Page 1

TX Platform

For TX Compact Utility Loaders

Model No. 22475 —Serial No. 270000001 and Up

Model No. 22476 —Serial No. 270000001 and Up

Form No. 3356-522 Rev A

Installation Instructions

Safety

General Operation

• Do not modify the platfor m or use it on

non–appro v ed mac hines .

• Ensure that the platfor m is properly attac hed

to the mac hine and is in g ood w orking order

prior to use .

• Allo w only the mac hine operator on the

platfor m.

• Do not allo w use of the platfor m b y untrained

operators .

• Use appropriate personal protecti v e apparatus

for eyes , feet, hands , and head.

• Look behind and do wn before bac king up to

be sure of a clear path. Use extra care when

operating in rev erse .

• Dismount and latc h the platfor m in the

transpor t position when loading and unloading

the mac hine .

• Do not place y our feet under the platfor m.

• Slo w do wn before tur ning . Shar p tur ns on any

ter rain ma y cause loss of control.

• Do not ste p off of the platfor m with the load

raised.

the unit in areas where there is sufficient

clearance for the operator to safely maneuv er

the platfor m.

• Ensure that the area is clear of other people

before operating the traction unit with the

platfor m. Stop the traction unit if any one

enters the area.

• Do not ex ceed the rated operating capacity , as

the traction unit with the platfor m ma y become

unstable whic h ma y result in loss of control.

Service

• Stop the engine before perfor ming any ser vice ,

re pairs , maintenance , or adjustments .

• K ee p n uts and bolts tight. K ee p equipment

clean and in g ood condition.

• Nev er tamper with safety devices . Chec k safety

systems for proper operation before eac h use .

• Stop and inspect the equipment if y ou strik e

an object. Mak e any necessar y re pairs before

restar ting .

• Use only g en uine re placement par ts to ensure

that original standards are maintained.

• K ee p y our hands , feet, hair , and loose clothing

a w a y from any mo ving par ts .

• Do not tr y to stabilize the traction unit b y

putting y our foot on the g round.

• Do not operate platfor m on rough and unev en

ter rain.

• Ensure that y ou operate the platfor m in areas

where there are no obstacles in close pro ximity

to the operator . F ailure to maintain adequate

distance from trees , w alls , and other bar riers

ma y result in injur y as the platfor m bac ks up

or tur ns during operation if the operator is not

attenti v e to the sur roundings . Only operate

© 2006—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Register at www.Toro.com. Original Instructions (EN)

Printed in the USA.

All Rights Reserved

Page 2

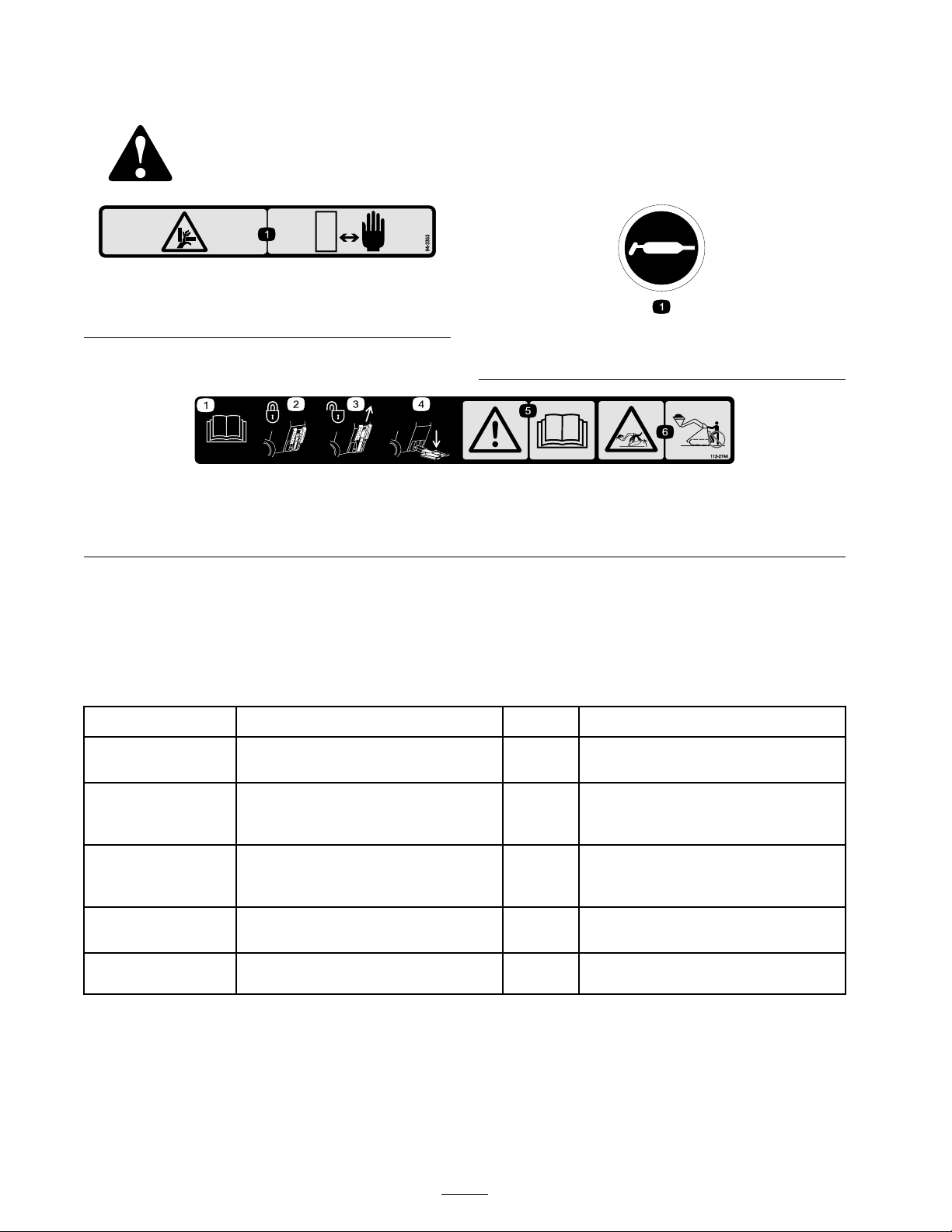

Safety and Instructional Decals

Safety decals and instr uctions are easily visible to the operator and are located near any

area of potential dang er . R e place any decal that is damag ed or lost.

94-3353

1. Crushing hazard of hand—keep your hands a safe distance

away.

112-2744

1. Read the Operator’s Manual.

2. Platform locked in storage position. 4. Lower the platform from the unlocked

3. Lift the platform up to unlock.

position to use.

58-6520

1. Grease

5. Warning—read the Operator’s Manual.

6. Tipping hazard—do not step off the

platform with a raised load.

Installation

Loose Parts

Use the chart below to verify that all parts have been shipped.

Step

1

2

3

4

5

No parts required

Platform assembly

Bolt (1/2 x 1-1/2 inches)

Flange-head nut (1/2 inch)

Counterweight

Bolt (1/2 x 1-1/4 inches)

Washer

Decal 112-2744

Handle

Flange-head bolts (5/16 x 3/4 inch)

Description

Qty.

–

1

4

4

1

4

4

1

1

2

Prepare the traction unit.

Install the platform.

Install the counter weight (TX 500

series traction units only).

Install the decal.

Install the handle.

Use

2

Page 3

Step

Step

1

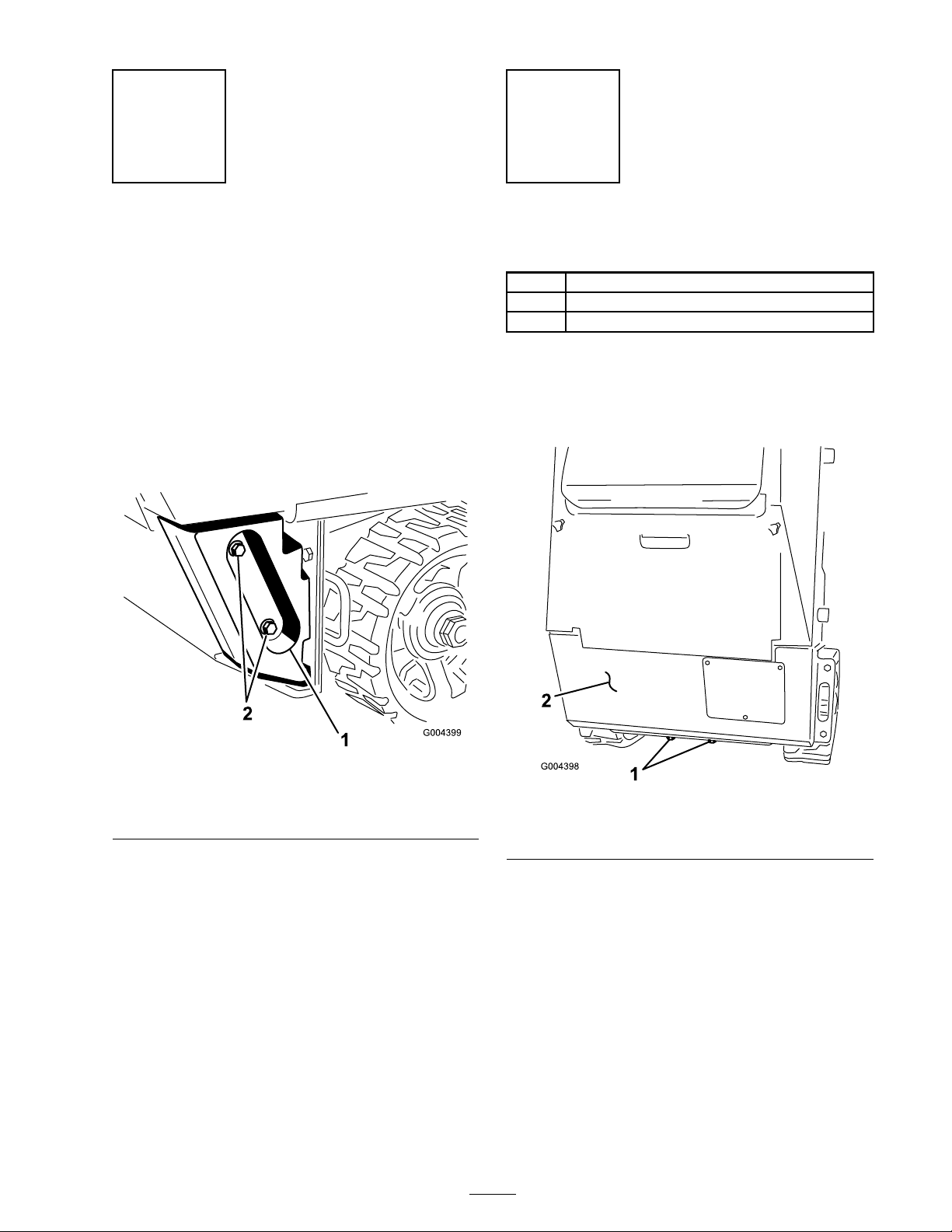

Preparing the Traction Unit

No Parts Required

Procedure

1. Stop the engine , lo w er the loader ar ms , set the

parking brak e , and remo v e the k ey .

2. W ash all dir t and debris from the traction unit.

3. If y ou are installing this kit on a TX 400 series

traction unit, remo v e the counterw eights and

their fasteners from the rear of the traction

unit and store them in a safe location ( Figure 1 )

2

Installing the Platform

Parts needed for this step:

1

Platform assembly

4

Bolt (1/2 x 1-1/2 inches)

4

Flange-head nut (1/2 inch)

Procedure

1. Chec k and tighten the bottom 2 bolts securing

the lo w er rear panel to the frame ( Figure 2 ).

Figure 1

Left counterweight not shown

1. Counterweight

2. Fasteners

1. Bolts

2. Rear panel ( do not remove )

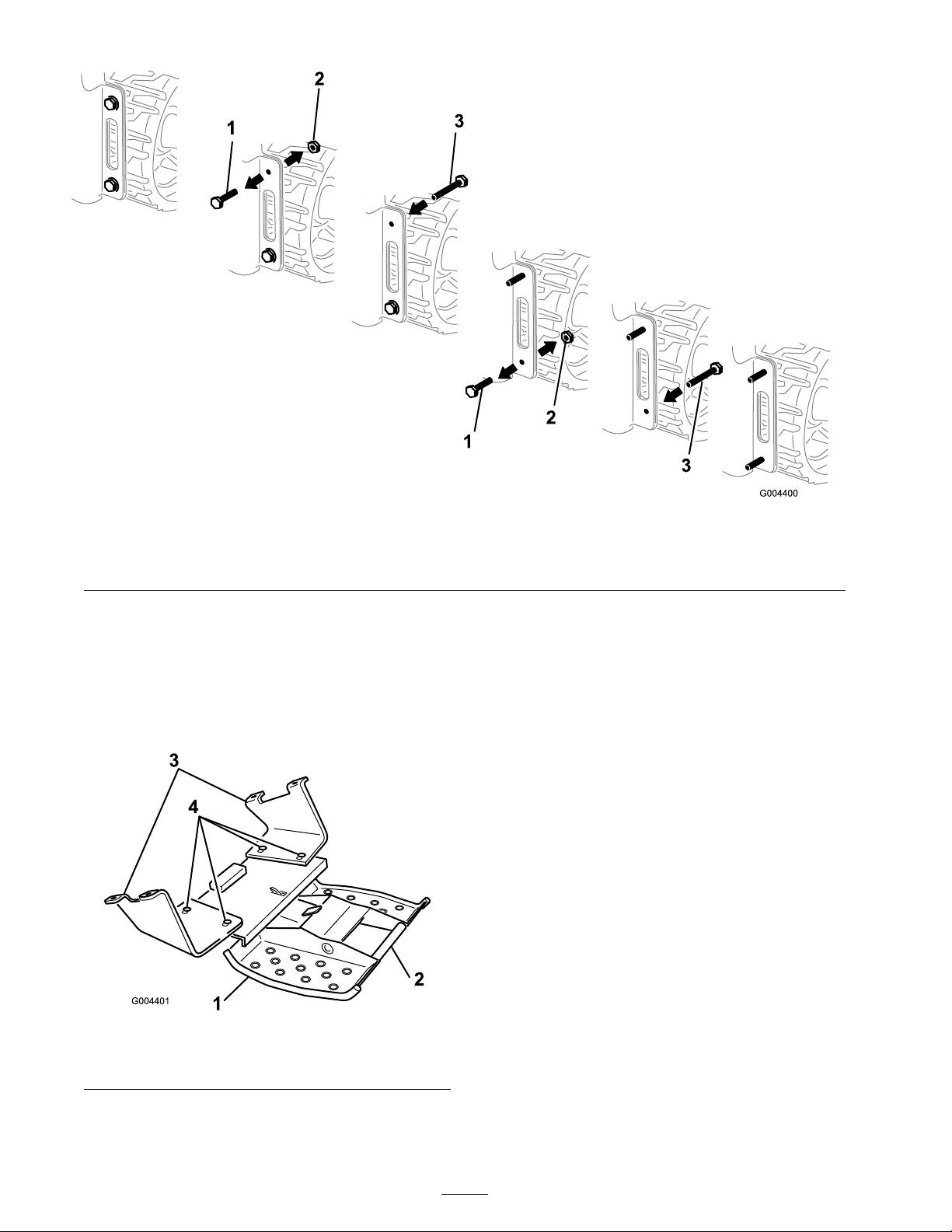

2. One at a time , remo v e and discard the 4 bolts

and n uts securing sides of the lo w er rear panel

to the frame , re placing eac h with a new bolt

(1/2 x 1-1/2 inc hes) installed from the front to

hold the space as pressure is released on the

rear panel ( Figure 3 ).

Important: Do not r emo v e the r ear

panel ( Figur e 2 ).

3

Figure 2

Page 4

Figure 3

Left side not shown

1. Bolt (2 on each side) 2. Flange-head nut (2 on each side) 3. Bolt (1/2 x 1-1/2 inches)

Note: Figure 3 sho ws a TX 500 series

traction unit. If y ou ha v e a TX 400 series

traction unit it will look slightly different, but it

is configured similarly .

3. Grab the platfor m handle and pull up on it to

extend the platfor m ( Figure 4 ).

Figure 4

1. Platform assembly 3. Mounting bracket

2. Handle 4. Loosen these bolts

4. By hand, loosen, but do not remo v e , the 4

bolts and n uts securing the platfor m assembly

to the mounting brac k ets ( Figure 4 ).

5. Install the mounting brac k ets onto the 4 bolts

(1/2 x 1-1/2 inc hes) y ou inser ted earlier and

secure then with 4 flang e-head n uts (1/2 inc h)

( Figure 5 ).

4

Page 5

1. Flange-head nut (1/2 inch)

6. T or que the flang e-n uts to 67 to 83 ft-lb (91 to

113 N ⋅ m).

7. Align the platfor m so that it is centered on

the mac hine , then tor que the 4 bolts and

n uts securing the platfor m assembly to the

mounting brac k ets to 67 to 83 ft-lb (91 to 113

N ⋅ m) ( Figure 4 ).

Figure 5

2. Platform

5

Page 6

Step

Step

3

Installing the

Counterweight (TX 500

Series Traction Units Only)

Parts needed for this step:

1

Counterweight

4

Bolt (1/2 x 1-1/4 inches)

4

Washer

Procedure

If y ou are installing this kit on a TX 500 series

traction unit, install the counterw eight to the front

of the traction unit using 4 bolts (1/2 x 1-1/4

inc hes) and w ashers ( Figure 6 ). Apply a loc king

compound to the threads of the bolts before

installing them. T or que the bolts to 54 to 66 ft-lb

(73 to 89 N ⋅ m).

4

Installing the Decal

Parts needed for this step:

1

Decal 112-2744

Procedure

1. Clean the area behind the traction control

( Figure 7 ) so that there is not dir t or g rease

on it.

Figure 6

1. Bolt (1/2 x 1-1/4 inches)

2. Washer 4. Mounting holes

3. Counterweight

Figure 7

1. Decal position

2. R emo v e the bac king from the decal and secure

it in place ( Figure 7 ).

Note: T o k ee p from g etting bubbles under

the decal, press it do wn in the center first and

r ub it outw ard to w ard the edg es .

6

Page 7

Step

5

Installing the Handle

Parts needed for this step:

1

Handle

2

Flange-head bolts (5/16 x 3/4 inch)

Procedure

1. R emo v e the rear access co v er; refer to y ou

traction unit Operator’ s Manual for instr uctions .

2. Locate and drill 2 holes (3/8 inc h diameter) on

the control panel belo w the loader ar m lev er ,

as sho wn in Figure 8 .

Note: If the holes already exist, skip this ste p .

Figure 9

1. Handle

2. Control panel

3. Flange-head bolt (5/16 x

4. Install the rear access co v er .

3/4 inch)

Figure 8

1. 55/64 inch 3. 2 inches

2. 5-3/4 inches 4. Drill 3/8 inch diameter

holes

3. Secure the handle to the control panel using 2

flang e-head bolts (5/16 x 3/4 inc h) installed

from the inside ( Figure 9 ).

7

Page 8

Operation

If y ou step of f of the platf or m with a hea vy

load raised, the machine could tip f orw ard

quickl y , injuring y our and/or pinning

bystander s.

Do not step of f of the platf or m with the load

raised.

Unless y ou ar e car r ying hea vy loads or

attachments, the platf or m with an operator

will mak e the r ear of the machine the hea vy

end.

Al w ays k eep the hea vy end of the machine

uphill when operating on slopes.

Figure 10

T o unfold the platfor m, pull up on it until the latc h

releases and then swing it out and do wn ( Figure

11 ).

Y ou could f all of f of the platf or m and be

seriousl y injur ed during operation.

Do not mo v e the contr ols unless y ou ar e

standing with both feet on the platf or m and

y our hands ar e holding the handles.

Folding/Unfolding the

Platform

T o fold the platfor m, lift up on the bac k of it

and swing it to w ards the traction unit ( Figure 10 ).

W hen the latc h contacts the mounting plate , the

platfor m will slide do wn into the tube and will

loc k in place .

Figure 11

Using the Platform

T o use the platfor m, ste p onto it before star ting

the mac hine . Fully stop the mac hine and apply the

parking brak e before g etting off of the platfor m.

Use the reference bar and handle to stabilize

y ourself while riding on the platfor m.

8

Page 9

Maintenance

Greasing the Platform

Grease all pi v ot joints ev er y 8 operating hours and

immediately after ev er y w ashing .

Grease T ype: General-pur pose g rease .

1. Lo w er the loader ar ms and stop the engine .

R emo v e the k ey .

2. Clean the g rease fittings with a rag .

3. Connect a g rease gun to eac h fitting ( Figure

12 ).

Checking the Shear Bolt

Chec k the shear bolt ( Figure 13 ) for w ear , crac ks ,

or damag e ev er y 8 operating hours . R e place it if

it is damag ed.

Important: Use onl y a gen uine T or o

r eplacement shear bolt and n ut. Other bolts

will not function cor r ectl y and may lead to an

unsafe condition.

Figure 13

1. Shear bolt

Figure 12

4. Pump g rease into the fittings until g rease

begins to ooze out (appro ximately 3 pumps).

5. Wipe up any ex cess g rease .

9

Page 10

Page 11

Page 12

The Toro Compact Utility Loader Product

Line Warranty

A One-Year Limited Warranty

Conditions and Products Covered

The Toro® Company and its afliate, Toro Warranty Company, pursuant

to an agreement between them, jointly warrant your Toro Dingo Product

(“Product”) to be free from defects in materials or workmanship. The

following time periods apply from the date the Product is delivered to

the original retail purchaser:

Products Warranty Period

All traction units and

attachments

All engines

Where a warrantable condition exists, we will repair the Product at no

cost to you including diagnosis, labor, and parts.

1 year or 1000 operational hours,

whichever occurs rst

2 years

Instructions for Obtaining Warranty Service

If you think that your Toro Product contains a defect in materials or

workmanship, follow this procedure:

1. Contact any Authorized Dingo Service Dealer to arrange service

at their dealership. To locate a dealer convenient to you, access

our website at www.Toro.com. U.S. Customers may also call

800-348-2424.

2. Bring the product and your proof of purchase (sales receipt) to the

Service Dealer.

If for any reason you are dissatised with the Service Dealer’s analysis or

with the assistance provided, contact us at:

LCB Customer Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Toll Free: 888-577-7466 (U.S. customers)

Toll Free: 877-484-9255 (Canada customers)

Owner Responsibilities

You must maintain your Toro Product by following the maintenance

procedures described in the Operator’s Manual . Such routine

maintenance, whether performed by a dealer or by you, is at your

expense. Parts scheduled for replacement as required maintenance

(“Maintenance Parts”), are warranted for the period of time up to the

scheduled replacement time for that part. Failure to perform required

maintenance and adjustments can be grounds for disallowing a warranty

claim.

Items and Conditions Not Covered

Not all product failures or malfunctions that occur during the warranty

period are defects in materials or workmanship. This express warranty

does not cover the following:

• Product failures which result from the use of non-Toro replacement

parts, or from installation and use of add-on, modied, or

unapproved accessories

• Product failures which result from failure to perform required

maintenance and/or adjustments

• Product failures which result from operating the Product in an

abusive, negligent or reckless manner

• Parts subject to consumption through use unless found to be

defective. Examples of parts which are consumed, or used up, during

normal Product operation include, but are not limited to, digging

teeth, tines, spark plugs, tires, tracks, lters, chains, etc.

• Failures caused by outside inuence. Items considered to be outside

inuence include, but are not limited to, weather, storage practices,

contamination, use of unapproved coolants, lubricants, additives, or

chemicals, etc.

• Normal “wear and tear” items. Normal “wear and tear” includes,

but is not limited to, worn painted surfaces, scratched decals or

windows, etc.

• Any component covered by a separate manufacturer’s warranty

• Pickup and delivery charges

General Conditions

Repair by an Authorized Toro Service Dealer is your sole remedy under

this warranty.

Neither The Toro® Company nor Toro Warranty Company is liable for

indirect, incidental or consequential damages in connection with the

use of the Toro Products covered by this warranty, including any cost or

expense of providing substitute equipment or service during reasonable

periods of malfunction or non-use pending completion of repairs under

this warranty.

Some states do not allow exclusions of incidental or consequential

damages, or limitations on how long an implied warranty lasts, so the

above exclusions and limitations may not apply to you.

This warranty gives you specic legal rights, and you may also have other

rights which vary from state to state.

Except for the Emissions warranty referenced below, if applicable, there is

no other express warranty. All implied warranties of merchantability and

tness for use are limited to the duration of this express warranty.

Note to California residents: The Emissions Control System on your

Product may be covered by a separate warranty meeting requirements

established by the U.S. Environmental Protection Agency (EPA) or the

California Air Resources Board (CARB). The hour limitations set forth above

do not apply to the Emissions Control System Warranty. Refer to the

California Emission Control Warranty Statement printed in you operator’s

manual or contained in the engine manufacturer’s documentation for

details.

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer) to obtain

guarantee policies for your country, province, or state. If for any reason you are dissatised with your Distributor’s service or have difculty obtaining

guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty Company.

Rev

Loading...

Loading...