Page 1

403U, 405U

403u405u-gb-02.pdf

Page 2

Declarations

Declaration of

conformity

When this pump unit is used as a stand-alone pump it complies with: Machinery Directive

2006/42/EC, EMC Directive 2004/108/EC.

Responsible person: Christopher Gadsden, Managing Director, Watson-Marlow Limited , Fa lmou th, Cornwall

Declaration of

Incorporation

When this pump unit is to be installed into a machine or is to be assembled with other machines

for installations, it must not be put into service until the relevant machinery has been declared in

conformity with the Machinery Directive 2006/42/EC.

TR11 4RU, England. Telephone +44 (0) 1326 370370. Fax +44 (0) 1326 376 00 9.

Two year warranty

W-M Alitea AB warrants, subject to the conditions below, through either W-M Alitea AB, its subsidiaries, or its

authorised distributors, to repair or replace free of charge, including labour, any part of this product which fails within

two years of delivery of the product to the end user. Such failure must have occurred because of defect in material or

workmanship and not as a re sult of operation of the product other than in accordance with the instructions given in

this manual.

Conditions of and specific exceptio ns to the above warranty are:

Consumable items such as tubing, rollers and mot or b rush es a re e xcluded.

Products must be returned by pre-arrangement carriage paid to W-M Alitea AB, its subsidiaries, or its authorised

distributor.

All repairs or modifications must have been made by W-M Alitea AB, its subsidiaries, or its authorised distributors

or with the express permission of W-M Alit ea AB, its subsidiaries, or its authorised distributors.

Products which have been abused, mis used, or subjected to malicious or accidental damage or electrical surge

are excluded.

Warranties purporting to be on behalf of W-M Alitea AB made by any person, including representatives of W-M Alitea

AB, its subsidiaries, or its distributors, which do not accord with the terms of this warranty shall not be binding upon

W-M Alitea AB unless expressly approved in writing by a Director or Manager of W-M Alitea AB.

Information for returning pumps

Equipment which has been contaminated with, or exposed to, body fluids, toxic chemicals or any other substance

hazardous to health must be decontaminated before it is returned to W-M Alitea AB or its distributor.

A certificate included at the rear of these operating instructions, or signed statement, must be attached to the outside

of the shipping carton.

This certificate is required eve n if the p ump is un us ed. If th e pump h as b ee n us ed , the fluid s that have be en in co ntact

with the pump and the cleaning procedure must be specified along with a statement that the equipment has been

decontaminated.

Safety

In the interests of safety, this pump and the tubing selected should only be used by competent, suitably trained

personnel after they have read a nd und er sto od this manual, and considered any hazard involved.

Any person who is involved in the installation or maintenance of this equipment should be fully competent to carry out

the work. In the UK this person should also be familiar with the Health and Safety at Work Act 1974.

There are dangerous voltages inside the pump. If access is required, isolate the pump

from the mains before removing the cover.

2

Page 3

Installation

The 403U and 405U drives are suitable for singl e ph ase main s ele ctr icity supplies only.

The pumps are supplied with a mains cable fitted with a moulded plug. The wires are colour coded in accordance

with the following code:

220-240V: Live- Brown; Neutral - Blue; Earth - Green/Yellow.

100-120V: Live - Black; Neutral - W hit e; Earth - Green.

403U and 405U drives with product codes ending in "U" (UK mains cable) and "E" (European mains cable) accept

230V, 50/60Hz only, whereas pumps with product codes ending in "A" (American mains cable) accept 110V,

50/60Hz single phase mains voltage.

Recommended operating procedures

keep delivery and suction lines as short as possible using a minimum number of swept bends.

DO

use suction and delivery pipelines wi th a bore equal to or lar ger than the bor e of the tube fitted in the pumphead.

DO

When pumping

cross sectional area several times greater tha n t he pumping element.

run at a slow speed when pumping viscous fluids.

DO

fit an extra length of pump tube in the system to enable tube transfer. This will extend tube life and minimise the

DO

downtime of the pumping circuit.

keep the track and rollers clean.

DO

The self-priming nature of pe ristaltic pumps means valves are not req uired. Any valves fitted must cause no res triction

to flow in the pumping circuit.

When using continuous lengths of Marprene tubing

pumphead by releasing the tra ck latch and pulling the tubing on the delivery side a little. This is to coun teract the

normal stretching that occurs with Marprene which can go unnoticed and result in poor tube life.

Tube selection

about the compatibility of a tube material and the duty fluid, request a tube sample card for immersion trials.

viscous

The chemical compatibility list published in the Watson-Marlow catalogue is only a guide. If in doubt

fluids, the losses cau sed by increased friction can be overc ome by using pipe runs with a

After the first 30 minutes of running, re-tension the tube in the

Troubleshooting

Should the pump fail to operate, make the following checks to determine whether or not servicing is required.

Check that mains supply is available at t he pu mp.

Check the mains supply fuse.

Check that the pump is not stalled by incorrect fitting of tubing.

Manual operation

Change the set speed by pres sing the or key. Pump speed is displayed in percentage of maximum s peed.

The 403U has a speed control ratio of 20:1. This will give a minimum speed of 0.5rpm for the 10rpm 403U drive

and 2.5rpm for the 50rpm 403U. The 405U has a sp eed control ratio of 10:1. This will give a minimum speed of

20rpm for the 200rpm 405U drive.

Start the pump or change rotor running direction by pressing the

clockwise) key. Stop the pump by pressing the

is indicated by the illumination of the LED above the ,

For maximum speed priming press the

If power is cut to the pump at the mains supply wh en under manu al control, after power is reconnec ted the pump

will remain stopped.

If returning from auto control to manual control, disconnect the process signal from the pump.

Max

key.

key. The direction of rotation of the rotor, or a stopped rotor,

Stop

and keys.

Stop

(clockwise rotation) or the

(counter

3

Page 4

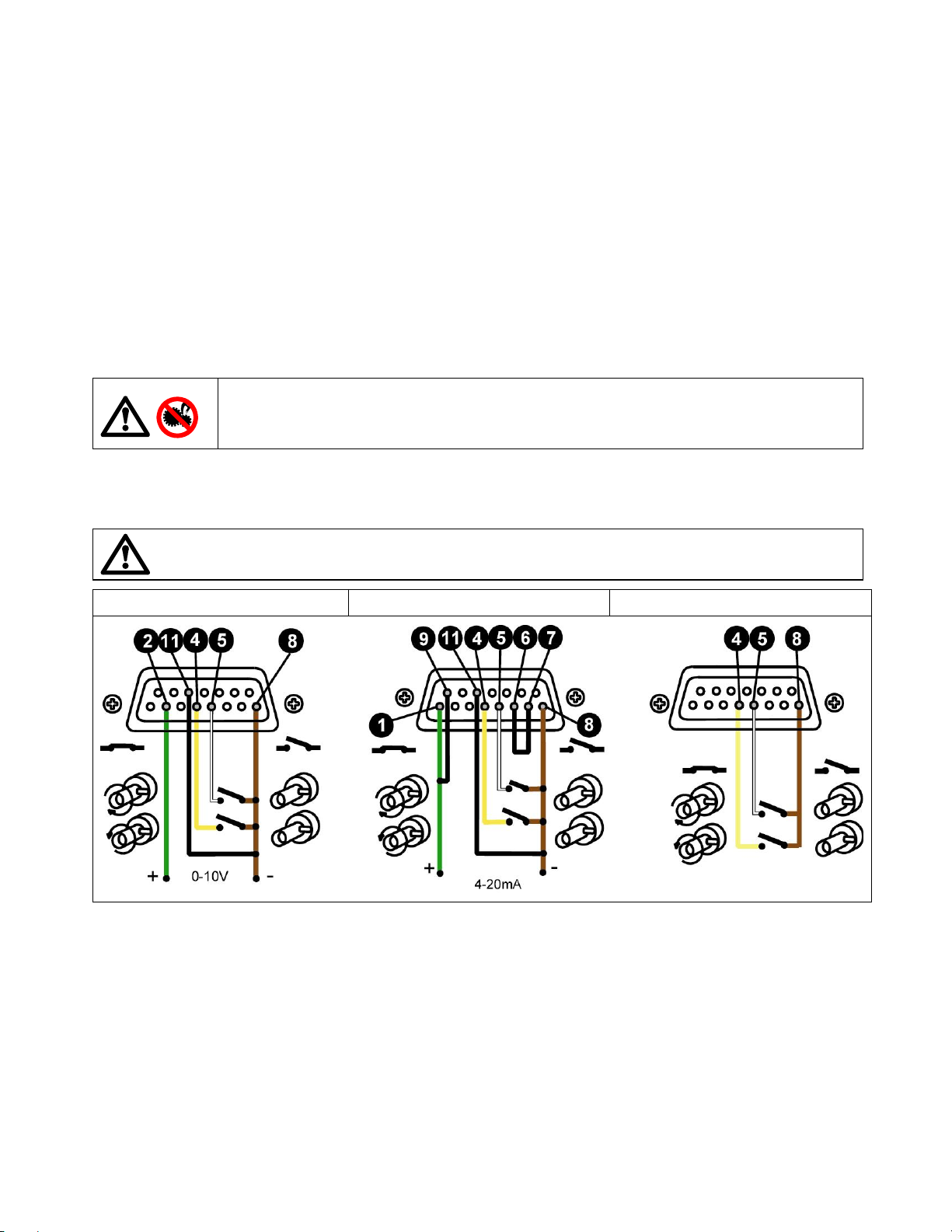

Remote control

The 403U and 405U dr ives can be controlled remotely via 0-10V or 4-20 mA anal ogue signals. 400AC1, 400AC2,

400AC3 and 400AC4 remote control cables with a 15-pin D-sub connector are available from your local WatsonMarlow dealer. Wiring diagrams for each control cable are shown at the bottom of this section.

When using the

switching cw/stop/ccw:

Set the pump to stop by pressing the

The keypad speed control setting sets the range of the remote speed signal, and it can be adjusted during remote

control use. (If the manual speed is set 50 %, only 50% of maximum speed will be achiev a ble at 10V or 20mA). It

is advisable to set the speed to 99.9 % f or fu ll an alogue speed range control.

Start or stop the pump in either cw or ccw direct ion remotely as shown in the relevant wiri ng diagrams. If the

remote switch is set to stop, cw or ccw direction switching can be a chie ved using the keypad.

When using the

Set the pump speed manually using the or keys.

Start or stop the pump in either cw or ccw direct ion remotely as shown in the relevant wiri ng diagram. If the

remote switch is set to stop, cw or ccw direction switching can be a chie ved using the keypad.

When using the

Set the pump to stop by pressing the

Pressing the footswitch will start the pump in the cw direction only. Releasing the footswitch will stop the pump.

400AC1 400AC2 400AC3

400AC1

400AC3

400AC4

In the event of a power failure when the pump is under remote control, the pump will automatically

re-start when the power is returned.

(0-10V) or

cw/stop/ccw remote cable

With a remote direction switch connected and the remote cw/stop/ccw switch set to cw or

ccw, you cannot switch direction manually. However, you can stop the pump manually

using the keypad which is designed to be used as an "emergency stop". The remote

cw/stop/ccw switch needs to be set to stop to release the "emergency stop".

start/stop 3m remote cable with footswitch fitted:

400AC2

(4-20mA) remote control cables for a na l og ue speed control and

key.

Stop

key

Stop

Care and maintenance

The only scheduled maintenance of the pump unit is to replace the motor brushes and to replace them when

necessary, understanding that motor brushes are not covered by the two year warranty. It is recommended that this

work be carried out by a Wats on-Marlo w ser vicing ag ent. Th e life of the b rus hes dep ends on the duty of the pu mp but

is expected to be at least 2500 hours at maximum speed for the 403U and 5000 hours for the 405U.

If the pump requires cleaning use a mild solution of detergent in water after removing the pumphead. Do not use

strong solvents.

4

Page 5

Pump spares

403U/VM 403U/R1 & 405U/R1

403U/L & 405U/L 403U/L2 & 405U/L2

Number Description

1

2

3

4

5

6

7

Tube clamping block 970075 990067 990029

Rotor 010020 010022 010017

Track 941024 941024 941024

Track occlusion arm 010040 010040 010040

Rotor screw MRX M5X10 A4 MRX M5X10 A4 MRX M5X10 A4

Rotor shaft pin CPR3H 8x 16 CPR3H 8x16 CPR3H 8x16

Case screws D6 B 35x10 NN A542

Part number

403U/VM2

SPTAND A4

Part number

D6 B 35x10 NN A542

SPTAND A4

Number Description

1

2

3

4

5

6

7

8

9

Tube clamps/block 010042 930325 010043

Rotor 010018 010019 010019

Track 970714 950058 950058

Track occlusion arm 010040 010040 010040

Rotor screw MRX M4X6 A4 MRX M5X6 A4 MRX M5X6 A4

Rotor shaft pin CPR3H 8x 16 CPR3H 8x16 CPR3H 8x16

Case screws D6 B 35x10 NN A542

Transparent guard 950163 950217 950217

Finger screw 950169 950169 950169

Part number

403U/R1, 405U/R1

SPTAND A4

Part number

403U/L, 405U/L

D6 B 35x10 NN A542

SPTAND A4

403U/VM3

Part number

403U/VM4

D6 B 35x10 NN A542

SPTAND A4

Part number

403U/L2, 405U/L2

D6 B 35x10 NN A542

SPTAND A4

5

Page 6

Specification

Maximum rotor speeds for 403U 10rpm, 50rpm

Maximum rotor speeds for 405U 200rpm

Voltage/frequency 040.****.**U 240V 50/60Hz

Voltage/frequency 040.****.**E 240V 50/60Hz

Voltage/frequency 040.****.**A 110V 50/60Hz

403U control range 20:1

405U control range 10:1

Operating temperature range 5 to 40C

Storage temperature range -40C to 70C

Noise <70 dBA @ 1m

Standards IEC 335-1, EN60529 (IP21)

Machinery Directive 2006/42/EC

EMC Directive 2004/108/EC

400R1, 400L & 400L2 and 400VM2, 400VM3 & 400VM4 pumpheads

Performance against pressure

The pressure and the suction height can be increased by compressing the spring in the track occlusion pin. A smaller

gap between the rollers and track will give better performance against pressure but will reduce tube life.

Other factors that will influence tube life in peristaltic pumps are pump speed (roller impacts/minute), chemical

compatibility of the duty fluid and viscosity of the duty fluid.

It is the pressure capability of the tubing that limits the operating pressure of the pump. The maximum pressure you

can obtain is dependent on the wall thic knes s, tu be bore and hardne ss of the tubing . Normally the ma ximum press ure

is 2 bar.

Key Safety Information

When fitting a new tube in the pumphead

Ensure that there is no pressure, liquid or gas in the pipeline.

Disconnect the pump from the mains to prevent the pump from starting unexpectedly.

Always replace any protective guard after tube changeover.

If a tube failure has occurred, ensure that any fluid in the pumphead has been allowed to drain to a safe area

Ensure that protective clothi n g and eye protection is worn if aggressive fluids are being pumped.

400R1 pumphead set-up

The 400R1 pumphead is designed to accept 1.6mm wall standard laboratory tubing up to 6.4mm bore. Care should

be taken to establish the normal tube life experienced within a set of operating parameters. Subsequent tubing

replacement should be scheduled wi thin the normal expected life of a tube. This will avoid unnecessary tube failure

and unplanned pump maintenance.

Tube loading (Pictures 1-9)

Remove the transparent guard.

Release the track by disengaging the track occlusion pin.

Before tube loading, mak e sur e that enough s uction and delivery tub ing is available to c onnect in to the remainin g

pipeline or to reach the suction reservoir and delivery point.

Locate the tubing into the suction side tube clamp. Feed the tubing in around the rotor, maintaining reasonable

tube tension so that the tube sits around the rotor, and locate into the delivery side tube clamp. Make sure that

there are no twists or kinks in the tubing after loading as this will adversely affect tube life.

Ensure the tube is lined up centrally in the track correctly secured at each clamp.

Re-position the track over the rotor and fix by slotting the track occlusion pin back into the track slot.

Re-attach the transparent guard.

Compressing the spring on the track occlusion pin (picture 10) will increase the suction height and performance

against back pressure.

6

Page 7

1 2 3 4

5 6 7 8

9 10 11 12

Occlusion setting

Increase the spring pressur e until the pump starts pumping and th en adjust the spring pr essure according to the

flow rate required, which will be governed by the suction condition.

pressure to the minimum required for satisfactory pumping.

Tube re-tensioning (pictures 10-12)

For longest tube life, set the spring

When using Marprene tubing

releasing the track occlusion pin and pulling the tubing on the discharge side a little. This is to counteract the

normal stretching that occurs with Marprene which can go unnoticed and result in poor tube life.

Tube removal

Release the track by disengaging the spru ng track occlusion pin and withdraw the tubi n g from the sprung clamps.

, after the first 30 minutes of running, re-tension the tube in the pumphead by

400L and 400L2 pumpheads set-up

The 400L is designed for 1.6mm wall elements up to 4.8mm bore, whereas the 400L2 accepts two 1.6mm wall

continuous lengths of tubing up to 4.8mm bore.

Care should be taken to establish th e normal tube life experien ced within a set of operatin g parameters. Subseq uent

tubing replacement should be scheduled within the normal expected life of a tube. This will avoid unnecessary tube

failure and unplanned pump maintenanc e.

Tube loading (Pictures 1-24)

Remove the transparent guard

Release the track by disengaging the track occlu sio n pin.

Before tube loading, mak e sur e that enough s uction and delivery tub ing is available to c onnect in to the remainin g

pipeline or to reach the suction reservoir and delivery point.

For 400L Y elements (pictures 1-9)

around the split rotor ensu ring that ea ch leg of th e elemen t sits centra lly over each sec tion of the roto r. Loc ate the

second y connection in the upper clamp block.

For 400L2 continuous tubing lengths (pictures 10-24)

Feed each tube in around the rotor, maintaining reasonable tube tension so that each tube sits centrally over each

locate one Y connection into the lower clamp block and feed the elements

locate the tubing into the suc tion side w-block clamp.

7

Page 8

section of the rotor. Locate into the delivery side w-block clamp. Make sure that there are no twists or kinks in the

tubing after loading as this will adversely affect tube life. If using a long length of tubing it is best to remove the wblock clamps to quickly locate a section of the tubing between the track and rotor.

Re-position the track over the rotor and fix by slotting the track occlusion pin back into the track slot.

Replace the transparent guard and secure in place.

Compressing the spring on the track occlusion pin (picture 9 and 22) will increase the suction height and

performance against back pressure.

1 2 3 4

5 6 7 8

9 10 11 12

13 14 15 16

17 18 19 20

21 22 23 24

8

Page 9

Tube re-tensioning (pictures 25-27)

When using Marprene tubing

releasing the track occlusion pin and upper w-block clamp and pulling the tubing on the delivery side a little. This

is to counteract the normal stretchin g that occurs with Marprene whic h can go unnoticed and result in poor tube

life.

, after the first 30 minutes of running, re-tension the tube in the pumphead by

25 26 27

Tube removal

Release the track by disengaging the tr ack occlu sion pin and withdraw the tubing from th e w-block clamps.

400VM2, 400VM3, 400VM4 pumpheads set up

The 410VM pumpheads are designed to acce pt two bridge manifold tubing only .

Tube loading (pictures 1-8)

Release the track by disengaging the track occlu sio n pin.

Locate the first tube bridge into the appropriate tube bridge holder slot. Feed the tubing around the rotor and

locate the centre tube br idge into the bridge ho lder slot immediately opp osite the first tube bridge. Repeat for th e

remaining one (400VM2) or two (400VM3) or three (400VM4) channels. Make sure that there are no twists or

kinks in the tubing after loading as this will adversely affect tube life.

Re-position each track over the rotor and fix by slotting the track occlusion pin back into the track slot.

Compressing the spring on the track occlusion pin (picture 8) will increase the suction height and performance

against back pressure.

1 2 3 4

5 6 7 8

Tube removal

Release the track by disengaging the track occlu sio n pin.

Remove both tubing bridges from thei r lo cation slots and remove the tubing from the pumphead.

9

Page 10

Flow rates

The tables below list the approximate water-flow rate per revolution for the 404D pumpheads. The flow rate will

depend on the duty fluid (viscosity, density etc.), pressure, temperature, speed, tubing and the installation. For

accurate flow rates and repeatability, calibrate the pump for your application.

400R1

Tube bore 0.5mm 0.8mm 1.6mm 2.4mm 3.2mm 4.0mm 4.8mm 6.4mm

Tube number 112 13 14 16 25 15

ml/rev

2.5 to 50rpm

20 to 200rpm

400L

Tube bore 0.5mm 0.8mm 1.6mm 2.4mm 3.2mm 4.0mm 4.8mm

Tube number 112 13 14 16 25

ml/rev

2.5 to 50rpm

20 to 200rpm

400L2

Tube bore 0.5mm 0.8mm 1.6mm 2.4mm 3.2mm 4.0mm 4.8mm

0.022 0.055 0.22 0.49 0.86 1.31 1.83 3.03

0.06-1.1 0.14-2.8 0.55-11 1.2-24 2.1-43 3.3-65 4.6-92 7.6-150

0.44-4.4 1.1-11 4.4-44 9.8-98 17-170 26-260 37-370 61-610

0.043 0.11 0.44 0.98 1.71 2.62 3.67

0.11-2.2 0.28-5.6 1.1-22 2.4-49 4.3-86 6.5-130 9.2-180

0.86-8.6 2.2-22 8.8-88 20-200 34-340 52-520 73-730

Tube number 112 13 14 16 25

ml/rev

2.5 to 50rpm

20 to 200rpm

0.022 0.055 0.22 0.49 0.86 1.31 1.83

0.06-1.1 0.14-2.8 0.55-11 1.2-24 2.1-43 3.3-65 4.6-92

0.44-4.4 1.1-11 4.4-44 9.8-98 17-170 26-260 37-370

400VM2, 400VM3, 400VM4

Colour Orange/black Orange/Red Orange/Blue Orange/Green Orange/yellow

Bore 0.13mm 0.005" 0.19mm 0.007" 0.25mm 0.010" 0.38mm 0.015" 0.50mm 0.020"

0.5-10rpm

2.5-50rpm

Colour Orange/White Black/Black Orange/Orange White/White Red/Red

Bore 0.63mm 0.025" 0.76mm 0.030" 0.88mm 0.035" 1.02mm 0.040" 1.14mm 0.045"

0.5-10rpm

2.5-50rpm

Colour Grey/Grey Yellow/Yellow Yellow/Blue Blue/Blue Green/Green

Bore 1.29mm 0.050" 1.42mm 0.055" 1.52mm 0.060" 1.65mm 0.065" 1.85mm 0.07

0.5-10rpm

2.5-50rpm

Colour Purple/Purple Purple/Black Purple/Orange Purple/White

Bore 2.05mm 0.080" 2.29mm 0.090" 2.54mm 0.100" 2.79mm 0.110"

0.5-10rpm

2.5-50rpm

0.001-0.01 0.001-0.03 0.002-0.004 0.005-0.1 0.01-0.2

0.003-0.06 0.006-0.13 0.011-0.2 0.025-0.5 0.04-0.9

0.01-0.3 0.02-0.4 0.03-0.5 0.03-0.7 0.04-0.9

0.07-1.4 0.10-2.0 0.13-2.6 0.17-3.5 0.21-4.3

0.05-1.1 0.06-1.3 0.07-1.4 0.08-1.7 0.10-2.0

0.27-5.4 0.32-6.4 0.36-7.2 0.41-8.3 0.50-10.0

0.12-2.3 0.14-2.7 0.16-3.1 0.17-3.4

0.59-12 0.69-14 0.78-16 0.85-17

10

Page 11

1.6mm wall continuous tubing

Tube product codes

mm " #

0.5 1/50 112 902.0005.016 903.0005.016 910.0005.016 913.0005.016

0.8 1/32 13 902.0008.016 903.0008.016 910.0008.016 913.0008.016

1.6 1/16 14 902.0016.016 903.0016.016 910.0016.016 913.0016.016

3.2 1/8 16 902.0032.016 903.0032.016 910.0032.016 913.0032.016

4.8 3/16 25 902.0048.016 903.0048.016 910.0048.016 913.0048.016

6.4 1/4 17 902.0064.016 903.0064.016 910.0064.016 913.0064.016

8.0 5/16 18 902.0080.016 903.0080.016 910.0080.016 913.0080.016

mm " # Butyl * Tygon Fluorel Neoprene

0.8 1/32 13

1.6 1/16 14 930.0016.016 950.0016.016 970.0016.016 920.0016.016

3.2 1/8 16 930.0032.016 950.0032.016 970.0032.016 920.0032.016

4.8 3/16 25 930.0048.016 950.0048.016 970.0048.016 920.0048.016

6.4 1/4 17 930.0064.016 950.0064.016 970.0064.016 920.0064.016

8.0 5/16 18 930.0080.016 950.0080.016 970.0080.016 920.0080.016

Marprene Bioprene Peroxide Silicone Platinum Silicone

920.0008.016

Manifold tubing product codes

Bore

mm Bore "

0.13 0.005 984.0013.000

0.19 0.007 984.0019.000

0.25 0.010 978.0025.000 980.0025.000 984.0025.000

0.38 0.015 978.0038.000 980.0038.000 984.0038.000

0.50 0.020 978.0050.000 980.0050.000 984.0050.000 986.0050.000

0.63 0.025 978.0063.000 980.0063.000 982.0063.000 984.0063.000 986.0063.000

0.76 0.030 978.0076.000 980.0076.000 982.0076.000 984.0076.000 986.0076.000

0.88 0.035 978.0088.000 980.0088.000 982.0088.000 984.0088.000 986.0088.000

1.02 0.040 978.0102.000 980.0102.000 982.0102.000 984.0102.000 986.0102.000

1.14 0.045 978.0114.000 980.0114.000 982.0114.000 984.0114.000 986.0114.000

1.29 0.050 978.0129.000 980.0129.000 982.0129.000 984.0129.000 986.0129.000

1.42 0.055 978.0142.000 980.0142.000 982.0142.000 984.0142.000 986.0142.000

1.47 0.058 982.0147.000

1.52 0.060 978.0152.000 980.0152.000 982.0152.000 984.0152.000 986.0152.000

1.65 0.065 978.0165.000 980.0165.000 982.0165.000 984.0165.000 986.0165.000

1.85 0.070 978.0185.000 980.0185.000 982.0185.000 984.0185.000 986.0185.000

2.05 0.080 978.0205.000 980.0205.000 982.0205.000 984.0205.000 986.0205.000

2.29 0.095 978.0229.000 980.0229.000 982.0229.000 984.0229.000 986.0229.000

2.54 0.100 978.0254.000 980.0254.000 982.0254.000 984.0254.000 986.0254.000

2.79 0.110 978.0279.000 980.0279.000 982.0279.000 984.0279.000 986.0279.000

Marprene

PVC

Silicone

Solvent

resistant

Acid

resistant

11

Page 12

Outline dimensions

r

403U/VM2 403U/VM3 403U/VM4

403U/R1 403U/L 403U/L2

405U/R1 405U/L 405U/L2

Watson-Marlow, Bioprene

Warning, these products are not designed for use in, and should not be used for patient connected

applications.

The information contained in this document is believed to be correct but Watson-Marlow Limited accepts no liability fo

any errors it contains, and reserves the right to alter s pecifications without notice.

and

Marprene

are trademarks of

Watson-Marlow Limited.

12

Page 13

Product use and decontamination declaration

.

.

.

.

In compliance with the

Regulations

you are returning to Watson-M arlow or any of its subsidiaries or dis tributors. Failure to do so will cause delays in

servicing the product. Therefor e, pleas e comp le te th is for m to en s ure th at we ha ve the inform ation be for e receip t of

the product(s) being returned. A FURTHER COPY

PACKAGING CONTAINING THE PRODUCT(S). You, the user, are responsible for cleaning and decontaminating

the product(s) before returning them.

Please complete a separate Decontamination Certificate for each pump returned.

1 Company

Address ……… ........................................................................Postcode ………………………………………

Telephone ……………………………………………. ................ Fax Number …………………………………..

2.1 Serial Number … … … … … … … … … … … … … ..........(a)………………………………………………….

2.2 Has the Product been used? (b)…………………………………………………

YES NO (c)…………………………………………………

(d)…………………………………………………

If yes, please complete all the following Sections. If no, please complete Section 5 only

3 Details of substances

pumped

3.1 Chemical names:

(a)……………… ..........................

(b)……………..............................

(c)……………… ..........................

(d)……………..............................

3.2 Precautions to be taken in handling these substances: To assist servicing, please describe any fault

(a)………… ......................................................... condition(s) you have witnessed

(b)………… ........................................................…………………………………………………

(c) ……………… ..................................................……………………………………………………………

(d)………………. ..................................................……………………………………………………………

3.3 Action to be taken in the event of human contact:

..........……………………………………………………………………………………………………

(a)………………………………………………………………….……………………………………………………………

(b)………………………………………………………………….……………………………………………………………

(c)………….……………………………………………………………………………………………………………………

(d)………….……………………………………………………………………………………………………………………

3.4 Cleaning fluid to be used if residue of chemical is found: ……………………………………………………………

(a)…………………………………………………………………. ……………………………………………………………

(b)…………………………………………………………………. ……………………………………………………………

(c)………….……………………………………………………………………………………………………………………

(d)………….……………………………………………………… ……………………………………………………………

Watson-Marlow Bredel Pumps . Falmout h . Cornwall TR11 4RU . England . Tel: 01326 370370 . Fax: 01326 376009

you, the user are required to declar e the substances which have b een in contact with the product(s)

UK Health & Safety at Work Act

4 I hereby confirm that the only substa nces(s) that the equipmen t specified has

pumped or come into contact with are th ose n amed, that the information give n is

correct, and the carrier has been informed if the consignment is of a hazardous

nature.

5 Signed …………………………………………………………………………………

Name …………………………………………………………………………………

Position ……………………………………………………………………………….

Date …………………………………………………………………………………..

and the

MUST

Control of Substances Hazardous to Health

BE ATTACHED TO THE OUTSIDE OF THE

RGA No:

…………………...

13

Loading...

Loading...