Page 1

User’s Manual

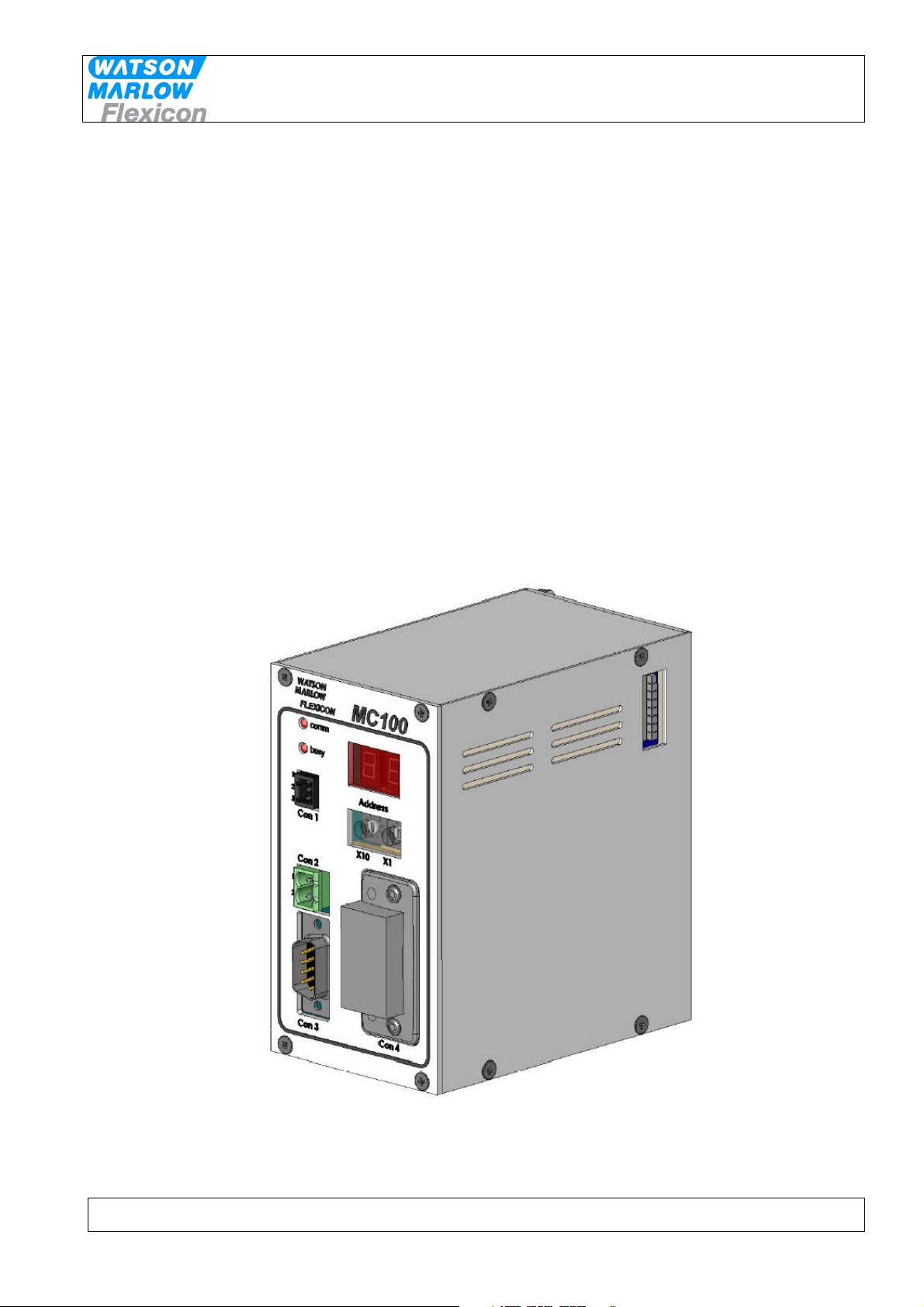

MC100

MC100

Pump Control Module

User’s Manual

(Profibus DP)

MC100 Users Manual Profibus DP -

rev 4

Rev. 3 Page 1 of 40

Page 2

Users Manual

MC100

CONTENTS:

1 Introduction ............................................................................................................................. 4

1.1 Terms used in this manual ...................................................................................................... 4

1.2 Precautions ............................................................................................................................. 4

2 General description of MC100 ................................................................................................ 5

2.1 Overview ................................................................................................................................. 5

2.2 Introduction & design purpose ................................................................................................ 5

2.2.1 How it works / Technical description of operation .................................................................... 5

2.3 Flexicon pumps used in multi-filling system, short description. ................................................ 6

2.4 How to operate the dispenser pumps ...................................................................................... 7

2.5 Communication on the Profibus .............................................................................................. 7

3 Technical specifications .......................................................................................................... 8

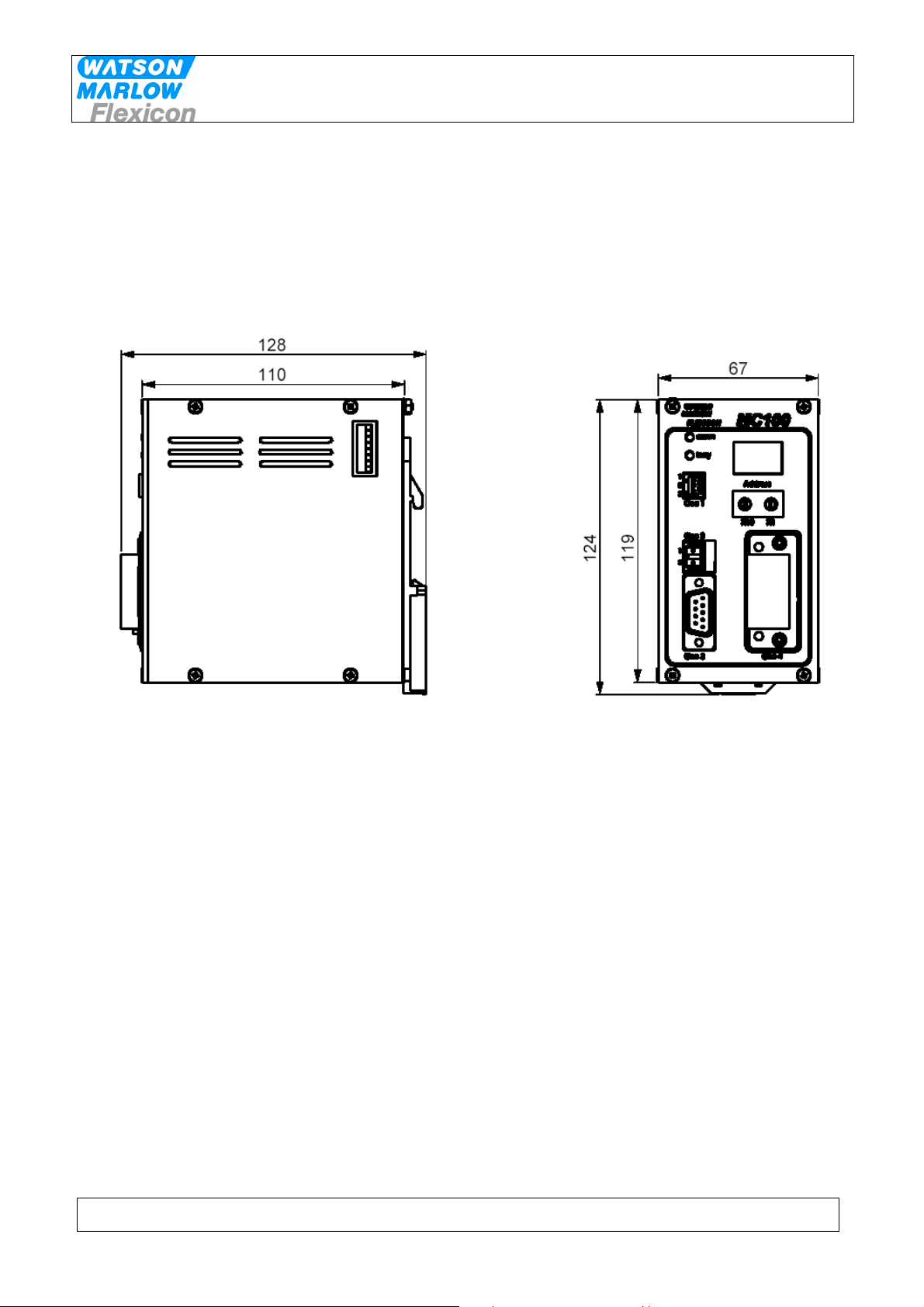

3.1 Dimensions ............................................................................................................................. 8

3.2 Specifications ......................................................................................................................... 9

3.3 Unpacking and inspection of MC100 ..................................................................................... 10

3.3.1 Identifying the module ........................................................................................................... 10

3.3.2 Identifying the parts .............................................................................................................. 11

3.4 Mounting ............................................................................................................................... 11

3.4.1 Choosing a place to mount the MC100 ................................................................................. 11

4 Wiring ................................................................................................................................... 12

5 Fieldbus network node address and front plate indicators ..................................................... 14

5.1 Network node address switches S1/S2: ................................................................................ 14

5.2 P1/P2 LED indicators: ........................................................................................................... 14

5.3 Display P4/P5 ....................................................................................................................... 15

5.3.1 Start up states....................................................................................................................... 15

5.3.2 Network address ................................................................................................................... 15

5.3.3 Alarm- and warning display ................................................................................................... 15

5.3.4 Dipswitch .............................................................................................................................. 15

6 Configuring the fieldbus network to the MC100 ..................................................................... 16

6.1 Connecting the MC100 and the pumps for the first time ........................................................ 16

6.2 Configuring to the Profibus DP network ................................................................................ 16

7 Operating the MC100 ............................................................................................................ 17

7.1 Process Data Exchange (Cyclic data) ................................................................................... 17

7.1.1 Structure of the data package sent to and received from the MC100 .................................... 17

7.1.2 Process control bits – word 0 (PLC MC100) ..................................................................... 20

7.1.3 Process status bits (MC100 PLC) ..................................................................................... 22

7.1.4 Process control bits for the pumps– word 1 to 9 (PLC MC100) ......................................... 23

7.1.5 Process status bits from the pumps – word 1 to 9 (MC100 PLC) ...................................... 24

7.2 Operation Parameters/Parameter specifications ................................................................... 25

7.2.1 List of basic parameters ........................................................................................................ 25

7.2.2 Control Data Word - data word 10 (PLC MC100) .............................................................. 27

7.2.3 Status words from parameters transfer (MC100 PLC) ...................................................... 28

7.2.4 Data word 11 ........................................................................................................................ 28

7.2.5 Alarm and warning (MC100 PLC) ..................................................................................... 28

7.3 Examples: ............................................................................................................................. 29

7.3.1 New speed to pump 1: .......................................................................................................... 29

7.3.2 New calibration value to pump 3: .......................................................................................... 30

8 Alarm and warnings .............................................................................................................. 32

8.1 Alarms handling .................................................................................................................... 32

8.1.1 Module alarms ...................................................................................................................... 32

8.1.2 Pump alarms ........................................................................................................................ 32

8.2 Warnings handling ................................................................................................................ 33

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 2 of 40

Page 3

Users Manual

MC100

8.2.1 Warnings .............................................................................................................................. 33

9 Trouble shooting ................................................................................................................... 34

9.1 Trouble-shooting ................................................................................................................... 34

9.2 Opening the MC100 for service/replacement of PCB’s ......................................................... 35

10 Decommissioning ................................................................................................................. 36

10.1 Advice about dismantling / removal / disposal ....................................................................... 36

10.2 Environmental conditions / -regulations................................................................................. 36

10.3 The WEEE system ................................................................................................................ 36

11 Appendix 1 ............................................................................................................................ 37

12 Appendix 2 ............................................................................................................................ 38

12.1 Tube tables ........................................................................................................................... 38

12.2 Volume, Speed and acceleration .......................................................................................... 39

12.2.1 PD12 .................................................................................................................................... 39

12.2.2 PD22 .................................................................................................................................... 39

12.2.3 GD30 .................................................................................................................................... 39

13 Declaration of Conformity ..................................................................................................... 40

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 3 of 40

Page 4

Users Manual

MC100

1 Introduction

1.1 Terms used in this manual

Fieldbus DeviceNet, Profibus.

Fieldbus interface module

Filling system

Pump

WMF

1.2 Precautions

This manual should be read thoroughly before using the MC100.

It is strongly advised that no wiring is connected or disconnected on the MC100 while power supply is

turned ON

Anybus Compact Com Module from HMS Industrial Networks AB

a MC100 and up to 16 pumps

Any Watson-Marlow Flexicon pump communicating on FlexNet (PDxx,

GDxx, DDxx)

Watson-Marlow Flexicon

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 4 of 40

Page 5

Users Manual

MC100

2 General description of MC100

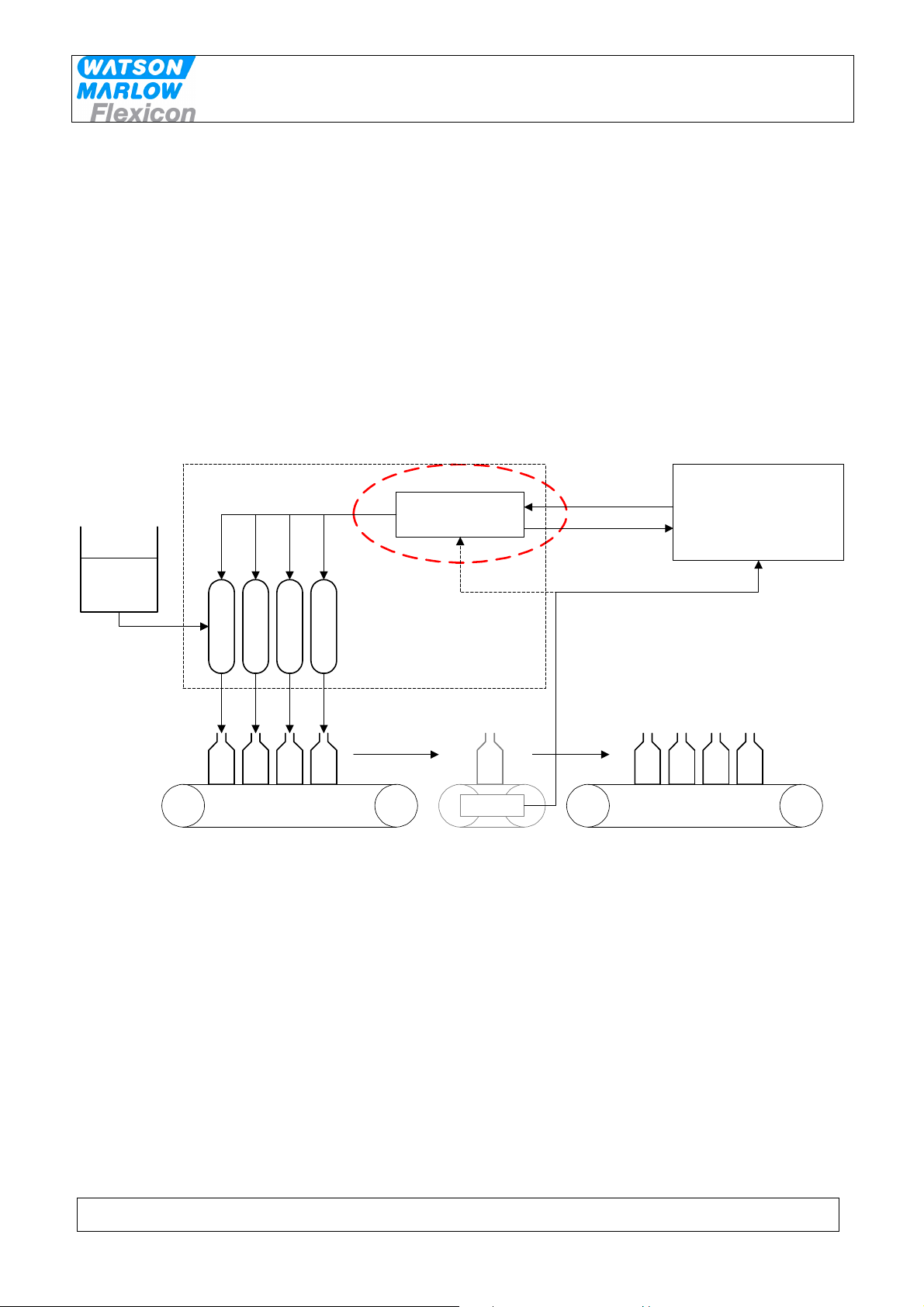

2.1 Overview

MC100 is a pump control module for controlling up to 16 WMF Pumps. The basic function is

• to receive filling data from the filling line control system through an industrial fieldbus

• based on data received from the filling line control system to calculate operating values for the

pumps

• to transmit data to the pumps connected to the MC 100 via FlexNet

• to receive data from the pumps connected to the MC 100 via FlexNet

• to transmit the pump data to the filling line control system

MC100 constitutes together with WMF pumps a filling system designed for incorporation into a larger

filling line as described below.

Filling system

Product

Recipe

MC100

Pump

Pump

Pump

Pump

Scale

Commands

Actual

parameter

Status

Achieved

fill amount

Filling line control system

incl. storing of recipe and

HMI

2.2 Introduction & design purpose

The MC100 is a small module for mounting inside the control cabinet of the filling line.

It is designed with the purpose of integrating Watson-Marlow Flexicon pumps into a filling line.

2.2.1 How it works / Technical description of operation

Via the fieldbus the MC100 receives operating data from and sending data to the control system for the

filling line. The data are divided in three types:

• General data for the pump system

• Set-up data for each pump

• Operation data for each pump

The MC100 sets up the pump system according to the data received from the control system for the

filling line.

All control and status signals for the individual pumps connected to the MC100 are sent to the MC100

via the fieldbus. The dispensing can also be controlled via hardwired signals. Please see the manual

for the pumps for more details regarding the hardwired signals.

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 5 of 40

Page 6

Users Manual

MC100

The MC100 cannot store data such as recipes and historical data. These data must be stores in the

control system for the filling line and be transmitted to the pump system when needed.

2.3 Flexicon pumps used in multi-filling system, short description.

The Watson Marlow Flexicon multi filling system consists of up to 16 filling dispensers (pumps)

connected via a fieldbus to a MC controller.

The dispensers can be peristaltic dispenser pumps (PD12 and PD22) and gear dispenser pumps

(GD30).

The MC controller can be either a MC12 controller with integrated keyboard and display to enter data

and control the dispensing or MC100 for integration in control systems.

This manual describes the MC100 controller.

The pumps are used for dispensing accurate doses of liquid into vials.

For this purpose there are a number of parameters, which are used to control the pump:

Speed: The range for the dispensing speed is 30 to 600 rpm depending on the pump

and the tube selected

Acceleration: The range is 1 to 200 rpm/s depending on the pump and the tube selected.

Reverse (back sucking): Is a figure between 1 and 10 defining a short reverse pumping to prevent

dripping after the dispensing.

Tube: The pumps hold a tube table of up to 10 tubes, which can be read from the

pumps. The tubes are depending on the pump type. Thus the pump table

can be down loaded from the pump software via the MC100.

Volume: The volume the pump has to dispense at each filling. Please also see serial

and parallel mode below.

Density: The density [g/cm3] for the product to be filled. Used when calculating the

calibration value.

Calibration: The net weight filled during dispensing. When a new volume is defined for a

pump it will dispense approximately 70 – 80% of this volume until calibrated.

The calibration is normally done by tare weighing a vial, filling it and weighing

it again to calculate the net filling weight. The net weight filled is sent to the

MC100. The MC 100 then calculates the dispensing data and sends it to the

pump in question.

Please see the manual for the pump for further details.

When more than 1 pump is connected to the MC100, it is possible to operate the filling system (MC

100 with pumps) in 3 different operating modes: Individual, parallel and serial mode.

Individual mode: All the different types of WM-Flexicon pumps can be connected and run

Parallel mode: This mode requires that all enabled pump are of the same type, i.e. all

Different pump types can be connected to the MC 100, but only pumps of

independently for all parameters.

PD12; all PD22 or all GD30.

the same type can be enabled and operated together in parallel mode.

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 6 of 40

Page 7

Users Manual

MC100

In parallel mode a virtual pump (pump no. 0) is be used to hold common

parameters for all the enabled pumps. However, the pumps will still have to

Serial mode: This mode requires that all enabled pump are of the same type, i.e. all

Different pump type can be connected to the MC 100, but only pumps of

2.4 How to operate the dispenser pumps

Before a new filling is started the parameters for this filling is loaded to the pumps from the filling

system.

The data are loaded to the pumps either individually or as common data depending on the operating

mode – please see above.

Initially the pumps need to be primed – i.e. the product has to be filled into the tubes and nozzles of the

filling system.

Hereafter the pumps must be calibrated.

For details of priming and calibrating please see the manual for the pumps attached.

During production a regularly re-calibration may be necessary – e.g. for each 1.000 filling depending on

the product to be filled. This can be done “on the fly”.

For details on how to send and receive data from the MC100 please see section 7.

be calibrated individually.

PD12; all PD22 or all GD30.

the same type can be enabled and operated together in parallel mode.

All pump data, except tube sizes, are stored in the virtual pump (pump no.

0).

The filling volume is divided to the pumps based on the tube sizes.

Calibration for all the pumps is done by calibrating the virtual pump 0.

2.5 Communication on the Profibus

The communication between the MC100 and the PLC system for the filling line runs continuously.

Changes in status of the pumps and commands to the MC100 and attached pumps are communicated

when required.

To send new data to the MC100 and the attached pumps the data are sent using a 23 data words

telegram. The details of this telegram are described in section 7.

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 7 of 40

Page 8

3 Technical specifications

3.1 Dimensions

Users Manual

MC100

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 8 of 40

Page 9

3.2 Specifications

Fieldbus:

- Profibus DP-V1

Pumps:

Up to 16 pumps can be connected to and controlled by one MC100.

The pumps must be able communicate with MC100 via FlexNet protocol.

Material and surface treatment:

- Mounting box made from aluminium.

- All aluminium parts anodised (conductive).

Environmental:

- Ingress protection according to IP30.

-

NEMA 1 enclosure.

Mounting:

- MC100 is to be mounted on DIN rail size 35.

Power supply:

-

Supply 24 VDC ± 10%.

- Power consumption less than 10 VA.

- Fuse max. 1A

Weight:

-

0.5 kg.

Users Manual

MC100

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 9 of 40

Page 10

Users Manual

Model number on nameplate

Fieldbus connector

MC100

3.3 Unpacking and inspection of MC100

The MC100 is delivered with

• The MC100

• Declaration of Conformity

• CD-ROM with documentation:

Manual for installation, programming and service of MC100

Documentation and support-files for Anybus Compact Com fieldbus module

Function blocks for Siemens Step7

GDS file for Siemens Step7

The latest revision of this manual and of the function blocks can be downloaded from our Internet site

at wmflexicon.dk.

Please check that all ordered items have been received and that no items were damaged during

transport. In case of any defects or omissions, please contact WMF or your supplier immediately.

Please verify that the model number stated on the nameplate and the installed fieldbus connector

matches your purchase order.

MC100 61-120-000 Profibus DP-V1

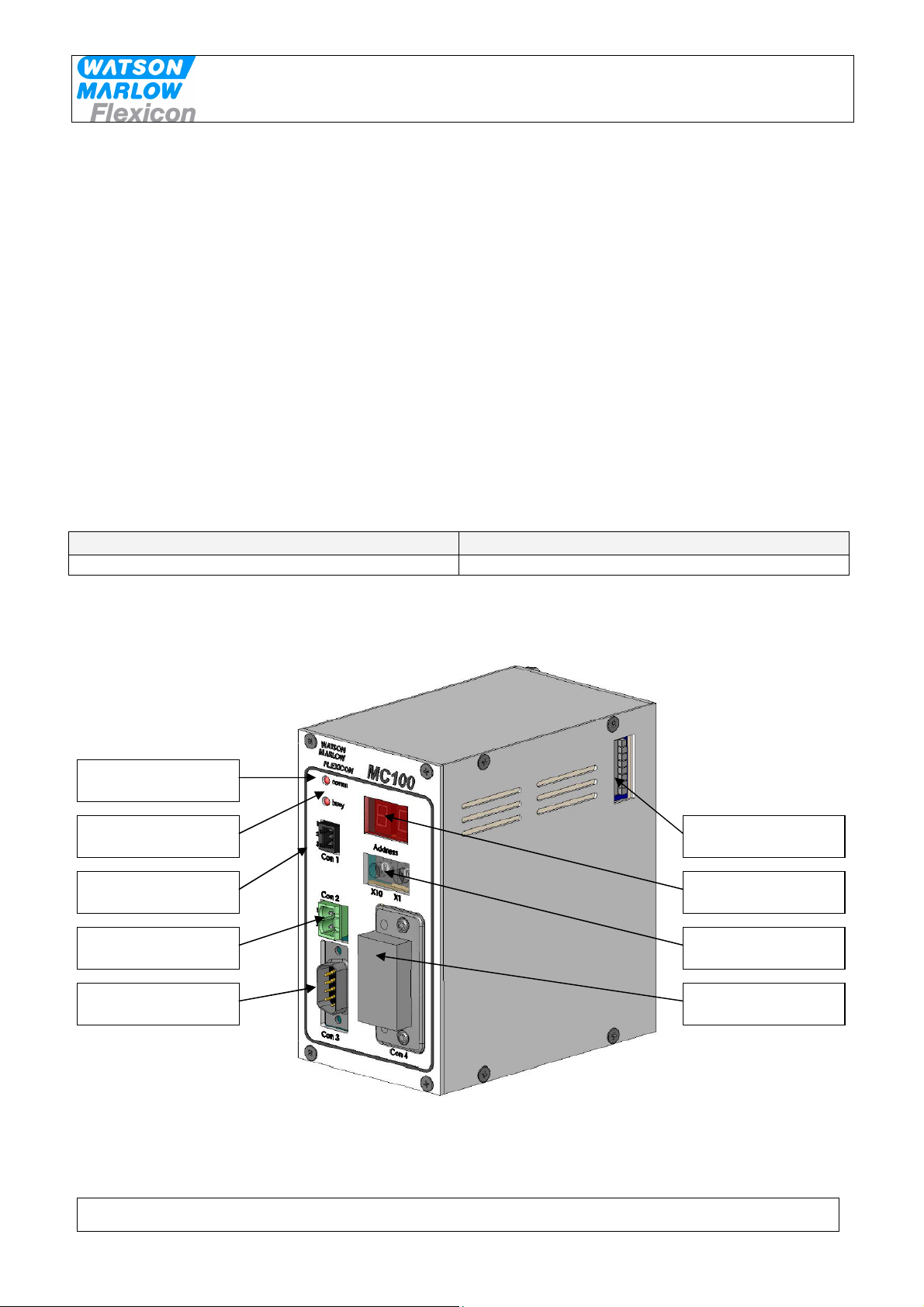

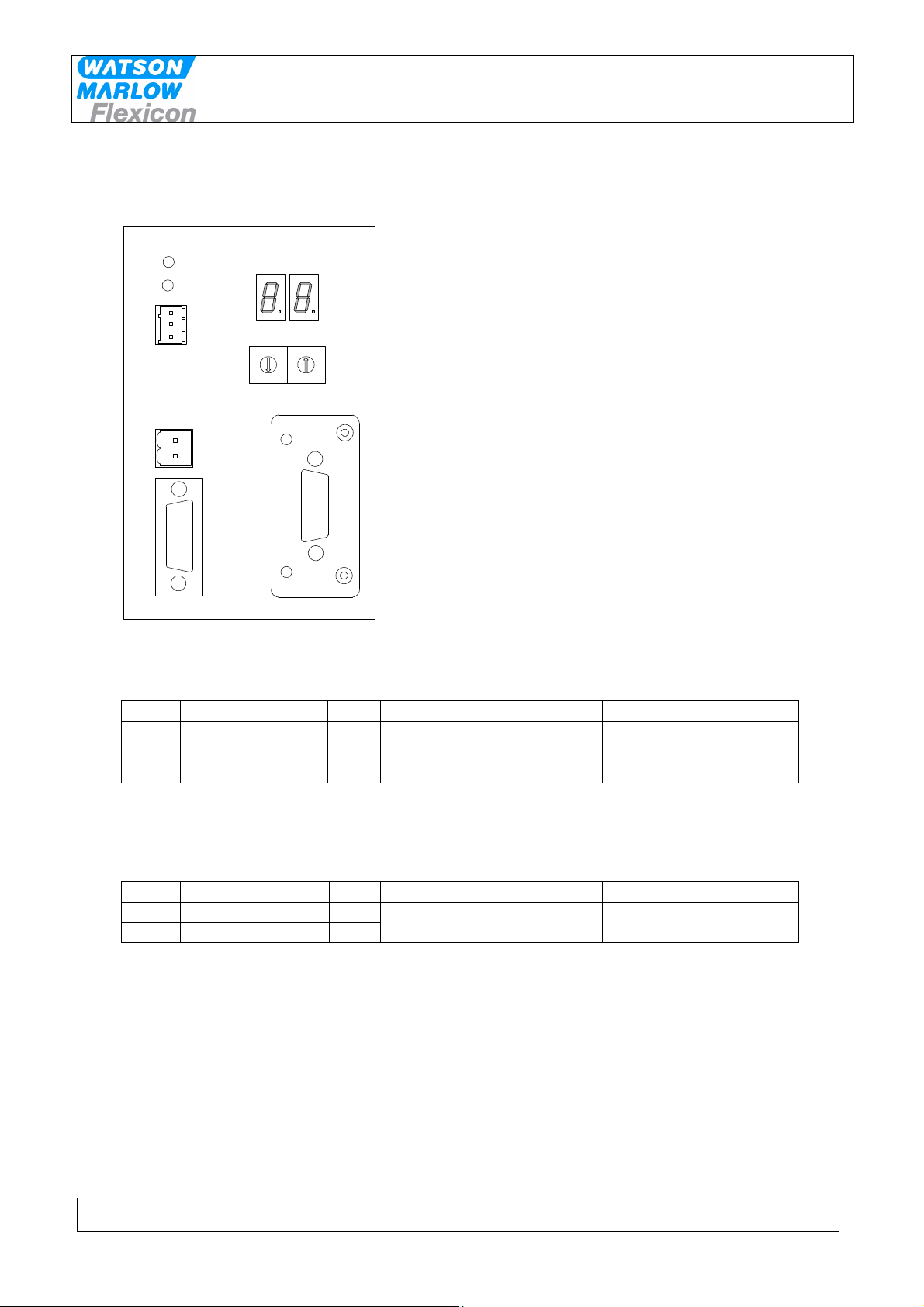

3.3.1 Identifying the module

MC100 module:

LED - Comm

LED - Busy

CON 1:

Flexnet connector

CON 2:

Power supply

CON 3:

9-pin SUB D connector

8-bit switch

2-digit LED display

Rotary switches

CON 4:

Fieldbus connector

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 10 of 40

Page 11

Users Manual

3.3.2

3.4 Mounting

3.4.1 Choosing a place to mount the MC100

The MC100 must be mounted in an environment that adheres to the specifications in 3.2.

The MC100 must be protected from the following conditions

On the left side of the module is a dipswitch (se 3.1), which should be accessible.

Identifying the parts

- MC100 module.

- Connector for FlexNet.

- Connector for Power Supply.

- Connector for Fieldbus.

- Rain and moistures

- Corrosive gasses

- Dust or metallic particles in the air

- Physical shock or vibration

- Magnetic noise (e.g. welding machines, power devices, etc.)

MC100

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 11 of 40

Page 12

Con1

FlexNet

Connector

Connect with

Con2

Power Supply

Connector

Connect w

ith

4 Wiring

1

2

3

Con 1

Con 2

1

2

MC100 Frontplate

COMM

BUSY

5

4

3

2

1

0

X10 X1

Address

6

3

7

2

8

9

Users Manual

MC100

5

4

6

7

8

1

9

0

Con 3

Connectors / Indicators / Switches

Con 4

1 /DATA I/O

2 GND 3 DATA I/O

PHOENIX

MC 0,5/ 3 –G-2,5THT

PHOENIX

FK MC 0,5/ 3 –ST 2,5

The FlexNet connector should be connected to the corresponding terminals on all the pumps,

establishing a multidrop network and the last pump should be terminated with a 120 ohm resistor

between DATA and /DATA.

Use 0.25 – 0.35 mm2 wires twisted or screened. Terminal tubes must be minimum 8 mm long.

1 +24V IN

2 0V IN

PHOENIX

MC 0,5/ 4 –G-2,5THT

PHOENIX

FK MC 0,5/ 3 –ST 2,5

Use 0.5 mm2 wires, terminal tubes must be minimum 8 mm long.

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 12 of 40

Page 13

Users Manual

Con3

Communication

Connector

Connect with

Con4

Fieldbus Interface

Profibus DP

9-

pole SubD Female

MC100

1 RS485 – A I/O

2 TxD OUT

3 RxD IN

4 N.C.

5 GND 6 NC

7 CTS OUT

8 RTS IN

9 RS485 – B I/O

1 - 2 - 3 B Line Positive RxD/TxD RS485 Level

4 RTS

5 GND Bus

6 +5V Bus output Max. 10 mA

7 - 8 A Line Negative RxD/TxD RS485 Level

9 - -

Housing

Cable Shield Internally connected to protective shield

9 pole SubD Male

Crossed cable to for

example PC

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 13 of 40

Page 14

Users Manual

MC100

5 Fieldbus network node address and front plate indicators

5.1 Network node address switches S1/S2:

The node address is setup on the 2 rotary switches S1 and S2.

Address-range 1 to 99

The address is normally set before powering up and connecting to the network for the first time, but if

the address is change after power up, the new address will flash on P4/P5 display for 5 seconds,

during which it is possible to change back to the old address.

After the 5 seconds the MC100 will do a total factory reset and start up using the new address.

5.2 P1/P2 LED indicators:

P1

P2

Green Continuously ON or flashing indication communication with the pumps

Red Flashing indicates Lost connection to at least 1 pump or internal error

Green Currently not used

Red

ON indicates at least 1 pump is active

Flashing together with P1 indicate fatal internal error in the module.

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 14 of 40

Page 15

Users Manual

P4/P5

Description

Note

Reset state

Dipswitch

Action

Description

MC100

5.3 Display P4/P5

This display is used for general indication of the start up states in the MC100 and for various other

purposes.

5.3.1 Start up states

S U Initial start up state

S.U. Internal communications started

S.0. Start initialisation of the fieldbus module Short state if no errors

S.1. Cyclic data now exchangeable with the network Short state if no errors

S.2. MC100 ready and waiting for connection

S.3. Intermediate state / special network state Short state / idle state

S.4. Connection to network established and working Short state

S.5. Internal error during initialization Steady state (see trouble shooting)

S.7. Internal error during initialization Steady state (see trouble shooting)

S 8 Factory Reset to default

S 9 Factory Reset to default

5.3.2 Network address

After initialization, the display is showing the network node address.

5.3.3 Alarm- and warning display

The node address is replaced by a flashing:

AL and the alarm number XX, when and alarm is present (see 8.1.1 Alarms).

Er and the warning number XX, when a warning (recoverable alarm) is present (see 8.1.2 warnings).

5.3.4 Dipswitch

The dipswitch on the right side of the MC100 module can be used to do a factory-reset function.

It can be necessary to do a factory reset before connecting the fieldbus network. During the factory

reset initialization, the MC100 determines the number and types of pumps connected on the Flexnet.

(Please see section 6.x.x).

0 All OFF None Normal runtime state

1 All OFF Remove power to MC100

MC100 starts up and reaches init state 2

2 SW 8 ON Apply power to MC100

3 SW 8 ON Remove power to MC100

4 SW 8 OFF Apply power to MC100 MC100 starts up normally

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 15 of 40

And the restart again initializing to factory

defaults and starts up.

Page 16

Users Manual

MC100

6 Configuring the fieldbus network to the MC100

6.1 Connecting the MC100 and the pumps for the first time

Make sure all pumps have been giving a unique address and all the pumps have been powered up.

The FlexNet is connected to the MC100 and to the pumps in a multidrop network.

Connect SubD connector X3 to a PC using a NULL-modem cable.

Start a terminal program on the PC for example HyperTerminal.

Set the communication-parameters to: 9600 baud, 8 bits, even parity and 1 stop-bit.

When applying power to the MC100, it will identify itself by printing the line:

“ MC100 MFSC Ver. x.yy.” (x.yy is the current version)

The MC100 will then try to identify all connected pumps on the Flexnet; the LED indicator X1 will flicker

and finally be steady green.

If for example 4 pumps holding address 1, 2, 3 and 4 are detected, the following line will be shown:

“Pumps: 1 2 3 4 1 4 4”

In this example pumps numbered 1-4 are detected, lowest number is 1 and highest number is 4 and

there are 4 pumps connected.

If the 2nd line is not printed and the MC12 has an alarm indication: AL01 or AL02 flashing, it must be

investigated if the FlexNet is correctly wired.

If everything is OK you continue to configure the Profibus master according to the guidelines from

HMS, please see below.

6.2 Configuring to the Profibus DP network

The description how to configure the MC100 for Profibus DP-V1 using Siemens Step7 PLC is

described in the HMS document PROFIBUS_Slave_Step7_2.1.pdf.

You find this document on the CD supplied with the MC100. The newest version of the document can

be downloaded from

http://www.hms.se/products/products.asp?PID=321&ProductType=Anybus-CompactCom

You find the GDS files on the CD supplied with the MC100.

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 16 of 40

Page 17

Users Manual

MC100

7 Operating the MC100

7.1 Process Data Exchange (Cyclic data)

Due to limitations in the Profibus structure the data for the MC100 and the attached pumps are

multiplexed as described below.

Data are sent to and from the MC100 on a cyclic basis in a data package of 23 data word (each of 2

bytes). The MC100 acknowledge by returning a package of 23 data words.

The communications runs continuously – i.e. also if no parameters are changed.

7.1.1 Structure of the data package sent to and received from the MC100

Data sent to the MC100 (PLC MC100):

Data

word no

0 MC100 control bits 7.1.2

1 Control pump 1 and 2 7.1.4

2 Control pump 3 and 4 7.1.4

3 Control pump 5 and 6 7.1.4

4 Control pump 7 and 8 7.1.4

5 Control pump 9 and 10 7.1.4

6 Control pump 11 and 12 7.1.4

8 Control pump 13 and 14 7.1.4

9 Control pump 15 and 16 7.1.4

10 Header for word 12 to 21 7.2.2

11 Header for special use 7.2.4

12 Volume data for the pump selected in word 0 – part 1 7.2.1

13 Volume data for the pump selected in word 0 – part 2 7.2.1

14 Tube used in the pump selected in word 0 7.2.1

15 Speed data for the pump selected in word 0 7.2.1

16 Acceleration data for the pump selected in word 0 7.2.1

17 Reverse data for the pump selected in word 0 7.2.1

18 Density data for the pump selected in word 0 – part 1 7.2.1

19 Density data for the pump selected in word 0 – part 2 7.2.1

20 Calibration data for the pump selected in word 0 – part 1 7.2.1

21 Calibration data for the pump selected in word 0 – part 2 7.2.1

22 Na

The data package will always consist of the control words for all possible pumps (word 1 to 9 – please

see above) regardless of the number of pumps attached to the MC100. The control for pumps which

are not present will be ignored.

The data are sent with the lowers number first i.e. from data word 0 to data word 22.

Content Described in section

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 17 of 40

Page 18

Users Manual

MC100

When the above data package is received by the MC100 it acknowledges by returning a new data

package (MC100 PLC). The structure of the returned data package is different if the return data are

requested as a data communication or a text string. This is selected in data word 10 as described in

section 7.2.2

If the PLC has requested a data communication:

Data

word no

0 MC100 control bits 7.1.3

1 Control pump 1 and 2 7.1.5

2 Control pump 3 and 4 7.1.5

3 Control pump 5 and 6 7.1.5

4 Control pump 7 and 8 7.1.5

5 Control pump 9 and 10 7.1.5

6 Control pump 11 and 12 7.1.5

8 Control pump 13 and 14 7.1.5

9 Control pump 15 and 16 7.1.5

10 Header for word 12 to 21 7.2.3

11 For future use 7.2.4

12 Volume data for the pump selected in word 0 – part 1 7.2.1

13 Volume data for the pump selected in word 0 – part 2 7.2.1

14 Tube used in the pump selected in word 0 7.2.1

15 Speed data for the pump selected in word 0 7.2.1

16 Acceleration data for the pump selected in word 0 7.2.1

17 Reverse data for the pump selected in word 0 7.2.1

18 Density data for the pump selected in word 0 – part 1 7.2.1

19 Density data for the pump selected in word 0 – part 2 7.2.1

20 Calibration data for the pump selected in word 0 – part 1 7.2.1

21 Calibration data for the pump selected in word 0 – part 2 7.2.1

22 Alarm and warning 7.2.5

Content Described in section

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 18 of 40

Page 19

If the PLC has requested a text string:

Data

word no

0 MC100 control bits 7.1.3

1 Control pump 1 and 2 7.1.5

2 Control pump 3 and 4 7.1.5

3 Control pump 5 and 6 7.1.5

4 Control pump 7 and 8 7.1.5

5 Control pump 9 and 10 7.1.5

6 Control pump 11 and 12 7.1.5

8 Control pump 13 and 14 7.1.5

9 Control pump 15 and 16 7.1.5

10 Header for word 12 to 21 7.2.3

11 For future use 7.2.4

12 Text byte 1 and 2

13 Text byte 3 and 4

14 Text byte 5 and 6

15 Text byte 7 and 8

16 Text byte 9 and 10

17 Text byte 11 and 12

18 Text byte 13 and 14

19 Text byte 15 and 16

20 Text byte 17 and 18

21 Text byte 19 and 20

22 Alarm and warning 7.2.5

Content Described in section

Users Manual

MC100

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 19 of 40

Page 20

Users Manual

MC100

7.1.2 Process control bits – word 0

Word 0 (2 bytes) is allocated for MC100 control bits as shown below.

Word 0

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

B1.7 B1.6 B1.5 B1.4 B1.3 B1.2 B1.1 B1.0 B0.7 B0.6 B0.5 B0.4 B0.3 B0.2 B0.1 B0.0

B0.0-4: Sets the active pump number

B0.5-7 Reserved for future use

B1.0: Mode bit 0; please see below

B1.1: Mode bit 1; please see below

B1.2-4 Reserved for future use

B1.5

B1.6 Rescan the FlexNet for pumps. The FlexNet is scanned for pumps and a new table of the

B1.7 Total reset of MC100.

Modes selected by mode bit 0 and 1:

MC100 working modes: Mode bit 0 Mode bit 1

Individual mode When selected the attached pumps are operated individually. I.e.

Parallel mode Parallel mode requires that all pumps not disabled are of the same

Alarm reset: will reset lowest alarm or warning number. To reset more alarms/warnings

B1.5 must be reset to 0 and then raised to 1 again for each alarm/warning.

attached pumps are written in the MC100.

NB. This will result in a reset of all the attached pumps.

NB. This will result in a reset of all the attached pumps to default values.

Individual 1 0

Parallel 0 1

Serial 1 1

Na 0 0

(PLC MC100)

volumes; dispense signals; calibration values etc. has to be sent to

each pump.

type, i.e. PD12 or PD22 or GD30.

In parallel mode the virtual pump 0 is used to hold common

parameters for all the enabled pumps.

In parallel mode the common data are:

• Volume

• Pump speed

• Acceleration

• Tube size

• Density

If parameters are sent to a pump different from pump 0, there is

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 20 of 40

Page 21

Users Manual

MC100

generated a warning 10 and the parameters are discarded.

Please note that in parallel mode the calibration is NOT a common

data. The pumps will still have to be calibrated individually to cope

with differences in the tubes, positioning of the tubes in the pump

head – etc. The MC100 will take care of sending the parameters

from pump 0 to all the connected enabled pumps.

If pumps of different types are not disabled in parallel/serial mode

before changing to serial mode Alarm 08 is generated.

Serial mode Serial mode requires that all pumps not disabled are of the same

type, i.e. PD12 or PD22 or GD30.

In serial mode the virtual pump 0 is used to hold common

parameters for all the enabled pumps.

In serial mode the common data are:

• Volume

• Pump speed

• Acceleration

• Density

• Calibration

Please note that in serial mode the tube size is NOT a common

data.

When parameters are sent to the MC100 in serial mode the MC100

takes all parameters EXCEPT tube-size when sent to pump 0 and

ONLY the tube size when sent to a pump number different from 0.

In serial mode the filling volume is divided to the enabled pumps

based on the individual tube sizes. The MC100 do a calculation, so

the distance the pumps runs are the same independent of the tube

size. I.e. if the tube sizes are different in the enabled pumps the

filling volumes from these pumps will also be different.

If the enabled pumps are using the same tube size the filling

volume will be divided equally between the pumps. Calibrations for

all the pumps are carried out by calibrating pump 0.

If pumps of different types are not disabled in parallel/serial mode

before changing to serial mode Alarm 08 is generated.

Na

If operation mode 0 is selected nothing will be changed in the

setup.

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 21 of 40

Page 22

Users Manual

MC100

7.1.3 Process status bits (MC100 PLC)

As acknowledgment of receiving word 0 the MC returns word 0 with

Word 0

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

B1.7 B1.6 B1.5 B1.4 B1.3 B1.2 B1.1 B1.0 B0.7 B0.6 B0.5 B0.4 B0.3 B0.2 B0.1 B0.0

B0.0-4 Active pump number

B0.5-7 Reserved for future use

B1.0 Mode status bit 0; please see above

B1.1 Mode status bit 1; please see above

B1.2-3 Reserved for future use

B1.4 Ready to receive acyclic parameter transfer

B1.5 Parameter error – is reset when new parameter is accepted.

B1.6 Ready

B1.7 Alarm

Note B1.4 in the MC100 control bits is used as a READY- /BUSY bit for explicit parameter transfer.

The data bit will go low when accepting an explicit parameter transfer and will go high again

when the data is processed, thereby enabling a new transfer. This handshake mechanism

MUST be respected otherwise data will be lost.1

1

Normally only used in DeviceNet versions of the MC100

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 22 of 40

Page 23

Users Manual

MC100

7.1.4 Process control bits for the pumps– word 1 to 9 (PLC MC100)

For each pump address (1 to 16) one byte is dedicated for control bits. I.e. one data word holds the

control bits for two pumps.

Regardless of the number of pumps attached to the MC100 all pump control words has to be sent. The

data for pumps not available are ignored.

Word 8 Word 7 Word 6 Word 5 Word 4 Word 3 Word 2 Word 1

P16 P15 P14 P13 P12 P11 P10 P9 P8 P7 P6 P5 P4 P3 P2 P1

Bit mapping in each command byte (P1 to P16):

7 6 5 4 3 2 1 0

Direction

Bit 0: START Start a single Dispense cycle, when the Pump is set in Dispense mode (Bit. 1)

This bit must be cleared upon receiving the BUSY bit in the status byte for the pump,

see below.

Bit 1: DISP Sets the pump in dispense mode and thereby enables the START bit to start

dispenses. If removed during dispensing the pump stops immediately.

Bit 2: PUMP2 Starts pump running continuously with the set speed.

Bit 3: Reserved for future use

Bit 4: RESET To be used with future pumps

Bit 5: Disable pump in parallel and serial mode. If set high the pump will ignore dispense

and pump bites.

Bit 6: Direction3 [1/0] [Backwards/Normal] pump and dispense direction.

Bit 7 Reserved for future use

Disable in

Par./Serial

RESET PUMP DISP START

2

The DISP bit has higher priority and must be cleared before setting the PUMP bit.

3

Available for pumps able to handle this function (GD30).

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 23 of 40

Page 24

Users Manual

MC100

7.1.5 Process status bits from the pumps – word 1 to 9 (MC100 PLC)

For each pump address (1 to 16) one byte is dedicated for status bits. I.e. one data word holds the

status bits for two pumps.

Regardless of the number of pumps attached to the MC100 all pump control words has to be sent. The

data for pumps not available are ignored.

Word 8 Word 7 Word 6 Word 5 Word 4 Word 3 Word 2 Word 1

P16 P15 P14 P13 P12 P11 P10 P9 P8 P7 P6 P5 P4 P3 P2 P1

Bit mapping in each status byte (P1 to P16):

7 6 5 4 3 2 1 0

ALARM Direction DONE Pump Dispense Tube Br. BUSY READY

Bit 0: READY Pump is ready (self check is OK).

Bit 1: BUSY 1 Indicate that the pump is active, either dispensing or pumping

0 the pump is idle

Bit 2: Tube Br. Tube bridge bit:

1 = tube bridge on

0 = tube bridge off.

Please note that due to security reasons the pump cannot run if the tube bridge

is off. This is controlled by the pump controller.

Bit 3: Dispense Dispense bit: 1 = dispense mode

Bit 4: Pump Pump bit: 1 = pump mode

Bit 5: DONE 4 Is set when pump goes from dispensing to idle / reset by a new START bit.

Bit 6: Direction Handshake for bit B5 from command byte (0=normal / 1=reverse direction.)

Bit 7: ALARM See Chapter 7.3.2.1.1 for further information

4

The DONE bit can be necessary to use if there is very short filling times, where the BUSY signal is not detected because of

transmission times on the fieldbus network.

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 24 of 40

Page 25

Users Manual

MC100

7.2 Operation Parameters/Parameter specifications

The section describes parameter exchange between MC100 and PLC5

7.2.1 List of basic parameters

Parameter Description Data type Range Default DW

1 Volume Double integer 1000-999990000 10000000 12-13

2 Tube Integer 1-10 6 14

3 Speed Integer 30-600 100 15

4 Acceleration Integer 1-200 10 16

5 Reverse Integer 0-5 0 17

6 Density Double integer 50000 – 200000 100000 18-19

7 Calibration value Double integer 50 –200 % of Volume

Please note that to allow the MC100 to be used with PLC’s without capability to use floating point data

the values in parameter 1, 6 and 7 (volume, density and calibration) is converted into double integer

values. The MC100 will handle the double integer as a floating point value with a fixed decimal point

with 5 decimals.

As a consequence of the above the PLC program must multiply the values for volume, density and

calibration by 100.000 before sending the value to the MC100.

Examples: Floating point value 123.45678 must be send to the MC100 as 12345678

Floating point value 1.2 must be send to the MC100 as 120000

The parameters above are:

Volume The volume to be dispensed at each filling. Please note that to avoid

overfilling the first dispense (before calibrating) will be approximately 80% of

the requested filling.

Tube The tube number (1 to 10) used selected from the tube table. The tube table

is specific for the pump type and can be downloaded from the pump controller

(please see next section). The tube table for each pump type is found in

appendix 2 in this manual.

Speed The revolutions per minute of the pump. If the product is foaming the

revolutions may have to be lowered. The speed range is 30 to 600; however,

the upper value is dependent on the pump type and the selected tube size.

Please see the details in appendix 2.

Acceleration A number indicating the ramp up and down when starting/stopping the

dispensing. The range is 1 to 200 rpm/s. The upper value is dependent on the

pump type and the selected tube size.

Reverse A number indicating the reversing of the pump after dispensing to avoid

dripping of the product between dispensing. The reverse is a number in the

range 0 to 10. The physical reversing is dependent on the pump type. For a

PD12 the value 10 gives ¼ reverse rotation where for a PD22 the value 10

gives a full reverse rotation.

Density The density of the product to use when calibrating. When calibrating the

- - - 20-21

5

These parameters can also be exchanged using DPV1 Class 2 acyclic data exchange (MSAC2), contact Watson-Marlow

Flexicon for a description if necessary

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 25 of 40

Page 26

Users Manual

MC100

weight of the filled amount of the product is entered. If the product has a

density other than 1 the MC100 has to take that into the calculation of the

pump data for filling to convert to volume. The density must be in the range

0,5 to 2,0 g/cm

Calibration value The weight of the product in g filled (found by subtracting the weight of the vial

from the total weight of the filled vial). When receiving the weight MC100

calculates new pump parameters for the actual pump and send it to the pump

controller. The pump will use the new setting from the first dispensing after

having received the new data.

If the volume is changed the calibration is reset. To avoid overfilling the fillings

after entering a new volume will be approximately 70 – 80% of the requested

filling volume. Hereafter a new calibration must be made.

Please note that if the calibration value is outside the limits (below 50% or

above 200% of the volume) a warning is generated and the calibration value

is ignored.

When transmitting and receiving the value for calibration please note the

conversion to integer as described above.

Please consult the manual for the actual pump type for a more detailed description of the parameters.

3

. Please note the conversion to integer as described above.

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 26 of 40

Page 27

Users Manual

MC100

7.2.2 Control Data Word - data word 10 (PLC MC100)

DW 10

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

PS P7 P6 P5 P4 P3 P2 P1 - - - N4 N3 N2 N1 N0

N4-0 DW12-21 Comments

0 Not Used

1 Request for MC100 FBM Version

2 Application Name

3 Pump version For the active pump selected in DW0

4 Alarm text strings Text string for the pending alarm

5 Warning text strings Text string for the pending warning

6 Reserved

7 Reserved

8 Reserved

9 Reserved

10 Tube table for active pump

N4-0 Selects the parameters type to be received in DW 12-21 if text string is requested.

P7-1 is set if the corresponding parameter has a new value to be send to the active pump

(selected in DW0)

P1: A new value for the volume is set in word 12 and 13 is ready to be retrieved by the MC100

P2: A new value for the tube size is set in word 14 is ready to be retrieved by the MC100

P3: A new value for the speed is set in word 15 is ready to be retrieved by the MC100

P4: A new value for the acceleration is set in word 16 is ready to be retrieved by the MC100

P5: A new value for reverse is set in word 17 and is ready to be retrieved by the MC100

P6: A new value for density is set in word 18 and 19 and is ready to be retrieved by the MC100

P7: A new value for calibration is set in word 20 and 21 and is ready to be retrieved by the

MC100

You can send more parameters to a pump in one data package – e.g. when sending a new recipe.

PS is set to request a test string in DW12 to 21. The data is selected in N4 – N0 as described

above.

Please remember to reset the flags when the data has been received by the MC100.

Tube table consisting of 10 bytes with tube

diameters. 6

6

Tube diameter is an integer value with a hidden decimal point - e.g. 16 equals 1.6 mm ID

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 27 of 40

Page 28

Users Manual

MC100

7.2.3 Status words from parameters transfer (MC100 PLC)

DW 10

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

PS P7 P6 P5 P4 P3 P2 P1 - - - 0 0 0 0 0

P7-1 and PS are handshake for parameter bit(s) in Control DW 10.

The bits are set by the MC100 when the information is received and used.

Please also check the acknowledgements in the data words. Here the MC100 sends the values

present in the pump after the data has been changed. It should correspond to the data sent.

7.2.4 Data word 11

Word 11 is reserved for special functions

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

- - - - - - - - - - - - - - - -

7.2.5 Alarm and warning (MC100 PLC)

The alarms and warnings are transmitted from the MC100 to the PLC in DW21.

The structure is:

:

AB7 AB6 AB5 AB4 AB3 AB2 AB1 AB0 WB7 WB6 WB5 WB4 WB3 WB2 WB1 WB0

The alarms are described in details in section 8.1.1 and the warnings in section 8.1.2.

14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

15

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 28 of 40

Page 29

Users Manual

1

1

1

0 1 1

0

1

0

1

1

1

0 1 1

0

0

MC100

7.3 Examples:

7.3.1 New speed to pump 1:

In the following “Control” means data from the PLC to the MC100 and “Status” means data from

MC100 to the PLC.

The speed for pump 1 is set to 300 rpm.

Step 1: Set pump no. 1 in MC100 Control Word DW0 Control

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

- - - - - - - - - - - - 0 0 0

Step 2: Set 0 in DW10 Control

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

- - - - - - - - 0 0 0 0 0 0 0 0

Step 3:

Speed value 300 rpm to pump 1 in DW15 Control

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

- 0 0 0 0 0 0

Step 4: Set P3 (Bit 10) in DW10 Control

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

-

0 0 0

0 0 0 0 0 0 0 0 0 0

Step 5: Check P3 (Bit 10) in DW10 Status

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

-

0 0 0

0 0 0 0 0 0 0 0 0 0

Step5b: If required check the new value for the speed in DW15 Status

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

- 0 0 0 0 0 0

Step 6: Clear P3 (Bit 10) in DW10 Control

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

- 0 0 0 0

0 0 0 0 0 0 0 0 0 0

Step 7: Check Clear P3 (Bit 10) in DW10 Status

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

- 0 0 0 0

0 0 0 0 0 0 0 0 0 0

The cyclic data can be read in DW10-22 and will always have the selected(active) pump in DW10 LSB,

when NOT getting strings

0 0

0 0

0 0

0 0

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 29 of 40

Page 30

Users Manual

1 1

1

1

0

0

MC100

7.3.2 New calibration value to pump 3:

In the following “Control” means data from the PLC to the MC100 and “Status” means data from

MC100 to the PLC.

A new calibration value (10,034 g) is send for pump 3.

Step 1: Set pump no. 3 in MC100 Control Word Control

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

- - - - - - - - - - - - 0 0

Step 2: Set 0 in DW10 Control

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

- - - - - - - - 0 0 0 0 0 0 0 0

Step 3:

Place calibration value in DW20-21.

First the calibration value has to be converted into an integer as described earlier:

10,034 * 100.000 = 1003400

Then the value is placed in DW20 and DW21 where the LSB is DW20 bit 0 and MSB is DW21 bit 15

DW 20 Control

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 1 0 0 1 1 1 1 1 0 0 0 1 0 0 0

DW21 Control

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0- 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1

Step 4: Set P7 (Bit 14) in DW10 Control

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

-

Step 5: Check P7 (Bit 14) in DW10 Status

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

-

Step 5b: If requested check the new calibration value for the pump

DW 20 Status

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 1 0 0 1 1 1 1 1 0 0 0 1 0 0 0

DW21 Status

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0- 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1

Step 6: Clear P7 (Bit 14) in DW10 control

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

-

Step 7: Check Clear P7 (Bit 14) in DW10 Status

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

-

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 30 of 40

0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0

Page 31

Users Manual

1

1

1

MC100

7.3.2.1.1 Reading strings:

Set the request bit for receiving text strings in DW10 (bit 15) and the required text number in DW10 bit

0 – 4.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 - - - N4 N3 N2 N1 N0

Setting the number in DW10 and the PS bit in DW11 will read the string i DW12-25 status:

Example:

In the following “Control” means data from the PLC to the MC100 and “Status” means data from

MC100 to the PLC.

Request the FMB version as text

Step 1: Set the request bit for text string (bit 15) and the text number in DW10 Control

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0 0 0 0 0 0 - - - 0 0 0 0

Step 2: Receive the text string in DW 12 to 21 Status.

“MC100 FBM Ver. x.yy.z”

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 31 of 40

Page 32

Users Manual

MC100

8 Alarm and warnings

8.1 Alarms handling

When MC100 is in Alarm state, the only possible action is to reset the alarm. Only applies if the alarm

causes are removed, otherwise the alarm will re-appear at the next attempt.

Alarms are cleared one-by-one, starting top down – meaning lowest number first.

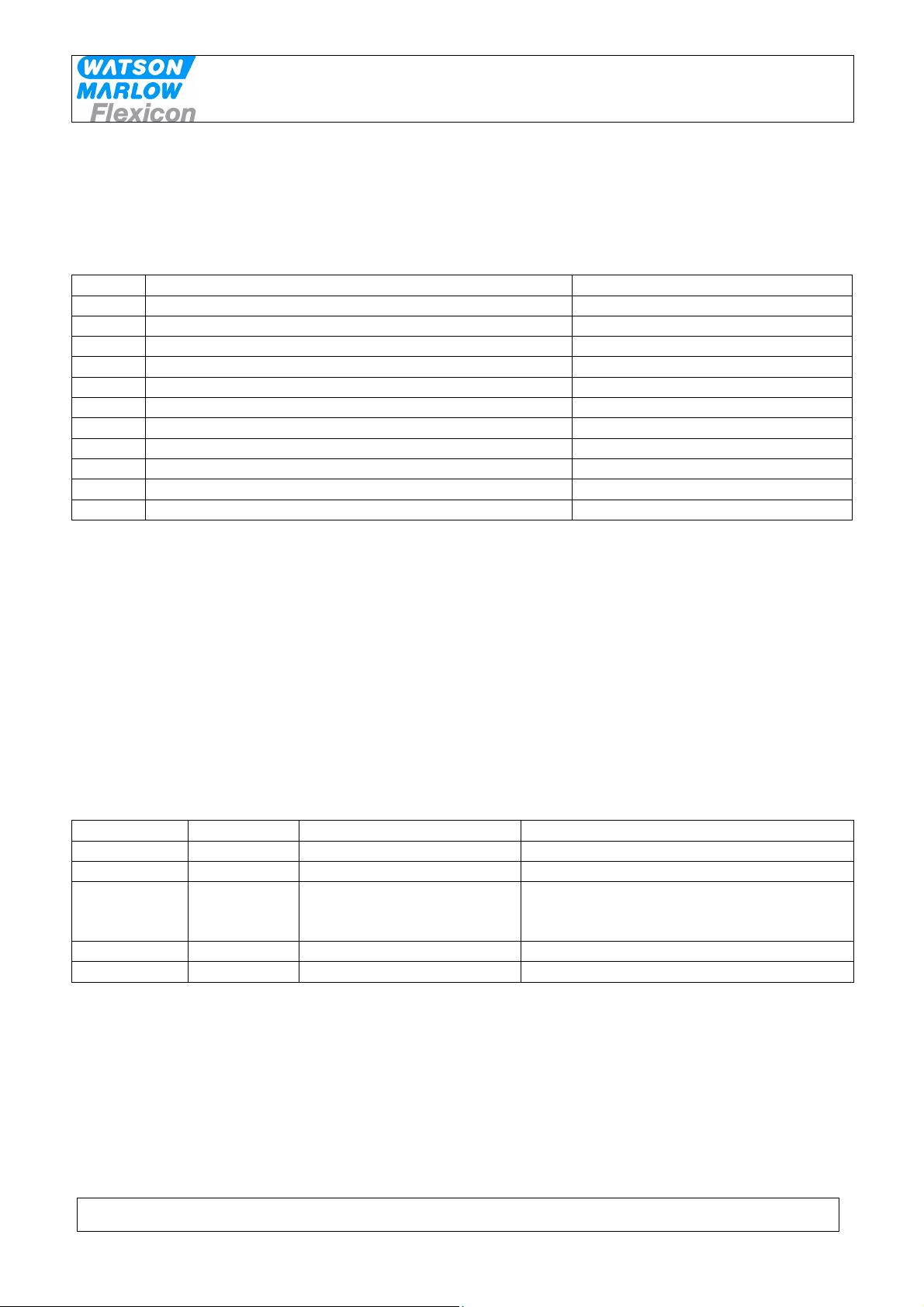

8.1.1 Module alarms

Alarm no.

0 No pending alarms

1

2

3

4

5 Reverse direction not available

6

7

8

9

10 Reserved

11 Run length limit Run less than 5 or more than 16777215 steps

12 -17 Reserved

NN

8.1.2 Pump alarms

20 Dispense not finished Dispensing has stopped before finishing.

21 Tube bridge off at dispense start Dispensing or pumping cannot start

22 Tube bridge off while dispensing Dispense not finished

23 Tube bridge off at pumping start Trying to start pumping with tube bridge off

24 Tube bridge off while pumping Removing tube bridge while pumping

Alarm description Action

No pumps connected during

power up

Connection to one or more

pumps lost

Connected pumps not equal to

last time

Attempt to access not

connected pump

Unstable FlexNet: Check

pumps 7

FRAM storage failure: Restart

or Reset

Mode change not completed:

check pumps

Missing or defect Anybus

CompactCom Module

FB module not Ready 8

Check connections /power to pumps

Check connections /power to missing pump

Configuration changed – Investigation or new

initialization must be done

Pump command Bit 5: Direction

set for one direction pump

Changing mode was not possible, check pump

versions, if change was to parallel or serial mode

No Alarm string available, because module not working

Internal MC100 module check, possible replacement of

module.

7

Expected to be implemented in a later version

8

Alarm is only displayed with the 2 LED’s on MFSC module – both flashes RED.

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 32 of 40

Page 33

Users Manual

MC100

8.2 Warnings handling

All warnings are cleared automatically, when data within limits are received via FB, or with clear-bit:

MC100 command B1.4

In warning 08-13 by the phrase individual pumps, means “real” connected pumps and pump 0 means

the pseudo pump, which holds common parameters in parallel and serial mode

8.2.1 Warnings

Warning no. Warning description Action

0 No pending warnings

1 Fill volume out of range

2 Tube number is not in table

3 Speed setting is out of range

4 Acceleration setting is out of range

5 Reverse setting is out of range

6 Density setting is out of range

7 Calibration is out of range

8 Common calibration in parallel

9 Individual calibration in serial

10

11

Attempt to set common parameters to

individual pump in serial mode

Attempt to calibrate pump 0 (fictive common

pump) in individual mode

Attempt to set parameter that is

outside limits.

Set new parameter.

Calibration attempt for Pump 0.

Calibrate pumps individually.

Calibration attempt for individual

pump, calibrate pump 0 only

Set parameters via pump 0

(fictive common pump) or clear

warning.

Clear by calibrating physical

connected pumps (1 to 15).

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 33 of 40

Page 34

Users Manual

MC100

9 Trouble shooting

9.1 Trouble-shooting

Different kind of problems can cause machine stop, errors etc. Most trouble-shooting will be based on

the information from the front plate indicators and display and the Alarm list information (see 8.1.1)

Examples:

Problem: Display is flashing AL / 01 when applying power to the module, indication that the MC100

cannot find any pumps connected.

Solution: First check if power is applied to the pump(s) and they are ON, then check cabling and

connectors for faults.

To check if problem has been solved, it’s necessary to turn power OFF and ON again

Problem: Display is flashing AL / 03 when applying power to the module.

Solution: First check if all the pump(s) has power applied and are indicating power ON.

If this is OK, then the MC100 has stored a different configuration and must be

reconfigured using the factory default configuration.

Make a factory reset to default by following the steps below:

1. Locate the dipswitches on the right side of the cabinet, turn dipswitch 8 ON.

2. Turn power ON to the module, which now starts up with the Alarm, but shortly after

starts the reset sequence and starts up again without the alarm 03.

3. Turn power OFF and turn dipswitch 8 back to OFF.

4. Turn power ON again and confirm that the alarm is still removed.

Alternative:

Use the Node address switch to do a factory reset. see section 5.1

Problem: Display is shoving “S.2.”. As a follow up on the configuration problem above, this will be

the display, when the master/scanner has a different configuration of the number of cyclic

bytes.

Solution: 1. If this is the initial configuration, please use section 6. Configuring the fieldbus

network to the MC100 and the supplied documentation and files on the CD-rom to

setup the network.

2. If this situation occurs after the system has been running normally, but after a factory

reset, focus must be moved to the pumps, where probably one or more pumps is not

communicating on the FlexNet.

Use the description in 6.1 Connecting the MC100 and the pumps for the first time,

to control the number of pumps that are detected on the FlexNet. When the problem

is solved and the correct pumps corresponding to the correct configuration is verified,

it will be necessary to do a factory reset again.

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 34 of 40

Page 35

Users Manual

MC100

9.2 Opening the MC100 for service/replacement of PCB’s

1 Power OFF for the 24V to the Module

2 Remove all cables attached the MC100.

3 To access the 2 circuit boards, remove the front cover by removing the 4 countersunk pozidrive

screws and the front cover will come off. The 2 PCB’s are connected with a ribboncable and has

to be pulled out together for service on either one.

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 35 of 40

Page 36

Users Manual

MC100

10 Decommissioning

10.1 Advice about dismantling / removal / disposal

Disconnect all services prior to dismantling the MC100

Disconnect all connections to other equipment.

10.2 Environmental conditions / -regulations

A MC100 is subject to the WEEE-system and may not be disposed using normal refuse collection.

The machine must be collected and disposed separately as it contains electrical components such as

batteries, electrolytic capacitors and printed circuit boards. ?

Further information is available on our web-site www.flexicon.dk.

10.3 The WEEE system

WEEE stands for: ”Waste Electrical and Electronic Equipment” and the term is used commonly

throughout the EU for waste from electrical and electronic equipment (EEE).

The WEEE Directive stipulates common EU regulations on treatment of WEEE. The rules are based on

consideration for the environment, and they aim at limiting the amount of WEEE we have to dispose of.

The objective is, on the one hand, to encourage producers to manufacture environmentally friendly

products, and, on the other, to increase reuse, recycling and other forms of recovery.

The WEEE rules provide for producer responsibility, which means that producers and importers of

electrical products must organise and finance take-back and treatment of WEEE, and report

information to a producer register.

WEEE pictogram:

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 36 of 40

Page 37

Users Manual

MC100

11 Appendix 1

Operating modes for MC100

(1) Individual

Individual filling means that each Pump has its own operating parameters and that fills, calibration and

pumping will not be synchronized with any other connected Pump. In theory, this means that the MC12

can control up to 16 Pumps concurrently.

Calibration is carried out by first selecting the pump number via MC100 control bits as in Individual

Mode and then sending the calibration value through the use of DW10 and DW20-21.

The parameters are sent to the individual Pump number after setting the pump number by the MC100

control bits.

(2) Parallel

Parallel filling is used in a multi-head filling system in which a number of bottles are changed in each

cycle and filled at the same time. This gives a very high capacity. The number of Pumps and the

number of bottles changed at each cycle should be identical.

If more Pumps are connected to the MC100, they can, if they are of the same type, work synchronously

with the same set of parameters. In parallel mode, only parameters in Pump 0 will be used i.e. all

Pumps use same volume, tube size, speed, etc.

Calibration must be carried out for the individual Pumps, by first selecting the pump number via MC100

control bits as in Individual Mode and then sending the calibration value through the use of DW20-21

(3) Serial

Serial filling is used to boost the overall capacity in a semi or fully automated system by using each

Pump to fill part of the total volume.

Similar to parallel filling, Pump 0 is used for setting parameters for all connected pumps, with the

exception of Function 2 for tube diameter.

For setting tube diameter, select the Pump number by the MC100 control bits as in Individual Mode

and then send the tube number using DW10 and DW14. In this way, the last Pump may for instance fill

a smaller part of the total volume than the other Pumps in the system. This is done by applying a

smaller tube in the last Pump.

When all Pumps have been programmed, the MC100 will automatically calculate which part of the total

volume the individual Pumps should fill, so that they are completed simultaneously. This gives the best

capacity.

Calibration is also carried out in Pump 0, as the system perceives the whole system as one single

Pump. I.e. selecting pump number 0 via MC100 control bits as in Individual Mode and then sending the

calibration value through the use of DW10 and DW20-21 (see example in section.

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 37 of 40

Page 38

Users Manual

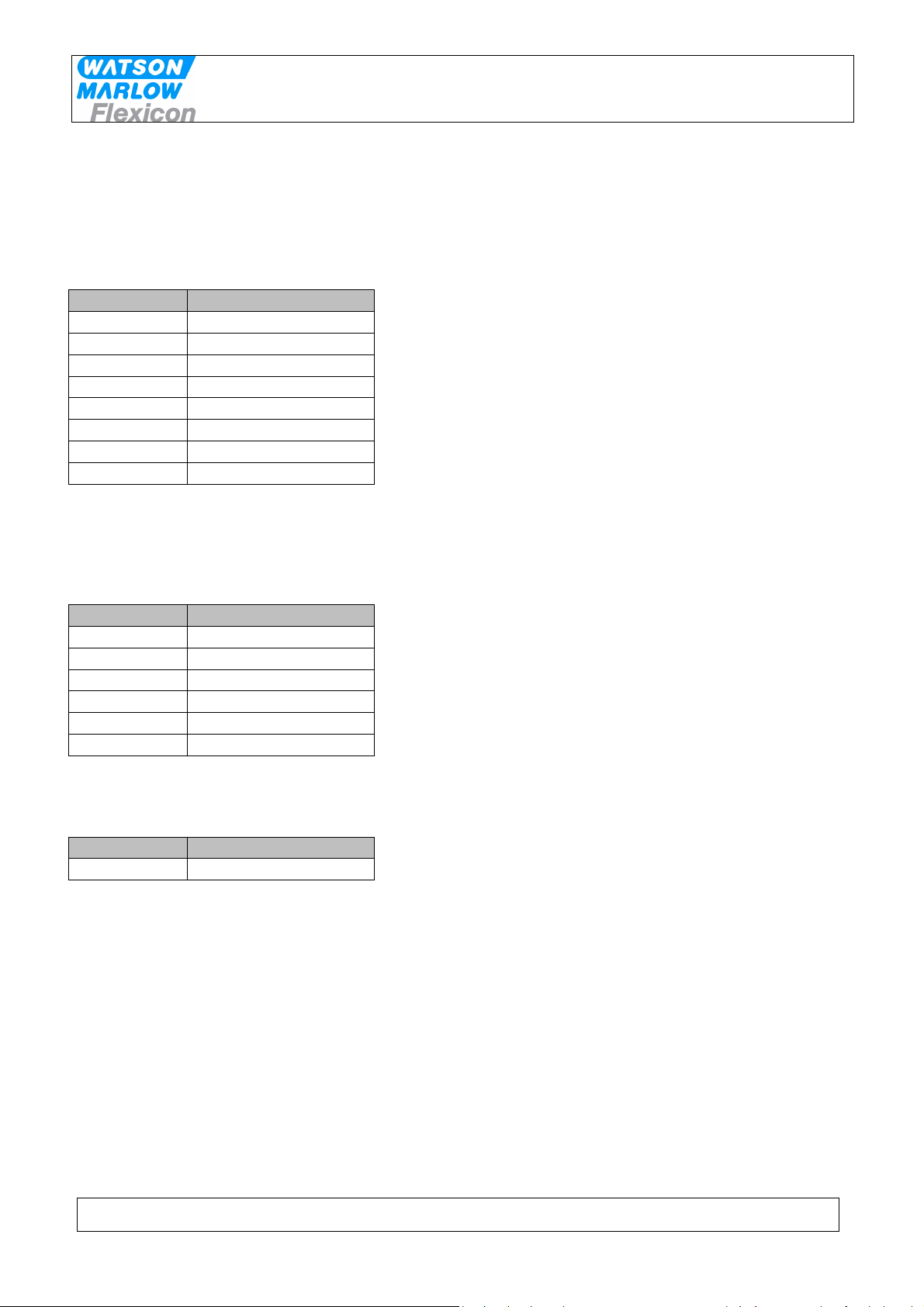

Tube Number

Inner Diameter [mm]

1 0.8

2 1.6

3 3.2

4 4.8

5 6.0

6 8.0

7 1.2

8 0.5

Tube Number

Inner Diameter [mm]

1 3.0

2 5.0

3 6.5

4 8.0

5 10.0

6 12.5

Tube Number

Inner Diameter [mm]

1 1.0 (pseudo number)

MC100

12 Appendix 2

12.1 Tube tables

12.1.1.1 PD12

Tube number 1 to 6 is valid for all versions of PD12 where the tube number 7 and 8 only is valid for

PD12 B (PD12 from after date??? )

12.1.1.2 PD22

12.1.1.3 GD30

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 38 of 40

Page 39

Users Manual

MC100

12.2 Volume, Speed and acceleration

The range for speed and acceleration is dependent on the pump type and the tube size:

12.2.1 PD12

Volume range: 0,01 to 9999,9 ml (NB remember the conversion to integer)

Speed range using tube 1, 2, 7 and 8: 30 to 600 rpm

Speed range using tube 3: 30 to 500 rpm

Speed range using tube 4 to 6: 30 to 400 rpm

Acceleration using tube 1, 2, 7 and 8: 1 to 200 rpm/s

Acceleration range using tube 3: 1 to 150 rpm/s

Acceleration using tube size 4 to 6: 1 to 100 rpm/s

12.2.2 PD22

Volume range: 10 to 9999 ml (NB remember the conversion to integer)

Speed range: 30 to 250 rpm

Acceleration range: 1 to 250 rpm/s

12.2.3 GD30

Volume range: 10 to 9999 ml (NB remember the conversion to integer)

Speed range: 30 to 750 rpm

Acceleration range: 1 to 100

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 39 of 40

Page 40

Users Manual

®

13 Declaration of Conformity

We Watson-Marlow Flexicon

Frejasvej 2-6

DK-4100 Ringsted

Declare on our sole responsibility that the product:

Pump control module: MC100

Model: 91-120-000 / 91-121-000

Flexicon a s

denmark

Model

Serial No.

Supply

Year

To which this declaration relates is in conformity with the following standard(s):

EN55022

Information technology equipment - Radio

disturbance characteristics - Limits and methods

of measurement

EN61000-6-2 Electromagnetic compatibility (EMC) - Part 6-2:

Generic standards - Immunity for industrial

environments

EN61000-6-3 Electromagnetic compatibility (EMC) - Part 6-3:

Generic standards - Emission standard for

residential, commercial and light-industrial

environments

According to the provisions in the Directives:

2004/108/EC On the approximation of the laws of the Member

States relating to electromagnetic compatibility

Signature:

September 2009

Ringsted, Denmark

Jørn Jeppesen, Development Manager

MC100

XXXX XXXX

24VDC

2009

Made in Denmark

MC100

MC100 Users Manual Profibus DP - rev 4 Rev. 4 Page 40 of 40

Loading...

Loading...