Service

Workshop Manual

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839,

turbocharger)

Engine ID

Edition 11.2020

DCB

E

Service Department. Technical Information

List of Workshop Manual Repair Groups

Re pa ir G ro up

00 - Technical data

10 - Removing and installing engine

13 - Crankshaft group

15 - Cylinder head, valve gear

17 - Lubrication

19 - Cooling

21 - Turbocharging/supercharging

24 - Mixture preparation - injection

26 - Exhaust system

28 - Ignition system

93 - Electric drive systems

Service

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness

and safety. In addition, the normal basic safety precautions for working on motor vehicles must, as

a matter of course, be observed.

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

Contents

00 - Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Safety precautions when working on high-voltage system . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety precautions when working in the vicinity of high-voltage components . . . . . . . . . . 2

1.3 Safety regulations for working on fuel supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Safety measures when working on vehicles with a start/stop system . . . . . . . . . . . . . . . . 3

1.5 Safety precautions when using testers and measuring instruments during a road test . . . . 3

1.6 Safety precautions when working on subframe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.7 Safety precautions when working on ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.8 Safety precautions when working on the cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.9 Safety precautions when working on exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Engine number/engine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Numbering of cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Repair instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Rules for cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Foreign objects in engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Contact corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Routing and attachment of lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5 Fitting radiator and condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.6 Checking fuel system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Hazard classification of high-voltage system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

10 - Removing and installing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1 Removing and installing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.1 Removing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.2 Separating engine and gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

1.3 Removing engine from scissor-type assembly platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

1.4 Securing engine on engine and gearbox support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

1.5 Installing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

2 Assembly mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

2.1 Assembly overview – assembly mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

2.2 Supporting engine in installation position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

2.3 Removing and installing engine mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

2.4 Removing and installing gearbox mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

2.5 Removing and installing power unit mounting senders . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

2.6 Calibrating electrohydraulic engine mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3 Engine cover panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3.1 Removing and installing engine cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

13 - Crankshaft group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

1 Cylinder block (pulley end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

1.1 Assembly overview - cylinder block (pulley end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

1.2 Assembly overview - sealing flange, belt pulley end . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

1.3 Removing and installing poly-V belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

1.4 Removing and installing tensioner for poly V-belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

1.5 Removing and installing vibration damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

1.6 Removing and installing bracket for ancillaries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

1.7 Removing and installing engine support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

1.8 Renewing crankshaft oil seal - belt pulley end . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

1.9 Removing and installing sealing flange on pulley end . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

2 Cylinder block, gearbox end . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Contents i

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

2.1 Assembly overview - cylinder block, gearbox end . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

2.2 Removing and installing drive plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

2.3 Renewing crankshaft oil seal (gearbox end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

3 Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

3.1 Assembly overview - crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

3.2 Crankshaft dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

3.3 Allocation of main bearing shells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

3.4 Measuring axial clearance of crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

3.5 Measuring radial clearance of crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

3.6 Removing and installing sender wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

3.7 Checking sender wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

3.8 Removing and installing crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

4 Balancer shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

4.1 Assembly overview - balance shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

4.2 Removing and installing balance shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

5 Pistons and conrods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

5.1 Assembly overview - pistons and conrods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

5.2 Removing and installing pistons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

5.3 Removing and installing oil spray jets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

5.4 Checking pistons and cylinder bores . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

5.5 Checking radial clearance of conrods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

15 - Cylinder head, valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

1 Cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

1.1 Assembly overview - cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

1.2 Assembly overview - camshaft housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

1.3 Removing and installing cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

1.4 Removing and installing camshaft housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

1.5 Checking compression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

2 Cover for timing chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

2.1 Assembly overview - cover for timing chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

2.2 Removing and installing timing chain cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

3 Chain drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

3.1 Assembly overview - camshaft timing chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

3.2 Assembly overview - drive chain for oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

3.3 Removing camshaft timing chain from camshafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

3.4 Removing and installing camshaft timing chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

3.5 Removing and installing chain tensioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

4 Valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

4.1 Assembly overview - valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

4.2 Measuring axial play of camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

4.3 Measuring radial play of camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

4.4 Removing and installing camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

4.5 Removing and installing cam actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

4.6 Removing and installing camshaft control valve 1 N205 . . . . . . . . . . . . . . . . . . . . . . . . . . 243

4.7 Removing and installing valve stem seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

5 Inlet and exhaust valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

5.1 Checking valve guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

5.2 Checking valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

5.3 Valve dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

17 - Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

1 Sump, oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

1.1 Assembly overview - sump/oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

1.2 Engine oil: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

ii Contents

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

1.3 Removing and installing lower part of sump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

1.4 Removing and installing upper part of sump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

1.5 Removing and installing oil baffle plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

1.6 Removing and installing oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

1.7 Removing and installing oil level and oil temperature sender G266 . . . . . . . . . . . . . . . . . . 280

2 Engine oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

2.1 Assembly overview - engine oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

2.2 Removing and installing engine oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

2.3 Removing and installing spray nozzle valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

3 Crankcase ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

3.1 Assembly overview - crankcase breather system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

3.2 Removing and installing crankcase breather module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

4 Oil filter, oil pressure switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

4.1 Assembly overview - oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

4.2 Assembly overview - oil pressure switches/oil pressure control . . . . . . . . . . . . . . . . . . . . . . 291

4.3 Removing and installing oil pressure switch F22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

4.4 Removing and installingoil temperature sender G8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

4.5 Checking oil pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

4.6 Removing and installing oil filter housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

4.7 Removing and installing oil pressure regulating valve N428 . . . . . . . . . . . . . . . . . . . . . . . . 297

4.8 Removing and installing oil pressure sender G10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

19 - Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

1 Cooling system/coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

1.1 Connection diagram - coolant hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

1.2 Overview of fitting locations – cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

1.3 Assembly overview – coolant expansion tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

1.4 Checking cooling system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

1.5 Draining and adding coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

1.6 Removing and installing coolant expansion tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

2 Coolant pump, regulation of cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

2.1 Assembly overview - coolant pump, thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

2.2 Assembly overview - electric coolant pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

2.3 Assembly overview - coolant temperature sender . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

2.4 Assembly overview – coolant valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

2.5 Removing and installing electric coolant pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365

2.6 Removing and installing coolant pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

2.7 Removing and installing map-controlled engine cooling thermostat F265 . . . . . . . . . . . . . . 372

2.8 Removing and installing coolant temperature sender G62 . . . . . . . . . . . . . . . . . . . . . . . . 374

2.9 Removing and installing engine outlet coolant temperature sender G82 . . . . . . . . . . . . . . 375

2.10 Removing and installing radiator outlet coolant temperature sender G83 . . . . . . . . . . . . . . 377

2.11 Removing and installing temperature sender for engine temperature regulation G694 . . . . 380

2.12 Removing and installing coolant valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

2.13 Removing and installing coolant temperature sender for high-voltage system . . . . . . . . . . 387

3 Coolant pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 397

3.1 Assembly overview - coolant pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 397

3.2 Removing and installing coolant pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 399

4 Radiator, radiator fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

4.1 Assembly overview – radiator, radiator fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 407

4.2 Removing and installing radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 412

4.3 Removing and installing radiator cowl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 417

4.4 Removing and installing radiator fan V7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 422

4.5 Removing and installing radiator for high-voltage system coolant circuit . . . . . . . . . . . . . . 422

4.6 Removing and installing air ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 425

Contents iii

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

21 - Turbocharging/supercharging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

1 Turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

1.1 Assembly overview - turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

1.2 Removing and installing turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 435

1.3 Renewing vacuum unit for turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 441

1.4 Removing and installing temperature sender for engine cover panel G765 . . . . . . . . . . . . 447

2 Charge air system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 448

2.1 Assembly overview - charge air system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 448

2.2 Assembly overview - charge-air hose connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 453

2.3 Removing and installing air pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 454

2.4 Removing and installing pressure pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 457

2.5 Removing and installing charge air cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 461

2.6 Removing and installing charge pressure sender G31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 464

2.7 Removing and installing overrun air recirculation valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

2.8 Checking charge air system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 465

24 - Mixture preparation - injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 468

1 Injection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 468

1.1 Overview of fitting locations - injection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 468

1.2 Checking fuel system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 478

2 Vacuum system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 479

2.1 Connection diagram - vacuum system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 479

2.2 Checking vacuum system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 479

3 Injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 481

3.1 Assembly overview - fuel rail with injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 481

3.2 Removing and installing fuel rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 483

3.3 Removing and installing injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 485

3.4 Cleaning injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 491

4 Air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 494

4.1 Assembly overview - air filter housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 494

4.2 Removing and installing air filter housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 495

5 Intake manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 497

5.1 Assembly overview – intake manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 497

5.2 Removing and installing intake manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 498

5.3 Removing and installing throttle valve module J338 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 501

5.4 Cleaning throttle valve module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 503

6 Senders and sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 505

6.1 Assembly overview - actuator for structure-borne sound and control unit for structure-borne

sound . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 505

6.2 Assembly overview - pressure differential sender, models with particulate filter . . . . . . . . 506

6.3 Removing and installing actuator for structure-borne sound R214 . . . . . . . . . . . . . . . . . . 507

6.4 Removing and installing control unit for structure-borne sound J869 . . . . . . . . . . . . . . . . 508

6.5 Removing and installing intake manifold sender GX9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 508

6.6 Removing and installing fuel pressure sender G247 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 509

6.7 Removing and installing fuel pressure sender for low-pressure G410 . . . . . . . . . . . . . . . . 510

6.8 Removing and installing pressure differential sender for particulate filter G1037, models

with particulate filter (petrol) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 510

7 Engine control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 514

7.1 Assembly overview – motor control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 514

7.2 Removing and installing engine control unit J623 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 514

8 High-pressure pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 516

8.1 Assembly overview - high-pressure pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 516

8.2 Removing and installing high-pressure pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 520

8.3 Removing and installing high-pressure pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 523

iv Contents

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

9 Lambda probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 527

9.1 Assembly overview - Lambda probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 527

9.2 Removing and installing Lambda probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 528

26 - Exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 533

1 Exhaust pipes and silencers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 533

1.1 Assembly overview – silencers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 533

1.2 Removing and installing front silencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 540

1.3 Separating exhaust pipes from silencers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 543

1.4 Removing and installing silencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 544

1.5 Aligning exhaust system free of stress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 545

1.6 Checking exhaust system for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 546

2 Emission control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 547

2.1 Assembly overview – emission control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 547

2.2 Removing and installing catalytic converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 550

2.3 Removing and installing particulate filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 551

3 Exhaust gas temperature regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 554

3.1 Removing and installing exhaust gas temperature sender 3 G495 . . . . . . . . . . . . . . . . . . 554

28 - Ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 556

1 Ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 556

1.1 Assembly overview - ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 556

1.2 Removing and installing ignition coils with output stage . . . . . . . . . . . . . . . . . . . . . . . . . . 558

1.3 Removing and installing knock sensor 1 G61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 562

1.4 Removing and installing Hall sender . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 563

1.5 Removing and installing engine speed sender G28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 564

93 - Electric drive systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 566

1 High-voltage components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 566

1.1 Overview of fitting locations - high-voltage components . . . . . . . . . . . . . . . . . . . . . . . . . . 566

2 Warning stickers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 569

2.1 Checking warning stickers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 569

3 High-voltage battery unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 573

3.1 Assembly overview – high-voltage battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 573

3.2 Visual inspection of high-voltage battery 1 AX2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 575

3.3 Diagnosing high-voltage battery 1 AX2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 576

3.4 Searching for leaks from high-voltage battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 577

3.5 Removing and installing high-voltage battery 1 AX2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 584

3.6 Removing and installing battery regulation control unit J840 . . . . . . . . . . . . . . . . . . . . . . . . 593

3.7 Removing and installing switching unit for high-voltage battery SX6 . . . . . . . . . . . . . . . . . . 594

4 High-voltage battery components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 597

4.1 Assembly overview – high-voltage battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 597

4.2 Overview of fitting locations - battery modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 602

4.3 Overview of fitting locations – battery connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 603

4.4 Marking battery modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 604

4.5 Removing battery module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 605

4.6 Installing battery module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 619

5 Power and control electronics for electric drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 635

5.1 Overview of fitting locations - power and control electronics for electric drive . . . . . . . . . . 635

5.2 Removing and installing power and control electronics for electric drive . . . . . . . . . . . . . . 638

5.3 Removing and installing bracket for power and control electronics for electric drive JX1 . . 642

6 Electric drive motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 644

6.1 Assembly overview – electric drive motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 644

6.2 Removing and installing three-phase current drive VX54 . . . . . . . . . . . . . . . . . . . . . . . . . . 648

Contents v

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

6.3 Removing and installing centring sleeve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 648

6.4 Removing and installing drive motor temperature sender G712 . . . . . . . . . . . . . . . . . . . . 650

6.5 Removing and installing drive motor rotor position sender 1 G713 . . . . . . . . . . . . . . . . . . 651

6.6 Removing and installing torsion damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 652

6.7 Removing and installing actuator for disengagement clutch V606 . . . . . . . . . . . . . . . . . . . . 654

6.8 Removing and installing coolant connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 657

6.9 Transporting three-phase current drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 658

6.10 Checking ease of movement of disengagement clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 659

7 High-voltage cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 661

7.1 Overview of fitting locations - high-voltage cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 661

7.2 Removing and installing high-voltage wiring harness for high-voltage battery . . . . . . . . . . 668

7.3 Removing and installing high-voltage wiring harness for drive motor . . . . . . . . . . . . . . . . 673

7.4 Removing and installing high-voltage cable for electrical air conditioner compressor . . . . 678

7.5 Removing and installing high-voltage cable for high-voltage heater (PTC) . . . . . . . . . . . . 681

8 De-energising high-voltage system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 689

9 Re-energising high-voltage system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 691

10 Potential equalisation lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 692

10.1 General notes - potential equalisation lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 692

10.2 Overview of fitting locations - potential equalisation lines . . . . . . . . . . . . . . . . . . . . . . . . . . 692

10.3 Removing and installing potential equalisation line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 694

11 Charging socket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 698

11.1 Assembly overview – charging socket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 698

11.2 Removing and installing high-voltage battery charging socket 1 UX4 . . . . . . . . . . . . . . . . 699

11.3 Removing and installing module for battery charge selector buttons EX32 . . . . . . . . . . . . 704

12 Charging unit for high-voltage battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 705

12.1 Assembly overview – charging unit for high-voltage battery . . . . . . . . . . . . . . . . . . . . . . . . 705

12.2 Removing and installing charging unit 1 for high-voltage battery AX4 . . . . . . . . . . . . . . . . 705

12.3 Removing and installing bracket for charging unit 1 for high-voltage battery AX4 . . . . . . . . 710

vi Contents

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

00 – Technical data

1 Safety information

(VRL014943; Edition 11.2020)

⇒ p1.1 recautions when working on high-voltage system”, page

1

⇒ p1.2 recautions when working in the vicinity of high-voltage

components”, page 2

⇒ r1.3 egulations for working on fuel supply”, page 2

⇒ m1.4 easures when working on vehicles with a start/stop

system”, page 3

⇒ p1.5 recautions when using testers and measuring instru‐

ments during a road test”, page 3

⇒ p1.6 recautions when working on subframe”, page 3

⇒ p1.7 recautions when working on ignition system”, page 3

⇒ p1.8 recautions when working on the cooling system”, page

4

⇒ p1.9 recautions when working on exhaust system”, page 4

Touareg 2018 ➤

1.1 Safety precautions when working on high-voltage system

Danger to life from high voltage

The high-voltage system is under high voltage. Severe or fatal

injury from electric shock.

– Persons with life-preserving or other electronic medical devi‐

ces in or on their body must not perform any work on the

high-voltage system. Such medical devices include internal

analgesic pumps, implanted defibrillators, pacemakers, insu‐

lin pumps and hearing aids.

– The high-voltage system must be de-energised by a suitably

qualified technician.

Risk of injury from engine starting unexpectedly

On electric and hybrid vehicles, the operational readiness of the

vehicle is difficult to detect. There is a risk of parts of the body

becoming trapped or drawn in.

– Switch off ignition.

– Always store the ignition key outside the vehicle.

Risk of damage to high-voltage cables

Improper handling of high-voltage cables or high-voltage con‐

nectors may result in damage to their insulation.

– Never support body weight on high-voltage cables or high-

voltage connectors.

– Never support any tools on high-voltage cables or high-volt‐

age connectors.

1. Safety information 1

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

– Never kink or severely bend high-voltage cables.

– Always observe the coding when connecting high-voltage

connectors.

Risk of injury from activated stationary air conditioning

On electric and hybrid vehicles with activated stationary air con‐

ditioning, the stationary air conditioning could switch on uninten‐

tionally. Risk of limbs becoming trapped or drawn in by the

radiator fan starting automatically.

– Deactivate the stationary air conditioning.

1.2 Safety precautions when working in the vicinity of high-voltage compo‐

nents

Danger to life from high voltage

The high-voltage system is under high voltage. Damage to highvoltage components or high-voltage cables can result in severe

or fatal injury from electric shock.

– Perform visual check of high-voltage components and high-

voltage cables.

– Never use cutting or forming tools, or any other sharp-edged

tools.

– Never use heat sources such as welding, brazing, soldering,

hot air or thermal bonding equipment.

1.3 Safety regulations for working on fuel supply

Risk of injury from highly pressurised fuel.

The fuel system is pressurised. Injury from fuel spray possible.

Before opening the fuel system:

– Wear protective goggles.

– Wear protective gloves.

– To release pressure, wrap a clean cloth around the connec‐

tion and carefully loosen the connection.

Danger of fire caused by escaping fuel

When the battery is connected and the driver door opens, the

door contact switch activates the fuel pump. Escaping fuel can

ignite and cause a fire.

– Disconnect voltage supply to fuel pump before opening the

fuel system.

2 Rep. gr.00 - Technical data

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

1.4 Safety measures when working on vehicles with a start/stop system

Risk of injury due to unexpected engine start

If the vehicle’s start/stop system is activated, the engine can

start unexpectedly. A message in the dash panel insert indi‐

cates whether the start/stop system is activated.

– Deactivate start/stop system by switching off the ignition.

1.5 Safety precautions when using testers and measuring instruments during a road test

Risk of injury caused by unsecured testing and measuring in‐

struments

When the front passenger airbag is triggered in an accident, in‐

sufficiently secured testing and measuring instruments become

dangerous projectiles.

– Secure testing and measuring instruments on the rear seat.

or

– Have a second person operate the test and measuring

equipment on the rear seat.

1.6 Safety precautions when working on subframe

Risk of damage to components

If the assembly mountings, steering rack or subframe cross

brace are not installed correctly, components can become dam‐

aged when the vehicle is settled on its wheels.

– Never settle the vehicle on its wheels if running gear compo‐

nents are loose.

– Never support the vehicle if running gear components on the

subframe or subframe cross brace are loose.

1.7 Safety precautions when working on ignition system

Risk of injury due to electric shock

The ignition system is under high voltage when the engine is

running. Touching the ignition system may result in an electric

shock.

– Do not touch or disconnect ignition cables when the engine

is running or being turned at starter speed.

1. Safety information 3

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

Risk of damage to components

Connecting or disconnecting electric cables or washing the en‐

gine while it is running may damage components.

– Switch off the ignition before connecting or disconnecting

electric cables.

– Switch off the ignition before washing the engine.

1.8 Safety precautions when working on the cooling system

Danger of scalding by hot coolant

On a warm engine, the cooling system is under high pressure.

Danger of scalding by steam and hot coolant.

– Wear protective gloves.

– Wear protective goggles.

– Reduce excess pressure by covering cap of coolant expan‐

sion tank with cloths and opening it carefully.

1.9 Safety precautions when working on exhaust system

Risk of poisoning due to chemical substances

Exhaust gas temperature senders may contain chemical sub‐

stances. There is a risk of poisoning or injuries to respiratory

system.

– Never open an exhaust gas temperature sender by cutting,

sawing or any other means.

Risk of injury due to hot condensate and particles in the ex‐

haust system.

The exhaust system could contain hot condensate and/or parti‐

cles. There is a risk of injury to the eyes, skin and respiratory

system, as well as poisoning.

– Always wear protective gloves and eye protection when cut‐

ting the exhaust system.

– When cutting, use an extraction system or otherwise ensure

sufficient ventilation.

4 Rep. gr.00 - Technical data

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

2 Identification

⇒ n2.1 umber/engine data”, page 5

⇒ o2.2 f cylinders”, page 6

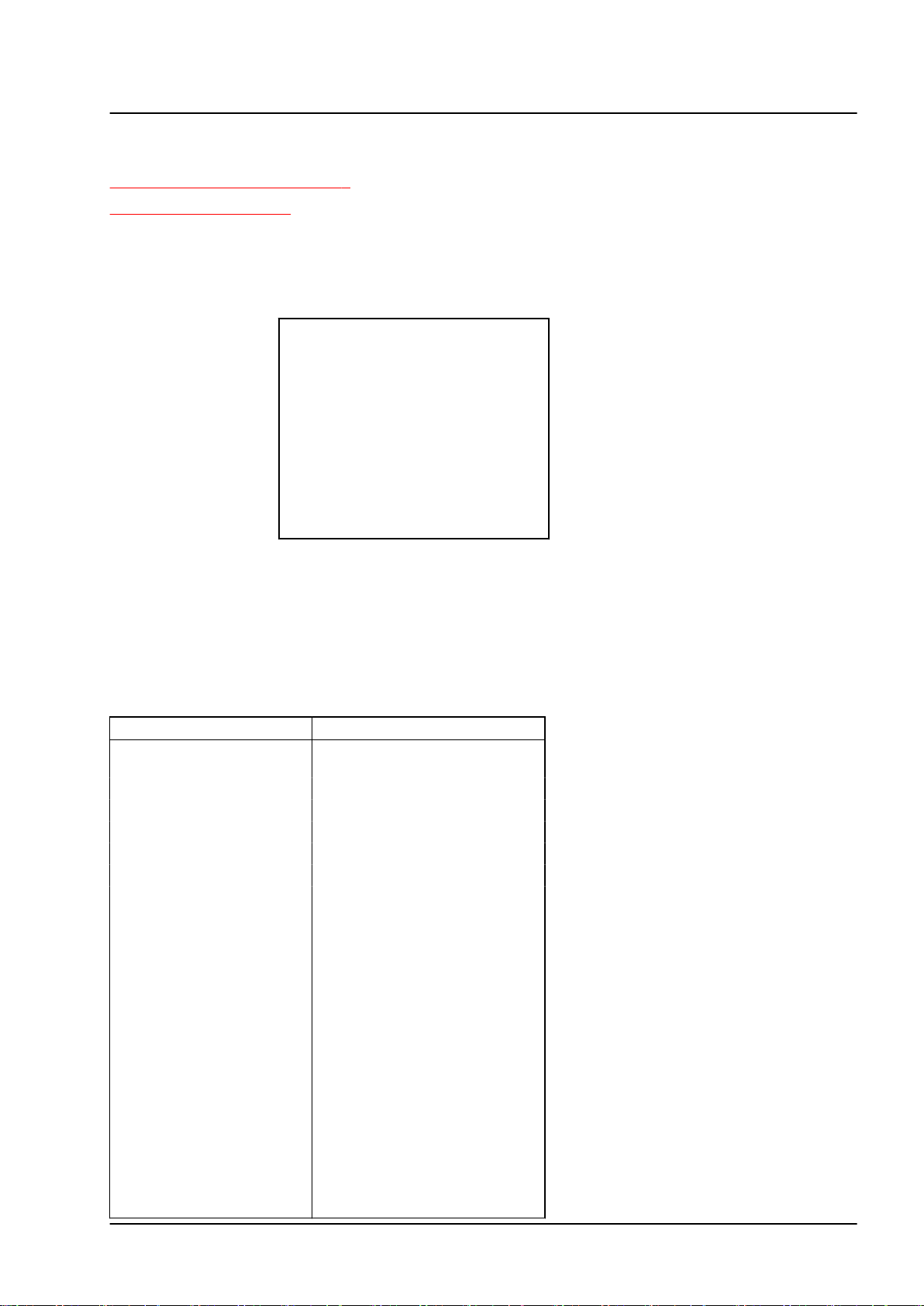

2.1 Engine number/engine data

Engine number

♦ Engine number is visible once air filter housing has been

removed.

Touareg 2018 ➤

♦ Engine number is located on rear of cylinder block at top.

1 - Serial number engine code

♦ There is also a sticker on the timing chain cover (top) show‐

ing the “engine code” and the “serial number”.

♦ The engine code is also indicated on the vehicle data stick‐

ers.

Engine data

Code DCBE

Displace‐

ment

Power kW at rpm 250/5300

Torque Nm at rpm 450/1500 to 5300

Bore Diameter, mm 84.5

Stroke mm 89.0

Compression ratio 11.2

RON min.

Ignition and injection sys‐

tems

Exhaust

emissions

fulfil

Firing order 1-4-3-6-2-5

Exhaust gas recirculation No

Charging Turbocharger

Knock control Yes

Lambda regulation Yes

Charge air cooling Yes

Camshaft timing adjustment Yes

Variable intake manifold No

Secondary air system No

Valves per cylinder 4

l 2.99

98

FSI direct injection

EU 6

1)

2. Identification 5

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

1)

92 RON also permitted

but with reduced power

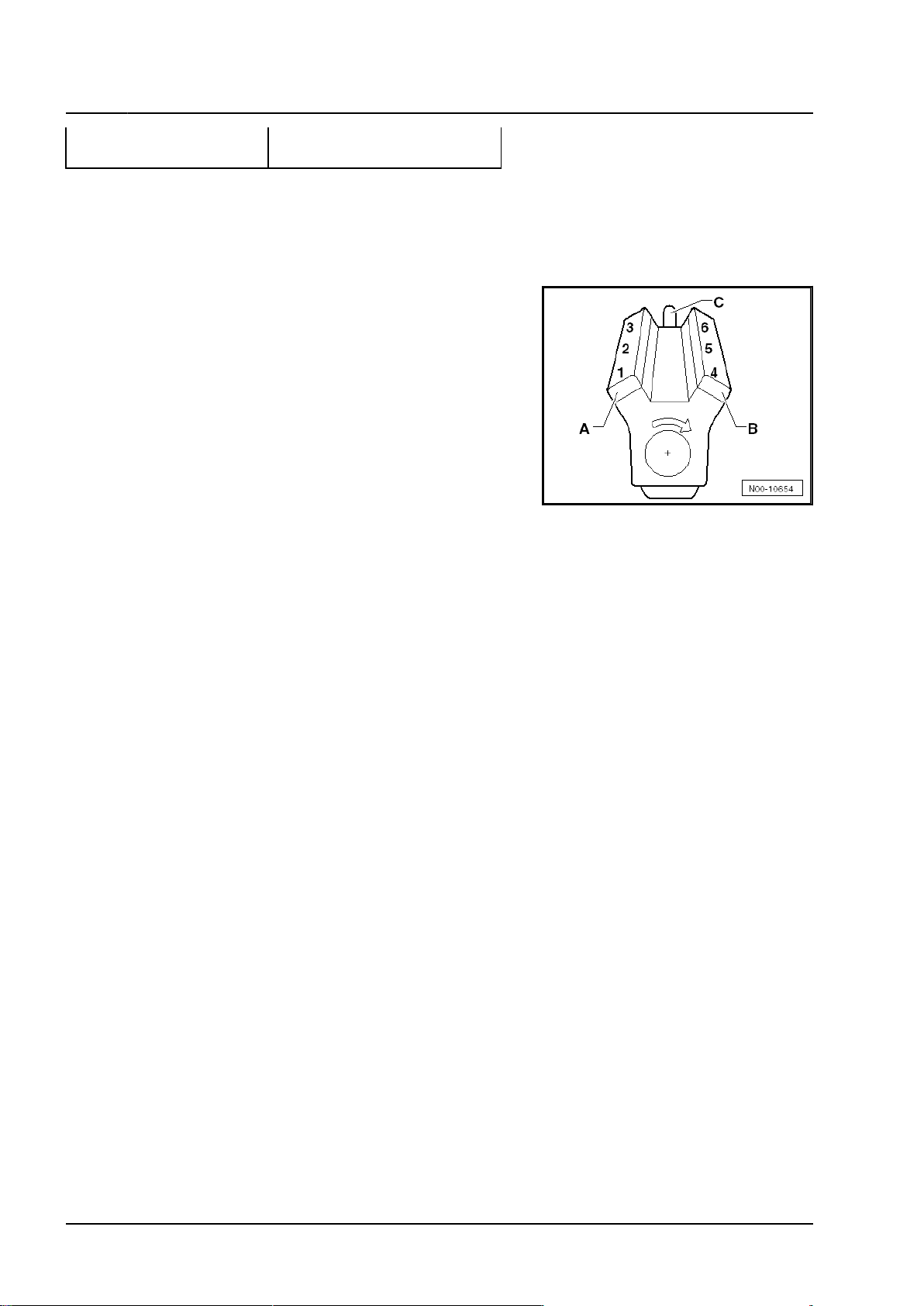

2.2 Numbering of cylinders

Cylinders are numbered beginning with the right side -A- (cylin‐

der bank 1) from the driver's perspective, not from the power

output end -C-. The cylinders are counted on each side in suc‐

cession. -B- = cylinder bank 2.

6 Rep. gr.00 - Technical data

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

3 Repair instructions

⇒ f3.1 or cleanliness”, page 7

⇒ o3.2 bjects in engine”, page 7

⇒ c3.3 orrosion”, page 7

⇒ a3.4 nd attachment of lines”, page 8

⇒ r3.5 adiator and condensers”, page 8

⇒ f3.6 uel system for leaks”, page 8

3.1 Rules for cleanliness

Even slight soiling can cause faults. For this reason, observe

the following rules for cleanliness when working on the fuel

supply system, the charge air system and the injection system:

♦ Carefully clean connection points and the surrounding area

with engine cleaner or brake cleaner and dry thoroughly

before opening.

♦ Seal open pipes and connections immediately with clean

plugs for example from the engine bung set -VAS 6122-.

♦ Place removed parts on a clean surface. Cover with lint-free

cloths only.

♦ If repair work cannot be performed immediately, carefully

cover or seal components.

♦ Install clean components only. Do not remove replacement

parts from packing until immediately before installing. Do not

use parts that have been stored outside their packaging (e.g.

in tool boxes).

♦ When the system is open, do not work with compressed air

or move the vehicle.

♦ Make sure that no fuel gets onto the fuel hoses. Should this

occur, the fuel hoses must be cleaned immediately.

♦ Protect disconnected electrical connectors from dirt and wa‐

ter, and reconnect them only when dry.

Touareg 2018 ➤

3.2 Foreign objects in engine

♦ To prevent the ingress of foreign bodies during work on

the engine, seal open channels of the intake and exhaust

sections with suitable bungs, for example from the engine

bung set -VAS 6122-.

♦ To prevent subsequent damage when a cylinder bank is

damaged mechanically, check the intake and exhaust sec‐

tions as well as the combustion chambers of the opposite

cylinder bank for foreign bodies.

♦ In the event of mechanical damage on turbocharger refer to

⇒ page 435 .

3.3 Contact corrosion

Contact corrosion can occur if unsuitable connecting elements

(screws, bolts, nuts, washers, etc.) are used.

For this reason, only connecting elements with a special surface

coating have been fitted.

In addition, rubber, plastic and adhesives are made of non-con‐

ductive materials.

3. Repair instructions 7

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

If there is any doubt about the suitability of parts, a general rule

is to use new parts ⇒ Electronic parts catalogue.

Observe the following:

♦ Use only genuine parts which are tested and compatible with

aluminium.

♦ Damage resulting from contact corrosion is not covered by

the warranty.

3.4 Routing and attachment of lines

♦ To prevent interchanging and to maintain the original instal‐

lation position, mark the fuel, hydraulic system, vacuum and

ACF system pipes or any wiring for example prior to remov‐

al. Make sketches or take photographs if necessary.

♦ To avoid damaging pipes and wires, ensure adequate clear‐

ance from all moving or hot components in the engine com‐

partment on account of the confined space.

3.5 Fitting radiator and condensers

Even if installed correctly, the radiator, the condenser and the

charge air cooler may have small dents in their fins. This does

not mean that these components have been damaged. It is

not permissible to renew radiators, condensers or charge air

coolers only because of such minor dents.

3.6 Checking fuel system for leaks

– Allow engine to run at average revs for a few minutes.

– Switch off ignition.

– Check entire fuel system for leaks.

– If leaks are found although the connections have been tight‐

ened to the correct torque, the relevant component must be

renewed.

– Then test drive the vehicle, accelerating to full throttle at

least once.

– Then, check the high-pressure system for leaks again.

8 Rep. gr.00 - Technical data

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

4 Hazard classification of high-voltage

system

DANGER

The vehicle’s high-voltage system and the high-voltage bat‐

tery are dangerous and can cause burns or other injuries and

even lead to a fatal electric shock.

– Any work on the high-voltage system, or on systems which

could be indirectly affected by it, may only be carried out

by properly trained and qualified expert personnel.

– In the event of queries or uncertainties regarding the terms

"high-voltage technician" or "high-voltage expert", or those

concerning the high-voltage system, the responsible im‐

porter must be contacted prior to the commencement of

any work.

– Any repair work must be performed in accordance with ap‐

plicable laws and regulations, the recognised engineering

practices, any relevant accident prevention regulations (in

Germany, including but not limited to the Information of

the German Social Accident Insurance (DGUV) 200-005 –

Qualification training for work on vehicles with high-voltage

systems), as well as this workshop manual.

Touareg 2018 ➤

Before work on the high-voltage system is started, a high-volt‐

age technician must de-energise the high-voltage system ⇒

h8 igh-voltage system”, page 689 .

The types of work for which the high-voltage system has to

be de-energised are indicated in the list entitled “Work on the

high-voltage system” ⇒ page 11 .

Work for which the high-voltage system has to be de-energised:

♦ Only the HVT is authorised to certify that the high-voltage

system has been de-energised.

♦ All work on an e-Golf must be carried out only by those who

are at least qualified as electrically instructed persons (EIP).

♦ Regardless of the work to be performed, visually inspect

high-voltage components in the work area.

♦ High-voltage cables must not be overly bent or kinked.

♦ In the event of conspicuous findings or uncertainties, the

high-voltage technician (HVT) or the high-voltage expert

(HVE) must be consulted.

♦ Any work involving metal-removing, deforming and sharp-

edged tools or heat sources such as welding, soldering, hot

air, thermal bonding and infrared drying in the vicinity of

high-voltage components and cables is prohibited. In this

case the high-voltage system must be de-energised and the

respective component removed or sufficiently protected.

♦ All listed work refers to the removal and installation or the

renewal of the individual components.

♦ For regular maintenance work, the high-voltage system does

not have to be de-energised.

For reasons of safety, the following activities must not be car‐

ried out during charging.

♦ Activities that prolong the charging process.

♦ Activities for which the vehicle must be de-energised and

made safe in accordance with the ensuing hazard rating.

4. Hazard classification of high-voltage system 9

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

♦ Activities during which the vehicle is moved and cables and

connectors could be placed under strain (pulled).

♦ Activities during which the connected charging cable could

present a danger of tripping and injury.

♦ Activities during which the charging cable could block work

paths and emergency exit routes.

♦ Activities on the 12V battery.

The following activities may be carried out with the vehicle diag‐

nostic tester during charging.

♦ Interrogation of event memory and measured values permit‐

ted

♦ The vehicle and control units may be identified.

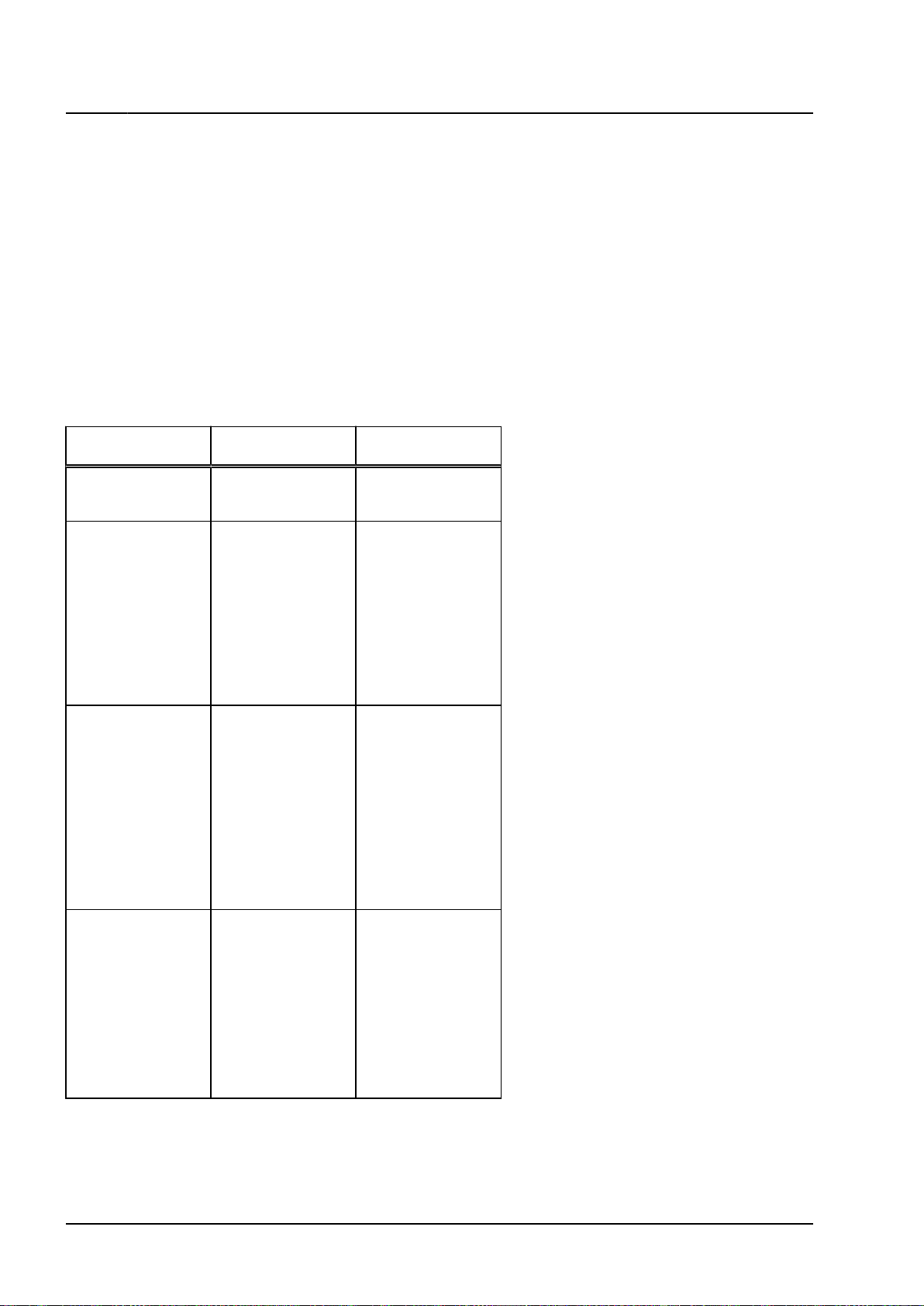

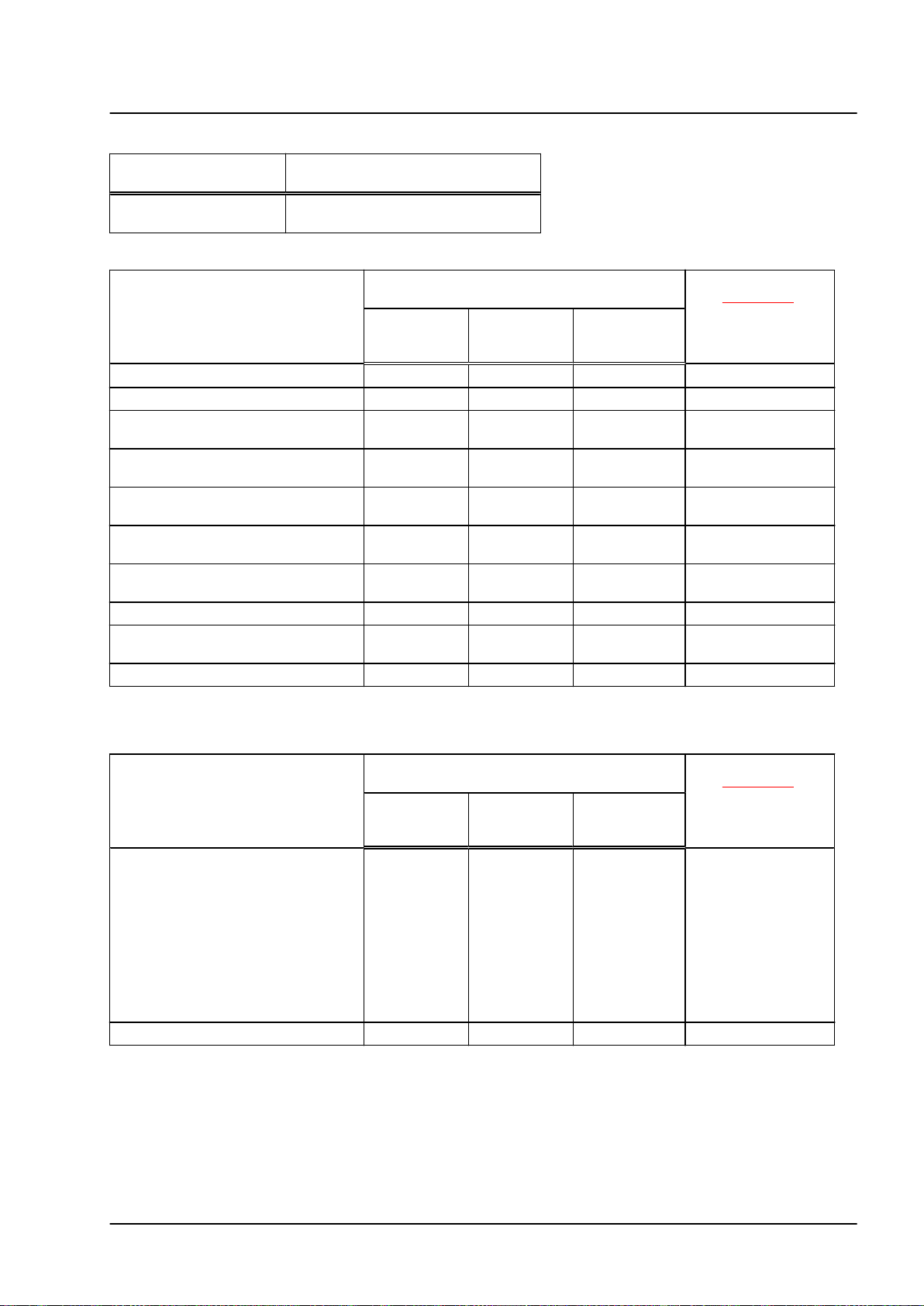

Explanation of qualifications

Qualification Volks‐

wagen

EIP (person with

electrical training)

HVT (high-voltage

technician)

HVE level 1 (highvoltage expert)

DGUV-I 200-005 Scenario

Chapter 2 Induction training

for non-electrical

work (< 60 VDC)

Chapter 3.1 b Working on inher‐

ently safe HV pro‐

duction vehicles

♦ Vehicles are de-

energised exclu‐

sively with certif‐

ication.

♦ Complete con‐

tact protection in

place.

Chapter 3.2 b Working on not in‐

herently safe HV

production vehicles

♦ Vehicles are al‐

so de-energised

without certifica‐

tion or there is

no complete

contact protec‐

tion in place,

e.g. in the event

of an accident.

HVE level 2 (highvoltage expert)

Chapter 3.3 Working on live ac‐

10 Rep. gr.00 - Technical data

cumulators

♦ Working on

parts supplied

with voltage, in‐

evitably with no

contact protec‐

tion, for fault

finding, compo‐

nent replace‐

ment, etc.

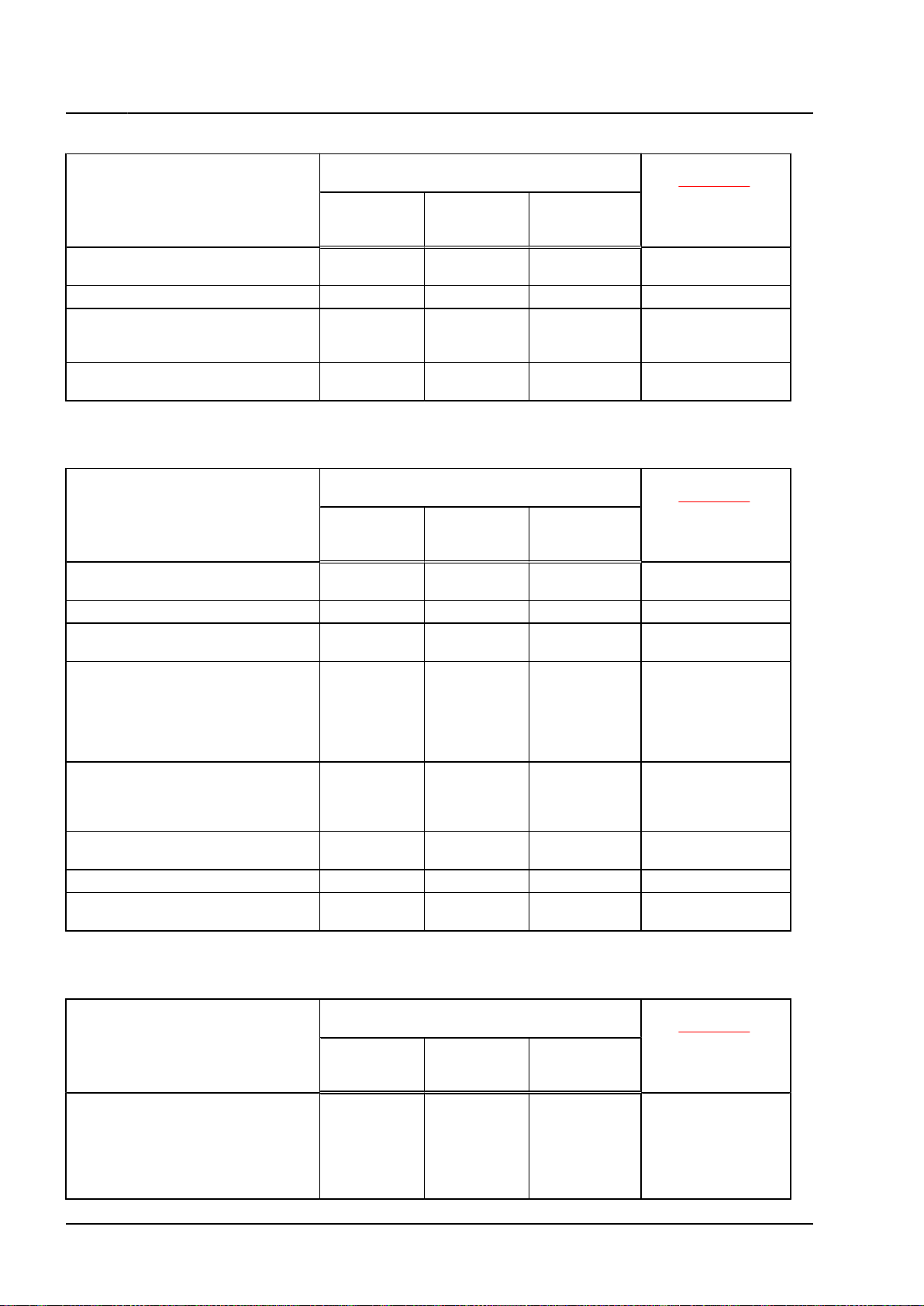

Work on high-voltage system

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

When working on the

Minimum qualification

following components:

De-energise high-volt‐

age system

Work on power unit

When working on the following

components:

three-phase current drive -VX54-

Electric drive motor -V141Mechatronic unit for dual clutch

gearbox -J743Drive motor temperature sender/ro‐

tor position sender -G712-/-G713Lambda probe 1 ahead of catalytic

converter -GX10Lambda probe 1 after catalytic con‐

verter -GX7Coolant pumps -V467-, -V468-, -

V508-, -V590Valves in coolant circuit

Oil level and oil temperature sender

-G266Combustion engine

HVT

Must the HVT de-energise high-voltage sys‐

tem before work is started?

yes (manual

de-energisa‐

tion)

yes (only di‐

agnostic de-

energisation)

X

X

X

X

X

no

X EIP

X EIP

X EIP

X EIP

X EIP

Minimum qualifica‐

tion: ⇒ page 10

EIP

EIP

EIP

EIP

EIP

Work on power and control electronics for electric drive

When working on the following

components:

Must the HVT de-energise high-voltage sys‐

tem before work is started?

Yes (manual

power discon‐

nect)

Power and control electronics for

electric drive -JX1- with

♦ Electric drive control unit -J841-

♦ Intermediate circuit capacitor 1

-C25-

♦ Voltage converter -A19-

♦ DC/AC converter for drive motor

-A37-

High-voltage system fuse 3 -S353-

yes (only di‐

agnostic de-

energisation)

X

X

no

Minimum qualifica‐

tion: ⇒ page 10

EIP

EIP

4. Hazard classification of high-voltage system 11

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

Work on high-voltage system

When working on the following

components:

Potential equalisation lines (earth)

with connection to HV components

Measure insulation resistance

Maintenance connector for high-

voltage system (service connector,

service disconnector)

PX – high-voltage cables (orange)

in vehicle

Work on heating and air conditioning system

When working on the following

components:

Electrical air conditioner compres‐

sor -V470-

High-voltage heater (PTC) -Z115Work on heating and air condition‐

ing system in vehicle interior

Refrigerant lines in vehicle periph‐

ery. Work which is not directly on

the AC compressor and can be car‐

ried out without opening the refrig‐

erant circuit, e.g. loosening and se‐

curing refrigerant lines.

Air conditioning performance test.

For checking the pressure levels in

the refrigerant circuit by means of

air conditioning service equipment.

Refrigerant lines directly on the AC

compressor

Extract, evacuate or fill refrigerant

Heat exchanger for high-voltage

battery -VX63-

Must the HVT de-energise high-voltage sys‐

tem before work is started?

Yes (manual

power discon‐

nect)

Must the HVT de-energise high-voltage sys‐

tem before work is started?

Yes (manual

power discon‐

nect)

yes (only di‐

agnostic de-

energisation)

yes (only di‐

agnostic de-

energisation)

Minimum qualifica‐

tion: ⇒ page 10

no

X

X

X

X

X

X

X EIP

Minimum qualifica‐

tion: ⇒ page 10

no

X EIP

X EIP

X EIP

X EIP

X EIP

HVT

HVT

HVT

EIP

EIP

EIP

Work on charging connection

When working on the following

components:

High-voltage battery charging sock‐

et 1 -UX4- with

♦ Temperature sender for charg‐

ing socket 1 -G853-

♦ Actuator for locking

12 Rep. gr.00 - Technical data

Must the HVT de-energise high-voltage sys‐

tem before work is started?

Yes (manual

power discon‐

nect)

yes (only di‐

agnostic de-

energisation)

X

no

Minimum qualifica‐

tion: ⇒ page 10

EIP

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

When working on the following

components:

Module for battery charge selector

buttons -EX32♦ LED module for charging socket

1 -L263-

Manual release mechanism for

charging connector

Charge high-voltage battery in

workshop area

Work on charging unit

When working on the following

components:

Charging unit 1 for high-voltage

battery -AX4With control unit for high-voltage

battery charging unit -J1050-

Must the HVT de-energise high-voltage sys‐

tem before work is started?

Yes (manual

power discon‐

nect)

yes (only di‐

agnostic de-

energisation)

X

no

X

X EIP

Must the HVT de-energise high-voltage sys‐

tem before work is started?

Yes (manual

power discon‐

nect)

yes (only di‐

agnostic de-

energisation)

X

no

Minimum qualifica‐

tion: ⇒ page 10

EIP

EIP

Minimum qualifica‐

tion: ⇒ page 10

EIP

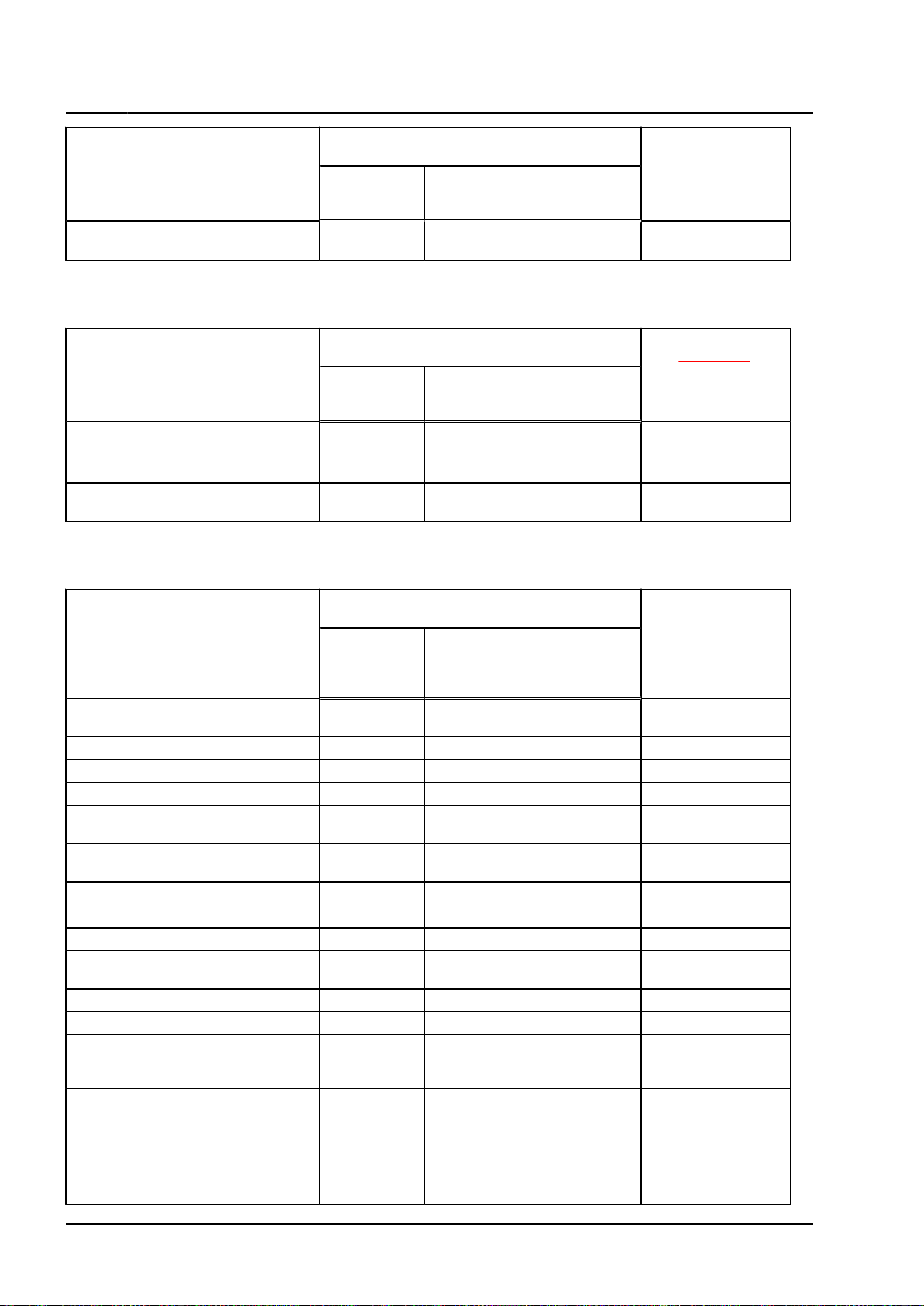

Work on high-voltage battery

When working on the following

components:

Removing and installing underbody

cladding

Removing and installing high-volt‐

age battery 1 -AX2-, de-energised,

high voltage system connection and

DC charging connection disconnec‐

ted. Approval by technician quali‐

fied at least as HVT.

Disconnect high voltage system

connection

Disconnect low-voltage connection

of high-voltage battery

Battery regulation control unit J840-

Switching unit for high-voltage bat‐

tery -SX6- (battery removed)

Module monitor control unit for bat‐

teries -J497- (battery removed)

Open high-voltage battery 1 -AX2(battery removed)

Bond/screw high-voltage battery 1

-AX2- (battery removed)

Must the HVT de-energise high-voltage sys‐

tem before work is started?

Yes (manual

power discon‐

nect)

yes (only di‐

agnostic de-

energisation)

X

X

no

X

X EIP

X EIP

Minimum qualifica‐

tion: ⇒ page 10

EIP

EIP

HVT

HVE

HVE

HVE

HVE

4. Hazard classification of high-voltage system 13

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

When working on the following

components:

Battery module 1 -J991- and other

battery modules (battery removed)

Work on accident vehicles

When working on the following

components:

Status assessment / initial assess‐

ment of risk status

Body work (with straightening jig)

Paint vehicle – observe instructions

in paint manual

Work in vicinity of high-voltage components

Must the HVT de-energise high-voltage sys‐

tem before work is started?

Yes (manual

power discon‐

Must the HVT de-energise high-voltage sys‐

tem before work is started?

Yes (manual

power discon‐

yes (only di‐

agnostic de-

nect)

nect)

energisation)

yes (only di‐

agnostic de-

energisation)

X

Minimum qualifica‐

tion: ⇒ page 10

no

HVE

Minimum qualifica‐

tion: ⇒ page 10

no

HVT

X EIP

EIP

When working on the following

components or for following work:

Body work (assembly work as well

as glass and dent repairs)

Gearbox with electric drive motor

Steering rack

Subframe, front

Exhaust system, in front area of ve‐

hicle

Exhaust system, in rear area of ve‐

hicle

Front brakes

Rear brakes

Brake servo

Brake pressure accumulator for en‐

ergy recovery

Rear axle and running gear

Underbody cladding

When welding, cover high-voltage

components and visually inspect af‐

terwards

Work involving metal-removing, de‐

forming and sharp-edged tools or

heat sources such as welding, sol‐

dering, hot air, thermal bonding

and infrared drying in the vicinity

of high-voltage components and ca‐

bles

Must the HVT de-energise high-voltage sys‐

tem before work is started?

yes (diagnos‐

tic and man‐

ual power dis‐

connection)

Yes (only di‐

agnostic pow‐

er disconnec‐

tion)

X

X

X

no

X

X EIP

X EIP

X EIP

X EIP

X EIP

X EIP

X EIP

X EIP

X EIP

X EIP

Minimum qualifica‐

tion: ⇒ page 10

EIP

EIP

EIP

EIP

14 Rep. gr.00 - Technical data

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

When working on the following

components or for following work:

Work for which the engine is lifted,

on right side (e.g. engine mounting)

Work for which the engine is lifted,

on left side (e.g. gearbox mounting)

Control units and electric compo‐

nents of 12-V system (excluding

airbag)

Battery -AFront left headlight -MX1Front right headlight -MX2Change bulb in headlight

General work

When working on the following

components:

Drain and fill fluids (coolant and

oils)

Coolant circuit and coolant expan‐

sion tank

Change tyres

Miscellaneous work on 12 V system

(excluding airbag)

Work on earth points of 12 V sys‐

tem (without potential equalisation

lines)

Tail lights

Renew/repair windows

Repairs in vehicle interior

Repairs in roof area

Repairs on rear lid

Repairs on bumpers

Move lock carrier to service position

Removing and installing lock carrier

Repair work on lock carrier

Must the HVT de-energise high-voltage sys‐

tem before work is started?

yes (diagnos‐

tic and man‐

ual power dis‐

connection)

Yes (only di‐

agnostic pow‐

er disconnec‐

tion)

no

X

X EIP

X EIP

X EIP

X EIP

X EIP

X EIP

De-energise high-voltage system before work

is started?

yes (diagnos‐

tic and man‐

ual power dis‐

connection)

Yes (only di‐

agnostic pow‐

er disconnec‐

tion)

no

X

X EIP

X EIP

X EIP

X EIP

X EIP

X EIP

X EIP

X EIP

X EIP

X EIP

X EIP

X EIP

X EIP

Minimum qualifica‐

tion: ⇒ page 10

EIP

Minimum qualifica‐

tion: ⇒ page 10

EIP

4. Hazard classification of high-voltage system 15

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

10 – Removing and installing engine

1 Removing and installing engine

⇒ e1.1 ngine”, page 16

⇒ e1.2 ngine and gearbox”, page 49

⇒ e1.3 ngine from scissor-type assembly platform”, page 57

⇒ e1.4 ngine on engine and gearbox support”, page 58

⇒ e1.5 ngine”, page 61

1.1 Removing engine

⇒ e1.1.1 ngine – vehicles without high-voltage system”, page

16

⇒ e1.1.2 ngine – vehicles with high-voltage system”, page 30

1.1.1 Removing engine – vehicles without high-voltage system

Special tools and workshop equipment required

♦ Hook -10-222A/20-

♦ Engine bung set -VAS 6122-

16 Rep. gr.10 - Removing and installing engine

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

♦ Scissor-type assembly platform -VAS 6131 B-

♦ Set of mountings for Audi -VAS 6131/10-

Touareg 2018 ➤

♦ Supplement set, Audi A8 >2002 -VAS 6131/11-, not shown

♦ Supplement set, Audi Q7 > 2005 -VAS 6131/13-

♦ Coolant collection system -VAS 5014- or drip tray for work‐

shop hoists -VAS 6208-

1. Removing and installing engine 17

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

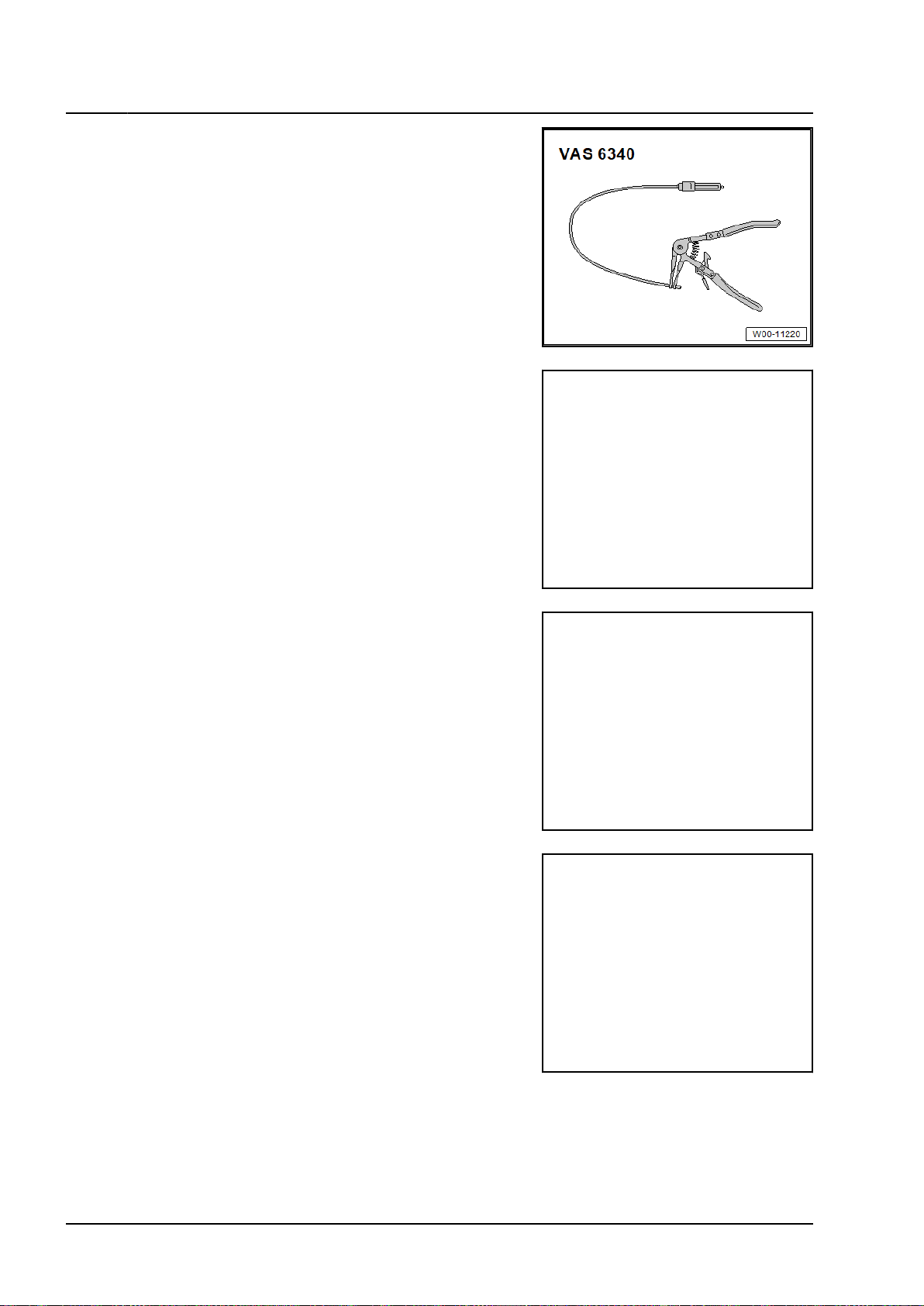

♦ Hose clamp pliers -VAS 6340-

♦ Spring-type clip pliers -VAS 6362-

♦ Engine and gearbox jack -VAS 6931-

♦ Ball joint splitter -VAS 251 805-

18 Rep. gr.10 - Removing and installing engine

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

♦ Tensioning strap -T10038-

♦ Stepladder, commercially available

♦ Safety goggles

♦ Safety gloves

Procedure

♦ The engine is removed from underneath together with the

gearbox and subframe (with lock carrier installed).

♦ Fit cable tie in same place when installing.

♦ Observe rules for cleanliness ⇒ f3.1 or cleanliness”, page 7 .

♦ All bolts on running gear components with bonded rubber

bushes may be tightened only when the component is in the

unladen position (normal position).

♦ Bonded rubber bushes can be twisted only to a limited

extent. Axle components with bonded rubber bushes must

therefore be brought to a position equivalent to the unla‐

den (normal) position before being tightened. Otherwise, the

bonded rubber bush would be subject to torsion loading,

shortening its service life.

– Before starting work, determine unladen position ⇒ Running

gear, axles, steering; Rep. gr. 00; Repair instructions; Rais‐

ing vehicles with coil springs, wheel bearing in unladen posi‐

tion.

• To be able to turn the propshaft during removal, the electro‐

mechanical parking brake must be released before discon‐

necting the battery.

– Move front wheels to straight-ahead position.

– Switch off ignition.

– Disconnect earth wire from battery terminal ⇒ Electrical sys‐

tem; Rep. gr. 27; Battery, Disconnecting and connecting bat‐

tery.

Touareg 2018 ➤

– Remove air filter housing ⇒ a4.2 nd installing air filter hous‐

ing”, page 495 .

– Remove lock carrier cover ⇒ General body repairs, exterior;

Rep. gr. 63; Body - front; Removing and installing attach‐

ments.

– Remove front wheels ⇒ Running gear, axles, steering; Rep.

gr. 44; Wheels, tyres.

– Remove front wheel housing liner on left and right as well as

wheel spoiler ⇒ General body repairs, exterior; Rep. gr. 66;

Wheel housing liner; Assembly overview - front wheel hous‐

ing liner.

1. Removing and installing engine 19

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

– Remove noise insulation ⇒ General body repairs, exterior;

Rep. gr. 66; Noise insulation; Removing and installing noise

insulation.

– Remove front lower longitudinal member ⇒ General body

repairs, exterior; Rep. gr. 50; Lock carrier; Removing and

installing lower longitudinal member.

– Remove cross strut for subframe ⇒ Running gear, axles,

steering; Rep. gr. 40; Subframe; Removing and installing

cross struts for subframe.

– Remove propshaft ⇒ Propshaft and rear final drive; Rep.

gr. 39; Propshaft; Removing and installing propshaft.

– Unscrew bolts -arrows- on left and right, and detach upper

part -1- of subframe shield.

– Remove front silencers on left and right ⇒ a1.2 nd installing

front silencer”, page 540 .

– Drain coolant ⇒ a1.5 nd adding coolant”, page 323 .

– Release hose clips -1 and 3-, remove air hose from air pipe.

– Disconnect fuel hose -2- ⇒ Fuel supply; Rep. gr. 20; Plug-in

connectors; Disconnecting plug-in connectors.

20 Rep. gr.10 - Removing and installing engine

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

– Release hose clip -1- and disconnect hose for activated

charcoal filter system.

– Seal open pipes and connections with thoroughly cleaned

plugs from engine bung set -VAS 6122-.

– Release hose clip -1-, pull off air pipe, push towards left and

tie in place.

Touareg 2018 ➤

– Release fastener -arrow- and open electronics box -1-.

– Unscrew nut -2- and expose B+ wire.

– Free off electric wire -1- from wiring duct.

1. Removing and installing engine 21

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

– Unscrew nut -2- and free off earth wire.

– Remove bolt -3- and nut -4- and free off wiring duct.

– Lift retaining clip -1- and disconnect coolant hose.

– Equipment version without auxiliary heater: release fastener

-arrow- and push coolant circulation pump -V50- to one side.

– Release hose clip -1- and detach coolant hose.

– Lift retaining clip -2-, remove upper left coolant hose from

radiator.

– Release fastener -arrow-, detach vacuum hose -1-, ensuring

when doing so that it is not damaged.

22 Rep. gr.10 - Removing and installing engine

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

– Separate electrical connectors -1- on engine control unit

-J623- and free off.

Touareg 2018 ➤

– Take electrical connector -2- out of bracket, unplug it and

move electrical wiring clear.

– Remove connector -3- from retainer, disconnect it and lay

wire to one side.

– Loosen nut -arrow- a few turns, free off electrical connector

-2- and separate.

– Unscrew nut -1- and free off earth wires.

– Unscrew nut -arrow- and free off earth wires.

1. Removing and installing engine 23

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

– Separate electrical connectors for electrohydraulic engine

mounting solenoid valves on left and right -arrow-, free off

electrical wires.

– Separate left and right electrical connector -2- for front

speed sensor -G45-/-G47- and free off electrical wire.

– If fitted, separate left and right electrical connector -arrow-

for front vehicle level sender -G78-/-G289- and free off elec‐

trical wire.

24 Rep. gr.10 - Removing and installing engine

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

– Remove brake caliper and, with brake hose still connected,

suspend it in wheel housing using wire ⇒ Brake system;

Rep. gr. 46; Front brake; Removing and installing brake cali‐

per.

– Loosen threaded connection -1-.

Touareg 2018 ➤

NOTICE

Danger of damage to wheel bearing housing from deforma‐

tion.

– Do not widen slots in wheel bearing housing.

– Pull out joint pins of upper suspension link -2- from wheel

bearing housing.

– Repeat work sequence on opposite side of vehicle.

– Unscrew nut -4- on both sides. (Bolt -3- is removed at later

stage.)

1. Removing and installing engine 25

Touareg 2018 ➤

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

Note

♦

Bolt -3- will be removed later.

♦

-Items 1 and 2- can be disregarded.

– Remove anti-roll bar ⇒ Running gear, axles, steering; Rep.

gr. 40; Subframe; Removing and installing anti-roll bar.

– Remove cross strut for subframe ⇒ Running gear, axles,

steering; Rep. gr. 40; Subframe; Removing and installing

cross struts for subframe.

– Remove intermediate steering shaft from steering rack

and push together ⇒ Running gear, axles, steering; Rep.

gr. 48; Steering column; Removing and installing intermedi‐

ate steering shaft.

NOTICE

Risk of irreparable damage to poly V-belt that has already

been used by reversing direction of rotation.

– Mark direction of rotation before removing.

– Observe direction of rotation when re-installing.

– Loosen poly V-belt by swivelling tensioning device clockwise

-arrow- using socket Torx T 60 -T40087-.

– Remove poly V-belt and lock tensioning device using locking

pin -T40098-.

– Disconnect electrical connector -1-.

26 Rep. gr.10 - Removing and installing engine

6-cyl. direct injection (3.0 l, 4V, EA 839, turbocharger) - Edition 11.2020

NOTICE

Danger of damage to refrigerant lines and refrigerant hoses

as air conditioner compressor is removed and swivelled.

– Do NOT stretch, kink or bend refrigerant lines and hoses.

– Unscrew bolts -arrows-, remove air conditioner compressor

from bracket and raise and tie on left-hand side.