Toshiba VN-M150HE, VN-M350HE, VN-M650HE, VN-M250HE, VN-M800HE Service Manual

...

Air to Air Heat Exchanger

SERVICE MANUAL

FILE No. A10-021

Concealed microcomputer control type

Model name:

VN-M150HE

VN-M250HE

VN-M350HE

VN-M500HE

VN-M650HE

VN-M800HE

VN-M1000HE

1

Contents

1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Model List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 Parts Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Control Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 Applied Control and Functions (Including Circuit Configuration) . . . . . . . . . . . . . 28

8 Air to Air Heat Exchanger Unit and Air-Conditioning System. . . . . . . . . . . . . . . . . 37

9 Failure Diagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10 Exchanging and Assembling the Main Components . . . . . . . . . . . . . . . . . . . . . . . . 51

11 Owner’s Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

12 Installation Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

13 How to replace the PC board for service on the Air to Air Heat Exchanger . . . . 139

14 Exploded Diagram/Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

2

Original instruction

Please read carefully through these instructions that contain important information which complies with the

“Machinery” Directive (Directive 2006/42/EC), and ensure that you understand them.

Some of the details provided in these instructions differ from the service manual, and the instructions provided here

take precedence.

Generic Denomination: Air to Air Heat Exchanger

Definition of Qualified Installer or Qualified Service Person

The Air to Air Heat Exchanger must be installed, maintained, repaired and removed by a qualified installer or

qualified service person. When any of these jobs is to be done, ask a qualified installer or qualified service person

to do them for you.

A qualified installer or qualified service person is an agent who has the qualifications and knowledge described in

the table below.

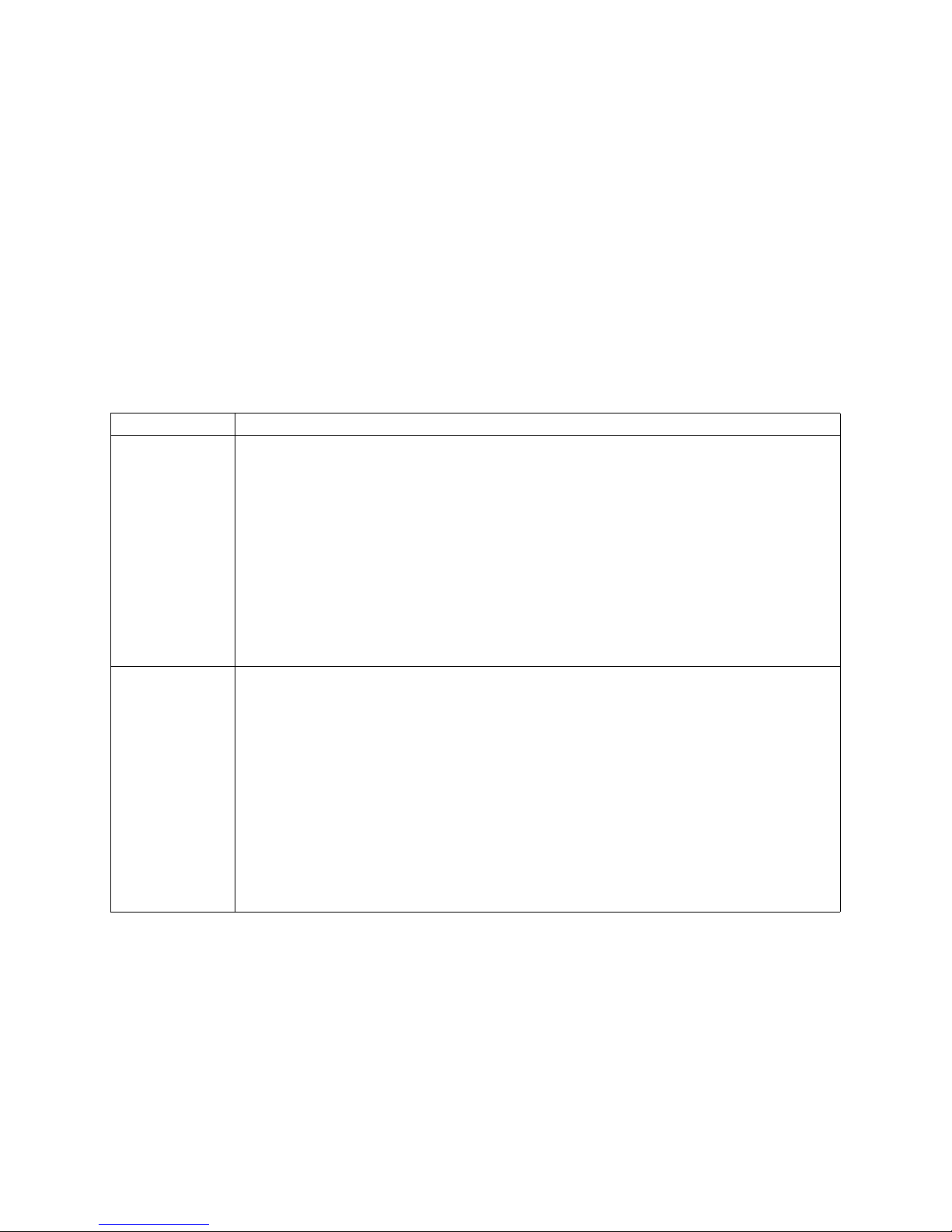

Agent Qualifications and knowledge which the agent must have

Qualified installer

• The qualified installer is a person who installs, maintains, relocates and removes the Air to Air Heat

Exchanger made by Toshiba Carrier Corporation. He or she has been trained to install, maintain,

relocate and remove the Air to Air Heat Exchanger made by Toshiba Carrier Corporation or,

alternatively, he or she has been instructed in such operations by an individual or individuals who have

been trained and is thus thoroughly acquainted with the knowledge related to these operations.

• The qualified installer who is allowed to do the electrical work involved in installation, relocation and

removal has the qualifications pertaining to this electrical work as stipulated by the local laws and

regulations, and he or she is a person who has been trained in matters relating to electrical work on

the Air to Air Heat Exchanger made by Toshiba Carrier Corporation or, alternatively, he or she has

been instructed in such matters by an individual or individuals who have been trained and is thus

thoroughly acquainted with the knowledge related to this work.

• The qualified installer who is allowed to work at heights has been trained in matters relating to working

at heights with the Air to Air Heat Exchanger made by Toshiba Carrier Corporation or, alternatively,

he or she has been instructed in such matters by an individual or individuals who have been trained

and is thus thoroughly acquainted with the knowledge related to this work.

Qualified service

person

• The qualified service person is a person who installs, repairs, maintains, relocates and removes the

Air to Air Heat Exchanger made by Toshiba Carrier Corporation. He or she has been trained to install,

repair, maintain, relocate and remove the Air to Air Heat Exchanger made by Toshiba Carrier

Corporation or, alternatively, he or she has been instructed in such operations by an individual or

individuals who have been trained and is thus thoroughly acquainted with the knowledge related to

these operations.

• The qualified service person who is allowed to do the electrical work involved in installation, repair,

relocation and removal has the qualifications pertaining to this electrical work as stipulated by the local

laws and regulations, and he or she is a person who has been trained in matters relating to electrical

work on the Air to Air Heat Exchanger made by Toshiba Carrier Corporation or, alternatively, he or she

has been instructed in such matters by an individual or individuals who have been trained and is thus

thoroughly acquainted with the knowledge related to this work.

• The qualified service person who is allowed to work at heights has been trained in matters relating to

working at heights with the Air to Air Heat Exchanger made by Toshiba Carrier Corporation or,

alternatively, he or she has been instructed in such matters by an individual or individuals who have

been trained and is thus thoroughly acquainted with the knowledge related to this work.

3

Definition of Protective Gear

When the Air to Air Heat Exchanger is to be transported, installed, maintained, repaired or removed, wear

protective gloves and ‘safety’ work clothing.

In addition to such normal protective gear, wear the protective gear described below when undertaking the special

work detailed in the table below.

Failure to wear the proper protective gear is dangerous because you will be more susceptible to injury, burns,

electric shocks and other injuries.

The important contents concerned to the safety are described on the product itself and on this Service Manual.

Please read this Service Manual after understanding the described items thoroughly in the following contents

(Indications/Illustrated marks), and keep them.

[Explanation of indications]

* Property damage: Enlarged damage concerned to property, furniture, and domestic animal/pet

[Explanation of illustrated marks]

Work undertaken Protective gear worn

All types of work Protective gloves

‘Safety’ working clothing

Electrical-related work Gloves to provide protection for electricians and from heat

Work done at heights

(50 cm or more)

Helmets for use in industry

Transportation of heavy objects Shoes with additional protective toe cap

Indication Explanation

DANGER

Indicates contents assumed that an imminent danger causing a death or serious injury of the repair

engineers and the third parties when an incorrect work has been executed.

WARNING

Indicates possibilities assumed that a danger causing a death or serious injury of the repair

engineers, the third parties, and the users due to troubles of the product after work when an incorrect

work has been executed.

CAUTION

Indicates contents assumed that an injury or property damage (*) may be caused on the repair

engineers, the third parties, and the users due to troubles of the product after work when an incorrect

work has been executed.

Mark Explanation

Indicates prohibited items (Forbidden items to do)

The sentences near an illustrated mark describe the concrete prohibited contents.

Indicates mandatory items (Compulsory items to do)

The sentences near an illustrated mark describe the concrete mandatory contents.

Indicates cautions (Including danger/warning)

The sentences or illustration near or in an illustrated mark describe the concrete cautious contents.

4

Warning Indications on the Air to Air Heat

Exchanger Unit

[Confirmation of warning label on the main unit]

Confirm that labels are indicated on the specified positions.

If removing the label during parts replace, stick it as the original.

Warning indication Description

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect all remote electric power supplies before servicing.

WARNING

Moving parts.

Do not operate unit with inspection cover removed.

Stop the unit before the servicing.

CAUTION

High temperature parts.

You might get burned when removing this cover.

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect all remote

electric power supplies

before servicing.

WARNING

Moving parts.

Do not operate unit with

inspection cover removed.

Stop the unit before the servicing.

CAUTION

High temperature parts.

You might get burned

when removing this cover.

5

Precautions for Safety

The manufacturer shall not assume any liability for the damage caused by not observing the description of this

manual.

DANGER

Turn off breaker.

Before carrying out the installation, maintenance, repair or removal work, be sure to set the circuit breaker for Air

to Air Heat Exchanger to the OFF position. Otherwise, electric shocks may result.

Before opening the electrical control cover or inspection cover of the Air to Air Heat Exchanger, set the circuit

breaker to the OFF position.

Failure to set the circuit breaker to the OFF position may result in electric shocks through contact with the interior

parts.

Only a qualified installer (*1) or qualified service person (*1) is allowed to remove the electrical control cover or

inspection cover of the Air to Air Heat Exchanger and do the work required.

When cleaning the filter or heat exchange element of the Air to Air Heat Exchanger, set the circuit breaker to OFF

without fail, and place a “Work in progress” sign near the circuit breaker before proceeding with the work.

When you have noticed that some kind of trouble (such as when an error display has appeared, there is a smell of

burning, abnormal sounds are heard, water is leaking) has occurred in the Air to Air Heat Exchanger, do not touch

the Air to Air Heat Exchanger yourself but set the circuit breaker to the OFF position, and contact a qualified service

person. Take steps to ensure that the power will not be turned on (by marking “out of service” near the circuit

breaker, for instance) until qualified service person arrives. Continuing to use the Air to Air Heat Exchanger in the

trouble status may cause mechanical problems to escalate or result in electric shocks or other failure.

Electric shock

hazard

When you access inside of the electrical control cover to repair electric parts, wait for about five minutes after

turning off the breaker. Do not start repairing immediately.Otherwise you may get electric shock by touching

terminals of high-voltage capacitors. Natural discharge of the capacitor takes about five minutes.

Prohibition

Place a “Work in progress” sign near the circuit breaker while the installation, maintenance, repair or removal work

is being carried out.

There is a danger of electric shocks if the circuit breaker is set to ON by mistake.

Before operating the Air to Air Heat Exchanger after having completed the work, check that the electrical control

cover and inspection cover are closed, and set the circuit breaker to the ON position. You may receive an electric

shock if the power is turned on without first conducting these checks.

Stay on

protection

If, in the course of carrying out repairs, it becomes absolutely necessary to check out the electrical parts with the

electrical control cover and inspection cover removed in order to find out exactly where the trouble lies, wear

insulated heat-resistant gloves, insulated boots and insulated work overalls, and take care to avoid touching any

live parts.

You may receive an electric shock if you fail to heed this warning. Only qualified service person (*1) is allowed to

do this kind of work.

6

WARNING

General

Before starting to repair the Air to Air Heat Exchanger, read carefully through the Service Manual, and repair the

Air to Air Heat Exchanger by following its instructions.

Only qualified service person (*1) is allowed to repair the Air to Air Heat Exchanger.

Repair of the Air to Air Heat Exchanger by unqualified person may give rise to a fire, electric shocks, injury, water

leaks and/or other problems.

Only a qualified installer (*1) or qualified service person (*1) is allowed to carry out the electrical work of the Air to

Air Heat Exchanger.

Under no circumstances must this work be done by an unqualified individual since failure to carry out the work

properly may result in electric shocks and/or electrical leaks.

Wear protective gloves and safety work clothing during installation, servicing and removal.

When repairing the electrical parts or undertaking other electrical jobs, wear gloves to provide protection for

electricians and from heat.

Failure to wear this protective gear may result in burn.

Electrical wiring work shall be conducted according to law and regulation in the community and installation manual.

Failure to do so may result in electrocution or short circuit.

Only a qualified installer (*1) or qualified service person (*1) is allowed to undertake work at heights using a stand

of 50 cm or more or to remove the electrical control cover or inspection cover of the Air to Air Heat Exchanger to

undertake work.

When working at heights, use a ladder which complies with the ISO 14122 standard, and follow the procedure in

the ladder’s instructions.

Also wear a helmet for use in industry as protective gear to undertake the work.

When working at heights, put a sign in place so that no-one will approach the work location, before proceeding with

the work.

Parts and other objects may fall from above, possibly injuring a person below.

When executing address setting, test run, or troubleshooting through the checking window on the electric parts box,

put on insulated gloves to provide protection from electric shock. Otherwise you may receive an electric shock.

Use a hand track or forklift to carry the unit. When carrying it by human power, have four persons or more;

otherwise, you may strain your back.

When transporting the Air to Air Heat Exchanger, wear shoes with protective toe caps, protective gloves and other

protective clothing.

When transporting the Air to Air Heat Exchanger, do not take hold of the bands around the packing carton.

You may injure yourself if the bands should break.

Use wiring that meets the specifications in the Installation Manual and the stipulations in the local regulations and

laws. Use of wiring which does not meet the specifications may give rise to electric shocks, electrical leakage,

smoking and/or a fire.

Exchange to parts specified in service manual, which meet the specification or listed in parts list of service manual.

Failure to use specified parts may result in electrical shock, smoke, and/or fire.

Confirm whether there is a risk of the Air to Air Heat Exchanger falling down during maintenance or repairing work.

Inspect the Air to Air Heat Exchanger unit for any falling hazard of the unit before maintenance or repair.

Before you open the Supply/Exhaust air grill, set the circuit breaker to the OFF position. Otherwise, your hand may

be caught in the rotating parts inside and an injury may result.

Check earth

wires.

After completing the repair or relocation work, check that the earth wires are connected properly.

Be sure to connect earth wire. (Grounding work) Incomplete earthing causes an electric shock.

Do not connect earth wires to gas pipes, water pipes, and lightning rods or earth wires for telephone wires.

Prohibition of

modification.

Do not modify the products. Do not also disassemble or modify the parts.

It may cause a fire, electric shock or injury.

Use specified

parts.

When any of the electrical parts are to be replaced, ensure that the replacement parts satisfy the specifications

given in the Service Manual (or use the parts contained on the parts list in the Service Manual).

Use of any parts which do not satisfy the required specifications may give rise to electric shocks, smoking and/or

a fire.

7

Do not bring a

child close to the

equipment.

If, in the course of carrying out repairs, it becomes absolutely necessary to check out the electrical parts with the

electrical control cover of one or more of the Air to Air Heat Exchanger removed in order to find out exactly where

the trouble lies, put a sign in place so that no-one will approach the work location before proceeding with the work.

Third-party individuals may enter the work site and receive electric shocks if this warning is not heeded.

Insulating

measures

Connect the cut-off lead wires with crimp contact, etc., put the closed end side upward and then apply a water-cut

method, otherwise a leak or production of fire is caused at the users’ side.

Assembly/

Wiring

After repair work, surely assemble the disassembled parts, and connect and lead the removed wires as before.

Perform the work so that the electrical control cover does not catch the inner wires.

If incorrect assembly or incorrect wire connection was done, a disaster such as a leak or fire is caused at user’s

side.

Insulator check

After the work has finished, be sure to use an insulation tester set (500V Megger) to check the resistance is 1M:

or more between the charge section and the non-charge metal section (Earth position).

If the resistance value is low, a disaster such as a leak or electric shock is caused at user’s side.

Check after

repair

Once the repair work has been completed, check for the insulation resistance.

Then perform a trial run to check that the Air to Air Heat Exchanger is running properly.

After repair work has finished, check there is no trouble. If check is not executed, a fire, electric shock or injury may

be caused. For a check, turn off the power breaker.

After repair work (installation of electrical control cover and inspection cover) has finished, execute a test run to

check there is no generation of smoke or abnormal sound.

If check is not executed, a fire or an electric shock is caused. Before test run, install the electrical control cover and

inspection cover.

Be sure to fix the screws back which have been removed for installation or other purposes.

Check after

reinstallation

Only a qualified installer (*1) or qualified service person (*1) is allowed to relocate the Air to Air Heat Exchanger. It

is dangerous for the Air to Air Heat Exchanger to be relocated by an unqualified individual since a fire, electric

shocks, injury, water leakage, noise and/or vibration may result.

Check the following items after reinstallation.

1) The earth wire is correctly connected.

2) The power cord is not caught in the product.

3) There is no inclination or unsteadiness and the installation is stable.

If check is not executed, a fire, an electric shock or an injury is caused.

Installation

Only a qualified installer (*1) or qualified service person (*1) is allowed to install the Air to Air Heat Exchanger. If

the Air to Air Heat Exchanger is installed by an unqualified individual, a fire, electric shocks, injury, water leakage,

noise and/or vibration may result.

Before starting to install the Air to Air Heat Exchanger, read carefully through the Installation Manual, and follow its

instructions to install the Air to Air Heat Exchanger.

Be sure to use the company-specified products for the separately purchased parts. Use of non-specified products

may result in fire, electric shock, water leakage or other failure. Have the installation performed by a qualified

installer.

Do not supply power from the power terminal block equipped on the outdoor unit to another outdoor unit. Capacity

overflow may occur on the terminal block and may result in fire.

Do not install the Air to Air Heat Exchanger in a location that may be subject to a risk of expire to a combustible gas.

If a combustible gas leaks and becomes concentrated around the unit, a fire may occur.

Install the Air to Air Heat Exchanger at least 2.5 m above the floor level since otherwise the users may injure

themselves or receive electric shocks if they poke their fingers or other objects into the Air to Air Heat Exchanger

while the it is running.

Install a circuit breaker that meets the specifications in the installation manual and the stipulations in the local

regulations and laws.

Install the circuit breaker where it can be easily accessed by agent.

When installing a circuit breaker outdoors, install one which is designed to be used outdoors.

Do not place any combustion appliance in a place where it is directly exposed to the wind of Air to Air Heat

Exchanger, otherwise it may cause imperfect combustion.

8

Relocation

• Only a qualified installer (*1) or qualified service person (*1) is allowed to relocate the Air to Air Heat Exchanger.

It is dangerous for the Air to Air Heat Exchanger to be relocated by an unqualified individual since a fire, electric

shocks, injury, water leakage, noise and/or vibration may result.

(*1) Refer to the “Definition of Qualified Installer or Qualified Service Person.”

9

Specifications

* Under 70 dBA

Declaration of Incorporation

of Partly Completed Machinery

NOTE

This declaration becomes invalid if technical or operational modifications are introduced without the manufacturer’s

consent.

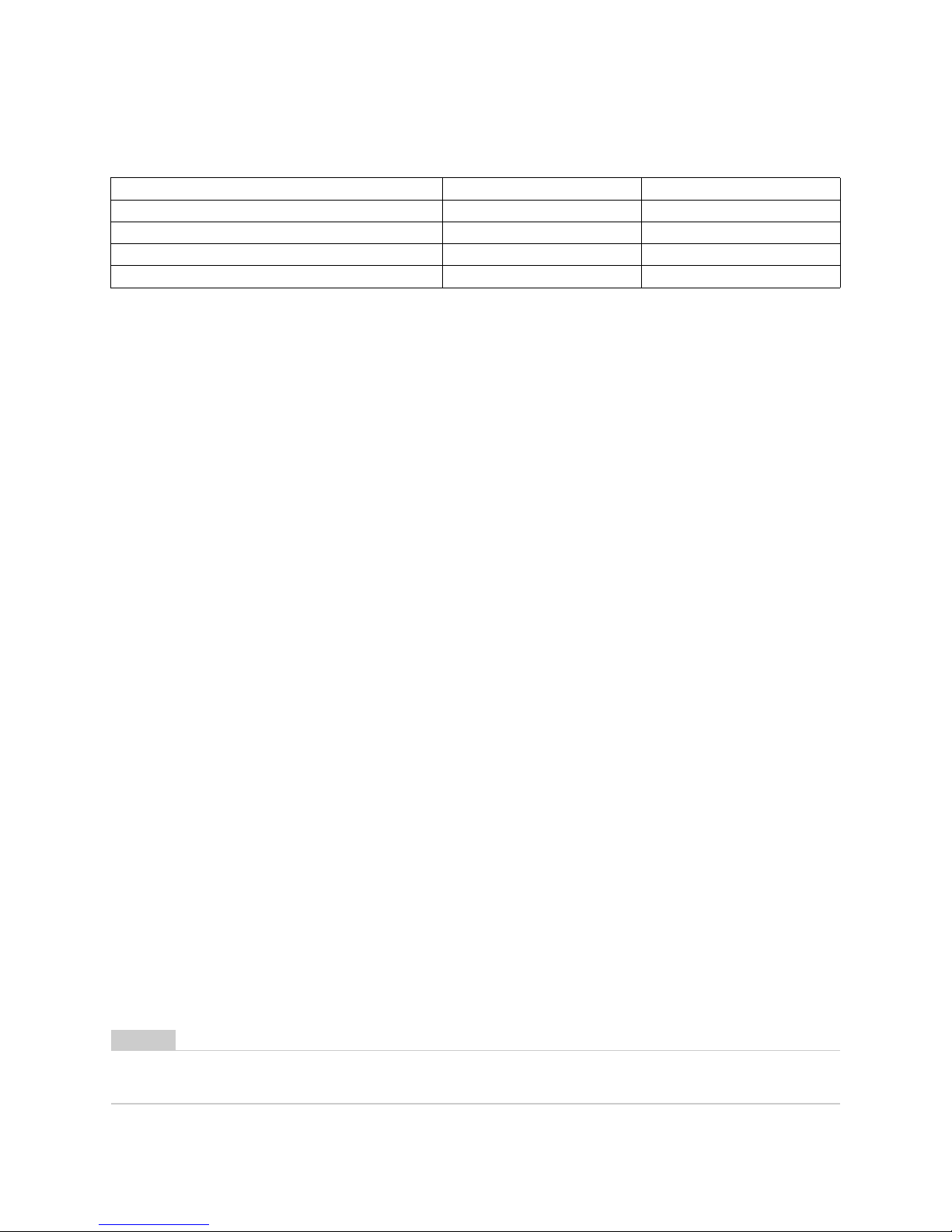

Model Sound power level (dBA) Weight (kg)

VN-M150HE, M250HE

*36

VN-M350HE

*38

VN-M500HE, M650HE

*53

VN-M800HE, M1000HE

*70

Manufacturer: Toshiba Carrier Corporation

336 Tadehara, Fuji-shi, Shizuoka-ken 416-8521 JAPAN

Representative/

TCF holder:

Toshiba Carrier UK Ltd.

Porsham Close, Belliver Industrial Estate,

PLYMOUTH, Devon, PL6 7DB.

United Kingdom

Hereby declares that the machinery described below:

Generic Denomination: Air to Air Heat Exchanger

Model/type: VN-M150HE

VN-M250HE

VN-M350HE

VN-M500HE

VN-M650HE

VN-M800HE

VN-M1000HE

Commercial name: TOSHIBA Air to Air Heat Exchanger

Complies with the provisions of the “Machinery” Directive (Directive 2006/42/EC) and the regulations transposing

into national law.

Must not be put into service until the final machinery into which it is to be incorporated has been declared in

conformity with the provisions of Machinery Directive, where appropriate.

10

1 Features

Main features

◆ Power saving ventilation

The cost of cooling and heating is reduced thanks to

the unit efficiently retrieving thermal energy (outdoor

air load) which has been lost during ordinary

ventilation.

◆ Space saving

Significant reduction of outdoor air load and the ability

to retrieve thermal energy enable the production of

smaller air conditioning devices.

◆ Humidity control

When cooling, highly humid outdoor air is conditioned

to near the humidity of the dehumidified (cooled) indoor

air before being supplied.

When heating, moisture from the return air is

transferred to the dry outdoor air before the outdoor air

is supplied.

◆ Comfortable ventilation

Ventilation without big changes in temperature is

realized.

In addition, stable ventilation is possible even in an air

tight room due to simultaneous air intake and

expulsion.

◆ Sound insulation

Air trunks and heat exchange elements provide sound

insulation.

They reduce the incoming of outdoor noise and the

outward flow of sounds indoor and help keep the office

or shop, and their surroundings quiet.

◆ Easy installation

The linear air supplying/exhausting method enables

simple design and installation.

Inverted installation is possible and only one inspection

slot is required for two units.

A complete inspection is possible through a single

inspection slot.

◆ Other

The filter has excellent dust filtering performance

(mass spectrometry 82%).

The air volume can be switched between Extra High

and High.

The ventilation balance of air supplying and air

exhausting can be changed.

The filter inspection display function calculates the total

running time and prompts you through the remote

controller to inspect the filter.

The cold mode function automatically makes the air

supplying motor run intermittently when the outdoor air

temperature is -10°C or lower.

The timer function allows you to set the unit to start/

stop operation at the specified time.

The separately sold central controller enables central

control of 128 groups.

The separately sold wired remote controller enables

group operation control of up to 8 units.

The unit can operate in cooperation with an airconditioner (SMMS series, DI/SDI series).

About ventilation modes

The unit has three ventilation modes.

• Heat exchange mode

Exchanging heat between the outdoor air and return

air and making the temperature and humidity of the

outdoor air closer to those of the return air before

supplying it.

• Bypass mode

Outdoor air is taken into a room as it is. This mode is

mainly used in spring and summer.

• Automatic mode

1. For an Air to Air Heat Exchanger system

The heat exchange mode and the bypass mode are

automatically switched between following the

information from the return air and outdoor air

temperature sensors in the unit.

2. For an Air to Air Heat Exchanger system linked with

air conditioners

The heat exchange mode and the bypass mode are

automatically switched between depending on the

operation status of the air conditioner (cooling,

heating, dry, fan, or temperature setting) and the

information from the return air and outdoor air

temperature sensors in the unit.

CAUTION

If the outdoor air temperature becomes about to 15°C or

less in [Automatic mode] or [Bypass mode], the system

will automatically start to run in [Heat exchange mode]

regardless of the mode setting to prevent condensation

in the Air to Air Heat Exchanger.

* The indication of the ventilation mode setting does not

change.

11

2 Specifications

Concealed microcomputer control type

Item

Model No.

Fan Speed

VN-

M150HE

VN-

M250HE

VN-

M350HE

VN-

M500HE

VN-

M650HE

VN-

M800HE

VN-

M1000HE

Type Concealed type

Power Supply (V) Single phase 220-240V~,50Hz 220V~,60Hz

Characteristics

Power

consumption

(W)

Heat

Exchange

Mode

(Extra high)

50Hz 68-78 123-138 165-182 214-238 262-290 360-383 532-569

60Hz 76 131 209 260 307 446 622

High

50Hz 59-67 99-111 135-145 176-192 240-258 339-353 494-538

60Hz 65 105 162 206 283 408 589

Low

50Hz 42-47 52-59 82-88 128-142 178-191 286-300 353-370

60Hz 45 54 94 144 206 333 411

Bypass

Mode

(Extra high)

50Hz 68-78 123-138 165-182 214-238 262-290 360-383 532-569

60Hz 76 131 209 260 307 446 622

High

50Hz 59-67 99-111 135-145 176-192 240-258 339-353 494-538

60Hz 65 105 162 206 283 408 589

Low

50Hz 42-47 52-59 82-88 128-142 178-191 286-300 353-370

60Hz 45 54 94 144 206 333 411

Current (A)

Heat

Exchange

Mode

(Extra high)

50Hz 0.31-0.33 0.58-0.61 0.76-0.76 0.99-1.00 1.25-1.30 1.67-1.63 2.47-2.46

60Hz0.360.600.991.201.402.032.84

High

50Hz 0.27-0.28 0.47-0.49 0.62-0.61 0.81-0.81 1.14-1.13 1.57-1.50 2.31-2.28

60Hz0.280.490.740.941.301.852.69

Low

50Hz 0.20-0.20 0.25-0.26 0.38-0.37 0.59-0.60 1.25-1.30 1.31-1.27 1.62-1.57

60Hz0.200.250.430.660.951.521.87

Bypass

Mode

(Extra high)

50Hz 0.31-0.33 0.58-0.61 0.76-0.76 0.99-1.00 1.25-1.30 1.67-1.63 2.47-2.46

60Hz0.360.600.991.201.402.032.84

High

50Hz 0.27-0.28 0.47-0.49 0.62-0.61 0.81-0.81 1.14-1.13 1.57-1.50 2.31-2.28

60Hz0.280.490.740.941.301.852.69

Low

50Hz 0.20-0.20 0.25-0.26 0.38-0.37 0.59-0.60 1.25-1.30 1.31-1.27 1.62-1.57

60Hz0.200.250.430.660.951.521.87

Maximum

running

Current (A)

Heat

Exchange

Mode

(Extra high)

50Hz 0.32-0.33 0.61-0.65 0.81-0.82 1.19-1.23 1.37-1.41 2.15-2.23 2.89-2.94

60Hz0.360.651.091.381.592.403.37

High

50Hz 0.27-0.28 0.46-0.49 0.61-0.62 0.87-0.91 1.17-1.20 1.84-1.94 2.57-2.61

60Hz0.300.470.730.961.342.012.95

Low

50Hz 0.20-0.21 0.25-0.26 0.42-0.44 0.64-0.68 0.90-0.95 1.49-1.58 1.85-1.87

60Hz0.210.250.450.680.981.591.96

Bypass

Mode

(Extra high)

50Hz 0.32-0.33 0.61-0.65 0.81-0.82 1.19-1.23 1.37-1.41 2.15-2.23 2.89-2.94

60Hz0.360.651.091.381.592.403.37

High

50Hz 0.27-0.28 0.46-0.49 0.61-0.62 0.87-0.91 1.17-1.20 1.84-1.94 2.57-2.61

60Hz0.300.470.730.961.342.012.95

Low

50Hz 0.20-0.21 0.25-0.26 0.42-0.44 0.64-0.68 0.90-0.95 1.49-1.58 1.85-1.87

60Hz0.210.250.450.680.981.591.96

12

Characteristics

Air Volume (m3/h)

(Extra high)

50Hz 150 250 350 500 650 800 1000

60Hz 150 250 350 500 650 800 1000

High

50Hz 150 250 350 500 650 800 1000

60Hz 150 250 350 500 650 800 1000

Low

50Hz 110 155 210 390 520 700 755

60Hz 110 155 210 390 520 700 755

External

Static

Pressure (Pa)

Heat

Exchange

Mode

(Extra high)

50Hz 82-102 80-98 114-125 134-150 91-107 142-158 130-150

60Hz 99 97 167 181 134 171 185

High

50Hz 52-78 34-65 56-83 69-99 58-82 102-132 97-122

60Hz 59 38 33 63 68 102 120

Low

50Hz 47-64 28-40 65-94 62-92 61-96 76-112 84-127

60Hz46223944525855

Bypass

Mode

(Extra high)

50Hz 82-102 80-98 114-125 134-150 91-107 142-158 130-150

60Hz 99 97 167 181 134 171 185

High

50Hz 52-78 34-65 56-83 69-99 58-82 102-132 97-122

60Hz 59 38 33 63 68 102 120

Low

50Hz 47-64 28-40 65-94 62-92 61-96 76-112 84-127

60Hz46223944525855

Sound

pressure level

(dB)

Heat

Exchange

Mode

(Extra high)

50Hz 26.0-28.0 29.5-30.0 34.0-35.0 32.5-34.0 34.0-36.0 37.0-38.5 39.5-40.5

60Hz 27.5 31.5 35.5 33.5 35.5 38 41.5

High

50Hz 24.0-25.5 25.0-27.0 30.0-32.0 29.5-31.0 33.0-34.0 35.5-37.0 38.5-40.0

60Hz 24.5 25 29.5 29 34 35 39

Low

50Hz 20.0-22.0 21.0-22.0 27.0-29.0 26.0-29.0 31.0-32.5 33.5-35.0 34.0-35.5

60Hz 20 21 23.5 24.5 29.5 32.5 33.5

Bypass

Mode

(Extra high)

50Hz 26.0-28.0 29.5-30.0 34.0-35.0 32.5-34.0 34.0-36.0 37.0-38.5 39.5-40.5

60Hz 27.5 31.5 35.5 33.5 35.5 38 41.5

High

50Hz 24.0-25.5 25.0-27.0 30.0-32.0 29.5-31.0 33.0-34.0 35.5-37.0 38.5-40.0

60Hz 24.5 25 29.5 29 34 35 39

Low

50Hz 20.0-22.0 21.0-22.0 27.0-29.0 26.0-29.0 31.0-32.5 33.5-35.0 34.0-35.5

60Hz 20 21 23.5 24.5 29.5 32.5 33.5

Temperature Exchange

Efficiency (%)

(Extra high)

50Hz 81.5 78 74.5 76.5 75 76.5 73.5

60Hz 81.5 78 74.5 76.5 75 76.5 73.5

High

50Hz 81.5 78 74.5 76.5 75 76.5 73.5

60Hz 81.5 78 74.5 76.5 75 76.5 73.5

Low

50Hz 83 81.5 79.5 78 76.5 77.5 77

60Hz 83 81.5 79.5 78 76.5 77.5 77

Enthalpy

exchange

Efficiency (%)

for

heating

(Extra high)

50Hz 74.5 70 65 72 69.5 71 68.5

60Hz 74.5 70 65 72 69.5 71 68.5

High

50Hz 74.5 70 65 72 69.5 71 68.5

60Hz 74.5 70 65 72 69.5 71 68.5

Low

50Hz 76 74 71.5 73.5 71.5 71.5 71.5

60Hz 76 74 71.5 73.5 71.5 71.5 71.5

for cooling

(Extra high)

50Hz 69.5 65 60.5 64.5 61.5 64 60.5

60Hz 69.5 65 60.5 64.5 61.5 64 60.5

High

50Hz 69.5 65 60.5 64.5 61.5 64 60.5

60Hz 69.5 65 60.5 64.5 61.5 64 60.5

Low

50Hz 71 69 67 66.5 64 65.5 64.5

60Hz 71 69 67 66.5 64 65.5 64.5

Item

Model No.

Fan Speed

VN-

M150HE

VN-

M250HE

VN-

M350HE

VN-

M500HE

VN-

M650HE

VN-

M800HE

VN-

M1000HE

13

* Sound Power Level is less than 70 dBA

* Sound pressure level of the product is the value which was measured at the acoustic room. Actually, in the

established condition, that under go influence by the echoing of the room and so that become bigger than the display

numerical value.

* The power consumption, the current and the exchange efficiency are values at the time of the mentioned air volume.

* Sound pressure level shall be measured 1.5m below the center of the unit.

* The temperature exchange efficiency averages that of when cooling and heating.

Construction

Frame Zinc steel sheets

Motor 4-pole capacitor dielectric motor (E type)

Fan PP resin

Heat exchanger Special paper + Resin

Filter Nonwoven fabric (Collection effect weighing method 82%)

Adapter Zinc steel sheets

External dimensions (Length x Width x Height)

(mm)

900 x 900 x 290 1140 x 1140 x 350 1189 x 1189 x 400

Product weight (kg) 36 38 53 70

Applicable duct nominal diameter (mm) Ø100 Ø150 Ø200 Ø250

Package

Shape Corrugated board package

Dimensions (Length x Width x Height) (mm) 1394 x 362 x 932 1634 x 422 x 1172 1683 x 472 x 1221

Weight (kg) 42 45 61 79

No. of stacked boxes 3

Accessory Adapter: 4, Screw: 16/24, Installation Manual: 1, Owner’s Manual: 1

Item

Model No.

Fan Speed

VN-

M150HE

VN-

M250HE

VN-

M350HE

VN-

M500HE

VN-

M650HE

VN-

M800HE

VN-

M1000HE

14

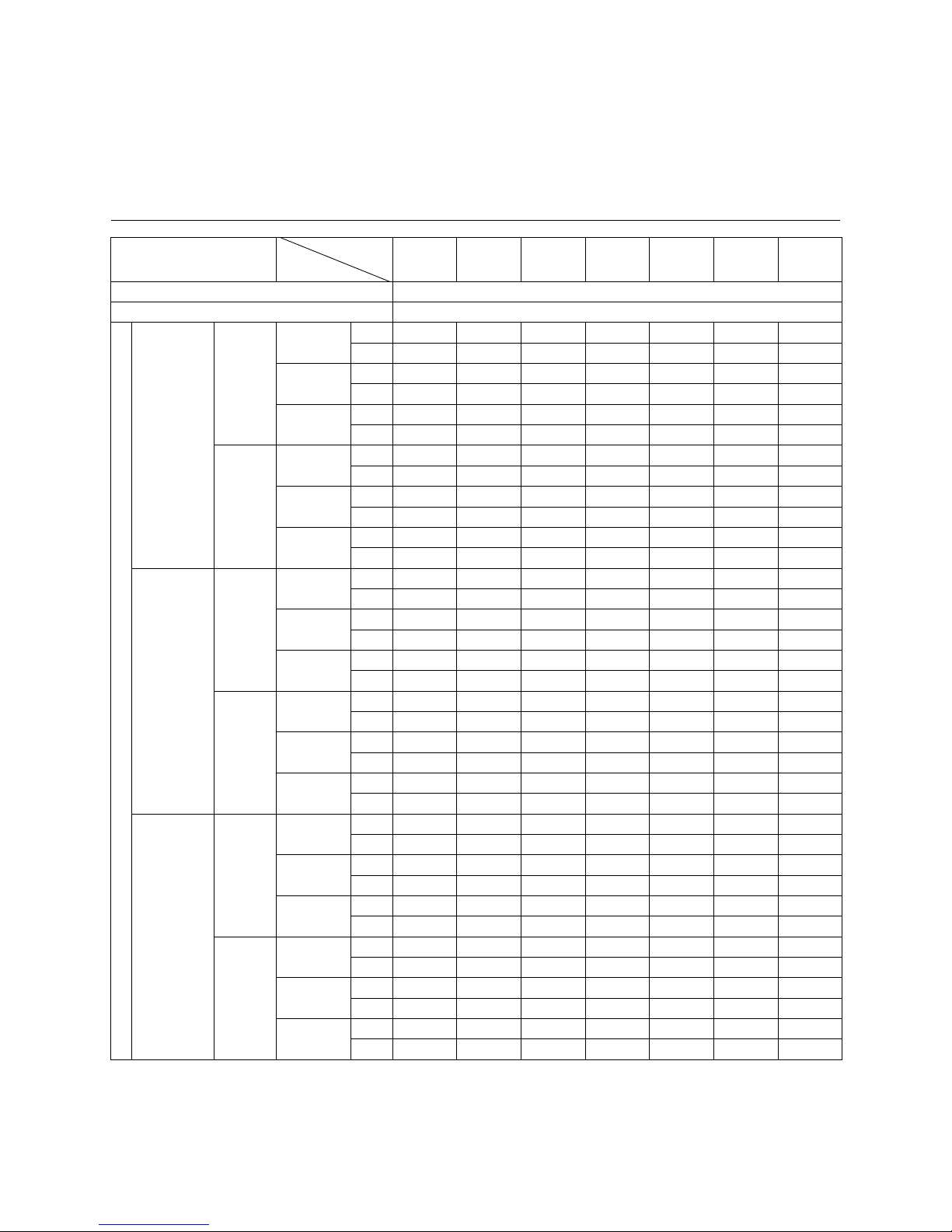

3 Model List

Unit: mm

Item Count Material Remarks Item Count Material Remarks

Adapter 4 Galvanized steel sheet Filter 4 Nonwoven fabric

Collecting

efficiency (Mass

Spectrometry):

82%

Electrical control cover 1 Damper 1

Inspection cover 1 Galvanized steel sheet Damper motor 1

Motor (Exhaust air) 1 Hanging bracket 4 Galvanized steel sheet

Motor (Supply air) 1 Electrical control base 1 Galvanized steel sheet

Heat exchange

element

2

Fire-resistant paper +

Resin

Air to air heat

exchanger

Fixing lever 1 SUS304

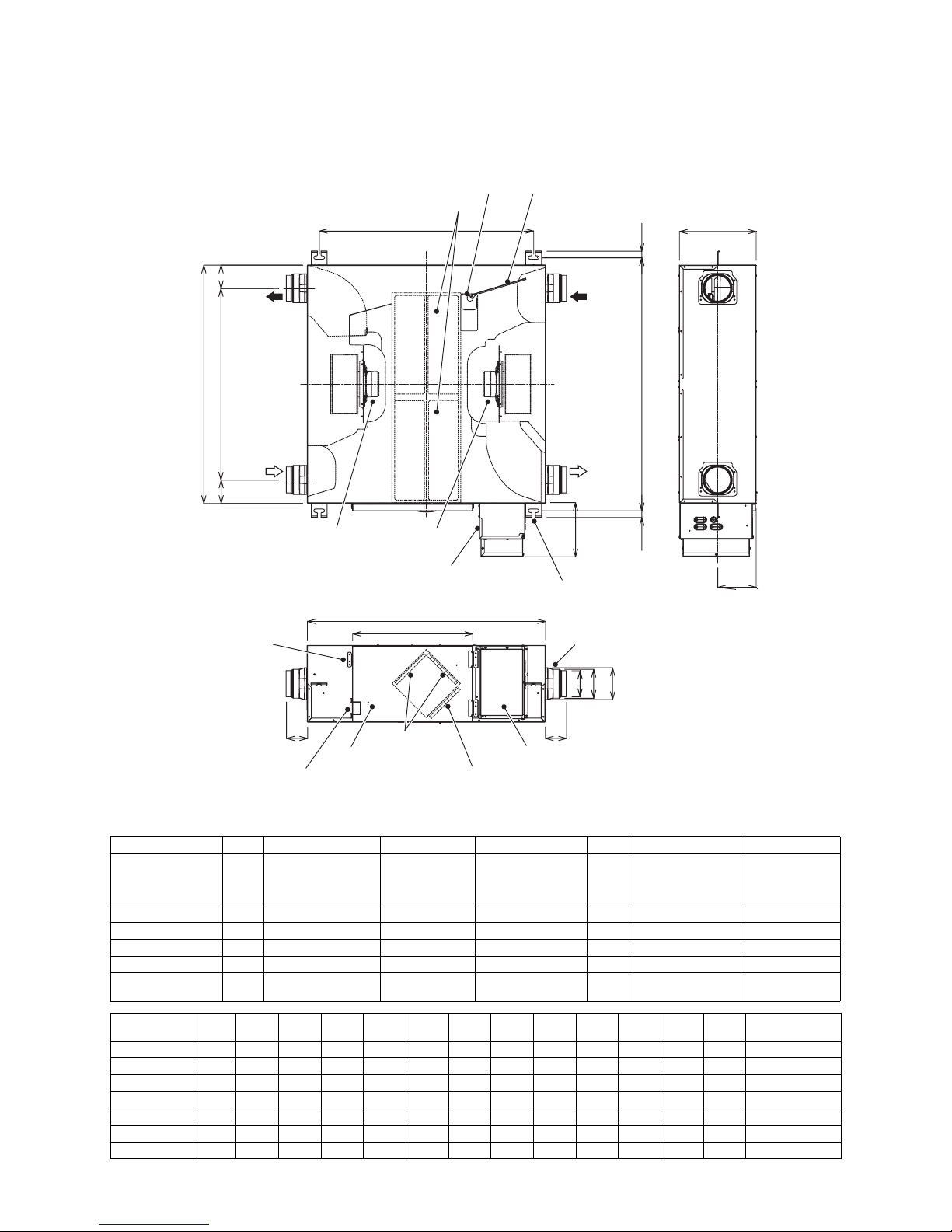

Model name A B C D E F G H I J K L M

Applicable duct

nominal diameter

VN-M150HE 900 724 88 810 957 900 454 80 Ø98 Ø110 121 290 145 Ø100

VN-M250HE 900 670 115 810 957 900 454 97 Ø145 Ø158 162 290 145 Ø150

VN-M350HE 900 670 115 810 957 900 454 97 Ø145 Ø158 162 290 145 Ø150

VN-M500HE 1140 800 170 1050 1197 1140 454 80 Ø195 — Ø212 350 175 Ø200

VN-M650HE 1140 800 170 1050 1197 1140 454 80 Ø195 — Ø212 350 175 Ø200

VN-M800HE 1189 800 195 1099 1246 1189 454 85 Ø245 — Ø262 400 200 Ø250

VN-M1000HE 1189 800 195 1099 1246 1189 454 85 Ø245 — Ø262 400 200 Ø250

D

A

B

25

L

CC

200

E

M

25

F

G

I

K

J

H H

SA

(Supply air)

RA

(Return air)

EA

(Exhaust air)

OA

(Outdoor air)

Indoor

side

Outdoor

side

Damper

Damper motor

Heat exchange element (2)

Hanging bracket (4)

4 - 13 X30 Oval hole

Electrical control base

Motor

(Supply Air)

Motor

(Exhaust air)

Fixing lever

Adapter (4)

Inspection cover

Filter (x 2)

High efficiency filter

(One for each element)

(sold separately)

Electrical control cover

Fixed part of

inspection cover

15

4 Connection diagram

1. The dotted line represents a wire procured locally, and the dashed line represents an option sold separately.

2. represents a terminal block, represents a connection terminal, and represents a connector on

the printed circuit board.

3. represents a protective earth.

4. represents a printed circuit board.

5. Using a no voltage a-contact input of the external input (sold separately), the following operations are available:

Between 1 and 2: Selecting the remote controller operation (Invalid/Valid)

Between 1 and 3: Adjusting the ventilation fan speed (Low/High)

Between 1 and 4: Selecting the ventilation mode (Bypass mode/Heat exchange mode)

Between 1 and 5: Operation (ON/OFF)

Use a microcurrent contact (DC12V, 1mA). In addition, ON/OFF operation is possible when using a voltage of

DC12V or 24V.

6. Blue wire (High) is connected as factory default. To switch to “Extra High”, connect black wire’s connector

instead of blue.

7. When the temperature of the outdoor air is below -10°C, the unit runs in the cold mode (the ventilator for air

supply runs intermittently). The unit cannot run when the temperature of the outdoor air is below -15°C. The

ventilator for air supply stops running and the ventilator for air exhaust also stops depending on the settings.

8. Even if “Bypass mode” is selected manually, the unit switches to “Heat exchange mode” automatically to prevent

condensation when the temperature of the outdoor air is below 15°C. However, “Bypass mode” is still displayed.

TR

A

SW301

CN105

1

SW701

RY701

RY704

S(N)R(L)

TB1

CN67

1

3

ON

OFF

1

SW702

OFF

DC 5V

DC20V

DC12V

ON

U4

TB2

U3

BA

2

OFF

CN040

1

4322341

2

1

3

CN041

OFF

ON

SW703

ON

CN106

1

2

t°

TOA

t°

1

7

43F22

3

43F12

5

23

43F11

5

13

55

43F21

132

C C

P01

CN701

8

43F12

FM1

M

1~

M

1~

M

FM2

777

CN704

RY705

RY702

35 13

CN760

5

2

134

RY709

RY708

RY710

65

1 3 975

6

CN702

43F21

888

43F11 43F22

DAM

3

12 45

TB3

4

CN705

213

CN706

1

52

1

5

2

2

B

A

+

-

Power supply for the Air

to Air Heat Exchanger

220-240V~, 50Hz

220V~, 60Hz

Earth

Air to Air Heat

Exchanger

represents the connector to switch between

Extra High and High.

Wiring for central control Wiring for the remote

controller

Wired remote

controller (sold

separately)

Indoor control

circuit board

MCC1615

Connector

(White)

White

Connector

(Black)

White

Orange

External output

(220-240V~, under 1A each)

*5 External input (sold

separately)

No voltage a-contact input

Voltage DC (12V, 24V) input

Operation output

White

White

White

Red

Red

White

Red

Blue

Black

Connector

(White *6)

White

Yellow

Yellow

Black

Brown

Blue

Black

Connector

(Red *6)

White

Red

(White)

Gray Light blue

Gray

Yellow

Blue

Light blue

Pink

Brown

White

Yellow

Blue

Black

Red

(White)

(Red)

1 Common

2 Remote controller operation

3 Ventilation fan speed

4 Ventilation mode

5 Operation

(Black)

Power

supply

(Blue) (Blue)

(Brown)

(White)

Black

Blue Blue

Black

F01

T3.15A

250V~

Common

External damper output

Abnormal/Bypass mode output

Code Part name

CN*** Connector

F01 Fuse

FM1 Air supplying motor

FM2 Air exhausting motor

DAM Damper motor

TRA TRA sensor

Code Part name

TOA TOA sensor

RY701, RY702 Relay for air supplying motor

RY704, RY705 Relay for air exhausting motor

TB1 Terminal block (power supply)

TB2 Terminal block (communication)

TB3 Terminal block (external output)

Code Part name

SW301, SW701

SW702, SW703

DIP switch

43F11, 43F12 Relay for air supplying motor

43F21, 43F22 Relay for air exhausting motor

16

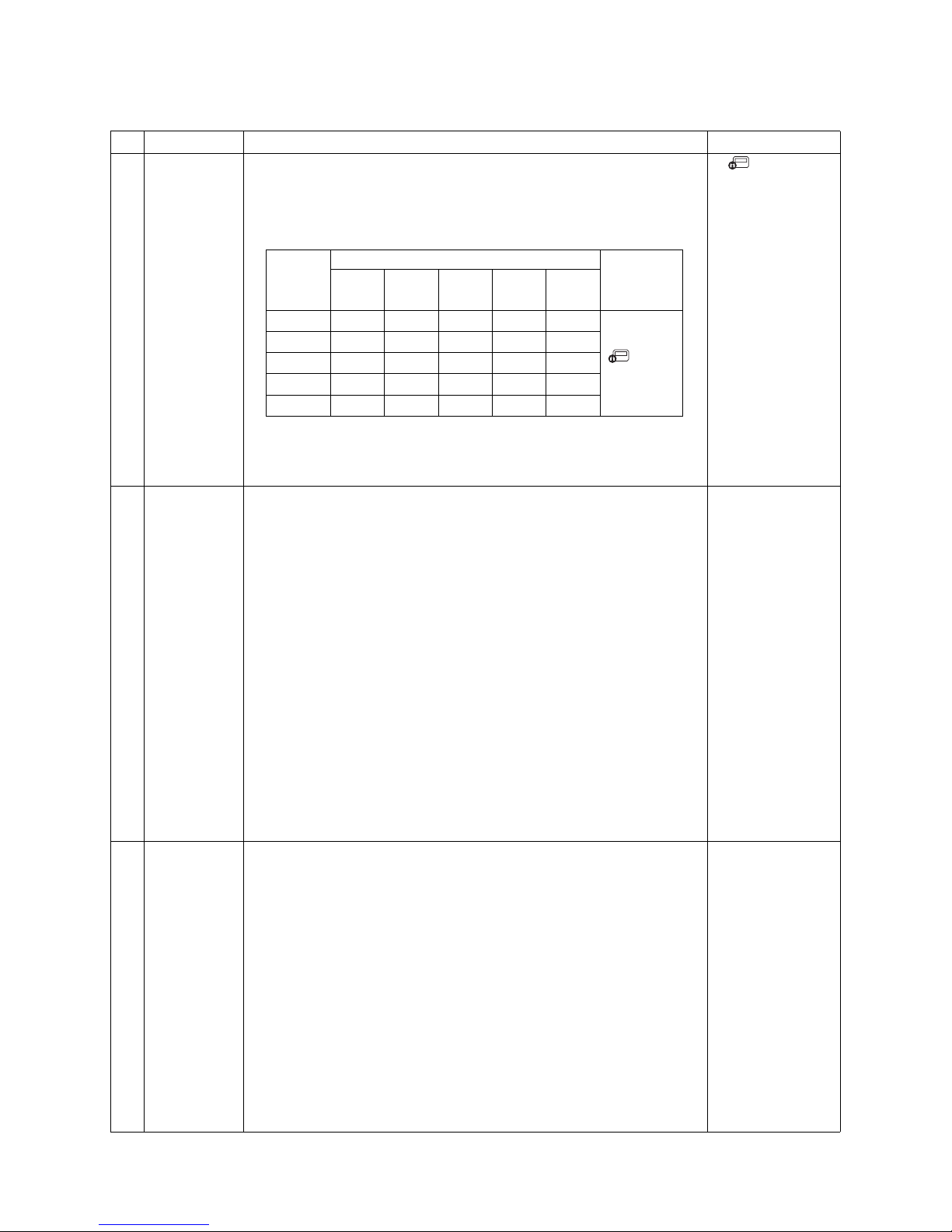

5 Parts Rating

Model VN-M 150HE 250HE 350HE 500HE 650HE 800HE 1000HE

Running condenser for supply air

fan motor

450V

1ȝF

450V

1ȝF

450V

3ȝF

450V

3ȝF

450V

3ȝF

450V

5ȝF

450V

10ȝF

(5ȝF x 2)

Running condenser for exhaust

air fan motor

450V

1ȝF

450V

1ȝF

450V

3ȝF

450V

3ȝF

450V

3ȝF

450V

5ȝF

450V

10ȝF

(5ȝF x 2)

TOA sensor Ø5 size lead wire length:

900mm vinyl tube (Blue)

Ø5 size lead wire length:

1040mm vinyl tube (Blue)

TRA sensor Ø5 size lead wire length:

1010mm non-migratory tube (Black)

Ø5 size lead wire length:

1270mm non-migratory tube (Black)

Relay LY-1F

Rated voltage: AC220V/240V Rated load: 10A AC220V

Damper motor MP24ZN

17

6 Control Outline

Air to Air Heat Exchanger

Control Specifications

NO. Item Specification outline Remarks

1

When the power

is reset

1. If the power supply is reset during the occurrence of an error, the check code is

cleared.

If an abnormal state continues even after the unit is restarted by pressing the [ON/

OFF] button on the remote controller, the check code is redisplayed on the remote

controller.

2

Ventilation

mode control

Air to Air Heat Exchanger system and Air to Air Heat Exchanger system linked with

air conditioners

1)Ventilation mode control

• The control method of the automatic mode is different depending on whether

it is an Air to Air Heat Exchanger system or an Air to Air Heat Exchanger

system linked with air conditioners.

• There are three ventilation modes: Automatic, Heat Exchange, and Bypass.

2)When a system without a remote controller or RBC-AMT32E, RBC-AMS41E

remote controller is used:

• The ventilation mode can be changed with CODE No. (DN) [EA] of the DN

setting.

3)Bypass mode control

• If OA RA/10 + 12.5, the system automatically runs in Heat Exchange mode

to prevent condensation. (For details, see the section “Cold Mode Control.”)

• The display on the remote controller remains “Bypass” regardless of the

ventilation mode in actual operation.

• When operation starts in Bypass mode, the Heat Exchange mode is

maintained for three minutes if the state before stop is Heat Exchange mode

(cold mode control).

1. Air to Air Heat Exchanger system

1)Automatic mode control

• One of the following three zones is selected by the TOA and TRA sensors:

Cooling zone, Fan zone, Heating zone

• Automatic ventilation control is performed in the Cooling and Heating zones.

• For the Fan zone, the mode is fixed to Heat Exchange.

• For five minutes after the start of Automatic mode, the Heat Exchange state is

maintained.

• The display on the remote controller remains “Automatic” regardless of the

ventilation mode in actual operation.

2)Criteria for each zone:

[Cooling zone]

OA 24°C or OA 20°C and RA 24°C

[Fan zone]

20°C OA < 24°C and 20°C RA < 24°C

[Heating zone]

Temperature range out of the Cooling and Fan zones

3)Bypass mode condition in automatic ventilation control

[Cooling zone]

RA 26°C and OA 22°C and RA OA + 3°C

[Heating zone]

RA 18°C and RA/10°C + 14.5°C OA 22°C and OA RA + 3°C

• If the system is in an undefined zone when operation starts, the system is

operated in Heat exchange mode. If the state moves to this zone during

operation, the previous state is retained.

TOA sensor

TRA sensor

CODE No. (DN)

[EA] [EC]

18

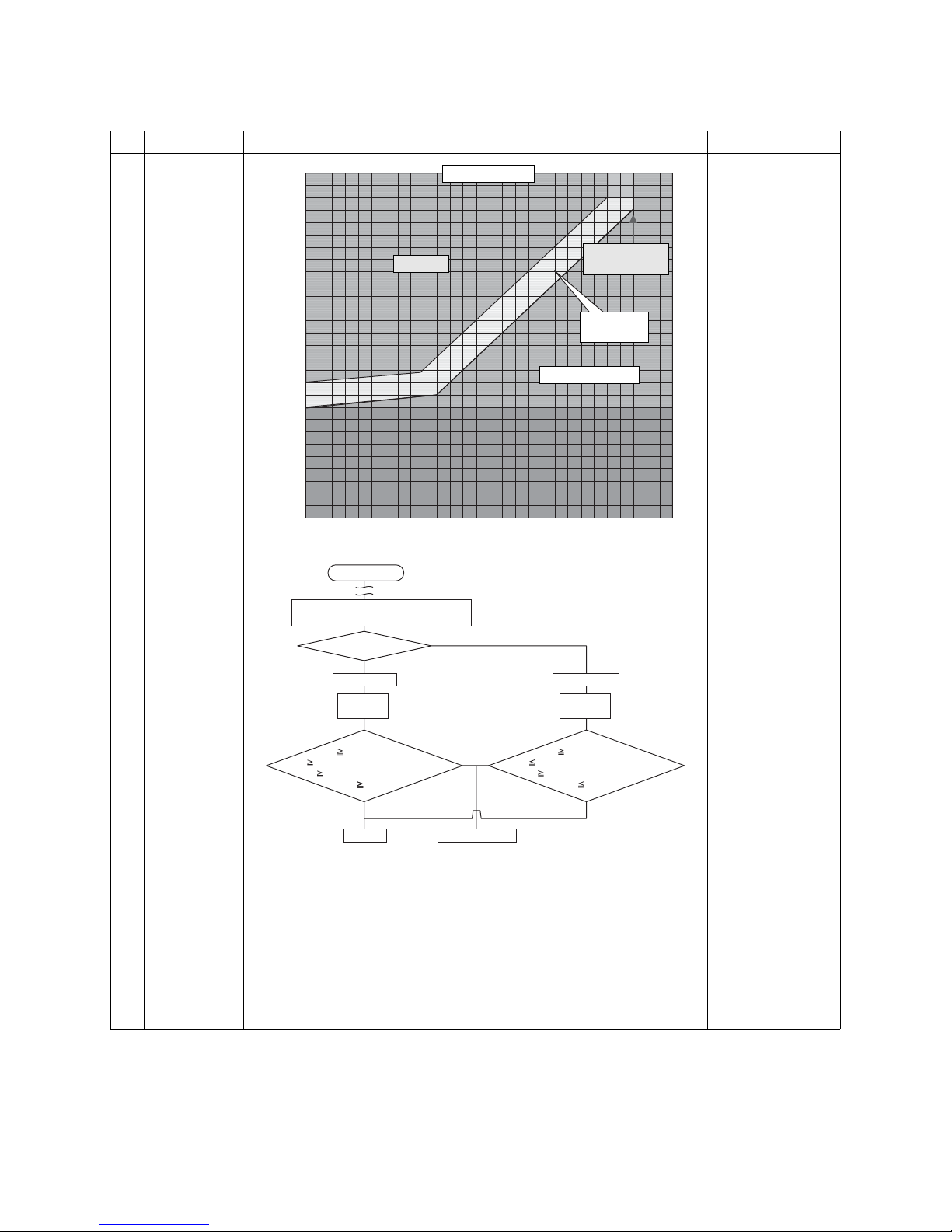

2

Ventilation

mode control

(continued)

NO. Item Specification outline Remarks

48

12

16 20 24 28 32

8

12

16

20

24

28

32

Automatic ventilation mode control in the Air to Air Heat

Exchanger system

Heat Exchange

Cooling zone

Bypass

Fan zone

Heat Exchange

Bypass

Heat Exchange

Heating zone

Undefined

zone

Undefined

zone

OA: Outdoor Air (°C)

RA: Return Air (°C)

Cooling zone Heating zone

Bypass

Y

N

Y

N

N

Y

N

Y

N

Y

N

Y

Fan zone

Heat Exchange

Continue current ventilation mode

Y

N

Y

N

Y

N

Y

N

N

Y

Start operation

Y

N

OA

24°C

RA

24°C

RA

20°C

OA

20°C

Automatic ventilation determination

in air-conditioning linkage

RA, OA

detection

DN [EC]

Invalid: 0002

DN [EC]

Valid when stopped:

0001

Other than Fan

mode

and OA RA + 3°C

RA 18°C and RA/

10°C + 14.5°C OA 22°C

RA 26°C and OA 22°C

RA OA

+

3°C

Air

conditioner

operation

Ventilation

mode Automatic

Single system

19

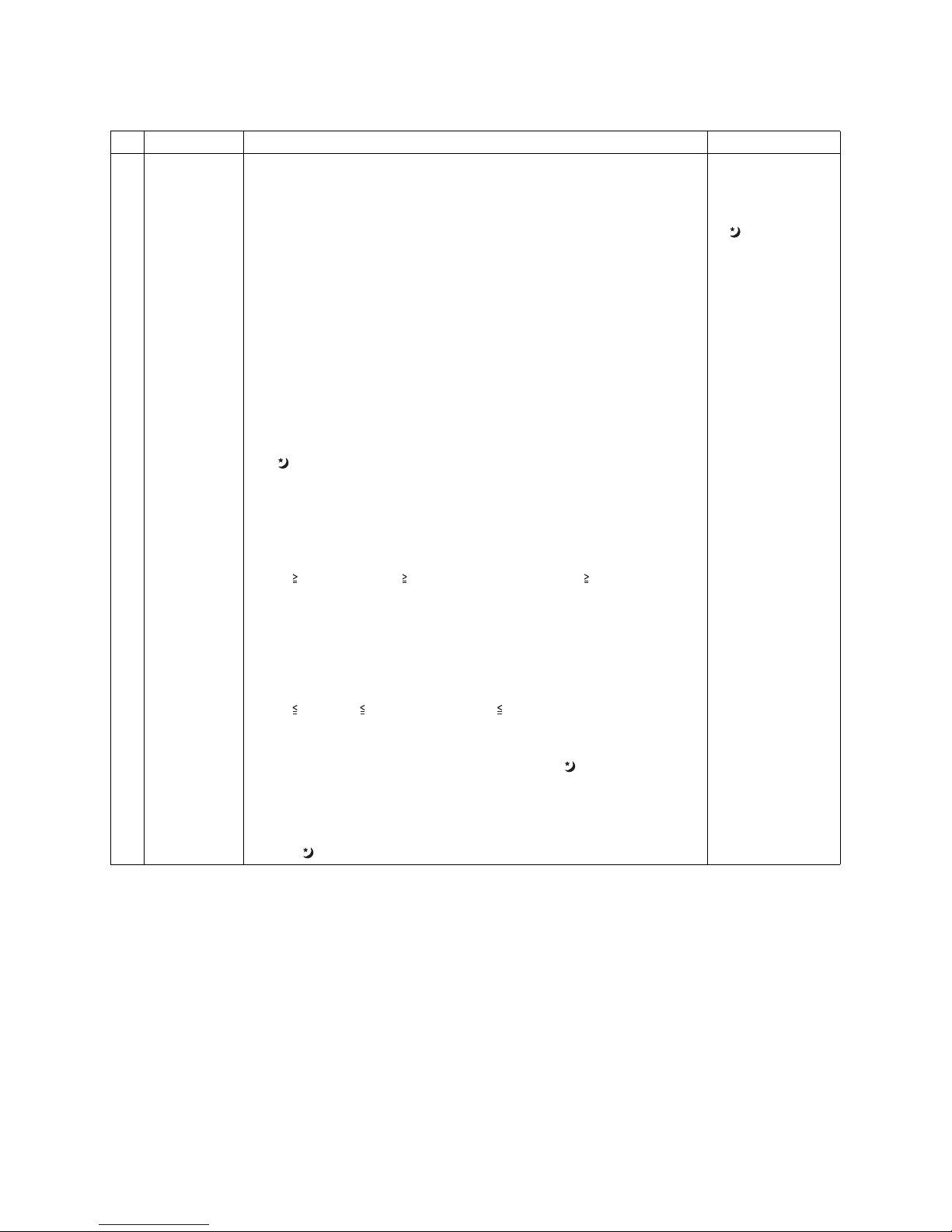

2

Ventilation

mode control

(continued)

2. Air to Air Heat Exchanger system linked with air conditioners

1)Automatic ventilation mode control in the air-conditioning linkage

• Determine the mode from the operation mode of the air conditioner.

[Cooling zone]: The air conditioner operation mode is Automatic cooling,

Cooling, or Drying mode.

[Heating zone]: The air conditioner operation mode is Automatic heating or

Heating mode.

In Fan mode, the zone is determined by the automatic ventilation mode control

in the Air to Air Heat Exchanger system.

• The setting of the automatic ventilation control in the Air to Air Heat Exchanger

system linked with air conditioners can be changed with CODE No. (DN) [EC]

of the DN setting.

0000: Valid only when the air conditioner is running (factory default). When the

air conditioner is stopped, the zone is determined by the automatic

ventilation mode control of the Air to Air Heat Exchanger system.

0001: Valid even if the air conditioner is stopped. If the air conditioner is

stopped, the zone is determined by the operation mode and set

temperature before stop.

0002: Invalid. The zone is determined by the automatic ventilation mode

control in the Air to Air Heat Exchanger system.

2)The Bypass condition at the time of automatic ventilation mode control in the Air

to Air Heat Exchanger system linked with air conditioners (excluding Fan mode)

[Cooling zone]

RA OA + 3°C and RA set temperature + 2°C and OA RA/10°C + 14.5°C

and RA 20°C

[Heating zone]

OA RA + 3°C and RA set temperature - 2°C and OA RA/10°C + 14.5°C

and RA 27°C

• Condition for returning to Heat Exchange (determined by the set temperature

before stop, even when the air conditioner is stopped)

(For details, see the section “Cold Mode Control.”)

[Cooling zone] RA set temperature - 2°C or RA 18°C

[Heating zone] RA set temperature + 2°C or RA 29°C

• If the system is in an undefined zone when operation starts, the system is

operated in Heat exchange mode. If the state moves to this zone during

operation, the previous state is retained.

NO. Item Specification outline Remarks

48

12

16 20 24 28 32

8

12

16

20

24

28

32

Automatic ventilation mode control in the Air to Air Heat

Exchanger system linked with air conditioners

Cooling zone

Heat Exchange

Bypass

Undefined

zone

OA: Outdoor Air (°C)

RA: Return Air (°C)

Minimum set

temperature

20

2

Ventilation

mode control

(continued)

3

Ventilation fan

speed control

1. By pressing the [VENT FAN] button, Ventilation Fan Speed High/Low and SA >

EA/SA < EA can be switched.

• SA > EA and SA < EA can be changed with CODE No. (DN) [48] of the DN

setting.

0000: Normal (factory default)

0001: SA (High) > EA (Low) active

0002: SA (Low) < EA (High) active

* “High” may be “Extra High.”

2. When a system without a remote controller or RBC-AMT32E, RBC-AMS41E

remote controller is used:

• The ventilation mode can be changed with CODE No. (DN) [EB] of the DN

setting.

CODE No. (DN)

[EB][48]

NO. Item Specification outline Remarks

48

12

16 20 24 28 32

8

12

16

20

24

28

32

Heat Exchange

Bypass

Undefined

zone

OA: Outdoor Air (°C)

RA: Return Air (°C)

Maximum set

temperature

Heating zone

Y

N

Y

N

N

Y

Cooling zone Heating zone

Bypass Heat Exchange

Start operation

Automatic ventilation determination in

air conditioning linkage

Cooling or Drying mode

RA, OA

detection

RA, OA

detection

RA OA + 3°C and

RA set temperature + 2°C and

RA OA/10°C + 14.5°C and

RA 20°C

OA RA + 3°C and

RA set temperature - 2°C and

OA RA/10°C + 14.5°C and

RA 27°C

21

4

24-hour

ventilation

control

1. 24-hour ventilation operation and setting

• By operating the [ON/OFF] and [VENT] buttons during operation of Air to Air

Heat Exchangers, they stop operation and the system moves to 24-hour

ventilation (low): 60 minutes ON, 60 minutes OFF.

The ventilation mode is fixed to Heat Exchange.

* The setting of 24-hour ventilation (Valid/Invalid) needs to be changed with

CODE No. [49] of the DN setting.

0000: Invalid (factory default); 0001: Valid

2. Setting the on/off ratio of 24-hour ventilation

• The on/off ratio complaint response mode can be changed with CODE No. (DN)

[4A] of the DN setting.

0000: Normal; the air volume of ventilation: 1/2, fan is ON for 60 minutes and

OFF for 60 minutes (factory default).

0001–0059: the air volume of ventilation: Fan is ON for [SET DATA of DN]

minutes and OFF for [60-SET DATA of DN] minutes.

3. Changing the ventilation fan speed of 24-hour ventilation

• The setting of the ventilation fan speed of the 24-hour ventilation can be

changed with CODE No. (DN) [47] of the DN setting.

0000: Operate with ventilation fan speed fixed to Low (factory default)

0001: Operate with the ventilation fan speed that was set before stop.

4. In the Air to Air Heat Exchanger system, Air to Air Heat Exchangers stop if the

[ON/OFF] button is pressed when they are running, and the system enters 24hour ventilation mode.

5. In the Air to Air Heat Exchanger system linked with air conditioners, Air to Air Heat

Exchangers and air conditioners stop if the [ON/OFF] button is pressed when they

are running, and the system enters 24-hour ventilation mode.

6. In the Air to Air Heat Exchanger system linked with air conditioners, Air to Air Heat

Exchangers stop if the [VENT] button is pressed when only the Air to Air Heat

Exchangers are running or when both the Air to Air Heat Exchangers and air

conditioners are running, and the system enters 24-hour ventilation mode.

* The setting of the single operation of the Air to Air Heat Exchanger needs to be

changed with CODE No. (DN) [31] of the DN setting. (Setting for the header air

conditioner)

0000: Invalid (factory default); 0001: Valid

7. Operation during 24-hour ventilation

• During 24-hour ventilation, the ventilation fan speed and the ventilation mode

cannot be changed, and they are not displayed.

8. Stop of 24-hour ventilation

• From the NRC-01HE, 24-hour ventilation can be stopped temporarily by holding

the [VENT FAN] button down for four seconds when 24-hour ventilation is in

operation.

• The “ ” display goes out.

CODE No. (DN)

[47][31][49][4A]

• “ ” lights up

5

Delayed

operation

control

1. The delay setting needs to be changed with CODE No. (DN) [4B] of the DN setting

in the Air to Air Heat Exchanger system linked with air conditioners.

After pressing the [ON/OFF] button, operation of the Air to Air Heat Exchanger is

delayed by [SET DATA of DN] × 10 minutes.

0000: No delay (factory default)

0001–0006: Delay by [SET DATA of DN] × 10 minutes

* The delay time can be set between 10 and 60 minutes in the unit of 10 minutes.

* If the [VENT] button is pressed during single operation of Air to Air Heat

Exchangers, delayed operation is not performed.

2. During delayed operation, “ ” lights up.

CODE No. (DN)

[4B]

• “ ” lights up.

NO. Item Specification outline Remarks

22

6

Nighttime heat

purge control

This function is valid only for the Air to Air Heat Exchanger system linked with air

conditioners (invalid for the Air to Air Heat Exchanger system).

1. If the [ON/OFF] button is pressed during operation, the Air to Air Heat Exchangers

and the air conditioners stop, and the system enters the nighttime heat purge

mode (standby mode).

* The setting of nighttime heat purge (Valid/Invalid) needs to be changed with

CODE No. (DN) [4C] of the DN setting.

0000: Invalid (factory default)

0001–0048: Temperature monitoring operation starts after [SET DATA of DN] ×

1 hour.

2. Conditions that make the nighttime heat purge setting valid

• Only when the air conditioners and Air to Air Heat Exchangers are stopped

• Only when the operation mode before the stop of the air conditioner header unit

is Automatic cooling, Drying, or Cooling

• When 24-hour ventilation is set to Invalid

• Invalid when only the Air to Air Heat Exchangers are stopped

• Invalid when the air conditioners are stopped in states where only the Air to Air

Heat Exchangers are stopped

3. When the nighttime heat purge setting is valid

• The mode moves from the stop of the Air to Air Heat Exchangers to the nighttime

heat purge operation mode (standby mode).

“ ” lights up, and the system enters the nighttime heat purge operation

standby mode.

4. Nighttime heat purge operating conditions:

• The nighttime heat purge monitoring operation start time specified in the DN

setting (1 to 48 hours) has passed.

• Temperature monitoring operation is performed for five minutes (Heat

Exchange mode) and nighttime heat purge operation starts if the following

conditions are met.

• RA 0A + 3°C and RA set temperature + 2°C and OA RA/10°C + 14.5°C

5. During nighttime heat purge operation

• The ventilation fan speed can be changed with CODE No. (DN) [47] of the DN

setting.

0000: Operate with the ventilation fan speed fixed to Low (factory default)

0001: Operate with the ventilation fan speed that was set before stop

• During nighttime heat purge operation, the ventilation mode (fixed to Bypass

mode) cannot be changed, and it is not displayed.

6. Nighttime heat purge temporary stop condition (one-hour stop)

• RA OA or RA set temperature or OA RA/10°C + 12.5°C or one hour has

passed since the start of nighttime heat purge

7. Nighttime heat purge stop (termination) conditions

• The air conditioners or Air to Air Heat Exchangers start operation.

• When single operation of the fan is performed while “ ” is lit, nighttime heat

purge stops. When single operation of the Air to Air Heat Exchanger is stopped,

the mode does not return to “Nighttime heat purge.”

• 48 hours have passed since the start of nighttime heat purge operation (start of

temperature monitoring operation).

8. When nighttime heat purge operation stops:

• The “ ” display goes out.

CODE No. (DN)

[4C][47]

• “ ” lights up.

NO. Item Specification outline Remarks

23

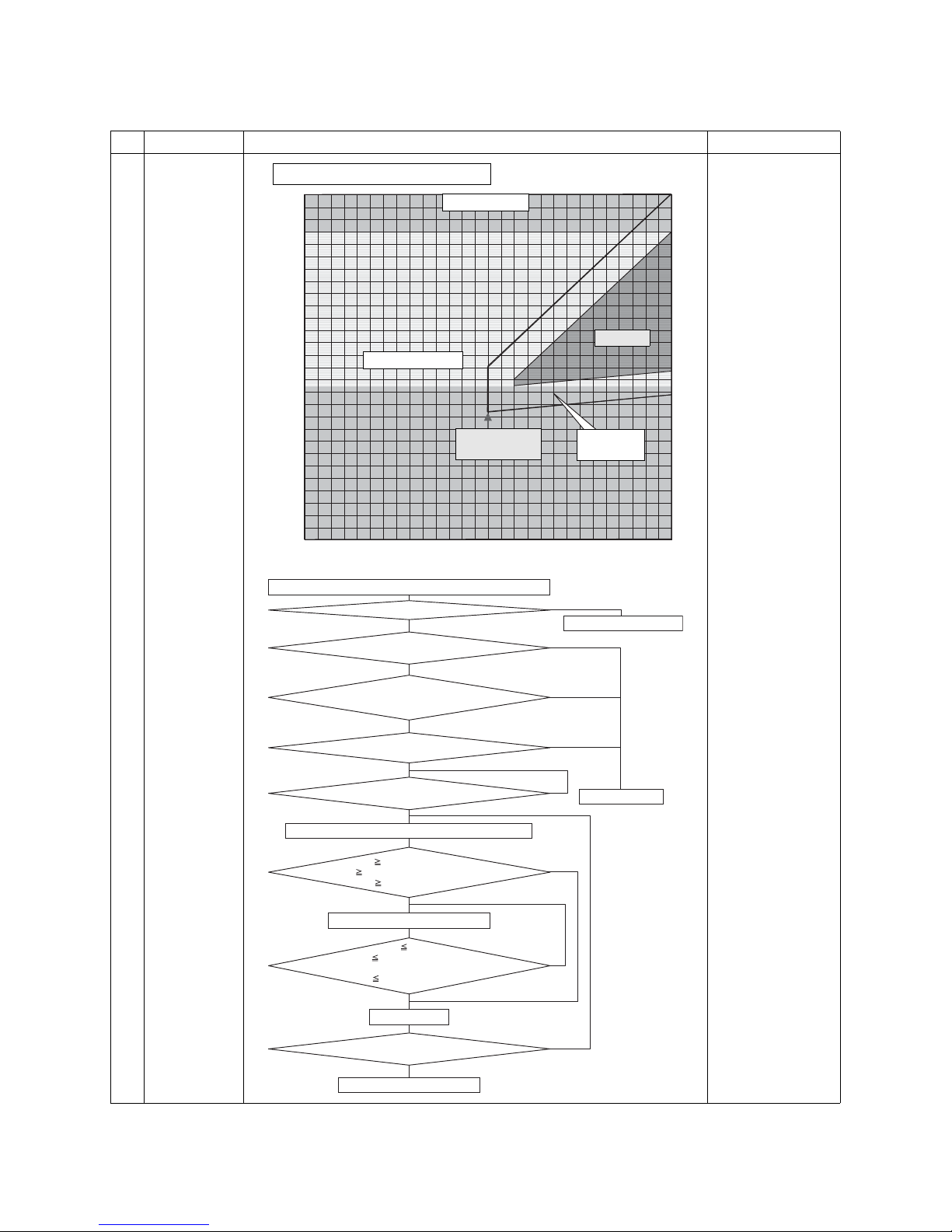

6

Nighttime heat

purge control

(continued)

NO. Item Specification outline Remarks

48

12

16 20 24 28 32

8

12

16

20

24

28

32

Nighttime heat purge control

Cooling zone

Heat Exchange

Bypass

Undefined

zone

OA: Outdoor Air (°C)

RA: Return Air (°C)

Minimum set

temperature

Y

N

Y

N

Y

N

Y

N

N

Y

N

Y

Y

Y

N

N

Nighttime heat purge operation

End of nighttime heat purge

Stop of 1 hour

Start 24-hour ventilation

Remain stopped

24-hour ventilation setting invalid

Air to Air Heat Exchangers and air conditioners are stopped.

Air to Air Heat Exchanger system

linked with air conditioners

Nighttime heat purge setting valid

Set time to start of monitoring operation between

1 and 48 hours

Operation mode before stop

Cooling or Drying mode

As monitoring operation start time,

1 to 48 hours have passed

48 hours have passed since start of

monitoring operation

RA OA and + 3°C and

RA set temperature + 2°C and

OA RA/10°C + 14.5°C

RA OA or

RA set temperature or

One hour has passed or

OA RA/10°C + 12.5°C

Monitoring operation (5 minutes of Heat Exchange)

24

7

Cold mode

control

1. Even in Bypass mode control, the system automatically enters Heat Exchange

mode to prevent condensation if OA RA/10°C + 12.5°C.

• The display on the remote controller remains “Bypass mode” regardless of the

ventilation mode in actual operation.

• When operation starts in Bypass mode, the system runs in Heat Exchange

mode for three minutes if the state before stop is Heat Exchange mode (cold

mode control).

2. The ON time in each zone is maintained for at least three minutes. When the

temperature condition moves to another zone, the system starts the OFF

condition in another zone.

3. In the B zone condition, the supplying fan performs intermittent operation (stops

for 10 minutes and runs for 60 minutes). The exhausting fan runs continuously.

4. In the C zone condition, the supplying fan stops. However, it stops for 60 minutes

and runs for five minutes.

The setting of the exhausting fan can be changed with CODE No. (DN) [4D] of the

DN setting.

0000: Exhausting fan runs (factory default)

0001: Exhausting fan stops

CODE No. (DN)

[4D]

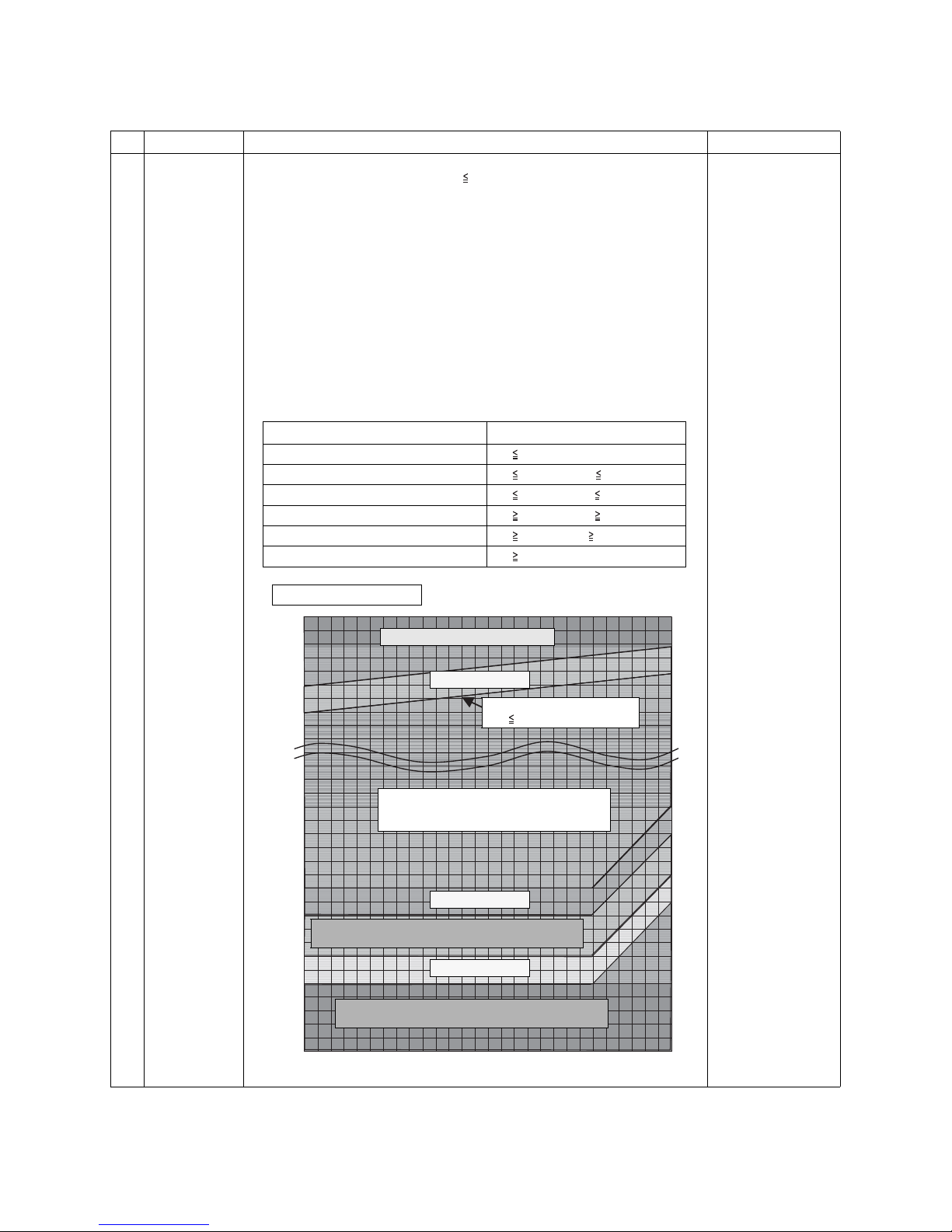

NO. Item Specification outline Remarks

Zone Zone criterion

Bypass mode permitted zone Zone A OA RA/10°C + 12.5°C

Zone A Zone B OA – 10°C or OA RA – 36°C

Zone B Zone C OA

– 15°C or OA RA – 41°C

Zone C Zone B OA

– 13°C or OA RA – 39°C

Zone B Zone A OA

– 8°C or OA RA – 34°C

Zone A Bypass mode permitted zone OA RA/10°C + 14.5°C

4 8 16 20 24 28 32

–12

–8

–4

0

16

–16

–20

12

20

12

Cold mode control

Undefined zone

Bypass mode permitted zone

Zone A: Normal operation

(Even in Bypass mode, the mode is

automatically switched to Heat Exchange.)

OA: Outdoor Air (°C)

RA: Return Air (°C)

Heat Exchange condition

OA RA/10 + 12.5

Undefined zone

Undefined zone

Zone B: The supplying fan operates intermittently.

The exhausting fan runs continuously.

Zone C: The supplying fan operates intermittently.

The exhausting fan operation is set in the DN.

25

7

Cold mode

control

(continued)

8

Filter symbol

display

1. The indoor header unit’s cumulative hours of operation are counted, and when

they exceed the prescribed value, a filter replacement signal is sent to the remote

controller to display a filter symbol on the remote controller.

• The setting of the prescribed number of hours can be changed with CODE No.

(DN) [01] of the DN setting.

0000: None

0001: 150 hours

0002: 2,500 hours (factory default)

0003: 5,000 hours

0004: 10,000 hours

2. When a filter reset signal is received from the remote controller, the timer

measuring cumulative hours is cleared. If the prescribed number of hours has

been exceeded, the measurement time is reset with the symbol on the remote

controller display erased.

1)In the Air to Air Heat Exchanger system linked with air conditioners, the

cumulative time of operation of the indoor header unit is the representative of

the group.

* In the Air to Air Heat Exchanger system linked with air conditioners, the

cumulative time of 24-hour ventilation operation is not counted.

* In the Air to Air Heat Exchanger system linked with air conditioners, the

cumulative time of the nighttime heat purge operation is not counted.

2)In the Air to Air Heat Exchanger system, the cumulative operating time of the

exhausting fan of the Air to Air Heat Exchanger header unit is the representative

of the group.

* In the Air to Air Heat Exchanger system, the cumulative operating time of 24-

hour ventilation is counted.

3)When the degree of dirt of the filter is set, its time is half the standard time.

• The setting of the degree of dirt of the filter can be changed with CODE No. (DN)

[02] of the DN setting.

0000: Standard (factory default)

0001: High degree of dirt (half the standard time)

CODE No. (DN)

[01][02]

• “ ” lights up

NO. Item Specification outline Remarks

Zone A?

Y

N

Y

N

N

Y

N

Zone B?

Y

Operating

Present ventilation mode continues

Zone C

Heat Exchange

Heat Exchange

mode continues

OA

RA/10°C + 12.5°C

Heat Exchange Supplying fan

stops (OFF for 10 minutes and

ON for 60 minutes) Exhausting

fan runs continuously

Heat Exchange Supplying fan

stops (OFF for 60 minutes and

ON for 5 minutes) Exhausting

fan runs continuously

Heat Exchange Supplying fan

stops and Exhausting fan

stops (OFF for 60 minutes

and ON for 5 minutes)

DN [4D]

Exhausting fan runs:

0000

26

9

Selection of

central control

mode

1. The range of operations that can be performed by operating the remote controller

of the Air to Air Heat Exchanger can be determined through the setting of the

central controller.

2. Setting details

• TCC Link central control

* The ventilation start/stop operation applies only to operation linked with air

conditioners. It becomes effective when “single operation of the fan” is set to

0001 (valid) in CODE No. (DN) [31].

• “ ” lights up while

in central control

mode.

• The display blinks

when a control

function

inaccessible to a

remote controller is

chosen.

10

Operation

output

(Connecting an

auxiliary fan)

1. Operation output setting

• The output setting can be changed by CODE No. (DN) [ED]

0000: Contact is on only during normal operation.

* Contact is off during 24-hour ventilation or nighttime heat purge

operation.

* Contact is off during cold mode (while the temperature is below -10 °C).

0001: Contact is on during normal operation, 24-hour ventilation, or nighttime

heat purge operation.

* Contact is on when 24-hour ventilation is stopped intermittently.

* Contact is off when nighttime heat purge operation is on standby.

(paused before the monitoring operation of the nighttime heat purge

operation starts)

* Contact is off during cold mode (while the temperature is below -10 °C).

0002: Contact is on during 24-hour ventilation or nighttime heat purge operation.

* Contact is on when 24-hour ventilation is stopped intermittently.

* Contact is off during normal operation or when the nighttime heat purge

operation is on standby. (paused before the monitoring operation of the

nighttime heat purge operation starts)

* Contact is off during cold mode (while the temperature is below -10 °C).

0003: Contact is on only when SA fan (Supplying fan) is running.

* Contact is off when 24-hour ventilation is stopped intermittently, so do

not connect an auxiliary fan.

0004: Contact is on only when EA fan (Exhausting fan) is running.

* Contact is off when 24-hour ventilation is stopped intermittently, so do

not connect an auxiliary fan.

CODE No. (DN)

[ED]

• External output

terminal block

((1) – (2))

11

Electric damper

output

1. Output setting for electric damper

• The setting can be switched between Normal and Complaint Response Setting

in the DN setting.

• The output setting can be changed with CODE No. (DN) [5C] of the DN setting.

0000: Normal (factory default)

0001: 24-hour ventilation, nighttime heat purge operation supported

2. Operation ON/OFF condition in normal setting

• ON during intermittent stop in 24-hour ventilation mode

• ON in cold mode control (Zones B and C)

• ON if the fan is stopped when switching the damper (Heat exchange mode/

Bypass mode)

• ON from the start of monitoring operation of nighttime heat purge to the end of

nighttime heat purge

• OFF during delayed operation

• OFF during the stop of normal operation (including 24-hour stop)

3. Operation output ON/OFF condition when support of 24-hour ventilation and

nighttime heat purge operation is set

The settings are the same as those for normal settings except the following:

• OFF during intermittent stop in 24-hour ventilation mode

• OFF during temporary stop in nighttime heat purge mode

CODE No. (DN)

[5C]

• External output

terminal block

((3) – (4))

NO. Item Specification outline Remarks

(O: Accessible ×: Inaccessible)

Operation

from TCC

Link central

control

Operation on NRC-01HE

NRC-01HE

display

Setting

start/stop

Setting

ventilation

start/stop

Setting

timer

Setting

ventilation

fan speed

Setting

ventilation

mode

Individual

OOOOO

“” is

displayed

[Central 1]

×O×OO

[Central 2]

×O×OO

[Central 3]

OOOOO

[Central 4]

OOOOO

27

12

Linked

operation with

external devices

Connect the Remote ON/OFF adapter (NRB-1HE: sold separately) to the

connectors CN706(2P) and CN705(5P) on the control circuit board of the Air to Air

Heat Exchanger.

1. Output signals of external devices

• DC12V, DC24V: Connect to CN706(2P)

• No voltage a-contact: Connect to CN705(5P) and use (1) Green – (5) Black

2. Pulse/Static switch of output signals of external devices (Static: OFF by default)

• No. 1 of the switch SW701 on the board (Pulse: ON)

3. Linked operation with external devices

• You can set the Air to Air Heat Exchanger operations for ON/OFF signals of

external devices by CODE No. (DN) [4E].

0000: The Air to Air Heat Exchanger starts/stops together with the starting/

stopping of an external device. (The latter operation of the remote

controller or the switch of the external device overrides the former.)

0001: The Air to Air Heat Exchanger starts together with the starting of an

external device. Use the remote controller to stop operation.

0002: The Air to Air Heat Exchanger stops together with the stopping of an

external device. Use the remote controller to start operation.

Operation signals DN [4E]

CODE No. (DN)

[4E]

• Remote ON/OFF

adapter (NRB-1HE:

sold separately)

• No. 1 of the switch

SW701 on the board

Pulse: ON

Static: OFF (Factory

setting)

NO. Item Specification outline Remarks

Mode

External signals: Static External signals: Pulse

ON/OFF

linked

(0000)

ON

linked

(0001)

OFF

linked

(0002)

External signal

Remote control

SW pressed

Operation

status

ON

OFF

External signal

Remote control

SW pressed

Operation

status

ON

OFF

External signal

Remote control

SW pressed

Operation

status

ON

OFF

External signal

Remote control

SW pressed

Operation

status

ON

OFF

External signal

Remote control

SW pressed

Operation

status

ON

OFF

External signal

Remote control

SW pressed

Operation

status

ON

OFF

28

7 Applied Control and Functions

(Including Circuit Configuration)

7-1. Heat Exchanger Controller Block Diagram

RS RS

Main (sub) center remote controller

(up to 2 units)

Function setting

Key switch

DC5V

DC5V

CN2

*1

CN1

EEPROM

Switch

MCU

MCU

MCU

External

input

External

output

DC5V

DC12V

DC20V

BABA AB

#2 #3

TRA sensor

RS

EEPROM

Display

LCD

Display

LCD

LCD

driver

Display

LCD

Remote controller

communication circuit

Remote controller

communication circuit

Power

supply

circuit

Rechargeable

battery

Power

supply

circuit

Schedule timer

(when in weekly timer mode)

Air to Air Heat Exchanger

#1

Function setting

Key switch

Damper

motor

Supplying

fan motor

Exhausting

fan motor

Power

supply circuit

Fan motor

relay circuit

Fan motor

relay circuit

Driver

TOA sensor

• Driving

• Damper

• Abnormal/

Bypass

mode

• Remote

controller

invalid

• Low/High

• Bypass

mode/Heat

Exchange

mode

• Start/Stop

AC

synchronous

signal input

circuit

BUS

communication

circuit

Power

supply

Power

supply

Central

control

Same

as left

Same

as left

Up to 8 units can be connected.

*1 A weekly timer cannot be

connected to a subremote

controller.

• Indoor unit

address switching

• Group address

switching

• Central control

address switching

• Pulse/Static

switching

Power supply

220-240V~, 50 Hz

220V~, 60 Hz

29

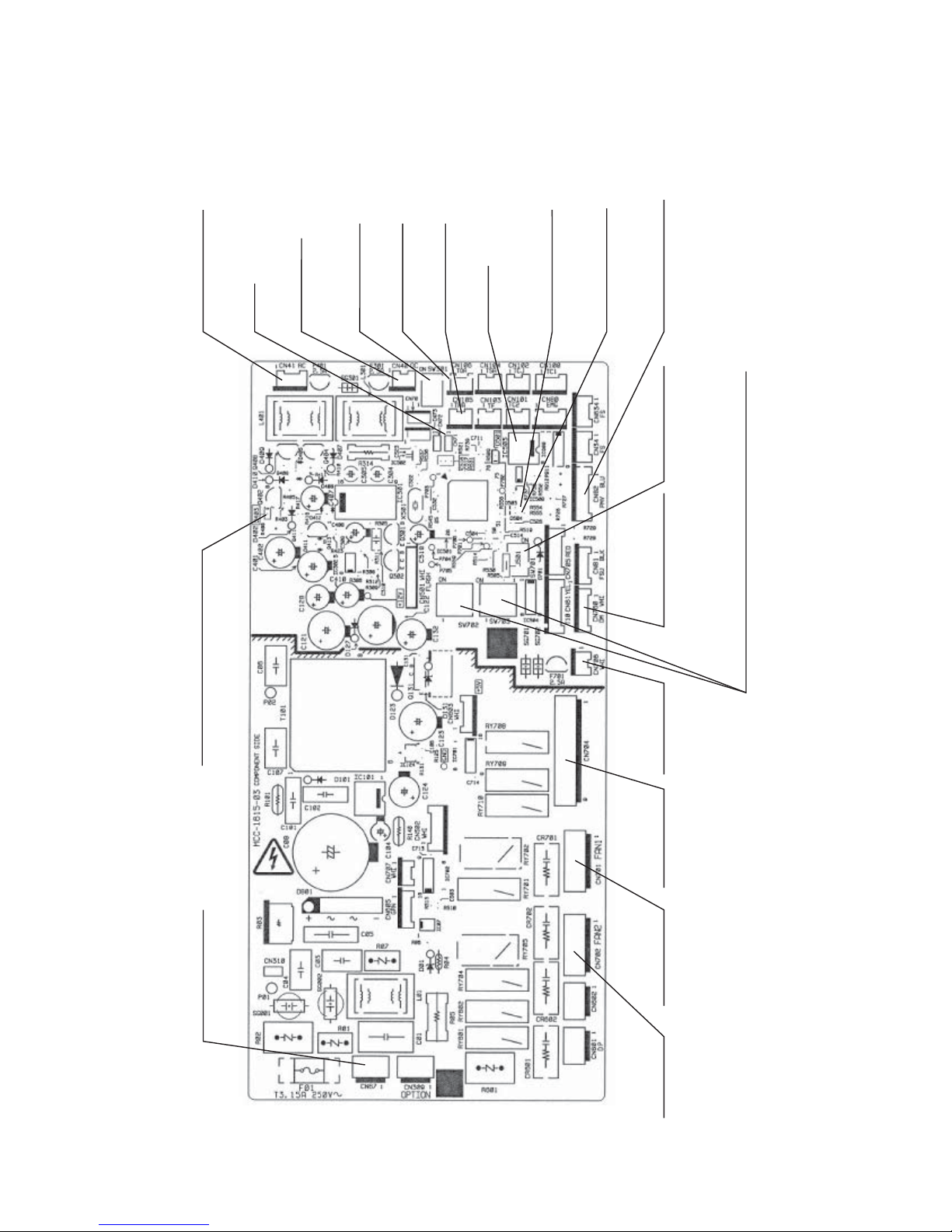

7-2. Indoor Printed Circuit Board

MCC-1615

Remote controller power source LED

D403 (red)

Remote controller

CN41 (blue), DC20V

Central control

CN40 (blue)

CHK

CN71

Central control

electrical termination

SW301

TOA sensor

CN106 (white)

TRA sensor

CN105 (brown)

EEPROM

IC503

Central control

communication LED

D503 (yellow)

Remote controller

communication LED

D504 (green)

Connectors for the

external input

CN705 (red), DC12V

Pulse/Static

changeover switch

SW701

Damper motor

CN760 (white), DC12V

Connectors for

the external input

CN706 (white)

Connectors for

the external output

CN704 (white)

Supply air fan

motor

CN701 (white)

Exhaust air fan

motor

CN702 (red)

SW702, SW703

Power supply

CN67 (black), AC100V

Changeover switch for the indoor unit address

Changeover switch for the central control address

Changeover switch for the group address

Loading...

Loading...