Page 1

Commercial/Retail Wedge Decoder

Page 2

Disclaimer

Welch Allyn reserves the right to make changes in specifications and

other information contained in this document without prior notice, and the

reader should in all cases consult Welch Allyn to determine whether any

such changes have been made. The information in this publication does

not represent a commitment on the part of Welch Allyn.

Welch Allyn shall not be liable for technical or editorial errors or

omissions contained herein; nor for incidental or consequential

damages resulting from the furnishing, performance, or use of this

material.

This document contains proprietary information which is protected by

copyright. All rights are reserved. No part of this document may be

photocopied, reproduced, or translated into another language without the

prior written consent of Welch Allyn, Incorporated.

Page 3

1998 Welch Allyn, Inc. All rights reserved.

Page 4

STATEMENTS OF AGENCY COMPLIANCE

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including

interference that may cause undesired operation.

FCC Class A Compliance Statement

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user

will be required to correct the interference at his own expense.

Caution: Any changes or modifications made to this device that are not

expressly approved by Welch Allyn, Inc. may void the user’s authority to

operate the equipment.

Note: To maintain compliance with FCC Rules and Regulations, cables

connected to this device must be

wire(s) have been grounded (tied) to the connector shell.

Canadian Notice

This equipment does not exceed the Class A limits for radio noise emissions as

described in the Radio Interference Regulations of the Canadian Department of

Communications.

Le present appareil numerique n’emet pas de bruits radioelectriques depassant

les limites applicables aux appareils numeriques de la classe A prescrites dans

le Reglement sur le brouillage radioelectrique edicte par le ministere des

Communications du Canada.

shielded

cables, in which the cable shield

Page 5

The CE mark on the product indicates that the system has been tested to and

conforms with the provisions noted within the 89/336/EEC Electromagnetic

Compatibility Directive and the 73/23/EEC Low Voltage Directive.

European Contact: European Regulatory Manager

Welch Allyn Ltd.

28 Sandyford Office Park

Foxrock, Dublin 18

Ireland

or

Welch Allyn Ltd.

1st Floor

Dallam Court Dallam Lane

Warrington, Cheshire W A2 7LT

England

Welch Allyn shall not be liable for use of our product with equipment

(i.e., power supplies, personal computers, etc.) that is not CE marked and

does not comply with the Low Voltage Directive.

Page 6

LIMITED WARRANTY

Welch Allyn, Inc., hereby warrants its products to be functional and free

from manufacturing defects at the time of delivery. Welch Allyn, Inc.

further warrants that it will replace or repair, at its option, any unit that fails

to perform according to Welch Allyn’s published specifications during a

period of two (2) years from the time of shipment by Welch Allyn, Inc. to

the user or the time it is purchased from any of Welch Allyn, Inc.’s

Authorized Distributors. Any attempt on the part of the user to

disassemble or service the equipment shall void the warranty.

The warranty does not apply to products which have been damaged by

improper handling, shipping, or misuse. The warranty does not apply, if, in

the sole opinion of Welch Allyn, Inc., the unit has been damaged by

accident, misuse, neglect, improper shipping, or handling. Since the unit is

sensitive to static, the responsibility to protect it from static damage is

solely that of the user. The warranty is valid only if the device has not been

tampered with or serviced by any party unauthorized by Welch Allyn, Inc.

as a repair facility.

THE WARRANTIES SET FORTH HEREIN ARE IN LIEU OF ANY

AND ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. THE BUYER

ACKNOWLEDGES THAT NO OTHER REPRESENTATIONS WERE

MADE OR RELIED UPON WITH RESPECT TO THE QUALITY AND

FUNCTION OF THE DEVICE HEREIN SOLD.

In no event shall Welch Allyn, Inc. or its resellers be liable for any loss,

inconvenience or damage whether direct, incidental, consequential, or

otherwise, and whether caused by negligence or other fault resulting from

the breach of any express warranty except as set forth herein. Some states

do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitations or exclusions may not apply to you.

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state or country to country.

Limited Warranty iii

Page 7

iv

Limited Warranty

Page 8

TABLE OF CONTENTS

Chapter Page

ST ATEMENT OF AGENCY COMPLIANCE i

LIMITED WARRANTY iii

INTRODUCTION xiii

CHAPTER 1 – SCANTEAM 2000 DECODER

DESCRIPTION 1–1

1.1 Introduction 1–1

1.2 System Hardware Overview 1–2

1.2.1 Connection Options 1–2

1.2.2 Serial Wedge Capability 1–4

1.2.3 Cloning 1–4

1.2.4 Interface Cables/Connectors 1–7

1.3 System Software Overview 1–7

1.3.1 Programmable Selections 1–7

1.3.2 Non–Volatile Memory 1–7

1.3.3 Memory T ests 1–8

1.4 Scanning Devices 1–8

CHAPTER 2 – SYSTEM HARDWARE DESCRIPTION 2–1

2.1 Decoder Unit 2–1

2.2 Terminal Interface Cable 2–2

2.3 Interface Port 2–2

2.4 Auxiliary Port 2–3

2.4.1 Description 2–3

2.4.2 Receive Operation 2–3

2.4.3 Transmit Operation 2–4

2.5 Scanner Ports 2–4

2.6 Magnetic Stripe Triple T rackReader (MSR) Port 2–4

2.7 Power Requirements 2–6

2.7.1 Keyboard Wedge Applications 2–6

2.7.2 RS–232D Auxiliary Port 2–7

Table of Contents

v

Page 9

Chapter Page

CHAPTER 3 – SET–UP and INSTALLATION 3–1

3.1 Preparation 3–1

3.2 Set–Up Procedure 3–1

3.2.1 2000/C Set–up 3–1

3.2.2 2000/R Set–up 3–4

CHAPTER 4 – PROGRAMMING THE DECODER 4–1

4.1 Beeper Sequence and Meaning 4–1

4.2 The Programming Menu 4–2

4.2.1 Programming Menu Page 4–3

4.2.2 The Bar Code Chart 4–5

4.3 Recommended Programming Sequence 4–6

4.4 T erminal Selection Menu Page 4–7

4.5 Output Parameters Menu Page 4–8

4.5.1 Output Parameters Menu Page Continued 4–10

4.6 Code Selection I (Industrial) Programming Menu Page 4–18

4.7 Code Selection II (Retail) Menu Page 4–21

4.8 Auxiliary Port 4–24

4.9 Data Formatting 4–32

4.9.1 Data Formatter 4–32

4.10 Data Formatter Editor Selections 4–33

4.10.1 Programming Example 4–34

4.10.2 Data Formatter Priority/Hierarchy 4–36

4.11 Editor Command Sequences 4–36

4.11.1 Editing Command Examples 4–38

4.12 Welch Allyn – DCA Coded ASCII Protocol 4–42

4.12.1 DCA Character Representation 4–42

4.12.2 Programming Example – Retail 4–43

4.13 MSR Data 4–44

4.14 Keyboard Layouts and Delimiters 4–46

CHAPTER 5 – SERVICE/TECHNICAL ASSISTANCE 5–1

vi

Table of Contents

Page 10

Chapter Page

APPENDIX A – BAR CODE BASICS AND SCANNING

TECHNIQUES A–1

A.1 A Closer Look at Bar Code Symbols A–1

A.2 Bar Code Scanning A–1

A.3 Learning How to Use a Bar Code Scanner A–3

A.3.1 Wand Type Scanner A–4

A.3.2 Laser T ype Scanner A–5

A.3.3. CCD T ype Scanner A–6

A.3.4 Magnetic Stripe Reader A–7

A.3.5 Bar Code Badge Reader A–8

A.4 Caring for Your Scanner A–9

A.5 Inspection A–9

APPENDIX B – TECHNICAL SPECIFICATIONS B–1

B.1 General Operation Specifications B–1

B.2 Electrical Specifications B–2

B.3 Connector Specifications B–2

B.4 Bar Code Label Specifications B–4

APPENDIX C – CONNECTING THE 2000/R TO POS AND

PC TERMINALS C–1

C.1 NCR 2151 Interface Cable Installation C–1

C.2 NCR 2152 Interface Cable Installation C–7

C.3 NCR 2950 Interface Cable Installation C–10

C.4 IBM 3653 Interface Cable Installation C–13

C.5 IBM 3683 Interface Cable Installation C–18

C.6 IBM 4683 Interface Cable Installation C–23

C.7 NCR 7052 OCIA Port Interface Cable Installation C–24

C.8 NCR 7052 Keyboard Wedge Interface Cable Installation C–25

C.9 FUJITSU 7990 OCR Interface Cable Installation C–26

C.10 PC/XT, PC/AT, PS/2 And Data Terminal

Keyboard Wedge Interface Cable Installation C–27

APPENDIX D – KEYBOARD FUNCTION

RELATIONSHIPS D–1

D.1 Keyboard Function Relationships D–1

D.2 Index for Terminal Types D–2

D.2.1–D.2.30 Keyboard Function Codes D–33–

Table of Contents

D–36

vii

Page 11

viii

Table of Contents

Page 12

LIST OF FIGURES AND TABLES

Figures Page

1 SCANTEAM 2000 DECODER DESCRIPTION

Figure 1.1 Keyboard Wedge Connection 1–2

Figure 1.2 Direct Connection 1–3

Figure 1.3 Cloning Example 1–5

Figure 1.4 Clone Cable Pin Layout 1–6

2 HARDWARE DESCRIPTION

Figure 2.1 Front/Rear Panel Layout 2–1

Figure 2.2 Power Configuration 2–6

3 SET–UP and INST ALLATION

Figure 3.1 “Y” Interface Cable 3–2

Figure 3.2 SCANTEAM 2000 Connections 3–5

4 PROGRAMMING THE DECODER

Figure 4.1 Programming Menu Page 4–3

Figure 4.2 Bar Code Chart 4–5

Figure 4.3 One–For–One Flow 4–30

Figure 4.4 On Match Flow 4–31

Figure 4.5 Alternate Format Purchase 4–35

Figure 4.6 Code 128 IBM 3683 (19 Characters, 4 fields) 4–41

Figure 4.7 IBM 4683/48 Key T erminal 4–46

APPENDIX A – BAR CODE BASICS AND SCANNING

TECHNIQUES

Figure A–1 Common Scanner T ypes A–2

List of Figures/Tables

ix

Page 13

Figures Page

APPENDIX C – CONNECTING THE 2000/R TO POS AND PC

TERMINALS

NCR 2151 Interface Cable Installation

Figure C.1 C–1

Figure C.2 C–2

Figure C.3 C–3

Figure C.4 C–3

Figure C.5 C–4

Figure C.6 C–5

Figure C.7 C–5

NCR 2152 Interface Cable Installation

Figure C.8 C–7

Figure C.9 C–8

NCR 2950 Interface Cable Installation

Figure C.10 C–10

Figure C.11 C–11

IBM 3653 Interface Cable Installation

Figure C.12 C–13

Figure C.13 C–14

Figure C.14 C–15

Figure C.15 C–16

Figure C.16 C–17

IBM 3683 Interface Cable Installation

Figure C.17 C–18

Figure C.18 C–19

Figure C.19 C–19

Figure C.20 C–21

Tables Page

1 SCANTEAM 2000 DECODER DESCRIPTION

T able 1.1 Terminal Interfaces 1–1

2 HARDWARE DESCRIPTION

T able 2.1 Magnetic Stripe Triple Track Formats 2–5

x

List of Figures/Tables

Page 14

Tables Page

4 PROGRAMMING THE DECODER

T able 4.1 Beeper Sequence and Meaning 4–1

T able 4.2 Country Codes 4–16

T able 4.3 Industrial Codes 4–18

T able 4.4 Retail Codes 4–21

T able 4.5 Retail Keyboard Wedge Terminal Types 4–33

T able 4.6 Data Formatter Priority 4–36

T able 4.7 DCA Conversion Table 4–42

T able 4.8 Magnetic Stripe Formats 4–44

B TECHNICAL SPECIFICATIONS

T able B.1 General Operating Specifications B–1

List of Figures/Tables

xi

Page 15

xii

List of Figures/Tables

Page 16

SCANTEAM 2000 DECODER

TECHNICAL MANUAL INTRODUCTION

The SCANTEAM 2000 Series Decoders are used in both the retail and the

commercial environments. The retail environment includes point–of–sale

uses, while the commercial environments include industrial type

applications (e.g., time and attendance information gathering).

Both the retail and the commercial applications of the SCANTEAM 2000

Series Decoders are described in this technical manual. If information

applies only to the retail product, the heading indicates it is R(etail)

information only. If information applies to the commercial product, the

heading indicates it is C(ommercial) information only.

Appendix C is exclusively Retail information, and Appendix D is

exclusively Commercial information.

This technical manual is an extension of the SCANTEAM 2000

Programming Menu. The Programming Menu contains information and

bar codes that you will use to set up your system to meet your needs. This

manual provides you with additional, in–depth information about the

options in the Programming Menu.

Chapter 1 provides a description of the 2000 Series decoder features,

including serial wedge capabilities, Flash E Prom downloading, and

cloning.

Chapter 2 is a description of the system’s hardware, including connectors,

ports, and power requirements.

Chapter 3 explains how to set up and install your decoder.

Chapter 4 explains how to program your decoder to meet your specific

needs. Refer to Chapter 4 for detailed information when you are using the

2000 Programming Menu.

Chapter 5 explains how to obtain service and technical assistance.

Introduction to the SCANTEAM 2000 Decoder

xiii

Page 17

Appendix A is a guide to bar code basics and scanning techniques.

Appendix B provides information about mechanical, electrical, and bar

code label specifications.

Appendix C describes how to connect the 2000/R(etail) decoder to

point–of–sale and PC terminals.

Appendix D lists keyboard function relationships and cable part numbers

for the 2000C(ommercial) decoder.

xiv

Introduction to the SCANTEAM 2000 Decoder

Page 18

SCANTEAM 2000 DECODER

DESCRIPTION

1.1 Introduction

The SCANTEAM 2000 Series Decoder is a convenient and cost effective

means of adding bar code, mag stripe, and RS–232D data entry capabilities

to point–of–sale terminals, CRT terminals, and personal computers.

The SCANTEAM 2000 Series decoder is a menu programmable bar code

and magnetic stripe reader designed to connect to the terminals listed in

T able 1.1.

1

Keyboard

Wedge

(Retail)

IBM 3683/3684

3653, PC/AT,XT

PS2/30, 50, 60,

70, 80

NCR 2151

2152/2950

7052

2153

IBM Terminals

Keyboard

Wedge

(Commercial)

COMTERM 6178

DDC 3596, 3761

DEC VT–220,

320, 330, 340,

420

HP 700/92

IBM 3151, 3178,

3179/80/91, 3192,

3196/97, 3471/72,

3476, 3477,

PC/AT, PC/XT, PS/2

Telex

78/79/80/180/191/

196/1191/1471/

1472/1476

Wyse 30, 60, 85,150

REI 030 OCR

Parallel Interface

Device

IBM 4683 (Port 21)

3683

Fujitsu 7000 series

(Wand port)

8000 series

(Wand port)

9000 series

(OCR port)

Serial

Direct

Connect

Retail

OCIA

NCR

Nixdorf

& other

terminals

IBM 4680

Port 5B

Port 9B

Port 17

Dual Track

MSR

Table 1.1 Terminal Interfaces

SCANTEAM 2000 Hardware/Software Overview

1–1

Page 19

Note: These terminal interfaces reflect the current level of firmware. New

interfaces may be added to those listed in Table 1. Contact Customer

Service for an updated list.

1.2 System Hardware Overview (2000/R and 2000/C)

The basic SCANTEAM 2000 system includes connectors that are

compatible with a bar code scanner, a magnetic stripe reader, RS–232D

Aux port, and terminal and PC interface cables. All SCANTEAM 2000

decoder and keyboard interface hardware is mounted on a single, printed

circuit board. The electronics is housed in a rugged, plastic cabinet that

can be securely attached to the terminal.

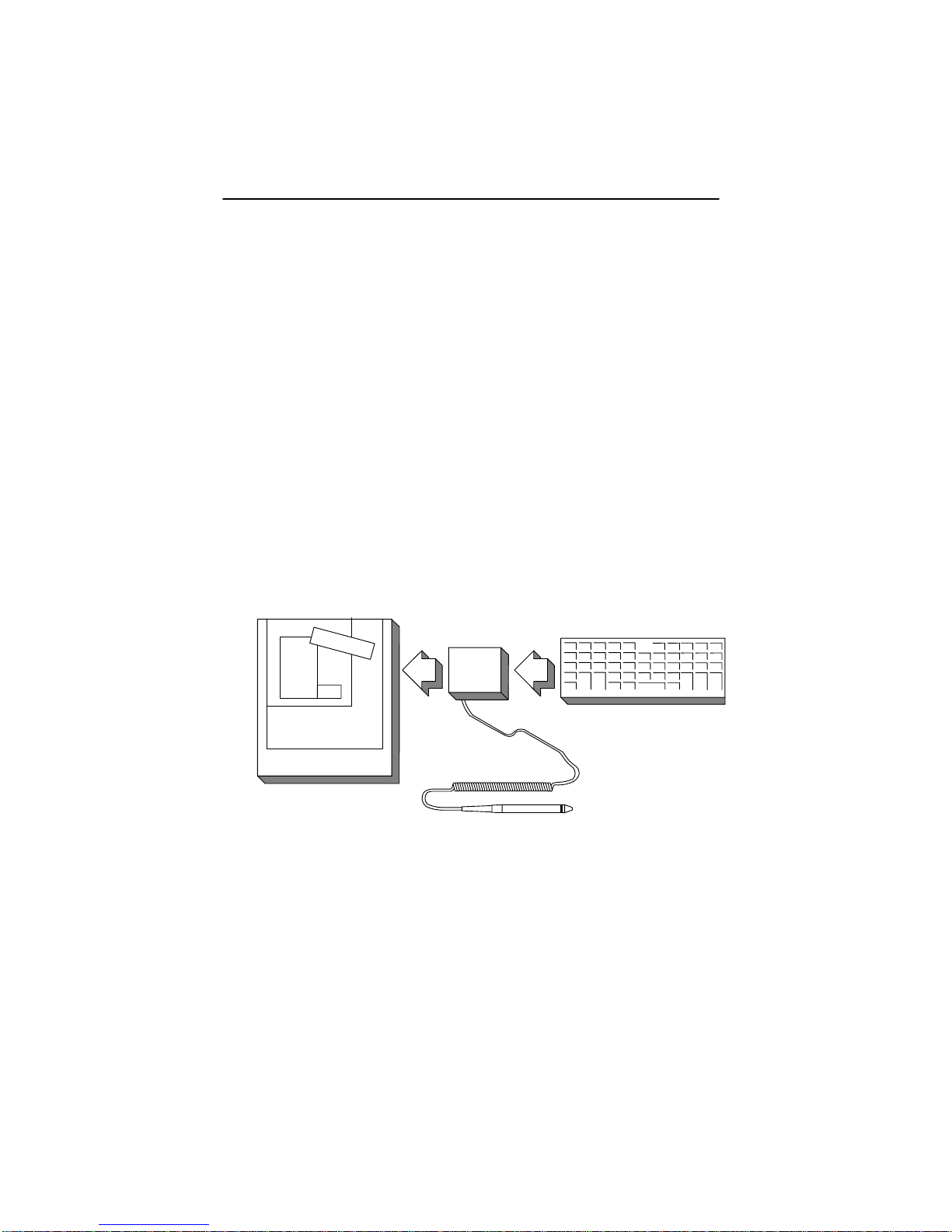

1.2.1 Connection Options

The SCANTEAM 2000 Series has two connection schemes that can be

selected depending upon the requirements of the bar code application. In

the first connection scheme, illustrated in Figure 1.1, the decoder is used as

a keyboard wedge.

T erminal

Keyboard

2000

1–2

Figure 1.1 Keyboard Wedge Connection

SCANTEAM 2000 Hardware/Software Overview

Page 20

In this configuration the SCANTEAM 2000 provides a transparent

interface between the keyboard and the keyboard input port of the terminal

or PC. Output data format from the decoder unit is programmed using a

bar code programming menu. When installed, bar code symbols decoded

by the SCANTEAM 2000 are translated to corresponding keyboard

keycodes and sent to the keyboard input port of the terminal or PC. Thus,

bar code data appears as if it had been keyed in at the keyboard.

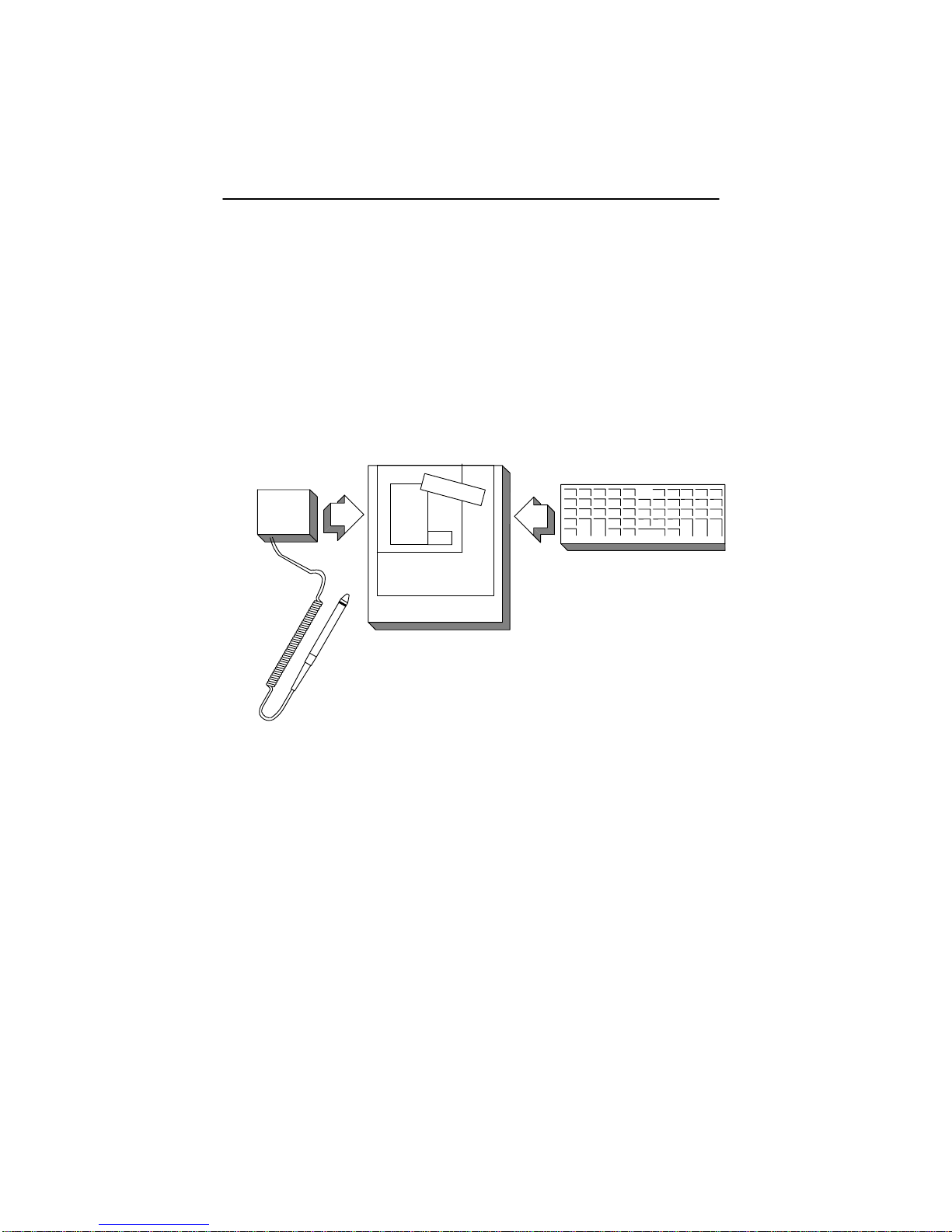

Figure 1.2 illustrates the second connection scheme. The SCANTEAM

2000 is configured for direct connection.

T erminal

Keyboard

2000

Figure 1.2 Direct Connection

With the addition of optional field installable IC’s, the SCANTEAM 2000

supports IBM 4683 Port 17/5B/9B and RS–232 (“serial wedge”)

input/output capability.

SCANTEAM 2000 Hardware/Software Overview

1–3

Page 21

1.2.2 Serial Wedge Capability ( 2000/ C Only)

The SCANTEAM 2000/C may also be used as a serial wedge. In this

configuration the SCANTEAM 2000/C is hooked to both a terminal and a

host computer. The decoded information is displayed on the terminal and

gathered and disseminated on the host. For example, if, in a commercial

environment, bar code readers are used to gather production data, an

assembler may complete a job and indicate that the job is finished by

scanning the information using a bar code reader. The SCANTEAM

2000/C then decodes the information and sends it to a terminal on a

supervisor’s desk, and simultaneously, sends it to a host computer where

the job is registered as done, inventory counts are changed, and the master

schedule is updated.

The serial wedge capabilities are compatible with RS–232 levels, offering

programmable communication to the host, to the terminal, or to both.

When idle, the SCANTEAM 2000/C enables the loop through of both

T erminal TX, RX, and Host TX, RX. All lines are monitored before data

is transmitted to make dure that the data being sent through the 2000 will

not be corrupted. The 2000 does not support RTS/CTS handshaking and is

not capable of processing and receiving data.

The programmable serial wedge parameters are baud rate (300–19200 bps),

parity (odd, even, mark/none, space), data bits (7, 8), and output modes (T o

Host and T erminal, To Host, or To Terminal).

1.2.3 Cloning

The SCANTEAM 2000 Series wedge includes a cloning capability which

provides a way to re–program installed wedges from a “source” wedge.

This capability eliminates the need to use a PC for each download. You

would use the Flash E Prom software program at a terminal to download

the information to the SCANTEAM 2000 “source” wedge. The Flash E

Prom is a programmable/erasable ROM (Read Only Memory) which

enables you to download new interfaces and upgrades without opening the

decoder. The “source” wedge would then be used to program the

“destination” wedges.

Note: Some terminals and power supplies support only one wedge.

1–4

SCANTEAM 2000 Hardware/Software Overview

Page 22

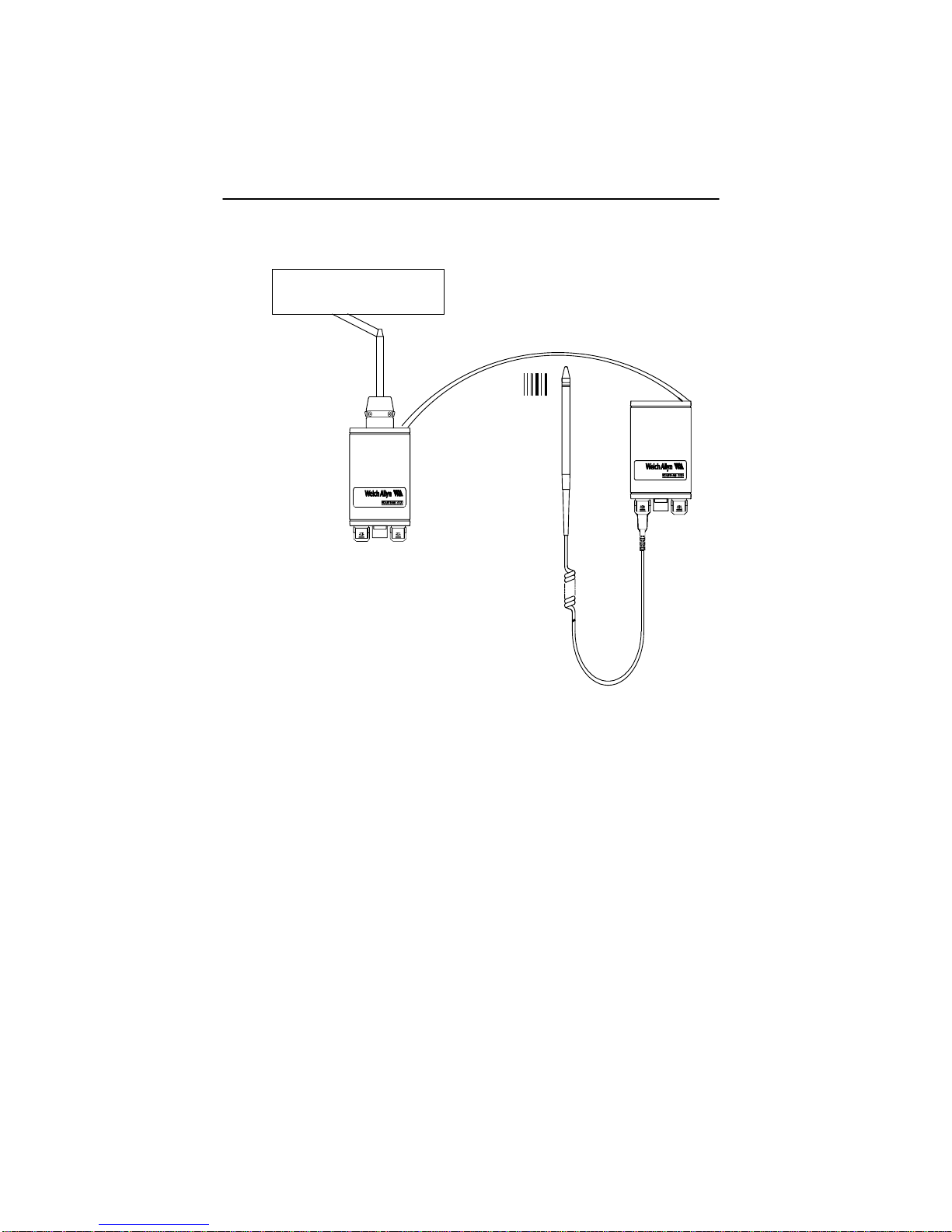

T erminal

“Destination”

Wedge

“Source”

Wedge

Figure 1.3 Cloning Example

Note: If you are using the cloning feature, make sure that the “source” wedge

is at the latest firmware revision level.

If you are going to use the cloning capability, make sure that the “source”

wedge is at the latest revision level of firmware. When you use the cloning

capability, you must make sure that the parity and baud rate of the

“destination” and the “source” are the same.

SCANTEAM 2000 Hardware/Software Overview

1–5

Page 23

After you check the parity, baud rate, and RS–232D chip compatibility, you

would scan the bar code below. The “source” wedge sends a Syn Del

Return message to the “destination” putting it in cloning mode.

Cloning Bar Code

Caution: DO NOT scan this bar code unless you are going to clone a

wedge. If you do, you will lock up your wedge and will have to

turn the power off and back on.

The “source” then sends 512 64 byte blocks of information followed by a

block check character. This takes approximately 20 seconds. When the

information has been downloaded to the “source,” ROM and RAM tests

are performed. If the cloning is successful in the 2000R, one beep will

sound. If the cloning is successful in the 2000C, two beeps will sound. If

the 2000 fails the ROM and/or RAM tests, you will hear three beeps (five

beeps if both tests fail).

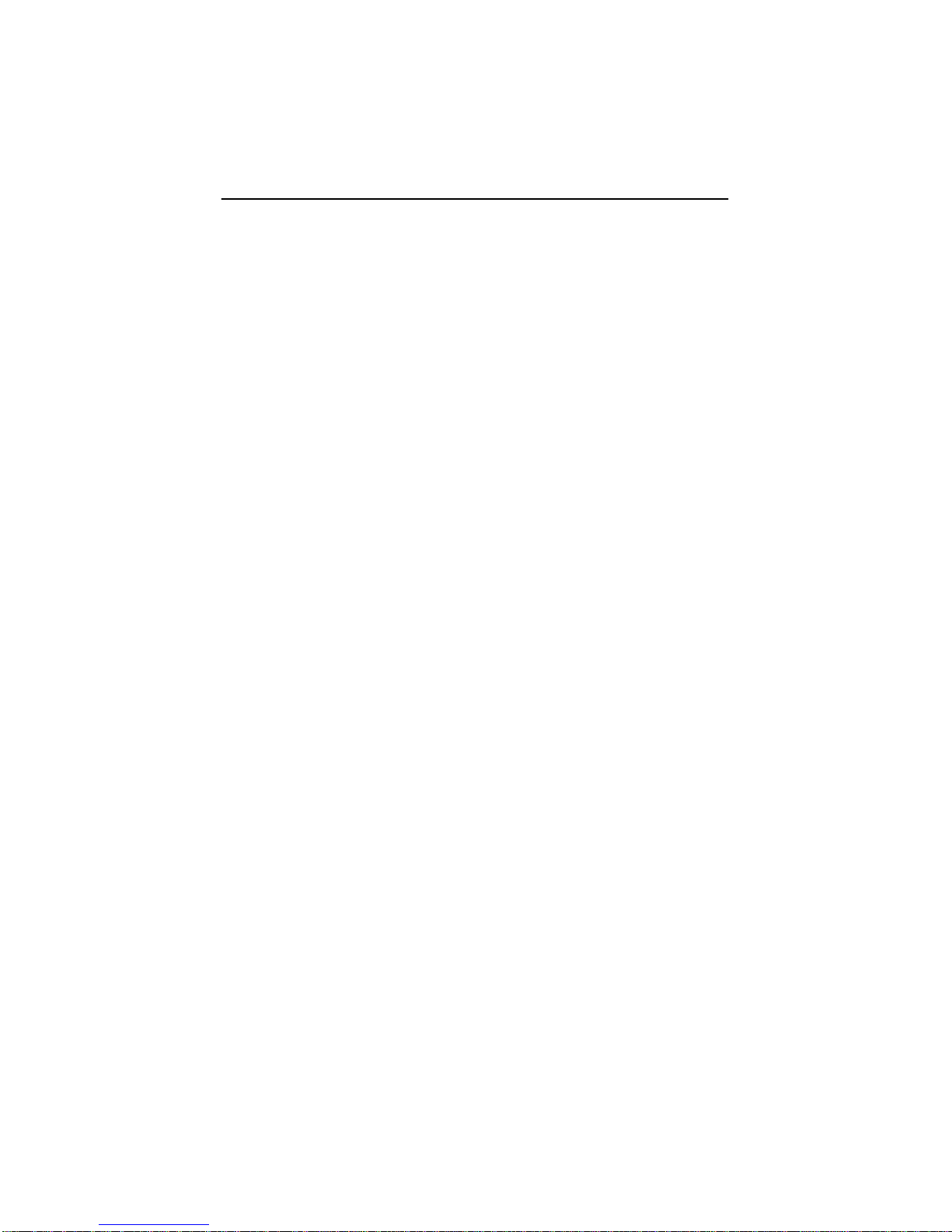

The following figure illustrates the pin layout for the cloning cable.

1–6

1

2

3

4

5

6

Figure 1.4 Clone Cable Pin Layout

SCANTEAM 2000 Hardware/Software Overview

1

2

3

4

5

6

Page 24

1.2.4 Interface Cables/Connectors

The SCANTEAM 2000/R is configured for a particular interface by

connecting the correct interface cable. The unit supports OCR interfaces

with +5V only pull–ups in the host device. Higher voltage pull–ups may

damage the SCANTEAM 2000 output chips.

The SCANTEAM 2000/C is configured by scanning the proper terminal ID

from the Programming Menu and by connecting the proper interface cable.

The OCR, OCIA and RS–232D cable connectors on the terminal end vary

in connector type and pinout as determined by your equipment.

1.3 System Software Overview

1.3.1 Programmable Selections

The SCANTEAM 2000 can be programmed to autodiscriminate among the

following bar code symbologies and their variations: CODABAR, Code 3

of 9, UPC, EAN/JAN, Code 2 of 5, Interleaved 2 of 5, Code 93, MSI, Code

128, Matrix 2 of 5, Plessey, and Code 11.

The SCANTEAM 2000/R software is designed to support keyboards

equipped with either data entry or telephone style number pads, and is

capable of emulating keyboard function keys.

The SCANTEAM 2000/C software is configured to support data entry or

CTRL + keyboard configurations. Refer to page 6 of the SCANTEAM

2000 Programming Menu.

In addition to decoding selections, data output formats and auxiliary port

parameters are also menu programmable using the SCANTEAM 2000

scanning device.

1.3.2 Non–Volatile Memory

The SCANTEAM 2000 contains 512 bytes of non–volatile memory which

are used to store operating parameters programmed by means of the bar

code programming menu.

SCANTEAM 2000 Hardware/Software Overview

1–7

Page 25

An internal power monitor circuit resets the SCANTEAM 2000 hardware

when the nominal +5.0V operating voltage drops below +3.9V. A

software watchdog routine re–initializes the SCANTEAM 2000 if illegal

program execution occurs. A power monitor circuit is included to

re–initialize the SCANTEAM 2000 in the event a temporary power

interruption.

1.3.3 Memory Tests (2000/R ONLY)

When powered–up the SCANTEAM 2000 performs a ROM test and a

RAM test. A test failure causes the SCANTEAM 2000 to issue a single or

double beep sequence, respectively. A test of non–volatile memory

contents also is performed. If the SCANTEAM 2000 fails this test, it

issues a triple beep. Refer to T able 4.1 in Chapter 4, Programming the

Decoder for the beeper sequence and meaning.

1.4 Scanning Devices

The SCANTEAM 2000 is compatible with all Welch Allyn contact and

non–contact bar code scanners, including bar code contact wands, laser

guns, CCDs, and swipe readers. In addition, the product offers a dedicated

port for magnetic stripe scanning applications and supports “triple track”

scanning. Consult your Welch Allyn Sales Coordinator for specific model

numbers of compatible scanners.

1–8

SCANTEAM 2000 Hardware/Software Overview

Page 26

SYSTEM HARDW ARE DESCRIPTION

2.1 Decoder Unit

The SCANTEAM 2000 Decoder front and rear views are shown in Figure

2.1.

Front Panel

SCAN 1 MAG SCAN 2

Rear Panel

2

AUX INTERFACE PWR

LED Indicator

Figure 2.1 Front/Rear Panel Layout

SCAN 1 and SCAN 2 – Accepts 9 pin D–type, female, plastic,

squeeze–to–release connector. Compatible with all Welch Allyn wand,

CCD, or laser scanners.

MAG (Magnetic Stripe Reader) – Standard 8–pin modular connector.

This is a dedicated port for use only with a Welch Allyn one–, two–, or

three–track Magnetic Stripe Reader (MSR).

Hardware Description

2–1

Page 27

AUX (Auxiliary) – Standard 6–pin modular connector. Adds RS–232D

input/output capability to the SCANTEAM 2000.

INTERFACE – 40–pin high density connector. Universal port for

attaching the T erminal Interface Cable.

PWR (External Power Supply) – 4–pin, mini–din connector. For

SCANTEAM 2000 applications which require an external +5VDC power

supply .

2.2 Terminal Interface Cable

A single T erminal Interface Cable (depending upon decoder application) is

supplied with every SCANTEAM 2000 decoder. Interface cable options

and their associated part numbers are listed in Appendix C.

Keyboard Interface cables are custom fabricated for the designated

terminal/keyboard layout. They are properly terminated with all necessary

connector(s) to mate with the user terminals. The user end of T erminal

Interface Cables intended for OCR (SCANTEAM 2000/R),

OCIA(SCANTEAM 2000/R), and RS–232D applications varies in

connector type and pinout as required by your device.

2.3 Interface Port

The SCANTEAM 2000 Interface Port is a 40–pin high density connector

located on the back panel. This connector provides the signals necessary to

connect to and operate with the terminal. The output data format of the

Interface Port must be programmed before the decoder communicates

properly with the terminal.

The Interface Port is programmed using the Data Formatting Editor, the

Bar Code Chart, and Auxiliary Port Data Formatter pages in the

SCANTEAM 2000/R/C Programming Menu. Instructions for their use are

contained in Chapter 4, Programming the Decoder.

2–2

Hardware Description

Page 28

2.4 Auxiliary Port

2.4.1 Description

The SCANTEAM 2000 Auxiliary port is a 6–pin modular connector on the

rear panel of the decoder. It is only supported if the SCANTEAM 2000 is

equipped with an option chip configured for Aux RS–232D. The function

of this port is to transmit RS–232D data with RTS/CTS handshake and

receive the same according to the protocols outlined in Chapter 4,

Programming the Decoder.

The SCANTEAM 2000/R decoder must receive input data with the

following format: 1 Start, 7or 8 Data, 1 Parity, and 1 Stop Bit. The Aux

port can be programmed to operate at baud rates of 300, 600, 1200, 2400,

4800, 9600, 19200, and 38400 and with mark, space, even, odd, or none

parity. For proper operation the SCANTEAM 2000 must be programmed

for the same baud rate and parity as the connected RS–232D device.

The SCANTEAM 2000/R Aux Port is equipped with a buffer that holds up

to 256 characters. If an incoming message exceeds this length, the decoder

stores the extra characters by overwriting those characters stored at the

beginning of the buffer.

2.4.2 Basic Receive Operation

In the SCANTEAM 2000/R decoder data transfer is initiated when the

RS–232D device sends data. (Refer to Page 4–24 for 2000/C information.)

The SCANTEAM 2000 continues to receive and store data until receipt of

an End of Record Character.

The SCANTEAM 2000 lowers the CTS line and transmits the data to the

POS interface or terminal. Data is framed by the Preamble/Postamble if

preambles or postambles have been programmed. When all data has been

sent to the POS interface or terminal, the SCANTEAM 2000 raises the

CTS line causing the Aux Port to return to ready status. New Aux Port

data is now permitted. Refer to Chapter 4, Programming the Decoder, for

information on the operation of the 2000/C.

Hardware Description

2–3

Page 29

Aux Port data can be formatted according to the SCANTEAM 2000

terminal program requirements for keyboard interface applications using

the Data Formatter page in the programming menu. Instructions

concerning the formatting are contained in Chapter 4, Programming the

Decoder of this manual.

2.4.3 Transmit Operation

When RS232 Aux transmission is needed. select the terminal selection 00.

Data is sent with preambles and postambles if preambles/postambles are

programmed using valid ASCII characters (00–7F Hex).

2.5 Scanner Ports

The SCANTEAM 2000 features two scanner ports that are compatible with

all Welch Allyn industrial grade digital wand–type scanners, as well as the

Welch Allyn Model 5500 Series and 3000 CCD scanners. Some

non–Welch Allyn scanners may also be supported.

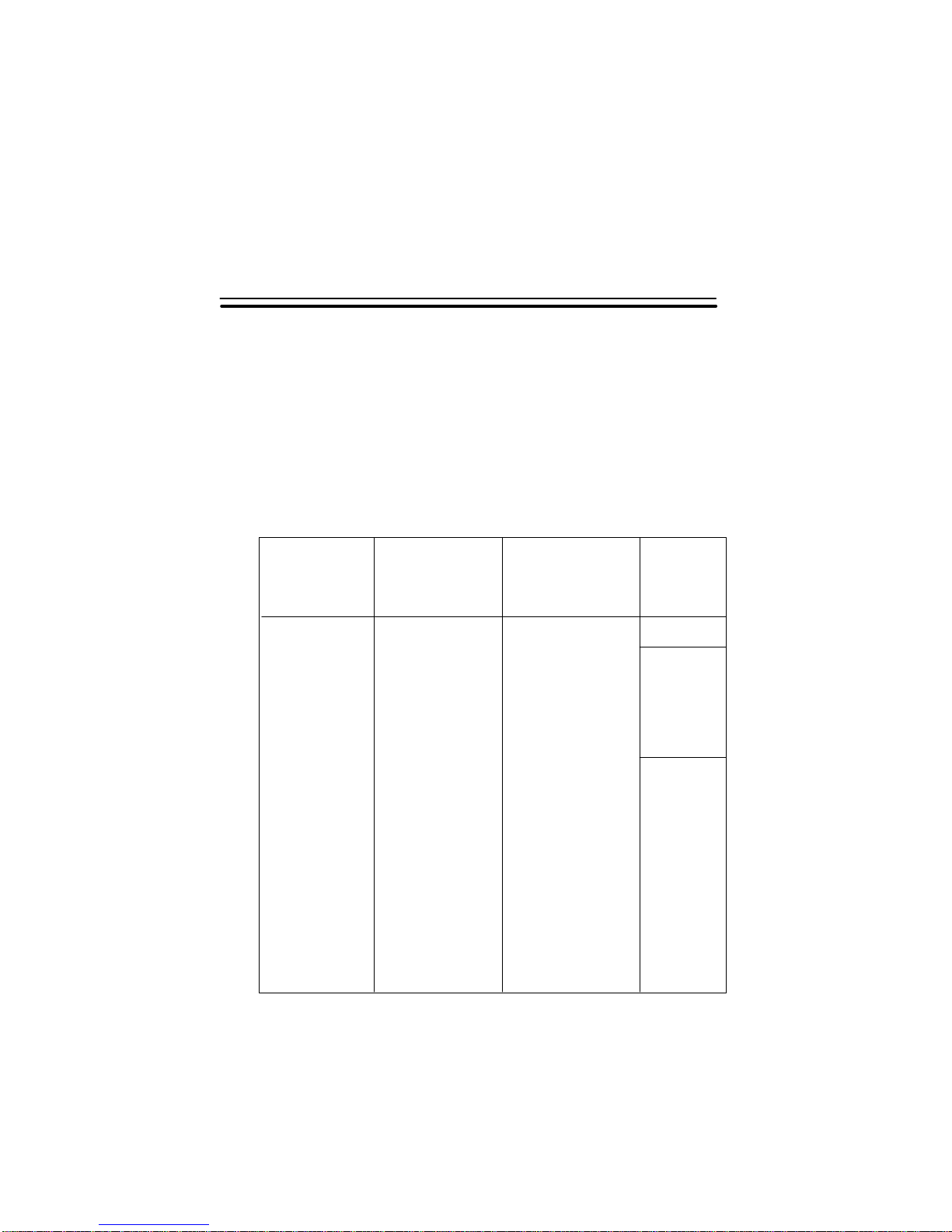

2.6 Magnetic Stripe Triple Track Reader (MSR) Port

The MSR port on the front panel of the SCANTEAM 2000 is dedicated to

the MSR 6900 magnetic stripe reader and is designed to accept undecoded

digital signals. T o process output from the reader, the MSR port must be

programmed through the scanner port using the programming menu. The

SCANTEAM 2000 MSR port cannot be programmed using the magnetic

stripe reader.

Data contained on bank credit cards and travel and entertainment cards

(i.e., American Express, etc.) as defined by ANSI are contained on tracks

1, 2, and/or 3 as shown in T able 2.1. The SCANTEAM 2000 user may

select either track as a source for data: (a) either track 1, 2, or 3; (b) tracks

1, 2, and 3; or (c) any one combination of the eight desired coding.

Specific instructions for programming the MSR port are discussed in

Chapter 4 of this manual and described in the SCANTEAM 2000

Programming Menu.

2–4

Hardware Description

Page 30

Track 1 Record Formats

Max. Record Length = 79 Char.

Length

1

*

* The length of these fields is card

issuer dependent.

** This is always the last 11 positions of Track 1, excluding the end

sentinel and Longitudinal Redundancy Check character.

Name of Field

Start Character (%)

Format Character1

Primary Acct Number13 or 16

Field Separator (^)1

Cardholder Name2–26

Field Separator (^)1

Card Expiration Date4

Service Code*

PIN Verification Field*

Discretionary Data

VISA Reserved*

Stop Character (?)1

LRC Character1

Track 3 Record Formats

Max. Record Length = 107 Char.

Length

1

2

Name of Field

Start Character (;)

Format Character

Primary Acct NumberUp to 19

Field Separator (=)1

Use & Security DataUp to 49

Additional DataUp to 33

End Character (?)1

LRC Character1

Track 2 Record Formats

Max. Record Length = 40 Char.

Length

1

*

*The length of these fields is card

issurer dependent.

Name of Field

Start Character (;)

Primary Acct Number13 or 16

Field Separator (=)1

Card Expiration Date4

Service Code*

PIN Verification Field*

Discretionary Data

Stop Character (?)1

LRC Character1

Table 2.1 Magnetic Stripe Triple Track Formats

Hardware Description

2–5

Page 31

2.7 Power Requirements

2.7.1 Keyboard Wedge Applications

When the SCANTEAM 2000 functions as a keyboard wedge, you may

choose to have the terminal supply power through the keyboard interface

connector. The SCANTEAM 2000 Decoder needs +5VDC +/–10% and

draws approximately 140 milli–Amps when connected to a terminal with a

wand scanning device. Power can come from an external power supply or

from the terminal to which the SCANTEAM 2000 is hooked. If you are

using an external power supply, you may need to change the internal power

jumper. See Figure 2.2 for jumper settings.

Jumper Settings

JP5

–12 VDC on pin 1

of Scan 2 Port

No connection

on pin 1 of

Scan 2 Port

Scan 1 Port

Mag Stripe Port

(2000 board with edge nearest beeper toward you.)

JP4

+12 VDC on pin 9

of Scan 2 Port

+5 VDC on pin 9

of Scan 2 Port

Power Supply Port

JP3

JP4

JP5

JP3

External

Power

Terminal

Power

Interface Port

Aux

Port

Beeper

2–6

Scan 2 Port

Figure 2.2 Power Configuration

Hardware Description

Page 32

RS–232D Auxilliary Port

The SCANTEAM 2000 can supply power to or be powered by a connected

device on the Aux Port with +5VDC available on pin 6.

Note: In many keyboard wedge applications, the terminal is capable of

supplying reasonably stable +5VDC power. The SCANTEAM 2000 has

a power monitor circuit which monitors the +5VDC line and shuts down

the microprocessor when voltage drops below +3.9VDC. When power

is not adequate or available, a +5VDC external power supply is

available.

Hardware Description

2–7

Page 33

2–8

Hardware Description

Page 34

SET–UP AND INSTALLATION

3.1 Preparation

The SCANTEAM 2000 Decoder and its associated components, including

scanning devices and interface cables, are bulk shipped in individual

corrugated cartons. Upon receipt, you should open each carton and check

the contents and part numbers to confirm that each item on the packing list

has been supplied in the proper quantity.

You also should thoroughly inspect the contents for possible shipping

damage. Any damage to components should be reported immediately to

the carrier which delivered the shipment. Damage claims due to handling

during shipping should be placed directly with the carrier.

T o assure proper operation and prevent possible damage to the

SCANTEAM 2000 decoder or terminal, you should perform the following

installation procedures in the sequence in which they are presented.

3

3.2 Set–up Procedure

Caution: The SCANTEAM 2000 contains static sensitive components.

Precautions must be taken to eliminate potential static discharge

to any printed circuit board. The SCANTEAM 2000 is configured

to support 5 volt lasers. However, you should be aware of the

following precautions when installing the 2000/C. (The 2000/R

set–up procedures follow the 2000/C set–up procedures.)

3.2.1 2000/C Set–up

(1) Turn off the power to the terminal to which the 2000/C will be

connected.

Set–up and Installation

3–1

Page 35

(2) Attach the decoder to the terminal.

(a) Locate the “Y” interface cable shipped with the 2000/C and

verify that it is the correct number. Cable part numbers are

provided in Appendix D.16 and on the page facing the T erminal

Selection instructions in the SCANTEAM 2000 Programming

Menu.

The general “Y” Interface Cable connections are illustrated in

Figure 3.1.

B

A

Figure 3.1 “Y” Interface Cable

C

3–2

(b) Plug the 40–pin male connector (A) of the Y” interface cable

into the 40–pin female connector located on the back panel of

the 2000/C until it clicks into place.

(c) Disconnect the keyboard from the terminal (display) and insert it

into the mating connector on the short leg of the “Y” interface

cable (B).

Set–up and Installation

Page 36

(d) Complete the cabling procedure by inserting the remaining long

leg of the “Y” interface cable (C) into the terminal keyboard

connector. (Connector from which the keyboard cable was

removed.)

(3) Position the 2000/C so that all cables run freely and smoothly. If

desired, the decoder can be secured to the terminal cabinet or table top

using the mounting strips supplied with the unit.

(4) Attach the scanning device(s) into the appropriate front panel

connector on the 2000/C. The scanning device cable will click into place

when properly seated in the connector port.

(5) Confirm the SCANTEAM 2000/C power supply rating. The 2000/C

can be ordered with one of several optional external power supplies,

depending upon user requirements. Inspect the rating plate on the power

supply module and the rating plate that is attached to the bottom of the

decoder. Confirm that the power supply provides the required operating

values.

(6) Connect the external power supply (if required). Make sure that the

external power supply is not connected to an AC power source. Install the

external power supply (if it is required) by plugging the 4–pin male DIN

output connector of the power supply into the 2000/C port labeled,

POWER, located on the back panel of the decoder.

(7) If an auxiliary RS–232D input/output device is to be used, plug the

6–pin modular plug of the auxiliary port cable (specified at the time of the

order) into the 6–pin modular socket on the back panel of the 2000/C until

it clicks into place. Connect the other end of the cable to the RS–232D

input device.

(8) When the 2000/C is fully connected, reconnect main AC power to the

terminal. If an external power supply is required, follow the steps below.

(a) Plug the external power supply into the appropriate line voltage

source. The green LED power indicator on the back panel of the

2000/C should light. The wedge issues two beeps.

Set–up and Installation

3–3

Page 37

(b) Turn on the terminal power. Do not try to enter data until the

host terminal has fully initialized.

If an external power supply is not needed, simply turn on the terminal

power. The green LED power indicator on the back panel of the 2000/C

should light. The wedge should issue two beeps. Do not try to enter data

until the host terminal has fully initialized.

3.2.2 2000/R Set–up

(1) When you install a keyboard wedge interface cable, turn off the system

power.

(2) Keyboard Wedge Applications

(a) Check the cable name/part number on the Keyboard Interface

Cable and confirm that it is the proper cable for your terminal.

Install the keyboard interface cable in your terminal using the

procedures listed in Appendix C.

Note: Although other installation techniques may be used, we strongly

suggest you follow the step–by–step instructions provided for your

particular terminal. These procedures have been developed and

tested by Welch Allyn engineers.

(b) When the terminal end of the interface cable has been installed,

plug the 40–pin high density connector of the interface cable

into the 40–pin high density connector labeled INTERFACE on

the SCANTEAM 2000.

3–4

Set–up and Installation

Page 38

HRL 5510 Laser

Interface Cable

40 Pin Connector

Scanner

Welch Allyn SCANTEAM 2000

8 Pin Modular Connector

MSR

(Magnetic Stripe Reader)

Figure 3.2 SCANTEAM 2000 Connections

(3) Plug the scanning device, either a CCD scanner, moving beam laser, or

hand held wand into the 9–pin male squeeze D connector labeled SCAN 1

or SCAN 2.

(4) Attach the Magnetic Stripe Reader (MSR) if one is being used. Plug

the reader into the 8–pin modular connector labeled MAG.

(5) If an auxiliary RS–232DC input device is to be used, plug the

connector of the Aux port cable into the connector labeled AUX. Connect

the other end of the cable to the RS–232D input device.

(6) Turn the power on the terminal. The green LED power indicator on

the rear panel of the SCANTEAM 2000 should light, and the unit should

issue a single beep.

Set–up and Installation

3–5

Page 39

This completes set–up and installation of the SCANTEAM 2000 Decoder.

You are now ready to configure the unit for your particular application.

Instructions for configuring the SCANTEAM 2000 using the Programming

Menu are provided in Chapter 4, Programming the Decoder.

3–6

Set–up and Installation

Page 40

PROGRAMMING THE DECODER

Before the SCANTEAM 2000 decoder can be placed in operation, it must

be programmed for the particular application by scanning bar code symbols

from the Programming Menu. The information and data format

instructions are stored in non–volatile memory when the programming

session is exited.

4.1 Beeper Sequence and Meaning

The table below lists the number and the meaning of the beeps your

decoder emits.

Sequence Meaning

1 Beep Valid bar code, mag stripe, or

RS–232D input; successful power–up

(2000/R).

2 Beeps Successful enter into and exit out of

Programming Mode; successful

power–up (2000/C).

3 Beeps Invalid bar code or program entry,

mag stripe, or RS–232D input.

4

3 beeps Fail ROM test on power up. (2000/R)

3 beeps Fail RAM test on power up. (2000/R)

5 beeps

Table 4.1 Beeper Sequence and Meaning

Programming the 2000 Decoder

Fail ROM and RAM test on power up.

(2000/R)

4–1

Page 41

4.2 The Programming Menu

The Programming Menu is divided into nine main sections: (1) T erminal

Selection, (2) Output Parameters, (3) Industrial Codes, (4) Retail Codes,

(5) Auxiliary Port, (6) Data Formatter, (7) Status Check, (8) the Bar Code

Chart, and (9) Code 3 of 9 Symbols.

Each section contains a menu page(s) which lists certain decoder

parameters and defines the scanning sequences for selecting specific

configuration options. A System Guide, in the beginning of the menu,

describes the programming menu page layout and identifies other helpful

information for the programming process.

4–2

Programming the 2000 Decoder

Page 42

4.2.1 Programming Menu Page

A typical programming menu page is shown in Figure 4.1.

3

scan

ENTER

scan

DEFAULT

4

SCANTEAM 2000 Programming Menu

USE THIS PAGE

1

To select the pre–programmed asterisked (*) values by scanning DEFAULT symbol.

To enable or disable listed code selections.

selections variables

2

UPC

ID = c

(HEX 63)

EAN

ID = d

(HEX 64)

UPC & EAN

ADDENDA REQ’D.

MSI

ID = g

(HEX 67)

PLESSEY

ID = n

(HEX 6E)

UPC/EAN ADDENDA

FORMAT

scan scan

Version A

Version D(4)

Version E0

Version E1

Check Digit Xmit

Number System Xmit

Version E Expand

2–Digit Addenda

5–Digit Addenda

EAN/JAN 13

EAN/JAN 8

Check Digit Xmit

2–Digit Addenda

5–Digit Addenda

Enable Yes/No*

Enable

Minimum Length

Maximum Length

Enable

Minimum Length

Maximum Length

With space *Yes/No

SELECTION II

CODE

(RETAIL)

scan

*Yes/No

A

B

C

D

E

F

G

H *Yes/No

I

A

B

C

DE*Yes/No

A

B

A

B

No*

*Yes/No

*Yes/No

%Yes/No#

%Yes/No#

Yes/No*

*Yes/No

*Yes/No

*Yes/No

%Yes/No#

*Yes/No

#Yes/No%

*04–Max

Min–48*

#Yes/No%

*04–Max

Min–48*

5

scan

EXIT

Notes:

(1) * Designates DEFAULT selections for the 2000/C and 2000/R.

6

(2) # Designates DEFAULT 2000/C selections.

(3) % Designates DEFAULT 2000/R selections.

(4) UPC Version D is not supported at this time.

Figure 4.1 Programming Menu Page

Programming the 2000 Decoder

4–3

Page 43

All of the SCANTEAM 2000 programming menu pages follow a similar

layout and contain the same basic programming elements.

(1) A “USE THIS PAGE” statement indicates the general programming

capabilities which appear on that menu page.

(2) The SELECTIONS/VARIABLES table lists primary programming

selections, variables which can be used to modify the basic selection,

and the bar code scanning sequence that must be used to configure the

decoder to these values.

Three discrete bar code commands allow global menu selections and

control movement between menu pages.

(3) Scanning the ENTER command bar code symbol activates that

particular menu page. The ENTER code for each menu page is

unique, and must be scanned before configuring commands from that

page will be recognized by the decoder.

(4) A generic DEFAULT command causes the Selection/Variables on the

activated menu page to automatically default to those values marked

by an asterisk (*). If a selection applies only to the 2000/C, the

option contains a “#.” If a selection applies only to the 2000/R, the

option contains a “%.” The “*,” “#,” and “%” signs are used as

indicators to distinguish the defaults. Do not scan these symbols.

(5) The common EXIT command terminates programming on the active

menu page. The EXIT symbol must be scanned before moving to

another page of the programming menu.

Information regarding special bar code applications is often provided at the

bottom of menu pages.

(6) This includes the special NOTES which are used to explain unusual

programming requirements and/or refer you to necessary information

or examples elsewhere in the menu or the SCANTEAM 2000 manual.

Additionally, the facing page for each programming menu is frequently

used to supplement or clarify material presented on the front of the menu

page. It may contain charts, diagrams, or detailed programming

instructions.

4–4

Programming the 2000 Decoder

Page 44

4.2.2 The Bar Code Chart

The SCANTEAM 2000 Bar Code Chart is shown below in Figure 4.2.

SCANTEAM 2000 Programming Menu

USE THIS PAGE

In combination with the adjoining menu pages to program the 2000.

The bar codes on this page correspond to symbols in shaded areas on adjoining menu pages. SCAN these bar

codes in the sequence indicated on menu page to program desired selections and variables.

BAR CODE CHART

ROMAN NUMERALS LETTERS DIGITS OTHERS

I

XI

II

XII

III

XIII

IV

XIV

V

A

0 (YES)

B

1 (NO)

C

2

D

3

E

ESCAPE

DEFAULT

EXIT

ALT–A

VI

VII

XV

F

XVI

G

XVII 6

Figure 4.2 Bar Code Chart

Programming the 2000 Decoder

4

ALT–B

5

ALT–C

4–5

Page 45

Note that symbol groupings include ROMAN NUMERALS, DIGITS,

LETTERS as well as discrete YES, NO, and EXIT symbols. The sequence

in which these symbols are scanned produces the programming commands

that enable or disable specific decoder functions.

Note: The bar codes must be scanned through the SCANTEAM 2000 Scanner

Port; the decoder cannot be configured using the magnetic stripe reader

or RS–232D input device. A Welch Allyn wand scanner is best for this

purpose.

4.3 Recommended Programming Sequence

The SCANTEAM 2000 operating parameters can be programmed in any

order by moving from one menu page to another. However, since the

programming process typically requires numerous scans, it is

recommended that you plan and document each configuration command in

advance. The following sequence is recommended for programming

decoder parameters:

STEP 1) TERMINAL SELECTION

STEP 2) OUTPUT Parameters

STEP 3) CODES (Industrial)

STEP 4) CODES (Retail)

STEP 5) AUXILIARY PORT

STEP 6) DATA FORMATTER

After you complete the programming process, use the STATUS CHECK

page in the Programming Menu to verify your settings.

4–6

Programming the 2000 Decoder

Page 46

4.4 Terminal Selection Menu Page

The Terminal Selection page of the Programming Menu is used to

configure the decoder for operation with a specific terminal device, or to

instruct the decoder to output data through the RS–232D Aux port. No

default parameters are included on this menu page. All terminal selections

must be programmed using the bar code chart at the end of the

Programming Menu.

In addition to identifying the proper selection/variable combination, the

correct “Y” interface cable must be installed. A table showing

terminal–to–part number relationships is provided in Appendix D and on

the Information & Examples page facing the T erminal Selection section of

the Programming Menu. Cable installation procedures are described in

section 3.0 of this manual.

Example: Configure the SCANTEAM 2000 TERMINAL SELECTION to the

following values:

T erminal: IBM PC/AT

(Refer to the Selections/Variables table on the TERMINAL SELECTION

page of the Programming Menu.)

Program these operating parameters following the scanning sequence

below .

FUNCTION SELECTION VARIABLE

Enter Menu Page ENTER

Enable IBM PC/AT 0

3

Leave Menu Page EXIT

Scanning the EXIT symbol stores the terminal type (IBM PC/AT)

information in non–volatile memory. This parameter will not have to be

programmed again unless the SCANTEAM 2000 is connected to a

different terminal type.

Programming the 2000 Decoder

4–7

Page 47

4.5 Output Parameters Menu Pages

The Output Parameter Menu pages of the programming menu is used to

configure beeper volume and tone, enable an inhibit check function,

specify that a secondary keyboard type is being used, and set intercharacter

and intermessage delays. An explanation of programmable selections

follows.

Beeper Volume/Tone

The volume of the audible signal used to indicate a “good read” and to

communicate other beeper sequences is programmable. The beeper

volume range is 00 – FFFF. You may silence the beeper (by programming

“00”), or select another value to obtain a sound level to meet your work

environment needs. You must scan once for volume and again for tone.

The tone of the beeper signal ranges from 00 – FFFF. No tone = 00; the

highest tone = equals FFFF. The following list presents suggestions for

high, medium, low, and off: high = 1919, medium = 4949, low = 0C0C,

and off=0000. Feel free to experiment with the beeper/tone setting to

determine an appropriate range for your environment.

Keyboard Style

This menu selection allows you to program the decoder to support special

keyboard features such as CAPS LOCK, SHIFT LOCK, Data Entry, and

CTRL + codes (e.g., CR, CTRL +“M.”) The facing page of the Output

section of the Programming Menu (page 4) lists the keyboard style options

for the SCANTEAM 2000.

Keyboard Layout III (Keypad) (SCANTEAM 2000R ONLY)

The Keyboard Layout option allows you to program the decoder to

transmit the proper keycodes when interfacing with a telephone, calculator,

or PC/AT–type numeric keypad layout. If your terminal only has a

numeric keypad and it is set up in a telephone keypad layout, enable the

telephone keyboard layout (Layout 1). If your numeric keypad is set up

like a calculator, enable the calculator keyboard layout (Layout 2). If your

terminal is equipped with a fully populated alphanumeric keyboard, use

Layout 3.

4–8

Programming the 2000 Decoder

Page 48

4683 I/O Port Selection (SCANTEAM 2000/R ONLY)

This menu selection permits you to specify the type of input port of an

IBM 4683 POS terminal to which the SCANTEAM 2000 should respond.

Unless programmed otherwise, the SCANTEAM 2000 defaults to accept

signals from Port 5B. The other options are Port 9B and Port 17.

OCIA Format Selection (SCANTEAM 2000/R ONLY)

This menu selection allows you to specify the type of output OCIA format

to which the SCANTEAM 2000 should respond. Unless programmed

otherwise, the SCANTEAM 2000 defaults to accept signals from NCR

“S.” The other options are NCR “F,” Nixdorf, and Spectra Physics.

OCR Format Selection (SCANTEAM 2000/R ONLY)

The OCR Format Selection allows you to specify the type of OCR input

port to which the SCANTEAM 2000 should respond. Unless programmed

otherwise, the SCANTEAM 2000 defaults to accept signals from Fujitsu.

The other option is IBM.

Intercharacter Delay

Intercharacter delay is the time delay between data characters output by the

SCANTEAM 2000. The delay is in x5 milliseconds, and you may set the

value to between 0000 and 9999 (x5ms).

Interfunction Delay

Interfunction delay is the time delay between function key characters

output by the SCANTEAM 2000. The delay is in x5 millisecond. You

may select any value between 0000 and 9999 (x5ms).

Intermessage Delay

Intermessage delay is the time delay between messages/records output by

the SCANTEAM 2000. The delay is in x5 milliseconds. You may set the

value to between 0000 and 9999 (x5ms).

Programming the 2000 Decoder

4–9

Page 49

4.5.1 Output Parameters Continued

Preamble

Preambles are assigned to a particular symbology using the SCANTEAM

2000 Series Programming Menu. When the preamble selection is enabled,

one or more characters are transmitted as a header immediately preceding

scanned bar code data. Any combination of ASCII characters or function

codes can be programmed. Preamble characters will be transmitted in the

order in which the selections were made. The preamble can be returned to

“none” by selecting Preamble and then selecting the symbology, scanning

FF and EXIT. A total of all of the preambles and postambles is limited to

40 characters.

Postamble

Postambles are programmable data identifiers which follow the bar code or

keyboard messages. Postambles are assigned to a particular symbology

using the SCANTEAM 2000 Series Programming Menu. Any

combination of ASCII characters or function codes may be programmed.

The postamble can be returned to “none” by selecting Postamble and then

selecting the symbology, and scanning FF and EXIT. A total of all of the

preambles and postambles is limited to 40 characters.

Note: The SCANTEAM 2000 translates characters 01–1F (keyboard function

codes) into keyboard function keys. The assigned translation is

dependent upon the terminal being used. Refer to Appendix D for

additional information about the keyboard function relationships.

Buffer Scans

If the Buffer Scans option is set to Yes, the decoder can accept a second

scan while it is outputting the current scan. If Single Scan is selected, the

decoder cannot accept additional scans until the current scan is outputted.

The default is Yes for the 2000/C and No for the 2000/R.

Input Inhibit Check (SCANTEAM 2000/C ONLY)

In most terminal environments, the terminal is often “inhibited” from

sending data to the host CPU if the CPU is engaged in a certain data

processing activity. Input inhibit originates at the CPU and most likely

occurs immediately after a screen, or page of data is sent to the host CPU

or when the operator activates the “XMIT,” “SEND,” or “ENTER” key at

the terminal keyboard. As long as the “inhibit” signal is present, further

input from the keyboard is ignored by the terminal.

4–10

Programming the 2000 Decoder

Page 50

In many bar code data collection systems the Input Inhibited condition is

communicated to the operator on the terminal screen. However, since the

SCANTEAM 2000 can emulate the operator’s action of sending data to the

host CPU which could generate an Input Inhibit condition, the Input Inhibit

condition must be monitored by other than visual means if available.

That is the purpose of the Input Inhibit Check menu selection. When Input

Inhibit Check is enabled, the monitoring function is performed

automatically by the decoder. The SCANTEAM 2000 continually checks

for the Input Inhibit signal and will not attempt to transmit data as long at

the inhibit option is present.

SPECIAL IBM 3178 PROGRAMMING NOTE (SCANTEAM 2000/C ONLY):

If the Input Inhibit capability is to be used in conjunction with an IBM

3178 terminal, the SCANTEAM 2000 Input Inhibit feature must be

enabled, and the 3178 Key Click should be turned OFF. Proper operation

can be confirmed by making sure the terminal only clicks when it is in the

input inhibited state.

Code ID Transmit

When this menu selection is enabled the decoder transmits a single lower

case ASCII character to identify which symbology was decoded. For

example, Code 3 of 9 is identified by a lower case “b,” while Code 128 is

identified by a lower case “j.” The default is No.

The code identifier for each bar code symbology is listed below and

appears immediately following the symbology name on the Symbology

Selection Menu Page.

SYMBOLOGY CODE ID

CODABAR a

Code 3 of 9 b

UPC c

EAN d

Interleaved 2 of 5 e

Code 2 of 5 f

MSI g

Code 1 1 h

Code 93 i

Code 128 j

Matrix 2 of 5 m

Plessey n

Programming the 2000 Decoder

4–11

Page 51

Function Codes

When this menu selection is enabled, and function codes are contained

within the scanned data, the SCANTEAM 2000 transmits the key code to

the terminal which corresponds to the decoded ASCII function code.

ASCII function codes are represented by the HEX values (00–1F).

When the Function Codes selection is disabled, the decoder does not

transmit the key codes which correspond to the HEX characters 01–1F

unless they are in preambles or postambles. Instead, the characters 01–1F

are stripped from the bar code data. Any keyboard function codes in the

scanner port preamble and postamble will be sent to the terminal regardless

of the parameter. Function codes in preambles and postambles are

automatically translated to key codes.

Note: Care should be taken not to embed keyboard function codes that will

cause an input inhibit condition within records, preambles, and

postambles. Attempts to embed function codes may result in loss of

data.

Example – Keyboard Function Codes (Commercial Application):

The SCANTEAM 2000 is connected to an IBM PC; Keyboard Function

Codes within data and the Preamble and Postamble on the continuation

page of the Output section of the Programming Menu.

The SCANTEAM 2000 is programmed as follows:

Preamble: GS (1D)==>F10 key

Postamble: CR (OD)==>ENTER key

Full ASCII Code 3 of 9 Decoding: enabled

Note: When programming preambles and postambles you must scan a

symbology before scanning in a scan code.

Consider the case of a Code 3 of 9 bar code symbol:

1 2 3 4 “HT” 5 6 7 8

The function emulated depends not only upon the Keyboard Function

Code, but also upon the terminal being used with the SCANTEAM 2000.

Appendix D lists, by terminal type, the key function emulated by each

Keyboard Function Code. (The codes in the center column change.)

4–12

Programming the 2000 Decoder

Page 52

CASE 1 – Function Codes “Enabled”

With the Scanner Port Function Codes enabled, the SCANTEAM 2000

outputs 1234HT5678 to the terminal as:

F10 1 2 3 4 “TAB ”5 6 7 8 ENTER

preamble postamble

Notice that Keyboard Function Code, HT, has been translated and sent as

the TAB key .

CASE 2 – Function Codes “Disabled” (Commercial Application):

When the Scanner Port Function Codes are disabled, the SCANTEAM

2000 outputs 1234HT5678 to the terminal as:

F10 1 2 3 4 5 6 7 8 ENTER

Notice now that HT has been stripped from the data string. Note also, that

Keyboard Function Codes contained within the Preamble and Postamble

(F10 and ENTER) are not affected by the Scanner Port Function Code

selection (IV) and so they are translated and sent.

Keyboard Function Records

Keyboard Function Records are special incoming data records which can

originate from either the Aux Port or the Scanner Port.

Keyboard Function Records are translated by the SCANTEAM 2000 and

sent to the terminal as keyboard function keys. The function which is

emulated depends upon both the Keyboard Function Record and the

terminal selection. The key functions emulated by each Keyboard

Function Record are listed according to terminal type in Appendix Section

C.1 to C.15.

Keyboard Function Records differ from Keyboard Function Codes in the

following ways:

(1) Keyboard Function Records cannot be disabled by menu

programming.

(2) Keyboard Function Records cannot be embedded within other

Aux Port or Scanner Port data; they are stand alone records, and

if embedded, will be treated as normal data.

Programming the 2000 Decoder

4–13

Page 53

(3) When Keyboard Function Records are entered, any

Preambles/Postambles which may have been programmed will

not be added to the output transmission.

Example – Keyboard Function Records (Commercial Application)

The following examples illustrate the effect of Keyboard Function Records

on data transmission when used in conjunction with the Scanner Port and

the Aux Port.

Scanner Port Data

In this example the SCANTEAM 2000 is connected to an IBM PC, and the

function key F10 is to be emulated using a Keyboard Function Record

entered via the Scanner Port. The symbology Full ASCII Code 3 of 9 has

been enabled.

When configured in this way, scanning a Code 3 of 9 label containing the

following characters:

/ C 3 1

will produce a decoded output of (#31).

The SCANTEAM 2000 translates this scanner output (#31) and sends the

designated Keyboard Function Record (F10) to the terminal. (Refer to the

Keyboard Function Record relationships listed in C.1 to C.17.)

OCIA and Wedge (SCANTEAM 2000/R ONLY)

This function allows you to determine which output mode (OCIA or

wedge) in which the bar code and MSR data will be output.

IBM 4680 Dual Track MSR Track 1 and 2 (SCANTEAM 2000/R ONLY)

Enabling this selection causes the SCANTEAM 2000 to emulate an IBM

4680 dual track reader.

IBM 4680 Dual Track MSR Track 2 and 3 (SCANTEAM 2000/R ONLY)

Enabling this selection causes the SCANTEAM 2000 to emulate an IBM

4680 dual track reader.

4–14

Programming the 2000 Decoder

Page 54

Wand/Laser Port Modes

Laser Timeout

When Laser Timeout is enabled, the SCANTEAM 2000 turns off power to

the laser scanner 4 seconds after the trigger has been pulled and a valid

decode is not accomplished. Power to the laser is not restored until the

trigger is released and pulled again. If the timeout selection is not enabled,

the laser may not turn off until the trigger is released (depending upon the

laser manufacturer and configuration). If the laser does not turn off, the

scanning may continue until a valid scan is obtained.

Laser Redundancy

When this selection is enabled, the SCANTEAM 2000 requires three (3)

consecutive and identical decodes resulting from a laser scan before issuing

a “good read” beep and transmitting the bar code data. When this function

is disabled, the “good read” will be issued and data is transmitted to the

terminal following one (1) valid scan.

Dual Wand

If you are using two wands, change this setting to Yes for improved

scanning response time.

Country Code (2000/C)

The SCANTEAM 2000/C re–maps the keyboard layout appropriately for

the selected country. Country Codes are listed below in Table 4.2 and

appear on the OUTPUT PARAMETERS II page of the Programming

Menu.

Programming the 2000 Decoder

4–15

Page 55

Country

Code

United States

Belgium

Denmark/Finland/Norway/Sweden

France

Germany/Austria

Italy

Switzerland

United Kingdom

Denmark (WYSE 30, 60)

Norway (WYSE 30, 60)

Spain

00 (Default setting)

01

02

03

04

05

06

07

08

09

10

Table 4.2 Country Codes

As a general rule, the following characters are not supported by the

SCANTEAM 2000 for countries other than the United States:

@ | $ # ^ ‘{ } [ ] = / \ < > ~

Note: PC users may need to program an Intercharacter Delay of at least 1 X

5ms when a country other than the United States is selected.

The following example includes the scanning sequences needed to

configure the SCANTEAM 2000 Output Port/Beeper settings to the

following values.

Beeper Volume/Tone: Volume =10 Tone = 10 (This is a 4–digit

scan. The first two digits set the volume; the second two digits set the tone.

The default is 1919.)

Inhibit Input Check: Enable

T erminal: IBM PC/XT

Keyboard: CAPS LOCK (Secondary Keyboard)

Intercharacter Delay: 10ms (2x5ms)

Interfunction Delay: 50ms (10x5ms)

Intermessage Delay: 10ms (2x5ms)

4–16

Programming the 2000 Decoder

Page 56

The scanning sequence to program these operating parameters would be:

FUNCTION SELECTION VARIABLE

Enter Menu Page ENTER

Set DEFAULT Values DEFAULT

Set Beeper Volume/Tone I

T o level “1010” 1

0

1

0

Specify Secondary (CAPS LOCK)

Keyboard II

B

Set Intercharacter Delay VII

T o 10 milliseconds 0

0

0

2

Set Interfunction Delay VIII

T o 50 milliseconds 0

0

1

0

Set Intermessage Delay IX

T o 10 milliseconds 0

Leave Menu Page EXIT

(Refer to the Selections/Variables options on the OUTPUT Parameters

pages in the SCANTEAM 2000 Programming Menu.)

Programming the 2000 Decoder

0

0

2

4–17

Page 57

4.6 Code Selection I (Industrial) Menu Page

The SCANTEAM 2000 autodiscriminates between the following Industrial

symbologies: CODABAR, Code 3–of–9, Interleaved 2 of 5, 2–of–5, Matrix

2 of 5, Code 11, Code 93, Code 128, and Code 16K.

All codes can be disabled or enabled via the programming menu. When a

code is disabled, the unit ignores any scans of that particular code. No

error signal (beep) is issued. Menu selection XIX allows you to disable all

codes, including retail codes. Available Industrial codes and their options

are listed in T able 4.3.

Code

Symbology

CODABAR

Code 3 of 9 00 Full ASCII, symbol

Length

Min Max

01 Concatenation

60

Options

48

appendation, check character

transmission

I 2 of 5 02 80 Check digit, check digit

(even #’s only) transmission

2 of 5 01 48 None

Matrix 2 of 5 01 80 None

Code 11 01 80 1 or 2 check digits required

Code 93 00 64 None

Code 128 00 80 EAN-128 Programming

ISBT None

Code 16K 00 154 Function character

transmission

Table 4.2 Industrial Codes

Decoding Algorithm

Decoding algorithm will select the decoding aggressiveness of the 2000/C

decoder. The Adaptive style is a more forgiving type of decoding and will

be “snappier” when it is decoding, allowing decoding of bar codes that are

consistently out of tolerance and do not conform to the symbology

specifications. The Traditional style will ensure correct decoding and not

allow any variances from the normal bar code specification. This menu

selection applies to Codabar, Code 39 and Interleaved 2 of 5 symbologies.

4–18

Programming the 2000 Decoder

Page 58

Example: Configure the SCANTEAM 2000 to decode the following

symbologies:

Code 39: Maximum Length = 14

Minimum Length = 8

Start/Stop: Transmit

Check Digit: Required

Check Digit: Transmit

Full ASCII: Yes

Code 128: Maximum Length = 12

Minimum Length = 6

Refer to the Selections/Variables options on the CODE Selection I

Industrial page of the Programming Menu.

Note: If Check Digit is required and the code does not contain a check digit,

the SCANTEAM 2000 will not read the code.

The scanning sequence to program the decoder to read these Code 39 and

Code 128 formats would be:

FUNCTION SELECTION VARIABLE

Enter Menu Page ENTER

Set DEFAULT Values DEFAULT

Set Code 3 of 9 II

Set Minimum Length A

To 8 0

8

Set Maximum Length B

To 14 1

4

Programming the 2000 Decoder

4–19

Page 59

Set Start/Stop Characters C

To Transmit Yes

Set Check Char Required D

T o Required Yes

Set Check Digit E

To Transmit Yes

Set Full ASCII F

T o enabled Yes

Set Code 128 VIII

T o enabled Yes

Set Minimum Length A

To 6 0

6

Set Maximum Length B

To 12 1

2

Leave Menu Page EXIT

(1)

– To maximize reading ef ficiency and security, all unused codes should

be disabled.

Code 3–of–9 may have the “append” function enabled or disabled with the

programming menu, whereas the Code 128 “append” function cannot.

4–20

Programming the 2000 Decoder

Page 60

4.7 Code Selection II (Retail) Menu Page

The SCANTEAM 2000 autodiscriminates between the following Retail

symbologies: UPC, EAN, MSI and Plessey and their variations. All codes

can be disabled or enabled via the programming menu. When a code is

disabled, the unit ignores any scans of that particular code, and no error

signal (beep) is issued. Available Retail codes and their options are shown

below in T able 4.4.

Code

Symbology

UPC

Length

Min Max

Options

Not Selectable Enable V ersion (A, E), V ersion

E output compressed or expanded, 2 or 5 digital addendum, check digit transmission,

number system digit transmission.

EAN/JAN Not Selectable

Enable V ersion 8 and 13, 2 or

5 digit addendum, check digit

transmission ISBN conversion.

UPC & EAN Addenda Required Y es or No

UPC & EAN Addenda Format Space/No Space

Code MSI 04 48 None

Plessey 04 48 None

Table 4.4 Retail Codes

A code with an incorrect check character is ignored (i.e., it is treated as a

disabled code). The check character for all applicable codes may be

transmitted or not, depending on the menu selection made. UPC Version E

may be transmitted as an expanded code (i.e., with zero’s inserted or in its

compressed state as shown in the human readables).

Programming the 2000 Decoder

4–21

Page 61

For example, consider the decoded UPC–E data message 078349. The

number system digit and check digit transmissions are disabled. When the

“compressed” option is enabled, data will be transmitted as 078349.

If the “expanded” option (Version E Expand) is enabled, the same data

message will be transmitted as 0783400009.

In order to assure highest reading accuracy, all unused codes which do not

default to the disabled state should be disabled. Since the codes MSI and

Plessey default to disabled status, it is not necessary to program these codes

to a disabled state.

Example: Configure the SCANTEAM 2000 to the following retail code

symbologies and values:

UPC–A will be sent with the following properties:

Check Digit Xmit Disabled

# System Digit Disabled

2–digit Addenda Disabled

5–digit Addenda Disabled

Read UPC Version E (expanded)

Refer to the Selections/Variables table on the CODES RETAIL menu page.

The scanning sequence to program the decoder to read only this UPC Code

format would be:

FUNCTION SELECTION VARIABLE

Enter Menu Page ENTER

Set DEFAULT Values DEFAULT

Enable UPC–A I A

Yes

Enable UPC Version E 0 C

Yes

4–22

Programming the 2000 Decoder

Page 62

Enable UPC Version E 1D

Yes

Disable Check Digit Xmit E

No

Disable # System Xmit F

No

Enable UPC–E Expanded G

Yes

Disable 2–digit Addenda H

No

Disable 5–digit Addenda I

No

Disable EAN II

Disable EAN/JAN 13 A

No

Disable EAN/JAN 8 B

No

Disable UPC & EAN III

Addenda Required No

Disable MSI IV No

Disable Plessey V No

Leave Menu Page EXIT

Note: To assure highest reading accuracy, all unused codes (EAN/JAN13,

EAN/JAN 8, MSI, and Plessey) were disabled.

Programming the 2000 Decoder

4–23

Page 63

4.8 Auxiliary Port

The AUXILIARY PORT menu page is used to configure the baud rate,

parity, data length,and protocol for the Auxiliary RS–232D Port.

Baud Rate

Baud rate is a means of expressing data transmission speed. The Baud rate

must match that of the device with which you are communicating. The

programming selection permits the user to specify any of the eight (8)

values including 300, 600, 1200, 2400, 4800, 9600, 19,200, and 38,400

baud.

Parity

Parity provides a means of checking character bit patterns for validity. The

Parity must match that of the device with which you are communicating.

The SCANTEAM 2000 can be configured to operate under odd, even,

mark, none, or space parity.

Data Length (2000/C)

Data Length presents a way for you to specify the system word length (7 or

8) in bits. The Data Length must match that of the device with which you

are communicating.

Protocol (2000/C)

A protocol is a set of rules concerning the exchange of data between

communicating devices. The SCANTEAM 2000/C supports Record,

Burst, and ACK/NAK protocols when receiving data from a RS–232D

device. In explaining these protocols, the terms Start of Record, End of

Record, Start of Block, and End of Block are used.

Start of Record Character (SOR) (2000/C)

The Start of Record Character is one of the characters 01h–7Fh that

indicates the start of a SCANTEAM 2000/C Aux Port data record.

End of Record (EOR)

The End of Record Character is one of the characters 01h–7Fh that marks

the end of a SCANTEAM 2000 Aux Port data record.

4–24

Programming the 2000 Decoder

Page 64

Start of BLOCK (SOB) (2000/C)

The Start of Block Character is one of the characters 01h–7Fh that

indicates the start of a block of data within a SCANTEAM 2000/C Aux

Port data block.

End of Block (EOB) (2000/C)

The End of Block Character is one of the characters 01h–7Fh that indicates

the end of a block of data within a SCANTEAM 2000/C Aux Port data

block.

Note: SOB, EOB, SOR, and EOR characters are not considered data, and,

therefore, are not sent to the terminal.

Record Protocol (2000/C)