Toshiba VF-SX User Manual

TOSHIBA

E6580496 0

ULTRA-COMPACT

DIGITAL INVERTER

VF-SX

OPERATION MANUAL

JUNE, 1993

TOSHIBA

TOSHIBA VF-SX INVERTER

OPERATION MANUAL

TABLE OF CONTENTS

INTRODUCTION ............................................................ I-l

CHAPTER 1 Inspection Procedure Upon Receipt

...........................

I-I

CHAPTER 2 Proper Environment for Installation

.........................

2-1

CHAPTER 3 External Views and Connection Diagrams

......................

3-1

3.1 External Views.................................................3-2

3.2 Connection Diagrams .......................................... 3-4

CHAPTER 4 Application Precautions

.......................................

4-1

CHAPTER 5 Wiring Guidelines and Warnings

..............................

5-1

5.1 Inverter Wiring................................................5-2

5.2 Installation of a Molded Case Circuit Breaker (HCCB)

........

5-4

5.3 Installation of a Primary Magnetic Contactor (HC)

............

5-5

5.4 Installation of an Output Magnetic Contactor (MC)

............

5-5

5.5 Installation of an External Overload Relay

..................

5-6

5.6 Installation of an Input Reactor...............................5-6

5.7 Incorrect Wiring and Incorrect External Components

..........

5-6

5.8 Basic Wiring Recommendations ................................. 5-7

Chapter 6 Standard Connections ........................................ 6-1

6.1 Examples of Standard Wiring .................................. 6-2

6.2 Terminal Functions ........................................... 6-7

Chapter 7 Parameter Groups

..............................................

7-1

7.1 Definitions of SX Drive Group Parameters

....................

7-2

7.2 Parameter Group Tables

.......................................

7-3

Chapter 8 Basic Operation Theory

........................................

8-1

8.1 Operation of the Touchpad Control Panel

.....................

8-2

8.2 Display Modes.................................................. 8-4

8.2.1 Drive Mode................................................... 8-5

8.2.2 Monitor Mode

.................................................

8-8

8.2.3 Programming Mode............................................8-10

8.2.4 Jogging Mode from the Touchpad..............................8-11

8.3 PANEL/REHOTE Control ........................................ 8-12

8.4 Selection of Stopping Method from the Touchpad

...............

8-12

8.5 Starting the Drive from the Touchpad

..........................

8-14

8.6 Changing Frequency from the Touchpad

..........................

8-16

8.7 Error Reset................................................... 8-17

8.8 Warning Displays

............................................

8-18

8.9 Fault Relay Information ..................................... 8-19

CHAPTER 9 Fundamental Operation Parameters and Functions [GC~ .F] . 9-1

9.1 Setting of Voltage and Frequency Characteristics

............

9-4

9.1.1 Maximum Frequency [fH]

.....................................

9-4

9.1.2 Base Frequency [UL]

.........................................

9-5

9.1.3 Torque Boost [Ub]

...........................................

9-7

9.1.4 V/f Patterns [P t].........................................9-8

9.2 Upper Limit Frequency and Lower Limit Frequency [U L ,L L] 9-9

9.3 Forward and Reverse Run [f,rj

......................

.........

9-10

9.3.1 Operation from the Touchpad ............................... 9-10

9.3.2 Operation Using External Signals

.........................

9-11

9.4 Acceleration and Deceleration

...............................

9-14

9.4.1 Acceleration and Deceleration Time [R C C I },

[dèe / ], [R C C d], [d E C c]..............9-14

9.4.2 Acceleration/Deceleration Pattern [Pt / ], [Pt P] . . 9-15

9.4.3 Selection of Acceleration/Deceleration 1 and 2

[Rd^], [Rd^F]

.......................................

9-17

9.5 Setting of Standard Parameter Groups [ t ^ P]

............

9-19

Chapter 10 Terminal Selection Parameters [GC.S t]

...............

10-1

10.1 Command Mode Selection [ cnodi

.........................

10-2

10.2 Frequency Setting Commands [P fl R d]

...................

10-3

10.3 Parameter Setting Disable Function [PR 0 d]

.............

10-3

10.3.1 Security Considerations and Parameter [PR Od] .... 10-4

10.4 Input Terminal Selection [ I t b]

......................

10-4

10.5 Output Terminal Selection [Otb]

.......................

10-6

10.6 Low Speed Signal Output and Speed Reached Signal Output

[LF], [LFHL], [FrCH], [CCH], irrCH] , 10-7

10.6.1 Low Speed Signal Output Frequency [ i. F] and Speed

Reached Logic Signal [ LFHL]

...................

.........

10-7

10.6.2 Speed Reached Signal Output irCH]

.................

. . . 10-7

10.7 Frequency Setting via Remote Control Signals

..............

10-9

10.7.1 Types of Frequency Setting Signals

.....................

10-10

10.7.2 RR Terminal Input Priority C C ], [ I U I O] . . 10-12

10.8 Frequency Setting Signals [P / ], [F*“P I ] and

[PP], [P —PP]

......................... ....................

10-12

10.9 Jogging Run via Remote Control [ tJ 0 0], [d SEP] 10-14

10.10 Multiple Speed Run [ST.D], [StI — StI] . . 10-17

^_____________________TOSHIBA

______________________

Chapter 11 Protection Parameters [ Gr.Pn

....................

.... 11-1

11.1 Regenerative Discharge Braking Selection [P b] and

Overvoltage Limiting Action Selection [OP 5 b]

.............

11-2

11.2 DC Injection Braking Start-up Frequency [dbF],

DC Injection Braking Voltage [ dbU] t and DC Injection

Braking Time [d b b]..................... .............11-4

11.3 Emergency Stop [EScP]

.....................................

11-6

11.3.1 Emergency Stop from the Touchpad...........................11-6

11.3.2 Emergency Stop Using Remote Control Signals

.............

11-7

11.3.3 Emergency DC Injection Braking Stop Control Time

[fdbfc] ................................................11-8

11.4 Retry [T try]

.............................................

11-8

11.5 Power Control Function [UuC]........................... 11-10

11.6 Electronic Thermal Protective Level [b Hf~] 11-11

11.7 Stall Prevention Function Activation Level [5 fc /.] ... 11-11

11.8 Electronic Thermal Protection Characteristic Selection

[0 L il]

.............................................

11-11

11.9 Retention of Trip [t^CL]

................................

11-11

Chapter 12 Control and Communication Parameters [ 0 f. C C ] 12-1

12.1 Differences Between Startup Frequency and Operation Starting

Frequency....................................................12-2

12.2.1 Start-Up Frequency [F~5t]

.............................

12-3

12.2.2 Operation Starting Frequency [ Frurt]

......................

12-4

12.2.3 Operation Starting Frequency Hysteresis [ FHdS] . . . 12-4

12.3 Jump Frequency and Jump Bandwidths [ F J.H],

[ F J / ] and [ b F <J / ], [ F J d ] and [ b F J (? ].

[ F J 3 ] and [ b F J 3 ] 12-5

12.4 PWM Carrier Frequency [CF] and

Motor Tone Selection [CF5]

.................................

12-6

12.5 Output Voltage Adjustment rPOUb] and Power Voltage

Compensation Function [ ppddi .......................... 12-6

12.6 Automatic Torque Boost [ Rub]

.........................

12-8

12.7 Slip Frequency Compensation [5FC]

.................

12-10

______________________TOSHIBA

_____________________

3

TOSHIBA

Chapter 13 Meter Adjustment Parameters [ Gr.RH] ............. . . . . 13-1

13.1 Meter Connections [FnRfl] .

.

........................ 13-2

13.1.1 Connection of a Frequency Meter [F fl]

..............

13-2

13.1.2 Connection of an Ammeter [R /7]

..........................

13-3

13.2 Frequency Setting Signal [rr—b], [rr—C]

................

13-5

13.3 Universal Unit Multiplication Factor [d 5 P (?]

............

13-7

Chapter 14 General Drive Specifications

..........................

14-1

14.1 Drive Specifications ....................................... 14-2

14.2 External Dimensions ........................................ 14-4

Chapter 15 Options.......................................................15-1

15.1 Input Reactor

..............................................

15-2

15.2 Radio Noise Reduction Filter

..............................

15-2

15.3 Braking Resistor ........................................... 15-2

15.4 Connection Cable ........................................... 15-2

Chapter 16 Error Displays, Explanations, and Remedies

..................

15-1

16.1 Inverter Trip Causes and Remedies

.........................

16-2

16.2 Other Errors and Remedies

...................................

16-4

Chapter 17 Maintenance and Inspection ................................... 17-1

Chanter 18 Storage and Warranty ....................................... 18-1

18.1 Storage..................................................’ ] 18_2

18.2 Warranty...................................................] 18-2

Appendix....................................................... H-1

APPENDIX 1 — TABLE OF TRIP CODES AND WARNING CODES

............

! ! A-2

APPENDIX 2 ~ INPUT TERMINAL INFORMATION AND OUTPUT TERMINAL

INFORMATION

.................................................

A-3

APPENDIX 3 — LEO ALPHANUMERIC CROSS REFERENCE

.....................

A-4

TOSHIBA

i-i

IHTRODUCTIOH

Thank you for purchasing the Toshiba Compact Inverter "TOSVERT VF-SX".

The VF-SX variable speed drive Is a high performance Inverter that has numerous

built-in functions, making It suitable for many applications. This Inverter Is

very easy to program and operate. All instructions are entered via the membrane

keyboard panel (the "touchpad"). The latest technology and features, including

current limit, auto-restart, dynamic braking, and stall prevention are Included.

This product offers flexible operation for numerous applications, and helps

prevent nuisance tripping, even for difficult loads and applications.

Please thoroughly review this manual before attempting use of the VF-SX drive,

so that the features of this drive can be properly applied for each unique

applIcatlon.

Please keep this manual for future reference, operation, and maintenance of the

VF-SX drive.

Always ground the Inverter in accordance with Article 250 of the National

Electrical Code or Section 10 of the Canadian Electrical Code, Part I. The

grounding conductor should be sized In accordance with NEC Table 250-95 or CEC,

Part I, Table 16.

See Chapter 6 for simplified power and control wiring instructions and

recommendations.

TOSHIBA

1-1

CHAPTER 1 Inspection Procedure Upon Receipt

1-2

TOSHIBA

1. Inspect the Toshiba Model VF-SX variable speed drive. Confirm that no

parts have been damaged during transit.

2. Confirm that the model number inscribed on the nameplate is the same as

that ordered.

3. If the inverter will not be placed in service immediately upon receipt,

store the device in a dust free environment. Be sure the room is

ventilated with cool, dry air. Store this device in its original packing

material whenever possible.

4. Every reasonable precaution is taken during the production, packaging, and

shipping of this device to prevent damage to the unit before installation.

If there is any damage upon receipt, contact the dealer and the freight

company immediately.

TOSHIBA

2-1

CHAPTER 2 Proper Environment for Installation

2-2

TOSHIBA

The VF-SX inverter Is a solid state device. Use caution to install the device

in the proper environment, as instructed in the general recommendations shown

below. See Chapter 14 for detailed specifications of the proper operating

environment.

1. Confirm that the input power supply is within +/- 10% of the nominal

voltage. The protective circuit will activate and trip if the permissible

input voltage range is exceeded. Extreme voltage conditions may damage

the inverter.

2. Do not install the inverter in places where high temperature or humidity

are present. Do not install in dusty environments, or environments

contaminated with metal particles or metallic powder.

3. Do not mount the inverter on any device subject to intense vibration.

4. Operate the inverter only in an environment between -10 deg C to 40 deg C.

The inverter generates heat when operating. When it is installed on a

subpanel or backplate be sure there is adequate ventilation on all sides

of the inverter, including the back of the inverter where the heat sinks

are located. In high ambient temperatures it may be necessary to remove

the stick-on seal on the top of the inverter to allow more ventilation

through the Inverter.

Certain electrical equipment, if installed too near the inverter, may

cause malfunctions. Examples of this type of equipment can include:

If a magnetic contactor is installed near the inverter install a

urge suppression device across the coil of the contactor to prevent

surging magnetic fields from interfering with the operation of the

inverter.

Do not install the inverter near fluorescent lighting.

Keep other heat generating electrical equipment, such as resistors

or heaters, away from the inverter.

5.

6.

7.

8.

A.

B.

C.

Always properly ground the inverter chassis to prevent electrical noise

and nuisance tripping. Proper earth ground should not exceed 100 ohms.

Install the inverter ONLY on incombustible subpanels, such as a metal

subpanel. If the inverter is installed on a heat insulating subpanel then

mount the inverter on a metal subpanel first, and attach this assembly to

the insulated subpanel.

Always have at least 10 centimeters free space above and below the

inverter. Always have at least 5 centimeters free space on EACH side of

the inverter. If more than one inverter is mounted in a row, leave at

least 10 centimeters between each drive, from side to side. If fans are

installed in the enclosure or near the drives this space requirement may

be reduced. Consult the Toshiba factory for details.

TOSHIBA

3-1

CHAPTER 3 External Views and Connection Diagrams

3-2

TOSHIBA

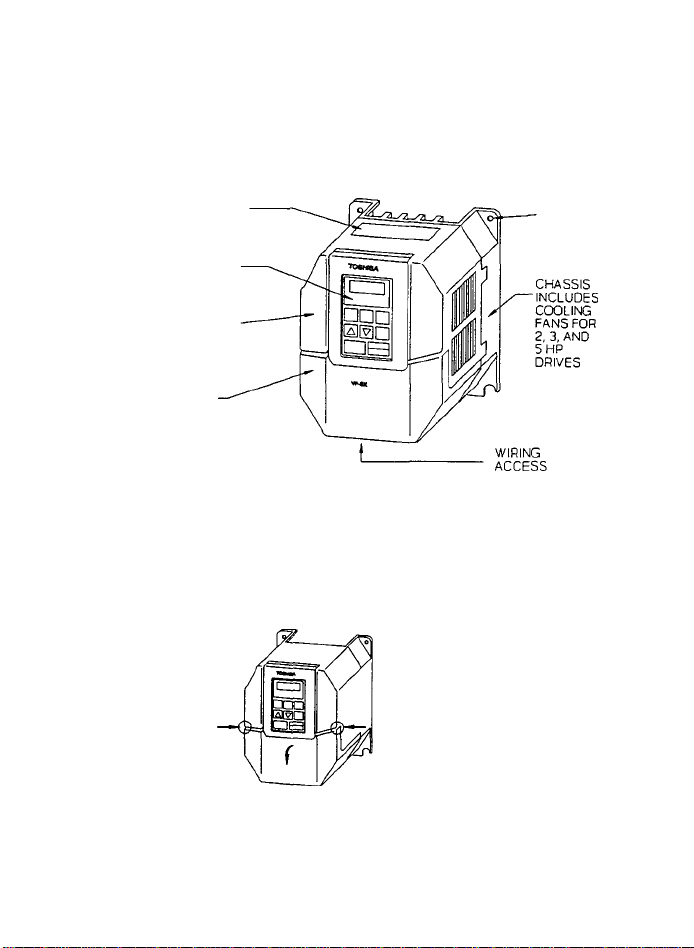

3.1 External Views

REMOVE THIS SEAL

WHEN USING THE

INVERTER IN A HOT

PLACE

TOUCHPAD CAN

BE REMOVED

UPPER COVER

DOES NOT NEED

TO BE REMOVED

UNLESS THE

EXTERNAL SIGNAL

SELECTION

JUMPERS ARE

CHANGED

LOWER COVER MUST

BE REMOVED WHEN

THE TOUCHPAD IS

REMOVED OR WHEN

WIRING IS

CONNECTED TO THE

TERMINALS

FOUR

INSTALLATION

HOLES

PRESS THE LOWER COVER

ON BOTH SIDES (AS

SHOWN) SWULTANEOUSLY.

PULL THE COVER FORWARD,

TO INSTALL THE COVER,

insert the COVER CLASPS

IN THE BOTTOM HOLES,

ROTATE THE TOP OF THE

LOWER COVER BACK INTO

POSTITON, AND GENTLY

PRESS UPPER CLASPS INTO

PLACE

TOSHIBA

3-3

CONTROL CIRCUIT

TERMINAL BLOCKS

MAIN CIRCUIT

TERMINAL BLOCKS

THESE terminal

BLOCKS ARE FOR

INPUT, OUTPUT,

GROUND, AND

OPTIONAL BRAKING

RESISTOR

CONNECTIONS

LOWER COVER INLET

CONNECTOR FOR

TOUCHPAD OR

TOUCHPAD EXTENSION

CABLE

SCREW HOLD FOR

TOUCHPAD

TO REMOVE UPPER

COVER, INSERT A

BLADE SCREWDRIVER

UNDER 4 CLASPS

AND LIFT GENTLY

CHARGE I AMP

DO NOT CHANGE WIRING

OR REMOVE UPPER

COVER WHEN LIT

SINGLE PHASE

MCCB

POWER » ►

SUPPLY ^

SmOLE PHASE * ^

2Ù0.230VAC, 50/60HZ

RESET

FORWARD

REVERSE'

: : ¿‘ÎNTÊWloâC

.......

....

■

MULTI- / : 1 f ■■■■

FUNCTION T

T

.............

........

SIGNAL \ ! ■...............

INPUT ^ ‘

..........................

ANALOG INPUT

. \AUtO :

^

AUTO +

REFERENCE

] i

D

PA PB

VF-SX

RST

F

R

ST

cc

SSl

JOG/SS2

BX/SS3

AD2

PP

RR

CC

T1(U),

T2(V),

T3(W)

FLA

FAULT

FLB

' FLC

FM/AM.

CC

P24

LOW/LL

RCIVUL,

GND(E)

M

FAULT SIGNAL

OUTPUT

FREQUENY/CURRENT

r*‘™X"*:i.SipNAL

I \SCAl£r

• ; 1mA

+24VÒC

T MULTI- FUNCTION

i SIGNAL OUTPUT

w

N»

O

O

CD

n

D»

la

"t

A>

B

(/)

CO

MAX

TOTAL

♦DBR NOT AVAILABLE ON SINGLE PHASE 1/8, 1/4HP UNITS.

THREE PHASE

MCCB

DBR*

POWER

--------------

SUPPLY

--------------

THRBBPHÂSB ’ *

200 - 230VAC, 5(V60Hz

RESET

* FORWi^

i « RÌBvSiSÈ''

! isINTERLOCK

....

MULTI- / ; ± -

FUNCTION f ;

SIGNAL \ '

..........

INPUT ^

................

..............

ANALOG INPUT

;vAUTO

ÌìjìanrTv;;],

iAUTO

¡REFERENCE

-.JÎÏ7

+ .¡.j..

L1(R)

U(S)

L3CD

RST

F

R

ST

cc

SSI

JOG/SS2

EX/SS3

AD2

PP

- RR

; CC

}■ IV

PA PB xi(U)

T2(V)

T3(W)

FLA

VF-SX

FAULT

RELAY.

■fi

FLB

FLC

FM/AM -

□ □ □

□ □ □

cc

P24

LOW/LL

RCHAJL

GND{E)

7T

M

FAULT SIGNAL

OUTPUT

FREQUENY/CURRENT

-■‘•FtnX—

: ¡SCALE/'

I ;AT

: MmA

i +24Vdc

..

f-

...

MAX

TOTAL

MULTI- FUNCTION

SIGNAL OUTPUT

*DBR NOT AVAILABLE ON THREE PHASE 1/8, I/4HP UNITS.

O

C/3

s

5

>

TOSHIBA

4-1

CHAPTER 4 Application Precautions

4-2

TOSHIBA

1. If the drive is very lightly loaded (approximately 5*) or if the inertia

of the driven load is very small, the drive may become unstable. The

result could be abnormal vibration or overcurrent trip. If this condition

persists lower the PWM carrier frequency (parameter [C F]). See Chapter

12 for instructions.

2. Unstable results may occur if:

A. The output rating of the drive is less than the output rating of the

motor.

B. The drive is used with a motor with special ratings, such as an

explosion proof motor, or a motor specially built for high inertia

applications.

C. The drive is used with a pulsing load, such as a load requiring

repeated piston type operation.

3. The motor will coast to stop if the power is lost. If an immediate stop

or very quick deceleration of the motor is required use an auxiliary brake

device. Select the appropriate stopping method as described in Chapter 11

for an emergency stop.

4. GROUNDING

The inverter should be grounded in accordance with Article 250 of the

National Electrical Code or Section 10 of the Canadian Electrical Code,

Part I. The grounding conductor should be sized in accordance with NEC

Table 250-95 or CEC, Part I, Table 16.

TOSHIBA

5-1

CHAPTER 5 Wiring Guidelines and Precautions

5-2

TOSHIBA

This chapter of the manual discusses some of the basic wiring configurations and

external devices commonly associated with the installation and application of

variable speed drives. Local codes, specifications, requirements, and operating

conditions may require the addition of other devices or modifications to the

following basic recommendations.

5.1 Inverter Wiring

(Refer to Figure 5.1 and 5.2)

1. It can be difficult to remove the upper cover after wiring, so change the

jumper selectors J1 or J2 on the internal PC board for "external signal

selection" before wiring the inverter. See Chapter 6 for the approximate

location of jumpers J1 and J2 inside the drive.

When a signal between 0 to 5V is used as frequency signal, switching the

jumper is necessary. Refer to Chapter 10, Table 10-9 for details.

2. Always turn the main line power OFF and confirm that there is no voltage

present with a testing tool before connecting power, motor leads, or

control wires.

3. WTOJIN^ Wait until the "CHARGE" lamp has turned off before working on

the drive. An internal capacitor stores electrical charge in the inverter

and electrocution may result due to inadvertent contact with this

capacitor. Do not touch the terminals or remove the cover while the

"CHARGE" lamp is on. This indicator is located in the lower right-hand

side of the drive near the terminal blocks, and it is a brightly lit red

LED when the drive is fully charged.

4. WARNING: Do not wire input power to the output terminals (U, V, W) of the

drive, this will damage the drive. Before energizing, confirm that motor

leads are attached to terminals U, V, and W and that the main power leads

are attached to terminals R, S, and T.

5. Exercise caution when wiring the control signals, as shown.

A. Install a surge suppressor on any electromagnetic coil on any

contactor wired to the drive. This includes line and load side

contactors.

B. Use shielded wire or twisted pair wire for control circuit wiring.

Keep this wire isolated from power wire.

C. Always isolate the input control signals from the main power wiring.

This restriction applies to all control terminals except FLA, FLB,

and FLC.

6. Wire sizes:

A. For wire to an ammeter, wire to a frequency meter, and wire carrying

input speed reference signals, use at least 16 gauge shielded wire.

B. For all other control wiring, use at least 12 gauge PVC coated wire.

TOSHIBA

, 5-3

Inverter Main Circuit Terminal Block

Figure 5.1 Main Circuit Wiring

5-4

TOSHIBA

MCCB

MC

—oln

---

L_o o

----

—

/^jr^MCCB-Trip Coil

R

U

s

V

T

W

F

FLB

R

FLC

CC

FLA

Forward

Run/Stop

h

Reverse

Run/Stop

Figure 5.2 Simplified Power and Control Wiring

5.2 Installation of a Molded Case Circuit Breaker (MCCB)

1. Install a molded case circuit breaker (HCCB) on the line side of the drive

for protection of the incoming power wiring only.

2. Turn the drive ON and OFF via control devices or the touchpad whenever

possible, and not by manual operation of the HCCB or MC. Use the control

terminals F. R, and CC to receive control signals from the appropriate remote

control devices.

TOSHIBA

5-5

5.3 Installation of a Primary Magnetic Contactor (MC)

1. Install a magnetic contactor (HC) on the line side of the inverter to prevent

restart after either a loss of power, a trip of an external overload relay, or

an operation of the internal drive protective device.

2. The VF-SX has an internal fault detection relay. The HC can be opened when

the inverter protective circuit operates by connecting this contact point to the

primary MC operation circuit.

3. The inverter can be used without an HC. In this case use a shunt trip style

main breaker (MCCB) and open the main circuit by tripping the breaker when the

inverter protective circuitry operates.

4. When using a braking resistor with an overload relay, install an HC or an

MCCB with shunt trip on the line side of the inverter. Connect these devices so

that the power circuit will open when the internal fault detection relay (Ft) or

externally installed overload relay operates. Emergency stop is also possible

by connecting the overload relay contact point between the terminals of SS3 (EX)

and CC of the inverter. See Chapter 11 for details of the Emergency Stop

parameter.

5. Use control signals on terminals F, R, and CC for frequent starting and

stopping. Avoid turning the inverter on and off with the primary HC.

6. Always install a surge suppressor across any contactor coil.

5.4 Installation of an Output Magnetic Contactor (MC)

1. Avoid starting and stopping the motor with an output contactor (HC) installed

between the inverter and the motor. Excessive surge currents could damage the

output devices of the drive. Use control signals on terminals F, R, and CC

instead.

2. For Bypass Operation; Be sure the motor has stopped and the drive is OFF

before turning on the bypass contactor to run the motor directly from line power.

Use an external timer, PLC, or similar device as required. Always make sure that

the bypass contactor does not allow voltage to backfeed into the inverter output

terminals.

5-6

TOSHIBA

5.5 Installation of an External Overload Relay

1. An electronic overload relay is standard on the VF-SX drive. However, for

the following applications Toshiba recomtnends Installing an overload relay that

coordinates with the internal solid state relay and the motor connected to the

drive. Connect the external relay between the drive and the motor.

A. When using a motor with non-standard current ratings, or the motor

ratings are not comparable to standard duty motors.

B. When operating a single motor smaller than the rating of the drive.

C. When operating several motors simultaneously from the drive. In this

case Install an overload relay on EACH motor.

2. When applying the VF-SX drive to a constant torque load, change the

electronic overload characteristics, or Install a separate overload relay. See

Chapter 11, Parameter [ bHrj.

3. When a motor continuously runs at low speeds it is recommended to use a motor

with an Internal overload relay, for additional protection.

5.6 Installation of an input Reactor

An input reactor Is used to suppress high frequency elements and sudden changes

In power fluctuations. Install an Input reactor when the Inverter Is connected

to electrical systems with the any of the following characteristics:

1. When the power capacity Is 200 KVA or more and the power capacity is

10 times or more than the Inverter capacity.

2. When the Inverter Is connected to the same system as a thyristor

commutation type controller.

3. When the inverter Is wired to an electrical system which also

contains a distortion source such as an arc furnace or a large

capacity inverter.

5.7 Incorrect Wiring and Incorrect External Components

WARHINS:

DO NOT INSTALL A POWER FACTOR IHPROVEHENT CAPACITOR ON THE INVERTER INPUT OR

OUTPUT. Current and voltage surges associated with the use of power factor

capacitors can damage the drive components.

If power factor correction is required add an optional input line reactor to

correct power factor.

TOSHIBA

5-7

Radio Freouencv Interference

During operation of the drive there may be noise generated by the drive in the

frequency range associated with radio transmission signals. This noise may

adversely affect sensitive electronic equipment near the drive. If this

condition persists install a RF/EMI (Radio Frequency or Electromagnetic

Interference) filter on the input to the drive. Shield the motor leads in

metallic conduit. These steps will reduce radio frequency interference.

Contact Toshiba for details, or see Chapter 15.

WARWIH6:

Do not operate or energize the inverter before checking between the motor and the

inverter for mis-wiring or short circuits in the motor. Do not operate the drive

if the motor is shorted. Do not ground the neutral point of the motor star

winding.

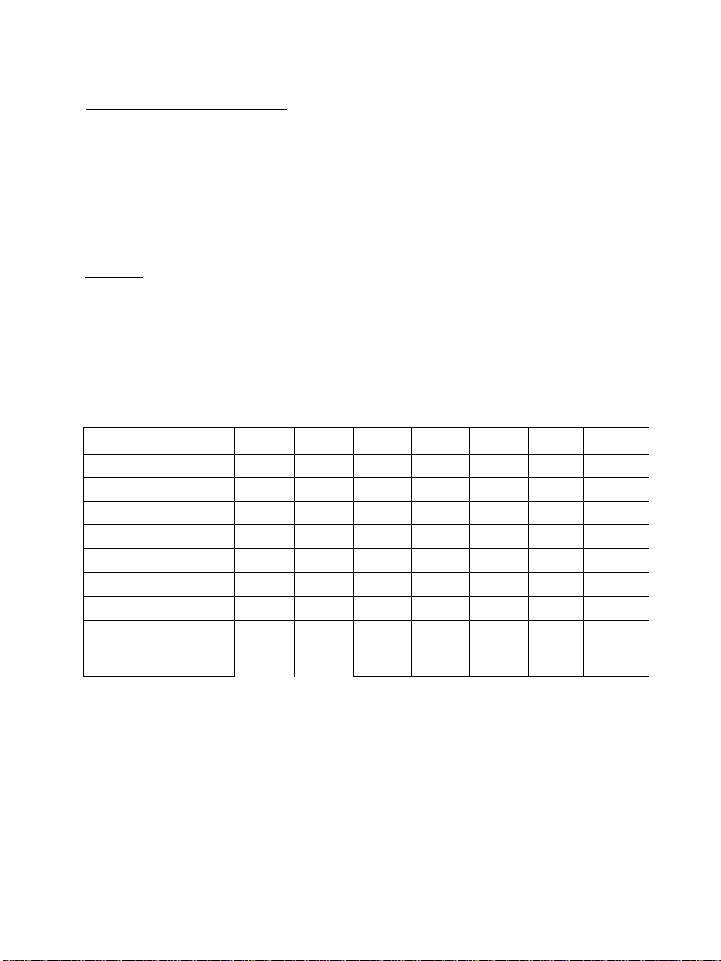

5.8 Basic Wiring Recommendations

TABLE 5-1: BASIC WIRING RECOHMENOATIONS

DRIVE MODEL VFSX- 2001UP

2002UP 2004UP

2007UP

2015UP1

2022UP12037UP1 1

KW RATING 0.1 0.2

0.4 0.75

1.5

2.2 3.7 1

HP RATING

1/8 1/4

1/2

1 2

3 5 j

MCCB SIZE 5 A

5 A 5 A 10 A

15 A 20 A

30 A 1

HC AMPS (1) 12 A

12 A 12 A

12 A 12 A

12 A

18 A 1

OL RELAY RATING 0.7 A

1.3 A 2.3 A

4.2 A

6.6 A

9.3 A 15 A 1

POWER WIRE SIZE 12 GA

12 GA

12 GA

12 GA 12 GA

12 GA 10 GA 1

CONTROL WIRE SIZE 18 GA

18 GA

18 GA 18 GA

18 GA

18 GA 18 GA 1

WIRE SIZE FOR

REGENERATIVE

BRAKING RESISTOR

N/A N/A 14 GA

14 GA

12 GA 12 GA 12 GA 1

NOTES:

1.

2.

3.

4.

Always use a surge suppression device on the coil of the MC contactor.

Use shielded cable on control circuits. See Figure 5.2.

Use 10 gauge wire or larger for ground circuit.

Power wire sizes in table above are minimum size. For cable lengths over

100 feet, or where voltage drops may cause application problems, larger

wire may be required.

TOSHIBA

6-1

Chapter 6 Standard Connections

6-2

TOSHIBA

The items printed in Italics in this chapter are Paraaeter names.

Refer to Chapter 7 for a list of all parameter names and Chapters 8 through 13

for instructions to set or adjust the parameters.

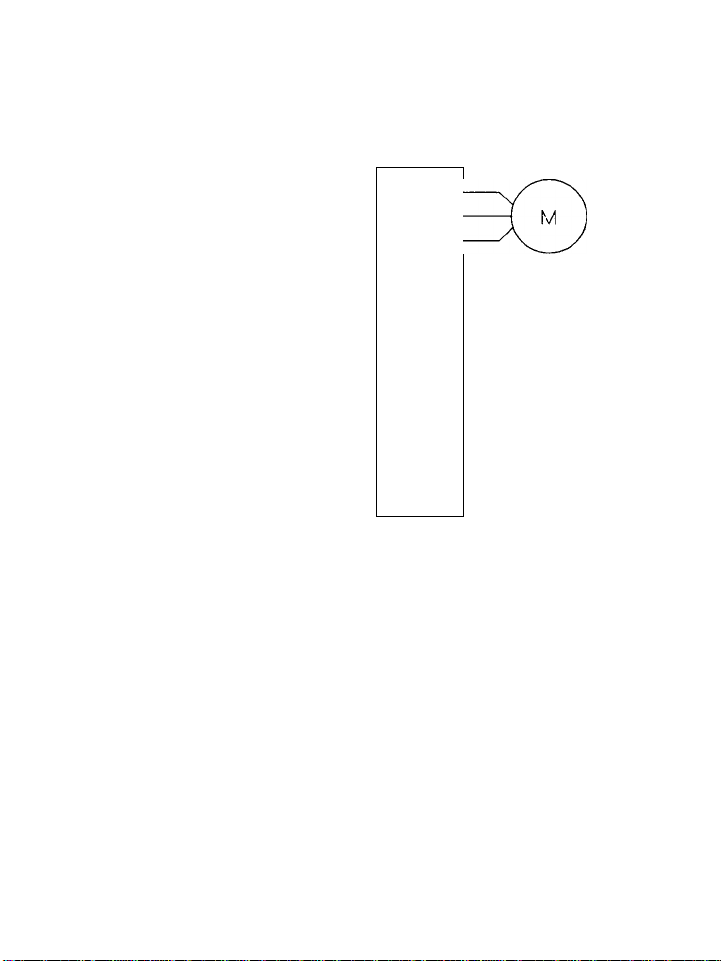

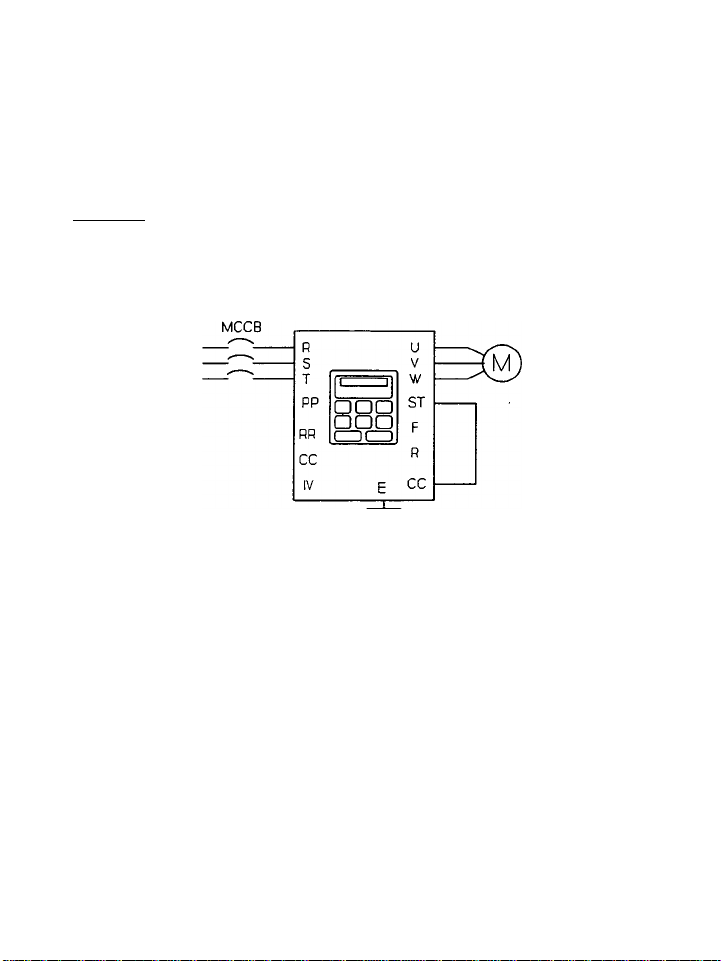

6.1 Examples of Standard Wiring

Example 1: To set the operation frequencies, and conduct forward/reverse run

and/or decelerating stop from the touchpad.

5X DRIVE

Figure 6.1

Setting: In the parameter group [Ci~. 5 t ] the Coaaand Mode Selection is set

to 3 (control terminal or touchpad input). Also, in the same parameter group,

the Frequency Setting Mode Selection is set to 3 (control terminal or touchpad

input). All Model VF-SX drives are shipped with these settings as the factory

default settings.

In Figure 6.1 above:

1. Incoming power is 200-230 volts, three phase, 50 or 60 Hz.

2. A factory installed jumper is present between terminals ST and CC.

3. All drive operation is from the touchpad control panel.

TOSHIBA

6-3

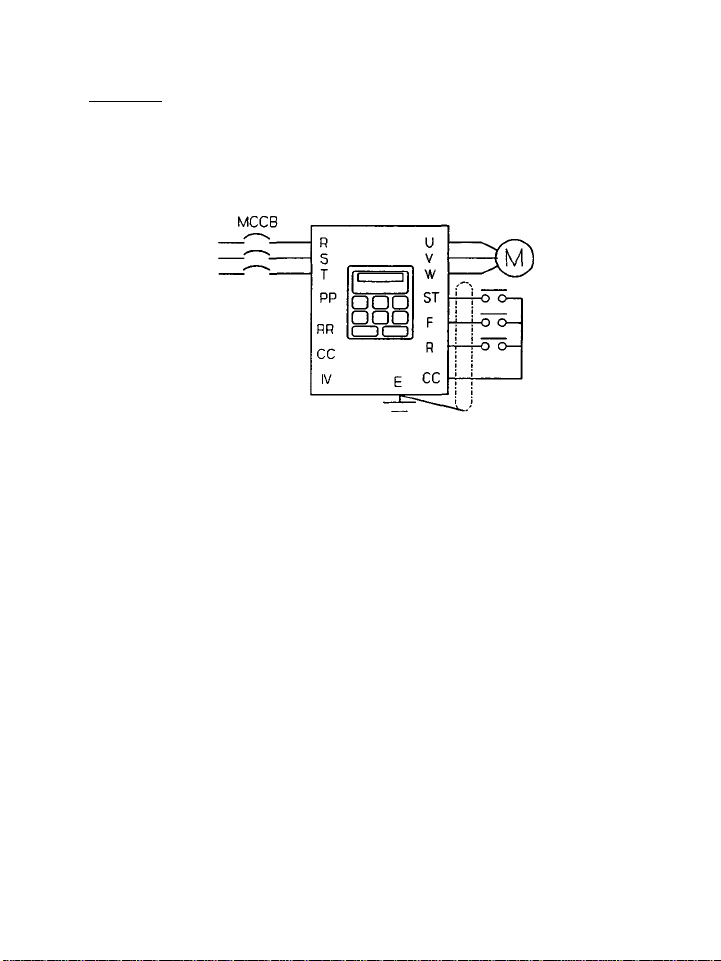

Example 2: To set the operation frequencies from the touchpad, and conduct

forward/reverse run, decelerating stop, and/or coast!ng-to-stop with external

signals.

5X DRIVE

Figure 6.2

Setting; In the parameter group [0 l~. 5 t ] the Command Mode Selection is set

to 3 (control terminal or touchpad input). Also, in the same parameter group

the Frequency Setting Mode Selection is set to 2 (only touchpad input valid).

In Figure 6.2 above:

1.

2.

3.

4.

Incoming power is 200-230 volts, three phase, 50 or 60 Hz.

When the ST-CC contact is open the drive will "Coast-to-Stop".

When the ST-CC contact is closed, and the F-CC contact is closed the

drive will run "Forward". If the F-CC contact is opened the drive

will decelerate stop.

When the ST-CC contact is closed, and the R-CC contact is closed the

drive will run "Reverse". If the R-CC contact is opened the drive

will decelerate stop.

Loading...

Loading...