Page 1

313F, 313S, 313U, 313T

313fstu-gb-03.pdf

Page 2

Declarations

Declaration of

conformity

When this pump unit is used as a stand alone pump it complies with: Machinery Directive

98/37/EC EN60204-1, Low Voltage Directive 73/23/EEC EN61010-1, EMC Directive

89/336/EEC, EN50081-1/EN50082-1.

Declaration of

Incorporation

Responsible person: Dr R Woods, Managing Director, Watson-Marlow Limited, Falmouth, Cornwall TR11 4RU, England.

Telephone 01326 370370 Fax 01326 376009.

Two year warranty

Watson-Marlow Limited warrants, subject to the conditions below, through either Watson-Marlow Limited, its

subsidiaries, or its authorised distributors, to repair or replace free of charge, including labour, any part of this product

which fails within two years of delivery of the product to the end user. Such failure must have occurred because of defect

in material or workmanship and not as a result of operation of the product other than in accordance with the instructions

given in this manual.

Conditions of and specific exceptions to the above warranty are:

When this pump unit is to be installed into a machine or is to be assembled with other

machines for installations, it must not be put into service until the relevant machinery has

been declared in conformity with the Machinery Directive 98/37/EC EN60204-1.

• Consumable items such as tubing, rollers and brushes are excluded.

• Products must be returned by pre-arrangement carriage paid to Watson-Marlow Limited, its subsidiaries, or its

authorised distributor.

• All repairs or modifications must have been made by Watson-Marlow Limited, its subsidiaries, or its authorised

distributors or with the express permission of Watson-Marlow Limited, its subsidiaries, or its authorised distributors.

• Products which have been abused, misused, or subjected to malicious or accidental damage or electrical surge are

excluded.

Warranties purporting to be on behalf of Watson-Marlow Limited made by any person, including representatives of

Watson-Marlow Limited, its subsidiaries, or its distributors, which do not accord with the terms of this warranty shall not

be binding upon Watson-Marlow Limited unless expressly approved in writing by a Director or Manager of Watson-Marlow

Limited.

Information for returning pumps

Equipment which has been contaminated with, or exposed to, body fluids, toxic chemicals or any other substance

hazardous to health must be decontaminated before it is returned to Watson-Marlow or its distributor.

A certificate included at the rear of these operating instructions, or signed statement, must be attached to the outside of

the shipping carton.

This certificate is required even if the pump is unused. If the pump has been used, the fluids that have been in contact

with the pump and the cleaning procedure must be specified along with a statement that the equipment has been

decontaminated.

Safety

In the interests of safety, this pump and the tubing selected should only be used by competent, suitably trained

personnel after they have read and understood this manual, and considered any hazard involved.

Any person who is involved in the installation or maintenance of this equipment should be fully competent to carry out the

work. In the UK this person should also be familiar with the Health and Safety at Work Act 1974.

There are dangerous voltages (at mains potential) inside the pump. If access is required,

isolate the pump from the mains before removing the cover.

Page 3

Recommended operating procedures

DO keep delivery and suction lines as short as possible using a minimum number of swept bends.

DO use suction and delivery pipelines with a bore equal to or larger than the bore of the tube fitted in the pumphead.

When pumping viscous fluids, the losses caused by increased friction can be overcome by using pipe runs with a cross

sectional area several times greater than the pumping element.

DO fit an extra length of pump tube in the system to enable tube transfer. This will extend tube life and minimise the

downtime of the pumping circuit.

DO keep the track and rollers clean.

The self-priming nature of peristaltic pumps means valves are not required Any valves fitted must cause no restriction to

flow in the pumping circuit.

When using Marprene tubing, after the first 30 minutes of running, re-tension the tube in the pumphead by releasing

the tube clamp on the delivery side a little and pulling the tube tight. This is to counteract the normal stretching that

occurs with Marprene which can go unnoticed and result in poor tube life.

Tube selection The chemical compatibility list published in the Watson-Marlow catalogue is only a guide. If in doubt

about the compatibility of a tube material and the duty fluid, request a tube sample card for immersion trials.

Installation

The 313F, 313S and 313U are suitable for single phase mains electricity supplies only.

To ensure correct lubrication of the gearbox the pump should be run only while its feet are standing on a horizontal

surface. The pump should be positioned to allow a free flow of air around it.

Set the voltage selector to either 120V for 100-120V 50/60Hz supplies or 240V for 220-240V 50/60Hz supplies.

A mains cable fitted with a moulded plug is supplied with the pump. The wires are colour coded in accordance with the

following code:

• 220-240V: Live - Brown; Neutral - Blue; Earth - Green/Yellow.

• 100-120V: Live - Black; Neutral - White; Earth - Green.

Troubleshooting

Should the pump fail to operate, make the following checks to determine whether or not servicing is required.

• Check that the power switch is on.

• Check the mains supply is available at the pump.

• Check the voltage selector switch is in the correct position. l

• Check the fuse in the mains socket.

• Check that the pump is not stalled by incorrect fitting of tubing.

313F/D manual operation

• Set the voltage selector to either 120V for 100-120V 50/60Hz single phase AC supplies or 240V for 220-240V 50/60Hz

single phase AC supplies.

• Set the pump to the desired high or low speed setting using the horizontal slider switch on the rear panel.

• Stop Stop the pump by turning the Forward/Off/Reverse switch to its central Off position.

313S/D, 313U/D manual operation

• Set the voltage selector to either 120V for 100-120V 50/60Hz single phase AC supplies or 240V for 220-240V 50/60Hz

single phase AC supplies.

• Set the pump to the desired speed output using the front panel potentiometer.

• Turn the pump on using the mains power switch on the rear panel.

• Start up direction Start the pump by turning the Forward/Off/Reverse switch to the required direction of rotation.

• Stop Stop the pump by turning the Forward/Off/Reverse switch to its central Off position.

Note: When the pump is running clockwise in manual operation and is switched to standby, it will come to a dead stop.

When running counter clockwise it will freewheel to a stop. Any application requiring braking should have the pump set

up for clockwise running.

3

Page 4

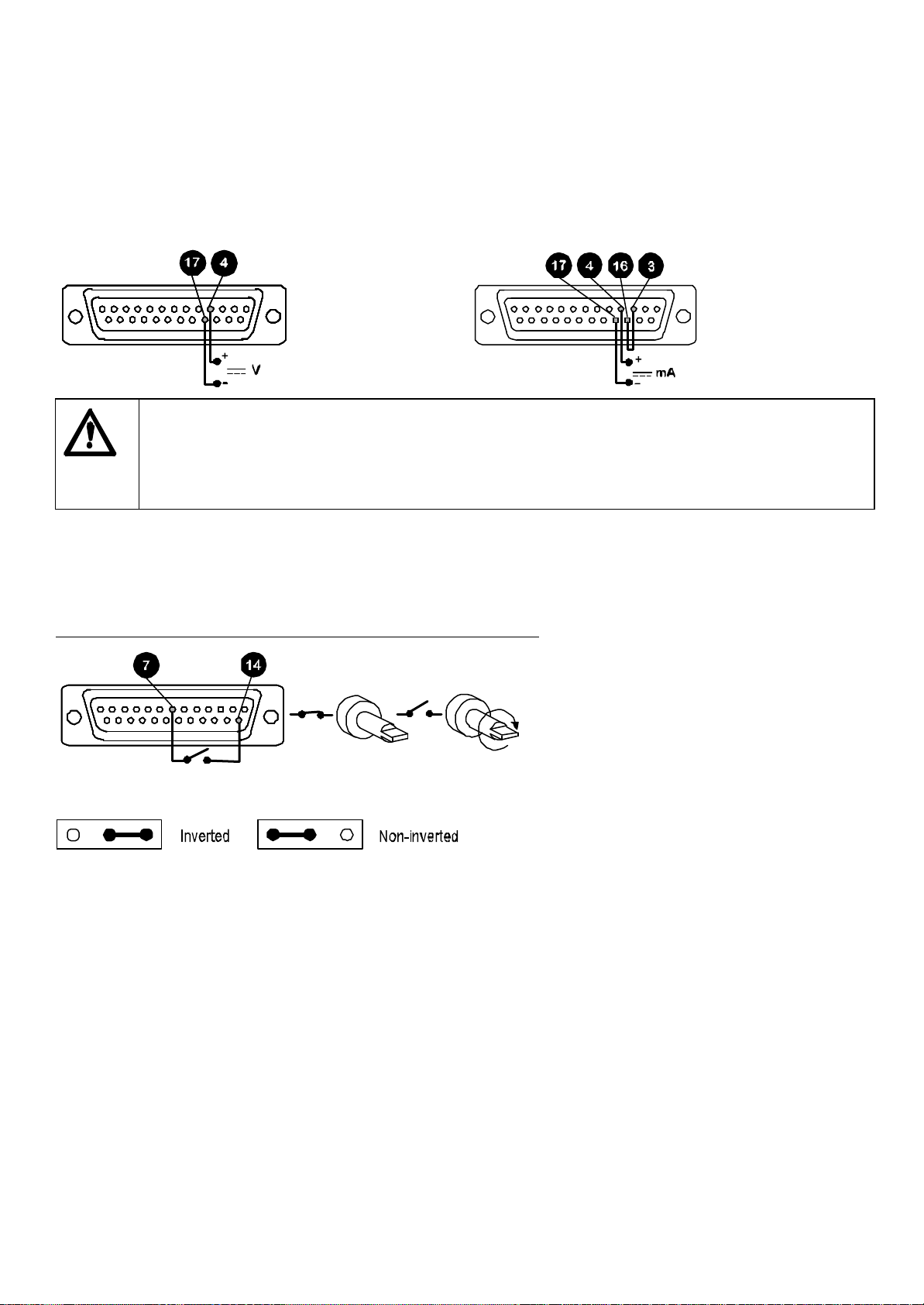

313U automatic operation

For the pump to be controlled by a process signal, the auto volts/manual/auto current (V M I) slider switch on the rear

panel should be set to either auto volts or auto current depending upon the type of control signal to be used. Ensure that

the mains switch on the rear panel is off. The process signal must be connected to the 25-way Dee plug provided, which

must be inserted in the rear panel 25-way Dee connector. The pump is controllable by an analogue process signal of up

to 0 to 10V or 4 to 20mA. The pump will provide an increasing flow rate for rising control signal (non-inverted response ).

Voltage signal

Input impedance 220 kohms. Maximum

voltage signal 10V

Current signal

Input impedance 250 ohms

Never apply mains voltage across any pins on the 25D socket. Up to 10V may be applied across pins

4 and 17, but no voltage should be applied across other pins. Permanent damage, not covered by

Remote control

Stop/Start

Connect remote switch between pins 7 and 14 of the 25 pin socket. Close contact to stop the pump, open to run. With

no connection, the pump will default to running. A remote stop/start signal will control the pump whilst running under

manual operation.

A TTL compatible logic input (Low 0V High 5V ) may be applied to pin 7.

To invert the response to the signal input move the remote stop signal inverter link (see 313 "U" upgrade card, item 4,

LK2) to the inverted pin positions on the signal inverter link block.

warranty may result in both instances. Do not use the mains power switch to control the pump for a

high repetition of stop/starts. The auto-control facility should be used.

When setting the drive control mode with the V M I switch ensure that power to the drive is switched

off using the mains switch on the rear panel.

Note: When the pump is running in either direction and is stopped remotely, it will freewheel to a stop.

4

Page 5

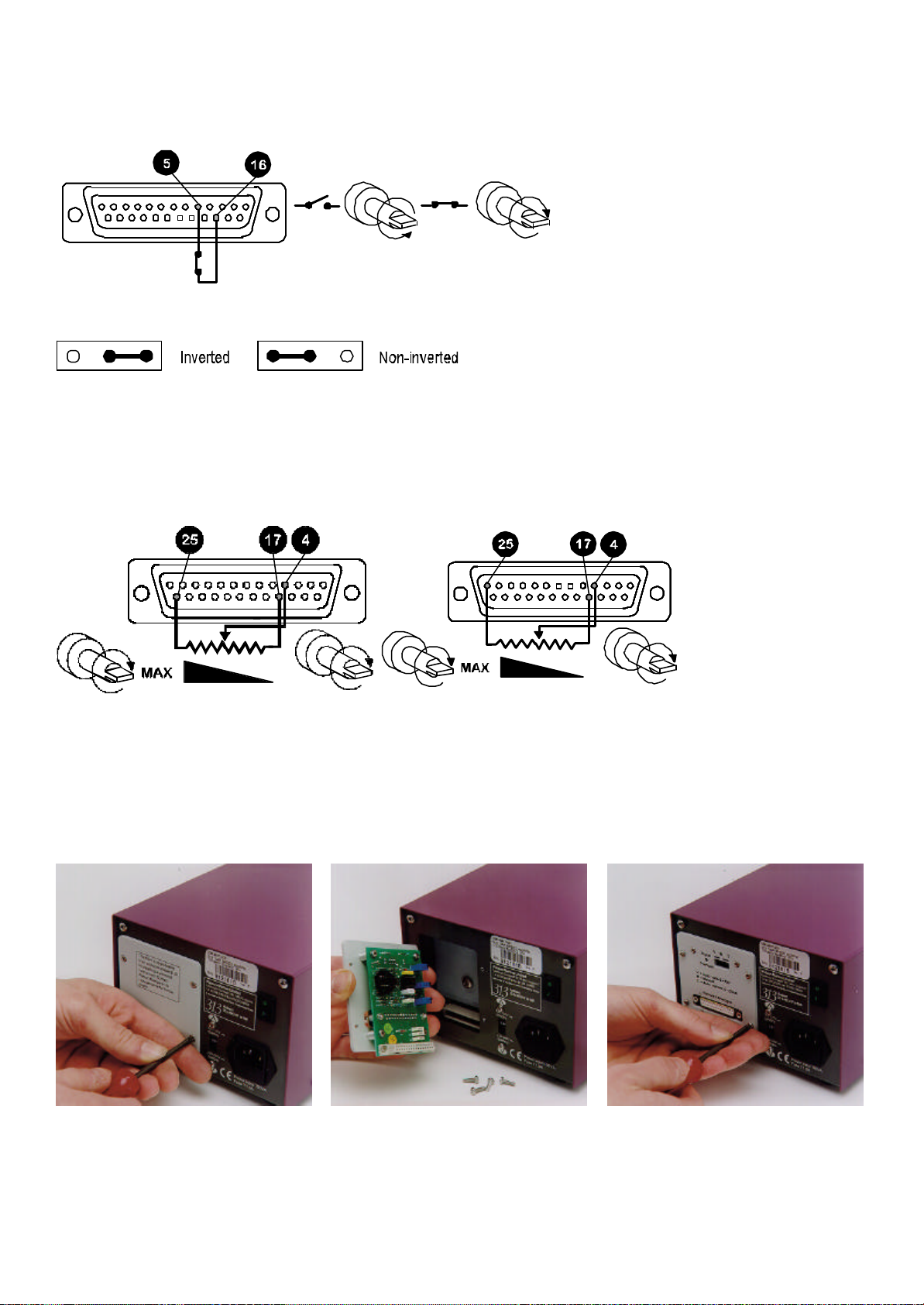

Direction

The remote direction facility operates with the front panel direction switch set in the anti-clockwise direction

only. Connect remote switch between pins 5 and 16. Open switch for anti-clockwise rotation, close for clockwise

rotation. With no connection, the pump will default to anti-clockwise

To invert the response to the signal input move the remote direction signal inverter link LK1 (see 313 "U" upgrade card,

item 6, LK1) to the inverted pin positions on the signal inverter link block.

Note: When the front panel switch is set to CCW rotation, the drive rotates according to the remote switch direction set

by LK1. When the front panel switch is set to CW rotation the remote switch is inhibited.

Speed

A remote potentiometer with a nominal value of between 1K and 2K with a minimum of 0.25W should be wired as shown.

When using a remote potentiometer, do not apply a voltage/current control input signal at the same time. Set the drive

control mode to auto volts (0-10V). Ensure that when changing the drive control mode, power to the drive is switched off

using the rear panel mains switch.

Note: As the remote potentiometer utilises the 0-10V range the speed response is only over 10/

ths

of the potentiometer's

12

electrical travel. The signal overload illuminates at this point and there is no further increase in speed.

313U upgrade card

To upgrade the manually controllable 313S/D into a remote or 0-10V/4-20mA analogue controllable 313U/D a 313U

upgrade card will be required (part number 039.3001.U00). To install the "U" card, undo the four M3 screws on the drive

rear panel "S" version cover plate and remove. Slot the 313U upgrade card into the rear panel recess, drop down to align

the DIN edge connectors and push into position. Replace the four M3 screws on the card to secure it firmly to the rear

panel.

5

Page 6

313U upgrade card spares

Item Part number Description

1 SD 0087 Signal overload LED indicator

2 DE 1645S Cover plate

3 US 0072 25-way Dee connector socket

4 US 0047 Remote stop signal inverter link

5 SW 0160 Auto voltage / manual / auto current switch 50V 2A

6 US 0047 Remote direction signal inverter link

7 PC 0147P Analogue PCB

8 SL 0091 DIN edge connector

6

Page 7

313T

The function of the 313T timer card is to convert 313S/D manually controlled drives into 313T/D drives allowing simple

dosing operations to be performed.

The single/continuous/ repeat slider switch allows the user to select between single shot dosing, continuous manual

pumping, or repeat dosing operations.

This publication should be used in conjunction with the manual provided with the pump.

Installation

Dosing

For the pump to be controlled as a simple dosing pump, the Single/Continuous/Repeat slider switch should be set to

Single or Repeat. When set on continuous, the timing functions are over-ruled and the pump operates as a manual

control variable speed unit, (front panel control).

The pump has a braking feature in the counter clockwise direction when viewed from the front of the pump, but not in the

clockwise direction. The dosing operation will therefore be more accurate when run counter clockwise.

The dosing times are set by means of two manually adjusted potentiometers on the "T" card. The right hand knob

adjusts the run time from zero to 10 seconds and the left hand one adjusts the off time from zero to 10 seconds.

Single dose set-up

• Set the slider switch to Single.

• Set the "on time" (dosing) knob on the rear of the pump as required and set pump speed to provide the required dose.

• Ensure the pump is set to run in the counter clockwise direction.

• The pump can be operated either from the Start button on the rear of the pump, or by closing a contact briefly across

pins 8 and 9 on the 25 pin socket.

Repeat dose set-up

• Set the slider switch to Repeat.

• Set the "on time" (dosing) knob and the "off time" knob on the rear of the pump as required and set pump speed to

provide the required dose.

• Ensure the pump is set to run in the counter clockwise direction.

• The pump can be operated either from the Start button on the rear of the pump, or by closing a contact briefly across

pins 8 and 9 on the 25 pin socket.

To stop the dosing operation either:

• Turn the CW/Standby/CCW to standby

• Pressthe Start button for longer than the off time,

• Close the contacts on pins 8 and 9 for longer than the off time.

For monitoring purposes, there is an unbuffered strobe output on pin 10 where 0V is stop and +5V is run in the timing

modes. For use with external instrumentation it must be buffered.

7

Page 8

313T major components

1 PCB cover

2 "Off time" knob

3 Pushbutton switch

4 Slider switch

5 "On time" knob

6 25 Din socket

Care and maintenance

The only scheduled maintenance of the 313F, 313S and 313U is to inspect the motor brushes and to replace them before

their length is less than 6mm 1/4". The life of the brushes will depend on the duty of the pump, which is expected to be

at least 7,500 hours at maximum speed. When the pump needs cleaning, remove the pumphead and use a mild solution

of detergent in water. Do not use strong solvents.

If the gearbox is dismantled, it should be filled with a good quality grease such as Castrol MS3.

Specification

313F/D nominal rotor speeds 5/50rpm, 200/400rpm

313U/D, 313S/D maximum rotor speeds 50rpm and 400rpm

Operating voltages and frequencies 110-240V 50/60Hz

313 S/D, 313U/D speed control ratio 20:1

Power rating 100VA

Operating temperature 5C to 40C

Storage temperature range -40C to 70C

Weight 5.35kg, 12Ib

Noise <70dBA at 1m

Standards IEC 335-1, EN60529 (IP31)

Machinery Directive:98/37/EC EN60204-1

Low Voltage Directive:73/23/EEC EN61010-1

EMC Directive:89/336/EEC EN50081-1/ EN50082-1

8

Page 9

313 and 314 pumpheads

The 313F/D, 313S/D and 313U/D can only be fitted with 313 three roller or 314 four roller pumpheads.

The 313 pumphead has three rollers and is designed to provide high flow rates, whilst with four rollers, the 314 pumphead

provides the option of less pulsation and greater pumping precision.

Both pumpheads employ a "clamp and stretch" tube clamping motion which ensures that the tube is held correctly in

position with no unwanted tube slackness.

The flip top track provides easy front end tube loading with no removal of components.

The simple bayonet mounting action for standard and extension pumphead fitting allows easy fast set up of ganged

installations.

Installation

All 313 drives are provided with bayonet plate fittings attached. To fit a 313 or 314 pumphead, align the slot in the

pumphead to the drive tang and using the bayonet fittings, turn the pumphead clockwise and snap into position.

To remove the pumphead push the bayonet plate locking lever back towards the rear of the drive and turn the pumphead

anti-clockwise until it is freed from the bayonet plate fittings.

Flow rates

Flow rates for the 313F, 313S and 313U were obtained using silicone tubing, with the pumphead rotating clockwise at

100rpm, pumping water at 20C with zero suction and delivery pressures (unless otherwise stated). For critical

applications determine flow rates under operating conditions.

9

Page 10

Tube loading

• Switch off the pump before tube loading.

• Lift the "flip top" track until fully open.

• Set the pumphead tube clamps, with the track open to the required tube size, using the calibrations on each side of

the pumphead.

• In some applications (where the outside of the tube is dirty or there is a high suction lift), the tube clamps may need

to be adjusted to a smaller setting to give effective tube clamping

• Select the length and bore size of tube required, ensuring the tube is long enough to cover the source to delivery

distance and the curvature of the track.

• Fit the tubing across the pumphead rotor and lower the track. Ensure the tubing is fitted correctly between the rollers

and track, and that there is no pinching of the tubing by the tube clamps. The tubing must lie naturally against the

track and must not be twisted or over stretched.

10

Page 11

Fitting an extension pumphead

• Remove the first 313 or 314 pumphead by pushing the bayonet plate locking lever back towards the rear of the drive

and turn the pumphead anti-clockwise until it is freed from the bayonet plate fittings. The extension pumphead can

now be fitted.

• Align the slot in the extension pumphead to the drive tang and using the bayonet fittings turn the pumphead clockwise

and snap into position.

• Align the drive slot of the next pumphead to the drive tang of the extension pumphead, turn the next pumphead

clockwise and snap into position.

If aggressive liquids are spilled onto the pumphead, it should be removed and cleaned using a mild solution of detergent

and water. Remove any tubing from the pumphead, and wash thoroughly.

Check moving parts of the rotor from time to time for freedom of movement. Lubricate pivot points and rollers occasionally

with Teflon lubricating oil.

11

Page 12

Drive spares

Item Part number Description

1 DE 1654B Rotary switch

2 DE 1663B Potentiometer

3 DE 1647M Soft touch knob

4 DEA1609A Bayonet plate

5 FB 0009 Foot

6 DEA1616A Motor gearbox 50rpm

DEA1611A Motor gearbox 400rpm

7 DEA1636A 313S Control PCB: calibrated at 400 rpm

DEA1635A 313S Control PCB: calibrated at 50 rpm

DEA1638A 313F Control PCB: calibrated at 400 rpm

DEA1637A 313F Control PCB: calibrated at 50 rpm

8 DE 1666M 313S PCB cover

9 SW 0123 Speed selector switch (slider) 313F

10 SW 0167 Switch (slider) 250VAC

11 FS 0003 Fuse 1.0 amp T type

12 SW 0147 Switch (rocker) 250VAC

13 DE 1661H Earth lead

14 DE 1649H LT/AC harness

15 TF 0047 Transformer

16 DE 1650H/ DE 1632H Control harness 313S/D, 313U/D/ 313F/D

BM 0019 Motor brush

12

Page 13

313 (ml/min) flow rates

Tube number

Tube bore

Tube bore

Rpm

Rpm

Rpm

Rpm

Rpm

Rpm

314 (ml/min) flow rates

Number

Bore

Bore

Rpm

Rpm

Rpm

Rpm

Rpm

Rpm

313 and 314 maximum number of pumpheads

313 and 314 Peroxide/ Platinum Silicone

Number

Bore

Bore

Rpm

Rpm

Rpm

Rpm

313 and 314 Marprene, Tygon, Neoprene, Viton.

Number

Bore

Bore

Rpm

Rpm

Rpm

Rpm

# 112 13 14 16 25 17 18 112 13 14 16 25 17 18

mm 0.5 0.8 1.6 3.2 4.8 6.4 8.0 0.5 0.8 1.6 3.2 4.8 6.4 8.0

" 1/50 1/32 1/16 1/8 3/16 1/4 5/16 1/50 1/32 1/16 1/8 3/16 1/4 5/16

5

50

200

400

# 112 13 14 16 25 17 18 112 13 14 16 25 17 18

mm 0.5 0.8 1.6 3.2 4.8 6.4 8.0 0.5 0.8 1.6 3.2 4.8 6.4 8.0

" 1/50 1/32 1/16 1/8 3/16 1/4 5/16 1/50 1/32 1/16 1/8 3/16 1/4 5/16

5

50

200

400

# 112 13 14 16 25 17 18

mm 0.5 0.8 1.6 3.2 4.8 6.4 8.0

" 1/50 1/32 1/16 1/8 3/16 1/4 5/16

5 0.15 0.33 1.3 5 11 18 25

50 1.5 3 13 50 110 180 250

200 6 14 54 200 440 720 1000

400 12 28 108 400 880 1440 2000

2.5 - 50 0.07-1.5 0.15-3 0.65-13 2.5-50 5.5-110 9-180 12.5-250

20 - 400 0.6-12 1.4-28 5.4-108 20-400 44-880 72-1440 100-2000

# 112 13 14 16 25 17 18

mm 0.5 0.8 1.6 3.2 4.8 6.4 8.0

" 1/50 1/32 1/16 1/8 3/16 1/4 5/16

5 0.15 0.3 1.2 4.2 9.5 15 20

50 1.5 3.0 12 42 95 150 200

200 6 12 50 170 330 600 800

400 12 24 100 340 760 1200 1600

2.5-50 0.07-1.5 0.15-3.0 0.6-12 2.1-42 4.8-95 7.5-150 10-200

20-400 0.6-12 1.2-24 5-100 17-340 38-760 60-1200 80-1600

(0 = bar = 2) (0.5 = bar = 2.0)

6 6 6 6 6 4 3 6 6 6 6 5 3 3

6 6 6 6 6 4 3 6 6 6 6 5 3 3

6 6 5 3 2 2 1 6 6 5 3 2 1 1

6 6 5 3 2 2 1 6 6 5 3 2 1 1

(0 = bar = 0.5) (0.5 = bar = 2.0)

6 6 6 6 5 3 3 6 6 6 6 4 3 3

6 6 6 6 5 3 3 6 6 6 6 4 3 3

6 6 4 2 2 1 1 6 6 4 2 2 1 1

6 6 4 2 2 1 1 6 6 4 2 2 1 1

13

Page 14

Tubing for 313D, 314D, 313X and 314X pumpheads

Product codes

Bore Bore

Mm " # Marprene Bioprene Peroxide Silicone Platinum Silicone

0.5 1/50 112 902.0005.016 903.0005.016 910.0005.016 913.0005.016

0.8 1/32 13 902.0008.016 903.0008.016 910.0008.016 913.0008.016

1.6 1/16 14 902.0016.016 903.0016.016 910.0016.016 913.0016.016

3.2 1/8 16 902.0032.016 903.0032.016 910.0032.016 913.0032.016

4.8 3/16 25 902.0048.016 903.0048.016 910.0048.016 913.0048.016

6.4 ¼ 17 902.0064.016 903.0064.016 910.0064.016 913.0064.016

8.0 5/16 18 902.0080.016 903.0080.016 910.0080.016 913.0080.016

Bore Bore

mm " # Tygon Fluorel Neoprene STA-PURE

0.8 1/32 13 920.0008.016

1.6 1/16 14 950.0016.016 970.0016.016 920.0016.016 960.0016.016

3.2 1/8 16 950.0032.016 970.0032.016 920.0032.016 960.0032.016

4.8 3/16 25 950.0048.016 970.0048.016 920.0048.016 960.0048.016

6.4 1/4 17 950.0064.016 970.0064.016 920.0064.016 960.0064.016

8.0 5/16 18 950.0080.016 970.0080.016 920.0080.016 960.0080.016

Tubing for 313D2, 314D2, 3132X and 3142X pumpheads

Product codes

Bore Bore

mm " # STA-PURE Marprene Peroxide Silicone Platinum Silicone

0.5 1/50 105 902.0005.024 910.0005.024 913.0005.024

0.8 1/32 108 902.0008.024 910.0008.024 913.0008.024

1.6 1/16 119 960.0016.024 902.0016.024 910.0016.024 913.0016.024

3.2 1/8 120 960.0032.024 902.0032.024 910.0032.024 913.0032.024

4.8 3/16 15 960.0048.024 902.0048.024 910.0048.024 913.0048.024

6.4 1/4 24 960.0064.024 902.0064.024 910.0064.024 913.0064.024

8.0 5/16 121 960.0080.024

Flow rates against suction and pressure

14

Page 15

313F outline dimensions

313S and 313U outline dimensions

Watson-Marlow, Bioprene and Marprene are trademarks of Watson-Marlow Limited.

Tygon is a trademark of the Norton Company.

Warning, These products are not designed for use in, and should not be used for patient connected

applications.

The information contained in this document is believed to be correct but Watson-Marlow Limited accepts no liability for

any errors it contains, and reserves the right to alter specifications without notice.

15

Page 16

Product use and decontamination declaration

In compliance with the UK Health & Safety at Work Act and the Control of Substances Hazardous to Health

Regulations you, the user are required to declare the substances which have been in contact with the product(s) you

are returning to Watson-Marlow or any of its subsidiaries or distributors. Failure to do so will cause delays in servicing

the product. Therefore, please complete this form to ensure that we have the information before receipt of the

product(s) being returned. A FURTHER COPY MUST BE ATTACHED TO THE OUTSIDE OF THE PACKAGING

CONTAINING THE PRODUCT(S). You, the user, are responsible for cleaning and decontaminating the product(s)

before returning them.

Please complete a separate Decontamination Certificate for each pump returned. RGA No: …………………...

1 Company

Address ………...................................................................Postcode ………………………………………

Telephone ……………………………………………. .................Fax Number …………………………………..

2.1 Serial Number … … … … … … … … … … … … … ........... (a)………………………………………………….

2.2 Has the Product been used? (b)…………………………………………………

YES NO (c)…………………………………………………

(d)…………………………………………………

If yes, please complete all the following Sections. If no, please complete Section 5 only

3 Details of substances pumped

3.1 Chemical names:

(a)………………..........................

(b)…………….............................

(c)………………..........................

(d)…………….............................

3.2 Precautions to be taken in handling these substances: To assist servicing, please describe any fault

(a)………… .................................................... condition(s) you have witnessed

(b)………… ................................................... …………………………………………………

(c) ………………............................................... ……………………………………………………………

(d)………………................................................ ……………………………………………………………

3.3 Action to be taken in the event of human contact: ……………………………………………………………………………………………………

(a)…………………………………………………………………. ……………………………………………………………

(b)…………………………………………………………………. ……………………………………………………………

(c)………….……………………………………………………… ……………………………………………………………

(d)………….……………………………………………………… ……………………………………………………………

3.4 Cleaning fluid to be used if residue of chemical is found: ……………………………………………………………

(a)…………………………………………………………………. ……………………………………………………………

(b)…………………………………………………………………. ……………………………………………………………

(c)………….……………………………………………………… ……………………………………………………………

(d)………….……………………………………………………… ……………………………………………………………

4 I hereby confirm that the only substances(s) that the equipment specified has

pumped or come into contact with are those named, that the information given is

correct, and the carrier has been informed if the consignment is of a hazardous

nature.

5 Signed …………………………………………………………………………………

Name …………………………………………………………………………………

Position ……………………………………………………………………………….

Date …………………………………………………………………………………..

Watson-Marlow Bredel Pumps . Falmouth . Cornwall TR11 4RU . England . Tel: 01326 370370 . Fax: 01326 376009

16

Loading...

Loading...