Page 1

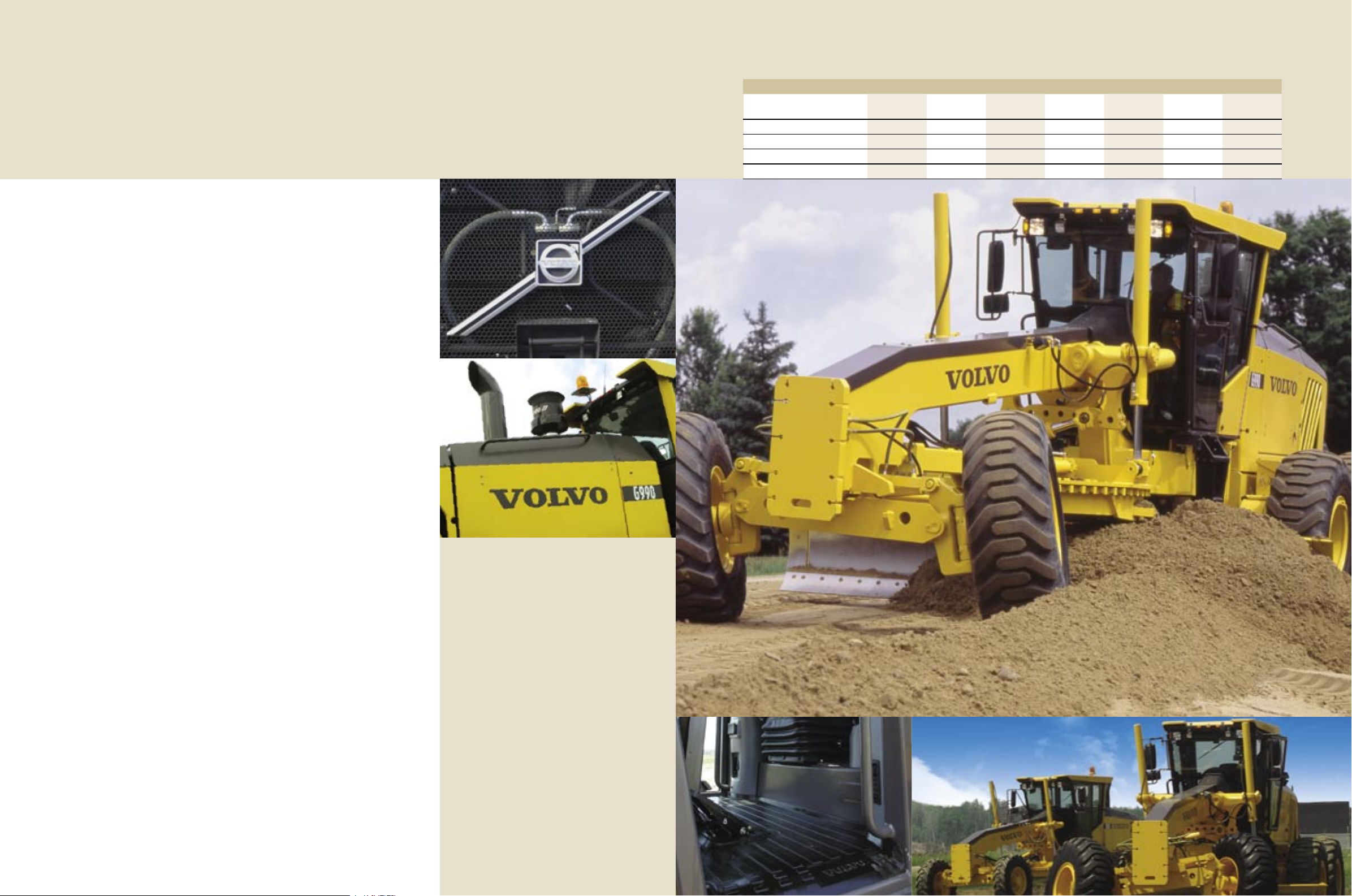

VOLVO MOTOR GRADERS

G970, G976,

G990

Page 2

MORE CARE:

MORE THAN AN IDEA

All the value you expect from Volvo now

comes through in the Volvo D9-powered

G900 Motor Grader family.

Volvo G900 Motor Graders

Model G930 G940 G946 G960 G970 G976 G990

Base operating

weight - approximate

Engine model/displacement D7/7.2 L D7/7.2 L D7/7.2 L D7/7.2 L D9/9.4 L D9/9.4 L D9/9.4 L

Low range net power

Mid range net power hp (kW) 175 (131) 195 (145) 215‡ (160‡) 215 (160) 230 (171) 245‡ (183‡) 245 (183)

High range net power hp (kW) 195 (145) 215 (160) 235‡ (175‡) 235 (175) 250 (186) 265‡ (198‡) 265 (198)

lb

(kg)

hp (kW) 155 (116) 175 (131) 195‡ (145‡) 195 (145) 210 (157) 225‡ (168‡) 225 (168)

34,300

(15 560)

35,200

(15 970)

36,700

(16 645)

36,800

(16 690)

39,000

(17 700)

‡ With All Wheel Drive engaged

40,500

(18 370)

46,300

(21 000)

More care. Built in.

Volvo Construction Equipment makes

this promise to customers everywhere:

every Volvo machine will satisfy your

highest expectations for equipment that’s

productive, operator-friendly, reliable and

easy to service. Now, Volvo introduces

three new motor graders powered by the

renowned D9 Volvo engine, all designed,

built and tested to keep that same

promise in every way.

The Volvo way

The complete family of seven G900

Motor Graders, includes four Volvo

D7- and three Volvo D9-powered

models. These machines deliver on the

brand promise of “More care. Built in.”

through a combination of proven Volvo

technologies and processes:

• bottom-line productivity on the job site

• a safe and comfortable operator

environment

• long lasting reliability

• unmatched ease of serviceability with

low maintenance demands

This Volvo Motor Grader offering includes

three highly efficient and versatile

models, all using the field-proven Volvo

D9 engine. The result is a selection of

graders with outstanding power, torque

and fuel efficiency: the 39,000 lb

(17 700 kg) G970 tandem drive, the

40,500 lb (18 370 kg) G976 All Wheel

Drive (AWD) model and, at 46,300 lb

(21 000 kg), the largest machine in

the Volvo Motor Grader family: the G990

tandem drive.

Quality with confidence

No family of motor graders anywhere

has been subject to more rigorous

testing than Volvo G900 Motor Graders.

By continuing to listen and respond to

customer needs and by investing in new

design innovations, the Volvo continuous

improvement program will lead the G900

family to ongoing quality leadership.

At home in the Volvo fleet

From end-to-end, from the ground up,

G900 Motor Graders are fit and finished

to take their place in your fleet. Design

details and styling provide a familiar work

environment inside and out for owners

and operators of any Volvo machine.

Care for the environment, one of the

Volvo core values, is reflected in the

environmental performance of the G900

Motor Graders. The G900 family meets

EU Stage IIIA and US Tier 3 Emission

Regulations as well as EU noise

standards. Volvo engineering minimizes

whole body vibration to maximize

operator productivity.

For grader operators and owners

everywhere, the G900 Motor Graders

will mean a new standard in grading

performance and productivity.

The Volvo standard.

Behind the scenes

The development of the G900

Motor Graders resulted in more than

a new family of Volvo machines.

It also created a new process for

grader design and support, based

on industry-leading production

methods and refined by the Volvo

commitment to best practices.

From fit and finish to familiar design

detailing, the G900 family will leave

no doubt in the minds of equipment

owners and operators everywhere:

It’s a Volvo!

32

Page 3

BUILT-IN PRODUCTIVITY

G900 Motor Graders put power and precision at

your fingertips, for smooth performance in every job.

Expect more

With the G900 Motor Graders, Volvo

puts the keys to new levels of grader

productivity in your hands.

What you’ll notice first, is the power

Dig into the job and Volvo digs in with

you. Volvo D9 engines are renowned

for high torque at low RPMs, producing

responsive, fuel-efficient performance

under all operating conditions. When

you call for power to muscle through

heavy overburden or to hold and turn

loads smoothly under power, your Volvo

G900 Motor Grader comes through

without hesitation.

Then there’s the touch

Wide stance blade lift cylinders coupled

with the low angle side shift cylinder

provide the most stable grading platform

in the industry. Proportional Demand

Flow (PDF) hydraulics, ideally suited

for Automatic Blade Control systems,

along with heavy-duty inching clutches

and a powerful twin-gear direct-drive

circle turn system result in a precise,

instantly responsive earthmoving tool.

You get more one-pass finishes with

cost-saving accuracy.

4

Gearing up for the bottom line

Volvo HTE transmissions, including

standard 8-speed and optional 11-speed

models, translate engine output into

intelligent power for faster, simpler duty

cycles. With selectable Manual, optional

Autoshift and Travel modes, Volvo Motor

Graders offer power and speed the way

you want it, when you want it.

With the Volvo Autoshift mode, you just

select your gear and go. Your Volvo HTE

transmission does the rest to get you up

to speed in your working gear ranges

quickly, economically and smoothly.

The innovative shuttle shift feature

standard on all transmissions ensures

the industry’s quickest, simplest duty

cycles ever. Shuttle between selected

forward and reverse gears in a single

smooth motion without clutching, without

pausing, for easy effortless control and,

best of all, less fatigue at the end of a

long day.

HTE1160: the first 11-speed

grader transmission

With 11 forward speeds and

6 reverse, the optional HTE1160

from Volvo expands the gear range

of the grader to offer more control

in the low-speed range, more

efficient travel speed in the high

range, more precision in the working

range and exceptional fuel efficiency

for every task. The HTE1160 comes

standard with Volvo Autoshift,

combining maximum control with

ultimate simplicity of operation.

Page 4

EVERY DAY BEGINS WITH

SAFETY FIRST

To make your work environment more productive,

Volvo starts by making it safe and comfortable.

A healthy workplace

Open the cab door to your Volvo Motor

Grader – with automatic illumination set

for the steps and handholds, you step up

to the industry’s easiest entry and exit.

A sloped rear wall provides extra headroom and more side window visibility. A

constant flow of fresh double-filtered air

fills the cab from 10 well-placed outlets.

Inflows of outside air can be adjusted for

maximum cab pressurization or increased

re-circulation for fast warm-ups or cool

downs. High capacity air conditioning

and heating systems keep temperatures

comfortable in any weather. Windows to

the front and sides open wide for natural

ventilation. Spend the day in peace and

quiet with extensive noise and vibration

suppression designed into the cab and

the quiet-running Volvo engine behind.

What you see

Expansive glass areas provide

exceptional floor-to-roof visibility through

the front of the grader, down to the

moldboard and close in to the sides.

The rear view is equally clear with

sculpted side posts opening the line of

sight over the shoulder, complemented

by a unique arrangement of interior and

exterior mirrors. From the operator seat,

all essential operational controls and

displays are directly front and center on

the pedestal. Environmental and service

controls are also packaged together

conveniently in the right-hand console.

What you get

A wide range of comfort amenities

and ergonomic design features make

G900 Motor Graders a great place to

spend the working day. Long hours get

easier with the low-effort levers, loweffort pedals, all controls within easy

reach and a clear view to all displays.

The spacious cab quickly adjusts to the

individual preferences. Designed with

extensive operator input to ensure a

highly functional interior layout and lines

of sight, you’ll find all G900 controls and

displays located right where you need

and expect them.

The comforts of home:

Standard:

• Contronics Monitoring System

• 50,000 BTU heater with 10 outlets

• Two high capacity air filters

• Interior lights

• Illuminated entry

• Non-skid steps

• Cup holder

• Coat hook

• Ashtray

• Storage compartments

Optional:

• 30,000 BTU air conditioner

• Wide-angle wiper pattern (for low profile cab)

• Air suspension seat

• Opening side windows

• Opening lower front windows

• Lunch box and thermos

• Radio/CD player

...and much more!

6

Page 5

ASSURED QUALITY

LIFELONG RELIABILITY

Volvo Motor Graders set the standard

worldwide for performance you can bank on

every day, for every job.

Volvo D9 engine

Real world flexibility

G900 Motor Graders are purposebuilt with a true tool-carrier frame

designed to withstand the rigors of

all-season service.

The full perimeter rear frame

provides effective support for

rear and side attachments while it

protects powertrain components

from the severe load stresses of

ripping, scarifying, plowing, pushing

and snow-clearing.

With attachments built and approved

by Volvo, G900 Motor Graders

adapt to year-round duties without

compromising design integrity.

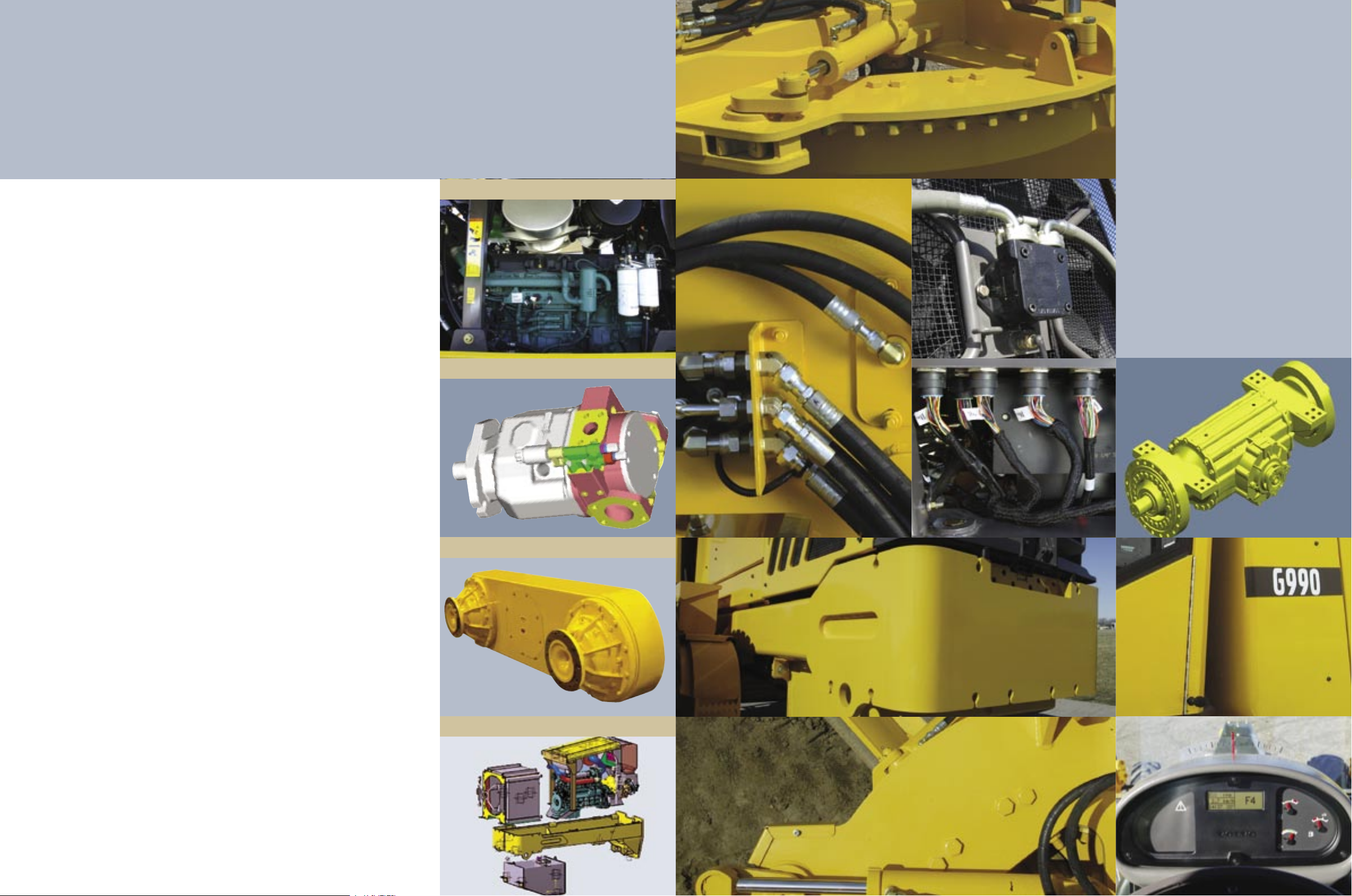

All in the family

Built on a solid foundation of fieldproven Volvo components including the

D9 engine, Volvo transmissions, the

Contronics monitoring system and many

service items, G900 Motor Graders have

been engineered with years of reliable

service already built in.

Keep on rolling

Trust Volvo G900 Motor Graders for a

long life of hard work.

The modular Volvo assembly process

and precise welding technology

ensure uniform end-to-end strength

in all structural components for lasting

durability. Exclusive DURAMIDE

support bearings prevent metal-tometal contact to keep critical tolerances

tight and the circle turning smoothly.

Innovative design of the articulation

joint achieves a robust assembly that

simplifies and protects the routing for

hydraulic lines.

Volvo APR planetary reduction axles

with operator-controlled hydraulic

clutch differential lock deliver power to

the ground efficiently while ensuring

dependable long-life service. In every

detail, G900 Motor Graders reflect the

Volvo commitment to lasting value.

TM

circle

Day after day

At Volvo, the details make the difference

in day-to-day reliability: extra-strength

four-wire hydraulic hoses; sealed

electrical connectors; fuse panel

connections kept clean and dry inside

the cab; premium hydraulic couplings

along with smart routing of wiring and

hoses to resist wear and abrasion.

Through every minute of operation,

Volvo Contronics provides a three-level

warning system on all vital functions

for continuous monitoring including an

engine protection feature as standard.

Year after year

Built for work in the real world and

offering superb customer protection, the

G900 frame is available with an optional

first user lifetime warranty. This industry

exclusive warranty also includes the

maintenance-free articulation pins and

bearings for continuous peace of mind.

Ask for G900 warranty documentation.

See the details!

Axial piston pump

Tandem and final drive

Modular component design

8

Page 6

LESS WORK

MORE PRODUCTION

The Volvo approach to servicing lets you spend

more time working on the job, less time working

on the machine.

Ease of service,

low maintenance demands

G900 Motor Graders carry on the Volvo

approach to maximum uptime: minimize

the machine’s need for service, then

simplify the service tasks it does require.

Start every day easy. Sensible Volvo

service design starts with fueling and all

engine service points accessible from

ground-level, with minimal grease points

and no daily greasing required. Sight

glasses and level sensors make daily

checks virtually effortless.

Open for business

With an Easy Lift rear hood, gull-wing

side panels and removable hydraulic tank

cover, G900 Motor Graders are unrivaled

for easy routine service. The complete

rear cowling opens wide to allow quick,

thorough service checks, then back to

work quickly.

Keep it simple, smart

With their modular powertrain design

concept, G900 Motor Graders simplify

maintenance on major components and

allow new levels of flexibility for optimal

service scheduling.

The hydraulic system is designed for fast

manual or pressure fills through the top

of the tank. All added fluids must pass

through a large, full flow return filter to

prevent accidental contamination in the

reservoir that could lead to down time.

Hoses are routed over the surface of the

frame for simple inspections.

The Volvo cooling module eliminates

stacked cores. Instead, multiple cooling

cores are positioned to receive fresh,

cool ambient air continuously.

A thermostatically controlled, hydraulically

driven fan maximizes available power

and fuel savings. An auto-reversing

cooling fan option allows continuous

self-cleaning to further improve cooling

performance and reduce service needs.

Everything you want to know

The G900 electronic monitoring

system provides a familiar window to

the standard Volvo Contronics system,

providing a complete record of grader

functions to help operators, owners and

service technicians achieve optimum

machine performance.

V-ACT

The new generation of D9 engines

with Volvo Advanced Combustion

Technology (V-ACT) is tailored for

grader applications, designed to run

cleanly and efficiently without the

extra service requirements

of additional equipment or

after-treatment of exhaust gases.

10

Page 7

ALL-PURPOSE ALL WHEEL DRIVE

Discover more ways to get more production:

the G976 All Wheel Drive Motor Grader.

The drive to succeed

When you’re looking for excellence

in every grader task, Volvo All Wheel

Drive is the grader that gets you there.

Having a Volvo AWD is like having three

drive systems in one: a highly efficient

4-wheel tandem drive, a powerful

6-wheel drive plus the exclusive frontwheel Creep Mode for exceptional

fine-grading control.

When the going gets tough

Volvo All Wheel Drive can deliver up to

8,500 lb (3 855 kg) of additional rim

pull at the front wheels for increased

blade loads. With 16 selectable levels

of aggression, operators can match

traction to any operating conditions,

from highways to haul roads. Now with

advanced inching capability, Volvo AWD

performance raises the bar industry-wide

for starting with high blade loads from a

full stop.

Reaching a top speed up to 23.0 mph

(36,8 km/h) with the optional* HTE1160

transmission in AWD mode, the G976

is today’s top-of-the-line for optimum

snow-clearing operations or any high

speed AWD application.

* 19.6 mph (31,4 km/h) with standard

HTE840 transmission

When fine-grading deadlines are tight,

G976 Creep Mode gets you to the finish

line first with ultimate precision and

effortless control.

Biggest is best

The G976 Motor Grader stands out

as the largest AWD machine in its class.

With a base weight of 40,500 lb

(18 370 kg) and its Volvo D9 engine

generating up to 265 hp (198 kW),

the G976 gives you the most of what

you’re looking for to get maximum

AWD performance.

A firm footing for AWD

The Volvo AWD system is built around

two variable displacement axial piston

pumps feeding direct drive wheel motors:

no planetary gear reductions, no clutch

packs. Displacement is controlled in

response to the aggression switch setting

for precise wheel power control. The

system requires no flow divider valve,

providing efficient transmission of power

from the pumps to the motors with

minimal pressure drops. Hydraulic hoses

for the front wheel drive are positioned

safely out of harm’s way. AWD monitoring

is integrated with the Contronics system,

ensuring extensive safeguards for lasting

reliability.

Ultimate precision

Operating at speeds under 2.5 mph

(4,0 km/h), the exclusive Volvo

Creep Mode allows the operator

to grade using only the hydrostatic

front-wheel drive; the rear tandems

roll freely behind to minimize

scuffing and rework.

Creep Mode is easily selected

via the transmission controller.

Ground speed is controlled simply

by pressing the accelerator pedal.

Creep Mode allows extremely

smooth starts and stops, eliminating

ridges often left by the moldboard in

a conventional grader. The result is

more precise passes in less time

to complete the job.

12 13

Page 8

G900 MOTOR GRADERS

FROM THE GROUND UP

“The Voice of the Customer” is evident in every

element of the G900 design, from the manufacturing

process that builds it to the styling details that say

“It’s a Volvo”.

14

11

1

4

2

5

13

6

12

15

17

6

6

7

9

10

16

8

1

Productivity

The complete structural design of G900

Motor Graders is balanced to focus their

weight and power for optimum blade

down force and drawbar pull values.

Heavy-duty front axle

2

Purpose-built axle with high center

ground clearance; a minimum of

components ensures long life with

minimum maintenance; achieves sharp

steering angle for tight turning radius.

3

AWD

G976 models are equipped with three

easy-to-use operating modes: efficient

standard tandem drive, rugged All Wheel

Drive or Volvo exclusive Creep Mode for

the industry’s best fine-grading control.

4

Frame

Rugged front and rear frames, designed

for quick installation of a full range

of attachments.

5

Blade Lift System

Twin-gear direct-drive circle turn system

provides maximum strength to either

hold or to turn the moldboard smoothly

while moving under full load; wide-stance

blade lift cylinders provide fine grading

stability with the full range of mobility for

any application.

6

Service access

Easy Lift rear hood opens wide for easy

cleaning access to the radiator; cover

panels for the engine, hydraulic centre

and battery pack all open up fully for

ease of service; ground-level access to

all engine service points.

7

Volvo engine

Volvo D9 Tier 3/Stage IIIA engine

with V-ACT technology matched to the

powertrain with three power levels as

standard for optimum performance and

fuel efficiency.

8

Planetary rear axle with clutched

differential lock

Volvo APR90 axles with planetary

reduction final drives reduce loading on

tandem chains for maximum service life;

purpose-built differential with hydraulic

clutch lockup ensures maximum tractive

effort at the flick of a switch.

High capacity cooling system

9

Hydraulically driven, variable-speed

fan draws power only when needed;

optional auto-reversing feature reduces

maintenance, improves efficiency.

10

Serviceability

No daily greasing or weekly servicing is

required; optional 500-hour engine oil

change interval. Tandem and final drive

sight glasses make level checks fast

and easy. Large capacity hydraulic filter

extends change intervals and prevents

re-fill contamination as all top-up oils

must pass through the filter prior to

entering the hydraulic tank.

11

Contronics

Contronics display provides detailed

system status to the operator in real

time: records up to 25 points of interest

for service analysis through the exclusive

Matris system from Volvo.

12

Volvo transmission

The full power shift HTE840 and

optional HTE1160 transmissions were

developed expressly for motor graders.

Manual, optional Autoshift and Travel

modes optimize performance and fuel

economy. Standard shuttle shift feature

enables smooth shifting between forward

and reverse gears without using the

inching pedal.

3

13

Autoshift

Just select a target gear in the working

range and the transmission shifts

automatically through turns and grades,

as needed. Optional for HTE840

transmission, standard with HTE1160.

14

Operator-friendly cab

ROPS/FOPS enclosed operator

compartment lives up to every

expectation for a Volvo cab with

industry-leading comfort, safety and

efficiency. Ergonomic design includes

low-effort, short-throw levers; adjustable

pedestal with all most frequently used

operating controls centered in front

of the operator; unobstructed

wide-angle views to reduce operator

fatigue, increase productivity and

maximize safety.

15

Rear-view visibility

Interior and exterior mirrors combine for

a clear wide-angle view to the sides and

rear of the grader. Rear cab posts are

positioned to optimize operator visibility.

16

Fast refueling

Two-stage pop-up rear hood allows

quick, convenient access for ground level

refueling; lockable panels provide added

security on the job site or in the yard.

17

PDF Hydraulics

Proportional Demand Flow (PDF) is an

intelligent closed center, load-sensing

hydraulic system that delivers the exact

amount of hydraulic oil flow when and

where it is needed; variable displacement

axial piston pump provides excellent

multi-function control while conserving

fuel; minimal connections for high

reliability and low service requirements.

Go big with G990

The G990 Motor Grader is the

largest model in the Volvo family,

offering extra size and power.

These key features translate into

maximum strength and control for

your toughest jobs.

The G990 combines power with a

wide range of special features to

make light work of mining, forestry

and haul road projects, highway

construction and heavy-duty

snow-clearing plus the most

demanding fine-grade applications.

• Larger tires standard

• Taller moldboard standard

• Heavy duty circle support system

with DURAMIDE

• Extra length in front frame

• Long bladebase for more cutting

capability

• High blade pull

• Three engine power curves

TM

14 15

Page 9

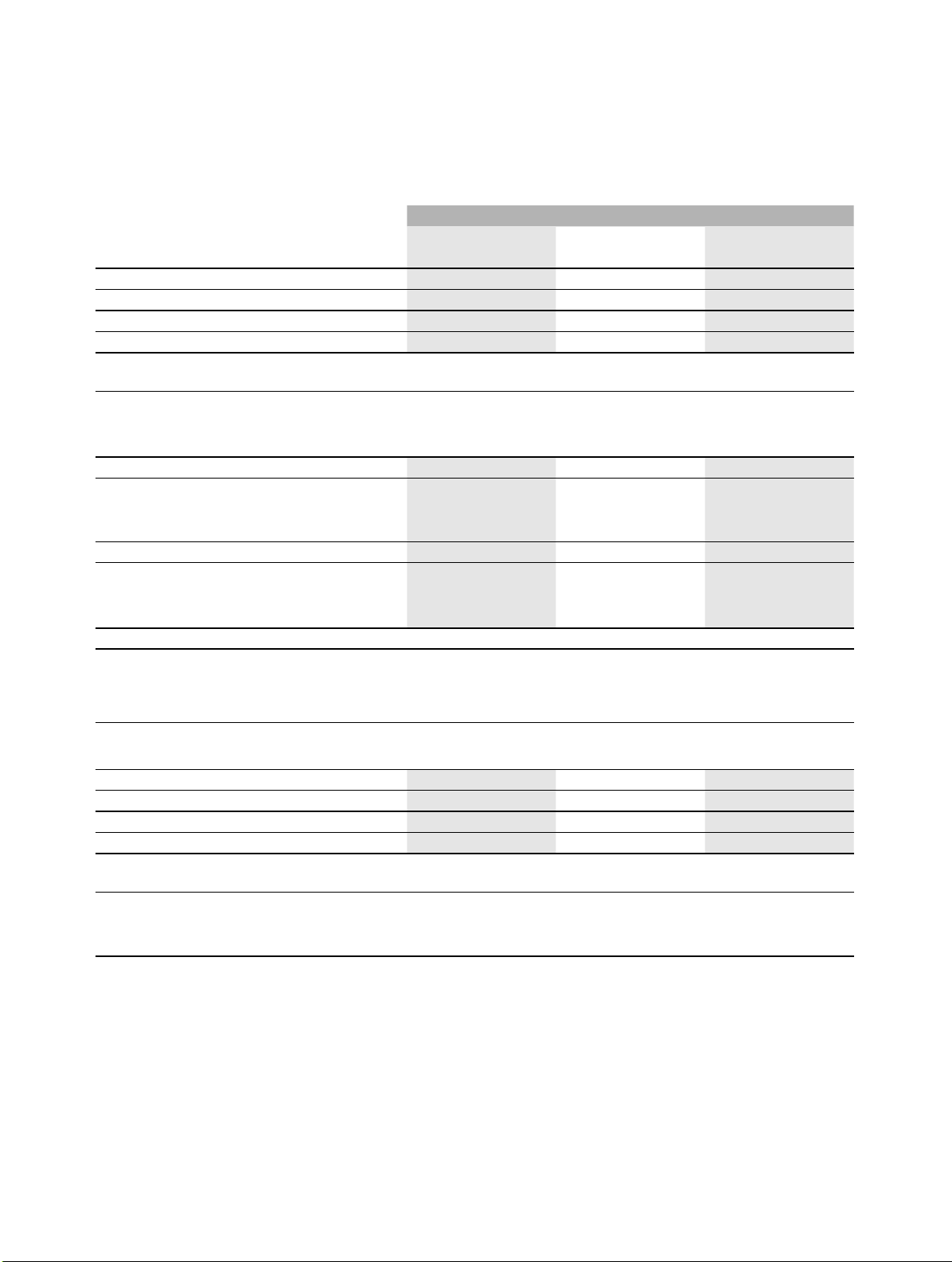

SPECIFICATIONS

High Range

Mid Range

Low Range

Engine Power

Engine Torque

G970 G976 G990

Base operating weight - approximate

Weights shown include full cab with ROPS, all operating

fluids, operator and standard equipment.

Base - Total

On front wheels lb (kg) 12,300 (5 580) 12,750 (5 785) 14,350 (6 500)

On rear wheels lb (kg) 26,700 (12 120) 27,750 (12 585) 31,950 (14 500)

Maximum combined capacity lb (kg) 50,000 (22 680) 51,500 (23 360) 60,000 (27 216)

Maximum weight - front lb (kg) 18,500 (8 391) 18,500 (8 391) 18,500 (8 391)

Maximum weight - rear lb (kg) 34,100 (15 468) 35,000 (15 876) 42,000 (19 051)

Note that adding weight and attachments to the base grader may necessitate a tire upgrade as maximum weight capacity of tire may be exceeded.

Productivity (Standard equipment)

Blade pull at base weight

(0.9 traction co-efficient)

Blade pull at maximum base weight

(0.9 traction co-efficient)

Blade down force capability lb (kg) 21,074 (9 558) 21,845 (9 909) 25,160 (11 395)

Blade down force is the maximum downward force which may be applied at the cutting edge.

Engine data

Model Volvo D9 Volvo D9 Volvo D9

Type Turbocharged,

No. of cylinders In Line 6 In Line 6 In Line 6

Bore & stroke in

Displacement cu in (l) 573 (9,4) 573 (9,4) 573 (9,4)

Engine complies to EPA Tier 3, EU Stage IIIA exhaust emission standards.

Electrical system 24 volt - 80 amp

Batteries (two 12 volt) SAE J537 @ 0º F (-18º C) 950 Cold

1300 CCA batteries available optionally

lb (kg) 39,000 (17 700) 40,500 (18 370) 46,300 (21 000)

lb (kg) 24,030 (10 908) 33,475 (15 183) 28,755 (13 050)

lb (kg) 30,690 (13 921) 40,000 (18 144) 37,800 (17 146)

(mm)

Aftercooled

4.76 x 5.51

(120 x 138)

(1920 watt) alternator

cranking amps

Turbocharged,

Aftercooled

4.76 x 5.51

(120 x 138)

24 volt - 80 amp

(1920 watt) alternator

950 Cold

cranking amps

Turbocharged,

Aftercooled

4.76 x 5.51

(120 x 138)

24 volt - 80 amp

(1920 watt) alternator

950 Cold

cranking amps

Engine performance curve

Legend

High Range

Mid Range

Low Range

Engine Power

Engine Torque

16

G970/G976*

*G976 AWD off

Net Torque (Nm) Net Power (kW)

Engine Speed (rpm)

Net Power (hp) Net Torque (lb.ft)

G976‡/G990

‡

G976 AWD on

Net Torque (Nm) Net Power (kW)

Net Power (hp) Net Torque (lb.ft)

Engine Speed (rpm)

Page 10

G970 G976 AWD on G990

3 Range engine power control

G976 AWD off

Low range power

§

Rated net brake horsepower @ 2100 RPM

Torque @1200 RPM

hp (kW) 210 (157) 225 (168) 225 (168)

lb.ft (N.m) 857 (1 162) 910 (1 234) 910 (1 234)

Mid range power

Rated net brake horsepower @ 2100 RPM

Torque @1400 RPM

§

hp (kW) 230 (171) 245 (183) 245 (183)

lb.ft (N.m) 860 (1 165) 913 (1 237) 913 (1 237)

High range power

Rated net brake horsepower @ 2100 RPM

Torque @1550 RPM

§

hp (kW) 250 (186) 265 (198) 265 (198)

lb.ft (N.m) 876 (1 188) 929 (1 260) 929 (1 260)

No engine derating required up to 9,800 ft (3 000 m) altitude. Rated net horsepower SAE J1349/ISO 9249.

§

Rating is @ 2100 RPM except for EU which is rated @ 1900 RPM in low and mid ranges.

Transmission

Fully sequential, direct drive, Volvo powershift transmission. Engine cannot be started if transmission is in gear. Single lever electronic transmission controller

provides self-diagnostics and overspeed protection. Optional HTE1160 has automatic shifting and travel mode as standard equipment.

Ground speeds at 2100 RPM with 14:00 tires. G990 ground speeds with 16:00 tires.

G970 G976 G990

Transmission model

HTE840 HTE1160 HTE840 HTE1160 HTE840 HTE1160

Gear

F1 mph (km/h) 2.6 (4,1) 2.0 (3,2) 2.6 (4,1) 2.0 (3,2) 2.6 (4,2) 2.1 (3,3)

F2 mph (km/h) 3.6 (5,8) 2.6 (4,2) 3.6 (5,8) 2.6 (4,2) 3.7 (5,9) 2.7 (4,3)

F3 mph (km/h) 5.1 (8,1) 3.5 (5,6) 5.1 (8,1) 3.5 (5,6) 5.2 (8,3) 3.6 (5,7)

F4 mph (km/h) 7.1 (11,3) 4.5 (7,2) 7.1 (11,3) 4.5 (7,2) 7.2 (11,6) 4.6 (7,4)

F5 mph (km/h) 10.0 (16,0) 6.0 (9,5) 10.0 (16,0) 6.0 (9,5) 10.3 (16,4) 6.1 (9,7)

F6 mph (km/h) 14.0 (22,4) 7.7 (12,3) 14.0 (22,4) 7.7 (12,3) 14.3 (22,9) 7.8 (12,6)

F7 mph (km/h) 19.6 (31,4) 10.2 (16,2) 19.6 (31,4) 10.2 (16,2) 20.1 (32,2) 10.4 (16,6)

F8 mph (km/h) 27.4 (43,8) 13.5 (21,6) 27.4 (43,8) 13.5 (21,6) 28.1 (44,9) 13.9 (22,2)

F9 mph (km/h) 17.5 (28,1) 17.5 (28,1) 18.0 (28,7)

F10 mph (km/h) 23.0 (36,8) 23.0 (36,8) 23.5 (37,7)

F11 mph (km/h) 29.8 (47,6) 29.8 (47,6) 30.5 (48,8)

R1 mph (km/h) 2.5 (4,1) 2.0 (3,2) 2.5 (4,1) 2.0 (3,2) 2.6 (4,2) 2.0 (3,2)

R2 mph (km/h) 5.0 (7,9) 3.4 (5,5) 5.0 (7,9) 3.4 (5,5) 5.1 (8,1) 3.5 (5,6)

R3 mph (km/h) 9.9 (15,8) 5.8 (9,3) 9.9 (15,8) 5.8 (9,3) 10.1 (16,1) 6.0 (9,5)

R4 mph (km/h) 19.3 (30,1) 7.7 (12,3) 19.3 (30,1) 7.7 (12,3) 19.8 (31,6) 7.9 (12,6)

R5 mph (km/h) 13.3 (21,3) 13.3 (21,3) 13.6 (21,8)

R6 mph (km/h) 22.6 (36,2) 22.6 (36,2) 23.2 (37,1)

Transmission Gear

Engine Power Range Volvo HTE840 Volvo HTE1160

Low

F1, F2 R1 F1, F2, F3 R1, R2

Mid F3, F4, F5 R2, R3 F4, F5, F6, F7 R3, R4

High F6, F7, F8 R4 F8, F9, F10, F11 R5, R6

17

Page 11

G970 G976 G990

Tandems

Depth in (mm)

Height in (mm)

Thickness

inner wall in (mm)

outer wall in (mm) .78 (20) .78 (20) .78 (20)

Center distance in (mm)

Drive chain pitch

Oscillation degrees ±

Differential / Final drive

Model

Planetary final reduction with an operator controlled lock/unlock differential.

Wheels & tires (Standard equipment)

Tire size

Ply rating (PR)

Rim size in (mm) 10 (254)

Bolt-on rims interchangeable between front and rear Yes

Front axle and articulation

Wheel lean degrees R & L

Oscillation degrees up & down

Ground clearance in (mm)

Minimum turning radius using front axle steering,

articulation, wheel lean and unlocked differential

Steering arc degrees

Frame articulation angle

Anti-drift lock valve ensures stable operation. Articulation lock standard.

Hydrostatic power steering of front wheels incorporating two steering cylinders. Meets SAE J1511 FEB. 94, ISO 5010:1992 with optional secondary steering.

in (mm)

in (mm)

degrees

8.9 (226,5) 8.9 (226,5) 8.9 (226,5)

24.25 (616) 24.25 (616) 24.25 (616)

1 (25) 1 (25) 1 (25)

61 (1 550) 61 (1 550) 66 (1 675)

2 (51) 2 (51) 2 (51)

15º 15º 15º

Volvo APR90 Volvo APR90 Volvo APR90

14:00 x 24, G-2 14:00 x 24, G-2 16:00 x 24, G-2

12 12 12

10 (254)

One piece rim

18º 18º 18º

16º 16º 16º

22 (551) 22 (551) 23.5 (596)

312 (7 925) 312 (7 925) 321 (8 150)

50º 50º 50º

21º 21º 21º

Three piece rim

No Yes

10 (254)

One piece rim

Brakes

Service Brakes: Foot operated

Fade resistant, hydraulically actuated, wet multiple disc service brakes located at the 4 tandem drive wheels are fully sealed and maintenance free.

System features crossover dual braking circuits for uniform braking on both sides of the grader. Includes reserve power assist and operator warning system

(visual and audible).

Parking Brake

Spring applied hydraulically released enclosed wet multiple disc type parking brake in final drive. Effective on all 4 tandem drive wheels.

Transmission cannot be engaged with park brake on.

Braking systems comply to SAE J/EN ISO 3450:1996.

Volvo uses asbestos free brake components.

18

Page 12

G970 G976 G990

Frame

Front

Minimum dimensions of box section

Plate thickness

Vertical section modulus at arch cu in (cm3) 163 (2 671) 163 (2 671) 185 (3 032)

minimum cu in (cm3) 137.7 (2 256) 137.7 (2 256) 157.9 (2 588)

maximum cu in (cm3) 283.9 (4 652) 283.9 (4 652) 324.3 (5 626)

Rear

Minimum dimensions in

Optional first user lifetime warranty on frame and articulation joint.

Moldboard

Standard moldboard with replaceable end bits

Moldboard material

Edge: through hardened in (mm) 6 x 5/8 (152 x 16)

Bolt spacing in (mm) 6 (152) 6 (152) 6 (152)

Bolt size in (mm) 5/8 (16) 5/8 (16) 3/4 (19)

Slide rails supported by DURAMIDE™ bearings Yes Yes

Slide rails supported with adjustable metallic bearings Yes

in

(mm)

in (mm) 1 & 1.2 (25 & 30) 1 & 1.2 (25 & 30) 1.2 & 1.6 (30 & 40)

(mm)

in

(mm)

10.5 x 13.4

(267 x 340)

11 x 4

(280 x 102)

1.0 x 29 x 144

(25 x 737 x 3 658)

SAE 1050

high carbon steel

boron steel

10.5 x 13.4

(267 x 340)

11 x 4

(280 x 102)

1.0 x 29 x 144

(25 x 737 x 3 658)

SAE 1050

high carbon steel

6 x 5/8 (152 x 16)

boron steel

10.5 x 13.4

(267 x 340)

11 x 4

(280 x 102)

1.0 x 31 x 168

(25 x 787 x 4 267)

SAE 1050

high carbon steel

8 x 1 (203 x 25)

boron steel

Moldboard range: Moveable Blade Control System

(Dimensions shown with standard tires and moldboard)

Reach outside tires - articulated frame

Reach outside tires - straight frame in

Moldboard slide

Circle side shift in

Maximum bank sloping angle, left - right degrees 90º 90º 90º

Moldboard ground clearance

Moldboard cutting depth in (mm) 31 (787) 31 (787) 32 (813)

Moldboard tilt range degrees forward

degrees back

Superior moldboard mobility permits steep ditch cutting angles and back sloping outside overall machine width.

in

(mm)

(mm)

in

(mm)

(mm)

in (mm) 17.5 (445) 17.5 (445) 17 (432)

Left/Right Left/Right Left/Right

118/117.5

(2 997/2 985)

77.5/77

(1 969/1 956)

26.5/26.5

(673/673)

30.5/29.5

(775/749)

44º

6.5º

118/117.5

(2 997/2 985)

77.5/77

(1 969/1 956)

26.5/26.5

(673/673)

30.5/29.5

(775/749)

44º

6.5º

121.5/121

(3 086/3 073)

89/88.5

(2 261/2 248)

26.5/26.5

(673/673)

30/29.5

(762/749)

46º

13º

19

Page 13

G970 G976 G990

Circle

Pitch diameter

Thickness in (mm) 1.25 (32) 1.25 (32) 2.0 (51)

Adjustable guide shoes - standard / optional 3 / 5 3 / 5 5 / -

Adjustable clamp plates - standard / optional 3 / 5 3 / 5 5 / -

Upper circle wear plates - standard / optional 3 / 5 3 / 5 5 / -

Circle to drawbar support is provided by DURAMIDE™ wear plates and bearings at the clamp and guide shoes. DURAMI DE™ prevents metal-to-metal contact

and provides maximum service life.

in (mm)

64 (1 626) 64 (1 626) 64 (1 626)

Circle drive

The Volvo dual gear Circle Drive System uses direct acting hydraulic power for exceptional turning and holding capability under full load. Circle Drive System uses

two hardened drive pinions and is protected against impact damage by an overload relief valve as standard equipment.

Rotation degrees 360º 360º 360º

Drawbar

Dimensions of box section

Plate thickness in (mm) 1 & .75 (25 & 19) 1 & .75 (25 & 19) 1.5 & .75 (38 & 19)

Cab & controls

Low profile cab with ROPS/FOPS

Interior height in (mm) 64 (1 625) 64 (1 625) 64 (1 625)

An optional full height cab is available with an inside height of 72.5” (1 842 mm).

All Volvo Grader cabs and canopies are designed to meet or exceed SAE J/ISO 3471-1:2004 and EN 13510:2000 ROPS requirements and SAE J/pr EN ISO

3449:2002 Level 2 FOPS requirements.

The retractable seatbelt is 3” (76 mm) wide and meets SAE J386 NOV. 97 and EN ISO 6683:1999. Industry standardized control lever arrangement.

Interior operator noise levels average 75 dB(A) per ISO 6394:1998 (enclosed cab).

Implement hydraulics

Circuit type: Closed center, load sense Proportional Demand Flow (PDF) Hydraulic System, with O-ring face seal hose connections.

Main implement pump type Axial piston type Axial piston type Axial piston type

Maximum pressure psi (Bar) 3,000 (207) 3,000 (207) 3,000 (207)

Output 2100 RPM

Stand by pressure psi (Bar) 350 (24) 350 (24) 350 (24)

Filtration

Large capacity, replaceable in-tank filter. Filters both system and re-fill oil. With low level and high temperature operator warning.

in

(mm)

gpm (lpm) 55 (208) 55 (208) 55 (208)

6.5 x 6.5

(165 x 165)

6.5 x 6.5

(165 x 165)

6.5 x 6.5

(165 x 165)

Hydraulic fan drive pump

Type

Axial piston pump dedicated to the variable speed cooling fan. Reversible cooling fan optionally available.

20

Page 14

G970 G976 G990

Capacities

Fuel tank

Transmission

Final drive U.S. Gal. (l) 6 (23) 6 (23) 6 (23)

Tandems (each)

Hydraulic oil tank U.S. Gal. (l) 28 (106) 42 (159) 28 (106)

Coolant antifreeze protection to

-58º F (-50º C) approx

Engine oil U.S. Gal. (l) 10 (39,1) 10 (39,1) 10 (39,1)

Attachments

(Optional unless otherwise stated as standard equipment)

Push Block

Ripper includes rear frame arch support and links

Mid Mount Scarifier

Front Mount Scarifier

Dozer: 9’ (2,7 m) lb (kg) 2,360 (1 070) 2,360 (1 070) 2,360 (1 070)

10’ (3,0 m) lb (kg) 2,415 (1 095) 2,415 (1 095) 2,415 (1 095)

All Wheel Drive

Typical operating pressure

Maximum operating pressure psi (Bar) 5,000 (345)

Minimum operating pressure psi (Bar) 500 (34)

Top speed

Creep Mode speed mph (km/h) 0 - 2.5 (0 - 4)

Maximum rim pull lb (kg) 8,500 (3 855)

When equipped with the HTE840 transmission, the Volvo high torque All Wheel Drive System operates in forward gears 1-7 and reverse gears 1-4.

When equipped with the HTE1160 transmission, the Volvo high torque All Wheel Drive System operates in forward gears 1-10 and reverse gears 1-6.

In addition, the Volvo system provides the operator with the ability to fine grade in Creep Mode using only hydrostatic front wheel drive, between

0 - 2.5 mph (0 - 4 km/h).

U.S. Gal. (l) 125 (473) 125 (473) 125 (473)

U.S. Gal. (l) 15.9 (60) 15.9 (60) 15.9 (60)

U.S. Gal. (l) 26.4 (100) 26.4 (100) 27.7 (105)

U.S. Gal. (l) 12.4 (47) 12.4 (47) 12.4 (47)

lb (kg) 1,050 (475) 1,050 (475) 1,050 (475)

lb (kg) 3,200 (1 450) 3,200 (1 450) 3,200 (1 450)

lb (kg) 1,900 (850)

lb (kg) 1,552 (704) 1,552 (704)

psi (Bar)

mph (km/h) 20.4 (33)

2,500 (172)

Dimensions

All dimensions are approximate. A

F

D

E

in (mm) 377 (9 578) 377 (9 578) 386 (9 800)

B in (mm) 107 (2 718) 107 (2 718) 113 (2 870)

in (mm) 257 (6 531) 257 (6 531) 263 (6 681)

C

D in (mm) 88 (2 239) 88 (2 239) 92 (2 340)

in (mm) 104 (2 657) 104 (2 657) 111 (2 809)

E

in (mm) 127 (3 220) 127 (3 220) 129 (3 260)

F

Legend

A = Overall length

B = Bladebase

C = Wheelbase

D = Width - Tire center lines

A

C

B

E = Width - Outside tires

F = Overall height

with Low Profile Cab

21

Page 15

STANDARD FEATURES / OPTIONAL EQUIPMENT

Model (S - Standard / O - Optional) G930 G940 G946 G960 G970 G976 G990

Powertrain

Volvo engines meets off-road Tier 3 / Stage IIIA emission criteria - 3 power curves

Rear axle, operator controlled, lock/unlock differential with planetary final reduction

4 wheel wet disc braking system with crossover dual circuits and reserve power assist S S S S S S S

Spring applied wet multiple disc park brake with operator warning alarm and indicator S S S S S S S

Electronic hand throttle with RPM hold and resume functions

Operator controlled Power/Speed engine mode

Direct drive, power shift Volvo HTE840 transmission with 8 forward and 4 reverse gears

Transmission guard

Single transmission control lever, with electronic over speed protection, advanced memory

shift and park position lockout

Transmission Autoshift and Travel functions

Direct Forward to Reverse shuttle shift capability without using the Inching pedal

Volvo HTE1160 Transmission - 11 speeds forward 6 speeds reverse includes

Autoshift and travel functions

Reversible cooling fan - manual or automatic modes

Engine protection feature - return to idle

Electrical

Cab mounted headlights with dimmer switch

Lights; backup, tail, stop and directional

Backup alarm with automatic volume levels

Moldboards work lights - 2 or 4

Rear work lights - 2 or 4

Corner cab work lights - left or right - 2 O O O O O O O

Maintenance free batteries S S S S S S S

100 amp (2400 watt) alternator O O O O O O O

24 volt to 12 volt converter - 25 or 60 amp (600 or 1440 watt) O O O O O O O

Productivity

7 position Blade Control System for optimum blade mobility

Twin gear direct drive circle turn system with impact protection

DURAMIDE™ wear strips prevent metal-to-metal contact for maximum service life

Heavy duty circle support system

Hinged cooling module fan door for easy trash clean out

Ground level fueling S S S S S S S

Lockable tool box with storage space for scarifier shanks

Moldboards: 12’ x 25” x 7/8” (3 658 x 635 x 22 mm)

13’ x 25” x 7/8” (3 962 x 635 x 22 mm)

14’ x 25” x 7/8” (4 267 x 635 x 22 mm)

12’ x 29” x 1” (3 658 x 737 x 25 mm)

13’ x 29” x 1” (3 962 x 737 x 25 mm)

14’ x 29” x 1” (4 267 x 737 x 25 mm) O O

14’ x 31” x 1” (4 267 x 787 x 25 mm) S

16’ x 31” x 1” (4 877 x 787 x 25 mm) O

Moldboard extensions RIGHT or LEFT - 2’ (610 mm)

Moldboard edges - carbide 3/4” x 5” (19 x 127 mm) or 1” x 8” (25 x 203 mm) harden steel

Brackets for Automatic Blade Control System installation

Metallic lower slide bearing O O O O O O S

Tires

Consult your Volvo dealer for full offering

:00 X 24 - G2 S S S S S S

Tires: 14

17:5 x 25, 12 PR, G-2

16:00 X 25 O O S

20:5 X 25 O O

S S S S S S S

S S S S S S S

S S S S S S S

S S S S S S S

S S S S S S S

S S S S S S S

S S S S S S S

O O O O O O O

S S S S S S S

O O O O O O O

O O O O O O O

S S S S S S S

S S S S S S S

S S S S S S S

S S S S S S S

O O O O O O O

O O O O O O O

S S S S S S S

S S S S S S S

S S S S S S S

O O O O O O S

S S S S S S S

S S S S S S S

S S S S

O O O O

O O O O

S S

O O

O O O O O O O

O O O O O O O

O O O O O O O

O O O O O O

22

Page 16

Model (S - Standard / O - Optional) G930 G940 G946 G960 G970 G976 G990

Hydraulics

Proportional Demand Flow hydraulic system with short throw, low effort control levers

10 section hydraulic control valve - includes two spare sections S S S S S S S

Circle turn relief located integral with main manifold S S S S S S S

Hydraulic oil level monitor via Contronics S S S S S S S

Blade Lift Float Control, right and left detent style

Front attachment float control, detent style, independent of other float valves

Several remote valve locations for attachments

Secondary steering (power assisted)

Operator Cab

Illuminated entry when cab doors are opened - enclosed cab only S S S S S S S

Adjustable steering control pedestal with tilt head for maximum operator comfort S S S S S S S

Gauges include: coolant temperature, engine oil pressure, fuel level, hourmeter,

articulation angle indicator

Multi-function Volvo Contronic Monitoring System with visual and audible warnings

Deluxe, cloth covered, fully adjustable suspension seat when grader is equipped with

an enclosed cab - 3” (75 mm) retractable seatbelt

Deluxe air suspension, cloth covered, fully adjustable suspension seat -

3” (75 mm) retractable seatbelt

Left and right outside dual rear view mirrors S S S S S S S

Fold-away left and right outside dual rear view mirrors

Dual interior rear view mirrors S S S S S S S

Enclosed Low Profile Cab with ROPS and FOPS

Enclosed High Profile Cab with ROPS and FOPS O O O O O O O

Low Profile Cab (SPLIT) with ROPS and FOPS

Low Profile canopy shell (SPLIT) with ROPS O O O O

Cab heater - 50,000 BTU with cab pressurizer and replaceable filters

Air conditioner - 35,000 BTU • HFC-134a (non-CFC refrigerant)

Defroster fan with multiple outlets O O O O O O O

Radio/CD player with 4 speakers

Single arm front cab wiper and washer, enclosed cab

Single arm wiper and washer - rear window O O O O O O O

Single arm wiper and washer - lower windows front left & right O O O O O O O

Dual arm front windshield, Low Profile Cab only

Intermittent wipers O O O O O O O

Window - lower front - opening

Window - left/rightside - opening sliders

Lower cab shield, encloses bottom of cab to frame

Attachments

Fenders front or rear

Dozer Blade: 8’ (2 438 mm)

9’ (2 743 mm)

10’ (3 048 mm) O O O

Front Mounted Scarifier with 5 scarifier teeth

Mid Mount Scarifier with 5 scarifier teeth

Push Block

Ripper/Scarifier, rear with 3 ripper shanks

Other

Painted high gloss Volvo yellow and grey

First user lifetime frame warranty

Paint - custom colors

Low ambient fluids for extreme cold conditions below -14

Tool kit

Sound reduction packages (Standard in EU markets)

Rear licence plate bracket

Air compressor - engine driven with tank O O O O O O O

Partial listing of available options. Certain features may be standard or not available within specific market.

Consult your Volvo Motor Grader distributor for more information.

º F (-10º C) O O O O O O O

S S S S S S S

O O O O O O O

O O O O O O O

O O O O O O O

O O O O O O O

S S S S S S S

S S S S S S S

S S S S S S S

O O O O O O O

O O O O O O O

S S S S S S S

O O O O

S S S S S S S

O O O O O O O

O O O O O O O

S S S S S S S

O O O O O O O

O O O O O O O

O O O O O O O

O O O O O O O

O O O O O O

O O O O

O O O O

O O O O O O

O O O O

O O O O O O O

O O O O O O O

S S S S S S S

O O O O O O O

O O O O O O O

O O O O O O O

O O O O O O O

O O O O O O O

23

Page 17

Volvo Construction Equipment is different. It’s designed, built

and supported in a different way. That difference comes from

an engineering heritage of over 170 years. A heritage of

thinking first about the people who actually use the machines.

About how to help them be safer, more comfortable, more

productive. About the environment we all share. The result

of that thinking is a growing range of machines and a global

support network dedicated to helping you do more. People

around the world are proud to use Volvo. And we’re proud

of what makes Volvo different – More care. Built in.

All products are not available in all markets. Under our policy of continuous improvement, we reserve the right to change

specifications and design without prior notice. The illustrations do not necessarily show the standard version of the machine.

Ref. No. VOE 21 A 100 2235 English

Printed in Canada 2005.11-5,0 GRD

Volvo, Goderich

Loading...

Loading...