Toshiba MCY-MAP0601HT, MCY-MAP0501HT, MCY-MAP0401HT QUICK REFERENCE

Engineering Data Book

File No. E06-311

1

-1

The engineering data book details all relevant data, charts and drawings to

enable you to get the best performance from the Toshiba Mini-SMMS for various

applications.

The information is aimed to assist you by providing greater system details and

the wider applications that system covers.

It is recommended that the data book be used in accordance with the following

as references.

Design manual: File No.A06-111

Installation manual: File No.A06-211

Service manual: File No.A05-016

2

-1

Contents

1. Forward ...................................................................................................................... 1-1

2. Contents .................................................................................................................... 2-1

3. Introduction ............................................................................................................... 3-1

4. System overview ....................................................................................................... 4-1

4-1. Summary of system equipments ....................................................................... 4-1

4-2. Outdoor units .................................................................................................... 4-2

4-3. Indoor units ....................................................................................................... 4-3

4-4. Branching joints and headers ........................................................................... 4-5

4-5. PMV Kit............................................................................................................. 4-5

4-6. Remote controller ............................................................................................. 4-6

5. Capacity compensation chart .................................................................................. 5-1

6. Piping requirements ................................................................................................. 6-1

7. Refrigerant cycle diagram ........................................................................................ 7-1

8. Wiring guideline ........................................................................................................ 8-1

9. Indoor unit line up ..................................................................................................... 9-1

9-1. 4-way Air Discharge Cassette Type ............................................................... 9-1-1

9-2. Compact 4-way Cassette (600 × 600) Type ................................................... 9-2-1

9-3. 2-way Air Discharge Cassette Type ............................................................... 9-3-1

9-4. 1-way Air Discharge Cassette Type (Included NewType) .............................. 9-4-1

9-5. Concealed Duct Standard Type ..................................................................... 9-5-1

9-6. Slim Duct Type ............................................................................................... 9-6-1

9-7. Concealed Duct High Static Pressure Type ................................................... 9-7-1

9-8. Under Ceiling Type ........................................................................................ 9-8-1

9-9. High Wall (1 series) Type ............................................................................... 9-9-1

9-10. High Wall (2 series) Type ............................................................................. 9-10-1

9-11. Floor Standing Cabinet Type ....................................................................... 9-11-1

9-12. Floor Standing Concealed Type .................................................................. 9-12-1

9-13. Floor Standing Type ..................................................................................... 9-13-1

9-14. Optional parts of indoor units ....................................................................... 9-14-1

10. PMV Kit .................................................................................................................... 10-1

11. Outdoor unit ............................................................................................................ 11-1

12. Controls ................................................................................................................... 12-1

World’s best class energy savings

• World-class energy savings — COP of 4.61* achieved by Toshiba’s

unrivalled SMMS technologies and newly developed components

*4HP CDU system

Flexible and easy installation

• Greater application versatility—13 types of indoor units for use in up to 9

rooms; max. 6 HP

• Small and light weight outdoor unit

• Total piping length 180 m* (forthest 100 m)

• Maximum height variation for indoor units

(Outdoor unit is up to 30 m higher than indoor unit / outdoor unit is up to 20 m lower than indoor unit)

*150 m with PMV kit

Pursue unexpected quieter operation

• Quiet operation enables a tranquil interior environment, which can be

further enhanced with our optional PMV* kit

• Product made from quieter outdoor unit by adoption of Bat wing fan

*Pulse Motor Valve

Toshiba MiNi-SMMS Air Conditioning

Greater Flexibility for Even More Comfort

• Superior new Toshiba VRF system for small and mid-sized buildings

• Toshiba’s innovative spirit — concept of VRF, all advantages of SMMS

Mini-SMMS Data book

Introduction

3

3

-1

1

2

3

4

5

6

7

8

9

10

11

12

World’s best class energy savings

World-class energy savings — COP of 4.61* achieved by Toshiba’s unrivalled

SMMS technologies and newly developed components

*4HP CDU system

Vector-controlled inverter

Twin-rotary DC compressor

Vector IPDU control changes motor current

wave to a smooth sinusoidal pattern so that

noise emitted from the drive units is greatly

reduced.

Bat wing fan

DC fan motor

• High output / high

efficiency DC motor

• 600W output

• Sine wave drive

Heat exchanger

High-efficiency R410A

heat-transfer tube

Configuration of the finned

heat-transfer tube

Smooth sign curve liquid

realizes efficient-izing and

low noise-ization.

Efficient circuit built-in

and new PIM adoption

New development for high

pressure low sound fan

→

The bat wing fan realizes

the sound level equivalent

to current model.

New

New

New

New

New

Greater motor efficiency

from improved coil design

More effective

compression from

high-precision

components

Higher refrigerant

compression from

redesigned

compression

channels

High reliability

The enhanced DC twin-rotary compressor delivers stable performance with minimum friction:

Ideal for noise-sensitive applications. The outdoor unit is almost imperceptible.

• Low vibrations

• Super-quiet

operation

• High reliability

TWIN-ROTARY COMPRESSOR

DC twin rotary compressor (A3 comp) features

Partial load range

*Most frequent operation

Nominal range

Total efficiency of

compressor

DC Twin

rotary type

Conventional

Scroll type

Frequency of compressor (rps)

(%)

Comparison of DC twin rotary and Scroll compressor

Anti-eddy projection

Anti-eddy projection prevents

big eddies and reduces air

resistance.

Reverse-arc-shape wing

Reverse-arc-shape wing

reduces air resistance.

Toshiba Twin-Rotary

Traditional Compressor

This difference is the

reason for actual energy

savings

3

Introduction

1

2

3

4

5

6

7

8

9

10

11

12

3

-2

3

Introduction

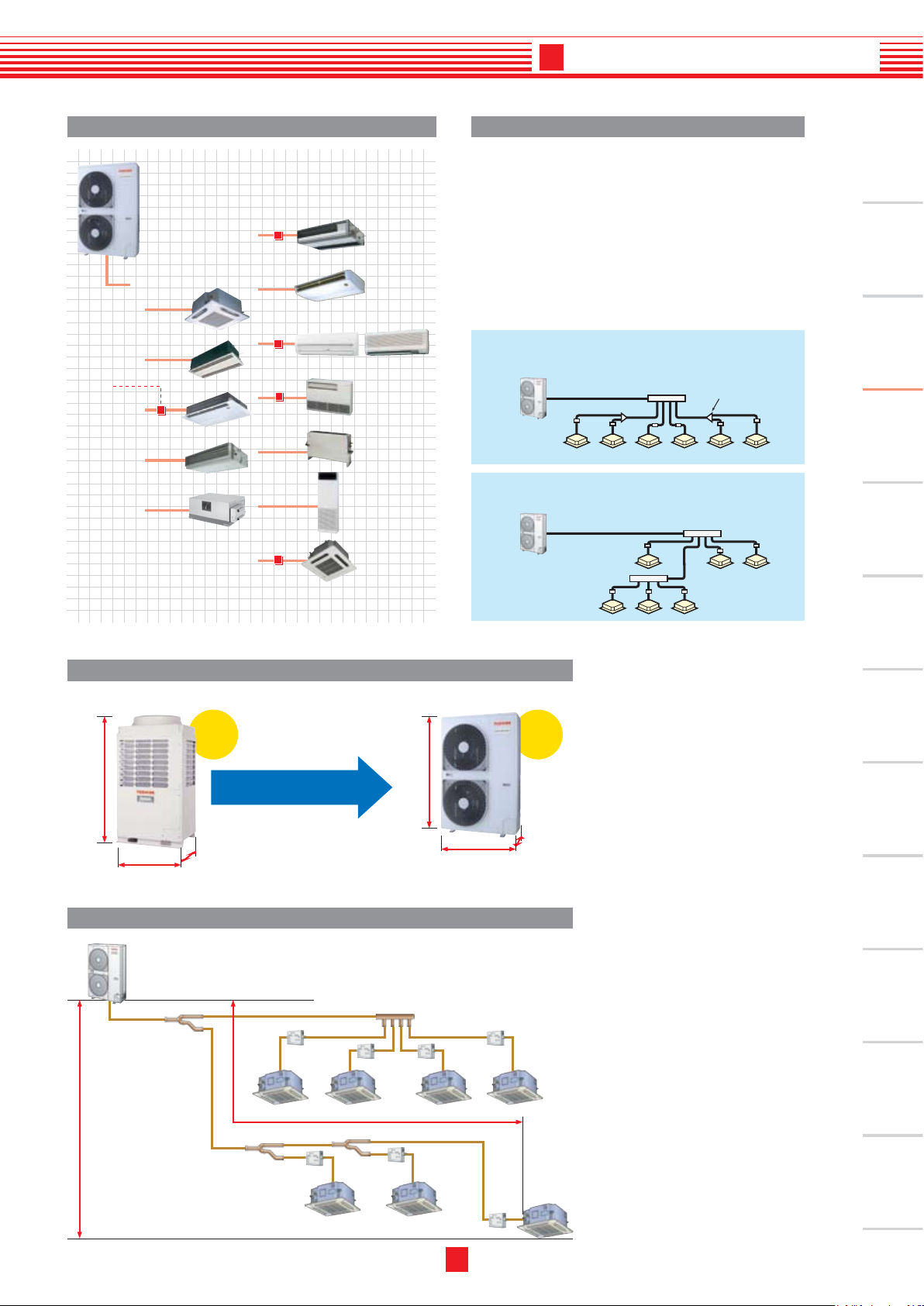

New compact 4-way

cassette

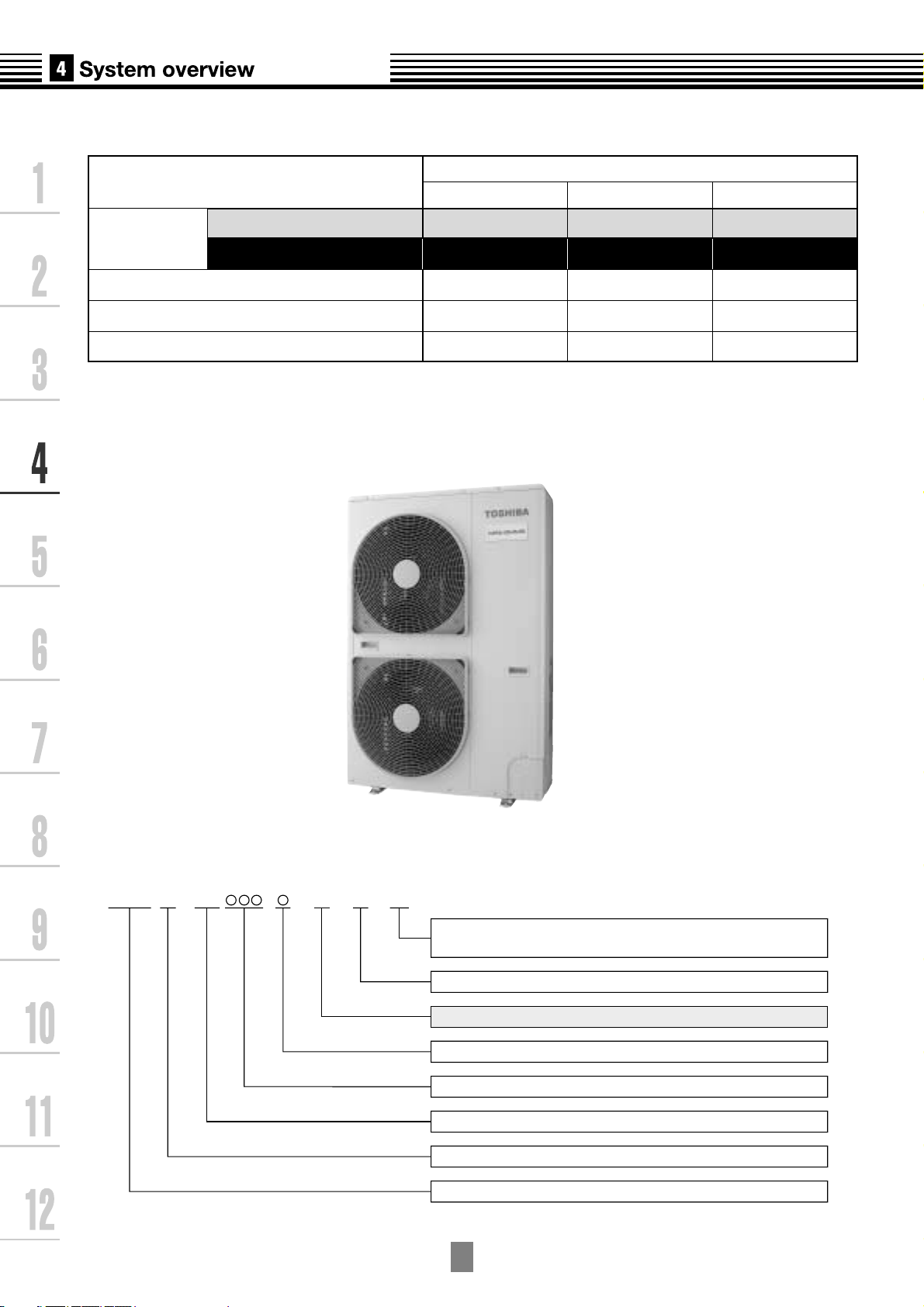

PMV-Kit

Line branching after header branching

Outdoor unit

Indoor unit

Br

anching joint

Header

PMV kit

Header branching after header branching

Outdoor unit

Indoor unit

Header

Header

PMV kit

Combination of line and header branching is highly

flexible, allowing the shortest route possible thereby

saving on installation time and costs. Line/header

branching after header branching is only available

with TOSHIBA.

Expansive variety in our line-up of indoor units Shortest route design by free branching

Small and lightweight

Piping length

900 mm

117kg228kg

1,340 mm

320 mm

1,800 mm

750 mm

990 mm

1-phase3-phase

Mini-SMMS outdoor unitSuper-MMS outdoor unit

Mini-SMMS is born from

our supreme VRF technology

Compact

- Line branching

- Header branching

- Line + Header branching

Best-in-class piping length and height

1

2

3

4

5

6

7

8

9

10

11

12

(Revised edition in 7.Apr.2006)

3

-3

New bat

wing fan

DC fan

motor

Quiet er sound

and

power saving

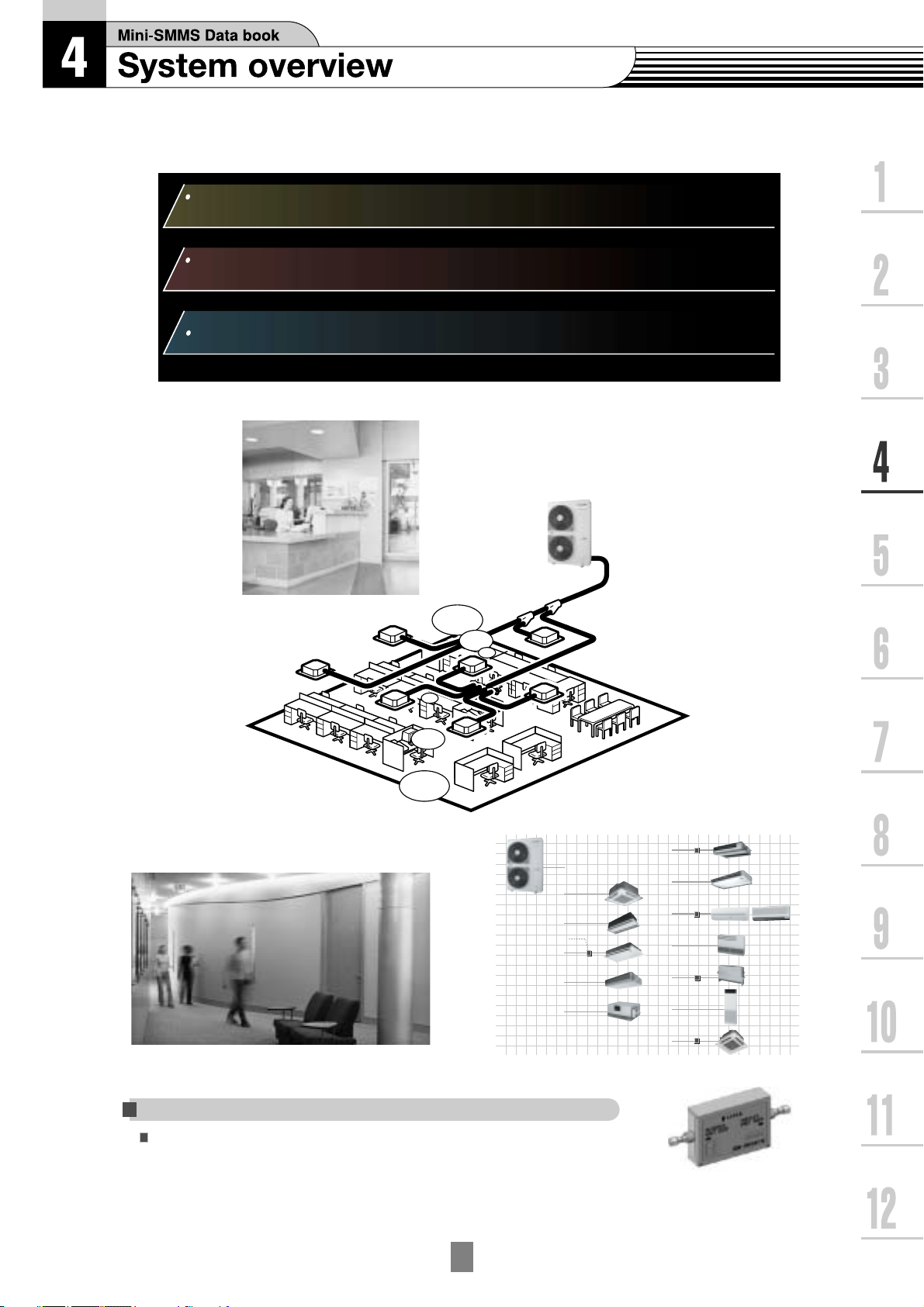

Day

Day

Night

Night

Mi ni-SMMS ha s ti med , Night O peration , allowing

queter operation at night.

(A timer or a switch is local arrangements)

P M V k it (R B M- PM V0 3 61 E/ RB M -

PMV0 901E) sh all be re quired f or

q ui t e r p la c e a pp l ic a t io n a s an

optional to reduce refrigerant sound

especially in oil retrieval control or

in transient operation as start up.

4HP

5HP

6HP

49dB

50dB

51dB

46dB

46 dB

47dB

Daytime Night

Clears nighttime residential noise ordinances.

Can be used without obstructing peaceful

neighborhoods at night.

Bat Wing fan

Night operation mode

PMV kit

Quieter with smoother wind flow

Die-away Zone

Suppress particular-Hz noise away Suppress overall noise levels

(Hz) (Hz)

3

Introduction

1

2

3

4

5

6

7

8

9

10

11

12

3

-4

Outdoor unit

(Revised edition in 7.Apr.2006)

4

-1

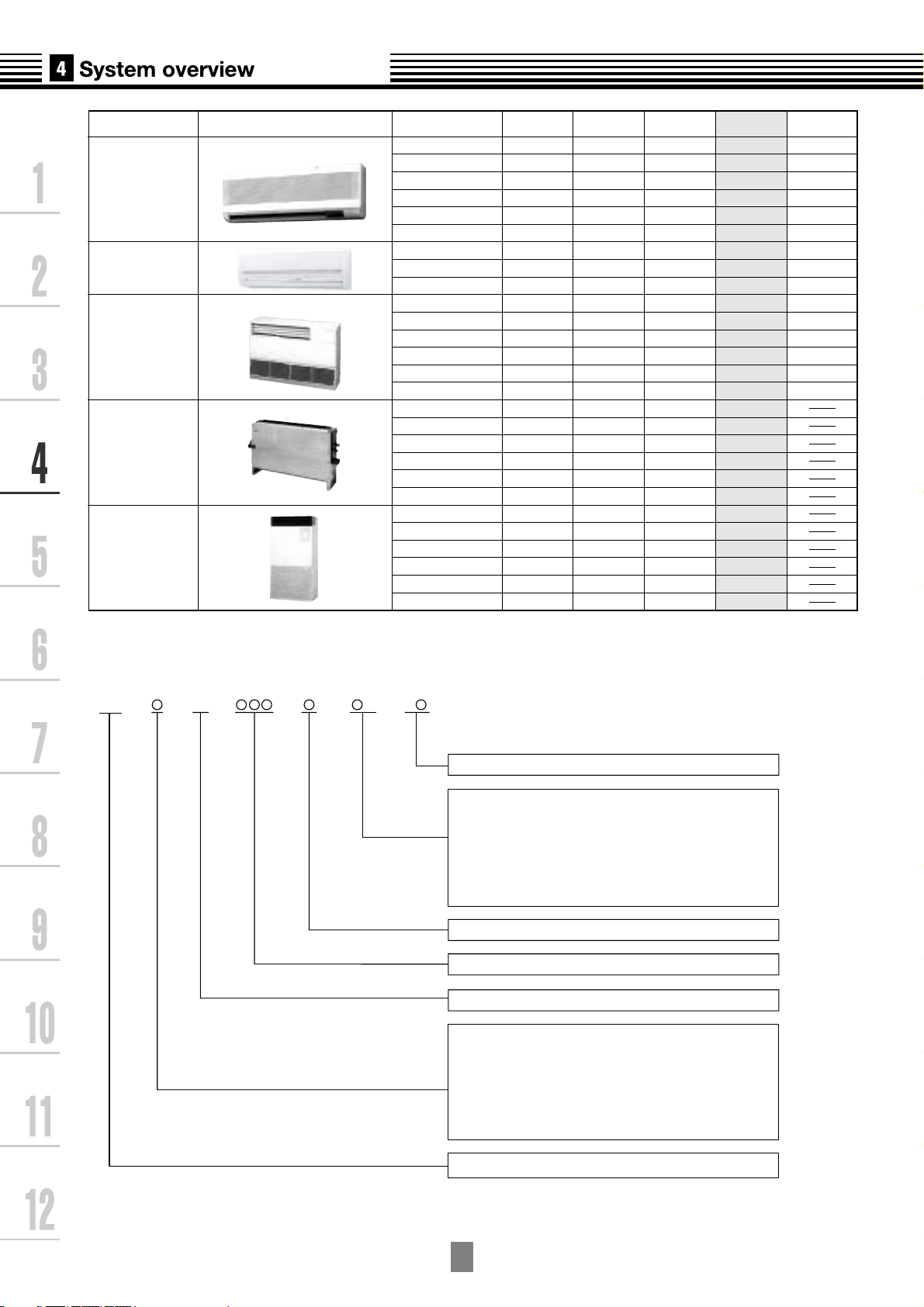

4-1. Summary of system equipments

Sales launch scheduled for early 2006. Specifications differ by region.

For questions regarding availability, please contact your local distributor.

World-class energy savings

_

COP of 4.61* achieved by Toshiba’s unrivalled

S-MMS technologies and newly developed components

Quiet operation can be further enhanced with an optional PMV

(flow regulating valve) Kit.

Versatile application

_

13 types of indoor units for use in up to 9 rooms (6 HP)

*

4HP CDU system

*

Pulse Motor Valve

Use of quieter place

Necessity of PMV Kit (RBM-PMV0361E / RBM-PMV0901E) for

quieter place application as an optional.

New compact 4-way

cassette

PMV Kit

4

-2

4-2. Outdoor units

MCY- 2DMAP H T

Corresponding HP

Model

name

Heat pump(50Hz) MCY-

Heat pump(60Hz) MCY-

Cooling capacity(kW)*1

Heating capacity(kW)*1

No.of connectable indoor units

Inverter unit

4HP 5HP 6HP

MAP0401HT MAP0501HT MAP0601HT

MAP0401HT2D MAP0501HT2D MAP0601HT2D

12.1

12.5

6

14.0

16.0

8

15.5

18.0

9

*1 Rated conditions

Cooling:Indoor air temperature 27

o

C DB/19

o

CWB,Outdoor air temperature 35

o

CDB

Heating:Indoor air temperature 20

o

C DB,Outdoor air temperature 7

o

CDB/6

o

CWB

Allocation standard of model name

No mark: Power supply specification, 1O

/

220-240V, 50Hz

2D : Power supply specification, 1

O

/

220V, 60Hz

T : Inverter unit

H : Heat pump

Development Number

Capacity rank HP

x

10

R410A

M : Individual unit

Multi Compact Type

4

-3

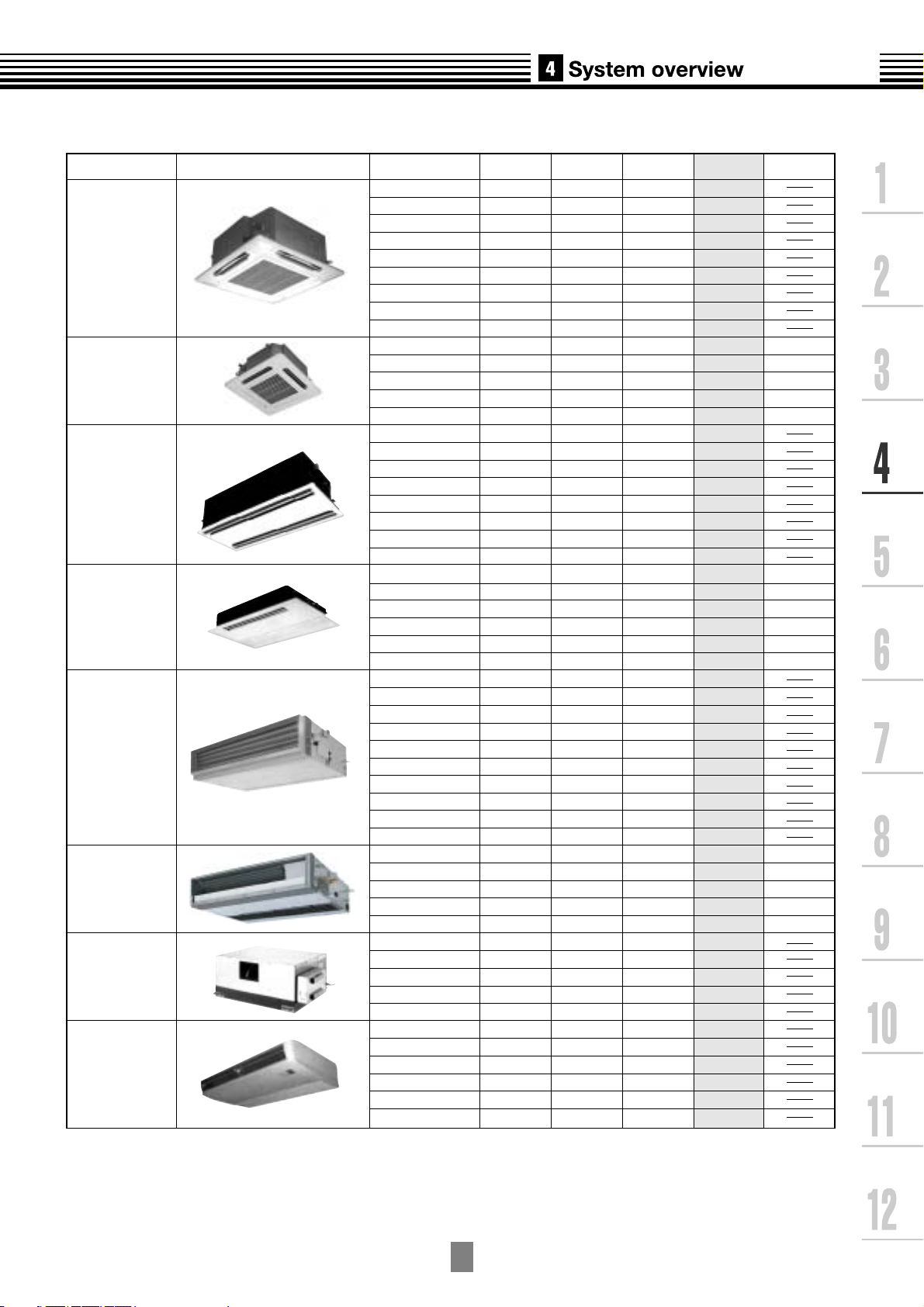

Type

Appearance

Model name

Capacity rank

Capacity

code

Cooling

capacity (kW)

Heating

capacity (kW)

4-way Air Discharge

Cassette Type

2-way Air Discharge

Cassette Type

1-way Air Discharge

Cassette Type

Slim Duct Type

Concealed Duct

Standard Type

Concealed Duct

High Static

Pressure Type

Under Ceilling Type

PMV Kit

Compact 4-way

Air Discharge

(600x600) Type

MMU-AP0091H

MMU-AP0121H

MMU-AP0151H

MMU-AP0181H

MMU-AP0241H

MMU-AP0271H

MMU-AP0301H

MMU-AP0361H

MMU-AP0481H

MMU-AP0071MH

MMU-AP0091MH

MMU-AP0121MH

MMU-AP0151MH

MMU-AP0181MH

MMU-AP0071WH

MMU-AP0091WH

MMU-AP0121WH

MMU-AP0151WH

MMU-AP0181WH

MMU-AP0241WH

MMU-AP0271WH

MMU-AP0301WH

MMU-AP0071YH

MMU-AP0091YH

MMU-AP0121YH

MMU-AP0152SH

MMU-AP0182SH

MMU-AP0242SH

MMD-AP0071BH

MMD-AP0091BH

MMD-AP0121BH

MMD-AP0151BH

MMD-AP0181BH

MMD-AP0241BH

MMD-AP0271BH

MMD-AP0301BH

MMD-AP0361BH

MMD-AP0481BH

MMD-AP0071SPH

MMD-AP0091SPH

MMD-AP0121SPH

MMD-AP0151SPH

MMD-AP0181SPH

MMD-AP0181H

MMD-AP0241H

MMD-AP0271H

MMD-AP0361H

MMD-AP0481H

MMC-AP0151H

MMC-AP0181H

MMC-AP0241H

MMC-AP0271H

MMC-AP0361H

MMC-AP0481H

009 type

012 type

015 type

018 type

024 type

027 type

030 type

036 type

048 type

007 type

009 type

012 type

015 type

018 type

007 type

009 type

012 type

015 type

018 type

024 type

027 type

030 type

007 type

009 type

012 type

015 type

018 type

024 type

007 type

009 type

012 type

015 type

018 type

024 type

027 type

030 type

036 type

048 type

007 type

009 type

012 type

015 type

018 type

018 type

024 type

027 type

036 type

048 type

015 type

018 type

024 type

027 type

036 type

048 type

1.00

1.25

1.70

2.00

2.50

3.00

3.20

4.00

5.00

0.80

1.00

1.25

1.70

2.00

0.80

1.00

1.25

1.70

2.00

2.50

3.00

3.20

0.80

1.00

1.25

1.70

2.00

2.50

0.80

1.00

1.25

1.70

2.00

2.50

3.00

3.20

4.00

5.00

0.80

1.00

1.25

1.70

2.00

2.00

2.50

3.00

4.00

5.00

1.70

2.00

2.50

3.00

4.00

5.00

2.8

3.6

4.5

5.6

7.1

8.0

9.0

11.2

14.0

2.2

2.8

3.6

4.5

5.6

2.2

2.8

3.6

4.5

5.6

7.1

8.0

9.0

2.2

2.8

3.6

4.5

5.6

7.1

2.2

2.8

3.6

4.5

5.6

7.1

8.0

9.0

11.2

14.0

2.2

2.8

3.6

4.5

5.6

5.6

7.1

8.0

11.2

14.0

4.5

5.6

7.1

8.0

11.2

14.0

3.2

4.0

5.0

6.3

8.0

9.0

10.0

12.5

16.0

2.5

3.2

4.0

5.0

6.3

2.5

3.2

4.0

5.0

6.3

8.0

9.0

10.0

2.5

3.2

4.0

5.0

6.3

8.0

2.5

3.2

4.0

5.0

6.3

8.0

9.0

10.0

12.5

16.0

2.5

3.2

4.0

5.0

6.3

6.3

8.0

9.0

10.0

16.0

5.0

6.3

8.0

9.0

12.5

16.0

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

4-3. Indoor units

4

-4

--AP H

MM

Allocation standard of model name

M : Compact 4-way Cassete Type

W : 2-way Cassete Type

S : 1-way Cassete Type

Y : Small sized 1-way Cassete Type

B : Built-in Type (Built-in Duct Type)

(Floor concealed Type)

SP(S) : Slim Duct Type

C : China model

U : Cassette Type

D : Duct Type

C : Under Ceiling Type

K : High Wall Type

L : Floor Type (Cabinet type)

(Concealed type)

F : Floor Standing Type

Development series No.

Based on the cooling capacity (Btu/h)/1,000

R410A

MM : Modular Multi Type

PMV Kit

007 type

009 type

012 type

015 type

018 type

024 type

007 type

009 type

012 type

007 type

009 type

012 type

015 type

018 type

024 type

007 type

009 type

012 type

015 type

018 type

024 type

015 type

018 type

024 type

027 type

036 type

048 type

Type Appearance Model name

Capacity

rank

Capacity

code

Cooling

capacity (kW)

Heating

capacity (kW)

Floor Standing

Cabinet Type

Floor Standing

Concealed Type

Floor Standing Type

MMK-AP0071H

MMK-AP0091H

MMK-AP0121H

MMK-AP0151H

MMK-AP0181H

MMK-AP0241H

MMK-AP0072H

MMK-AP0092H

MMK-AP0122H

MML-AP0071H

MML-AP0091H

MML-AP0121H

MML-AP0151H

MML-AP0181H

MML-AP0241H

MML-AP0071BH

MML-AP0091BH

MML-AP0121BH

MML-AP0151BH

MML-AP0181BH

MML-AP0241BH

MMF-AP0151H

MMF-AP0181H

MMF-AP0241H

MMF-AP0271H

MMF-AP0361H

MMF-AP0481H

0.80

1.00

1.25

1.70

2.00

2.50

0.80

1.00

1.25

0.80

1.00

1.25

1.70

2.00

2.50

0.80

1.00

1.25

1.70

2.00

2.50

1.70

2.00

2.50

3.00

4.00

5.00

2.2

2.8

3.6

4.5

5.6

7.1

2.2

2.8

3.6

2.2

2.8

3.6

4.5

5.6

7.1

2.2

2.8

3.6

4.5

5.6

7.1

4.5

5.6

7.1

8.0

11.2

14.0

2.5

3.2

4.0

5.0

6.3

8.0

2.5

3.2

4.0

2.5

3.2

4.0

5.0

6.3

8.0

2.5

3.2

4.0

5.0

6.3

8.0

5.0

6.3

8.0

9.0

10.0

16.0

High Wall Type

(2 series)

High Wall Type

(1 series)

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

Available

4

-5

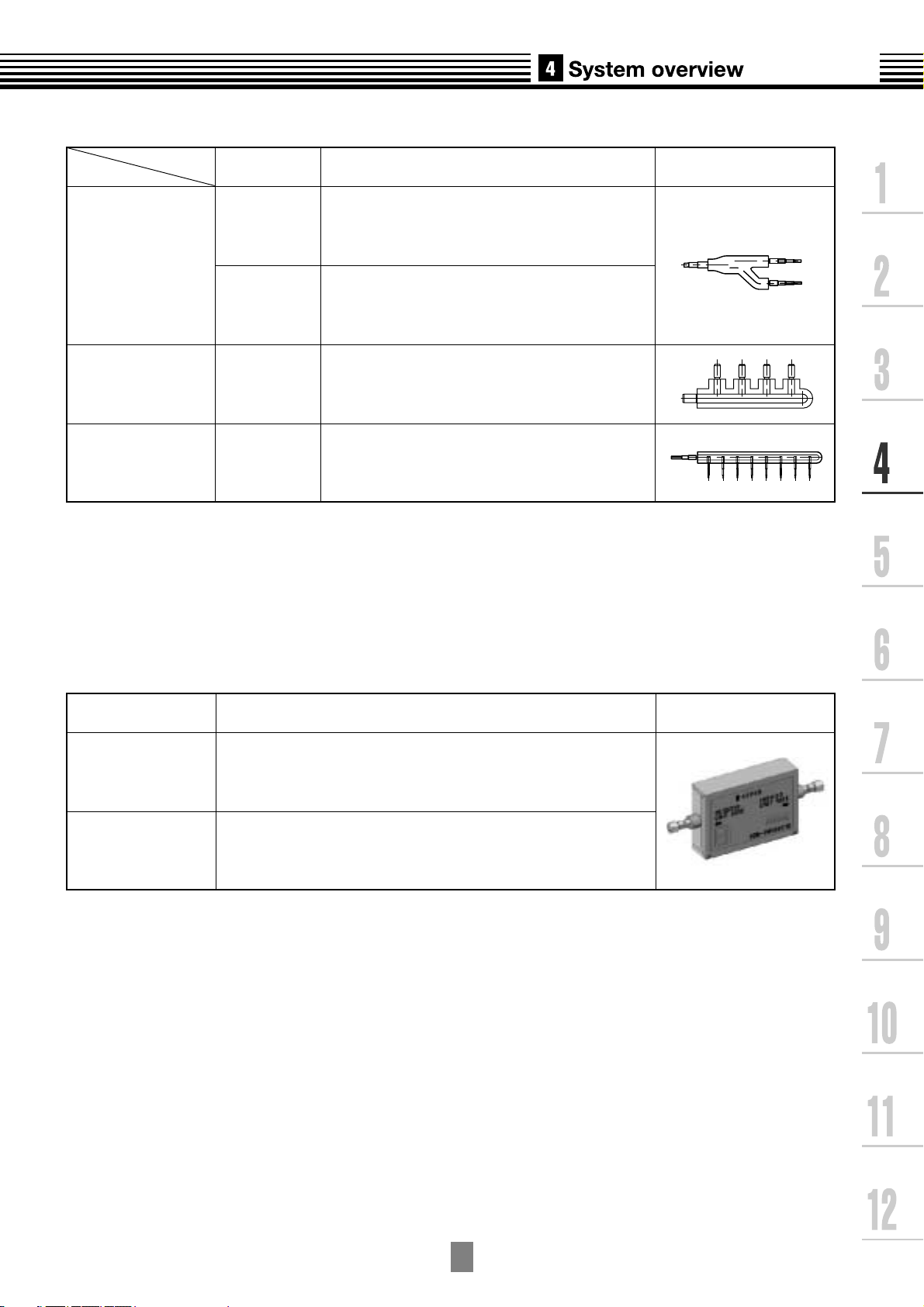

4-4. Branching joints and headers *1

*1 If total capacity code value of indoor unit exceeds that of outdoor unit, apply code of outdoor unit.

*2 "capacity code" can be obtained from page~. (capacity code is not actual capacity)

*3 When using Y-shape branching joint for 1st branching, select according to the capacity code of outdoor unit.

Model name

Usage Appearance

Y-shape branching joint

4-branching header

8-branching header

RBM-BY53E

RBM-BY103E

RBM-HY1043E

RBM-HY1083E

Indoor unit capacity code (*2) :Total below 6.4

Indoor unit capacity code (*2) :Total 6.4 or more

and below 7.8

Indoor unit capacity code (*2) :Total below 7.8

Indoor unit capacity code (*2) :Total below 7.8

4-5. PMV Kit

Indoor unit capacity type Appearance

RBM-PMV0361E

RBM-PMV0901E

007, 009, 012 type

015, 018, 024 type

For more information see Chapter 10.

Model name

4

-6

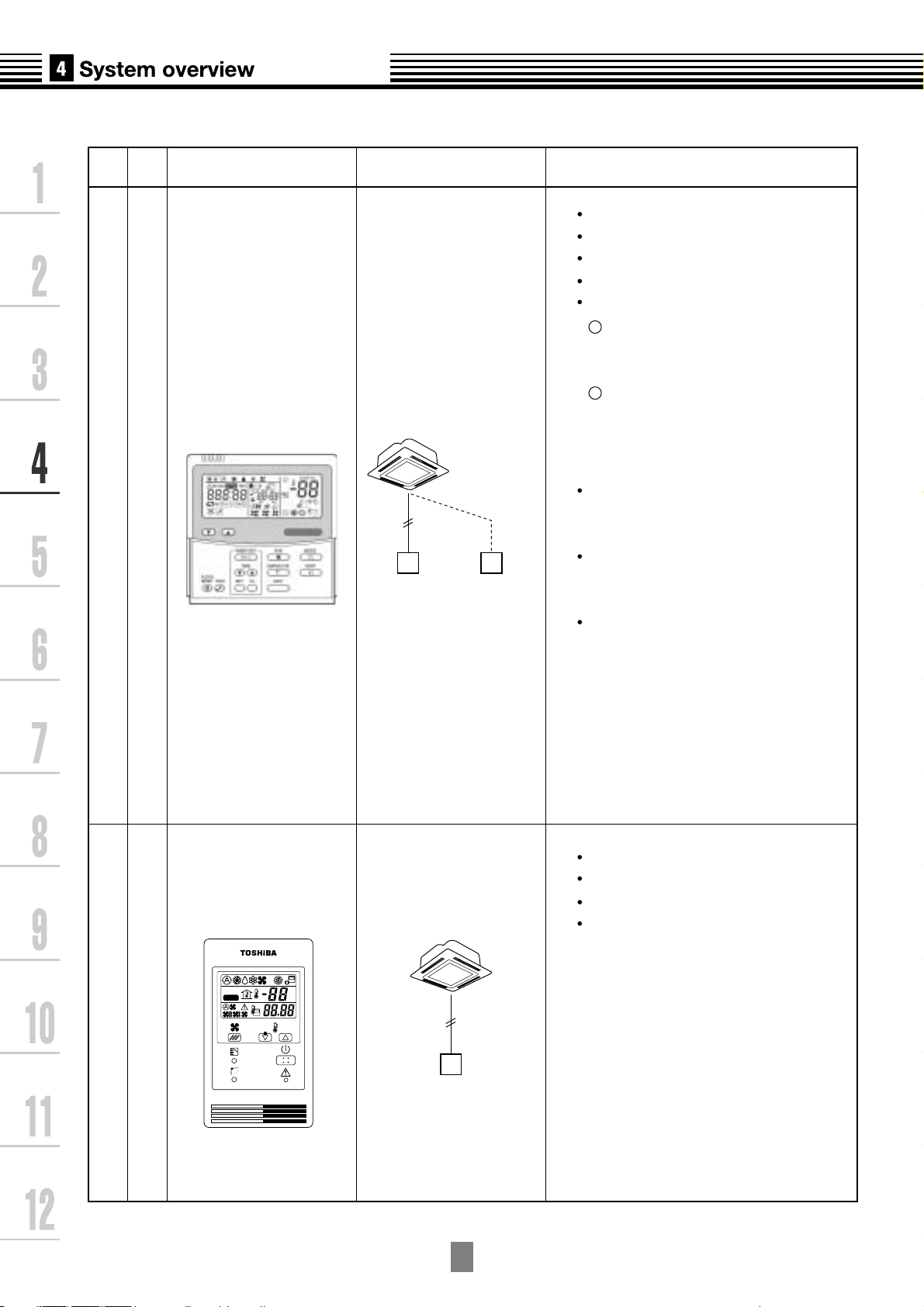

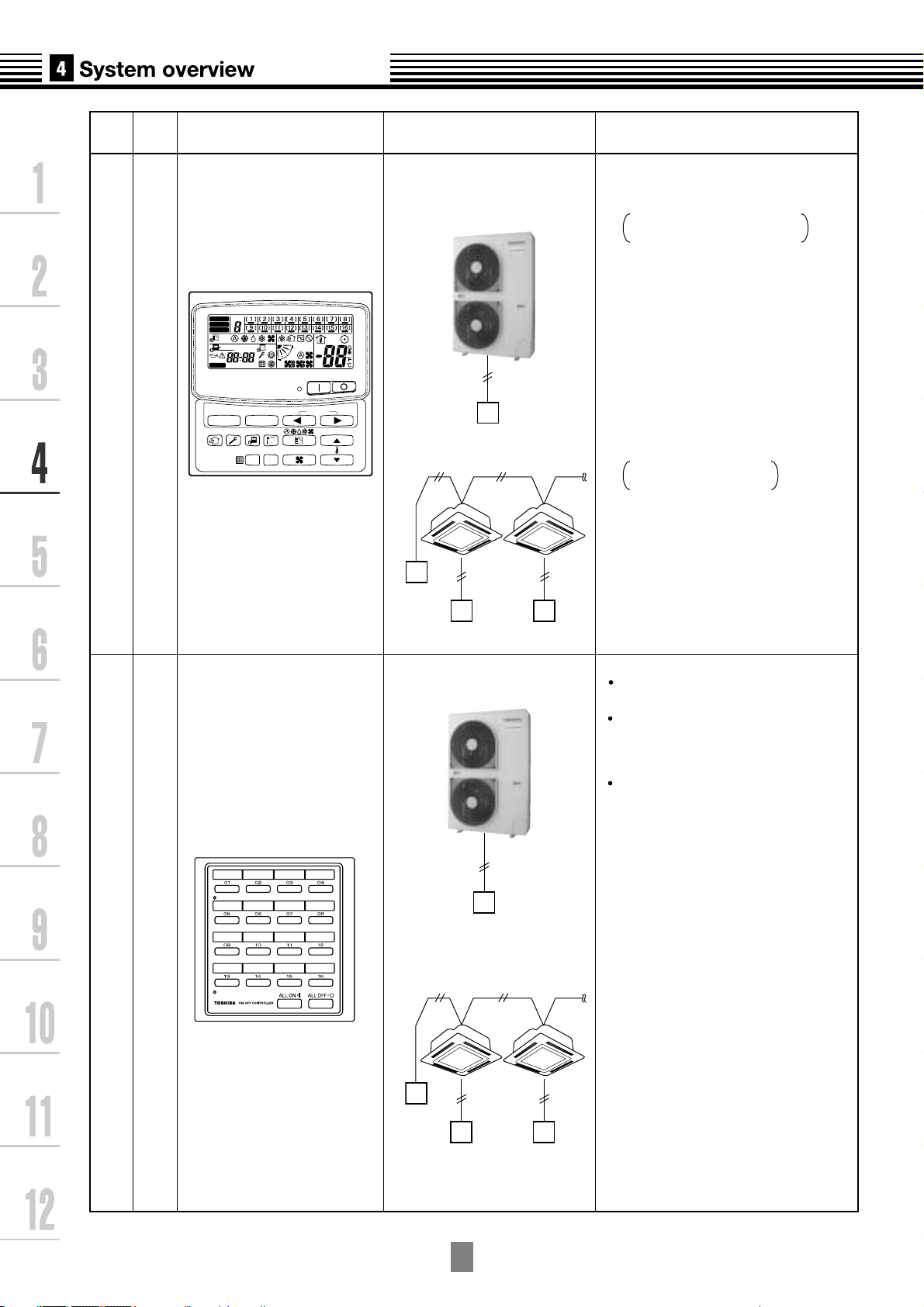

4-6. Remote controller

Name

Model

name

Appearance Application Function

Wired remote controllerSimple wired remote controller

RBC-AS21E2

RBC-AMT31E

Connected to indoor unit

Connected to indoor unit

Simple remote controller

Wired remote

controller

Wired remote

controller

(In case of control

by 2 remote

controllers)

Start / Stop

Mode Change

Temperature setting

Fan speed

Timer function

Filter dirty indicator

Displays automatically maintenance

time of indoor filter by flashes.

Self-diagnosis function

Pressing "CHECK" button

displays status code.

Control by 2 remote controllers is

available.

Two remote controllers can be

connected to one indoor unit.

The indoor unit can be separately

operated from a different location.

1

2

Start / Stop

Temperature setting

Change of air flow

Check code display

On or off elapsed timer

with 30 minite increments.

Automatic off function

Weekly when combined with

RBC-EXW21E2

weekly schedule operation can

be operated.

ûC

ûF

TEST

SETTING

4

-7

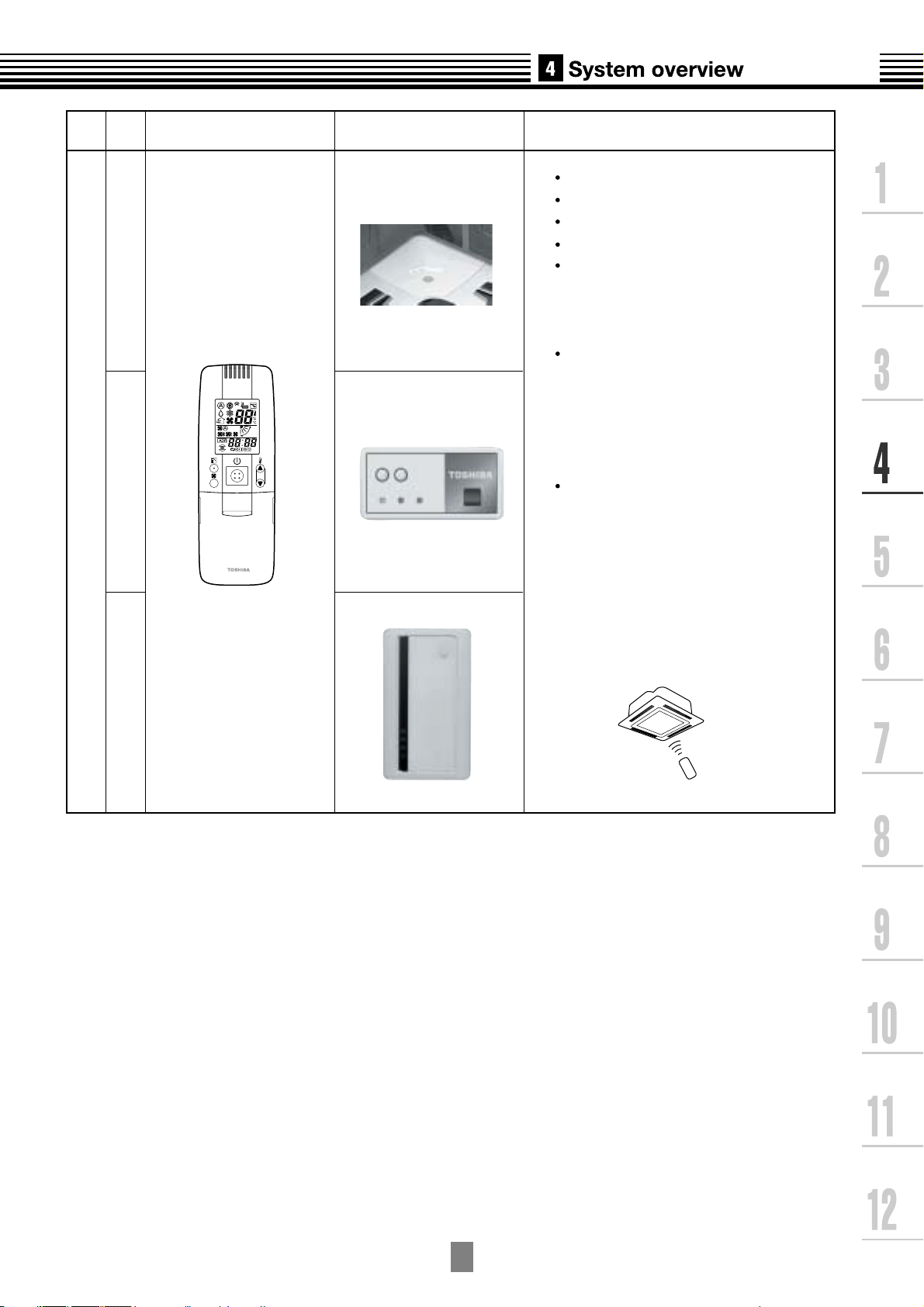

Wireless remote controller kit

TCB-AX21E2 RBC-AX22CE2 TCB-AX21U(W)-E2

Name

Model

name

Appearance Function

Start / Stop

Mode change

Temperature setting

Change of air flow

Timer function

On or off timer operation, setting in

30 minute increments.

Automatic Off function

Control by 2 remote controllers is

available.

Two wireless remote controllers can

operate one indoor unit. The indoor unit

can be separately operated from a

different location.

Check code display

TCB-AX21U(W)-E2

(for 4-way airdischarge cassette)

RBC-AX22CE2

(for under ceiling)

TCB-AX21-E2

(for other units except for the con-

cealed duct high static pressure)

4

-8

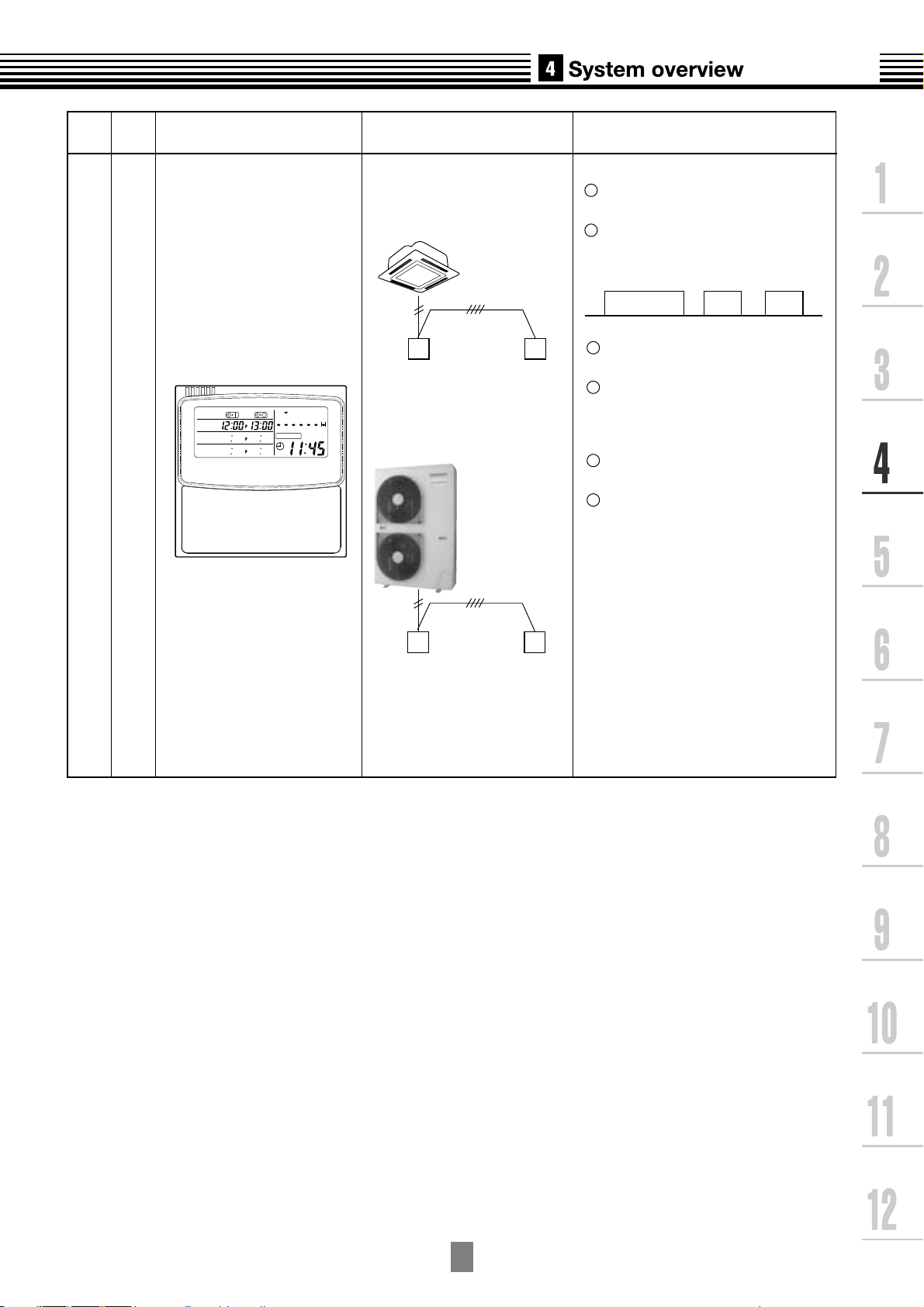

Name

Model

name

Appearance Application Performance

Central remote controller

TCB-SC642TLE2

Connected to outdoor unit,

or indoor unit

Outdoor

unit

Central

remote controller

Indoor

remote controller

Central

remote

controller

Individual control up to 64 indoor units.

Individual control for max. 64 indoor

units divided into 4 zones.

Up to 16 indoor units for each

zone

Up to 16 outdoor units are

connectable.

Four selectable central control settings to

restrict individual remote controller

operations.

Setting for one of 1 to 4 zones is

available.

Can be used with other central control

devices (Up to 10 central control

devices with in one control circuit)

Two selectable control modes

Central controller mode

Remote controller mode

Setting of simultaneous ON/OFF 3

times for each day of the week

combined with a weekly timer.

ON-OFF controller

TCB-CC163TLE2

Connected to outdoor unit,

or indoor unit

Indoor unit

Indoor

remote controller

Outdoor unit

ON-OFF

controller

ON-OFF

controller

Setting of simultaneous ON-OFF 3

times for each day of the week when

combined with a weekly timer.

Individual control up to 16 indoor units.

Connected to 2 remote controllers is

possible.

SELECT ZONE

CL

SET

GROUP

CODE

No.

UNIT No.

No.

R.C.

TEST

ZONE

ALL

ZONE

GROUP

SETTING

1234

SET DATA

4

-9

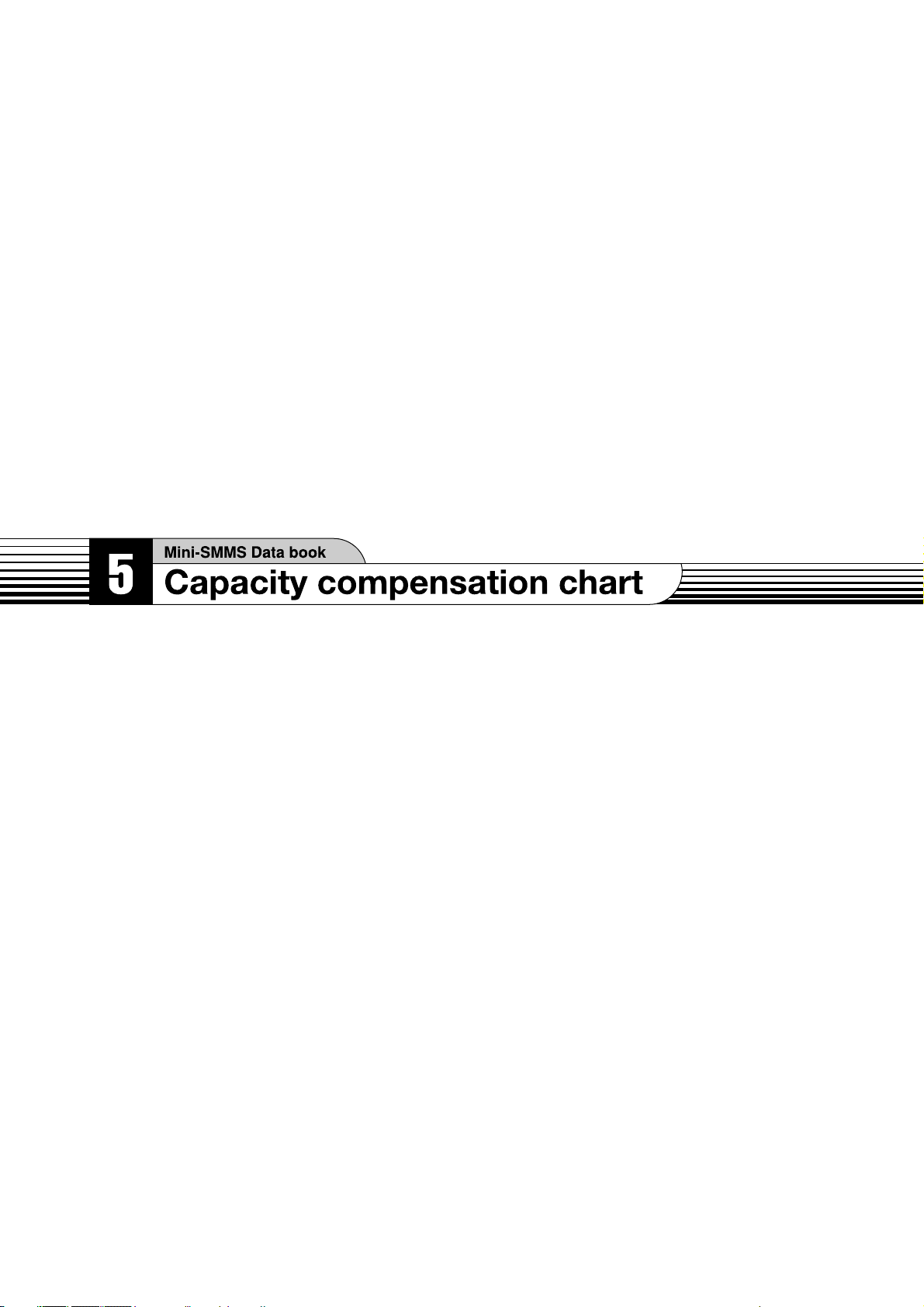

Name

Weekly timer

Model

name

Appearance Application Performance

RBC-EXW21E2

Connected to central

remote controller or

wired remote controller

Wired

remote controller

Weekly

timer

Outdoor unit

Central

remote controller

Weekly

timer

Weekly schedule operation

Setting different start / stop time for each

day of the week

ON / OFF can be set 3 times

a day.

1

2

3

Two different schedules for a

week can be specified.

(Summer schedule and winter

schedule, etc.)

4

5

If power supply fails, the setting

contents are stored in the memory for

100 hours.

6

"CHECK" "PROGRAM" "DAY"

button copying of settings easy.

"CANCEL" "DAY" button enables

holiday setting.

WEEKLY TIMER

ERROR

SuMoTuWeThFr Sa

PROGRAM1

PROGRAM2

PROGRAM3

ON

8:00 12:00 13:00 18:00 19:00 21:00

OFF ON OFF ON OFF

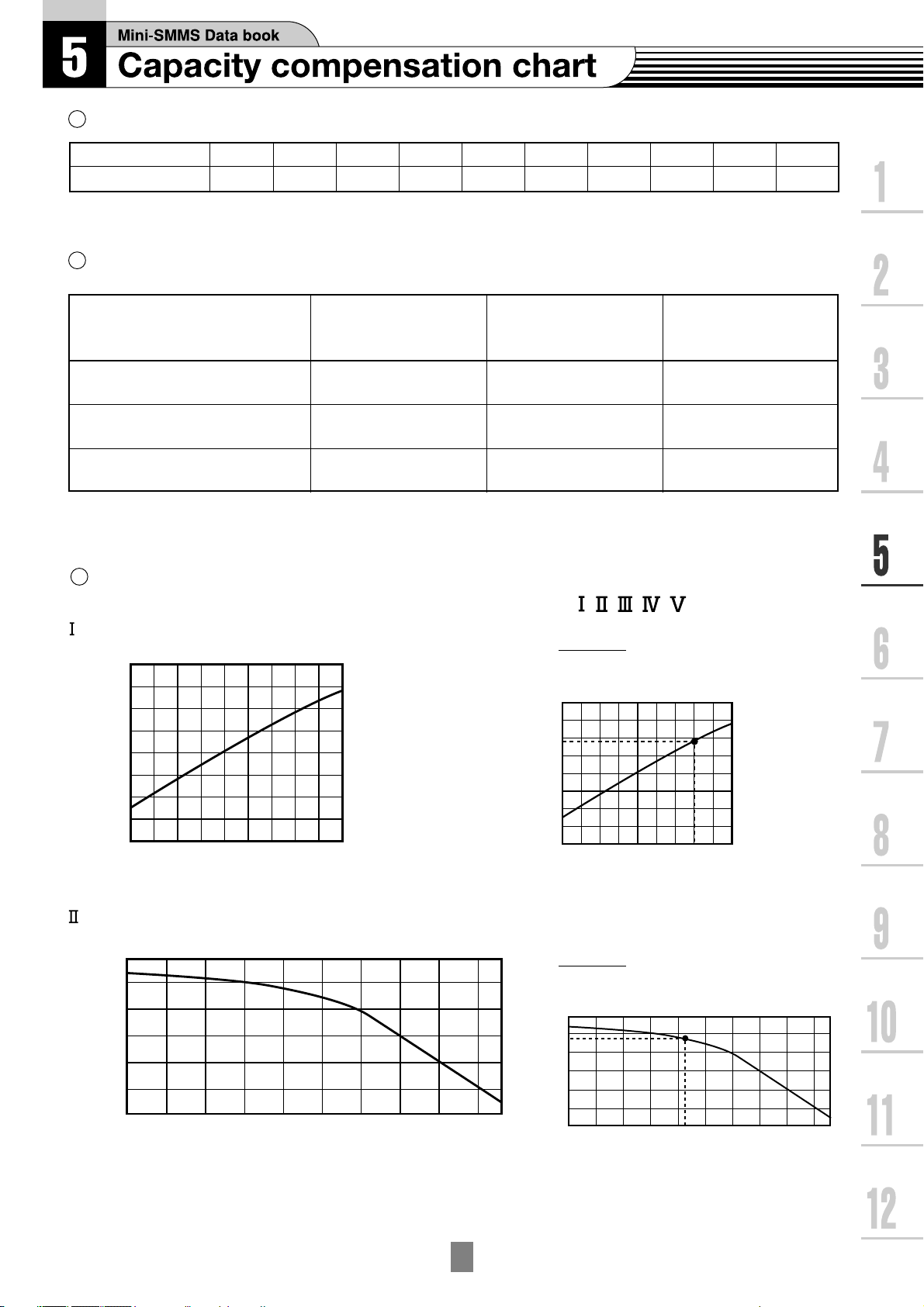

5

-1

For indoor unit, the capacity code is decided for each capacity rank.

NOTE :

Capacity rank : Correspondence to Btu/h. Capacity code : Correspondence to Horsepower.

For outdoor unit, maximum No. of connectable indoor units and total capacity code of indoor units

are decided.

Capacity rank type

Capacity code

007

0.8

009

1

012

1.25

015

1.7

018

2

024

2.5

030

3.2

036

4

048

5

027

3

Outdoor unit

Capacity code of

outdoor unit

Max. No. of

indoor units

Total capacity code

of indoor units

MCY-MAP0401HT

MCY-MAP0401HT2D

4

5

6

6

8

9

3.2 to 5.2

4.0 to 6.5

4.8 to 7.8

1

2

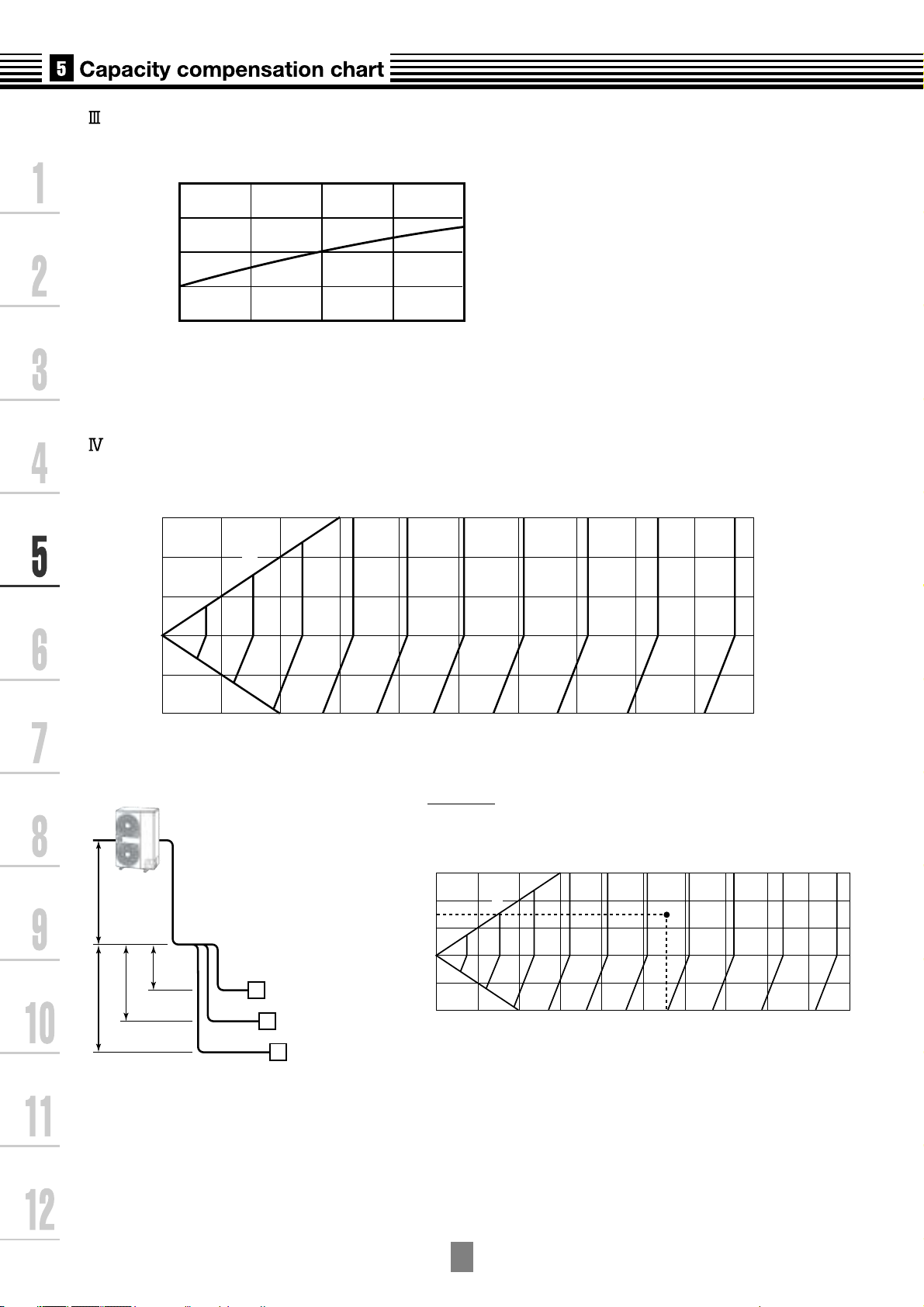

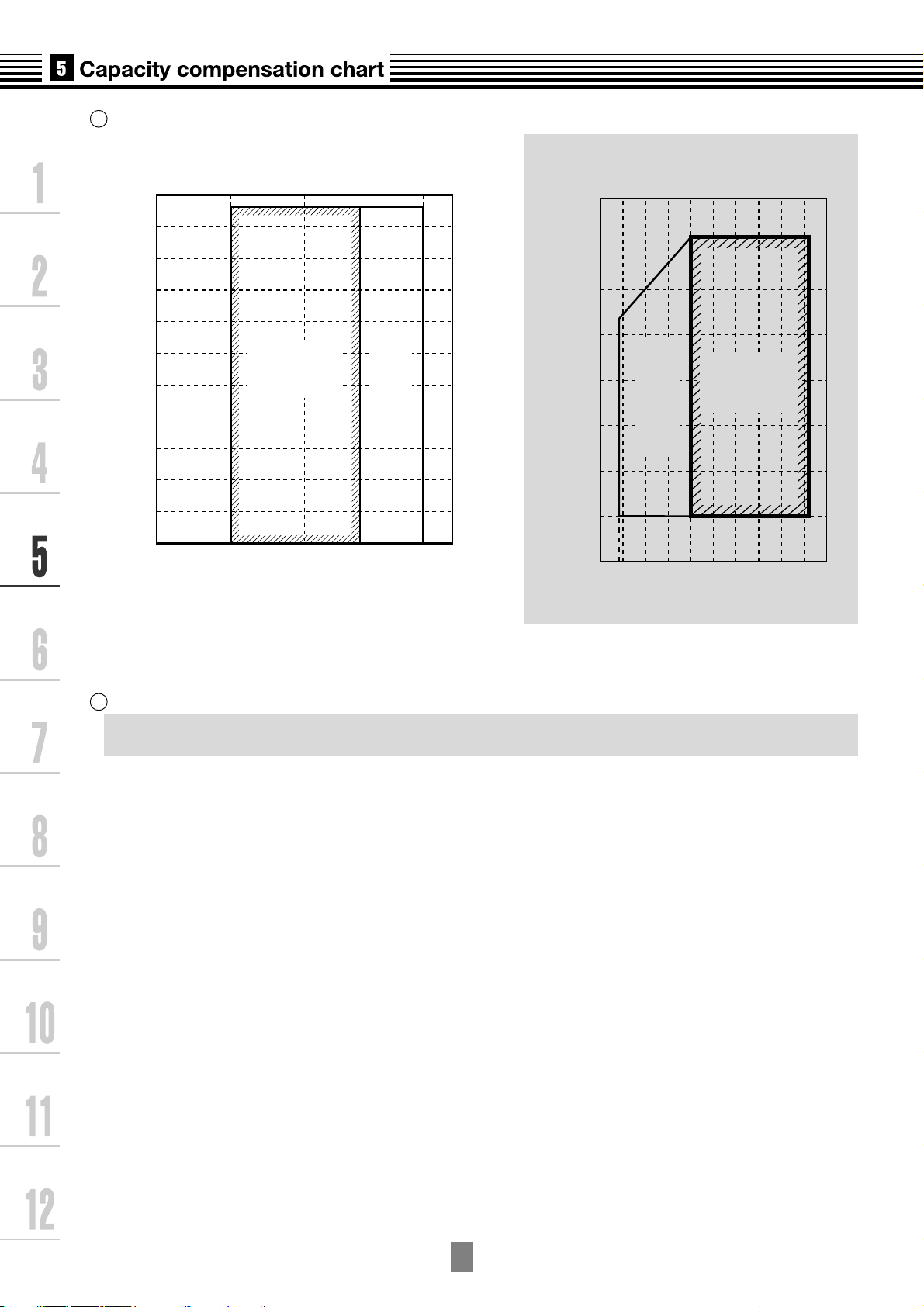

5-1. Cooling/heating capacity characteristics

Cooling capacity calculation method :

Required cooling capacity = Cooling capacity x Factor ( , , , , *

1

) kW

Indoor air wet bulb temperature vs. capacity correction value

1

Indoor air wet bulb temp. (

o

C)

Capacity correction value

15

1.2

1.1

1.0

0.9

0.8

20 24

Outdoor air dry bulb temperature vs.capacity correction value

Indoor air wet bulb temp. (

o

C)

Capacity correction value

15

1.2

1.1

1.0

0.9

0.8

20 24

(Example)

Design Outdoor conditions : 17

o

C DB

Capacity correction value : 1.14

Outdoor air dry bulb temp. (

o

C)

Capacity correction value

-

50 51015202530354043

0.9

1

1.1

1.2

Outdoor air dry bulb temp. (

o

C)

Capacity correction value

-

50 51015202530354043

0.9

1

1.1

1.2

MCY-MAP0501HT

MCY-MAP0501HT2D

MCY-MAP0601HT

MCY-MAP0601HT2D

(Example)

Design Indoor conditions : 22

o

C WB

Capacity correction value : 1.09

*

1 : Coefficient to use for correction of outdoor unit capacity when total capacity of the indoor

units are not equal to the outdoor unit capacity.

5

-2

Air flow variation ratio of indoor unit vs. capacity correction (For concealed duct type only)

Capacity correction value

1.1

1.0

0.9

80 90 100 110 120

Air flow variation ratio (%)

30

20

10

0

-

10

-

20

010203040

Pipe length (Equivalent length) L(m)

Hight of outdoor unit H (m)

50 60 70 80 90 100

100%

98

96

94

92

90

88

86

84

82

Outdoor unit

Indoor unit

L is the longest one of

(Ll + a, Ll + b, Ll + c)

H = ho +

(Largest one of ha, hb, and hc)

A

ha

hb

hc

ho Ll

a

b

c

B

C

30

20

10

0

-

10

-

20

010203040

Pipe length (Equivalent length) L(m)

Hight of outdoor unit H (m)

50 60 70 80 90 100

100%

98

96

94

92

90

88

86

84

82

(Example)

Design Pipelength : 55m

Height of outdoor unit : 15m

Capacity correction value: 89%

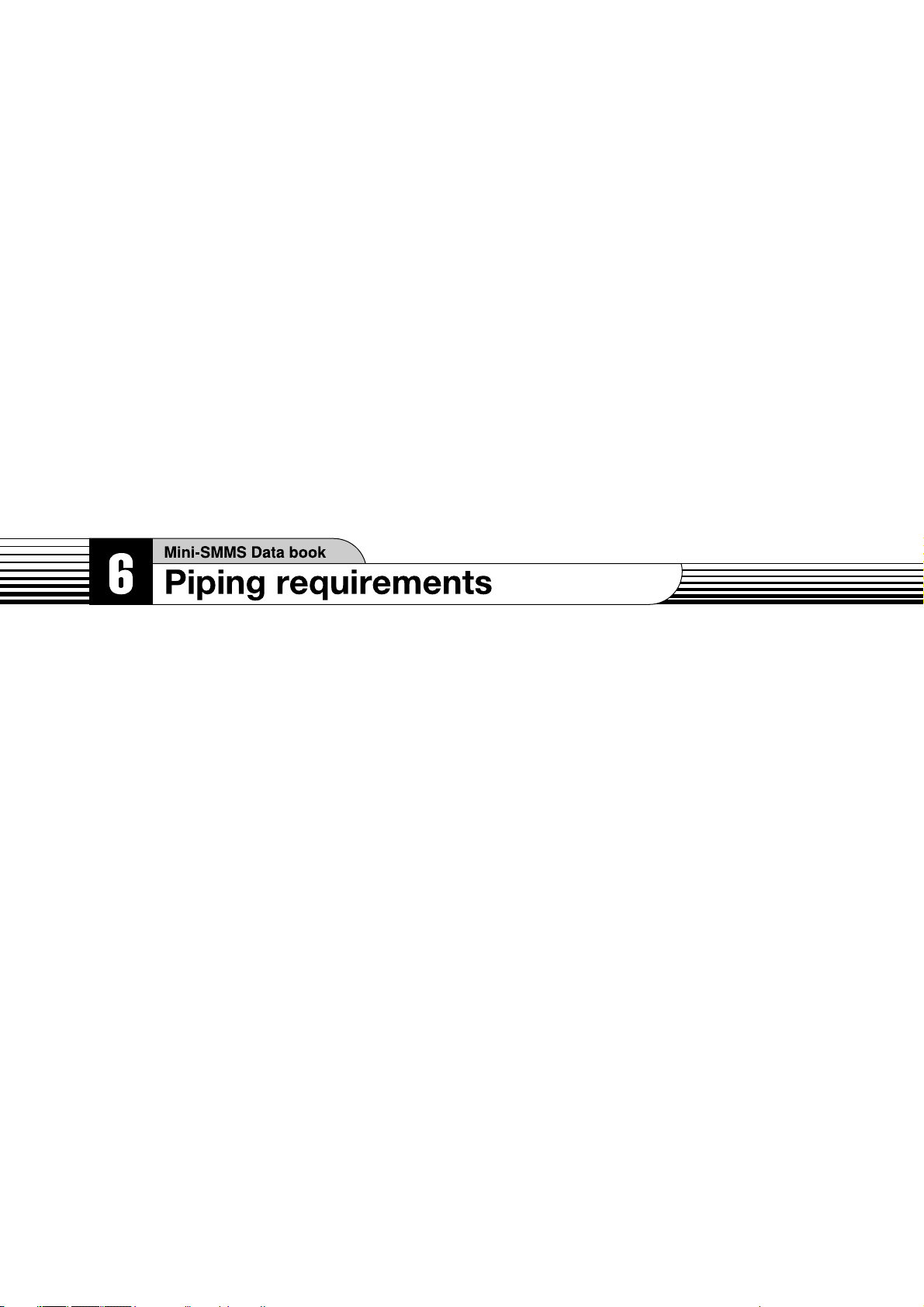

Connecting pipe length and lift difference between indoor and outdoor units vs. capacity correction value

5

-3

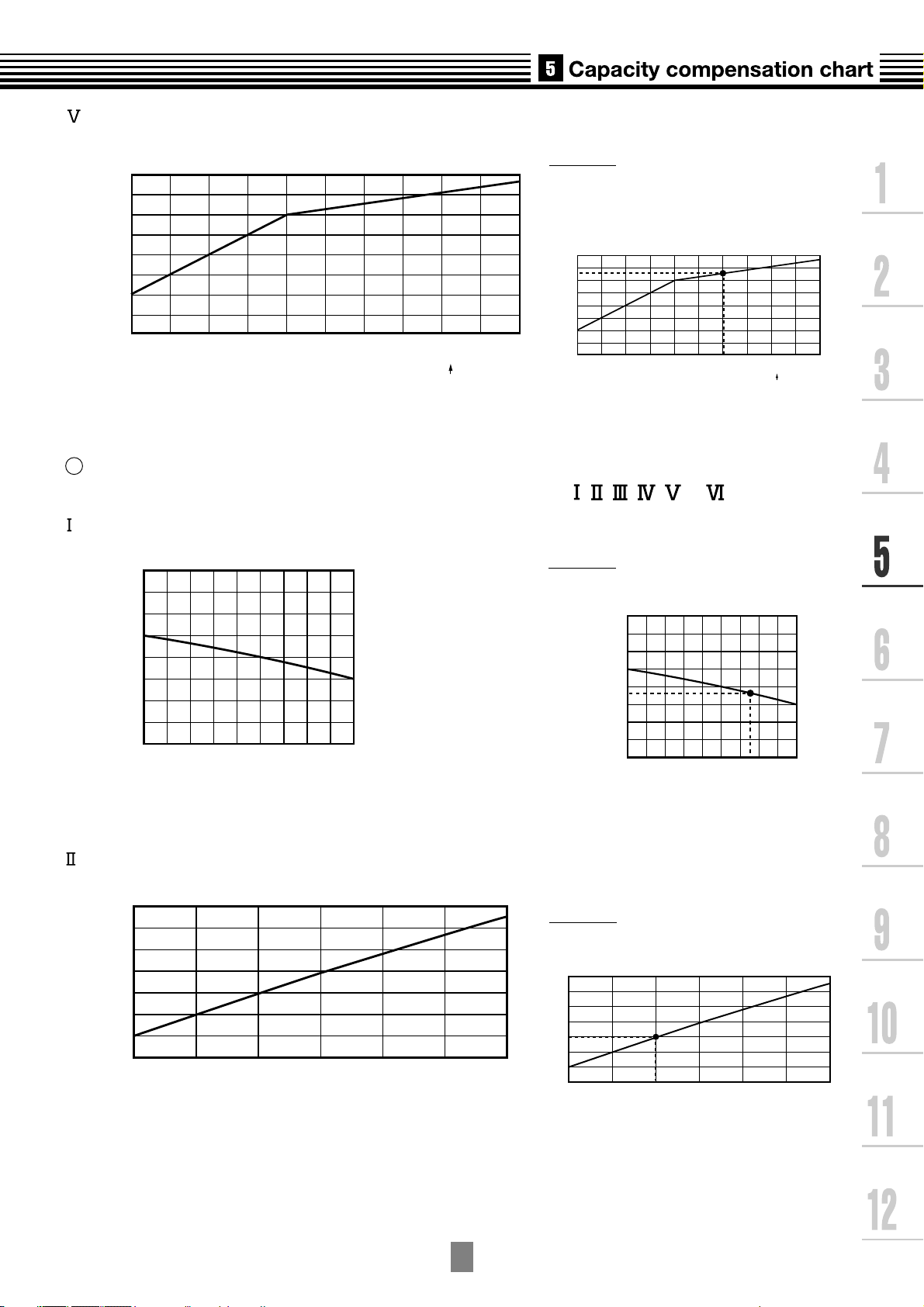

Correction of outdoor unit diversity

Heating capacity calculation method :

Required heating capacity = Heating capacity x Factor ( , , , , *

1

, *

2

) kW

Indoor air dry bulb temperature vs. capacity correction value

Outdoor air wet bulb temperature vs. capacity correction value

2

Indoor air dry bulb temp. (

o

C)

Capacity correction value

0.8

15 20 24

0.9

1.0

1.1

1.2

(Example)

Design Outdoor unit : 5.0HP

Indoor units total capacity : 5.5HP

(Capacity ratio : 110%)

Capacity correction value : 1.03%

Indoor air dry bulb temp. (

o

C)

Capacity correction value

0.8

15 20 24

0.9

1.0

1.1

1.2

(Example)

Design Indoor conditions : 21.5

o

C DB

Capacity correction value : 0.98

(Example)

Design Outdoor conditions :

-

5

o

C WB

Capacity correction value : 0.8

Outdoor air wet bulb temp. (

o

C)

Capacity correction value

1.2

1.1

1

0.9

0.8

0.7

0.6

0.5

-

15

-

10

-

50 51015

Outdoor air wet bulb temp. (

o

C)

Capacity correction value

1.2

1.1

1

0.9

0.8

0.7

0.6

0.5

-

15

-

10

-

50 51015

1.1

1

0.9

0.8

0.7

80 80 100 110 120 130

Capacity correction value

Indoor units total capacity ratio (%)

Standard capacity ratio

1.1

1

0.9

0.8

0.7

80 80 100 110 120 130

Capacity correction value

Indoor units total capacity ratio (%)

Standard capacity ratio

*

1 : Coefficient to use for correction of outdoor unit capacity when total capacity of the indoor

units are not equal to the outdoor unit capacity.

*

2 : Refer to item 3.

5

-4

Air flow variation ratio of indoor unit vs. capacity correction (For concealed duct type only)

Capacity correction value

Air flow variation ratio (%)

0.9

1.0

1.1

80 90 100 110 120

Connecting pipe length and lift difference between indoor and outdoor units vs. capacity correction value

Pipe length (Equivalent length) L (m)

Height of outdoor unit H (m)

30

99

98

97

96

95

94

20

10

0

-

10

-

20

0 102030 405060708090100

100%

Outdoor unit

Indoor unit

L is the longest one of

(Ll + a, Ll + b, Ll + c)

H = ho +

(Largest one of ha, hb, and hc)

A

ha

hb

hc

ho Ll

a

b

c

B

C

Pipe length (Equivalent length) L (m)

Height of outdoor unit H (m)

30

99

98

97

96

95

94

20

10

0

-

10

-

20

0 10 20304050607080 90100

100%

(Example)

Design Pipe length : 75m

Heigh of outdoor unit : 15m

Capacity correction value : 95.1%

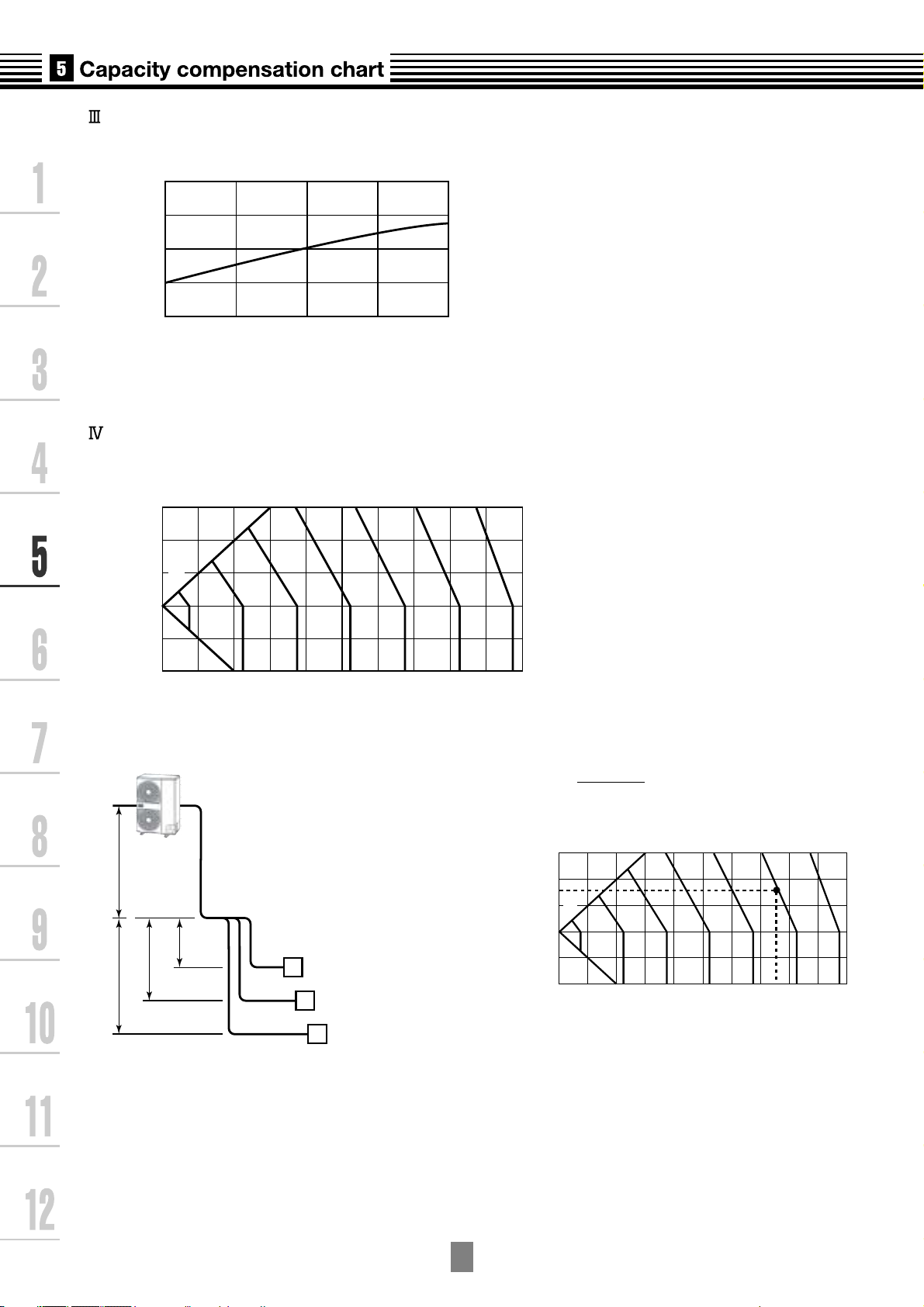

5

-5

Correction of outdoor unit diversity

*

1 : Coefficient to use for correction of outdoor unit capacity when total capacity of the indoor

units are not equal to the outdoor unit capacity.

Capacity correction in case of frost on the outdoor heat exchanger in heating

Correct the heating capacity when frost was found on the outdoor heat exchanger.

Heating capacity = Capacity after correction of outdoor unit × Correction value of capacity resulted from frost

(Capacity after correction of outdoor unit : Heating capacity calculated in the above item 2.)

3

0.8

0.9

1.0

-

15

-

10

-

50 510

Outdoor air wet bulb temp. (

o

C)

Capacity correction value

Capacity correction in case of frost on the outdoor heat exchanger

Capacity calculation for each indoor unit

Capacity for each indoor unit

= Capacity after correction of outdoor unit x

Required standard capacity of indoor unit

Total value of standard indoor unit capacity

4

(Example)

Design Outdoor unit : 5HP

Indoor units total capacity : 4.5HP

(Capacity ratio : 90%)

Capacity correction value : 0.9%

1.1

1

0.9

0.8

0.7

80 90 100 110 120 130

Capacity correction value

Indoor units total capacity ratio (%)

Standard capacity ratio

1.1

1

0.9

0.8

0.7

80 90 100 110 120 130

Capacity correction value

Indoor units total capacity ratio (%)

Standard capacity ratio

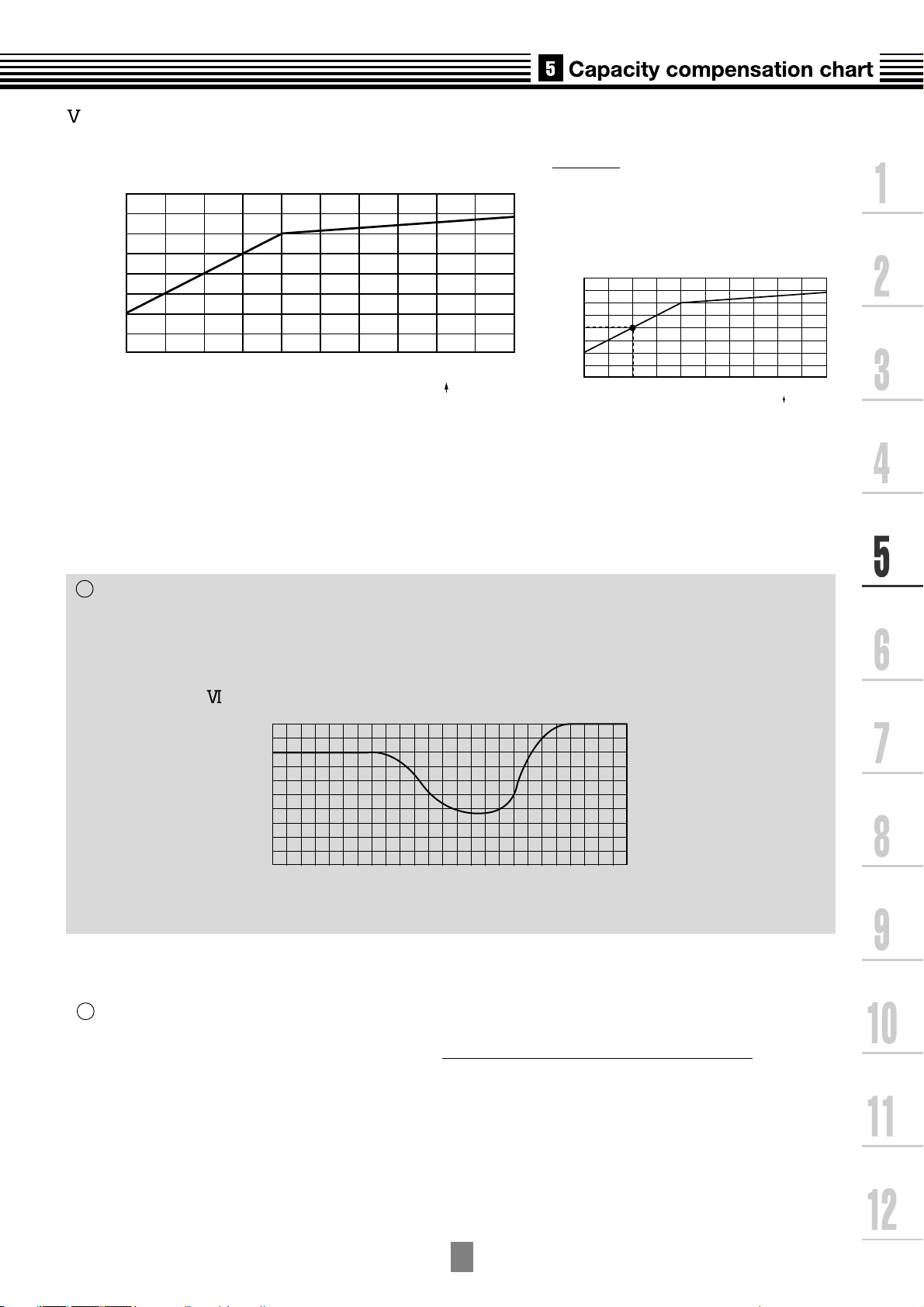

5

-6

Rated conditions

Cooling :

Indoor air temperature 27

o

C DB/19.0

o

C WB, Outdoor air temperature 35

o

C DB

Heating :

Indoor air temperature 20

o

C DB, Outdoor air temperature 7

o

C DB/6

o

C WB

5

6

Operating temperature range

3025 28201510

-

10

-

5

0

5

10

15

20

25

30

35

40

45

Indoor air wet bulb temp. (

o

C)

In cooling time

Outdoor air dry bulb temp. (

o

C)

Continuously

operable

range

Usable range

(in pull down)

Indoor air dry bulb temp. (

o

C)

In heating time

Outdoor air wet bulb temp. (

o

C)

-

20

-

15

-

10

-

5

0

5

10

15

20

5 1015202530

Continuously

operable

range

Usable range

(in warming-up)

6

-1

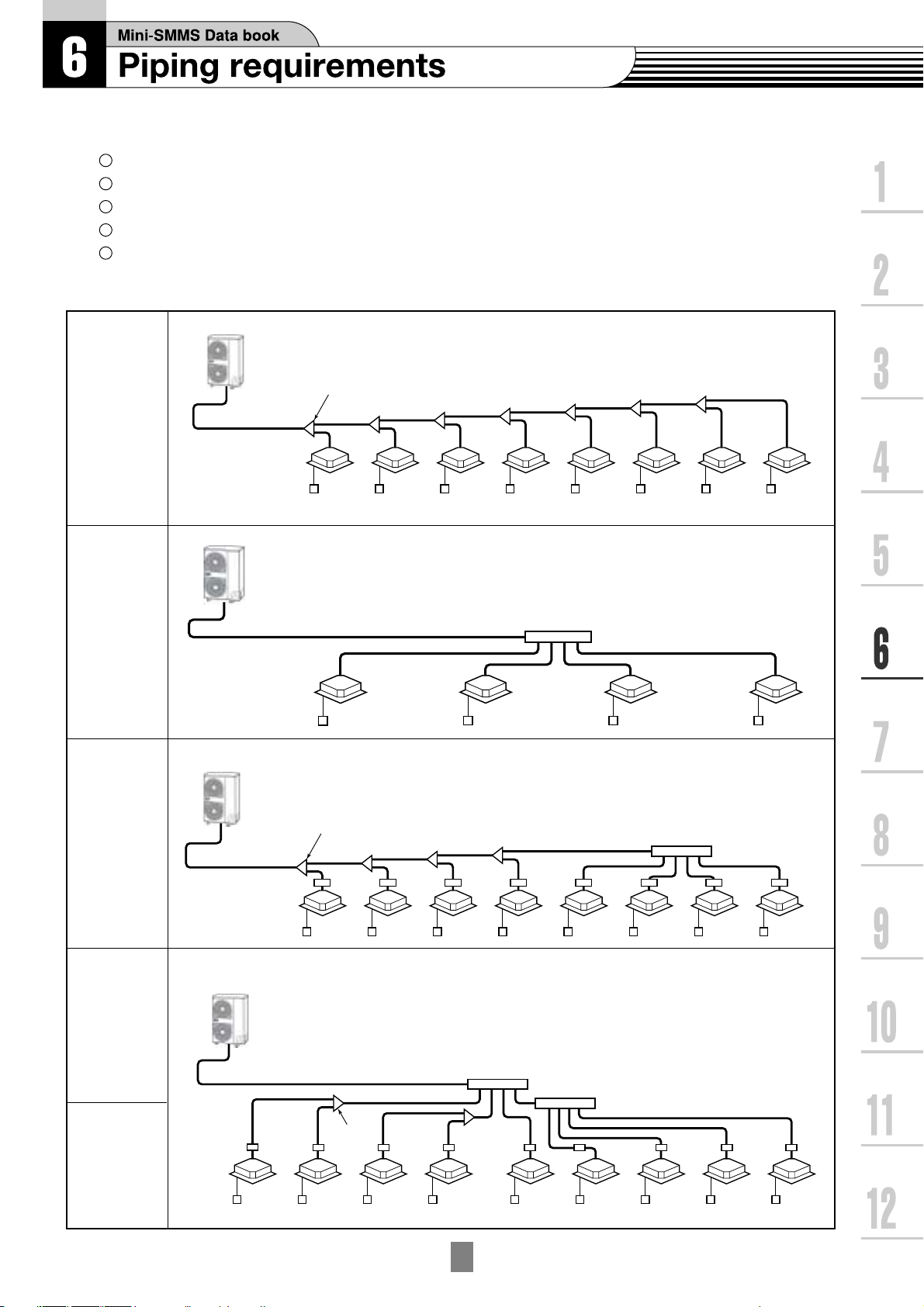

Line

branching

system

Header

branching

system

Header

branching

system

after line

branching

Line

branching

system after

header

branching

Header

branching

system after

header

branching

6-1. Free branching system

Line branching system

Header branching system

Header branching system after line branching

Line branching system after header branching

Header branching system after header branching

The above five branching systems are available to dramatically increase the flexibility of refrigerant piping design.

1

2

3

4

5

Outdoor unit

Branching joint

Remote

controller

Indoor unit

Branching header

Remote controller

Indoor unit

Outdoor unit

Branching joint

Remote

controller

Indoor unit

PMV

Kit

Branching header

Outdoor unit

Branching

joint

Remote

controller

Indoor

unit

Branching header

Outdoor unit

PMV

Kit

* In case of "PMV Kit"

* In case of "PMV Kit"

6

-2

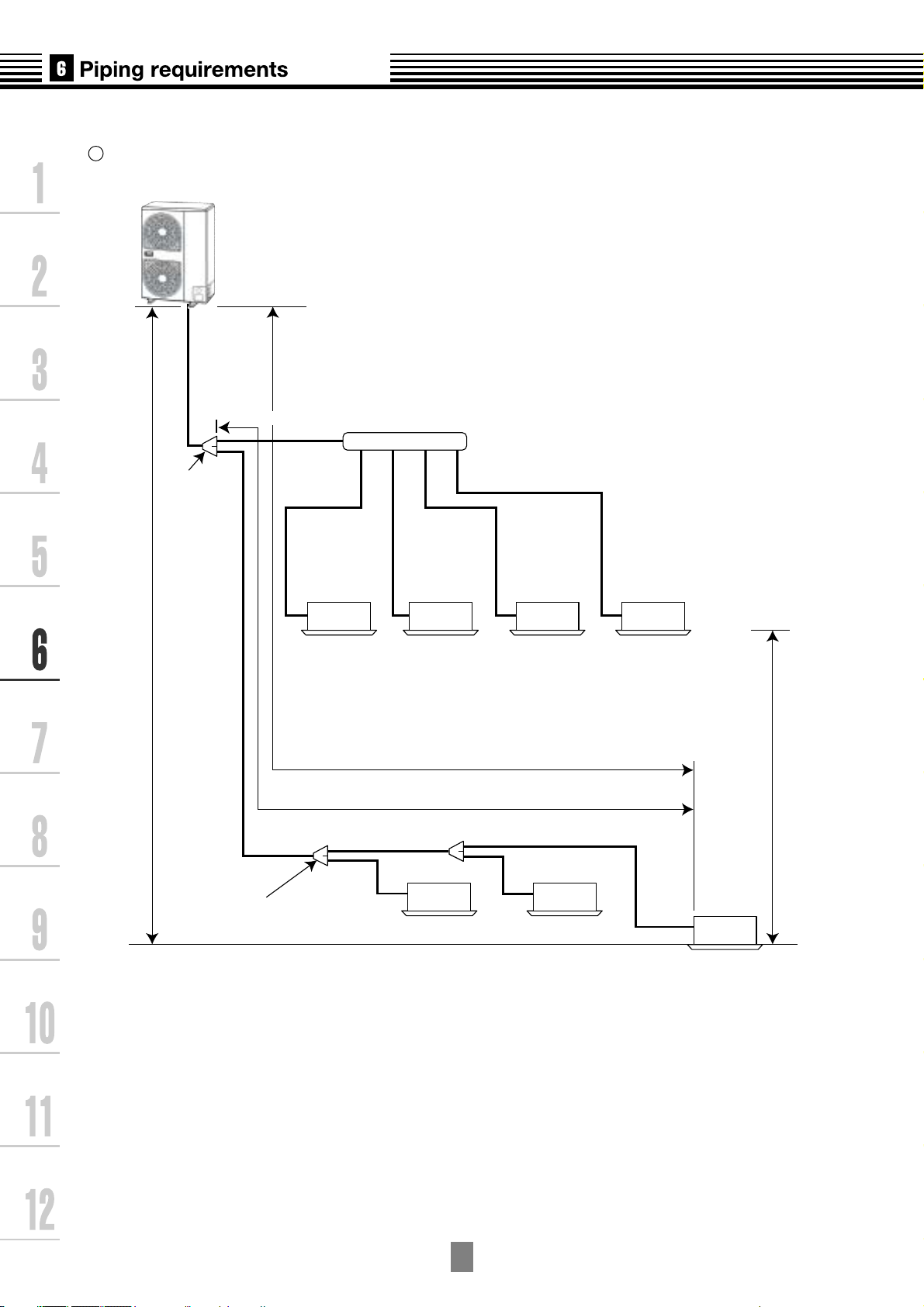

6-2. Refrigerant piping length and piping size

A

Outdoor unit

Main

pipe

Branching header

Branching

pipe

Height

difference

between

Indoor and

outdoor unit

Equivalent length corresponded to farthest piping

Equivalent length corresponded to farthest piping after 1st branching Li

Indoor unit

Y-shape

branching joint

Height difference

between indoor units

1st branching

section

L2

L3

L4

L

ef

g

H1

H2

L1

ab cd

Branching pipe

Allowable length and height difference of refrigerant piping

1

Loading...

Loading...