Page 1

WARRANTY.....Top Flite Models guarantees this kit to be free of defects in both

materials and workmanship at the date of purchase. This warranty does not cover any component parts

damaged by use or modification. In no case shall Top Flite’s liability exceed the original cost of the

purchased kit. Further, Top Flite reserves the right to change or modify this warranty without notice.

In that Top Flite has no control over the final assembly or material used for final assembly, no

liability shall be assumed nor accepted for any damage resulting from the use by the user of the final

user-assembled product. By the act of using the user-assembled product the user accepts all

resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the

buyer is advised to immediately return this kit in new and unused condition to the place of purchase.

Top Flite Models

P.O. Box 721

Urbana, IL 61801

Technical Assistance - Call (217) 398-8970

CES6 V1.2.5

READ THROUGH THIS INSTRUCTION BOOK FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

™

Entire Contents © Copyright 1994

Page 2

INTRODUCTION........................................... 3

PRECAUTIONS ............................................ 4

DECISIONS YOU MUST MAKE EARLY

IN THE BUILDING SEQUENCE................... 4

Engine Selection........................................... 4

Flaps............................................................. 4

Operational Lighting ..................................... 5

Notes for Competition-Minded Modelers...... 5

Documentation ............................................. 5

Other Items Required .................................. 5

Suggested Supplies and Tools ..................... 5

Common Abbreviations................................ 6

Metric Conversions....................................... 6

Types of Wood.............................................. 6

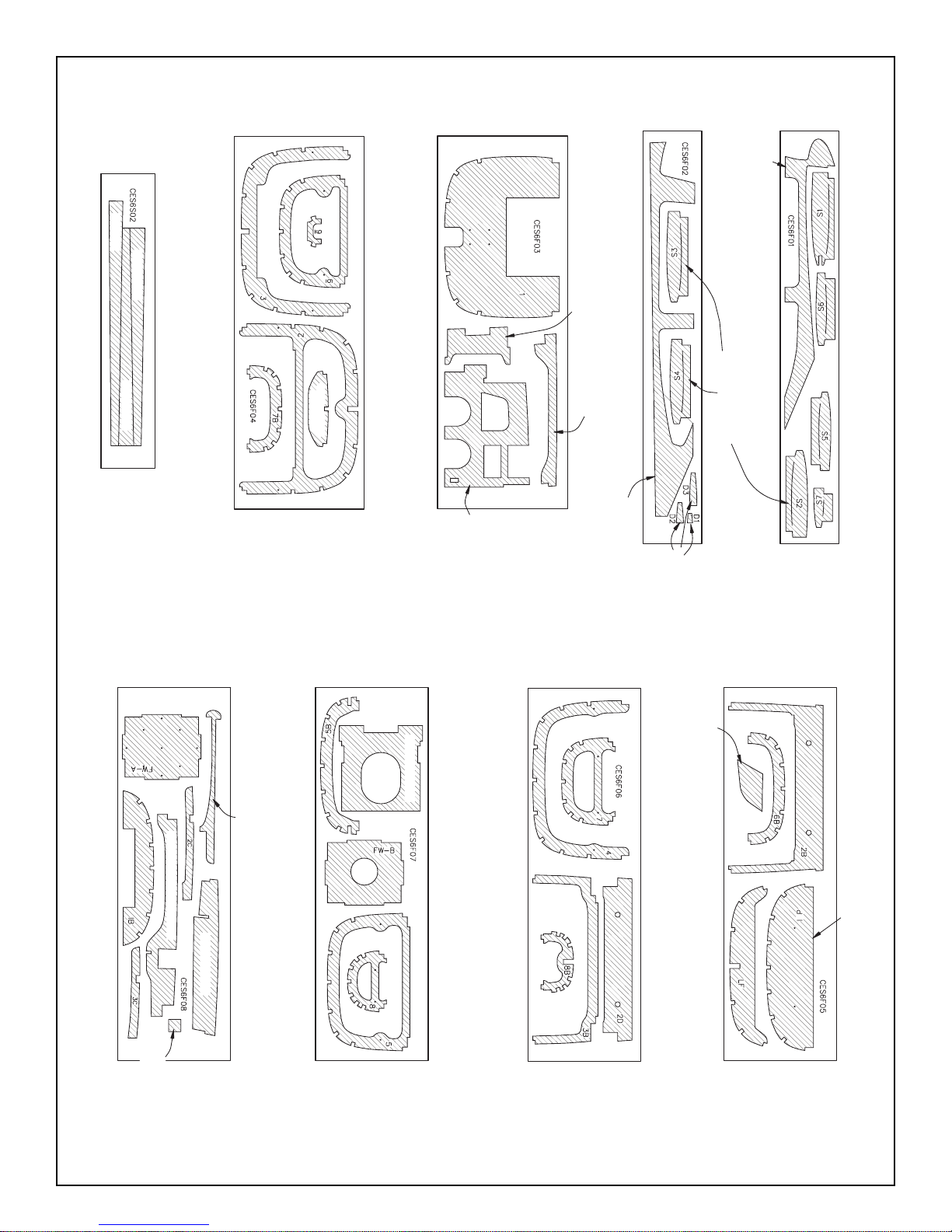

DIE-CUT PATTERNS ................................7&8

Get Ready to Build ....................................... 9

BUILD THE TAIL SURFACES ...................... 9

Build the Horizontal Stabilizer....................... 9

Tips for Making Wing & Stab Skins.............10

Build the Elevators.......................................12

Build the Fin.................................................14

Build the Rudder..........................................15

BUILD THE WING........................................16

Build the Center Section..............................16

Build Outer Wing Panels .............................18

Prepare the Polyhedral Braces....................20

Join the Wing Panels...................................21

Sheet the Bottom of the Wing......................22

Prepare the Wing Panels for the Flaps........24

Sheet the Top of the Wing ...........................24

Wing Completion.........................................25

Build the Flaps.............................................27

Fit the Flaps.................................................27

BUILD THE FUSELAGE..............................28

Build the Fuselage Bottom Frame...............28

Sheet the Fuselage Bottom Frame..............31

Fuel Proof and Paint the interior..................33

Install Pushrods and Servos........................33

Frame the Fuselage Top..............................33

Install Nose Gear Steering ..........................35

Install the Engine and Tank .........................36

1.20 Engine Servo Option ...........................37

Attach the Stab and Fin...............................37

Tips for Silver Soldering ..............................39

Complete the Fuse Top ...............................39

Mount the Wing to the Fuselage..................41

HINGE THE CONTROL SURFACES...........42

Hinge the Elevator, Rudder & Ailerons........42

FUSELAGE FINISHING TOUCHES............43

Assemble the Cowl......................................44

Fit the Cowl to the Fuse and Engine ...........44

Assemble and Install Wheel Pants..............45

Install Wing Struts and Fairings...................47

FINISHING ...................................................47

Final Sanding...............................................47

Fuel Proofing...............................................47

Balance the Airplane Laterally.....................47

Cover the Structure with MonoKote

®

...........48

Painting........................................................49

Draw Door and Hatch Outlines....................49

Apply the Decals..........................................49

Cockpit Finishing.........................................50

Install Control Surface Corrugations............50

FINAL HOOKUPS AND CHECKS...............51

Flap and Aileron Control Hookup ................51

Install Receiver, Battery, and Antenna.........51

Control Surface Throws...............................52

Balance your Model.....................................52

PRE-FLIGHT................................................53

AMA SAFETY CODE...................................54

FLYING.........................................................54

Balance the Propeller..................................54

Takeoff.........................................................55

Flying...........................................................55

Landing........................................................55

TWO-VIEW DRAWING.................Back Cover

2

TABLE OF CONTENTS AND BUILDING SEQUENCE

Page 3

Your Cessna 182 Skylane is not a toy, but

rather a sophisticated, working model that

functions very much like an actual airplane.

Because of its realistic performance, the

Skylane, if not assembled and operated

correctly, could possibly cause injury to yourself

or spectators and damage property.

To make your R/C modeling experience

totally enjoyable, we recommend that you get

experienced, knowledgeable help with

assembly and during your first flights. You’ll

learn faster and avoid risking your model before

you’re truly ready to solo. Your local hobby shop

has information about flying clubs in your area

whose membership includes qualified instructors.

You can also contact the national Academy of

Model Aeronautics (AMA), which has more than

2,300 chartered clubs across the country.

Instructor training programs and insured

newcomer training are available through any one

of them.

Contact the AMA at the address or toll-free

phone number below.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

(800) 435-9262

Thank you for purchasing the Top Flite

GOLD

EDITION

Cessna 182 Skylane.

The Top Flite 182 Skylane makes an

excellent sport scale competition aircraft. Its

large size and accurate scale outline afford the

opportunity for the scale builder to

go all out

with

the surface details and finish. With the

abundance of Cessna 182s in airports around

the world, finding a full-scale plane to document

and duplicate for competition shouldn’t present a

problem.

The Top Flite Cessna 182 has demonstrated

flight characteristics rarely found in any scale

model. Anyone who has mastered a trainer with

ailerons should be able to fly this model

with a high level of proficiency from the first

flight. It handles very much like a full-size

Cessna—

smooth and predictable

. Our 11 pound

prototype was flown with an O. S. .61SF

2-stroke and 12 x 6 prop throughout much of its

flight testing. This combination provided more

than ample power for all normal flight maneuvers

and aerobatics.

Because of its 81” wingspan, the Top Flite

Cessna 182 is eligible to be entered at IMAA*

events. In order to be IMAA

-legal,

some of the

control components and hardware may need to

be replaced to conform to Giant Scale rules

even though

this

model does not require heavy

duty hookups.

The cockpit interior has been engineered to

be free of obstructions, servos and pushrods.

This feature provides the modeler with the space

to build a scale interior with front and rear seats,

baggage compartment, and full figure pilot.

Simulated Fowler Flaps allow beautifully slow

approaches and landings. Half flap takeoffs

require less ground roll to rotate and allow a

fairly steep climb over obstacles.

The nose of this model has been engineered

to allow you to completely hide most 2-stroke

engines in the recommended range. A Top Flite

2-stroke muffler with headers to fit several of the

recommended engines have been specifically

designed for and tested in the Skylane and other

Top Flite models. This muffler provides good

sound reduction while fitting entirely inside the

cowling. More information on the recommended

engines and related items can be found in the

Engine Selection Section

on page 4.

* IMAA is the

International Miniature Aircraft

Association

, an organization that promotes

non-competitive flying of giant scale models.

IMAA

International Miniature Aircraft Association

205 S. Hilldale Road

Salina, KS 67401

Please inspect all parts carefully before

starting to build! If any parts are missing,

broken or defective, or if you have any

questions about building or flying this

model, please call us at (217) 398-8970 and

we’ll be glad to help. If you are calling for

replacement parts, please look up the part

numbers and the kit identification number

(stamped on the end of the carton) and have

them ready when calling.

INTRODUCTION

PROTECT YOUR

MODEL, YOURSELF &

OTHERS – FOLLOW

THIS IMPORTANT

SAFETY PRECAUTION

3

Page 4

1. You must build the plane according to the

plans and instructions. Do not alter or modify

the model, as doing so may result in an unsafe

or unflyable model. In a few cases the plans

and instructions may differ slightly from the

photos. In those instances you should

assume the plans and written instructions

are correct.

2. You must take time to build straight, true

and strong.

3. You must use a proper R/C radio that is in

first-class condition, a correctly-sized engine

and correct components (fuel tank, wheels,

etc.) throughout your building process.

4. You must properly install all R/C and other

components so that the model operates properly

on the ground and in the air.

5. You must test the operation of the model

before the first and each successive flight to

ensure that all equipment is operating, and you

must make certain that the model has remained

structurally sound. Be sure to check external

nylon clevises often and replace them if they

show signs of wear.

6. You must fly the model only with the

competent help of a well experienced R/C pilot if

you are not already an experienced R/C pilot at

this time.

Remember: Take your time and follow

directions to end up with a well-built model

that is straight and true.

The prototype Skylane that weighed 11

pounds with all of the options, including flaps

and operational lighting, was flown with an OS

.61 SF. This engine provided excellent

performance and more than enough power,

even in gusty winds. Although larger engines

can be used to power this model, the extra

horsepower is not needed.

The included adjustable engine mount will

hold a range of engines from .60 2-stroke

through 1.20 4-stroke.

A special Top Flite header and muffler are

available that will fit inside your cowling. They

are primarily designed for 2-stroke engines

mounted horizontally, as used on our prototype.

Header for O.S .61SF (TOPQ7920)

Header for SuperTigre S61K, S75K

(TOPQ7925)

Muffler for above (TOPQ7916)

OPTIONAL FLAPS

This model is designed to incorporate

scale flaps; however, be assured that flaps are

optional and not necessary for an excellent

flying experience. The only difference is,

without flaps the takeoff roll is a little longer

and the landing speed is slightly faster.

The flaps are not difficult to assemble, but

they do require good craftsmanship if they are to

fit well. They add nicely to the model’s flight

characteristics and scale appearance while

causing no bad effects. Only slight trim correction

is needed when they are used with the

recommended throws. The flaps add drag and lift

to the model on landing approaches, which gives

the plane a very steady , loc k ed-in f eel.

ENGINE SELECTION

The recommended engine size range is as

follows:

.60 to .91 cu. in. 2-stroke

.90 to 1.20 cu. in. 4-stroke

The Cessna 182 Skylane will fly well with

any of the recommended engines. The

4-stroke engines and most .90 2-stroke

engines will turn a larger prop at lower rpm.

This is often desirable for scale realism. Many

.60 2-stroke engines produce about as much

horsepower as the popular .90 2-stroke

engines. Both are fine choices for the Skylane.

If you use a .60 2-stroke, a Schnuerle-ported

engine is preferred.

DECISIONS YOU MUST

MAKE EARLY IN THE

BUILDING SEQUENCE

NOTE: We, as the kit manufacturer, can

provide you with a top quality kit and great

instructions, but ultimately the quality and

flyability of your finished model depends on

how you build it; therefore, we cannot in any

way guarantee the performance of your

completed model, and no representations are

expressed or implied as to the performance or

safety of your completed model.

PRECAUTIONS

4

Page 5

If you plan to compete with the trim scheme

shown on the box, here are a few things

to consider:

The full-size Cessna 182 “Q” Skylane,

N735PE, that was modeled for this kit is

hangered near Birmingham, Alabama. The

182Q version was manufactured from 1977

through 1980. During this time 2,540 were built.

We designed our model from Cessna’s own

1979 3-view drawings for accurate scale outline.

If you plan to enter your Skylane in

competition, this kit will qualify for the Sport

Scale categor y without any changes. Always

work from photos of a full-size aircraft when

finishing your model because that is what you

will need for judging documentation. For

dimensional accuracy, the Top Flite Cessna 182

is exactly 1:5

1

¼3

scale.

❏ 4 to 6 channel radio with 5 to 7 servos.

❏ Engine (see page 4)

❏ Propellers (see engine instructions for

recommended sizes).

❏ 1 or 2 Pilot figures (1/5 scale recommended)

❏ Fuel Tank (Great Planes

®

12 oz. GPMQ4105

recommended)

❏ 3-1/4” Main Wheels (2) (Dubro 325T)

❏ 2-3/4” Nose wheel (1) (Dubro 275T)

❏ (2) 3/16” Wheel Collars (Great Planes

GPMQ4308 recommended)

❏ Top Flite Super MonoKote

®

(3-4 rolls, See

Finishing

section)

❏ Paint (see

Finishing

section)

❏ 24” Silicone Fuel Tubing (Great Planes

GPMQ4131 recommended)

❏ 1/2” Latex Foam Rubber Padding (Hobbico

®

HCAQ1050 recommended)

❏ 2-1/4” Spinner

(Top Flite TOPQ5405 recommended)

Optional:

❏ Fuel Filler Valve (Great Planes GPMQ4160

recommended)

❏ (6) Large Hinge Points (for flaps) (Robart

#309 recommended)

❏ Top Flite Header & In-Cowl Muffler (See

page 4 for more information)

Optional Lighting:

❏ Ram #03 Landing Lights (RAMQ2303)

❏ Ram #04 Rotating Beacon (RAMQ2304)

❏ Ram #14 Big Airplane Navigation Lights

(RAMQ2314)

We recommend Top Flite Supreme™CAs

and Epoxies

❏ (2) 2 oz. CA (Thin) (TOPR1003)

❏ (2) 2 oz. CA+(Medium) (TOPR1008)

❏ 1 oz. CA- (Thick) (TOPR1011)

❏ 6-Minute Epoxy (TOPR1040)

❏ 30-Minute Epoxy (TOPR1043)

❏ Titebond

®

Wood Glue (optional)

❏ Hand or Electric Drill

❏ Drill Bits: 1/16”, 3/32”, 1/8”, 5/32”, 3/16”,

13/64”, 1/4”, 15/64”

❏ Soldering Iron and Silver Solder

❏ Sealing Iron (Top Flite)

❏ Heat Gun (Top Flite)

❏ Hobby Saw (X-ACTO

®

Razor Saw)

❏ Hobby Knife, #11 Blades

❏ Razor Plane (Master Airscrew)

❏ Pliers

❏ Screwdrivers (Phillips and flatblade)

❏ Round file (or similar tool)

❏ T-Pins (short & long)

❏ String

❏ Straightedge with scale

SUGGESTED SUPPLIES AND TOOLS

OTHER ITEMS REQUIRED

DOCUMENTATION

Three-view drawings and photo packs of

N735PE and other Cessna 182’s are available

from:

Scale Model Research,

3114 Yukon Ave, Costa Mesa, CA 92626

(714) 979-8058

NOTES FOR COMPETITION

MINDED MODELERS

The flaps require one extra channel, a

Y-harness, and two standard servos. They are

a highly recommended

fun option

for those who

wish to install them. More information on the

use of the flaps may be found in the “Flying”

section.

OPERATIONAL LIGHTING

We installed an operational lighting system

for added realism and scale appearance. If you

plan to use a similar system you should route

the wiring before enclosing the wing and fin.

In lieu of installing the actual wires, string can

be taped into position for use in pulling the

wires through the structure after covering. We

used a separate servo connected to the

retract

circuit of the radio (instead of “Y-ing” into the

flap servo) to operate the landing lights. The

rotating beacon and position lights were

connected to a hidden toggle switch. (See

Optional Lighting

in the next section)

5

Page 6

❏ Nylon Strapping Tape

(required for bending sheeting)

❏ Masking Tape (required for construction)

❏ Sandpaper (coarse, medium, fine grit)*

❏ T-Bar Sanding Block (or similar)

❏ Chalk Stick (local drug store)

❏ Waxed Paper

❏ Thin Cardstock or a File Folder

❏ Lightweight Balsa Filler, such as Hobbico

HobbyLite

™

❏ 1/4-20 and 8-32 Taps and Tap Wrench

❏ Isopropyl Rubbing Alcohol (70%)

❏ Auto Body Filler (Bondo

®

or similar)

❏ Dremel

®

Moto-Tool®or similar (optional)

*NOTE: On our workbench, we have four 11”

T-Bar sanders, equipped with #50, #80, #150

and #220-grit sandpaper. This setup is all that is

required for almost any sanding task. Custom

sanding blocks can be made from balsa for

sanding hard to reach spots. We also keep

some #320-grit wet-or-dry sandpaper handy for

finish sanding before covering.

COMMON ABBREVIATIONS USED IN THIS

BOOK AND ON THE PLANS:

Deg = Degrees

Elev = Elevator

Fuse = Fuselage

LE = Leading Edge (front)

LG = Landing Gear

Lt = Left

Ply = Plywood

Rt = Right

Stab = Stabilizer

TE = Trailing Edge (rear)

”

= Inches

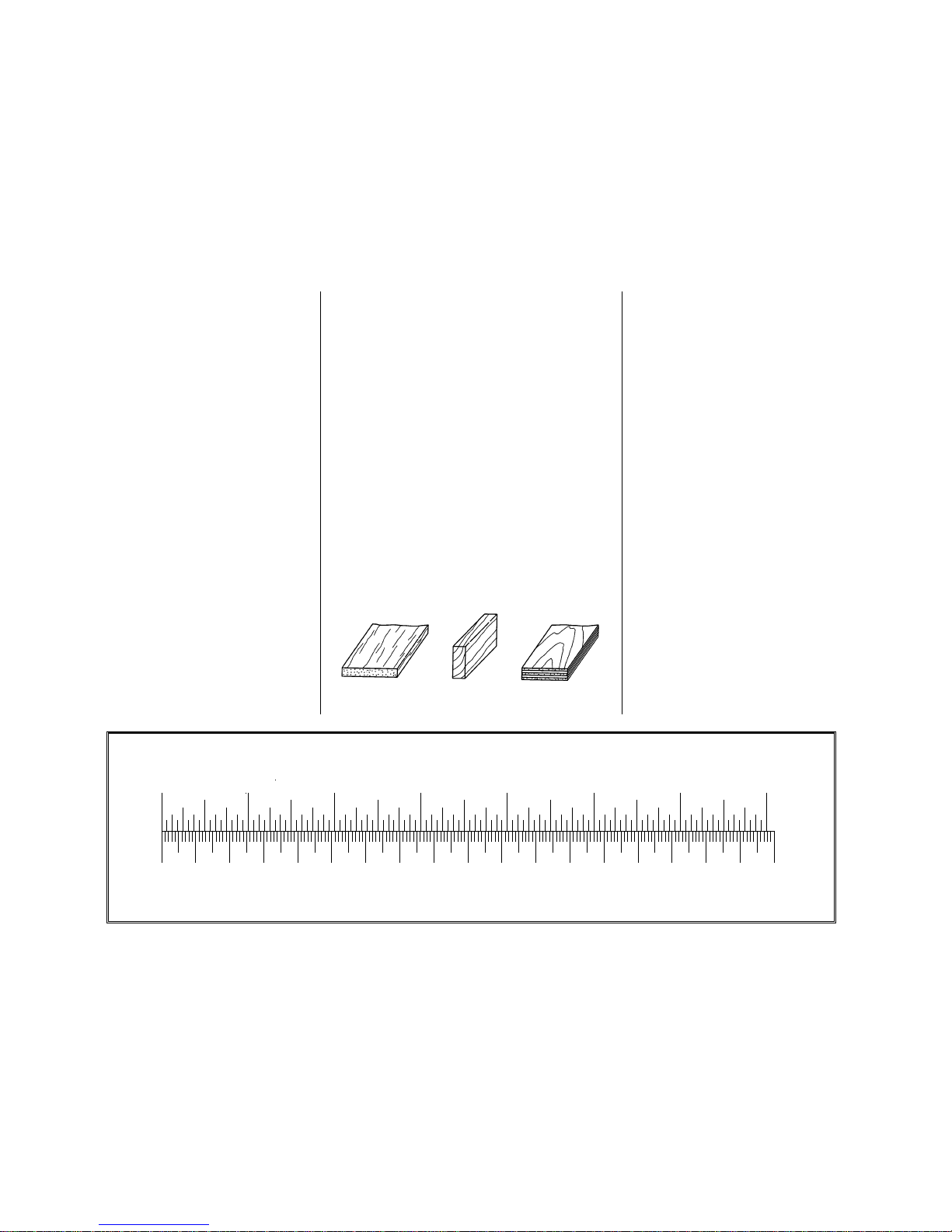

TYPES OF WOOD

BALSA BASSWOOD PLYWOOD

Metric Conversion Chart

Inches x 25.4 = mm (conversion factor)

1/64” = .4 mm

1/32” = .8 mm

1/16” = 1.6 mm

3/32” = 2.4 mm

1/8” = 3.2 mm

5/32” = 4.0 mm

3/16” = 4.8 mm

1/4” = 6.4 mm

3/8” = 9.5 mm

1/2” = 12.7 mm

5/8” = 15.9 mm

3/4” = 19.0 mm

1” = 25.4 mm

2” = 50.8 mm

3” = 76.2 mm

6” = 152.4 mm

12” = 304.8 mm

18” = 457.2 mm

21” = 533.4 mm

24” = 609.6 mm

30” = 762.0 mm

36” = 914.4 mm

6

0" 1" 2" 3" 4" 5" 6" 7"

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

Inch Scale

Metric Scale

Page 7

7

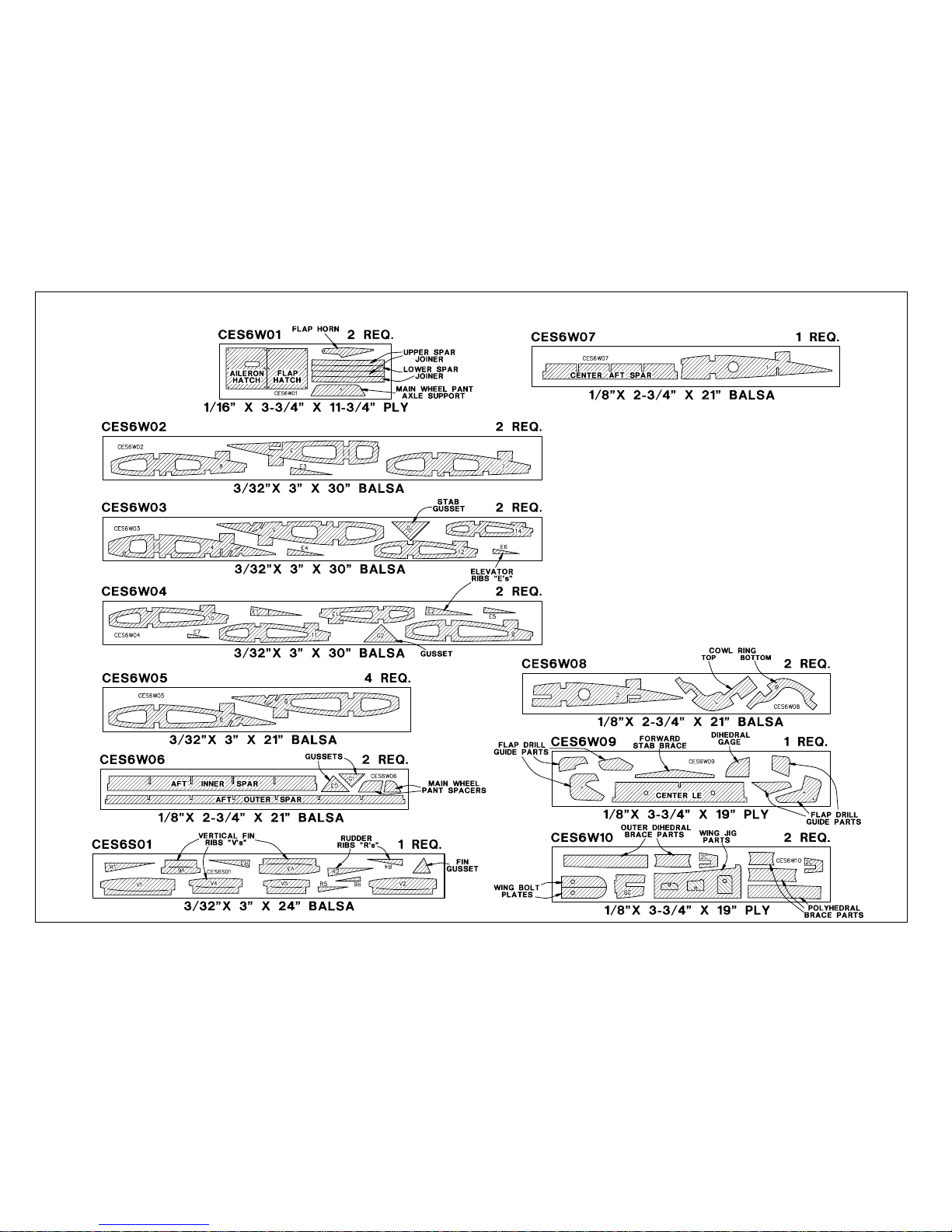

1/4" X 2-3/4" X 15" BALSA

DIE-CUT PATTERNS

FIN TE

STAB TE

CES6S02

STAB TE

1 REQ.

CES6F04

1/8" X 6-5/8" X 19" PLY

NOSE GEAR

DOUBLER

1/8" X 6-5/8" X 19" PLY

CES6F03

3/32" X 3" X 21" BALSA

SIDE SUPPORTS

FIREWALL

WINDOW

FRAME

CES6F02

CABIN SIDE

TOP

3/32" X 3" X 18" BALSA

HORIZONTAL STAB

RIBS “S’s”

CES6F01

1 REQ.

SERVO

TRAY

2 REQ.

2 REQ.

CABIN SIDE

BOTTOM

DORSAL FIN

FORMERS

2 REQ.

CES6F08

1/8" X 5-3/4" X 19" PLY

SADDLE

WING SADDLE BRACE

1/8" X 5-3/4" X 19" PLY

STAB

CES6F07

TANK ROOF

1/8" X 5-3/4" X 19" PLY

CES6F06

GUIDE

1/8" X 5-3/4" X 19" PLY

FIN DRILL

CES6F05

INSTRUMENT PANEL

FUSE KEEL

2 REQ.

REINFORCEMENT

HORN

1 REQ.

1 REQ.

1 REQ.

Page 8

8

DIE-CUT PATTERNS

Page 9

1. Unroll the plan sheets. Re-roll the plans

inside-out to make them lie flat.

2. Remove all parts from the box. As you do,

figure out the name of each part by comparing it

with the plans and the parts list included with this

kit. Using a felt tip or ball point pen, lightly write

the part name or size on each piece to avoid

confusion later. Use the die-cut patterns shown

on pages 7 and 8 to identify the die-cut parts and

mark them before removing them from the

sheet. Save all scraps. If any of the die-cut parts

are difficult to punch out, do not force them!

Instead, cut around the parts with a hobby knife.

After punching out the die-cut parts, use your TBar or sanding block to lightly sand the edges to

remove any die-cutting irregularities.

3. As you identify and mark the parts, separate

them into groups, such as fuse (fuselage), wing,

fin, stab (stabilizer), and hardware.

1. Work on a flat surface over the plans covered

with waxed paper. Refer to the plans to identify

the parts and their locations.

The plans may be

cut apart if space is a problem.

2. Punch out both sets of the die-cut 3/32” balsa

ribs S-1 through S-7. There is a jig tab on the

bottom edge of each of these ribs. If any of these

break off, carefully glue them back on with a drop

of thin CA. Lightly sand any imperfections. You

may need to finish cutting the notch in the forward

portion of S-1 for the Stab Joiner (SJ) with a

knife. Use a pen to mark the extensions of the

bottom edge of the ribs across the fore and aft

ends of the jig tabs. These marks will help when

you trim off the jig tabs later.

3. The stab Trailing Edges (S) are die-cut from

1/4” balsa. Since some crushing may occur

during die-cutting wood of this thickness, they

are supplied slightly long and can be trimmed.

True up all edges of these pieces with a T-bar.

❏❏4. Cut the stab Leading Edges (LE’s) to

length from the 1/4” x 15” tapered balsa stock.

They should be about 1/4” longer than the length

shown on the plans for the stab LE.

❏❏5. Center the 1/2” x 5/8” x 9-3/4” balsa TE

Center Brace over the plans and pin it in place.

Use a triangle and pen to mark the inboard ends

of the Stab TE. Remove the TE Center Brace

from the building board.

❏❏6. Apply thick CA to one half of the TE

Center Brace, then align the inboard end of a

Stab TE with the reference line you just drew.

Glue the TE Center Brace in position. The TE

Center Brace must be centered on the Stab

TE. Repeat this operation for the other half of

the TE, then use long T-pins to pin the assembly

over the plans.

NOTE: Position the outboard ends of the

TE about 1/2” above the board. The TE

Center Brace should be raised about 3/8”.

(See next photo.)

FIN / STAB LE

Build the horizontal stabilizer

BUILD THE TAIL SURFACES

Zipper-top food storage bags are a handy

way to store your small parts as you sort,

identify, and separate them into sub-assemblies.

Get ready to build

9

Page 10

❏❏7. Pin the left and right S-3 and S-6 ribs to

the building board over their locations on the

plans. Adjust the height of the Stab TE to align it

evenly with the aft edge of the ribs. Glue the ribs

to the Stab TE and to the TE Center Brace with

thin CA.

❏❏8. Align and glue all of the remaining Stab

ribs to the TE.

❏❏9. Glue the two die-cut 3/32” balsa Stab

Gussets into the junction of S-6 and the Stab

TE. The Gussets should be centered between

the top and bottom of the ribs and Stab TE. Glue

the die-cut 1/8” ply Forward Stab Brace into the

slots in the S-1 ribs and to the inside edges of

the S-2 ribs.

❏❏10. Sand one end of two shaped balsa

Stab LE’s to exactly match the angle at the

center of the Stab.

Leave the outboard ends long

for the time being.

Center, then tack glue the

Stab LE’s to the forward edge of ribs S-1 and S6 and to the Forward Stab Brace (this will align

the LE). Glue the remaining ribs to the LE,

checking for straightness as you proceed.

❏❏11. Glue both S-7 ribs to the Stab LE.

❏❏12. Glue the 1/4” x 1/2” x 7/8” balsa Stab

Sub TE to the aft edge of S-7 and to the side of

S-6. Make sure that the Stab Sub TE is

positioned exactly 90 degrees to S-6.

❏❏13. Tr im the Stab LE’s flush with the S-7’s.

Reinforce all of the joints with medium CA.

Sand the tips of the LE, sub TE, and TE flush

with S-7 and S-6.

❏❏14. Remove the pins, then lightly sand the

top surface of the stab frame to blend all parts

and remove any excess CA. Take care not to

change the shape of the airfoil.

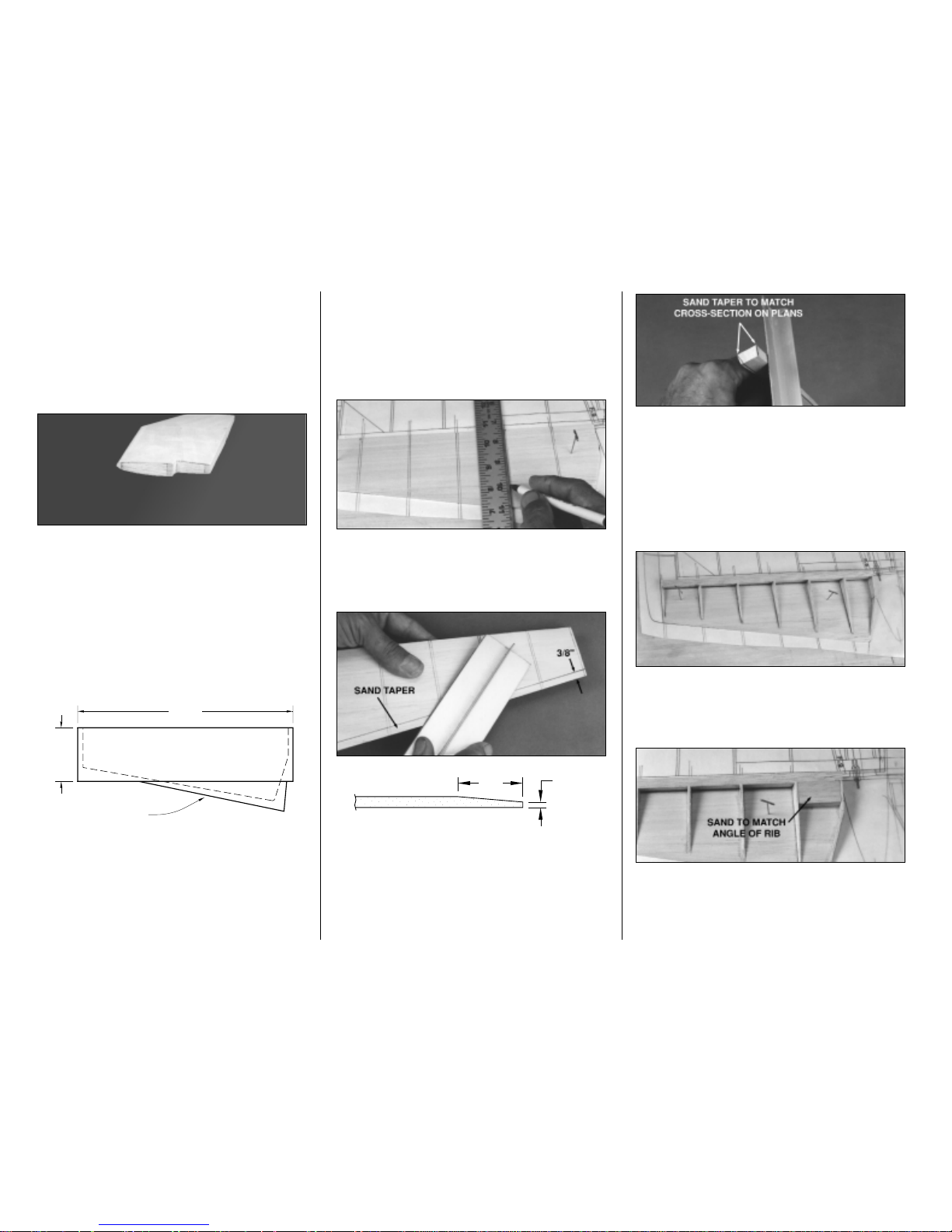

HOW TO MAKE WING AND STAB SKINS

A. Wherever practical, pre-join the balsa

sheets to make a “skin” before attaching them

to the structure.

B. Many modelers like to sort the wood so they

can put the best wood with the most even

grain structure on the top of the wing and stab.

C. Make your skin larger than needed to allow

Lightly sand a bevel along the front edge of

the Stab ribs to match the sweep angle of the

LE. This will give you a better fit and a stronger

glue joint.

10

Page 11

❏❏15. Make two 6”x 30” stab skin planks

from four 1/16” x 3” x 30” balsa sheets. From

these planks, cut four stab skins. See the sketch

for the proper layout on the wood. Refer to the

plans for the exact shapes and sizes, but

remember to make the skins slightly oversize.

❏❏16. Pin the stab structure to your building

surface using pins only at the tips and diagonally

under the LE & TE. Make sure that the jig tabs

are flat on the building surface. Don’t hide the

pins under the skin.

❏❏17. Use the off-cut 1/16” material from the

skin planks to make a 1” wide cross-grain strip to

fit between the S-1’s from the LE to the TE. Glue

the strip in place between the ribs, flush with the

top edge.

❏❏18. Test-fit the skins over the stab frame.

Make sure the skins meet flush at the center.

Adjust them with a sanding block if necessary.

Apply an even bead of medium or thick CA to

the upward-facing edges on one side of the

frame. Place a skin in its proper position and

press it firmly down until the glue has set.

Repeat this step for the other top skin. Trim off

the excess balsa, but save any big scraps for

use when making the elevators.

❏❏19. Remove the stab from the building board.

Tr im off the jig tabs with a sharp knife. Trim and

blend the LE and TE to the ribs as you did before.

Check all glue joints, adding glue as necessary.

❏❏20. Cut another 1” wide cross-grain strip

from 1/16” x 6” off-cut balsa sheeting and glue it

between the two S-1 ribs flush with their bottom

edges.

❏❏21. It’s important to get a good glue bond

between the stab frame and the bottom stab

skins. Apply a heavy bead of medium or thick

STAB SKIN

12-1/8"13"

13"12-1/8"

3"

STAB SKIN

for misalignment. On a large surface such as

the wing, 3/8” extra is suggested.

D. To make skins, the following steps

are suggested:

1. Tr ue up the edges of the sheets with a

metal straightedge and a sharp knife or a

“T-Bar” sanding block.

2. Test-fit the sheets together to make sure

they match well.

3. METHOD “A”: Edge glue the sheets

together with thin CA, over a flat surface

covered with waxed paper. A quick wipe of the

joint with a fresh paper towel will remove

excess glue and make sanding easier. Mark

the poorest surface to identify it as the “inside”

surface.

METHOD “B”: Edge glue the sheets

together with Titebond

®

wood glue. (Titebond

is easier to sand and won’t leave a ridge at the

seam, as CA is prone to do.) Smear the glue

lightly along an edge with your finger, then join

the sheets over a flat (waxed paper covered)

building board. Pin the sheets to the board to

hold them together. Wipe off any excess glue

before it dries.

4. Place the skin on a large flat surface

and sand it with a large flat sanding block and

fresh, sharp 220 paper. Use light pressure and

a brisk circular motion.

5. Tr im the perimeter of the sheet to even

things out.

11

Page 12

CA to all of the

upward facing

edges on one side

of the stab frame. Place a skin on the frame and

hold it in place with your hands until the glue

sets. Repeat this for the other bottom skin. Be

careful not to bend or twist the stab during

this step.

❏❏22. Tr im off the excess balsa from around

the perimeter of the stab. True up the ends of

the stab with a sanding block. Round the LE of

the stab to match the cross section on the plan.

❏❏1. Cut two 1/16” x 3” x 30” balsa sheets in

half to make four 15” long sheets. Refer to the

sketch and the elevator plans, then glue the

leftover balsa “wedges” that you cut from the stab

skins to the 15” sheets. These joined sheets will be

used to make the top and bottom Elevator skins.

❏❏2. Use the pattern on the plans to cut four

Elevator skins. Sort the skins so that the best

surfaces will be facing outward, and on the top.

NOTE: Save time by building both

elevators simultaneously.

❏❏3. Cover the elevator plan with waxed

paper, then pin a skin in position. Use the “tic”

marks on the plan to draw the rib locations on

the skin.

❏❏4. Draw a line along the length of the skin’s

TE 3/8” in from the edge. Remove the skin from

the building board, then holding it along the

edge of your work bench, sand a taper from the

line towards the TE so that the TE will be

approximately 1/32” thick.

❏❏5. Locate the 3/8” x 3/4” x 11-5/8” shaped

balsa Elevator LE. Draw two lines, 1/32” in from

each edge, on one side of the LE as shown in

the photo. Use the lines as a reference to taper

the top and bottom of the LE toward the elevator

TE with a T-bar sander. Proceed carefully,

checking your progress against the height of

the elevator ribs at each location.

❏❏6. Glue the LE to the inside surface of the the

elevator skin, flush with the forward edge of the

skin. Glue the 3/32” die-cut balsa ribs (E-1 through

E-7) to the skin and to the LE with thin CA.

❏❏7. Test fit a 1/2” x 1” x 1-5/8” balsa Torque

Rod block between ribs E-1 and E-2. Sand the

ends, if necessary, for a good fit. Sand a slight

angle on the forward edge of the Torque Rod

3/8"

1/32"

3"

SCRAP

15"

ELEVATOR SKIN

Build the elevators

12

Page 13

block (the one that will contact the elevator’s LE)

to match the angle of the LE. Glue the Torque

Rod block in position when you are satisfied with

the fit.

❏❏8. Carefully sand the top of the Torque Rod

block flush with the taper of the ribs.

❏❏9. Mark and sand the

inside

TE of an

elevator skin as you did in step 4. Apply a bead

of thick CA to LE, TE, and all ribs, then glue the

top skin into position. Hold the assembly flat until

the CA cures.

❏❏10. Tr ue up all edges with a T-bar or

sanding block.

❏❏11. Test fit the Stab, Elevator, 5/8” x 1” x 6-

1/2” shaped balsa Stab Tip, and the 5/8” x

27/32” x 1-9/16” balsa Elevator Balance Tab

together. Make any adjustments with light

sanding. Mark the

“break”

between the Stab and

the Elevator on the Stab Tip. Cut the Stab Tip

apart along this line.

❏❏12. Glue the forward balsa Stab Tips

in position.

❏❏13. Glue the Elevator Balance Tab flush

with the Elevator Tip. Center the Stab Tip on the

outboard end of the Elevator, before using thick

CA to glue in place. Make sure that both the

Elevator LE and TE are centered before the

CA cures.

❏❏14. Tape the elevator assembly to the Stab.

Make sure that the Stab Tip and Elevator

Balance Tab are flush along the outside edge.

There should be a 1/32”-1/16” gap between the

Elevator Balance Tab and the Stab. If not, use

your T-bar sander to correct the problem by

alternately sanding the inside edges of the

Elevator Balance Tab and the Stab.

❏❏15. When satisfied with the fit, use a razor

plane and sanding block to shape the Stab Tip

to blend with the Elevator and Stab.

❏❏16. Sand a radius around the Balance Tab

as shown in the photo.

❏❏17. Sand a radius around the outboard

edges of the Stab and Elevator Tip.

13

Page 14

❏ 18. Tape the Elevators to the Stab making

sure that you have the correct clearance around

the Balance Tabs. Hold the bent 1/8” Elevator

Joiner Wire and Horn up to the Elevator and

mark the location of the Joiner Wire holes that

will be perpendicular to the hinge line (see the

plans for the joiner location).

NOTE: The Elevator Horn is off-center.

When looking at the top surface of the

Stab, the Horn will be to the right of

Stab center.

❏ 19. Drill 17/64” holes in the elevators for the

Joiner wire. Cut slots inboard of the holes to

allow the wire to be inset into the elevators, flush

with the LE. Sand the Elevator LE to a “V”

shape to allow for Elevator travel — refer to the

plans for the correct angle.

❏ 20. Test-fit the joiner wire into the Elevators.

Check to see that the Elevators align with each

other properly and that they fit the Stab without

binding. Make adjustments by removing the

Joiner Wire and then bending it, if required.

❏ 1. Cover the Fin/Rudder section of the plans

with waxed paper.

❏ 2. Punch out the die-cut 3/32” balsa ribs V-1

through V-6. Be sure to preserve their jig tabs.

NOTE:

If you plan to install an operational

beacon light on top of the Fin drill a 3/16”

hole through the center (front to back, top

to bottom) of each rib. This hole will

provide a passage for the wiring.

❏ 3. Cut a 15” length of the tapered 1/4” balsa

Stabilizer/Fin LE stock to match the plans

exactly, as the length of the LE sets the angle of

the fin.

Notice that the Fin LE fits into a notch on

top of F-8.

❏ 4. Punch out the die-cut 1/4” balsa Fin TE

and lightly sand the edges to touch them up.

Sand (or cut) the tips to match the sweep angle

as shown on the plans.

❏ 5. Sand an angle on the ends of each rib to

match the sweep angle of the LE and TE. Pin

ribs V-1 and V-6 to the building board over their

proper locations. Center the LE on the front of

the ribs and glue it in place. Center the Fin TE

on the aft edge of the ribs and glue it in place.

❏ 6. Put ribs V-2 through V-5 into their places

and glue them to the LE and TE. Remember, all

jig tabs should contact the work surface.

❏ 7. Glue the die-cut 3/32” balsa Fin Gusset

into the corner of V-6 and the Trailing Edge.

❏ 8. Apply extra CA+ glue to any joints that do

not appear to be well glued.

❏ 9. Blend the LE to match the ribs on the

upward facing (left) fin side. Sand the TE, if

necessary, to blend smoothly with the ribs.

❏ 10. Make a skin for each side of the fin using

1/16” x 3” x 30” balsa sheet. Leave excess balsa

on one edge of the skin so it overhangs past

V-1 about 5/8”; this will allow fitting to the stab

later. With the structure flat on the table, glue on

the left (upward-facing) skin.

30"

3"

FIN SKIN

Build the fin

14

Page 15

❏ 11. Remove the fin from the building board

and trim off the jig tabs. Blend the LE and TE to

the ribs on the right side of the fin.

NOTE:

If you plan to route wiring for a

beacon through the fin, install a 15” length

of outer pushrod tube (not supplied)

through the 3/16” holes you drilled in step

#2. Glue it in position with medium CA,

leaving the excess tube protruding from V-1.

❏ 12. Use medium or thick CA to glue on the

right side skin. Be sure to get a good bond

between the ribs and the skin.

❏ 13. True up the edges of the fin sheeting with

a sanding block. Shape the LE to match the

cross section on the plans. Don’t trim the bottom

edge of the sheeting at this time.

❏ 14. Glue the shaped 3/4” balsa Fin Tip to the

top of the fin. Shaping should be done later, with

the fin taped to the rudder.

NOTE:

If adding a beacon light, drill a hole

through the top of the Fin Tip that aligns with

the wiring tube before you glue it in place.

❏ 1. Use one 1/16” x 3” x 30 balsa sheet to

make two rudder skins, using the rudder skin

pattern on the wing plan. You will need to edge

glue a small wedge shaped piece of sheeting to

the TE of the skin to provide the correct width.

You should have more than enough material left

over from the previous assemblies to accomplish

this step.

❏ 2. Pin one of the rudder skins to the (wax

paper covered) plans and draw the location of

each rib using the “tic” marks as a guide. Draw a

line the length of the rudder skin, 3/8” in from the

aft edge, as you did with the elevators. Remove

the rudder skin from the board and taper the aft

edge to 1/32”. Taper the aft edge of the other

rudder skin to 1/32”. (See next photo.)

❏ 3. Locate the 3/8” x 3/4” x 12” tapered balsa

rudder LE. Cut the tips to match the sweep

angle of the rudder. Lightly sand both sides of

the rudder LE to match the angle toward the aft

edge of the rudder.

❏ 4. Re-pin the rudder skin over the plans. Glue

the rudder LE to the surface of the rudder skin,

flush with the front edge, using medium CA. The

wide end of the rudder LE is at the bottom end

of the rudder.

❏ 5. Slightly taper the forward edge of the rudder

ribs R-1 through R-6 to match the sweep angle of

the rudder LE, then glue them in position over

the location lines that you drew in step #2.

❏ 6. Shape one end of the 1/4” x 1/2” x 1-1/4”

balsa rudder Torque Block to match the angle

at the intersection of the rudder LE and R-1.

Glue the Torque Block in position when satisfied

with the fit.

❏ 7. Remove the rudder assembly from the board,

then lightly sand the frame to blend all joints. Glue

the second rudder skin to the frame with thick CA.

To prevent twists, be sure that the assembly is held

on a flat surface while the CA cures.

EXCESS

30"

3"

Build the rudder

15

Page 16

❏8. True up all rudder edges with a sanding block.

❏ 9. Position the rudder against the TE of the fin

with the top of the rudder 1/32” above the top

of the main body of the fin. Tape the fin and

rudder securely together with masking tape.

NOTE: Before proceeding, study the photo

at step 15 to see what you will accomplish

in the next six steps.

❏ 10. Test fit the 3/4” shaped balsa Rudder Tip

on top of the rudder. It should butt against the

Fin Tip squarely, and have a clearance gap of

1/32” above the fin. Make adjustments with a

sanding block if needed.

❏ 11. Use thick CA to glue the Rudder Tip to the

rudder. Be sure that everything is centered

before the CA cures.

❏ 12. Draw a center reference line across the

top of the rudder and fin blocks. A piece of

masking tape stretched across the center of the

blocks will help you draw a fairly straight line.

❏ 13. Use a razor plane and sanding block to

shape the top of the fin and rudder. For scale

realism, the Rudder Tip should be slightly

wider than the rudder. Apply 4 layers of masking

tape to each side of the rudder to prevent you

from removing too much material. The Fin Tip

may be sanded flush with the fin. Round off the

top 3/8” of both the Fin and Rudder Tips. When

the top is shaped and sanded, remove all

masking tape.

❏ 14. Draw a centerline on the rudder’s LE.

Sand a “V” bevel along this line with reference to

the plans for the correct angle. Hinging and

installation of the torque rod will come later in

the assembly process.

❏ 15. Sand a radius around the forward edge of

the Rudder Tip. Hold the fin and rudder together

to check the clearance between the Rudder Tip

and the Fin Tip. Continue sanding the Rudder

Tip radius until there is a 1/32” gap between the

two parts.

Okay, the tail feathers are more or less

complete, so by now you are on a roll. The stab

looks like the wing for a .20-size model, doesn’t

it? We’ll build the wing next so you’ll really have

something to impress your buddies when they

drop in to see “how the ol’ Cessna is doing.”

NOTE: The wing panels are built “UPSIDEDOWN” on the plans. The jig tabs are

attached to what is, in the end, the TOP

surface of the wing. Since it is the standard

convention to show the Top View of the wing,

and the wing panels are built upside-down,

the LEFT wing panel is built over the RIGHT

Wing Top View and vice-versa. This does not

present any problems — just be sure to build

a left and a right wing.

❏ 1. Punch out all the die-cut 3/32” and 1/8”

balsa wing Ribs. Smooth out any imperfections

with sandpaper. Be sure to keep the jig tabs

attached to the ribs.

❏ 2. Punch out the 1/8” ply Doublers and Wing

Bolt Plates.

Build the center section

BUILD THE WING

16

Page 17

❏ 3. Lay out both sets of balsa Ribs W-2 and W-

3, ply Doublers W-2B and W-2C, and the ply

Wing Bolt Plates exactly as shown in the photo.

This way you won’t assemble two right or two left

sides.

Glue the Doublers to the Ribs and laminate

the two pairs of Wing Bolt Plates with

30-Minute Epoxy. After the epoxy has cured, test

fit the Wing Bolt Plates into the slots at the aft end

of W-2 and W-3. Make slight adjustments to the

slots if required, but don’t make the fit too loose

as this is a critical area for a nice tight bond.

❏ 4. Attach the wing plan (the par t showing the

center section) to a flat building board and cover

it with waxed paper.

Cutting apart the wing panel

sections of the plan makes handling easier.

❏ 5. Locate the 3/8” x 3/8” x 20” basswood

Center Spar. Cut two 9-1/4” pieces from it. Pin

one of the 3/8” x 3/8” x 9-1/4” basswood Center

Spars to the plan using the method shown in the

sketch. The Center Spar is a little longer than

actually needed to allow for the dihedral angle at

W-3. It will be trimmed to size later.

❏ 6. Position rib W-1 and rib assemblies W-2

and W-3 on the Center Spar with the jig tabs

touching the plan. Be sure that the ply doublers

are facing the correct direction.

❏ 7. Insert (without gluing) the die-cut 1/8” balsa

Center Aft Spar into the slots above the jig tabs.

Insert the second basswood Center Spar into

the forward rib notches. Make sure that both

Spars are flush with the upper edge of the ribs.

❏ 8. Interlock the 1/8” die-cut ply Center LE with

the tabs on the LE of ribs W-3 and W-1.

❏ 9. Study the str ucture. Are all parts over their

respective locations on the plans and in

alignment? If not, lightly use fine grit sandpaper

to adjust the fit.

Don’t reach for the CA yet!

❏ 10. Make sure the W-3 ribs are flush with the

Aft Spar and the Center LE. Use the 1/8” die-cut

ply Dihedral Gauge on the inside of the W-3

ribs at the forward Spars to set the ribs angle at

this location. Hold a straightedge alongside the

W-3’s to check for straightness.

❏ 11. When you are sure that everything is

straight and true (sight down the TE and shim

any low ribs with folded paper under the jig tabs)

wick thin CA into every joint. Hold the LE and

W-3’s in tight contact for a few seconds to allow

the CA to work. Follow the initial gluing by

applying a fillet of medium CA around the joints.

Isn’t interlocking construction great?!

NOTE: Do not use any CA until step 11.

17

Page 18

❏ 12. Check the fit of the 1/4” x 1-7/8” Dowels

and the Wing Bolt Plates. Mix up a small batch of

6-Minute Epoxy, then glue these parts in position.

NOTE: The Wing Bolt Plates must be flush

with the outside surface of the W-3’s.

❏ 13. Trim and sand only the basswood Center

Spar ends flush with the W-3’s. Be sure to leave

the

tips

of the Center Aft Spar and the Center

LE in place as they will be used when joining

the center section to the outer wing panels.

❏ 14. Cut a 9-1/4” length from a 3/32” x 1/2” x

30” tapered balsa TE stick. Look at the cross

section on the fuse plan for the angle of the TE.

Center the TE on the aft edge of the center

section ribs, then glue it in place with thin CA.

Carefully sand the ends flush with the W-3’s.

❏ 15. Trim four of the pre-cut 1/16” x 2-3/4” x 1-

1/2” Shear Webs to fit between the W-1 and W-

2 ribs at the forward Center Spars. Glue the

Shear Webs to both sides of the Center Spars

with medium CA

This completes the wing center section frame,

so, zipping right along, let’s move on to the outer

wing panels.

HINT: You will speed up the building process if

you prepare two “wing panel kits” before you

start gluing. We also suggest that you assemble

all four spars even though you may only be

building one half of the wing at a time.

❏ 1. Place a wing panel plan on your building

board and cover it with waxed paper.

❏❏2. Cut four 1/8” x 3/8” x 24” hard balsa

Outer Spar Doublers to 22-3/4”. Sand a chisel

point on one end of each piece starting 2” from

the end.

❏❏3. Use medium CA to glue the Outer Spar

Doublers to the 1/4” x 3/8” x 36” balsa Outer

Spars. The un-tapered end of the Outer Spar

Doubler must be flush with one end of the

Outer Spar.

❏❏4. Pin an Outer Spar assembly to the

building board at three or four locations using

the cross-pinning technique.

NOTE: Do not

apply glue to Ribs until Step 7.

❏❏5. Position the die-cut 3/32” balsa ribs W-4

through W-14 on the spar. These should be

vertical and aligned over their appropriate

locations as indicated on the plans.

The jig tabs

located near the aft end of the ribs should all

contact the work surface.

OUTER SPAR

SPAR DOUBLER

2"

Build outer wing panels

WING TE

18

Page 19

❏❏6. NOTE: Complete this step only if

you’re adding operational flaps. Slide two

layers of waxed paper between ribs W-6 and W7 from the TE to just forward of the Aft Inner

Spar notch. The waxed paper will help prevent

the ribs from sticking together when you cut the

Flaps free later on.

❏❏7. Fit the die-cut 1/8” balsa Aft Inner Spar

and Aft Outer Spar into the aft notches of ribs W4 through W-6 and W-7 through W-14

respectively. The upward facing edge of the Aft

Inner Spar protrudes above the ribs. Make a

mental note of the protruding angle, then, after

removing the Aft Inner Spar from the frame, sand

a bevel on this edge so that it will be flush with the

ribs.

Although you could sand it in place, you

would run the risk of deforming the wing ribs.

❏❏8. Sight down the TE of the wing from the

root end making sure all ribs are aligned. Use

paper to shim under the jig tabs of any ribs that

are low.

❏❏9. Check that the upward-facing edges of

the ribs and the top surface of the Aft Spars are

even and that all of the jig tabs are touching the

work surface or shims. When everything is

aligned, wick thin CA into all joints. Wick thin CA

into all seams around the mating surfaces of

W-6 and W-7.

❏❏10. Place part A and B of the 1/8” die-cut

ply Outer Dihedral Braces over the pattern on

the plan and mark the indicated reference line

on both long edges of each piece.

NOTE: Both parts are slightly narrower at

one end. Use 6-Minute Epoxy to glue the

parts together as shown in the photo. Be

sure to make one left and one right set.

❏❏11. Use a razor saw to cut a 1/4” wide slot

from the upper forward Spar notch down to the

lower Spar through ribs W-6 and W-7. Insert the

Outer Dihedral Brace into the slot you just cut

with the narrow end toward the wing tip and the

short portion of the assembly facing the leading

edge. The angled edge should be facing upward

between ribs W-7 and W-8. Don’t glue it in

place yet, but leave it in position.

❏❏12. Hold the upper Outer Spar in position

on the ribs, with the inboard end flush with W-4.

Mark the Spar at the seam between ribs W-6

and W-7. Score the inside of the spar two thirds

of the way through with a razor saw.

The

inside

is the side with the tapered 1/8” Outer

Spar Doubler.

❏❏13. Press the upper Outer Spar into the

wing notches and check for a flush fit at each rib.

When satisfied, remove the Outer Spar, then use

30-Minute Epoxy to glue the Outer Dihedral

Brace in position. Apply a bead of epoxy to the

upper edge of the Outer Dihedral Brace, and,

before the epoxy cures, install the Outer Spar

Assembly and glue it to all the ribs with thin CA.

NOTE: Work some epoxy into the the sawcut before laying the Spar in place.

❏❏14. Cut four 3-1/8” long Servo Hatch Rails

from 1/4” x 3/8” x 30” balsa. Glue two of these

pieces into the notches in ribs W-4 and W-5 and

two between ribs W-7 and W-8. These will

19

Page 20

support the flap and aileron servo hatches.

Install the rails even if you don’t plan to add

flaps, as they add a little extra strength and fill in

the notches.

❏❏15. Glue the 1/8” die-cut Gusset G-3 to the

Aft Outer Spar and W-7, as shown on the plans.

❏❏16. Hold the 36” shaped balsa LE up to the

wing and mark it at W-7. Cut three quarters of

the way through the LE (from the flat side) with a

razor saw to allow it to flex at W-7. Center the

LE vertically on the ribs, then tack glue it in

position at W-4, W-7 and W-14. Sight down the

LE from both ends to check that all of the ribs

are centered and that the frame isn’t curved or

twisted. Once again, be sure that all the jig tabs

are firmly on the building board, then

permanently glue the LE to all of the ribs.

❏❏17. Cut the tapered 30” balsa Flap Spar to

fit from W-4 to W-7 then glue it into the “V”

notches just behind the aft Inner Spar.

❏❏18. Center a 1/2” x 15” tapered balsa TE on

the aft edge of W-4 and the last W-6, then glue it

in position to only W-4 and W-6. Lay a

straightedge across the aft end of the ribs to

check that all ribs are aligned and level and that

the TE is straight. When everything looks good,

glue all the remaining ribs to the TE, centering

each rib as you proceed.

❏❏19. Glue the die-cut 1/8” balsa gussets G1

and G2 in position, as shown on the plans.

❏❏20. Tr im the excess material from the

Spars, LE, TE, etc., and sand all ends flush.

Reinforce all joints that still need extra glue by

adding medium CA.

❏❏21. Refer to the plan for the location of the

single and double 1/16” x 2-3/4” x 1-1/2” balsa

Shear Webs. Glue the Shear Webs in position

with thick CA (Not between W-4 and W-5).

❏❏22. Locate the 1/2” x 1/2” x 6” balsa stick.

Cut six 1” lengths to use as Aileron Hinge

Blocks. Fit and glue 3 blocks where shown on

the plans. Save the other 3 for use on the

second wing panel.

Well, that about wraps up the framing for half of

the wing. Take a shor t break to admire your

handiwork, have a cup of coffee, clean the CA off

your fingers, and kiss your spouse good night.

When you’re fully revived, clean the sawdust off

your bench, swap the plan sheets, and get busy

building the other half. You can rest later.

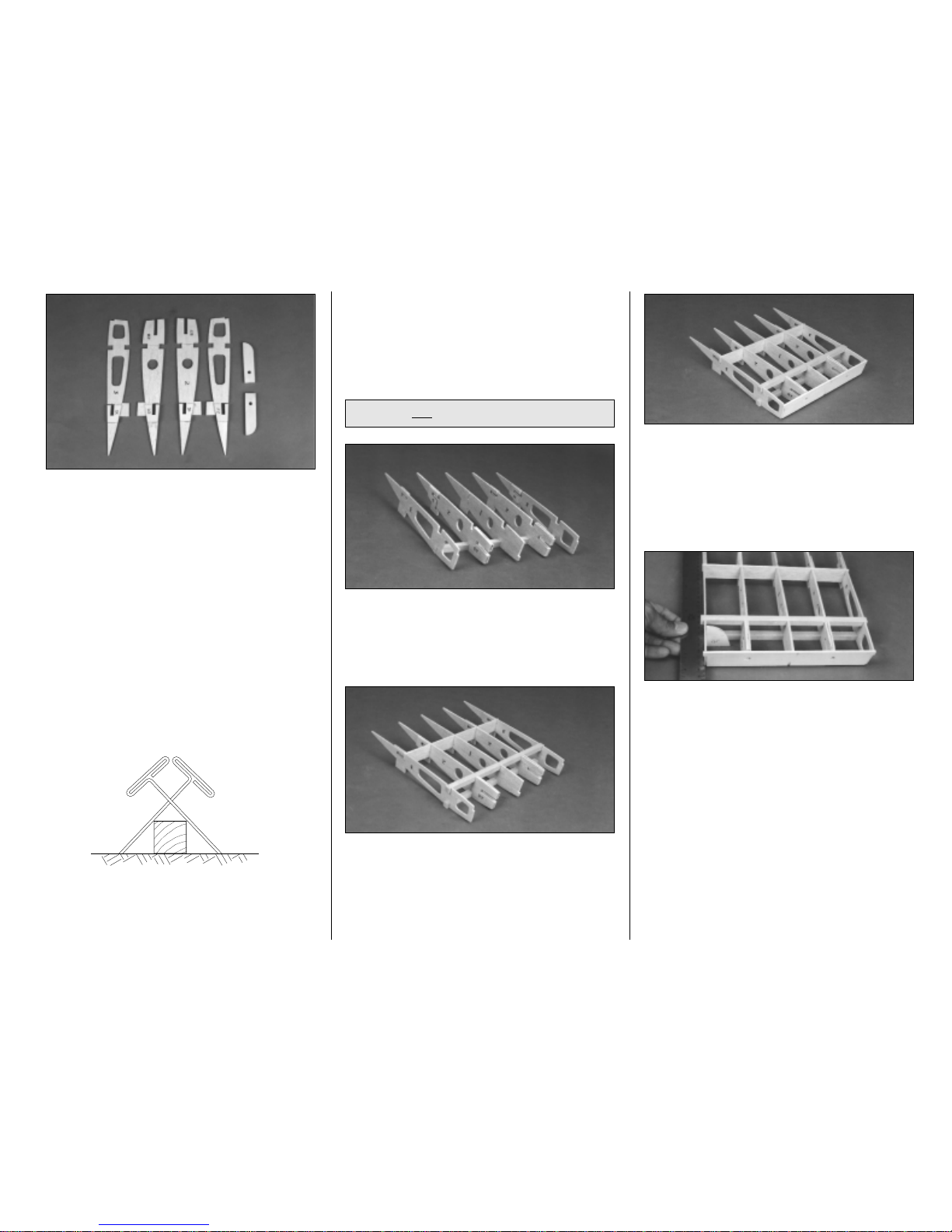

❏❏1. Position the three 1/8” ply parts of the

Polyhedral Braces over the sketch on the

plans. Look carefully at each piece and you will

notice that they form a slight “V” shape, with one

end longer than the other. After you align each

piece over the drawing, mark an index line on

each part as shown, then extend it around to

both edges.

❏❏2. Without gluing, stack the three pieces

together and compare the assembly with the

photo and the plans. Repeat this process with

the second set of braces,

but this time flip the

pieces end-for-end

when you stack them.

Prepare the polyhedral braces

FLAP SPAR

20

Page 21

You should now have a right hand and a left

hand set of Polyhedral Braces, as shown in the

photo.

Tracing around the edges of the two

shorter parts will help alignment when you glue

them together.

❏❏3. When satisfied that the braces are accurate,

use 6-Minute Epoxy to glue the parts together with

the alignment marks perfectly aligned.

❏❏1. Carefully remove a 3/8”-wide strip of balsa

from between the spars on both the W-3 ribs of

the Center Section and the W-4 ribs of the outer

panels. This will allow the Polyhedral Braces to be

inserted and glued between the spars.

❏❏2. Test fit (but don’t glue) the Polyhedral

braces into the center and outboard wing panels.

The longer end of the joiner is the end that

plugs into the outboard panels. Sand the

ends, if necessary, for a good fit. The wing

panels should mate evenly along the joint

without any unnecessary twisting or bending to

line things up. If you have to force the panels to

fit, locate the problem and fix it before

proceeding. Any twists will become a permanent

part of the structure after the panels are joined

and will be difficult to correct.

❏❏3. Use only a spot of CA to glue the two

1/4” x 1-1/16 “ x 5-7/8” balsa Wing Jig Blocks

to the W-2 jig tabs and the top of the spar.

Now for the hard part — cleaning a space on

your work bench large enough to spread out and

join the wing.

IMPORTANT: Check your work surface with

a metal straightedge to make sure that it’s

perfectly flat before proceeding. Make a

“dry run” of the following step before

actually performing it with glue.

❏❏4. Place the Center panel on the Jig Blocks

in the middle of your work bench. Add some

weight to hold it in place (a few magazines or

small sandbags are handy for this). Prepare 1/2

ounce of 30-Minute Epoxy. Liberally apply

epoxy to the W-3 Ribs, the Polyhedral

Braces,and the spar ends.

(If you will be

installing Flaps, don’t put epoxy on the “Flap”

portion of the ribs. Insert waxed paper between

W-3 and W-4 at the flaps.)

Plug the Polyhedral

Braces into the Outboard Wing Panels. Plug

the Outboard Wing Panels into the Center

Section and align the Ribs for a flush fit. The

protruding Center Section LE and Aft Center

Spar tabs will help with alignment. Once all the

panels are in position, clamp the ribs together

and center the Polyhedral Braces between the

Spars as shown on the top view of the plans.

Put weights on the two W-14 ribs to hold the

jig tabs and spars on the work surface. Before

the epoxy

kicks off

, double check your work.

IMPORTANT: Make certain that both the upper

and lower Spars touch their mates on the

adjoining panel. If, after all your efforts, you end

up with a small gap, pack epo xy into the cavity.

❏❏5. Use a razor saw to cut a 1/6” wide x 3/8”

deep slot on both sides of the bottom spars at

W-3.

Remember, the wing is upside down on the

bench so the bottom spars are presently on

the “top.”

Join the wing panels

21

Page 22

❏❏6. Test fit the 1/16” die-cut ply bottom Spar

Joiner in the slots. Just like the Polyhedral

Braces, the Spar Joiners have one end that is

longer than the other. The longer end points

towards the wing tip. Equally sand the ends if

needed for a good fit between the ribs. Use 6minute or 30-Minute Epoxy to glue the Spar

Joiners in position.

Clothes pins make handy

clamps while the epoxy cures.

❏❏7. Tur n the wing over and repeat the

process of installing the Spar Joiners on the top

wing spars.

Our suggested wing sheeting process allows

you to sheet each of the wing panels with one

skin per side — plus a little extra for the flaps.

This technique is better than sheeting the wing

with individual sheets, and allows you to

pre-

sand

all of the seams that will be over open

structure.

All balsa sheeting will usually bend when it’s cut

from the log since internal stresses are relieved.

For the best results, trim the edges of the wing

sheeting with a long metal straightedge and a

sharp knife before joining them. You may also

try turning the sheets different ways to see if the

edges will line up evenly. If the bend is only

slight, use 150-grit sandpaper on a long sanding

block to smooth out the curvature. For more

information on making wing skins refer back

to page 10 for the

Hot Tip.

NOTE: Do the following steps for both the

right and left wing panels.

❏ 1. Sor t through the remaining 1/16” x 3” x 36”

balsa sheets and pick out the 6 best sheets to

be used for the top surfaces of the outboard

wing panels. Pick the best three sheets from the

1/16” x 3” x 21” sheeting to use for the top

Center Section skin

❏ 2. Lay waxed paper over a flat, smooth

work surface.

❏ 3. Make four outboard wing skins by edge

gluing three 1/16” x 3” x 36” balsa wing sheets

together to make (four) 9” x 36” skins. Make one

center section skin using four sheets of 1/16” x

3” x 21” balsa. This skin will be cut in half after

sanding to make two 12” x 10-1/2” skins. Refer

to page 10 for tips on making skins.

NOTE: When sheeting, be sure that the

wing is resting squarely on the center

section Jig Blocks, weighted down on a flat

surface, and that the W-14 jig tabs are in

solid contact with the building surface.

❏ 4. Hold a 1/16” x 12” x 10-1/2” center section

skin on the bottom surface of the wing with one

edge butted up to the LE. Mark the perimeter of

the skin. The side edges of the skin should be

centered on the joint between ribs W-3 and W-

4. Cut the skin close to the correct size then

sand it for an exact fit.

❏ 5. Glue the center skin in position using

medium or thick CA. Hold the skin in contact

with the frame until the glue has cured.

❏❏6. Fit one of the 9” x 36” skins in place on

an outboard wing panel, with one long edge

butted tightly against the inner LE. The inboard

edge should overlap the center section. Tape the

skin in place. With a flexible ruler, mark the edge

that mates with the center panel. Flip the wing

over and mark the tip and TE from the back side.

Allow an extra 1/4” around these two edges

.

Remove the skin and cut it to the marked size. If

necessary, use 220 grit sandpaper to

fine tune

the inboard edge for an exact fit.

The photo at

step #9 shows approximately what your sheet

should look like when it’s trimmed.

Sheet the bottom of the wing

22

Page 23

❏❏7. Working quickly, apply a bead of thick

CA to the structure that the skin will touch. Don't

glue hatch rails yet. Apply glue to the Spar last.

Position the skin over the frame, then press it

into place. Important: Before the CA kicks off,

weight down the center panel and the TE of the

wing at W-14 to set the washout angle. Repeat

steps 6 and 7 for the other outer wing panel.

❏❏8. After the CA has cured, turn the wing

over and apply a bead of thick CA to the inside

of the LE / Skin junction and any other areas

that need a little extra glue.

❏❏9. Cut two 14-1/2” pieces from a 1/16” x 3” x

36” balsa sheet. Save the off-cut piece for use in

a few minutes. Cut the 14-1/2” sheets to the fit the

uncovered area of the flaps. Use a leftover piece

of 1/16” balsa sheeting to make two triangular

pieces to fill in remaining un-sheeted area.

❏❏10. Tur n the wing over and place it on foam

rubber or a soft surface to avoid premature

hangar rash.

NOTE: if you are not installing flaps, don’t

mark or cut the two inboard openings.

❏❏11. Use a sharpened piece of wire or long

T-pin to bore small holes through the skin from

the inside to mark the location of the flap and

aileron servo hatches.

❏❏12. Rough cut the hatch openings on the

inside of your guide holes, then use a 1/16” ply

Hatch Cover to mark and cut the full size

opening.

Remember, it’s faster to enlarge a hole

that’s too small than to shrink one that’s oversize.

After enlarging holes, use thin CA to glue the

skin to the hatch rails.

❏❏13. Use a sharpened piece of wire to bore

through the exposed side of the Wing Bolt plate

to mark the holes in the bottom wing skin for the

wing bolts. Mark these holes now, as it will be

difficult to find the location after the top wing skin

is applied. To avoid splitting the balsa, bore the

holes in the skin with a grinding stone and mototool rather than going through with a drill.

❏❏14. You can simplify the job of “fishing” the

servo wires through the enclosed wing with a

little preparation. Tape one end of a 30” length of

string to the inside of the wing sheeting just past

the aileron servo hatch opening. Thread the

string through the lightening holes in the ribs into

the center section. Bore a 1/2” hole for the servo

leads to exit through the bottom of the wing.

Secure the string next to the hole with another

piece of tape. Repeat this procedure for the

other wing panel. When the time comes to

thread the servo wires, just tie them to the string

from the hatch end and pull them through to the

center compartment exit hole.

If you plan to install navigation lights on the wing

The best balsa filler is no balsa filler! Take

your time fitting all sheeting and skins in place.

With a little bit of careful sanding you will be

rewarded with perfectly matched joints and a

lighter, stronger airframe.

23

Page 24

tips, use the string technique described in the

previous step, or glue two large-diameter

pushrod tubes (not supplied) inside the wing,

ahead of the spars, to serve as a conduit for

the wires.

❏❏15. Glue the 1/2” x 1/2” x 1” basswood

Wing Strut Mount Block to the inboard side of

the W-6 rib and to the sheeting at the location

shown on the plans. We recommend

6-Minute Epoxy for this job. To help locate the

blocks later, drill a 1/16” hole through the center

of the blocks, out through the bottom sheeting.

❏❏16. Tr ue all edges with a sanding block.

Mark the location of the Aileron Hinge Blocks on

the outside edge of the aft Outer Spar.

❏❏17. Carefully cut off all of the jig tabs on the

top surface of the wing. Lightly sand the tops of

the ribs and spars. Clean up any glue blobs that

will interfere with the top sheeting, then double

check your work.

If you aren’t installing operational flaps (the neat

looking, highly effective, simulated Fowler Flaps)

skip the next section and proceed to “Sheet

The Top Of The Wing”. Are you sure you

won’t reconsider?

NOTE: This kit includes a special set of

wing jigs to hold the wing at the proper

washout angle (2 degrees washout at each

tip) while you apply the top skins. Twisted

wings are a major cause of bad flight

characteristics. Polyhedral angles can vary

slightly, so if your tip jigs require

adjustment, just be sure that both tip jigs

are modified the same, and are therefore

identical. Be careful not to change the

washout angle (the negative angle of attack

of the tip ribs) if you adjust the jigs.

❏❏1. Locate all of the 1/8” die-cut ply wing jigs

as shown in the photo. Assemble the two parts

of both TE Jigs as shown.

Sheet the top of the wing

❏❏3. Tur n the wing over, then carefully cut

away the balsa sheeting from between the

marks. Don’t cut through the ribs until the top

of the wing has been sheeted and you are

instructed to do so.

That’s all you need to do for now regarding the

flaps. Let’s move on and put the skins on the

top of the wing.

❏❏2. Mark the location for the Flap LE by

inserting a sharpened wire through the

sheeting at the locations shown in the photo.

❏❏1. Cut the shaped 5/8” x 9” balsa Flap

Hinge Block into four pieces 1-1/2” long, and

two pieces 1” long. Glue the blocks to the aft

Inner Spar, sheeting, and ribs as shown on

the plans.

Do the following steps if you are building

operational flaps.

Even though building operational flaps requires

a little bit of patience and elbow grease, you

will be rewarded by more scale appearance

and slower landings than the less ambitious

modeler. If that isn’t enough, they look great

during slow fly-bys and shorten the takeoff roll.

Prepare the wing panels

for the flaps

24

Page 25

❏❏2. Slide the die-cut 1/8” ply LE Jigs over

the dowels, with the flat edge towards the

sheeted (bottom) side of the wing.

❏❏3. Tack glue the die-cut 1/8” ply TE Jigs to

the sheeting at the TE of W-3.

❏❏4. Place a die-cut 1/8” plywood Tip Jig

under each W-14 rib with the raised tip of the jig

butting up to the TE spar. Tack glue it in place.

NOTE: Use the same procedure to sheet the

top of the wing as you used for the bottom.

❏❏5. Cut the top Center Panel Skin from the

skin you made earlier. Remember that it should

line up with the dividing line between ribs W-3

and W-4. When satisfied with the fit, glue it in

place with thick CA.

❏❏6. Check the fit of an outboard skin to the

wing structure. Make adjustments if required to

fit flush with the LE and Center Panel. Sand a

slight bevel to the edge of the skin that will

contact the LE to allow for a better gluing

surface. Use thick CA to glue the skin in

position. Hold the skin firmly in place while the

CA cures.

Magazines make good weights.

Wick

thin CA along the LE seam, wiping off any

excess CA before it hardens.

❏❏7. Repeat step 6 for the other outer panel.

❏❏8. Measure, cut and glue a 1/16” x 3” x 36”

balsa sheet to fit over the Flaps and the

openings at the aft edge of the wing skins, as

you did for the bottom of the wing.

At this point you should have the main wing

structure fully sheeted. You may now remove all

Jig parts from the wing and sand off any

glue marks.

❏❏1. Tr im the sheeting where it protr udes past

the edge of the structure.

❏❏2. Sand the wing Leading Edge until it

blends well with the sheeting to form a

smooth airfoil.

❏❏3. Square off the wing tips with a T-bar.

❏❏4. Use a pointed piece of wire to mark the

holes for the wing bolts from the bottom,

through the top wing skin. Use a hobby knife to

carefully cut a 1/4” hole in the sheeting around

the points you marked. Insert one of the 1/4”

nylon wing bolts through the wing from the top,

and trace around the head with a pen. Enlarge

the holes to the circles you just drew to allow the

wing mounting bolts to seat against the wing

mounting plates. Use a round file or Moto-Tool

and grinding drum to avoid tearing the sheeting.

IMPORTANT: The Ailerons must be fitted to

the wing and the hinge bevels sanded

before installing the wing tips or cutting the

flaps loose.

❏❏5. Tape a tapered 2-3/32” x 21” balsa

Aileron to the Outer Aft Spar with one end

against W-7.

Don’t be alarmed if the Aileron TE

is higher than the TE at W-7; this will be taken

care of when the aileron LE is tapered.

Draw a

line on the Aileron, parallel to the edge of W-7.

Remove the Aileron, then cut and sand it to this

line. Check the fit and make any minor

corrections as needed.

WING COMPLETION

Glue a piece of scrap ply to the side of the jig

and also to the W-14 ribs (as shown here) to

prevent the jig from moving or having to glue it

to the sheeting.

25

Page 26

❏❏6. Tape the Aileron back into position. Mark

the tip end with a straightedge placed along W-

14. Draw a line 1/16” inboard of the first line.

Cut off the Aileron tip on the second (inboard)

line. By so doing the Aileron will have 1/32”

clearance on both ends when it’s installed.

❏❏7. Draw a centerline on the LE of the

Aileron. Sand a “V” shaped bevel along this

edge. Refer to the wing cross section on the

plans for the required angle.

❏❏8. Tape the Aileron securely in position

with its TE aligned with the TE at W-7.

❏❏9. Tape a shaped balsa Wing Tip in position.

It should be centered on W-14 and the aft end

should be centered on the TE of the Aileron. Trace

the airfoil onto the inside edge of the wing tip.

NOTE: Horner Tips are an option on

full-scale Cessnas. If you prefer, you may

simply carve a standard tip without the

undercamber. Draw an arc the width of the

Aileron’s TE (as shown on the plans) if you

want to carve Horner Tips. Remove the tip.

❏❏10. Use a long carving blade to carve away

most of the excess wood and rough in the shape

of the tip. To carve a Horner Tip, cut away a

wedge of balsa as shown in the photo, then use

a round sanding tool (e.g., 80-grit sandpaper

wrapped around a short piece of broom handle)

to curve the underside.

❏❏11. When the Wing Tip has been shaped

close to finished size, glue it to W-14 with

medium CA.

Don’t glue it to the Aileron

. Finish

sanding the Wing Tip with 220 grit sandpaper,

blending it with the wing sheeting and LE. Fine

tune the curved undercamber portion of the

Wing Tip with a round sanding tool and 220 grit.

The thickness of the Tip’s TE should match the

thickness of the Aileron TE.

❏❏12. Refer to the plans for the aileron horn

location. Position a die-cut 1/8” x 5/8” x 5/8” ply

Horn Reinforcement on the bottom of the

aileron at this location and score around its

perimeter with a hobby knife. Remove balsa

from within the score marks to recess the horn

reinforcement. Use thick CA to glue the horn

reinforcement in place.

❏❏13. Repeat steps 5-12 for the other

wing panel.

If you are building your wing without operational

flaps, there’s nothing left to do except fit the wing

to the cabin during final assembly. Invite your

buddies back to the shop for a progress update.

Also, your floor needs sweeping.

NOTE: If you are NOT building operational

Flaps, skip the following section and

proceed to BUILD THE FUSELAGE.

26

Page 27

❏❏9. Tr im off the excess balsa from the

Inner Aft Spar, then use a 3/4” dowel wrapped

with 220-grit sandpaper to sand a radius on

the protruding portions of the ribs. Cut a 1/4” x

1/2” slot in the Inner Aft Spar to allow the Flap

Horn and Clevis to clear.

❏❏10. Reinforce the underside of the wing

sheeting (where it overhangs the aft inner spar

at the Flaps) by gluing leftover 1/16” x 1/4”

balsa strips between the ribs on the underside

of the top sheeting. Sand a bevel along this

edge to allow the flap to clear when it’s in the

up

position.

Fit the flaps

❏❏1. Use a T-bar to true-up the aft edge of

the wing sheeting in the flap section.

❏❏7. Shape the Flap LE to match the cross

section on the plans. A razor plane, whittling

knife, and coarse sandpaper help the job go

quickly. The die-cut 1/8” ply Flap Hinge Drill

Guide may be used to test the curvature of the

LE (

See step # 2 of “Fit The Flaps”

).

❏ 8. Repeat steps 1 - 7 for the other Flap.

❏❏6. Cut a 1/2” x 1-1/4” x 14-1/2” balsa Flap

LE to fit on both sides of the Flap Hor n. Cut a

1/16” deep notch in one of the Flap LE

sections to allow passage of the Flap Horn.

Glue the Flap LE in position exactly as shown

in the photo, with the bottom of the Flap flush

with the bottom of the Flap LE.

❏❏4. Sand the LE of the Flap Ribs flush

(and at the same angle) with the Flap Spar.

Use a long T-bar or sanding block to maintain

a straight LE.

❏❏5. Refer to the plans for the location of

the 1/16” die-cut birch ply Flap Horn. NOTE:

There is a different Flap Horn location for each

flap, so double check your work over the plans.

Glue the Flap Horn in position with

thick CA.

together, cut the inboard and outboard ends of

the Flaps free with a hobby knife or razor saw.

❏❏3. Use a new #11 blade to carefully cut

through each rib at the aft die-cut line. In the

event that some CA has glued the wax paper

❏❏2. Turn the wing over, then use a

straightedge and hobby knife to cut through

the top sheeting, across the two reference

marks, along the length of the flap.

❏❏1. When you look inside the slot that you

cut in the sheeting along the Flap LE, you will

see two partially die-cut lines on each rib.

Insert a pointed piece of wire between the

lines, through the top wing sheeting at each

end of the flap. We are using a wing section

mockup for the purpose of explanation.