Page 1

Supplementary instructions

Bypass for continuous level

measurement of liquids

VEGAPASS 81

Document ID: 42749

Page 2

Contents

Contents

1 Product description

2 Mounting

3 Supplement

3.1 Technical data .................................................................... 8

3.2 Dimensions ...................................................................... 11

42749-EN-130227

Editing status: 2013-01-29

2

VEGAPASS 81 •

Page 3

Features and ttings of

the bypass tube

1 Product description

1 Product description

The VEGAPASS 81 is a bypass (reference vessel) for use in combination with a continuous level measuring instrument or a point level

sensor.

Depending on the process pressure or process temperature, the

bypass tube can be used in combination with e.g. the VEGAFLEX 81

or VEGAFLEX 86 sensors.

1

C

ersions

V

B

100 %

D

M

0 %

B

2

E

3

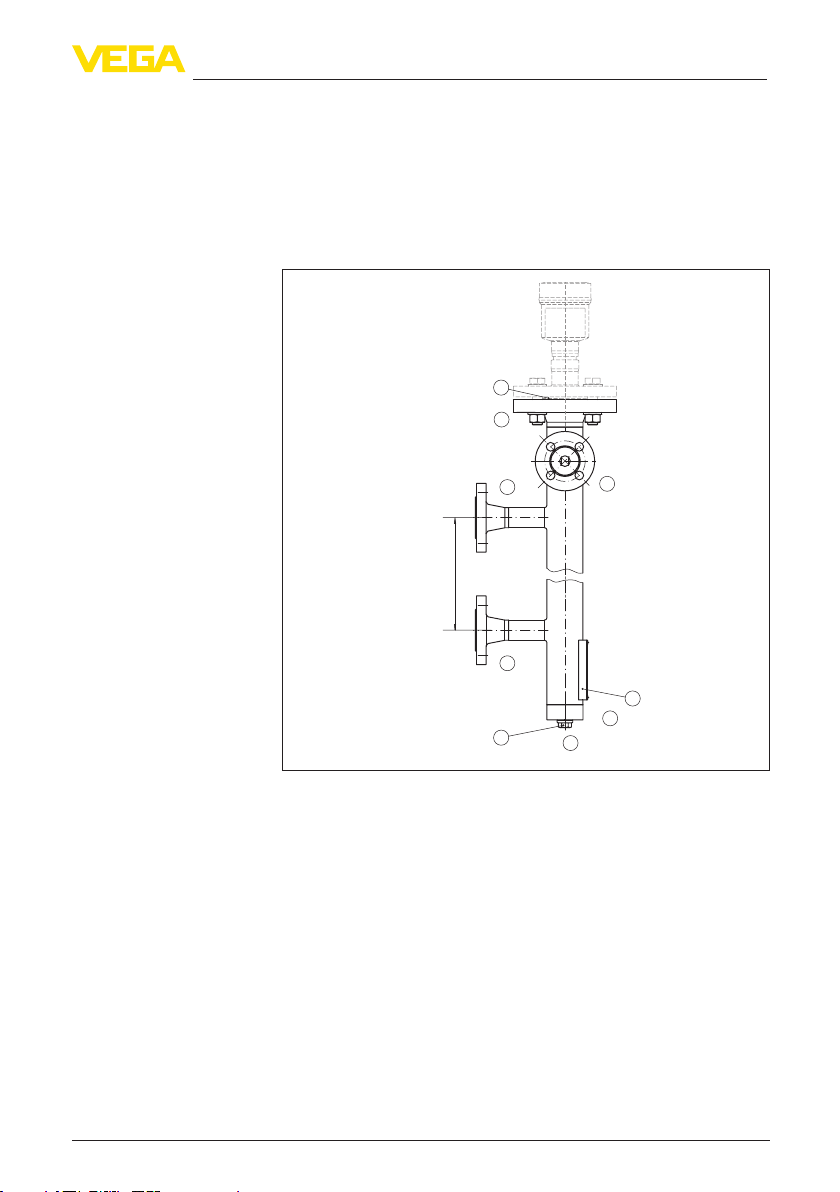

Fig. 1: Typical conguration of VEGAPASS 81 with integrated VEGAFLEX

1 Seal - measuring instrument ange

2 Type plate

3 Closure rinsing connection, e.g. blind plug

B Vessel connection top/bottom

C Measuring instrument ange

D Ventilation connection (optional)

E Chamber closing

F Rinsing connection

M Dimension: Pipe center to pipe center

F

The following versions are possible:

42749-EN-130227

VEGAPASS 81 •

3

Page 4

1 Product description

XX

1 2 3

C

X

C

C

D D D

200mm (7.87")

B

M

B

100mm (3.94")

E

F

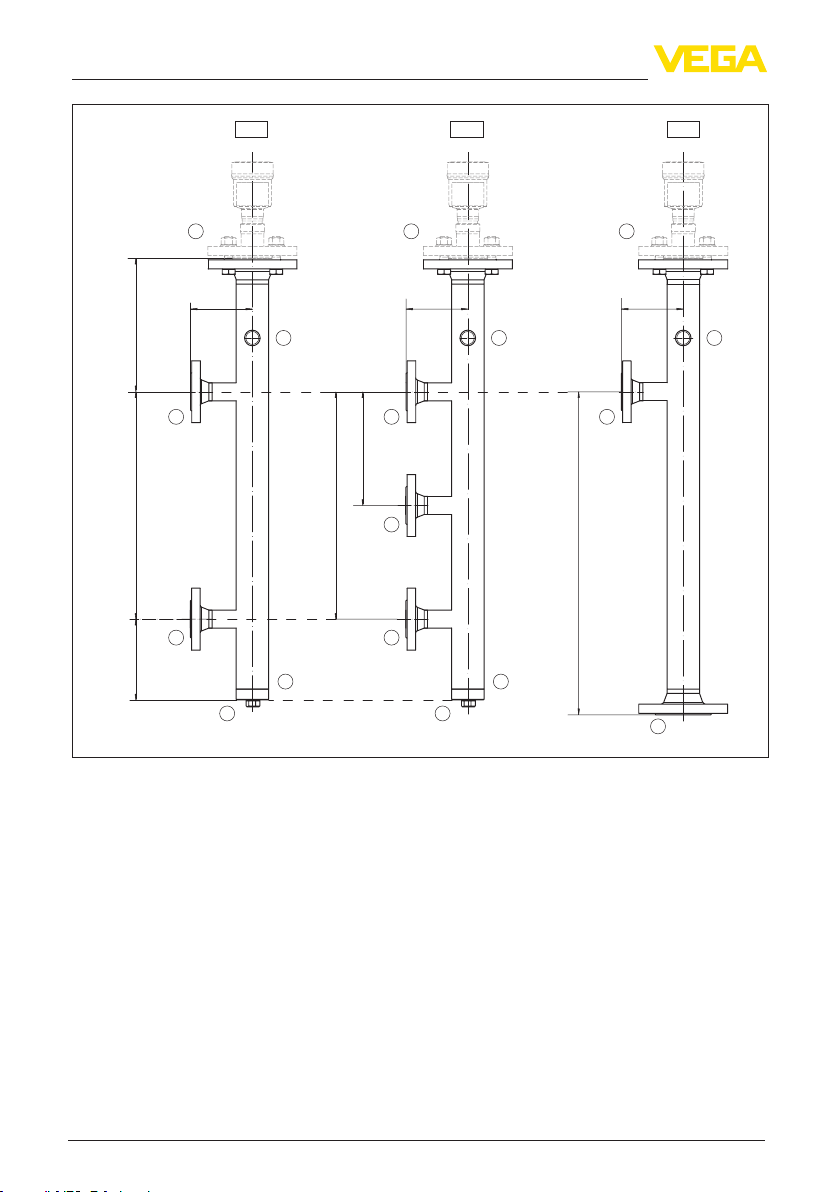

Fig. 2: Versions VEGAPASS 81 - Part 1

1 Version: Side - Side (two connections)

2 Version: Side - Side - Side (three connections)

3 Version: Side - Bottom (two connections)

B Vessel connection top/bottom

C Measuring instrument ange

D Ventilation connection (optional)

E Chamber closing

F Rinsing connection

M Dimensions: tube center to tube center, 300 … 4000 mm (11.8 … 157.5 in)

M1 Dimensions: tube centre to tube center (center connection), 300 … 3700 mm (11.8 … 145.7 in)

L Dimensions: tube center to ange surface, 300 … 4000 mm (11.8 … 157.5 in)

X Dimensions: length tube center to connection ange, 150 … 400 mm (5.91 … 15.75 in)

B

M1

M

B

B

L

B

E

F

B

42749-EN-130227

4

VEGAPASS 81 •

Page 5

1 Product description

4 5 6

C

C

B

B

D D D

200mm (7.87")

200mm (7.87")

B

X

L

L

Y

Y

L

X

B

B

E

100mm (3.94")

F

E

F

B

100mm (3.94")

Fig. 3: Versions VEGAPASS 81 - Part 2

4 Version: Side - Side bottom (two connections)

5 Version: Side top - Side (two connections)

6 Version: Side top - Side bottom (two connections)

B Vessel connection top/bottom

C Measuring instrument ange

D Ventilation connection (optional)

E Chamber closing

F Rinsing connection

L Dimensions tube centre: to ange surface, 300 … 4000 mm (11.8 … 157.5 in)

X Dimensions: length tube centre to connection ange, 150 … 400 mm (5.91 … 15.75 in)

Y Dimension: length pipe centre to pipe centre

C

200mm (7.87")

Y

Y

E

100mm (3.94")

F

42749-EN-130227

VEGAPASS 81 •

5

Page 6

1 Product description

1 2 3

C

D

200mm (7.87")

(5.91")

150mm

C

BB

Fig. 4: Possible ventilation connections (D)

1 Ventilation connection - Flange

2 Ventilation connection - thread G½ or ½ NPT (internal thread)

3 Ventilation connection - thread G¾ or ¾ NPT (internal thread)

B Vessel connection top/bottom

C Measuring instrument ange

D Ventilation connection (optional)

C

D

D

B

42749-EN-130227

6

VEGAPASS 81 •

Page 7

Operating instructions

2 Mounting

2 Mounting

Also take note of the operation instructions of the level or point level

sensor.

Seals

Close openings

V

essel pressure test

Centering

The seals for the vessel connections (B) and the ventilation tting

(optional) must be provided by the customer.

The seals for the measuring instrument ange (C) and the rinsing

connection (F) are already attached to the shipment. You can nd the

seal materials in chapter "Technical data".

Before use, check if the seal material is resistant against the medium,

the process pressure and the process temperature.

The max. permissible pressure of the sensor is specied in the operating instructions manual of the sensor in chapter "Technical data" or

on the type label of the sensor.

Close all emptying and rinsing connections before the setup of VEGAPASS 81. Check if all connections of VEGAPASS 81 are tight.

An assembled bypass tube must be integrated in a probably neces-

sary pressure test of the vessel. Keep the pressure specication of

the type plate in mind.

Avoid contact of the probe with the vessel wall.

For sensors with rod probes use one or several spacers and for sensors with cable probes a centering weight or a spacer on the gravity

weight.

42749-EN-130227

VEGAPASS 81 •

7

Page 8

3 Supplement

3 Supplement

3.1 Technical data

General data

Take note of the information in the operating instructions manual of the installed level sensor

Material 316L corresponds to 1.4404 or 1.4435

Materials

Ʋ Bypass tube 316L/CS (ASTM A105, A106)

Ʋ Spacer ≤ 250 °C PEEK

Ʋ Spacer > 250 °C (optional) StSt (1.4568/AISI 631)

Seal - measuring instrument ange

Ʋ max. 250 °C/40 bar (482 °F/580 psig) Klingersil C-4500

Ʋ max. 400 °C/40 bar (752 °F/580 psig) Graphite

Ʋ max. 400 °C/100 bar

Convex B45A graphite laminate

(752 °F/1450 psig)

Ʋ > 400 °C/> 100 bar

RJF seal rings

(> 752 °F/> 1450 psig)

Tube diameter (outer)

Ʋ Version 2" ø 60.3 mm (2.37 in)

Ʋ Version 3" ø 88.9 mm (3.5 in)

Wall thickness 2 … 11,13 mm (0.079 … 0.438 in)

Process temperature max. 450 °C (842 °F) - see process tting connection

ange (B)

Process pressure

Ʋ Standard version see process tting - connection ange (B)

Ʋ According to pressure device directive

max. 90 bar (1305 psig) - Cat. III, Fluid group I

(PED)

Ʋ According to ASME directive max. 205 bar (2973 psig)

1)

Process tting - connection ange top/bottom (B)

Process pressure in bar (psig) depending on the process temperature

Pressure-Temperature-Assignment - DIN anges

Material 316L (1.4404)

Pressure

range

PN 40 37.9 bar 34.4 bar 31.8 bar 29.9 bar 27.6 bar 26.4 bar 25.7 bar 25.0 bar

PN 63 59.7 bar 54.3 bar 50.1 bar 47.1 bar 43.5 bar 41.7 bar 40.5 bar 39.4 bar

PN 100 94.7 bar 86.1 bar 79.5 bar 74.7 bar 69.0 bar 66.1 bar 64.2 bar 62.6 bar

1)

CS = Carbon steel

8

100 °C 150 °C 200 °C 250 °C 300 °C 350 °C 400 °C 450 °C

VEGAPASS 81 •

42749-EN-130227

Page 9

3 Supplement

Pressure-Temperature-Assignment - ASME anges

Material 316L (1.4404)

Temperature range Class 150 Class 300 Class 400 Class 600 Class 900 Class

1500

-29 … +38 °C 15.9 bar 41.1 bar 55.2 bar 82.7 bar 124.1 bar 206.8 bar 344.7 bar

50 °C 15.3 bar 40.0 bar 53.4 bar 80.0 bar 120.1 bar 200.1 bar 333.5 bar

100 °C 13.3 bar 34.8 bar 46.4 bar 69.6 bar 104.4 bar 173.9 bar 289.9 bar

150 °C 12.0 bar 31.4 bar 41.9 bar 62.8 bar 94.2 bar 157.0 bar 261.6 bar

200 °C 11.2 bar 29.2 bar 38.9 bar 58.3 bar 87.5 bar 145.8 bar 243.0 bar

250 °C 10.5 bar 27.5 bar 36.6 bar 54.9 bar 82.4 bar 137.3 bar 228.9 bar

300 °C 10.0 bar 26.1 bar 34.8 bar 52.1 bar 78.2 bar 130.3 bar 217.2 bar

325 °C 9.3 bar 25.5 bar 34.0 bar 51.0 bar 76.4 bar 127.4 bar 212.3 bar

350 °C 8.4 bar 25.1 bar 33.4 bar 50.1 bar 75.2 bar 125.4 bar 208.9 bar

375 °C 7.4 bar 24.8 bar 33.0 bar 49.5 bar 74.3 bar 123.8 bar 206.3 bar

400 °C 6.5 bar 24.3 bar 32.4 bar 48.6 bar 72.9 bar 121.5 bar 202.5 bar

425 °C 5.5 bar 23.9 bar 31.8 bar 47.7 bar 71.6 bar 119.3 bar 198.8 bar

450 °C 4.6 bar 23.4 bar 31.2 bar 46.8 bar 70.2 bar 117.1 bar 195.1 bar

Tab. 2: ASME B16.5-2003

Class

2500

Pressure-Temperature-Assignment - ASME anges

Material A105

Temperature range Class 150 Class 300 Class 400 Class 600 Class 900 Class

1500

-29 … +38 °C 19.6 bar 51.1 bar 68.1 bar 102.1 bar 153.2 bar 255.3 bar 425.5 bar

50 °C 19.2 bar 50.1 bar 66.8 bar 100.2 bar 150.4 bar 250.6 bar 417.7 bar

100 °C 17.7 bar 46.6 bar 62.1 bar 93.2 bar 139.8 bar 233.0 bar 388.3 bar

150 °C 15.8 bar 45.1 bar 60.1 bar 90.2 bar 135.2 bar 225.4 bar 375.6 bar

200 °C 13.8 bar 43.8 bar 58.4 bar 87.6 bar 131.4 bar 219.0 bar 365.0 bar

250 °C 12.1 bar 41.9 bar 55.9 bar 83.9 bar 125.8 bar 209.7 bar 349.5 bar

300 °C 10.2 bar 39.8 bar 53.1 bar 79.6 bar 119.5 bar 199.1 bar 331.8 bar

325 °C 9.3 bar 38.7 bar 51.6 bar 77.4 bar 116.1 bar 193.6 bar 322.6 bar

350 °C 8.4 bar 37.6 bar 50.1 bar 75.1 bar 112.7 bar 187.8 bar 313.0 bar

375 °C 7.4 bar 36.4 bar 48.5 bar 72.7 bar 109.1 bar 181.8 bar 303.1 bar

400 °C 6.5 bar 34.7 bar 46.3 bar 69.4 bar 104.2 bar 173.6 bar 289.3 bar

425 °C 5.5 bar 28.8 bar 38.4 bar 57.5 bar 86.3 bar 143.8 bar 239.7 bar

450 °C 4.6 bar 23.0 bar 30.7 bar 46.0 bar 69.0 bar 115.0 bar 191.7 bar

Tab. 3: ASME B16.5-2003

Class

2500

42749-EN-130227

VEGAPASS 81 •

9

Page 10

3 Supplement

ASME anges In the same pressure class (Class) anges of CS steel

can withstand higher pressures than anges of material

316L. Flanges of measuring instruments are often made

of 316L. If VEGAPASS 81 is manufactured of CS steel

(ASTM A106, A106), then you select a ange (316L)

with higher nominal pressure (Class) for the measuring

instrument used.

Note: You will nd a complete overview of the available pro-

cess ttings in the "congurator" on our homepage at

www.vega.com/congurator.

Process tting - Measuring instrument ange (C)

Flange DIN DN 50, DN 80

Flange ASME 2", 3"

Thread G (DIN 3852-A), NPT (ASME B1.20.1)

Ventilation connection (D)

Thread G½ (DIN 3852-A), ½ NPT (ASME B1.20.1)

Thread G¾ (DIN 3852-A), ¾ NPT (ASME B1.20.1)

Flange from DN 15 or ½"

Chamber closing (E)

Tube sheet

Flange DIN DN 50, DN 80 (with blind ange)

Flange ASME 2", 3" (with blind ange)

Process tting - Rinsing air connection (F)

Thread up to G1 (DIN 3852-A), 1 NPT (ASME B1.20.1)

10

42749-EN-130227

VEGAPASS 81 •

Page 11

3.2 Dimensions

100 %

0 %

3 Supplement

1

C

150 mm

(5.91")

B

200 mm (7.87")

D

M

B

100 mm (3.94")

3

150 mm

(5.91")

F

E

ø 88,9 mm

(3.5")

2

ø 60,3 mm

(2.37")

Z

Fig. 5: Bypass tube with VEGAFLEX

1 Seal - measuring instrument ange

2 Type plate

3 Closure rinsing connection, e.g. blind plug

B Vessel connection top/bottom

2)

C Measuring instrument ange

D Ventilation connection (optional)

E Chamber closing

F Rinsing connection

M Dimensions: tube center to tube center, 300 … 4000 mm (11.8 … 157.5 in)

z Length - Ventilation connection (depending on the connection)

2)

The distance to the measuring instrument ange is variable - Standard: 200 mm (7.87 in)

42749-EN-130227

VEGAPASS 81 •

11

Page 12

Printing date:

All statements concerning scope of delivery, application, practical use and operating conditions of the sensors and processing systems correspond to the information

available at the time of printing.

Subject to change without prior notice

© VEGA Grieshaber KG, Schiltach/Germany 2013

VEGA Grieshaber KG

Am Hohenstein 113

77761 Schiltach

Germany

Phone +49 7836 50-0

Fax +49 7836 50-201

E-mail: info.de@vega.com

www.vega.com

42749-EN-130227

Loading...

Loading...