Page 1

205BA pumphead

Introduction

Thank you for selecting the Watson-Marlow 205BA pumphead.

This pump head is very similar to the 202AA pu mph ead, but the 502BA has eight driven

rollers giving the benefit of d elivering low er pu lsatio n. It is easy-loadin g, uses the same

range of manifold tubing as the 202AA and is available in 4, 8 and 12 channel versions.

These supplementary instructions should be read in conjunction with either the

202U/AA or 202S/AA operating instruction manual.

Tube range

The tubing used in the 205BA is th e same sizes and five materials of manifold tubing

manufactured for the 202AA - please see the relevant page in your manual.

Flow rates

These flow rates w ere obtained pumping water at 20C with zero su ction and delivery

pressures. If flow rate is critical, it should be measured under operating conditions

where the important factors are suction and delivery, temperature and viscosity.

Installation and

operating

nstructions i

205BA flow rates at the maximum speed setting (50rpm)

Tubing internal diameter

0.13mm 0.19mm 0.25mm 0.38mm 0.50mm 0.63mm 0.76mm

0.005" 0.007" 0.01" 0.015" 0.02" 0.025" 0.03"

ml/min 0.025

Tubing internal diameter

0.88mm 1.02mm 1.14mm 1.29mm 1.42mm 1.47mm 1.52mm

0.035" 0.04" 0.045" 0.05" 0.055" 0.058" 0.06"

ml/min

Tubing internal diameter

1.65mm 1.85mm 2.05mm 2.38mm 2.54mm 2.79mm

0.065" 0.07" 0.08" 0.09" 0.1" 0.11"

ml/min

1.40 1.85 2.28 2.93 3.48 3.75 3.98

4.60 5.75 6.90 8.95 10.0 11.7

0.060 0.130 0.240 0.40 0.75 1.05

Cassette loading

For safety reasons, all cassettes should be in position in the pumphead during

normal running, even if some do not contain tubing.

Do not place fingers in the p umphead

Pumphead care and maintenance

When the pumph ead needs cleaning, sw itch the drive o ff and isolate it from the mains.

Withdraw the cassettes from th e pu mp head and remo ve th e tubin g. Wash the cassettes

in water and mild detergent. If fluid has been spilled into the pumphead, removal of the

pumphead from the drive will make cleaning easier. Periodically, inspect all moving

parts for wear and ensure all bearings and rollers are free to rotate.

Page 2

Remove the pumphead from the drive to lubricate the drive dog every 6 months if the

pump is being used for continuous duty. 12 months interval will be sufficient if it is

used intermittently

Pumphead spares

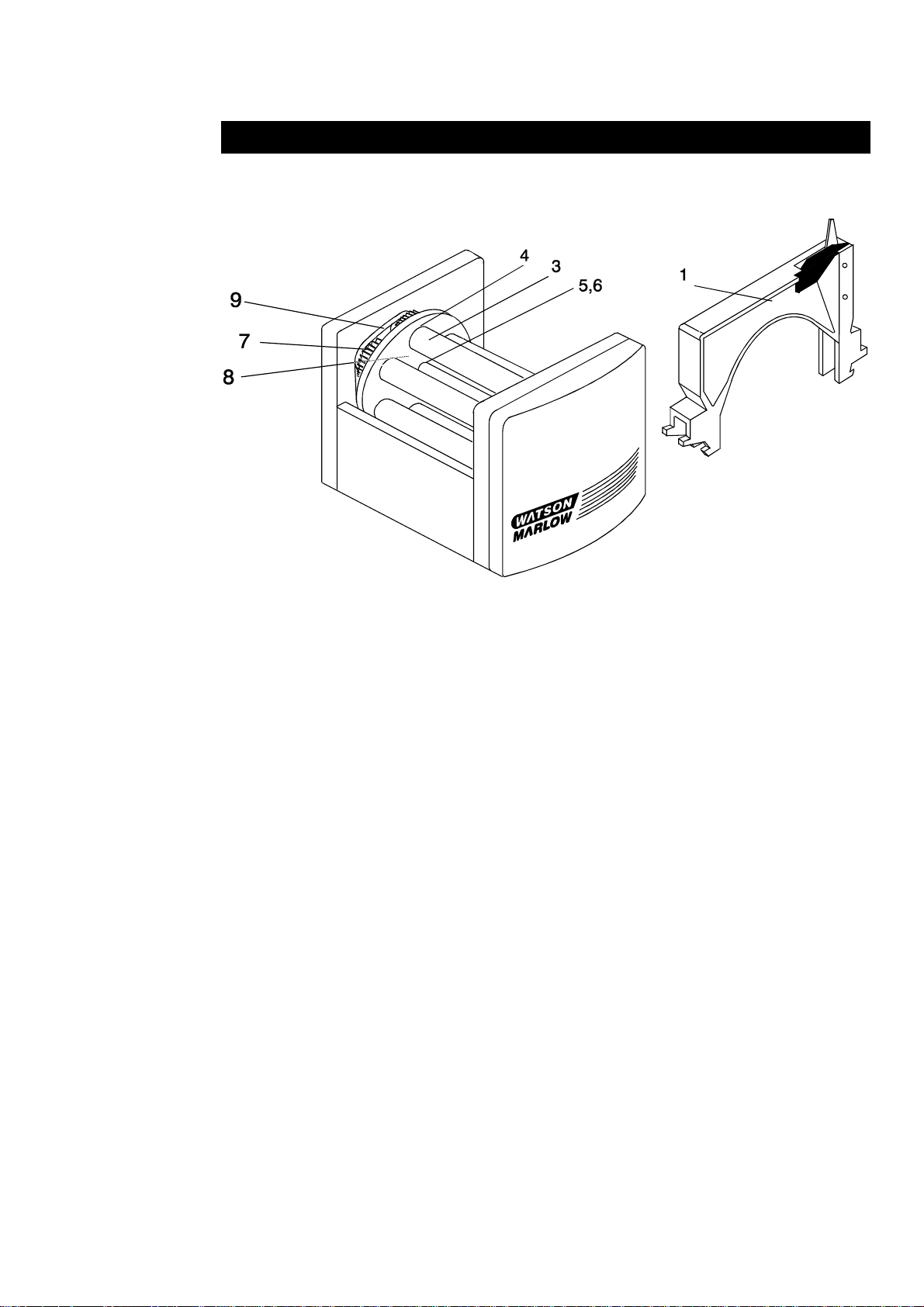

# Description Part number No per drive

1 Cassette DEA0014A

3 Roller 4 way DE 0981T 8

Roller 8 way DE 0982T 8

Roller 12 way DE 0983T 8

4 Roller bearing BB 0034 2 per roller

5 Centre shaft bearing BB 0038 2

6 Centre spacer bearing BB O014 2

7 Roller gear MN 0983M 8

8 Centre gear MN 0982M 1

9 Friction O ri ng OS 0013 1

4 channel pumphead 023.0102.000

8 channel pumphead 023.0302.000

12 channel pumphead 023.0502.000

PB0178

Page 3

Page 3

Loading...

Loading...