Page 1

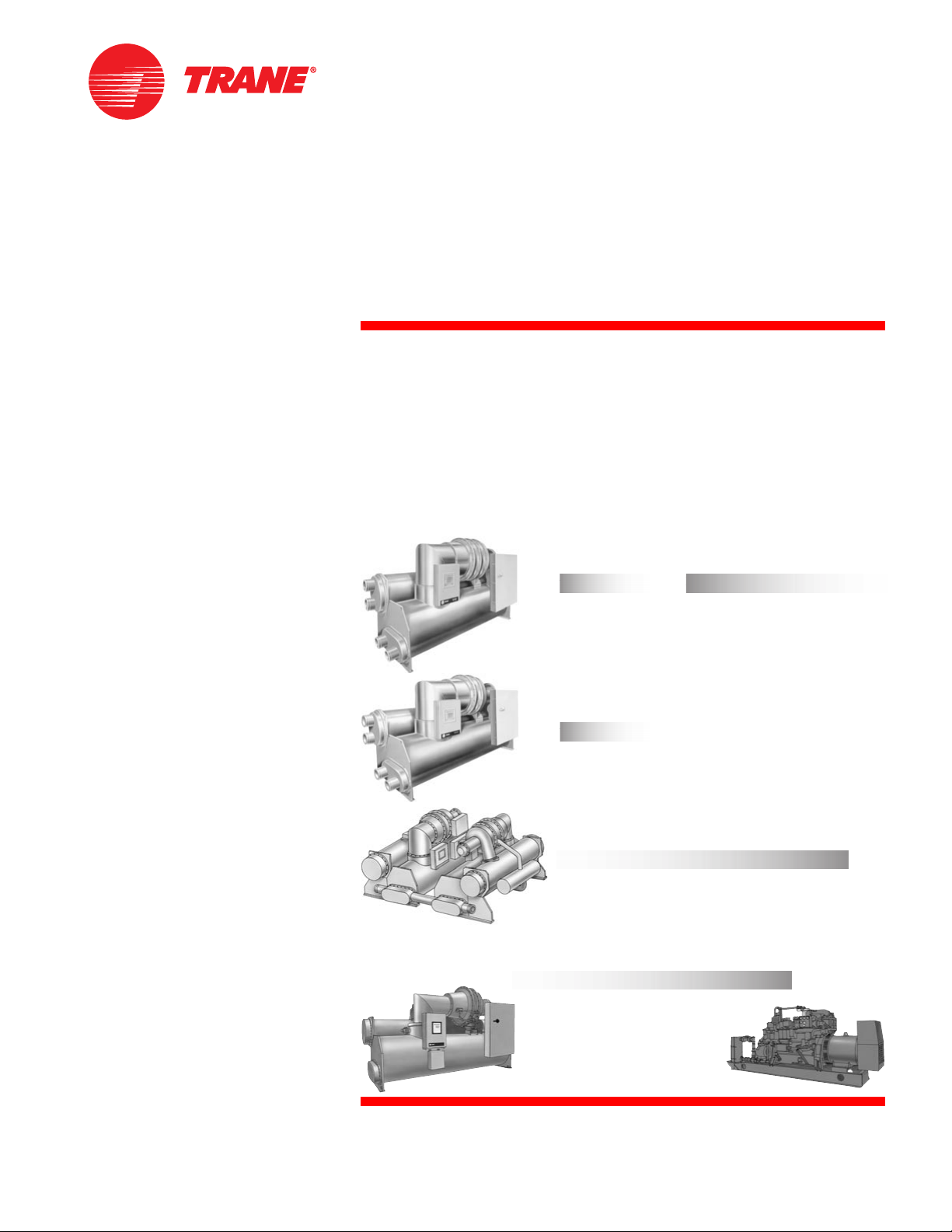

CenTraVac

™

Liquid Chillers

Centrifugal Liquid Chillers/

Water-Cooled

170-3500 Tons

50 and 60 Hz

Built For the Industrial and Commercial Markets

CVHE — Three Stage

170

CVHF — Two-Stage CenTraVac

325 1750

LHCV — Module CenTraVac

1300

GPC — Gas Powered CenTraVac Package

170

500

CVHG — Three Stage

450 1300

3500

3500

CTV-PRC007-ENApril 2001

Page 2

World’s Most

Efficient Lowest

What We Mean By Earth•Wise

Breaking the .48 kW/Ton

Efficiency Barrier

The Trane Earth•Wise CenTraVac has a

proven track record as literally the

world’s most efficient, lowest emissions

chiller. In fact, a portion of the product

line is selectable at an unmatched

efficiency level of .48 kW/ton, at standard

ARI rated conditions. This is an efficiency

level of 16 to 25 percent better than

competitive chillers using other

alternative refrigerants, which are

typically in the .56 to .60 kW/ton range.

On a 1000-ton chiller, this efficiency

difference can provide savings of over

$24,000 per year or nearly three quarters

of a million dollars over the life of the

machine . . . typically more than twice

the initial cost of the machine. And, at

part-load conditions, the kW/ton ratings

are even better; a fact that can be seen

by comparing Trane’s ARI certified

applied part load values (NPLV’s) to

those of competitive units.

The development of the .48 kW/ton

chiller also has a positive environmental

impact. Consider this:

If every centrifugal chiller in the world

were able to operate at .48 vs .56 kW/ton,

utility generated greenhouse gas

emissions could be reduced annually by

nearly 17 billion pounds of CO

SO

and NO

2

64 and 27 billion grams, respectively.

This reduction is equivalent to removing

more than two million cars from the

road or to planting nearly 500 million

trees each year.

could be reduced by over

x

while

2

Introduction

Lowest Total Refrigerant

Emissions In The Industry

Furthermore, the Trane “near zero”

emissions Earth

the lowest total refrigerant emissions in

the industry. So low that it’s essentially

a closed system.

The key to the industry’s highest energy

efficiency and lowest leak rate is the

use of a low pressure refrigerant

DuPont calls SUVA-123; a refrigerant

that has the lowest direct-effect global

warming potential and the highest

thermodynamic efficiency of all nonCFC refrigerants; a refrigerant in use in

more new centrifugals today than all

other alternatives combined.

Balancing Our Accountability

for Ozone Depletion, Global

Warming and Energy

Efficiency

Reduced power plant emissions and

the industry’s lowest refrigerant

emission rate put the Trane .48 kW/ton

Wise centrifugal chiller in a class

Earth

•

by itself, from both a business and an

environmental standpoint. The future

lies in the prudent balance that takes

into account the importance of ozone

depletion, global warming and energy

efficiency. A balance that is right for

both business and the environment.

Wise chiller also has

•

Emissions Chiller

Built For The Industrial Market

Direct drive for reliability

•

Multi-stage compressor for efficiency.

•

“Near Zero” refrigerant emission

•

design.

Evaporator and condenser designed to

•

maximize efficiency and reduce

operating costs.

Proven shell and tube design offering a

•

variety of high performance heat

transfer surfaces.

Evaporator, condenser and

•

compressor combinations allow

selection of a chiller that best meets

the system requirements.

Options like heat recovery, free

•

cooling, auxiliary condensers, ice

storage and a unit-mounted starter for

expanded capability and maximum

efficiency.

Complete factory assembly of the

•

CenTraVac

assembly labor and expense.

Machines designed for operating with

•

environmentally acceptable HCFC-123.

Trane patented fixed orifice system for

•

ensuring proper refrigerant flow at all

load conditions. This eliminates the

need for other moving parts such as

float valves, expansion valves.

Low speed direct drive capability offers

•

up to 5 percent more energy efficiency,

at full load, than gear drive chillers.

Also, low speed direct-drive operation

improves reliability and maintenance

costs are also lower.

CenTraVac control panel

•

Adaptive Control

•

Microprocessor based

•

Complete operating status and

•

diagnostics display.

Interfaces with building management

•

system.

High efficiency Purifier™ Purge works

•

as an early warning leak detector that

also takes purge refrigerant emissions

to an industry low.

™

options for reduced jobsite

™

CTV-PRC007-EN©American Standard Inc. 2001

Page 3

Contents

Introduction

Features and Benefits

Components, Standard and Optional Features,

Factory Performance Testing,

Refrigeration Cycle, Control Panel

Unit Options

Unit Mounted Starter, Adaptive Frequency Drives,

Free Cooling

System Options

Auxiliary Condenser, Ice Storage, Heat Recovery,

Chilled Water Resets

Application Considerations

Selection Procedure

Performance Data

Jobsite Connections

2

6

13

21

26

28

30

32

CTV-PRC007-EN

Controls

Weights

Physical Dimensions

Mechanical Specifications

33

39

41

48

3

Page 4

Trane Hermetic

Centrifugal

A Tradition of Innovation

The first Trane centrifugal chiller, the

Turbovac™ was introduced in 1938. The

simple, direct drive, slow speed design

of the Turbovac revolutionized the air

conditioning industry. The chiller was

attractive to customers because its

hermetic design reduced frequent

service requirements.

™

In 1951 the Trane CenTraVac

chiller was introduced. Its unique two

stage compressor with multiple inlet

guide vanes and patented economizer

reduced energy consumption on typical

applications to less than 0.8 kW/ton.

The model PCV CenTraVac chiller that

was introduced in 1966, allowed quality

air conditioning for applications as small

as 120 tons.

In 1982 the CenTraVac chiller solidified

its position as the industry leader by

introducing a three-stage compressor

and a two-stage economizer. As a result,

this chiller was 5 to 20 percent more

efficient than previous designs.

Today’s CenTraVac chiller still relies on

the dependability of the proven direct

drive and exclusive slow speed

operation. Low operating costs and high

reliability continue to be the CenTraVac

chiller hallmark.

When a source of energy other than

electricity is required

The Trane CenTraVac has the standard

option of being coupled to a Waukesha

Enginator to quite simply convert

natural gas to chilled water. With COPs

in the range of 1.5 to 2.2 depending on

options selected, makes this option a

very simple and attractive alternative

when an alternative fuel source is

desired.

centrifugal

Introduction

Trane GPC* Benefits

Combines two industry-recognized

•

and proven products, the Trane

Earth•Wise CenTraVac and Waukesha

Enginator

Ability to do both base and peak

•

shaving

No on-site piping connections

•

Refrigerant leaks minimized

•

No need to remove refrigerant

•

charge from chiller during downtime

Installations more flexible, simpler

•

and cost effective

Ability to place the engine generator

•

set in a location remote of the chiller

Allows for efficient use of plant floor

•

space

Provides flexibility in sound sensitive

•

work areas

*Limited availability for International orders –

Please contact International CenTraVac Marketing

Group.

Unmatched Expertise

The performance and reliability of a

CenTraVac

of experienced field sales engineers with

support from headquarters experts. No

other manufacturer can offer that degree

of support to its customers.

In the design phase, application

engineers can help answer your

questions or solve your problems.

During the selection phase, software

engineers are available to help you

evaluate equipment alternatives. At the

installation stage, field start-up of the

CenTraVac chiller is included in the

purchase price. Trane offers this support

and more when you need it.

Delivery And Design Flexibility

If delivery time is a priority, Trane can

meet your needs with a variety of quick

shipment choices. Most fast track

building schedules can be met with one

of these choices.

Design flexibility means Trane can

custom build a unit to specific job

requirements. Design parameters such

as shell type, compressor, kW/ton,

waterside pressure drop, as well as full

and part load performance can be built

to meet requirements.

™

chiller is backed by a team

Water Chillers

ISO 9001 Certification

ISO 9001 Certification applies to the

Trane La Crosse Business Unit. This

process is based on the La Crosse

Business Unit’s ISO 9001 certified quality

system. This system is documented in

procedures which define how quality

assurance activities are managed,

performed, and continuously monitored.

Included in the system are verification

checkpoints from the time the order is

entered until final shipment. In addition,

product development for the

marketplace is subjected to formal

planning, review and validation. The

system is designed to assure maximum

consistency in meeting customer

requirements.

The Beauty of Simplicity

The reliability of a centrifugal chiller

starts with its basic product design. At

Trane we’ve found that the straightest

path to reliability is simplicity. Years of

research and field testing have honed

the design of the CenTraVac chiller to a

simple, precise solution to a complex

engineering problem.

This simple design provides efficiency

and reliability benefits. The Trane

CenTraVac chiller has only one moving

part — no gear boxes, couplings or extra

shafts. The single rotating shaft is

supported by two aircraft turbine grade/

rated bearings. This direct drive concept

minimizes the chance of failure for

moving parts. It also reduces wear and

drag on parts, resulting in more efficient

operation.

CTV-PRC007-EN4

Page 5

Introduction

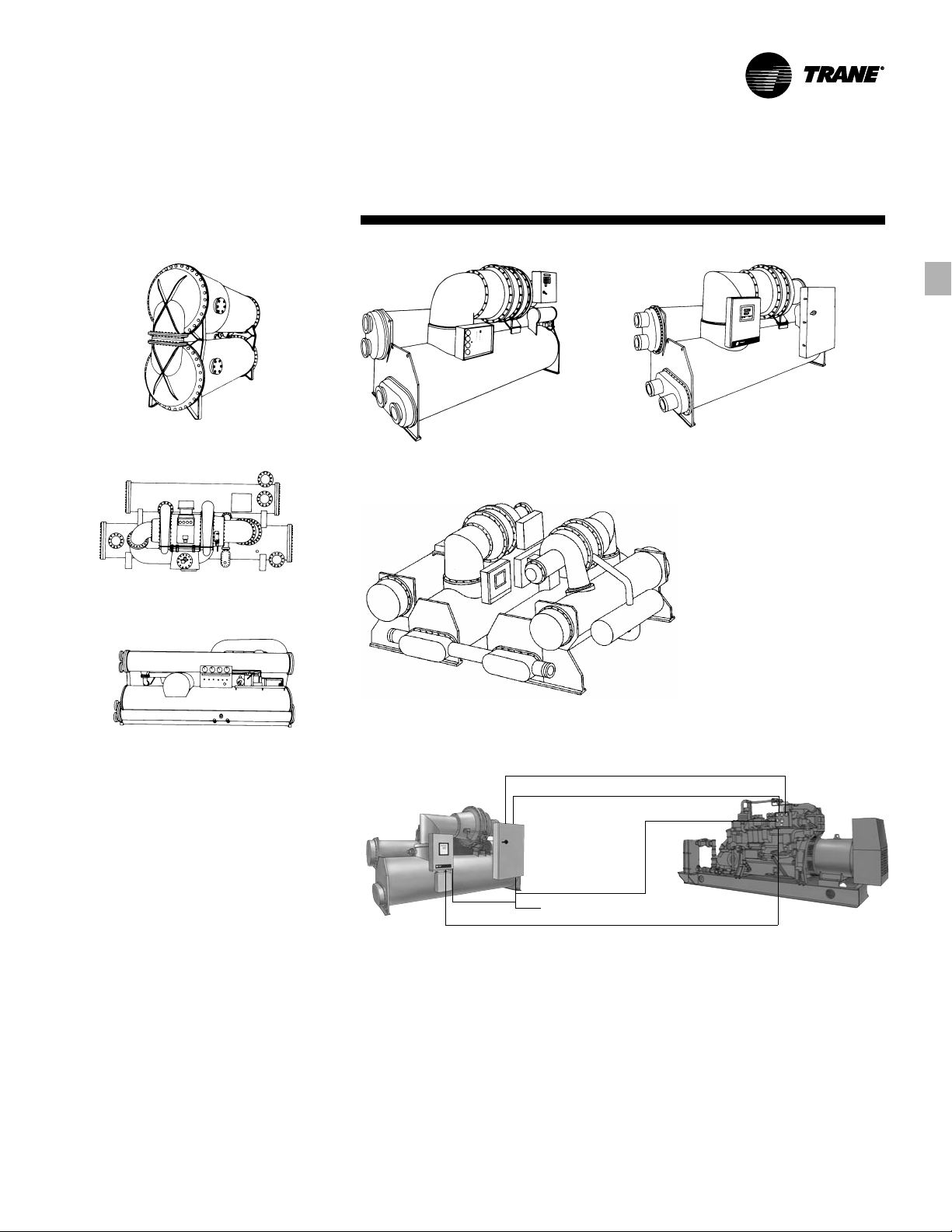

1939 — The Trane Turbovac

1951 — The original Trane CenTraVac

chiller

1965 — The Model PCV CenTraVac

chiller

Specific Trane centrifugal chiller

performance is certified by ARI Standard

550/590. Trane centrifugal chillers tested

within the scope of the ARI program

display the ARI symbol of compliance

(shown on back cover) to certification

sections of ARI Standard 550/590.

™

Purifier

rated in accordance with ARI

Standard 580.

Those applications in this catalog

specifically excluded from the ARI

certification program are:

•

•

•

•

•

•

•

purge with Purifier Plus™ are

Low temperature applications,

including ice storage

Glycol

Chillers above 2000 tons

Free cooling

Heat recovery

Auxiliary condenser

Chillers that are 50 Hertz

1992 — The two-stage CVHF CenTraVac

1982 — The three-stage CVHE CenTraVac

Chiller

1992 — The LHCV CenTraVac Modular Chiller system

//

115 VAC/60 Hz/50 Hz

//

1997 — The Gas Powered CenTraVac (GPC) Chiller Package

Chiller

3 Phase Power

Control Interface

Control Interface

CTV-PRC007-EN

5

Page 6

Attributes of

Features and Benefits

Comparing the Attributes of

Low Pressure Chiller Operation

to High Pressure Chiller

Operation.

Trane CenTraVac chillers continue to offer

time tested and proven low pressure

refrigerants including the alternative

Evaporator

Condenser

Monitoring

of leak rate in-leakage with a purge timer — periodic leak checks

Typical

Pressures Evap: 18.7 inches of Mercury Evap: 33.1 psig

(38°F evap.) Cond: 6.1 psig Cond: 124.1 psig

(100°F cond.)

*Trane Purifier Purge efficiency does not exceed 0.002 lbs./refrigerant/lbs.-air

Low Pressure Medium/High Pressure

Always at low negative pressure

•

Air leaks inward at low rate

•

Refrigerant lost: (# air leak in) x purge efficiency*

•

No refrigerant loss is into equipment room (vented to the

•

outside via purge)

At positive pressure during operation

•

Usually at negative pressure during inactivity (air leaks

•

inward)

Refrigerant leaks outward at very low rate during operation

•

Trane Purifier Purge is able to continuously monitor

•

Refrigerant monitor as required by ASHRAE — purchase refrigerant monitor

•

Purge timer can be connected to building automation

•

system for notification of increased purge operation (inleak). Similarly, the refrigerant monitor can be connected to pressure chiller is during spring start-up. This means that a

the building automation system. chiller which develops a leak in the summer, may leak

HCFC-123 HFC-134a

environment friendly HCFC- 123. Trane

CenTraVac chillers provide the safety of

low pressure with continued product

improvement in leak proof design.

Consider the following benefits of low

pressure over high pressure chillers.

Always at positive pressure

•

Refrigerant leaks outward at moderate rate

•

Refrigerant loss is into equipment room

•

Always at high positive pressure

•

Refrigerant leaks outward at very high rate

•

Only ways to monitor leak rate on high pressure chiller are

•

Refrigerant monitor as required by ASHRAE

•

Normally the only time that a leak is detected on a high

•

continuously until the following spring.

Low Pressure

Chiller Operation

CTV-PRC007-EN6

Page 7

Features and

Control

Benefits

Operator Control Panel

Trane has multi-language support for all

chillers controlled by the UCP2

including but limited to: CVHE, CVHF,

CVHG, GPC and LHCV alarm. The

standard Clear Language Display (CLD)

supports eight languages including

English, French, German, Spanish,

Katakana, Italian, Portuguese and Dutch.

The Complex Character CLD was added

to support languages such as Traditional

and Simplified Chinese, Japanese, Thai

and Korean.

The Complex Character CLD is available

as a retrofit kit for the standard CLD on

the UCP2 panel. With the same wiring

and mounting, it is as simple as

disconnecting two wires, unbolting the

existing CLD, bolting on the Complex

Character CLD and reconnecting the two

wires.

™

Panel

Capabilities include:

Super-twist LCD display with

•

backlighting for readability.

Chiller data (more than 200 items)

•

including:

- Status

- Setpoints

- Field start-up items

- Machine configuration items

- Service test items

Status reports:

•

- Chiller Report

- Refrigerant Report

- Compressor Report

Custom report capability.

•

More than 100 diagnostic messages

•

including a history log of the last 20

diagnostics

- An alarm indicator

- Expanded help messages

- Operator security

- Internationally recognized symbols

CTV-PRC007-EN

7

Page 8

Features and

Internally enhanced or

smooth bore tubes

Benefits

Various tube materials

and thicknesses

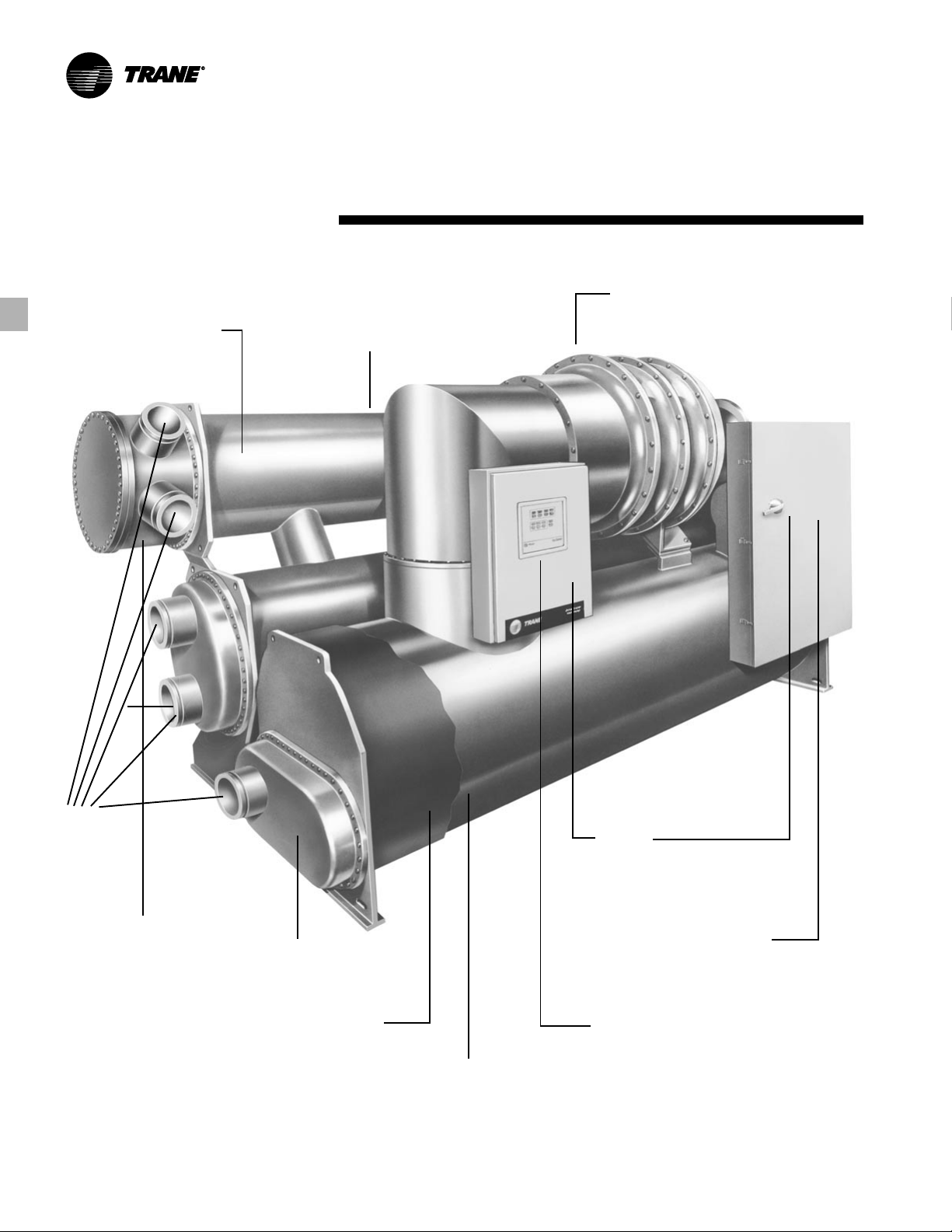

Components

Controls and paints for outdoor

use or corrosive environments

Victaulic or

flanged

connections

Marine or standard

waterboxes

1, 2, 3, pass evaporator

Factory installed insulation

Special construction to facilitate

chiller disassembly for construction

projects with tight space clearances

or component weight limitations

UL label

Full complement of electrical

starters and accessories

(unit mounted or remotely)

- Panel chilled water reset

- External chilled water and current limit

setpoints

- Evaporator / Condenser differential

pressure

- Condenser relief request

- Maximum capacity

- Communication link to BAS

- Printer module

CTV-PRC007-EN8

Page 9

Standard

Features and

Benefits

Standard Features

The following features are provided as

standard with all Trane CenTraVac

chillers:

Motor-compressor assembly with

•

integral lubrication system.

Evaporator condenser assembly.

•

Two-stage economizer assembly on

•

CVHE/CVHG style units (single-stage on

CVHF style units).

Prewired instrument and control panel.

•

Oil and refrigerant charge.

•

Oil heater.

•

Isolation pads

•

Wiring and conduit for purge and oil

•

system interconnection to the main

control panel.

Installation, operation, and

•

maintenance instructions.

Start-up and operator instruction

•

service.

Advanced motor protection.

•

CenTraVac Motor

The motor provided in the Trane

CenTraVac chiller is a specially designed

squirrel cage, two pole induction motor

suitable for 50 and 60 hertz, three-phase

current.

Trane CenTraVac motors are cooled by

liquid refrigerant surrounding the motor

windings and rotor. Use of liquid

refrigerant results in uniform low

temperatures throughout the motor,

thereby promoting long motor life.

Refrigerant/Oil Pump Motor

The oil pump motor is a 120 volt,

50/60 hertz,

protective fusing and panel mounted

contactor.

Purge

The purge unit motor is a 120 volt,

50/60 hertz,

integral overload protection and panel

mounted contactor.

The use of an air-cooled condensing unit

obtains separation temperatures in the

purge drum as low as 0°F. Normal

operating efficiency does not exceed

0.002 lbs. of refrigerant lost per pound of

dry air removed. The purge system can

be operated at any time, independent of

chiller operation.

3

/4 hp, 1 phase motor with

3

/4 hp, 1 phase motor with

™

and Optional

Features

Optional Features

Trane offers a selection of optional

features to either complete the basic

chiller installation or to allow

modification for special purpose

applications.

Medium voltage (over 600 volts)

•

hermetic compressor motor

construction.

Complete line of compressor motor

•

starters.

Unit mounted starter accessory on low

•

voltage units up to an RLA of

1080 amps.

Marine waterboxes for evaporators

•

and condensers

High pressure (300 psig working

•

pressure) water side construction.

Free cooling.

•

Heat recovery or auxiliary condensers.

•

Smooth bore tubing.

•

Factory-applied thermal insulation

•

One-inch deflection spring isolators for

•

vibration-sensitive installations.

Building automation systems (BAS)

•

interface

Variable speed drives

•

Internally enhanced tubes

•

Various tube wall thicknesses

•

UL Label

•

Three pass evaporator/one pass

•

evaporator

Special construction to facilitate chiller

•

disassembly at the job

CuNi Tubes

•

Special paint and controls for outdoor

•

use or corrosive environments

Unit mounted refrigerator monitor

•

CTV-PRC007-EN

9

Page 10

Factory

Factory Testing for

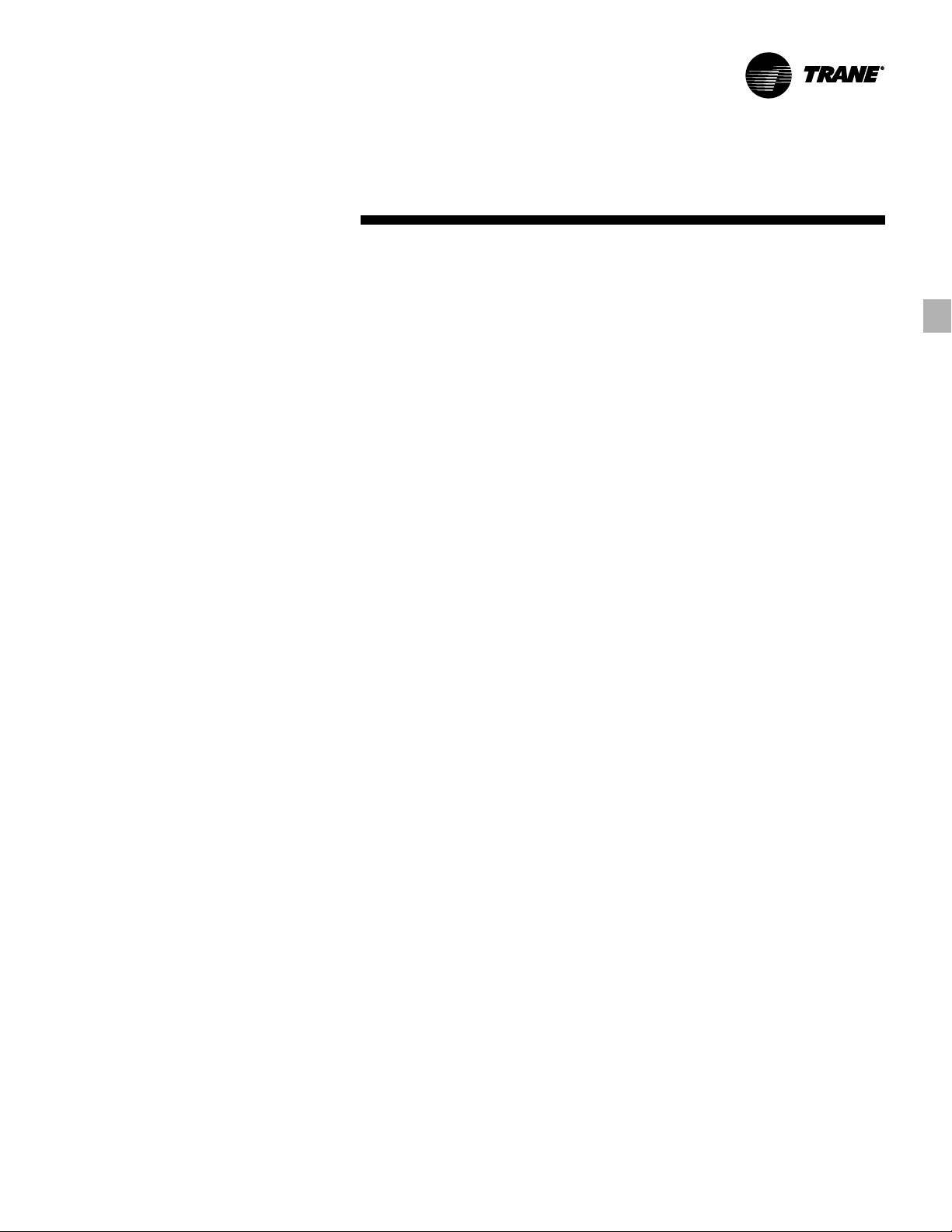

Assured Performance

To prove that your chiller will perform as

promised, Trane offers factory

performance testing, which you can

witness.

Trane provides laboratory-grade,

calibrated performance testing on

ARI approved test loops that proves the

performance of the chiller tailored to

your application. The test provides:

Confirmed efficiency

•

Confirmed capacity

•

Smooth trouble-free start-up confirmed

•

through factory testing and

commissioning of both chiller and

controls

Trane believes centrifugal chiller testing

is so important that we invested over $2

million in CenTraVac testing facilities.

Testing is in accordance with ARI

Standard 550/590 and calibration of

instrumentation meets or exceeds the

National Institute of Standards

Technology (NIST).

The industry has responded to the

demand for more efficient chillers by

developing machines with component

mix-matching and many money saving

options. It’s possible that with the

thousands of component combinations

available, a specific chiller combination

may be laboratory tested for the first

time.

Trane offers two levels of CenTraVac

performance testing:

A performance test at design

•

conditions plus a certified test report.

A customer-witnessed performance

•

test at design conditions plus a certified

test report.

Trane is part of the ARI 550/590

certification program. The selection

program and machines bear the ARI seal

of approval. Performance testing is a key

part of this program. While the

certification program is technically

sound, a factory run test, with your

machine on the test stand, is still the best

way to confirm machine performance

and a trouble-free start-up.

Features and

Benefits

The single package design of the

CenTraVac chiller allows testing of each

assembled chiller at the factory. Actually

all components including the evaporator,

condenser, compressor and control

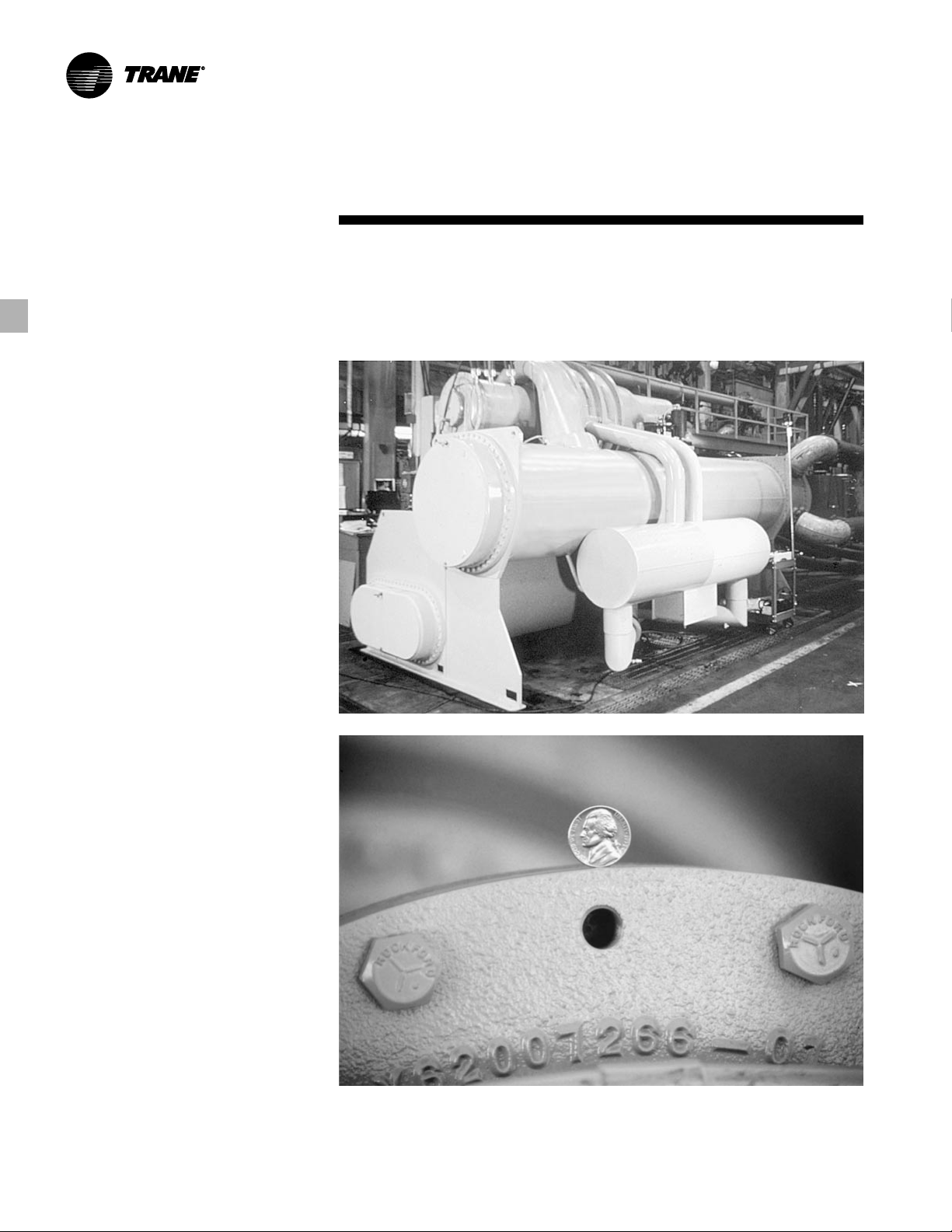

During customer witnessed performance tests of Trane CenTraVac chillers, a nickel

can be balanced on the edge of the compressor-motor assembly, demonstrating the

extremely low vibrations generated by the unit while operating at full and part load

conditions.

Performance

Testing

panel are tested before final assembly.

After assembly, performance testing of

the chiller can confirm proper operation

and virtually eliminate jobsite start-up

problems.

CTV-PRC007-EN10

Page 11

Features and

Refrigeration

Design Simplicity

Impellers are keyed directly to the motor

shaft for high reliability and performance

and low life-cycle costs.

Reliable Motor Cooling

The motor is engulfed in liquid

refrigerant to provide efficient, complete

cooling at all load conditions. This

system is reliable and easy to maintain.

Fixed Orifice Flow Control

For proper refrigerant flow control at all

load conditions, the CenTraVac design

incorporates the Trane patented fixed

orifice system. It eliminates float valves,

thermal expansion valves and other

moving parts. Since there are no moving

parts, reliability is increased.

Quiet Operation

With only one moving component — the

rotor and impeller assembly — the Trane

low speed, direct drive design operates

exceptionally quietly. The smoothly

rotating CenTraVac compressor is

inherently quieter than other compressor

types. Typical CenTraVac chiller sound

measurements are among the quietest in

the industry. Trane can guarantee sound

levels with factory testing and

measurements in accordance with

ARI standard 575.

The Reliability Standard

Just as a multi-stage turbine is more

efficient than a single stage turbine, the

CenTraVac multi-stage compressors are

more efficient and reliable than singlestage designs.

Benefits

Cycle

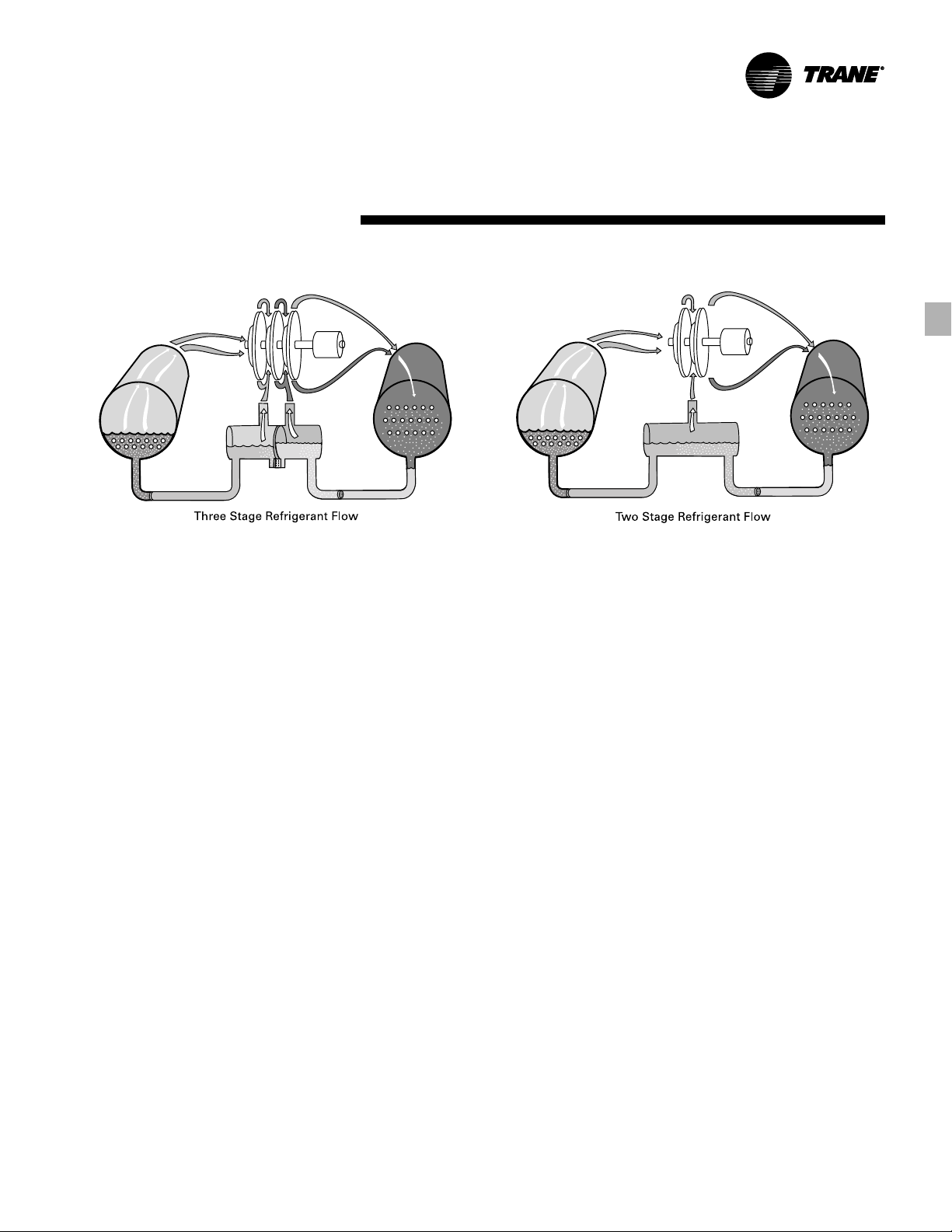

The CenTraVac™ Chiller Operating Cycle

Direct Drive Design — No Gear Losses

The direct drive compressor operates

without speed increasing gears, thus

eliminating gear energy losses.

Compressors using gears suffer mesh

losses and extra bearing losses in the

range of three to five percent at full load.

Since these losses are fairly constant

over the load range, increasingly larger

percentage losses result as load

decreases.

Multiple Stages of Compression

The compressor operates more

efficiently over a wide range of

capacities, virtually eliminating the need

for energy wasting hot gas bypass as

typically found on single stage chillers.

The radial component of velocity

determines the ability of the chiller to

resist interruption of smooth refrigerant

flow when operating at light loads and

with high condensing temperatures. This

interruption in flow and unstable

operation, called “surge” is avoided with

the two-stage design.

Inlet Guide Vanes

Part load performance is further

improved through use of moveable

designed variable inlet guide vanes. Inlet

guide vanes improve performance by

throttling refrigerant gas flow to exactly

meet part load requirements and by

prerotating refrigerant gas for optimum

entry into the impeller. Prerotation of

refrigerant gas minimizes turbulence and

increases efficiency.

Two-Stage Economizer

The CVHE/CVHG CenTraVac chiller has a

two-stage economizer — providing up to

seven percent greater efficiency than

designs with no economizer. Since the

CVHE/CVHG uses three impellers, it is

possible to flash refrigerant gas at two

intermediate pressures between the

evaporator and condenser pressures,

significantly increasing chiller efficiency.

This improvement in efficiency is not

possible in single-stage chillers since all

compression is done by one impeller.

Single Stage Economizer

The CVHF CenTraVac chiller has a singlestage economizer — providing up to 4

percent greater efficiency than designs

with no economizer.

Since the CVHF CenTraVac uses two

impellers, it is possible to flash

refrigerant gas at an intermediate

pressure between the evaporator and

condenser pressures, significantly

increasing chiller efficiency. This

improvement in efficiency is not possible

in single-stage chillers since all

compression is done by one impeller.

1

/2

CTV-PRC007-EN

11

Page 12

Features and

Refrigeration

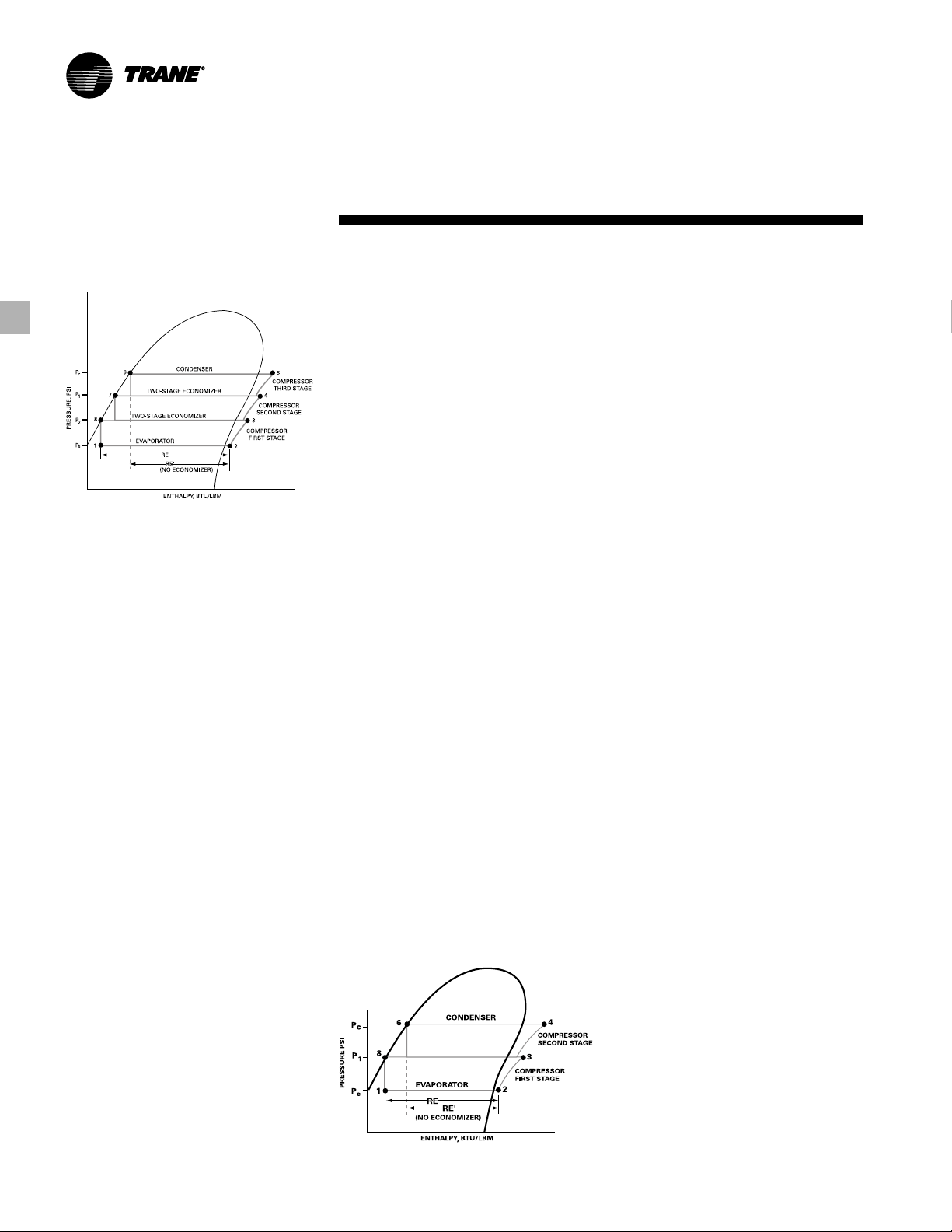

Three-Stage CenTraVac P-H Diagram

CenTraVac™ Three-Stage P-H Diagram

The pressure-enthalphy (P-H) diagram

describes refrigerant flow through the

major CVHE/CVHG chiller components.

This diagram confirms the superior

operating cycle efficiency of the threestage compressor and two-stage

economizer.

Evaporator — A liquid-gas refrigerant

mixture enters the evaporator at state

point 1. Liquid refrigerant is vaporized to

state point 2 as it absorbs heat from the

system cooling load. The vaporized

refrigerant then flows into the

compressor first stage.

Compressor First Stage — Refrigerant

gas is drawn from the evaporator into

the first stage compressor. The first stage

impeller accelerates the gas increasing

its temperature and pressure to state

point 3.

Compressor Second Stage —

Refrigerant gas leaving the first stage

compressor is mixed with cooler

refrigerant gas from the low pressure

side of the two-stage economizer. This

mixing lowers the enthalpy of the

mixture entering the second stage. The

second stage impeller accelerates the

gas, further increasing its temperature

and pressure to state point 4.

Compressor Third Stage — Refrigerant

gas leaving the compressor second

stage is mixed with cooler refrigerant

gas from the high pressure side of the

two-stage economizer. This mixing

lowers the enthalpy of the gas mixture

entering the third stage compressor. The

third stage impeller accelerates the gas,

Benefits

further increasing its temperature and

pressure to state point 5, then discharges

it to the condenser.

Condenser — Refrigerant gas enters the

condenser where the system cooling

load and heat of compression are

rejected to the condenser water circuit.

This heat rejection cools and condenses

the refrigerant gas to a liquid at state

point 6.

Patented Two-Stage Economizer and

Refrigerant Orifice System-Liquid

refrigerant leaving the condenser at state

point 6 flows through the first orifice and

enters the high pressure side of the

economizer. The purpose of this orifice

and economizer is to preflash a small

amount of refrigerant at an intermediate

pressure called P1. P1 is between the

evaporator and condenser pressures.

Preflashing some liquid refrigerant cools

the remaining liquid to state point 7.

Refrigerant leaving the first stage

economizer flows through the second

orifice and enters the second stage

economizer. Some refrigerant is

preflashed at intermediate pressure P2.

Preflashing the liquid refrigerant cools

the remaining liquid to state point 8.

Another benefit of preflashing refrigerant

is to increase the total evaporator

refrigeration effect from RE’ to RE. The

two-stage economizer provides a seven

percent energy savings compared to

chillers with no economizer.

To complete the operating cycle, liquid

refrigerant leaving the economizer at

state point 8 flows through a third orifice

system. Here, refrigerant pressure and

temperature are reduced to evaporator

conditions at state point 1.

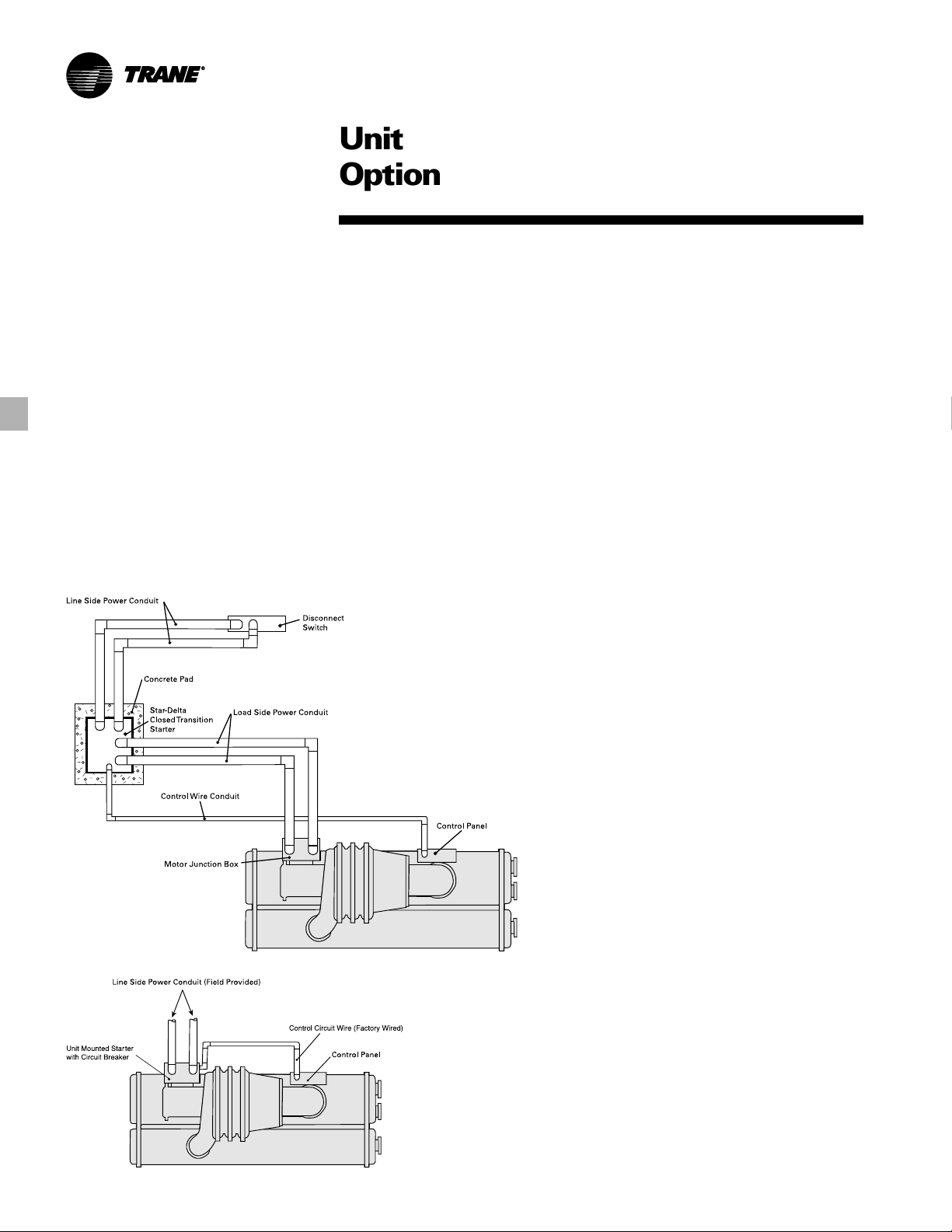

Two-Stage CenTraVac P-H Diagram

Cycle (Cont.)

CenTraVac Two-Stage P-H Diagram

The pressure-enthalphy (P-H) diagram

describes refrigerant flow through the

major CVHF chiller components. This

diagram confirms the superior operating

cycle efficiency of the two- stage

compressor and economizer.

Evaporator — A liquid-gas refrigerant

mixture enters the evaporator at state

point 1. Liquid refrigerant is vaporized to

state point 2 as it absorbs heat from the

system cooling load. The vaporized

refrigerant then flows into the

compressor first stage.

Compressor First Stage — Refrigerant

gas is drawn from the evaporator into

the first stage compressor. The first stage

impeller accelerates the gas increasing

its temperature and pressure to state

point 3.

Compressor Second Stage —

Refrigerant gas leaving the first stage

compressor is mixed with cooler

refrigerant gas from the economizer.

This mixing lowers the enthalpy of the

mixture entering the second stage. The

second stage impeller accelerates the

gas, further increasing its temperature

and pressure to state point 4.

Condenser — Refrigerant gas enters the

condenser where the system cooling

load and heat of compression are

rejected to the condenser water circuit.

This heat rejection cools and condenses

the refrigerant gas to a liquid at state

point 6.

Economizer and Refrigerant Orifice

System-Liquid refrigerant leaving the

condenser at state point 6 flows through

the first orifice and enters the

economizer. The purpose of this orifice

and economizer is to preflash a small

amount of refrigerant at an intermediate

pressure called P1. P1 is between the

evaporator and condenser pressures.

Preflashing some liquid refrigerant cools

the remaining liquid to state point 8.

Another benefit of flashing refrigerant is

to increase the total evaporator

refrigeration effect from RE’ to RE. The

economizer provides a 4

energy savings compared to chillers with

no economizer. To complete the

operating cycle, liquid refrigerant leaving

the economizer at state point 8 flows

through a second orifice system. Here,

refrigerant pressure and temperature are

reduced to evaporator conditions at state

point 1.

1

/2 percent

CTV-PRC007-EN12

Page 13

Unit

Unit Mounted

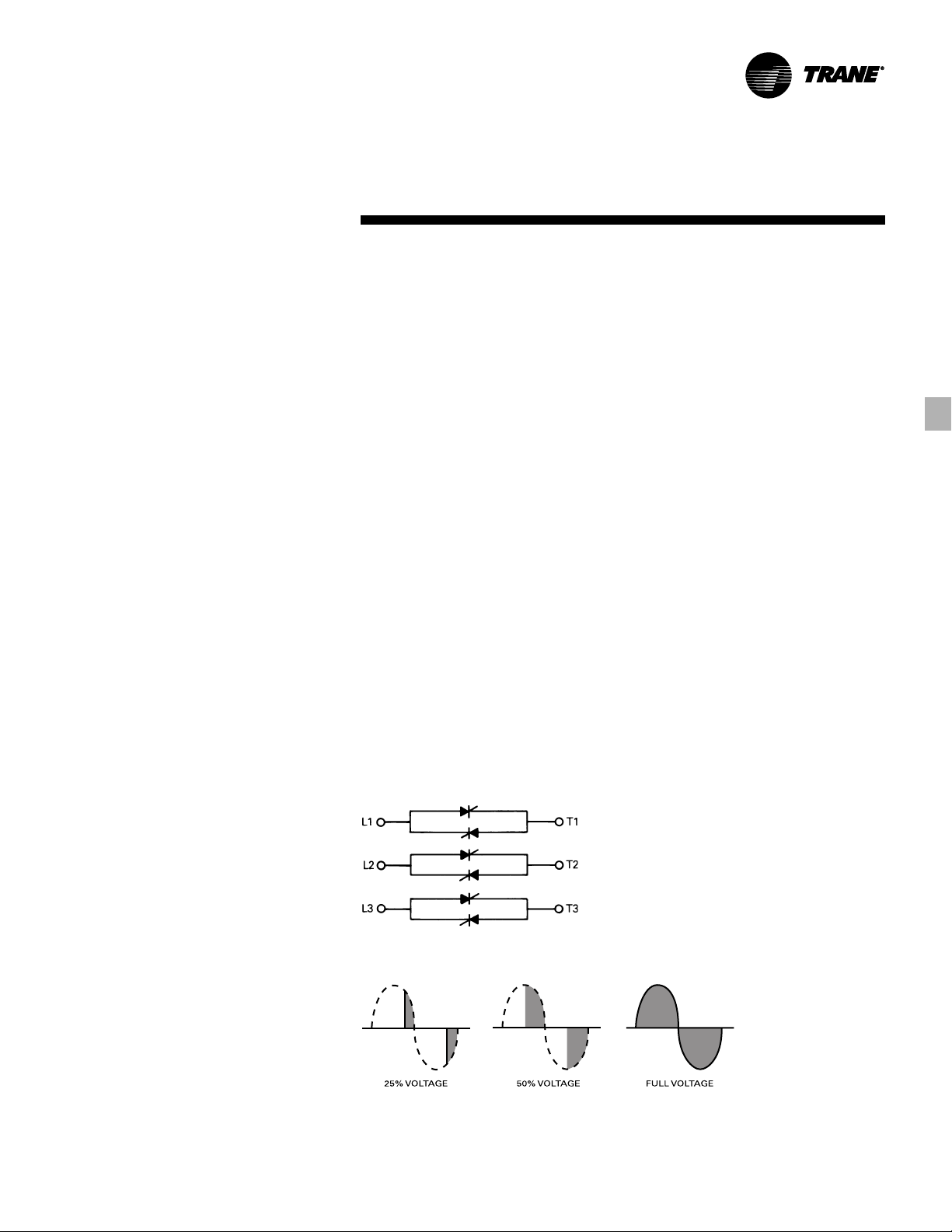

Unit-Mounted Starters

Trane factory installed options make

installation of a CenTraVac™ chiller easier,

faster and less costly. Another example

of the Trane packaged concept is the

factory installed unit-mounted star delta

starter available on CenTraVac chillers up

to 1300 tons capacity or solid-state

starters up to 1000 tons, depending on

jobsite electrical requirements. It’s a

single chiller/starter package designed

for years of reliable operation and low

life-cycle costs.

Installation cost is reduced by eliminating

chiller-to-starter, starter-to-disconnect

and starter-to-control panel field wiring.

All this wiring is completed and tested in

the factory, ensuring electrical integrity.

Since most wiring is factory completed,

electrical system design time is reduced.

Starter components are pre-engineered

and selected to provide a reliable, cost

effective chiller/starter package. This

single source responsibility for the

CenTraVac chiller and unit-mounted

starter package is a real advantage.

Potential scheduling problems

associated with separate starter and

chiller installations are eliminated. When

the CenTraVac chiller arrives at the

jobsite with the unit-mounted starter, the

only remaining wiring is the main power

wiring to the disconnect switch, and a

few simple electrical interlocks to the

chilled water and condenser water flow

sensing devices.

To ensure a trouble-free start-up on the

electrical side, the unit-mounted starter is

tested with the chiller as part of the

factory performance testing program.

Our commitment to customer and

equipment safety offers the Underwriters

Laboratories Inc. (UL) mark of safety on

both chiller and starter and available

accessories.

Compressor Motor Starting Equipment

Features

Trane can provide compressor motor

starting equipment built to rigid Trane

specifications. The types of starters

available include:

Low Voltage (200 to 600 volts)

Star (wye)-delta closed transition

•

Full voltage

•

Options

Autotransformer, closed transition

•

Solid-state starters

•

Medium Voltage (2300 to 6000 Volts)

Full voltage

•

Primary reactor, closed transition

•

Autotransformer, closed transition

•

Medium voltage starters are provided as

standard with a non-load break isolation

switch and current limiting fuses.

All starters provided by Trane include the

following standard features for safe,

efficient application and ease of

installation:

NEMA 1 starter enclosure.

•

120 volt, 60 hertz, 1 phase fused pilot

•

and safety circuits.

Control power transformer (4.0 KVA)

•

with 120 volt, 50 or 60 hertz, singlephase.

One pilot relay to initiate start

•

sequence from CenTraVac control

circuit signal.

Starter enclosures capable of being

•

padlocked.

Automatic transfer from wye to delta

•

on any two-step starter.

In addition, Trane offers a wide selection

of optional starter features.

Starters with standard or high

•

interrupting capacity circuit breakers,

to provide disconnect means and short

circuit protection (low voltage only).

Ammeters and voltmeters.

•

Special function pilot lights.

•

Special NEMA enclosures.

•

Ground fault protection.

•

Power factor correction capacitors.

•

I.Q. Data Plus monitor device.

•

If the CenTraVac compressor starting

equipment is provided by others, the

starter must be designed in accordance

with the current Trane standard

engineering specification “Water-Cooled

CenTraVac

also recommended that two copies of

the interconnecting and control circuit

wiring diagrams be forwarded to The

Trane Company for review. This service

is provided at no charge, and is intended

to help minimize the possibility that

Trane CenTraVac chillers will be applied

in improper starting and control

™

Starter Specification.” It is

Starter

systems. However, the responsibility for

providing proper starting and control

systems must remain with the system

designer and the installer.

Contact your local Trane sales office for

further information.

The typical equipment room layout for a

Trane CenTraVac

mounted starter are shown in Figures

O-1 and O-2. A NEMA 1, star-delta (wyedelta) type closed transition reduced

voltage motor starter is mounted, as an

optional accessory, on Trane CenTraVac

chillers rated up to and including 1080

RLA on low voltage (600 volts and

below) systems. All power and control

wiring between the starter and the chiller

are factory assembled. Factory assembly

enhances total system reliability and

integrity. Total installed chiller/starter

costs are significantly reduced by the

unit mounted starter option rather than a

conventional remote mounted starter.

Benefits

Reduces starter installation costs 20 to

•

35 percent:

By eliminating chiller-to-starter field

•

wiring

By eliminating starter-to-disconnect

•

switch field wiring (when optional

circuit breaker is used)

By eliminating field installed

•

disconnect switch (when optional

circuit breaker is used)

By eliminating starter mounting pad

•

and required equipment room floor

space

By eliminating control wiring from

•

starter to control panel

Electrical system reliability is

•

enhanced:

By reducing the number of field

•

electrical connections

By making starter-to-chiller electrical

•

connections under factory-controlled

conditions

By testing the entire chiller/starter

•

combination, in the factory

By providing control components

•

designed to operate with the unique

CenTraVac motor/compressor start and

protection subsystem

Single Source Responsibility

•

Trane retains complete responsibility

for the starter and associated chiller/

starter interconnecting wiring.

™

unit or remote

CTV-PRC007-EN

13

Page 14

Unit

Unit Mounted

Options

System Design Time Cost Savings

•

System design time is reduced, since

all starter components and

interconnecting wiring are preengineered and selected.

Complete package available with

•

Agency Approval

Application

•

The Trane unit mounted starter can be

applied on low voltage (600 volts) and

below applications up to

approximately 1300 tons capacity. To

determine the unit mounted starter to

be used with a particular selection, it is

necessary to know the current draw of

the compressor motor. The starter

current draw must be greater than, or

equal to, the compressor motor

current draw.

Figure O-1 – Typical Equipment Room Layout – Conventional Remote Star-Delta Starter

Figure O-2 – Typical Equipment Room Layout – Unit-Mounted Star-Delta Starter

Reliability

•

The unit mounted starter is a star-delta

closed transition electromechanical

starter. Motor starters of this

configuration have proven reliability in

thousands of centrifugal chiller

applications around the world. The

proven electromechanical concept plus

the use of industrial quality

components makes the CenTraVac unit

mounted starter dependable in all kinds

of service applications.

Operation

The unit mounted starter is a star (wye)

delta, closed transition, reduced voltage

starter. When starting and during

acceleration, the motor is connected in

its wye configuration. Because of this

arrangement the voltage applied to the

Starter (Cont.)

motor windings is reduced to one

divided by the square root of three or

0.58 times line voltage. This reduction in

winding voltage results in a reduction in

inrush current. The inrush current is 0.33

times the full voltage locked rotor current

rating of the motor. The accelerating

torque of the motor is also reduced to

0.33 times the full voltage torque rating.

This is sufficient to fully accelerate the

compressor motor. The unit control

panel monitors motor current during

operation via current transformers

located in the starter enclosure. When

during acceleration the line current

drops to approximately 0.85 times rated

load current, transition is initiated. The

closed transition feature provides for a

continuous motor current flow during

transition by placing resistors in the

circuit momentarily. This prevents

buildup of damaging torques to the

system during this period. With the

completion of transition, the motor

windings are connected in the delta

configuration with full line voltage.

Three precision current transformers

monitor phase current. Contactor

position and various voltage signals

provide extensive interlocking between

the starter and the microcomputer in the

CenTraVac

subsequent instruction originate in the

unit control panel. Protection against the

following starter defects is provided:

High motor current (starting and

•

running)

Improper starter circuitry

•

Excessive accelerating time

•

Incomplete starting sequence

•

Loss of phase

•

Phase amperage unbalance

•

Phase reversal

•

Distribution fault

•

Features

The Trane CenTraVac Unit Mounted

Starter includes the following standard

features:

NEMA 1 enclosure, designed to

•

accommodate padlock

3 KVA control power transformer with

•

120V secondary

Fused 120V control circuit

•

3-phase incoming line terminals

•

6 output load terminals factory-

•

connected to the motor

™

control panel. All logic and

CTV-PRC007-EN14

Page 15

Unit

Unit Mounted

Available options include:

Circuit Breaker — A standard

•

interrupting capacity circuit breaker is

available. The circuit breaker is

mechanically interlocked to disconnect

line power from the starter when the

starter door is open.

High Interrupting Capacity Circuit

•

Breaker — A high interrupting capacity

circuit breaker is available. This breaker

is also interlocked to disconnect line

power from the starter when the

starter door is open.

Circuit Breaker with Ground Fault —

•

Ground Fault protection is available

with either standard or high

interrupting capacity circuit breakers.

An indicating light is provided to

indicate if a ground fault has occurred.

Current Limiting Circuit Breaker — A

•

standard circuit breaker incorporating

the current limiters with fuse links is

available. A fault current in excess of

the circuit breaker capacity will blow

the fuse links and interrupt the fault

current. The circuit breaker cannot be

reset until the blown current limiters

are replaced.

Ground fault detection and protection

•

(available only with circuit breaker

options)

Options

The solid-state starter controls the

starting characteristics of a motor by

controlling the current that flow to the

motor. It does so through the use of

SCRs (Silicon Controlled Rectifiers),

which are solid-state switching devices,

and an integral bypass contactor for

power control.

SCR’s

An SCR will conduct current in one

direction only when a control signal

(gate signal) is applied. Because the

solid-state starter is for use on AC

(alternating current), two SCR’s per

phase are connected in parallel,

opposing each other so that current may

flow in both directions. For three- phase

loads, a full six-SCR configuration is

used. The connection is shown in Figure

O-3.

During starting, control of current or

acceleration time is achieved by gating

the SCR on at different times within the

half-cycle. The gate pulses are originally

applied late in the half-cycle and then

gradually applied sooner in the halfcycle. If the gate pulse is applied late in

the cycle, only a small increment of the

wave form is passed through, and the

output is low.

Starter (Cont.)

If the gate pulse is applied sooner in the

cycle, a greater increment of the wave

form is passed through, and the output

is increased. So, by controlling the SCR’s

output voltage, the motor’s acceleration

characteristic and current inrush can be

controlled. These forms are shown in

Figure O-4.

Integral Bypass Contactors

When the SCR’s are fully “phased on,”

the integral bypass contactors are

energized. The current flow is transferred

from the power pole to the contactors.

This reduces the energy loss associated

with the power pole, which is otherwise

about one watt per amp per phase.

When the starter is given the stop

command, the bypass contactors are deenergized, which transfers the current

flow from the contactors back to the

power poles. Two-hundred fifty

milliseconds later, the SCR’s are turned

off, and the current flow is stopped.

CTV-PRC007-EN

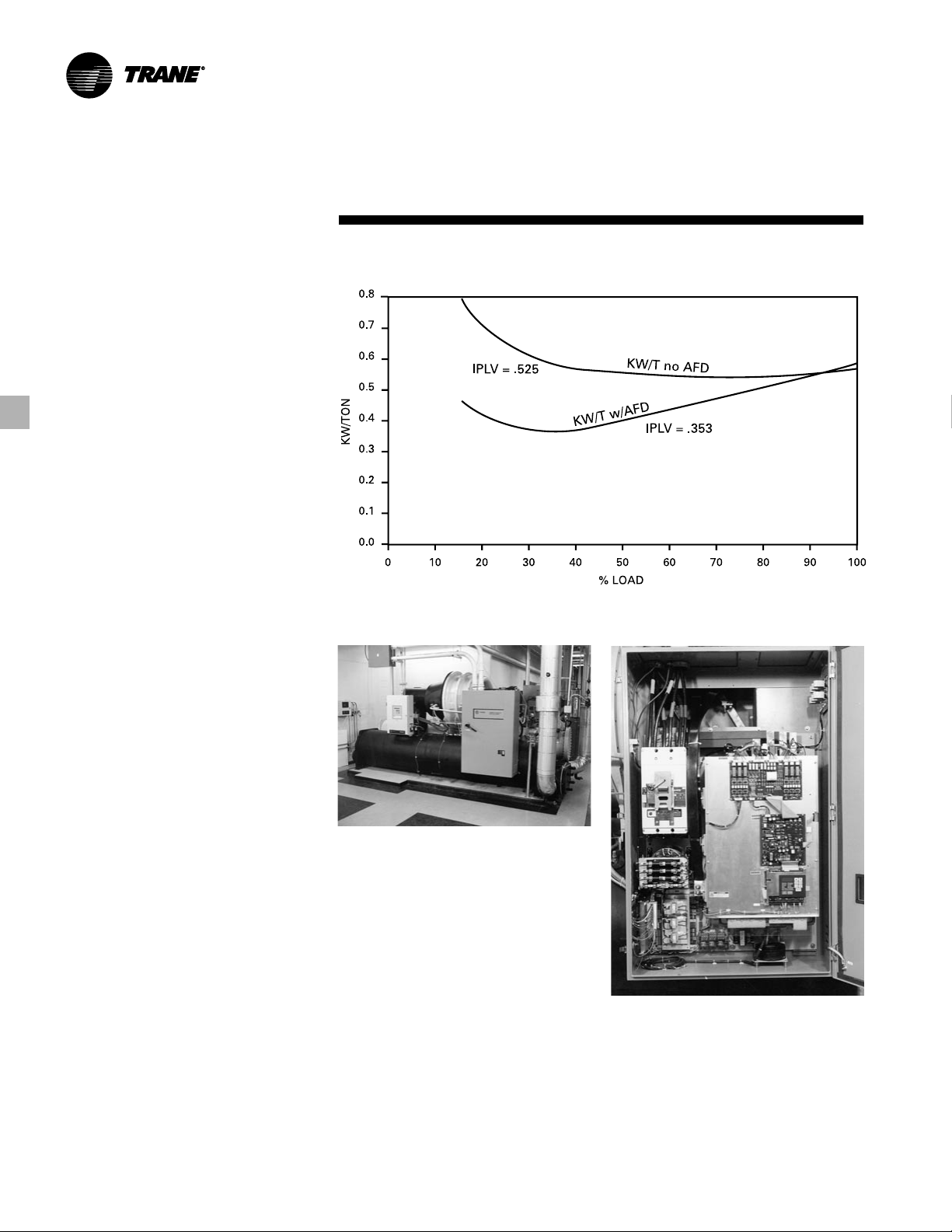

Figure O-3 — Six-SCR Configuration

Figure O-4 — Wave Forms

15

Page 16

Unit

Adaptive

Benefits

Trane Adaptive Frequency drives*

provide motor control, but they are

much more than just starters. They also

control the operating speed of the chiller

compressor motor by regulating output

voltage in proportion to output

frequency. Varying the speed of the

compressor motor can translate into

significant energy cost savings.

Reliable, Optimized Compressor

Efficiency for Energy Savings

Conventional chillers use inlet vanes to

provide stable operation at part-load

conditions. Capacity is reduced by

closing the vanes while maintaining a

constant motor speed. The drive can be

used to significantly reduce power

consumption by reducing motor speed

at low load conditions. Trane patented

AFD Adaptive Control

allows inlet guide vane and speed

control combinations that optimize partload performance.

To Avoid Mechanical Stress

Controlled “soft” start with linear

acceleration results in limited starting

current to eliminate motor stress, reduce

power line disturbance and provide a

lower power demand on start. Reduced

motor speed as a result of reduced

chiller load means less current drawn,

less heat generated, increased motor

winding life. This translates into longer

time between compressor maintenance

and less downtime throughout the life of

the machine.

Application

Certain system characteristics favor

installation of an AFD because of energy

cost savings and shorter payback.

Among them are:

A large number of part-load operating

hours annually

Figure O-4, based on a CVHE500, 500-ton

load at standard ARI conditions, shows

that major kW savings occur at part-load

conditions, typically below 90 percent

load.

™

logic safely

Options

Figure O-4 — CVHE500 Part Load Efficiencies with/without AFD

Frequency Drives

CTV-PRC007-EN16

Page 17

Unit

Adaptive

Options

Condenser water temperature relief of

chilled water reset

Compressor lift reduction is required for

a chiller application, both to provide

stable chiller operation at part-loads and

to achieve greater energy savings.

Intelligent control to reduce condenser

water temperature, or chiller water reset

strategies are key to AFD savings in

chiller applications.

High kW Charges

Electric utility bills normally include both

demand and energy components. The

demand or kW portion is established by

usage during utility peak hours, by

individual peak usage or a combination.

This portion may or may not be

influenced by installation of an AFD. But

the energy or kWh portion will almost

certainly be reduced because of the

improved efficiency of the chiller plant

during part-load conditions throughout

the year. The greater the kWh charge, the

shorter the payback.

Operation

The Trane AFD controls the speed of the

chiller compressor by regulating the

output voltage in proportion to the

output frequency to provide a nominally

constant rate of voltage to frequency as

required by the characteristics of the

compressor motor. Motor speed is

proportional to this applied frequency.

The Trane AFD is a voltage source, pulsewidth modulated (PWM) design. It

consists of three basic power sections:

Converter — Semi-conductor bridge

•

rectifier takes incoming AC power and

converts it to a fixed voltage DC bus.

DC bus filter — The converted DC bus

•

voltage contains a significant amount

of ripple. The DC bus filter smooths the

voltage ripple from the converter with

capacitors and a DC link reactor to

supply a fixed constant voltage to the

inverter section. It also minimizes the

electrical harmonics generated by the

drive back to the distribution system.

Frequency Drives

Inverter — Converts the DC voltage

•

into a sinusoidal synthesized output

AC voltage. This synthesized output

controls both the voltage and

frequency which is applied to the

motor.

A fourth element of AFD design is the

microprocessor control logic which is

the intelligence for the power section. It

also includes all feedback sensors

required for stability in the system and

any required shutdown due to a fault.

Soft Start: Inrush Current and Torque

Trane AFD’s are programmed to start the

compressor motor from low frequency

and low voltage. The motor is brought

up to speed by increasing both

frequency and voltage at the same ratio.

Thus current and torque are much lower

during start-up and acceleration than the

high current, high torque associated with

across-the-line or even reduced voltage

starters.

Note that the actual torque developed by

the AFD is the total of the torque

required by the load and the accelerating

torque. The AFD is rated by output

current and is limited to a maximum of

100 percent continuous RLA through the

chiller control (UCP2). A 100 percent

output current capability results in 100

percent torque generated by the motor.

In other words, the drive regulates

output voltage in proportion to output

frequency to maintain ideal motor flux

and constant torque producing

capability.

CTV-PRC007-EN

17

Page 18

Unit

Free Cooling Allows

Reduced Operating Costs

Consider a CenTraVac™ chiller option that

can provide up to 45 percent of the

nominal chiller capacity — without

operating the compressor. Think of the

significant energy and cost savings

possible in many applications. This

option is available on all Trane chillers,

factory installed.

Free cooling operation is based on the

principle that refrigerant migrates to the

area of lowest temperature. When

condenser water is available at

temperatures lower than the required

leaving chilled water temperature

(typically 50 to 55°F), the unit control

panel starts the free cooling cycle

automatically.

When the free cooling cycle can no

longer provide sufficient capacity to meet

cooling requirements, mechanical

cooling is restarted automatically by the

unit control panel.

For example, a building with a high

internal cooling load is located in a

climate with cold winters. It is possible to

cool the building exclusively with free

cooling three to six months of the year!

Free cooling payback can easily be less

than a year.

Free cooling is completely factory

installed and requires no more floor

space or piping than the standard

CenTraVac chiller (unlike plate frame heat

exchangers).

Benefits

The Trane patented free cooling

accessory for Trane CenTraVac

adapts the basic chiller so it may

function as a simple heat exchanger

using refrigerant as the working fluid.

When condenser water is available at

temperatures lower than the desired

chilled liquid temperature, free cooling

can provide up to 45 percent of nominal

chiller capacity without operation of the

compressor. This feature may result in

substantial energy cost savings on many

installations.

™

chillers

Options

Free Cooling Operation Schematic

Reliability

Two simple valves are the only moving

parts.

Single-Source Responsibility

Free cooling is Trane engineered,

manufactured and installed.

Ease of Operation

Changeover on free cooling by single

switch control.

Ease of Installation

Completely factory-installed and leaktested components. All valve operators

and controls are factory wired.

Application

Modern buildings often require some

form of year-round cooling to handle

interior zones, solar loads, or computer

loads. As the outside air temperature

decreases below the inside air design

temperature, it is often possible to use

an outside air economizer to satisfy the

cooling requirements. There are a

number of instances, however, where

CenTraVac free cooling offers a number

of advantages over the use of an outside

air economizer. It is possible for the free

cooling chiller to satisfy the cooling load

for many hours, days, or months during

the fall, winter, or spring seasons without

operation of the compressor motor. This

method of satisfying the cooling

requirement can result in significant total

energy savings over other types of

systems. The savings available are most

easily determined through the use of a

computer energy analysis and economic

program, such as TRACE

Conditioning and Economics).

™

(Trane Air

Free Cooling

The suitability of free cooling for any

particular installation depends upon a

number of factors. The availability of

low temperature condensing water, the

quality of the outside air, the type of

airside system, the temperature and

humidity control requirements, and the

cost of electricity all have a direct impact

on the decision to use a free cooling

chiller.

The use of CenTraVac free cooling

depends on the availability of cold

condenser water from a cooling tower,

river, lake, or pond. As a general rule of

thumb, locations which have a

substantial number of days with

ambient temperatures below 45°F wet

bulb or more than 4000 degree-days per

year are well suited to free cooling

operation. A cooling tower usually must

be winterized for off-season operation

and the minimum sump temperature is

limited by some cooling tower

manufacturers. Cooling tower

manufacturers should be consulted for

recommendations on low temperature

operation. With river, lake or pond

supply, condenser water temperatures

down to freezing levels are possible.

Areas which have badly fouled air may

be more conducive to free cooling

operation than the use of an outside air

economizer.

Airside systems which both heat and

cool the air can often effectively use a

free cooling chiller. Dual-duct, multizone,

and reheat systems fall into this general

category. As the outside temperature

begins to fall, the cool outside air

satisfies the cooling requirements

(through an outside air economizer). As

the outdoor air temperature becomes

very low, the outdoor air may need to be

heated in order to maintain the design

supply air temperature when it is mixed

with return air. This “heating penalty”

can be eliminated by using CenTraVac

free cooling. Warm chilled water

temperatures provided by the free

cooling chiller would allow a warmer air

temperature off the chilled water coils,

eliminating the heating energy required

by using only an outside air economizer.

With today’s high cost electricity in most

areas of the country, this heating penalty

can be very significant.

CTV-PRC007-EN18

Page 19

Unit

Temperature and humidity control

requirements are important

considerations when evaluating the use

of CenTraVac free cooling. Low

temperature outside air (from the

outside air economizer) often requires a

large amount of energy for

humidification purposes. Free cooling

operation helps to reduce these

humidification costs on many

applications.

It is important to note that those

applications which require extremely

precise humidity control typically cannot

tolerate warmer than design chilled

water temperatures. Therefore, since

free cooling chillers normally deliver

warmer than design chilled water

temperatures, free cooling operation is

usually not applicable with systems

which require precise humidity control.

Also, free cooling is generally not used in

conjunction with heat recovery systems,

since mechanical cooling must be used

to recover heat that will be used

elsewhere in the building for

simultaneous heating.

Operation

Free cooling operates on the principle

that refrigerant flows to the area of

lowest temperature in the system. The

™

system/Chiller Plant Manager

Tracer

(CPM) can be used for automatic free

cooling control. When condenser water

is available at a temperature lower than

the required leaving chilled water

temperature, the CPM starts the free

cooling cycle. If the load cannot be

satisfied with free cooling, the CPM

or a customer supplied system can

automatically switch to the powered

cooling mode. If desired, the chiller

can be manually switched to the free

cooling mode at the unit control panel.

Upon changeover to free cooling, the

shutoff valves in the liquid and gas lines

are opened and a lockout circuit

prevents compressor energization.

Liquid refrigerant drains by gravity from

the storage tank into the evaporator,

flooding the tube bundle. Since the

refrigerant temperature and pressure

will be higher in the evaporator than in

the condenser, due to the water

temperature difference, the refrigerant

gas boiled off in the evaporator will flow

to the condenser. The gas then

CTV-PRC007-EN

Options

condenses and flows by gravity back to

the evaporator. This automatic

refrigeration cycle is sustained as long as

a temperature difference exists between

the condenser water and evaporator

water.

The difference in temperature between

the condenser and evaporator

determines the rate of refrigerant flow

between the two shells and hence the

free cooling capacity.

If the system load becomes greater than

the free cooling capacity either the

operator manually stops free cooling, a

binary input from a customer-supplied

system disables free cooling or the CPM

can automatically perform this function.

The gas and liquid valves close and the

compressor starts. Refrigerant gas is

drawn out of the evaporator by the

compressor, compressed and introduced

into the condenser. Most of the

condensed liquid first takes the path of

least resistance by flowing into the

storage tank which is vented to the high

pressure economizer sump by a small

bleed line. When the storage tank is

filled, liquid refrigerant must flow

through the bleed line restriction. The

pressure drop through the bleed line is

greater than that associated with the

orifice flow control device, hence liquid

refrigerant flows normally from the

condenser through the orifice system

and into the economizer.

The free cooling accessory consists of

the following factory-installed or

supplied components:

A refrigerant gas line, including an

•

electrically actuated shutoff valve,

installed between the evaporator and

condenser.

A valved liquid return line including an

•

electrically activated shutoff valve,

between the condenser sump and

evaporator.

A liquid refrigerant storage vessel.

•

Added refrigerant charge.

•

Manual free cooling controls on the

•

unit control panel.

For specific information on free cooling

applications, contact the local Trane sales

office.

Free Cooling

Figure O-5 — Compressor Operation

Schematic

Figure O-6 — Free Cooling Operation

Schematic

19

Page 20

System

Auxiliary

Options

Auxiliary Condenser

The Trane auxiliary condenser provides

economical heat recovery for

applications with small heating demand.

It’s well-suited to preheat applications

including domestic hot water, boiler

makeup water and swimming pools.

The Trane auxiliary condenser option

consists of a separate condenser

connected in parallel with the standard

condenser to provide simple heat

recovery capability for applications

where full heat recovery or high heating

water temperatures are not required.

Heat which normally would be rejected

to the regular condenser water is picked

up in the auxiliary condenser before the

water enters the hot water heating

system. Typical uses for this water

include domestic water preheat, boiler

makeup water preheat, and reheat air

conditioning systems, as opposed to

traditional heat recovery applications

where higher temperature water is used

to satisfy a building heating load,

provide full heat input for domestic hot

water, or provide the typically larger flow

rates of hot water for process

applications.

The auxiliary condenser not only

captures energy otherwise lost, it also

increases chiller efficiency.

Auxiliary condensers are available in two

sizes: standard and large. Because the

auxiliary condenser is a separate

condenser, there is no cross

contamination between the cooling

tower water and the heat recovery water

circuits.

No temperature controls are required.

Auxiliary condensers are factory

mounted and tested.

Condenser

Benefits

Simplicity

No temperature controls are required.

Auxiliary condensers are factorymounted and tested.

Flexibility

Two auxiliary condenser sizes are

available — standard and large. Either

auxiliary condenser can be applied to

any size CenTraVac

Safe

Because the auxiliary condenser is a

separate condenser, there is no

possibility of cross contamination

between the cooling tower water and the

auxiliary condenser water circuits.

Efficient

Use of the auxiliary condenser option

actually increases the chiller’s efficiency

by increasing condenser heat transfer

surface area and lowering the pressure

differential the compressor must

generate.

Decreased life cycle operating costs

result through use of the auxiliary

condenser option because heat, which

normally would be rejected by the

cooling tower circuit, is now used for

building heating requirements.

Application

A simultaneous demand for heating and

cooling is necessary to apply any heat

recovery system. Common uses for

heated water from an auxiliary

condenser include domestic water

preheat, reheat air conditioning systems,

and boiler makeup water. Building use is

not limited to the traditional heat

recovery candidates. Schools, hospitals,

office buildings, and hotels have all

proved to be excellent applications for

the auxiliary condenser option.

™

.

CTV-PRC007-EN20

Page 21

System

Auxiliary

Options

Controls

The auxiliary condenser was designed

for simplicity of operation. Machine load,

water flow rate, and temperature

determine the amount of heat recovered.

There are no controls needed for heating

water temperature because no attempt

is made to maintain a specific hot water

temperature in or out of the auxiliary

condenser.

Operation

The auxiliary condenser is a factorymounted, separate, shell and tube heat

exchanger available on water-cooled

CenTraVac chillers.

Because hot refrigerant gas always

migrates to the area of lowest

temperature, auxiliary condenser

operation is simple. As hot gas leaves

the compressor, it is free to flow to the

auxiliary condenser or the standard

condenser. Since water entering the

auxiliary condenser is normally colder

than that entering the standard

condenser, the auxiliary condenser will

have a lower bundle temperature and

will attract the refrigerant gas. The

auxiliary condenser will recover as much

heat as the machine cooling load,

Condenser (Cont.)

heating water temperature, and flow rate

will allow. All remaining heat will

automatically be rejected through the

standard condenser to the atmosphere

through the cooling tower. No controls

are needed to balance heat rejection in

the two condensers.

Good system design will include a

heated water bypass to ensure that

water does not circulate through the

auxiliary condenser when the chiller is

de-energized. There are several ways to

bypass the auxiliary condenser. When

the hot water system is installed as

shown in the figure below, the bypass is

automatic if the heating water pump is

interlocked with the chiller compressor

motor.

Another bypass arrangement is to install

a diverting valve. When interlocked with

the compressor motor, this valve diverts

the heating water flow to the

conventional heating system whenever

the chiller is not operating. These are

only examples of the many ways of

accomplishing a bypass.

Contact your local Trane sales office for

further specific information.

CTV-PRC007-EN

Table O-1 — Auxiliary Condenser Flow Limits and Connection Sizes

Auxiliary Two Pass

Condenser Inter Enhanced Smooth Bore Connection

Bundle Minimum Maximum Minimum Maximum Size

Size Gpm Gpm Gpm Gpm (In)

Standard 74 276 70 258 5

Large 121 453 115 423 5

21

Page 22

System

Ice Storage Provides

Reduced Electrical Demand

Ice storage is the hottest thing in cooling

today. It has been accepted by building

owners and tenants who are concerned

about utility costs.

An ice storage system uses a standard

chiller to make ice at night when utilities

charge less for electricity. The ice

supplements or even replaces

mechanical cooling during the day when

utility rates are at their highest. This

reduced need for cooling results in big

utility cost savings.

Another advantage of ice storage is

standby cooling capacity. If the chiller is

unable to operate, one or two days of ice

may still be available to provide cooling.

In that time the chiller can be repaired

before building occupants feel any loss

of comfort.

The Trane CenTraVac chiller is uniquely

suited to low temperature applications

like ice storage because it provides

multiple stages of compression.

Competitive chillers provide only one

stage. This allows the CenTraVac chiller

to produce ice efficiently, with less stress

on the machine.

Simple and smart control strategies are

another advantage the CenTraVac chiller

has for ice storage applications. Trane

™

building management systems

Tracer

can actually anticipate how much ice

needs to be made at night and operate

the system accordingly. The controls are

integrated right into the chiller. Two

wires and preprogrammed software

dramatically reduce field installation cost

and complex programming.

Trane centrifugal chillers are well suited

for ice production. The unique multistage compressor design allows the

lower suction temperatures required to

produce ice and the higher chiller

efficiencies attributed to centrifugal

chillers. Trane three stage and two stage

centrifugal chillers produce ice by

supplying ice storage vessels with a

constant supply of 22 to 24°F glycol.

Centrifugal chillers selected for these

lower leaving fluid temperatures are also

Options

selected for efficient production of

chilled fluid at nominal comfort cooling

conditions. The ability of Trane chillers to

serve “double duty” in ice production

and comfort cooling greatly reduces the

capital cost of ice storage systems.

A glycol solution is used to transfer heat

from the ice storage tanks to the

centrifugal chiller and from the cooling

coils to either the chiller or ice storage

tanks. The use of a freeze protected

solution eliminates the design time, field

construction cost, large refrigerant

charges, and leaks associated with ice

plants. Ice is produced by circulating 2224°F glycol through modular insulated

ice storage tanks. Each tank contains a

heat exchanger constructed of

polyethylene tubing. Water in each tank

is completely frozen with no need for

agitation. The problems of ice bridging

and air pumps are eliminated.

When cooling is required, ice chilled

glycol is pumped from the ice storage

tanks directly to the cooling coils. No

expensive heat exchanger is required.

The glycol loop is a sealed system,

eliminating expensive annual chemical

treatment costs. The centrifugal chiller is

also available for comfort cooling duty at

nominal cooling conditions and

efficiencies. The modular concept of

glycol ice storage systems and the

proven simplicity of Trane Tracer

controls allow the successful blend of

reliability and energy saving

performance in any ice storage

application.

Ice Storage Demand Cost Savings

™

Ice Storage

The ice storage system is operated in six

different modes: each optimized for the

utility cost of the hour.

1 Provide comfort cooling with chiller

2 Provide comfort cooling with ice

3 Provide comfort cooling with ice and

chiller

4 Freeze ice storage

5 Freeze ice storage when comfort

cooling is required

6 Off

Tracer optimization software controls

operation of the required equipment and

accessories to easily transition from one

mode of operation to another. For

example:

Even with ice storage systems there are

numerous hours when ice is neither

produced or consumed, but saved. In

this mode the chiller is the sole source of

cooling. For example, to cool the

building after all ice is produced but

before high electrical demand charges

take effect, Tracer sets the centrifugal

chiller leaving fluid setpoint to its most

efficient setting and starts the chiller,

chiller pump, and load pump.

When electrical demand is high, the ice

pump is started and the chiller is either

demand limited or shut down

completely. Tracer controls have the

intelligence to optimally balance the

contribution of ice and chiller in meeting

the cooling load.

The capacity of the chiller plant is

extended by operating the chiller and ice

in tandem. Tracer rations the ice,

augmenting chiller capacity while

reducing cooling costs.

When ice is produced, Tracer will lower

the centrifugal chiller leaving fluid

setpoint and start the chiller, chiller and

ice pumps, and other accessories. Any

incidental loads that persists while

producing ice can be addressed by

starting the load pump and drawing

spent cooling fluid from the ice storage

tanks.

For specific information on ice storage

applications, contact your local Trane

sales office.

CTV-PRC007-EN22

Page 23

System

Options

Heat Recovery

Use of the Heat Recovery CenTraVac

can significantly reduce the energy

operating costs of many buildings by

using heat which normally would be

rejected to the atmosphere. Typical uses

for this heat are perimeter zone heating,

reheat air conditioning systems and any

hot water requirements. Any building

with a simultaneous heating and cooling

load is a potential candidate.

Most heating applications require water

temperatures higher than the

85°F to 95°F typically sent to the cooling