Page 1

RC-31 INSTRUCTION MANUAL

INTRODUCTION

TOP FLITE is proud to present the ANTARES, a multi task

capable, Standard Class sailplane that was designed

expressly to take a lot of the "mystery" out of flatwing,

aileron-equipped configurations and at the same time

offer you new levels of soaring capabilities There is no

denying that national and international competition has

made its' presence known at even the club-level of con-

test work The airfoil work alone has provided most of us

with capabilities in a wide variety of weather conditions

that just a few short years ago were unheard of Of course

there is a

U S and foreign R/C sailplane pilots long ago realized

that FAI - F3B competition was extremely hard on airframes, in particularthe speed portion of the three-event

format. This one aspect of the F3B competitions has

spurred a great deal of work in the areas of wing construction and spar engineering This to withstand the tremend

ous loads imposed on the wings during fully-ballasted

launches using extremely strong winches Work in this

area, particularly in Europe, has gone into the use of

exotic materials and methods that, for most of us, are

simply too costly and time consuming to even consider

All of this brings us to the reasons behind the design of

the ANTARES The design had to be efficient We were

looking for, and feel we have achieved, a tremendous

glide ratio with the ANTARES by use of a combination of

the top polars of the Eppler 193 "married" to the bottom

plots of the Eppler 205 and adding flaps to this combina

tion These flaps, as well as the rest of the controls, are

driven by a single servo in the fuselage with very simple

and straight-forward cable and tube connections This

airfoil was designed expressly for the use of flaps and we

think you will find that their use provides you with the

kind of control over the airplane that you have not ex

penenced before Our experience has been that these

flaps provide very tall, non critical launchesoneven the

weakest of launch devices, very precise speed control

during flight and remarkable glide path control during

the landing phase If you feel for any reason that you are

paying some kind of "penalty" in the use of flaps, con

sider the above If you feel that spoilers may be superior

to flaps, consider that the servo required is only of use

during one aspect of the total flight—landing, while the

servo required for the use of these flaps provides im

provement and modification of the total flight.

lot

more

going

on

than just airfoil work The top

The ANTARES uses both ailerons and rudder (coupled) to

provide extremely flat, precise turning capability. We

discovered early on with the prototypes that we were

comfortably working light I lift at much lower altitudes and

distances than we would have ever done with our polyhedral ships and still making it easily back to the spot

when the time came We also found that wind became

much less of a factor in our thinking when making the

ever present "continue to thermal or return" decision.

With the reflexing capability of the flaps, returning to the

spot at high speed, even from low altitudes, certainly

bought us more time to work lift

You will also notice on the plans that we have shown the

optional installation of four Estes BT 5 rockettube bodies,

two in each wing panel on each side of the spar structure.

These are used to introduce lead ballast into the airframe,

thus increasing your wing loading and therefore your

speed and or ability to penetrate This feature, relatively

easy to do, has been incorporated into all of our prototypes and used to good advantage on more than one

occasion

support this increase of weight and you will have yet

another tool to work with in your flying There is more on

this aspect of the design in the Ballasting section of this

manual

A word about the radios that may or may not be suitable

for this design In this day and age of specialization it

simply is not possible to set-up a design such as the

ANTARES to carry every radio system currently or historically on the market Most of the radios currently on the

market, with the use of standard small or micro servos

will fit and work with the ANTARES CHECK YOUR RADIO

SYSTEM FIRST FOR SIZE AND FIT BEFORE STARTING

CONSTRUCTION Secondly, radio systems which are

equipped with such features as electronic RUDDER/

AILERON mixing servo reversing and, of less importance but a nicety non the less, EPA or "end point adjustment , tend to be great for this design If your radio

does not have RUDDER AILERON mixing, you will have

to do one of three things, 1. Obtain and install an electronic mixer such as ACE R/C's Christy Mixer", 2.

mechanically (with linkage) connect the rudder to the

aileron servo using a modified servo output arm or 3.

learn to fly the airplane uncoupled, co-ordinating both

The wing

structure

when built to the plans,

will

TOP FLITE MODELS INC.

-Product Support

(Do Not Remove From Department)

Original Copy of Manual

1901 NORTH NARRAWAGANSETT AVENUE: • CHICAGO ILLINOIS 60639

Page 2

the left (rudder) and right (ailerons) sticks It is important

to remember that the ANTARES, like all "flat wing" configurations employs the use of coupled ailerons and

rudder to eliminate unwanted adverse yaw during turns

It is important to realize this now and make provisions for

it such as outlined above It should be noted that if you

choose option #2 above (mechanical inter connect of the

ailerons and rudder), the need for a separate rudder servo

is obviated and the airplane can then be flown using a

three channel system All of the above is certainly not

meant to scare you off but simply to inform you ahead of

time, what your options and limitations are in order for

you to plan ahead now instead of halfway into the project

We have launched this design using all available

methods, hi-starts, normal winches and super strong

winches The results have been quite uniform, with the

use of flaps at about 15 degrees down, the tows are

arrow straight, highly controllable and always high

Dropping the flaps a little on launch certainly helps the lift

situation and it also imparts a fully washed out condition

to the wings, drastically lowering the possibility of the

dreaded "tip stall at launch" Over the developmental

period of the design, we have come up with a very good

launch sequence, be sure to read the FLYING SECTION of

this manual

As good as we feel the ANTARES is, there are still some

fundamental requirements to get you from this stage to

the winner's circle This design, as well as all others,

requires careful, accurate attention to details during con

struction This is almost surely the single largest factor in

success or failure We have earnestly tried to give you all

of the tools with this kit to provide success What remains

isyourcraftsmanship and attention to detail to guarantee

it The other ingredient required is a pilot A flat wing

four-channel aileron and flap equipped sailplane is a

different kind of flying — we think superior — when

compared to polyhedral types Learn to fly the ANTARES

in the manner it was intended, we think you will be

delighted

IMPORTANT

NOTE-

TOP Flite does not necessarily recommend the ANTARES

as a first R/C sailplane unless you have access to and use

experienced assistance in its construction and flying If

you are a beginner to R/C model aircraft, consider this

Flying this or any other radio controlled model aircraft is

a PRIVILEGE and not a RIGHT and this privilege begins

with the utmost safety considerations to others and yourself as well An R/C model airplane in inexperienced

hands has the potential of doing serious personal or

property damage These safety considerations start at

the building board by following instructions, seeking

competent help when you are confused and avoiding

shortcuts These considerations have to be carried over

to the flying field where safety must come first and

limitations cannot be exceeded We urge you to

1. Send for and obtain your AMA (Academy of Model

Aeronautics) membership which will provide insur

ance for your R/C activities — DO NOT RELY ON

HOMEOWNERS INSURANCE

2. Join an AMA sanctioned R/C flying club in your area

where you can obtain competent, professional

instruction in trimming and learning how to fly this

model

Check with your favorite local hobby shop for the required AMA forms or the address where they can be

obtained

"WARNING"!

A radio controlled model is not a "toy" Care and

caution must be taken in properly building the

model, as well as in the installation and use of the

radio control devise It is important to follow all

directions as to the construction of this kit as well as

installation and use of the engine and radio gear

The advice and assistance of a well experienced

builder and pilot is highly recommended Don't take

chances! Improper building, operation or flying of

this model could result in serious bodily injury to

others, yourself, or property damage.

PRE-CONSTRUCTION NOTES

The ANTARES, like other Top Flite kits employs the use of

die cut wood to ease the task of construction, parts fit and

identification The dies used for this kit have been rigorously checked for absolute accuracy and should provide

you with excellent fit Die cut parts should be carefully

removed from their sheets by first lightly sanding the

back of each sheet of parts and then carefully removing

each part Use a light garnet paper for the sanding and

keep a sharp hobby knife with an X acto #11 blade or

equivalent handy for assistance in removing any parts

that might not have been completely cut through on the

dies Parts which oppose one another and must be precisely uniform—such as fuselage sides ribs, etc —

should be carefully matched after their removal from

the parts sheets Matching is the process of holding the

opposing pieces together with either pins, tape or spot

gluing and lightly sanding the edges of the parts until

they are identical A sand ing block with light garnet paper

is most useful for this and other phases of construction

Your building surface should be at least large enough to

accommodate the wing panels This surface should be as

absolutely flat as possible and yet be able to accept pins

easily We have found that a product such as Celotex fiber

board works quite well for this purpose Another good

surface can be found in most well stocked hardware

stores, this is a 2' x 4' fiber board ceiling tile—these are

quite inexpensive and can be used for several airplanes

before needing replacement

As with most R/C kits that are constructed from wood, a

selection of tools—most of which can be found in the

average workshop—are a must to do the job correctly

Hobby knife and sharp #11 blades

Single-edge razor blades

T pins

Sanding blocks in assorted

sizes

Sandpaper in various grits

Hand held hobby saw such as an X acto

Dremel tool or power drill and assorted drill

bits

Straight edge, preferably metal at least 36" long

90 triangle

Soldering iron, flux (silver) and solder

Carbide cut off wheel for wire cutting

Small power jig saw, such as a Moto Saw

Razor plane

Tapes such as masking and cellophane

2

Page 3

Our ANTARES' were constructed using a variety of common hobby adhesives including 5-minute epoxy, Cyanoacrylates, aliphatic resin (such as Titebond) and 1-hour

epoxy was used to secure the main wing wire tubes in the

wing roots Since all of us have our own construction

techniques and favorite adhesives, stick with the ones

that you are familiar with and prefer However, in certain

areas there will bo callouts for certain types of adhesives

and we urge you to try not to substitute since doing so

could possibly cause problems structurally later on.

The last thing we should touch on before we begin actual

construction is the sequence in which the ANTARES is

assembled The sequence given to you in this booklet has

been proven to be the most straight forward and provides the finished components in the order that you will

need them to progress to the next assembly phase Try to

stick with the building order presented here to avoid

mistakes.

Spread the plans out on your work surface, cover them

with a clear plastic material, such as the backing from a

roll of Monokote or plastic food wrap and commence

construction

F3B MODIFICATION SUGGESTIONS

If your sole intention is to campaign the ANTARES in allout F3B competitions you may want to even further

"beef-up" its already tough structure We have already

flown the stock aircraft in such contests and came out

quite well In the speed portion of the event, we have had

the stock airframe loaded to an excess of 100 ounces

without breaking anything However, it is realized that not

everyone flies thesame.someofusare harder on aircraft

than others Based on our experience with the proto

types, the following are some ideas that you might want

to incorporate into your own bird In all1 of this, try to

remember that weight is always a factor and that we have

always felt that starting out with a relatively light strong,

well-built airframe and having the ability to add ballast to

increase wing loading was superior to having a heavy

airplane to begin with In F3B competition we have

observed that relatively "heavy dry (unballasted)

weights for the aircraft are somewhat the norm Your

ANTARES is still capable of operating well at heavier dry

weights but you will be giving up some of the light air

capabilities

FUSELAGE You may wish to fiberglass the fuselage fin

structure If so

we

would

suggest

two

(2)

layers

of3/4

or

ounce cloth The first layer should be applied 100%tothe

fuselage from about 4 behind the trailing edges of the

F-10 fuse ribs forward to the nose This layer should be

carefully sanded and cleaned off The second layer

should cover the entire fusel a ge and fin The entire st ruc

tu re should be lightly sanded filled as required and either

Monokoted or painted (yes, Monokote will work we ll with

th is com bi nation,j u st lower the heat a little and work with

it) Remember that in F3B work, anything that could

possibly present parasitic drag, will Carefully fillet all

joints and work toward a truly clean, drag free structure

WINGS As mentioned earlier, the stock wing structure

has been subjected to some rather drastic loads (in relationship to normal thermal flying activities) and survived

quite well However, it is realized that no structure is fully

"bullet proof especially in extremely hiqh stress situa

tions Therefore you may wish to further strenghten the

wings Suggestions that we might offer would be such

things as the addition of 5 or 6 carbon fiber reinforcing

strands glued to the bottom surface of the bottom Va" x

3/8" spruce spars and the same treatment to the top

surface of the top spars You may also consider moving

the forward W-21 ply full-depth spar facing pieces to

behind the spar structure, thus replacing the shorter

W 22 piece And replace W 21 with a full length 1/16" ply

facing all the way from the wing root rib to the tip Of

course this means that all of the wing ribs would have to

be two piece You might also consider internalizing all of

the cable drive links and aileron and flap horns and closing

the hinging gaps for these surfaces with Monokote.

Another suggestion might be to totally replace all of the

1/16" balsa wing sheeting with medium, straight-grained

3/32" sheeting and sanding down to a true 1/16" (a lot of

work, but possible) Yet an other suggestion that we've

heard is the possibility of totally fiberglassing the two

wing panels While this might be feasible, the potential is

there for a large weight gain

HORIZONTAL STABILATOR This structure is quite strong

as it is However, you may wish to substitute the 1/8" x 1/4"

upright balsa 'spars with the same size in spruce You

will also note that we have you making the stab root caps

from 3/8" wide 3/32" ply instead of 1/4" wide material This is

just in case some of you might wish to substitute the 1/16"

top and bottom stab sheeting with 1/8", thus thickening

the cross section of the stab to 3/8" (we have tried this and

could not discern any difference at all) Another "trick"

that we have tried and found to work isthe substitution of

the stock .090 dia M W stab joining wires with #41 drill

rod stock that is cut to the correct length This material is

an absolute, play free fit to the 092 I D brass tubes in the

stab halves and its use greatly minimizes the usual "rocking stab" phenomenon found on virtually all sailplanes

with full-flying stabs #41 drill rod stock can be found at

most industrial metal supply houses.

FIN/RUDDER You might consider totally fairing-in the

hinge

Iine

of

these

two

surfaces

and

may

be

even

far as to internalize the cable and horn system.

Note that in all of the above we have not shown sketches

of how to do these things Frankly, there has been a great

deal written in the magazines in the last few years cover-

ing everything (and more) that we have said here It is

assumed that these kinds of alterations and modifications are simply not for everyone and that those individu-

1

als who might be prone to doing them tend to have a lot

of prior experience and will know what it is that they want

to do in the first place

FUSELAGE ASSEMBLY

The following sequence of instruction assumes that you

addressed yourself to the questions posed in the Intro-

duction section of this manual concerning your radio, its

fit and the need to couple the ailerons with the rudder.

The following assumes that electronic (via radio) cou-

pling will be used

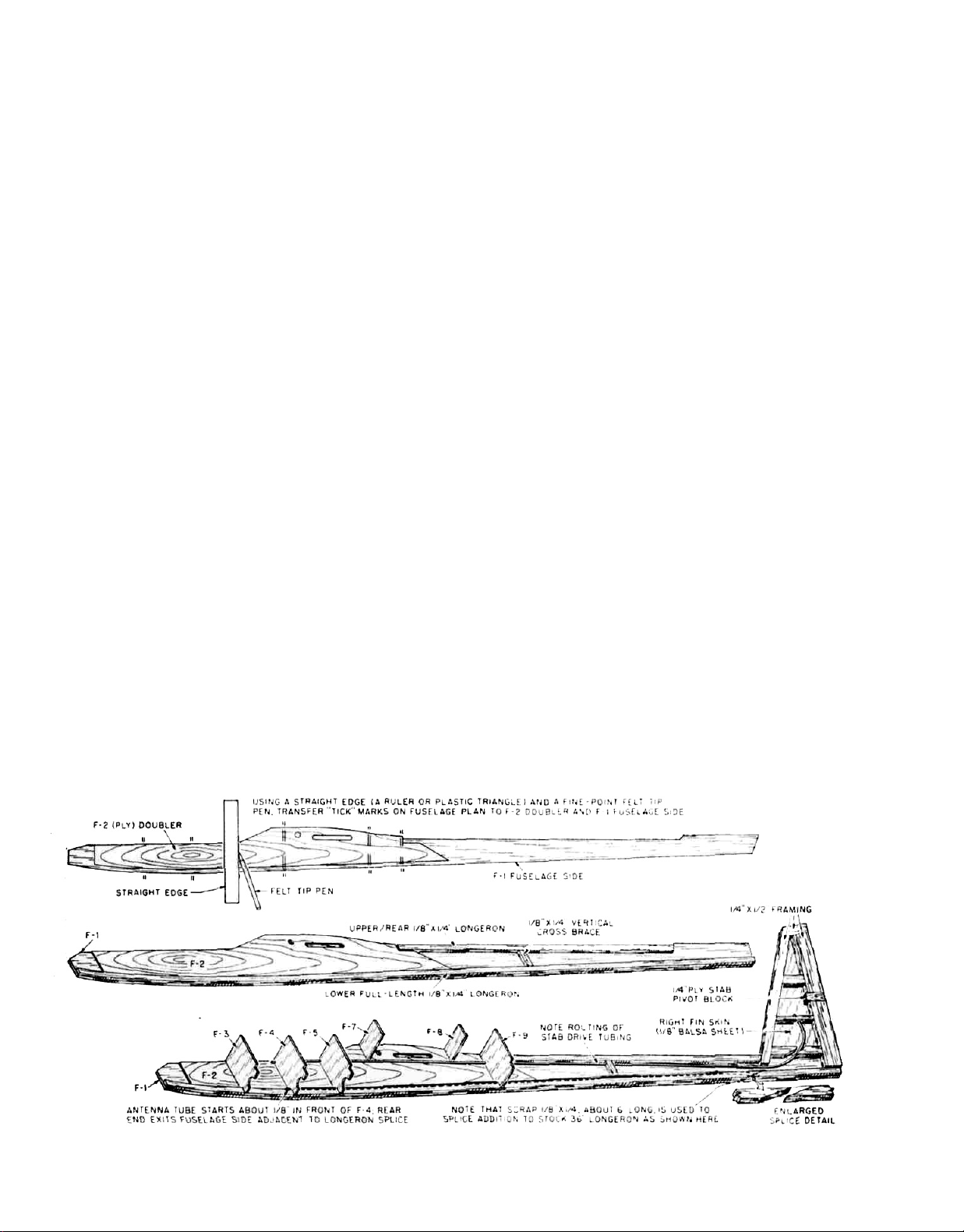

1 Remove die-cut fuselage parts, F-1, F 2 (ply)—do this

carefully and, as mentioned earlier, use an X-acto

knife to expedite this Start construction, by gluing

(we used contact cement) the F-2 fuselage doublers

to the F-1 fuselage sides Do this as accurately as

possible, lining up slots and holes for the wing mating points and making sure these doublers are flush

3

going

as

Page 4

with the top edges of the fuselage sides—MAKE A

LEFT AND RIGHT FUSELAGE SIDE.

2. Using the

1/8" x 1/4" x 36"

balsa stock supplied, glue the

bottom fuselage longerons in place, starting at the

front of the F-2 doubler, pinning and gluing as you

work aft. Note that you will need to add an additional

6" of this longeron stock at the rear to complete to fulllength bottom longeron.

3. Cut and glue the top rear

1/8" x 1/4"

balsa longerons in

place. Note that this longeron extends from the back

of the F-9 former position to the leading edge of the

fin location where it is cut on an angle to match the

fin.

4. Using a sharp pencil and a straightedge, mark the

locations of all fuselage formers; F-3, F-4, F-5, F-7, F-8

and F-9, including the location of the rear

1/8"

x 1/4"

fuselage uprights, behind former F-9—mark these

locations on the right fuselage side. Holding the left

fuselage side to the right, so that they are accurately

matched, transfer the former locations to the left

fuselage side.

5. You will now need to drill an angled hole in the left

rear fuselage side for the outer plastic rudder cable

housing. Note its location on the plans and its distance from the rudder hinge line. Don't deviate from

this location because if it is too far forward, the rudder

cable may be prone to "bending" during'operation

and too far aft will mean that you can't get full rudder

throw. Repeat this process on the right fuselage side

for the internal antenna tube — first check the length

of your antenna to be sure that at least 1" of it will

protrude from the tube at the rear. A sharpened piece

of 1/8" dia. brass tubing works very well for drilling

these holes at the right angles and cleanly.

6. Pin, tape or lightly spot glue the two fuselage sides

together, with their outer surfaces touching — align

them to each other very carefully. Using a sanding

block, sand their outer edges to match them identically. While the sides are still together, carefully

match the main wing tube holes and access slots. We

have purposely made the main wing tube holes a

very tight fit, work carefully to open them up enough

to

accept a length of

11/32"

O.D.

brass

tubing

(3

pieces

supplied in the kit). The main wing tube holes must

line-up accurately.

7. Remove both W-1 ply wing root ribs and both F-10

fuselage root ribs carefully from their sheets.

Remove the main wing tube holes from each of the

ribs and access slots from the F-10 ribs—use a hobby

knife to assist you. Take one of the F-10 ribs and locate

the identification at the back. Drill a 1/8"dia. hole in this

rib,

at

90°

to

its

surface—this

rib

is

now

your

"drill

guide" for the rest of the ribs. Insert one of the main

wing wire tubes into the hole in the "drill guide" rib,

letting one end of it extend out from the rib about 1/16".

Now drill the 1/8" dia. hole needed in the remaining

F-10 and W-1's, by placing the rib onto the wing wire

tube, lining up the rib to be drilled with the "drill

guide" rib and drilling the hole—repeat this process

until all four ribs have accurately aligned and drilled

holes. Use the same procedure on the now matched

fuselage sides; insert one of the main wing wire

tubes into the hole in the fuselage side, slide an F-10

rib onto the tube and down flat against the outside of

the fuselage side, position as shown on the plans and

drill the 1/8" dia. hole. Repeat this process with the

other

fuselage side.

8. Remove ply tailskid from its sheet. Position the tailskid in place on one of the fuselage sides, as shown

on the plans. Mark its forward edge location on the

bottom, rear longeron in pencil. With a single edge

razor blade, remove approximately 1/32" of the thickness of the longeron, forward to the pencil mark —

this becomes half of the slot that the tailskid will fit

into. Repeat this process to the other fuselage side

to

create the 1/16" wide tailskid slot.

9. Lay the right fuselage side on your work

front

of

you with

the

inside

facing

you.

"Take

surface in

one of the

servos that you plan to use for either the stabilizator or

rudder and position it on the fuselage side between

the F-4 and F-5 former locations. Note the position of

the output arm. With a pencil, mark this location onto

the inner fuselage side. Note on the plans and crosssections that both the stab and rudder outer cable

housing tubes are positioned aft, through formers F-5

4

Page 5

and F-9 Now remove formers F-4, F-5 and F-9 from

their sheets Usingarulerand pencil,line the ruler up

with the mark made earlier for the servo output arm

location and draw a light intersect line at the positions of F-5 and F 9 Hold F 5 in place on the fuselage

side and mark the location of the intersect line onto

the former Repeat this for F 9 Mark the other side of

the formers for the output arm location for the rudder

cable housing Sand or file a 1/8" slot on each side of

these two formers, thus creating positioning and

mounting locations for the rudder and stab cable

housing tubes after these formers are in place (see

F-5 and F 9 cross sections) Lastly, sand or file a

similar slot in the lower right corner of formers F-4,

F-5 and F-9 for clearance of the internal antenna tube

Note on the plans, at least with the radio installation

shown, that the rudder and stab tubes are in place

just over the top of both the aileron and flap servo

rails Check how your installation will fit in place and

be sure everything clears

10. In this step we are going to "pre-position" both the

aileron and flap servos Studying the plans you can

see how the operation of these two servos affects the

two control surf aces and a I so what the relationshipof

their locations within the fuselage needs to be in

relationship to the wing panels Note that the flap

servo is located as far aft as possible to allow plenty

of clearance for the spring wing retainerand hooks In

the case of the use of a releasable or captive towhook

system, such as that shown, clearance is available for

getting to and tightening screws as needed Access

to the flap servo is directly through the top, rear

hatch, as shown The flap servo, as you can see,

needs to be positioned so that its output arm is

roughly centered within the slots on each side of the

fuselage This assures easy, bind-free operation of

the flaps and quick, non critical assembly of the airplane at the flying field Mark the locations of the

required two lengths of1/32"x 3/8" ply servo rails for the

flap servo onto the sides of the fuselage A trick that

we have used is to now cut a short length of 1/16" x 1/4"

balsa and glue it in place on each fuselage side to

later act as a gluing shelf and locator for the servo

rails We have used this technique for all of the servos

and it really saves time and frustration later on Next,

we are going to do the same thing for the aileron

servo Looking at the Top View of the fuselage plans,

you can see that access to this servo is meant to be

provided by the heavy fuselage canopy angle at this

section You will also note that we did not provide

aileron linkage holes through the fuselage sides or

the ply root ribs The reason for this is simple, different radio systems and servos would not all work For

this reason, these holes will have to be made by you,

based on your servos and their shapes The first step

for positioning the aileron servo is to develop the

proper output wheel for driving the ailerons Note the

drawing at the bottom of the fuselage plans This is a

typical servo output wheel that is trimmed as shown.

The two arm s that are I eft arc a bout 3/8"apart( hole-tohole). As you can see from the Top View shown on the

left-hand side of the wing plan, the left aileron clevis

attaches to one arm and the right side uses the other

arm. This sim ple system of connecting the ailerons to

the servo also imparts a highly desirable feature to

the actual operation of them—this is called differential Simply put, differential is the unequal movement

of the ailerons, in our case about 2 1 Full throw in

one direction will move one aileron a total of 1/2" "up"

and at the same time only moves the other aileron 1/4"

"down " Almost all flat-wing, high aspect ratio air-

craft (such as sailplanes) use some differential to

correct adverse yaw conditions The set-up we show

on the ANTARES plans works extremely well and has

the virtue of simplicity Once you have made this

output arm and have it in place on the aileron servo.

place the servo directly onto the right fuselage side,

about where it is shown on the plans Note that it

must fit in place behind F-5 and high enough to

position the output arm within the outline of F-10.

However, it must not be so high as to interfere with

the seating of the canopy Once satisfied, mark the

locations of the servo rails to mount it and mark or

roughly sketch a 1/4" dia circle where the output arm

will pick-up the aileron cable and clevis Again, we

would suggest that you memorialize the locations of

the aileron servo rails with the short lengths of 1/16" x

1/4" balsa for ease of installation later

Now drill a 1/4" dia. hole directly through the fuselage

side at the point marked for the aileron output arm.

This then becomes your "drill guide" for the remaining fuselage side and both W-1's and F-10's As before, use a length of 11/32" tube and 1/8" tube to first

accurately locate each part

to

the

"drill

guide"

fuse

side, then drill the 1/4" dia hole

11. Remove three (3) 36" lengths of the white cable housing tubes from your kit box Rough-up their outer

surf aces with medium sandpaper Do this completely,

we want adhesive to adhere to them Set these aside

for

installation shortly,

12.

Next, make

the

fin

tailpost

You can see

from

the

plans

that this is made from 1/4" x 1/2" balsa stock, laminated

edge-to-edge and cut to the taper shown Now locate

the shaped and drilled 1/4" ply stab pivot block Accu-

rately note its location on the tailpost with a pencil.

Take care here to be as accurate as possible—this

block ultimately locates your stabilator to the fin Cut

the tailpost apart to accept the pivot block and glue

the block in place Allow to dry and remove from the

building board.

13 Locate the die cut sheet holding the two 1/8" balsa "fin

skins " Remove these from the sheet and while holding them accurately together, matching outer edges

and the oblong cut outs, use a sanding block and

light sandpaper to "match" their outer edges identically—we want them exactly the same Now take one

of these skins and lay it directly over the plans and

with a pencil mark the locations of the top and center

1/4" x 1/2" balsa horizontal braces and the lower 1/4" sq.

cross-brace and stab cable tubing support. Set aside

for use in Step 14

14. You have already removed and modified formers F-4,

F-5 and F-9 back in Step 9 Remove formers F-7 and

F-8 from their sheet as well Formers F 5, F-7, F-8 and

F-9 are all exactly the same width, 15/8 Hold them all

together and use a sanding block to make sure

they're all the same width Lay the right fuselage side

over the side view of the plans and pin accurately in

5

Page 6

place Using a triangle, glue formers F 5, F-7, F 8 and

F-9 in place at 90 to the fuselage side, using the

pencil marks made earlier for location (please note

the "alternate F-7 location" note and the reason for it

on the plans) Moving to the rear of the fuselage side,

glue the previously marked (Step 13) fin skin to the

top, rear section Now glue the previously assembled

tailpost and stab pivot block assembly to the rear of

the fuselage side and fin skin Cut, fit and glue the 1/4"

x 1/2" balsa fin leading edge in place to the fuselage

side and fin skin (note that this piece terminates at the

bottom edge of the top, rear fuselage 1/8" x 1/4" longe-

ron) Cut, fit and glue the two top 1/4" x 1/2" balsa

horizontal braces whose locations were noted earlier

on the fin skin Cut, fit but do not glue the 1/4" sq.

brace Using the plans, note the location of the stab

cable housing tube and drill an 1/8 dia hole through

this brace at the point marked—now glue this brace

in place Cut, fit but do not glue the bottom 1/4" x 1/2"

balsa fuselage fin brace Again using the plans, note

the location of the stab tubing and the bend it takes at

this point Use an X acto knife or a Dremel tool with a

small router bit to carve a channel", at least 1/8" deep

into this brace to countersink and house the tubing,

once

satisfied, glue this

last

remaining brace in place,

half of its width on the fin skin and the other half on

the fuselage side Inspect your work carefully for

good glue joints, double glue if necessary Onceallof

this is sealed-up, you will not have access to it again

15.

Take one of the 36", roughed-up cable housing tubes

and install it (without glue yet) in place, through the

slots in formers F-5 and F 9, the channel cut in the

bottom fin fuselage brace and through the hole in the

1/4" sq brace on the fin skin Note that this stab drive

tube is meant to fit from just inside of the rudder stab

servo compartment, F 5, along the fuselage side,

through the slot in F-9, all the way along the bottom

edge of the top, rear longeron, through the channel

cut earlier in the bottom fin fuselage brace and finally

through the hole drilled in the 1/4"sq brace We used a

thick CA adhesive, such as Pacer's Zap-a-Gap or SloZap to now glue this tube in place along its entire

length Be sure that it is firmly glued in place—we

don't want it moving Using the marks made earlier,

glue the short 1/8" x 1/4" balsa upright in place between

the stab tube and the bottom fuse longeron

16.

Remove the right fuselage side assembly from the

building board. The left fuselage side is now pre-

pared for assembly to the right byfirstgluing in place

the two short lengths of 1/8" x 1/4" balsa that is the rear

upright — note the 1/8" wide channel that is left to

capture the rudder cable drive tube as it curves down

toward the rear, angled rudder tube exist hole, drilled

earlier. Trial-fit the left fuselage side to the right side

assembly Since all of the formers in place are the

same width, the left fuselage side should come in

firm,

square contact

with

their left edges Once

fied, carefully glue the left fuselage side in place

against F-5, F-7, F-8 and F 9, using the location marks

made earlier Take pains to be sure that the structure

is

truely square

17.

Install another 36" length of cable housing tubing

along the left fuselage side, from just forward of F-5,

through its slot, F-9, along the fuse side. through the

satis-

channel in the upright and out the angled exit hole at

the rear Leave some tubing exposed at the rear for

trimming (see plans) As with the stab tube, glue the

rudder tube in place completely along its entire

length.

18.

Cut, fit and glue the

1/8"x1/4"balsa

cross-brace

in

place

on the fuselage bottom, just behind the towhook

location, as shown Use CA adhesive to glue former

F-4 in place while gently and equally bending the two

fuselage sides together at the nose, when dry repeat

the process while installing former F 3 Now glue the

shaped hardwood noseblock in place Note that this

block fits between the two fuselage sides, flush with

the bottom edges of each and up against the edges of

the two F-2 ply fuselage doublers Tape and/or clamp

in position and allow to dry Cut, fit and glue the two

lengths of 1/4" triangular stock in place behind the

noseblock As you proceed through this step we

strongly suggest that you continually check for symmetry and squareness of the assembly

19. Locate and glue the shaped balsa forward canopy

mount in place against the top rear of the noseblock

and the fuselage sides Sand the edges flush with the

fuselage sides Carefully remove ply former F-6 from

its sheet Clean up the inside edges with sandpaper.

With a sanding block, bevel the two bottom edges of

this former to match the fuselage sides when it's in

place Note that when in place this former stands tall

of the fuselage sides, this is to pick up the top 1/8"

sheet Glue F 6 in place and when dry, sand its outer

edges flush with the fuselage sides

20 Using about an 8" length of one of the 1/16" x 3" x 36"

balsa sheets provided, cut and fit the canopy/hatch

base Use your sanding block to bevel each end of

this base to fit accurately to the forward canopy hatch

block and the angled F 6 rear former Lightly tack glue

this piece in place and sand its edges flush with the

fuselage sides Remove canopy formers C-2, C-3, C-4

and C-5 from their sheet Sand the required bevel into

the bottoms of C-2 and C-5 Carefully glue these two

formers in place on the canopy base being careful to

not glue them to the fuselage — their outside edges

should be flush with the fuselage sides Now center

and glue the C 3 and C 4 formers in place per the

plans (these fit directly over F-3 and F 4 respectively).

Remove the two C-1 canopy sides from their sheets.

Using a flat work surface, glue and pin the y4"tnangular stock piovided to the inside top edge of the C-1

canopy sides — be sure to make a right

and a left

When dry, carefully fit these sides in place, trim as

needed to get a good fit and glue them in place With

the canopy assembly still tack glued to the fuselage,

use your sanding block to bring the sides flush with

the fuselage sides

21. With ready access to both the inside of the canopy/

hatch and the fuselage, now is the time to build the

canopy hold-down system Note the views shown in

the upper left corner of the fuselage plans These

demonstrate how the canopy is secured to the fusel-

age, at the nose with a ply 'lip' that is glued to the

bottom of the canopy base and fits beneath the

canopy hatch block, in the middle it is held to the

fuselage by two wire hooks and a rubber band and at

6

Page 7

the

rear

there

is a length

(1/8" x 1/4" x 1-5/8")

balsa

to the back of C-5 that fits into the cut out in F-6 This

system is easy to install at this stage and has worked

beautifully in actual practice Cut, fit and glue the ply

"lip in place, being careful not to glue it to the fuselage Cut or drill the 3/8"dia hole inthecanopy base—

in the center — just behind C 4 Bend and install the

two wire hooks shown, one on C-4 and the other

toward the bottom of F-4 Cut, fit and glue the 1/8" 1/4"

x

1-5/8""

balsa

piece

to the

back

of

C-5

(trim this piece

carefully for a qood, snug fit as it is meant to keep the

canopy from shifting left or right Once satisfied, use

the piece of 1/8" x 3" x 12" balsa provided to sheet

(cross-grain) the top of the canopy (see side view).

When dry, sand the edges flush with the sides.

22.

From your packaged wood parts and hardware,

locate the 11/32" 0 D x 2-5/16"

main

wing

wire tube, the

1/8" O.D. x 2-3/16" rear incidence pin tube and the maple

U-block tube nest Use rough sandpaper to rough-up

the outside surfaces of the brass tubes Insert the

tubes into their respective holes and center them —

note that each tube protrudes past the fuselage sides

to pick-up the installation of F-10 later Now trial-fit

the U-block onto the main wing tube inside of the

fuselage, sand edges as needed for good fit and

remove for gluing Cut a 1-5/8" length of 1/8" x 1/4" balsa

to fit beneath the rear incidence tube and against F 8.

Using 1-hour epoxy, apply glue to each end of the Ublock and fill the channel a bout one third Slide the U-block

over the tube as shown on the plans—carefully

wipe-off the glue that oozes onto the fuselage sides

Using more epoxy, "bury' the tube in glue, rotate the

tube itself to make sure there are no air bubbles.

Again using epoxy, glue the 1/8" x 1/4" balsa shelf

directly under the rear incidence tube and to F-8

"Bury" this tube in adhesive as well Take a break and

let the whole thing set-up — watch for runs

23.

Use the remaining piece of roughed-up outer plastic

tube to make the internal antenna housing Install this

tube from just inside of the receiver compartment (in

front of F-4), aft along the bottom right fuselage side

and out through the angled hole made earlier. Note

that the tube fits into the slots you made in F-4, F-5

and F-9 Glue securely in place.

24

. Decision time, are you going to use a radio-actuated

captive towhook system, such as the Fourmost Products shown on the plans or the fixed towhook pro-

vided in the kit While both systems work well, if you

are planning contest work with your ANTARES, we

highly recommend a captive system such as that

shown You will note on the plans that we are releasing the towhook by radio, using a 3/4" "up" elevator

signal. While at first this might sound suicidal, in

actual practice this system, in conjunction with use of

flaps on launch, makes for wonderfully tall "ping"

launches You might take a look at the Flying section

of this manual and read how we have been doing this

before you decide which towhook system to use

Installation of the Fourmost hook is quite simple and

accurately depicted on the plans In fact, when we

used this system, WP pro-slotted the ply floor,

installed the mounting rails and secured the Fourmost hook in place on them and then installed the ply

floor to the fuselage

glued

If you are installing the stock, fixed towhook, start by

locating

the 3/32" x 2" x 17"

ply

forward

fuselage

Mark a centerline down its length in pencil. Hold it in

position against the bottom of fuselage with its rear

edge covering half of the 1/8" x 1/4" cross-brace be-

tween F-5 and F-9 With a pencil, mark the outside

fuselage side outlines, trim off the excess off with a

saw Glue the ply floor in place on the bottom of the

fuselage with the previously drawn centerline on the

outside

Use a 5-7/167"

length of the

3/32" x 3/8"

ply stock

provided and glue it in place to the inside centerofthe

ply floor, between F-5 and the rear cross-brace as

shown on the plans From the plans, determine the

towhook location and from the outside, drill a 1/8" dia.

hole through the fuselage floor and the ply doubler

just installed. Epoxy the 4-40 blind nut provided into

this hole from the inside — use glue liberally around

the nut's base without getting any into the threads.

25. Using the remaining 1/8" balsa sheet, finish sheeting

the top of the fuselage as shown on the plans Note

that one piece extends aft from the rear face of F-6 to

the rear edge of F-7 This sheeting is then resumed

(always cross-grain) from the forward edge of F-8

back to the rear edge of F-9 "Cap" the top of the two

fuselage sides between the two edges of the sheeting

with 1/8" x 1/4" balsa, aligning the outer edges with the

fuselage sides The resulting rectangular opening in

the fuselage top is for the access hatch.

26 As shown on the plans, the access hatch is a simple

frame made from 1/8" x 1/4" balsa, on edge, with 1/8" x

1/4" gussets in each of the four corners We used

scraps of bond paper front, back and on each side for

spacing while making this frame. As shown, install

two pieces of 1/8" x 1/4" balsa as shelves on the back

face of F-7 and the front face of F-8 to seat this hatch.

Sheet the hatch with the last of the 1/8" balsa provided,

cross-grain Lightly sand the edges flush with the

frame and lightly tack glue the hatch in place for final

sanding

27. Trim off and sand flush any protruding rudder and

antenna tubes on the right and left fuselage sides.

Trial-fit the two rear fuselage sides together to be sure

they will fit without any obstructions Once satisfied,

we will now glue the two fuselage sides together at

the rear This step is important and should be done

carefully to avoid unequal bending of the fuselage

sides (boloid) We would suggest that you place the

fuselage directly over the top view on the plans as

this supplies you with a centerline reference. Firmly

secure the fuselage with heavy objects that have right

angles (bricks, one on each side, are great). Use a

slow drying glue such as 1-hour epoxy and apply

adhesive to the inside of the fuselage sides, just

ahead of the fin (see plans), aft to the tail —keep glue

out of the tailskid slot Clamp the structure together.

Check very carefully for squareness and alignment.

Make sure that the fin structure is at 90° to the work

surface and that it is aligned down the center of the

fuselage when viewed from the front Let this assem-

bly cure completely.

28. From your hardware, locate one length of 36" braided

metal cable and the stab drive fitting The stab drive

hole in this small fitting is slightly undersize and

needs

to

have a #42 or

7

3/32"dia.

drill

bit

run

through

floor.

it.

Page 8

You don't want the fit between the forward stab drive

wire and the fitting loose but it still should be made to

pass through the fitting without binding Insert one

end of the cable into the "tube" end of the fitting and

solder securely (we recommend the use of Hams'

STAY-BRITE silver solder and particularly their STAYCLEAN flux for this and all other solder joints on this

airplane) Clean the joint completely and insert the

other end of the cable through the stab tube at the fin

and push it through to the servo compartment Cutoff the excess, leaving yourself a little extra to trim

later when installing thecoupler Once satisfied, usea

1/8" dia drill bit through the rear 1/4" ply stab pivot

block hole and right fin skin Glue the left fin skin in

place, align carefully and allow to dry

29. Cut, fit and glue the 1/8" x 1/4" fuselage cross braces in

place, top and bottom, at the aft mid point of the

fuselage Cut, fit and glue the 1/4" balsa turtle-deck in

place on the top rear of the fuselage — note the bevel

needed for the fin's leading edge angle Turn the fuselage over and using the 3/32" x 3'x 18" balsa provided,

sheet the bottom from the rear edge of the ply floor

all the way back to the tailpost, keeping glue out of the

tailskid slot Note that this sheeting is applied crossgrain Use a sharp razor blade to cut the tailskid slot

into the bottom sheet at the tail Glue the tailskid in

place Locate the shaped 1/2" fuselage/fin fairing If

needed, use your sanding block to achieve a precise

fit and glue this fairing in place Use a sanding block

and 120 grit sandpaper to sand the fuselage sides, top

and bottom smooth Pay particular attention to the

side-view contour at the top of the fuselage where the

1/8" sheet meets the 1/4" turtledeck Sand the side and

top view shapes into the fuselage all the way through

the noseblock but don't start rounding any edges yet.

Work around the protruding wing tubes for now Note

the fin/fuselage joints are completely flush and

smooth Use the 1/8" dia drill to clear-out the remain-

ing hole needed in the left fin skin Trim the 1/8"O D x

7/8" brass tube used for the rear stab pivot bushing to a

little more than 1/2" long Rough-up its surface and

glue it in place into the hole provided atthe rear of the

fin, sand the edges flush with the fin.

CUT I/I6"SLOT IN FUSELAGE BOTTOM TO ACCEPT

TAILSKID. CHECK FIT, THEN GLUE IN PLACE.

30. Temporarily install thetwo F 10's onto theirtubes and

against the fuselage sides Use a soft pencil to trace

their outline's onto the fuselage sides and remove the

ribs Using the plans for reference start sanding the

fuselage to final shape Note that at the top of the

fuselage, at the F 10 location, it is only rounded to the

outline you just drew, don't undercut it — see cross

sections Use the heavier grits of sandpaper for the

initial shapes, progressing to lighter grades to finishup This fuselage and fin can be sanded to an almost

ovoid shape in many of the cross sections — take

yourtimeanddoa complete and tho rough job, it can

look really sexy when you do it right Note the suggestion of adding a couple of pieces of scrap 1/8" balsa

to each side of the tailskid and then sanding the

whole thing into tho cross section of the fuselage.

When finished, carefully break loose the canopy.

RUDDER

1. Construct the rudder over the plans, starting with the

outside 1/4"x 1/2" balsa frame, the three corner gussets

and then the 3/32" x 1/4" geodetic "ribs" and their two

gussets Use a sanding block lightly on each side of

this structure

2 Locate and remove the two R-1 (ply) rudder horn

mounts Sandtheir edges flat andgluein place atthe

bottom leading edge of the rudder—one on each

side

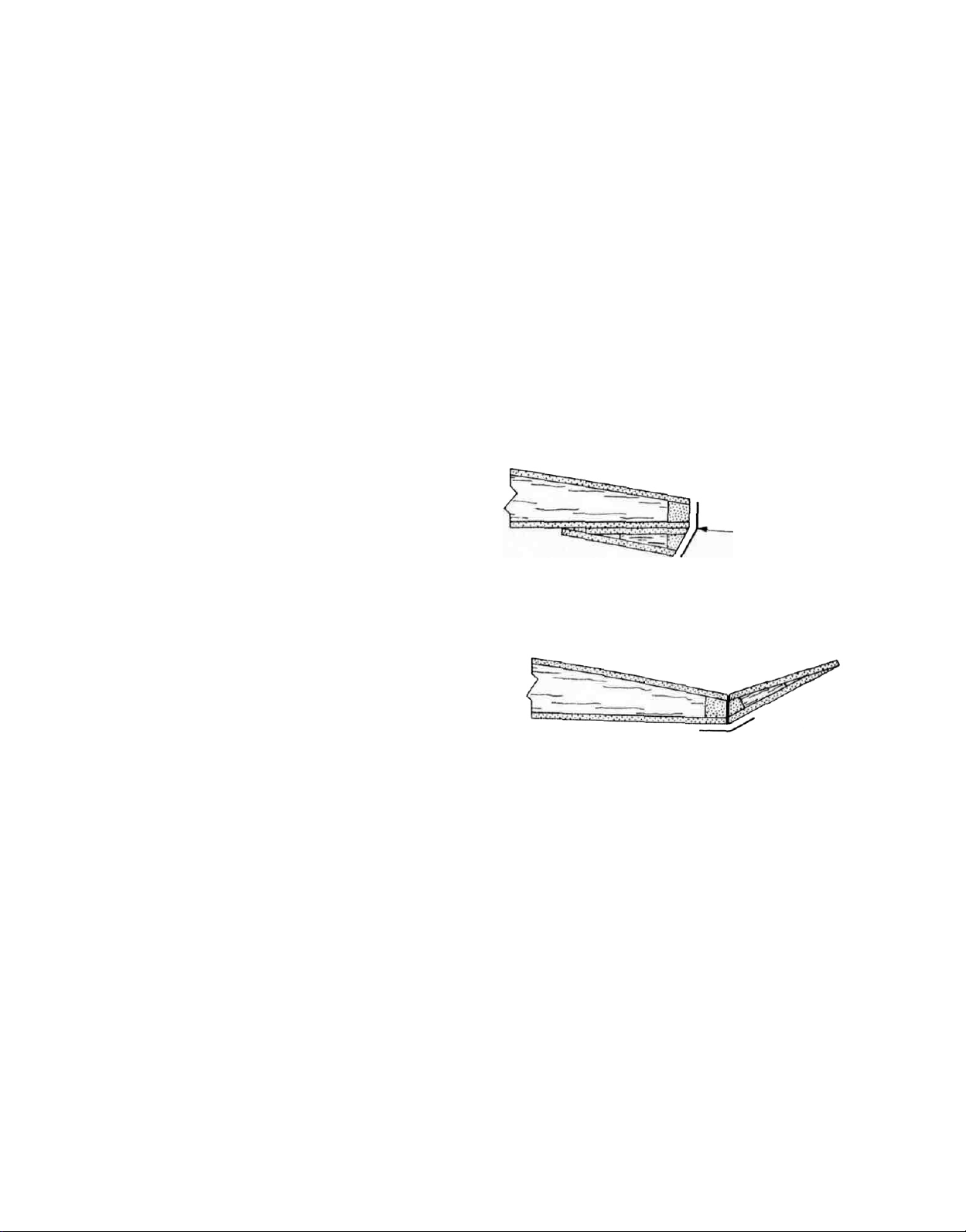

3 Use the 1/16" x 1/2" x 36 balsa strip provided to "build-

up" each side of the rudder, as shown on the

exploded view on the plans.

4 Use a sanding block to bevel the leading

rudder, on its centerline, to provide

movement—

see cross section on plans.

edge of the

unobstructed

5 Sand rudder to its final cross section shape with a

sanding block Cut slots for hinges in the leading

edge of the rudder and the trailing edge of the fin—

check fit Mount rudder in place on the fin and

hold

with masking tape at the hinge line Sand the final fin/

rudder shapes rounding all edges carefully to match

— see plans Remove rudder and lunges from fin.

STABILATOR

1. Locate and remove the two required E-1's and E-2

stab parts from their die-cut sheet Start construction

by using the remaining piece ofthe1/16"x3"x 36" balsa

sheet that was used for making the canopy base, to

make four (4) 1/16" duplicates, without slots, of both

E 1 and E-2 A sharp razor and straight edge will do

the job quickly—note the desired grain direction.

(Note that if you wish to build a thicker stabilator, as

discussed in the F3B Modification section, substitute

the 1/16" stock with 1/8" sheet balsa Realize that this

means a change in the size of the leading edge, spar

and qeodetic material—the tips and trailing edge

material could be shimmed with scrap to center

them )

2 Using the 3/32" x 3/8" ply stock provided, cut two 3-1/16"

lengths to serve as the stabilator "roots" (save the

balance of the ply stock, it will be used for servo

mounting rails) As the drawing shows, accurately

mark and drill the 1/8" dia holes for the brass tubes

We think this is best done with a drill press of some

8

Page 9

kind, since the right angles are important. At this

point, if you are going ahead with the VA" stabs, you

should trim Vis" off of each side of these ribs. We

would suggest that now is a good time to check and

make sure that these holes are properly spaced and

will

fit.

Locate

the two W dia. x 2%" M.W. stab joining wires. Temporarily install the four tubes into the holes in the ply

stab root ribs and assemble these to the fin with the

joining wires. The fit should be smooth and non-

binding when moved up and down at the front of the

fin. All of this serves to confirm that the hole spacing

is correct—if it isn't, correct as needed.

3. Next, take one of the 1/8" O.D. stab tubes and slip the

1/8" I.D. wheel collar over one end. As shown on the

plans, mark the location of the wheel collar's setscrew hole, removethecollarand fileorgrind a notch

into and through the wall of the tube large enough to

let the set-screw pass, when tightened. Carefully

clean-out any metal "flash" on the inside and outside

of the tube, re-install the collar and test fit the setscrew for clearance. Once satisfied, apply a small

amount of thick CA adhesive to the collar tube joint.

This is your one and only stab-locking tube (see stab

plan).

4. Cut or route-out a slot in one of the rear E-2's to

the

wheel collar—trial-fit to be sure. Leaving the tube

and collar in place in the

the

1/16" balsa laminates in place with your fingers,

press

indention on the inside of each skin. "Scoop-out"

firmly with your fingers to create the collar's

four

(4)

Va"

O.D. x TVie"

E-2 p

brass

art, fit and hold two

tubes and

accept

balsa carefully from the indented areas, thus leaving

clearance for the collar. In the bottom skin, carefully

make a 1/8" hole for the set-screw.

5. Assemble the stabs directly over the plans

with accurately locating and pinning in place the 1/8"X

1/4" upright "spar". Assemble the rest of the

structure as shown being careful to not get glue into

the joiner tubes. Be sure to use epoxy to secure the

tubes into their respective slots and that these tubes

are laying flat.

6. When dry, remove the stabs from the plan and use

your sanding block to sand them flat. Next, hold them

together and "match" their outside shapes—you

want them identical. Before going any further, trial-fit

the stabs to the fin. You will have to trim a little of the

length of the joiner wires to get the stabs to fit flush

with the fin sides as we have left these a little longer

for fitting purposes. What you're looking for during

this trial-fit is that the two stabs sit at 90° to the fin

sides and that their roots are flush with the fin sides

as well. Remove the stab halves and the joiner wires.

File or grind a small "flat" on one end of the rear

joiner wire for the set screw to bottom-out on when in

place—re-install and test-fit, including the set-screw.

Once satisfied, remove all of the components from

the fuselage.

7. As with the rudder, use your sanding block and

of

grit sandpaper to carefully bring the stabs down

the cross sections shown. Note that what you are

trying to achieve here is a symmetrical airfoil. Also

starting

stab

120

to

9

Page 10

note that the "entry" or lead ing edges a re not particu-

larly sharp, but not just "rounded" either. Approach

thistaskwith care tocreatethe intended shapes. Final

sand with light paper and set aside for covering.

BALLASTING

As

we mentioned earlier in the Introduction to this

manual, having the capability to incrementally increase

your wing loading to match certain weather or contest

conditions is of great value and simply adds additional

scope to your flying abilities with the ANTARES If you

have opted to build-in the four ballast tubes into the

wings, you now need to develop the weights necessary to

fill

them

As

mentioned

earlier,

we

chose

to

use 2'lengths

of1/2"O.D. brass tubing ("off the shelf" K&S brand), filled

with poured lead These should weigh about 2.5 ounces

each. Each end of these "slugs" should be carefully

dressed so that they slip easily into and out of the wing's

ballast tubes. Since each wing tube has a capacity of

13-3/4",

then

each

tube

can

hold

up

to a total of six

(6)

slugs

and therefore the total system can hold up to 24 slugs or

60 additional ounces of ballast.

IMPORTANT:

When melting and pouring lead use extreme caution.

Always work with this material in a well ventilated area,

preferably outdoors Always wear heat resistant gloves

Always wear a protective mask over your mouth and

nostrils to avoid fumes (such as a painter's mask). Avoid

prolonged contact with the lead itself to your skin. Always

wear safety glasses or goggles'"

To make these slugs you will need to obtain four (4) stock

12" lengths of K&S Engineering's 1/2" O D. tubing, their

stock #139 and about 4 pounds of lead—we use large

sinkers obtained from the local tackle shop, while the

tubing itself is available from your local hobby shop The

lead was melted in an old iron pot over a hot plate The

tubing was prepared for filling by first using thick CA

adhesive to glue a small circle of 1/8" plywood over one

end The tube was then securely propped-up, on the

ground, sealed end down, with bricks The melted lead

(about 1 pound at a time) was then poured into the open

end of the tube until filled and allowed to cool on it's own

—do not attempt to cool it with water or any other type of

coolant as this will cause shrinkage of the lead within the

tube. Once the tube has cooled and can be handled,

knock-off the 1/8" ply plug Repeat this process on the

remaining three tubes until you have four lead filled 12"

long slugs.

The slugs are now marked off in 2" increments and sawed

into individual slugs We used a hacksaw for this pur-

pose Now dress the ends of each of the slugs to remove

flash. When complete, you should have 24, 2" brasslined lead ballasting slugs Minor discrepancies in

weight between these slugs is not important while anything over about 1/3rd of an ounce might be—check them

with a scale.

Obviously, the lead slugs are loaded into the wing tubes

from the wing roots but these slugs must be held in place,

as close to the fuselage as possible without having the

freedom to move outboard We use pre-measured and

cut lengths of common 1/2" dowel (found in most hardware and I umber supply stores) to hold the slugs in place

These are sanded carefully to fit freely into the wing

tubes So, in order to load, say, four lead slugs into the

wings you will need four 11 3/4" long 1/2" dia dowel "fil-

lers" These fillers a re inserted into the wing ballast tubes

first, followed by four slugs This should render the slugs

im mobile a gainst the fuselage F-10 ply ribs and the dowel

fillers in the wing tubes In this particular instance, you

have now increased the weight of the airplane by 10

ounces (plus the weight of the dowels, about .064 ounces

per inch) and the wing loading accordingly.

If you are so inclined, as we were, you can now make up a

carrying case of sorts that will hold all of your ballast

slugs and dowel fillers We have gone as far as including

in this case a chart that shows all of the possible wing

loading configurations obtainable with ballast—this case

goes with us to all flying sessions and contests and has

proven itself to be a valuable tool in handling both condi-

tions (weather) and tasks

Remember, all ballast must be as close to the fuselage as

possible, never load the slugs first Also remember that

all ballasting must be symmetrical, the same amount in

the same location on each side of the fuselage Lastly,

remember that the dowel fillers are mandatory for this

ballasting system—a loose lead slug that weighs 2-1/2

ounces develops inertia quickly and can rearrange the

inside of your wing—be sure that it is immobilized by the

filler dowels

WING ASSEMBLY

Before starting this assembly sequence you must decide

whether to build-in the ballast tube option The option is

relatively easy, requiring only the four Estes #BT-5 rocket

tube bodies and the holes for them in the effected wing

ribs. Just make sure that when you make the required

holes and insert the tubes, that they don't bend in any

way—they must be straight

1. Start by removing all of the wing ri bs, not the trai lingedge "riblets", from their die-cut sheets Do this

carefully, use the X-acto knife if needed. We have

made it a practice of stacking all of the ribs together,

in the order that they are used and lightly sanding

them to uniform shape with the sanding block Also

be sure that the top and bottom spar notches line-up,

again using the X-acto knife if needed.

2 Next we are going to prepare all of the 1/16" wing

sheeting for use Note that the top and bottom lead-

ing-edge sheeting is 1/16" x 4" x 48", in other words, all

one piece The rest of the sheeting must be "scarfed"

together from the 36" and 18" lengths to produce the

required 48" sheets While the diagram shows you

how to do this, the Wing plan shows you exactly

where to cut and join these sheets (We prefer using

white glue or aliphatic resin type glues, such as

Titebond for these Joints ) This operation should be

done carefully to produce good joints and straight

edges When dry, lightly use a sanding block to

smooth the joints until they cannot be felt with your

fingers When complete, you should have the following pieces of wing sheeting available for assembly:

4 pcs. 1/16" x 4" x 48" unscarfed, top and bottom

leading-edge

4 pcs. 1/16" x 4" x 48" scarfed from 36" and 18" lengths,

top and bottom T.E

10

Page 11

2 pcs 1/16" x3" x 48" scarfed from 36" and 18" lengths,

top center section

2 pcs.

1/16"x3"x 18"

It is important to note that all of the wing sheeting

pieces have clean, straight edges Use a metal

straight edge and a razor to do this Lastly use the

straight edge to accurately cut the taper into the four

trailing edge sheets, 3-1/8 at the root to 3-1/2 at W 20

3. Lay the bottom trailing edge sheeting in place on the

plans and with a pencil mark the aileron flap hinge

line at each end of it—1 1/2" ahead of the trailing edge

Use a straight edge to connect these two marks with a

soft pencil Now note the location, at W 12 of the

aileron/flap break line Again using a straight edge,

cut this line through the sheeting from the hinge line

back to the trailing edge Now accurately pin the

trailing edge sheeting directly over the wing plan

(your plans should be covered with clear plastic

material such as the backing from a rollofMonokote)

4 Now accurately position and pin in place the bottom

leading edge sheeting on the plan—note that this

sheet extends from the rear edge of the bottom spar,

forward to the front edge of the 3/8 sq leading edge

Cut, fit and glue the bottom center section sheeting in

place Using the rib tick marks provided on the

plan, mark the location of all ribs—W 2 through W 20

on the bottom wing sheeting Cut, fit and glue all

bottom 1/16" x 1/4" cap strips in place from W 7 out to

W 20 Accurately locate and glue in place the bottom

1/8" x 3/8" x 48 spruce spar Use a straight edge to make

certain that it is truly straight and use pins and blocks

to hold it that way.

unscarfed, bottom center section

5 Once again using your straight edge for alignment,

gluethe1/4 sg x48"wing trailing edge in place along

the hinge line drawn earlier The 1/4" sq leading edges

for the ailerons and flaps (two pieces, one for each

surface, cut from the 48 stock provided) are now

glued in place to the bottom sheeting, also along the

hinge line—do not glue these to the wing's trailing

edge—spacing these two pieces from the trailing

edge of the wing with scraps of common card stock.

6 Using the top spars (1/8" x3/8" x 48"), lift and support the

bottom leading edge sheeting to conform to the

bottom, forward shape of the ribs Take care to accu-

rately position this spacer" to provide uniform

sheeting curvature from the root to the tip Check this

curvature with the ribs you are looking for uniform

contact with them from the spar forward

7. Locate and remove both W 21 's and W-22's (ply) from

their sheets Note that these parts are tapered and

that the wing root angle is in their root ends, therefore

there is a definite way they are to be installed Use

your sanding block to clean up their edges Glue the

forward W 21 in place to the bottom sheeting and the

leading edge of the spar, with its angled inboard end

terminating at the inboard edge of the wing sheeting

—be sure that W 21 is in place at 90° to the bottom

sheeting to assure proper rib-end contact

8 Locate ply root rib W 1 and the 1/8" W-2A "half-rib".

Hold W 1 in place against the inboard end of the

wing, W 21 and the 1/4" sq trailing edge Hold W-2A in

place against W 1,with its rear edge up against W-21.

Use a pencil to outline the forward 1/4"dia hole drilled

in W 1 for the aileron linkage onto W-2A, set aside

W-1 for now Drill a 1/8 dia hole through the approxi-

11

Page 12

NOTE HOW UPPER SPAR IS USED AS A WEDGE

TO SUPPORT BOTTOM FRONT SHEETING

WITH WING FRAMEWORK PINNED TO A FLAT

WORK AREA, PRESS SPAR BACK UNTIL THE

SHEETING MATCHES RIB CONTOUR

mate center of the 1/4"dia pencil mark you just made

on W-2A Using this rib as your guide, drill similar 1/8"

dia holes through all of the remaining ribs that hold

the aileron cable tube—W 3A through W 15

9. Starting with tip rib W 20 and working inboard, glue

all wing ribs in place * Use a triangle or a small block

with right angles to ensure that these ribs are in place

at 90° to the bottom sheeting *NOTE W-2A is

installed at the same angle as the inboard end of

W-21, this provides the root dihedral angle required.

Do not install W-2B or W-3B at this time.

10. Locate and glue the 3/8" sq leading edge in place

11 Cut, glue and fit the 1/16" x 1/4" "sheeting shelves" that

fit between each rib, flush with their top edges and

against the inside of the 3/8 sq leading edge These

are made from the 1/16" x 1/4" x 36 stock provided

12. Locate,

flap "riblets" on the bottom sheeting, againstthe rear

edge of the 1/4"sq stock in place Note that there are

two #12's provided for each wing panel and that they

are glued in place on each side of the aileron flap cut

made earlier, use a piece of card stock to space them

13. Remove the top spars from underneath the leading

edges of the wing panels and temporarily install

them into the top rib slots Align their inboard ends

flush with the top inboard end of W-21 Using the

remove and glue in place all of the aileron and

spars as spacers, glue the rear ply W 22's in place to

the bottom sheeting and the rear face of the bottom

spar—do not glue to the top spdr Note that W 22 is

meant to fit from the inboard edge of the bottom

wing sheeting out to rib W 4B Remove the top spar

and re-install it beneath the leading edge of the wing

panel

14 Locate the bag containing the 3/8" x 5/8" x 3" vertical-

grain balsa shear webs These are now trimmed and

accurately installed between each rib starting from

W 4B out to W 20 Note that these webs must be

carefully fitted in place between each rib and the top

and bottom spar locations—do not allow any gaps or

bad joints, the integrity of your wing depends on

these webs!

15 Use the 1/16" x 1" x 36 balsa strips provided to cut, fit

and glue in place the horizontal grain web facing

caps which are full depth, from W 9 through W 20

These are glued to the front faces of all the 3/8" vertical

webs just installed—see plans and cross sections

16 In this step we want to prepare the top of the wing for

sheeting This is best done with the largest, longest

Sanding bloc k that you have with light sandpaper

The tops of the 1/4" sq trailing edges and the 1/4" sq.

aileron and flap leading edges have to be tapered as

shown on the plans Also, the bottom, trailing edge

sheeting must be tapered as shown Take your time

here to ensure accuracy We have used masking tape

over the ribs, in front of and behind the 1/4" sq.

material to avoid gouging Once satisfied, cut, fit and

glue the 3/32" ply aileron and flap horn mounts into the

locations shown (riblet 8 and 16) These too are

tapered—see cross sections

17 Locate and mark the required hole positions for the

aileron and flap horns (4 40 flat head bolts) The

measurement from the hinge line back to the centerline of these holes is 5/16" Drill these holes, at right

angles to the work surface with either a 5/64" dia drill

bit or a #42 index bit

12

Page 13

18.

Glue rib W 3B in place Glue rib W 2B in place at the

correct root angle Remove the wing panels from

your

building board.

19 In this step you are going to "final sand" the correct

wing root angle into each panel The cor rect angle, as

shown ontheplans is imparted to the root ribs when

the tip, at W 20, is blocked up to 2" off of your work

surface Take pains to firmly position each panel on

the edge of your work surface before sanding this

angle into the root ribs—note th at the leading edge of

the wing, when viewed from the top is 90 to the root.

Once satisfied with the positioning of the wing panel,

use a large, flat sanding block with heavy sandpaper

to sand the root angle into each wing root

20.

Glue ply wing root ribs W 1 in place to wing roots,

accurately lining-up the main wing tube holes with

the cavity between W 21 and W-22 The trailing edge

ofthisshortened nbendsattheflaphingeline Runa

1/8" dia drill bit through the rear incidence pin tube

hold in W 1 and through W 2B Locate and epoxy the

1/2" sq maple wing hook mounting blocks in place

against the inside of W 2B—note this block is positioned 9/16" behind W-22

21.

Locate and get ready, the main

5/16" I D x 2-5/8"

brass

main wing tubes, the 5/16 dia main wing rod, the rear

3/32" I D x 1-3/16"

incidence tubes, the

3/32"

dia x 4-5/8"

MW incidence pin, W 23 s (ply, four) Also, in the

small bag of wood parts locate the four pieces of 1/16"

x

3/8" x 2-1/2"

ply

(these

are

spar box

"fillers",

see cross

sections at the wing root)

First rough-up the outside surface of all four of the

brass tubes with 120 grit sandpaper Next you need to

cap-off one end of each of these tubes to present

epoxy from seeping inside when they're mounted.

The easiest way to do this is to hold one end of the

tube over a piece of bond paper and apply CA adhesive to the joint When set use a small sanding block

to sand away excess, leaving just the capped end of

the tubing Next, trim, fit and glue the bottom 1/16" x

3/8" x 2-1/2"

spar box "filler' in

place

on top of the

bottom spar, between W-1 and W-4B Trim and sand

the four W-23's to fit in place but do not glue yet

We are now going to install the wing tubes, followed

by using the two wing rods to fixture" their final

locations Start by mixing a batch of slow drying

epoxy (use Hobby Poxy Formula 2) Apply glue liberally to theinsidoofthes par box where the main wing

tubesfit—fill itto the bottom of the hole inW 1 Insert

the main wing tubes, capped end first, through W-1.

Try to make sure there are no air bubbles Insert, but

do not glue yet the rear incidence pin wing tubes in

place, capped end first through 3/32" 1 Place the two

wing panels on your work surface with the twoW-1's

facing each other Prop one panel up at the tip 2", slide

the two wing rods inplaceinthcir tubes in this panel

Slip the other panel onto the wing rods and prop its

tip up to 2 also Make sure the two W 1 root ribs are

firmly in place on the work surface (use weights, if

needed) and that they are parallel (Note, it is not

necessary to push the two panels together tightly,

just enough to "bottom out" the two rods is suffi-

cient ) Apply epoxy liberally on and about the rear

incidence tubes, fittheW 23 sin place—hit them with

a little CA to keep them from moving—and fill the

cavity between them to the top with epoxy Note that

we have not yet filled the main wing tube cavity, this

will be done in due time Allow this entire assembly to

cure overnight.

22 Remove the wing rods from the wing panels Slip the

F 10 ribs in place over the tubes and up against the

fuselage sides Use your sanding block to bring these

tubes flush with the outside surface of the F-10's Do

the same thing to the protruding ends of the tubes

showing through W 1 Clean the edges with an Xacto blade to allow wing rod clearance Insert the

wing rods into the fuselage tubes and slip the wing

panels in place You may have to trim a small amount

of the rod's lengths to achieve proper seating—a

carbide cut-off wheel or a grinder will do the job but

do not cut-off too much, we want the tubes filled with

rod If any touch-up sanding is necessaryto achieves

smooth, flush fit between F-10's and W-1's,do it now.

Pull the panels out a little way on the rods to expose

th face of F-10, apply a few "dots" of glue to the

F-10's, push the panels back in place against them to

allow to dry This tack glues the F-10's accurately in

place for final sanding

23. With the panels still in place on the fuselage you must

now determine the exit locations for the flap drive

cables in relationship to your servo and its output

arm Note on the plans that these exit locations are

"staggered" to allow one servo to control both flaps.

As viewed from the top, install your flap servo on its

rails, directly on the centerline of the fuselage Attach

the output arm to th servo with it pointing directly

fore and aft along the same centerline The output

arm's clevis holes, in this position, is the mark(s) that

you're looking for Make a pencil mark on the tops of

the F-10 ribs at right angles to these two holes.

Remove the panels, along with the tack-glued F-10's,

from the fuselage

24. Use a sharp pencil to draw the oblong slot in F-10

onto W 1 With the wing panel flat on your work

surface, use a 90 triangle and pencil to pick-up the

marks you just made on top of F-10 and transferthem

to W-1, inside of the oblong slot With an 1/8" drill bit,

drill the flap exit holes through W-1, W-2B and W-3B,

as shown on the top view of the plans Carefully make

a hole in each rib, as shown on the plans, to "snake"

the flap tubing out to W 8B Going back to the wing

root once again, drill a small 1/32" dia guide hole,

inside of the oblong slot, at the front, through W-1

and into the maple hook block Make sure this hole

location is far enough behind the front of the slot

allow clearance of the wing hooks into the slot.

25 Prepare the remaining plastic tubes (2 @ 48" and 1 @

36") for installation into the wings Rough-up their

outer surfaces with sandpaper and cut the 36" piece

into two 18" lengths—these are for the flaps As

shown on the plans, 'snake" the flap tubes through

3/32" 1 andouttotheW 8B location, cut the tube leaving

about one extra inch at the end (outboard) for fitting

purposes later The inboard end should be flush with

thefaceofW 1 Install the longeraileron tubing inthe

same manner, again leaving about one extra inch at

the outboard end Mix a batch of epoxy and carefully

glue the tubing rib joints of each rib, on each side.

13

to