Page 1

Watson-Marlow 120 IP31 pumps 1

WATSON-MARLOW MANUALS

Watson-Marlow 120 cased pumps

120U/D1, 120U/DM2, 120U/DM3

m-120coversheet U-400-gb-01 Original instructions

Contents

1 General information

2 Operating manual

3 400D1, 400DM2, 400DM3

pumpheads

Page 2

Page 3

Watson-Marlow 120 IP31 pumps: general information 1

WATSON-MARLOW MANUALS

Watson-Marlow 120 cased pumps

Section 1 of 3: general information

m-120general-gb-01 Original instructions

Contents

1.1 Declaration of conformity 2

1.2 Declaration of incorporation 2

1.3 Three-year warranty 2

1.4 When you unpack your pump 3

1.5 Information for returning pumps 3

1.6 Peristaltic pumps - an overview 4

1.7 Safety notes and standards 5

1.8 Good pump installation practice 7

1.8.1 General

recommendations 7

1.8.2 Do’s and do not’s 8

1.9 Power supply 9

1.10 Dimensions 10

1.11 Start-up check list 11

1.12 Drive maintenance 11

1.13 Drive spares 11

1.14 Decontamination certificate 12

Page 4

Watson-Marlow 120 IP31 pumps: general information 2

1.1 Declaration of

conformity

This declaration was issued for WatsonMarlow 120 pumps on April 28, 2010.

When this pump unit is used as a standalone pump it complies with: Machinery

Directive 2006/42/EC, EMC Directive

2004/108/EC.

This pump is ETL listed: ETL control number 3050250. Cert to CAN/CSA std C22.2

No 61010-1. Conforms to UL 61010-1.

1.2 Declaration of

incorporation

When this pump unit is to be installed into a

machine or is to be assembled with other machines

for installations, it must not be put into service until

the relevant machinery has been declared in conformity with the Machinery Directive 2006/42/EC.

Responsible person: David Cole, Managing Director,

Watson-Marlow Limited, Falmouth, Cornwall TR11

4RU, England. Telephone +44 (0) 1326 370370 Fax

+44 (0) 1326 376009.

The information in this user guide is believed to be

correct at the time of publication. However, WatsonMarlow Limited accepts no liability for errors or

omissions. Watson-Marlow has a policy of continuous product improvement, and reserves the right to

alter specifications without notice. This manual is

intended for use only with the pump it was issued

with. Earlier or later models may differ.

The most up-to-date manuals appear on the

Watson-Marlow website:

http://www.wmpg.com

1.3 Three-year

warranty

Watson-Marlow Limited (“Watson-Marlow”) warrants, subject to the conditions and exceptions

below, through either Watson-Marlow, its subsidiaries, or its authorised distributors, to repair or

replace free of charge, any part of the pump drive

which fails within three years of the day of manufacture of the product. Such failure must have

occurred because of defect in material or workmanship and not as a result of operation of the product

other than in normal operation as defined in this

pump manual.

Watson-Marlow shall not be liable for any loss, damage, or expense directly or indirectly related to or

arising out of the use of its products, including damage or injury caused to other products, machinery,

buildings, or property, and Watson-Marlow shall not

be liable for consequential damages, including,

without limitation, lost profits, loss of time, inconvenience, loss of product being pumped, and loss of

production. This warranty does not obligate WatsonMarlow to bear any costs of removal, installation,

transportation, or other charges which may arise in

connection with a warranty claim.

Conditions of and specific exceptions to the above

warranty are:

Conditions

Products must be returned by pre-arrangement,

carriage-paid, to Watson-Marlow, or a WatsonMarlow approved service centre.

All repairs or modifications must have been

made by Watson-Marlow Limited, or a WatsonMarlow approved service centre or with the

express permission of Watson-Marlow.

Warranties purporting to be on behalf of

Watson-Marlow made by any person, including

representatives of Watson-Marlow, its subsidiaries, or its distributors, which do not accord

with the terms of this warranty shall not be

binding upon Watson-Marlow unless expressly

approved in writing by a Director or Manager of

Watson-Marlow.

Page 5

Watson-Marlow 120 IP31 pumps: general information 3

Exceptions

The warranty shall not apply to repairs or

service necessitated by normal wear and tear

or for lack of reasonable and proper

maintenance.

Tubing, a consumable item, is excluded.

Products which, in the judgment of Watson-

Marlow, have been abused, misused, or subjected to malicious or accidental damage or

neglect are excluded.

The 120F is excluded from all warranty when

pumping above 1 bar. The 120U and the 120S

are excluded from all warranty when pumping

above 2 bar.

Electrical surge as a cause of failure is

excluded.

Chemical attack is excluded

All pumphead rollers are excluded.

Ancillaries are excluded.

Pumpheads used with this pump drive carry their

own warranty.

1.4 When you unpack

your pump

Unpack all parts carefully, retaining the packaging

until you are sure all components are present and in

good order. Check against the components supplied

list.

Packaging disposal

Dispose of packaging materials safely, and in accordance with regulations in your area. The outer

carton is made of corrugated cardboard and can be

recycled.

Inspection

Check that all components are present. Inspect

components for damage in transit. If anything is

missing or damaged, contact your distributor immediately.

Components supplied

Dedicated 120F, 120S or 120U pump drive

fitted with a 114DV pumphead, 102R pumphead, 400D1, 400DM2 or 400DM3 pumphead

The designated external DC power supply unit

for your pump with plug adaptors

PC-readable CDROM containing these operating

instructions

Quick Start printed manual

Note: Some versions of this product will include

components different from those listed above.

Check against your purchase order.

Storage

This product has an extended shelf life. However,

care should be taken after storage to ensure that all

parts function correctly. Long-term storage is not

recommended for peristaltic pump tubing. Please

observe the storage recommendations and use-by

dates which apply to tubing you may wish to bring

into service after storage.

1.5 Information for

returning pumps

If you wish to return a pump for service or other

reasons, contact Watson-Marlow or your distributor,

quote your pump’s serial number, and ask for a

returns number. Include this number when you ship

the pump.

Equipment which has been contaminated with, or

exposed to, body fluids, toxic chemicals or any

other substance hazardous to health must be

decontaminated before it is returned to WatsonMarlow or its distributor.

A certificate included at the rear of these operating

instructions, or signed statement, must be attached

to the outside of the shipping carton. This certificate

is required even if the pump is unused. See 1.14

Decontamination certificate.

If the pump has been used, the fluids that have

been in contact with the pump and the cleaning procedure must be specified along with a statement

that the equipment has been decontaminated.

Page 6

Watson-Marlow 120 IP31 pumps: general information 4

1.6 Peristaltic pumps an overview

Peristaltic pumps are the simplest possible pump,

with no valves, seals or glands to clog or corrode.

The fluid contacts only the bore of a tube, eliminating the risk of the pump contaminating the fluid, or

the fluid contaminating the pump. Peristaltic pumps

can operate dry without risk.

How they work

A compressible tube is squeezed between a roller

and a track on an arc of a circle, creating a seal at

the point of contact. As the roller advances along

the tube, the seal also advances. After the roller has

passed, the tube returns to its original shape, creating a partial vacuum which is filled by fluid drawn

from the inlet port.

Before the roller reaches the end of the track, a second roller compresses the tube at the start of the

track, isolating a packet of fluid between the compression points. As the first roller leaves the track,

the second continues to advance, expelling the

packet of fluid through the pump’s discharge port.

At the same time, a new partial vacuum is created

behind the second roller into which more fluid is

drawn from the inlet port.

Backflow and siphoning do not occur, and the pump

effectively seals the tube when it is inactive. No

valves are needed.

The principle may be demonstrated by squeezing a

soft tube between thumb and finger and sliding it

along: fluid is expelled from one end of the tube

while more is drawn in at the other.

Suitable applications

Peristaltic pumping is ideal for most fluids, including

viscous, shear-sensitive, corrosive and abrasive fluids, and those containing suspended solids. They

are especially useful for pumping operations where

hygiene is important.

Peristaltic pumps operate on the positive displacement principle. They are particularly suitable for

metering, dosing and dispensing applications.

Pumps are easy to install, simple to operate and

inexpensive to maintain.

Page 7

Watson-Marlow 120 IP31 pumps: general information 5

This symbol, used on the

pump and in this manual,

means: Caution, refer to

accompanying documents.

This symbol, used on the

pump and in this manual,

means: Do not allow fingers

to contact moving parts.

Fundamental work

with regard to transportation, installation,

starting-up, maintenance and repair should be perfor med

by qualified personnel only. The unit

must be isolated from mains power

while work is being carried out. The

motor must be secured against accidental start-up.

1.7 Safety notes and

standards

In the interests of safety, this pump and the tubing

selected should only be used by competent, suitably

trained personnel after they have read and understood this manual, and considered any hazard

involved. If the pump is used in a manner not specified by Watson-Marlow Ltd, the protection provided

by the pump may be impaired.

Any person who is involved in the installation or

maintenance of this equipment should be fully competent to carry out the work. In the UK this person

should also be familiar with the Health and Safety at

Work Act 1974.

There are moving parts inside the pumphead.

Before opening the pumphead guard or track,

ensure that the following safety directions are

followed:

Ensure that the pump is isolated from the

mains power.

Ensure that there is no pressure in the pipeline.

If a tube failure has occurred, ensure that any

fluid in the pumphead has been allowed to

drain to a suitable vessel, container or drain.

Ensure that protective clothing and eye protec-

tion are worn if non-flammable hazardous fluids

are pumped.

Primary operator protection from rotating parts

of the pump is provided by the pumphead safeguard. Note that safeguards differ, depending

on the type of pumphead. See the pumphead

section of this manual.

This pump must be used only for its intended

purpose.

The pump must be accessible at all times to facilitate operation and maintenance. Access points must

not be obstructed or blocked. Do not fit any devices

to the drive unit other than those tested and

approved by Watson-Marlow. Doing so could lead to

injury to persons or damage to property for which

no liability can be accepted.

This product does not comply

with the ATEX directive and

must not be used in explosive

atmospheres.

Page 8

Watson-Marlow 120 IP31 pumps: general information 6

If hazardous fluids are to be pumped, safety procedures specific to the particular fluid and application

must be put in place to protect against injury to persons.

The exterior surfaces of the pump may get warm

during operation. Do not take hold of the pump

while it is running.

The exterior surfaces of the external DC power supply may get warm during operation. To be safe, let

it cool after use before handling it.

For safety, the pump must not be run without a

pumphead fitted.

Electrical safety

The power supply is Class II insulated: double

insulated with no earth connection.

The pump is Class III: safety extra-low voltage

(SELV).

Installation category (over-voltage category): II

Pump standards

EC

harmonised

standards

Safety of machinery—electrical equipment of machines: BS EN 60204-1

Safety requirements for electrical equipment for measurement, control and labora-

tory use: IEC/EN/UL 61010-1 incorporating A2 Category 2, Pollution degree 2

Degrees of protection provided by enclosures (IP code):

BS EN 60529 amendments 1 and 2

Conducted emissions: BS EN 55011 A1 and A2 Class A, called by BS EN61000-6-4

Radiated emissions: BS EN 55011 A1 and A2 Class A, called by BS EN61000-6-4

Electrostatic discharge: BS EN 61000-4-2 Criteria C

Radiated RF immunity: BS EN 61000-4-3 A1 and A2, called by BS EN 61000-6-2

Fast transient burst:

BS EN 61000-4-4 A1 and A2, Level 3 (2kV), called by BS EN 61000-6-2

Surge immunity: BS EN 61000-4-5 A1 and A2, called by BS EN 61000-6-2

Conducted RF immunity: BS EN 61000-4-6, called by BS EN 61000-6-2

Pumps and pump units for liquids—common safety requirements: BS EN 809

Other

standards

CAN/CSA-C22.2 No 61010-1

Conducted emissions FCC 47CFR, Part 15.107

Radiated emissions FCC 47CFR, Part 15

Power supply standards

Safety standards

UL 60950-1

CSA-C22.2

TUV EN 60950-1

EMC

EN 55022 Class B, FCC part 15/CIS PR 22 Class B

EN 61000-3-2, 3

EN61000-4-2, 3, 4, 5, 6, 8 and 11 Criteria A

Page 9

Watson-Marlow 120 IP31 pumps: general information 7

Power supply specifications

Insulation category Class II: double insulated, no earth

Mains voltage/frequency

90-264VAC, 47-63Hz, 1ph

Mains current 0.7A @ 100VAC; 0.4A @ 230VAC

Output voltage 24VDC

Output power 24W @ 30C; 18W @ 40C

Protection Hiccup mode: recovers automatically after fault removed

Overload protection 110%-200% of rated output power

Working temperature -10C to 50C, 14F to 122F

Operating humidity 20% to 90% RH, non-condensing

Over-voltage 115% to 135%

Note: Pump specifications are included in Section 2

of these instructions.

1.8 Good pump

installation practice

1.8.1 General

recommendations

Position

The 120 pump must be mounted in the upright position and not inverted or placed on its rear face.

A correctly engineered installation will promote long

tube life. Site the pump on a flat, horizontal, rigid

surface, free from excessive vibration, to ensure

correct lubrication of the gearbox. Allow a flow of air

around the pump to ensure that heat can be dissipated. Ensure that the temperature around the

pump does not exceed 40C.

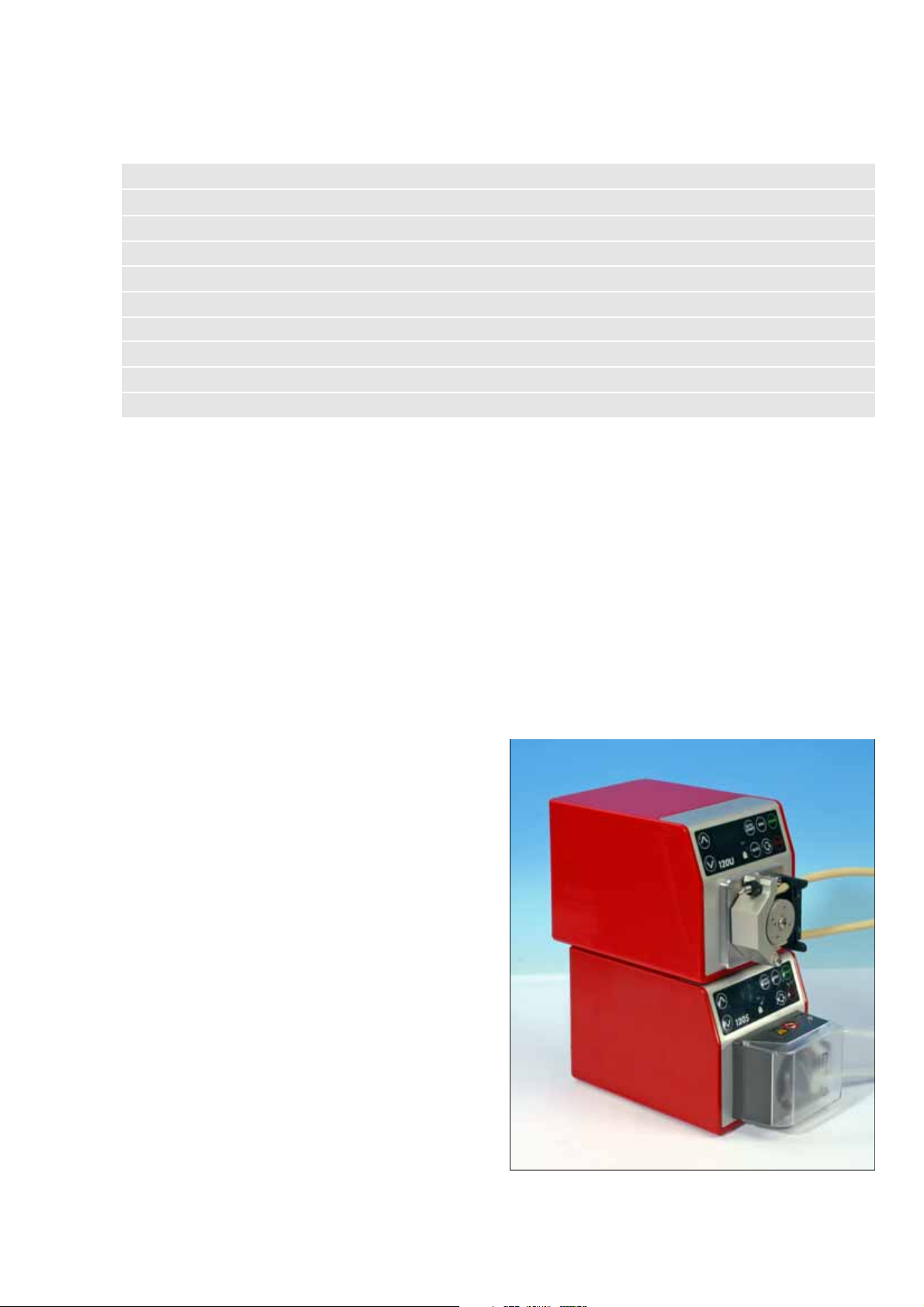

It is possible to stack only one other 120 pump on

top of this pump. The case’s third row of feet ensure

ventilation between pumps and allow the top pump

to be set back a little to give clear access to the

lower pump’s keypad. You can place other equipment on the pump’s upper surface as long as the

ambient temperature does not exceed 40C.

Emergency disconnection

The pump's external DC power supply is the disconnecting device, which must be readily identifiable

and easily reached, for isolating the motor drive

from the mains supply. Note: There may be a slight

delay after isolating the pump before the pump

stops.

Page 10

Watson-Marlow 120 IP31 pumps: general information 8

Valves

Peristaltic pumps are self-priming and self-sealing

against backflow. No valves are required in inlet or

discharge lines. Valves in the process flow must be

opened before the pump operates. Users are

advised to fit a pressure relief device between the

pump and any valve on the discharge side of the

pump to protect against damage caused by accidental operation with the discharge valve closed.

Pressure advice

In most circumstances,

rotor and tube life are

maximised if the pumphead is run slowly, particularly when pumping at

high pressure. Do not

exceed the pressures

shown here.

1.8.2 Do’s and do not’s

Do not build a pump into a tight location without

adequate airflow around the pump.

Do not strap together the control and and external

DC power supply cables.

Do keep delivery and suction tubes as short and

direct as possible - though ideally not shorter than

1m - and follow the straightest route. Use bends of

large radius: at least four times the tubing diameter. Ensure that connecting pipework and fittings are

suitably rated to handle the predicted pipeline pressure. Avoid pipe reducers and lengths of smaller

bore tubing than the pumphead section, particularly in pipelines on the suction side. Any valves in the

pipeline (not usually needed) must not restrict the

flow. Any valves in the flow line must be open when

the pump is running.

Do use suction and delivery pipes equal to or larger than the bore of the tube in the pumphead. When

pumping viscous fluids use pipe runs with a bore

several times larger than the pump tube.

Do site the pump at or just below the level of the

fluid to be pumped if possible. This will ensure

flooded suction and maximum pumping efficiency.

Do keep the pumphead track and all moving parts

clean and free from contamination and debris.

Do run at slow speed when pumping viscous fluids

(though see Pressure advice in 1.8.1 General rec-

ommendations). Flooded suction will enhance

pumping performance in all cases, particularly for

materials of a viscous nature.

120 pumps may be wiped with a damp cloth, but

should not be hosed or immersed. The front of the

pump is further protected against light spillages.

When using Marprene or Bioprene continuous

tubing, do re-tension the tube after the first 30 minutes of running.

Tube selection: The chemical compatibility lists

published in Watson-Marlow publications are

guides. If in doubt about the compatibility of a tube

material and the duty fluid, request a WatsonMarlow tube sample card for immersion trials.

120 pump RMS

pressure ratings

120F + any

pumphead

0 bar

120S+102R

120S+400DM2

120S+400DM3

120U+114DV

120U+400D1

120U+400DM2

120U+400DM3

2 bar

Page 11

Watson-Marlow 120 IP31 pumps: general information 9

1.9 Power supply

The 120 pump is suitable for single-phase mains

electricity supplies only via the double-insulated

(Class II) 90-264VAC-to-24VDC mains adaptor. Use

only the approved 24VDC Meanwell type GE24I24P1JK DC adaptor or the Powersolve ESA24-24 DC

adaptor supplied with the pump.

A well regulated electrical mains supply is required

along with cable connections conforming to the best

practice of noise immunity. It is not recommended

to site these drives alongside “dirty” electrical mains

supplies such as 3-phase contactors and inductive

heaters without special attention being paid to

unacceptable mains-borne noise.

To prepare your power supply

Select the mains input adapter appropriate to

your region—UK, US, Australia or Europe—and

slide it into position on the rear of the unit.

Ensure it clicks into place.

Stop/start power cycles: Do not power up/power

down for more than 100 starts per hour. A minimum interval of 3 seconds is required between power

cycles.

We recommend using commercially available supply

voltage surge suppression

where there is excessive

electrical noise.

USUK EuroAus

Page 12

Watson-Marlow 120 IP31 pumps: general information 10

Unit weights

Drive

only+114DV+ 102R+ 400D1+ 400DM2+400DM3

1.4kg 1.5kg 1.55kg 1.65kg 1.7kg 1.7kg

1.10 Dimensions

IP (ingress protection) definition

1st Digit: 3 2nd Digit: 1

Protected against

ingress of solid objects

with a diameter of more

than 2.5mm. Tools,

wires etc with a

thickness of more than

2.5mm are prevented

from approach

Protection against

dripping water falling

vertically. No harmful

effect must be produced

This pump’s ingress protection is rated IP31.

120 pump drive with

102R pumphead

120 pump drive with

114DV pumphead

Note: A 120U pump drive is shown here. All

drives have the same dimensions and weight

(apart from drive shaft dimensions).

120 pump drive with

400D1 pumphead

120 pump drive with

400DM2 pumphead

120 pump drive with

400DM3 pumphead

Page 13

Watson-Marlow 120 IP31 pumps: general information 11

1.11 Start-up check

list

Note: See also section 2 (120F, 120S or 120U

drives) and section 3 (102R, 114DV or 400 series

pumpheads) of these instructions.

Ensure that proper connections are achieved

between the pump tube and suction and discharge piping.

Ensure proper connection has been made to the

external DC power supply unit, and to a suitable power supply.

Ensure that the recommendations in the section

1.8 Good pump installation practice are fol-

lowed.

1.12 Drive

maintenance

There are no user-serviceable parts inside the

pump. The unit should be returned to WatsonMarlow or its appointed agents or distributors

for service.

1.13 Drive spares

Dedicated external DC power supply unit and

plug adaptors: MN2634B

Foot: FB0012

Page 14

Watson-Marlow 120 IP31 pumps: general information 12

1.14 Decontamination

certificate

In compliance with the UK Health and Safety at

Work Act and the Control of Substances Hazardous

to Health Regulations, you are required to declare

the substances which have been in contact with

product(s) you return to Watson-Marlow or its subsidiaries or distributors. Failure to do so will cause

Your name Company

Address

Postcode/zip Country

Telephone Fax

Product type Serial number

To speed the

repair, please

describe all

known faults

The product has ...

I Been used II Not been used

If the product has been used, please complete all the following sections.

If the product has not been used, please just sign this form.

Names of

chemicals handled

with product(s)

Precautions to be

taken in handling

these chemicals

Action to be taken

in the event of

human contact

I understand that the personal data collected will be kept confidentially

in accordance with the UK Data Protection Act 1998.

RGA number

Signature Your position

Date

Please print out, sign and fax to Watson-Marlow Pumps at +44 1326 376009.

delays. Please ensure that you fax us this form and

receive an RGA (Returned Goods Authorisation)

before you despatch the product(s). A copy of this

form must be attached to the outside of the packaging containing the product(s). Please complete a

separate decontamination certificate for each product.

You are responsible for cleaning and decontaminating the product(s) before return.

Page 15

Watson-Marlow 120U IP31 pumps: operating instructions 1

WATSON-MARLOW MANUALS

Watson-Marlow 120U cased pumps

Section 2 of 3: Operating manual

m-120u-ip31-gb-01 Original instructions

Contents

2.1 Pump specifications 2

2.2 Good pump installation practice 3

2.3 Switching the pump on 3

2.4 Manual operation 4

2.4.1 Keypad functions in

manual mode 4

2.4.2 Start and stop 4

2.4.3 Increase and decrease

pump speed 4

2.4.4 Change direction of

rotation 5

2.4.5 Prime the pump 5

2.4.6 Run the pump at

maximum speed 5

2.4.7 Run the pump at

minimum speed 5

2.4.8 Switch to automatic

control 5

2.4.9 Auto-start 5

2.4.10 Keypad beep 5

2.4.11 ROM 5

2.4.12 Keypad lock 6

2.4.13 Defaults 6

2.4.14 Set maximum allowed

speed 6

2.5 Remote control wiring 7

2.6 Remote/automatic control and

operation 9

2.6.1 Remote stop/start

when AUTO has not

been pressed 9

2.6.2 Direction 9

2.6.3 DC tacho output 10

2.6.4 Digital alarm output 10

2.6.5 Supply voltages 10

2.6.6 How to get into auto

speed operation 11

2.6.7 Remote stop/start

when AUTO has been

pressed 12

2.6.8 Speed: analogue input 12

2.6.9 Speed: remote

potentiometer input 13

2.6.10 Set maximum allowed

speed 13

2.7 Troubleshooting 14

2.7.1 Error codes 14

Page 16

Watson-Marlow 120U IP31 pumps: operating instructions 2

2.1 Pump

specifications

A nameplate is fixed to the rear of the pump. It contains manufacturer and contact details, product reference number, serial number and model details.

120U

This pump can be controlled from the keypad or

remotely. It features:

Manual control

Speed adjustment; run and stop; direction control; “max” key for rapid priming; “auto start”

for automatic power recovery; “auto” key for

changing between manual and auto control

Remote digital control

The pump can be digitally controlled with a

contact closure or logic input signal

Analogue control

The pump speed can be controlled through an

analogue signal input of 4-20mA or 0-10V

Outputs

Logic output designated for an alarm only

DC Tacho output

Pump specifications

Control range (turndown ratio)

Manual control:

With 102R: 0.1-32 rpm (320:1)

With 114DV: 0.1-200 rpm (2,000:1)

With 400D1: 0.1-200 rpm (2,000:1)

With 400DM2: 0.1-100 rpm (1,000:1)

With 400DM3: 0.1-100 rpm (1,000:1)

Auto control:

With 102R: 0.01-32 rpm (3,200:1)

With 114DV: 0.01-200 rpm (20,000:1)

With 400D1: 0.01-200 rpm (20,000:1)

With 400DM2: 0.01-100 rpm (10,000:1)

With 400DM3: 0.01-100 rpm (10,000:1)

Power supply DC input 24V @ 1A

Software version Accessible through combination keypress

Enclosure rating

IP31 to BS EN 60529. Equivalent to NEMA 2, suiable for indoor

use. Protected against dripping water and falling dirt. May be

wiped with a damp cloth, but should not be immersed

Pumphead options 114DV, 102R, 400D1, 400DM2 and 400DM3

Operating temperature range 5C to 40C, 41F to 104F

Storage temperature range -25C to 65C, -13F to 149F

Maximum altitude 2,000m, 6,560ft

Humidity (non-condensing) 80% up to 31C, 88F, decreasing linearly to 50% at 40C, 104F

Weight See Section 1, General information

Noise <60dB(A)

Function comparison, models 101U and 120U

Function 101U 120U

Analogue

input

0-30mA and

0-30V

4-20mA and 0-10V

Range and

off-set

trimming

possible

can only set the

maximum speed

Signal

inversion

possible not possible

Tacho

output

+5V and –5V at

maximum speed

5V at maximum

allowed speed

Input

impedance

255Ω 250Ω

Max speed

options

2 rpm or

32 rpm, modeldependant

single speed range,

pumpheaddependant

Speed

increments

10% or 1%

increments

0.1 rpm in manual

mode and 0.01 rpm

in analogue mode

Analogue

control

2,000:1

control ratio

20,000:1

control ratio

Page 17

Watson-Marlow 120U IP31 pumps: operating instructions 3

2.2 Good pump

installation practice

The 120 pump must be mounted in the upright

position and not inverted or placed on its rear face.

2.3 Switching the

pump on

The pump is powered by a dedicated 24V external

DC power supply unit which is supplied with the

pump.

Note: If you plan to operate the pump by

controls external to the pump, the 15-way

D-connector must be connected before power

is supplied to the pump (see 2.5 Automatic

control wiring and 2.6 Remote/automatic

control and operation). If any change is made

later to the 15-way D-connector, it must be

reconnected before power is supplied to the

pump.

Plug the power supply’s output connector into

the power socket on the rear of the pump.

Plug the power supply unit into a mains power

outlet and switch on. The pump performs a

power-on test to confirm proper functioning of

the memory and hardware. If a fault is found,

an error message is displayed. See 2.7.1 Error

codes.

Load the pumphead with tube: see Section 3 of

these instructions.

The pump is now ready to operate according

to the default settings.

Operating parameters may be changed by means of

key-presses. See 2.4 Manual operation.

To return the pump to its default settings, press and

hold DIRECTION on power up.

120U start-up defaults

Set speed 32 rpm

Maximum speed

Maximum possible speed

depending on pumphead

Direction Clockwise

Mode Manual

Display Speed in rpm

Display and LEDs On

Pump status Stopped

Keypad lock Off

Auto-start Off

Beeper On

Max (prime) Maximum possible speed

Scrolling

increment

0.1 rpm

Remote stop Open=run

Output 1 General alarm

Page 18

Watson-Marlow 120U IP31 pumps: operating instructions 4

2.4 Manual operation

2.4.1 Keypad functions in

manual mode

All settings and functions of the pump in manual

mode are set and controlled by means of key presses. Immediately after power-up, the currently

selected rotation speed is indicated on the display.

Start-stop status, auto-start status, automatic control status and direction of rotation are indicated by

LEDs beside their keys; keypad lock status is indicated by an LED beside the padlock symbol.

Note: Beeps sound to confirm the function of control keys only if keypad beep has not been turned

off (see 2.4.10 Keypad beep).

Note: Remote stop/start, direction, DC tacho output and digital alarm output are active in both manual and auto modes.

2.4.2 Start and stop

To start the pump at the speed and in the direction

indicated (see 2.4.4 Change direction of rotation),

press the green START key on the keypad. A beep

sounds and the LED beside the START key illuminates to confirm that the pump is operating. We

recommend that the speed is reduced to a minimum

(0.1 rpm) before starting the pump.

To stop the pump, press the red STOP key on the

keypad. A beep sounds, the pump stops and the

LED beside the START key goes out to confirm that

the pump is stopped. The display continues to show

the previous speed and direction. The pump will

return to this speed and direction when the START

key is pressed again.

2.4.3 Increase and

decrease pump speed

Press and hold UP to increase the speed shown on

the display in minimum steps of 0.1 rpm (unless the

speed displayed is already the maximum allowed

speed). Beeps sound while the key is held. If the

pump is then started by pressing the START key, it

operates at the new speed. If the pump is running

when UP is pressed, the change takes effect immediately.

The pump can be stopped at

all times by pressing STOP

on the keypad, whether it is

in manual or auto mode.

Page 19

Watson-Marlow 120U IP31 pumps: operating instructions 5

Press and hold DOWN to decrease the speed shown

on the display in minimum steps of 0.1 rpm. Beeps

sound while the key is held. If the pump is then

started by pressing the START key, it operates at

the new speed. The minimum running speed possible is 0.1 rpm. If the pump is running when DOWN

is pressed, the change takes effect immediately.

Note: You can reduce the pump speed from

0.1 rpm to 0 rpm by a further press on the DOWN

key. The LED beside the START key goes out. The

pump is still in the running state and you can press

the UP key to return the pump to the minimum

speed.

2.4.4 Change direction of

rotation

Press DIRECTION to toggle the sense of rotation.

A beep sounds and the LED beside the clockwisepointing arrow to the key’s right illuminates to

indicate clockwise rotation; the LED beside the

counter-clockwise-pointing arrow to the key’s left

illuminates to indicate counter-clockwise rotation. If

the pump is then started by pressing the START

key, it rotates in the new direction. If the pump is

running when DIRECTION is pressed, the change

takes effect immediately.

2.4.5 Prime the pump

While pressed, MAX operates the pump at the maximum allowed speed and in the direction indicated.

Beeps sound while the key is held. When released,

the pump returns to its previous status. Priming can

be achieved by pressing the MAX key until fluid

flows through the pump and reaches the point of

discharge, and then releasing the MAX key.

2.4.6 Run the pump at

maximum allowed speed

Press MAX and UP together to set the pump to

maximum allowed speed. Beeps sound while the

keys are held. If the pump is then started by pressing the START key, it operates at the new speed. If

the pump is running when MAX and UP are

pressed, the change takes effect immediately.

2.4.7 Run the pump at

minimum speed

Press MAX and DOWN together to set the pump to

minimum speed. Beeps sound while the keys are

held. If the pump is then started by pressing the

START key, it operates at the new speed. If the

pump is running when MAX and DOWN are

pressed, the change takes effect immediately.

2.4.8 Switch to automatic

control

Press AUTO to toggle the pump into and out of

analogue control. A beep sounds and the LED beside

the AUTO key illuminates to confirm that the pump

is under analogue control, and will respond to any

remote/auto signal. When started, the pump runs at

the speed set by any analogue signal applied to the

pump, and in the direction indicated.

When toggled from automatic control to manual

control, the pump retains its speed setting.

2.4.9 Auto-start

Press AUTO START to toggle the auto-start function on and off. A beep sounds and the LED beside

the AUTO START key illuminates to indicate that

the auto-start function is on. If auto-start is on, the

pump starts in the last selected condition following

a power supply interruption. If auto-start is off, the

pump waits for a press on the START key before

starting in the last selected condition following a

power supply interruption.

2.4.10 Keypad beep

While the pump is stopped, press DIRECTION and

UP together to toggle the keypad beep on and off.

2.4.11 ROM

While the pump is stopped, press DIRECTION and

DOWN together to display the pump’s ROM version.

Beeps sound while the keys are held.

Page 20

Watson-Marlow 120U IP31 pumps: operating instructions 6

2.4.12 Keypad lock

The keypad can be locked to prevent changes to

pump speed or other settings, and make it possible

only to start or stop the pump.

To lock the keypad while the pump is running:

Hold down the START key for more than one

second. A beep sounds, the LED beside the

padlock symbol flashes briefly then illuminates

and the keypad is locked. Only the START and

STOP keys function. If another key is pressed

while the keypad is locked and the pump is

running, a message is briefly displayed: Hold

Strt. This tells the user to press and hold the

START key for more than one second to unlock

the keypad and make the required key

available.

To lock the keypad while the pump is stopped:

Hold down the STOP key for more than one

second. A beep sounds, the LED beside the

padlock symbol flashes briefly then illuminates

and the keypad is locked. Only the START and

STOP keys function. If another key is pressed

while the keypad is locked and the pump is

stopped, a message is briefly displayed: Hold

Stop. This tells the user to press and hold the

STOP key for more than one second to unlock

the keypad and make the required key

available.

To unlock the keypad while the pump is running:

Hold down the START key for more than one

second. A beep sounds, the LED beside the

padlock symbol flashes briefly then goes out

and the keypad is unlocked.

To unlock the keypad while the pump is stopped:

Hold down the STOP key for more than one

second. A beep sounds, the LED beside the

padlock symbol flashes briefly then goes out

and the keypad is unlocked.

Note: In auto mode only, START pressed for

more than 1 second toggles the keypad lock on

or off.

2.4.13 Defaults

To return the pump to its default settings, press

and hold DIRECTION on power up. See 2.3

Switching the pump on.

2.4.14 Set maximum

allowed speed

While the pump is stopped, press AUTO and UP

together to put the pump into Setup mode. The

display shows the current maximum allowed speed,

and flashes to indicate that the pump is in Setup

mode. Use the UP and DOWN keys to select a new

maximum allowed speed. Press AUTO to confirm

the new maximum allowed speed. Press STOP to

escape from the the change sequence and revert to

the previous maximum allowed speed. The

minimum maximum speed is 2 rpm.

Page 21

Watson-Marlow 120U IP31 pumps: operating instructions 7

2.5 Remote control

wiring

Interfacing the pump with other devices is by

means of a female 15-pin D-connector at the rear of

the pump.

A mating male connector, screened for EMC compatibility, must be conventionally soldered to a

screened control cable.

Recommended control cable: 7 strands 0.2mm,

24AWG, screened, circular, up to 15-core.

The 15-way D-connector must be connected

before power is supplied to the pump. If any

change is made later to the 15-way D-connector, it must be re-connected before power is

supplied to the pump.

This pump passes all EMC compatibility requirements with up to 3m (10ft) of the cable type

specified above. Beyond this distance it is the user’s

responsibility to ensure the pump is safe and

reliable under remote and automatic control.

To minimise EMC interferance the wiring to the 15pin D-connector must be screened. The screen must

be earthed at the signal end of the wiring. To further

reduce EMC the screened wiring must be threaded

once or twice through a ferrite tubular cable shield

or a hinged clamp core.

The signal ground and DC supply ground lines on

this pump are isolated from ground by the external

DC supply unit. It can be connected to isolated 0V

or grounded 0V interfaces. The TTL (transistor

transistor logic) output is composed of two states:

nominally 0V and 5V; but in practice <0.4V

(<16mA) and 2.4-5V (<0.4mA). They are not

suitable for driving relays.

Pin

no

Input or output Function Referenced to

1 Digital input

Analogue Voltage

or Current Signal

Input Select

Connect to Digital

Ground for Current

2 Analogue input

Analogue Voltage

or Current Signal

Input (+)

Referenced to

Analogue Ground

3 Ground Analogue Ground (0V)

4 Digital input

Remote Direction

Enable

Connect to Digital

Ground to enable

5 Digital input Remote Direction

Connect to 5VDC

for counter-clockwise operation

7 Digital input

Manual or Auto

Mode Select

Connect to 5VDC

Supply for Auto

Mode

8 Digital input Remote Start/Stop

Connect to 5VDC

Supply to stop

9 Analogue output

Analogue Tacho

Output

Referenced to

Analogue Ground

(0-5VDC signal)

10 Ground Analogue Ground (0V)

11 Ground Digital Ground (0V)

12 Ground Digital Ground (0V)

13 DC supply 5VDC Supply (+)

Referenced to

Ground

14 Digital output

Alarm Output (5V

TTL)

Referenced to

Digital Ground

15 DC supply 12VDC Supply (+)

Referenced to

Ground

Note: The pin allocation of the 120U differs

from the pin allocation of the 101U and the

401U. See overleaf for details.

Page 22

Watson-Marlow 120U IP31 pumps: operating instructions 8

Pin no 101U 401U 120U

1

Analogue input current

resistor (link to 0V)

Analogue input current

resistor

Analogue voltage/current

signal selection

2 Analogue speed input Analogue speed input (+10V)

Analogue speed input

(voltage/current)

3 Tacho output (0-5VDC) Supply +5V Ground 0V (analogue)

4 Remote direction enable Remote direction (reverse) Remote direction enable

5 Remote direction control Remote direction (forwards)

Remote direction selection

(CW/CCW)

6 Remote auto/man enable Linked for current offset For future use

7 Remote auto/man control Linked for current offset Remote auto/man selection

8 Remote stop Ground 0V Remote stop

9 Tacho output (0-5VDC) Analogue control (+1V) Tacho output (0-5VDC)

10 Ground 0V Supply +18V Ground 0V (analogue)

11 Ground 0V Remote auto/man control Ground 0V (digital)

12 Ground 0V Not connected Ground 0V (digital)

13 Supply +5V Not connected Supply +5V

14 Supply -5V Not connected Alarm output (5V TTL)

15 Supply +12V Ground 0V Supply +12V

Pin allocations, models 101U, 401U and 120U

Page 23

Watson-Marlow 120U IP31 pumps: operating instructions 9

2.6 Remote/automatic

control and operation

The pump can be operated by controls external to

the pump: manually by a switch or potentiometer;

or by an automatic control station. You need not

press the AUTO key unless you wish to control

speed remotely: remote stop/start, direction,

DC tacho output and digital alarm output are

active in both manual and auto modes.

Check that the pump is ready to run before

remote/automatic operation. Signals may start the

pump without warning.

2.6.1 Remote stop/start

when AUTO has not been

pressed

Fit a switch between pins 8 and 13.

OR:

Apply a TTL logic signal to pin 8, ground to pin 12.

Press START on the keypad to enable remote

stop/start.

See 2.6.6 Remote stop/start for remote stop/start

instructions after AUTO has been pressed.

2.6.2 Direction

For remote direction change:

Enable remote direction control and disable the

DIRECTION key on the keypad by fitting a link

between pins 4 and 11.

Fit a switch between pins 5 and 13.

OR:

Apply a TTL logic signal to pin 5, ground to pin 12.

Never apply mains voltage

to the 15-way D connector.

Apply the correct signals to

the pins shown below. Limit

signals to the maximum

values shown. Do not apply

voltage across other pins.

Permanent damage, not

covered by warranty, may

result.

The pump can be stopped at

all times by pressing STOP

on the keypad, whether it is

in manual or auto mode.

Page 24

Watson-Marlow 120U IP31 pumps: operating instructions 10

2.6.3 DC tacho output

For DC tacho output:

Connect external instrumentation: positive terminal

to pin 9; negative terminal to pin 3.

Note: This output is designed for low-resistance

equipment inputs of nominally 1kΩ.

2.6.4 Digital alarm output

For digital alarm output (system errors only):

Connect an external TTL device: positive terminal to

pin 14; negative terminal to pin 12.

2.6.5 Supply voltages

+5VDC is available on pin 13. +12VDC is available

on pin 15. Tolerances better than 10%. Both supplies are stabilised. Ground to pin 11 or pin 12.

DC

Voltage

Max

load

Pin Typical use

+5V 10mA 13

Voltage supply for

inputs using remote

switch.

+12V 10mA 15

Possible voltage supply for inputs using

remote switch.

Page 25

Watson-Marlow 120U IP31 pumps: operating instructions 11

2.6.6 How to get into

auto speed operation

Check that the pump is ready to run before

remote/automatic operation. Signals may start the

pump without warning.

Press the AUTO key to select automatic

operation. A beep sounds and the LED beside

the AUTO key illuminates to indicate that the

pump is under automatic speed control.

The pump responds to the analogue signal as

soon as this is done. Auto-start is automatically

switched on. The only keys active are STOP,

AUTO and DIRECTION.

If remote direction input is active and the

direction-enable link is applied, the

DIRECTION key is disabled. If keypad lock is

set, only STOP and START are active. STOP

stops the pump and switches it to manual

control (or, if the pump was put into auto mode

by remote switching, to the auto-stop

state—see Alternatively, below). START

pressed for more than 1 second toggles the

keypad lock on or off.

The pump displays the speed at which the

pump will rotate after receiving a high signal

(20mA or 10V).

Alternatively ...

A remote signal can select auto or manual control,

overriding the keypad AUTO key setting.

Fit a switch or link between pins 7 and 13.

OR:

Apply a TTL logic signal to pin 7, ground to pin 12.

Page 26

Watson-Marlow 120U IP31 pumps: operating instructions 12

2.6.7 Remote stop/start

when AUTO has been

pressed

Fit a switch between pins 8 and 13.

OR:

Apply a TTL logic signal to pin 8, ground to pin 12.

See 2.6.1 Remote stop/start for remote stop/start

instructions if AUTO has not been pressed.

2.6.8 Speed: analogue

input

When AUTO has been pressed, pump speed can be

controlled remotely by an analogue process signal

within the range 0-10V; or 4-20mA. The pump

provides an increasing flow rate for a rising control

signal.

Voltage signal

0-10VDC. Input impedance: 24kΩ.

Connect a voltage source: negative terminal to pin

10; positive terminal to pin 2.

Current signal

4-20mA. Input resistance: 250Ω.

Fit a link between pins 1 and 11.

Connect a current source: negative terminal to pin

10; positive terminal to pin 2.

Page 27

Watson-Marlow 120U IP31 pumps: operating instructions 13

2.6.9 Speed: remote

potentiometer input

For remote potentiometer speed input, when AUTO

has been pressed:

Connect a potentiometer (±5% tolerance recommended) between pins 12 and 15, with a resistor in

series on the Max side of the potentiometer. Typical

potentiometer value is 1kΩ-5kΩ. The resistor value

should be 180R when a 1kΩ potentiometer is used;

the resistor value should be 1kΩ when a 5kΩ

potentiometer is used.

Note: The resistor value may have to be adjusted

higher or lower to achieve the full pump speed

range.

Connect the potentiometer wiper to pin 2.

Note: Set the pump to analogue control. Do not

apply a voltage or current control input signal at the

same time. Performance will depend on the

tolerances of components used.

2.6.10 Set maximum

allowed speed

While the pump is stopped, press AUTO and UP

together to put the pump into Setup mode. The display shows the current maximum allowed speed,

and flashes to indicate that the pump is in Setup

mode. Use the UP and DOWN keys to select a new

maximum allowed speed. Press AUTO to confirm

the new maximum allowed speed. Press STOP to

escape from the the change sequence and revert to

the previous maximum allowed speed. The

minimum maximum speed is 2 rpm.

Note: To increase the control resolution when the

maximum speed of the pump is not required,

decrease the the maximum allowed speed. This is

particularly useful if you are replacing a 101U/R

2 rpm pump with a higher-speed 120U/R pump.

200 rpm

2 rpm

0 rpm

Voltage0V 10V

Max allowed

200 rpm

Speed

Max allowed

2 rpm

Page 28

Watson-Marlow 120U IP31 pumps: operating instructions 14

2.7 Troubleshooting

If the pump fails to operate, make the following

checks:

Check that the dedicated external DC power

supply unit is plugged into a working mains

power source which is switched on. Check that

the power supply unit’s LED is illuminated (if

fitted).

Check that the dedicated external DC power

supply unit’s output connector is plugged into

the pump.

If the pump runs but there is little or no flow, make

the following checks:

Check that tubing is installed in the pumphead;

check that it is the correct wall thickness:

1.6mm. See section 3 of these instructions.

Check that the tube is not split or burst.

Check for any kinks or blockages in the lines.

Check that any valves in the lines are open.

Check that the rotor is in the pumphead, that

it rotates and that the rollers are in good

condition.

Check that fluid is supplied to the pump.

Error

code

Error condition Suggested action

Er 0 FRAM write error Attempt to reset by switching power OFF / ON. Or seek support

Er 1 FRAM corruption Attempt to reset by switching power OFF / ON. Or seek support

Er 2

FLASH write error

during drive update

Attempt to reset by switching power OFF / ON. Or seek support

Er 3 FLASH corruption Attempt to reset by switching power OFF / ON. Or seek support

Er 4 FRAM shadow error Attempt to reset by switching power OFF / ON. Or seek support

Er 9 Motor stalled

Stop pump immediately. Check pumphead and tube. Power OFF/ON

may reset. Or seek support

Er10 Tacho fault Stop pump immediately. Power OFF/ON may reset. Or seek support

Er14 Speed error Stop pump immediately. Power OFF/ON may reset. Or seek support

Er15 Over current

Stop pump immediately. Check system. Power OFF/ON may reset.

Or seek support

Er16 Over voltage

Stop pump immediately. Check mains voltage selector switch. Check

supply. OFF/ON may reset. Or seek support

Er17 Under voltage

Stop pump immediately. Check mains voltage selector switch. Check

supply. OFF/ON may reset. Or seek support

Er19 Over temperature Stop pump immediately. Turn OFF. Seek support

Er20 Signal out of range

Check analogue control signal range. Trim signal as required. Or

seek support

Er21 Over signal Reduce the analogue control signal

Er30 Over power

Turn OFF. Check power supply. Check pumphead and tubing. Wait

30 minutes. Power ON may reset. Or seek support

Err General error condition Turn OFF. Seek support

2.7.1 Error codes

If an internal error occurs, an error screen is

displayed.

Note: Signal out of range and Over signal

report the nature of an external signal.

Page 29

Watson-Marlow 400D1, 400DM2 and 400DM3 pumpheads: operating instructions 1

WATSON-MARLOW MANUALS

Watson-Marlow 120 cased pumps

Section 3 of 3: 400D1, 400DM2,

400DM3 pumpheads

m-400-gb-01 Original instructions

Contents

3.1 Pumphead specifications 2

3.2 400D1, 400DM2 and 400DM3

key safety information 2

3.3 400D1, 400DM2 and 400DM3

installation 2

3.4 400D1 tube loading and removal 3

3.5 400DM2 and 400DM3 tube check 3

3.6 400DM2 and 400DM3 tube

loading and removal 4

3.7 400D1, 400DM2 and 400DM3

pumphead spares 4

3.8 400D1, 400DM2 and 400DM3

performance 5

3.9 Tubing product codes 7

3.10 Trademarks 8

3.11 Do not use in patient-connected

applications 8

3.12 Publication history 8

Page 30

Watson-Marlow 400D1, 400DM2 and 400DM3 pumpheads: operating instructions 2

3.1 Pumphead

specifications

The 400D1 pumphead is designed to accept 1.6mm

wall thickness tubing in four different bore sizes.

The 400DM2 and 400DM3 pumpheads are designed

to accept three-bridge manifold tubing only.

3.2 400D1, 400DM2

and 400DM3 key

safety information

There are moving parts inside the pumphead.

Before opening the tool-unlockable pumphead

track, ensure that the following safety directions

are followed.

Ensure that the pump is isolated from the

mains power.

Ensure that there is no pressure in the pipeline.

If a tube failure has occurred, ensure that any

fluid in the pumphead has been allowed to

drain to a suitable vessel, container or drain.

Protective clothing and eye protection must be

worn if hazardous fluids are pumped.

3.3 400D1, 400DM2

and 400DM3

installation

A correctly engineered installation will promote the

best possible tube life, so please ensure that the

following guidelines are followed:

Avoid tight pipeline bends, pipe reducers and

excessive lengths of smaller bore tubing than

that in the pumphead, particularly in pipelines

on the suction side.

Ensure that connecting pipework and fittings

are suitably rated to handle the predicted

pipeline pressure.

If rigid pipework comes in close proximity to

the pumphead, a drop-out section of pipework

will simplify tube replacement.

Page 31

Watson-Marlow 400D1, 400DM2 and 400DM3 pumpheads: operating instructions 3

3.4 400D1 tube

loading and removal

Release the track by disengaging the sprung

track pin.

Before tube loading, make sure that enough

suction and delivery tubing is available to

connect into the remaining pipeline or to reach

the suction reservoir and delivery point.

Locate the tubing into the suction side tube

clamp. Feed the tubing in around the rotor,

maintaining reasonable tube tension so that the

tube sits around the rotor, and locate into the

delivery side tube clamp. Make sure that there

are no twists or kinks in the tubing after

loading as this will reduce tube life.

Ensure the tube is lined up centrally in the

track and correctly secured at each clamp.

Reposition the track over the rotor and fix by

slotting the track pin back into the track slot.

To remove the tube, reverse the sequence.

Note: over-tightening the sprung track pin can

damage the tube and the pumphead.

Tube re-tensioning

When using Marprene tubing: After the first 30

minutes of running, re-tension the tube in the

pumphead by releasing the sprung track pin

and pulling the tubing on the delivery side a

little. This is to counteract the normal

stretching that occurs with Marprene which can

go unnoticed and result in poor tube life.

Tube removal

Release the track by disengaging the sprung

track pin and withdraw the tubing from the

sprung clamps.

3.5 400DM2 and

400DM3 tube check

The 400DM2 and 400DM3 pumpheads are designed

to accept three-bridge manifold tubing only. Each

piece of three-bridge manifold tubing has two

pumping sections. Reduced flow performance in one

section is a sign of tube wear and should be used as

an indicator to switch over to using the second

section. When the switch to the second section is

made, check the first section of tubing is not

adversely affected by normal line pressure. If this is

the case then the complete section of tubing will

need to be replaced.

Always isolate the pump from

the mains power supply before

opening the guard or

performing any positioning,

removal or maintenance

activity.

00:30:00

Over-tightening the sprung

track pin can damage the tube

and the pumphead.

Page 32

Watson-Marlow 400D1, 400DM2 and 400DM3 pumpheads: operating instructions 4

3.6 400DM2 and

400DM3 tube loading

and removal

Release the track by disengaging the sprung

track pin.

Locate the first tube bridge into the appropriate

tube bridge holder slot. Feed the tubing in

around the rotor. Locate the centre tube bridge

into the bridge holder slot immediately opposite

the first tube bridge. Repeat for the remaining

one (400DM2) or two (400DM3) channels. Make

sure that there are no twists or kinks in the

tubing after loading as this will adversely affect

tube life.

Reposition the track over the rotor and fix by

slotting the track pin back into the track slot.

Note: over-tightening the sprung track pin can

damage the tube and the pumphead.

Tube removal

Release the track by disengaging the sprung

track pin.

Remove both tubing bridges from their location

slots and remove the tubing from the pumphead.

3.7 400D1, 400DM2

and 400DM3

pumphead spares

Description Part code

400D1 pumphead 043.001D.D1C

400DM2 pumphead 043.001D.D2C

400DM3 pumphead 043.001D.D3C

Over-tightening the sprung

track pin can damage the tube

and the pumphead.

Page 33

Watson-Marlow 400D1, 400DM2 and 400DM3 pumpheads: operating instructions 5

3.8 400D1, 400DM2

and 400DM3

performance

Tube life and performance against

pressure

The pressure and the suction height can be

increased by compressing the spring in the sprung

track pin. A smaller gap between the rollers and

track will give better performance against pressure

but will reduce tube life.

Other application factors that will influence tube life

in peristaltic pumps are pump speed and number of

rollers (roller impacts/minute), temperature,

chemical compatibility of the duty fluid and viscosity of the duty fluid. Several tubing materials are

available offering different levels of life expectancy.

The tubing’s dimensional tolerances from the

manufacturing process will also influence the life of

a tube.

This means that it is impossible to predict tube life

in any particular application.

In perfect conditions of no suction or discharge

pressure, in a clean environment at normal room

temperature, and pumping water, nominal tube life

may be:

Marprene and Bioprene: less than 6,000 hours

Silicone: less than 250 hours

Others: less than 100 hours

The factors highlighted above will tend to reduce

tube life. For precise and repeatable

performance it is important to determine flow

rates under operating conditions for each new

piece of tubing.

Note: Flow rates quoted have been rounded for

simplicity, but are accurate to within 5%—well

within the normal tubing tolerance variation of flow

rate. They should therefore be taken as a guide.

Real flow rates in any application must be determined empirically.

400D1 Pumpsil (ml/min)

Speed range 0.5mm 0.8mm 1.6mm 2.4mm 3.2mm 4.0mm

120U

0.1-200 rpm

0.001-2.2 0.003-5.8 0.011-23 0.02-49 0.041-81 0.06-120

120S

1-200 rpm

0.01-2.2 0.03-5.8 0.11-23 0.24-49 0.41-81 0.59-120

Note: The 120S and the 120U must be run counterclockwise to achieve pressures up to 2 bar.

Page 34

Watson-Marlow 400D1, 400DM2 and 400DM3 pumpheads: operating instructions 6

400DM2 and 400DM3 Pumpsil (ml/min)

Speed range 0.13mm 0.19mm 0.25mm 0.38mm 0.5mm 0.63mm

120U

0.1-100 rpm

0.0001-0.1 0.0002-0.2 0.0004-0.4 0.0008-0.8 0.001-1.4 0.002-2.2

120S

1-100 rpm

0.001-0.1 0.002-0.2 0.004-0.4 0.008-0.8 0.014-1.4 0.022-2.2

400DM2 and 400DM3 Pumpsil (ml/min)

Speed range 0.76mm 0.88mm 1.02mm 1.14mm 1.29mm 1.42mm

120U

0.1-100 rpm

0.003-3.1 0.004-4.3 0.006-5.5 0.007-7.0 0.009-8.9 0.011-11

120S

1-100 rpm

0.031-3.1 0.043-4.3 0.055-5.5 0.070-7.0 0.089-8.9 0.110-11

400DM2 and 400DM3 Pumpsil (ml/min)

Speed range 1.52mm 1.65mm 1.85mm 2.05mm 2.38mm 2.54mm 2.79mm

120U

0.1-100 rpm

0.012-12 0.014-14 0.018-18 0.021-21 0.026-26 0.031-31 0.036-36

120S

1-100 rpm

0.120-12 0.14-14 0.180-18 0.210-21 0.260-26 0.310-31 0.360-36

Page 35

Watson-Marlow 400D1, 400DM2 and 400DM3 pumpheads: operating instructions 7

3.9 Tubing product codes

400D1 continuous tubing product codes

mm inch # Marprene Bioprene Pumpsil

GORE

STA-PURE PCS

0.5

1

/50 112 902.0005.016 903.0005.016 913.A005.016

0.8

1

/32 13 902.0008.016 903.0008.016 913.A008.016

1.6

1

/16 14 902.0016.016 903.0016.016 913.A016.016 960.0016.016

2.4 902.0024.016 903.0024.016 913.A024.016

3.2

1

/8 16 902.0032.016 903.0032.016 913.A032.016 960.0032.016

4.0 902.0040.016 903.0040.016 913.A040.016

400DM2 and 400DM3 segment tubing product codes

mm inch # Neoprene PVC Fluorel

GORE

STA-PURE PFL

0.8

1

/32 13 920.0008.016

1.6

1

/16 14 920.0016.016 950.0016.016 970.0016.016 965.0016.016

3.2

1

/8 16 920.0032.016 950.0032.016 970.0032.016 965.0032.016

Colour code

wallmmboremmAutoclavable

Marprene

Marprene PVC Silicone

Orange/black 0.8 0.13 981.0013.000

Orange/red 0.8 0.19 981.0019.000

Orange/blue 0.8 0.25 979.0025.00+ 979.0025.000 981.0025.000

Orange/green 0.8 0.38 979.0038.00+ 979.0038.000 981.0038.000

Orange/yellow 0.8 0.50 979.0050.00+ 979.0050.000 981.0050.000

Orange/white 0.8 0.63 979.0063.00+ 979.0063.000 981.0063.000 983.0063.000

Black/black 0.8 0.76 979.0076.00+ 979.0076.000 981.0076.000 983.0076.000

Orange/orange 0.8 0.88 979.0088.00+ 979.0088.000 981.0088.000 983.0088.000

White/white 0.8 1.02 979.0102.00+ 979.0102.000 981.0102.000 983.0102.000

Red/red 0.8 1.14 979.0114.00+ 979.0114.000 981.0114.000 983.0114.000

Grey/grey 0.8 1.29 979.0129.00+ 979.0129.000 981.0129.000 983.0129.000

Yellow/yellow 0.8 1.42 979.0142.00+ 979.0142.000 981.0142.000 983.0142.000

Yellow/blue 0.8 1.52 979.0152.00+ 979.0152.000 981.0152.000 983.0152.000

Blue/blue 0.8 1.65 979.0165.00+ 979.0165.000 981.0165.000 983.0165.000

Green/green 0.8 1.85 979.0185.00+ 979.0185.000 981.0185.000 983.0185.000

Purple/purple 0.8 2.05 979.0205.00+ 979.0205.000 981.0205.000 983.0205.000

Purple/black 0.8 2.29 979.0229.00+ 979.0229.000 981.0229.000 983.0229.000

Purple/orange 0.8 2.54 979.0254.00+ 979.0254.000 981.0254.000 983.0254.000

Purple/white 0.8 2.79 979.0279.00+ 979.0279.000 981.0279.000 983.0279.000

Page 36

Watson-Marlow 400D1, 400DM2 and 400DM3 pumpheads: operating instructions 8

3.10 Trademarks

Watson-Marlow Bioprene, Pumpsil and

Marprene are trademarks of Watson-Marlow

Limited.

Fluorel is a trademark of 3M.

GORE STA-PURE PCS and GORE STA-PURE PFL

are trademarks of W.L.Gore and Associates.

3.11 Do not use

pumps in patientconnected applications

Warning These products are not designed for use

in, and should not be used for patient-connected

applications.

3.12 Publication

history

m-400-gb-01.qxp: Watson-Marlow 400 pumpheads

First published 07.10

Loading...

Loading...