Page 1

INSTALLATION INSTRUCTIONS

ELECTRIC DRYER

Table of Contents ............................................................................................... 2

IMPORTANT: Save for local electrical inspector’s use.

3397627C

Page 2

TABLE OF CONTENTS

DRYER SAFETY .........................................................................2

INSTALLATION INSTRUCTIONS ............................................... 4

Tools and Parts ........................................................................ 4

Location Requirements ............................................................ 4

Electrical Requirements ........................................................... 5

Electrical Connection ............................................................... 6

Venting Requirements ..............................................................7

Plan Vent System ..................................................................... 7

Install Vent System ..................................................................8

Install Leveling Legs ................................................................ 8

Conect Vent .............................................................................9

Level Dryer ............................................................................... 9

Check Operation ...................................................................... 9

Change Door Swing ............................................................... 10

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

2

Page 3

3

Page 4

INSTALLATION INSTRUCTIONS

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Tools needed:

■ Flat-blade screwdriver

■ Phillips screw driver

■ Adjustable wrench that

opens to 1" (25mm) or

hex-head socket wrench

(for adjusting dryer feet)

■ Level

Parts supplied:

Parts package is located in dryer drum. Check that all parts

are included.

4 Leveling legs

■ Utility knife

■ 1/4" socket wrench or

1/4" nut driver

■ Vent clamps

■ Caulk gun and caulk (for

installing new exhaust

vent)

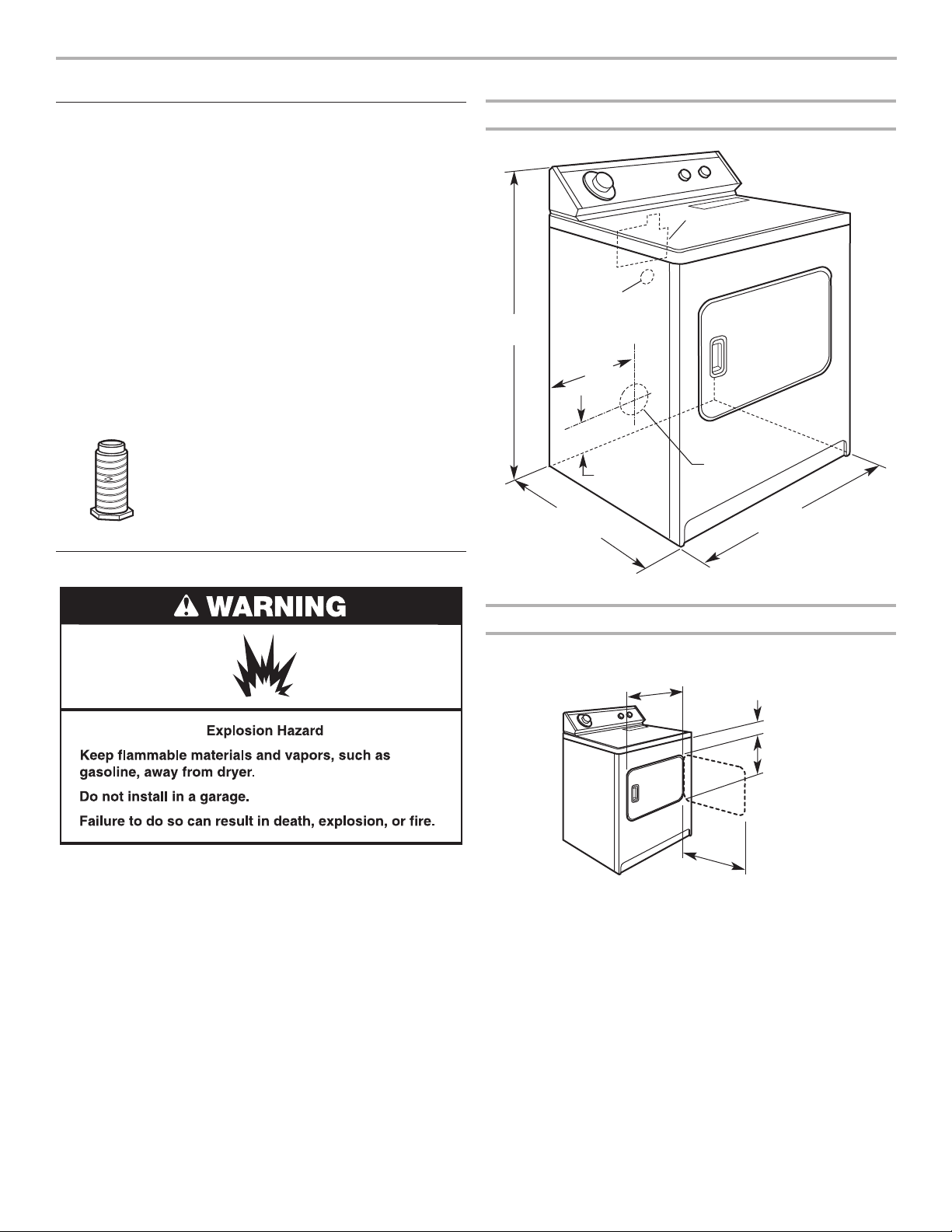

Dryer Dimensions

power supply

423/8"*

(1076 mm)

cord/cable

1

14

(368 mm)

28" max.

(711 mm)

opening

/2"

6"

(152 mm)*

terminal block

cover

dryer

exhaust

vent

29"

(737 mm)

Location Requirements

IMPORTANT: Observe all governing codes and ordinances.

■ Check code requirements: Some codes limit or do not permit

installation of clothes dryers in garages, closets, or sleeping

quarters. Contact your local building inspector.

■ Make sure that lower edges of the cabinet, plus the back and

bottom sides of the dryer, are free of obstructions to permit

adequate clearance of air openings for combustion air. See

“Recessed Area and Closet Installation Instructions” for

minimum spacing requirements.

Door Clearance

*from oor with

dryer feet extended

1" (25 mm)

3

22

/4"

(578 mm)

223/4"

(578 mm)

7

/8"

3

(98 mm)

(486 mm)

19

1

/8"

NOTE: The dryer must not be installed in an area where it will be

exposed to water and/or weather.

4

Page 5

Recessed Area and Closet Installation Instructions

This dryer may be installed in a recessed area or closet. For

recessed area and closet installations, minimum clearances

can be found on the serial tag on the dryer.

The installation spacing is in inches and is the minimum

allowable. Additional spacing should be considered for

ease of installation, servicing, and compliance with local

codes and ordinances.

If closet door is installed, the minimum unobstructed air

opening in the top and bottom is required. Louvered doors

with equivalent air openings are acceptable.

The dryer must be exhausted outdoors.

No other fuel-burning appliance may be installed in the same

closet as the dryer.

Minimum Installation Clearances

14" max.

(356 mm)

18"*

Closet

door

(457 mm)

Electrical Requirements

Important: Observe all governing codes and ordinances.

A two-wire plus separate ground wire, or a 3-wire, single-phase

230-volt, 50-Hz, AC only, electrical supply is required on a

separate 15-amp circuit, fused on both sides of the line. A timedelay fuse or circuit breaker is recommended.

It is the personal responsibility and obligation of the customer

to contact a qualied electrician to assure that the electrical

installation is adequate and is in conformance with all local

codes and ordinances.

0"

(0 mm)

0"

(0 mm)

1"

(25 mm)

4"

(102 mm)

Recessed front view Closet side view

Additional clearances for wall, door, and oor moldings may be required or if

external exhaust elbow is used.

3" (76 mm)

2

48"

(310 cm2)*

Front

View

24"

2

Closet

Door

(155 cm2)*

3" (76 mm)

Louvered doors with equivalent air openings are acceptable.

*Opening is the minimum for a closet door.

If codes permit and a separate grounding wire is used, it is

recommended that a qualied electrician determine that the

grounding path is adequate.

This dryer is equipped with a power supply cord. To minimize

possible shock hazard, the cord must be plugged into a mating

wall receptacle.

If your electrical requirements are different, contact your

authorized Whirlpool service center or a qualied electrician.

5

Page 6

Direct Wire

It is recommended that installation should be done by a qualied

electrician.

This dryer can be connected directly to the fused disconnect or

circuit breaker box with two-wire or three-wire exible, armored

or non-metallic sheathed copper cable (with ground wire). Do Not

use two-wire with bare ground wire. All current-carrying wires

must be insulated.

A conduit connector must be installed at each end of the power

supply cable (at the dryer and at the junction box.) USE ONLY

10-GAUGE SOLID COPPER WIRE. DO NOT USE ALUMINUM

WIRE. Allow 4 ft (1.22 m) of slack in the line so the dryer can be

moved if servicing is ever necessary.

Recommended Ground Method

■ It is your responsibility to contact a qualied electrical installer

to ensure that the electrical installation is adequate and in

conformance with the National Electrical Code, ANSI/NFPA

70, latest edition, and all local codes and ordinances.

Electrical Connection

Plug power supply cord into the grounded outlet or connect

direct wire to power supply. Turn power supply on.

6

Page 7

Venting Requirements

WARNING: To reduce the risk of re, this dryer MUST BE

EXHAUSTED OUTDOORS.

Elbows:

Plan installation to use the fewest number of elbows and turns.

Good Better

Clamps:

■ Use clamps to seal all joints.

■ Exhaust vent must not be connected or secured with screws

or other fastening devices which extend into the interior of the

vent and catch lint. Do not use duct tape.

IMPORTANT: Observe all governing codes and ordinances.

Dryer vent must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building.

If using an existing vent system

■ Clean lint from the entire length of the system and make sure

exhaust hood is not plugged with lint.

■ Replace any plastic or metal foil vent with rigid heavy metal

vent or exible metal vent.

■ Review Vent System Chart. Modify existing vent system if

necessary to achieve the best drying performance. Only rigid

or exible metal vent shall be used for exhausting.

If this is a new vent system

Vent material

■ Use a heavy metal vent. Do not use plastic or metal foil vent.

■ 4" (102 mm) heavy metal vent and clamps must be used.

4" (102 mm) heavy metal exhaust vent

Rigid metal vent

■ Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent

■ Must be fully extended and supported when the dryer is in it’s

nal location.

■ Remove excess to avoid sagging and kinking that may result

in reduced airow and poor performance.

■ Do not install exible metal vent in enclosed walls, ceilings, or

oors.

Exhaust

Recommended hood styles. Acceptable hood style.

B

4"

(102 mm)

A

4"

(102 mm)

4"

(102 mm)

A. Louvered hood style

B. Box hood style

C. Angled hood style is acceptable

■ An exhaust hood should cap the vent to keep rodents and

C

2

½"

(64 mm)

insects from entering the home or business.

■ Exhaust hood must be at least 12" (305 mm) from the ground

or any object that may be in the path of the exhaust (such as

owers, rocks, or bushes).

■ Do not use an exhaust hood with a magnetic latch.

■ A four-inch outlet hood is preferred. However, a 2

1

⁄2" (64 mm)

outlet exhaust hood may be used. A 21⁄2" (64 mm) outlet

creates greater back pressure than other hood types. For

permanent installation, a stationary vent system is required.

Plan Vent System

Determine vent path:

■ Vent outlet is located at the center of the bottom dryer back.

■ The vent can be routed up, down, left, right, behind the dryer,

or straight out the back of the dryer.

■ When using elbows or making turns, allow as much room as

possible.

■ Bend vent gradually to avoid kinking.

7

Page 8

Vent System Length

Maximum length of vent system depends upon the type of vent

used, number of elbows, and type of exhaust hood. The

maximum length for both rigid and exible vent is shown in the

chart.

Vent System Chart

Number of

90° elbows

Type

of vent

Box/louvered

hoods

Angled

hoods

Install Leveling Legs

0

1

2

3

4

For vent systems not covered by the vent specication chart, see

Whirlpool Service Manual, “Exhausting Whirlpool Dryers,” Part

No. LIT603197, available from your Whirlpool parts distributor.

If dryer is installed in a conned area, such as a bedroom,

bathroom, or closet, provision must be made for enough

air for combustion and ventilation. (Check governing codes

and ordinances.) See “Recessed Area and Closet Installation

Instructions” in the “Location Requirements” section.

Rigid metal

Rigid metal

Rigid metal

Rigid metal

Rigid metal

64 ft. (20 m)

54 ft. (16.5 m)

44 ft. (13.4 m)

35 ft. (10.7 m)

27 ft. (8.2 m)

58 ft. (17.7 m)

48 ft. (14.6 m)

38 ft. (11.6 m)

29 ft. (8.8 m)

21 ft. (6.4 m)

Install Vent System

1. Install exhaust hood. Use caulking compound to seal exterior

wall opening around exhaust hood.

12" min.

(305 mm)

1. Remove tape from dryer cabinet. Open dryer door and

remove tape from dryer drum. (Not all dryer drums are

taped.) Remove drying rack, if included. Turn dryer drum

counterclockwise to make sure all tape was removed. Wipe

drum with damp cloth to remove any dust.

2. Take two cardboard corners from dryer carton and place

them on oor in back of dryer. Firmly grasp body of dryer and

gently lay it on its back on the cardboard corners.

12" min.

(305 mm)

2. Connect exhaust vent to hood. Vent must t inside exhaust

hood. Secure vent to exhaust hood with vent tape.

3. Run exhaust vent to dryer location. Use the straightest path

possible. Avoid 90º turns. Use vent tape to seal all joints.

8

diamond

marking

3. Start to screw legs into holes by hand. Use an adjustable

wrench or 1" (25 mm) hex-head socket wrench to nish

turning legs until you reach the ridge with the diamond

marking.

4. Place a carton corner post from dryer packaging under each

of the 2 dryer back corners. Stand the dryer up. Slide the

dryer on the corner posts until it is close to its nal location.

Leave enough room to connect the exhaust vent.

Page 9

Connect Vent

1. Using a 4" (102 mm) clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure the vent is

clean. Dryer vent must t over dryer exhaust outlet and inside

exhaust hood. Check that vent is secured to exhaust hood

with a 4" (102 mm) clamp.

102 mm (4")

clamp

102 mm (4")

clamp

2. Move dryer into nal position.

3. Once exhaust vent connection is made, remove corner posts

and cardboard.

Check Operation

1. Check that you:

■ Did not skip any steps.

■ Installed all parts.

■ Properly installed dryer legs.

■ Leveled dryer.

■ Have all the tools you started with.

2. Plug power supply cord into grounded outlet or connect

direct wire to power supply. Turn power supply on.

3. Read the “Use and Care Guide” to fully understand your

new dryer. Select a full heat cycle (not the air cycle) and start

dryer. After ve minutes, open dryer door. You should feel

heat inside dryer.

If the dryer will not start, check the following:

■ Electrical supply is connected

■ House fuse is intact and tight, or circuit breaker

has not tripped.

■ Dryer door is closed.

■ Controls are set in a running or “On” position.

■ Start button has been pushed rmly.

Level Dryer

Check levelness of dryer by placing a level on top of dryer, rst

side to side, then front to back.

If the dryer is not level, prop up the dryer using a wood block.

Use a wrench to adjust the legs up or down and check again for

levelness.

If legs are not long enough to level dryer, order Extended Dryer

Feet Kit, Part No. 279810 (sold two legs per kit), from your dealer.

If dryer makes an unusual noise, check that the dryer is level.

9

Page 10

Change Door Swing

If not reversing door swing, skip ahead to “Level and Exhaust the

Dryer” steps.

Avoid scratching or chipping paint.

A

E

D

C

B

1. Place a large towel or soft cloth (A) on top of dryer to avoid

damaging the surface.

2. Open dryer door. Remove bottom screws from cabinet

side of hinges (B). Loosen (do not remove) top screws from

cabinet side of hinges.

3. Lift door until top screws in cabinet are in large part of hinge

slot. Pull door forward off screws. Set door (handle side up)

on top of dryer. Remove top screws from cabinet.

4. Remove screws attaching hinges to door.

5. Remove screws at top, bottom, and side of door. Holding

door over towel on dryer, grasp sides of outer door and

gently lift to separate it from inner door. Do NOT pry apart

with putty knife. Do NOT pull on door seal or plastic door

catches.

7. Attach door hinge to door so large part of hinge slot is at

bottom of hinge.

8. Gently remove 4 hinge hole plugs (C) on left side of cabinet.

Insert plugs in hinge holes on right side of cabinet.

9. Insert screws in bottom holes on left side of cabinet. Tighten

screws halfway. Position door so large end of door hinge

slot is over screws. Slide door up so screws are in bottom

of slots. Tighten screws. Insert and tighten top screws in

hinges.

10. Remove door strike (D) from cabinet. Remove door strike

plug. Insert door strike in new hole and secure with screw.

Insert door strike plug in original door strike hole and secure

with screw.

11. Close door and check that door strike aligns with door catch

(E). If door does not close completely, slide door catch left or

right within slot until strike snaps into catch.

6. Turn and reattach outer door panel to inner door panel so

handle is on the side where hinges were just removed. Be

sure to keep cardboard spacer centered between doors.

10

Page 11

Notes

11

Page 12

3397627C

© 2011 3/11

12

All rights reserved Printed in U.S.A.

Loading...

Loading...