Page 1

205S, 205U

205suca-gb-02.pdf

Page 2

Declarations

Declaration of

conformity

When this pump unit is used as a stand alone pump it complies with: Machinery Directive

2006/42/EC, EMC Directive 2004/108/EC.

Responsible person: Christopher Gadsden, Managing Director, Watson-Marlow Limited, Falmouth, Cornwall TR11

4RU, England. Telephone 01326 370370 Fax 01326 376009.

Two year wa rranty

Watson-Marlow Limited warrants, subject to the conditions below, through either Watson-Marlow Limited, its

subsidiaries, or its authorised distribu tors, to re pair or r eplace free of cha rge, inc luding labou r, any part of this prod uct

which fails within two years of delivery of the product to the end user. Such failure must have occurred because of

defect in material or workmanship and not as a result of operation of the product other than in accordance with the

instructions given in this manual.

Conditions of and specific exceptio ns to the above warranty are:

Warranties purporting to be on behalf of Watson-Marlow Limited made by any person, including representatives of

Watson-Marlow Limited, its subsidiaries, or its distributors, which do not acco rd with the terms of this warranty shall

not be binding upon Watson-Marlow Limi te d unless expressly approved in writing by a Direct or or Ma na ge r of

Watson-Marlow Limited.

Information for returning pumps

Equipment which has been contaminated with, or exposed to, body fluids, toxic chemicals or any other substance

hazardous to health must be decontaminated before it is returned to Watson-Marlow or its distributor.

A certificate included at the rear of these operating instructions, or signed statement, must be attached to the outside

of the shipping carton.

This certificate is required eve n if the p ump is un us ed. If th e pump h as b ee n us ed , the fluid s that have be en in contact

with the pump and the cleaning procedure must be specified along with a statement that the equipment has been

decontaminated.

Safety

In the interests of safety, this pump and the tubing selected should only be used by competent, suitably trained

personnel after they have read a nd under stood this manual, and considered any hazard inv o lved.

Any person who is involved in the installation or maintenance of this equipment should be fully competent to carry out

the work. In the UK this person should also be familiar with the Health and Safety at Work Act 1974.

Declaration of

Incorporation

Consumable items such as tubing and rollers are excluded.

Products must be returned by pre-arrangement carriage paid to Watson-Marlow Limited, its subsidiaries, or its

authorised distributor.

All repairs or modifications must have been made by Watson-Marlow Limited, its subsidiaries, or its authorised

distributors or with the express permission of Watson-Marlow Limited, its subsidiari es, or its authorised distributors.

Products which have been abused, mis used, or subjected to malicious or accidental damage or electrical surge

are excluded.

When this pump unit is to be installed into a machine or is to be assembled with other

machines for installations, it must not be put into service until the relevant machinery has

been declared in conformity with the Machinery Directive 2006/42/EC.

There are dangerous voltages (at mains potential) inside the pump. If access is required,

isolate the pump from the mains before removing the cover.

2

Page 3

Recommended operating procedures

keep delivery and suction lines as short as possi ble usin g a minimum number of swept bends.

DO

use suction and delivery pipelines wi th a bore equal to or lar ger than the bor e of the tube fitted in the pumphead.

DO

When pumping

cross sectional area several times greater than the pu mping element.

fit an extra length of pump tube in the system to enable tube transfer. This will extend tube life and minimise the

DO

downtime of the pumping circuit.

keep the track and rollers clean.

DO

The self-priming nature of pe ristaltic pumps means valves are not r equired. Any valves fitted must cause no restriction

to flow in the pumping circuit.

When using Marprene tubing

the tube clamp on the delivery side a little and pulling the tube tight. This is to counteract the normal stretching that

occurs with Marprene which can go unnoticed and result in poor tube life.

Tube selection

about the compatibility of a tube material and the duty fluid, request a tube sample card for immersion trials.

Installation

The 205S and 205U are suitable for single phase mains electricity supplies only.

To ensure correct lubrication of the gearbox the pump should be run only while its feet are standing on a horizontal

surface. The pump should be positioned to allow a free flow of air around it.

Set the voltage selector to ei ther 120V for 100-120V 50/60Hz supplies or 240V for 220-240V 50/60Hz supplies.

A mains cable fitted with a moul ded plug is supplied with the pu mp. The wires are colour coded in ac cordance with

the following code:

220-240V: Live - Brown; Neutral - Blue; Earth - Green/Yellow.

100-120V: Live - Black; Neutral - White; Earth - Green.

Troubleshooting

Should the pump fail to operate, make the fo llo wing che cks to d et ermin e wh ether or not servicing is required.

Check that the power switch is on.

Check the mains supply is available at the pump.

Check the voltage selector switch is in the correct position.

Check the fuse in the mains socket.

Check that the pump is not stalled by incorrect fitting of tubing.

205S / 205U Manual operation

Press the

Change the set speed by pressing the or key. The 205S & 205U speed control ratio is 180:1.This will give a

minimum gearbox speed of 0.5rpm and a maximum of 90rpm.

Change direction by pressing the

(CW: clockwise

Select the maximum speed: press the key and the

Select the minimum speed: press the key and the

Select the low pulse speed (approx 0.01rpm) in dicated by "Lo" on the display by pressing the key again. One

more press of the key and the pump will stop and displ ay 0.0rpm.

The keypad has a locking facility to avoid resetting or tampering. If the pump is stopped, press

padlock symbol illuminates. If the pump is running, press

disabled except for

The pump can be set to automatically restart in its operating state set prior to interruption, or set so that after

power is reconnected the pump will remain stopped. To invoke the Auto-restart facility switch off power to the

pump at the mains supply. Press the

illuminates. Now press

then pressing the

Press

viscous

The chemical compatibility list published in the Watson- Marlow catalogue is only a guide. If in doubt

Man/Auto

to start the pump. Press

Start

fluids, the losses cau sed by increased friction can be overc ome by using pipe runs with a

, after the first 30 minutes of running, re-ten sion th e tube in the pumphe ad by releas ing

key (205U). When the AUT symbol is not flashing the pump is in manual mode.

CW/CCW

: counter clockwise).

CCW

and

Start

Start

key whilst turning the mains supply back on. The ! symbol will not be illuminated.

Stop

. Press these keys until the padlock symbol extinguishes to unlock the keypad.

Stop

to start the pump. This facility can be cancelled by turning the mains supply off and

Stop

key. Check the flashing

key together.

Max

key together.

Max

until the padlock symbol illuminates. All keys will be

Start

key down when the mains supply is switched back on until the ! symbol

Start

to stop the pump.

CW/CCW

symbol for actual direction setting

Stop

until the

3

Page 4

205U Automatic operation

Press the

The pump is controllable by an a nalogue process sign al of up to 30V or 32mA. The pu mp will provide an increas ing

flow rate for rising control signal (non-inverted response ) or an increasing flow rate for falling control signal (inverted

response ).

Man/Auto

Signal offset

Signal range

For example, when using a 4mA to 20mA process signal:

Pump response

Non-Inverted 4mA 16mA

Inverted 20mA 16mA

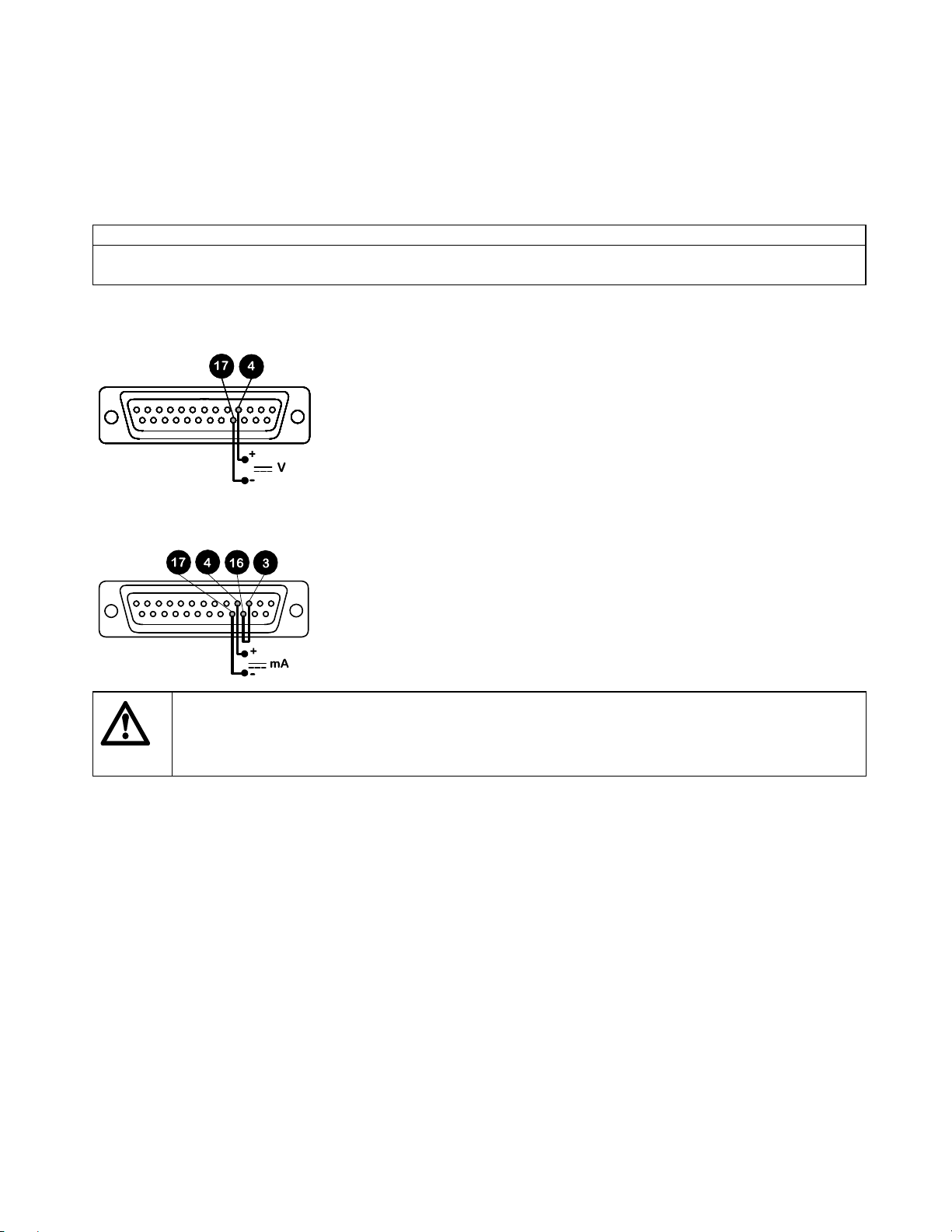

For voltage modes a stable variable DC voltage source can be used in conjunction with a DC voltmeter, (maximum

30V DC). (Refer to 25D pin connector wiring detail as an example of control circuitry) Circuit impedance 100 kohms.

Polarity set for non-inverted response. Reverse polarity for inverted response.

For current modes the same DC source can be used in conjunction with a DC milliampere meter, (maximum 32mA).

(See 25 pin Dee connector detail). Circuit impedance 250 ohms. Polarity set for non-inverted response. Reverse

polarity for inverted response.

key. When the

is the process signal level which has to be reached in order for the pump rotor to start rot ating.

is the change in process signal level necessary to produce the required change in pump rotor speed.

symbol flashes the pump is in manual mode.

AUT

Signal offset Signal range

Never apply mains voltage across any pins on the 25D socket. Up to 30V may be applied across

pins 4 and 17, and 5V TTL on pins 7 and 5, but no voltage should be applied across other pins.

Permanent damage, not covered by warranty may result in both instances. Do not use the mains

power switch to control the pump for a high repetition of stop/starts. The auto-control facility

Calibration procedure

Turn the signal offset potentiometer (marked "Offset" on back panel) clockwise until the slider traverse limit is

reached and is signified by a clicking noise. Now turn the potentiometer te n turns anticlockwise. Repeat for the

signal range potentiometer. This en sures correct potentiomete r set up for calibration.

Set the process signal offset.

Turn the signal offset potentiometer clockwise to set the drive shaft speed to t he desir ed minimum.

Set the process signal at its upper rang e limit (not exceeding 30V or 32mA).

Turn the signal range potentiomete r (marked "Ra nge" on back pa nel) clock wise to set the d rive shaft sp eed to the

desired maximum.

If the process signal or dr ive speed are set above their d esignated maximums the drive will be overloaded wh ich is

signified by the flashing of

operate within these levels.

Repeat the procedure until pump response coincides exactly with the process signal.

should be used.

. This is an indication of the limiting control and speed levels of the drive. Reset to

AUT

4

Page 5

Remote control

Stop/Start

Connect remote switch between pins 7 and 15 of the 25 D connec tor. A TTL compatib le logic input (L ow 0V, High 5V)

may be applied to pin 7. Low input stops th e pump, high input runs the pump. With no connection, the pump will

default to running.

Direction

Connect remote switch between pins 5 and 16 and disable the front panel reversing control by linking pins 6 and 18 of

the 25D connector. Open switch for clockwise rotation, close for counter-clockwise. Alternatively a TTL compatible

logic input (Low 0, High 5V) may be applied to pin 5. Low input will run the pump in a counter-clockwise direction,

High input in a clockwise rotation. No connection; the pump will default to clockwise rotation.

Speed

A remote potentiometer with a nominal value of between 1k and 2k with a minimum of 0.25W should be wired as

shown. When using a remote potentiomete r, do not apply a voltage/cu rrent contro l input signal at th e same time. The

speed control signal will require calibration relative to the minimum and maximum settings of the poten tiometer. Use

the offset and range potentiometers as described under calibration.

Strobe

The state of the pump may be monitored by utilising a 5V Hi Lo signal available at the 25D remote socket on the

pump rear panel. The strobe line will change sta te as soon as the motor starts or stops.

Tachometer output

This facility can be used to indicate motor speed or total the number of motor revolutions.

90rpm 4.8 kHz

5

Page 6

Error messages

If a fault condition is detected in the drive unit it will stop, all keys will be disabled, and the display will flash:

Er1

Er2

Er3

Er4

Er5

Er6

Er9

Care and maintenance

The only scheduled maintenance of the 205S or 205U is to inspect the motor brushes and to replace them b efore

their length is less than 6mm 1/4". The life of the brushes will depend on the duty of the pump, which is expected to be

at least 3,000 hours at maximum speed. When the pump needs cleaning, remove the pumphead and use a mild

solution of detergent in water. Do not use strong solvents.

If the gearbox is rebuilt you should use 15 ml of the recommended lubricant, which is RD-105, this is a SAE 30

mineral oil loaded with molybdenum disulphide to form a soft fluid grease.

205S / 205U Specification

Maximum rotor speed 90rpm

Minimum rotor speed 0.5rpm

Voltage/frequency 100-120/220-240V 50/60Hz

Power consumption 100VA

Shaft Torque 2.2Nm

Operating temperature range 5 to 40C

Storage temperature range -40C to 70C

Weight 3.8kg (8.4Ib)

Noise <70dBA at 1m

Standards IEC 335-1, EN60529 (IP31)

Machinery Directive 2006/42/EC

EMC Directive 2004/108/EC

Pumphead installation

If the pumphead is fitted ignore this section (applicable for all cassette pumpheads).

Remove the planetary gear system cover by pulling gently towards the front of the pumphead.

Apply grease to the drive tongue, align to pumphead centre shaft and locate together.

Tighten the socket head retaining screws at each side of the pumphead with a 5mm A/F ball ended Allen key.

Replace the cover.

EEPROM exhausted error. There is a max i mu m nu mber of times the EEPROM can be written to.

If Er6 is displayed, the EEPRO M must be replaced.

Tachometer fault

Over temperature error

EEPROM error

EEPROM read error

EEPROM write error

RAM corruption error

6

Page 7

Fitting an extension pumphead

Remove the front cover plate.

Remove the end plate using a N o.2 Pozi screwdriver on the first pumphead to expose the two lo cating pins and

drive shaft slot.

Remove the planetary gear system cover from the extension pumph ead.

Fit the extension pumphead onto the two locating pins, ensuring the tongue of its drive shaft aligns with the

pumphead centre shaft.

Tighten the socket head retainin g screws on th e right and left of the extension pu mphead. Fit the end plate to th e

last pumphead and replace the cov e rs.

CA cassette loading

Only use cassettes with manifold tubing.

Place the tube into the tube retaining slots without twisting or stretching it, 1.

Lift the cassette release lever 2.

Load the cassettes into the pumphead, ensuring that they ar e engaged on to the cassette guides at each end, 3.

Ensure that both r etaining lips are engage d and then squeeze the cassette release lever a nd the tube retaining

lug together, until you hear a click, 4.

7

Page 8

CA cassette removal

Lift the cassette release lever and pull out the cassette.

With care, a single cassette can be removed for tube changing without stopping the drive and disturbing the

pumping action of other cassettes.

All cassettes should be in position in the pumphead during normal running, even if some

do not contain tubing. Do not place fingers inside the pumphead.

CA Cassette adjustment and flow rates

Flow rates for pumping water at 20C with zero suction and delivery pressure in PVC tubing, with clockwise

rotation of the pumphead are pu blished at the back of this manual.

Dedicated occlusion adjustment with a vernier indicator has been incorporated into the cassette. This is to enable

repeatable accurate flow rates despite var iations tha t may be caus ed by th e system or w hen pu mping fluids othe r

than water.

The track geometry has been designed so that when the indicator is at the centre position it is indicating the

normal set-up.

To adjust, pull out the adjusting knob and turn. To lock, push back.

Moving the indicator towards the '+' will increase the track occlusion (reduced roller/track gap) enabling higher

pressures to be obtained without a fall off in flow rate.

Moving the indicator towards the '-' wi ll reduc e th e occ lusio n. Remembe r th at high er the o cc lusion, the sho rter th e

tube life.

The mechanism also enables small adjustments in th e flow rate. This is particularly useful when usin g a number

of channels where the inter channel flow rate is critical. As a guide only, one graduation move will vary the flow by

approximately 1%

Care and maintenance

When the pumphead needs c leaning, switch the drive off and isolate it from the mains. Remove the cass ettes from

the pumphead and remove the tubing. Wash the cassettes in water and mild detergent.

If fluid has been spilled into the pumphead, removal of the pumphead from the drive will make cleaning easier.

Periodically, inspect all moving parts for wear and ensure all bearings and rollers are free to rotate.

8

Page 9

Pumphead spares

Number Spare Description

1 DE 0410M End plate

2 DE 0412M Front cover plate

3 DE 0416T Roller 4 way

DE 0417T Roller 8 way

DE 0418T Roller 12 way

DE 0419T Roller 16 way

4a BB 0038 (2 off) Center shaft bearing

4b BB 0014 (2 off) Center spacer bearing

5 DE 0429T Center gear

6 MN 0983M Roller gear

7 OS 0047 Friction O ring

8 DE 0411M Planetary system gear cover

9 BB 0034 (2 per roller) Roller bearing

10 DE 0407M Cassette guide

11 DEA0080A Cassette PVDF (option)

DEA0081A Cassette Acetal (standard)

12 N/A Cassette release lever

9

Page 10

Drive spares

Number Spare Description

1 DEA0065A 205S Control PCB

1 DEA0066A 205U Control PCB

2 DEA0068A Transformer

3 SW 0147 On/Off switch

4 SW 0086 Voltage selector swicth

5 DEA 0062A Motor/gearbox

6 DEA0063A 205S Tacho PCB assembly

6 DEA0064A 205U Tacho PCB ass embly

7 MN 0787A Tacho disc

8 BM0014 Motor brush

9 DEA0067A 205S CPU/Display PCB

9 MNA0431A 205U CPU/Display PCB

DE 0306B/ DE 0307B 205S/ 205U Membrane keypad

FS 0003 Mains fuse 1A T type

Specific drive performance details such as loaded drive speed variation against mains supply voltage fluctuation and

drive stability from a cold start to normal operating temperature are available on request. For further information please

contact Watson-Marlow Technical Support.

10

Page 11

205S/CA and 205U/CA flow rates (ml/min)

Bore mm Bore " 0.5-90rpm Bore mm Bore " 0.5-90rpm

0.13 0.005 0.0006-0.10

0.19 0.007 0.0009-0.16

0.25 0.010 0.0013-0.23

0.38 0.015 0.0036-0.65

0.50 0.020 0.0056-1.01

0.63 0.025 0.0083-1.49

0.76 0.030 0.011-2.02

0.88 0.035 0.016-2.92

1.02 0.040 0.021-3.76

1.14 0.045 0.026-4.68

205 manifold tubing product codes

Bore

mm Bore "

0.13 0.005 984.0013.000

0.19 0.007 984.0019.000

0.25 0.010 978.0025.000 980.0025.000 984.0025.000

0.38 0.015 978.0038.000 980.0038.000 984.0038.000

0.50 0.020 978.0050.000 980.0050.000 984.0050.000 986.0050.000

0.63 0.025 978.0063.000 980.0063.000 982.0063.000 984.0063.000 986.0063.000

0.76 0.030 978.0076.000 980.0076.000 982.0076.000 984.0076.000 986.0076.000

0.88 0.035 978.0088.000 980.0088.000 982.0088.000 984.0088.000 986.0088.000

1.02 0.040 978.0102.000 980.0102.000 982.0102.000 984.0102.000 986.0102.000

1.14 0.045 978.0114.000 980.0114.000 982.0114.000 984.0114.000 986.0114.000

1.29 0.050 978.0129.000 980.0129.000 982.0129.000 984.0129.000 986.0129.000

1.42 0.055 978.0142.000 980.0142.000 982.0142.000 984.0142.000 986.0142.000

1.47 0.058 982.0147.000

1.52 0.060 978.0152.000 980.0152.000 982.0152.000 984.0152.000 986.0152.000

1.65 0.065 978.0165.000 980.0165.000 982.0165.000 984.0165.000 986.0165.000

1.85 0.070 978.0185.000 980.0185.000 982.0185.000 984.0185.000 986.0185.000

2.05 0.080 978.0205.000 980.0205.000 982.0205.000 984.0205.000 986.0205.000

2.38 0.095 978.0238.000 980.0238.000 982.0238.000 984.0238.000 986.0238.000

2.54 0.100 978.0254.000 980.0254.000 982.0254.000 984.0254.000 986.0254.000

2.79 0.110 978.0279.000 980.0279.000 982.0279.000 984.0279.000 986.0279.000

Marprene

PVC

1.29 0.050 0.033-5.95

1.42 0.055 0.040-7.20

1.47 0.058

1.52 0.060 0.043-7.69

1.65 0.065 0.051-9.12

1.85 0.070 0.063-11.3

2.05 0.080 0.076-13.8

2.38 0.095 0.092-16.5

2.54 0.100 0.11-19.3

2.79 0.110 0.12-22.0

Silicone

Solvent

resistant

resistant

Acid

11

Page 12

Outline dimensions

Watson-Marlow, Bioprene

Tygon

Warning, These products are not designed for use in, and should not be used for patient connected

applications.

The information contained in this docu me nt i s believed to be correct but Watson-Marlow Limi te d accepts no liability for

any errors it contains, and reserves the right to alter s pecifications without notice.

is a trademark of the

and

Marprene

Norton

are trademarks of

Company.

Watson-Marlow Limited.

12

Page 13

Product use and decontamination declaration

To comply with the UK Health & Safety at Work Act and the Control of Substances Hazardous to Health

Regulations you, the user, are required to declar e the substances w hich have been in contact w ith the product(s)

you are returning to Watson-Marlow or any of its subsidiaries or distributors. Failure to do so will cause delays in

servicing the produc t(s). Please complete this form to ens ure that we have the information before we rec eive the

product(s). A further copy must be attached to the outside of the packaging containing the product(s). The user is

responsible for cleaning and decontaminating the product(s) before ret urn.

Please complete a separate Decontaminat io n Declaration for each pump returned.

1 Company ………………………………………………………………………………………………………………………

Address …………………………………………………………………………………………………………………………

………………….........................................................................Postcode ………………………………………………

Telephone ……………………………………………. ................. Fax Number …………………………………..………

2.1 Serial Number ………………………………………………… (One product per declaration)

2.2 Has the Product been used? Yes No

If yes, please complete all the following Sections. If no, please complete Section 5 only

RGA No:

…………………...

3 Details of substances

pumped

3.1 Chemical names:

(a)……………… .........................

(b)…………….............................

(c)……………… .........................

3.2 Precautions to be taken in handling these substances: To assist servicing, please describe any fault

(a) ………………………………………………………………… condition(s) you have witnessed

(b) ………………………………………………………………… .........................................……………………………

(c) …………………………………………………………………

3.3 Action to be taken in the event of human contact:

(a)………………………………………………………………….

……………………………………………………………

(b)………………………………………………………………….

……………………………………………………………

4 I confirm that the only substances(s) t h at the equipment specified has pumped

or come into contact with are those named, that the information given is

correct, and the carrier has been informed if t he consig nment is of a hazardous

nature.

5 Signed ………………………………………………………………

Name ………………………………………………………………

Position ………………………………………………………………

Date …………………………………………………………………

(c)………….………………………………………………………

3.4 Cleaning fluid to be used if residue of chemical is found: ……………………………………………………………

(a)………………………………………………………………….

……………………………………………………………

(b)………………………………………………………………….

……………………………………………………………

(c)………….………………………………………………………

Watson-Marlow Bredel Pumps . Falmouth . Cornwall TR11 4RU . England . Tel: 01326 370370 . Fax : 01326 376009

13

Loading...

Loading...