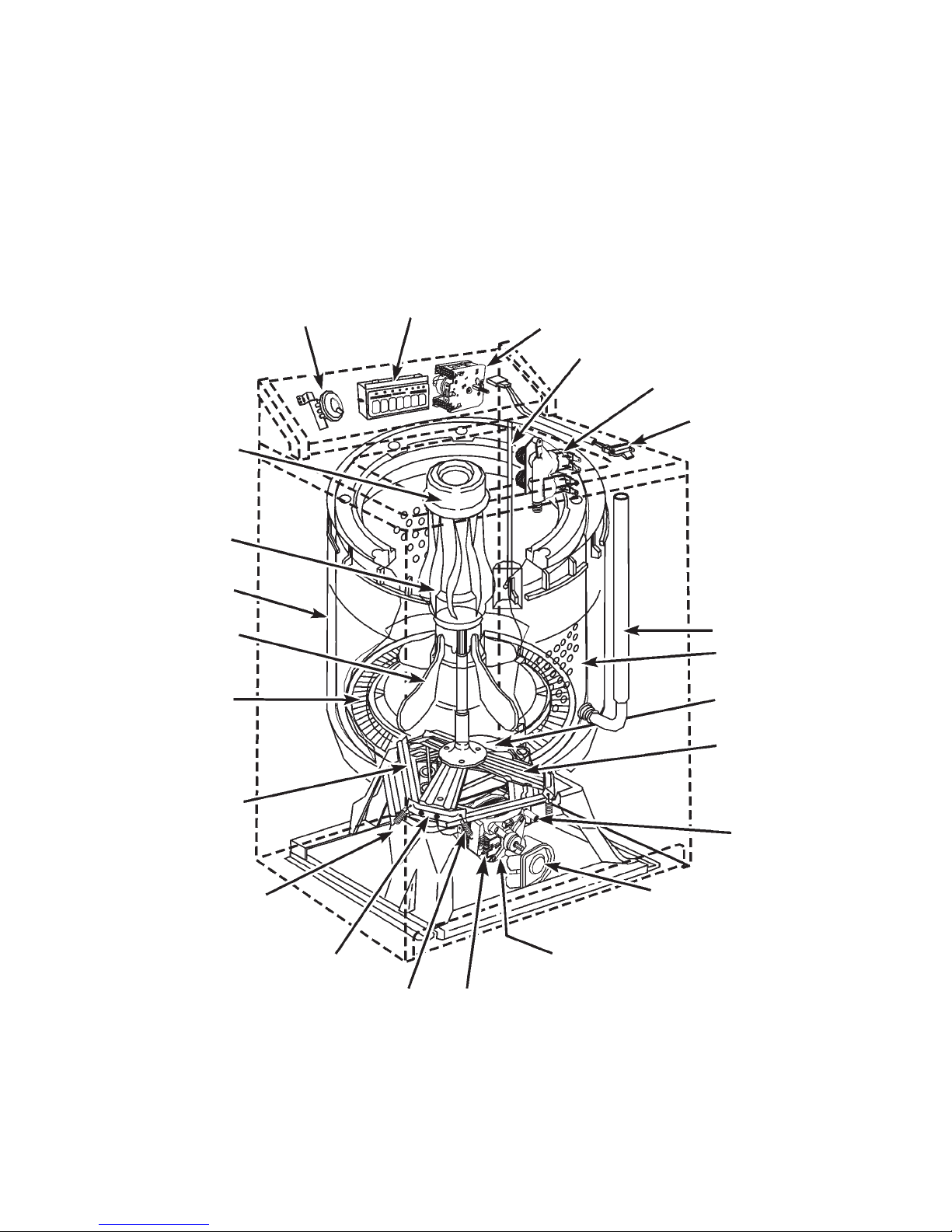

COMPONENT LOCATION

FABRIC

SOFTENER

DISPENSER

MANUAL

LINT FILTER

(if equipped)

TUB

AGITATOR

MAGICCLEAN

LINT FIL TER

(if equipped)

TUB

SUPPORT

WATER

LEVEL

SWITCH

PUSH-BUTTON

SWITCH

TIMER

PRESSURE DOME TUBE

FILL V AL VE

LID SWITCH

BLEACH

DISPENSER

HOSE

BASKET

FILTER VANES

(UNDER AGITATOR

PLATE)

SUSPENSION

PLATE

SPRING

SPRING BRACKET

GEARCASE

CAPACITOR

DRAIN

PUMP

CENTRIFUGAL

SWITCH

DRIVE

MOTOR

Fig. 3-1

15

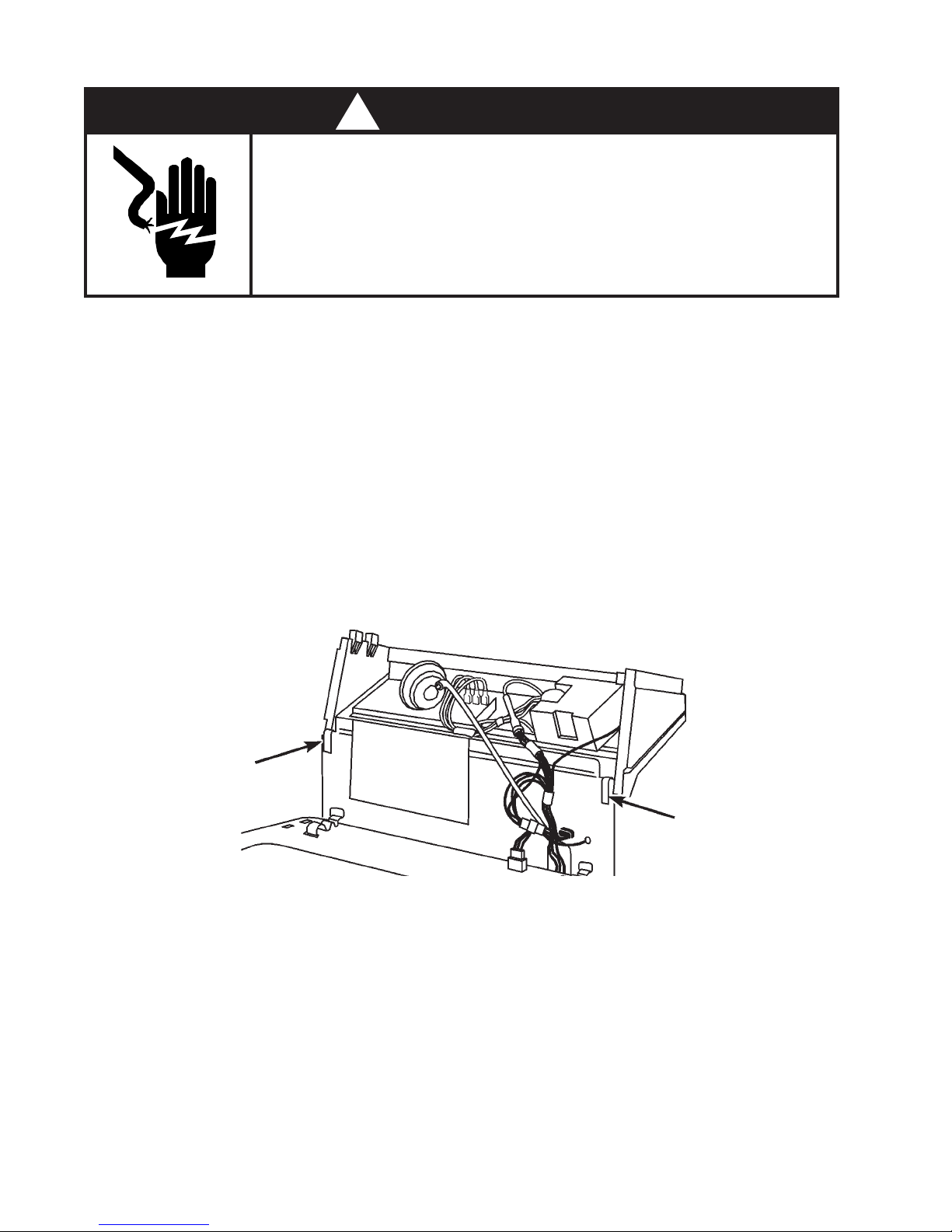

! W ARNING

ELECTRIC SHOCK HAZARD

Disconnect the washer from the electrical power outlet

before performing any service or repairs.

Replace all panels before operating.

Failure to follow these instructions could result in death or electrical shock.

ACCESSING COMPONENTS IN THE CONSOLE

A number of critical components can be accessed from inside the control console. These components

are:

1. Timer

2. Push-button Switch Assembly

3. Water Level Switch

Servicing Components in the Console

1. Remove the two Phillips-head screws securing the front corners of the console to the washer

top.

2. Tip the console back on the hinges that secure the top of the console to the washer back.

(Fig. 3-2)

HINGE

HINGE

Fig. 3-2

16

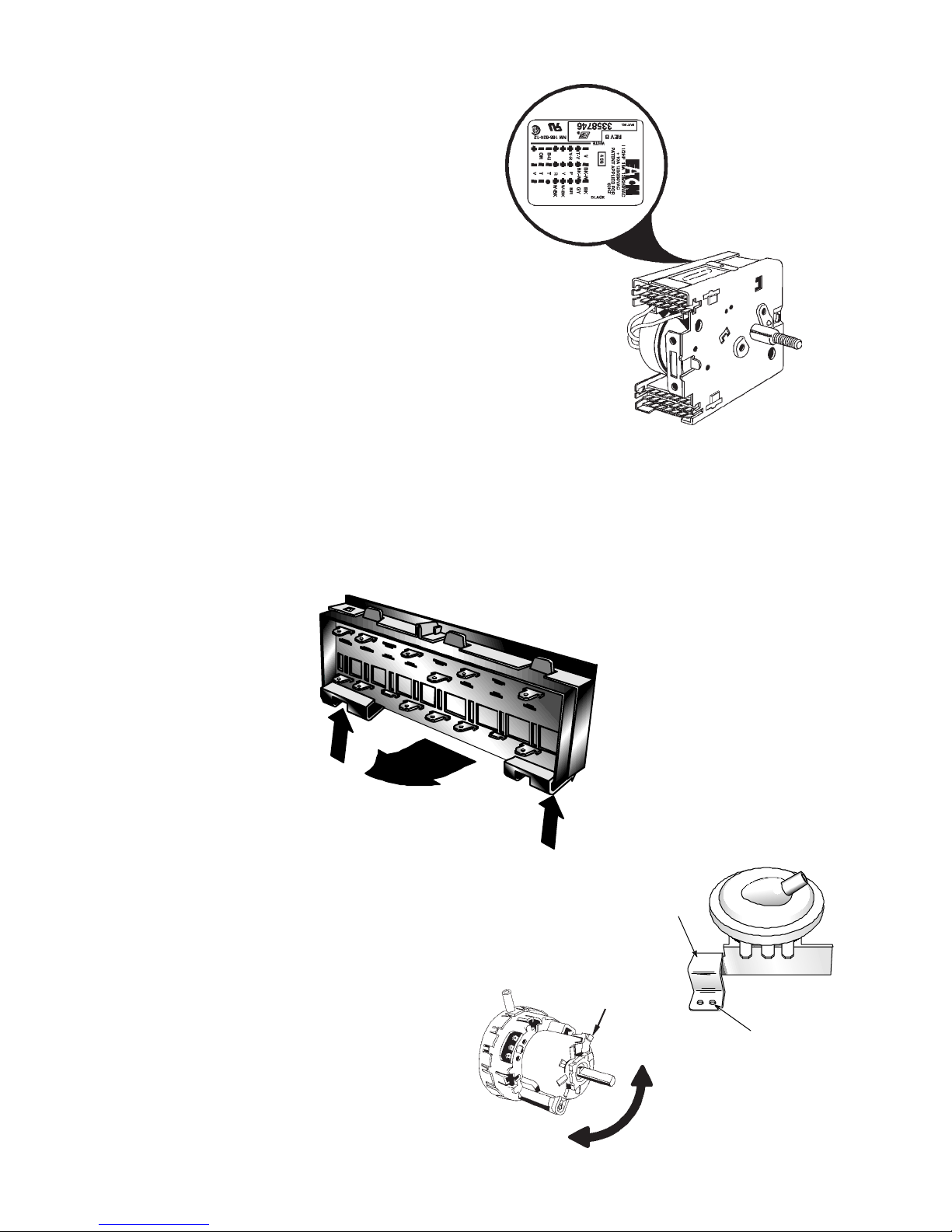

Removing the Timer

There are two types of timers. One can be identified by a plastic body. The other has a metal body.

Plastic Body

NOTE:DO NOT ATTEMPT TO REMOVE THE TIMER KNOB BY PULLING FROM

THE FRONT. Doing so will damage the split shaft and require replacing the

entire timer assembly.

1. To remove the timer knob, push the knob in from the front.

2. At the back of the timer, pull the black tab out approximately 3/16”, then pull the timer knob

off the shaft.

BLACK T AB

Fig. 3-3

3. Slide the timer dial from the timer hub.

4. Unplug the wiring harness connector from the timer assembly terminals.

5. Remove the one (1) Hex-head screw securing the left side of the timer assembly to the console

mounting plate. Then lift the left side and slide the tabs at the right side of the timer assembly

from the console mounting plate.

MOUNTING SCREW

Fig. 3-4

17

Metal Body

1. To remove the timer knob, push the knob

in from the front and unscrew it from the

timer shaft.

(Fig. 3-5)

2. Slide the timer dial from the timer hub.

3. Remove the two (2) Hex-head screws

securing the timer assembly to the console

mounting plate.

4. Unplug the wiring harness connector from

the timer assembly terminals.

Fig. 3-5

Removing the Push-Button Assembly

1. Unplug the wiring harness connectors from the switch assembly terminals using a pair of

needlenose pliers.

2. Press in the the two (2) tabs at the bottom of the switch assembly. Then, lift the bottom of the

switch assembly up and lift it away from the console mounting plate.

(Fig. 3-6)

Fig. 3-6

PUSH

IN

TIP UP

and

LIFT OUT

Removing the Water Level Switch

1. Pull the knob off of the switch shaft.

2. Unplug the wiring harness connector from

the switch assembly terminals and remove

pressure switch tubing.

3. Remove the Hex-head screw securing the

water level switch mounting bracket to the

console mounting plate

depress tab and rotate the switch 90°and

pull it from the console mounting plate.

(Fig. 3-7-B)

(Fig. 3-7-A)

OR

PUSH

IN

Fig. 3-7-B

MOUNTING

BRACKET

Fig. 3-7-A

DEPRESS

TAB

MOUNTING

HOLES

ROTA TE 90°

TO REMOVE

18

ACCESSING COMPONENTS INSIDE THE W ASHER CABINET

Components inside the washer cabinet can be accessed by completely removing the outer cabinet as

one unit. Refer to

Figure 3-8

1. Remove the console mounting screws and tilt the console into the service position.

2. Unplug the lid switch harness connector from the receptacle in the washer top.

3. Remove the cabinet mounting clips by placing the flat blade of a screwdriver in the clip as

shown in

Figure 3-8, Inset 1

CLIP

for the following instructions.

.

INSET 1

Fig. 3-8

CLIP

4. Remove the cabinet by tilting it forward and pulling it away from the washer.

Fig. 3-9

CABINET

NOTE:If necessary, the washer can be operated

in all cycles with the cabinet removed.

Install a jumper wire in the lid switch

harness connector as shown.

(Fig. 3-10)

GRAY

Fig. 3-10

VIOLET

(Fig. 3-9)

JUMPER

WIRE

IMPORTANT: Use extreme caution when

operating the washer with

the cabinet removed.

HARNESS

CONNECTOR

19

5. The rear panel can be tilted back for additional access to components at rear of machine by

twisting the rear panel support 90°, and then tilting the rear panel back.

REAR P ANEL SUPPORT

(Fig. 3-11)

Fig. 3-11

REASSEMBLY NOTES

When reassembling the cabinet make sure the following steps are taken:

1. When reinstalling the rear panel support, press in on the rear panel and rotate the support

to lock the panel in position.

2. The cabinet front flange must be under the washer base.

3. Holes in the cabinet side flange must be placed over the tabs in the washer base.

(Fig. 3-13-B)

(Fig. 3-12)

(Fig. 3-13-A)

Fig. 3-12

REAR P ANEL SUPPORT

Fig. 3-13

A

B

TABS

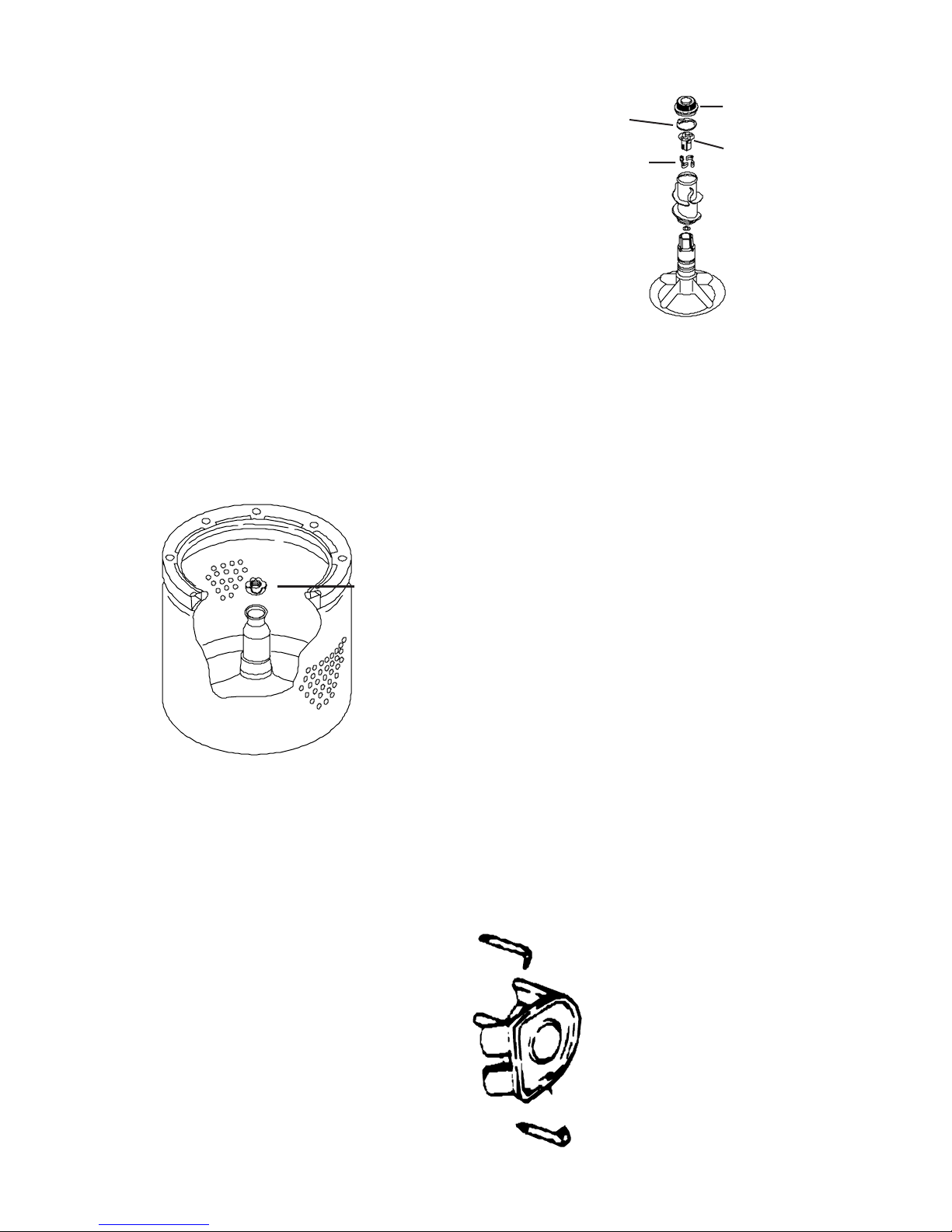

SERVICING THE TUB AND BASKET

1. To service the tub and basket, the cabinet must be removed.

2. If it is necessary to remove the inner basket, begin by removing the tub ring by unsnapping the

slots from the tabs on the tub. There are a total of eight tabs, one of which is a locator tab and

has a narrower slot than the others.

Fig. 3-14

(Fig. 3-14)

LOCAT OR TAB

20

3. The Surgilator Agitator is removed by first

pulling off the agitator cap and inner cap.

Then unscrew the 7/16” bolt found under the cap and pull straight up on the twopiece agitator assembly. The clutch and

clutch dogs that provide the Surgilator action are found in the upper portion of the

agitator assembly.

(Fig. 3-15)

Inner Cap

Clutch Dogs

Agitator Cap

Clutch

Fig. 3-15

4. Complete the removal of the basket by

loosening the spanner nut on the spin tube

and expand the drive block with a wide

bladed screw driver .

(Fig. 3-16)

The basket can now be lifted straight up and out

of the tub.

Spanner Nut

Fig. 3-16

5. The tub assembly is secured to the tub

SUSPENSION

PLATE

BASE

support at three locations. There are two

screws, a suspension spring and a locating tab at each of these locations.

(Fig. 3-17)

SUSPENSION

SPRING

BRACKET

SPRING

Fig. 3-17

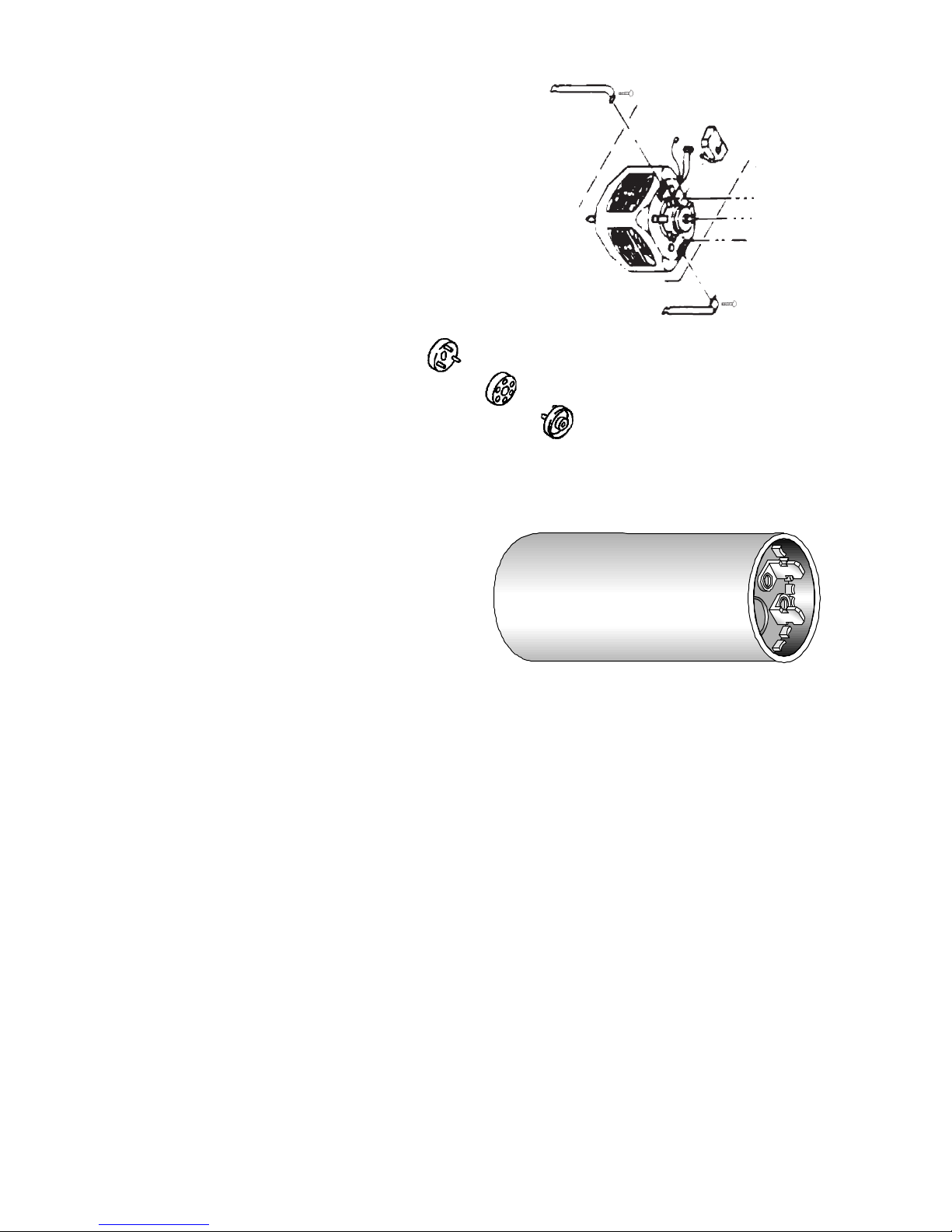

SERVICING THE DRIVE MOT OR AND PUMP

The drive motor and pump can be accessed by removing the cabinet. The pump is a sealed unit and

cannot be serviced. It should be replaced if it does not operate properly . The pump engages the drive

motor directly and is held in place by two retainer clips.

Fig. 3-18

(Fig. 3-18)

21

The motor of the Whirlpool Direct Drive Washer

is a reversing type, running in one direction for

agitation and in the other direction for drain and

spin. The motor is held in place by two retaining

clips and is coupled to the gearcase with two

three-prong couplers and an isolation coupler.

(Fig. 3-1)

MOTOR COUPLER

The motor coupler serves as a cushion

between the motor and gearcase and a

safeguard to protect the motor in the

event of a binding of the gearcase.

The coupler ends can be removed by

prying the outer pieces from the motor

and gearcase. If service to any of the

pieces is required, they must all be replaced.

ST ART CAP ACITOR

Fig. 3-19

Fig. 3-20

In older models the motor start capacitor is

located in the console.

is attached to the motor.

Figure 3-21

is a typical capacitor .

In newer models it

Fig. 3-21

SERVICING THE FRICTION PADS ON THE SUSPENSION PLATE AND

BASE ASSEMBLY

The tub support and brake assembly are attached to the suspension plate, which rests on the base

plate. This allows the tub and basket assembly to move in a gimbaling action.

The suspension plate and base assembly have friction resistance pads that provide protection between the metal assemblies.

1. Remove the outer cabinet from the washer.

2. Disconnect the wiring harness plug from the drive motor terminals.

3. Disconnect the tub outlet hose from the tub.

4. Remove the pump and motor.

5. Remove the gearcase. (See next page)

6. Lift the entire tub, basket and tub support out as one unit.

The pads on the suspension plate are now accessible for replacement.

7. Lift the suspension plate from the base assembly.

The pads on the base assembly are now accessible for replacement.

22

Loading...

Loading...