Toshiba VN250-SE, VN-1KSAE SERVICE MANUAL

FILE NO. A02-012

Revised on : 2005/Feb./15

SERVICE MANUAL

HEAT EXCHANGE VENTILATORS

VN-250SE

VN-350SE

VN-500SE

VN-800SE

VN-1KSAE

VN-500SE

PRINTED IN JAPAN, Jan.,2003 ToMo

|

CONTENTS |

|

1. |

SAFETY CAUTIONS ................................................................................. |

3 |

2. |

TECHNICAL POINTS (PERFORMANCE) ............................................... |

7 |

3. |

REFERENCE DRAWING FOR INSTALLATION ...................................... |

7 |

4. |

SPECIFICATIONS...................................................................................... |

8 |

5. |

NAME AND DIMENSION OF EACH PARTS .......................................... |

11 |

6. |

WIRING DIAGRAM .................................................................................. |

12 |

7. |

OWNER’S MANUAL (EXTRACT) ........................................................... |

13 |

8. |

INSTALLATION MANUAL (EXTRACT) .................................................. |

19 |

9. |

HOW TO DIAGNOSE THE TROUBLE..................................................... |

24 |

10. |

HOW TO REPLACE THE MAIN PARTS.................................................. |

25 |

11. |

CHECK WHEN REPAIR WORK COMPLETED ...................................... |

28 |

12. |

Q & A FOR HEAT EXCHANGE VENTILATORS .................................... |

29 |

13. |

EXPLODED VIEWS AND PARTS LIST .................................................. |

30 |

– 2 –

1. SAFETY CAUTIONS

The important contents concerned to the safety are described on the ventilator body and in this Service manual.

Preserve the described items after understanding clearly the following contents (indications/illustration symbols) and reading this manual thoroughly.

n Explanation of indications

Indication |

Meaning |

|

|

DANGER |

Indicates the contents which a danger such as death or serious injury is caused in |

emergency on the repair engineers or the surrounding third party by an incorrect work. |

|

|

|

WARNING |

Indicates the contents which a possibility such as death or serious injury is caused on the |

repair engineers or the surrounding third party by an incorrect work, or on the customers |

|

|

by a trouble of the products. |

|

|

CAUTION |

Indicates the contents which occurrence of injury (*) or damage of property is supposed |

on the repair engineers or the surrounding third party by an incorrect work, or on the |

|

|

customers by a trouble of the products. |

|

|

* Damage of property : expanded damage concerned to property/household effects or domestic animals/pets

n Explanation of illustration symbols

Illustration symbol |

Meaning |

Indicates prohibition (Never do it.).

The concrete contents of prohibition are indicated with illustrations or descriptions near the illustration symbol.

Indicates forced work (Necessarily do it.).

The concrete contents of forced work are indicated with illustrations or descriptions near the illustration symbol.

Indicates cautions (including danger/warning).

The concrete contents of cautions are indicated with illustrations or descriptions near the illustration symbol.

1-1. Warning and caution exclusive in service work

WARNING

WARNING

•Be sure to ask the customers not to let children close to the work place.

The tools or disassembled parts may cause an injury on children.

•Be sure to turn off the breaker before work when power-ON is unnecessary such as a case of disassembling.

If doing so, an electric shock may be caused.

• Use the substitute parts corresponded to the model for repair. And do not modify the products.

It causes an abnormal operation or a trouble resulted in leakage or fire, that is a cause of customers’ disaster.

•For connection of the cut lead cables, connect the cables with application terminals, direct the closed end side upward, and then apply the draining process.

If the post-process of connection is not carried out, a cause of customers’ disaster such as leakage or fire generates.

•After the work, check the insulation resistance between live part (pin of SL terminal) and non-current carrying part (motor frame) using a insulation megger (500V) and confirm 10MW or more is kept.

If the insulation resistance is not confirmed, a cause of customers’ disaster such as leakage or fire generates.

CAUTION

• Use the protective materials such as gloves, etc. for check/repair inside of the unit.

If touching inside of the unit with bare hands, an injury may be caused.

– 3 –

1-2. DANGER/WARNING/CAUTION Described in Owner’s Manual

DANGER

•Do not use as an air circulators for open-type burners (heaters).

When gas or oil stoves are used in the home, separate equipment for circulating the air should be used.

WARNING

WARNING

•When any abnormal condition (scorching smell or others) is found, stop the operation immediately and keep the exclusive circuit breaker “OFF”.

If you continue the operation without removing the cause, it could cause an electric shock or a fire.

• When the system needs a repair, consult your dealer.

•When the system is checked and the power cable undergoes maintenance, stop the operation, and switch the exclusive circuit breaker “OFF”.

The internal fan is revolving at high speeds and can cause serious injury. And when using a stepladder, etc., make sure to fix it properly.

•The external air intake opening should be positioned away from the exhaust openings of combustion gases etc.

The intake of such gasses could lead to a lack of oxygen in the room.

•If there is combustible gas leakage from other appliances, ventilate the room by opening windows.

If operation were to be attempted in such a situation, sparking at electrical contact points could cause an explosion.

•Netting or something similar should be provided at the external air intake opening to prevent birds etc. interfering with the unit.

Nests or other foreign objects should be removed. That could lead to a lack of oxygen in the room.

•If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similarly qualified person in order to avoid a hazard.

•The external air intake opening should not be positioned where discharged air may directly enter it.

A situation like this will lead to the room being contaminated and this may pose a health risk.

•When Heat Exchange Ventilators are relocated, contact your dealer or a professional installer.

Improper practice of installation could cause a drop of the unit, a water leakage, an electric shock or a fire.

• Ask the sales office or the engineering shop to perform the work.

•Don't push a finger or a stick into the open-air inlet or the exhaust outlet.

A fan with a high rpm will injure you.

•Modification of the system is strictly prohibited.

Improper practice of repair could cause a water leakage, an electric shock or a fire.

• When the system needs a repair, consult your dealer.

– 4 –

CAUTION

•If Heat Exchange Ventilators are not used for a long period of time, keep the exclusive circuit breaker “OFF” for safety reasons.

If the power is left on, any build-up of dust could cause a heat generation or a fire.

•The system should never be used for any other purposes than intended such as for preservation of foods, flora and fauna, precision devices or work of art.

•It could cause deterioration of foods or other problems.

•Install at a stable place of sufficient strength.

Please note that there might be some places not strong enough to install due the structure of building.

•Provide an exclusive circuit breaker that can completely break contacts on all the poles by more than 3mm through direct connection to the power terminals.

Depending upon the environment for installation, it becomes necessary to install an earth leakage breaker. Unless the earth leakage breaker is installed, it could cause an electric shock.

•Ask the sales office or the engineering shop to perform the work.

•Never fail to install the unit inside the heat insulting walls or, in other words, in the space insulated from the open air.

If you install it outside or in the space equivalent to the open-air conditions, dew is condensed inside the body in the winter season.

•The filter should be cleaned regularly.

Dust or dirt building-up on it can lead to a lack of oxygen in the room.

•Use gloves when cleaning the filter or heat exchange element.

Doing so will reduce any possibility of injury.

•It is strictly prohibited to place a container of combustible gas or liquid near Heat Exchange Ventilators or to spray it directly with the gas or liquid.

It could cause a fire.

•Do not use outside the rated voltage.

It could cause a fire or an electric shock.

•Combustion apparatus should not be placed allowing a direct exposure to wind of Heat Exchange Ventilators.

Incomplete combustion could occur on the apparatus.

•Don’t put a container of water on Heat Exchange Ventilators.

When water spills, it is likely to enter inside the unit and degrade electric insulation, possibly resulting in an electric shock.

•Don’t incline Heat Exchange Ventilators when taking them out.

Otherwise, water remaining inside is likely to drop and wet the furniture or other property.

•Ask the sales office or the engineering shop to perform the work.

•Do not install in locations where harmful or corrosive gasses may be present (i.e. acidic, alkali, organic solvent, paint gasses etc. from machinery or factories)

Installation in such a location could cause a gas-poisoning and a fire.

•Do not install in locations where oily smoke or soot may be present.

There is a possibility that oil will adhere to the filter, heat exchange element etc. and make operation impossible.

•Do not install in locations with high humidity, such as close to bathroom etc.

Installation in such a location could cause a breakdown.

•Don’t use benzene or metal brush when cleaning the filter and heat exchange element.

Otherwise, the unit will get unfit for use.

•Don’t blow directly against animals or plants.

Likely to cause bad effect on animals and plants.

•Do not wash Heat Exchange Ventilators with water.

It could cause an electric shock.

•Do not handle switches with a wet hand.

It could cause an electric shock.

–5 –

1-3. WARNING/CAUTION Described in Installation Manual

WARNING

WARNING

Never fail to ask the sales office from which you bought the unit or the installing service shop to install the unit. If you install it by yourself, any inappropriate installing works would cause an electric shock or a fire.

Carry out the installing works accurately in line with this installation manual. Improper practice of installation could cause an electric shocks or a fire.

Choose the installing place where is endurable in quality as well as in weight, then install the unit accurately with adequate strength and completeness of installation in accordance with the installation manual. Otherwise, it is likely to cause an electric shock, a fire, a drop of the unit, thus causing the injury on the human body.

Carry out electrical work in accordance with the laws and regulations prevailing in the country concerned, technical standard and explanation for work, and make absolutely sure that an exclusive circuit is used. Any insufficient capacity of power circuit and improper work can result in electric shock and fire hazard.

The external air intake opening should be positioned away from the exhaust openings of combustion gases etc. The intake of such gases could cause a lack of oxygen in the room.

Netting or something similar should be provided at the external air intake opening to prevent birds etc. interfering with the unit. Nests or other foreign objects should be removed.

That could cause a lack of oxygen in the room.

When the system is checked and the power cable undergoes maintenance, stop the operation, and switch the exclusive circuit breaker “OFF”. Otherwise, it could cause an electric shock.

Carry out the GND work. Never connect the GND wire to a gas pipe, a water supply pipe, a lightning conductor, a GND line of a telephone, etc. An incomplete GND wire is likely to cause an electric shock.

CAUTION

CAUTION

Provide an exclusive circuit breaker that can completely break contacts on all the poles by more than 3mm through direct connection to the power terminals. Depending upon the environment for installation, it becomes necessary to install an earth leakage breaker.

When you want to pierce the metal duct through the metal lath or the wire lath or the metal plate of the wooden facility, do not forget to insulate electrically between the duct and the wall.

Otherwise, it would cause an electric shock or an electric leakage.

Don’t use other parts than specified (including the auxiliary parts) for installing works.

If you do not use the specified parts, it is likely to cause a drop of the unit, a fire, an electric shock, etc.

Install the outdoor duct in a falling gradient toward the outside so as to prevent water from coming in. If it is not installed so, the building is likely to be flooded, wetting the household effects.

Heat-insulate the outdoor duct (including the indoor side, if necessary) to prevent dewing.

If heat insulation is not adequate, water likely goes indoor and wets the household properties.

When it is high humid and high temperature inside the ceiling, a ventilation system must be installed inside the ceiling. Otherwise, it could cause a fire or an electric leakage.

Connect the power line and the connecting line with accuracy using the specified cables and fix them firmly so as not to put the outer stress of the cables on the pin connecting area.

Incomplete connection or fixing is likely to cause a heat generation or a fire.

Install the power line and the connecting line with accuracy so the power source cover may not float.

If the installation of the power source cover is inappropriate, the pin connection area is likely to cause a heat generation, a fire and an electric shock due to dust or powder.

Never install the unit near the place where there is a fear of leakage of an inflammable gas. If gas happens to leak and stays around the unit, it is likely to cause a fire.

Don’t use the unit at the other voltages than the rated one. It could cause a fire or an electric shock.

Do not install the unit in locations with large amounts of oily smoke, such as food preparation areas. It could cause a fire.

Don’t install the unit at the place of a high temperature or a flame. It could cause a heat generation or a fire.

Do not install in locations where harmful or corrosive gasses may be present (i.e. acidic, alkali, organic solvent, paint gasses etc. from machinery or factories).

Installation in such a location could cause a gas-poisoning and a fire.

Do not install in locations with high humidity, such as close to bathroom etc. It could cause an electric shock or an electric leakage etc.

– 6 –

2.TECHNICAL POINTS (PERFORMANCE)

•Energy-saving ventilation to save the cooling/heating cost because the heat energy (outside air load) to be lost by ventilation is effectively recovered.

•Compact construction to downside the cooling/heating equipment with size corresponding to heat energy amount to be recovered because the outside air load can be vastly decreased.

•By using the heat exchanger, humidity control effect which sucks the humidity approached to near the humidity in the room.

•Comfortable ventilation by simultaneous air suction/discharge which sucked air approached to the temperature in the room and the stable ventilation to be performed even in the high airtight room.

•Noise-proof effect to prevent entering of outside noise or flowing of noise to outside.

•Suction/discharge air system on straight line which is easy to be designed or installed.

•The high-level long filter is mounted to increase the effect of dust collection for removing. ( Weight: 82%)

•Reverse installation up and down is possible, which 2 units use the same check port.

•Especially powerful notch is mounted, which can increase air volume and is selectable in the main unit.

•Only one check port is used for all the maintenance works.

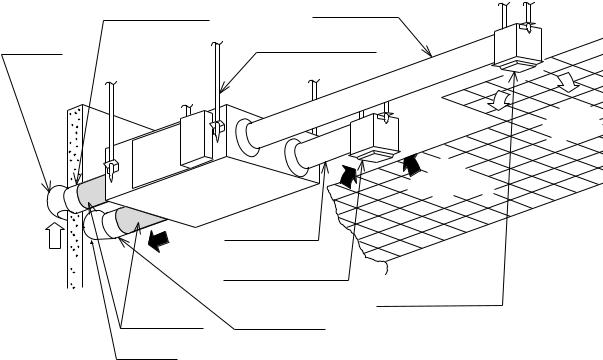

3.REFERENCE DRAWING FOR INSTALLATION

|

Outside Intake Duct |

Supply Air Duct |

|

|

|

Pipe Hood |

|

Ceiling Suspension Bolt |

SA

(Supply Air)

|

RA |

|

|

(Outside Air) |

|

EA |

Room Intake Duct |

|

|

||

(Exhaust Air) |

||

|

Room Intake Opening |

|

OA |

(Supply/Exhaust Air Grill) |

|

Inside Supply Opening |

||

(Outside Air) |

||

|

||

Heat Insulation |

(Supply/Exhaust Air Grill) |

|

Material |

Exhaust Air Duct |

|

Pipe Hood

– 7 –

4. SPECIFICATIONS

<VN-250SE, VN-350SE>

|

Model |

|

|

|

|

|

VN-250SE |

|

|

|

|

|

|

|

VN-350SE |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type |

|

|

|

|

|

|

|

|

|

Concealed duct type |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Ventilation system |

|

|

|

Heat exchange |

|

Normal ventilation |

|

Heat exchange |

Normal ventilation |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Rating |

|

|

|

|

|

|

|

|

50Hz 220 – 240V, 60Hz 220V |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Extra |

High |

Low |

|

Extra |

High |

|

Low |

|

Extra |

|

High |

Low |

Extra |

High |

Low |

|

|

|

|

|

|

high |

|

high |

|

|

high |

|

high |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

50Hz |

0.48–0.5 |

0.46–0.48 |

0.37–0.39 |

0.47–0.5 |

0.46–0.48 |

0.37–0.39 |

0.63–0.65 |

0.59–0.6 |

0.56–0.57 |

0.61–0.63 |

0.57–0.6 |

0.54–0.56 |

||||

|

Current |

|

(A) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60Hz |

0.59 |

0.55 |

0.39 |

|

0.59 |

0.55 |

|

0.39 |

|

0.85 |

|

0.75 |

0.67 |

0.83 |

0.74 |

0.67 |

|||

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50Hz |

104–119 |

99–114 |

79–90 |

|

103–119 |

98–114 |

|

79–90 |

|

137–154 |

124–137 |

117–128 |

133–151 |

119–132 |

113–125 |

|

|

Power consumption |

(W) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

60Hz |

128 |

118 |

78 |

|

128 |

118 |

|

77 |

|

178 |

|

149 |

132 |

176 |

145 |

131 |

||||

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50Hz |

250 |

250 |

170 |

|

250 |

250 |

|

170 |

|

350 |

|

350 |

280 |

350 |

350 |

280 |

|

Air volume |

(m³/H) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

60Hz |

250 |

250 |

135 |

|

250 |

250 |

|

135 |

|

350 |

|

350 |

240 |

350 |

350 |

240 |

||||

|

|

|

|

|

|

|

|

|

|||||||||||||

Characteristics |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50Hz |

90 |

80 |

37 |

|

90 |

80 |

|

37 |

|

95 |

|

65 |

42 |

95 |

65 |

42 |

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

Static pressure |

|

(pa) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60Hz |

125 |

100 |

30 |

|

125 |

100 |

|

30 |

|

155 |

|

90 |

43 |

155 |

90 |

43 |

|||

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50Hz |

27–28 |

26–27 |

21–22 |

|

27–28 |

26.5–27.5 |

|

21.5–22.5 |

|

31–32 |

|

29–30 |

25–26 |

31–32 |

30–31 |

26–27 |

|

Noise |

|

(dB) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60Hz |

28 |

26 |

21 |

|

28 |

26.5 |

|

21.5 |

|

33 |

|

30 |

22 |

33 |

30 |

23 |

|||

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50Hz |

75 |

75 |

77 |

|

— |

— |

|

— |

|

75 |

|

75 |

77 |

— |

— |

— |

|

Temp. exchange rate (%) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

60Hz |

75 |

75 |

78 |

|

— |

— |

|

— |

|

75 |

|

75 |

79 |

— |

— |

— |

||||

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

In heating |

50Hz |

70 |

70 |

73 |

|

— |

— |

|

— |

|

69 |

|

69 |

71 |

— |

— |

— |

||

|

Enthalpy |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

60Hz |

70 |

70 |

75 |

|

— |

— |

|

— |

|

69 |

|

69 |

73 |

— |

— |

— |

||||

|

|

|

|

|

|

|

|

||||||||||||||

|

exchange |

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

rate |

|

|

|

50Hz |

63 |

63 |

66 |

|

— |

— |

|

— |

|

66 |

|

66 |

69 |

— |

— |

— |

|

(%) |

|

|

|

|

|

|

|

|||||||||||||

|

In cooling |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

60Hz |

63 |

63 |

68 |

|

— |

— |

|

— |

|

66 |

|

66 |

71 |

— |

— |

— |

|||

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Frame |

|

|

|

|

|

|

|

|

|

|

Zinc iron plate |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Motor |

|

|

|

|

|

|

|

4-pole capacitor dielectric motor (E type) |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sirocco fan |

|

|

|

|

|

|

|

|

|

|

ABS resin |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Construction |

Heat exchanger |

|

|

|

|

|

|

|

|

Combustion-proof sheet |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Filter |

|

|

|

|

|

|

|

Nonwoven fabric (Collection effect weighing method 82%) |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adapter |

|

|

|

|

|

|

|

|

|

|

ABS resin |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Mounting pipe diam. |

|

(mm) |

|

|

|

|

|

|

Ø150 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

External dimension |

|

(mm) |

|

|

599 x 882 x 270 |

|

|

|

|

|

|

|

804 x 882 x 270 |

|

|

|||||

|

(Length x Width x Height) |

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product mass |

|

|

(kg) |

|

|

|

29 |

|

|

|

|

|

|

|

37 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Shape |

|

|

|

|

|

|

|

|

Corrugated board package/ventilator |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dimension |

|

|

(mm) |

|

|

335 x 1138 x 795 |

|

|

|

|

|

|

|

335 x 1138 x 1000 |

|

|

||||

Package |

(Length x Width x Height) |

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mass |

|

|

(kg) |

|

|

|

34 |

|

|

|

|

|

|

|

42 |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

No. of stacked boxes |

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Accessory |

|

|

|

|

|

|

|

• Installation Manual: 1, |

• Owner’s Manual: 1 |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 8 –

<VN-500SE, VN-800SE>

|

Model |

|

|

|

|

|

VN-500SE |

|

|

|

|

|

|

|

|

VN-800SE |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type |

|

|

|

|

|

|

|

|

|

|

Concealed duct type |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Ventilation system |

|

|

|

Heat exchange |

|

Normal ventilation |

|

Heat exchange |

|

Normal ventilation |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Rating |

|

|

|

|

|

|

|

|

|

50Hz 220 – 240V, 60Hz 220V |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Extra |

High |

Low |

|

Extra |

|

High |

|

Low |

|

Extra |

|

High |

Low |

|

Extra |

High |

Low |

|

|

|

|

|

|

high |

|

high |

|

|

|

high |

|

|

high |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50Hz |

0.86–0.9 |

0.79–0.81 |

0.72–0.73 |

|

0.84–0.88 |

|

0.76–0.77 |

|

0.71–0.73 |

|

1.51–1.54 |

|

1.48–1.5 |

1.44–1.46 |

|

1.47–1.5 |

1.45–1.48 |

1.41–1.43 |

|

Current |

|

(A) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60Hz |

1.14 |

1.0 |

0.81 |

|

1.12 |

|

0.96 |

|

0.8 |

|

2.05 |

|

1.92 |

1.68 |

|

2.04 |

1.87 |

1.68 |

|||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

50Hz |

188–214 |

169–188 |

151–166 |

184–210 |

161–182 |

145–164 |

316–347 |

309–329 |

302–327 |

309–337 |

300–325 |

297–316 |

||||||

|

Power consumption |

(W) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

60Hz |

244 |

202 |

162 |

|

243 |

|

196 |

|

161 |

|

424 |

|

391 |

347 |

|

417 |

387 |

346 |

||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50Hz |

500 |

500 |

370 |

|

500 |

|

500 |

|

370 |

|

800 |

|

800 |

650 |

|

800 |

800 |

650 |

|

Air volume |

(m³/H) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

60Hz |

500 |

500 |

310 |

|

500 |

|

500 |

|

310 |

|

800 |

|

800 |

575 |

|

800 |

800 |

575 |

||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

Characteristics |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50Hz |

33–34 |

31–32 |

25–26 |

|

34–35 |

|

32–33 |

|

26.5–27.5 |

|

38–39 |

36.5–37.5 |

32–34 |

|

38.5–39.5 |

37–38 |

33–35 |

||

|

|

|

|

|

50Hz |

105 |

70 |

38 |

|

105 |

|

70 |

|

38 |

|

140 |

|

110 |

70 |

|

140 |

110 |

70 |

|

Static pressure |

|

(pa) |

60Hz |

165 |

85 |

33 |

|

165 |

|

85 |

|

33 |

|

190 |

|

100 |

50 |

|

190 |

100 |

50 |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

Noise |

|

(dB) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60Hz |

35 |

31 |

23 |

|

36 |

|

33 |

|

24 |

|

39 |

|

36 |

31 |

|

39.5 |

37 |

31 |

|||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50Hz |

75 |

75 |

77 |

|

— |

|

— |

|

— |

|

75 |

|

75 |

76 |

|

— |

— |

— |

|

Temp. exchange rate (%) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

60Hz |

75 |

75 |

79 |

|

— |

|

— |

|

— |

|

75 |

|

75 |

77 |

|

— |

— |

— |

||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

In heating |

50Hz |

67 |

67 |

71 |

|

— |

|

— |

|

— |

|

71 |

|

71 |

74 |

|

— |

— |

— |

||

|

Enthalpy |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

60Hz |

67 |

67 |

74 |

|

— |

|

— |

|

— |

|

71 |

|

71 |

75 |

|

— |

— |

— |

||||

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

exchange |

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

rate |

|

|

|

50Hz |

62 |

62 |

67 |

|

— |

|

— |

|

— |

|

65 |

|

65 |

68 |

|

— |

— |

— |

|

(%) |

|

|

|

|

|

|

|

|

|

|||||||||||||

|

In cooling |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

60Hz |

62 |

62 |

69 |

|

— |

|

— |

|

— |

|

65 |

|

65 |

69 |

|

— |

— |

— |

|||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Frame |

|

|

|

|

|

|

|

|

|

|

|

Zinc iron plate |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Motor |

|

|

|

|

|

|

|

|

4-pole capacitor dielectric motor (E type) |

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sirocco fan |

|

|

|

|

|

|

|

|

|

|

|

ABS resin |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Construction |

Heat exchanger |

|

|

|

|

|

|

|

|

|

Combustion-proof sheet |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Filter |

|

|

|

|

|

|

|

Nonwoven fabric (Collection effect weighing method 82%) |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adapter |

|

|

|

|

|

|

|

|

|

|

|

Zinc iron plate |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Mounting pipe diam. |

|

(mm) |

|

|

Ø200 |

|

|

|

|

|

|

|

|

Ø250 |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

External dimension |

|

(mm) |

|

|

904 x 962 x 270 |

|

|

|

|

|

|

|

|

884 x 1322 x 388 |

|

|

||||||

|

(Length x Width x Height) |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product mass |

|

|

(kg) |

|

|

|

43 |

|

|

|

|

|

|

|

|

|

71 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Shape |

|

|

|

|

|

|

|

|

|

Corrugated board package/ventilator |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dimension |

|

|

(mm) |

|

|

335 x 1218 x 1100 |

|

|

|

|

|

|

453 x 1538 x 1075 |

|

|

|||||||

Package |

(Length x Width x Height) |

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mass |

|

|

(kg) |

|

|

|

48 |

|

|

|

|

|

|

|

|

|

79 |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

No. of stacked boxes |

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

3 |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Accessory |

|

|

|

|

|

|

|

• Installation Manual: 1, |

• Owner’s Manual: 1 |

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 9 –

<VN-1KSAE>

|

Model |

|

|

|

|

VN-1KSAE |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Type |

|

|

|

|

Concealed duct type |

|

|

|||

|

|

|

|

|

|

|

|

|

|

||

|

Ventilation system |

|

|

Heat exchange |

|

|

Normal ventilation |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Rating |

|

|

|

|

50Hz 220 – 240V |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Extra high |

High |

|

Low |

|

Extra high |

|

High |

Low |

|

|

|

|

|

|

|

|

|

|

|

|

|

Current |

(A) |

1.97–2.04 |

1.85–1.93 |

|

1.68–1.76 |

|

1.95–2.03 |

|

1.84–1.92 |

1.67–1.74 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Power consumption |

(W) |

399–445 |

360–399 |

|

332–367 |

|

392–438 |

|

358–392 |

329–362 |

Characteristics |

|

|

|

|

|

|

|

|

|

|

|

Air volume |

(m²/H) |

1000 |

1000 |

|

810 |

|

1000 |

|

1000 |

810 |

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Static pressure |

(pa) |

90 |

55 |

|

35 |

|

90 |

|

55 |

35 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Noise |

(dB) |

37.5–38.5 |

36–37 |

|

31–33 |

|

38–39 |

|

36.5–37.5 |

31.5–33.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Temp. exchange rate |

(%) |

75 |

75 |

|

76 |

|

— |

|

— |

— |

|

|

|

|

|

|

|

|

|

|

|

|

|

Enthalpy exchange rate |

In heating |

71 |

71 |

|

73 |

|

— |

|

— |

— |

|

|

|

|

|

|

|

|

|

|

|

|

|

(%) |

In cooling |

65 |

65 |

|

68 |

|

— |

|

— |

— |

|

|

|

|

|

|

|

|

|

|

|

|

|

Frame |

|

|

|

|

Zinc iron plate |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Motor |

|

|

|

4-pole capacitor dielectric motor (E type) |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Sirocco fan |

|

|

|

|

ABS resin |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Construction |

Heat exchanger |

|

|

|

|

Combustion-proof sheet |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Filter |

|

|

Nonwoven fabric (Collection effect weighing method 82%) |

|

|||||||

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Adapter |

|

|

|

|

Zinc iron plate |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Mounting pipe diam. |

(mm) |

|

|

Ø250 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

External dimension |

(mm) |

|

|

|

1134 x 1322 x 388 |

|

|

|||

|

(Length x Width x Height) |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product mass |

(kg) |

|

|

83 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Shape |

|

|

|

Corrugated board package/ventilator |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Dimension |

(mm) |

|

|

|

453 x 1538 x 1325 |

|

|

|||

Package |

(Length x Width x Height) |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Mass |

(kg) |

|

|

91 |

|

|

|

|

|||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

No. of stacked boxes |

|

|

|

3 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Accessory |

|

|

• |

Installation Manual: 1, • |

Owner’s Manual: 1 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

– 10 –

Loading...

Loading...